Page 1

HDS 995 M Eco HDS 995 MX Eco

HDS 1295 S Eco HDS 1295 SX Eco

www.kaercher.com 5.961-300 A2008544 05/04

Page 2

Deutsch

7

Magyar

198

English

Français

Italiano

Nederlands

Español

Português

ЕллЮнйкЬ

ЕллЮнйкЬ

ЕллЮнйкЬЕллЮнйкЬ

Dansk

23

38

55

72

88

104

120

138

Česky

Slovensko

Polska

Româneşte

Türkçe

Русский

Slovensky

Hrvatski

214

230

246

263

280

296

314

330

Norsk

Svenska

Suomi

2

153

168

183

Srpski

Български

346

362

Page 3

-

Page 4

1

5

2

3

4

6a

6b

7

Page 5

8

11b

9

10

11a

12

13

14

Page 6

15

16

17

19

18

Page 7

Operating Instructions English

Contents

Warning!

Environmental protection 23

Unit illustration 24

Prior to initial operation it is mandatory to

read the operating instructions and the

notes on safety no. 5.951-949!

Operating controls 24

Reference to operating

instructions 25

Commissioning 25

Operation 27

After every operation 29

Decommissioning 30

Maintenance 30

Maintenance tasks 31

Faults 32

Warranty 35

General notes 35

EC conformity declaration 36

Technical data 37

Parts list 379

Inform retailer immediately of any

transportation damage.

Environmental protection

Please dispose of packaging

environmentally responsibly

The packaging materials are recyclable.

Please do not throw the packaging in with

household rubbish but take it to a recycling

centre.

Please dispose of scrapped units

environmentally-responsibly

Scrapped units consist of valuable

recyclable materials that should be taken to

a recycling centre. Batteries, oil and similar

products must not be allowed to

contaminate the environment. Therefore,

please dispose of scrapped units via

appropriate disposal systems.

Danger: Steam!

Danger of scalding! Steam escapes here.

Please ensure engine oil, fuel oil, diesel

and petrol

to contaminate the environment. Please

protect the ground and dispose of used oil

ecologically.

23

Page 8

English Operating Instructions

Unit illustration

Operating controls

1 Fuel tank inlet

2 Handle

3 Instrument panel

4 Window with the

maintenance/fault display

5 Cover latch

6 Compartment für accessories

7 Short operating instructions

8 Cover for compartment

9 Unit cover

10 Cover for tank inlet

11 Tank inlet für scale inhibitor

12 tank inlet for cleaning agent

13 High-pressure nozzle

14 Handle grips in the chassis

15 Steel pipe

16 Pressure and flow control

17 Swivel caster with parking brake

18 Water connection with strainer

19 High-pressure connection

20 Handgun with high-pressure hose

22 Electric power cord

23 Unit switch

24 Temperature regulator

25 Fuel indicator lamp

26 Scale inhibitor indicator lamp

27 CHEM1, CHEM2 indicator lamp

(applies only to HDS 1295)

28 Engine/electronics indicator lamp

29 Ready for working indicator lamp

30 Pressure gauge

31 Metering valve for cleaning agent

32 Hose reel (applies only to MX/SX)

33 Crank (applies only to MX/SX)

34 Fine filter

24

Page 9

Operating Instructions English

Reference to operating

instructions

All of the item numbers described below in

the operating instructions are referenced in

the illustration of the unit.

Commissioning

Warning!

Unit, piping, high-pressure hose and

connections must be in perfect working

order!

! Lock the hand brake.

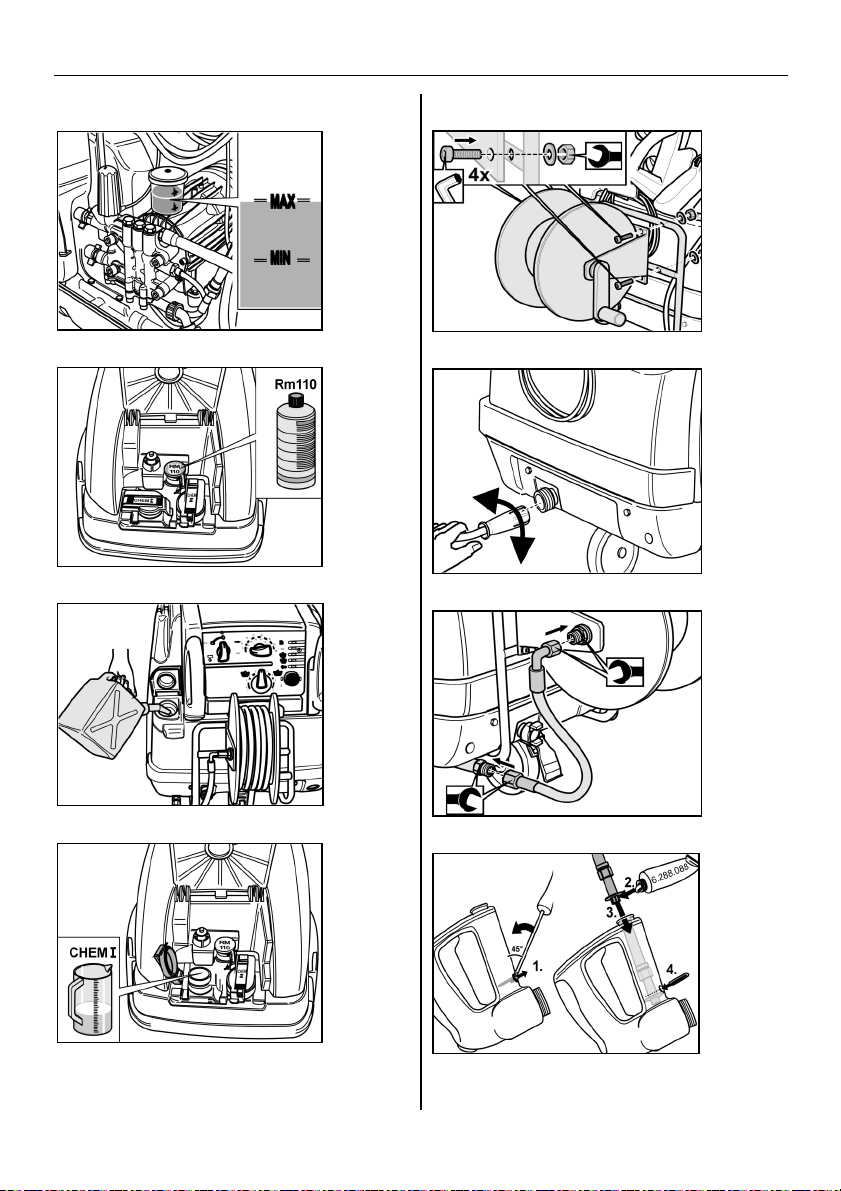

Checking oil level

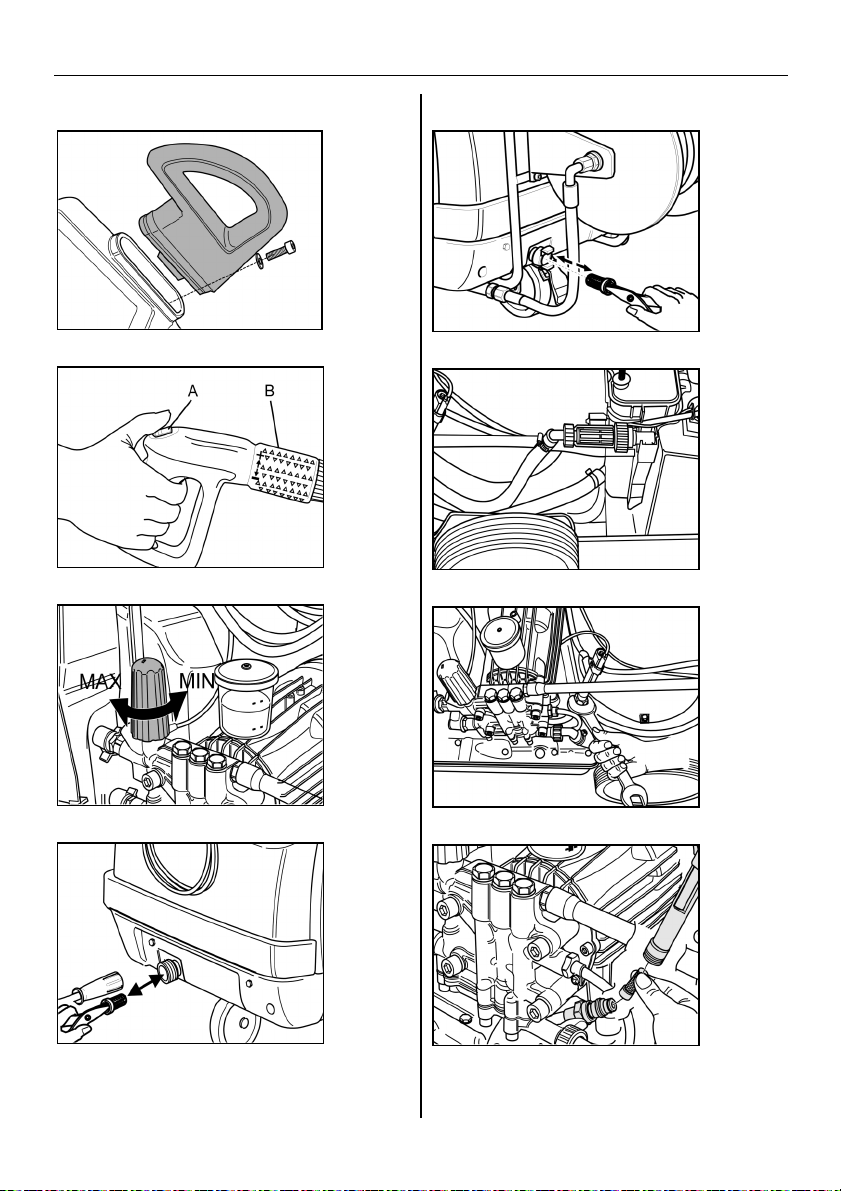

Fig. 1

Warning!

Immediately consult the Kärcher service

station when oil turns milky!

! If oil level is approaching MIN mark, fill

up with oil as far as MAX mark.

! Seal oil filler inlet.

Refer to technical data for oil grade.

Filling with scale inhibitor

Fig. 2

! For other water hardnesses request

services of a Kärcher service station and

have it adapted to local conditions.

Filling with fuel

Warning!

Never operate unit with fuel tank empty!

Fuel pump would otherwise be destroyed!

Warning!

Fig. 3

Only fill with diesel fuel or light fuel oil.

It is forbidden to use unsuitable fuels,

e.g. benzine (explosion hazard, damage to

unit).

! Close tank cap

! Wipe off excess fuel

Fill with cleaning agent

— Use only Kärcher products.

— Never pour in solvent (petrol, acetone,

thinner etc.)!

— Avoid contact with eyes and skin

— Pay attention to cleaning-agent

manufacturer's instructions on safety

and handling

(sample pack included with scope of

delivery)

Scale inhibitor stops heating coil becoming

calcified when using hard tap water. Is is

metered in at the inlet in the water reservoir

one drop at a time.

By the manufacturer metering is set to a

mean water hardness.

Kärcher offers a customised cleaning

and care agent range.

Your dealer will be pleased to advise you.

Fig. 4

Fill with cleaning agent

25

Page 10

English Operating Instructions

Installing the handgun (units

without hose reel)

! Connect steel pipe (item 15) with

handgun (item 20)

! Insert high-pressure nozzle in union nut

! Mount and tighten unit nut

! Install the high-pressure hose to high-

pressure connection of unit. (Figure 6a)

Installing the handgun and the

hose reel (units with hose reel)

! Connect steel pipe (item 15) with

handgun (item 20)

! Insert high-pressure nozzle in union nut

! Mount and tighten unit nut

! Install the hose reel (item 32) with the

provided Allen screws, washers and

nuts (4 of each). (Figure 5)

! Install the high-pressure hose at the

high-pressure connection of hose reel

and unit. (Figure 6b)

! Connect high-pressure hose of handgun

to hose reel

! Wind high-pressure hose onto hose reel

with the smallest possible bends

(direction of turns – clockwise -)

Drawing in water from tank

When you suction water out of an open

container you should

! remove water connection at pump head.

! screw off the top supply hose with the

fine filter to the water tank and connect

to pump head.

! Use a water suction hose with a suction

filter and a diameter of at least 3/4".

Until the pump sucks up water you should:

! Turn the pressure and flow control to

"MAX".

! close the metering valve for the cleaning

agent.

Warning!

Never suction up water out of a potable

water tank.

Never suction up solvent-bearing liquids

such as paint thinner, benzine, oil or

unfiltered water. The seals in the unit are

not resistant to solvents. The mist of

solvents is highly inflammable, explosive

and poisonous!

Mounting of spare high-pressure

hose

Fig. 7

Mounting handle

Fig. 8

Water connection

! See Technical Data for connected loads.

! Install supply hose at water connection

(item 18) of unit.

(supply hose is not part of scope of

delivery)

26

Mains connection

See technical data and rating plate for

connected load.

Warning!

It is not permissible to exceed the

maximum permissible mains impedance at

the electrical terminal (see Technical Data).

Warning!

Whenever socket is changed, check

direction of rotation of motor

Page 11

Operating Instructions English

— If direction of rotation is correct, powerful

jet of air will be felt at exhaust-gas

opening of burner.

— If the direction of rotation is

wrong: Change the poles at the unit

plug. See Fig. 18.

! When an extension cable is used it

should always be complety unwound

and have an adequate cross-section.

Operation

Switch on the machine

! Set unit switch (item 23) to "I"

Ready for working indicator lamp (item 29)

is lit

Warning!

The temperature regulator (item 24) must

be set to "0", since otherwise the burner

possibly switches on

Unit starts up briefly and is switched off as

soon as operating pressure is reached.

Stop the unit immediately when one of the

indicator lamps (items 25-28) light up

during operation. Eliminate fault, refer to

Faults.

Fig. 9

! Release the safety of the handgun (A)

Actuation of handgun switches unit back on

again.

Setting cleaning temperature

! Set the remperature regulator (item 24)

to the required temperature

30°C to 90°C

Hot water cleaning

100°C to 150°C

Cleaning with steam

! Replace high-pressure nozzle by the

steam nozzle (see operation using

steam)

Setting operating pressure and

flow rate

Fig. 10

— Turning control spindle

clockwise: Increasing operating pressure

(MAX)

— Turning it counterclockwise: Reducing

operating pressure (MIN)

Servopress control

! Set the temperature regulator (item 24)

to max. 98°C.

! Set regulator to maximum operating

pressure.

Fig. 9

Adjust operating pressure and flow rate by

turning (infinitely variable) at the pressure

and flow control (B) (+/-)

Set pressure on unit if use is to be made of

reduced pressure for a lengthy period.

See Fig. 10

Bleed pump if no water emerges from highpressure nozzle. See problems, "Unit does

not build up pressure"

27

Page 12

English Operating Instructions

Measuring out cleaning agents

— Use cleaning agents sparingly to protect

the environment

— The cleaning agent must be appropriate

for the surface to be cleaned.

! Using the cleaning agent metering valve

(item 31) set the concentration of the

cleaning agent as specified by the

manufacturer

Approximate values at maximum operating

pressure

Intended use

For cleaning: machines, vehicles, buildings,

tools, facades, patios, gardening

implements, etc.

Warning!

— Heed appropriate safety regulations for

use at petrol stations or in other

hazardous environments.

Please ensure waste water containing

mineral oil

does not contaminate soil, lakes and rivers

or the sewerage system. Therefore, please

wash engines and underbodies only in

appropriate washing installations provided

with oil traps.

Working with high-pressure nozzle

Spray angle is crucial to efficiency of highpressure jet.

Use is normally made of 25°fan jet nozzle

(included).

Recommended nozzles, available as

accessories

— For stubborn dirt

0°full jet nozzle

— For sensitive surfaces and superficial

dirt

40°-fan jet nozzle

— For thick-film, stubborn dirt

Dirt blaster

— Nozzle with adjustable spray angle,

adaptable to many cleaning tasks

Variable-angle nozzle

Cleaning

! Set pressure/temperature and detergent

concentration appropriately to surface to

be cleaned

Always start by directing high-pressure jet

from a good distance at object to be

cleaned to avoid damage caused by

excessive pressure.

Recommended cleaning method

Loosen up dirt:

! Spray on cleaning agent sparingly and

allow to react for 1...5 min (do not allow

to dry on).

Remove dirt:

! Spray off loosened-up dirt with high-

pressure jet.

Operation with cold water

Removal of slight contamination and rinsing

e.g: gardening implements, patio, tools, etc.

28

! Set operating pressure as required

! Set temperature control (item 24) to "0"

Page 13

Operating Instructions English

Operation with hot water

Warning!

Danger of scalding

! Set the remperature regulator (item 24)

to the required temperature

We recommend the following cleaning

temperatures

— Slight contamination 30-50°C

— Protein soiling, e.g. in foodstuffs industry

max. 60°C

— Motor vehicle cleaning, machine

cleaning 60-90°C

Safety deactivation

If the handgun is not opened or closed for

more than 30 minutes, for safety reasons

the pump switches off automatically.

— To switch it on again turn the main

switch to "0" and then back to "I".

(EPROM without shut down 6.682-595

available from service)

! Set operating pressure to minimum

value. See Fig. 10

! Set the temperature regulator (item 24)

to min. 100°C

Danger: Steam!

Danger of scalding!

We recommend the following cleaning

temperatures

— Preservative removal, extremely greasy

dirt 100-110°C

— Thawing of aggregates, certain facade

cleaning operations up to 140°C

After every operation

Warning!

Danger of scalding with hot water.

After operating it with hot water or steam, to

cool it the unit must be operated at least

two minutes with cold water with an open

handgun.

Operation with steam

Danger: Steam!

At operating temperatures above 98°C

operating pressure must not exceed 32 bar

(HDS 1295: 28 bar).

Therefore the following steps must be

taken without fail:

! Replace high-pressure nozzle by steam

nozzle

Manufacture no.:

4.766-023 HDS 995

4.766-024 HDS 1295

! Fully open water delivery control at the

handgun, in the + direction to the stop.

See Figure 9 (B)

Following operation with cleaning agent

! Set cleaning agent metering valve

(item 31) to "0"

! Set unit switch (item 23) to "I"

! Actuate handgun and flush unit for

approx. 1 min

Stopping machine

! Set unit switch (item 23) to "0"

! Shut off water supply

! Switch the pump briefly on with the unit

switch (item 23) (approx. 5 sec.)

! Remove mains plug from socket ONLY

with dry hands

! Remove water connection

! Actuate handgun to depressurise unit

! Put on safety of handgun Figure 9 (A)

! Engage spray lance in cover holder

29

Page 14

English Operating Instructions

! Reel up the high-pressure hose and

electric cables and attach them to

fastenings

Note!

Take care not to kink high-pressure hose

and cable!

Note!

Frost will destroy unit if water is not drained

off completely!

! Store unit in a frost-free location

Observe the following if the unit is

connected to a flue:

Danger of damage caused by cold air

entering through the flue. Disconnect unit

from flue at outside temperatures below

0°C.

Immobilise unit if frost-proof storage is not

possible.

Decommissioning

In the event of lengthy periods of non-use

or if frost-free storage is not possible:

! Drain off water and flush out equipment

with antifreeze

! Drain cleaning fluid tank

Drain off water

! Unscrew water supply hose and high-

pressure hose

! Screw off supply line at boiler base and

completely drain heating coil

! Run unit for max. 1 min until pump and

lines are empty

Flushing unit with anti-freeze

! Fill the float tank with a commercially

available antifreezing compound

! Swith the unit on (without the burner)

until it is thoroughly purged

! Observe handling instructions of

antifreeze manufacturer

By this means, a certain degree of

corrosion protection is achieved

Maintenance

Warning!

Disconnect unit from mains before carrying

out any maintenance or repair work.

Always use genuine spare parts

Turn off unit prior to all work, see "After

every operation".

! Set unit switch (item 23) to "0"

! Pull power plug out of socket

! Shut off water supply

! Actuate handgun to depressurise unit.

! Remove water connection

! Allow unit to cool down

Your Kärcher dealer will be pleased to

inform you on the performance of

regular safety inspections

and conclusion of a maintenance

contract

30

Page 15

Operating Instructions English

Maintenance intervals

Once a week

— Clean strainer in water connection

— Clean the fine filter

— Check oil level

Immediately consult the Kärcher service

station when oil turns milky!

Once a month

— Clean strainer in low water protection

— Clean filter at cleaning-agent suction

hose

After 500 hours of operation, at least

once a year

— Change oil

Maintenance tasks

Engine/electronics indicator

lamp (item 28) is lit

— This warning lamp lights up when certain

maintenance work is necessary due to

accumulated operating hours.

! When you open the cover (item 8) of

the compartment (item 6) the electronic

display is visible in the window (item 4).

! When the necessary maintenance work

has been completed you should depress

the RESET button next to the display for

at least 7 seconds until the warning lamp

goes out.

Display

Necessary maintenance work

! Visual inspection

! Check that the high-pressure

connections do not leak

! Clean the fuel tank and the filter

Display

Necessary maintenance work

! Check that the pump does not leak

! Change the pump's oil

! Clean strainer in water connection

! Clean the strainer (coarse) fitted in front

of the low water protection

Display

Necessary maintenance work

! Decarbonise the heating coil *

! Descale the heating coil *

! Clean/replace the ignition electrodes *

! Cleaning/replacing the burner nozzle *

! Adjust the burner *

Display

Necessary maintenance work

! Check the overflow valve for leaks *

! Check the high-pressure hose *

! Clean the handgun

! Check the pulsation damper *

* This maintenance work should be

performed only by after-sales service.

31

Page 16

English Operating Instructions

Clean strainer in water

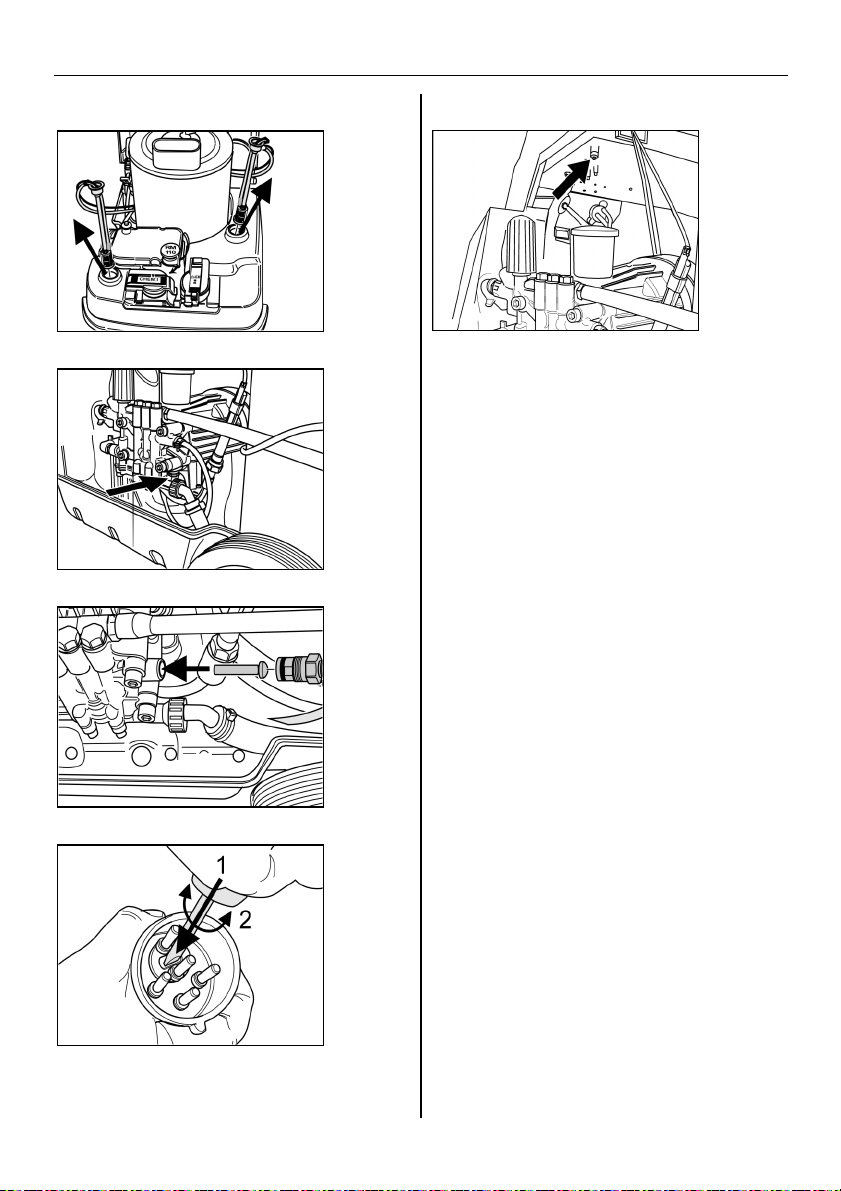

connection

Fig. 11

! Remove strainer

! Clean in water and re-insert

Clean the fine filter

Fig. 12

! Cut pressure to unit

! Screw off cover with filter

! Clean filter with clean water or with

compressed air

! Assemble in the reverse order

Clean strainer in low water

protection

Fig. 13

! Unfasten union nut and detach hose

Fig. 14

! Take out strainer

If necessary, screw-in screw M8 by

approx. 5 mm and pull out the strainer with

this screw

! Clean strainer in water

! Slide in strainer

! Mount hose

! Tighten union nut

Clean filter at cleaning-agent

suction hose

Fig. 15

! Pull the cleaning agent suction inlet pipe

out

! Clean filter in water and re-insert

Change oil

Fig. 16

! Provide a collecting container for

approx. 1 litres of oil

! Unscrew drain plug

Dispose of used oil ecologically or hand it

in at a dump.

! Retighten drain plug

! Top up oil slowly up to the MAX mark

Air bubbles must be able to escape

Refer to technical data for oil grade and

quantity to be used.

Faults

Engine/electronics indicator lamp

(item 28) flashes

— This warning lamp flashes if there is a

problem.

! When you open the cover (item 8) of the

compartment (item 6) the electronic

display is visible in the window (item 4).

! The warning lamp goes out when the

problem has been resolved and the unit

is switched on again.

Display

Troubleshooting

! Increase the water inlet volume

! Clean strainer in water connection

! Clean the strainer (coarse) fitted in front

of the low water protection

32

Page 17

Operating Instructions English

Display

Troubleshooting

! Replace the reed switch for the low

water protection *

! Clean the low water protection *

Display

Troubleshooting

! Eliminate the leakage in the high-

pressure system

Display

Troubleshooting

Motor overloaded/overheated

! Turn monitoring switch to "0" and allow

engine to cool for at least 5 min

! Have unit checked by After-Sales

Service if this does not remedy fault

! Cbeck exhaust gas temperature limiter,

reset, if necessary (Figure 19)

Display

Troubleshooting

! This error code appears only on units

equipped with the – accessory kit flame

monitoring system ! See the assembly instructions –

accessory kit flame monitoring system -

* This maintenance work should be

performed only by after-sales service.

Ready for working indicator lamp

(item 29) goes out

— Motor overloaded/overheated

! Set selector switch to "0" and allow

engine to cool off for at least 5 min.

! Have unit checked by After-Sales

Service if this does not remedy fault.

! No mains voltage

(see – unit does not run -)

Fuel indicator lamp (item 25) lights up

— Fuel tank empty

! Fill up

Liquid softener indicator lamp (item 26)

lights up

— Scale inhibitor reservoir empty; for

technical reasons there is always a

residual quantity in the reservoir.

! Fill up

— Dirt on electrodes in reservoir

! Clean electrodes

Unit does not run

— No mains voltage

! Check electric mains/power cord

Unit does not build up pressure

— Air in system

Bleed pump:

! Set cleaning agent metering valve

(item 31) to "0"

! Switch the unit switch on and off several

times keeping the handgun open.

! With handgun open, open and close

regulator (Fig. 10).

Venting is accelerated by removing the

high-pressure hose from the high-pressure

connection.

33

Page 18

English Operating Instructions

! Fill up cleaning-agent tank if empty.

! Check connections and lines

— Pressure set to MIN

! Set pressure to MAX

— Strainer in water connection is dirty

! Clean strainer

! Clean fine filter, replace it if necessary

— Insufficient water supply

! Check water supply volume (refer to

technical data)

Unit leaking, water dripping out at

bottom

— Pump leaking

3 droplets/min are permitted.

! In the event of a major leak, have unit

checked by After-Sales Service.

Unit constantly switched on and off with

handgun closed

— Leak in high-pressure system

! Check high-pressure system and

connections for leaks

Unit does not draw in cleaning agent

! Run the unit with an opened cleaning

agent metering valve and a closed water

supply until the float tank is sucked dry

and the pressure drops to "0".

! Now reopen the water inlet.

If the pump still does not suction up

cleaning agent the reasons can be as

follows:

— Filter in cleaning-agent suction hose

dirty

! Clean filter

Burner not ignited

— Fuel tank empty

! Fill up

— Lack of water

! Check water connection, check supply,

clean low water protection.

— Fuel filter is dirty

! Replace fuel filter.

— Incorrect direction of rotation. If direction

of rotation is correct, powerful jet of air

will be felt at exhaust-gas opening of

burner.

! Check direction of rotation. If necessary,

change round poles of unit plug. See

Fig. 18.

— No ignition spark

! Have unit checked by After-Sales

Service if no ignition spark is visible

through inspection glass during

operation.

Set temperature not attained when

working with hot water

— Excessive operating pressure/flow rate

! Reduce operating pressure/flow rate by

way of regulator (Fig. 10)

— Soot deposits on heating coil

! Have After-Sales Service remove soot

deposits from unit

The unit must be checked by after sales

service if the problem cannot be

remedied.

— Non-return valve gummed up

! Pull the cleaning agent hose off and

detach the non-return valve with a blunt

object, see Figure 17.

34

Page 19

Operating Instructions English

Warranty

The warranty terms and conditions issued

by our responsible sales company apply in

every country. Within the warranty period,

any faults in the unit will be rectified free of

charge provided that the problem was

caused by a material defect or

manufacturing error.

The warranty only applies if the dealer fills

in, stamps and signs the enclosed reply

card when the unit is sold and the

purchaser then returns it to the appropriate

local distributor.

In the event of a warranty claim, please

contact your dealer or the nearest

authorised After-Sales Service office and

produce both accessories and proof of

purchase.

General notes

Safety features

Overflow valve with two pressure

switches

— When reducing water volume at pump

head or with the servopress control, the

overflow valve will open and part of the

water will flow back to the pump suction

side.

— If the handgun is closed off so that all

the water flows back to the pump suction

side, the pressure switch at the overflow

valve turns off the pump.

— Reopening the handgun causes the

pressure switch at the cylinder head to

switch the pump back on again.

The overflow valve is set at the factory and

lead-sealed. Adjustment can only be made

by After-Sales Service.

Safety valve

— The safety valve opens if the overflow

valve or pressure switch is defective.

The safety valve is set at the factory and

sealed. Adjustment can only be made by

After-Sales Service.

Low water protection

— The low water protection prevents the

burner switching on when water is

insufficient.

— A strainer prevents dirt accumulation on

the protection and must be regularly

cleaned.

Motor protection switch

— The motor protection switch interrupts

the circuit should overloading occur.

Switching on procedures

— Switching on procedures generate brief

voltage drops.

— Impairments of other appliances can

occur in cases of unfavourable mains

conditions.

— No problems are to be expected with a

mains impedance of less than 0,15 ohm.

35

Page 20

English Operating Instructions

EC conformity declaration

We hereby declare that the machine

specified below as the marketed desigh,

the machine specified below complies with

the relevant fundamental safety and health

requirements of the EC directives listed

below.

Modification of the machine without our

approval invalidates this declaration.

Product: High-pressure cleaner

with a steam stage

Type: 1.027-xxx, 1.028-xxx

Relevant EC directives

EC machine directive (98/37/EC)

EC low voltage directive (73/23/EEC)

amended by 93/68/EEC

EC directive on electromagnetic

compatability (89/336/EEC) amended by

91/263/EEC, 92/31/EEC, 93/68/EEC

EC high-pressure equipment directive

(97/23/EG)

EC guideline on noise emissions

(2000/14/EU)

Applied harmonised standards

DIN EN 60335-1

DIN EN 60335-2-79

DIN EN 55014-1:2000 + A1:2001

DIN EN 55014-2:1997

DIN EN 61000-3-2:2000

DIN EN 61000-3-3:1995 + A1:2001

(HDS 995)

DIN EN 61000-3-11:2000 (HDS 1295)

Measured sound power level:

HDS 995 89 dB(A)

HDS 1295 88 dB(A)

Guaranteed sound power level:

HDS 995 91 dB(A)

HDS 1295 89 dB(A)

Internal measures ensure that the in series

produced units always comply with the

requirements of current EC directives and

applied standards. The signatories act for

and in authority of management.

5.957-649 (02/04)

Alfred Kärcher Limited Partnership.

Registered office: Winnenden. Registration

court: Waiblingen, HRA 169.

Personally liable partner. Kärcher

Reinigungstechnik GmbH. Registered

office Winnenden, 2404 Waiblingen

Company Register, HRB

Managing directors:

Dr. Bernhard Graf, Hartmut Jenner,

Georg Metz

Alfred Kärcher GmbH & Co. KG

Cleaning Systems

Alfred-Kärcher-Strasse 28-40

P.O.Box 160

D-71349 Winnenden

Phone: ++49 7195 14-0

Fax :++49 7195 14-2212

Applied national standards

---

Applied conformity valuation method

Appendix V

36

Page 21

230 V

3~50 Hz

400 V

3~50 Hz

230 V

3~50 Hz

3~50 Hz

Type HDS 995 M / MX Eco HDS 1295 S / SX Eco

Mains connection 400 V

Technical Data English

Connected load 6,8 kW 6,8 kW 8,2 kW 8,2 kW

Fuse (slow blow) 16 A 25 A 16 A 35 A

Maximum permissible mains impedance --- --- (0,307+j 0,192) Ω (0,307+j 0,192) Ω

Water connection

Supply temperature max. 30 °C max. 30 °C

Supply volume min. 1200 l/h (20 l/min) min. 1500 l/h (25 l/min)

Suction height when drawn

from open tank (at 20°C water temperature) 0,5 m 0,5 m

Performance data

Flow rate: cold/hot water 470-1000 l/h (7,8-16,7 l/min) 600-1200 l/h (10-20 l/min)

Operating pressure: cold/hot water (with standard nozzle supplied) 3-18 MPa (30-180 bar) 3-18 MPa (30-180 bar)

Flow rate: steam 470 l/h (7,8 l/min) 600 l/h (10 l/min)

Operating pressure: steam max. 3,2 MPa (32 bar) max. 2,8 MPa (28 bar)

Steam nozzle part number 4.766-023 4.766-024

Operating temperature

- Hot water max. 95 °C max. 95 °C

- Steam 98-155 °C 98-155 °C

Cleaning-agent intake 0 - 40 l/h (0-0,7 l/min) 0 - 48 l/h (0-0,8 l/min)

Burner output 86 kW 103 kW

Maximum fuel oil consumption 6,9 kg/h 8,3 kg/h

Recoil force of handgun 43 N 60 N

Noise emission

Sound pressure level (EN 60704-1) 75 dB (A) 73 dB (A)

Guaranteed sound power level (2000/14/EC) 91 dB (A) 89 dB (A)

Machine vibration

Rated vibration value (ISO 5349)

Handgun 2,5 m/s² 1,7 m/s²

Spray lance 1,8 m/s² 1,7 m/s²

Fuels

Fuel Heizöl EL oder Diesel Heizöl EL oder Diesel

Oil quantity 0,75 l 0,75 l

Oil grade Hypoid SAE90 (6.288-016) Hypoid SAE90 (6.288-016)

Dimensions and weights

Length x Width x Height 1285x690x835 mm 1285x690x875 mm

Weight not incl. accessories 133 kg 155 kg

Weight not incl. accessories, MX Eco / SX Eco 141 kg 163 kg

Fuel tank 25 l 25 l

Cleaning-agent tank 20 l 20 + 17 l

37

Page 22

379

Page 23

380

Loading...

Loading...