Page 1

SB MB

59638780 04/17

Page 2

2

Page 3

- 1

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent owners.

Before first start-up it is definitely necessary to read the safety indications Nr.

5.956-309.0!

– All users: Users include trained auxilia-

ry personnel, operators and experts.

– Experts: Experts are individuals, who

are, according to their professional education, able to install the equipment

and to operate the same.

To understand this operating instructions

manual it is first necessary to know these

terms. The technical terms indicated in bold

are used through out the operating instructions manual.

raw water, tap water, city water

Water softening unit

Soft water

Reverse osmosis

Waste water enriched with salts and minerals from the reverse osmosis process

Osmosis water, demineralised water, fully

desalinated water

Water from an organic water treatment system.

Please do not expose motor oil, fuil, diesel

and gazoline into the environment. Please

protect the ground and dispose of used oil

properly.

Notes about the ingredients (REACH)

You will find current information about the

ingredients at:

www.kaercher.com/REACH

Mishandling or misuse can prove to be hazardous to the operator and other persons

through

– high water pressure,

– hot water,

– Hot exhausts

– high electrical voltage,

– Detergent,

– damage to stomach and food pipe by

drinking large quantities of permeate.

To avoid danger to persons, animals and

property before the first operation of the

system, read:

– the operation instructions

– all safety notices

– according to the national requirements

of each country

– that safety notices included in the

cleaning agents used (normally on top

of the package stated).

Please remember:

– that you have understood all the in-

structions

– that all users of the plant are informed

about the instructions and have under-

stood them.

All individuals,who are involved, in the installation, the operation, the maintenance

and service of this equipment, must be

– qualified accordingly,

– they must know and obey the operation

instructions,

– they must know the appropriate regula-

tions, and must obey the same.

In the operation of self service, the owner

must provide cleaned and well exposed notice signs, which have to state

– possible danger,

– Safty device,

– Operating the equipment

If the equipment is operated in a close room

– , exhaust must be lead through appro-

priate pipes or chimneys,

– and there has to be sufficient fresh air

circulation.

DANGER

Risk of burns due to hot exhaust gases;

hence, do not reach over the exhaust opening. Do not touch the chimney cover.

Risk of burns due to hot system parts such

as pumps and motors. Be careful when

opening the system; allow system parts to

cool down first.

몇 WARNING

Do not use the system in the vicinity of people, unless they are wearing protective

gear.

The jet must not be directed by the user at

him/herself or at other persons to clean

clothing or footwear.

High-pressure hoses, fixtures and couplings are important for the safety of the appliance. Only use high-pressure hoses, fixtures and couplings recommended by the

manufacturer.

The system must not be used if a connecting line or important parts of the appliance,

e.g. safety devices, high-pressure hoses,

spray guns, are damaged.

– Please follow the national rules and

regulations for fluid spray jets of the respective country.

– All national laws and regulations about

installation of electrical appliances must

also be followed.

– Please follow the national rules and

regulations for accident prevention of

the respective country. Fluid spray jets

must be tested regularly and the results

of these tests must be documented in

writing.

– The heating appliance of the machine is

an ignition plant. All national laws and

regulations about heating systems

must also be followed.

– If the plant is operated in rooms, then

there should be adequate measures for

safely diverting the exhaust gases out

of the room (smoke gas pipes without

draught interceptors). Further, there

must also be adequate supply of fresh

air.

– Only Customer Service engineers

trained by Kärcher may perform settings and carry out maintenance tasks

and repairs.

– The local guidelines must be followed

while installing the chimney.

Before installing the machine, it is necessary to get the approval of the gas supply

company and the local chief chimney

cleaner.

The statutory requirements of civil engineering laws, trade laws and emission control norms must be followed at the time of

installation. We wish to bring to your notice

the following statutory regulations, guidelines and standards:

– The device may only be installed by a

specialized company according to the

national regulations.

Contents

About this operating instructions

manual. . . . . . . . . . . . . . . . . . . EN 1

Environmental protection. . . . . EN 1

Safety instructions . . . . . . . . . . EN 1

Operation. . . . . . . . . . . . . . . . . EN 2

Open the system . . . . . . . . . . . EN 4

Settings . . . . . . . . . . . . . . . . . . EN 5

Filling in detergents . . . . . . . . . EN 11

Manual interventions . . . . . . . . EN 11

Sales indicator . . . . . . . . . . . . . EN 12

Frost protection . . . . . . . . . . . . EN 12

Shutting down . . . . . . . . . . . . . EN 14

Shutdown. . . . . . . . . . . . . . . . . EN 14

Function. . . . . . . . . . . . . . . . . . EN 15

Technical specifications. . . . . . EN 23

Maintenance and care . . . . . . . EN 26

Troubleshooting. . . . . . . . . . . . EN 34

Accessories . . . . . . . . . . . . . . . EN 44

Warranty . . . . . . . . . . . . . . . . . EN 44

Transport . . . . . . . . . . . . . . . . . EN 44

Storage . . . . . . . . . . . . . . . . . . EN 44

Installing the unit (only for ex-

perts) . . . . . . . . . . . . . . . . . . . . EN 45

EU Declaration of Conformity . EN 51

Log of high pressure testing . . EN 52

About this operating

instructions manual

Target group for these instructions

Technical terms

Fresh water

Base exchanger

De-hardened or softened water

Reverse Osmosis (Abbreviation: RO)

Concentrate

Permeate

Processed water

Environmental protection

The packaging materials are recyclable. Please do not throw

packaging in the domestic waste

but pass it on for recycling.

Old units contain valuable recyclable materials. Batteries, oil

and similar substances may not

be released into the environment.

Therefore please dispose of old

units through suitable collection

systems.

Safety instructions

General

Specifications and Guidelines

Gas burner (option)

3EN

Page 4

- 2

– Installation of gas pipes - especially the

gas connections to the machine should only be done by a technical

company that has been approved by

the Industrial Association for Gas and

Water Installations.

– Settings, maintenance tasks and re-

pairs on the gas burner must only be

performed by authorised expert staff of

the burner manufacturers.

DANGER

Pointer to immediate danger, which leads

to severe injuries or death.

몇 WARNING

Pointer to a possibly dangerous situation,

which can lead to severe injuries or death.

몇 CAUTION

Pointer to a possibly dangerous situation,

which can lead to minor injuries.

ATTENTION

Pointer to a possibly dangerous situation,

which can lead to property damage.

DANGER

Risk of injury from the high-pressure jet. Do

not point the high-pressure jet to humans or

animals. Risk of injury from electric shock.

Do not point the high pressure jet towards

electrical devices, cables and the system.

The sound level in the plant amounts to 65

dB(A). If parts (such as large sheets) that

amplify sound are shot blasted, it can give

rise to higher noise levels. If so, wear ear

plugs.

Turn the programme selection switch at

the operating panel to "STOP".

This SB washing system is to be used for

cleaning

– Vehicles and

– Trailers

with water and detergents added to it.

It is wrong and therefore prohibited to use

the plant for cleaning

– human beings and animals. There is a

high risk of injury due to the high pres-

sure jet.

– Loose parts. These can get thrown off

due to the high pressure jet and can

cause damage to persons or other parts

of the plant.

To disconnect from the drinking water network, a system separator type BA, category 4 must be installed between the system

and the drinking water network. In addition

to that, the local regulations must be adhered to.

ATTENTION

Risk of damage to the plant if water supply

is not of suitable quality. The system must

only be supplied with water in drinking water quality.

The plant may be used for diverting combustible gases only in the open.

If the plant is to be housed under a roof or

in a closed room, then it must be connected

to a chimney to provide an outlet for the exhaust gases. If the plant is to be connected

to a chimney, then the burner needs to be

adjusted and the exhaust values must be

checked by the concerned chimney cleaner.

ATTENTION

The system is frost-safe up to -20°C under

the conditions outlined in the section

"Frost-protection" and must be shut down if

the temperatures fall below this limit.

– Coins are thrown in at the control panel

and the washing programme is selected.

– Cleaning is done using the hand-spray

gun.

DANGER

Risk of injury, risk of burns. Washing operation only when the system is locked.

– The inner areas of the plant should only

be accessed by trained persons for

maintenance tasks. The door must be

closed when the plant is in operation.

Turn the programme selection switch at

the operating panel to "STOP".

The following washing programs are available:

Stop

Interrupts the programme.

Basic position, washing tools in the tool

holders.

Note:

"STOP" function is active in all switch positions without washing programme.

High-pressure wash

Removes coarse dirt.

Warm water with shampoo

Distance of high pressure nozzle approx 30 cm.

Hazard levels

Symbols on the plant

Risk of electric shock!

Only electricians or authorised

technicians are permitted to

work on parts of the plant.

Hearing protection

Behaviour in emergency situations

Proper use

Workstation

Operation

Switch-off in case of emergency

Washing programmes

Standard programmes

4 EN

Page 5

- 3

Foam Wash

Deep cleaning with active foam.

Only use foam brush when the programme

is running and after the high-pressure

wash.

Rinse

Rinse off shampoo and foam.

Distance of high pressure nozzle approx 50 cm.

Hot wax

Warm water with paint protection.

Use after rinsing.

Distance of high pressure nozzle approx 80 cm.

Top care

For Spot-free drying.

Demineralised water leaves a spot-free

high gloss finish.

Distance of high pressure nozzle approx 80 cm.

Dirt Loosening

Removes persistent dirt.

Warm water with special detergent.

Distance of high pressure nozzle approx 30 cm.

Micro emulsion, model A

Removes persistent dirt.

Warm water with special detergent.

Distance of high pressure nozzle approx 30 cm.

Micro emulsion, model B, with external

high pressure pump

Removing bitumen road coating residue.

Spraying a special detergent.

Insects Loosening

Loosens insects.

Warm water with special insect removing

detergent.

Distance of high pressure nozzle approx 30 cm.

Rim cleaning, model A, with dosing

pump

Loosens brake dust.

Warm water with special or increased detergent addition.

Alkaline-based detergents only.

Distance of high pressure nozzle approx 30 cm.

Application before the car wash and only

on coated or painted wheels.

Rim cleaning, model B, with external

high pressure pump and mixing tank

Loosens brake dust.

Cold water with special high-dose detergent addition while mixing in compressed

air.

Application before the car wash and only

on coated or painted wheels.

Intensive foam

Loosens persistent contamination.

Foam with special detergent addition.

Distance of foam nozzle approx 30 cm.

Under-chassis Wash

Removing coarse dirt from the underchassis.

Washing cycle begins with a delay of approx. 10 seconds; drive the vehicle backwards and forwards over the under-chassis

wash.

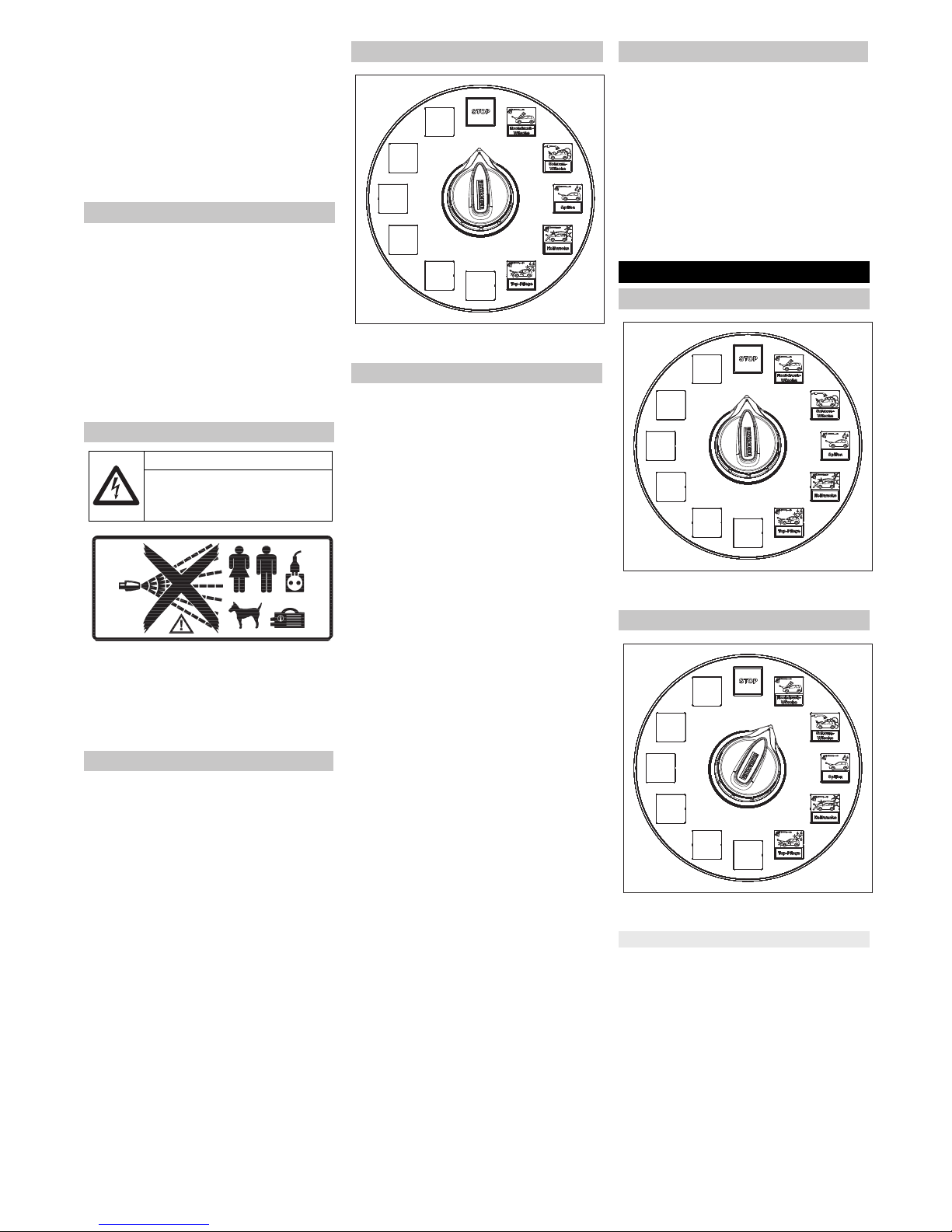

1 Rest value display

2 Program selection switch

3 Throwing in the coin

1 Rest value display

2 Program selection switch

3 Throwing in the coin

Select the washing programme using

the programme selection switch.

Throw in the coin.

1 Washing brush

2 Locking lever

3 Hand spray gun

4 Lever for trigger gun

5 Safety lever

Press the locking lever for washing us-

ing high-pressure jet; pull the washing

brush towards the rear and lock it in.

To wash using the washing brush,

press the locking lever, push the wash-

ing brush forward and lock it in.

Unlock the trigger gun and pull the lever

of the gun.

The hand-spray gun and washing brush

are available as separate tools.

Hand spray gun:

Unlock the trigger gun and pull the lever

of the gun.

Washing brush:

Clean the washing brush with the hand

spray gun prior to use.

Set the washing programme "foam

wash" and clean the vehicle.

– Washing time starts after the coin is

thrown in.

– The remaining value display shows the

remaining washing credit in washing

units.

Note:

The washing time is running even if the programme selector switch is in the "STOP"

position.

If more coins are thrown in during the washing time, the same are registered and added to the existing washing time.

Additional programmes (option)

Operations procedure

Single tool version

Double tool version (optional)

Washing time

5EN

Page 6

- 4

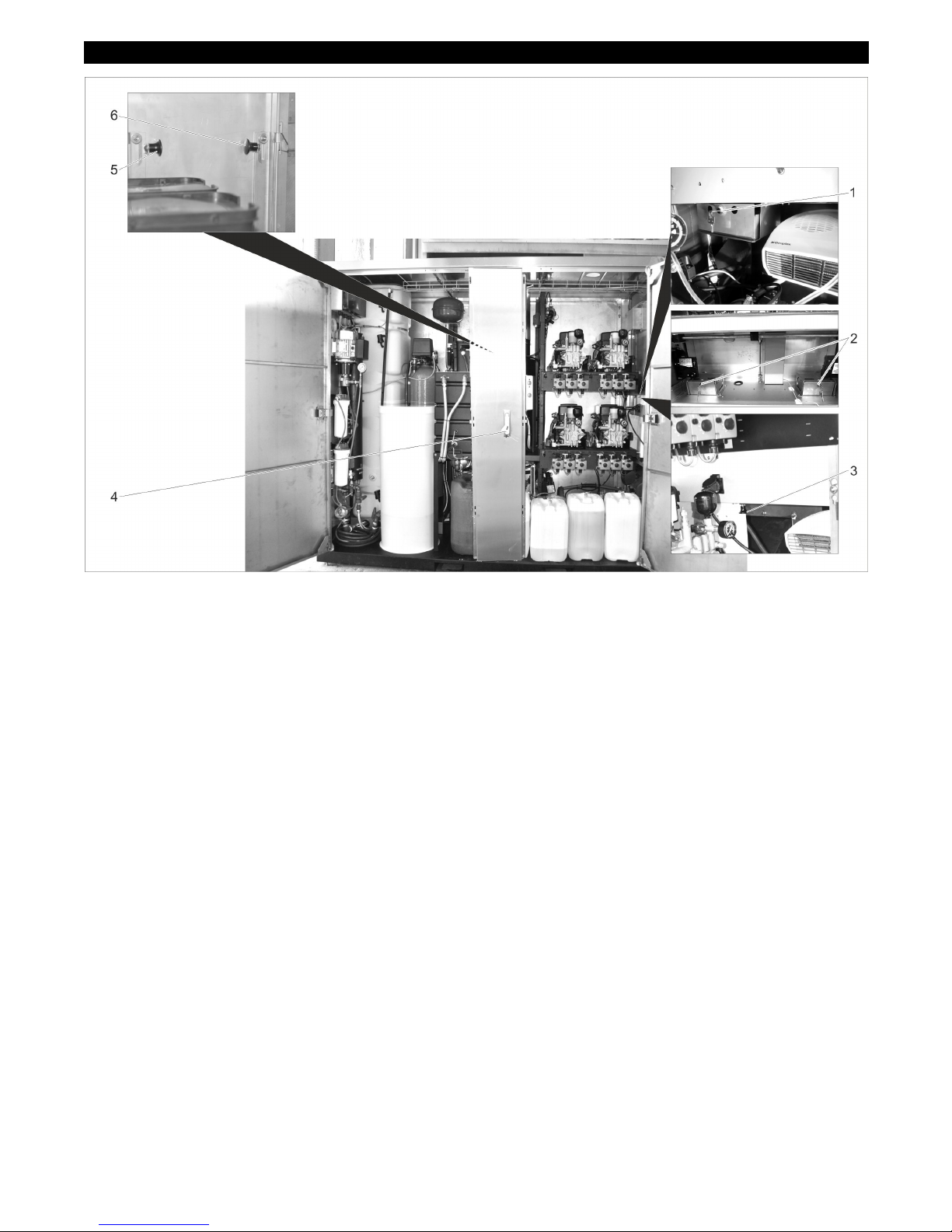

1 Coin acceptor door lock

only for SB MB Comfort

2 Coin cassette lock (optional)

only for SB MB Comfort

3 Unlock the coin acceptor door

Only for SB MB standard

Pull down to unlock.

4 Front door unlock

Lift up to unlock.

5 Unlock of left rear door

Lift up to unlock.

6 Unlock of right rear door

Lift up to unlock.

Open the system

6 EN

Page 7

- 5

1 Dry foam station

2 Display of control (in control cabinet)

3 Display of control

Only for SB MB standard

4 Control board

5 Main switch

6 Dosing pump, dry foam station

7 Hot air blower

8 Dosing pumps

9 Frost protection with lost water (option),

installation site 2

10 Frost protection with lost water (option),

installation site 1

11 Emergency frost protection (option)

12 Rim cleaner (option)

13 Heat exchanger washing station heater

14 Head of base exchanger

15 Blending device (option)

1 Pressure switch air

2 Manometer

3 Compressed air connection for service

work

4 Pressure reducer

Set pressure reducer to 0.4...0.5 MPa

(4...5 bar).

1 Dosing pump high pressure wash (DP 1)

2 Dosing pump hot wax (DP 2)

3 Dosing pump top care (DP 3)

4 Dosing pump optional (DP 4), for addi-

tional programmes

The dosing pumps dose the washing water

with the detergents in accordance with the

wash programme and the equipment of the

system.

Note:

The dosage amount is optimally set by the

fitter when the system is assembled. Generally no reset is necessary.

Fine adjustments are made on the control

(see Settings/Control). The standard setting of the dosing pumps remains unchanged.

Settings

Main switch

Position

1 Plant is working.

Frost protection (option) is active.

0 Entire system turned off (frost

protection also).

Adjust compressor Setting dosing pumps

7EN

Page 8

- 6

1 Ventilation lever

2 Ventilation button

3 Adjustment knob dosing volume

Pull out the adjustment knob for the

dosing volume.

Press and release the ventilation button

repeatedly and at the same time, rotate

the adjustment knob to the desired set-

ting.

Release the ventilation key.

Push in the adjustment knob for the

dosing volume.

1 Outlet water/detergent

2 Dosing valve water/detergent

3 Inlet water/detergent

4 Dosing valve air

5 Output air

6 Manometer compressed air

7 Pressure reducer air

8 Manometer water

9 Pressure reducer water

1 Dosing pump for dry foam

Open fresh water supply.

Use wash programme "Foam wash" at

a washing area.

Set pressure reducer for water to 0.25

MPa (2.5 bar).

Set the dosing pump for dry foam to

20%.

See "Adjusting dosing pumps" for procedure.

Open fresh water supply.

Remove the hose at the distribution

block water/chemicals outlet and replace with a 400 mm hose piece (PVC

hose 6/4).

Use wash programme "Foam wash" for

this washing area.

Set the fluid stream from the hose piece

by adjusting the dosing valve water/detergent to 300 ml/min (measure with

measuring cylinder).

End wash programme "foam wash".

Remove the hose piece and reconnect

the hose to the washing area.

Repeat the setting of the dosing valves

water/chemicals for the remaining

washing areas.

Set pressure reducer for air to 0.25

MPa (2.5 bar).

Use the service tool 6.901-074.0 be-

tween the output air and the hose to the

washing area.

Use wash programme "Foam wash" for

this washing area.

Adjust the dosing valve air so that the

pressure gauge of the service tool displays 0.15 MPa (1.5 bar).

End wash programme "foam wash".

Remove the service tool and reconnect

the hose to the washing area to the distributor block air.

Repeat the setting of the dosing valves

air for the remaining washing areas.

Note:

After performing the basic setup, the consistency of the foam should only be

changed by adjusting the dosing valves air.

1 Input of detergent

2 Nozzle insert

3 Suction hose for detergent

Pull off the suction hose.

Select the nozzle insert for the desired

mixing ratio:

Slide the nozzle insert all the way into

the detergent input.

Insert the suction hose.

1 Adjustment screw

Adjust the pressure via the adjustment

screw:

Basic adjustment

Detergent Position of

adjustment

knob (%)

High pressure

wash

RM 806 50

Wet foam

(Option)

RM 806 50

Dry foam (option)

RM 812 50

Hot wax RM 820 50

Top care RM 821 50

Contaminant removal (option)

RM 806 50

Insect removal

(option)

RM 803 50

Dry foam station

Basic setting water

Basic setting water/chemicals

Basic setting air

Wheel cleaner/intensive foam

(option)

Nozzle colour Water/detergent

Wheel

cleaner

Intensive

foam

no nozzle 1:1 4:1

grey 1.2:1 5:1

black 2:1 6:1

beige 4:1 8:1

red 6:1 17:1

white 9:1 23:1

blue 10:1 25:1

light brown 13:1 36:1

green 21:1 48:1

orange 26:1 64:1

brown 30:1 75:1

yellow 38:1 90:1

purple 50:1 120:1

pink 100:1 240:1

Basic setting water/chemicals

Rim clean-erIntensive

foam

Detergent RM 801 RM 838

Nozzle colour blue yellow

Mixing ratio 10:1 38:1

Rim cleaner Intensive foam

8.0...8.5 bar

8 EN

Page 9

- 7

Adjust the air pressure reducer:

ATTENTION

Risk of damage due to acidic detergents.

Only use alkaline detergents for wheel

cleaning.

Note:

After performing the basic setup, the spray

pattern should only be changed by adjusting the pressure reducer for air.

Wheel cleaner:

The uniform application onto the rims is facilitated if a suitable colouring agent is added to the rim cleaner concentrate.

1 Adjustment screw

Adjust the pressure of the micro emul-

sion as needed by turning the adjust-

ment screw.

The booster heater is supplied with partly

softened water with a water hardness of

7° dH.

For this purpose, the blending device mixes

fresh water and softened water.

1 Sampling tap

2 Outlet valve (to the booster heater)

3 Adjusting screw, fine adjustment

4 Adjusting screw, coarse adjustment

5 Inlet valve fresh water

Completely open outlet valve and inlet

valve.

Close both adjusting screws (turn in

clockwise direction).

Establish water inlet to the warm water

tank.

Open the sampling tap.

Slightly open adjusting screw coarse

adjustment.

Collect water from the sampling tap and

measure the water hardness.

Adjust the bypass valve until it is just

under 7° dH.

Set the water hardness to 7° dH using

the adjusting screw fine adjustment.

Close the sampling tap.

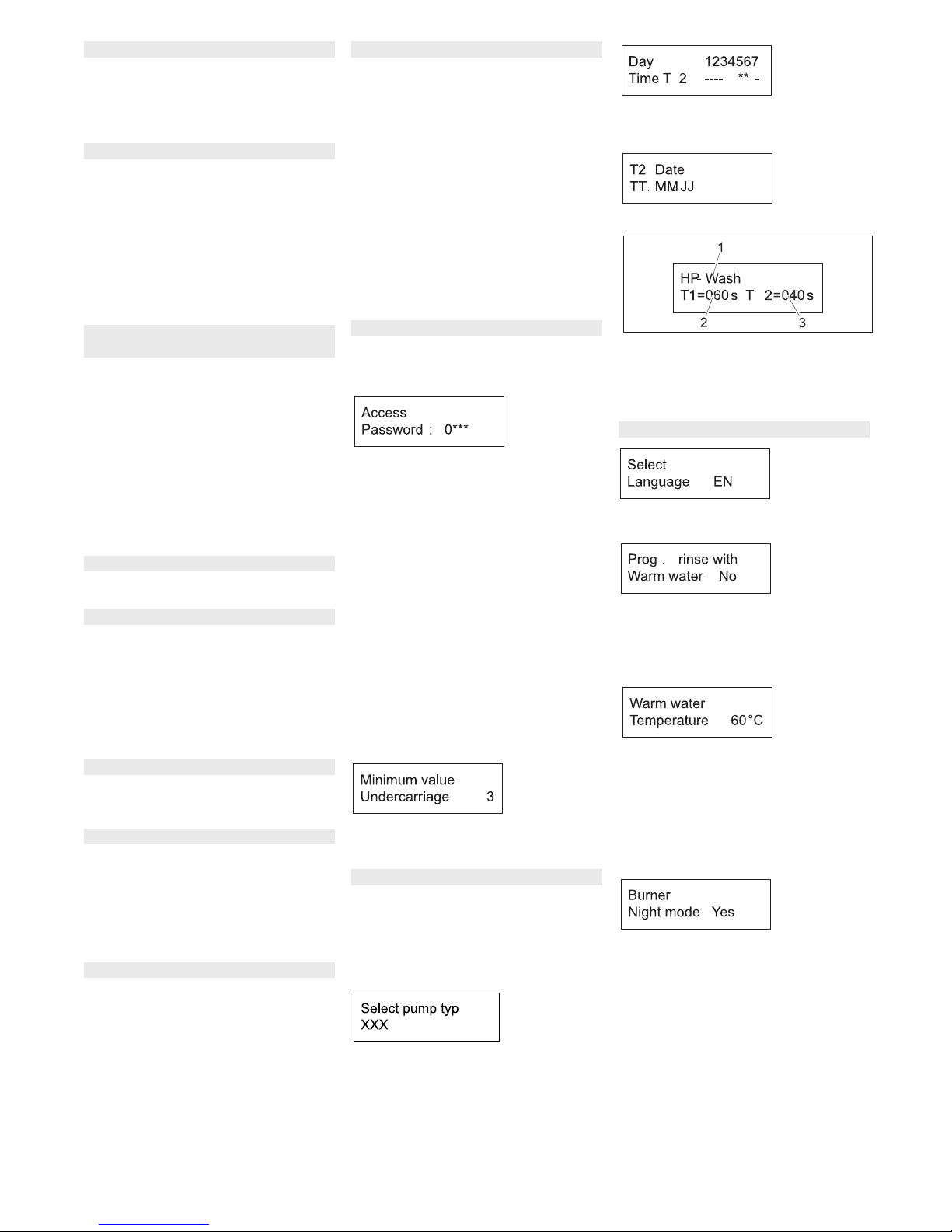

1 Key "1/ON"

2 Control lamp operating state

3 Display

4 LEFT key

5 RIGHT key

6 OK button

7 ESC button

1 Display

2 LEFT key

3 RIGHT key

4 OK button

5 ESC button

During normal operating mode, the control

panel display alternates between:

Day of the week, date, time, summer time

(Som)/winter time (Wint)

Operating time of the system on the current

day

Maintenance work due from customer service (example).

If more than one maintenance procedure is

required, these will be shown in sequence.

If no maintenance procedures are required,

nothing will be shown.

Fault occurred (example).

If more than one fault is present, these will

be shown in sequence.

The number in parentheses shows the total

number of faults present.

If no faults are present, nothing will be

shown.

Note:

To acknowledge faults see "Troubleshooting"

Press OK button for more than 2 sec-

onds.

Press the RIGHT button.

Press the OK button.

The menu "customer settings" (see following page) has been reached.

Basic setting air

Rim cleaner Intensive foam

2.5...3.0 bar 3.0 bar

Micro emulsion (option)

Blending device (option)

Controls

SB MB standard

SB MB comfort

Normal operation

Open the menu "customer settings"

9EN

Page 10

- 8

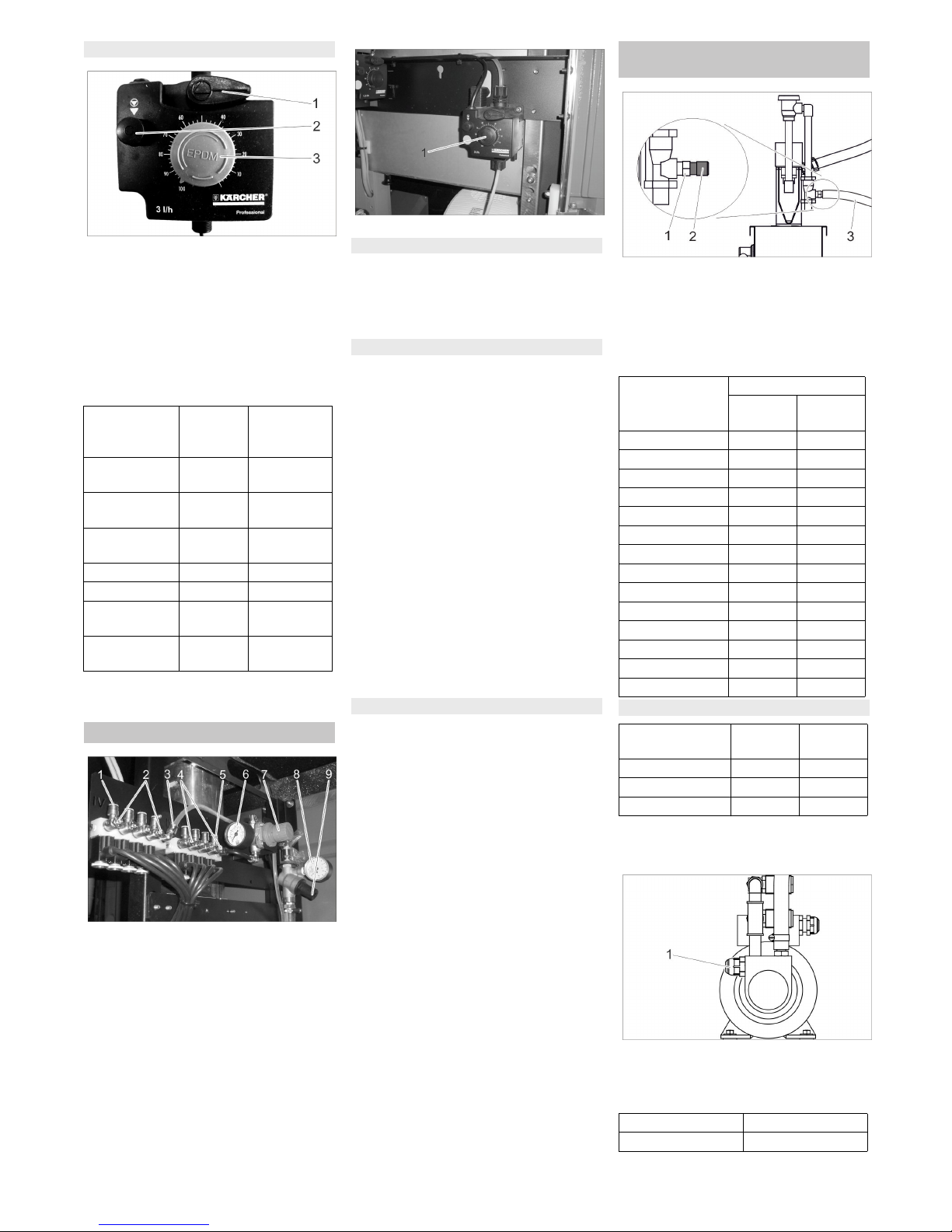

1 Menu item

2 Parameter

10 EN

Page 11

- 9

Select the menu item with the buttons

LEFT and RIGHT.

Press OK to open the parameter group.

Use the LEFT and RIGHT buttons to

select the paramater you want to set.

Press the OK button.

The selectable variable blinks.

Use the LEFT and RIGHT buttons to

select the variable value.

Press and hold the button for a swift

change of the variable.

Press the OK button to save the select-

ed value.

or

Press ESC to abort the change.

Press the OK button.

The selectable variable blinks.

Use the LEFT and RIGHT buttons to

select the variable value.

Press and hold the button for a swift

change of the variable.

Press OK briefly to save the value and

to jump to the next variable.

Press the OK button for more than 1

second to save set values.

or

Press ESC to abort the change.

Press the ESC ro return to the next

higher menu.

The plant is open during the operating time.

The plant is locked outside the operating

time.

24 hours open: Set beginning and end of

the operating time to the same value.

24 hours closed: Set the end of the operating time to an earlier value than the beginning of the operating time

During the lighting time, the washing station lights can be adjusted by a dimmer

switch.

Fixed public holidays are on the same day

every year.

On the set public holidays the operating

time selected for public holidays applies.

Note:

Set the date to 00.00.XX for unused public

holidays.

Variable public holidays are on different

days every year. They must newly be set

every year.

On the set public holidays the operating

time selected for public holidays applies.

Note:

Set the date to 00.00.00 for unused public

holidays.

Setting date, time and summer/winter time

change

Auto summer / winter time = YES:

Automatic change active. Summer time

(daylight saving time) begins on the last

sunday in March at 2:00 o'clock. Winter

time (normal time) begins on the last sunday in October at 3:00 o'clock.

Auto summer / winter time = NO:

No automatic time change.

Note:

If automatic switching is active, either

"Som" (for summer) or "Wint" (for winter) is

displayed along with the date and time in

the right bottom corner of the display during

normal operation.

The coin value, as well as the coins, will tell

the different canals of the coin inspector,

how to evaluate them.

Note:

Upon the initial start-up, the password is

"1111“. For security reasons, we recommend changing the password during the

first use (see "Changing password" at the

end of the chapter).

Use the LEFT and RIGHT buttons to

select the blinking location of the password.

Confirm your entry using the "OK" key.

Set the other characters of the pass-

word in the same fashion.

Press the "OK" key for more than 1 sec-

ond to save the password.

Select the menu item with the buttons

LEFT and RIGHT.

Value: Value of the coins in washing units.

Re: Value in currency units (e.g. Euro).

Undercarriage wash:

Minimum number of required washing units

to execute the undercarriage washing programme.

Here, the run time of the different washing

programmes are set per washing unit.

If the system includes different high pressure modules, different run times can be

set up of each type of pump.

Selecting pump type:

Two washing times can be set up for each

programme:

T1: Standard washing time

T2: Special washing time, applies to certain weekdays or to a certain date

T2 applies to weekdays marked with an "*".

1=Monday,,,7=Sunday. T1 will apply on the

other days.

Additionally, T2 is applied on the set date.

1 Washing programme

2 Standard washing time T1 per washing

unit

3 Standard washing time T2 per washing

unit

Display language.

YES: Programme "Rinse" is executed with

warm water.

NO: Programme "Rinse" is executed with

cold water.

Temperature in the swimmer tank for warm

water. Can be adjusted between 30 and 60

°C.

Note:

If the circulation pump washing station

heating is in use, the water is automatically

heated to 60 °C.

YES: The burner shuts off after operation

and restarts 10 minutes prior to operation.

Note:

If the circulation pump for the washing station heating is turned on for frost protection,

the burner will turn on in spite of night

mode.

NO: The burner keeps the warm water in

the swimmer container at nominal temperature, even outside operating hours.

Select the parameter you want to set

Set the parameter with a variable

Settng a parameter with several

variables

Exiting the menu

Operating times

Lighting time

Fixed holidays

Non-fixed holidays

Date / Time

Coin value

Programme run times

System settings

11EN

Page 12

- 10

YES: The hose heater is switched off after

operation and restarts one hour prior to operation.

NO: The hose heater is also active outside

the operating hours.

The washing stations marked with an "*"

are blocked. These washing stations will

not accept coins.

This function is provided for maintenance

work or repairs.

YES: Operating time and lighting time are

controlled externally, bypassing the settings in the control. The holiday settings are

ineffective.

NO: The washing station is operated as set

up in the control.

actual: currently measuring dimming value.

nominal: Set dimming value, from which

point forward the basic and washing station

lights are switched on within the set up

lighting time.

Forced regeneration of base exchanger

1 = Monday...7 = Sunday.

Regeneration starts on the set day at 2:00.

– Adjustable between 1% and 100%.

– Off = pulse off (0%)

The adjustment of the dosing pumps is executed as described in the beginning of this

chapter (see "Adjusting parameter with one

variable“).

This menu item is not used.

Two hot air ventilators heat up the inside

room of the plant to protect it against freezing.

몇 WARNING

Risk of fire from overheating of the fan

heater. The incoming and outgoing air

openings may not be covered up.

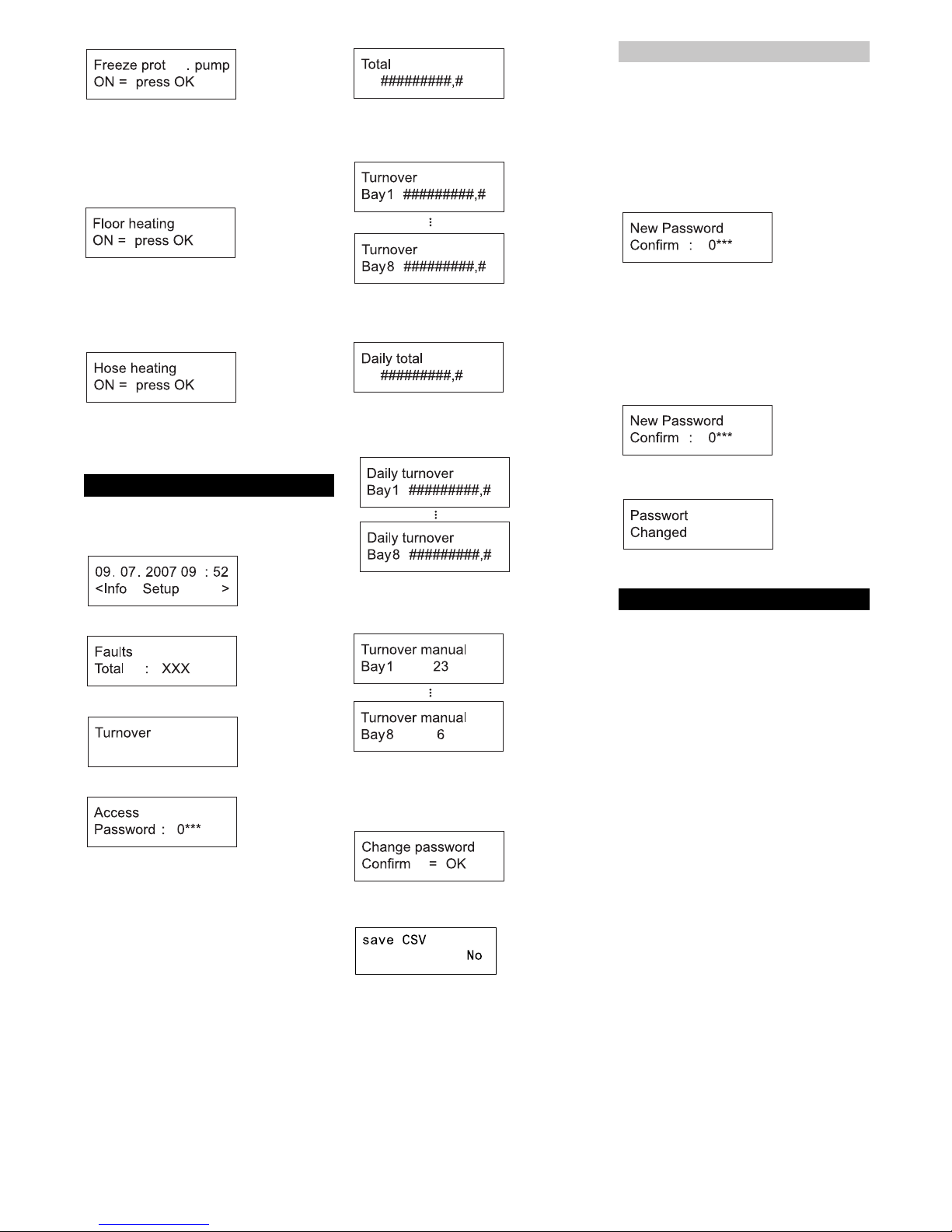

1 Output regulator

2 Thermostat

1 Thermostat mixing valve

The thermostat mixing valve regulates the

feed temperature depending on the return

flow temperature.

Basic setting: 22°C=Value 3 on the scale

Rectify the setting, if required, accord-

ing to the following table:

This frost protection system is activated by

the control if there is a risk of frost.

Fresh water flows through the high pressure lines and hand spray guns, and these

are thus protected from freezing.

1 Pressure reducer

Switch on the frost protection pump

(see Chapter "Manual procedures").

Adjust the pressure reducer so that at

least 0.5 l/min of water flows from each

hand spray gun.

Switch the frost protection pump off.

The emergency frost protection is activated

in case of a power outage.

Fresh water flows through the high pressure lines and hand spray guns, and these

are thus protected from freezing.

1 Pressure reducer

Turn the main switch to position “0”.

Adjust the pressure reducer so that at

least 0.5 l/min of water flows from each

hand spray gun.

The external thermostat switches on the

following anti-frost equipment depending

on the external temperature:

– below +3°C:

Hose heater dry foam (option)

Heating cartridge and trace heating

ABS fuel oil tank (option)

– below +1°C:

Circulation pump for washing place

heating

Circulation pump for anti-frost

Note:

The switching temperature of the exterior

thermostat can be set by customer service.

Setting the dosing pumps

System

Regener. 1234567

WS ----*--

Hot blowers

Hot air ventilator SB MB

Hot air blower

0°C... -10°C

-10°C...-20°C

Up Output regulator II II

Thermostat II III

Down Output regulator II II

Thermostat * I

Washing station heater

Value on the

scale

012345

Return flow temp °C10 14 18 22 26 30

Value on the

scale

678910–

Return flow temp °C34 38 42 46 50 –

Frost protection with lost water

Emergency frost protection

External thermostat

12 EN

Page 13

- 11

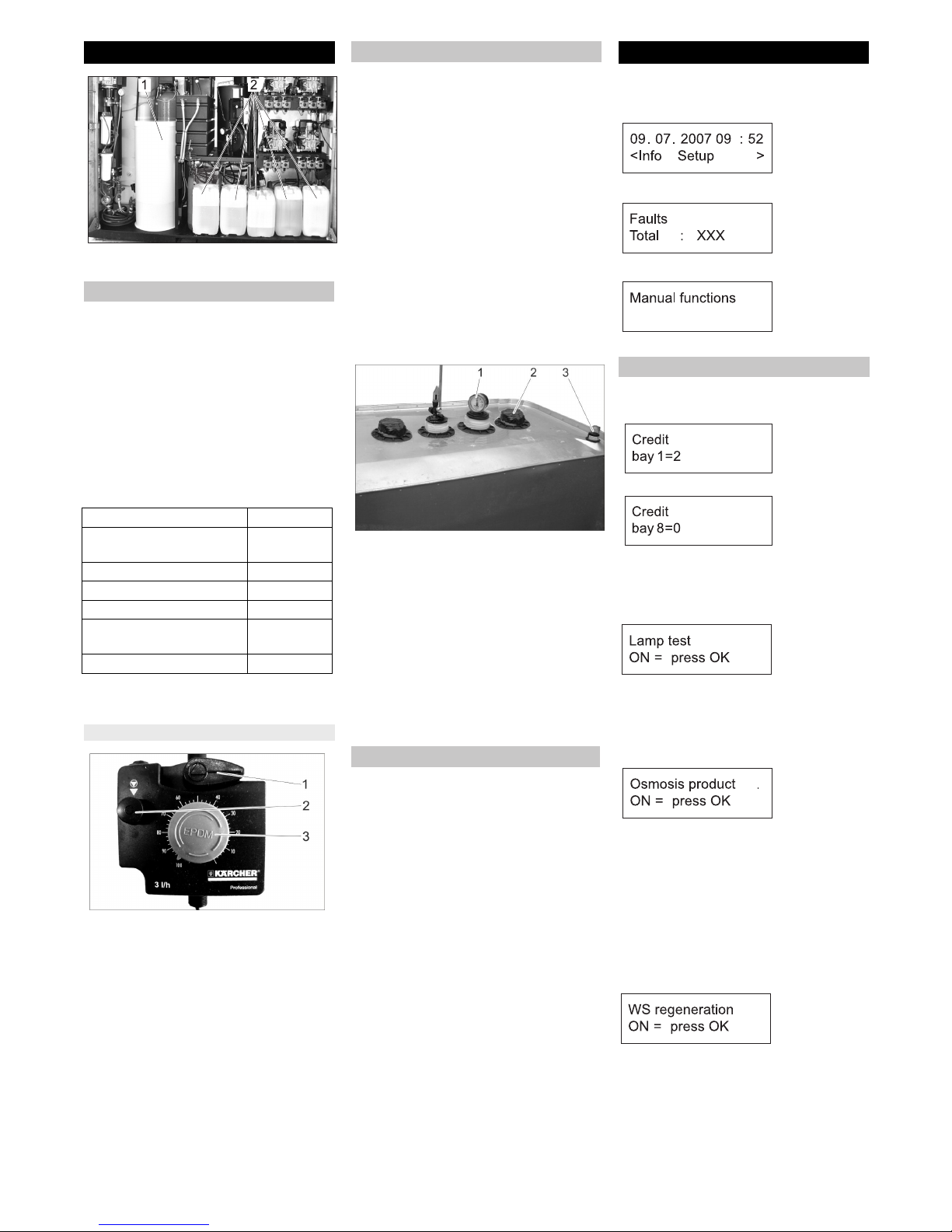

1 Softening salt

2 Detergent

ATTENTION

If the detergent container is empty, the

high-pressure pump will draw air and can

get damaged. Check the detergent tank at

regular intervals.

DANGER

Risk from hazardous materials. All

KÄRCHER cleaning agents to contain

safety, and application notices. Notices

concerning the application must be read

and obeyed. Wear specified protective

clothing/protective equipment.

Only use KÄRCHER-approved detergents.

This system uses undiluted detergents.

Hang in the detergent hose into the de-

tergent can.

1 Ventilation lever

2 Ventilation button

3 Adjustment knob dosing volume

The compressed air supply of the system

must be operating.

Turn the ventilation lever in an anti-

clockwise direction until it stops.

Set the dosing volume to 100%.

Press the ventilation key until the deter-

gent emerges from the ventilation line

at the bottom of the dosing pump with-

out bubbles.

Set the dosing volume to the required

value.

Turn the ventilation lever in a clockwise

direction until it stops.

DANGER

Risk of fire. Observe local regulations for

handling fuels.

Do not use unsuitable fuels, as they may be

dangerous.

ATTENTION

If the fuel tank is empty, the fuel pump runs

dry and can get damaged. Check the fuel

tank regularly.

Wrong fuel can cause functional disruptions in the burner and poor combustion.

Use only the fuel specified in the "Technical

data" section.

Use heating oil with additives (flow promoters) while operating in winter if there is risk

of frost

Fuel expands on heating and can overflow.

Do not fill the fuel tank up to the brim.

1 Filling level display

2 Filling nozzle

3 Inspection opening

Close the lid of the filling nozzle.

Fill fuel till the filling level display indi-

cates full level.

Note:

Ensure that no fuel overflows and goes into

the inspection opening. This fuel can be

taken for a leakage during subsequent inspection.

Close the filling nozzle.

ATTENTION

Risk of functional disturbances. While filling

the softening salts, use only the softening

salt in the tablet form listed in the chapter

"Accessories".

Open the salt tank.

Fill the softening salt right until the top.

Close the salt tank.

Note:

An empty salt tank will cause a malfunction!

Fill the salt tank at the latest when water is

visible in the salt tank while removing the

lid. Filling the salt container to the top does

not mean that there will be an increase in

salt consumption.

When the system is functioning properly,

the ratio of salt consumption to water consumption remains constant.

We recommend documenting the salt and

water consumption in an operations log.

In normal operating mode, press the

"OK" key on the control longer than 2

seconds.

Press the LEFT button.

Press the RIGHT button twice.

Press the OK button.

Select the menu item with the buttons

LEFT and RIGHT.

Every pressing of the "OK" key increases

the washing credit of the selected washing

station (box) by one washing unit.

When the "OK" key is pressed, the washing

station lights turn on for 3 minutes.

If the "OK" key is pressed again prior to the

time elapse, the function is terminated.

Pressing the "OK" key activates the permeate production in the ABS WSO. Permeate

production will end when the buffer tank is

filled with permeate. If the buffer tank is already full when permeate production starts,

the permeate production cycle will end after

3 minutes.

If the "OK" key is pressed again prior to the

time elapse, the function is terminated.

Pressing the "OK" key activates the regeneration of the base exchanger in the ABS

WSO. The regeneration cannot be exited.

Filling in detergents

Provide detergent

Detergent

High pressure wash / wet

foam

RM 806

Dry foam RM 812

Hot wax RM 820

Top care RM 821

Rim cleaner

(Model B)

RM 801

Intensive foam RM 838

Bleed dosing pump.

Refill fuel

Fill softening salts

Manual interventions

Menu for manual interventions

13EN

Page 14

- 12

When the "OK" key is pressed, the circulation pump activates frost protection for 3

minutes.

If the "OK" key is pressed again prior to the

time elapse, the function is terminated.

When the "OK" key is pressed, the washing

station heater is activated for 3 minutes.

If the "OK" key is pressed again prior to the

time elapse, the function is terminated.

When the "OK" key is pressed, the foam

hose heater is activated for 3 minutes.

If the "OK" key is pressed again prior to the

time elapse, the function is terminated.

In normal operating mode, press the

"OK" key on the control longer than 2

seconds.

Press the LEFT button.

Press the RIGHT button three times.

Press the OK button.

Note:

Upon the initial start-up, the password is

"1111“. For security reasons, we recommend changing the password during the

first use (see "Changing password" at the

end of the chapter).

Use the LEFT and RIGHT buttons to

select the blinking location of the pass-

word.

Confirm your entry using the "OK" key.

Set the other characters of the pass-

word in the same fashion.

Press the "OK" key for more than 1 sec-

ond to save the password.

Select the menu item with the buttons

LEFT and RIGHT.

Total sales since start-up of the washing

system.

Sales per washing station since start-up of

the washing system.

Total sales since the the beginning of the

day (0:00 Uhr).

Sales per washing station since the the beginning of the day (0:00 Uhr).

Sales from the manually increased washing units per washing station (see "Manual

interventions").

Press the "OK" key to change the password.

YES: The daily storage on an USB flash

drive contains the sales data.

NO: The daily storage does not contain any

sales data.

Note:

Press "ESC" to cancel the change of the

password.

Upon the initial start-up, the password is

"1111“. For security reasons, we recommend changing the password upon the first

use.

For security reasons, the password may

only be changed by the operator.

Use the LEFT and RIGHT buttons to

select the blinking location of the password.

Confirm your entry using the "OK" key.

Set the other characters of the pass-

word in the same fashion.

Press the "OK" key for more than 1 sec-

ond to save the password.

Reenter the password as described

above to confirm.

The successful change of the password will

be confirmed.

The anit freeze equipment contains:

– Recirculation blower

– Hot air blower

– Frost protection circuit or frost protec-

tion without lost water

– Washing station heater

– Emergency frost protection

– Heating cartridge in the oil tank

몇 WARNING

Risk of accident due to ice formation. In

case of ice formation the plant must be

closed off to prevent ice-related accidents.

Note:

The following functions are guaranteed:

– Unrestricted washing with the high-

pressure spray lance up to -15°C.

For systems with 4 washing stations it is

recommended to lock one washing sta-

tion at temperatures below -10 °C (for

systems with 4 high-pressure modules

type 908 already at a warmer tempera-

ture).

– Restricted washing operations using

washing brush at temperatures sub-

zero temperatures.

During restricted washing, all washing

brushes must be checked for ice-forma-

tion at regular intervals. Foam wash

with frozen washing brushes can dam-

age the vehicle. Take the following

steps if the washing brushes are frozen:

– The system is frost-safe up to -20°C.

The device must be shut down at tem-

peratures below -20°C in accordance

with the instructions in "Shutdown in

case of frost".

Sales indicator

Changing the password

Frost protection

14 EN

Page 15

- 13

Note:

The pre-requisites for frost protection are:

– The main switch must be in position 1.

– The doors of the system must be

closed.

– Uninterrupted power, water and fuel

supply must be ensured.

– Water supply must also be protected

against freezing.

– The fuel supply must be protected

against frost (e.g. heating cartridge in

the tank, trace heating),

– Instructions for assembling and installa-

tion are given in chapter "Installing the

plant".

– The hot air ventilators have been set

correctly.

– All maintenance steps according to

"Maintenance and Care" have been

carried out correctly.

– All cleaning tools are placed back in the

storage compartment.

– The trigger guns with frost protection

holes that are part of the system are installed.

Note:

The washing place heating can function

properly provided the washing area has

been built properly according to the

KÄRCHER recommendations.

The heating power is sufficient for a heated

washing station surface of 50/60* m

2

. If the

heated surface exceeds this value, the frost

protection cannot be guaranteed.

Snow layers and large volumes of ice pieces fallen from the vehicles require a very

high heating capacity. It is necessary to remove these deposits.

* 50 m

2

with gas burner (64 kW); 60 m2 with

oil burner (72 kW); with 4 high-pressure

modules type 908 the washing station surface must be further reduced.

Before the onset of the frost period,

maintenance tasks must be carried out

"every year before the onset of the forst

period" according to section "Maintenance and Care".

Carry out the following tasks for keep-

ing the frost protection intact.

Note:

Maintenance not being done on time or

from experts will mean, that there is no

guarantee concerning frost damage.

1 Locking valve 1 Throttle with sieve (marked red), 1-tool-

model

1 Filter for frost-protection pump

Washing station heater Maintenance jobs before and during

the frost period

Time Activity Assembly affected Performance By whom

many times

daily

opinion Washing brush Check for dirt and ice formation; lock foam wash if needed. Operator

daily Clean the

filter

Filter for frost-protection

pump

Clean the filter and replace Operator

opinion Hot blowers Are the hot air ventilators working (even for ABS fuel tank, option)? Operator

Recirculation blower Check function. Operator

Initially daily,

later on based

on experience

opinion Filling level of the fuel tank Will the heating oil be sufficient till next inspection? Take into ac-

count increased consumption due to anti-frost equipment. Insuffi-

cient fuel can lead to failure and damage to the system.

Operator

weekly opinion Heating ABS heating oil

tank (option)

With temperatures below 3°C, check if the trace heating of the heat-

ing oil line between the heating oil tank and SB MB is warm.

Operator

monthly or after 200 operating hours;

more frequently if

needed

opinion Quantity of frost water pro-

tection in the frost protection circuit

Target value: approx. 0.5 l/min per washing tool

Water quantity is higher: Change the node piece in the hand-spray

gun.

몇 WARNING

Risk of injury and damage. If the frost protection water volume is big-

ger than the admissible value, the cleaning tool may move uncon-

trollably due to the exiting water stream. If the frost protection water

volume is too big, replace the union piece in the trigger gun by all

means.

Water quantity is lesser Clean filter for frost protection pump; clean

sieve in throttle, clean pipes, check the rotation direction of the

pump.

Operator

15EN

Page 16

- 14

Turn the main switch to position "0"

Turn the main switch to position "1".

Lock the operating time at the control.

Filling the fuel tank.

If the equipment is to be shut down, and

there is not danger of frost,

disconnect the water input,

disconnect the power supply.

Screw off water supply hose and high

pressure hose.

Remove the RO membrane and store it

under anti-freezing conditions.

Empty all swimmer containers; unscrew

the hoses and let the water drain off.

Empty the permeate buffer tank.

Disconnect the water pipe between

base exchanger and swimmer tank for

warm water.

Rinse the plant (without base exchang-

er) with an anti-frost solution.

Rinse the base exchanger with concen-

trated salt solution.

Unscrew both the hoses under the boil-

er and let the water drain off.

Blow out all water-carrying parts with

oil-free compressed air.

Note:

All parts of the plant except the base exchanger must be rinsed with anti-frost solution during longer operational breaks to

prevent the system against corrosion.

In case of doubt, call Customer Service to

carry out the shutdown operations.

Shutting down

Shutdown during Frost Conditions

Shutdown

Shutdown during frost period

16 EN

Page 17

- 15

Washing station 3 and 4 not shown.

1 Fine filter for fresh water (80-100 μm,

option)

2 Locking valve for fresh water

3 Locking water for fresh water for soften-

ing

4 Locking valve for softened water

5 Salt tank

6 Hardness sensor

7 Water counter *

8 Control head of base exchanger

9 Base exchanger bottle

10 RO membrane

11 Flowmeter permeate *

12 Distribution block

13 Restrictor

14 Swimmer tank for cold water

15 Level sensor BUFFER TANK FULL

16 Level switch PUMP RO ON *

17 Level sensor BUFFER TANK EMPTY

18 Locking valve for permeate tank

19 Buffer tank for permeate

20 Pressure switch for RO water shortage

21 Manometer working pressure

22 RO pump

23 Discharge valve for softened water

24 Active carbon filter

25 Ultra-fine filter *

26 Solenoid valve in salt tank

27 Solenoid valve for cold water

28 Solensoid valve for permeate

29 Bypass valve semi load with throttle,

only for high pressure module type 908

30 High pressure pump

31 Overflow valve

32 Hand-spray gun with washing brush

33 Dosing pump

34 Pressure switch air (optional)

35 Compressor

36 Suction hose for detergent

37 Detergent filter, foot valve

38 Solenoid valve for warm water

39 Drain valve

40 Water shortage safeguard

41 Swimmer tank for warm water

42 Circulation pump for warm water

43 Temperature sensor warm water

44 Flow indicator

45 Temperature sensor for burner outlet

46 Burner inclusive flow-type heater

47 Fuel tank (Option)

48 Burner blower with fuel pump

49 Solenoid valve for fuel

50 Exhaust thermostat

51 Flame indicator

52 Blending device (option)

Double tool version (Option)

A Solenoid valve for high-pressure

B Solenoid valve for foam

C Hand-spray gun with spray pipe

D Washing brush

* Only for SB MB standard

Function

Flowchart system with wet foam

17EN

Page 18

- 16

Washing station 3 and 4 not shown.

1 Fine filter for fresh water (80-100 μm,

option)

2 Locking valve for fresh water

3 Locking water for fresh water for soften-

ing

4 Locking valve for softened water

5 Salt tank

6 Hardness sensor

7 Water counter *

8 Control head of base exchanger

9 Base exchanger bottle

10 RO membrane

11 Flowmeter permeate *

12 Distribution block

13 Restrictor

14 Swimmer tank for cold water

15 Level sensor BUFFER TANK FULL

16 Level switch PUMP RO ON *

17 Level sensor BUFFER TANK EMPTY

18 Locking valve for permeate tank

19 Buffer tank for permeate

20 Pressure switch for RO water shortage

21 Manometer working pressure

22 RO pump

23 Discharge valve for softened water

24 Active carbon filter

25 Ultra-fine filter *

26 Solenoid valve in salt tank

27 Solenoid valve for cold water

28 Solensoid valve for permeate

29 Bypass valve semi load with throttle,

only for high pressure module type 908

30 High pressure pump

31 Overflow valve

32 Foam lance (2 tool version)

33 Foam mixing chamber (double tool ver-

sion)

34 Hand spray gun (2 tool version)

35 Dosing pump

36 Hand-spray gun with washing brush

(single tool version)

37 Foam mixing chamber (single tool ver-

sion)

38 Solenoid valve for pressure relief

39 Pressure switch air (optional)

40 Compressor

41 Suction hose for detergent

42 Detergent filter, foot valve

43 Solenoid valve for warm water

44 Drain valve

45 Water shortage safeguard

46 Swimmer tank for warm water

47 Circulation pump for warm water

48 Temperature sensor warm water

49 Flow indicator

50 Temperature sensor for burner outlet

51 Burner inclusive flow-type heater

52 Fuel tank (Option)

53 Burner blower with fuel pump

54 Solenoid valve for fuel

55 Exhaust thermostat

56 Flame indicator

57 Pressure reducer air

58 Solenoid valve

59 Distribution block air

60 Air dosing valve

61 Pressure reducer water

62 Dosing pump

63 Chemical container

64 Distributor water/detergent

65 Solenoid valve water/chemicals

66 Water/chemicals dosing valve

67 Blending device (option)

* Only for SB MB standard

Flowchart system with dry foam

18 EN

Page 19

- 17

1 Fine filter for fresh water (80-100 μm,

option)

2 Pump attachment kit disconnection

from mains (optional)

3 Swimmer tank for cold water

Attachment kit disconnection from mains (optional)

19EN

Page 20

- 18

A Rim cleaner

B Intensive foam

C Node piece

1 Swimmer valve

2 Manometer

3 Detergent solution (water + detergent)

4 Pump for detergent solution

5 Cleaning agent container

6 Injector

7 Sieve

8 Compressor

9 Pressure reducer

10 Solenoid valve for compressed air,

washing station 1

11 Solenoid valve for detergent solution,

washing station 1

12 Throttle, for volume control

13 Backflow valve

14 Foam device

15 High-pressure pump

16 Ceiling gyroscope

17 Trigger gun

1 Ceiling gyroscope

2 Spray tool

3 Solenoid valve for micro emulsion,

washing station 1

4 Micro emulsion pump

5 Micro emulsion container

1 High pressure pump

2 Backflow valve with throttle and sieve

3 Hand-spray gun with washing brush

4 Solenoid valve, interrupts frost protec-

tion with dry foam operation

5 Locking valve for fresh water

6 Swimmer tank with anti-freeze

7 2.0 mm throttle

8 filter anti freeze pump

9 Anti-frost pump

Wheel cleaner/intensive foam (option)

Micro emulsion (option) Frost protection 1-tool (option, SB-

MB 2 pump Fp only)

20 EN

Page 21

- 19

1 Washing brush

2 Backflow valve with throttle and sieve

3 Solenoid valve for high-pressure

4 Solenoid valve for foam

5 High pressure pump

6 Hand-spray gun with spray pipe

7 Locking valve for fresh water

8 2.0 mm throttle

9 Swimmer tank with anti-freeze

10 Anti-frost pump

11 filter anti freeze pump

A 4. Type of water

B Fresh water

C Softened water, warm

D Permeate

E to high-pressure pump

1 Temperature sensor (option)

2 Drain valve float container warm water

Frost protection 2-tool, wet foam

(option, SB-MB 2 pump Fp only)

4. Type of water

21EN

Page 22

- 20

1 Hand spray gun (2 tool version)

2 High pressure pump

3 Backflow valve with throttle and sieve

4 Solenoid valve with backflow valve,

throttle and sieve

5 Backflow valve with mixing chamber for

foam and pressure release valve

6 Hand-spray gun with washing brush

(single tool version)

7 Receptacle

8 Restrictor

9 Frost protection circulation pump

10 Filter

11 Overflow

12 Container for the anti frost circuit water

13 Swimmer valve for soft water supply

Note:

With the 2 tool model with dry foam, electrically heated foam hoses are used for frost

protection.

For washing station 3 and 4, the frost protection water is lost.

Internal frost protection (optional)

22 EN

Page 23

- 21

1 Hand spray gun (2 tool version)

2 High pressure pump

3 Backflow valve with throttle and sieve

4 Solenoid valve with backflow valve,

throttle and sieve

5 Backflow valve with mixing chamber for

foam and pressure release valve

6 Hand-spray gun with washing brush

(single tool version)

7 Receptacle

8 Filter

9 Overflow

10 Swimmer valve for fresh water.

11 Collection box anti frost water station 3

Note:

With the 2 tool model with dry foam, electrically heated foam hoses are used for frost

protection.

External frost protection (optional)

23EN

Page 24

- 22

Washing station 3 and 4 not shown.

1 Burner inclusive flow-type heater

2 Circulation pump for warm water

3 Balancing vessel

4 Swimmer tank for warm water

5 Safety valve

6 Locking valve of feeder pipe

7 Pipes of washing place heating

8 Thermostat mixing valve

9 Heat exchanger

10 Locking valve for filling pipe

11 Circulation pump for washing place

heating

– Opens when the permissible operating

pressure is exceeded - also even the le-

ver for hand-spray gun is released and

circulates the water. The high-pressure

jet is available when the hand-spray

gun is opened again.

The overflow valve is set by the manufacturer and sealed. Setting only by customer

service.

– The safety valve protects the heating

circuit of washing place heating (option)

against excess pressure.

– Regulates the feed temperature for the

washing place heating (option) depend-

ing on the return flow temperature.

If the burner does not ignite or the flame extinguishes during operation, then the flame

monitor closes the fuel solenoid valve and

switches off the burner blower.

– If the exhaust temperature exceeds the

permissible value, then the exhaust

thermostat automatically switches off

the burner and locks it.

– If the water temperature in the swimmer

tank for warm water falls when hot water is removed and cold water flows in,

the tempreature sensor of the warm water circulation pump switches on and

switches off again when the maximum

temperature is reached.

– Prevents the formation of steam in the

boiler.

– The flow monitor switches on the burner

after the warm water circulation pump

has been started.

– Switches off the burner if there is very

little water in the warm water swimmer

tank.

– The motor protection switch interrupts

the electric circuit if the motor is overloaded.

SB MB standard:

If the residual hardness of the softened water exceeds a marginal value, the control

will calculate the residual capacity of the

base exchanger cylinder.

At the latest in the following night, the regeneration of the base exchanger bottle is

started.

SB MB comfort:

If the residual hardness of the softened water exceeds a limit value, the regeneration

of the base exchanger bottle begins immediately.

If there is no water, the plant is stopped in

order to prevent dry running of the pump.

Switches off the pump when the buffer tank

for permeate is full.

Switches on the RO pump to produce permeate.

Emits a signal to the system when the permeate buffer tank is empty.

Prevents the externally added water over

60°C from being led to the HP pumps and

damaging them.

In case of a malfunction, the system switches to an alternative water type (is set by the

service technician upon initial startup).

Washing place heating (option)

Monitoring and safety devices

Overflow valve of high-pressure pump

Safety valve

Thermostat mixing valve

Flame monitoring

Exhaust thermostat

Temperature controller

Temperature controller

Flow monitor

Water shortage safeguard

Motor protection switch

Hard water sensor

Pressure switch for RO water shortage

Level switch Buffer tank is full

Level sensor pump RO on

Level switch Buffer tank is empty

Temperature limiter 4. type of water /

warm (option)

24 EN

Page 25

- 23

Technical specifications

SB MB 5/10-2 9/12-2SB MB 5/10-3 9/12-

3

5/10-4 9/12-

4

High-pressure module 608, 608fl Piece 2 1 - 3 2 1 - 4 3 2 1 High pressure module 908 Piece - 1 2 - 1 2 3 - 1 2 3 4

Electrical connection

Voltage V/~/Hz 400/3~/50

Maximum allowed net impedance Ohm 0.301 + j 0.188

Protection version CAB (SKID version) IP X5 (IP X1)

Connected load kW 10 17 13 13 14 16 17 16 17 19 20 22

Connected load kW 10 17 13 13 14 16 17 16 17 19 20 22

Prefuse A 35 35 35 35 35 50 50 50 50 50 50 50

Output of connection (with frost protection) kW 15 17 18 18 20 21 23 21 22242527

Pre-fuse (with frost protection) A 35 35 50 50 50 50 50 50 50 63 63 63

Water connection

Water pressure, dynamic MPa (bar) 0.3...0.6 (3...6)

Nominal width (DN) mm 25

Input amount fresh water/4. water type m

3

/h 1.7 2.0 2.3 2.2 2.6 2.9 3.3 2.7 3.2 3.5 3.9 4.2

Input amount warm water by customer

2

m3/h 1.2 1.5 1.8 1.8 2.1 2.4 2.7 2.4 2.7 3.0 3.3 3.6

Container capacity

Swimmer tank for warm water l 80

Swimmer tank for cold water l 2.5 2 x 2.5

Performance data

Working pressure with supplied nozzle

1

MPa (bar) approx. 10 (100) / approx. 10 (100) / approx. 12 (120)

Working pressure for program hot wax, foam

wash

1

MPa (bar) approx. 3 (30) / approx. 10 (100) / approx. 4.5 (45)

Nozzle size

1

5004 / 5004 /4007

Recoil force of the trigger gun with supplied

nozzle

1

N 17 / 17 /29

Water consumption per washing station

1

l/h (l/min) approx. 500 (8.3) / approx. 500 (8.3) / approx. 900 (15)

Water consumption for program hot wax,

foam wash

1

l/h (l/min) approx. 250 (4.2) / approx. 500 (8.3) / approx. 450 (7.5)

Max. hot water temperature °C 60

Hot water temperature for continuous operation, all high-pressure modules type 608

3

°C about 55 about 42 about 30

Hot water temperature for continuous operation, all high-pressure modules type 608fl

4

°C about 28 about 20 about 16

Hot water temperature for continuous operation, all high-pressure modules type 908

5

°C about 40 about 32 about 22

Base exchanger

Capacity °dH/m

3

220 300 220 300

Hardness of softened water ° dH 0...0.3

Salt tank, CAB l 120 150 120 150

Salt tank, SKID l 120 200 120 200

RO plant

Min. permeate output (at 15 °C water temperature), CAB

l/h 200 300 200 400 300 400

Min. permeate output (at 15 °C water temperature), SKID

l/h 200

Operating pressure in new state, max. MPa (bar) 1.4 (14)

Desalination rate of membrane % 98...99

Water temperature range °C 2...30

Max. ambient temperature °C 40

Residual hardness of feed water ° dH 0...0.3

Max. conductivity of permeate for stain-free

drying

μS/cm under 100

Permeate buffer tank, CAB/SKID l 280/700

Miscellaneous

Oil quantity of HP pump l 0.7

Oil grade Hypoid SAE 90 (6.288-016.0)

1

high-pressure module 608 / high-pressure module 608fl / high-pressure module 908

2

for customer warm water supply the fresh water requirement decreases by the corresponding amount

3

Water supply temperature +8°C, floor heating not in operation, burner power 64 kW

4

Water supply temperature +8°C, floor heating not in operation, burner power 40 kW

5

Water supply temperature +8°C, floor heating not in operation, burner power 72 kW (only oil burner)

25EN

Page 26

- 24

General

Values determined as per EN 60335-2-79

Hand-arm vibration value

Hand spray gun m/s

2

<2.5

Spray lance m/s

2

<2.5

Uncertainty K m/s

2

0.1

Sound pressure level L

pA

dB(A) 65

Uncertainty K

pA

dB(A) 3

Sound power level L

WA

+ Uncertainty K

WA

dB(A) 86

Dimensions SB MB CAB

Width mm 2700

Depth mm 900

Height mm 2100

Empty weight, max. (with 30 kg of packaging) kg 1100

Maximum weight kg 1750

Data depending on the burner

SB MB 5/

10-2

SB

MB 9/

12-2

SB MB 5/10-3 SB

MB 9/

12-3

SB MB 5/10-4 SB

MB 9/

12-4

Oil burner

Heating output kW 34.5 50 72

Fuel consumption heating oil (11.86kWh/kg) kg/h 3.3 4.8 6.9

Fuel nozzle 0.85/60° 1.25/60° 1.75/60°

Fuel pressure MPa (bar) 1.025 (10.25) 40 kW: 1.05 (10.5)

64 kW: 1 (10)

1.05 (10.5)

Temperature difference between exhaust and

air

K 170

Exhaust gas loss with a burner power of less

than 50 kW (more than 50 kW)

% 10 (9)

Soot figure 0...1

Fuel Fuel oil EL or Diesel

ABS Fuel tank

Heating oil

l 60/700

Gas burner

Heating output kW 34.5 50 max. 64

Fuel consumption natural gas (9.4 kWh/m

3

)m3/h 4.1 5.9 7.6

Fuel consumption liquid gas (25.5 kWh/m

3

)m3/h 1.5 2.2 2.8

Nominal width supply line gas Inch 3/4

Fuel pressure (gas pressure supply line), nat-

ural gas *

mbar >22

Fuel pressure (gas pressure supply line), liquid gas *

mbar >50

Temperature difference between exhaust and

air

°C approx. 200...230

* depending on the local gas type, exact values available at the customer service

For further technical data of the gas burner, please see the operating instructions and data sheets of the burner manufacturer

26 EN

Page 27

- 25

Water type in the washing programme

Fresh water

De-hardened or softened water

Permeate

Used water

warm

cold

High-pressure wash X O * X

Foam wash, wet foam O

Foam wash, dry foam X X

Rinsing X O X

Hot wax X O * X

Top care X X

Dirt removal X O * X

Micro emulsion A X X

Micro emulsion B

Insect removal X O * X

Wheel cleaning A X X

Wheel cleaning B X

Intensive foam X X

Undercarriage

X = Standard, O = Option, * processed water must be heated on site

27EN

Page 28

- 26

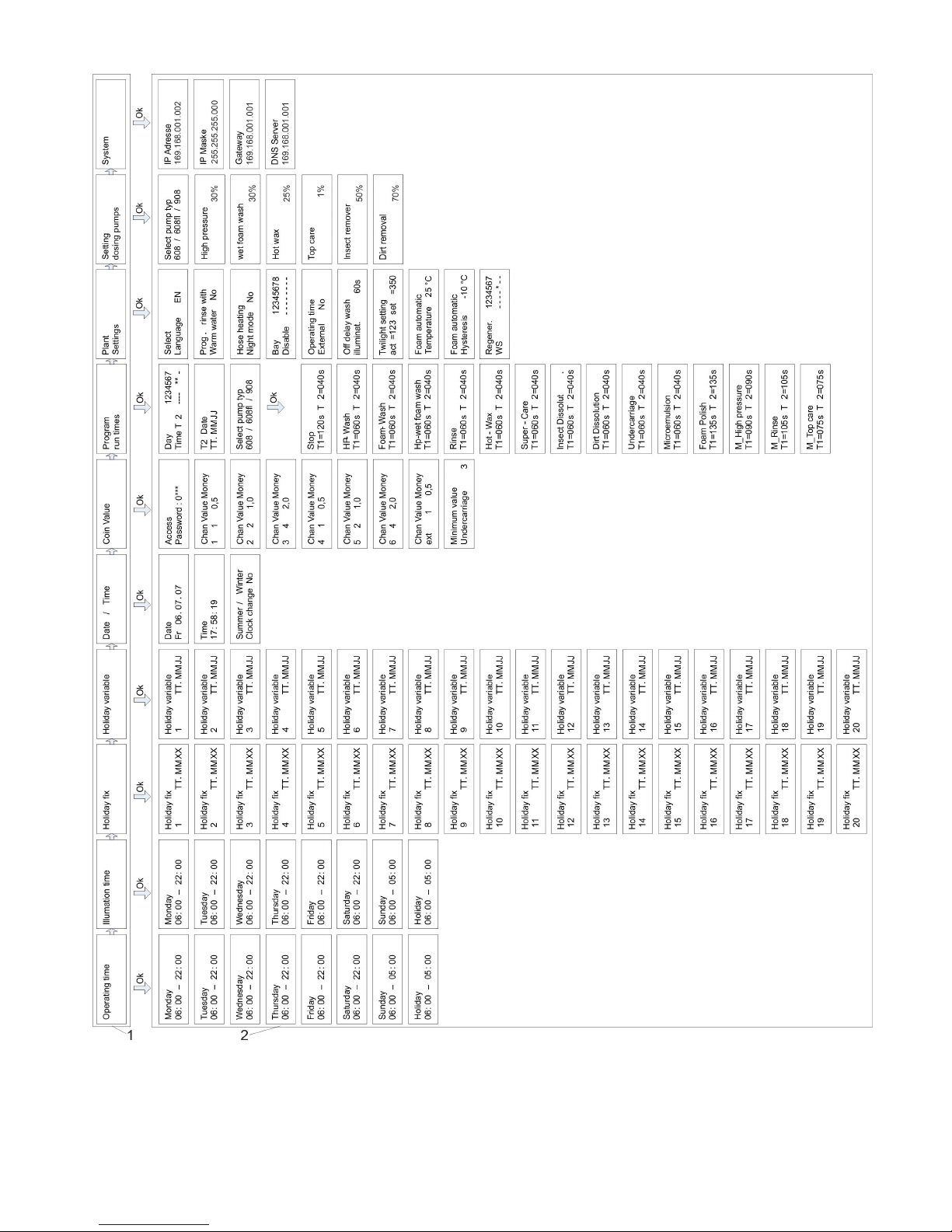

1 Balancing vessel

2 Fuel filter and fuel pump

3 Burner inclusive flow-type heater

4 High pressure pump 2

5 High pressure pump 3

6 High pressure pump 1

7 High pressure pump 4

8 Manometer for high-pressure pump

9 Fan heater

10 Tool storage box

11 Filter anti freeze pump

12 Detergent reservoir for top care

13 Detergent reservoir hot wax

14 Detergent reservoir high pressure wash

15 Detergent reservoir dry foam

16 Fuel tank, 60 l (option) *

17 Pump attachment kit disconnection

from mains (optional)

18 Wheel cleaner (option) *

19 Salt tank

20 Drain valve

21 Locking valve for fresh water

22 Circulation pump for washing place

heating

23 Thermostat mixing valve

24 Safety valve

25 Manometer for washing place heating

26 Active carbon filter WSO

27 Fine filter WSO

28 Swimmer tank for warm water

29 Recirculation blower

30 Blending device (option)

* Depending on the equipment of the system, the assembly intensive foam can be

attached in theses positions.

In normal operating mode, press the

"OK" key on the control longer than 2

seconds.

Press the LEFT button.

Press the RIGHT button four times.

Menu overview on next page.

Maintenance and care

System overview

Show system status

28 EN

Page 29

- 27

29EN

Page 30

- 28

1 Appliance component

2 Time until next maintenance (minus

symbol if maintenance is due)

3 Date of last maintenance

Current value of the control voltage

Exterior temperature measured by exterior

temperature sensor.

Software version and data set version of

control

Display of the core module (processor)

Water temperature in the swimmer tank for

warm water.

Water temperature at the outlet of the continuous heater. At temperatures above

96°C, the burner is turned off.

Minimal break between switching the burner off and back on.

Trailing time of the burner fan after the

burner has been turned off.

Trailing time of the circulation pump for

warm water after the burner has been

turned off.

Select the washing station number

(box) with the buttons LEFT and

RIGHT.

Press the OK button.

The status of the selected washing station

is shown.

Currently selected washing programme.

Remaining value of the washing credit in

washing units.

Remaining run time in seconds.

Current pickup of the high pressure pump.

Active outputs of the pump electronics.

Run times of the individual washing programmes since system start-up.

Voltage supply to the remote controls.

A Overview of status

B Details of status

1 Status of base exchanger

2 Status of reverse osmosis

3 Status of buffer tank for permeate

Press the OK button.

Select the desired display using the

"LEFT" and "RIGHT" keys.

Depending on the operating state, one of

the displays below may appear.

Base exchanger in operation, XXXX litres

of water de-hardended since the last regeneration.

Calculated residual capacity until the next

regeneration.

Regeneration was activated, control has

been waiting for response from base exchanger for XXX seconds.

Base exchanger has been conducting regeneration for XXX minutes.

Maintenance

Version / info

Status burner

Status of washing stations

Status WSO

30 EN

Page 31

- 29

The salt solution in the salt tank is regenerated. The process is completed within XXX

minutes. There can be no regeneration of

the base exchanger before then.

There was an error in the base exchanger.

Reverse Osmosis is ready.

The prerinse of the RO membrane will be

completed in X seconds.

The reverse osmosis produces permeate.

The final rinse of the RO membrane will be

completed in XX seconds.

Permeate production blocked as the base

exchanger is performing a regeneration.

No water pressure at inlet of the system.

Buffer container for permeate filled with

permeate to the level sensor BUFFER

CONTAINER FULL.

Water level in the buffer container for permeate is below level sensor BUFFER

CONTAINER FULL.

Water level in the buffer container for permeate is below level sensor BUFFER

CONTAINER EMPTY.

Dry run delay active after XXX minutes.

During this period, the SB-C is supplied

with cold water.

The buffer container for permeate is empty,

the SB-C is supplied with cold water.

Here, the operaing hours of the individual

system components since system start-up

are shown.

The different menu items are shown in the

overview at the beginning of this chapter.

The bases of a safe operating of the equipment is thr regularly maintenance according to the following maintenance plan.

Use only original parts of the manufacturer

or part suggested by him, such as

– parts and wearing parts,

– accessories parts,

– operating materials,

– cleaning agents.

DANGER

Risk of accident while working on the unit!

During all tasks:

Turn off the water supply; close the

fresh water tap,

First switch-on in voltage-less state,

switch off the emergency stop switch in

the building and secure it against being

switched on again.

ATTENTION

Risk of damage. Never use a high-pressure

jet to clean the inside of the system.

– Operator

Work designated with the sign “Operator” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the

washing system.

– Customer Service

Work designated with the sign “Customer Service” may only be done by the

fitters of Kärcher Customer Service.

In order to ensure a reliable operation of the

plant, we recommend that you conclude a

maintenance contract with us. Please refer

to you local KÄRCHER service department.

DANGER

Risk of injury due to high-pressure jet exiting possibly defective components, risk of

burns due to hot plant parts. When working

on the opened plant, proceed with particular care and observe all safety instructions.

The following parts are possible to be hotter than 50 °C:

– exhaust pipe and exhaust opening

– Burner inclusive flow-type heater

– cylinder head of the high pressure

pump

– high pressure hose

Operating hours

Maintenance instructions

Who may perform maintenance?

Maintenance contract

31EN

Page 32

- 30

Maintenance schedule

Time Activity Assembly affectedPerformance By whom

once a year

before the

frosting period starts

Clean the filter Antifreezing circula-

tion

Empty and clean the collection chute for the frost protection water.

Clean the filter on the immersion pump.

Clean the filter of the frost protection pump (in the casing of the SB

MB).

Clean the tool compartment and check for free flow.

Clean the throttle valve (in the area of the high pressure pump outlet).

Fill the collection chute for the frost protection water with fresh water.

Operator/

Customer

Service

opinion Washing station

heater

Check functioning and rotation direction of the circulation pump

Check concentration of anti-freezing agent: Take out a little anti-freez-

ing solution from the safety valve and check its correct concentration

using a special tester (6.419-070.0). Target value -25°C

Check pressure in the heating circuit. Nominal value with running circulation pump of the washing station heater 0.07...0.15 MPa (0.7...1.5

bar)

Check setting of the thermostat mixing valve.

Check the function of the balancing vessel: Remove the valve flap.

Press in the valve pin briefly using a matchstick. The balancing vehicle

is OK if air comes out. If water comes out, then the balancing vessel

needs to be replaced. If nothing comes out, then use a car air pump to

pump in air in the balancing vehicle according to the values on the type

plate.

opinion External thermostatCheck function. Operator

opinion Recirculation blow-erCheck function. Operator

opinion Hot blowers Have the regulators been set correctly? (See section "Settings/hot air

ventilator".)

Operator

opinion Frost protection

with lost water

Switch on the frost protection pump (see Chapter "Manual procedures").

Check if at least 0.5 l/min of water exits each hand spray gun, if neces-

sary, readjust the pressure reducer.

Operator

opinion Emergency frost

protection

Turn the main switch to position “0”.

Check if at least 0.5 l/min of water exits each hand spray gun, if neces-

sary, readjust the pressure reducer.

Operator

Clean the filter Pass boiler Recommendation: These half-yearly maintenance tasks are to be done

before the frosting period starts.

Customer

Service

measuring Burner

daily opinion High pressure hos-

es, foam hoses

(with 2 tool model)

Check high pressure hoses for mechanical damages such as scraping,

visible hose duck, bends, porous and cracked rubber. Replace dam-

aged high pressure hoses.

Operator

opinion Information signs at

the washdown yard

Check whether the warning boards for the users are available and leg-

ible.

Operator

opinion Washing station

lighting

Check the function of the washing station lighting and replace defective

lights.

Operator

opinion Spray lance Check for tightness; replace O-ring if necessary. Nozzle protection and

handle pipe OK? Replace if necessary.

Operator

opinion Hand spray gun Check for tightness; replace O-ring if necessary. Operator

Can the high-pressure hose be rotated, and is the lever running

smoothly? Lubricate if nessary (see section „Maintenance work“).

opinion Tool storage box Check from the outside for foreing matters and contamination. Remove

coarse contaminants.

Operator

opinion Fill levels of the de-

tergent container

Check filling level, refill or replace if necessary. Operator

empty Coins container Open the coin acceptor doors and empty the coin container. Operator

Initially daily, later on

based on experience

opinion Filling level of the

fuel tank

Will the heating oil be sufficient till next inspection? Take into account

increased consumption due to anti-frost equipment. Insufficient fuel

can lead to failure and damage to the system.

Operator

empty Compressor Drain the condensate from the pressure container of the compressor. Operator

Everyday

under frost

conditions

opinion Anti frost devices Are the hot air ventilators working (even for ABS fuel tank, option)? Operator

Clean the filter Filter for frost-pro-

tection pump

Clean the filter and replace Operator

32 EN

Page 33

- 31

After 40 operating hours

or once a

week

opinion Tightness of systemCheck pumps and pipes for leaks. Inform Customer Service if there is

oil under the high pressure pump, if more than 3 drops of water drop

out of the high pressure pump when the pump is running.

Operator