KARI Float Switch

Operation

Manual

3H 3L 3Y 3A 3HE 3LE 3YE 3AE

High level alarm

Issued when the level of liquid

gets too high, or initiates valve

discharging when, for example,

the pump is out of order.

3

Start

Large amount of liquid.

Discharging pump starts.

Stop

Lower limit for discharging.

Discharging pump stops.

Image 3H shows the operation

of the KARI Float Switch

KARI Float Switch

– compact and reliable

The KARI Float Switch is a control device for charging and discharging pumps

and motor and magnetic valves. It is also an alarm device that alerts the

user at specied surface levels. Thanks to its large oat casing (Ø 170 mm),

the KARI Float Switch has a buoyancy that guarantees smooth, troublefree operation under all conditions. SGS FIMKO Oy (the Finnish Electrical

Inspectorate) has performed testing in accordance with the Low Voltage

Directive (LVD) and approved the KARI Float Switch for use in non-ammable

liquids at 250 volts.

FUNCTIONS

DISCHARGING-PUMP CONTROL CHARGING-PUMP CONTROL

Discharging-pump control + high level alarm.

3H

Pump control with one switching element.

Discharging-pump control + isolated high

level alarm. Pump control with one switching

3HE

element.

Discharging-pump control + high level alarm

3Y

Pump control with two switching elements.

Discharging-pump control + isolated high

level alarm. Pump control with two switching

3YE

elements.

ORDER CODE

3HE

K N Au

Gold-plated contacts (Au)

1 mA ... 100 mA

Heat-resistant cable types

N = TPU

S = silicone

T = teon

U = UL/CSA PVC

Cable types

Empty = PVC

A = rubber

N = TPU

S = silicone

T = teon

U = UL/CSA PVC

K = heat-resistant

Circuit diagram

3H, 3L, 3Y, 3A, 3HE, 3LE, 3YE, 3AE

Deviating

surface levels (cm)

Dxx-xx

Special type ID

Vxx

Charging-pump control + low level alarm.

3L

Pump control with one switching element.

Charging-pump control + isolated low level

alarm. Pump control with one switching

3LE

element.

Charging-pump control + low level alarm.

3A

Pump control with two switching elements.

Charging-pump control + isolated low level

alarm. Pump control with two switching

3AE

elements.

_KP

_20

Cable

length

(m)

1st letter

Non-standard cable weight

K = 700 g

L = 1000 g

2nd letter

P = pressure-resistant

3H | 3L | 3Y | 3A | 3HE | 3LE | 3YE | 3AE

INSTALLATION AND

ADJUSTMENT

The KARI Float Switch is mounted

to hang from its own cable. The oat

switch oats on the surface of the liquid

and follows the movement of the liquid’s

surface. Functions are controlled in

the various tilt angles of the oat. The

switching distance differential is adjusted

by moving the weight along the cable.

Installation considerations

• The height at which the oat hangs

and the distance of the cable weight

from the oat can be adjusted. The

differential between the start and stop

levels is at its lowest when the cable

weight is about 10 cm from the tip of

the oat’s strain-relief (see page 7).

• If the viscosity of the liquid is high

or oating to the sides needs to be

restricted, we recommend a heavier

weight of cable, which we supply as

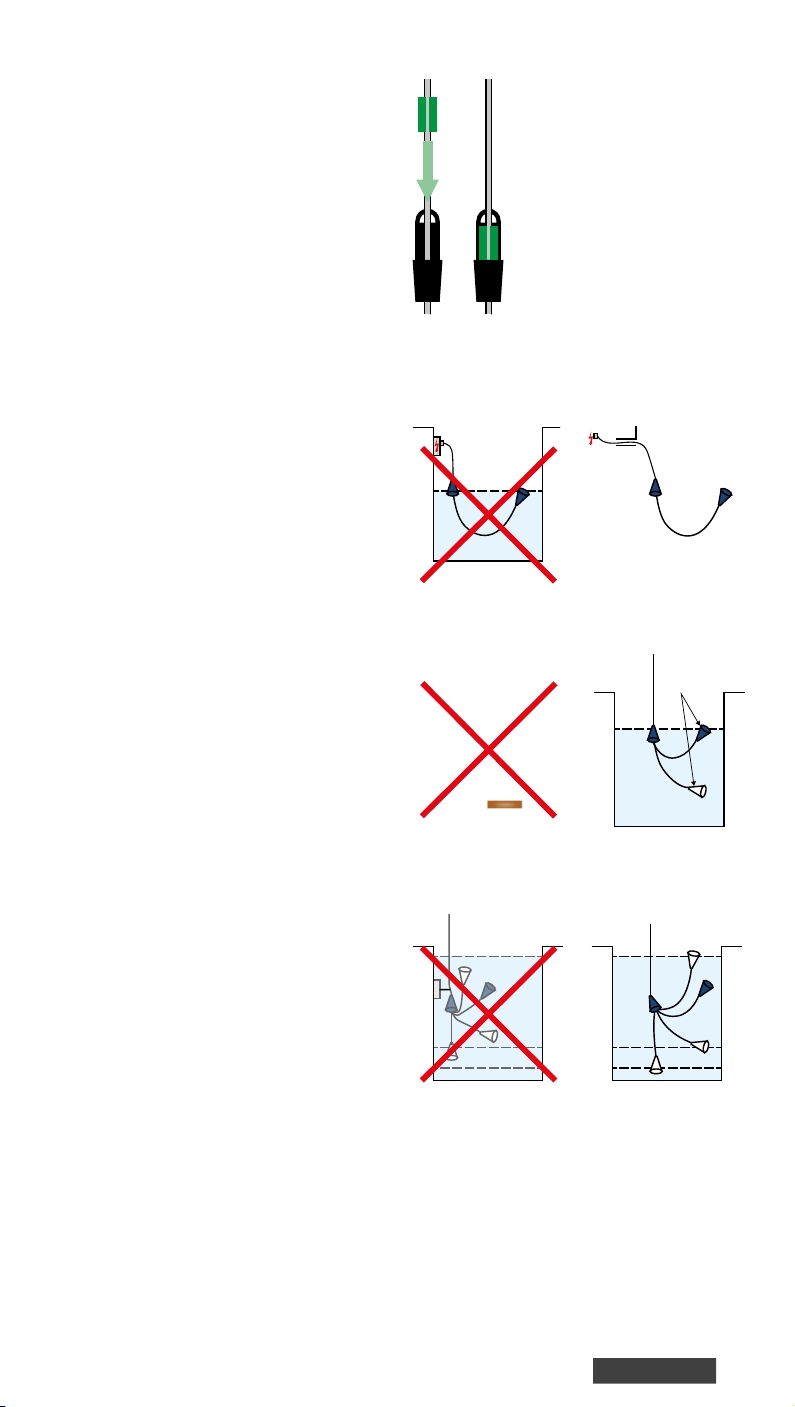

required. The weights are xed to the

cable with a clamp wedge (see Image 1).

• It is important to keep the junction

box in a dry environment. If this is not

possible, the ends of oat switch cables

must be covered with, for example,

protective grease (see Images 2 and 3).

An IP68 junction box is also available.

• The oat switch needs a cable weight

or other anchor point to operate.

• The installation site must be selected

such that the oat cannot become

caught under or stay on top of any

surface or get entangled in other

structures (see Image 4).

• When the oat switch is tested without

being oated, its correct orientation

must be considered: the ‘UP’ mark on

the side of the bottom portion must

face upward. For example, when placed

on the oor on its side, the oat switch

settles into this position because of its

internal keel weight (see Image 5).

• Tying the oat switch from its cable

near the oat to, for example, the

ascension pipe of the pump decreases

the useful life of the cable; the oat

switch should hang freely from its cable

(as shown in Image 6).

A) B)

Image 1. Cable weights and the hanging loop are

xed to the cable with a clamp wedge (A–B).

Image 2. Avoid extending or

connecting the cable in humid

conditions.

Image 4. Take care to ensure

the free movement of the

oat.

Image 6. Avoid xing the oat such that

a sharp corner can cause kinks or wear to the cable.

Image 3.

Up!

Image 5. Note the correct

orientation of the oat.

i

Loading...

Loading...