Kasco 8400JF, 3.1JF, 5.1JF Owner's Instructions Manual

Owners Manual

J Series Decorative Aerators

Contents

Important Safety Instructions. . . . pg2

General Owner’s Instructions. . . . pg2

Unit Specs. . . . pg3

Parts Included. . . . pg3

Assembly Instructions. . . . pg4

Nozzle Options & Pattern Sizes. . . . pg7

Optional Premium Nozzles. . . . pg8

Installation Instructions. . . . pg9

Control Panel Installation. . . . pg10

C85 / C95 non-metallic Wiring Diagram. . . . pg12

3 Phase Startup Procedure. . . . pg13

C85 / C95 non-metallic and 3 Phase Control Panel Timer. . . . pg14

8400JF Replacement Parts. . . . pg15

2.3JF Replacement Parts. . . . pg16

3.1JF Replacement Parts. . . . pg17

3.3JF Replacement Parts. . . . pg18

5.1JF Replacement Parts. . . . pg19

5.3JF Replacement Parts. . . . pg20

7.3JF Replacement Parts. . . . pg21

Maintenance Recommendations. . . . pg22

Warranty Policy. . . . pg23

Troubleshooting Tips. . . . pg24

Customer Repair Form. . . . pg26

Registration Information. . . . pg28

C

Intertek

3020379

ANSI/UL 778: 2016

Ed.6+R:22Feb2017

CSA C22.2 #108: 2014 Ed.5

Kasco Marine, Inc.

800 Deere Rd.

Prescott, WI 54021

PH (715) 262-4488

FAX (715) 262-4487

www.kascomarine.com

Rev. 02/08/18

THANKS

We at Kasco Marine, Inc. would like to both thank and

congratulate you on your purchase of the JF model

decorative aerator. We appreciate you choosing Kasco

and for your purchase. Your decision to purchase Kasco’s Decorative Aerator will not disappoint you. The

JF Series Decorative aerator will be a great addition

to your body of water. It will help improve the water

quality by adding much needed oxygen and circulation. It will also enhance the aesthetics of the pond or

lake with beautiful patterns. The lighting package (if

purchased) will illuminate your aerator for beauty day

and night. We thank you for choosing Kasco for your

aerator needs and want you to be completely satised

with your purchase.

Important Safety Instructions

Please read and follow these extremely important

safety and handling instructions for your Kasco equipment. Following these instructions will help ensure

your safety and the quality performance of your equipment.

• Under NO circumstances should anyone enter the

water with the electrical equipment plugged in and/

or in operation. All Kasco equipment is ETL approved to UL and CSA standards for safety in water.

However, it is NEVER recommended to enter the

water with the equipment in operation.

• Caution should be used when dealing with any electrical and/or moving equipment.

• NEVER run the unit out of water. It will damage the

seals and create a dangerous situation for the operator.

• Extreme caution should be used around water, especially cold water, such as in Spring, Fall, and Winter.

Cold water poses a hazard in and of itself.

• NEVER lift or drag the aerator by the power or light

cord. If you need to pull the unit to the side of the

pond, use the anchoring ropes.

• Do not use waders in deep ponds/lakes or ponds/

lakes with drop-offs, drastic slopes, or soft bottom

material.

• Do not use boats that tip easily for aerator installation , such as a canoe, and follow all boating safety

rules and regulations, including wearing a PFD (Personal Flotation Device).

• Single phase aerators (8400, 3.1, and 5.1JF ) are supplied with an internal grounding conductor and/or a

grounding-type attachment plug. To reduce the risk

of electrical shock, be certain the aerator is properly

connected to the Kasco supplied control panel. (re-

fer to the C-85 & C-95 Control instruction)

• 3 phase aerators (2.3, 3.3, 5.3, 7.3JF) require a

startup test after wiring to ensure proper rotation of

the impeller. If the impeller is rotating in the opposite direction, the unit will not perform properly and

internal damage to the unit may occur. (See 3 phase

startup procedure)

• Control panels must be installed a minimum of

5ft(3m in Canada) from the inside wall of the pond,

unless separated from the body of water by a fence

wall, or other permanent barrier that will make the

unit inaccessible to persons in the water.

• Control panels must be installed by a qualied electrician.

• Ground Fault Circuit Interrupters (GFCI) should be

tested upon each installation and every month there-

after to ensure proper operation.

General Owner’s Instructions

INSPECT THE SHIPMENT

Immediately inspect your Kasco aerator shipment for

any visible damages. Also cross reference the parts

supplied with the Parts Included sheet to check for

shortages. Shortages should be reported immediately

to your Kasco Marine distributor or representative and

damages reported to your carrier and Kasco Marine.

ASSEMBLY & INSTALLATION

Please see the proper Assembly and Installation In-

structions enclosed in this manual. Each is specic

for your model and size of aerator. Note: Use a nylon

tie to help keep the power cords for the unit and lights

free of the impeller by tying each cord to either side of

the oat. If you have a light kit, make sure that the unit

cord is tied to one side of the oat and the light cord to

the other for balance. Note: It is extremely important

to test the GFCI in the control panel upon each installation/reinstallation of the unit to ensure proper functioning.

USE AND OPERATION

Kasco Aerators are designed and engineered for

continuous duty, such as on sh farms or other aquaculture applications, or on-demand use, as needed in a

recreational water feature.

During otation operation, the water is pulled from

O

360

around the unit and from below the unit. The

water is pulled upward and thrust through the otation

collar into the air.

2

Your Kasco Marine aerator is ready for immediate use

(after installation). Make sure to keep the motor housing clean from hard water deposits and/or algae. (See

Maintenance Recommendations)

It is extremely important that proper and sufcient

voltage is supplied to the aerator motor. Unit should

be protected by a GFCI. Control panels must be

installed by a qualied electrician. (See Installation

instructions).

Kasco aerators are lightweight, energy efcient, and

easy to install and operate. We strive to produce products that exceed customer expectations. We hope you

enjoy your Kasco aerator.

UNIT STORAGE

When storing units during the offseason, it is important to store them upside down if they are going to be

sitting for long periods of time. Units that sit upright

on a shelf for many months, or even years have a

greater likelihood of seals drying out. Storing upside

down will ensure oil is lubricating the seals and prevent drying.

Unit Specs

Single Phase

208-240 Volt

Voltage 208-240 208-240 208-240

Amps 10.5 13.4 20

Lock rotor

amps

Control box

connection

Aerator

connection

8400JF 3.1JF 5.1JF

40 61 97

C-85

Hardwire at

shore

plug or

hardwire

into C-85

C-95

Hardwire at

shore

plug or

hardwire

into C-85

Hardwire at

hardwire

into C-95

C-95

shore

Parts Included

8400JF, 3.1JF, or 5.1JF Aerator

2.3JF, 3.3JF, or 5.3JF Aerator

(Unit with cord or unit with Disconnect) (1)

A1. Cord in separate box (1) (depending on size of cord)

B. Float in separate box (1) (Diagram)

# Item Part # Qty

Float Sections (2, 3 HP only)

1a

Float Sections (5, 7.5 HP only)

1b

Top Float Bracket

2

Bottom Float Bracket w/Rope

3

9.5” x 3/8” Bolt

4

3/8” Lock Nut

5

Bottom Screen

6

Top Screen

7

Top Screen Clip

8

1/4-20 x 3/4” brass screw

9

1/4” Lock Washer

10

1/4” Nut

11

Bottom Screen Clip

12

3/8” x 1” Bolt

13

3/8” lock washer

14

Mesh screen

15

Cable ties for mesh

16

8400JF, 3.1JF, 2.3JF, 3.3JF parts diagram

284001 3

251001 3

840157 3

840158 3

840159 6

462214 6

990162 1

840175 1

223111 3

664750 3

840537 3

840536 3

223240 3

566250 3

566230 3

990170 1

415038 10

3 phase 208-

2.3JF 3.3JF 5.3JF 7.3JF

230 Volt

Voltage 208 208 208 208

Amps @208V 7.5 10.3 16.0 20.0

Lock rotor

40 70 100 100

amps

3 phase 460

2.3HJF 3.3HJF 5.3HJF 7.3HJF

Volt

Voltage 460 460 460 460

Amps 3.6 5.1 7.8 10.0

Lock rotor

24 40 49 50

amps

5.1JF, 5.3JF, 7.3JF parts diagram

3

Control Panel in separate box (1) (if purchased)

Set of Interchangeable Nozzles (5) (Diagrams)

# Item Part # Qty

1 #6 x 1/2” Self Tap Screw 820405 3

2 3/8” x 4” bolt 820090 1

3a Linden Nozzle (2, 3 HP) 820110 1

3b Linden Nozzle (5 HP) 820109 1

3c Linden Nozzle (7.5 HP) 703320 1

4a Redwood Y Insert (2 HP) (in #7) 820170 1

4b Redwood Y Insert (3 HP) (in #7) 820332 1

4c Redwood Y Insert (5 HP) (in #7) 820352 1

5 Juniper Nozzle 820140 1

6 Willow Nozzle 820150 1

7a Redwood/Spruce Nozzle (2 HP) 820160 1

7b Redwood/Spruce Nozzle (3 HP) 820330 1

7c Redwood/Spruce Nozzle (5 HP) 820350 1

8a Sequoia Nozzle (5 HP) 820130 1

8b Sequoia Nozzle (7.5 HP) 703200 1

9 3/8” x 2.5” Bolt 820095 1

8400JF, 3.1JF, 2.3JF, 3.3JF Nozzle Diagram

• #10 x 1” long or longer screw(s) for mounting the

control panel (4)

• 7/16” Socket & Wrench (1)

• 7/16” Wrench (1)

• 9/16” Socket & Wrench (1)

• 9/16” Wrench or adjustable crescent wrench (1)

• Flat head screw driver (1)

Assembly Instructions

1. Remove all contents from package and place on

a clean, at surface. Inspect the shipment for any

damages. If damages are found, immediately notify

your carrier and your Kasco Marine, Inc. representative. Next, cross reference the parts included in the

shipment with the Parts Included sheet in this manual.

Make sure you have all the parts needed. If any shortages are found, contact your Kasco representative

immediately.

2. Arrange the three Float Sections (Part #B1) upright

(plug on bottom) so the overlap of one section aligns

with the next section and loosely push the three sections together to form a continuous ring.

8400JF, 3.1JF, 2.3JF, 3.3JF

5.1JF, 5.3JF Nozzle Diagram

7.3JF Nozzles include linden and sequoia.

NOTE: Extra hardware may be included.

Tools & Supplies Needed

• Anchors or stakes for installing unit (3)

• Philips head screw driver for mounting C-85

• Electrical Supply near pond on a post with room

for mounting the control panel

• Three 12” galvanized pipe for weighting ropes

(optional)

4

5.1JF, 5.3JF, 7.3JF

3. Position one Top Float Bracket (Part #B2) so that

the bolt holes in the bracket align with the bolt holes

in the two adjoined oat sections and insert two 9.5”

Coated Bolts (Part #B4) through the assembly. This

may require some minor repositioning of the oat sections as you push the bolt all the way through. Do not

force the bolt through. Repeat for the remaining two

joints.

4. Turn the assembly upside down and place the Bot-

tom Float Brackets (Part #B3) over the bolts, the ends

of which should now be extending through the assembly. Loosely install the six 3/8” Lock Nuts (Part #B5)

on the ends of the bolts (do not tighten yet).

7. Take at mesh pattern and wrap into cone shape by

overlapping both vertical edges by approximately 1

inch and aligning top and bottom edges of mesh. Secure mesh vertical seam at the top, bottom and middle

using (3) cable ties.

Overlap vertical edges

5. Rest the oat on the base plate of the unit. Connect

the oat to the base plate using the 3/8” x 1” bolt (Part

#B13) and 3/8” lock washer (Part #B14). Tighten using a 9/16” wrench.

Attach 3 cable ties

1 inch overlap

6. Center the Top Screen (Part #B7) inside the three

Top Float Brackets. Attach the screen by spanning

each Top Screen Clip (Part #B8) across the two

innermost rings on the screen and the hole in the oat

bracket. Insert the 3/4” Brass Screws (Part #B9) and

attach with 1/4” Lock Washers (Part #B10) and 1/4”

Nuts (Part #B11) to secure the screen to the oat

assembly.

Place mesh cone on at surface with small diameter at

bottom. Insert existing stainless steel screen centered

inside mesh cone with approximately 2 inches of mesh

overlap to the top ring of the screen. Attach mesh

to the top ring of the screen in (3) equally spaced

locations using cable ties.

5

Attach 3 cable ties

to top ring equally spaced

2 inch overlap

Flip mesh and screen assembly over and use

remaining cable ties to secure mesh to small bottom

diameter of the stainless steel ring.

Attach 2 cable ties

to bottom ring equally spaced

Bottom Screen Clips (Part #B12) over the bolts as

shown. The power cord can be slid under the bottom

screen between the oat and screen where two oat

sections come together before the 3/8” Lock Nuts

are replaced. Replace the three inside Lock Nuts and

tighten all 3/8” Lock Nuts using the 9/16” wrench and

socket.

Clip off excess cable tie material once mesh is secured

into place.

8. Return the unit to its upright position and select a

nozzle (See Nozzle and Pattern Options). Insert the

Shaft Bolt (Part #D2) into the Nozzle Head so it ts

snugly into the molded socket for those nozzles that

use the bolt. Install the Nozzle by threading it into

the inner cone of the pump. Make sure to tighten the

Nozzle all the way down.

NOTE: If the nozzle does not look centered, see the

steps in the troubleshooting section for adjusting

the inner cone that the nozzle screws into.

Position the Bottom Screen (Part #B6) over the oat

so the motor housing (can) passes through the large

hole in the center of the screen. Remove the center

three 3/8” Lock Nuts from the 9” Bolts and place the

6

To install the Redwood nozzle, make sure the Y Insert

(Part #D4) is installed and seated properly into the

Nozzle Housing (Part #D7). Push the nozzle down

over the cone assembly (it may require light taps with

a rubber mallet to seat properly). Next, use the 3 Self

Tapping Screws (Part #D1) provided in the 3 holes on

the nozzle and tighten the screws into the cone assembly. Once you feel resistance, two more turns will

be sufcient. To install the Spruce nozzle, follow the

same steps, but do not install the Y Insert.

9. On power cord lengths of 100 feet or longer with

the watertight Quick Disconnect, the power cord is

shipped separately. It should now be attached to the

stub cord by lining up the male and female halves of

the disconnect and hand tightening the blue collar. On

these cords, the Additional Strain Relief should be

attached to one of the lower oat brackets as pictured.

If you receive a 3 chain strain relief (6 or 8 gauge

cord), attach one chain to each of the three lower oat

brackets. If there is not Strain Relief, use the Nylon

Cable Tie provided to secure the cord to a rope to

prevent damage by the propeller. Double check the

Quick Disconnect to make sure the threaded collar has

not come loose in shipping before placing in the water.

If installing a new Quick Disconnect, please refer to

Quick Disconnect instructions. Also, at this time,

lights can be installed if purchased.

• The Spruce nozzle must have the Insert removed

prior to nozzle placement.

• The Birch display does not require a nozzle.

The Redwood nozzle uses the 3 self tapping screws to

attach over the pump housing and the Y Insert must be

installed.

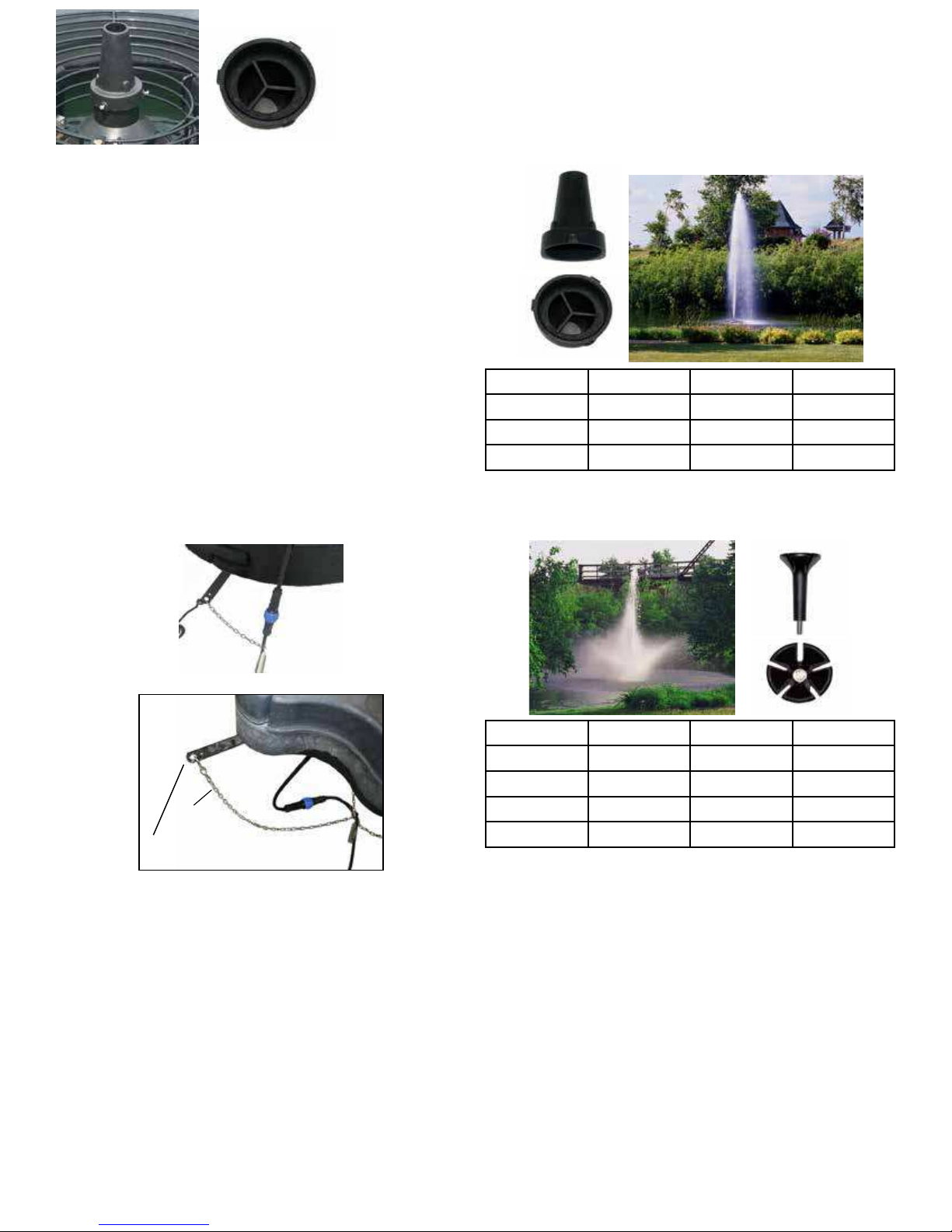

Model HP Height Width

8400, 2.3 2 22’ 7’

3.1, 3.3 3 24’ 8’

5.1, 5.3 5 26’ 8’

The Linden nozzle (marked L inside one of the ns)

uses the 3/8” x 4” bolt.

1 chain strain relief

Chain

Bottom Float Bracket

3 chain strain relief

Nozzle Options & Pattern Sizes

NOTE: Pattern sizes listed are approximate in feet.

Variations in voltage caused by regional electrical differences or voltage drop due to long power cords may

result in reduced pattern sizes.

• All ve (or six) nozzles are included with the

package.

• The Linden, Willow, and Juniper nozzles use the

3/8” x 4” bolt.

• The Sequoia (5.1JF only) uses the 3/8” x 2.5” bolt.

• The Redwood nozzle must have the Y Insert installed prior to nozzle placement.

Model HP Height Width

8400, 2.3 2 18’ 30’

3.1, 3.3 3 19’ 35’

5.1, 5.3 5 20’ 35’

7.3 7.5 24’ 28’

7

The Willow nozzle (marked W on the inside of the

cone) uses the 3/8” x 4” bolt

Model HP Height Width

8400, 2.3 2 12.5’ 28’

3.1, 3.3 3 13’ 35’

5.1, 5.3 5 14’ 36’

The Juniper nozzle (marked with J on in inside of the

nozzle cone) uses the 3/8” x 4” bolt.

The Birch display does not use a nozzle or bolt. It is

the aerator unit running without any nozzle and allows

for the best ow rate and oxygen transfer!

Model HP Height Width

8400, 2.3 2 12’ 11’

3.1, 3.3 3 14.5’ 10’

5.1, 5.3 5 14’ 12’

7.3 7.5 14.5’ 13’

The Sequoia nozzle (marked S on the inside of the

cone) uses the 3/8” x 2.5” bolt.

5.1JF, 5.3JF ONLY

Model HP Height Width

8400, 2.3 2 8’ 46’

3.1, 3.3 3 9’ 48’

5.1, 5.3 5 10’ 50’

The Spruce nozzle uses the three self tapping screws

to attach over the pump housing and the Y Insert must

be removed.

Model HP Height Width

8400, 2.3 2 19’ 10’

3.1, 3.3 3 21’ 13’

5.1, 5.3 5 24’ 15’

Model HP Height Width

5.1, 5.3 5 21’ 10’

7.3 7.5 26’ 10’

Optional Premium Nozzles

The following are optional premium nozzles available

for the J Series Decorative Aerators. Premium nozzles

offer splendid beauty above and beyond our included

patterns.

Madrone Premium Nozzle:

8

Magnolia Premium Nozzle:

Installation Instructions

Before installing 3 phase units (2.3, 3.3, 5.3, 7.3) into

the pond, please refer to 3 phase startup procedure.

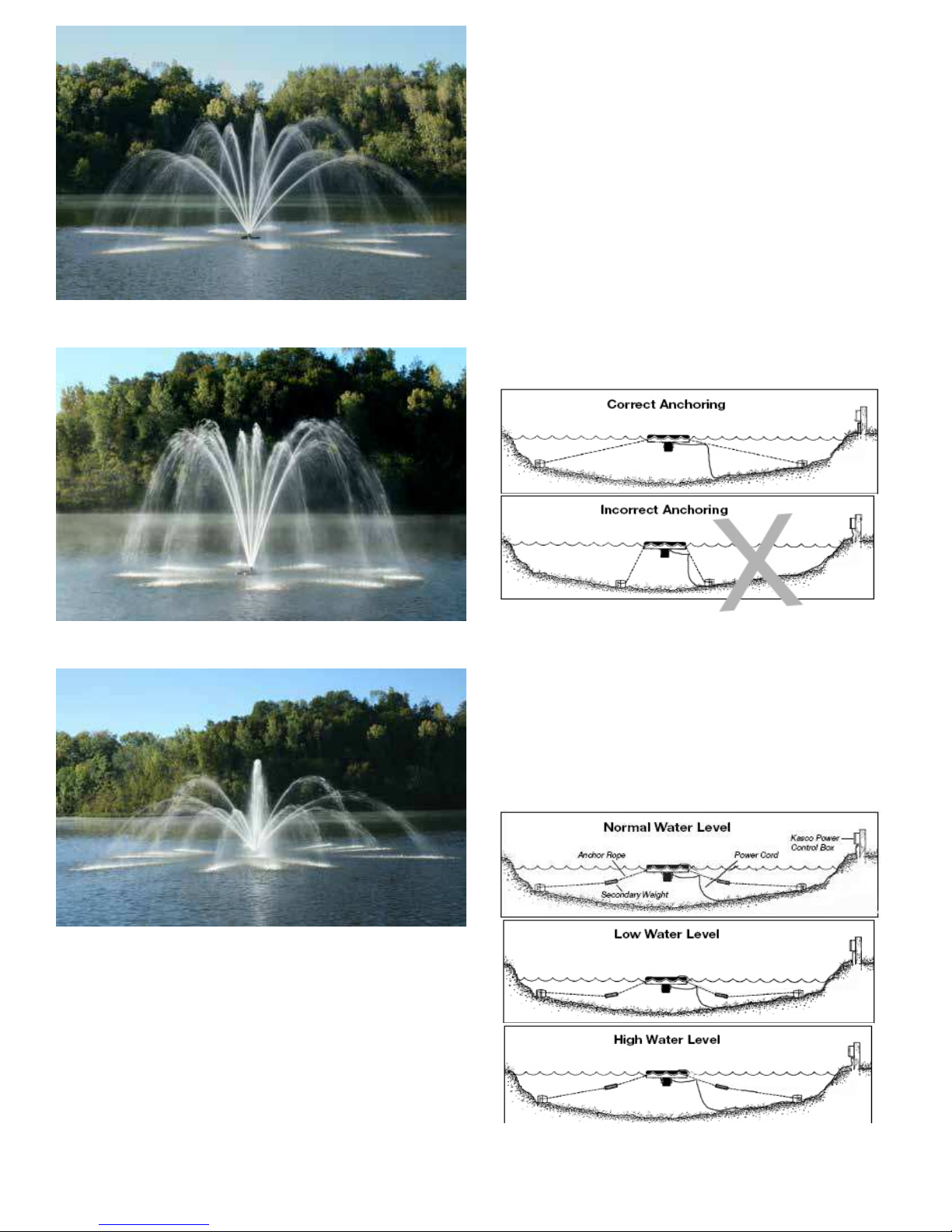

Use the ropes to position the aerator in the desired

location in the pond/lake. Anchor the ropes or secure

them to the shoreline so the ropes are free of slack, but

not tight. To prevent twisting of the unit due to torque,

you should place the anchor at least 3 feet from the

oat for each foot of depth (Ex. A 6 foot deep pond

would require an anchor 18 feet horizontally from the

oat.)

Palm Premium Nozzle:

Mahogany Premium Nozzle:

For ease of removal, you may choose to keep at least

one anchor within reach from shore, just below the

water’s surface.

(ALTERNATE INSTALLATION)

In ponds where the water level uctuates signicantly,

you may need to suspend a small weight (12” of 1”

galvanize pipe works well) at the mid-point of the

rope to take up any slack as the water level drops. The

weight should be light enough so the aerator can rise

as the water level rises. This can also help hide ropes

by sinking them further below the surface.

Contact your authorized Kasco distributor or visit

www.kascomarine.com for more information.

9

Loading...

Loading...