Page 1

KT-300

Door Controller

Installation Manual

DN1315-0707

Page 2

Table of Contents

Pre-Installation Information ..........................................................................................................................1

Copyright Info ..........................................................................................................................................................1

Safety Instructions............................................................................................................................................ ... .... 1

Components Required to Install KT-300 ............................................................. ... ...............................................1

Technical Support ...................................................................................................................................................1

KT-300 Compliance Specifications.............................................................................................................. 2

FCC & IC Compliance .............................................................................................................................................2

CE Compliance Notice ............................................................................................................................................2

UL Compliance Notice .............................................................................................................................................2

Overview ......................... .... ... ....................................... ... ....................................... ... ..................................3

Technical Specifications ..................................... ... ....................................... ... ... .... ... ... ... ............................4

Electrical Specifications............................................................................................................................... 5

KT-300 Controller and Accessories .............................................................................................................5

Installing the KT-300 ....................................................................................................................................6

Physical Installation .................................................................................................................................................6

Earth Grounding ......................................................................................................................................................6

Door Locking Devices .............................................................................................................................................6

Hooking Up Inputs ...................................................................................................................................................7

Readers and Keypads .............................................................................................................................................7

Relay Controlled Outputs ........................................................................................................................................ 7

Auxiliary Outputs .....................................................................................................................................................8

Tamper Protection ...................................... .................................................. ... ........................................................8

Connecting the KT-300 ................................................................................................................................8

Connecting to the RS-485 Bus................................................................................................................................ 8

Connecting the Master Controller to the Host PC ...................................................................................................9

Powering the KT-300 .................................................................................................................................10

Installing Combus Modules .......................................................................................................................10

Introduction to Combus Modules ...........................................................................................................................10

Combus Specifications ..........................................................................................................................................10

Combus Repower (If Required) .............................................................................................................................10

Module Housing Cabinet .............................................................. .. .......................................................................11

KT-PC4108 - 8-Zone Input Expansion Module ..........................................................................................12

KT-PC4108 Introduction ........................................................................................................................................12

KT-PC4108 Specifications ....................................................................................................................................12

Unpacking the KT-PC4108 Module .......................................................................................................................12

Mounting the KT-PC4108 Module ................................................................................................. ........................12

Installation and Wiring ...........................................................................................................................................12

Assigning the Module ............................................................................................................................................12

KT-PC4204 - 4-Relay and Additional Power Supply Module ....................................................................13

KT-PC4204 Introduction ........................................................................................................................................13

KT-PC4204 Specifications ....................................................................................................................................13

Assigning the KT-PC4204 Module ........................................................................................................................14

KT-PC4216 - 16-Zone Output Expansion Module .....................................................................................14

KT-PC4216 Introduction ........................................................................................................................................14

KT-PC4216 Specifications ....................................................................................................................................14

Assigning the KT-PC4216 Module ........................................................................................................................15

KT3-LCD - Kantech LCD Time & Date Display Module .................................. ... .... ... ... ... .... ... ... ... ... .... ... ...15

KT3-LCD Introduction ............................................................................................... .. ...........................................15

KT3-LCD Specifications ...................................................... ..................................................................................15

Assigning the KT3-LCD Keypad ............................................................................................................................16

Troubleshooting Communication Problems ............................... ...... ....... ...... ...... ....... ...... ....... ...... .............16

Default Initialization ...............................................................................................................................................16

How to Use the Default Initialization (Hard Reset) ................................................................................................16

VITAL LED status indications ................................................................................................................................16

KT-300 Controller Maintenance Recommendations ..................................................................................17

KT-300 Wiring Diagram (North America Version) .....................................................................................18

KT-300 Wiring Diagram (EU Version) .......................................................................................................19

Page 3

KT-300 Door Controller Installation Manual

Pre-Installation Information

To the Installer: If you are familiar with the installation, you can use the checklist with the symbol.

Copyright Info

© 2007 Tyco Safety Products, Canada, Ltd. All specifications were current as of publication date and are subject to change without notice.

Kantech and the Kantech logo are trademarks of Tyco International Services AG or its affiliates in the U.S. and/or other countries.

Safety Instructions

ONLY SER VICE PERSONEL WILL INSTALL AND MAINTAIN THE KT -300. Service personnel must have appropriate technical training and

experience necessary to be aware of the hazards to which they are exposed and of measures to minimize the danger to themselves or other

persons.

The connection to the mains supply must be made as per local authorities rules and regulations: in the UK as per BS6701.

Provide an appropriate disconnect device, as part of the building installation. Where it is not possible to rely on the identification of the

NEUTRAL in the AC MAINS SUPPLY, the disconnecting device must disconnect both poles simultaneously (LINE and NEUTRAL).

If a knockout is removed during installation, it is the installer’s responsibility to ensure that the same degree of protection is provided for the

cabinet by the use of bushings, fittings, etc.

Secure the metal cabinet to the building structure before operation.

Internal wiring must be routed in a manner that prevents:

• Excessive strain on wire and on terminal connections;

• Loosening of terminal connections;

• Damage of conductor insulation.

The power supply must:

• Be permanently connected, fail safe, with double or reinforced insulation between primary and secondary circuits.

• In EU countries it must meet the applicable requirements of the Low Voltage Directive and protected as per EN60950 requirements.

• In other countries, it must be of approved type acceptable to local authorities.

The ground connection must be provided via the TERMINAL BLOCK at the PE (IEC 60417-5019 symbol) marked connection.

It is the end-user and/or installer’s responsibility to ensure that the disposal of the used batteries is made according to the waste recovery

and recycling regulations currently applicable.

It is the installer’s responsibility to provide protection against a short circuit on the input (bridge rectifier, C2, etc.).

Components Required to Install KT-300

• KT-300 Controller with accessory kit

• AC transformer 120/220 VAC/16 VAC, 40 VA, class 2*

• One 12 volt battery 7 A/h*

• Ground clamp*

A visual inspection should be made when unpacking the KT-300. Any missing item/part or damaged component should be reported

immediately.

*Not included

Technical Support

For technical assistance with the KT-300 and other Kantech products, contact technical support, Monday to Friday 8:00 AM to 8:00 PM

(GMT -5:00)

• Toll-Free phone (US & Canada): 1 (888) 222-1560

• Phone: +1 (450) 444-2030

• Fax: +1 (450) 444-2029

• Internet: www.kantech.com

• E-mail: kantechsupport@tycoint.com

DN1315-0707

1

Page 4

KT-300 Compliance Specifications

FCC & IC Compliance

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received including interference that may cause undesired operation.

This class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations. The KT-300 is also

compliant with EN55022:1994, amendment 1:1995, Class B.

CE Compliance Notice

This equipment has been tested and found to comply with the limits of EN 50130-4: 1995.

This equipment is designed to be used in an environment that meets a maximum pollution degree of 2 and over voltages category II - NON

HAZARDOUS LOCATIONS, indoor only. The equipment is FIXED and PERMANENTLY CONNECTED. It must be installed in a metal

cabinet by service personnel only. Service personnel is defined as: Persons having the appropriate technical training and experience

necessary to be aware of hazards to which they are exposed in performing a task.

UL Compliance Notice

To comply with UL listings, the following requirements must be met:

• Use of a UL listed computer

• Use of UL listed readers (Wiegand 26 and 34 bits, mag stripe 26 and 34 bits, have been tested and found to comply)

• Use of a UL recognized tamper switch on every housing cabinet for the KT-300

• Do not use the SmartLink option

• Use the Kantech IP Link Enhanced Ethernet Device

• Us the KT3-LCD module on each KT-300 controller (should be installed near the controller)

• Do not use a 220 V transformer (not UL listed)

• Use only UL listed cables

• Use only UL listed adaptors

• Use only a UL listed transformer such as Kantech TR1640P/UL or DSC PRD1640

• Use Kantech BD7-12 battery

NOTE: Backup battery provides operation of up to 12 hours but has been tested only 4 hours per Section 33 of UL294, fifth edition.

NOTE: All circuits are power limited.

2

DN1315-0707

Page 5

KT-300 Door Controller Installation Manual

Overview

The KT-300 will operate with the EntraPass software

Innovative and Powerful

The Kantech KT-300 Door Controller is designed to meet the highest standards of access control and point monitoring applications.

Downloadable Firmware

The firmware program, stored in the controller’s flash memory, is updated without changing the memory chips. The firmware program can

be uploaded from any EntraPass workstation.

Speed selection - Fast! Up to 115,200 Bauds

The KT-300 automatically detects the site communication speed set by EntraPass.

Trouble and Reporting

The KT-300 constantly supervises battery condition and reports “Low battery” or “No battery” status to the EntraPass system. Power outputs

are supervised and individually protected against short-circuits and surges by self-resetting PTC. Locking devices are also supervised for

short and open circuits.

Built-in Combus Expansion

The KT-300 supports expansion modules to add inputs, outputs and an LCD time and date display for Time & Attendance purposes.

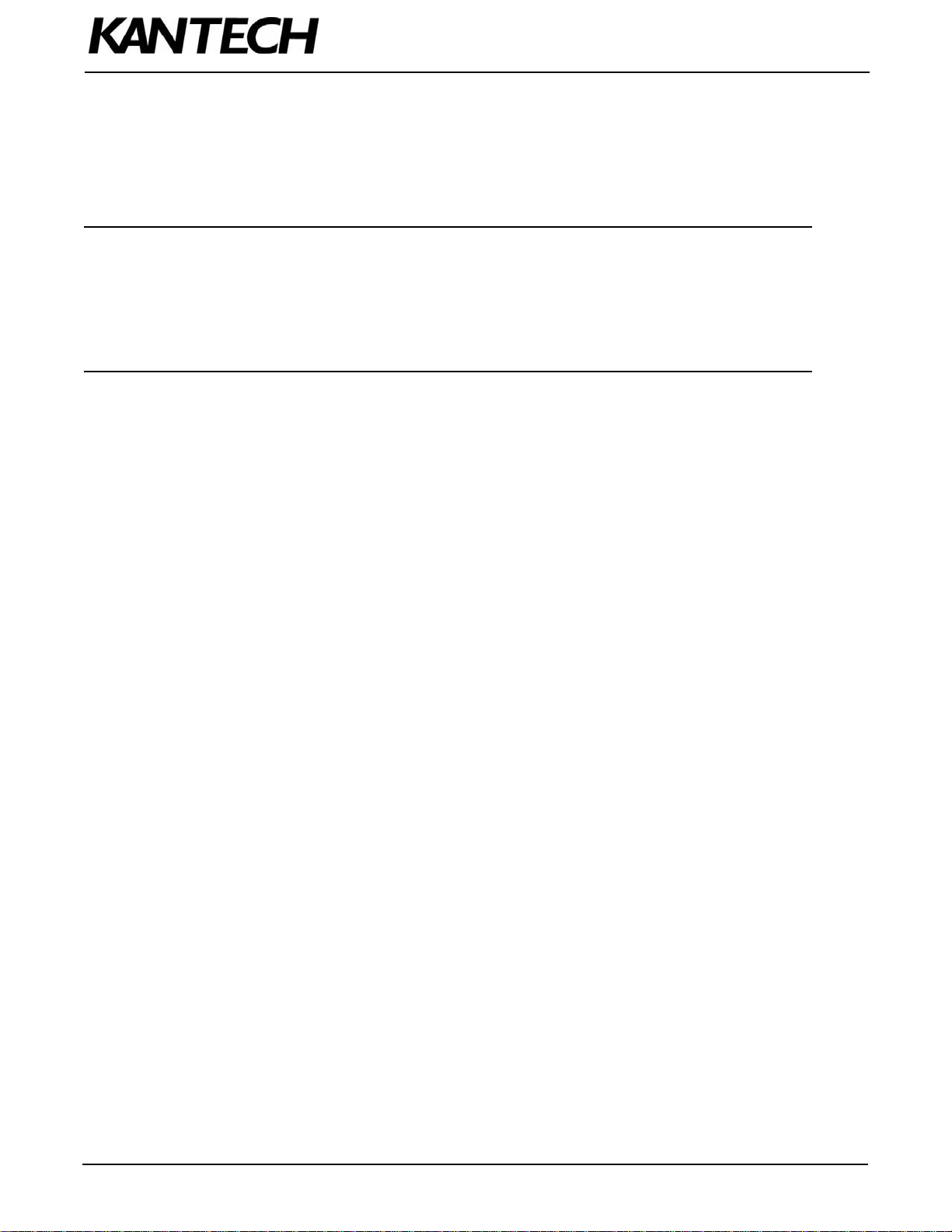

KT-PC4108 - 8-Zone Input

Expansion Module

KT-PC4216 - 16-Output

Expansion Module

KT-3LCD-LCD Time and Date Display

for Time & Attendance Functions

KT-PC4204 - 4-Relay and Combus

Additional Power Supply Module

DN1315-0707

3

Page 6

Technical Specifications

Specification Description

AC power 16VAC, 40VA, class 2 transformer

Battery back-up 1battery 12VDC, 7Ah, supervised, provides up to 12 hours of operation, Kantech BD7-12 battery tested for 4 hours

standby for UL294

Operating temperatures From 2°C to 40°C (35°F to 110°F)

Cabinet Dimensions (H-W-D) 29.9 cm x 28.8 cm x 7.7 cm (11-3/4” x 11-3/8” x 3”) EMT 1.9 cm (3/4”)

Cabinet Weight 2.4 kg (5.4 lbs)

PCB dimension 18.3 cm x 12.18 cm x 5.20 cm (7-1/4” x 4-3/4” x 2-1/16”)

Reader types Wiegand, proximity, bar code, magnetic, integrated keypad and others

Reader power output 12 VDC and 5VDC @ 175mA max, protected and supervised

Monitored points 8 monitored points, NO/NC, w/without EOL’s (expandable to 16), use UL recognized tamper switch on cabinet housing

to conform with UL 294

Points maximum wiring AWG #22 - 600 meters (2,000 feet)

Door strike power 12 V DC, 250mA max each, supervised

Auxiliary outputs 4 outputs, 25mA max each, open collector

Relay controlled output 2-relay controlled outputs, 25mA max each. Open collector to ground (use form “C” relays Kantech #KT-RM1 if

needed)

Auxiliary power output 11.5 to 13.85 VDC @ 175mA max, protected and supervised

Communication ports RS-232, RS-485 and Combus

Communication speed Up to 115.200 baud (automatic detection)

Firmware Flash memory 128 K

RAM memory 128 K (512 K unit available) Protected by a lithium battery

Network autonomy Distributed data and processing

Certifications / Listing CE, FCC, UL294 listed

4

DN1315-0707

Page 7

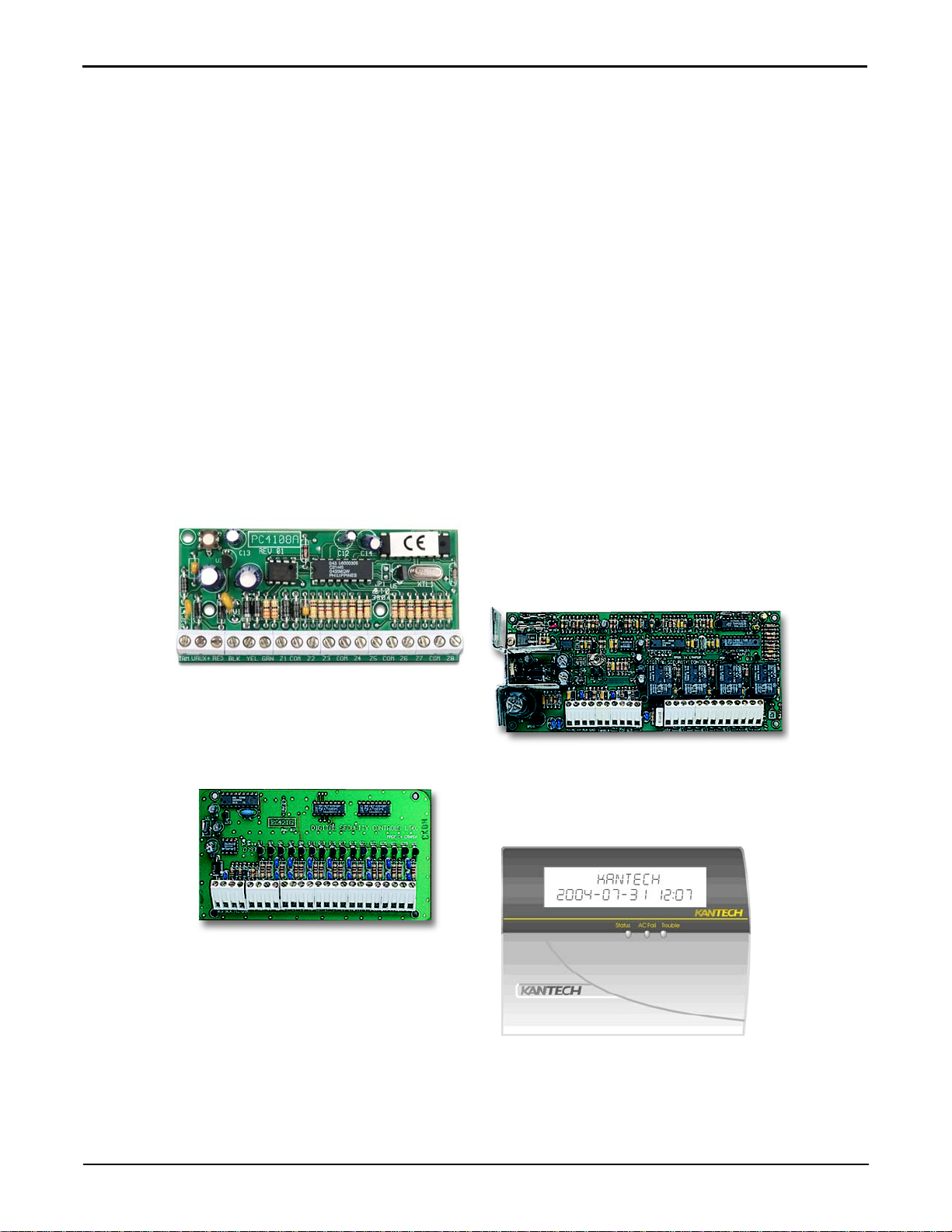

Electrical Specifications

VOLTAGE OUTPUTS MAXIMUM CURRENT ABSOLUTE COMBINED

Lock Outputs (12 VDC) 500 mA

Auxiliary Power (11.5 to 13.85 VDC) 175 mA

Reader 5 VDC and 12 VDC 175 mA

Combus 500 mA

Battery Charging (12 VDC) 250 mA 1.5 A

OPEN COLLECTOR OUTPUTS MAXIMUM CURRENT

LED (door 1 & 2) 25 mA (each)

Buzzer (Buz, door 1 & 2) 25 mA (each)

Controlled Relay 1 & 2 (RL1 & RL2) 25 mA (each)

KT-300 Door Controller Installation Manual

MAXIMUM

(250 mA each)

KT-300 Controller and Accessories

Kantech Model Description

KT-300/128K Door controller with 128K memory including KT-300CAB, KT-300ACC and KT-LOCK

KT-300/512K Door controller with 512K memory including KT-300CAB, KT-300ACC and KT-LOCK

KT-300PCB/128 KT-300/128K PCB only and KT-300 ACC

KT-300PCB/512 KT-300/512K PCB only and KT-300 ACC (not UL listed)

KT-300ACC Accessory kit including: 2 X 1.0k ohm, 10 x 5.6k ohm, 2 x 120 ohm, PCB standoffs, lock hole

cover, ground wire and screwdriver

KT-PC4108 8-zone input expansion module for KT-300

KT-PC4204 4-Relay and Combus additional power supply module for KT-300

KT-PC4216 16-Output expansion module for KT-300

KT-RM1 External isolation relay SPDT for KT-300 output (RL1/RL2) (not UL listed)

KT3-LCD Time & date LCD display unit for KT-300

KT-300CAB KT-300 black metal cabinet including KT- LOCK

KT-4051CAB Standard black metal cabinet for KT-PCxxx modules (order keylock separately)

KT-LOCK Keylock for KT-300CAB/KT-4051CAB metal cabinet (2keys/same as KT-200)

KT-TAMP Tamper switch for KT-300CAB/KT-4051CAB metal cabinet

TR1637W/CSA Transformer, Wire-in, 110V/16V (37VA) CSA (not UL listed)

TR1640P/CSA Transformer, Plug-in, 110V/16V (40VA) CSA (not UL listed)

TR1640P/UL Transformer, Plug-in, 110/16V (40VA) UL or DSC PTD1640 www.dsc.com

TR1640W-220 Transformer, Wire-in, 220V/16V (40VA) CE (not UL listed)

VC-485 or USB-485 Multi-function communication interface

DN1315-0707

5

Page 8

Installing the KT-300

Physical Installation

Check for ideal indoor location.

Stay away from electrical or communication devices.

The KT-300 Controller cabinet has been designed to be mounted on a wall without any additional enclosures. The cabinet is large enough to

accommodate the battery backup supply and the necessary wiring connections for most applications. EMT (Electrical Metallic Tubing)

conduit knockouts are provided in 2.2 cm (7/8”) on all sides of the cabinet.

The cabinet should be mounted indoors, in a secure location providing normal temperature and humidity, leaving 23 cm (8”) clear space

around all sides and a minimum of 33 cm (13”) clear space in front of the cabinet. The location should be easily accessible for servicing the

equipment and it is recommended that controllers be located close to the controlled doors.

Controllers must be located at a minimum distance of 2 m (6 feet) from any high voltage equipment or wiring and from electrical equipment

susceptible of generating electrical interference, at a minimum distance of 1 m (3 feet) from telephone equipment or lines, and at a minimum

of 8 m (25 feet) from any transmitting equipment.

Physical access, using keys, on controlled doors must be provided so that the KT-300 can easily be accessed for servicing in case of

malfunction.

Earth Grounding

AWG#18 grounding wire to EGND.

Since the KT-300 uses high performance communication, proper grounding must be provided to ensure proper operation.

An AWG#18 single conductor copper wire must be used to ground each controller to good earth ground as per the local

electrical code (be careful of ground loops). The ground clamp should be located below any other ground.

It is also recommended that you install an AWG#18 single conductor copper wire between each controller.

Door Locking Devices

Connect door locks to + and LK1- (+ and L2-)

Maximum 250mA @ 12 VDC per output

Check for local “magnetic lock” regulations

LK1-, LK2- and + terminals are located on the bottom left to the KT-300 terminal

strip. The locking device outputs are controlled according to the end-user

programmed parameters for allowing access to or unlocking doors according to

schedules and access levels. These door locking device outputs can operate DC

powered locking devices such as electromechanical strikes and can be configured

to operate fail-safe or fail-secure (normal or reverse action). Maximum DC current

for each lock output is 250 mA.

NOTE: Use 1K ohm EOL (End-Of-Line resistor) between + and LK- if not used.

This resistor is already included within the controller packaged box (KT300ACC).

WARNING: Controlled door locks may be governed by regulatory bodies and

should always be installed according to local regulations. In most

instances, there are strict limitations to installing fail-secure devices

and fail-safe locking devices such as magnetic locks or other similar

locking devices on doors used as emergency exits.

6

DN1315-0707

Page 9

Hooking Up Inputs

Connect devices to inputs 1 to 8.

Resistors (included with KT-300) for all

inputs 5.6K ohm (if selected).

The KT-300 has an on-board capability of

monitoring 8 input points (expandable to 16 if KTPC4108 module is used). Each input is

supervised with or without end-of-line resistors

(5.6K ohm). The maximum distance of one line is

600m (2,000 feet) with AWG#22.

NOTE: Inputs can be defined with: none or one

EOL (End-Of-Line) resistor according to

your EntraPass software settings.

Inputs 1-2 are automatically reserved for the first

controlled door. The contact is assigned input 1

and the associated request-to-exit detector as

input 2. Inputs 3 and 4 are automatically reserved

for the second controlled door. The contact is

assigned input 3 and the associated request-toexit detector as input 4. There is no obligation to

follow these rules but this standard convention

facilitates servicing.

KT-300 Door Controller Installation Manual

Readers and Keypads

READER CONNECTION TERMINAL WARNING

Connection the red wire lead (or power lead) of a 5 VDC reader to the

12 VDC terminal may damage the reader. See your reader installation

procedure for proper power connection.

Up to 2 readers can be connected to a KT-300. They can be installed

on one door to control both entry and exit or on two separate doors

operating independently to control one-way access.

The distance between the readers and the KT-300 controller varies by

reader type (please consult the installation manual for details).

Auxiliary outputs provide visual and/or audible access operation

feedback at the controlled door. Outputs “OUT DOOR 1 LED & BUZ”

are used for the first door and “OUT DOOR 2 LED & BUZ” are used for

the second door.

The 12 VDC auxiliary power can also be used to power low current

audible devices usually located at the controlled door.

Relay Controlled Outputs

Connect controlled outputs to low voltage devices (25 mA

max).

Add external relays for high voltage devices (optional - Kantech # KT-RM1).

The KT-300 provides two controlled outputs -RL1 & RL2 (open collector to ground-current limited to 25 mA). Use a KT-RM1 (optional) to

switch larger currents or voltages or to supply a dry contact.

Can be expanded up to 16 controlled outputs when using a KT-PC4216 module. This module allows a maximum of 16 outputs and a

maximum of up to 50 mA per output. SInce the KT-300 only supports 500 mA, a power supply module can be used to provide an additional

1 A to the Combus.

NOTE: If you are using a KT-PC4204 in “repower” mode and other KT-PC4216 modules that are assigned as relays 1-16 are also

connected to the same loop, do not use relay 1 of those modules or relay 1 of the KT-300 Door Controller (see the Combus

Repower section for more information).

DN1315-0707

7

Page 10

Auxiliary Outputs

Connect auxiliary outputs to readers and local warning devices.

Auxiliary outputs are used for visual and audible signals. They can be activated according to schedules, input conditions or events and local

alarms. Auxiliary outputs “OUT DOOR 1 & 2 LED” provide visual feedback of access operation, and auxiliary outputs “OUT DOOR 1 & 2

BUZ” can activate audible warning devices, such as T-REX, to signal door alarms.

Tamper Protection

Install tamper switch on cabinet (Kantech #KT-TAMP).

A tamper switch must be installed on the unit to detect unauthorized cabinet opening.

The normally closed tamper switch is connected to an input (choose an unused input (5 to 8) as tamper input or any other unused inputs on

the KT-PC4108 module (if used)).

NOTE: The tamper switch is required for a UL listed installation.

Connecting the KT-300

Connecting to the RS-485 Bus

Connect RS’485 cable to X1+, X1- and GND.

If not using VC-485 or USB-485: connect a 120 ohm end-of-line resistor on the first/last KT-300 (X- & X+).

If using VC-485 or USB-485: connect a 120 ohm end-of-line resistor on the last KT-300 only (X- & X+).

Controllers are linked together through their RS-485 connectors. The maximum communication loop length is 1.2 kilometers (4,000 feet)

using appropriate cabling. Connecting several KT-300 controllers at a single point is not acceptable nor are splitters or “spider web

networks.”

The RS-485 communication loop should be wired with Ethernet Category 3 double twisted pair network cable (see cable specifications

Belden 1227A, or equivalent). The RS-485 loop can operate from 1,200 to 115,200 bauds under normal conditions.

Intermittent communication problems or erratic operation may require network speed drops to 9,600 or 19,200 Bauds. Varying the network

speed does not perceptibly change the operation speed of the system. Usually, most installations should be set to 19,200 Bauds.

Important:

• Without a VC-485 or USB-485: Connect a 120 ohm end-of-line resistor between terminals X1- and X1+ of the first and last KT-

300.

• With a VC-485 or USB-485: connect a 120 ohm end-of-line resistor between terminals X1- and X1+ of the last KT -300. No need

to connect on the first KT-300 since the VC-485 contains an end-of-line resistor.

NOTE: To learn more about USB-485 wiring, refer to the USB-485 Installation Sheet, DN1482.

8

DN1315-0707

Page 11

KT-300 Door Controller Installation Manual

Connecting the Master Controller to the Host PC

Connect flat cable from KT-300 to the PC.

From 0 to 30m (0 to 100 feet) :

If the local master controller is located less than 30m (100

feet) from the host computer, use the on-board RS-232 RJ12

jack and the supplied flat cable.

From 30m to 60m (100 to 200 feet)

Since the master controller can be located up to 60m (200

feet) from the host computer, an extra 100 feet cable can be

added to the existing cable.

NOTE: If you plan to locate the host PC more than 30m (100

feet) away from the controller, be sure to use a VC485 interface. Otherwise, reduce the communication

speed to a minimum to avoid data loss.

From 60m to 1.2 km (200 to 4,000 feet)

If the master controller is located more than 60m (200 feet),

an optional VC-485 multi-function communication interface

must be used. It can also be used when running a

communication cable in areas unusually high in electrical

noise.

NOTE: The host computer is used to program the KT-300

Controllers.

RS-232 WITHOUT VC-485

KT-300

C

8

LED

OUTDOOR 1

RS-485 WITH VC-485

S/N

+5V

GND

READER PWR

+12V

X1+

RS485

X1-

VITAL

BUZ

LED

RL1

BUZ

OUTDOOR 2

An optional VC-485 must be used when the PC is located

more than 60m (200”) from the master controller

V+ = 5-14 VDC

DB25 (740-1012)

OR

DB9 (740-1022)

EGND

RJ12F

P3

RL2

VC-485

RS-232/RS-485

CONVERTER

CABLE DESCRIPTION: 1.2 METERS (4”)

AWG#26, 6 WIRES, INCLUDED WITH

VC-485. (MAX LENGTH 60 METERS (200”))

CBLK-20

MAX 60 M (200’)

ORANGE

ORANGE WHITE

BLUE

BLUE WHITE

RED

BLACK

DB9F

(740-1021)

CABLE DESCRIPTION: UNSHIELDED TWISTED PAIR

DATA CABLE, 24 GAUGE ETHERNET GRADE 3,

2 PAIR, BELDEN #1227A

KT-300

KT-300

TB1

+

LK1- LK2-

+12v-

16V

AC

LOCK 12V

AUX

DB25F

(740-1011)

+5V

TB2

WHT

+5V

READER PWR

+12V GND

ORANGE

X1+

ORANGE WHITE

BLUE

RS485

X1-

BLUE WHITE

EGND

*NOTE:

CONNECT A 120 OHMS END

OF LINE RESISTOR ON THE

LAST KT-300

Over Corporate Network (LAN)

If the master controller is used in a LAN-enabled corporate setting, use TCP/IP-to-RS-232

converter (such as the Kantech IP Link or the Lantronix UDS-1100 communication interface) to

connect the controller to the corporate network. This method uses existing wiring for data

exchange between EntraPass and the controllers. The diagram on the left shows how to connect a

DB-9 to RJ-12 flat cable between the master controller and the converter. Consult Application Note

DN1506 to learn how to set up the communication interface.

For remote sites

If the master controller is used in remote areas,

modems must be used to send and receive access

control data over telephone lines. For this application

Kantech supports US Robotics 56K external

Sportster modems at both ends of the communication

line. As shown on the right, a modem connects to the

master controller only using a DB25 to RJ-12 flat

cable. For dial-up communication settings via

software, refer to your communication settings.

EntraPass

Gateway

US Robotics Sportster

External 56k

Part# DU-MODEM-HOS

Host Modem Dipswitch Settings

1, 2, 6 UP

(Optional Host Modem

to receive alarms only)

EntraPass Dial-Up Setup with KT-300

Phone

Jack

Phone

Jack

Phone Line

US Robotics Sportster

External 56k

Part# DU-MODEM-RS

Remote Modem Dipswitch Settings

1, 6 UP

Phone

Jack

VITAL

Adaptor modem

to KT-300 (DB-25)

Part #740-1035

Flat cable

Part #CAB-15

RJ12

CONNECTOR

KT-300 MASTER

DN1315-0707

9

Page 12

Powering the KT-300

BAT

Install 120 / 220VAC / 16VAC, 40 VA, class 2 transformer.

Place battery in cabinet.

Power the KT-300 controller.

The KT-300 Controller must be powered by a 16VAC/40VA class 2 wire-in or plug-in

transformer.

After you have completed all the necessary steps, you may power the KT-300 Controller.

Connect AC power and connect the battery. Once powered, check the VITAL LED status

indicator to determine the status of communication and other vital parameters. Consult the

troubleshooting section for VITAL LED behavior identification.

If the AC supply is removed, the 12 Volt 7 A/h led-type backup battery will support normal

operation for up to 12 hours if fully charged. Internal battery verification will cutoff battery

power if the battery voltage level falls below 9.5 Volts.

NOTE: The KT-300 Controller will not start on battery alone.

NOTE: Power should only be applied to the unit when all connections are completed and

tested.

Installing Combus Modules

120 / 220 VOLTS 40VA

CLASS 2 (WIRE-IN)

RED

BLACK

SEALED RECHARGEABLE

12 VOLT

12 V BATTERY

7Ah MAXIMUM

TB1

BATTERY

7 AMP/h

16V

AC

AC LED

KT-300

LK1-+LK2-

+12v-

AUX

KANTECH PART #

KT-BD7-12

RED BLK YEL

LOCK 12V

PLUG-IN ALSO AVAILABLE

DO NOT CONNECT TO

RECEPTACLE CONTROLLED

BY A SWITCH

COMBUS

GRN

Introduction to Combus Modules

The Combus terminals on the KT-300 Controller are used to connect expansion modules to add more inputs, outputs, relays and LCD time

and date display. The four Combus terminals of the main panel must be connected to the four Combus terminals or wires of all modules.

Four expansion modules can be connected to KT-300’ s Combus (more specifications on each of these modules can be found later on in this

document.):

• KT-PC4108 - 8-Zone input expansion module

• KT-PC4204 - 4-Relay/Power supply expansion module

• KT-PC4216 - 16-Zone output expansion module

• KT3-LCD - Kantech LCD keypad module

Combus Specifications

The Combus provides 500 mA at 12 Volts (13.85 VDC). The recommended cable is #22

AWG. Each loop (module to KT-300) cannot exceed 300 m (1,000 feet) and the total

maximum cable length of all connected loops cannot exceed 1,200 m (4,000 feet).

For example:

• Only four wireruns at 1,000 feet from the KT-300.

• Only eight wireruns at 500 feet from the KT-300.

• Only ten wireruns at 400 feet from the KT-300

Shielded wire should only be used in areas with excessive RF noise of electromagnetic

interference. Modules can be straight run, connected in a daisy chain or T-tapped anywhere

on the Combus.

Keep in mind that the new modules must be defined in the EntraPass system when they are added to the Combus. Refer to the Controller

Definition section in the EntraPass Reference Manual to learn how to assign modules to your system.

10

DN1315-0707

Page 13

KT-300 Door Controller Installation Manual

Combus Repower (If Required)

Depending on how many modules are connected to the Combus

and how far they are from the KT-300 controller , you may need to

“repower” the controller’s Combus.

The Combus needs to be “repowered” if the voltage drops below

12.5 Volts between black and red wires of the last module of each

loop (the modules will still operate but there will be no

communication between the modules and the controller and a

“Combus module defect” event will be generated from the

controller). This voltage drops if modules are drawing too much

current (500mA maximum for the Combus of each KT-300).

Verify this voltage with a multi meter , and determine if you need to

install a KT-PC4204 in “repower” mode. Using this configuration,

you will be provided with an additional 1 amp of current on the

controller’s Combus. The KT-PC4204 is generally installed at the

beginning of the loop.

When using the KT-PC4204 in “repower” mode, the first relay of

the module will be reserved for the “repower function”. You will

have to assign an “all valid” schedule to the first relay so it is

“always activated” (refer to the Controller definition section of your

EntraPass User Reference Manual for the exact procedure.)

If you are using a KT-PC4204 in “repower” mode and other KTPC4204 modules that are assigned as relays 1-4 or KT-PC4216 modules that are assigned as relays 1-16 are also connected to the same

loop, do not use relay 1 of those modules or relay 1 of the KT-300 door controller. Please also note that all KT-PC4204 modules that are

used for Combus repower should be assigned as relays 1-4.

NOTE: Jumper 1 “J1” on the KT-PC4204 must be moved to the Combus relay position.

NOTE: Do not use any power supply other than the KT-PC4204 to repower the Combus. In the event of a power surge or transient, a

module may lock up and cease to communicate with the controller. If the KT-300 loses communication with the module, it will

initiate a module reset and will power down the Combus for five seconds in an attempt to reset the problem module. After five

seconds, the controller will reapply power to the Combus and the problem module should begin to operate as intended.

Module Housing Cabinet

Kantech Part: KT-4051CAB

Measurement: 16.8” H x 10.4” W 4.1” D (42,5cm H x 26.4 cm W x 10.4 cm D)

Color: Black

Cabinet will hold either:

• One KT-PC4204 power supply/relay module with batteries and one KT-PC4108/KTPC4216.

• Three KT-PC4216/KT-PC4108 modules

DN1315-0707

11

Page 14

KT-PC4108 - 8-Zone Input Expansion Module

KT-PC4108 Introduction

The KT-PC4108 module is a zone input module that adds up to 8 fully

programmable zones to the KT-300 Controller.

KT-PC4108 Specifications

• Connects to the controller via 4-wire Combus

• Current draw: 30 mA (from Combus)

• Supports single end-of-line and no end-of-line (5600 ohm resistors) zone loops

• AUX+ output: 12 VDC, 250 mA max. (drawn from Combus)

• Tamper contact input

Unpacking the KT-PC4108 Module

The KT-PC4108 package includes the following parts:

• One KT-PC4108 circuit board

• 16 end-of-line resistors (5600 ohm)

• Four plastic standoffs

Mounting the KT-PC4108 Module

The KT-PC4108 module should be located inside a compatible cabinet (Kantech

part no. KT-4105 CAB), mounted in a dry, secure location. Preferably, it should be

placed at a convenient distance from the connected devices.

Perform the following steps to mount the unit:

1. Press the four plastic standoffs through the mounting holes on the back of the cabinet.

2. Secure the cabinet to the wall in the desired location. Use appropriate wall anchors when securing the cabinet to drywall, plaster, concrete, brick or any other surfaces.

3. Press the circuit board into the four plastic standoffs to secure the unit to the cabinet.

NOTE: Wiring may take place once the unit is mounted.

Installation and Wiring

Before wiring the unit, ensure that all power sources (AC transformer and battery) are disconnected from the controller. Perform the

following steps to complete wiring:

1. Connect the four Combus wires to the KT-PC4108. Connect the Red, Black, Yellow and Green Combus wires to the RED, BLK, YEL and GRN terminals, respectively.

2. Complete all zone wiring to the zone input terminals (Z1-Z8).

3. Connect the external tamper switch, if used.

NOTE: Consult the wiring diagram above for further information.

Applying Power

After wiring is completed, apply power to the controller. Connect the battery leads to the battery, then connect the AC transformer.

NOTE: Do not connect the power until all wiring is completed.

Assigning the Module

Once all wiring is completed, the module must be assigned to the system. To assign the module, perform the following steps:

1. Establish communication between EntraPass and controller.

2. Remove the tamper switch wire.

3. A serial number should be displayed on screen. In the same window where the serial number is located, you should see the type of module and on which controller it is connected.

4. From the EntraPass user interface, go to the Controller definition menu and select the functionality of the module and enter the serial

number in the appropriate field (refer to Chapter 4, Defining Devices of your EntraPass Reference Manuel for more details).

NOTE: Do not forget to reconnect the tamper switch (or the wire, if there is no tamper switch).

12

DN1315-0707

Page 15

KT-300 Door Controller Installation Manual

KT-PC4204 - 4-Relay and Additional Power Supply Module

KT-PC4204 Introduction

The KT-PC4204 module is an output module with four programmable

relays. This module can be used to “repower” the Combus. The KTPC4204 can also be used for elevator control.

NOTE: Do not use any power supply other than the KT-PC4204 module

to repower the Combus. If a power supply other than the KTPC4204 is used, the Combus repower function will not operate

as intended.

KT-PC4204 Specifications

• Current draw: 30 mA (from Combus)

• 40 VA 16 VAC transformer required.

• Maximum 7 A/h battery required

• Connects to the controller via 4-wire Combus

• Four programmable relay contacts rated 2 A, 30 VDC

• AUX current: 1.0 A max.

• Tamper contact input

• Can be used to repower the Combus

Unpacking the KT-PC4204

The KT-PC4204 package should include the following parts/items:

• One KT-PC4204 circuit board

• One ground wire assembly

• Five plastic standoffs

• One 5 A replacement fuse

Mounting the KT-PC4204

The KT-PC4204 should be located inside a compatible cabinet (Kantech

part no. KT-4051CAB), mounted in a dry, secure location. Preferably, it

should be placed at a convenient distance from the connected devices.

Perform the following steps to mount the unit:

1. Push the five plastic standoffs through the mounting holes on the back of the cabinet.

2. Secure the cabinet to the wall in the desired location. Use appropriate wall anchors when securing the cabinet to dry wall, plaster, concrete, brick or other surfaces.

3. Press the circuit board into the plastic standoffs to secure the module to the cabinet.

NOTE: Wiring may take place once the unit is mounted.

Installation and Wiring

Before wiring the unit, ensure that all power (AC transformer and battery) is disconnected from the KT-300 controller. Perform the following

steps to complete wiring:

1. Connect the four Combus wires to the KT-PC4204. Connect the red, black, yellow and green Co mbus wires to the RED, BLK, YEL a nd GRN terminal respectively.

2. If the module is used for Combus Repower, connect the Combus wires according to the diagram on the right. Note that for this option, Jumper J1 must also be set to “Combus Relay”.

3. Complete all output wiring.

4. Connect the external tamper switch, if used.

Applying Power

After wiring is completed, apply power to the KT-300. Connect the battery leads to the battery, and connect the AC transformer. Then,

connect power to the KT-PC4204; the battery leads followed by the AC transformer.

NOTE: Do not connect the power until all wiring is complete.

DN1315-0707

13

Page 16

Assigning the KT-PC4204 Module

Once wiring is completed, the module must be assigned to the system. To assign the module, perform the following:

1. Establish communication between the PC and the controller.

2. Remove the tamper switch wire (or only the wire if tamper switch is not used).

3. A serial number should be displayed in the EntraPass message desktop. Look for the type of module and the controller to which it is connected.

4. From the EntraPass controller definition window, select the functionality of the module and enter the serial number in the appropriate field (refer to Chapter 4, Defining Devices or your EntraPass Reference Manual for more details).

5. If the module is used in “repower” mode, assign an “Always valid” schedule to relay 1 and assign the module’s functionality to “relay 1 to 4” in the EntraPass software.

NOTE: Do not forget to reconnect the tamper switch (or the wire, if there is no tamper switch).

NOTE: Ensure that Jumper J1 is set to “Combus Relay” position if used as “repower”.

KT-PC4216 - 16-Zone Output Expansion Module

KT-PC4216 Introduction

The KT-PC4216 module is an open-collector to 12 VDC 16-zone output module. Can be used for elevator access control (may require

additional hardware).

KT-PC4216 Specifications

• 16-output low current module, 12 VDC, 50 mA max. each, power drawn from Combus (since

Combus can handle a maximum of 500 mA, a KT-PC4204 module in “repower” mode can be used

to increase the current of the Combus of 1A).

• Connects to KT-300 via 4-wire Combus

• Nominal current draw of 15 mA

• Tamper contact input

• Can be used for elevator control

Unpacking the KT-PC4216

The KT-PC4216 package should include the following parts:

• One KT-PC4216 circuit board

• 4 plastic standoffs

Mounting the KT-PC4216

The KT-PC4216 should be located inside a compatible cabinet (part no. KT-4501CAB), mounted in a

dry, secure location. It should be placed at a convenient distance from the connected devices. Perform

the following steps to mount the units:

1. Press the four plastic standoffs through the mounting holes at the back of the cabinet.

2. Secure the cabinet to the wall in the desired location. Use appropriate wall anchors when securing the cabinet to drywall, plaster, concrete, brick or other surfaces.

3. Press the circuit board into the plastic standoffs to secure the module to the cabinet.

Wiring bay be started once the unit is mounted.

Installation and Wiring

Before beginning to wire the unit, ensure that all power (AC transformer and battery) is disconnected

from the controller. Perform the following steps to complete wiring:

1. Connect the four Combus wires to the KT-PC4216. Connect the Red, Black, Yellow and Green Combus wires to the RED, BLK, YEL and GRN terminals, respectively.

2. Complete all output wiring as illustrated on the next page.

3. Connect the external tamper switch, if used.

14

DN1315-0707

Page 17

KT-300 Door Controller Installation Manual

NOTE: Power is drawn from the

Combus. May require a

KT-PC4204 power

supply module if drawing

too much power from the

Combus.

Applying Power

1. After all wiring is completed, apply power to the KT-300.

2. Connect the battery leads to the battery.

3. Then, connect the AC transformer.

NOTE: Do not connect the power until all wiring is completed.

Assigning the KT-PC4216 Module

Follow the Instructions below for assigning and programming your KT-PC4216 module.

1. Establish communication between EntraPass and the controller.

2. Remove the tamper switch wire (or only the wire if tamper switch is not used).

3. A serial number, the type of module and on which controller it is connected should be displayed on the screen.

4. From the EntraPass user interface, go to the controller definition window and select the functionality of the module and enter the serial

number in the appropriate field (refer to Chapter 4, Defining Devices of your EntraPass Reference Manuel for more details).

NOTE: Do not forget to reconnect the tamper switch (or the wire, if there is no tamper switch).

NOTE: If you are using a KT-PC4204 in “repower” mode on the same loop, do not use the first relay of the KT-PC4216.

KT3-LCD - Kantech LCD Time & Date Display Module

KT3-LCD Introduction

The KT3-LCD module is an LCD readout module with integrated keypad which

provides date and time via a 32-character liquid crystal display.

KT3-LCD Specifications

• Connects to control panel via 4-wire Combus

• Current draw: 50 mA (from Combus)

• Input status (green), AC Fail (red) and Trouble (yellow) status lights

Unpacking the KT3-LCD

The KT3-LCD package includes the following parts/items:

• One KT3-LCD keypad

• Four mounting screws

Mounting the KT3-LCD

The keypad should be mounted where it is accessible to designated points to entry/exit. Once a dry and secure location is selected, perform

the following steps to mount the keypad:

1. Remove the keypad back plate by loosening the screw located at the base of the unit.

2. Secure the keypad back plate to the wall in the desired location. Use the included screws.

DN1315-0707

15

Page 18

Wiring the KT3-LCD

Before beginning to wire the unit, ensure that all power (AC transformer and battery) is

disconnected from the control panel.

To complete keypad wiring, connect the four Combus wires (Red, Black, Yellow and Green) to

keypad terminals R,B,Y and G.

Applying Power

1. Once all wiring is completed, turn the controller on.

2. Connect the battery leads to the battery.

3. Connect the AC transformer.

NOTE: Do not connect the power until all wiring is completed.

Assigning the KT3-LCD Keypad

Once all wiring is completed, the module must be assigned to the system. To assign the module, perform the following steps:

1. Establish communication between EntraPass and the controller.

2. Press the pound key (#) on each keypad. A serial number should be displayed in the EntraPass message desktop. Look for the type of module and the controller to which it is connected.

3. From the EntraPass controller definition window, select the functionality of the KT3-LCD and enter the serial number in the appropriate field (refer to Chapter 4, Defining Devices of the EntraPass Reference Manual for more details).

Troubleshooting Communication Problems

Default Initialization

The KT-300 default initialization is done at Kantech. The following steps should only be followed if:

a You are using a KT-300 from another site and there is no communication;

b The KT-300 was communicating via the RS-232 port and you installed a VC-485 to communicate via the

RS-485 port;

c You were using the KT-300 at a local site and now want to configure it for remote operation.

How to Use the Default Initialization (Hard Reset)

1. Disconnect both transformer and battery.

2. Remove all connection to DOOR1 and RL1 terminals.

3. Place a jumper between the DOOR1 and RL1 terminals.

4. Apply AC power to the transformer. The VITAL LED should flash 4 times. This means that the controller is in the initialization mode.

5. Remove jumper.

6. The VITAL LED will flash 3 beats at a time as soon as the controller communicates with the PC.

7. Reconnect the battery.

VITAL LED status indications

RL2

BUZ

OUTDOOR 2

LED

BUZ RL1

OUTDOOR 1

LED

8

C

7

6

AUX INPUTS

C

5

REX

2

C

DOOR

REX

1 DOOR

C

DOOR

Communication status and other vital controller parameters can be obtained from VITAL LED pulsations. This

information is particularly useful when connecting the controller to the rest of the access control system. Consult the

KT-300 Controller Wiring Diagram on page18 to locate the VITAL LED. The following table lists all conditions along with a brief description

.

VITAL LED Pulse Status Identification

1 per second Communication with EntraPass Global Gateway

2 per second Communication with master controller, modem online

3 per second Communication with EntraPass Corporate Gateway

4 per second Hard reset to factory defaults

Continuous Offline

0.5 second ON Reading access card

2.5 seconds ON Modem confirm

JUMPER

16

DN1315-0707

Page 19

KT-300 Door Controller Installation Manual

KT-300 Controller Maintenance Recommendations

The KT-300 circuit board includes a lithium battery (see the KT-300 Controller Wiring Diagram on page 18). This battery must be replaced

by a Kantech technician to avoid any risk of explosion. If the lithium battery stops working, return the circuit board to Kantech. Do not crush,

puncture, open, disassemble or otherwise mechanically interfere with the battery. Do not try to recharge the battery. If you need to dispose

of the circuit board and/or the lithium battery, wrap the KT-300 in non-conductive tape. Check with your local authorities for battery disposal

regulations.

WARNING: Do not store the batteries in such a way that they come into contact with each other or with any piece of metal. Explosion or

fire may occur. Should fire occur, use only dry chemical fire extinguishers. Do not use water to put out the fire. Do not heat

the batteries. Do not dispose of the batteries or circuit board in a fire. Do not disassemble the batteries. Do not apply

pressure to or deform the batteries. Ensure that the above precautions are strictly observed by related departments,

including, but not limited to, production, sales and outside contractors.

Regarding the recommended battery 7 A/12 V: It is the end-user and/or installer responsibility to assure that the disposal of used batteries is

made according to the waste recovery and recycling regulations currently applicable in their area. Use the recommended battery type

ONLY.

It is highly recommended to test the KT-300 Controller by performing the following tests:

1) Bi-annual test for battery:

Remove AC power from the controller and connect the battery to the controller for one hour. This test will ensure that in the event of a power

failure, the battery will be able to support normal operations. This test should be performed twice a year. Once the test has been performed

successfully, reconnect AC power to the controller.

2) Annual test for emergency lithium battery:

Measure voltage of lithium battery when power is totally removed from the controller (AC & DC power). To ensure maximum operation and

prevent loss of power, contact your distributor to return the KT-300 for maintenance if the lithium battery voltage measures below 2.5 VDC.

DN1315-0707

17

Page 20

KT-300 Wiring Diagram (North America Version)

(DATA0)

(DATA1)

(COMMON)

(POWER)

(BUZZER)

(LED)

BROWN

BLUE

RED (+12V)

BLACK

WHITE

GREEN

GRNWHTWHT GRN

TB2

KT300

ACCESS CONTROLLER

1

KANTECH SYSTEMS

U6

1

U7

WITH VC-485: ONLY TO

TO TERMINALS X1+ AND X1-

CONNECT A 120 OHMS

END OF LINE RESISTOR

*

READ1 READ2

+5VGND

IOPROX P325KP READER

THE LAST CONTROLLER

WITHOUT VC-485: FIRST

AND LAST KT-300

*

READER PWR

X1+

BAT

AC

CONTROLLER OR VC-485 AND LAST KT-300

CONNECT TO THE COMPUTER

60 METERS (200 FEET)

ENTRAPASS IF LESS THAN

USING

RS-232C

TO OTHER(S) CONTROLLER(S)

RS-485 NETWORK, ETHERNET CABLE

CATEGORY 3, UNSHIELDED, 4 CONDUCTORS

UP TO 1200 METERS (4000')

FROM THE FIRST AND LAST KT-300

WHITE

BLUE

WHITE

ORANGE

RS485

X1- +12V

EGND

RS232C

LED

VITAL

LED

*

2

1

5

TM

078

634

9

POLARIS

POLARIS 2KP READER

(LED)

(COMMON)

(POWER)

(DATA0)

(DATA1)

BROWN

BLUE (BUZZER)

RED (+5V)

BUZLEDLED BUZREXCBLK YEL GRN

WHITE

OUT DOOR 2

BLACK

NOTE: ONLY A SINGLE READER

FORMAT CAN BE SUPPORTED BY

EACH CONTROLLER. EXAMPLES

SHOWN HERE ARE ONLY TO

REPRESENT THE TYPICAL

CONNECTIONS FOR A WIEGAND

AND CLOCK & DATA INTERFACE

READERS.

WASHE R

NUT

NUT

KANTECH

SUPPLIED BY

OPEN

COLLECTOR

25mA MAX

WASHE R

CABINET

NOTE: ALL POWER OUTPUTS

ARE CURRENT LIMITED

BOLT

NCCOM

RELAY

NO

12 VOLTS DC

LOCAL RELAY

EARTH GROUND

KANTECH PART #

KT-RM1 (OPTIONAL)

GREEN

P3

+12V AUX

OUT DOOR 1

8567C

DOOR1 2 AUX. INPUTS

REX

DOOR

GREEN

NO OR NC

DRY CONTACT

7C

NC

CONTROLLER DEFINED

WITHOUT END OF LINE RESISTOR

C

NO

5600 5600

7

RESISTOR

NC DRY CONTACT

CONTROLLER DEFINED

WITH SINGLE END OF LINE

RESISTOR

NO DRY CONTACT

CONTROLLER DEFINED

WITH SINGLE END OF LINE

YELLOW

BLACK

COMBUS

LOCK 12V

AUXAC

RED

COMBUS EXPANSION

MODULES

DOOR CONTACT

120/240 VOLTS AC

REQUEST TO EXIT

TO RECEPTACLE

NOTE: DO NOT CONNECT

PLUG-IN ALSO AVAILABLE

CONTROLLED BY A SWITCH

16VAC, 40VA, CLASS 2, WIRE-IN

MOTION DETECTOR/SWITCH

RED

BLACK

IF NOT USED

DOOR LOCKING DEVICE

12 VOLTS DC 250 mA MAX.

CONNECT A 1000 OHMS RESISTOR

7 AMP/HR

BATTERY

SEALED RECHARGEABLE

7A/H

KT-BD7-12

12V BATTERY

12 VOLT

KANTECH PART #

RED C C

+

LK1- LK2- DOOR

+12V-

16V RL1 RL2

TB1

18

DN1315-0707

Page 21

KT-300 Wiring Diagram (UE Version)

KT-300 Door Controller Installation Manual

(DATA0)

(DATA1)

(COMMON)

BLACK

WHITE

GREEN

KT300

ACCESS CONTROLLER

(POWER)

(BUZZER)

(LED)

BROWN

BLUE

RED (+12V)

TB2

GRN

WHT

CONNECT A 120 OHMS

END OF LINE RESISTOR

WITH VC-485: ONLY TO

TO TERMINALS X1+ AND X1-

*

READ1 READ2

WHT

GRN

IOPROX P325KP READER

TO OTHER(S) CONTROLLER(S)

RS-485 NETWORK, ETHERNET CABLE

CATEGORY 3, UNSHIELDED, 4 CONDUCTORS

UP TO 1200 METERS (4000')

THE LAST CONTROLLER

WITHOUT VC-485: FIRST

AND LAST KT-300

ORANGE

WHITE

WHITE

*

READER PWR

+5VGND

X1+

FROM THE FIRST AND LAST KT-300

CONTROLLER OR VC-485 AND LAST KT-300

GREEN WIRE TO GROUND CONNECTION

BLUE

RS485

X1- +12V

EGND

LED

VITAL

CONNECT TO THE WORKSTATION (ENTRAPASS

V3.0) IF LESS THAN 60 METERS (200 FEET)

NOTE: ONLY A SINGLE READER FORMAT CAN BE SUPPORTED

BY EACH CONTROLLER. EXAMPLES SHOWN HERE ARE ONLY

TO REPRESENT THE TYPICAL CONNECTIONS FOR A WIEGAND

USING

RS232C

AND CLOCK & DATA INTERFACE READERS.

RS-232C

P3

BUZLEDLED BUZREXCBLK YEL GRN

(DATA0)

GREEN

OUT DOOR 2OUT DOOR 1

(DATA1)

WHITE

*

(COMMON)

(POWER)

RED (+5V)

BLACK

2

1

3

(LED)

BROWN

BLUE (BUZZER)

TM

098

654

7

POLARIS

25mA MAX

OPEN COLLECTOR

+12V AUX

NOTE: ALL POWER OUTPUTS

7C

NC

POLARIS 2KP READER

NC

COM

RELAY

NO

12 VOLTS DC LOCAL RELAY

KANTECH PART #KT-RM1 (OPTIONAL)

ARE CURRENT LIMITED

RESISTOR

NC DRY CONTACT

CONTROLLER DEFINED

WITH SINGLE END OF LINE

1

KANTECH SYSTEMS

U6

1

U7

8567C

2 AUX. INPUTS

REX

DOOR

DOOR

1

REQUEST TO EXIT

MOTION DETECTOR/SWITCH

GREEN

YELLOW

COMBUS

RED C C

+

LOCK 12V

LK1- LK2- DOOR

BAT

AC

LED

AUX

+12V-

AC

16V RL1 RL2

TB1

BLACK

RED

C

NO

7

NO OR NC

DRY CONTACT

CONTROLLER DEFINED

WITHOUT END OF LINE RESISTOR

DOOR CONTACT

COMBUS EXPANSION

MODULES

7 AMP/HR

5600 5600

RESISTOR

NO DRY CONTACT

CONTROLLER DEFINED

WITH SINGLE END OF LINE

IF NOT USED

DOOR LOCKING DEVICE

12 VOLTS DC 500 mA MAX.

CONNECT A 1000 OHMS RESISTOR

AC DC

POWER SUPPLY

AC

+DC

AC

BAT+

-

EARTH GROUND

12 VDC 1 AMP

POWER SUPPLY

DOOR LOCKING DEVICE

GREEN WIRE TO KT300

EGND CONNECTION

250 VAC

FUSE 20mm

315mA SLOBLOW

BATTERY

SEALED RECHARGEABLE

12 VOLT

RED

BLACK

12V BATTERY 7A/H

KANTECH PART #KT-BD7-12

240 VAC IN

16VAC 80VA OUT

TRANSFORMER

MAINS

NEUTRAL

LIVE

240 VAC

50 HERTZ

DN1315-0707

19

Page 22

20

DN1315-0707

Loading...

Loading...