KAPS SOM 42, SOM 52 User manual

ser

s

M

i

CA

M42/52C

64

scopes

<

MARKS

Licence

093623,

109666

LICEN

No.:

page

F

-

VDE

1 -

VD

EMV

ostfach

uropastrañe,

e-mail:info@kaps-optic.de

06441

Fax

1225,

www.kaps-optic.de

06441

/

80704-0

/

D-35608

D-35614

85985

Asslar

Asslar

KAPS

his

01.10.1997

microscope

is

manufactured

-roducts

according

of

medicine

Page

1

to

the

(MPG)

EU

direction

93

/

42

/

EWG

ser's

Manual

SOM

42

/

52

pam

+

oooo

POD

Security

„ON

Condition

Mounting

Mounting

4.1

Special

indications,

NTS

of

of

of

intended

material

rol

er

stand

at

appliance

indication

time

and

(Fig.

of

column

2)

use

supply

(Fig.

1)

(ο

οι

ο

5.0

6.0

4.2

4.3

Close

5.1

5.2

5.3

Additional

Measures,

electrical

Adjustment

lectrical

Changing

Control

load

weight

connections

connections

of

elements

of

mains

fuse

(Fig.

(Fig.

3)

(Fig.

(after

voltage

5)

removal

4)

of

the

defect)

ο

ο

60

60

060

NNN

4

2

D

70

8.0

Operating

7.1

7.2

7.3

fd

instru

8.1

On

-

Change

rakes

rightness

ctions

Adjusting

ins

/

off

-

for

ructions

switch

over

(Fig.

switch

control

using

the

eye

the

(Fig.

6)

lamp

(Fig.

6)

(Fig.

7)

microscope

distance

|

(Fig.

7)

/

lamp

8)

Il

(Fig.

6)

10,1

12,1

~

9.0

8.

8.4

3

reakdown

2

Changing

ow

to

focuse

yepieces

and

3reakdown

Changing

when

of

the

the

magnificatio

the

with

using

cold

of

the

the

xenon

object

reticle

television

light

(hel

illumination

cold

reflector

(Fig.

light

n

(Fig.

p

or

9)

for

photo

fine

illumination

lamp

9)

focussing

systems)

(Fig.

later

(Fig.

10)

during

on

9)

operation

12,1

12,1

OODODOOO

AAO

B

=0

NAON

hanging

hanging

0000

chedule

the

the

for

microscope

Compensation

Mounting

Observation

and

'hoto

assista

tube

of

beam

tube

nce

with

binocular

objectives

of

weight

splitter

tube

/

when

monocular,

tube

35

90°

mm

(Fig.

camera,

(Fig.

eyepieces

m

agnification

using

(Fig.

A

11)

3)

observa

14)

TV

(Fig.

and

accessories

tion

-

tube

12)

object

tube

with

binocular

video

field

(

Fig.

camera

measures

13)

(CC

이

O1

09

4

4

20.

2

22.0

POODIO

Accessories

Cleaning

hotographing

ow

andles

to

get

a

and

sharp

microscope

(survey

Jesinfection

distance

and

and

service

without

image

with

sterilization

holder

for

flash

ont

guides

order

sterilization

ne

TV

(Fig.

no.)

(

Fig.

18)

screen

17)

cover

(XOM

(Fig.

1

6)

))

{

Fig.

19)

23.0

echnical

23.1

Conformity

data

declaration

KAPS

01.10.1997

Page

2

1.0

e

SECURITY

equipment

his

microscope

and

complies

ser's

INDICATIONS,

is

manufactured

Man

INTEN

with

the

ab]

IS

according

indicated

42/52C

US

IEC

to

the

Puplications

security

indications

(IEC

601

of

- 1

electrical

/

9

9

9

N

condition.

o

this

his

For

60601

guarantee

user's

microscope

service

-1

manual

/

VDE

the

and

0750

normal

attentively.

is

repair only

allowed

part

and

authorized

1).

safety

to

use

This

use

in

that

instrument

persons

of

way

the

only

microscope

are

left

as

allowed

KAPS

described

Company

it

is

to

in

necessary

in

operate.

this

manual.

perfect

to

read

9

e

9

9

Spare

questions,

lease

rated

he

with

3e

microscope

protective

sure

parts

substitute

current,

that

and

please

switch

inlets

accessories

belongs

earth

contact

burned

-

and

off

conductors

outlets

out

characteristics).

to

must

our

safety

representatives.

fuses

of

be

by

class

only.

ventilation

admitted

fuses

|,

use

system

of

mains

by

the

the

same

manufacturer.

plug

for

cooling

type

and

only

mains

the

(rated

housing

If

there

voltage,

socket

are

are

both

any

open

e

e

not

he

e

Microscope

inlets

b

inking

reduces

his

covered).

microscope

microscope

or

activities

outlets

of

brightness

is

a

is

components.

protected

of

red

and

light

built

cooling

of

microscope

for

against

emitting

illumination

use

system

will

in

overheating.

diode

not

dry

are

rooms

unintentiona

(3),

automatically

be

Fig.

damaged.

only.

6,

A

defect

page

in

Take

cooling

After

covered)

y

10.

that

way

care

The

that

the

user's

that

system

will

protecting

no

a

fluids

(fan

be

indicated

surgeon

activities

can

is

system

can

are

enter

defect,

by

finish

e

being

possible

Very

icroscope!

ntended

he

medical

f

is

useful

finished,

please

important:

use

SOM

use.

42

for

cases

advice

Please

/

optimal

For

52

COLD

identification,

read

of

service

illumination

disturbances

it

from

LIGHT

department.

service

the

is

a

and

must

type

universal

magnification

label

be

people

instrument

eliminated

must

(4),

Fig.

know

6,

of

the

immediately,

page

for

the

operative

attendance

serial

10.

number

and

if

this

diagnostic

area

is

with

not

of

the

the

possibility

he

medical

intended

use

applications

of

of

use,

the

the

manual

SOM

there

is

42

as

no

variation

/

52

described

contact

COLD

of

between

magnification,

LIGHT

in

this

focus

is

instruction

patient

only

allowed

and

and

to

handbook.

SOM

imagefield.

authorized people

42

If

this

/

52.

and

instrument

is

in

KAPS

01.10.1997

Page

3

5

"s

tb

Manual

S

42

|

52

é

+

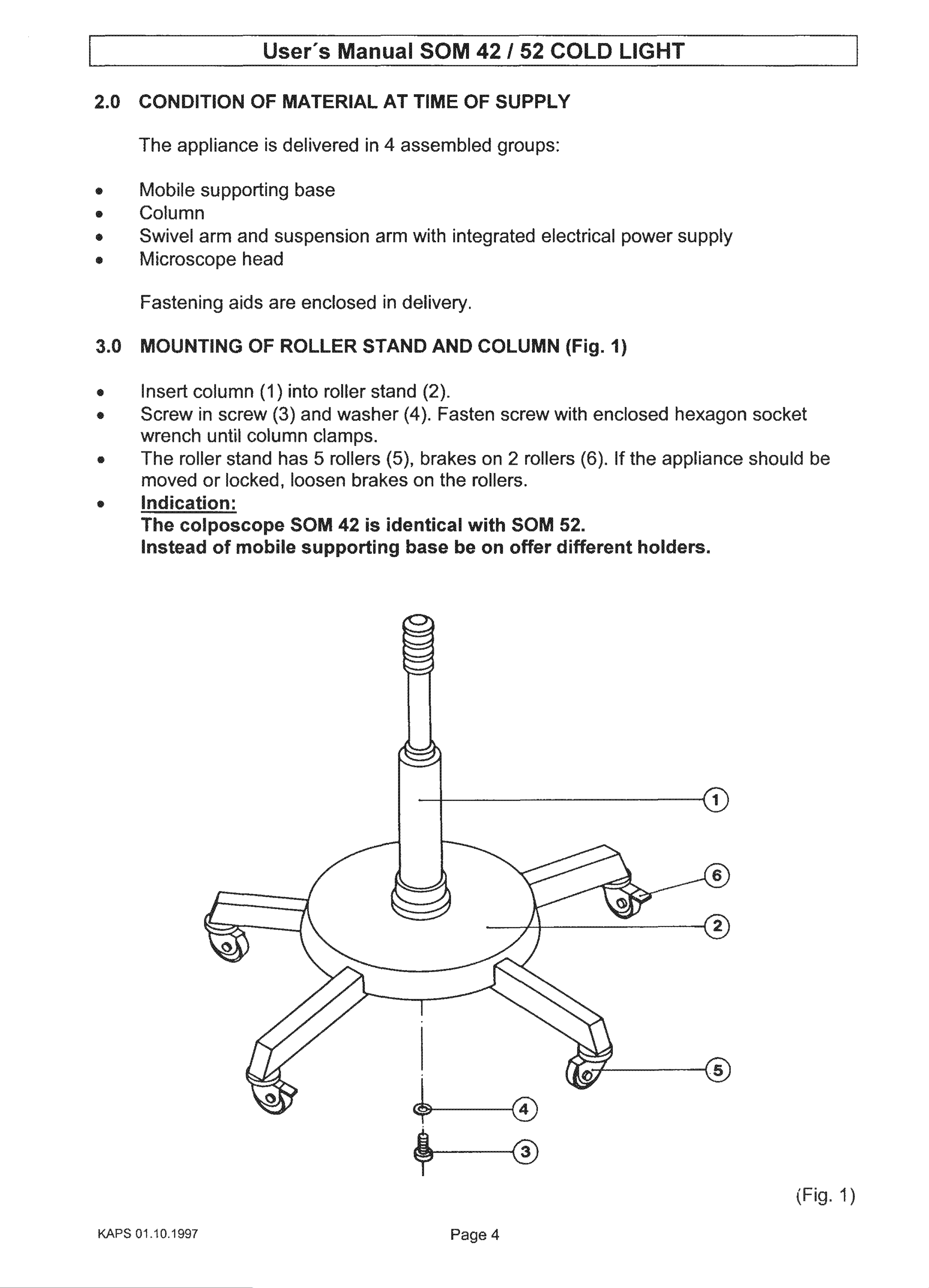

2.0

CON

he

appliance

Mobile

Column

ITION

OF

is

MA

delivered

supporting

base

IA

in

4

assembled

F

Y

SU

groups:

3.0

Swivel

arm

Microscope

Fastening

MOUNTING

aids

and

head

suspension

are

OF

enclosed

arm

in

STAND

with

delivery.

AN

integrated

6)

UMN

electrical

power

(Fig.

4)

supply

9

e

9

nsert

Screw

wrench

he

moved

he

column

in

screw

until

roller

or

colposcope

stand

locked,

(1)

column

into

(3)

and

has 5

loosen

SOM

roller

stand

washer

clamps.

rollers

brakes

42

is

(5),

identical

(2).

(4).

Fasten

brakes

on

the

screw

on

2

rollers

rollers.

with

SOM

with

enclosed

(6).

52.

If

the

hexagon

appliance

socket

should

be

instead

of

supporting

mobile

~

base

be

on

offer

differ

ent

holders.

©

©

KAPS

01.10.1997

Page

4

(Fig.

1)

9

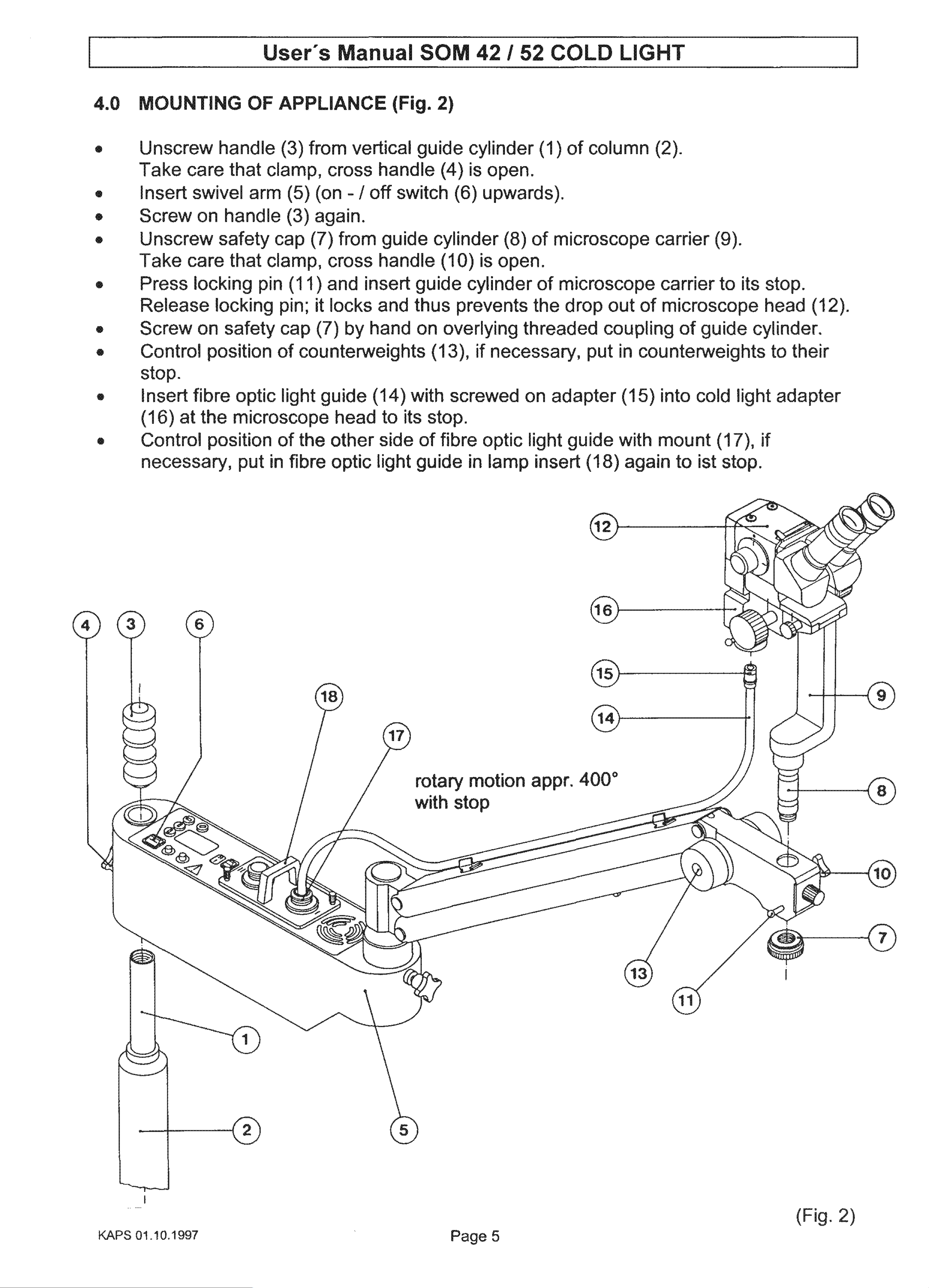

Unscrew

ake

care

ser's

handle

that

clamp,

(3)

Manual

IANC

from

cross

vertical

handle

(Fig.

SOM

guide

2)

(4)

42

/

cylinder

is

open.

52

(1)

a é

of

column

(2).

9

9

Unscrew

ake

ress

telease

care

locking

а

rm

ndle

safety

that

locking

cap

clamp,

pin

pin;

(5)

(3)

(on

again.

(7)

(11)

it

-

/

off

from

cross

and

insert

locks

-

switch

guide

cylinder

handle

and

guide

thus

(6)

(10)

is

cylinder

prevents

upwards).

(8)

of

microscope

open.

of

the

drop

carrier

microscope

out

of

carrier

microscope

(9).

to

its

stop.

head

(12).

9

9

9

e

Screw

Control

stop.

Insert

(16)

Control

at

on

safety

position

fibre

the

position

necessary,

cap

optic

of

light

counterweights

(7)

guide

microscope

put

of

in

fibre

the

by

hand

(14)

head

other

optic

side

light

to

its

on

overlying

(13),

with

screwed

stop.

of

guide

fibre

if

necessary,

optic

in

lamp

threaded

put

on

light

insert

adapter

guide

(18)

coupling

in

(15)

with

counterweights

into

mount

again

to

of

guide

cold

ist

cylinder.

light

(17),

stop.

if

to

their

adapter

|

18

©

©

Rs

CO

Sp,

я

rotary

with

stop

motion

appr.

400°

а

e

全

13

11

SD

KAPS

01.10.1997

-

5

Page

5

ser

s

Manual

SOM

42/52C

ον

as

oll

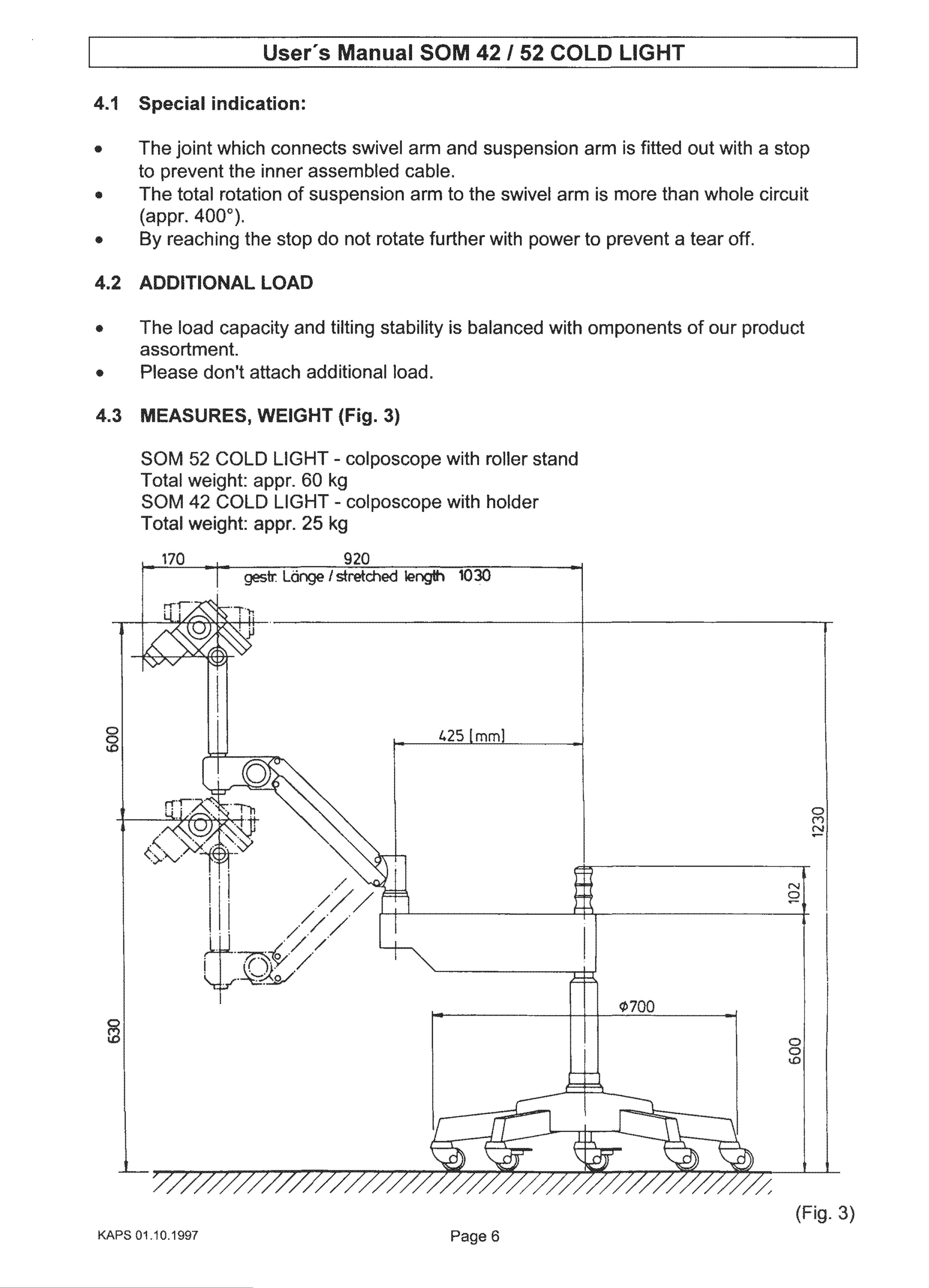

4.1

9

9

9

Special

to

(appr.

he

joint

prevent

he

y

total

reaching

indication:

which

the

rotation

connects

inner

of

400°).

the

stop

swivel

assembled

suspension

do

not

rotate

arm

and

cable.

arm

to

further

suspension

the

swivel

with

power

arm

arm

to

is

more

is

fitted

prevent

out

than

a

tear

with

whole

off.

a

stop

circuit

4.2

e

he

assortment.

9

4.3

lease

MEASURES,

ITIONA

load

don't

capacity

Å

and

attach

WEIGHT

tilting

additional

(Fig.

3)

stability

is

load.

balanced

with

omponents

of

our

product

SOM

otal

SOM

otal

170

52

weight:

42

COLD

COLD

weight:

LIGHT

appr.

LIGHT

appr.

-

Lange

60

25

-

colposcope

kg

-

colposcope

kg

920

/

stretched

with

with

length

roller

holder

1030

stand

600

630

KAPS

01.10.1997

Page

6

に 1

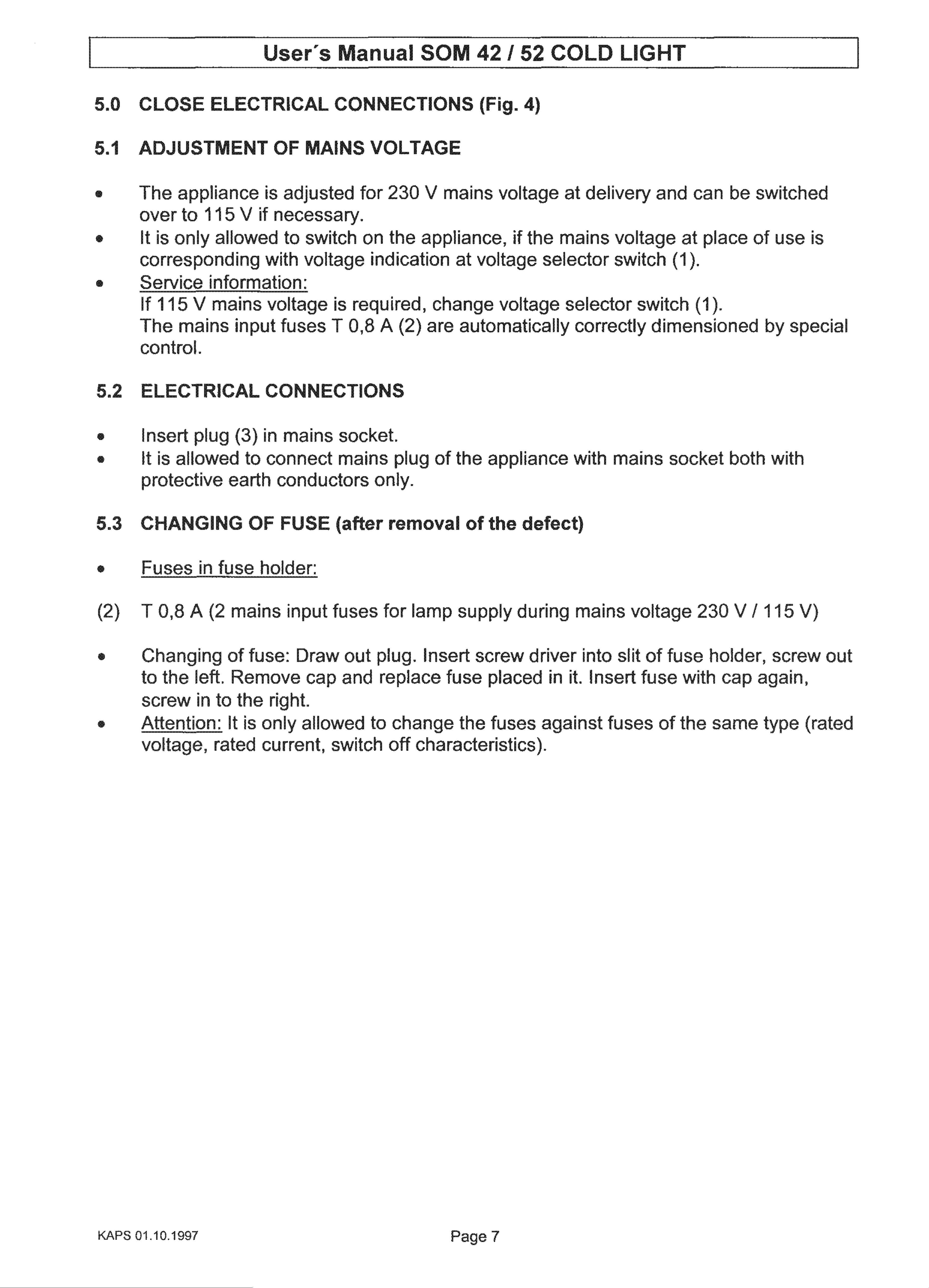

5.0

5.1

©

>

ADJUS

he

over

S

appliance

to

115

ο,

ná

NT

V

if

OF

is

adjusted

#

+

AL

MAINS

CONN

necessary.

V

for

230

AG

IONS

V

(Fig.

mains

4)

voltage

at

delivery

and

can

be

switched

It

correspond

Service

If

control.

is

115

he

only

information:

V

mains

>

mains

all

owed

ing

input

IC

to

with

switch

voltage

voltage

fuses

CONN

T

on

indication

is

required,

0,8

>TIONS

A

the

(2)

appliance,

at

voltage

change

are

automatically

if

voltage

the

selector

mains

voltage

switch

selector

correctly

at

place

(1).

switch

(1).

dimensioned

of

use

by

is

special

5.3

nsert

tis

allowed

protective

CHANGING

Fuses

plug

in

earth

fuse

(3)

in

to

OF

holder:

mains

connect

conductors

FUSE

socket.

mains

(after

plug

only.

removal

of

the

appliance

of

the

with

defect)

mains

socket

both

with

(2)

Changing

to

screw

Attention:

0,8

the

A

(2

left.

in

of

to

It

mains

input

fuse:

temove

the

is

right.

only

fuses

Draw

cap

out

and

allowed

for

plug.

lamp

Insert

replace

to

change

supply

screw

fuse

the

placed

fuses

during

driver

in

it.

against

mains

into

slit

Insert

fuses

voltage

of

fuse

fuse

with

of

the

230

V

holder,

cap

same

/

115

V)

screw

again,

type

out

(rated

voltage,

rat

ed

current,

switch

off

characteristics).

KAPS

01.10.1997

Page

7

ser

s

Man

$

>

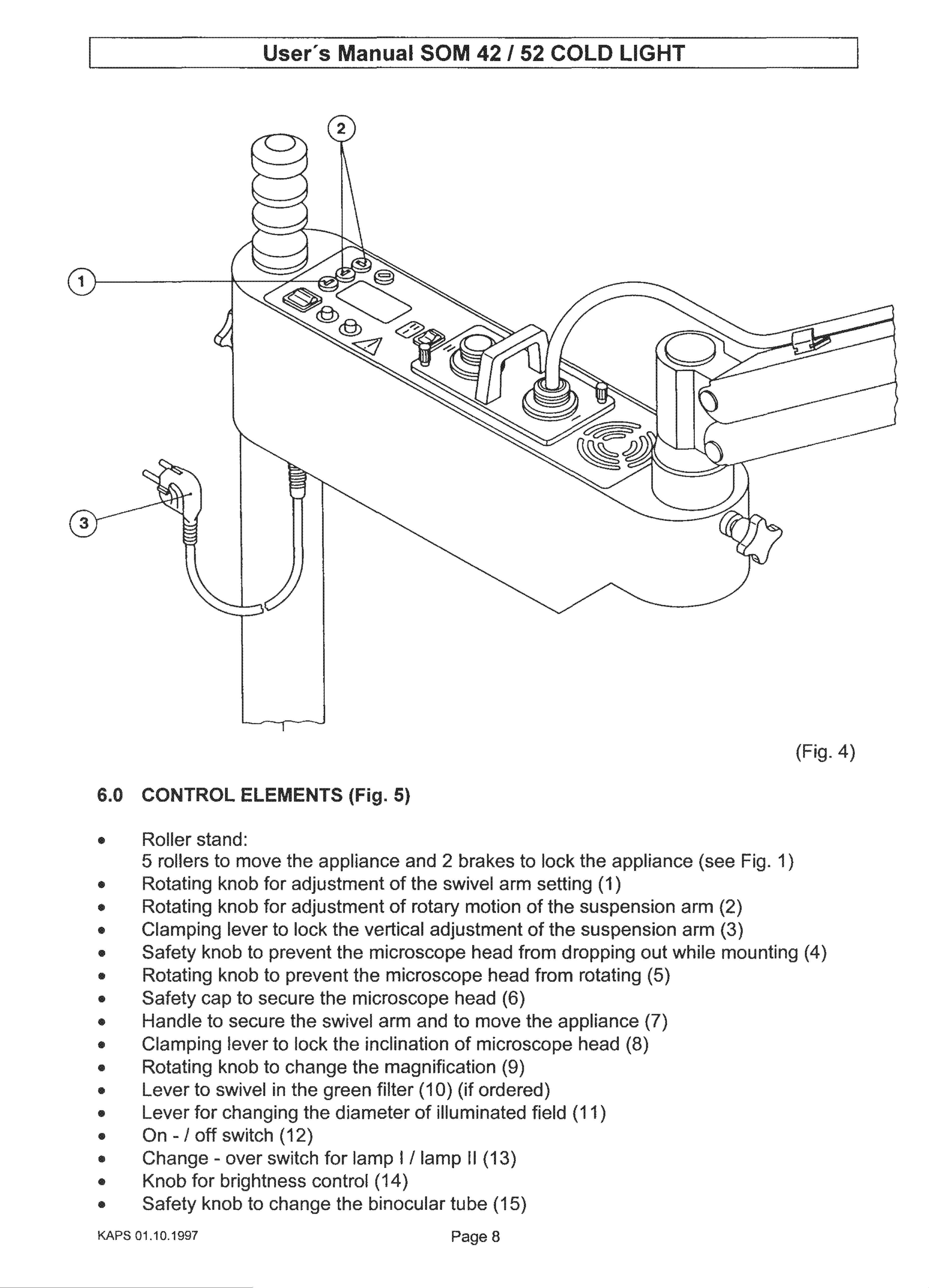

6.0

9

CONTR

Roller

5

rollers

.otating

ο

stand:

to

knob

move

for

the

adjustment

NTS

(Fig.

appliance

5)

and

of

the

2

swivel

brakes

arm

to

lock

setting

the

(1)

appliance

(see

Fig.

1)

0 © ϐ

© в e

© ©

A

ο

Clamping

Sa

Safety

andle

ating

fety

tating

mping

O

©

knob

cap

to

knob

lever

to

knob

to

secure

lever

for

prevent

to

secure

adjustment

to

to

lock

prevent

the

the

lock

swivel

the

the

the

microscope

the

of

vertical

microscope

i

microscope

arm

inclination

rotary

adjustment

and

motion

head

to

of

of

of

head

head

(6)

move

microscope

from

the

the

the

from

suspension

suspension

dropping

rotating

appliance

head

out

(8)

while

(5)

(7)

arm

arm

(2)

(3)

mounting

(4)

6 © 8

68

e

Rotating

Lever

Lever

On

Change

Knob

to

for

-

/

off

for

knob

swivel

-

brightness

to

changing

switch

over

switch

change

in

the

(12)

the

green

the

control

diameter

for

lamp

magnification

filter

|

(14)

(10)

of

/

lamp

illuminated

(if

ordered)

H

(13)

(9)

field

(11)

è e

KAPS

Safety

01.10.1997

knob

to

change

the

binocular

tube

Page

(15)

8

Knob

to

adjust

the

ser's

eye

Manual

distance

SOM

(16)

(straight

42

/

52

tube)

C

ss

SÉ,

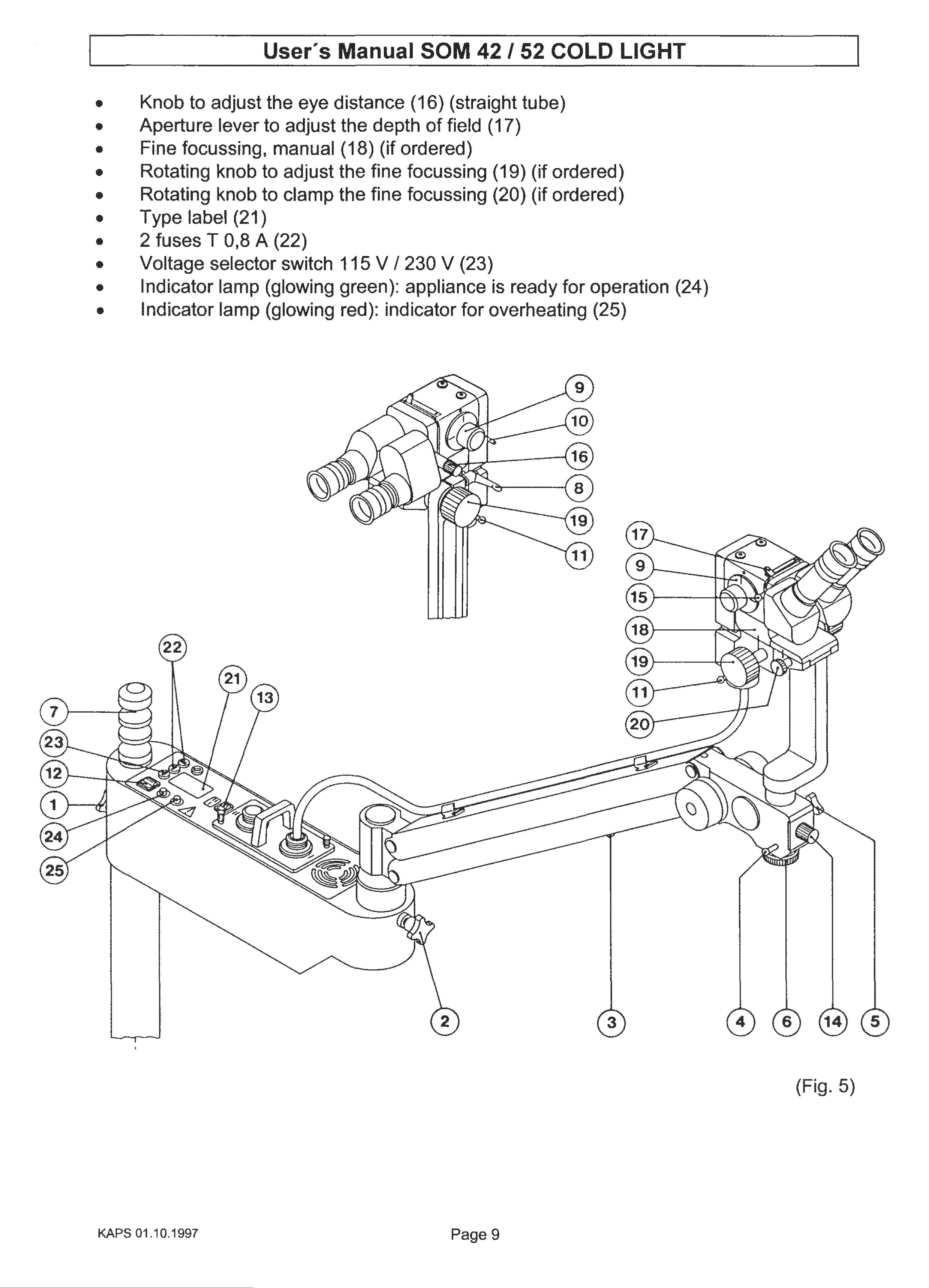

Aperture

Fine

focussing,

otating

totating

ype

2

fuses

Voltage

label (21)

T

selector

lever

knob

knob

0,8

to

to

to

A

adjust

manual

adjust

clamp

(22)

switch

the

depth

(18)

the

the

115

fine

fine

V

(if

ordered)

focussing

focussing

/

230

of

field

V

(17)

(19)

(20)

(23)

(if

(if

ordered)

ordered)

Indicator

indicator

lamp

lamp

(glowing

(glowing

green):

red):

appliance

indicator

for

is

overheating

ready

for

operation

(25)

(24)

7

23

22

21

13

11

20

(12)

©

s

>

S

=

©

|

KAPS

01.10.1997

Page

9

Loading...

Loading...