Synchronizer

SM-06

Instruction Manual

(version 4.2)

Copyright 2004-2017 by PUP Kared. All rights reserved.

This instruction manual may be reproduced and distributed in its entirety only.

PUP KARED Sp. o.o. reserves the right to make changes in our products consisting in ad -

vancement of their technical features. These changes can’t always be updated and taken

into consideration in the documentation.

Brand and product names mentioned herein are trademarks or registered trademarks be-

longing properly to their respective owners.

Manufacturer:

PUP KARED Sp. z o.o

ul. Kwiatowa 3/1

80-180 Gdańsk – Kowale

Phone +48 58 322 82 31

+48 58 324 86 45

Mobile phone +48 602 152 740

Fax +48 58 322 82 33

+48 58 324 86 46

E-mail kared@kared.com.pl

Internet http://www.kared.com.pl/

Copyright 2004-2017 by PUP Kared. All rights reserved.

This instruction manual may be reproduced and distributed in its entirety only.

IMPORTANCE OF INSTRUCTION MANUAL

In the event of doubt regarding the correct interpretation of the manual, please be

sure to ask manufacturer for explanation.

We will be grateful for any suggestions, opinions and criticisms of users and we kindly ask

you to transfer them in oral or written maner. This will help us make the instructions even

easier in use and take into account the wishes and requirements of users.

The device, to which this instruction manual is attached, includes impossible to

eliminate, potential threat to people and material values. Therefore, any person working

on the device or performing any activities related to the handling and preservation of the

device, must first be trained and know the potential danger. This requires careful reading,

understanding and compliance with the instruction manual, in particular the safety

instructions.

TABLE OF CONTENTS

IMPORTANCE OF INSTRUCTION MANUAL.......................................................................3

INFORMATION ON COMPLIANCE......................................................................................6

1. Device application..............................................................................................................7

1.1. Automatic synchronization with a constant lead time (SYN) ...................................7

1.2. Switching on separate objects in a given angle of incompatibility phase sector

(ZSK)..................................................................................................................................7

1.3. Switching on the generator switch on the mains without voltage (SBN).................7

1.4. Switching on the mains voltage on not-powered generator field (GBN)....................8

1.5. Switching on the switch with the absence of main and generator voltages (SGBN).8

1.6. The reviewing and modifying of the settings and measurements of some object pa-

rameters (TEST)................................................................................................................8

2. Safety rules........................................................................................................................8

3. Technical description and device operation....................................................................11

3.1. General description..................................................................................................11

3.2. Housing.....................................................................................................................11

3.3. The synoptic board...................................................................................................14

3.4. Signalling of errors....................................................................................................15

3.4.1. External errors...................................................................................................15

3.4.2. Internal errors....................................................................................................15

3.5. Operation description...............................................................................................15

3.5.1. Introduction - definitions and designations.......................................................15

3.5.2. Operating mode selection.................................................................................17

3.5.3. Starting and shutting down................................................................................17

3.5.4. Emergency discontinuation...............................................................................18

3.5.5. Operating modes...............................................................................................19

3.5.5.1. Automatic synchronization with a continous lead time ( SYN mode).......19

3.5.5.1.1. Voltage regulation...................................................................................21

3.5.5.1.2. Adjustment of the generator's rotational speed.....................................21

3.5.5.1.3. Prevention against not in-phase synchronous operation.......................22

3.5.5.1.4. Circuit breaker activation........................................................................22

3.5.5.2. Switching on separate objects in a set sector of phaze incompatibility

angle ( ZSK mode)..................................................................................................24

3.5.5.3. Closing the switch during voltage failure from one or both sides of the

circuit breaker (modes: SBN, GBN i SGBN)...........................................................26

3.5.5.4. Reviewing and modifying of settings and measurements of some object

parameters ( TEST mode)....................................................................................29

3.5.5.4.1. Settings...................................................................................................30

3.5.5.4.2. Network address.....................................................................................34

3.5.5.4.3. The measurement of tw time..................................................................35

3.5.5.4.4. Measurement of fi angle.........................................................................36

3.5.5.4.5. Measurement of C coefficient................................................................37

4. Technical data..................................................................................................................39

5. Data on completeness.....................................................................................................44

6. Installation and Commissioning.......................................................................................44

7. Monitoring the synchronization process..........................................................................45

7.1. Synchronization panel TS-10...................................................................................45

7.2. Visualization of synchronization process on a computer monitor............................47

7.3. Communication with the superior control system and control.................................47

7.3.1. Information available only during the correct operation of synchronizer..........48

7.3.2. Information also available in certain states of damage....................................54

8. Operation.........................................................................................................................55

8.1. Periodic checks........................................................................................................55

8.2. Troubleshooting........................................................................................................55

9. Transport and Storage.....................................................................................................55

10. Disposal.........................................................................................................................56

11. Warranty and Service....................................................................................................56

12. Ordering Guide..............................................................................................................57

INFORMATION ON COMPLIANCE

The device which is the subject of this manual is designed for use in industrial

environment. With the development and production of this device, such standards are

applied, which fulfillenes provide realization of assumed rules and safety measures, under

the condition that the user respects specified further guidelines for installation and

commissioning as well as the operation driving.

This device is a Class A. In a domestic environment it may cause radio

frequency interference. In such cases, the user can be requested for the

application of appropriate remedies.

This device is compatible with the provisions of EU directives:

• Low Voltage 73/23/EEC – introduced by the Regulation of the Minister of Economy,

Labour and Social Policy of 12.03.2003 (Journal of Laws No. 49, item 414)

• Electromagnetic Compatibility (EMC) 89/336/EEC – implemented by the Regulation

of the Minister of Infrastructure of 04.02.2003 (Journal of Laws No. 90 item 848).

Compliance with the directives has been confirmed by tests performed in independent

from manufacturer measurement and research laboratories.

Synchronizers SM-06 meet the essential requirements set out in Directives Low Voltage

and Electromagnetic Compatibility through compliance with the following standards:

The standard harmonized with Directive 73/23/EEC

• PN-EN 61010-1:2004 Safety requirements for electrical equipment for measure-

ment, control and laboratory units. General requirements.

The standards harmonized with Directive 89/336/EEC

• PN-EN 61000-6-2:2002 Electromagnetic Compatibility (EMC) – part 6-2: General

standards – Immunity for industrial environments.

• PN-EN 61000-6-4:2002 Electromagnetic Compatibility (EMC) – part 6-4: General

standards – Emission standards for industrial environments.

1. Device application

Microprocessor Automatic Synchronizer SM-06 is designed to automatically connect of

AC power facilities for parallel operation. It performs the following types of connections

(can operate in the following modes):

1.1. Automatic synchronization with a constant lead time (SYN)

After the power is turned on, synchronizer measures the the mains and generator voltage

and control signals on binary inputs. The measured value of the voltage and frequency

difference compares to the set limit values, and after signal "Start" generates regulatory

pulses, that reduce these differences to the set limit values. After the "alignment" of

voltages and frequencies generates switching the switch with a constant lead time. When

correctly executed connection it is discontinued.

Synchronizer is discontinued even if there are circumstances which prevent the

synchronization. Such discontinuation is an emergency discontinuation and causes

various alarms.

In the synchronizer relay signaling an error is activated and the display shows the

message indicating the reason for emergency discontinuation.

1.2. Switching on separate objects in a given angle of incompatibility phase sector (ZSK)

ZSK mode is used to connect the objects, when the synchronizer has no effect on the

voltage and frequency of connected objects, if the certain specified in the settings

connection conditions are fulfilled. When a signal "Start” was given, synchronizer will

generate the shutdown pulse of switch only, when the voltage difference, phase difference

and phase drift within the set time limit will not exceed the set limit values.

1.3. Switching on the generator switch on the mains without voltage (SBN)

SBN mode is used to close the breaker by a synchronizer, when the voltage and

frequency of the generator have the required values and mains rails are not powered.

When a signal "Start” was given, the synchronizer checks the voltages on both sides of

the switch and compares them to the set connecting conditions, which are the residual

voltage on the network rails and the voltage parameters on generator rails. If these values

fall within the preset range, generates a pulse closing switch. Checking the residual

voltage is designed to detect whether the network rails are not shorted.

1.4. Switching on the mains voltage on not-powered generator field (GBN)

GBN mode is used for switching the mains voltage on the not-powered mains of generator

own needs, using the synchronizer. When a signal "Start” was given, the synchronizer

checks the voltages on both sides of the switch and compare them to the set connecting

conditions, which are the voltage parameters on the mains rails and the residual voltage

on generator rails. If these values fall within the preset range, generates a pulse for circuit

breaker clousure. Checking the residual voltage is designed to detect whether the mains

rails are not shorted.

1.5. Switching on the switch with the absence of main and generator voltages

(SGBN)

SGBN mode is cused to the controlled by the the synchronizer circuit breaker clousure

when on its two sides is no power supply. Once a signal "Start" is given, the synchronizer

checks the voltage on both sides of the circuit breaker and compares it to the set

connecting conditions, which are the residual voltage on the mains rails and the residual

voltage on the generator rails. If these values fall within the preset range, generates

a pulse for circuit breaker clousure. Checking the residual voltage is designed to detect

whether the mains rails are not shorted.

1.6. The reviewing and modifying of the settings and measurements of some object parameters (TEST)

TEST mode is used to review and modify the settings of synchronizer and measurement

of certain parameters of the synchronized object, among others the circuit breaker closing

time.

2. Safety rules

The information contained in this section are intended to familiarize the user with the

proper installation and operation of the device. It is assumed that the installing, activating

and operating personnel of this device is properly qualified and is aware of the potential

dangers associated with the operation on the electrical equipment.

The device complies with applicable regulations and standards in terms of safety. In its

design particular attention to the safety of users was payed.

Device installation

The device should be installed on a place that provides appropriate environmental

conditions specified in the technical data. The device should be properly secured and

protected from mechanical damage and from accidental access of unauthorized persons.

The synchronizer is designed for panel or back panel mounting (depending on housing

version) in indoor switchgears. The synchronizer should be connected according to the

wiring diagram. External connections are connected by detachable spring connectors of

WAGO company. For connections of synchronizer it is recommended to use conductors

of LY type with section diameter 0,5÷1,5 mm2.

The synchronizer SM 06 is executed in first protection class and must be connected to the

protective conductor of the system to appropriately labeled terminal on the housing.

Commissioning

When you have installed the synchronizer its start-up in accordance with generally

accepted principles concerning protection devices, automation and control is to be carried

out.

Insulation test may cause a charge of the diffuse capacity to the dangerous voltage. After

each part of the test these capacities have to be discharged.

Operation of device

The device should work under the conditions specified in the technical data.

Personnnel operating the machine should be authorized and acquainted with the

instruction manual.

Removing the cover

Before performing any work with the necessity of housing removal, you must disconnect

all power supply and measurement voltages and then disconnect synchronizer from the

external circuits by dislodge all plugs.

Components used are sensitive to electrostatic discharge, thus device opening without the

proper antistatic equipment, can cause its damage.

Operation

After installing the device does not require additional service beyond the periodic checks

required by the relevant regulations. If you find any foult, please contact the manufacturer.

The manufacturer provides maintenance and post warranty services.

Warranty terms are specified in the Warranty Card.

Modifications and changes

Due to safety, any modifications and changes in functionality, covered by this manual are

not allowed. Device modifications to which the manufacturer does not give written

permission cause loss of any liability claims against the PUP KARED Sp. z o.o. Company.

Replacement of parts and components incorporated in the device from other

manufacturers than those used may affect the safety of its users and cause device

malfunctions.

PUP KARED Sp. z o.o. Company is not responsible for damages caused by use of

improper components and assemblies.

Disruptions

The possible disturbances observed in operation and other damage should be

immediately passed to the competent person.

Repairs may only be performed by qualified specialists.

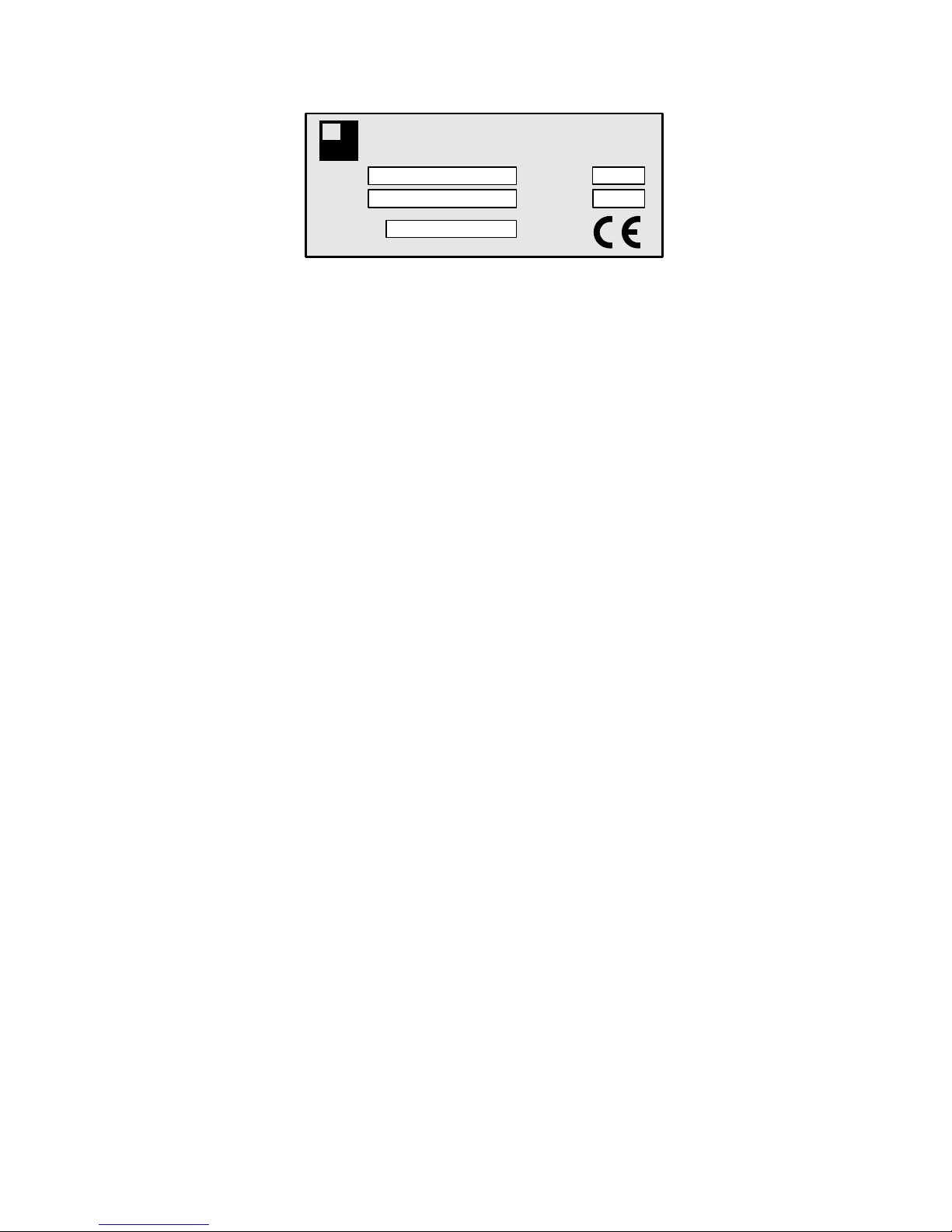

Rating and information plates, stickers

Always observe the instructions given in the form of descriptions on the device,

information signs and labels, and keep them in a condition for good readability. Plates and

stickers that have been damaged or become illegible, should be replaced.

Fig 2.1. Sample of name plate

Nazwa:

PUP KARED Sp. z o.o.

ul. Kwiatowa 3/1, 80-180 Kowale

Rok prod.:

Zasilanie:

220VDC / 10W

Typ:

Nr fabr.:

SYNCHRONIZATOR

SM-06B-xxxxx-x-x

2016

250

3. Technical description and device operation

3.1. General description

Synchronizer SM-06 was built based on the microprocessor technology. Components of

the device are placed in APRA 63T housing in the panel embodiment or in 19-or 12-inch

rack Euro 3U production of RADMOR S.A. (back panel mounting execution).

Mains measuring voltages and object synchronized voltages (alternating with a nominal

value 100 V RMS) and binary signals (boosted by the DC voltage of value 220, 110 or

24 VDC, depending on the version of the device) are supplied: the type of connection, lock

off, start and switches states selection, on the basis of which, synchronizer states

conditions for the operation and automatically implements the selected type of connection.

The synchronizer is adapted for operation with a mains frequency of 50 Hz.

On the front panel (Synoptic Board or in brief TS) light emitting diodes are placed (LED)

and liquid crystal display (LCD), which indicate the operating mode and allow the process

of linking tracking. Faulty connections of external circuits, defects or malfunctions are

indicated by displaying the appropriate voice written messages on TS and by stimulating

internal error signals relay.

On Client’s request synchronizer SM-06 can be equipped with:

• additional synoptic board located on the control panel in the control room (TS-10)

connected to the device using the optical fiber cable, or with,

• additional communication interface RS 485 used by the host system,

• a program that allows the observation of the synchronization process on the PC

monitor, ie. so called "Virtual Synchronization Column”.

3.2. Housing

Synchronizers SM-06 are manufactured in three housing versions and are respectively

indicated by a version number: 1, 2 or 3.

• Version 1 – panel mounting housing Profi Set 63T of APRA company, designed for

mounting on the relay board in the switchboard, or inside the cabinet

• Version 2 – back panel mounting housing (cassette Euro 12” 3U) width 49T,

designed for installation on the board in the control room or on the switchgear

elevation,

• Version 3 – back panel mounting housing (cassette Euro 19” 3U) width 84T

designed for installation in a typical cabinet adapted for mounting 19-inch cassettes.

There are possible also other unusual versions of housings agreed with the manufacturer.

Typical versions of housing shown in Fig. 3.1, 3.2 and 3.3

Fig. 3.1 Version 1: Panel mounted housing Profi Set 63T of APRA company

Legend:

Widok od frontu – Front view

Zacisk PE – PE terminal

Fig. 3.2 Version 2: Back panel mounting housing with a width 49T

Legend:

Zacisk PE – PE terminal

Fig. 3.3 Version 3: Back panel mounting housing housing with a width 84T

3.3. The synoptic board

Synchronizer SM-06 is equipped with a synoptic board, located on the front of the device

and especially facilitating the process of automatic synchronization at the first startup.

Fig. 3.4 View of the synchronizer SM-06B front panel

On the left side of the board the light emitting diodes (LEDs) are provided, to indicate

among others the selected operating mode, and on the right side: liquid crystal display

(LCD), keys (keyboard) and LEDs indicating the selected time of the switch closing. In the

lower right corner of the synoptic board socket RS 232C port for connecting a portable PC

is placed.

To the right from the LCD, the LED's indicating error are placed.

In the central part of the synoptic board under the inscription REGULATION, with

inscriptions VOLTAGES and ROTATIONS, illuminated arrows in tact to generate the

synchronizing pulses that affect the voltage regulators and the angular velocity of the

turbine set are placed. Arrows directed upwards are illuminated, when signals increasing

voltage and frequency are generated. Analogously arrows pointing downward, when the

signals lowering voltage and frequency are generated.

The status of the circuit breaker depict a cross-shaped lamps. Beam of the cross

illuminated in green (OFF) indicates that the circuit breaker is open, illuminated in red

(ON) that it is closed.

3.4. Signalling of errors

3.4.1. External errors

External errors are indicated by a corresponding written messages on the synchronizer's

LCD display. They include the damages or errors that occur outside the synchronizer, due

to lack of appropriate configuration of input signals (eg. broken cable, defective terminal,

etc.) or excess of signals (eg. short circuits). These errors cause the emergency

discountinuation of synchronizer and the detected terror signalling.

3.4.2. Internal errors

Internal errors can occur due to infringements of work of synchronizer. Which are

indicated in the form of digital code. In the event of an internal error, note its code, turn off

the power of synchronizer and turn it on again. If after restarting the same error will occur,

It is absolutely necessary to call the sernice, because it may indicate a internal damage of

synchronizer.

3.5. Operation description

This section describes detailing operation of SM-06 from device commissioning, handling

of irregularities, disabling and finally the implementation of the selected operating mode.

3.5.1. Introduction - definitions and designations

Synchronizer power supply

1.

Up –

the auxiliary voltage of the nominal value 220 VDC or 110 VDC or 24 V DC

(depending on the version of synchronizer) for providing power to

synchronizer. It is used also by an internal diode and Uv clamp to stimulate

inputs of operation mode selection and inputs for devices control. The

rated Up voltage, is also the rated voltage applied to all binary inputs.

Analog input signals

1.

Us –

mains voltage with a nominal value 100 V RMS and frequency 50 Hz from

the voltage relay,

2.

Ug –

voltage of object connected to the mains with a nominal value 100 V RMS

from the voltage relay (eg. generating set or power subsystem).

Discrete input signals (voltage, the Up value)

A. Operation mode selection signals:

1.

SYN –

automatic SYNchronization with a lead fixed time,

2.

ZSK –

Enabling of dedicated facilities in the set sector of non-compliance

phase angle,

3.

SBN –

Enabling the generator switch on a Mains Without Voltage,

4.

GBN –

Activation of mains voltage on not powered generator field (Generator

Bez Napięcia - Generator Without Voltage),

5.

SGBN –

Enabling the circuit breaker in the absence of mains and generator

voltages (Sieć i Generator Bez Napięcia – Mains and Generator Wi-

thout Voltage),

6.

TEST –

Reviewing and modification of settings and measurements of some

parameters of object.

B. Control signals:

1.

START -

START of the connecting process,

2.

BLKZ -

External interlock of signal activating a circuit breaker.

C. Switch status and selection circuit breaker settings signals:

1.

W1o –

circuit breaker W1 opened, settings of the circuit breaker W1

2.

W1z –

circuit breaker W1 closed,

3.

W2o –

circuit breaker W2 opened, settings of the circuit breaker W2

4.

W2z –

circuit breaker W2 closed,

Discrete output signals (relay contacts)

1.

ZW –

pulse switching circuit breaker on,

2.

BL –

error signaling,

3.

OG –

pulse signal increasing rotations of generator,

4.

OD –

pulse signal reducing rotations of generator,

5.

NG –

pulse signal increasing voltage of generator,

6.

ND –

pulse signal reducing voltage of generator.

3.5.2. Operating mode selection

You can select one of the following operating modes:

1.

SYN –

automatic SYNchronization with a lead fixed time

2.

ZSK –

Connecting of dedicated objects (eg. connecting of mains) in the set

sector of non-compliance phase angle, working quasi synchronously

3.

SBN –

Enabling the generator switch on a Mains Without Voltage

4.

GBN –

Activation of mains voltage on not powered generator field (Generator

Bez Napięcia - Generator Without Voltage)

5.

SGBN

–

Enabling the circuit breaker in the absence of mains and generator

voltages Mains and Generator Without Voltage

6.

TEST –

Reviewing and modification of settings and measurements of selected

parameters

Setting the operating mode takes place immediately after turning the power and device

auto testing. Then it is checked on which of the six inputs of operation mode selection is

the voltage. Corresponding to this input mode is selected and the subsequent change is

impossible, until the synchronizer power is turned off. If the voltage is on more than one of

the six inputs of operating mode selection, or is not on any, the device enters the emer -

gency withdrawal state. The state of voltages on the above inputs can not be varied for all

modes except for TEST, until the moment of voltage supply at the START input; and for

TEST mode until the power supply is turned off. Type of the selected mode is confirmed

by the illumination of the appropriate LED, on the left TS side.

3.5.3. Starting and shutting down

Synchronizer is started by switching the supply voltage Up with WZ circuit breaker (Fig.

4.1, 4.2). After powering synchronizer is performing the auto test, waits the time specified

by the setpoint Td (table 3.1, I.no. 46), and then checks the correctness of of input signals

(Td setpoint does not include the auto testing time, which is approx.1,8s). Correct status of

input signals occurs when following conditions are met simultaneously:

• Uv voltage– derived from synchronizer - is present on one and only one input of:

SYN, ZSK, SBN, GBN, SGBN, TEST,

• Uv voltage is not present at the START input,

• Uw voltage (.)is present on one and only one input of: W1o – W2o,

• Uw voltage (.) is not present on inputs W1z – W2z.

Where:

Uv –

constant voltage from the output of synchronizer power supply Z14

package, with a nominal Up value,

Uw(.) – constant voltage with a nominal Up value; dot in parentheses (.) – is the

number of the selected circuit breaker.

If the synchronizer detects an abnormal state of input signals, it proceeds to emergency

discontinuation status, but if the configuration of the of input signals is correct, to waiting

status (except for the TEST mode, as well as ZSK, where the standby staus is preceded

by drift measurement status). Standby staus continues until the appearance of START

signal (+Uv signal on START input), stimulating the set type of connection. When correctly

executed connection the synchronizer passes to discontinuation after switching status.

The synchronizer can be turned off at any time by turning off the power supply Up voltage

with the WZ circuit breaker.

The synchronizer uses the control system of UP supply voltage. If the value of this voltage

drops below Upmin (value is given in the technical data), device will enter the state of

emergency discontinuation. This is intended to prevent misinterpretation of the binary

input states, also supplied from Up voltage, in the event of voltage decrease below the

switching threshold of these inputs.

3.5.4. Emergency discontinuation

Emergency discontinuation takes place when synchronizer detects a bug that prevents the

proper execution of set connection.

Emergency discontinuation causes:

1. Error signalling – short circuit +BL from BL (relay contacts),

2. Display the error message on the LCD display,

3. Lighting of LED signaling an error.

If the reason for discontinuation is invalid status of the inputs, on the display after

DISCONTINUATION inscription code 15 is displayed– incorrect configuration of the input

binary signals after powering (see item 7.3.1 pag. 52).

OD S T AWI E N I E 1 5

Ug = 1 0 0 , 2 % F g = 5 0 , 0 0 H z

Us = 1 0 0 , 2 % F s = 5 0 , 0 0 Hz

f i g - f i s = 1 2 , 1 1 º

Fig. 3.5

Legend:

ODSTAWIENIE – DISCONTINUATION

indicate that the measured angle is the actual phase-angle measuring voltages

Ug and Us applied to the synchronizer inputs, (without correction of constant phase shift

angle).

3.5.5. Operating modes

In this section will be discussed the performance of synchronizer individual operating

modes.

3.5.5.1. Automatic synchronization with a continous lead time ( SYN mode)

In order to connect alternating current objects for parallel operation with the set lead time

(synchronization) it shouldt be:

1. Selector switch of the connection type (WRL, Fig. 4.1, 4.2) set in the SYN

position.

2. Close the correct key of switch selection (WW1 or WW2, Fig. 4.1, 4.2).

3. Turn on the synchronizer power.

After powering synchronizer starts with auto testing and validation of input signals. After

auto testing it goes to waiting status, unless earlier detects an error, then to the status of

emergency discontinuation.

In the waiting status (Fig. 3.6) there are displayed the current effective values of the

voltage measurements Us and Ug in % nominal value of 100V, and their frequency Fs

and Fg. In the last line the phase difference is displayed dfi = dfg – dfs and the status of

the signals on the two inputs: START - S and BLKZ – B. „0” - means inactive status of

input (no voltage), „1” – active status (it is the voltage + Uv).

In addition, the waiting status is signaled by lighting of the yellow LED: STANDBY

STATUS.

S Y N W 1 OC Z E K .

U g = 1 0 5 , 4 % F g = 5 0 , 5 6 H z

U s = 1 0 0 , 1 % F s = 4 9 , 99H z

d f i = - 1 3 º S = 0 B= 0

Fig. 3.6

In the waiting state the synchronizer does not send any signals and stays there until

a voltage appears at the START input. The voltage at the START input, does not have to

be kept, only you need a pulse.

Loading...

Loading...