KM 100/100 R D

1.280-114

www.kaercher.com

5.960-836 A2008261 05/04

KM 100/100 R D

Betriebsanleitung 3

Ersatzteilliste 187

Operating instructions 21

Spare Parts List 187

Notice d'utilisation 39

Liste des pièces de rechange 187

Istruzioni per l'uso 57

Elenco pezzi di ricambio 187

Gebruiksaanwijzing 75

Reserveonderdelenlijst 187

Instrucciones de servicio 93

Lista de piezas de requesto 187

Käyttöohje 111

Varaosalista 187

Driftinstruktion 129

Reservdelslista 187

Οδηγίες λειτουργίας 147

Бнфбллбкфйкб 187

Руководство по эксплуатации 168

Запасные части 187

2

Operating instructions KM 100/100 R D English

Contents

For your own safety! 22

General notes 22

Risk of overturning on too

high gradients! 23

Risk of overturning when

taking bends rapidly! 23

Danger of tipping over

given an unstable travelling

surface! 23

Danger of tipping over

given a sideways incline

that is too large! 23

For our environment 23

Please dispose of

packaging environmentally

responsibly 23

Please dispose of scrapped

units environmentally- responsibly23

Please dispose of batteries

and accumulators

ecologically 23

Please do not allow engine

oil, fuel oil, diesel and

petrol 23

Intended use 23

Function description sweeping machine 23

Control elements 24

Machine parts 24

Before first operating 24

Open/close unit cover 24

Moving road sweeping

machine with automotive

power 24

Operating sweeping

machine without

automotive power 25

Unloading instructions 25

Before every operation 25

General notes 25

Testing and maintenance

work 25

Commissioning 25

Adjust driver seat 25

Start machine 26

Run machine 26

Sweeping operation 27

Manual filter cleaning 27

Stop machine 28

Empty the swept material

container 28

Usage instructions 28

Safety instructions when

sweeping 28

Sweeping dry ground 28

Sweeping damp or wet

ground 28

Driving over obstacles 29

Decommissioning 29

Transport 29

Transport instructions 29

Cleaning and maintenance 29

Internal cleaning 29

External cleaning 29

Maintenance intervals 29

Elapsed-time meter 29

Maintenance by the

customer 29

Maintenance by the

customer service

department 30

Maintenance tasks 30

Notes on safety 30

Battery safety instructions 30

Mount and connect battery 30

Charge the battery 30

Checking the battery acid

level 31

Check the (fill) level of the

fuel tank 31

Refill fuel 31

Check the tyre air pressure 31

Changing wheels 31

Check engine oil level and

top-up 32

Change the engine oil 32

Checking/replacing the air

cleaner 32

Check and top up the

hydraulic oil level 33

Checking the vacuum

system 33

Check the side brush 33

Replacing side brush 33

Check the sweep roller 33

Replace the sweep roller 34

Check sweeping pattern of

the main brush 34

Adjusting and replacing

sealing strips 35

Replace the dust filter 35

Replacing the filter box

seal 36

Checking traction belt 36

Changing fuses 36

Fault instructions 36

Accessories 37

Technical data 37

EC conformity declaration 38

21

Operating instructions KM 100/100 R D English

For your own safety!

General notes

Reading and observing prior to

use of the machine is essential!

— Notify your sales outlet if during

unpacking you detect damage

that has occurred in transit.

! Read the operating instructions

of your machine prior to its initial

operation and especially observe

the safety notes.

— The warning and information

labels attached to the machine

provide important information on

its safe operation.

— In addition to the instructions in

the operating instructions,

general safety- and accident

prevention-regulations from

lawgivers must be followed.

Use

! The machine is to be used

exclusively according to the

specifications given in these

operating instructions.

! Prior to its use the machine and

its attachments must be checked

for their proper condition and

operational reliability. It must not

be used if its condition is not

faultless.

— No modifications permitted on the

machine.

— The machine is for sweeping

outdoor surfaces.

— Never absorb explosive liquids,

inflammable gases or undiluted

acids and solvents! These

include petrol, paint thinner or

fuel oil, which can develop

explosive vapours or mixtures

due to the turbulance of the

suction air, and also acetone,

undiluted acids and solvents,

since these attack the materials

used in the manufacture of the

machine.

— Do not sweep up/absorb burning

or smouldering objects.

Only if clearly identified as such

is this machine suitable for

suction removal of health

hazardous dusts.

Observe the safety-related notes

given in the operating instructions.

— Suitable only for the surfaces

listed in the operating

instructions.

— The appliance may be used on

only the areas cleared for its use

by the factory owner or a person

authorized by him.

— Keep clear of the danger area. Its

operation in explosion hazardous

locations is prohibited.

— The following applies generally:

Keep combustible materials away

from the machine (danger of

explosions-/fire).

Operation

— The rules, regulations and

stipulations applying to motor

vehicles must always be

observed.

— The operator must use the

machine for its agreed proper

purpose. When driving it he must

allow for the site’s conditions,

and when working with the

machine be must look out for

bystanders, especially children.

— The machine may only be used

by persons instructed in how it is

to be used, who have proved

their capability to use it and who

have expressly been instructed to

use it.

— It is forbidden for children or

juveniles to operate the machine.

! The ignition key must be

removed from machines provided

with it in order to prevent

unauthorised use of the machine.

! The machine must never be left

unsupervised while the motor is

running. The operator is not

allowed to leave the machine

unless the engine has been

turned off, the machine is

secured against unintended

movements, the parking brake, if

provided, is actuated, and the

ignition key has been removed.

— On slopes the angle of inclination

to the side and in the direction of

motion must not exceed the

value given in the operating

instructions.

Transport

! The motor must be turned off

when the machine is transported.

! Secure the machine with guy

belts, ropes or chains.

! Immobilise the machine at the

wheels with chocks.

Maintenance

! Switch off the machine and, if

provided with one, remove the

ignition key prior to cleaning it

and performing maintenance

work on it or when resetting it to

a different operation.

! The battery plug connection or

the battery must be disconnected

for work on the electrical

installation of battery-powered

machines.

— Do not clean the machine with

fluid jets.

— Repairs may only be carried out

by approved customer service

centres or by technical personnel

trained in this field which are

familiar with all relevant safety

regulations.

— Mobile, commercially used

machines are subject to the

safety inspection in compliance

with VDE 0701.

— Use only the main brushes/side

brushes supplied with the

machine or specified in the

operating instructions. Using

other main brushes/side brushes

can be detrimental to safety.

— The machine is not be be

cleaned by hosing down or with a

high-pressure water jet (danger

of short circuits or other

damage).

Accessories and spare parts

— Only accessories and spare parts

cleared by the manufacturer may

be used. Genuine accessories

and spare parts ensure that the

machine can be operated safely

and trouble-free.

Ride-on machine

— Ride-on machines are not

approved for public road traffic.

Please ask your retailer for the

conversion kit for streetworthiness.

— Giving companions lifts is not

permissible.

— Ride-on machines may be set in

motion only from the seat.

Machines with a combustion

engine

! The exhaust opening must not be

sealed.

! Do not bend over or touch the

exhaust opening (danger of

burns).

! Do not touch or grasp the drive

motor (danger of burns).

! Adequate ventilation and

extraction of exhaust emissions

must be provided when operating

the machine indoors. (Danger of

poisoning)

! Exhaust gases are toxic and

damaging to health; do not inhale

them.

! The engine takes approx. 3...4 s

to run down after being shut off.

Never enter operating area

during this period!

22

Operating instructions KM 100/100 R D English

The following must be observed

when refuelling machines with a

combustion engine:

! Only the fuel specified in the

operating instructions may be

used. An explosion hazard exists

with unsuitable fuels.

! The engine must be switched off.

! Do not fill-in fuel in closed rooms.

! Make sure that no fuel comes

into contact with hot surfaces.

! Do not use any burning or

glowing objects or carry or put

them near the machine during

refuelling (explosion hazard).

! Fill the tank at the most 1 cm

below the lower edge of the filler

neck, since the fuel expands in

heat.

! Wipe off spilled over fuel and

close tank cap tightly.

Risk of overturning on too

high gradients!

Danger!

The machine could topple over

when driving and turning on slopes.

— Drive only on slopes up to 18 %

in the travelling direction.

— At right angles to direction of

travel only negotiate gradients up

to a maximum of 15 %.

Risk of overturning when

taking bends rapidly!

Danger!

The machine can topple-over when

driving fast around curves.

! Drive slowly in curves.

Danger of tipping over

given an unstable travelling

surface!

Danger!

The machine can tip over given an

unstable travelling surface.

! Move the machine exclusively on

a solid travelling surface.

Danger of tipping over

given a sideways incline

that is too large!

Danger!

The machine can tip over given an

incline of more than 15 %.

For our environment

Please dispose of

packaging environmentally

responsibly

The packaging materials are

recyclable. Please do not throw the

packaging in with household rubbish

but take it to a recycling centre.

Please dispose of scrapped

units environmentallyresponsibly

Scrapped units consist of valuable

recyclable materials that should be

taken to a recycling centre.

Batteries, oil and similar products

must not be allowed to contaminate

the environment. Therefore, please

dispose of scrapped units via

appropriate disposal systems.

Please dispose of batteries

and accumulators

ecologically

Batteries and accumulators contain

substances that are not allowed to

contaminate the environment.

Please, therefore, dispose of them

in appropriate recycling systems.

Please do not allow engine

oil, fuel oil, diesel and

petrol

to contaminate the environment.

Please protect the ground and

dispose of used oil ecologically.

Intended use

— This sweeping machine is

designed for sweeping surfaces

in outdoor areas.

— It is not intended for use on

public traffic routes.

— It is not suitable for health-

hazardous dusts.

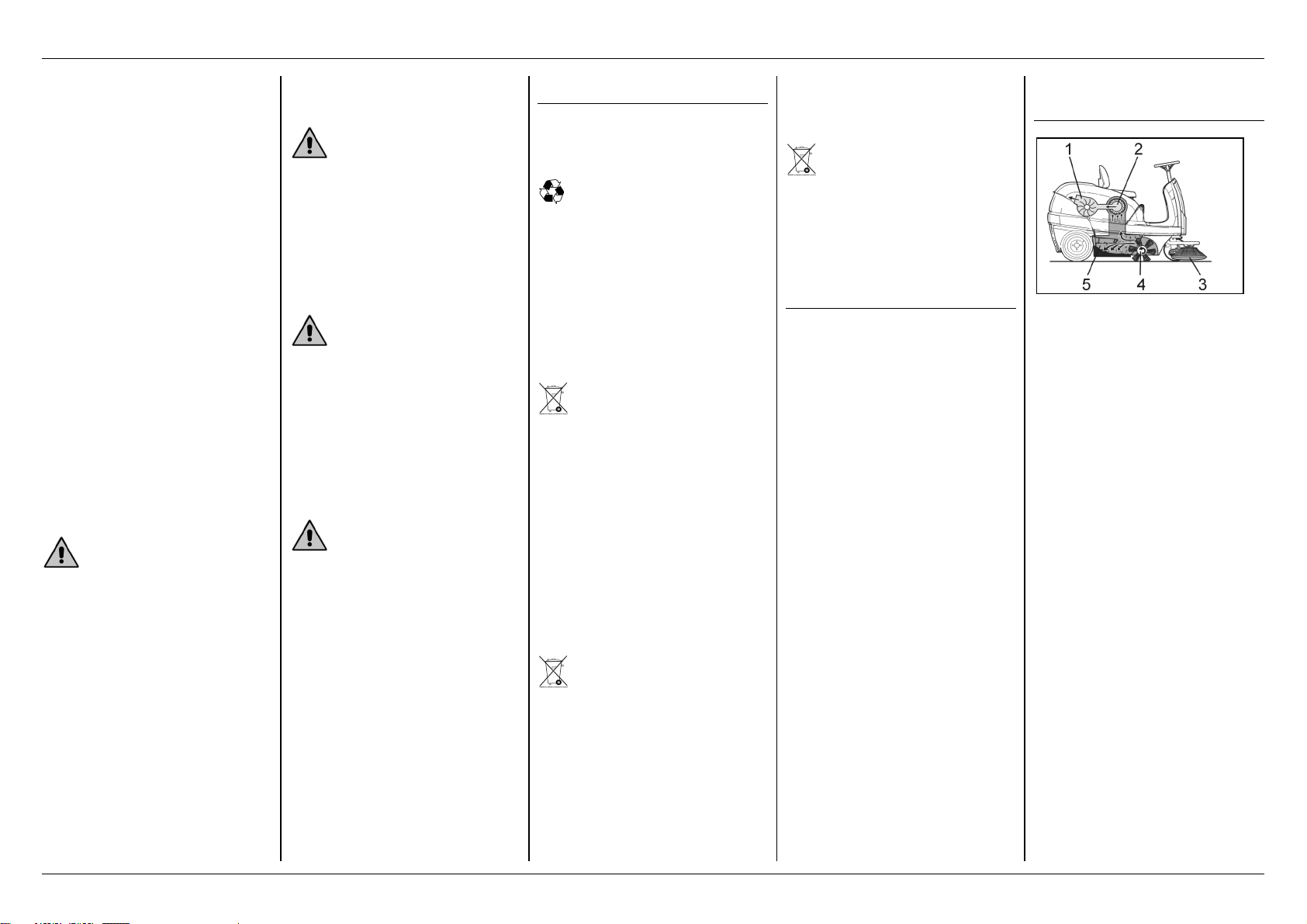

Function description sweeping machine

The KM 100/100 R sweeper

operates according to the throwover principle.

— The side brush (3) cleans corners

and edges of the sweeping

surface and transports the dirt in

the path of the main brush.

— The rotating main brush (4)

transports the dirt directly into the

debris container (5).

— The dust swirled up in the

container is separated by way of

the dust filter (2) and the filtered,

clean air removed by the suction

turbine (1).

23

Operating instructions KM 100/100 R D English

Control elements

1. Steering wheel

2. Raising/lowering coarse-dirt flap

pedal

3. Forward driving/reversing drive

pedal

Machine parts

1. Unit cover

2. Debris container (bilateral)

3. Coarse-dirt flap

4. Roller

5. Side brush

Before first operating

The sweeper is provided with a

hydrostatic drive. Therefore, when

the freewheel lever is engaged in its

top position it is only possible to

push the machine.

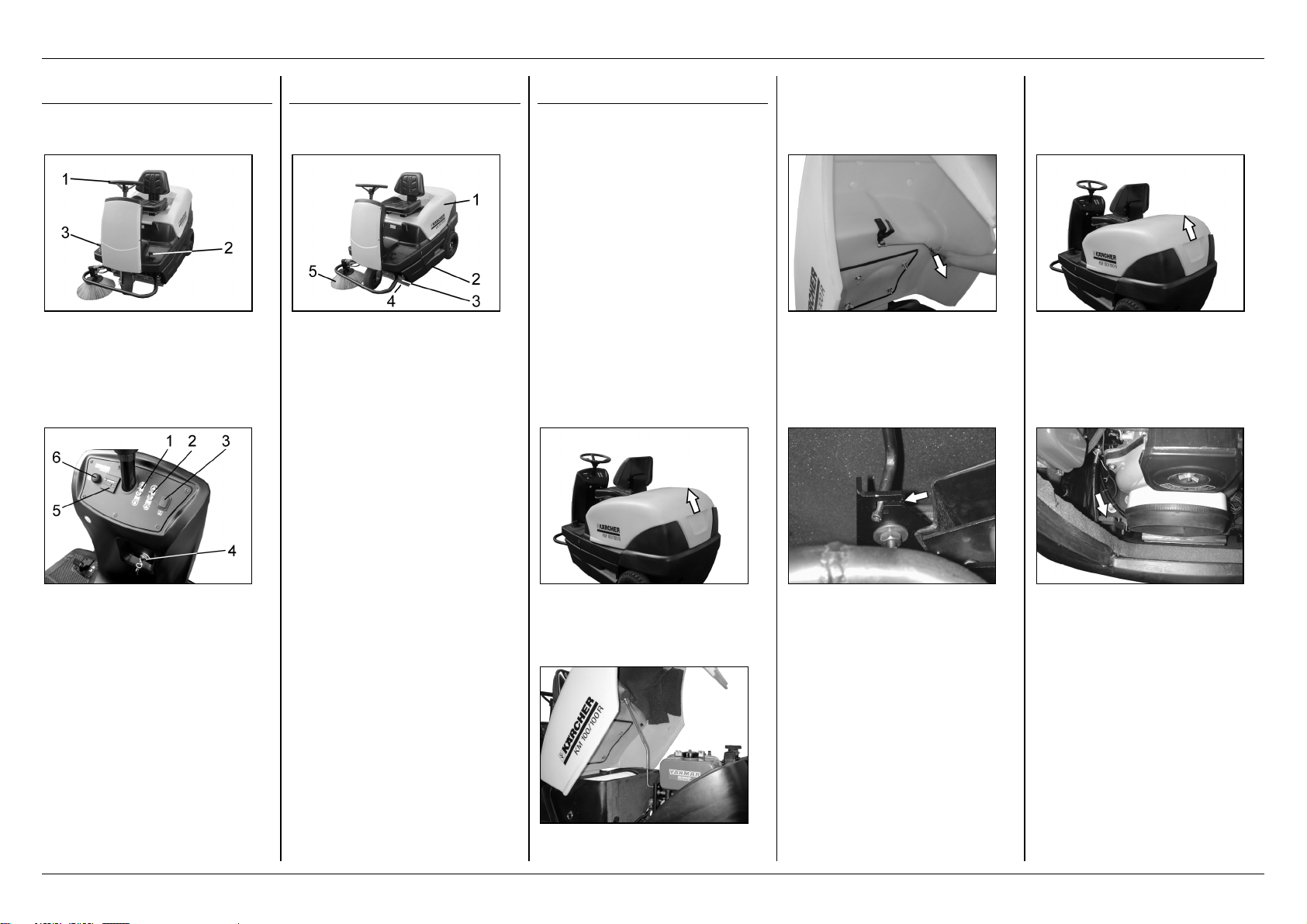

Open/close unit cover

! Pull stay bar out of the bracket

Moving road sweeping

machine with automotive

power

! Open unit cover, engage stay bar

1. Raising/lowering main brush

2. Raise/lower side brush

3. Filter de-duster

4. Ignition switch

5. Elapsed-time meter

6. Horn

Open unit cover

! Lift unit cover up at the provided

handle grip

In its open position the unit cover is

secured by a stay bar.

! Insert the stay bar into the

adapter at the suction turbine

! to close the unit cover pull the

stay bar out of its slot and

engage it in the bracket in the

unit cover

! Snap freewheel lever in place in

the bottom position

— Drive system and parking brake

are active

24

Operating instructions KM 100/100 R D English

Operating sweeping

machine without

automotive power

Danger!

Immobilise the machine against

inadvertent movement prior to

engaging the freewheel.

The brake is ineffective once the

freewheel has been engaged.

! Open unit cover, engage stay bar

! Pull freewheel lever up and latch

it in place in this position

— This makes the drive system

inoperable, it is possible to push

the machine

Note:

— When the sweeper is not self-

powered do not move it over

longer distances and not faster

than 6 km/h .

Unloading instructions

Warning!

When the machine is loaded the

freewheel lever must generally be

engaged in its bottom position. Only

then are the drive system and the

parking brake operable.

— The machine was secured on a

pallet with stretch belts or ropes

for safe transport. Proceed as

follows when unloading:

! Cut the plastic packing tape and

remove the film.

! Connect battery (see

maintenance work chapter)

! Remove the blocks for securing

the wheels and drive the machine

off the pallet using a suitable

ramp.

Warning!

Do not use a fork lifter for unloading;

the machine can be damaged by it.

Before every operation

General notes

! Stand sweeper on a flat surface

! Remove the ignition key

Testing and maintenance

work

! Check engine oil level *

! Check level of the fuel tank *

! Check level of hydraulic oil *

! Check side brushes *

! Check main brush *

! Empty the swept material

container

! Check tyre inflation pressure *

* See maintenance work chapter for

instructions

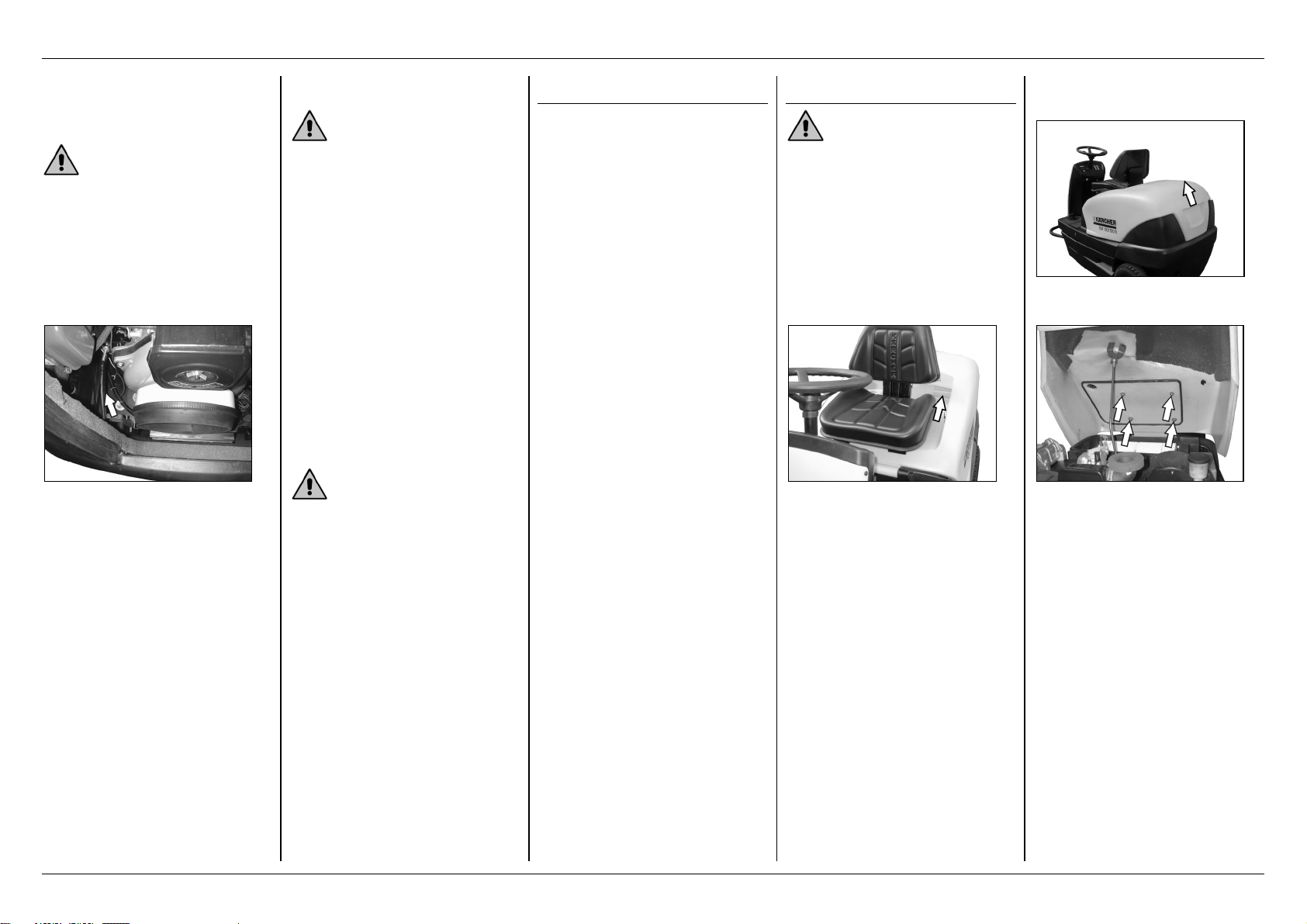

Commissioning

Warning!

It is not permissible to cover the air

suction openings behind the driver’s

seat.

It is not permissible to deposit

objects next to or behind the seat.

Suction openings

Adjust driver seat

! Open unit cover, engage stay bar

! Slightly loosen wing nuts of seat

runners

! Push the seat into the

appropriate position

! Retighten wing nuts

Note:

There is a further adjustment

possibility if the adjusting range is

insufficient

25

Operating instructions KM 100/100 R D English

! Unscrew the 4 screws at the seat

contact switch plate

! Remove the plate

! Turn the seat forward

! Unscrew the 4 screws of the seat

mounting

! Shift seat and refasten with

screws

! Remount seat contact switch

plate

Start machine

! Open unit cover, engage stay bar

Open the fuel tap

! Slide lever towards "O"

! Close unit cover

! Sit on the driver seat

! Do NOT actuate the drive pedal!

! Main brush switch in its upper

position

! Side brush switch in its upper

position

Note:

Never actuate the starter motor for

more than 10 s.

Wait at least 10 s before actuating

the starter motor again.

Run machine

Prior to start of the machine

! Main brush switch in its upper

position

Freewheel lever of axle drive must

be in its bottom position

! Start machine

Drive forwards

! Slowly press the driving pedal

Note:

The machine is equipped with a

seat contact switch. The machine is

switched off as the driver leaves the

seat and the parking brake

automatically actuated.

! Turn ignition key beyond

position 1

! When the machine starts, release

ignition key

! Side brush switch in its upper

position

26

Operating instructions KM 100/100 R D English

Sweeping operation

Warning!

In order to avoid damaging the floor

do not operate the sweeper while it

is stationary.

Drive backwards

! Slowly press the driving pedal

Note:

Driving behaviour

— The driving speed can be varied

continuously with the driving

pedals.

— Avoid abrupt actuation of the

pedal because this could damage

the hydraulic system.

— Slightly release drive pedal if

power decrease is registered

uphill.

Braking

! Release the driving pedal; the

machine brakes automatically

and comes to a standstill.

! Lower main brush

— Sweeping with the main brush

! The coarse-dirt flap must be

briefly raised for sweeping in

largish objects up to a height of

60 mm, e.g. drinks cans.

Raise coarse-dirt flap

! Press pedal forwards and keep it

depressed

! To lower it, lift foot off pedal

— Sweeping with raised coarse-dirt

flap

Note:

An optimal cleaning effect can be

achieved only when the coarse-dirt

flap is completely lowered

! Lower side brushes (for

sweeping in border areas

— Sweeping with side brushes

Notes:

— The main brush and the side

brushes start automatically.

! First it is always necessary to

activate the main brush, since

otherwise the sweeping system

does not start.

— The sweeping system is

activated using the rocker switch

at the instrument panel.

— The vacuum system must be

checked if the side brush cannot

be lowered.

See maintenance tasks chapter for

description

Vacuum canister for lowering the

side brush (to the left and next to

the front wheel viewed from the front

Manual filter cleaning

Clean the dust filter regularly when

sweeping large surfaces.

! Press filter cleaning switch

briefly. The dust filter is cleaned

for approx. 15 seconds. Do not

open the unit cover during this

period.

27

Operating instructions KM 100/100 R D English

Stop machine

! Raise the side broom

! Raise the sweep roller

! Open unit cover, engage stay bar

Close fuel shut-off valve

! Slide lever towards "S"

Note:

The machine is provided with an

automatic parking brake, which is

activated when the engine is

stopped and the driver leaves his

seat.

Empty the swept material

container

! Wait until automatic filter

dedusting is completed and the

dust has settled before opening

the debris container and

emptying it.

! Pull out debris container

! Empty the swept material

container

! Slide in and lock the debris

container

! Then perform the same

operations on the opposite debris

container

Usage instructions

Safety instructions when

sweeping

Warning!

— Never sweep up packing straps,

wires or the like as this could

damage the sweeping

mechanism.

— When the coarse-dirt flap is

open, the main brush can hurl

stones or stone chips forwards.

Make sure that nobody, no

animals or objects are

endangered.

Notes:

! For optimum cleaning effect,

match the driving speed to suit

the actual conditions.

! During operation the debris

container should be emptied at

regular intervals.

! Lower the sweeping roller for

surface sweeping.

! Lower the side broom for

cleaning side edges.

Sweeping dry ground

! Close the bypass cover on left

behind the seat

Sweeping damp or wet

ground

! Turn ignition key to "0" and

remove it

Note:

The dust filter is automatically

dedusted for approx. 15 s after

shutting down of the machine.

Do not open the unit cover while this

is going on.

! Open the bypass cover on left

behind the seat

— This protects the filter from damp

28

Operating instructions KM 100/100 R D English

Driving over obstacles

Fixed obstacles of up to 50 mm in

height

! Slowly and carefully drive over

them in the forward direction.

Fixed obstacles over 50 mm in

height

! May be driven-over only with a

suitable ramp.

Decommissioning

Please heed the following if

sweeper is not to be used for a

lengthy period:

! Stand sweeper on a flat surface

! Raise the sweep roller and side

broom to prevent damage to the

bristles

! Turn ignition key to "0" and

remove it

! Close fuel shut-off valve

! Secure sweeper to stop it rolling

away

! Clean inside and outside of

sweeper

! Turn off the machine on a

protected and dry place

! Change the engine oil

! Disconnect the batteries

! Recharge the battery at intervals

of approx. 2 months

Transport

Transport instructions

Warning!

When the machine is loaded the

freewheel lever must generally be

engaged in its bottom position. Only

then are the drive system and the

parking brake operable.

Uphill or downhill the machine must

always be moved automotively.

! Turn ignition key to "0" and

remove it

! Empty tank

! Secure the machine with wedges

on the wheels

! Secure the machine with stretch

belts or ropes

Fastening areas

Notes:

Observe markings for fastening

areas on base frame! (chain

symbols)

For loading or unloading the

machine may be operated on slopes

of only up to a max. of 18 %

Cleaning and maintenance

! Stand sweeper on a flat surface

! Turn ignition key to "0" and

remove it

Internal cleaning

Danger!

Wear dust mask!

Wear safety goggles!

! Open unit cover, engage stay bar

! Clean with a rag

! Blow-out with compressed air

External cleaning

Clean with a damp cloth previously

soaked in mild suds

Note:

Do not use any aggressive cleaning

agents!

Maintenance intervals

Elapsed-time meter

Elapsed-time meter indicates

maintenance interval times.

Maintenance by the

customer

Daily maintenance

! Check the engine oil level

! Check axle drive oil level

! Check the tyre air pressure

! Check roller and side brush for

wear and trapped straps

! Check the function of all

operating controls

Maintenance weekly

! Check air filter

! Check oil level of sweeping

hydraulics

! Check hydraulic hose for leaks

! Check freedom of movement of

Bowden cables and moving parts

! Check setting and wear of

sealing strips in sweeping area

! Check vacuum system (operation

of lowering side brushes)

Maintenance every 100 operating

hours

! Enging-oil change (first change

after 20 operating hours)

! Check operation of seat contact

switch

! Checking the battery acid level

! Check tightness, wear and

operation of drive belts (V-belts

and round belts)

Maintenance according to degree

of wear

! Replace sealing strips

! Replacing the sweep roller

! Replacing the side broom

See maintenance tasks chapter for

description

Note:

Where maintenance is undertaken

by the customer, all service and

maintenance work must be carried

out by a qualified employee.

A Kärcher specialist dealer can be

consulted whenever support is

necessary.

29

Operating instructions KM 100/100 R D English

Maintenance by the

customer service

department

Maintenance after 20 operating

hours

First inspection

Maintenance every 100 operating

hours

Maintenance every 300 operating

hours

Note:

To safeguard warranty rights, during

the warranty period all service and

maintenance work must be

performed by an authorised Kärcher

after sales service.

Maintenance tasks

Notes on safety

Warning!

Preparations

! Stand sweeper on a flat surface

! Turn ignition key to "0" and

remove it

Danger!

— The engine takes approx. 3...4 s

to run down after being shut off.

! Never enter operating area

during this period!

! Allow the machine to adequately

cool down prior to all

maintenance and repair work

! Do not touch hot parts such as

the driving engine and exhaust

system.

Please do not allow engine oil,

fuel oil, diesel and petrol

to contaminate the environment.

Please protect the ground and

dispose of used oil ecologically.

Battery safety instructions

Danger!

Always heed safety precautions for

handling batteries!

Observe the operating instructions

Work on batteries is permitted only

after instruction by trained personnel

Danger!

! Wear safety goggles and

protective clothing

! Observe regulations for the

prevention of accidents as well

as DIN VDE 0510, VDE 0105 T.1

Danger!

Risk of fire and explosion!

— Smoking prohibited

— No naked flames, glowing

embers or sparks in the vicinity of

batteries

— Do not place any objects or tools

on the battery because voltage is

always present between the

battery poles

— Areas in which batteries are

charged must be well ventilated,

as highly explosive gas forms

during charging

Danger of acid burns!

! Rinse out or rinse off splashes of

acid in the eye or on the skin with

copious quantities of clean water

! Then consult a doctor

immediately

! Wash contaminated clothing with

water

Please dispose of batteries and

accumulators ecologically

Batteries and accumulators contain

substances that are not allowed to

contaminate the environment.

Please, therefore, dispose of them

in appropriate recycling systems.

Mount and connect battery

! Open unit cover, engage stay bar

! Place battery in the battery

mounting

! Screw mountings to bottom of

battery

! Connect battery terminal clip (red

wire) to positive terminal post (+)

! Connect battery-terminal clip to

negative terminal post (-)

Note:

When removing the battery care

must be taken to ensure that first

the negative terminal post lead is

disconnected.

Check that the battery poles and

pole connectors are protected

adequately with pole protecting

grease

Charge the battery

Danger!

! Always heed safety precautions

for handling batteries!

! It is essential to observe the

instructions provided by the

manufacturerer of the charging

unit

! Disconnect the batteries

! Connect positive terminal post

lead of the battery charger with

the battery’s positive terminal

post connection

! Connect negative terminal post

lead of battery charger with the

battery’s negative terminal post

connection

! Plug in power plug and switch on

charger

30

Operating instructions KM 100/100 R D English

Checking the battery acid

level

Warning!

! Regularly check the fluid level of

acid-filled batteries.

! Screw out all cell plugs

! If the fluid level is too low fill up

cells with distilled water up to

mark

! Charge the battery

! Screw in the cell plugs

Check the (fill) level of the

fuel tank

! Open unit cover, engage stay bar

Fill level indicator

Refill fuel

Danger!

Explosion hazard

— Do not fill-in fuel in closed rooms

! Shut-off the engine

— Smoking and naked flames

prohibited

! Open tank cap

! Refuel with "Diesel"

! Fill tank to a maximum of 1 cm

below the bottom edge of the

filler pipe

! Wipe off overflowed fuel and

close tank cap

Check the tyre air pressure

! Set inflation pressure of front tyre

to 6 bar.

! The air pressure in the rear tyres

must be set to 6 bar.

Changing wheels

Danger!

Preparations

! Stand sweeper on a flat surface

! Remove the ignition key

! Wear warning clothing when

performing repair work on public

streets where it is dangerous

because of moving traffic .

! Check that the ground is stable

! Protect the machine additionally

from moving with a wheel chock

Recommended express

assistance:

! Check the tyre tread for

imbedded objects

! Remove the objects

! Use a suitable, commercially

available tyre repair agent

Notes:

Comply with the recommendations

of the respective manufacturers

Continuing the journey is possible if

the recommendations of the product

manufacturer are observed

Change the tyre or the wheel as

soon as possible

! Unscrew the wheel nuts

! Place the jack in position

31

Operating instructions KM 100/100 R D English

Fixing point for jack (front wheel)

Jack fixing point (rear wheels)

! Lift the machine with the jack

! Remove the wheel nuts

! Slide the wheel off

! Position the spare wheel

! Screw on wheel nuts

! Lower the machine with the jack

! Tighten the wheel nuts

Check engine oil level and

top-up

Danger!

Danger of burns!

! Let the engine cool-down

! Wait at least 5 minutes after

stopping engine before

performing the check

! Open unit cover, engage stay bar

! Turn out oil dip stock

! Wipe and insert oil dip stick

! Fill engine oil using the oil

change pump 6.491-538

! Close the oil fill opening

! Wait for at least 5 minutes

! Check the engine oil level

For oil grade see: Technical data

Change the engine oil

! Turn out oil dip stock

! Suck out engine oil with oil-

change pump 6.491-538 through

the oil filler

! Fill in new engine oil with a clean

6.491-538 oil change pump using

the oil filler

For oil grade see: Technical data

Checking/replacing the air

cleaner

! Open unit cover, engage stay bar

! Unscrew wing nut

Note:

Use suitable, commercially available

jacks

! Pull out oil dip stick

— At least a third of the oil dip stick

must be immersed into the oil.

— Refill engine oil up to lower edge

of tank inlet if the oil level is

below it.

! Close the oil fill opening

! Wait for at least 5 minutes

! Check the engine oil level

! Remove, check and clean filter

insert

! Insert clean or new filter insert

into the suction container.

! Tighten the wing nut

32

Operating instructions KM 100/100 R D English

Check and top up the

hydraulic oil level

Note:

The sweeper is provided with two

hydraulic circuits:

1. Sweeping hydraulics circuit

! Check of fill level in the storage

reservoir

! Open unit cover, engage stay bar

The oil level must be between the

"MIN" and "MAX" marks.

! Open the cap to refill

! Fill in hydraulic oil

! Close reservoir

For oil grade see: Technical data

2. Axle drive circuit

! Check of fill level in

compensating reservoir

Warning!

This check may be performed only

when the engine is cold.

! Open unit cover, engage stay bar

! Remove the reservoir cap

— In the reservoir its bottom may

just be covered with oil

! If necessary, carefully replenish

with oil

! Close reservoir

For oil grade see: Technical data

Checking the vacuum

system

— Adding a sweeping system is

with the aid of a vacuum system.

Note:

Always first add the main brush,

since otherwise the side brush does

not rotatet.

— The vacuum canister for lowering

the side brush is to be checked

for leaks and proper connection

of the hose if the side brush

cannot be lowered; attach the

hose, if necessary.

Hose connection to vacuum canister

of side brush lowering

— The vacuum system is leaking if

the side brush can still not be

lowered. In this case after-sales

service must be contacted.

Check the side brush

! Raise the side broom

! Drive sweeper over a flat, smooth

surface covered with a clear layer

of dust

! Lower side brush and start up

! Raise the side broom

! Drive aside backwards

! Check the sweep mirror

Width of sweeping range should be

between 40 - 50 mm

Note:

— The sweeping pattern is

automatically adjusted to wear of

the brushes due to the floating

suspension of the side brush.

— Replace the side brush when the

bristles are too worn.

Replacing side brush

! Unscrew fastening screws

(3 pieces) at the underside

! Slip side brush on carrier and

screw it tight

Check the sweep roller

! Stand sweeper on a flat surface

! Raise the sweep roller

! Turn ignition key to "0" and

remove it

! Secure the machine against

rolling away using a wedge

! Remove the debris container

from both sides of the unit

! Remove tapes and string from

the sweep roller

33

Operating instructions KM 100/100 R D English

Replace the sweep roller

— Replacing it is necessary when

the sweeping effect visibly

deteriorates due to wear of the

bristles.

! Stand sweeper on a flat surface

! Raise the sweep roller

! Turn ignition key to "0" and

remove it

! Secure the machine against

rolling away using a wedge

! Remove the debris container

from both sides of the unit

! Unscrew front screw of right side

panellint

! Unscrew screws

! Screw out screw at main brush

bracket

! Remove lifting rod from peg

! Lift off cover and remove main

brush

Note:

Pay attention to the position of the

bristle set when installing the new

main brush!

! Mount main brush cover

! Slide lifting linkage onto peg

! Slide main brush bracket onto

peg

! Retighten screw at the main

brush bracket

! Fit and tighten fastening screws

of main brush cover

! Screw on side panelling

! Insert the swept material

container

Check sweeping pattern of

the main brush

! Raise the sweep roller

! Raise the side broom

! Drive the sweeper on a flat and

smooth floor noticeably covered

with dust or chalk

! Lower the main brush and rotate

it briefly

! Raise the sweep roller

! Depress pedal to raise the

coarse-dirt flap and keep it

depressed

! Back the machine away

The form of the sweeping pattern

forms a regular rectangle, that is

between 50 - 70 mm wide.

Note:

— Due to the floating suspension of

the main brush The sweeping

pattern automatically adapts itself

to wear of the bristles.

— The main brush must be replaced

when the bristles are too worn.

! Unscrew rear screws of right side

panelling

! Remove bracket of main brush

pivoting arm

! Push main brush into main brush

box and position it onto the

driving peg

34

Operating instructions KM 100/100 R D English

Adjusting and replacing

sealing strips

! Stand sweeper on a flat surface

! Raise the sweep roller

! Turn ignition key to "0" and

remove it

! Secure the machine against

rolling away using a wedge

! Remove the debris container

from both sides of the unit

! Screw off side panelling on both

sides

! Unscrew front screw of side

panelling

Front sealing strip

! Slightly loosen fastening nut at

the front sealing strip, unscrew it

to replace it

! Screw on new sealing strip but

do not yet tighten nuts

Rear sealing strip

! The floor clearance of the sealing

strip is set so that it bends

backward with a lag of 5 - 10

mm

! Replace if worn

! Dismantle the sweeping drum

Side sealing strips

! Slightly loosen fastening nuts of

the side sealing strip, unscrew

them to replace it

! Screw on new sealing strip but

do not yet tighten nuts

! In order to set the clearance to

the floor slide in the 1 - 2 mm

spacer

! Align the sealing strip

! Tighten nuts

! Screw on side panelling

! Insert the swept material

container

Replace the dust filter

Danger!

! Empty the debris container prior

to beginning work on replacing

the dust filter

! Wear a dust protection mask

when working on the filter system

! Observe the safety precautions

for handling fine dust

! Open unit cover, engage stay bar

! Unscrew rear screws of side

panelling

! Align the sealing strip

! Set the sealing strip’s clearance

to the floor so that it bends

backwards with a lag of

35 - 40 mm

! Tighten nuts

! Unscrew fastening nuts of the

rear sealing strip

! Screw on new sealing strip

! Pull out handle of filter bracket to

limit and engage it

! Take out finned filter

! Insert the new filter

35

Operating instructions KM 100/100 R D English

! On the drive side, engage the

carrier into the holes

! Re-engage the handle of filter

dedusting

Note:

Make sure when mounting the new

filter that the lamella are not

damaged

Checking traction belt

Danger!

The engine takes approx. 3...4 s to

run down after being shut off.

Never enter operating area during

this period!

! Turn ignition key to "0" and

remove it

! Open unit cover, engage stay bar

Drive control/electronics fuses

! Unscrew the screws at both sides

of the covering

Note:

— See interior for fuse allocation

— Use only fuses with the same

current rating

Electric starter fuse in the engine

compartment

! Open unit cover

! Replacing blown fuses

! Close unit cover

Fault instructions

Machine will not start

! Sit on the driver seat

! Fill fuel tank

! Check fuse of electric starter,

replace if necessary

! Charge the battery

! Notify the Kärcher service station

Engine runs erratically

! Clean or replace the air cleaner

! Check fuel feed

! Notify the Kärcher service station

Motor running but machine not

moving

! Check position of freewheel lever

! Notify the Kärcher service station

Engine runs, but machine only

moves slowly

! Warm up the machine for

approx. 3 min. at temperatures

below zero

! Notify the Kärcher service station

Replacing the filter box

seal

Remove filter box seal from the

groove in the unit cover and insert

the new seal

Check round belts and V-belts for

tightness, wear and damage

Changing fuses

The drive control electronics are

beneath the front covering. The fuse

for the electric starter is in the

engine compartment

The front covering must be removed

or the unit cover opened when a

fuse has to be replaced.

! Replacing blown fuses

! Refasten front covering

Machine not sweeping properly

! Check main brush and side brush

for wear, replace them, if

necessary

! Check the operation of the

coarse-dirt flap

! Check sealing strips for wear,

adjust or replace them as

required

! Check (sweeping) hydraulic

system for leaks

! Check the seal on the vacuum

system

! Notify the Kärcher service station

36

Operating instructions KM 100/100 R D English

Machine making dust

! Empty debris container

! Check drive belts for the suction

turbine

! Check sealing cup at the suction

turbine

! Check dust filter, dedust or

replace it

! Check filter box seal

! Check sealing strips for wear,

adjust or replace them as

required

Poor sweeping around the edges

! Replacing the side broom

! Check sealing strips for wear,

adjust or replace them as

required

! Notify the Kärcher service station

Activation of side brush or main

brush does not function

! Check the seal on the vacuum

system

! Check (sweeping) hydraulic

system for leaks

! Notify the Kärcher service station

The lowering mechanism of the

side brushes or the main brush

does not function

! Check the seal on the vacuum

system

! Notify the Kärcher service station

Accessories

Side brush 6.905-986

Provided with standard bristles for

indoor and outdoor surfaces.

Soft side broom 6.906-133

For fine dust on indoor surfaces,

resistant to moisture.

Hard side broom 6.906-065

For cleaning hard to remove dirt

from outdoor surfaces.

Standard main brush 6.906-375

Wearproof and wetproof.

Universal bristles for indoor and

outdoor cleaning.

Main brush soft 6.906-533

With natural bristles specially for

sweeping fine dust on smooth

indoor floors. Not moisture-resistant,

not for abrasive surfaces.

Main brush hard 6.906-532

For removing stubborn external dirt,

damp-proof.

Dust filter 6.414-532

Technical data

Unit data

Length x width x height

2006 x 1005 x 1343 mm

Empty weight 315 kg

Permissible total weight 535 kg

Driving speed

8 km/h

Sweeping speed 6 km/h

Climbing ability max. 18 %

Main brush diameter 285 mm

Main brush width 710 mm

Side brush diameter 450 mm

Area performance

without side brush 7300 m²/h

with side brush 10400 m²/h

Working width

without side brush 710 mm

with side brush 1000 mm

Volume of debris

container 100 litres

Protection class drip-proof

IPX 3

Engine

Type Yanmar L70AE-DE,

1-cylinder four stroke

Displacement 296 cm³

Power, max. 4,4 kW/6 PS

at 3600 1/min

Fuel, diesel 3,3 l

Type of protection IP 22

Battery 12 V, 44 Ah

Fuel consumption ca. 1,5 l/h

Oil types

Engine approx. 1,1 l

SAE 15 W 40

Sweeper hydraulics HVLP 46

Axle drive SAE 10 W 60

Tyres

Large-size, front 4.00-4

Air pressure - front 6 bar

Large-size, rear 4.00-8

Air pressure - rear 6 bar

Brake

Service brake hydrostatic

Parking brake automatic

(with spring)

Filter and suction system

Fine dust filter surface 6,0 m²

Filter’s application class U

for non-health hazardous dusts

Rated vacuum of

suction system 12 mbar

Rated volumetric flow of

suction system 50 l/s

Ambient conditions

Temperature -5 - +40° C

Atmospheric humidity,

non-dew developing 0 - 90 %

Machine vibration

Total vibration value (ISO 5349)

Right arm 1,8 m/s²

Left arm 1,8 m/s²

Feet/seat area 0,7 m/s²

Noise emission

Sound pressure level

(EN 60704-1) 83 dB(A)

Garanteed sound

power level

(2000/14/EC) 101 dB(A)

37

Operating instructions KM 100/100 R D English

EC conformity declaration

We hereby declare that the machine

specified below

as the marketed desigh, the

machine specified below

complies with the relevant

fundamental safety and health

requirements of the EC directives

listed below.

Modification of the machine without

our approval invalidates this

declaration.

Product: Ride-on vacuum sweeper

Type: 1.280-xxx

Relevant EC directives

EC machine directive (98/37/EC)

EC directive on electromagnetic

compatability (89/336/EEC)

amended by 91/263/EEC,

92/31/EEC, 93/68/EEC

EC guideline on noise emissions

(2000/14/EU)

Applied harmonised standards

DIN EN 292-1

DIN EN 292-2

DIN EN 60335-1

DIN EN 60335-2-72

DIN EN 50082-2:1995

Internal measures ensure that the in

series produced units always

comply with the requirements of

current EC directives and applied

standards. The signatories act for

and in authority of management.

5.957-666 (01/02)

Alfred Kärcher Limited Partnership.

Registered office: Winnenden.

Registration court: Waiblingen,

HRA 169.

Personally liable partner. Kärcher

Reinigungstechnik GmbH.

Registered office Winnenden, 2404

Waiblingen Company Register, HRB

Managing directors:

Dr. Bernhard Graf, Hartmut Jenner,

Georg Metz

Alfred Kärcher GmbH & Co.KG

Cleaning Systems

Alfred-Kärcher-Strasse 28-40

P.O.Box 160

D-71349 Winnenden

Phone: ++49 7195 14-0

Fax :++49 7195 14-2212

Applied national standards

CISPR 12

Applied conformity valuation

method

Appendix V

Measured sound power level:

KM 100/100 R D 99 dB(A)

Guaranteed sound power level:

KM 100/100 R D 101 dB(A)

38

ETL KM 100/100 R D

0

KM 100/100 R D

1.280- 114.0

6.394- 048.0

6.491- 641.0

6.491- 642.0

6.368-217.0

6.435- 253.0

6.375- 212.0

6.414- 532.0

6.491- 532.0

4.120- 343.0

7.306- 031.0

6.491- 640.

5.115- 233.0

7.306- 031.0

7.304- 012.0

6.435- 408.0

6.906. 375.0

6.905- 986.0

03.2003

187

Loading...

Loading...