Page 1

BD 80/100 W Classic Bp

Register

your product

www.kaercher.com/welcome

English 3

Français 15

Español 28

59688290 (04/19)

Page 2

Page 3

Contents

IMPORTANT SAFETY INSTRUCTIONS .......................... 3

OPERATING SAFETY RULES AND PRACTICES........... 3

MAINTENANCE AND REBUILD PRACTICES ................. 4

FIRE SAFETY STANDARD .............................................. 4

General notes ................................................................... 4

Function ............................................................................ 4

Intended use ..................................................................... 4

Environmental protection .................................................. 5

Accessories and spare parts............................................. 5

Scope of delivery .............................................................. 5

Safety instructions ............................................................ 5

Description of the unit ....................................................... 6

Installation......................................................................... 7

Initial startup ..................................................................... 9

Operation .......................................................................... 9

Transport........................................................................... 11

Storage ............................................................................. 11

Care and service............................................................... 11

Troubleshooting guide ...................................................... 13

Warranty ........................................................................... 14

Accessories ...................................................................... 14

Technical data ................................................................... 14

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

몇 WARNING

To reduce the risk of fire, electric shock, or injury:

DO NOT LEAVE appliance unattended when plugged in.

Unplugfrom outlet when not in use and before servicing.

몇 WARNING

TO REDUCE THE RISK OF ELECTRIC SHOCK-USE INDOORS ONLY

Do not allow to be used as a toy. Close attention is nec-

essary when used by or near children.

Use only as described in this manual. Use only manu-

facturer’s recommended attachments.

Do not use with damaged cord or plug. If the unit is not

working as it should, has been dropped, damaged, left

outdoors, or dropped into water, return it to a service

center.

Do not pull or carry by the cord, do not use cord as a

handle, do not close a door on the cord, or pull cord

around sharp edges or corners. Do not run appliance

over cord. Keep cord away from heated surfaces.

DO NOT UNPLUG BY PULLING CORD. To unplug,

grasp plug, not cord.

Do not handle plug or appliance with wet hands.

Do not put any objects into openings. Do not use if

openings are blocked; keep free of dust, lint, hair, and

anything that may reduce air flow.

KEEP HAIR, CLOTHING, LOOSE JEWELRY, FIN-

GERS and all parts of the body away from openings and

moving parts.

Turn off all controls before unplugging.

Use extra care when cleaning on stairs.

Do not use to pick up flammable or combustible liquids,

such as gasoline, or use in areas where they may be

present.

Connect to a properly grounded outlet only. See

Grounding Instructions.

Always disconnect cord from electrical outlet before ser-

vicing appliance.

Never sweep off explosive liquids, combustible gases or

undiluted acids and solvents. This includes petrol, paint

thinner or heating oil which can generate explosive

fumes or mixtures upon contact with the air. Acetone,

undiluted acids and solvents must also be avoided as

they can harm the materials on the machine.

Do not vacuum up burning or smouldering objects!

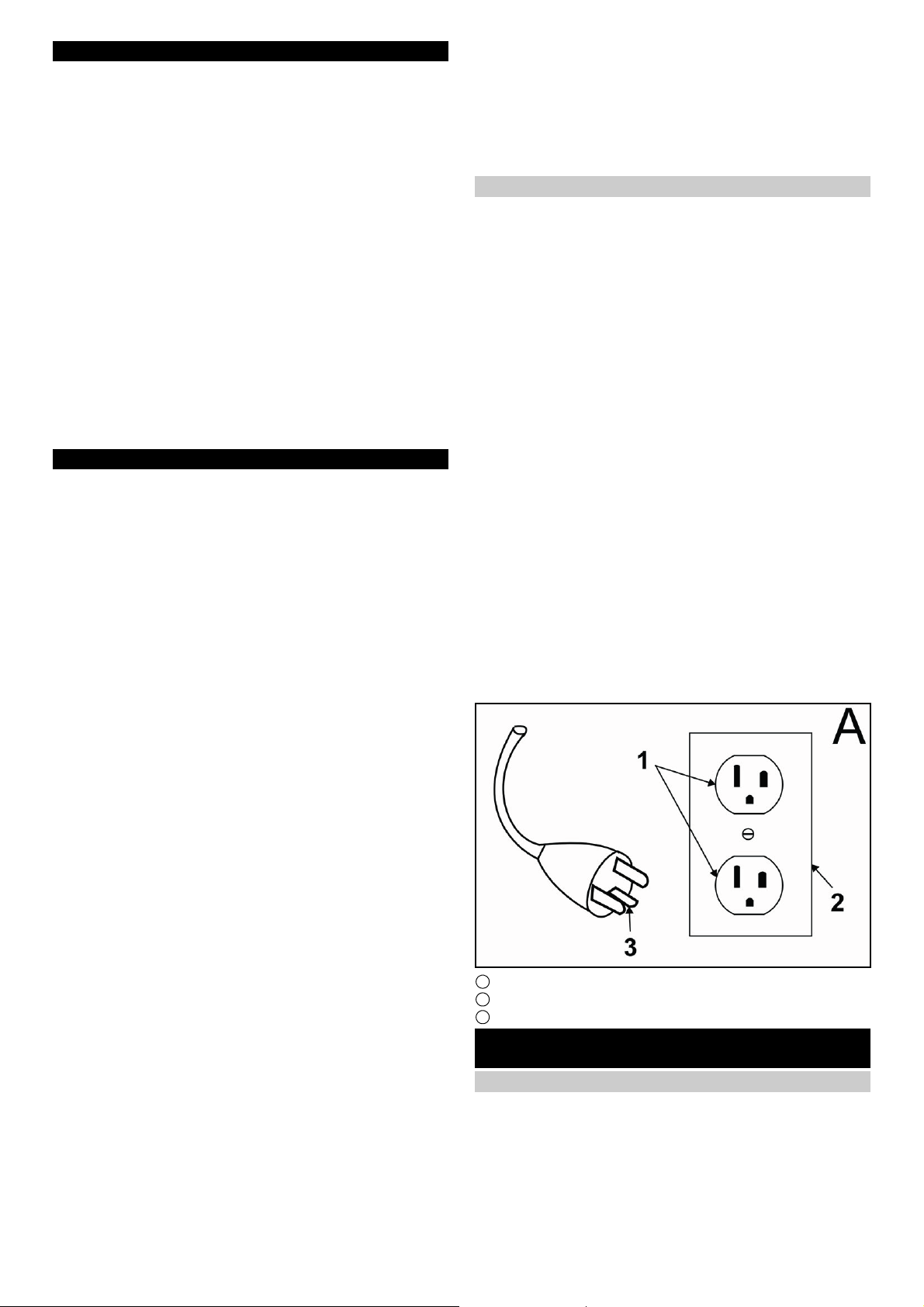

GROUNDING INSTRUCTIONS

This device must be grounded. If it should malfunction or

break down, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock.

This device is equipped with a cord having an equipment

grounding conductor and ground plug.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

DANGER

Improper connection of the equipmentgrounding conductor can result in a risk of electrocution.

Check with a qualified electrician or service personnel if

you are in doubt as to whether the outlet is properly

grounded.

Do not modify the plug provided with the product - if it will

not fit the outlet, have a proper outlet installed by a qualified electrician.

Do not use any type of adapter with this product.

This appliance is for use on a nominal 120-volt circuit and

has a grounding attachment plug that looks like the plug illustrated in sketchpicture A.

Make sure that the appliance is connected to an outlet having the same configuration as the plug.

No adaptor should be used with this appliance.

CONNECT TO A PROPERLY GROUNDED OUTLET ONLY

1 Grounded outlet

2 Grounded outlet box

3 Grounded pin

OPERATING SAFETY RULES AND

PRACTICES

Owner/User Responsibility

The owner and/or user must have an understanding of the

manufacturer’s operating instructions and warnings before

using this device.

Warning information should be emphasized and understood.

If the operator is not fluent in English, the manufacturer’s

instructions and warnings shall be read to and discussed

English 3

Page 4

with the operator in the operator’s native language by the

purchaser/ owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future reference the manufacturers’ instructions.

General

Before starting operation, the device must be in the operating position.

Do not start or operate the device, any of its functions or

attachments, from any place other than from the designated operator's position.

Before leaving the operator’s position:

1 bring the device to a complete stop;

2 if the device must be on an incline, block the wheels.

Maintain a safe distance from the edge of ramps, platforms, and other similar working surfaces.

Do not add to, or modify the device.

Do not block access to fire aisles, stairways or fire equipment.

Traveling

Yield the right of way to pedestrians and emergency vehicles such as ambulances and fire trucks.

Cross railroad tracks at an angle wherever possible. Do

not park closer than 6 ft (1800 mm) to the nearest rail of a

railroad track.

Keep a clear view of the path of travel and observe for other traffic, personnel, and safe clearances.

Under all travel conditions, operate the device at a speed

that will permit it to be brought to a stop in a safe manner.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors. Before driving over

a dockboard or bridge plate, be sure that it is properly secured. Drive carefully and slowly across the dockboard or

bridge plate, and never exceed its rated capacity.

When negotiating turns, reduce speed to a safe level consistent with the operating environment. Make the turns

smoothly.

Operator care of the device

If the device is found to be in need of repair or in any way

unsafe, or contributes to an unsafe condition, the matter

shall be reported immediately to the user’s designated authority, and the device shall not be operated until it has

been restored to safe operating condition.

If during operation the device becomes unsafe in any way,

the matter shall be reported immediately to the user’s designated authority, and the device shall not be operated until

it has been restored to safe operating condition.

Do not make repairs or adjustments unless specifically authorized to do so.

MAINTENANCE AND REBUILD PRACTICES

Operation of the device may be hazardous if maintenance

is neglected or repairs, rebuilds, or adjustments are not

performed in accordance with the manufacturer’s design

criteria. Therefore, maintenance facilities (on or off premises), trained personnel, and detailed procedures shall be

provided.

Maintenance and inspection of the device shall be performed in conformance with the following practices:

1 a scheduled planned maintenance, lubrication, and in-

spection system shall be followed; consult the manufacturer’s recommendations.

2 Only trained and authorized persons shall be permitted

to operate a powered floor scrubber. Operators of powered floor scrubbers shall be qualified as to visual, auditory, physical, and mental ability to operate the

equipment safely.

Avoid fire hazards and have fire protection equipment

present in the work area. Do not use open pans of fuel or

flammable cleaning fluids for cleaning parts.

FIRE SAFETY STANDARD

Any device not in safe operating condition shall be removed from service.

Repairs shall not be made in Class I, Class II, and Class III

locations.

Fire Prevention.The device shall be kept in a clean condition and reasonably free of lint, excess oil, and grease.

Noncombustible agents are preferred for cleaning the device. Flammable liquids [those having flash points at or

above 100°F (37,8°C)] are not allowed. Precautions regarding toxicity, ventilation, and fire hazard shall be appropriate for the agent or solvent used.

Nameplate Visibility. The device type designations as

shown on the nameplate and the type markers shall not be

covered over with paint so that their identification information is obscured.

General notes

Read these original operating instructions and

the enclosed safety instructions before using

the device for the first time. Proceed accordingly.

Keep both books for future reference or for future owners.

Function

This scouring and vacuum machine is used for wet cleaning of level floors.

The device can be adjusted to suit the respective cleaning

task by setting the water volume and detergent volume appropriately. The detergent dosing unit is adjusted via the

amount added to the tank.

The working width and the capacity of the fresh water and

waste water tanks (see chapter Technical data) allow effective cleaning over long working times.

The device has a drive. The device is supplied from 4 batteries.

Note

The device can be equipped with various accessories to

suit the respective cleaning order. Request a copy of our

catalog or visit our Internet website at www.kaercher.com.

Intended use

This device is suitable for commercial and industrial use,

e.g. in hotels, schools, hospitals, factories, shops, offices,

and rental companies. Use the device only in accordance

with the information in these operating instructions.

The device may only be used for cleaning smooth sur-

faces that are insensitive to water and polishing.

The device is not suitable for cleaning frozen floors (e.g.

in cold stores).

The device is not suitable for use in potentially explosive

environments.

The device is approved for operation on surfaces with a

maximum slope (see chapter Technical data).

4 English

Page 5

Environmental protection

The packing materials can be recycled. Please dispose of packaging in accordance with the environ-

mental regulations.

Electrical and electronic appliances contain valuable,

recyclable materials and often components such as

batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential threat

to human health and the environment. However, these

components are required for the correct operation of the

appliance. Appliances marked by this symbol are not allowed to be disposed of together with the household rubbish.

Notes on the content materials (REACH)

Current information on content materials can be found at:

www.kaercher.de/REACH

Accessories and spare parts

Only use original accessories and original spare parts. They

ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found

at www.kaercher.com.

Scope of delivery

During unpacking, check the contents for completeness. If

any accessories are missing or in the event of any shipping

damage, please notify your dealer.

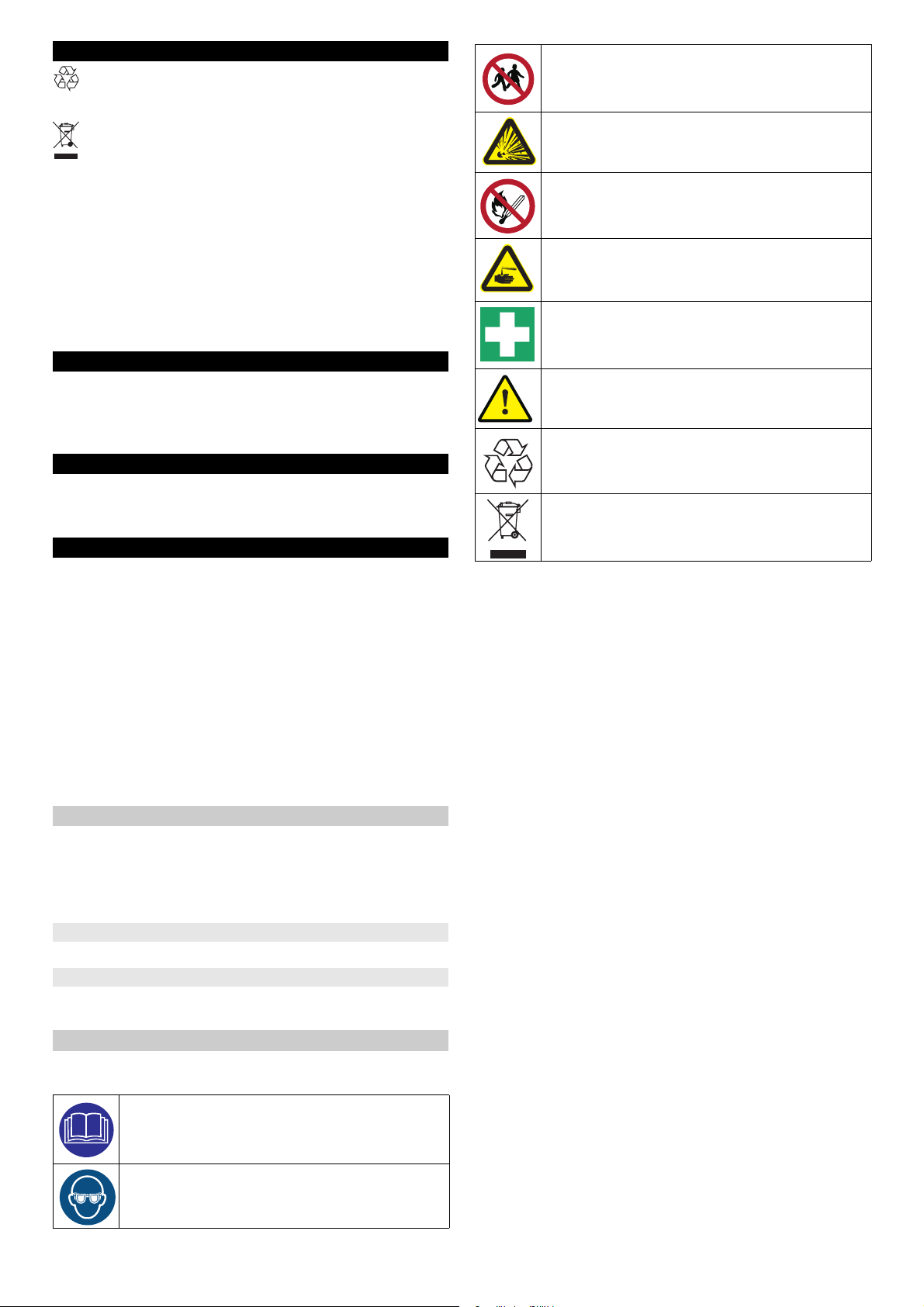

Keep acids and batteries away from children.

Risk of explosion

Fire, sparks, open flames and smoking are prohibited.

Risk of acid burns

First aid.

Warning note

Disposal

Do not throw batteries in the bin.

Safety instructions

Before using the device for the first time, read and observe

these operating instructions and the accompanying brochure: Safety instructions for brush cleaning units spray retraction devices, No. 5.956-251.0.

The device is approved for operation on surfaces with a

specified limited slope (see Chapter Technical data).

몇 WARNING

Device tipping over

Danger of injury

Do not operate the device on sloping surfaces.

The device may only be operated when the hood and all

covers are closed.

Safety devices

몇 CAUTION

Missing or modified safety devices

Safety devices are provided for your own protection.

Never modify or bypass safety devices.

Safety button

The device switches off when the safety button is released.

Key-operated switch

Pulling the key out of the key-operated switch secures the

device against unauthorized use.

Warning symbols

Observe the following warnings when handling the batteries:

Observe notes in the instructions of the battery,

on the battery and in these operating instructions.

Wear eye protection.

English 5

Page 6

18

19

20

21

22

23

22

24

20

25

26

27

28

29

30

31

32

33

9

4

5

17

1

3

6

7

8

9

10

11

13

5

1415

16

2

12

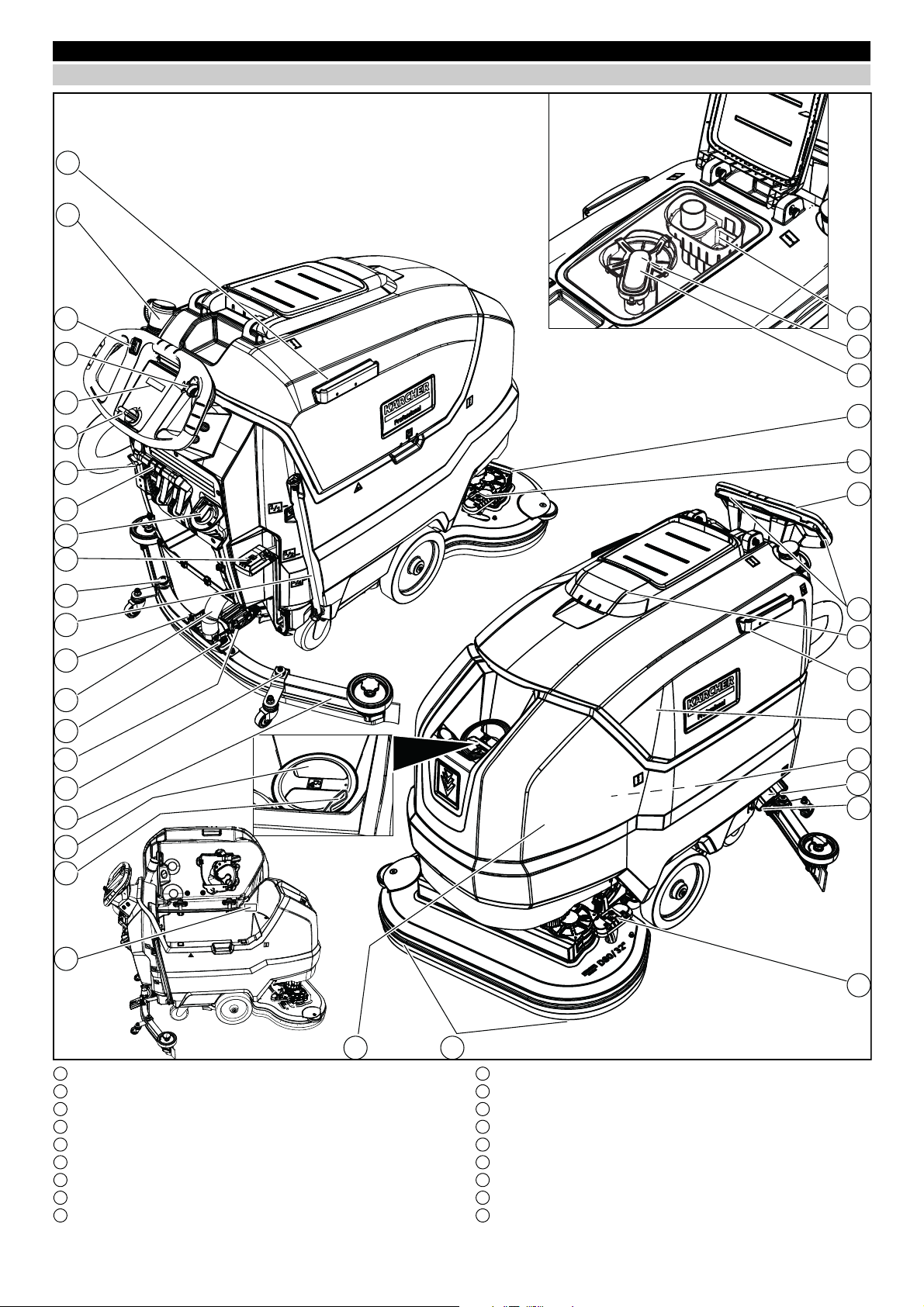

Description of the unit

Overview of the device

1 Coarse dirt sieve

2 Fluff filter

3 Float

4 Cleaning head

5 Brush replacement pedal

6 Push handle

7 Safety button

8 Waste water tank cap

9 Homebase retaining rail

10 Waste water tank

11 ** Battery

12 Fresh water filter

13 Fresh water tank lock

14 Disc brush

15 Fresh water tank

16 Type plate

17 Hose switch

18 Fresh water tank filling hole

6 English

Page 7

19 Suction bar

20 Suction bar height adjustment

21 Suction bar inclination adjustment

22 Wing nuts for fastening the suction bar

23 Suction hose

24 Fresh water filling level display

Fresh water drain hose

25 Cleaning head lever

26 Water volume regulation knob

27 Suction bar lever

28 Battery plug connector

29 Key-operated switch

30 Display

31 Working speed rotary knob

32 Travel direction switch

33 Waste water tank drain hose with dosing unit

** Not in scope of delivery

Color coding

Control elements for the cleaning process are yellow.

Control elements for maintenance and servicing are

light gray.

Symbols on the device

Fresh water tank drain opening

Waste water tank drain opening

Increased cleaning head contact pressure

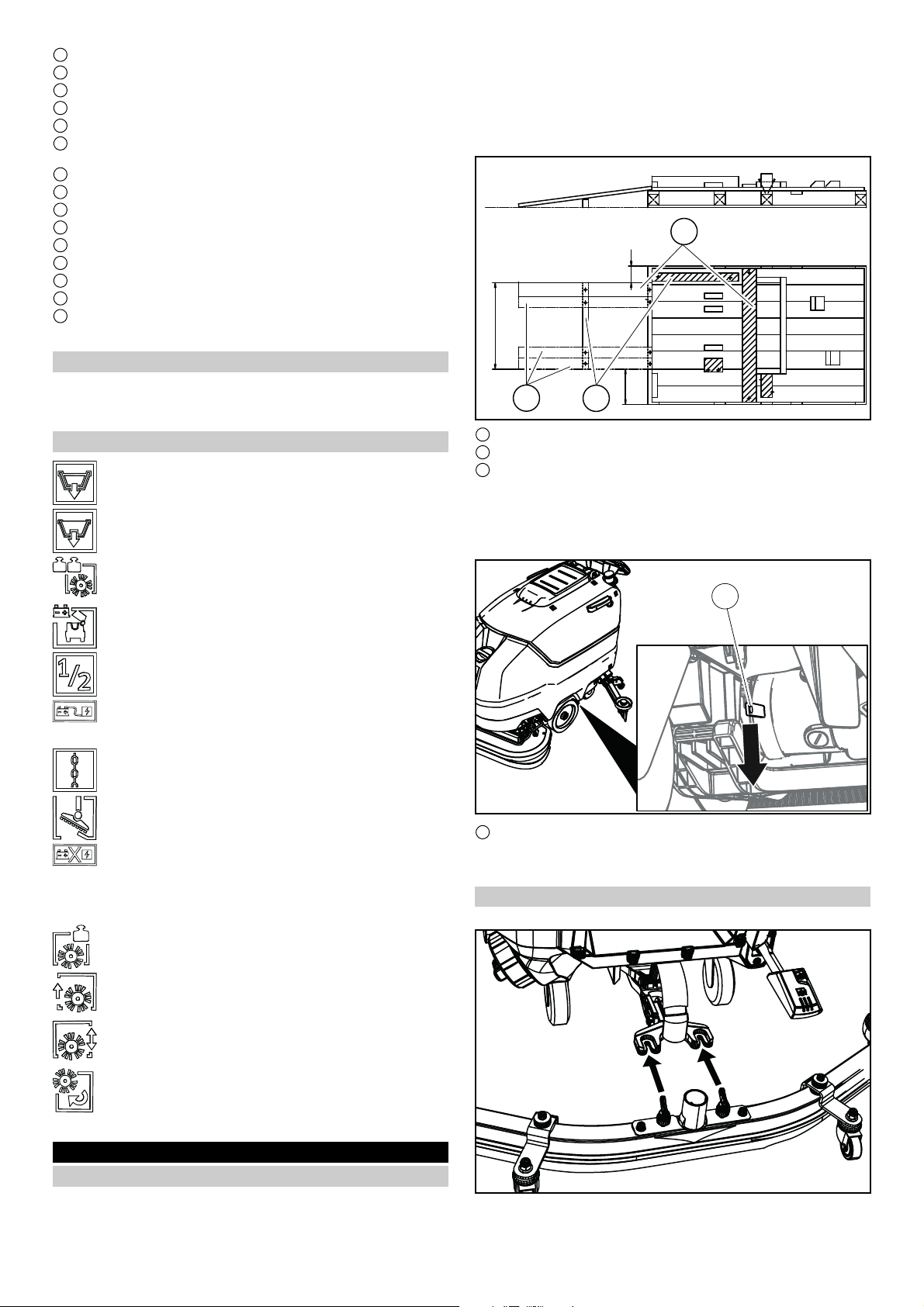

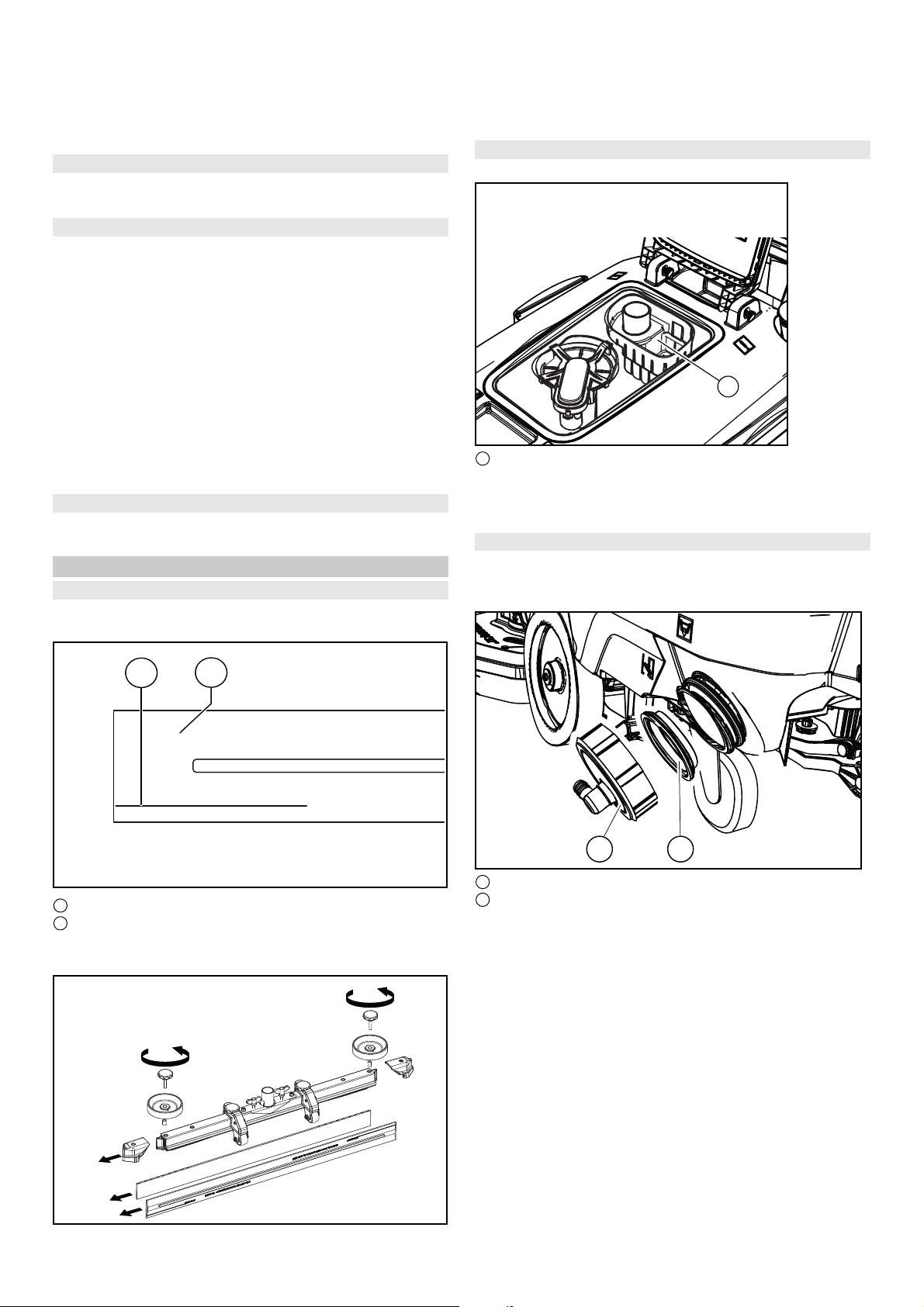

3. Remove the wooden blocks fastened to the pallet by

screws.

4. Using the 3 upper reinforcing boards of the carton packaging (80x24x970 mm) and the board screwed laterally

on the pallet (100x24x970 mm), place a ramp in front of

the pallet and secure it using board pallet screws.

3

120

625

2

1 Beam 80x60x625 mm

2 Board 80x24x970 mm

3 Board 100x24x970 mm

5. Push the beam which has been unscrewed from the pallet (80x60x625 mm) under the ramp for support and

screw into place.

6. Press the brake lever down.

225

1

Battery access

Fresh water tank filling level (50%)

Insert the charger plug here

Eyelet point

* Mop holder

ATTENTION

Incorrect socket

Risk of damage

DO NOT insert the charger plug here

Normal cleaning head contact pressure

Raise the cleaning head

Pedal for raising/lowering the cleaning head

1

1 Brake lever

7. Push the device forwards from the pallet.

8. Press the brake lever up.

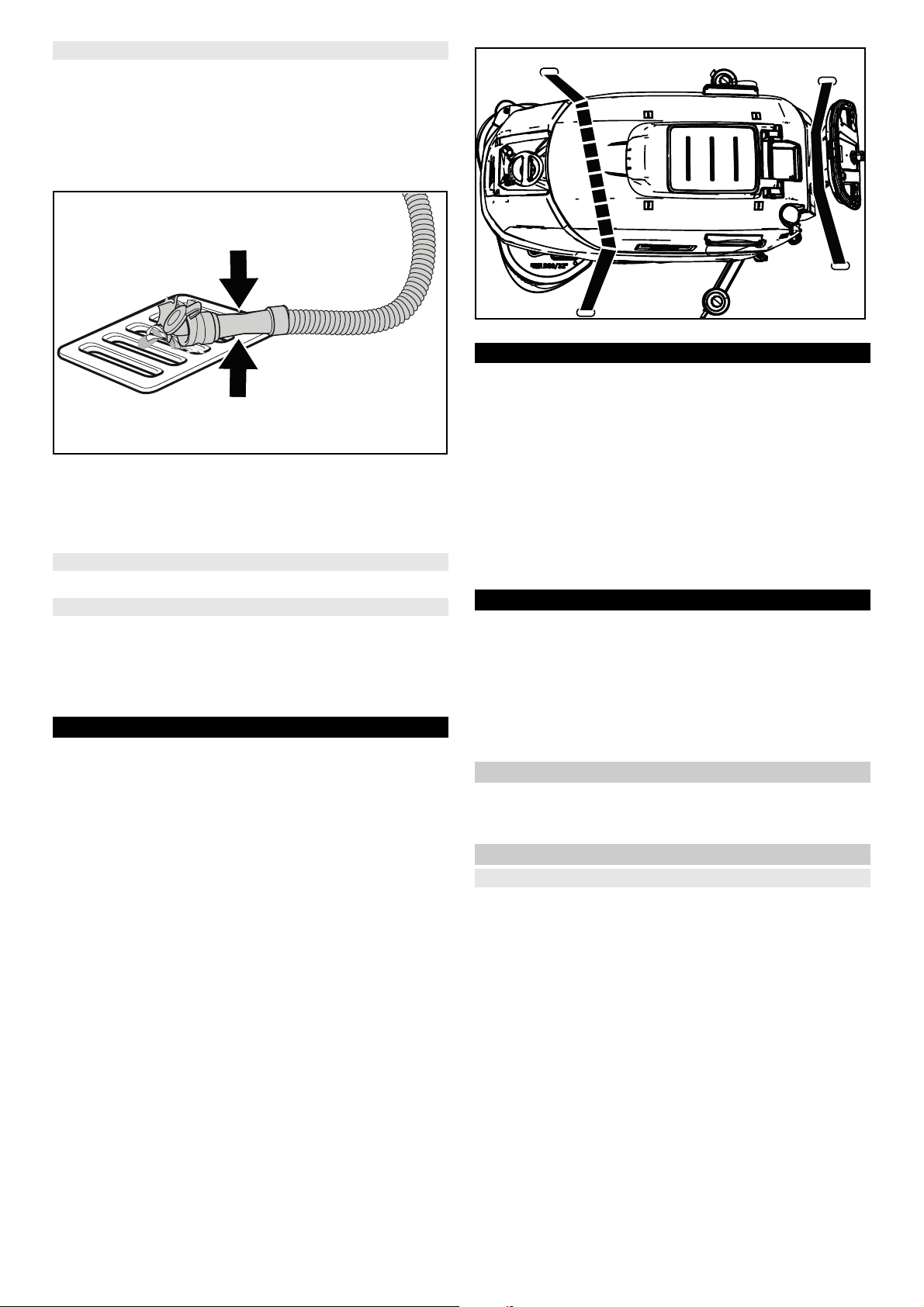

Installing the suction bar

1. Insert the suction bar in the suction bar mount.

Brush replacement pedal

* optional

1. Remove the carton.

2. Remove the straps.

Installation

Unloading

2. Tighten the wing nuts.

3. Fit the suction hose.

English 7

Page 8

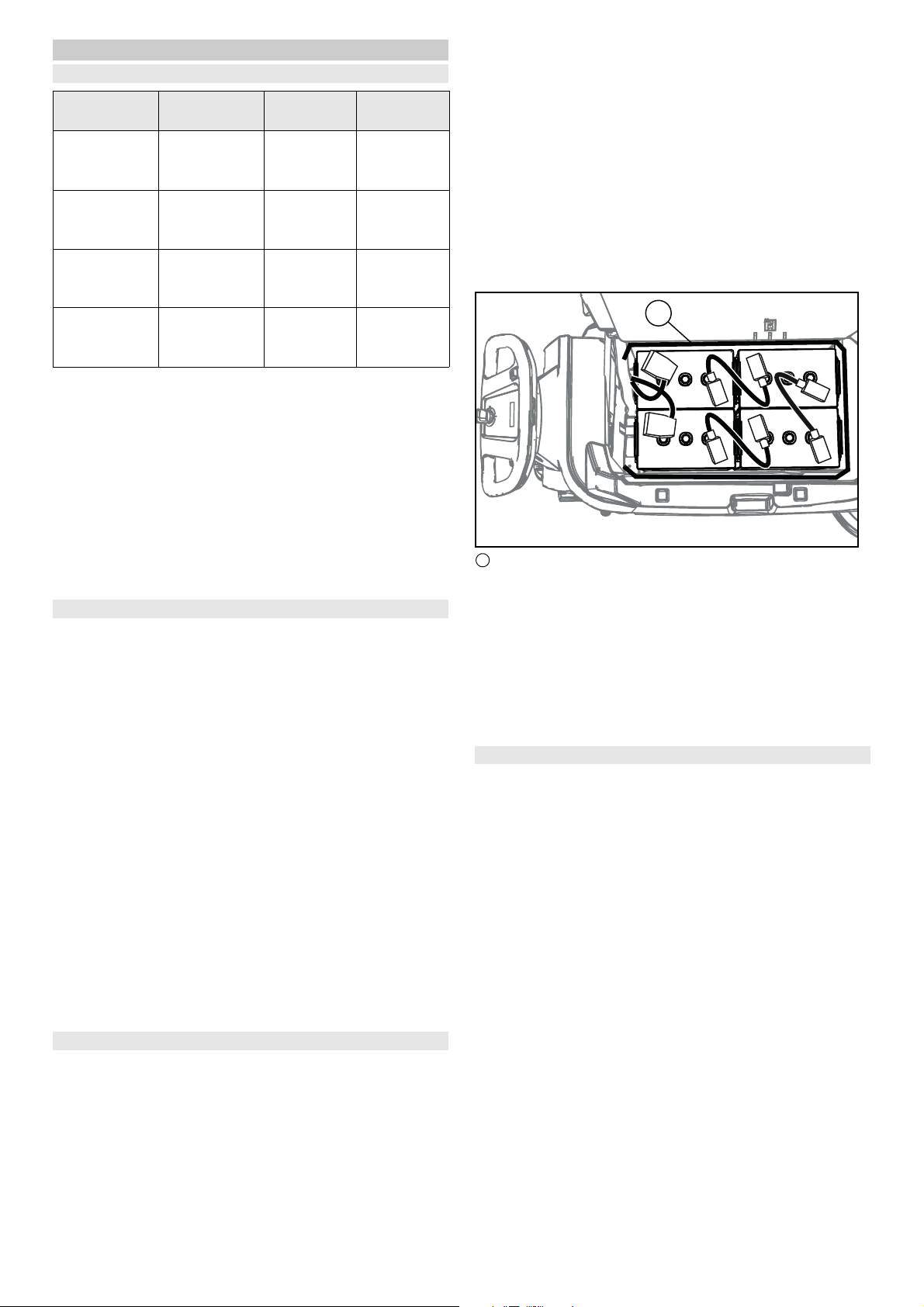

Batteries

+

+

+

+

-

-

-

-

1

Recommemded batteries

Description Order No. Volume

185 Ah - maintenance-free

(C20)

180 Ah - maintenance-free

(C5)

240 Ah - maintenance-free

(C5)

330 Ah - maintenance-free

(C20)

* Minimum volume of the battery charging room

** Minimum air flow between the battery charging room

and the surroundings

The device requires 4 batteries.

1 Complete set (24 V / 185 Ah) incl. connectingcable, or-

der no. 4.035-388.0

2 Complete set (24 V / 180 Ah) incl. connectingcable, or-

der no. 4.035-387.0

3 Complete set (24 V / 240 Ah) incl. connectingcable, or-

der no. 4.035-393.0

4 Complete set (24 V / 330 Ah) incl. connectingcable, or-

der no. 4.035-572.0

Low-maintenance batteries (wet batteries)

6.654-242.0

6.654-124.0

6.654-119.0

8.629-184.0

3

(m

)*

1)

--

2)

--

3)

--

4)

11,88 4,752

Air flow (m3/

h)**

DANGER

Refilling discharged batteries with water

Danger of acid burns from escaping acid, destruction of

clothes

Wear safety goggles when handling the batteries.

Observe the applicable regulations.

Immediately rinse off any splashed acid from the skin or

clothes using copious amounts of water.

ATTENTION

Using water with additives

Defective batteries, loss of warranty claim

Top up the batteries using only distilled or desalinated water (EN 50272-T3).

Do not use any foreign additives, so-called enhancing

agents, because this will invalidate the warranty.

1. Add distilled water one hour before the charging process comes to an end. Observe the correct acid level

according to the battery label.

All cells must produce gas at the end of the charging

process.

Installing and connecting batteries

몇CAUTION

Removing and installing the batteries

Unstable machine position

Ensure that the machine is positioned stably when removing and installing the batteries.

ATTENTION

Incorrect connection polarity

Destruction of the control electronics

Take care to ensure the correct polarity when connecting

the batteries.

ATTENTION

Deep discharge

Risk of damage

Charge the batteries before starting the device.

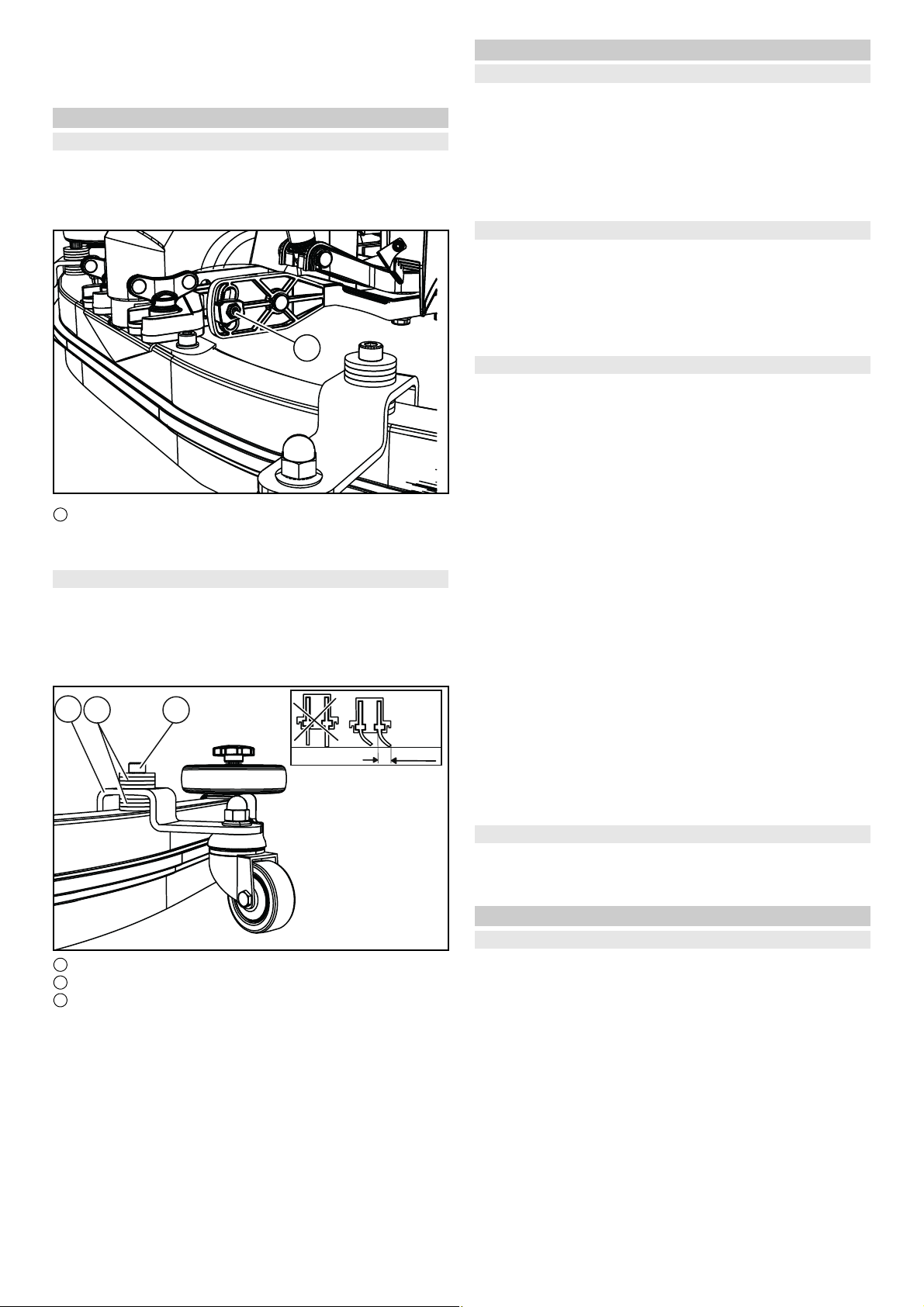

1. Drain the waste water.

2. Pivot the waste water tank upwards.

3. Place the battery in the device.

1 Strap

4. Fit the strap around the battery.

5. Clamp the batteries towards the rear using the strap.

6. Connect the battery terminals using the connecting cables provided.

7. Clamp the connecting cable to the (+) and (-) battery terminals that are still free.

8. Connect the device-side battery connector to the battery-side battery connector.

9. Pivot the waste water tank downwards.

Removing the battery

몇 CAUTION

Removing and installing the batteries

Unstable machine position

Ensure that the machine is positioned stably when removing and installing the batteries.

1. Turn the key-operated switch to "0" and remove the key.

2. Pull out the battery plug.

3. Drain the waste water.

4. Pivot the waste water tank upwards.

5. Disconnect the cable from the minus terminal at the battery.

6. Disconnect the remaining cables from the battery.

7. Release the strap.

8. Remove the battery.

9. Dispose of the used batteries in accordance with statutory provisions.

8 English

Page 9

Initial startup

1

1

2

Charging the battery

DANGER

Inappropriate use of the charger

Electric shock

Adhere to the mains voltage and fuse values specified on

the device type plate.

Only use the charger in dry rooms with sufficient ventilation.

ATTENTION

Accumulation of dangerous gases under the tank

during the charging process

Risk of explosion

Pivot the waste water tank upwards before charging lowmaintenance batteries.

ATTENTION

Using an unsuitable charger

Risk of damage

Do not connect the charger to the device-side battery connector.

Use only a charger suitable for the type of battery installed.

Read the operating instructions of the charger manufacturer and observe the safety instructions in particular.

Battery type Charger

6.654-242.0 6.654-434.0

6.654-124.0 6.654-434.0

6.654-119.0 6.654-435.0

8.629-184.0 6.654-419.0

The average charging time is approx. 10-15 hours.

The device cannot be used during the charging process.

Note

The device has deep discharge protection, i.e. the brush

motor and turbine are switched off automatically when the

permitted minimum capacity level is reached.

1. Drive the device directly to the charger and do not drive

on slopes.

2. Pull out the device-side battery connector.

1 Battery plug, device side

2 Battery plug, battery side

3. Connect the battery-side battery connector to the charger.

4. Plug the mains plug of the charger into the socket.

5. Carry out the charging process in accordance with the

6. Connect the device-side battery connector to the bat-

operating instructions for the charger.

tery-side battery connector.

Operation

ATTENTION

Risks during operation

Danger of injury

Release the safety button in the case of danger.

Filling with operating materials

Filling with fresh water

1. Open the fresh water tank lock.

2. Fill fresh water (max. 60 °C) to the lower edge of the filling nozzle.

Note: The fresh water hose can be clamped in the hose

switch during filling.

3. Close the fresh water tank lock.

Notes on detergents

몇 WARNING

Unsuitable detergents

Health risk, damage to the device

Use only recommended detergents. The operator carries

all increased risks relating to operational safety and increased risk of accidents if using other detergents.

Use only detergents free of solvents, salt and hydrofluoric

acid.

Adhere to the safety instructions stated on the detergent

packaging.

Note

Do not use heavily foaming detergent.

Recommended detergents

Usage Detergent

Maintenance cleaning of all water-resistant floors

Maintenance cleaning of polished

hard surfaces (e.g. granite)

Maintenance cleaning and basic

cleaning of industrial floors

Maintenance cleaning and basic

cleaning of fine stone tiles

Maintenance cleaning of tiles in sanitary areas

Cleaning and disinfection in sanitary

areas

Coating removal on all alkaline-resistant floors (e.g. PVC)

Coating removal on linoleum floors RM 754

Detergent

1. Fill the detergent into the fresh water tank.

Note: The cap of the fresh water tank filling hole can be

used for measuring the detergent. It is fitted with a scale

on the inside.

RM 746

RM 780

RM 755 es

RM 69 ASF

RM 753

RM 751

RM 732

RM 752

Adjusting the water volume

1. Adjust the water volume via the regulating knob to suit

the degree of contamination of the floor covering.

Note

Perform initial cleaning tests with a low water volume.

Increase the water volume step by step until achieving

the desired cleaning result.

English 9

Page 10

Note

1

10 mm

1

2 3

The cleaning head continues operating without a liquid

supply if the fresh water tank is empty.

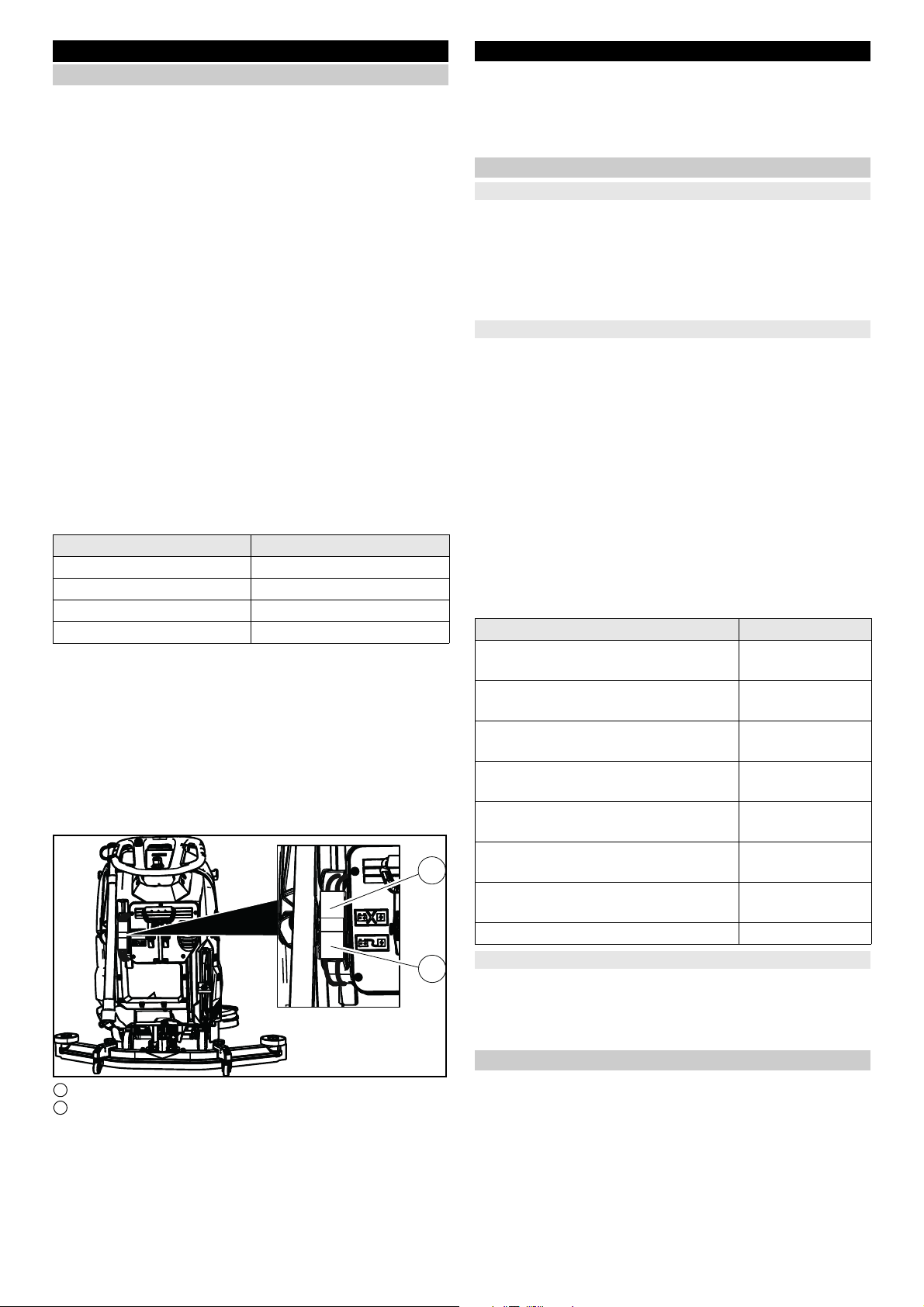

Adjusting the suction bar

Adjusting the inclination

The inclination must be adjusted so that the suction lips of

the suction bar make even contact with the floor over the

entire length of the suction bar.

1. Loosen the screw.

1 Screw

2. Adjust the inclination of the suction bar.

3. Tighten the screw.

Adjusting the height

The height adjustment affects the bending of the suction

lips on contact with the floor.

1. Push the device a small distance forwards.

2. Compare the bending of the suction lips with the illustration below.

´

1 Spacer roller with holder

2 Washer

3 Screw

3. Unscrew the screw.

4. Position a sufficient number of washers between the

suction bar and spacer roller so that the suction lips

have the correct bend.

5. Fit the remaining washers above the spacer roller.

6. Screw in and tighten the screw.

7. Repeat the entire procedure at the other spacer roller.

8. Push the device a small distance forwards.

9. Check the bending of the suction lips over the entire

length.

10.If necessary, repeat the entire adjustment process.

Cleaning

Switching the device on

1. Turn the key-operated switch to "1".

The display shows the following one after the other:

Period of time until the next after-sales Customer Ser-

vice

Software version, control panel

Charging state of the battery and number of operating

hours

Driving

Note

The travel direction can be changed during the cleaning

operation. This way, a certain position can be intensively

cleaned by driving back and forth several times.

1. Set the travel direction switch to "forward".

Cleaning

Note

The inclination and height of the suction bar can be adjusted to improve the vacuuming results (see chapter Adjusting the suction bar).

Note

When the waste water tank is full, the float switch closes

the suction opening and the suction turbine runs at a higher speed. In this case, raise the suction bar and drive to the

location for emptying the waste water tank.

1. Turn the working speed rotary knob to the desired value.

The speed is shown on the display during the adjustment. The display is shown in percentage of the maximum speed.

2. Set the water volume at the regulating valve.

3. Press the suction bar lever downwards.

The suction bar lowers.

Suctioning begins.

4. Press the cleaning head lever downwards, unlatch it

and allow it to move upwards.

5. Pull the safety button towards the push handle.

The cleaning head starts up and the device moves at

the set speed.

Increasing the brush contact pressure

1. Let go of the safety button.

2. Lift the cleaning head lever up with your hand and engage it towards the right.

Finishing operation

Finishing cleaning

1. Let go of the safety button.

2. Press the cleaning head lever downwards and engage

it towards the right.

3. Continue moving a short distance.

The residual water is vacuumed up.

4. Lift the suction bar.

The suctioning continues to run for 10 seconds afterwards.

5. Turn the key-operated switch to "0".

6. Charge the batteries if necessary.

10 English

Page 11

Draining the waste water

몇 WARNING

Improper disposal of waste water

Environmental pollution

Observe the local waste water treatment regulations.

1. Remove the drain hose from the support and lower it

over a suitable collecting device.

2. Press the dosing device together or kink the hose.

3. Open the dosing device cover.

4. Drain the waste water. Regulate the water volume by

pressing or kinking.

5. Rinse the waste water tank with clear water.

Draining fresh water

1. Pull off the filling level display hose and swivel it down.

Draining fresh water quickly

1. Unscrew the fresh water tank lock.

2. Allow the fresh water to drain away.

3. Fit the fresh water tank lock and screw into place.

Note: Ensure that the hose connection in the fresh water tank lock lies at the lowest point after screwing tight.

Transport

DANGER

Driving on slopes

Danger of injury

Observe the maximum permissible inclination when driving the device on slopes for loading and unloading purposes (see chapter Technical data).

Drive slowly.

1.

2.

7. First fit the strap under the waste water tank.

Storage

몇 CAUTION

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

ATTENTION

Frost

Destruction of the device through freezing water

Drain all water from the device.

Store the device in a frost-free location.

This device may only be stored indoors.

Care and service

DANGER

Inadvertently starting up device

Risk of injury, electric shock

Turn the key-operated switch to "0" and remove the key

before performing any work on the device.

Pull out the charger mains plug.

Drain and dispose of the waste water and fresh water.

Safety inspection/maintenance contract

You can agree on regular safety inspections or close a

maintenance contract with your dealer. Please seek advice

on this.

Maintenance intervals

Each time after use

몇 CAUTION

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.

1. Press the cleaning head lever downwards and engage

it towards the right.

2. Raise the suction bar.

3. Turn the key-operated switch to "1".

4. Select the travel direction at the travel direction switch.

5. Pull the safety button towards the push handle.

6. When transporting in vehicles, secure the device

against slipping and tipping over according to the applicable guidelines.

English 11

ATTENTION

Incorrect cleaning

Risk of damage.

Do not spray the device with water.

Do not use aggressive detergents.

A detailed description of the individual maintenance work

is provided in Chapter Maintenance work.

Drain the waste water.

Rinse the waste water tank with clear water.

Clean the exterior of the device using a damp cloth, wet-

ted with a mild washing lye.

Check the fluff filter and clean if required.

Clean the coarse dirt sieve.

Clean the suction lips, check for wear and tear and re-

adjust or replace if necessary.

Check the disc brushes for wear and tear and replace if

necessary.

Page 12

Charge the battery.

CHANGE LIP

2

1

1.

1.

2.

3.

1

12

If the charging state of the battery is below 50%,

charge the battery fully and without interruption.

If the charging state of the battery is above 50%, only

recharge the battery if the entire operating duration

will be required when next used.

Weekly

When used regularly, charge the battery fully and with-

out interruption at least once a week.

Monthly

A detailed description of the individual maintenance work

is provided in Chapter Maintenance work.

1. Drain the fresh water tank and flush out deposits.

2. Clean the fresh water filter.

3. Clean the float and fluff filter.

4. Check battery poles for oxidation, brush off if necessary.

Make sure the connection cables are firmly in place.

5. Clean the seals between the waste water tank and the

cover, check for leaks and replace if necessary.

6. Check the acid density of the cells if the batteries are not

maintenance-free.

7. For a longer downtime, shut down the device when the

battery is fully charged. Fully charge the battery at least

once a month.

Annually

Have the prescribed inspection performed by Customer

Service.

Maintenance work

Turn over or replace the worn suction lips

The suction lips must be turned over or replace when they

have worn down to the wear mark.

3. Pull off the plastic parts.

4. Pull off the suction lips.

5. Push in the turned over or new suction lips.

6. Push on the plastic parts.

7. Screw in and tighten the star handles.

Cleaning the coarse dirt sieve

1. Open the waste water tank cover.

1 Coarse dirt sieve

2. Pull the coarse dirt sieve upwards and off.

3. Rinse off the coarse dirt sieve under running water.

4. Reinsert the coarse dirt sieve into the waste water tank.

Cleaning the fresh water filter

1. Drain the fresh water (see Chapter Draining fresh water).

2. Unscrew the fresh water tank lock.

1 Wear mark

2 Suction lip

1. Remove the suction bar.

2. Unscrew the star handles.

12 English

1 Fresh water tank lock

2 Fresh water filter

3. Pull out the fresh water filter and rinse with clean water.

4. Insert the fresh water filter.

5. Fit the fresh water tank lock.

Note: Ensure that the hose connection in the fresh water tank lock lies at the lowest point after screwing tight.

Page 13

Clean the float and fluff filter

1

2

3

4

1. Open the waste water tank cover.

1 Latching hooks

2 Fluff filter

3 Float

4 Float housing

2. Release the latching hooks.

3. Pull the float housing downwards and off.

4. Remove the float from the float housing and clean it.

5. Clean the fluff filter.

6. Assemble all parts in the reverse order.

Replacing the disc brushes

1. Raise the cleaning head.

2. Press the brush replacement pedal down, beyond the

zone of resistance.

3. Pull the 1st disc brush sideways and out from underneath the cleaning head.

4. Hold the new disc brush under the cleaning head, then

press upwards and latch it into position.

5. Repeat the procedure for the 2nd disc brush.

Troubleshooting guide

DANGER

Inadvertently starting up device

Risk of injury, electric shock

Turn the key-operated switch to "0" and remove the key

before performing any work on the device.

Malfunction Rectification

The device cannot be

started

The water volume is insufficient

The suction performance

is too low

The cleaning results are

unsatisfactory

The suction turbine runs

at an increased speed

The brushes do not rotate 1 Check if the brushes are blocked by a foreign body and remove the foreign body if nec-

The device vibrates during

cleaning

1 Turn the key-operated switch to "1".

2 Actuate the safety button.

3 Insert the battery plug.

4 Check the battery and charge if necessary.

5 Check that the battery terminals are correctly connected.

1 Check the fresh water filling level and fill the tank if necessary.

2 Increase the water volume at the water volume regulating knob.

3 Clean the fresh water filter.

4 Check the hoses for clogging and clean if necessary.

1 Shut down the device and drain the waste water.

2 Clean the seals between the waste water tank and the cover, check for leaks and replace

if necessary.

3 Check that the suction hose is correctly connected to the waste water tank.

4 Check the fluff filter for contamination and clean if necessary.

5 Clean the suction lips at the suction bar, turn over or replace if necessary.

6 Check that the cap on the waste water drain hose is closed.

7 Check the adjustment of the suction bar.

8 Check the suction hose for clogging and clean if necessary. When fitting the suction hose

again, the white marking on the hose must lie at the retaining clip.

9 Check the suction hose for leaks and replace if necessary.

1 Reduce the driving speed.

2 Check the brushes for wear and tear and replace if necessary.

3 Check the suitability of the brush type and detergent used.

1 Drain the waste water.

2 Clean the float.

3 Check the fluff filter and clean if necessary.

4 Check the suction hose for clogging and clean if necessary.

5 Check the suction bar for clogging and remove any clogging if necessary

essary.

1 Use a softer brush.

Pull out the charger mains plug.

Drain and dispose of the waste water and fresh water.

Contact Customer Service in the case of malfunctions

that cannot be corrected using this table.

English 13

Page 14

Warranty

The warranty conditions issued by our relevant sales company apply in all countries. We shall remedy possible malfunctions on your appliance within the warranty period free

of cost, provided that a material or manufacturing flaw is

the cause. In a warranty case, please contact your dealer

(with the purchase receipt) or the next authorized customer service site.

(See overleaf for the address)

Accessories

Description Part

no.

Disc brush, red

(medium, stan-

4.905-

000.0

dard)

Disc brush, black

(hard)

Disc brush, natural color (soft)

Disc brush, white

(soft)

4.905-

032.0

4.905-

031.0

4.905-

030.0

Pad drive board 4.762-

447.0

Pad, white 6.371-

331.0

Pad, red (medium

soft)

Pad, green (medium hard)

6.371-

332.0

6.371-

333.0

Pad, black (hard) 6.371-

334.0

Pad, brown 6.371-

335.0

Pad, microfiber 6.371-

336.0

Suction bar, 1160

mm, curved

4.777-

102.0

Mop holder set 9.753-

023.0

Description

For use in all common cleaning

orders

For heavy contamination and

basic cleaning, only for nonsensitive surfaces

Made of natural fibers for

cleaning and polishing

For cleaning lightly contaminated or sensitive floors

For cleaning with pads, with

quick-change coupling and

center-lock

For polishing floors

For cleaning all floors

For cleaning heavily contaminated floors and for basic

cleaning

For stubborn soiling and for basic cleaning

For protective film application

on hard and elastic surfaces

For effective cleaning of microporous surfaces

Technical data

BD 80/100

W Classic

Waste water tank volume gal (l) 26.4 (100)

Water temperature max. °F (°C) 140 (60)

Water pressure max. psi (bar) 0.87 (0.06)

Max. working area slope % 2

Suctioning

Suction performance, air quantity CFM (l/s) 50.8 (24)

Suction performance, depression psi (kPa) 2.3 (16)

Cleaning brushes

Working width in (mm) 31.5 (800)

Brush diameter in (mm) 16.2 (410)

Brush speed 1/min 140

Brush contact pressure lbf (N) 88 / 200

(392 / 890)

Dimensions and weights

Approved total weight lbs (kg) 959 (435)

Net weight (transport weight) lbs (kg) 716 (325)

Battery compartment dimensions in (mm) 24.5 x 15.1

(622 x 384)

Determined values in acc. with EN 60335-2-72

Overall vibration value m/s

2

<2.5

Uncertainty K dB(A) 0.2

Sound pressure level L

Uncertainty K

Sound power level L

tainty

WA

pA

WA

pA

+ K uncer-

dB(A) 65

dB(A) 2

dB(A) 81

Subject to technical changes without notice.

BD 80/100

W Classic

Device performance data

Nominal voltage V 24

Battery capacity Ah 185 (C20) /

180 (C5) /

240 (C5) /

330 (C20)

Mean power input W 1320

Engine power W 300

Suction turbine power W 500

Brush drive power W 2 x 500

Theoretical surface performance ft

2

/h (m2/h)43000

(4000)

Fresh water tank volume gal (l) 26.4 (100)

14 English

Page 15

Contenu

CONSIGNES DE SÉCURITÉ IMPORTANTES ................ 15

REGLES DE SECURITE ET PRATIQUES RELATIVES A

L'UTILISATION ................................................................. 16

PROCEDURES D'ENTRETIEN ET DE REMISE EN ETAT 16

NORMES DE SECURITE INCENDIE............................... 16

Remarques générales....................................................... 17

Fonctionnement ................................................................ 17

Utilisation conforme .......................................................... 17

Protection de l'environnement .......................................... 17

Accessoires et pièces de rechange .................................. 17

Étendue de livraison ......................................................... 17

Consignes de sécurité ...................................................... 17

Description de l'appareil.................................................... 19

Montage............................................................................ 20

Mise en service................................................................. 22

Fonctionnement ................................................................ 22

Transport........................................................................... 24

Stockage........................................................................... 24

Entretien et maintenance.................................................. 24

Dépannage en cas de défaut............................................ 26

Garantie ............................................................................ 27

Accessoires ...................................................................... 27

Caractéristiques techniques.............................................. 27

CONSIGNES DE SÉCURITÉ IMPORTANTES

LIRE TOUTES LES INSTRUCTIONS AVANT D'UTILISER CET APPAREIL

몇 AVERTISSEMENT

Pour réduire les risques d'incendie, de choc électrique

ou de blessures :

NE PAS LAISSER l'appareil sans surveillance lorsqu'il est

branché. Débrancher la fiche de la prise en cas de non utilisation et d'entretien.

몇 AVERTISSEMENT

POUR RÉDUIRE LE RISQUE DE CHOC ÉLECTRIQUE UTILISATION EN INTÉRIEUR UNIQUEMENT

N’autorisez pas que l’appareil serve de jouet. Lors de

l’utilisation de l’appareil par des enfants ou à proximité

d’enfants, la plus grande attention est requise.

Utilisation uniquement comme cela est décrit dans ce

manuel. Utiliser uniquement les accessoires recommandés par le fabricant.

Ne pas utiliser avec un câble ou une prise endomma-

gés. Si l'unité ne fonctionne pas comme elle le devrait,

si elle est tombée, est endommagée, a été laissée dehors ou est tombée dans l'eau, la renvoyer à un centre

de SAV.

Ne pas tirer ou porter l'appareil avec le câble, ne pas uti-

liser de câble comme poignée, ne pas fermer une porte

sur le câble ou faire passer le câble au niveau de coins

ou d'angles coupants. Ne faire passer aucun appareil

sur le câble. Maintenir le câble à distance des surfaces

chaudes.

NE PAS DEBRANCHER LA FICHE SECTEUR DE LA

PRISE DE COURANT EN TIRANT SUR LE CABLE DE

BRANCHEMENT AU SECTEUR. Pour débrancher le

secteur, tirer sur la fiche secteur, pas sur le câble de

branchement au secteur.

Ne pas brancher la fiche ou l'appareil avec des mains

humides.

N’introduisez pas d'objet dans les ouvertures. N'utilisez

pas l'appareil lorsque les ouvertures sont colmatées.

Veillez à les garder exemptes de poussière, cheveux,

peluches ainsi que de tout ce qui serait susceptible

d’entraver le flux d'air.

Maintenir les CHEVEUX, VETEMENTS, BIJOUX PEN-

DANTS, DOIGTS et tous les membres du corps éloignés des ouvertures et des pièces mobiles.

Eteindre toutes les commandes avant de débrancher.

Soyez particulièrement prudents lors du nettoyage dans

les escaliers.

N’utilisez pas l’appareil pour aspirer des liquides inflam-

mables ou combustibles, par exemple de l’essence, et

ne placez pas l’appareil dans des endroits dans lesquels de tels liquides pourraient se trouver.

Raccordement uniquement à une prise mise à la terre

correctement. Voir Instructions de mise à la terre.

Débrancher toujours le câble de la prise électrique

avant d'entretenir l'appareil.

Ne jamais balayer des liquides explosifs, des gaz com-

bustibles ou des acides et des solvants non dilués. Cela

comprend l'essence, les diluants de peinture ou le fuel

domestique qui peuvent générer des fumées ou des

mélanges explosifs au contact de l'air. L'acétone, les

acides non dilués et les solvants doivent également être

évités car ils peuvent abîmer les matériaux sur la machine.

Ne pas aspirer des objets qui brûlent ou se consument.

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de dysfonctionnement ou de panne, la mise à la terre fournit un chemin

de moindre résistance pour le courant électrique afin de

réduire le risque de choc électrique.

Cet appareil est équipé d'un câble disposant d'un connecteur de mise à la terre de l'équipement et d'une fiche de

terre.

La fiche doit être branchée dans une prise appropriée installée correctement et mise à la terre conformément à

toutes les normes et ordonnances locales.

DANGER

Tout raccordement inapproprié du conducteur de

mise à la terre de l'équipement peut entraîner un

risque d'électrocution.

En cas de doute concernant la mise à la terre correcte

d'une prise de courant, faire appel à un électricien qualifié

ou au personnel de service.

Ne pas modifier la fiche fournie avec le produit - si elle ne

correspond pas à la prise de courant, faire installer une

prise de courant appropriée par un électricien qualifié.

Ne pas utiliser d'adaptateur avec ce produit.

Cet appareil est prévu pour être utilisé sur un circuit 120 V

nom. et dispose d'une fiche de branchement de terre qui

ressemble à la fiche illustrée sur la figure A.

Vérifier que l'appareil est raccordé à une prise de courant

ayant la même configuration que la fiche.

Aucun adaptateur ne doit être utilisé avec cet appareil.

RACCORDER UNIQUEMENT À UNE PRISE MISE À LA

TERRE CORRECTEMENT

Français 15

Page 16

1 Prise de terre

2 Boîtier prise de terre

3 Broche à la masse

REGLES DE SECURITE ET PRATIQUES

RELATIVES A L'UTILISATION

Responsabilité du propriétaire/de l'utilisateur

Avant d'utiliser ce nettoyeur pression, le propriétaire et/ou

l'utilisateur doit impérativement avoir pris connaissance

des consignes d'utilisation et mises en garde du fabricant.

Il est nécessaire d'insister sur les avertissements et de les

comprendre.

Si l'utilisateur ne parle pas couramment l'anglais, l'acheteur/le propriétaire doit lire les consignes et mises en

garde du fabricantavec l'utilisateur dans la langue maternelle de ce dernier et s'assurer qu'il en comprend bien le

contenu.

Le propriétaire et/ou l'utilisateur doit se familiariser avec

les consignes du fabricant et les conserver afin de pouvoir

s'y référerultérieurement.

Généralités

Avant de commencer à faire fonctionner l'unité, soyez

dans une position d'opération.

Ne pas démarrer ou utiliser l'appareil, ni aucune de ses

fonctions ou accessoires, à partir d'un autre endroit que

celui réservé à l'utilisateur.

Avant de quitter le poste de l'utilisateur :

1 arrêter l'appareil ;

2 si l'appareil doit stationner sur une pente, caler les

roues.

Conserver une distance de sécurité avec les bords des

rampes, des plates-formes et de toutes les autres surfaces

de travail du même type.

Ne pas ajouter d''accessoires à l'appareil ni le modifier de

quelque manière que ce soit.

Ne pas stationner à un endroit où l'appareil risque d'entraver les issues de secours, les cages d'escaliers ou les

équipements de lutte contre l’incendie.

Conduite

Céder la priorité aux piétons ainsi qu'aux véhicules d'urgence comme les ambulances et les camions de pompiers.

Traverser les voies ferrées à angle droit lorsque c'est possible. Ne pas garer l'appareil à moins de 1,8 m de la voie

ferrée ou du rail le plus proche.

Veiller à conserver une vue bien dégagée du trajet à emprunter et être attentif à la circulation des autres véhicules,

aux déplacements des membres du personnel, ainsi

qu'aux espaces de dégagement.

Quelles que soient les conditions de circulation, conserver

une vitesse permettant d'arrêter l'appareil en toute sécurité.

Ne jamais adopter de conduite dangereuse (cascades,

acrobaties etc.)

Ralentir sur les sols mouillés et glissants. Avant de déplacer l'appareil sur un pont de chargement ou un pont de laison, s'assurerque celui-ci est correctement sécurisé.

Avancer prudemment et lentement sur le pont de chargement ou pont de liaison. Ne jamais dépasser la charge

maximale autorisée.

Dans les virages, ralentir et adopter une vitesse de sécurité adaptée à l'environnement d'utilisation. Les virages

doivent être abordés sans à-coups.

Entretien de l'appareil par l'utilisateur

Si le véhicule a besoin d'être réparé ou présente un risque

quelconque, l'utilisateur doit le signaler immédiatement à

son responsable et ne pas utiliser l'appareil avant résolution du problème.

Si, en cours d'utilisation, le véhicule s'avère dangereux de

quelque façon que ce soit, signaler immédiatement le problème au responsable concerné et cesser l'utilisation de

l'appareil avant résolution du problème.

Ne pas effectuer de réparations ou réglages à moins d'y

être expressément autorisé.

PROCEDURES D'ENTRETIEN ET DE REMISE

EN ETAT

L'utilisation de l'appareil peut devenir dangereuse si l'entretien est négligé ou si la remise en état ou les réglages

nécessaires ne sont pas effectués en conformité avec les

recommandations du fabricant. Par conséquent, il est nécessaire de prévoir des ateliers de maintenance, à l'intérieur ou l'extérieur des bâtiments, avec du personnel

dûment formé, ainsi que d'établir des procédures détaillées.

La maintenance et l'inspection de l'appareil doivent être effectuées conformément aux procédures suivantes :

1 Les intervalles prescrits pour la maintenance, la lubrifi-

cation et le contrôle du système doivent être respectés;

se reporter aux instructions du fabricant.

2 Seules les personnes formées et habilitées sont autori-

sées à utiliser les autolaveuses motorisées. Les utilisateurs de ces appareils doivent avoir les aptitudes

visuelles et auditives ainsi que les capacités physiques

et mentales requises pour utiliser cet équipement en

toute sécurité.

Eviter les risques d'incendie et s'assurer que les locaux

sont dotés des équipements nécessaires pour la lutte

contre l'incendie. Ne jamais utiliser de bacs ouverts contenant du carburant ou des produits de nettoyage inflammables pour nettoyer les composants de l'autolaveuse

motorisée.

NORMES DE SECURITE INCENDIE

Tout appareil dont le fonctionnement représente un risque

doit être mis hors service.

Les réparations ne doivent pas être effectuées dans les

zones de classe I, II et III.

Prévention des incendies : L'autolaveuse motorisée doit

être tenue propre et dans la mesure du possible, protégée

des peluches, des déversements d'huile et de la graisse.

16 Français

Page 17

L'utilisation de produits non inflammables est recommandée pour le nettoyage de l'autolaveuse motorisée. Les liquides inflammables dont le point d'ignition est égal ou

supérieur à 37,8 °C (100 °F) ne sont pas autorisés.

Prendre les mesures appropriées concernant la toxicité,

l'aération, et les risques d'incendie selon le produit ou solvant utilisé.

Visibilité de la plaque signalétique : Les données techniques figurant sur la plaque signalétique de l'appareil ne

doivent pas être recouvertes de peinture et les informations d'identification doivent rester visibles.

Remarques générales

Veuillez lire le présent le manuel d'instructions

original et les consignes de sécurité jointes

avant la première utilisation de l'appareil. Suivez ces instructions.

Conservez les deux manuels pour une utilisation ultérieure

ou pour le propriétaire suivant.

Fonctionnement

Cette autolaveuse est utilisée pour le nettoyage à l'eau de

sols plats.

L'appareil peut être adapté à chaque de tâche de nettoyage en réglant la quantité d'eau et de détergent. Le dosage du détergent est adapté par ajout dans le réservoir.

La largeur de travail et la capacité du réservoir d'eau

propre et du bac d'eau sale (voir le chapitre Caractéristiques techniques) permettent un nettoyage efficace et une

durée d'utilisation élevée.

L'appareil est équipé d'un entraînement de traction. L'appareil est alimenté par 4 batteries.

saires pour le fonctionnement correct de l'appareil. Les appareils marqués par ce symbole ne doivent pas être jetés

dans les ordures ménagères.

Remarques concernant les matières composantes

(REACH)

Les informations actuelles concernant les matières composantes sont disponibles sous : www.kaercher.com/

REACH

Accessoires et pièces de rechange

Utiliser exclusivement des accessoires et pièces de rechange originaux. Ceux-ci garantissent le fonctionnement

sûr et sans défaut de votre appareil.

Des informations sur les accessoires et pièces de rechange sont disponibles sur le site Internet www.kaer-

cher.com.

Étendue de livraison

Lors du déballage, vérifiez que le contenu de la livraison

est complet. Si des accessoires manquent ou en cas de

dommage dû au transport, veuillez informer votre distributeur.

Consignes de sécurité

Avant la première utilisation de l'appareil, veuillez lire et

observer cette notice d'utilisation la brochure de consignes

de sécurité fournie pour les appareils de nettoyage à

brosses et les appareils d'injection-extraction, n° 5.956-

251.0 et agir en conséquence.

L'appareil est autorisé pour un fonctionnement sur des surfaces d'une inclinaison limitée (voir le chapitre Caractéristiques techniques).

Remarque

L'appareil peut être équipé de différents accessoires en

fonction des tâches de nettoyage souhaitées. Demandez

notre catalogue ou visitez notre site internet www.kaer-

cher.com.

Utilisation conforme

Cet appareil est conçu pour une utilisation professionnelle

et idustriels, p. ex. dans les hôtels, les écoles, les hôpitaux,

les usines, les bureaux et les magasins de loueurs. Utilisez

cet appareil uniquement suivant les indications dans cette

notice d'utilisation.

Utiliser l'appareil uniquement pour le nettoyage de sols

plats résistants à l'humidité et au polissage.

L'appareil n'est pas adapté au nettoyage de sols gelés

(p.ex. dans les chambres froides).

L'appareil n'est pas adapté à une utilisation dans des

environnements à risque d'explosion.

L'appareil est autorisé pour un fonctionnement sur des

surfaces d'une inclinaison maximale (voir le chapitre

Caractéristiques techniques).

Protection de l'environnement

Les matériaux d'emballage sont recyclables. Veuillez

éliminer les emballages dans le respect de l’environ-

nement.

Les appareils électriques et électroniques contiennent

des matériaux précieux recyclables et souvent des

composants tels que des piles, batteries ou de l’huile

représentant un danger potentiel pour la santé humaine et

l'environnement, s'ils ne sont pas manipulés ou éliminés

correctement. Ces composants sont cependant néces-

몇 AVERTISSEMENT

Basculement de l'appareil

Risque de blessures

N'utilisez pas l'appareil sur des surfaces inclinées.

Utilisez l'appareil uniquement si le capot et tous les couvercles sont fermés.

Dispositifs de sécurité

몇 PRÉCAUTION

Dispositifs de sécurité manquants ou modifiés

Les dispositifs de sécurité servent à vous protéger.

Ne modifiez, ni ne contournez jamais les dispositifs de sécurité.

Interrupteur de sécurité

Lorsque vous relâchez l'interrupteur de sécurité, l'appareil

s'éteint.

Interrupteur à clé

Si vous retirez l'interrupteur à clé, l'appareil est protégé

contre toute utilisation non autorisée.

Symboles d'avertissements

Respecter les avertissements suivants lors de la manipulation de batteries :

Observer les remarques dans le manuel d'utilisation de la batterie et sur la batterie ainsi que

dans ce manuel d'utilisation.

Porter une protection oculaire.

Français 17

Page 18

Tenir les enfants éloignés d'acides et de batteries.

Risque d'explosion

Le feu, les étincelles, les flammes nues et fumer

sont interdits.

Risque de brûlure chimique

Premiers secours.

Remarque d'avertissement

Élimination

Ne pas jeter la batterie à la poubelle.

18 Français

Page 19

18

19

20

21

22

23

22

24

20

25

26

27

28

29

30

31

32

33

9

4

5

17

1

3

6

7

8

9

10

11

13

5

1415

16

2

12

Description de l'appareil

Vue d'ensemble de l'appareil

1 Filtre à impuretés grossières

2 Filtre anti-peluches

3 Flotteur

4 Tête de nettoyage

5 Pédale de changement de brosse

6 Guidon

7 Interrupteur de sécurité

8 Couvercle du bac d'eau sale

9 Rail de retenue pour la station d'accueil

10 Bac d'eau sale

11 ** Batterie

12 Filtre d'eau propre

13 Fermeture du réservoir d'eau propre

14 Brosse à vitres

15 Réservoir d'eau propre

16 Plaque signalétique

17 Porte-flexible

18 Ouverture de remplissage du réservoir d'eau propre

Français 19

Page 20

19 Barre d'aspiration

1

20 Réglage en hauteur de la barre d'aspiration

21 Réglage de l'inclinaison de la barre d'aspiration

22 Écrou papillon pour la fixation de la barre d'aspiration

23 Tuyau d'aspiration

24 Indicateur du niveau de remplissage en eau propre

Flexible de vidange de l'eau propre

25 Levier de la tête de nettoyage

26 Bouton de réglage de la quantité d'eau

27 Levier de la barre d'aspiration

28 Fiche de la batterie

29 Interrupteur à clé

30 Écran

31 Molette de réglage de la vitesse de travail

32 Interrupteur du sens de marche

33 Flexible de vidange d'eau sale avec dispositif de do-

sage

** Non inclus dans l'étendue de la livraison

Code couleur

Les éléments de commande pour le processus de net-

toyage sont jaunes.

Les éléments de commande pour la maintenance et le

service sont gris clair.

Symboles sur l'appareil

Ouverture de vidange du réservoir d'eau

propre

Ouverture de vidange du bac d'eau sale

Pression d'appui augmentée de la tête de nettoyage

Montage

Déchargement

1. Retirer le carton.

2. Retirer les bandes de serrage.

3. Dévisser les cales de bois fixées à l'aide de vis sur la palette.

4. Avec les 3 planches de rigidité supérieures (80x24x970 mm)

de l’emballage en carton et la planche vissée à la transversale sur la palette (100x24x970 mm), poser une rampe devant la palette et la fixer à l’aide de vis pour contreplaqué.

3

120

625

2

1 Bois équarri 80x60x625 mm

2 Planche 80x24x970 mm

3 Planche 100x24x970 mm

5. Pousser le bois équarri (80x60x625 mm) dévissé de la

palette sous la rampe, pour supporter, et le visser.

6. Appuyer le levier du frein vers le bas.

225

1

Accès à la batterie

Niveau de remplissage du réservoir d'eau

propre (50%)

Brancher ici la fiche du chargeur

Point d'arrimage

* Support du balai laveur

ATTENTION

Mauvais emplacement

Risque d'endommagement

NE PAS brancher la fiche du chargeur ici

Pression d'appui normale de la tête de nettoyage

Tête de nettoyage levée

Pédale lever / baisser la tête de nettoyage

Pédale de changement de brosse

1 Levier du frein

7. Pousser l'appareil en marche avant de la palette.

8. Appuyer le levier du frein vers le haut.

Monter la barre d'aspiration

1. Accrocher la barre d'aspiration dans la suspension pour

la barre d'aspiration.

* en option

20 Français

Page 21

2. Serrer les écrous papillon.

+

+

+

+

-

-

-

-

1

3. Brancher le tuyau d'aspiration.

Batteries

Batteries recommandées

Description N° de com-

mande

185 Ah - sans

maintenance

(C20)

180 Ah - sans

maintenance

(C5)

240 Ah - sans

maintenance

(C5)

330 Ah - sans

maintenance

(C20)

* Volume minimum du local de remplacement de la batterie

** Débit d'air minimum entre le local de remplacement de

la batterie et l'environnement

Le dispositif a besoin de 4 batteries.

1 Kit complet (24 V / 185 Ah) avec câble de raccorde-

ment, n° de commande 4.035-388.0

2 Kit complet (24 V / 180 Ah) avec câble de raccorde-

ment, n° de commande 4.035-387.0

3 Kit complet (24 V / 240 Ah) avec câble de raccorde-

ment, n° de commande 4.035-393.0

4 Kit complet (24 V / 330 Ah) avec câble de raccorde-

ment, n° de commande 4.035-572.0

Batteries sans maintenance (batteries à éléments

6.654-242.0

6.654-124.0

6.654-119.0

8.629-184.0

humides)

Volume

3

(m

)*

1)

--

2)

--

3)

--

4)

11, 88 4 752

Débit d'air

3

(m

/h)**

DANGER

Remplir en eau lorsque la batterie est déchargée

Risque de brûlure dû à une fuite d'acide, destruction des

vêtements

Utilisez des lunettes de protection lors de la manipulation

d'acide de batterie.

Respectez les consignes.

Rincez immédiatement avec beaucoup d'eau les éventuelles projections d'acide sur la peau ou les vêtements.

ATTENTION

Utilisation d'eau avec des additifs

Batteries défectueuses, perte de garantie

Pour remplir les batteries, utilisez uniquement de l'eau distillée ou de l'eau déssalinisée (EN 50272-T3).

N'utilisez aucun additif externe, appelés améliorants, sous

peine d'annuler la garantie.

1. Ajouter de l'eau distillée une heure avant la fin du processus de charge. Ce faisant, observer le niveau

d'acide sur le repère de la batterie.

Toutes les cellules doivent expulser du gaz à la fin du

processus de charge.

Insérer et raccorder les batteries

Attention à la bonne stabilité de la machine lors du démontage et du montage des batteries.

ATTENTION

Inversion de polarité

Destruction de l'électronique de commande

Respectez la polarité lorsque vous raccordez la batterie.

ATTENTION

Décharge totale

Risque d'endommagement

Chargez les batteries avant la mise en service der l'appareil.

1. Vidanger l'eau sale.

2. Pivoter le bac d'eau sale vers le haut.

3. Insérer les batteries dans l'appareil.

1 Sangle de serrage

4. Entourer les batteries de la sangle de serrage.

5. Tendre les batteries vers l'arrière à l'aide de la sangle de

serrage.

6. Raccorder les pôles aux câble de raccordement fournis.

7. Brancher le câble de raccordement aux pôles encore

libres de la batterie (+) et (-).

8. Raccorder la fiche de la batterie côté appareil à la fiche

de la batterie côté batterie.

9. Pivoter le bac d'eau sale vers le bas.

Démontage de la batterie

몇 PRÉCAUTION

Démontage et montage des batteries

Manque de stabilité de la machine

Attention à la bonne stabilité de la machine lors du démontage et du montage des batteries.

1. Mettre l'interrupteur à clé à « 0 » et retirer la clé.

2. Retirer la fiche de la batterie.

3. Vidanger l'eau sale.

4. Pivoter le bac d'eau sale vers le haut.

5. Débrancher le câble du pôle moins de la batterie.

6. Débrancher les autres câbles des batteries.

7. Desserrer la sangle de serrage.

8. Sortir les batteries.

9. Éliminer les batteries usagées conformément aux dispositions en vigueur.

몇PRÉCAUTION

Démontage et montage des batteries

Manque de stabilité de la machine

Français 21

Page 22

Mise en service

1

1

2

Chargement de la batterie

DANGER

Utilisation non conforme du chargeur

Choc électrique

Respectez la tension du secteur et le fusible sur la plaque

signalétique de l'appareil.

N'utiliser le chargeur que dans les pièces sèches et suffisamment aérées.

ATTENTION

Accumulation de gaz dangereux sous le réservoir pendant la charge

Risque d'explosion

Avant de charger les batteries sans maintenance, pivotez

le bac d'eau sale vers le haut.

ATTENTION

Utilisation d'un chargeur non adapté

Risque d'endommagement

Ne raccordez pas le chargeur à la fiche de la batterie côté

appareil.

Utilisez uniquement un chargeur adapté au type de batterie installée.

Veuillez lire la notice d'utilisation du fabricant du chargeur

et respecter, en particulier, les consignes de sécurité.

Type de batterie Chargeur

6.654-242.0 6.654-434.0

6.654-124.0 6.654-434.0

6.654-119.0 6.654-435.0

8.629-184.0 6.654-419.0

La durée de charge est d'env. 10-15 heures.

Ne pas utiliser l'appareil pendant le processus de charge.

Remarque

L'appareil dispose d'une protection contre la décharge

complète, c'est à dire que lorsque la valeur minimale autorisée de capacité est atteinte, le moteur de brosse et la turbine sont éteints.

1. Déplacer l'appareil jusqu'au chargeur en évitant les

pentes.

2. Retirer la fiche de la batterie côté appareil.

5. Exécuter le processus de charge suivant les instructions dans la notice d'utilisation du chargeur.

6. Raccorder la fiche de la batterie côté appareil à la fiche

de la batterie côté batterie.

Fonctionnement

ATTENTION

Situation à risque pendant le fonctionnement

Risque de blessures

Relâcher l'interrupteur de sécurité en cas de danger.

Remplissage en fluides de fonctionnement

Remplissage en eau propre

1. Ouvrir la fermeture du réservoir d'eau propre.

2. Remplir en eau propre (60°C maximum) jusqu'au nord

inférieur de la tubulure de remplissage.

Remarque : Le flexible d'eau propre peut être coincé

avec le porte-flexible pendant le remplissage.

3. Fermer la fermeture du réservoir d'eau propre.

Consignes pour les détergents

몇 AVERTISSEMENT

Détergents non adaptés

Risque pour la santé, endommagement de l'appareil

Utilisez uniquement les détergents recommandés. En cas

d'utilisation d'autres détergents, l'exploitant est responsable du risque élevé envers la sécurité de fonctionnement

et le risque d'accident.

Utilisez uniquement des détergents sans solvant, sans

acide chloridrique ni acide fluorhydrique.

Respectez les consignes de sécurité sur les détergents.

Remarque

N'utilisez pas de détergents fortement moussants.

Détergents recommandés

Utilisation Détergents

Nettoyage d'entretien de tous les sols

résistant à l'eau

Nettoyage d'entretien de surfaces brillantes (granit, p.ex.)

Nettoyage d'entretien et nettoyage de

fond de sols industriels

Nettoyage d'entretien et nettoyage de

fond de carreaux de faïence

Nettoyage d'entretien de carrelages

dans les espaces sanitaires

Nettoyage et désinfection dans les espaces sanitaires

Désincrustation de tous les sols résistant aux alcalins (PVC, p.ex.)

Désincrustation de sols en linoléum RM 754

RM 746

RM 780

RM 755 es

RM 69 ASF

RM 753

RM 751

RM 732

RM 752

1 Fiche de la batterie, côté appareil

2 Fiche de la batterie, côté batterie

3. Raccorder la fiche de la batterie côté batterie au char-

4. Brancher la fiche secteur du chargeur dans la prise de

22 Français

geur.

courant.

Détergents

1. Verser le détergent dans le réservoir d'eau propre.

Remarque : Vous pouvez utiliser le couvercle de l'ouverture de remplissage du réservoir d'eau propre pour

doser le détergent. Il est équipé d'une échelle à l'intérieur.

Régler la quantité d'eau

1. Régler la quantité d'eau sur la molette de réglage en

fonction de l'encrassement du revêtement de sol.

Page 23

Remarque

1

10 mm

1

2 3

Réaliser les premiers essais de nettoyage avec une

faible quantité d'eau. Augmenter petit à petit la quantité

d'eau jusqu'à l'obtention du résultat de nettoyage souhaité.

Remarque

Lorsque le réservoir d'eau propre est vide, la tête de

nettoyage continue à fonctionner sans apport en liquide.

Régler la barre d'aspiration

Régler l'inclinaison

régler l'inclinaison de manière à ce que les lèvres d'aspiration de la barre d'aspiration soient appuyées régulièrement

sur le sol, sur toute leur longueur.

1. Desserrer la vis.

5. Placer les autres rondelles au-dessus du rouleau

d'écartement.

6. Insérer et serrer la vis.

7. Répéter la procédure sur le deuxième rouleau d'écartement.

8. Pousser l'appareil légèrement vers l'avant.

9. Contrôler de nouveau le pli des lèvres d'aspiration sur

toute leur longueur.

10.Répéter le réglage si besoin.

Nettoyer

Démarrer l'appareil

1. Mettre l'interrupteur à clé sur « 1 ».

L'écran affiche successivement :

La durée avant le prochain service après-vente

La version du logiciel, l'élément de commande

L'état de charge de la batterie et le nombre d'heures de

service

Conduite

Remarque

Vous pouvez modifier le sens de la marche pendant le nettoyage. En avançant et en reculant plusieurs fois, il est

alors possible de nettoyer intensément l'emplacement

choisi.

1. Mettre l'interrupteur du sens de la marche sur

« avance ».

Nettoyer

1 Vis

2. Régler l'inclinaison de la barre d'aspiration.

3. Serrer la vis.

Réglage de la hauteur

Le réglage de la hauteur adapte le pli des lèvres d'aspiration lors du contact avec le sol.

1. Pousser l'appareil légèrement vers l'avant.

2. Comparer le pli des lèvres d'aspiration au schéma cidessus.

´

1 Rouleau d'écartement avec support

2 Rondelle

3 Vis

3. Desserrer la vis.

4. Placer autant de rondelles entre la barre d'aspiration et

le rouleau d'écartement pour obtenir le pli de la lèvre

d'aspiration souhaité.

Remarque

Pour améliorer le résultat de l'aspiration, vous pouvez régler l'inclinaison et la hauteur de la barre d'aspiration (voir

le chapitre Régler la barre d'aspiration).

Remarque

Dès que le bac d'eau sale est plein, le flotteur ferme l'ouverture d'aspiration et la vitesse de rotation de la turbine

augmente. Dans ce cas, soulever la barre d'aspiration et la

déplacer pour vider le bac d'eau sale.

1. Tourner la molette de réglage de la vitesse de travail sur

la valeur souhaitée.

La vitesse est indiquée à l'écran pendant le réglage.

L'affichage est représenté en pour-cent de la vitesse

maximum.

2. Régler la quantité d'eau sur la vanne de régulation.

3. Appuyer le levier de la barre d'aspiration vers le bas.

La barre d'aspiration s'abaisse.

L'aspiration débute.

4. Appuyer le levier de la tête de nettoyage vers le bas, le

déclencher et le laisser remonter.

5. Tirer l'interrupteur de sécurité vers le guidon.

La tête de nettoyage démarre et l'appareil se déplace à

la vitesse réglée.

Augmenter la pression d'appui de la brosse

1. Relâcher l'interrupteur de sécurité.

2. Lever à la main le levier de la tête de nettoyage et l'enclencher à droite.

Terminer l'utilisation

Terminer le nettoyage

1. Relâcher l'interrupteur de sécurité.

2. Baisser à la main le levier de la tête de nettoyage et l'enclencher à droite.

Français 23

Page 24

3. Réaliser encore un petit déplacement.

L'eau résiduelle est aspirée.

4. Lever la barre d'aspiration.

L'aspiration continue encore pendant 10 secondes.

5. Mettre l'interrupteur à clé sur « 0 ».

6. Charger la batterie le cas échéant.

Vidange de l'eau sale

몇 AVERTISSEMENT

Élimination non conforme des eaux usées

Pollution

Respectez les prescriptions locales de traitement des

eaux usées.

1. Sortir le flexible de vidange du support et l'abaisser audessus d'un bac de collecte adapté.

4. Sélectionner le sens de la marche sur l'interrupteur du

sens de la marche.

5. Tirer l'interrupteur de sécurité vers le guidon.

6. En cas de transport de l'appareil dans des véhicules, le

bloquer contre le glissement et le basculement suivant

les normes en vigueur.

1.

2.

7. Poser d'abord la sangle de serrage sous le bac d'eau

sale.

Stockage

2. Presser ou plier le dispositif de dosage.

3. Ouvrir le couvercle du dispositif de dosage.

4. Vidanger l'eau sale. Réguler la quantité d'eau en pressant ou en pliant.

5. Rincer le bac d'eau sale à l'eau claire.

Vidanger l'eau propre

1. Retirer le flexible de l'indicateur de niveau de remplissage et le pivoter vers le bas.

Vidanger rapidement l'eau propre

1. Dévisser la fermeture du réservoir d'eau propre.

2. Laisser l'eau propre s'écouler.

3. Poser et visser la fermeture du réservoir d'eau propre.

Remarque : Veiller à ce que le raccord de flexible dans

la fermeture du réservoir d'eau propre soit placé au

point le plus bas après le vissage.

Transport

DANGER

Conduite en pente

Risque de blessures

Utilisez l'appareil pour le chargement et le déchargement

uniquement sur des pentes d'une valeur maximale de (voir

le chapitre Caractéristiques techniques).

Conduisez lentement.

몇 PRÉCAUTION

Non-observation du poids

Risque de blessure et d'endommagement

Observer le poids de l’appareil pour le transport.

1. Baisser à la main le levier de la tête de nettoyage et l'enclencher à droite.

2. Soulever la barre d'aspiration.

3. Mettre l'interrupteur à clé sur « 1 ».

몇 PRÉCAUTION

Non-observation du poids

Risque de blessure et d'endommagement

Tenir compte du poids de l’appareil pour le stockage.

ATTENTION

Gel

Destruction de l'appareil par le gel d'eau

Videz complètement l'appareil de toute son eau.

Rangez l'appareil à un endroit hors gel.

Stocker cet appareil uniquement à l'intérieur.

Entretien et maintenance

DANGER

Démarrage intempestif de l'appareil

Risque de blessures, risque d'électrocution

Avant les travaux, mettre l'interrupteur à clé de l'appareil à

« 0 » et retirer la clé.