Page 1

KT-400

Ethernet Four-Door Controller

Installation Manual

DN1726-0811

Page 2

Page 3

KT-400 Ethernet Four-Door Controller Installation Manual

Table of Contents

Pre-Installation Information ......................................................................................................................... 1

Copyright Information ............................................................................................................................................. 1

Safety Instructions ..................................................................................................................................................1

Technical Support ....................................................................................................................................... 2

Compliance Specifications .......................................................................................................................... 3

FCC & IC Compliance ................................................................................................................................. 3

UL Compliance ........................................................................................................................................... 3

UL 294 Compliance Notice ......................................................................................................................... 3

UL 1076 Compliance Notice ....................................................................................................................... 3

Overview ..................................................................................................................................................... 5

Compatible with all EntraPass Special, Corporate and Global Editions ..................................................... 5

Multiple Configuration Options .................................................................................................................... 5

Four Onboard doors .............. .... ... ....................................... ... ... ... .... ... ... ... .... ... ... ... ..................................... 5

Communication Ports .................................................................................................................................. 5

IP Connectivity .......................................... ... ... ....................................... ... .... .............................................. 5

Inputs .......................................................................................................................................................... 6

Lock Outputs ............................................................................................................................................... 6

Relay Outputs ............................................................................................................................................. 6

Reader Outputs ........................................................................................................................................... 6

Reader Interfaces ....................................................................................................................................... 6

Elevator Interface ........................................................................................................................................ 6

Alarm Panel Interface ................................................................................................................................. 6

Automatic Port Detection .......... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ..................................... 6

Downloadable Firmware ................. ... .... ... ... ... .... ... ... ... ... .... ... ... .................................................................. 7

Trouble and Reporting .................... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ............................................................... 7

Visual Status Indicators (LEDs) .................................................................................................................. 7

Built-in SPI Expansion ................................................................................................................................ 7

System Architecture .................................................................................................................................. 11

VITAL LED Heartbeat Patterns ................................................................................................................. 14

Technical Specifications ........................................................................................................................... 15

Electrical Specifications ........ .... ... ... ....................................... ... ... .... ... ... ... ................................................ 16

KT-400 Ethernet Four-Door Controller Models, Expansion Modules Models ........................................... 16

Models Information ................................................................................................................................... 18

Installing the KT-400 Ethernet Four-Door Controller ................................................................................. 19

Preparing to Install the KT-400 Ethernet Four-Door Controller ............................................................................ 19

Physical Installation .............................................................................................................................................. 19

Earth Grounding ............................................. ...................................................................................................... 19

Door Locking Devices ........................................................................................................................................... 19

Hooking Up Inputs ................................................................................................................................................ 20

Connect readers and keypads ............................................................................................................................. 20

Relay Controlled Outputs ............................... ... ................................................................................................... 21

Auxiliary Outputs .................................... ...................................................................... ........................................ 21

Tamper Protection ............................................................................................. .. .................................................21

Connecting the KT-400 Ethernet Four-Door Controller ............................................................................. 22

Connecting the VC-485 or the USB-485 to the RS-485 Bus ................................................................................22

Connecting over Corporate Network (LAN) ................................................ ............. ......... .......... ......... .......... .......... . 23

Powering the KT-400 Ethernet Four-Door Controller ............. ... ... .... .......................................... ... ... ... ...... 23

SPI Expansion Port ................... ... ... ... .... ...................................... .... ... ... ... .... ... ......................................... 24

Important Installation Rules about Expansion Modules ................................................ ... ... ... .... ... ... ... ... ... 25

Troubleshooting ........................................................................................................................................ 29

Default initialization ................................................................................................................................... 30

How to reset the KT-400 Ethernet Four-Door Controller for Factory Default DHCP mode .................................. 30

KT-400 Ethernet Four-Door Controller Maintenance Recommendations ................................................. 31

Configuring the KT-400 Ethernet Four-Door Controller with the Web Configuration Page ....................... 32

Optional Documentation .......................................................................................................................................32

DN1726-0811

iii

Page 4

Configuring the KT-400 Ethernet Four-Door Controller with the KT-Finder .............. ................................ 33

Installation Checklist ................................................................................................................................. 37

Inputs and Outputs Assignments Sheet .................................................................................................... 38

iv

DN1726-0811

Page 5

KT-400 Ethernet Four-Door Controller Installation Manual

Pre-Installation Information

To the Installer: If you are familiar with the installation, you can use the installation checklist on page 37 with

the symbol.

Copyright Information

Copyright © 2008 Tyco International Ltd. and its Respective Companies. All Rights Reserved. All specifications were

current as of publication date and are subject to change without notice. EntraPass, Kantech and the Kantech logo are

trademarks of Tyco International Ltd. and its Respective Companies.

Safety Instructions

Important: NEVER INSTALL THE EQUIPMENT DURING A LIGHTNING STORM!

This equipment, KT-400 Ethernet Four-Door Controller, shall be used installed and used within an environment that provides

the pollution degree max 2 and over voltages category II NON HAZARDOUS LOCATIONS, INDOOR only. The equipment is

FIXED and PERMANENTLY CONNECTED and is designed to be installed by Service Persons only; [service person is defined

as a person having the appropriate technical training and experience necessary to be aware of hazards to which that person

may be exposed in performing a task and of measures to minimize the risks to that person or other persons.] The equipment is

installed in a metallic cabinet that meets the applicable requirements for a FIRE ENCLOSURE.

1. The connection to the mains supply must be made as per the local authorities rule s and regulations: In the UK as per

BS6701. An appropriate disconnect device must be provided as part of the building installation. Where it is not possible to rely

on the identification of the NEUTRAL in the AC MAINS SUPPLY, the disconnecting device must disconnect both poles

simultaneously (LINE and NEUTRAL).

2. AVOID setting up the equipment near heaters, air conditioners, ventilators, and/or refrigerators;

DO NOT select a place that exposes your controller to direct sunlight, excessive heat, moisture, vapors, chemicals or dust.

3. If during the installation a knockout on the cabinet is removed, it is the installer's responsibility to ensure that the same

degree of protection for the cabinet is provided by the use of bushings, fittings, ad eq u ate sealant, etc.

4. The metallic cabinet must be secured to the building structure before operation. Use four (4) stainless steel tapping

screws #8, 32 mm (1.25 in) to mount the cabinet.

5. The ground connection must be as shown within the included diagram, or equivalent.

6. Internal wiring must be routed in a manner that prevents:

- Excessive strain on wire and on terminal connections;

- Loosening of terminal; connections;

- Damage of conductor insulation.

7. It is the end-user and/or installer's responsibility to ensure that the disposal of the used batteries is made according to the

waste recovery and recycling regulations applicable to the intended market.

8. There are no serviceable parts within the equipment; For any issues regarding the equipment please contact your

installer.

9. DISCONNECT POWER BEFORE SERVICING.

DN1726-0811

1

Page 6

Technical Support

For technical assistance with the KT-400 Ethernet Four-Door Controller and other Kantech products, contact technical

support, Monday to Friday. See the following table for the technical support phone numbers.

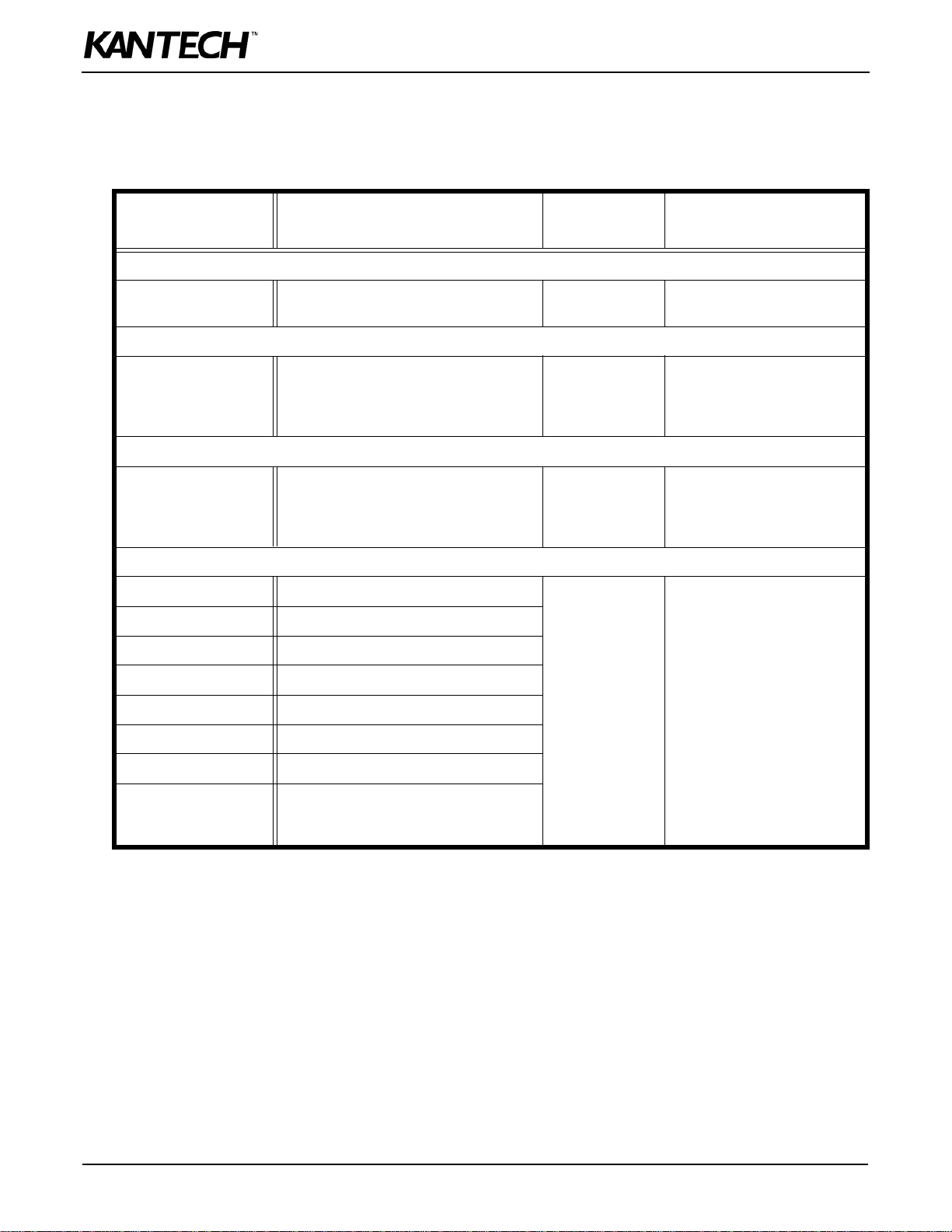

Country/Region Phone Numbers

North America Toll Free +888 222 1560 (GMT -05:00)

US and Canada

Argentina

Singapore

Europe Toll Free +800 CALL TYCO / +800 2255 8926 (GMT +01:00)

Bahrain +800 04127

France +33 04 72 79 14 83

Greece +00 800 31 22 94 53

Direct: +450 444 2030

Fax: +450 444 2029

Latin America (GMT -03:00)

Direct: +5411 4717 2929

Direct: +5411 4717 1320

Direct: +5411 4717 5525

Fax: +5411 4717 1060

Asia (GMT +08:00)

Direct: +65 6319 9820

Fax: +65 6319 9821

Direct: +65 6389 8297

Fax: +65 6389 8292

Support

Hours

8:00 to 20:00 kantechsupport@tycoint.com

9:00 to 18:00 ingenieria@tycoint.com

8:30 to 18:00

Email

swhuin@tycoint.com

wtooh@tycoint.com

Russia +8 10 800 2052 1031

Spain +900 10 19 45

Turkey +00 800 31 92 30 37

United Arab Emirates +800 0 31 0 7123

+44 08701 ADT SUP / 44 08701 238 787

United Kingdom

Direct: +31 475 352 722

Fax: +31 475 352 725

8:00 to 18:00 tfsemea.support@tycoint.com

2

DN1726-0811

Page 7

KT-400 Ethernet Four-Door Controller Installation Manual

Compliance Specifications

FCC & IC Compliance

This device complies with Part 15 of the FCC rules Class A. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received including

interference that may cause undesired operation. This class A digital apparatus meets all requirements of the Canadian

Interference Causing Equipment Regulations. The KT-400 Ethernet Four-Door Controller is also compliant with

EN55022:1998, amendment 1:1995, Class A.

UL Compliance

To comply with UL listings, the following requirements must be met:

• Use of a UL listed computer

• Use of UL listed readers (Wiegand 26 and 34 bits, mag stripe 26 and 34 bits, XSF 39 bits have been tested and found to

comply)

• Use of a UL recognized tamper switch on every housing cabinet for the KT-400 Ethernet Four-Door Controller

• Do not use the SmartLink option

• Do not use a 240 VAC transformer (not UL listed)

• Use only UL listed cables

• Use only UL listed adaptors

• Use only a UL listed transformer Hammond BF2F such as Kantech part number TR1675 (Available through Kantech

distributors or dealers, please refer to the Technical Support contact information on page 2 to obtain the specific

transformer)

Note: All circuits are power limited.

UL 294 Compliance Notice

• IP Connectivity: Only for supplementary use when planning to install the KT-400 Ethernet Four-Door Controller with a

UL 294 access control system.

• Use only UL 294 or UL 1076 listed power supply

• Connect Kantech part number KT-ACPW-LED status indicator to the 16 VAC black terminals of the KT-400

• Use Kantech part number KT-BATT-12 battery, see Note.

Note: Backup battery provides operation of up to 12 hours but has been tested for 4 hours per Section 33 of UL 294,

fifth edition.

UL 1076 Compliance Notice

• The KT-400 is UL 1076 Listed as a Commercial Proprietary Control Unit Accessory and Proprietary Burglar Alarm

Unit (Section 83.2), with EntraPass and Redundant Server, alarm system features, KT-300 Controllers, ioProx

Proximity readers, and TRex request to exit devices – othe r sensor devices (temperature, water level, etc.) may

be used as long as they are also UL 1076 Listed.

• The EntraPass and Redundant Server shall be running at all time, and manned 24 hours a day, 365 days a year

– The EntraPass and Redundant Server will each have their own operator workstation.

• Data processing equipment and office appliance and business equipment used as central supervisory equipment

station shall be listed to Information Technology Equipment - UL 60950.

• Should the EntraPass and/or Redundant Server be replaced, a UL 60950 listed computer must be used.

• The following recommended system requirements apply to the EntraPass Server, Redundant Server, Video Vault,

Card Gateway, SmartLink, and Workstation:

• Operating Systems: Windows® 2000/XP/2003 Standard and Enterprise Server Editions/Vista

• Processor: Pentium IV at 1.8 GHz

DN1726-0811

3

Page 8

• 1 GB RAM

• Minimum free hard disk space: 20 GB

• Color depth: 24-bit (16 million colors), required for Video Integration only

• Screen resolution: 1024 x 768

• Graphic adapter card: 32 MB

• 48X CD-ROM drive

• Network Interface card: 10/100 Base-T network adaptor

Note: Actual requirements may vary based on your operating system and configuration.

• The Central Supervisory Equipment shall employ supply lin e transient protection comply ing with the Standard for

Transient Voltage Surge Suppressors, UL 1449, with a maximum marked rating of 330 V.

• The Central Supervisory Equipment shall employ signal line Transient protection complying with the Standard for

Protectors for Data Communications and Fire Alarm Circuits, UL 497B, with a maximum marked rating of 50 V.

• The Central Supervisory Equipment shall employ that communication circuits and network components

connected to the telecommunications network shall be protected by secondary protectors for communication

circuits. These protectors shall comply with the Standard for Secondary Protectors for Communications Circuits,

UL 497A. These protectors shall be used only in the protected site of the telecommunications network.

• The Central Supervisory Equipment shall be installed in a temperature controlled environment. A temperature

controlled environment is defined as one that can be maintained between 13° - 35°C (55° - 95°F) by HVAC

system. Twenty-four hours on standby power shall be provided for the HVAC system. The standby power system

for the HVAC system may be supplied by an engine driven generator alone. A standby battery is not required to

be used.

• A marking to identify the application and signaling function of the product is located on the inside of the unit (inner

door sticker).

• For certified commercial proprietary control unit accessory applications, the requirements of UL 1076,

Commercial Proprietary Control Unit Accessory also apply.

• Use Kantech part number KT-3LED-PLATE 3-color LED indicators mounted on single plate when the KT-400 is

configured with the (APOU/ALVY) KT-NCC in an EntraPass Global Edition system for remote alarm monitoring.

Refer to the KT-NCC Installation Manual, DN1611 for additional details.

• The reader(s), that is(are) designated to arm or disarm the al arm system, must be w ithin the secured sid e of the

customer premises.

• The following Kantech readers have been validated by UL for the UL 1076 Standard: P225W26, P225KPW26,

P225XSF, P225KPXSF, P325W26, P325KPW26, P325XSF, P325KPXSF and P600.

Note: All readers can be ordered with or without the following suffixes: BEI, BEI-SE, GRY or GRY-SE.

• The KT-400 Ethernet Four-Door Controller is UL 1076 listed when used with the (APOU/ALVY) KT-NCC (Network

Communications Controller).

• All alarms shall be reported and acknowledged in the following priority:

Note: To set these priorities, please adjust the Event Parameters, found in EntraPass System

1. Fire alarm and industrial supervision where a risk of injury to persons, or damage or destruction of property may be

involved

2. Hold-up or panic alarm

3. Burglar alarm

4. Watchman tour (Guard tour)

5. Fire-alarm supervision

6. Burglar-alarm supervision

7. Industrial supervision where a risk of injury to persons, or damage or destruction of property will not be involved.

4

DN1726-0811

Page 9

KT-400 Ethernet Four-Door Controller Installation Manual

Overview

The KT-400 Ethernet Four-Door Controller is designed to meet the highest standards of access control and point

monitoring applications. Here are the features of the KT-400 Ethernet Four-Door Controller.

Compatible with all EntraPass Special, Corporate and Global Editions

The KT-400 Ethernet Four-Door Controller is compatible with all EntraPass Editions v4.01 and higher:

- EntraPass Special Edition

- EntraPass Corporate Edition with a Corporate Gateway

- EntraPass Global Edition with a Corporate Gateway

- EntraPass Global Edition with a Global Gateway

- EntraPass Global Edition with a KT-NCC Network Communications Controller

Multiple Configuration Options

- EntraPass: The KT-400 Ethernet Four-Door Controller can be configured with all EntraPass Editions v4.01 and

higher.

- Web Configuration Page: The Web Configuration Page is accessible through any browser. It can be used to verify

and configure the IP settings of the following Kantech devices: the KT-400 Ethernet Four-Door Controller, the KTNCC and the Kantech IP Link. Refer to the procedure “Configuring the KT-400 Ethernet Four-Door Controller with

the Web Configuration Page” on page 32 for further details.

- KT-Finder: The KT -Finder is a stand-alone application that can be used to verify and configure the IP settings of the

following Kantech devices: the KT-400 Ethernet Four-Door Controller, the KT-NCC and the Kantec h IP Lin k . Th e

Kantech device can be located within the same LAN or in a remote location over the internet. Refer to the procedure

“Configuring the KT-400 Ethernet Four-Door Controller with the KT-Finder” on page 33 for further details.

Four Onboard doors

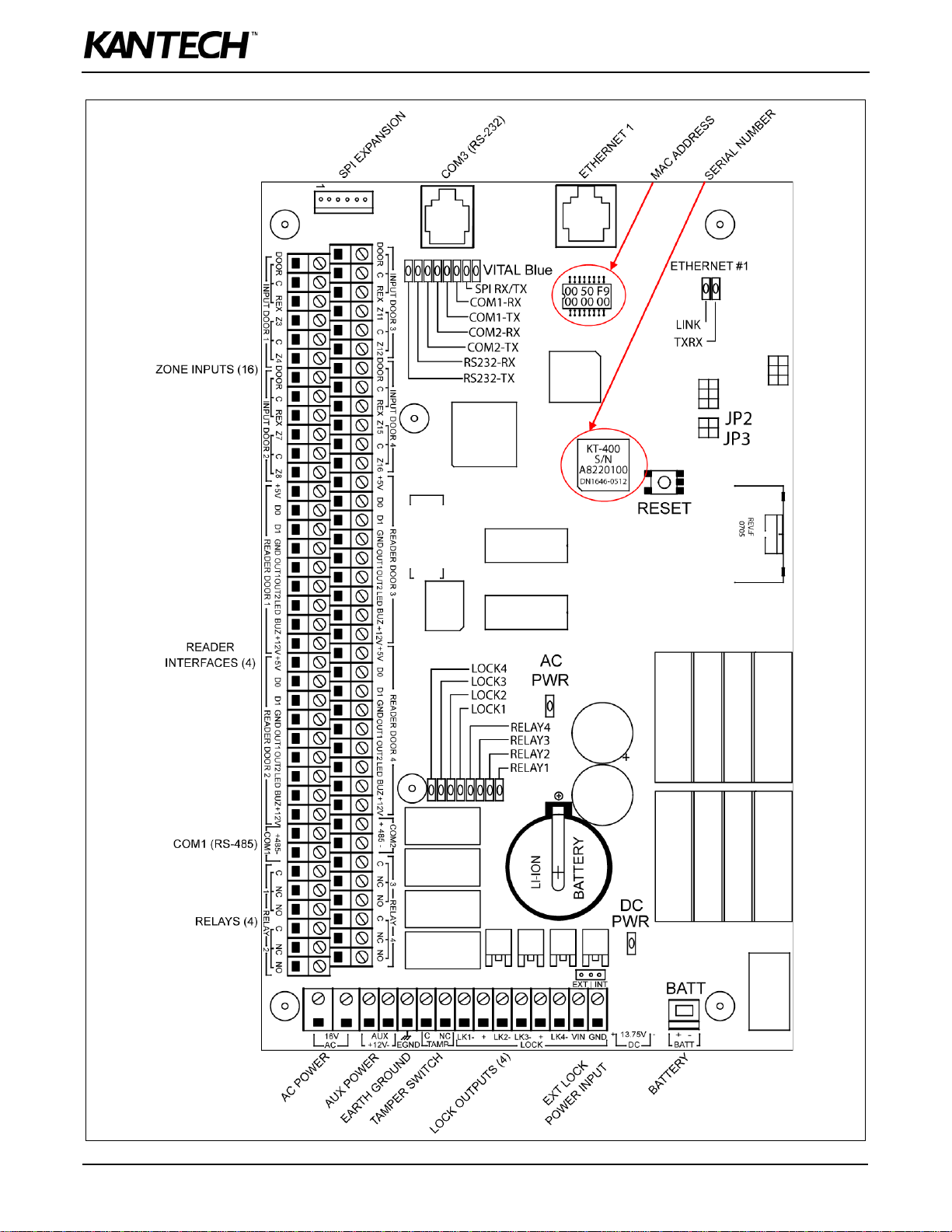

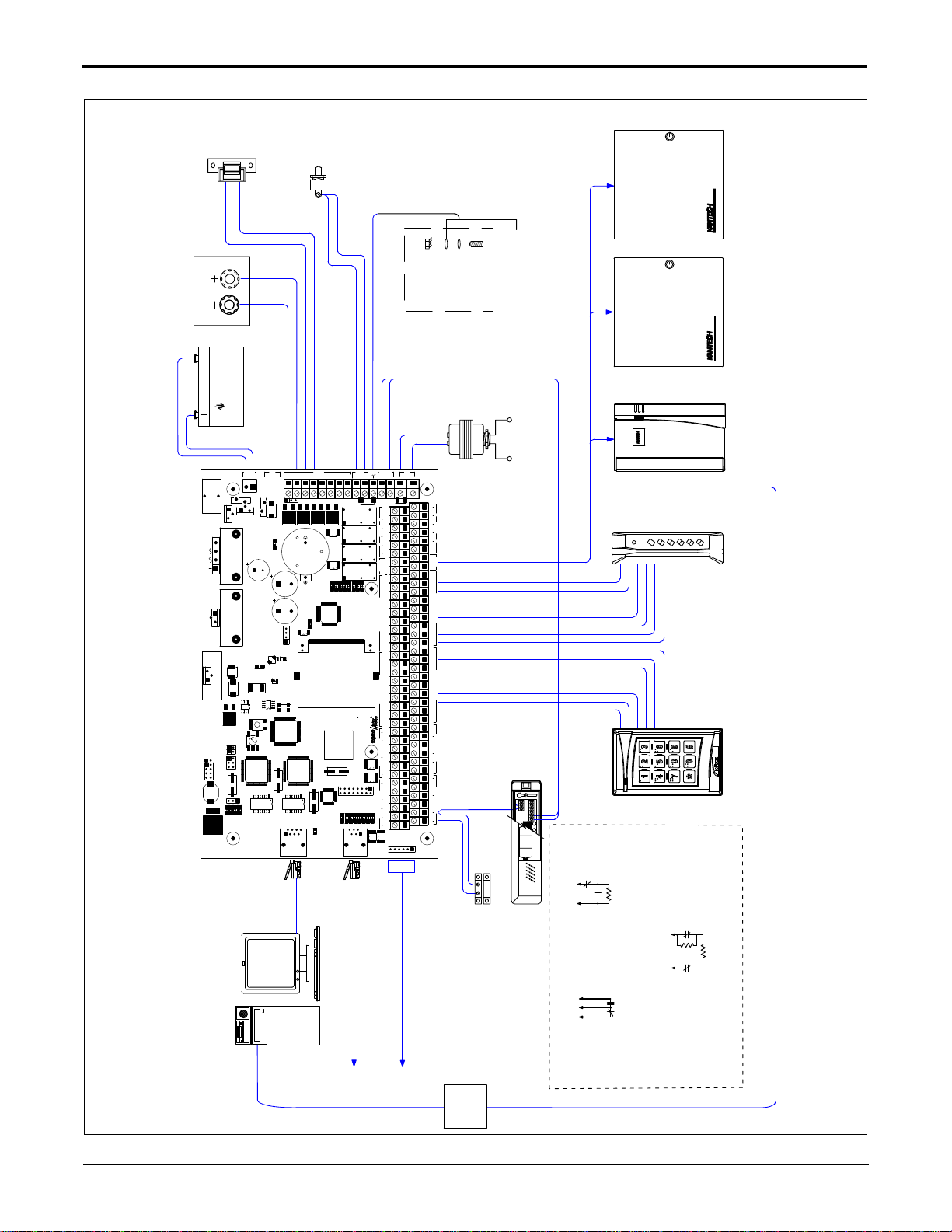

The KT-400 Ethernet Four-Door Controller is a full 4 onboard doors access controller. See Figure 1 for a description of

the PCB and Figure 2 for all the connection possibilities offered by the KT-400 Ethernet Four-Door Controller.

Communication Ports

• 1 10/100Base-T Ethernet for network connection with the EntraPass Gateway

• 1 RS-232 (COM3) for direct connection to the EntraPass Gateway and RS-485 communication with KT-100, KT-200,

KT-300 and KT-400

• 1 RS-485 (COM1) for RS-485 communication between the EntraPass Gateway and the KT-100, KT-200, KT-300 and

KT-400

• 1 SPI (Serial Peripheral Interface) port for expansion modules such as the KT-MOD-REL8 (8-Relay Outputs), the KTMOD-INP16 (16-Input) and the KT-MOD-OUT16 (16-Output)

IP Connectivity

The KT-400 Ethernet Four-Door Controller, when used with EntraPass Special Edition or a Corporate Gateway, can

report events, gather its configuration through an IP connection over the LAN (Local Area Network) and over the Internet

for a WAN (Wide Area Network). In this mode, the 1st or local controller becomes a “Master Controller” and can poll up

to 31 Kantech controller(s). The KT-400 Ethernet Four-Door Controller is compatible with all the controllers. Unlike the

other controllers, the KT-400 Ethernet Four-Door Controller asynchronously polls the controllers (KT-100, KT-200, KT-

300) and communicates with the EntraPass Gateway only when necessary. This significantly reduces the amount of

bandwidth required to operate your security system on the network.

• AES Encryption 128-Bit: The KT-400 Ethernet Four-Door Controller is extremely secure. It uses 128-bit AES

encryption to communicate with the Gateway which prev ents any hacking from the internet and ensures secure

communications when used over the internet on a wide area network (WAN).

DN1726-0811

5

Page 10

Inputs

There are 16 onboard inputs on the KT-400 Ethernet Four-Door Controller. Up to 240 more can be added through the

addition of expansion modules, such as the KT-MOD-INP16, for a total of 256 inputs. Each input can be individually

configured for one of the following application:

• Door contact (4 onboard)

• T.Rex (Request to Exit Detector) (4 onboard)

• Interlock (4 onboard)

• Floor Selection for Elevator Application

•Elevator Action

• External Alarm System Status (Armed / Disarmed)

• External Alarm System Alarm (Alarm / Secure)

• External Alarm System Zones

• Relays to trigger on each input in alarm event

• Zone shunt: Single or group of zones can be permanently or temporaril y 'shunted' to a secure state on the same

controller. Shunt method includes:

- Zone Shunt by another Zone - When a zone in alarm is programmed to shunt another zone / group of zones.

- Zone Shunt on Unlock - When a zone is temporarily frozen to its actual state (alarm or secured) after an access

granted.

- Manual Shunt - Operator can manually 'Shunt' a zone to a secure state.

- Disarmed Door Shunt - When alarm system is disarmed, some zones may be 'Shunted' to a secure state.

- Entry / Exit Delay Shunt - When a user is in the process of disarming / arming the alarm system and entry / exit

delay prevails, some zones may be 'Shunted' to a secure state.

• Arming / Disarming Request

• Postpone Arming Request

• Tamper switch input: The tamper switch is a non-programmable 'Fixed-Function' input. It is used to identify tampering of

the KT-400 cabinet.

Lock Outputs

There are 4 onboard lock outputs and they are supervised. The locking function can also be performed by any onboard

relay configured for this functionality.

Relay Outputs

There are 4 onboard relay outputs. Up to 256 relay output s can be supported th rough th e addition of exp ansion modul es

such as the KT-MOD-REL8.

Reader Outputs

There are 4 different possible outputs for each of the 4 onboard reader inte rfaces for a tot al of 16 programmable output s.

Reader outputs are used to give user visual and/or audible feedback on the ongoing access events.

Reader Interfaces

There are 4 onboard reader interfaces. They can be programmed for Wiegand or ABA (Clock and Data) readers.

Elevator Interface

The KT-400 Ethernet Four-Door Controller supports elevator interfacing with the addition of expansion modules such as

the KT-MOD-REL8, KT-MOD-INP16 and KT-MOD-OUT16.

Alarm Panel Interface

The KT-400 Ethernet Four-Door Controller supports alarm panel interfacing with the appropriate connections made

between zone inputs, relay outputs and the alarm system panel.

Automatic Port Detection

The KT-400 Ethernet Four-D oor Contro ller automatica lly detects the site communication speed set by EntraPass as well

as the communication port which can be IP (ETHERNET #1), RS-485 (COM1) or RS-232 (COM3).

6

DN1726-0811

Page 11

KT-400 Ethernet Four-Door Controller Installation Manual

Downloadable Firmware

The firmware program can be downloaded from any EntraPass workstation to the KT-400 Ethernet Four-Door Controller.

The firmware program, stored in the controller’s flash memory, is upgraded without having to change any parts.

Trouble and Reporting

The KT-400 Ethernet Four-Door Controller constantly supervises ac power and battery condition and reports “AC Lost”,

“Normal Battery”, “Low Battery”, “Battery Critical” or “No Battery”, status to the EntraPass system. Power outputs are

supervised and electronically protected against short-circuits and surges. Locking devices are also supervised for short

and open circuits.

Visual Status Indicators (LEDs)

The KT-400 Ethernet Four-Door Controller has multiple status indicators such as for troubleshooting, network activity,

power status and outputs activity. See Figure 1 for their locations.

- VITAL or Heartbea t: The VITAL blue LED indicates the communication status with EntraPass or the IP mode of the

controller. Refer to Table 1 for a descriptions of the heartbeat patterns.

- SPI Active (YELLOW): This LED signals activity on the SPI expansion port as well as communication between the

main CPU and the input/output CPU.

- COM1-RX, COM1-TX, COM2-RX, COM2-TX, RS232-RX and RS232-TX (YELLOW): The six serial port LEDs are

transmit/receive activity indicators. The COM2-RX and COM2-TX LEDs are for future use.

- LOCK1, LOCK2, LOCK3 and LOCK4 (RED): Each lock output (Open Drain) has an indicator which turns on each

time the corresponding output is activated.

- RELAY1, RELAY2, RELAY3 and RELAY4 (RED): Each relay output has an indicator which turns on each time the

corresponding relay is activated.

- AC PWR and DC PWR (GREEN): Theses LEDs are on when AC and DC power are present at the AC and/or DC

power input terminals.

- ETH1 LINK (GREEN): The LED is OFF when there is no Ethernet network or the cable is disconnected, and ON

when there is an Ethernet cable and network connection.

- ETH1 TXRX (YELLOW): The LED indicates network activity.

Built-in SPI Expansion

The KT-400 Ethernet Four-Door Controller allows connection of expansion modules in order to add outputs, like relays

and open drain outputs, and inputs. See Figure 10 and Figure 11 for an example with expansion modules.

- KT-MOD-REL8: The KT-MOD-REL8 is an 8-relay expansion module. Each relay is 3 Amps, 30 VDC Form C. The

module supports daisy-chaining which can add up to 32 KT-MOD-REL8 modules for a total of 256 relay outputs per

KT-400 Ethernet Four-Door Controller.

- KT-MOD-INP16: The KT-MOD-INP16 is a 16-zone input expansion module. The module supports daisy-chaining

which can add up to 15 KT-MOD-INP16 for a total of 240 external inputs per KT-400 Ethernet Four-Door Controller.

The KT-400 Ethernet Four-Door Controller has 16 onboard inputs which gives a total of 256 inputs per controller.

- KT-MOD-OUT16: The KT-MOD-OUT16 is a 16-output expansion module. Each output is capable of 750 mA. It

gives the opportunity to address the need for external LED, lock, relay, piezo and buzzer control. The module

supports daisy-chaining which can add up to 16 KT-MOD-OUT16 modules for a total of 256 external open drain

outputs per KT-400 Ethernet Four-Door Controller.

Note: The expansion modules support daisy chaining which can add up to 32 KT-MOD-REL8 modules for a total of 256

external relays per KT-400 Ethernet Four-Door Controller. Combining input and output expansion modules gives the

flexibility to connect up to 256 inputs and 256 outputs.

DN1726-0811

7

Page 12

Figure 1: KT-400 Ethernet Four-Door Controller PCB View

8

DN1726-0811

Page 13

KT-400 Ethernet Four-Door Controller Installation Manual

10/100 BASE-T ETHERNET PORT

COMPUTER NETWORK

KT-300

KT-100

RS485 BUS (COM1)

TAMPER

NC

C

NC

Z3

NC DRY CONTACT

INPUT DEFINED OPTION

WITH DOUBLE EOL RESISTORS

INPUT DEFINED

RED

BLACK

7 A/H MINIMUM

12V BATTERY

WITH EOL RESISTOR

INPUT DEFINED

DRY CONTACT

NO

OR NC

WITHOUT EOL RESISTOR

DRY CONTACT

NC

OR NO

1200-115200 BAUDS DEVICE

LOW SPEED RS232C

WITH INTEGRATED KEYPAD

IOPROX P325KP READER

BROWN

BLUE

RED (+12V)

BLACK

WHITE

GREEN

BROWN

BLUE

BLACK

RED (+5V)

WHITE

GREEN

POLARIS 2 READER

WITH INTEGRATED

KEYPAD

NO

NC

CZ3

(CONNECT 1K RESISTOR

WHEN INTERNAL PWR USED

12-13.75 VDC, 1 AMP MAX

DOOR LOCKING DEVICE

Z3C Z4

SPI EXPANSION PORT

OPTIONAL

INPUT CONFIGURATIONS

12-28 VDC POWER

LOCKING DEVICES SUPPLY

12-28 VDC, 3 AMPS MAX

OPTIONAL EXTERNAL

IF NOT USED)

OPTIONAL

TAMPER SWITCH

DOOR 1 CONTACT

DOOR 1

REQUEST TO EXIT DEVICE

12VDC PWR

R

R

RS485 from USB-485

USB

ACCESS CONTROL AND INTEGRATED SYSTEMS

TM

POLARIS

*

9 0

7 8

5 6

3 4

1 2

SEALED RECHARGEABLE

BATTERY

12 VOLT

7 AMP/HR

KT-400

ACCESS CONTROL AND INTEGRATED SYSTEMS

KT-300

KT-400

USB-485

0506

+12V-

COM2-RX

RS232-RX

INPUT DOOR 3

COPYRIGHT (C) 2007 TYCO INTERNATIONAL LTD.

RELAY4

RED

EGND

GND+5V

LK4-

LK2-LK1-

BUZ GND

4

GND+LK3-

LOCK

VIN

+

C

TAMP

NC

RS-232

ETHERNET #1

3

C NC NO C NC NO

RELAY

21

CCNCNO NCNO

RELAY

COM2

+485-

AUX

BUZ +12VD1+5V D0 GND GRN YEL

READER DOOR 2

RED BUZD1+5V D0 GRN YEL

READER DOOR 3

RED BUZ +12VD1D0 GRN YEL

READER DOOR 1

RED +12VD1+5V D0 GRN YELDOOR REX Z3 C Z4

INPUT DOOR 1

DOOR C REX Z7 C

Z8

INPUT DOOR 2

DOOR C REX Z11 C Z12 DOOR C REX C Z16

INPUT DOOR 4

READER DOOR 4

Z15

C

P/N:566-472K

REV.:E

+485-

COM1

+12V

HEARTBEAT

SPI ACTIVE

COM1-RX

COM1-TX

COM2-TX

RS232-TX

LOCK4

LOCK3

LOCK2

LOCK1

RELAY3

RELAY2

RELAY1

AC PWR

CPU JTAG

CPLD JTAG

RESET

SPI

LCD MODULE

ETH2 TXRX

ETH2 100

ETH1 TXRX

ETH1 100

GND

EXT | INT

16V

AC

13.75V

DC

+ -

BATT

+

-

DC PWR

Y6

U36

U35

Q56

Q53

Q51

PTF8

PTF7

PTF6

P8

L9

D22

HS3

HS2

HS1

Y3

Y1

Y2

Y4

U13

U26

U9

U20

U22

U2

U28

U24

U17

U6

U14

U5

U25

U7

U3

U23

TR2

TR1

SW2

RV1

R23

R12

Q3

Q4

Q6

Q7

PTF1

PTF3

P3

P6

P2

P1

P5

L1

L5

L4

L2

L3

K2

K4

K1

JP4

JP2 JP3

DL14

DL12

DL18

DL16

DL4

DL3

DL5

DL19

DL17

DL2

DL11

DL8

DL15

DL13

DL7

DL6

DL10

DL9

DL21

DL20

DL1

C27

C28

C29

BT1

P7

J2

J4

R5

D3

CON1

SW1

DL22

EARTH GROUND

CABINET

PEM

LOCKNUT

JUMPER JP4 ON EXT

JUMPER JP4 ON INT

120 VAC, 60 Hz IN

16 VAC, 75 VA OUT

CLASS 2, WIRE-IN

Figure 2: KT-400 Ethernet Four-Door Controller Inputs and Outputs View

DN1726-0811

9

Page 14

Figure 3: KT-400 Cabinet Model for North America

10

DN1726-0811

Page 15

KT-400 Ethernet Four-Door Controller Installation Manual

System Architecture

The KT-400 Ethernet Four-Do or Controller can be used through va rious si te applications w ith EntraPass Special Edition,

EntraPass Corporate Edition and EntraPass Global Edition.

Applications with EntraPass Special Edition and Corporate Edition with Corporate Gateway.

• Over the internet. See Figure 4.

• Over RS-232 with a USB-485. See Figure 5.

Application with EntraPass Global Edition and a Global Gateway.

• Over RS-232 with a VC-485. See Figure 6.

Application with EntraPass Global Edition and a KT-NCC.

• Over the internet with a KT-NCC. See Figure 7.

Application with EntraPass Special Edition, Corporate Edition and Global Edition.

• Over RS-232 straight from EntraPass RS-232 COM port. See Figure 8.

Figure 4: Over the Internet with EntraPass Special Edition and Corporate Edition with Corporate Gateway

DN1726-0811

11

Page 16

Figure 5: USB-485 with EntraPass Special Edition and Corporate Edition with Corporate Gateway

Figure 6: VC-485 with EntraPass Global Edition and Global or Corporate Gateway

12

DN1726-0811

Page 17

KT-400 Ethernet Four-Door Controller Installation Manual

Figure 7: Over the internet with a KT-NCC and EntraPass Global Edition

Figure 8: Over RS-232 straight from the EntraPass RS-232 COM port

DN1726-0811

13

Page 18

VITAL LED Heartbeat Patterns

Communication status and other vital controller parameters can be obtained from VITAL LED heartbeat patterns. It is

located near the RS-232 port (COM3), see Figure 1. This information is particularly useful when connecting the

controller to the rest of the EntraPass system. The fo llow ing table lists all conditions along with a brief d escription . Refer

to Table 3, if you must reset or change the communication mode of the KT-400 Ethernet Four-Door Controller.

Table 1: VITAL LED Heartbeat Patterns

Booting Up Steady

Factory Default DHCP Continuous LONG Pulses

Unable to Resolve DNS 2 LONG Pulses

Forced Default Static 3 LONG Pulses

DHCP Server Failed 4 LONG Pulses

Receive Broadcast Single 2.5 Sec. Burst

Card Read or Swipe

Hard Reset 4 SHORT Pulses

Corporate Gateway 3 SHORT Pulses

Global Gateway 1 SHORT Pulse

Fail Soft Continuous SHORT Pulses

Firmware Update 5 pulses / sec @ 50% duty cycle

Rebooting 10 pulses / sec @ 50% duty cycle

Single 0.5 sec burst, resume

previous flash

14

DN1726-0811

Page 19

KT-400 Ethernet Four-Door Controller Installation Manual

Technical Specifications

Type Description

Power input (KT-400) Transformer class 2, IN 120 VAC; OUT 16 VAC, 75 VA

Battery back-up (KT-BATT-12) 12 VDC, 7 Ah battery supervised, provides up to 12 hours of operation

Operating Temperatures From 2°C to 49°C (35°F to 120°F) indoor use only

Humidity Level 0 to 85% (relative humidity non-condensing).

Cabinet Dimensions

(High-Wide-Deep)

Cabinet Weight (KT-400) 4.0 kg (8.82 lb)

PCB dimension 22.86 cm (9 in) X 13.97 cm (5.5 in) X 5.20 cm (2.04 in)

Reader types Wiegand, proximity, ABA Clock and Data, bar code, magnetic, integrated keypad,

Reader power output 12 VDC and 5 VDC @ 175 mA max each, protected and supervised

Monitored points (inputs) 16 monitored points, single EOL (End of Line), double EOL, without EOL and

Points maximum wiring AWG #22 - 600 m (2,000 ft)

Door strike power 12 VDC, 250 mA max for KT-400 supervised

Reader outputs 16 outputs, 25mA max each, open collector outputs

Auxiliary outputs LEDs (LED, OUT1 and OUT2) and buzzer (Buz) for each individual door, 25mA max each,

Relay controlled output 4 onboard Form C Relay controlled outputs, 30 VDC, 3 Amps max each

Communication ports 1 x RS-232 with RJ-12, 1 x RS-485, 1 x Ethernet 10/100Base-T with RJ-45

Expansion port 1 x SPI 6-pin connector , bidirectional data exchange supported. Supplies 12 VDC, 500 mA

37.59 cm (14.8 in) x 30.48 cm (12.0 in) x 12.57 cm (4.95 in)

smartcard and others

1 fixed-function tamper switch input

open collector outputs

max shared with 12 VDC Auxiliary port

Auxiliary port 1 x Auxiliary 12 VDC, 500 mA maximum shared with SPI expansion port

Communication speed - Up to 115200 Bauds (automatic detection) over RS-232 and RS-485

- 10/100 Mb/s BaseT over Ethernet

Flash memory 16 MB for application storage

RAM memory 64 MB for application loading and running, protected by a Lithium-Ion battery for a

minimum of 75 hours

Network autonomy Distributed data and processing

Certifications / Listing EN55022, EN61000-6-1, EN61000-6-2

FCC: Class A

UL 294, UL 1076

DN1726-0811

15

Page 20

Electrical Specifications

OPEN COLLECTOR OUTPUTS MAXIMUM CURRENT

(T ypical)

LEDs (LED, OUT1 and OUT2) for each door reader 25 mA (each)

Buzzer (Buz) for each door reader 25 mA (each)

COMBINED MAXIMUM

CURRENT

OUTPUTS MAXIMUM CURRENT

1 for 12 VDC Auxiliary Power (11.2 to 13.75 VDC) polyswitch

protected, shared with SPI expansion port

4 for Controlled Readers (11.2 to 13.75 VDC) 500 mA

4 for Controlled Readers 5 VDC 400 mA

4 for Locks (11.2 to 13.75 VDC) when jumper JP4 is on INT

(internal)

4 for Locks (11.2 to 28 VDC) when jumper JP4 is on EXT

(external)

500 mA

1 Amp for KT-400

2 Amps for KT-400

3 Amp

KT-400 Ethernet Four-Door Controller Models, Expansion Modules Models, Related Documentation and Miscellaneous Items

Part number Description

KT-400 Ethernet Four-Door Controller Models

KT-400 KT-400 Ethernet Four-Door Controller, IP Ready with Accessory Kit in Metal Cabinet, see Table 2

KT-400-PCB KT-400 Ethernet Four-Door Controller PCB only, IP Ready with Accessory Kit, see Table 2

KT-400-CAB KT-400 Black Metal Cabinet with Lock and Keys, see Table 2

Expansion Modules Models

KT-MOD-INP16 KT-400 Expansion Module 16-Zone Inputs with SPI Cable 41 cm (16 in)

KT-MOD-REL8 KT-400 Expansion Module 8-Relay with SPI Cable 41 cm (16 in)

KT-MOD-OUT16 KT-400 Expansion Module 16-Output with SPI Cable 41 cm (16 in)

KT-MOD-CAB KT-400 Expansion Module Cabinet, Black, with SPI Cable 91 cm (36 in), Lock and Two Keys

KT-MOD-SPI16 KT-400 SPI Cable 41 cm (16 in) for SPI Interconnection within the Cabinet

KT-MOD-SPI36 KT-400 SPI Cable 91 cm (36 in) for SPI Interconnection between Cabinets

Related Documentation

DN1420 EntraPass Special Edition, Reference Manual - English version

DN1415 EntraPass Corporate Edition, Reference Manual - English version

DN1316 EntraPass Global Edition, Reference Manual - English version

DN1474 EntraPass Special Edition, Reference Manual - French version

16

DN1435 EntraPass Corporate Edition, Reference Manual - French version

DN1289 EntraPass Global Edition, Reference Manual - French version

DN1726-0811

Page 21

KT-400 Ethernet Four-Door Controller Installation Manual

Part number Description

DN1475 EntraPass Special Edition, Reference Manual - Spanish version

DN1436 EntraPass Corporate Edition, Reference Manual - Spanish version

DN1599 EntraPass Global Edition, Reference Manual - Spanish version

DN1514 EntraPass Special Edition, Reference Manual - German version

DN1598 EntraPass Corporate Edition, Reference Manual - German version

DN1597 EntraPass Global Edition, Reference Manual - German version

DN1684 EntraPass Special Edition, Reference Manual - Italian version

DN1683 EntraPass Corporate Edition, Reference Manual - Italian version

DN1682 EntraPass Global Edition, Reference Manual - Italian version

DN1796 Networking Basics, Application Note, English version

Dimensions Drawings

DN1846 KT-400-PCB Dimensions Drawing in DWG Format

DN1847 KT-400-PCB Dimensions Drawing in PDF Format

DN1848 KT-400-CAB Dimensions Drawing in DWG Format

DN1849 KT-400-CAB Dimensions Drawing in PDF Format

Miscellaneous Items

CBLK-10 Cable kit, RS-232 cable 30 m (100 ft) with RJ-12 connectors for PC to master KT-400, 740-1023

(DB9F to RJ-12) adaptor and 740-1041 (DB9M to DB25F) adaptor

USB-485 USB-485 interface, USB cable 0.9 m (3 ft) and USB drivers on CD-ROM

VC-485 VC-485 interface, RS-232 cable 3 m (10 ft) with RJ-12 connectors, 740-1012 (DB25F to RJ-12)

adaptor, 740-1022 (DB9F to RJ-12) adaptor and 740-1033 (DB25M to RJ-12) adaptor

KT-3LED-PLATE Three-color LED alarm indicator mounted on single plate

KT-ACPW-LED AC power LED indicator

KT-LOCK Keylock for cabinet with 2 keys

KT-SW1224 Internal Power Supply 12 VDC, 2 Amps, 24 Watts

KT-TAMPER Tamper switch for cabinet

DN1726-0811

17

Page 22

Models Information

• KT-400: Cabinet with one KT-400 for North America, up to three expansion modules can be installed in the cabinet,

• KT-400-PCB: KT-400 with parts,

• KT-400-ACC: Accessory kit,

• KT-400-CAB: Cabinet only for North America,

Table 2: Models Bills of Material

Item Description KT-400

(Notes 1,2)

KT-400 PCB 1 1 - -

Cabinet 1 - - 1

KT-400-ACC Accessory Kit 1 1 - -

Ground wire (PCB to cabinet) 1 1 - -

Ground wire (door to cabinet) 1 1 - 1

Tamper switch 1 - - -

Battery cable 1 - - -

Resistor 5.6K, 0.5W - - 32 -

Resistor 1K, 0.5W - - 4 -

Inner door sticker for North America,

DN1762, Figure 14

Installation Manual DN1725 - French 1 1 - -

Installation Manual DN1726 - English 1 1 - -

Note 1: The KT-400, KT-400-CAB models also include the KT-LOCK.

Note 2: The KT-400, KT-400-PCB models also include screws and locknuts.

1- - 1

KT-400-PCB

(Note 2)

KT-400-ACC KT-400-CAB

(Note 1)

18

DN1726-0811

Page 23

KT-400 Ethernet Four-Door Controller Installation Manual

Installing the KT-400 Ethernet Four-Door Controller

Preparing to Install the KT-400 Ethernet Four-Door Controller

Required to install KT-400 Ethernet Four-Door Controller

• For North America: AC transformer 120 VAC 60 Hz IN; 16 VAC, 75 VA OUT; class 2 (not included)

• One battery 12 VDC, 7 Ah (not included)

• Ground clamp (not included)

A visual inspection should be made when unpacking th e KT-400 Ethernet Four-Door Con troller . Any missing item/p art or

damaged component should be reported immediately.

Physical Installa tion

Check for ideal indoor location

Stay away from electrical or communication devices

The KT-400 cabinet has been designed to be mounted on a wall without any additional enclosures. The cabinet is large

enough to accommodate the battery backup supply and the necessary wiring connections for most applications. EMT

(Electrical Metallic Tubing) conduit knockouts are provided in 1.9 cm (0.75 in) on all sides of the cabinet.

The cabinet should be mounted indoors, in a secure location providing normal temperature and humidity, leaving 23 cm

(8 in) clear space around all sides and a minimum of 33 cm (13 in) clear space in front of the cabinet. The loca tion should

be easily accessible for servicing the equipment and it is recommended that controllers be located close to the controlled

doors.

Controllers must be located at a minimum distance of 2 m (6 ft) from any high voltage equipment or wiring and from

electrical equipment susceptible of generating electrical interference, at a minimum distance of 1 m (3 f t) from telepho ne

equipment or lines, and at a minimum of 8 m (25 ft) from any transmitting equipment. Physical access, using keys, on

controlled doors must be provided so that the KT-400 Ethe rnet Four-Door Controller can easily be accessed for servicing

in case of malfunction.

Earth Grounding

AWG #18 grounding wire to EGND

Since the KT-400 Ethernet Four-Door Controller uses high performance communication, proper grounding must be

provided to ensure proper operation.

An AWG #18 single conductor copper wire must be used to ground each controller to good earth ground as

per the local electrical code (be careful with ground loops). The ground clamp shou ld be locate d below any

other ground.

Door Locking Devices

Connect the door lock device to + and LK1-, (+ and LK2 -),

(+ and LK3- ) or (+ and LK4-)

Note: If you need additional power for ALL the external locks, you can use an

external +power supply. Connect the power supply to the VIN and GND

terminals and put jumper JP4 on EXT.

When jumper JP4 is on INT, the total maximum current draw is

1 Amp for KT-400 at 12 to 13.75 VDC, or

When jumper JP4 is on EXT, the total maximum current draw is

3 Amps at 12 to 28 VDC

Check for local “magnetic lock” regulations

LK1-, LK2-, LK3- and LK4- and + terminals are located near the battery

(BATT) terminals. The locking device outputs are controlled according to the end-user programmed parameters for

allowing access to or unlocking doors according to schedules and access levels. These d oors locking device output s can

operate DC powered locking devices such as electromechani cal strikes and can be con figured to operate fail-sa fe or failsecure (normal or reverse action).

Note: Use 1 K ohm EOL (End-of-Line resistor) between + and LK- terminals if not used.

DN1726-0811

19

Page 24

Warning: Controlled door locks may be governed by regulatory bodies and should always be installed according to local

regulations. In most instances, there are strict limitations to installing fail-secure devices and fail-safe locking devices

such as magnetic locks or other similar locking devices on doors used as emergency exits.

Hooking Up Inputs

Connect devices to inputs 1 to 16

Resistors for all inputs 5.6K ohm (if selected)

The KT-400 has an on-board capability of monitoring 16 input points

(expandable to 256 with expansion modules). Each onboard input is

supervised with or without end-of-line resistors (5.6K ohm). The

maximum distance of one line is 600 m (2,000 ft) with AWG #22 in a

single or double EOL configuration.

Note: Onboard Inputs can be defined with: none, single or double EOL

(End-of-Line) resistor(s) according to your EntraPass software

settings.

Inputs 1-2 are automatically reserved for the first controlled door.

The contact is assigned input 1 and the associated request-to-exit

detector as input 2. Inputs 5 and 6 are automatically reserved for the

second controlled door. The contact is assigned input 5 and the

associated request-to-exit detector as input 6. Inputs 9 and 10 are

automatically reserved for the third co ntrolled door. Inputs 13 and 14

are automatically reserved for the fourth controlled door. There is no

obligation to follow these rules but this standard convention

facilitates servicing.

Connect readers and keypads

READER CONNECTION TERMINAL WARNING

Connecting the red wire lead (or power lead) of a 5 VDC reader to

the 12 VDC terminal may damage the reader. See your reader

installation procedure for proper power connection. U p to 4 readers can be conne cted to a KT-400. They can be inst alled

on one door to control both entry and exit or on four separate doors operating independently to control one-way access.

The distance between the readers and the KT-400 varies by reader type (please consult the installation manual for

details). Auxiliary outputs provide visual and/or audible access operation feedback at the controlled door. Outputs

“READER DOOR 1 - OUT1 OUT2 LED & BUZ” are used for the first door, “READER DOOR 2 - OUT1 OUT2 LED &

BUZ” are used for the second door, “READER DOOR 3 - OUT1 OUT2 LED & BUZ” are used for the third door and

“READER DOOR 4 - OUT1 OUT2 LED & BUZ” are used for the fourth door.

20

DN1726-0811

Page 25

KT-400 Ethernet Four-Door Controller Installation Manual

Relay Controlled Outputs

The KT-400 provides four relay outputs RELAY1 to RELAY4 (3

Amps, 30 VAC/VDC). The KT-400 can be expanded up to 256

controlled outputs when using expansion modules.

• The KT-MOD-OUT16 module provides 16 outputs at a maximum of

750 mA per output.

• The KT-MOD-REL8 module provides 8 relay outputs at a maximum

of 3 Amps per relay.

Note: Since the KT-400 maximum output current draw on the SPI

expansion port is 500 mA when the 12V AUX terminals are not

used, an external power supply of 12 VDC, 2 Amps is required

when adding expansion modules to the same KT-400. See

“SPI Expansion Port” on page 24 for additional details

concerning the external power supply requirement for

expansion modules.

Auxiliary Outputs

Connect auxiliary outputs to readers and local warning

devices

Auxiliary outputs are used for visual and audible signal. They can

be activated according to input conditions or events and local

alarms. Auxiliary outputs “READER DOOR 1 to 4 - LED” provide

visual feedback of access operation, and auxiliary outputs “READER DOOR 1 to 4 - BUZ” can activate audible warning

devices, such as T-REX or reader buzzer, to signal door alarms.

T amper Protection

Install tamper switch on cabinet

A tamper switch must be installed on the unit to detect unauthorized cabinet opening.

The normally closed tamper switch must be connected to the dedicated tamper input, next to the EGND.

Note: The tamper switch is required for a UL listed installation.

DN1726-0811

21

Page 26

Connecting the KT-400 Ethernet Four-Door Controller

VC-485

(Preferred for Global Edition)

USB-485

(Preferred for Special Edition and

Corporate Edition)

RS232

GND

V+

GND

X- X+

RJ-12

V+

RECEIVE

TRANSMIT

PWR

RS-485

ORANGE

BLUE

WHITE

Up to 1.2 Km (4000 ft )

to the last controller

WHITE

BLUE

ORANGE

ORANGE

BLUE

WHITE

Max 30 m (100 ft)

DB25F

DB9F

VC-485

RS-232 / RS-485 CONVERTER

KANTECH SYSTEM INC.

Montreal - Canada

X+ X- GND

USB-485

RX

TX

PWR

USB

Powered from USB port

RS-485

DN1485-0302

To USB Port

To RS-232 Port

Max 0.9 m (3 ft)

POWER

GND V+

RS-232

GND

RS-485

X- X+

6 CTS WHITE

1 RTS BLUE

2 GND YELLOW

3 TX GREEN

4 RX RED

5 GND BLACK

RJ-12

Connecting the VC-485 or the USB-485 to the RS-485 Bus

Connect the RS-485 cable to (COM1) + 485 - and the RS-485 signal ground to the 12 VDC AUX - (negative)

Controllers are linked together through their RS-485 terminals. The maximum communication loop length is 1.2 km

(4,000 ft) using appropriate cabling. The RS-485 communication loop should be wired with Ethernet Category 3 double

twisted pair network cable or better. The RS-485 loop can operate from 1200 to 115200 Bauds under normal conditions.

Intermittent communication problems or erratic operation may require network speed drops to 9600 or 19200 Bauds.

Varying the network speed does not perceptibly change the operation speed of the system.

Note 1: Most installations should be set to 38400 Bauds.

Note 2: Connecting several KT-400 at a single point is not recommended neither are splitters or spider web (star) networks.

Note 3: If the 12 VDC - is already used, the RS-485 signal ground can be connected to the other GND terminals on the KT-400.

The EGND (earth ground) terminal cant be used for signal ground, only use the GND and 12 VDC - (negative)

terminals for signal ground.

Note 4: There is no end-of-line resistor to install on the RS-485 COM1 terminals on the last KT-400 controller of a loop.

Note 5: If you must make up your own RS-232 cable

with a RJ-12 connector, refer to the following

diagram for the RJ-12 pin-out.

DN1726-0811

22

Page 27

KT-400 Ethernet Four-Door Controller Installation Manual

Connecting the Master Controller to the Host PC via RS-232

Connect RS-232 cable from KT-400 to the PC (maximum length 30 m (100 ft))

If the local master controller is located more than 30 m (100 ft) from the host computer, you must use a VC-485 or

USB-485 interface.

Note 1: The CBLK-10 kit includes 30 m (100 ft) of RS-232 cable with RJ-12 connectors and the 740-1023 (DB9F to RJ-12)

adaptor

Note 2: If you must make up your own RS-232 cable with RJ- 12 connectors, refer to the following diagram for the RJ-

12 pin-out.

Connecting over Corporate Network (LAN)

If the master controller is used in a LAN-enabled corporate setting, u se the RJ-45 Ethernet port to connect the controller

to the corporate network. This method uses existing wiring for data exchange between EntraPass and the controllers.

Powering the KT-400 Ethernet Four-Door Controller

Install 120 VAC IN / 16 VAC, 75 VA OUT, class 2 transformer

Place battery in cabinet

Power up the KT-400 Ethernet Four-Door Controller

The KT-400 must be powered by a 16 VAC, 75 VA class 2 wire-in or plug-in transformer.

After you have completed all the necessary steps, you can power up the KT-400. Connect AC power and connect the

battery. Once powered, check the VITAL LED status indicator to determine the status of communication and other vital

parameters. Consult Table 1 for VITAL LED behavior identifications.

If the AC supply is removed, the 12 VDC, 7 Ah backup battery will support normal operation for up to 12 hours, if fully

charged. Internal battery verification will cutoff battery power if the battery voltage level falls below 9.5 Volts.

Note: The KT-400 will not start on battery power alone.

Power should only be applied to the unit when all connections are completed and

tested.

DN1726-0811

23

Page 28

SPI Expansion Port

The SPI (Serial Peripheral Interface) expansion port on the KT-400 is used to connect expansion modules, in order to

add more inputs and outputs such as relays. The maximum current draw for the SPI exp ansion port is 500 mA when the

12V AUX terminals are not used. The 6-pin SPI cable must be connected to the SPI IN of the first module. See Figure 9

and Figure 11 for examples of interconnection between the KT-400 and expansion modules.

Figure 9: KT-400 Interconnection Examples with Expansion Modules

The number of expansion modules that can be connected to the KT-400 SPI expansion port, without an additional

external power supply, can vary depending how much current is drawn from all the modules in the SPI chain.

Check the following table to calculate the SPI chain current draw:

Expansion Module Qty of modules x Maximum current draw Total

Current

KT-MOD-REL8 _______ x 330 mA ______ mA

KT-MOD-INP16 _______ x 40 mA ______ mA

KT-MOD-OUT16 _______ x 750 mA ______ mA

Maximum current draw from KT-400 SPI expansion port when the 12 VDC AUX terminals are not used. - 500 mA

If the total current is between 0 mA and 1850 mA (1.85 Amps), 1 external power supply is required.

If the total current is between 1851 mA and 3700 mA (3.70 Amps), 2 external power supply are required.

Example of current draw calculation:

1. 15 modules (KT-MOD-OUT16) x 750 mA = 11250 mA

2. 11250 mA - 500 mA (or 0 mA if the 12 VDC AUX of the KT-400 is used) = 10750 mA

3. 10750 mA divided by 1850 mA = 5.8 which means in fact 6 external power suppli es 12 VDC, 2 Amps are requi red.

4. Connect an external power supply at every expansion module where the current draw has reached 1.85 Amps.

5. Make sure the power jumper on the modules is in the correct position when using external power supply(ies).

24

DN1726-0811

Page 29

KT-400 Ethernet Four-Door Controller Installation Manual

Important Installation Rules about Expansion Modules

Note 1: The maximum current draw must be calculate each time there is a new module added to the SPI chain.

Rule 2: The SPI cable, between the KT-400 and the 1st module or between each modules, cannot exceed 1 m (3 ft). Shielded

wire should only be used in areas with excessive RF noise of electromagnetic interference. Keep in mind that the

expansion modules must be defined in the EntraPass system when they are installed.

Rule 3: There is already 4 relays available on the KT-400 Ethernet Four-Door Controller. Don't forget to check the relays

number assignments to prevent redundancy unless it has been planned on purpose.

For more details concerning the expansion modules, refer to the following documents:

Part number Description

DN1775 KT-MOD-INP16 Install Sheet - French version

DN1776 KT-MOD-INP16 Install Sheet - English version

DN1780 KT-MOD-OUT16 Install Sheet - French version

DN1781 KT-MOD-OUT16 Install Sheet - English version

DN1785 KT-MOD-REL8 Install Sheet - French version

DN1786 KT-MOD-REL8 Install Sheet - English version

DN1805 KT-MOD-CAB Install Sheet - French version

DN1806 KT-MOD-CAB Install Sheet - English version

DN1790 Expansion Modules Dimensions Drawing in DWG format

DN1791 Expansion Modules Dimensions Drawing in PDF format

DN1792 KT-MOD-CAB Dimensions Drawing in DWG Format

DN1793 KT-MOD-CAB Dimensions Drawing in PDF Format

DN1726-0811

25

Page 30

Figure 10: PCB View of Expansion Modules

26

DN1726-0811

Page 31

KT-400 Ethernet Four-Door Controller Installation Manual

MOTION DETECTOR

BUZZER

POWER

TAMPER

-++-

NO1NC1C1

12 VDC

CONTACT

DOOR LOCKING DEVICE

BUZZER

REGULATED POWER

SUPPLY 12 VDC, 2 Amps

FROM EXTERNAL SOURCE

REGULATED POWER

SUPPLY 12 VDC, 2 Amps

FROM EXTERNAL SOURCE

CONNECTION TO

OTHER INPUT

SPI OUT

MODULE

CONNECTION TO

OTHER OUTPUT

SPI IN EXT

MODULE

KT-MOD-REL8

KT-MOD-OUT16

LED

Neg

Pos

Neg

Pos

Neg

Neg

Pos

Pos

Pos

Neg

NC

65

CCNCNO

RELAY

SPI IN

GRN BLK REDYELWHT

1

CCNCNO

RELAY

NO

C 2007-08

43

CCNCNO NC

RELAY2

NC NO

BLU

SPI OUT

EXT

INT

PWR

0801 REV.A-1

566-494K

DC

EXT PWR

PCA

12V

+-

8

NC NO

WBGYRBK

7

CCNCNO

RELAY

NO

SPI MODULE

8 RELAYS

NC

6

5

CCNCNO

RELAY

SPI IN

GRN BLK REDYELWHT

1

CCNCNO

RELAY

NO

C 2007-08

43

CCNCNO NC

RELAY2

NC NO

BLU

SPI OUT

EXT

INT

PWR

0801 REV.A-1

566-494K

DC

EXT PWR

PCA

12V

+-

8

NC NO

WBGYRBK

7

CCNCNO

RELAY

NO

SPI MODULE

8 RELAYS

SPI OUT

5 - 24 VDC

OPTIONAL EXTERNAL

HIGH POWER SOURCE

566-493K

EXT PWR

ABSOLUTE TOTAL OUTPUTS

INTERNAL or EXTERNAL SUPPLY

12 VDC, up to 750 mA

O2

SPI IN

YEL REDWHTBLU BLKGRN

Pos

LED

Neg

+

O1

O11

24VDC

O12

+

O16

+

O14

+

O13 O15

EXT

INT

PWR

O10

Pos

Neg

OUTPUT DEVICE

5 to 24 VDC

up to 750 mA

BUZZER

Neg

O4+

O3

O8+O6+

O5 O7

+

O9

PCA

-+

DC

12V

GBKBW RY

-+

DC

12V

C 2007-08

0801 REV.A-0

16 OUTPUTS

SPI MODULE

Z12

SPI IN

EOL FAST NO

NCSLOWDRY

BLU

VITAL

CZ6

Z7

Z8Z4CZ2

Z3

C

Z5

C

Z10

C

Z9 Z11

C

Z1

YEL REDWHT BLKGRN

GBKRYBW

SPI EXP

C 2007-08

1

ON

JP4

BK

566-492K

EXT PWR

Z16

C

Z14

C

Z15

INT

EXT

PWR

GBW Y

-+

DC

12V

PCA

-+

DC

12V

Z13

SPI OUT

16 ZONES

0801 REV.A-1

SPI MODULE

R

Z12

SPI IN

EOL FAST NO

NCSLOWDRY

BLU

VITAL

CZ6

Z7

Z8Z4CZ2

Z3

C

Z5

C

Z10

C

Z9 Z11

C

Z1

YEL REDWHT BLKGRN

GBKRYBW

SPI EXP

C 2007-08

1

ON

JP4

BK

566-492K

EXT PWR

Z16

C

Z14

C

Z15

INT

EXT

PWR

GBW Y

-+

DC

12V

PCA

-+

DC

12V

Z13

SPI OUT

16 ZONES

0801 REV.A-1

SPI MODULE

R

Z12

SPI IN

EOL FAST NO

NCSLOWDRY

BLU

VITAL

CZ6

Z7

Z8Z4CZ2

Z3

C

Z5

C

Z10

C

Z9 Z11

C

Z1

YEL REDWHT BLKGRN

GBKRYBW

SPI EXP

C 2007-08

1

ON

JP4

BK

566-492K

EXT PWR

Z16

C

Z14

C

Z15

INT

EXT

PWR

GBW Y

-+

DC

12V

PCA

-+

DC

12V

Z13

SPI OUT

16 ZONES

0801 REV.A-1

SPI MODULE

R

KT-MOD-REL8

KT-MOD-INP16

KT-MOD-INP16

KT-MOD-INP16

TO KT-400 CONTROLLER

Neg

Jumper JP5

on EXT

Jumper JP5

on INT

Jumper JP5

on INT

Jumper JP1

on INT

Jumper JP1

on INT

Jumper JP1

on EXT

Figure 11: Example of KT-400 Ethernet Four-Door Controller Interconnection with Expansion Modules

DN1726-0811

27

Page 32

Figure 12: Expansion Modules Cabinet for North America

28

DN1726-0811

Page 33

KT-400 Ethernet Four-Door Controller Installation Manual

Troubleshooting

Table 3: Reset Types and Descriptions

Jumpers Heartbeats Patterns Resets

Soft Reset:

When JP2 and JP3 are ON, the controller will reset

on a) power up, b) pushbutton, or c) EntraPass

software 'Manual operator soft reset':

• All controller's memory definitions and

parameters are verified and kept intact if still

Continuous

quick flashing

4 short pulses

valid.

• With a corporate gateway, the internal event

buffer is maintained if still valid.

• With a global gateway, the internal event buffer

is cleared.

• IP address is kept if valid.

• Controller generates the appropriate message:

a) 'Power ON Soft Reset' b) 'Manual Pushbutton

Soft Reset' c) 'Operator Soft Reset'.

Hard Reset:

When JP2 is OFF and JP3 is ON:

• All controller's memory is settled to default

values.

• Internal event buffer is cleared.

• IP address is kept if valid.

• Controller generates the message, 'Controller

Hard Reset'.

• Internal RTC (Real Time Clock) and clock are

settled to the default time and date values

January 1st 2005, 00:00:00, Saturday.

3 long pulses

Continuous

long pulses

Forced Default Static:

When JP2 is ON and JP3 is OFF:

• Same as 'Soft Reset' condition, except IP

address is forced to the default static

IP: 192.168.1.2.

Factory Default DHCP:

When JP2 and JP3 are OFF:

• All controller's memory is settled to default

values.

• Internal event buffer is cleared.

• Controller generates the message 'Controller

Factory Default Reset'.

• The Ethernet port reverts to DHCP configuration

and waits for an IP address from the local DHCP

server.

• Internal RTC and clock are settled to the default

time and date values January 1st 2005,

00:00:00, Saturday.

DN1726-0811

29

Page 34

Default initialization

The KT-400 default initialization or Factory Default DHCP is done at Kantech. The following steps should only be

followed if:

a) You want to configure the KT-400 with the KT-Finder, see page 33.

b) The KT-400 was communicating via the RS-232 port and you have installed a VC-485 or USB-485 to communicate via

the RS-485 port.

c) The KT-400 was communicating via a VC-485 or a USB-485 interface and you want to communicate directly with the

serial (RS-232) port.

d) You are using a KT-400 from another site and there is no communication.

How to reset the KT-400 Ethernet Four-Door Controller for Factory Default DHCP mode

Before you start:

• Locate the reset button, the two jumpers JP2 - JP3 and the blue VITAL LED.

• The Ethernet cable must be connected to the corporate network. The green LINK LED should lit and the yellow

TXRX LED should be flashing.

• The blue VITAL LED should be flashing.

1. Remove JP2 and JP3 jumpers as described in Table 3 for Factory Default DHCP mode.

2. Press the reset button.

3. Check the blue VITAL LED heartbeat pattern.

4. Verify the IP address with the KT-Finder, see page 33.

5. Put back JP2 and JP3 jumpers.

6. Configure the KT-400 with the KT-Finder, see page 33.

Figure 13: KT-400 Factory Default Steps

30

DN1726-0811

Page 35

KT-400 Ethernet Four-Door Controller Installation Manual

KT-400 Ethernet Four-Door Controller Maintenance Recommendations

The KT-400 includes a lithium ion rechargable battery (see the KT-400 Ethernet Four-Door Controller PCB View on

page 8). This battery must be replaced by a Kantech technician to avoid any risk of explosion. If the Lithium-Ion battery

stops working, return the circuit board to Kantech. Do not crush, puncture, open, disassemble or othe rwise mechanically

interfere with the battery. Do not try to recharge the battery. If you need to dispose of the circuit board and/or the lithium

ion battery, wrap the KT-400 in non-conductive tape. Check with your local authorities for battery disposal regulations.

Warning: Do not store the batteries in such a way that they come into contact with each other or with any piece of metal.

Explosion or fire may occur. Should fire occur, use only dry chemical fire extinguishers. Do not use water to put out

the fire. Do not heat the batteries. Do not dispose of the batteries or circuit board in a fire. Do not disassemb le the

batteries. Do not apply pressure to or deform the batteries. Ensure that the above precautions are strictly observed

by related departments, including, but not limited to, production, sales and outside contractors.

Regarding the recommended battery 12 VDC / 7 Ah: It is the end-user and/or installer responsibility to assure that the

disposal of used batteries is made according to the waste recovery and recycling regulations applicable to the intended

market. Use the recommended battery type ONLY.

It is highly recommended to test the KT-400 by performing the following tests:

1) Bi-annual test for battery:

Remove AC power from the controller and let it work on battery power fo r one hou r. This test will ensu re that in the event

of a power failure, the battery will be able to support normal operations. This test should be performed twice a year.

Once the test has been performed successfully, reconnect AC power to the controller.

2) Annual test for emergency lithium ion battery:

Measure voltage of lithium ion battery when power is totally removed from the controller (AC, DC and backup battery

power). To ensure maximum operation and to prevent loss of the database, contact your distributor to return the KT-400

for maintenance if the lithium ion battery voltage measures below 2.5 VDC.

DN1726-0811

31

Page 36

Configuring the KT-400 Ethernet Four-Door Controller with the Web Configuration Page

This procedure is practical if you want to configure the KT-400 in advance before going on site.

Optional Documentation

Application Note, Networking Basics, DN1796.

Before you start

• The detachable Network Configuration Information Sheet is fully completed.

• Determine your connection to the KT-400 and choose the appropriate network cable that you need.

1. Make sure the KT-400 is in Forced Default Static mode before starting the configuration. Verify the heartbeat patterns to

determine the status. See Table 3 on page 29 for details.

2. Start your web browser and enter the following IP: 192.168.1.2 and press Enter.

3. Put a jumper on JP3. Both jumpers should now be on JP2 and JP3.

4. Enter the IP addresses as per the Network Configuration Information Sheet and click on Save configuration to KT-400.

5. When you will go to the site with the configured KT-400, you will have to enter the same details into the EntraPass

workstation.

32

DN1726-0811

Page 37

KT-400 Ethernet Four-Door Controller Installation Manual

Configuring the KT-400 Ethernet Four-Door Controller with the KT-Finder

The KT-Finder is an application used to configure the KT-400 over the local area network (LAN) or the wide area

network (WAN). It doesn’t require any installation.

Important: The KT-Finder application is:

• C:\Program Files\Kantech\Server_xE\Bin, or

• on the EntraPass CD-ROM, or

• available as a free download from http://www.kantech.com

1. Quit all EntraPass applications.

2. Make sure the KT-400 is in Factory Default DHCP mode. See Table 3 on page 29.

3. Start the KT-Finder.

Note: If you try to run the KT-Finder while running EntraPass, you will get an error message similar to this.

4. Select KT-400 from the Device menu.

5. Enter the MAC address of the KT-400 then click on Connect.

6. When the KT-400 is found, the configuration page will be displayed.

DN1726-0811

33

Page 38

Configuring the KT-400 Ethernet Four-Door Controller with the KT-Finder

(continued)

7. Put jumpers on JP2 and JP3.

8. Verify your Network Configuration Information Sheet:

• Enter the EntraPass IP address or the Domain name of the EntraPass Gateway. This information must be the same

as entered in EntraPass workstation for Devices > Site.

•Select Obtain an IP address automatically or Use the following IP address. This information must be the same as

entered in EntraPass workstation for Devices > Site.

9. Change the Port number, if required.

Note: The port number should only be changed when you have more than one KT-400 at the same remote site.

10.Click OK.

11.Repeat the procedure for each KT-400 at this site.

34

DN1726-0811

Page 39

KT-400 Ethernet Four-Door Controller Installation Manual

KT-400 Ethernet Four-Door Controller

Network Configuration Information Sheet

Please complete one sheet per KT-400 Ethernet Four-Door Controller

Company Name:

Site Name:

LAN or WAN (see other side)

Configuration in a Local Area Network (LAN)

For more details, refer to the EntraPass Reference Manual.

MAC Address: 00:50:F9: ______:______:______

Port (18810 by Default) or _________

IP Address Type:

DHCP

or

Stati c

IP Address: ______.______.______.______

Subnet Mask: ______.______.______.______

Default Gateway (Router): ______.______.______.______

EntraPass Special Edition / Corporate Gateway

IP Address: ______.______.______.______

DN1726-0811

35

Page 40

Configuration in a Wide Area Network (WAN)

EntraPass Site

For more details, refer to the EntraPass Reference Manual.

EntraPass Special Edition / Corporate Gateway

IP Address: ______.______.______.______

Router

Public IP Address:______.______.______.______

or

Domain name: ____________________________

Port Forwarding Checklist

For more details, refer to the EntraPass Reference Manual.

EntraPass Gateway Ports: 18001 (UDP) and 18801 (UDP)

KT-400 Ethernet Four-Door Controller Site

MAC Address: 00:50:F9: ______:______:______

IP Address Type: Static or Reserved DHCP

IP Address: ______.______.______.______

Subnet Mask: ______.______.______.______

Default Gateway (Router): ______.______.______.______

DNS Server IP Address:______.______.______.______

Router

Public IP Address:______.______.______.______

or

Domain name: ____________________________

Port Forwarding Checklist

Note: If you are using more than one KT-400 at the same remote site, you must use a unique port number for each KT-400.

KT-400 Ports: 18803 (UDP) and 18810 (UDP) or _________

36

DN1726-0811

Page 41

KT-400 Ethernet Four-Door Controller Installation Manual

Installation Checklist

To the Installer: If you are familiar with the installation, you can use the checklist with the symbol.

Installing the KT-400 Ethernet Four-Door Controller

Preparing to install the KT-400 Ethernet Four-Door Controller

Required to install KT-400 Ethernet Four-Door Controller

Physical Installa tion

Check for ideal indoor location

Stay away from electrical or communication devices

Earth Grounding

AWG#18 grounding wire to EGND

Door Locking Devices

Connect the door locked device to + and LK1-, (+ and LK2-), (+ and LK3-), or (+ and LK4-)