Installation Instructions for Part #: KFSB-AP-XX

Karcepts Front Sway Bar Kit for 2000-2009 Honda S2000

Specifically for track/autocross use, this sway bar kit offers zero compromises:

- Billet aluminum arms optimized for strength and weight utilizing the latest FEA software

- Like a blade style sway bar, roll stiffness can be adjusted quickly, and with one wrench

- Unlike a blade style sway bar, adjustments are finite, with no possibility of slipping position

- 6 adjustment positions per sway bar arm

- Light weight, zero deflection solid sway bar mounts provided for precise feel

- Low friction, lubrication free, dirt resistant, solid polymer bearings require no maintenance

- Heat treated and plated steel alloy PTFE lined endlinks and all hardware included

- 32mm (1.25") diameter high-grade spring steel splined center section for consistent rates

- Center section available in different wall thicknesses (0.120", 0.188", 0.250", and solid)

- Stiffest setting yields 11% more angular twist on a given center section compared to any other

splined style S2000 front sway bar on the market

Karcepts, Inc.

www.karcepts.com

info@karcepts.com

Parts Included With S2000 Front Sway Bar Kit

DESCRIPTION QTY

SOLID SWAY BAR MOUNT 2

M10X25 FLANGE BOLT 4

SPLINED SWAY BAR CENTER SECTION 1

CLAMP COLLAR 2

LEFT SWAY BAR ARM 1

RIGHT SWAY BAR ARM 1

M12X50 SOCKET HEAD CAP SCREW 2

SWAY BAR ENDLINK 2

3/8" NYLON-INSERT LOCKNUT 2

3/8" FLANGE NUT *4

*

Only quantity of 2 needed for assembly. Quantity of 2 extra provided as spares.

HEAVY DUTY CABLE TIES 4

Tools Required

Torque Wrench

Sockets - 17mm, 14mm, 10mm hex bit, 9/16", 3/16" hex bit

1/2" Open End Wrench

9/16" Ratcheting Combination Wrench

Tape Measure

Rubber Mallet

Note

Please read these instructions in full before attempting installation. If you do not

believe you are qualified in performing the necessary installation, please find an

experienced professional who can. Due to the nature of racing components

(external shock reservoirs, piggyback canisters, aftermarket brakes/brake lines,

oversized wheels/tires), it is your responsibility to make certain adequate clearances

between aftermarket chassis components and our sway bar are met. Karcepts,

Inc. will not be held responsible for damaged components due to unresolved

interference issues during installation.

This sway bar kit will only offer quick adjustment options with shock bodies that are

completely cylindrical in shape between the shock body and sway bar arm. Brake

line mounting brackets, remote reservoir lines, nitrogen fill connections, and any

other potential obstructions mounted inboard of the shocks can prohibit quick

adjustment. OEM shocks, Koni Sport shocks, and any other shocks with OEM style

brake line mounting brackets can still function when relocating the left shock to the

right side, and vice versa (or you may grind off the brake like brackets completely).

Since most brake line brackets cannot be utilized if desiring the quick adjustment

feature of this kit, always re-secure brake lines to the shock bodies with heavy duty

cable ties (provided). It's best to tie brake lines as high as possible onto the shock

bodies, as this will keep the lines out of the way when performing an adjustment.

Good (no interference) Bad (bracket needs addressed)

The succeeding installation instructions assume the above precautions have already

been checked or addressed.

Please consult us if you have any concerns with your application.

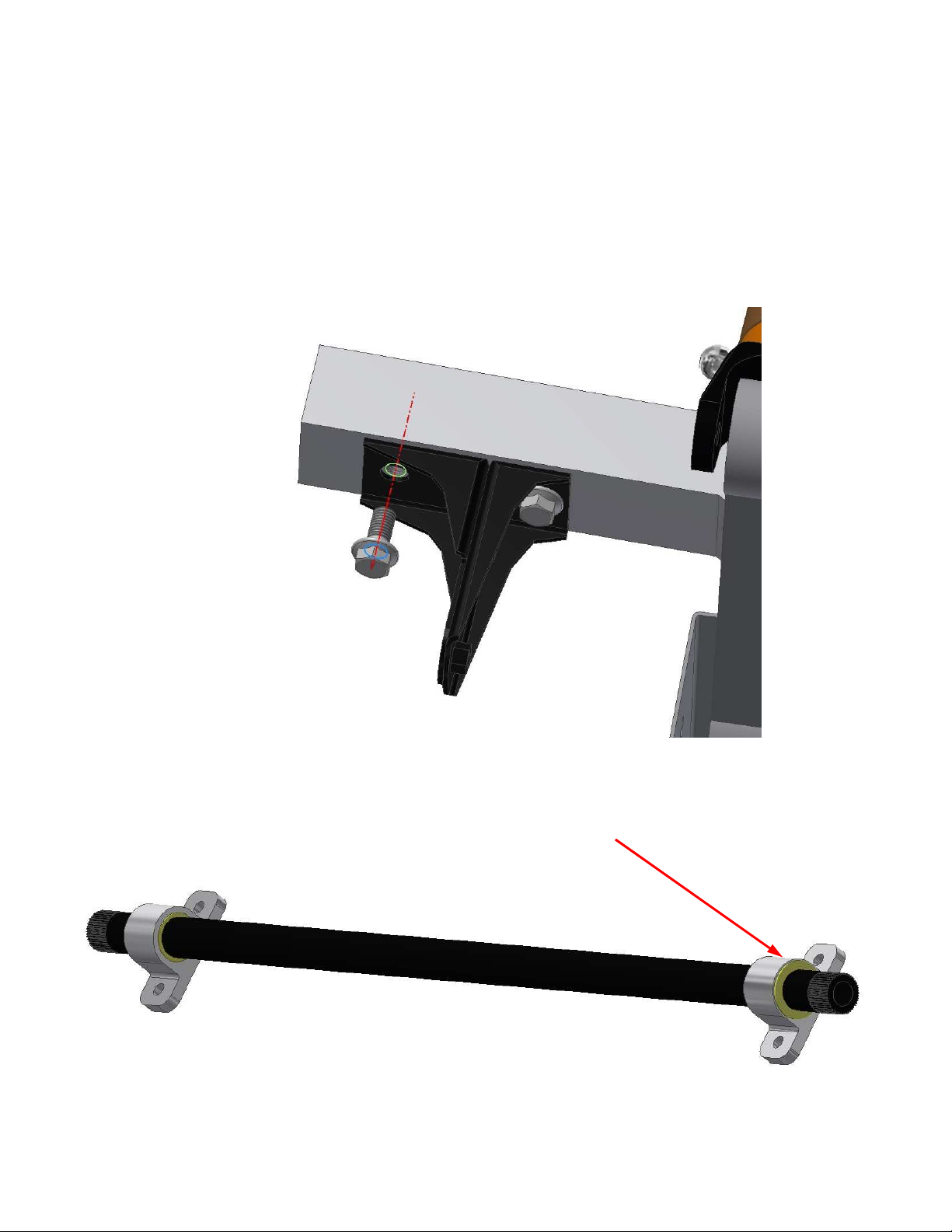

1. Solid Mount/Center Section Installation

A. Raise the front of the vehicle and support it with jack stands.

B. Remove the front wheels, splash shield, sway bar, sway bar bushing holders,

and endlinks.

C. The factory sway bar mounting brackets (OEM steel brackets that mount under

the frame rails) must be utilized in conjunction with the Karcepts Solid Sway Bar

Mounts. Never use any other aftermarket sway bar mounts with this kit as they

will alter the geometry. If the factory brackets are currently installed on the

vehicle, now is a good time to double check their tightness to the frame. The

factory torque spec on these M12 (17mm socket) bolts is 61 ft-lbs.

D. Slide a solid mount onto each end of the splined center section. Upon first

install, it can be normal if the mount bushings require some effort to slide onto

the shaft. Note the orientation of the bushing inside each mount. The flanged

side of the bushings must be positioned facing out.

DO NOT oil the bushings with any form of lubricant. The polymer bushings are

infused with solid lubricants and must break-in and run dry.

1. Solid Mount/Center Section Installation (continued...)

E. Install the solid mount/center section assembly onto the factory sway bar

mounting brackets with the provided M10x25 flange bolts and torque to 29 ftlbs with a 14mm socket. Do not be alarmed if observing high friction levels

when trying to rotate the bar at this time. With use, the bushings will break-in

and free up quickly.

F. Slide a clamp collar over each end of the splined center section. Leave the

collar screws loose. There is no need to center the bar perfectly at this time.

You will not be centering the bar based off how much shaft is protruding from

the sides of the mounts as that does not always give a clear indication of true

center (due to subframe position, eccentric alignment bolt positions, as well as

excess hole clearance in the factory sway bar mounting brackets to the frame).

2. Sway Bar Arm Installation

A. Slide the left sway bar arm over the splined end of the center section, leaving

1/16" of shaft protruding past the end of the arm. This is the optimal arm

installation position. Thread the M12x50 socket head cap screw through the

arm; and with a 10mm hex bit socket, torque to 50 ft-lbs.

B. Repeat the above for the right sway bar arm, making certain to clock the right

arm onto the shaft splines to an exact mirror image as the left arm.

Arms clocked properly Arms clocked incorrectly (off one tooth)

3. Quick Adjustment Setup

The quick adjustment feature of this sway bar kit is dependent upon:

1. Arm installation position relative to center section (Section 2 above)

2. Proper endlink length (subject to ride height & arm installation position)

3. Correct sway bar centering

Use the below table to determine ideal endlink length for your ride height:

RIDE HEIGHT *1 ENDLINK LENGTH *2

12.50" 2.63"

12.75" 2.69"

13.00" 2.75"

13.25" 2.81"

13.50" 2.88"

13.75" 2.94"

14.00" 3.00"

14.25" 3.06"

*1

Ride height is measured from the center of the hub to the bottom edge of the fender.

*2

Endlink length is measured from center of ball to center of ball.

A. Endlinks are pre-set to 2.75" by Karcepts, Inc. upon shipment. Re-set endlink

length if your ride height is not 13.00". You may loosen the lock nuts and rotate

one side of the endlink in or out 1.5 rotations to adjust for 1/16" (0.06") of endlink

length. (For example: Your ride height from center of hub to bottom of fender =

13.50". If following the table above, that would mean you need the endlinks to

be 1/8" longer. Simply loosen the lock nuts and unscrew one side of the link 3

full turns, then re-tighten to achieve a 2.88" long endlink.)

Depending on corner balance (differing heights per side of the car w/o driver), you

may realized the left link and right link should differ in lengths per the above table.

At this time, find a happy medium to set both endlinks to the same length. We will

need the endlinks at equal length in order to center the bar at full droop. In future

steps (after centering the bar), you may re-correct endlink length if finding the need

to even do so. We have built in fairly large clearances on this design for ease of

quick adjustment, so endlinks set at equal lengths even with slightly differing left to

right ride heights most likely will not need any correction.

14.50" 3.13"

3. Quick Adjustment Setup (continued...)

B. Install the male half of endlinks into Hole #4 of each sway bar arm and secure

with the 3/8" flange nuts. Proper torque on this nut is 28 ft-lbs, but since this is

the adjustment nut, it's impractical to assume you'll be using a torque wrench

every time you make a sway bar change. Just tighten by feel approximately

close to 28 ft-lbs. Plan to use a 9/16" ratcheting combination wrench on this nut

for quickest adjustments. Install female half of endlinks into the OEM sway bar

endlink locations on the lower control arms. Use a 1/2" open end wrench (to

hold the endlink stud from spinning) along with a 9/16" socket to secure the

provided 3/8" nylon-insert locknuts, and torque to 28 ft-lbs.

Male half of endlink Female half of endlink

3/8" nylon-insert locknut 3/8" flange nut (adjustment nut)

3. Quick Adjustment Setup (continued...)

C. Assuming all bolts and endlinks are tight (but with clamp collars still loose),

center the sway bar assembly by comparing the distance between the endlinks

and the shock bodies. Use a tape measure (or calipers) to assist in the

centering. Again, centering the bar based off how much shaft is protruding

from the sides of the mounts does not give a clear indication of true center (due

to subframe position, eccentric alignment bolt positions, as well as excess hole

clearance in the factory sway bar mounting brackets to the frame). You may

get lucky where that method could work out; but chances are, you must base

the centering off the distance between endlinks and shock bodies as shown

below. If necessary, use a rubber mallet to tap on the sway bar arms to adjust

the position until center is found. Once in position, slide clamp collars tight up

against the bushings of the solid mounts and torque clamp collar screws to 12

ft-lbs (144 in-lbs) with a 3/16" hex bit socket. Make certain there is no

clearance between the solid mounts and the shaft collars once torqued. As a

check, grab a hold of the sway bar center section with both hands, and with all

your strength, try to rock the bar side to side, back and forth (make sure the

vehicle is securely supported before doing so). If you feel any side to side play,

you will need to re-set one of the shaft collars to get rid of the excess

clearance. Functionally, if there is a little side to side play, there will be no ill

effects; however, some side to side play may attribute to a knocking noise.

3. Quick Adjustment Setup (continued...)

D. Lastly, for proper quick adjust functionality, the endlinks must be set to achieve

maximum articulation when installed in the current #4 Hole setting.

To do so, first loosen the endlink lock nut (middle nut of endlink).

Now, rotate both the top and bottom of the endlink halves clockwise until they

bottom out on themselves and will not rotate any further clockwise.

Finally, tighten the endlink lock nut. Once secure, you can rotate the endlink by

hand and should observe a good amount of sweep back and forth on the link,

verifying a large range of articulation has been achieved.

4. Quick Adjustment Procedure

Re-install the splash shield, wheels/tires, and get the car back on the ground. The

car is now ready to test the Quick Adjustment Procedure.

The adjustment procedure of this sway bar kit should take no longer than 3 minutes

to complete with adequate practice and knowledge of the product. For first timers,

you may find yourself spending more time than expected until familiarity is gained.

Additionally, when first learning the procedure, it's best to crank the wheel full lock to

the right when adjusting the left arm position and vice versa (so that you can view

what you are doing). With experience and feel, you will be able to make sway bar

adjustments with the wheels pointed straight ahead (which decreases the amount

of time to adjust).

Before attempting to make a sway bar adjustment quickly at the track or between

autocross runs, we highly recommend spending a good hour practicing and gaining

familiarity with the product/procedure. It's best to follow the below steps exactly as

provided. If trying to take any short-cuts in the below steps, you may cause yourself

excess time or frustration.

1. To start, (turn the wheels full lock to the right and then) loosen and remove the

adjustment nut on the back side of the left sway bar arm with a 9/16" ratcheting

combination wrench. Set the nut aside and remove the male stud of the

endlink from the arm. If there is any difficulty removing the stud due to any

preload, crack loose the adjustment nut on the right side arm, then come back

to the left side and you will be able to remove the stud from the release of

preload. Articulate the endlink around as required, and insert the stud of the

endlink into the newly desired hole position. Pay attention to the wrench flats

on the endlink stud as well as the machined slot of the sway bar arm. The flats

will need to lie within the slot of the sway bar arm. However, at this initial stage,

it can be common for the endlink not to want to install completely within the slot

of a new hole location. If there is any difficulty seating the stud fully within the

arm; do not force anything, just simply leave the stud sitting partially inserted

into the new hole position. If you do manage to seat the stud fully into the new

hole/slot, just leave as is and DO NOT affix the adjustment nut at this time, that

will be completed in Step 3.

2. (Turn the wheels full lock to the left and then) Loosen and remove the

adjustment nut on the back side of the right sway bar arm. Since the left side

endlink has still been left unsecure, it will be extremely easy to remove and reposition this right endlink. If any difficulties, simply push up or down on the

sway bar arm, and all should be free to re-position. Affix the right endlink stud

into the new desired adjustment hole by making certain the wrench flats of the

stud are seated fully into the machined slot of the arm (3/8" of thread will

protrude from the back of the arm). Re-install the adjustment nut and tighten

by feel to approximately 28 ft-lbs.

3. Lastly, go back to the left side of the vehicle (turn the wheels back full lock to

the right) and completely secure the left side endlink stud into the sway bar slot.

Re-install the adjustment nut and tighten by feel to approximately 28 ft-lbs.

5. Quick Adjustment Troubleshooting

If following the Quick Adjustment Procedure, there should be no issues completing

Steps 1 & 2. If there is any difficultly with Step 3 of the procedure, this can mean

one of a few things:

1. The vehicle's suspension has not settled properly back to ride height. Repeat

any above steps necessary within these instructions and get the endlinks

installed back into Hole #4 on each arm. Drive the car around, turn left and

right, do some hard braking, and get the suspension settled and re-try the

Quick Adjustment Procedure.

2. If the vehicle is sitting on extremely un-even pavement, there may be difficulties

due to additional preload. Reposition the vehicle on a different surface and retry the Quick Adjustment Procedure. However, if you are stuck on an un-even

surface, you can correct by performing the following: At the end of Step 2, after

seating the endlink stud fully within the slot of the right side sway bar arm,

thread on the adjustment nut; yet, do not tighten it fully. Let the nut remain a

full turn or two loose. Complete Step 3; and then for a final Step 4, go back to

the right side and finish tightening the adjustment nut.

3. Double check to make certain the sway bar is centered completely, then re-try

the Quick Adjustment Procedure.

4. Double check to make certain the proper endlink lengths are used per the table

in Section 3. If ride height is different between left and right sides of the vehcile,

set left and right endlink lengths accordingly.

5. If all else fails, the endlink length on one side of the vehicle may simply need to

be modified. So if at Step 3 the endlink seems too long or too short to install

into the newly desired hole position, with the car still on the ground, crack loose

on the center endlink lock nut, and then increase or decrease endlink length

until able to insert the endlink stud completely within the slot of the arm.

Tighten the adjustment nut onto the back of the arm. Now, re-set the

maximum endlink articulation by completing 3.D of these installation

instructions (but in this case, you will be completing 3.D with the vehicle still on

the ground). If making an endlink length correction, please test the Quick

Adjustment Procedure multiple times to confirm the new endlink length is ideal.

It should not be necessary to deviate far from the endlink lengths provided on

the table of Section 3.

If there are any issues installing endlinks into Hole #2 due to shock body

interference, this can mean one of two things:

1. Test installing endlinks into Hole #2 on both sides of the vehicle. If only one

side has interference, the sway bar is not centered properly. Re-center the

sway bar correctly and try again.

2. Shock bodies larger than 2.25" in diameter may encounter this interference. To

correct, re-set the arm installation position (Section 2) to a larger value than the

specified 1/16" until clearance is achieved. Endlink length must also be

increased from the Section 3 table values by the same additional increment of

length that was added to the 1/16" arm installation position.

Disclaimer/Warranty:

Due to the nature of high performance applications, Karcepts, Inc. products are

sold without any warranty of merchantability or fitness or purpose, express or

implied. It is expressly understood and agreed between Karcepts, Inc. and

purchasers that as part of the bargain between Karcepts, Inc. and purchasers,

consideration of doing business with each other, all purchasers take, select, and

purchase said products and services from Karcepts, Inc. “as is” and “with all faults”

and Karcepts, Inc. shall provide purchaser with a full and complete opportunity to

examine parts, inventory or services when purchasing from Karcepts, Inc.

Karcepts, Inc. shall not under any circumstances, be liable for any special,

incidental, or consequential damages, including, but not limited to, damages or loss

of other property of equipment, loss of profits or revenue, cost of purchased or

replacement goods, or claims of customers of the purchaser which may arise

and/or result from the sales, installation or use of these parts.

Parts sold or manufactured by Karcepts, Inc. may not meet legal requirements for

use on public roads. It is the user’s responsibility to know and comply with all local

and federal laws and regulations. Use or installation of Karcepts, Inc. products may

affect user insurance and/or vehicle warranty coverage. It is the user’s sole

responsibility for consequences that may occur due to having the product installed

in his/her vehicle.

Karcepts, Inc. assumes no legal responsibilities and/or liabilities, whether to user’s

vehicle, engine, person(s), and/or property(s), that result from the use of, or servicing

of a vehicle of which a Karcepts, Inc. product has been installed/attempted to be

installed, or to any other vehicle(s) and/or person(s), regardless of whether or not

this product has any involvement directly or indirectly and/or liability, and/or whether

or not proper installation has been carried forth.

Acquisition of a Karcepts, Inc. product will act as an acknowledgement of the legal

disclaimer stated herein.

Loading...

Loading...