Technical description

ULTRAFLOW® 54 DN150-250

Kamstrup A/S

Industrivej 28, Stilling

DK-8660 Skanderborg

TEL: +45 89 93 10 00

FAX: +45 89 93 10 01

info@kamstrup.com

www.kamstrup.com

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

2

5512-876 GB/04-2012/Rev. F1

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

Contents

1 General description ........................................................................................................ 5

2 Data ............................................................................................................................... 6

2.1 Electrical data ........................................................................................................................................ 6

2.2 Mechanical data .................................................................................................................................... 6

2.3 Flow data ............................................................................................................................................... 7

2.4 Material ................................................................................................................................................. 7

3 Type overview ................................................................................................................. 8

4 Ordering details.............................................................................................................. 9

4.1 Type numbers of ULTRAFLOW® 54 for MULTICAL® .................................................................................... 9

4.2 Type numbers of separate ULTRAFLOW® 54 ............................................................................................ 9

4.2.1 Ordering details of separate ULTRAFLOW® 54 .................................................................................. 10

4.2.2 Type numbers of output and supply modules .................................................................................. 10

4.2.3 Programming variants of pulse figures and pulse durations ............................................................. 11

4.3 Accessories ......................................................................................................................................... 12

4.3.1 Cables............................................................................................................................................ 13

5 Dimensioned sketches .................................................................................................. 14

6 Pressure loss ................................................................................................................ 16

7 Installation ................................................................................................................... 17

7.1 Installation angle of ULTRAFLOW® 54 ................................................................................................... 18

7.1.1 Mounting ULTRAFLOW® 54 in lifting ring .......................................................................................... 18

7.2 Mounting of ULTRAFLOW® 54 electronics box ....................................................................................... 19

7.2.1 Orientation of flow sensor electronics box ...................................................................................... 20

7.3 Straight inlet ........................................................................................................................................ 21

7.4 Operating pressure .............................................................................................................................. 21

7.5 Connection to calculator ...................................................................................................................... 22

7.5.1 ULTRAFLOW® 54 and MULTICAL®, galvanically coupled ................................................................... 22

7.5.2 ULTRAFLOW® 54 and MULTICAL®, galvanically separated ................................................................ 22

7.6 Connection of power supply ................................................................................................................. 24

7.6.1 Battery supply ................................................................................................................................ 24

7.6.2 Mains supply modules ................................................................................................................... 24

7.6.3 Mains supply cable ........................................................................................................................ 25

7.6.4 Danish regulations for the connection of mains operated meters ..................................................... 25

7.6.5 Cable connections .......................................................................................................................... 26

7.6.6 Change of supply unit ..................................................................................................................... 26

7.7 Example of connection of ULTRAFLOW® 54 for MULTICAL® .................................................................... 27

7.8 Calculator with two flow sensors .......................................................................................................... 28

7.9 Testing the function ............................................................................................................................. 28

8 Functional description .................................................................................................. 29

8.1 Ultrasound combined with piezo ceramics ........................................................................................... 29

8.2 Principles ............................................................................................................................................ 29

8.3 Transient time method ......................................................................................................................... 29

8.4 Signal paths ........................................................................................................................................ 31

8.5 Measuring sequences .......................................................................................................................... 31

8.6 Function .............................................................................................................................................. 32

8.7 Guidelines for dimensioning ULTRAFLOW® ........................................................................................... 33

8.8 Pulse output ........................................................................................................................................ 34

5512-876 GB/04-2012/Rev. F1

3

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

8.8.1 Galvanically coupled ...................................................................................................................... 34

8.8.2 Galvanically separated................................................................................................................... 35

8.9 Pulse emission ................................................................................................................................... 37

8.10

Accuracy ........................................................................................................................................ 37

8.11

Power consumption ....................................................................................................................... 38

8.12

Interface plug/serial data............................................................................................................... 38

8.13

Test mode ..................................................................................................................................... 39

8.14

Externally controlled start/stop ...................................................................................................... 39

8.15

Calibration procedure using serial data and externally controlled start/stop .................................. 40

9 Calibrating ULTRAFLOW® .............................................................................................. 41

9.1 Test instructions for ULTRAFLOW 54, DN150-250 ............................................................................... 41

9.1.1 Installation angle for ULTRAFLOW® ................................................................................................. 41

9.1.2 Technical data ............................................................................................................................... 41

9.1.3 Connection .................................................................................................................................... 42

9.2 Sealing ............................................................................................................................................... 43

9.3 Optimization in connection with calibration......................................................................................... 44

9.4 PULSE TESTER ..................................................................................................................................... 45

9.4.1 Technical data of PULSE TESTER ..................................................................................................... 45

9.4.2 Hold-function ................................................................................................................................ 47

9.4.3 Push-button functions ................................................................................................................... 47

9.4.4 Use of PULSE TESTER ..................................................................................................................... 47

9.4.5 Spare parts .................................................................................................................................... 48

9.4.6 Battery replacement ...................................................................................................................... 48

10 METERTOOL ................................................................................................................. 49

10.1

Introduction .................................................................................................................................. 49

10.2

System Requirements for PC .......................................................................................................... 49

10.2.1 Interface .................................................................................................................................... 49

10.2.2 Installation ................................................................................................................................ 51

10.3

METERTOOL for ULTRAFLOW® X4 .................................................................................................... 52

10.3.1 Files .......................................................................................................................................... 52

10.3.2 Utilities ..................................................................................................................................... 52

10.3.3 Windows ................................................................................................................................... 52

10.3.4 Help .......................................................................................................................................... 53

10.4

Application .................................................................................................................................... 53

10.4.1 COM-port selection .................................................................................................................... 53

10.4.2 Flow meter adjustment .............................................................................................................. 54

10.4.3 Programming of standard flow curve .......................................................................................... 54

10.4.4 Pulse Divider ............................................................................................................................. 55

10.4.5 Meter type ................................................................................................................................. 57

10.4.6 Help .......................................................................................................................................... 57

10.5

Update .......................................................................................................................................... 58

11 Troubleshooting ........................................................................................................... 59

12 Approvals..................................................................................................................... 60

12.1

Measuring Instruments Directive .................................................................................................... 60

12.2

CE-Marking .................................................................................................................................... 60

12.3

Declaration of conformity ............................................................................................................... 61

13 Disposal ....................................................................................................................... 62

14 Documents ................................................................................................................... 63

4

5512-876 GB/04-2012/Rev. F1

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

1 General description

ULTRAFLOW® 54 DN150-250 is a static flow sensor based on the ultrasonic measuring principle. It is primarily

used as a volume flow sensor for energy meters such as MULTICAL®. ULTRAFLOW® 54 DN150-250 has been

designed for use in heating and cooling installations where water is the heat-bearing medium.

ULTRAFLOW® 54 DN150-250 employs ultrasonic measuring techniques and microprocessor technology. All

calculating and flow measuring circuits are collected on one single board, thus providing a compact and rational

design and, in addition, exceptionally high measuring accuracy and reliability is obtained.

The volume is measured using bidirectional ultrasonic technique based on the transit time method, with proven

long-term stability and accuracy. Four ultrasonic transducers are used to send sound signals both against and

with the flow. The ultrasonic signal travelling with the flow reaches the opposite transducer first. The time

difference between the two signals can be converted into flow velocity and thereby also volume.

A three-wire signal cable is used to connect ULTRAFLOW® 54 DN150-250 to the Kamstrup MULTICAL® calculator.

The cable supplies the flow sensor and also transfers the signal from sensor to calculator. A signal corresponding

to the flow – or more correctly, a number of pulses proportional to the water volume flowing through – is

transmitted.

ULTRAFLOW® 54 DN150-250 is available with internal supply, e.g. if the distance between MULTICAL® and

ULTRAFLOW® is 10 meters or more. If ULTRAFLOW® 54 DN150-250 is used for other equipment (e.g. other brands

of calculators), the sensor must be fitted with a galvanically separated output module and a supply of its own.

5512-876 GB/04-2012/Rev. F1

5

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

2 Data

ULTRAFLOW®54 DN150-250

2.1 Electrical data

Supply voltage 3.6 V ± 0.1 V

Supply, galvanically coupled output

module (Y=1)

Powered by MULTICAL®

Supply, galvanically separated output

module (Y=2) 1)

Mains supply 230 VAC +15/-30%, 50 Hz

24 VAC ±50%, 50 Hz

Power consumption

< 1 W

Backup Integral SuperCap eliminates interruptions due to short-term power failures

Supply, galvanically separated output

module (Y=3)

Battery 3.65 VDC, D-cell lithium

Replacement interval

6-years @ t

< 30°C

BAT

Mains supply 230 VAC +15/-30%, 50 Hz

24 VAC ±50%, 50 Hz

Power consumption

< 1 W

Backup Integral SuperCap eliminates interruptions due to short-term power failures

Signal cable length, from flow sensor

Max. 10 m (powered by calculator)

electronics box with galvanically

coupled output module (Y=1)

Signal cable length, from flow sensor

electronics box with galvanically

Depending on calculator (use of own supply in ULTRAFLOW®).

See paragraph 7.5.2 for applications with MULTICAL®

separated output module (Y=2 and 3)

EMC data Fulfil DS/EN 1434:2007 class C, MID E1 and E2

2.2 Mechanical data

Metrological class 2 or 3

Environmental class Fulfils DS/EN 1434 class C

Ambient temperature 5…55°C (indoors)

Protection class IP67 When installed properly. See paragraph 7.2

Humidity 93% RH non-condensing

Mechanical environment MID M1 and M2

Temperature of medium 2…150°C (Heat-, heat/cooling meters)

2…50°C (Cooling meters)

At medium temperatures above 90°C (T

> 90°C)

med

or medium temperature more than 5°C below

ambient temperature (T

med

< T

amb

- 5°C), the

electronics box must be wall mounted or

mounted via the enclosed distance piece.

Storage temp. empty

-25…70°C, 60°C if battery mounted/enclosed

sensor

Pressure stage PN25

1)

It is possible to use battery supply in combination with output module (Y=2), e.g. for temporary supply of flow sensors installed at

construction sites.

6

5512-876 GB/04-2012/Rev. F1

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

p

1)

2)

qi:qpqs:q

1)

2)

2.3 Flow data

Nom. flow q

[m³/h] [mm] [imp/l]

150 DN150 1 1:100 2:1 450 0.02 300

250 DN150 0.6 1:100 2:1 750 0.055 500

400 DN150 0.4 1:100 2:1 1125 0.04 800

400 DN200 0.4 1:100 2:1 1125 0.01 800

400 DN250 0.4 1:100 2:1 1125 0.01 800

600 DN200 0.25 1:100 2:1 1800 0.022 1200

600 DN250 0.25 1:100 2:1 1800 0.022 1200

1000 DN250 0.15 1:100 2:1 3000 0.015 2000

Standard pulse figure. Appears from ULTRAFLOW® label. For other pulse figures see paragraph 4.

Saturation flow. Max. pulse frequency, 128 Hz, is maintained at higher flow rates.

2.4 Material

Wetted parts

Housing Stainless steel, W.no. 1.4307

Transducer holder Stainless steel, W.no. 1.4308

Transducer Titanium

Gaskets Fibre

Electronics box

Nom. diameter Pulse figures

Dynamic range

Table 1

Flow @ 125 Hz

p

[m³/h] [bar] [l/h]

∆∆∆∆p @ qpMin. Cutoff

Base, cover Thermoplastic, PC 10% GF

Fitting hardware, Thermoplastic, PPS 40% GF

distance piece for

electronics box

Signal cable (optional for separate ULTRAFLOW® 54)

Silicone cable (3x0.5 mm2)

Power supply cable 24/230 VAC (optional)

Cable with PVC-mantle (2x0.75 mm²)

5512-876 GB/04-2012/Rev. F1

7

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

p

[m³/h]

1000

DN250x600 mm

3 Type overview

Nom. flow q

150 DN150x500 mm

250 DN150x500 mm

400 DN150x500 mm DN200x500 mm DN250x600 mm

600 DN200x500 mm DN250x600 mm

Flange EN 1092, PN25

Overall lengths

Table 2

8

5512-876 GB/04-2012/Rev. F1

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

p qi qs

[m³/h]

[m³/h]

[m³/h]

[mm]

[imp/l]

65-5-

FGCR

-XXX *)

1000102000

DN250

25

600

0.15

493

Stainless steel

p qi qs

[m³/h]

[m³/h]

[m³/h]

[mm]

65-5-

FGCR

-YZ

-XXX *)

1000102000

DN250

25

600

Stainless steel

4 Ordering details

4.1 Type numbers of ULTRAFLOW® 54 for MULTICAL®

The table below shows a list of type numbers for ULTRAFLOW® 54 ordered with MULTICAL®

Type number CCC

65-5- FCCN -XXX 150 1.5 300 DN150 25 500 1 447 (489) Stainless steel

65-5- FDCN -XXX 250 2.5 500 DN150 25 500 0.6 481 Stainless steel

65-5- FECN -XXX 400 4 800 DN150 25 500 0.4 491 Stainless steel

65-5- FECP -XXX 400 4 800 DN200 25 500 0.4 491 Stainless steel

65-5- FECR -XXX 400 4 800 DN250 25 600 0.4 491 Stainless steel

65-5- FFCP -XXX *) 600 6 1200 DN200 25 500 0.25 492 Stainless steel

65-5- FFCR -XXX *) 600 6 1200 DN250 25 600 0.25 492 Stainless steel

XXX, code re marking and final assembly.

*) Cannot be delivered with MID approval

q

Connection PN

[mm] [bar]

Length Pulse figure

Material

flow sensor case

Table 3

4.2 Type numbers of separate ULTRAFLOW® 54

Type number

65-5- FCCN -YZ -XXX 150 1.5 300 DN150 25 500 Stainless steel

65-5- FDCN -YZ -XXX 250 2.5 500 DN150 25 500 Stainless steel

65-5- FECN -YZ -XXX 400 4 800 DN150 25 500 Stainless steel

65-5- FECP -YZ -XXX 400 4 800 DN200 25 500 Stainless steel

65-5- FECR -YZ -XXX 400 4 800 DN250 25 600 Stainless steel

65-5- FFCP -YZ -XXX *) 600 6 1200 DN200 25 500 Stainless steel

65-5- FFCR -YZ -XXX *) 600 6 1200 DN250 25 600 Stainless steel

q

Connection PN

[mm] [bar]

Length

Material

flow sensor case

XXX, code re marking and final assembly.

*) Cannot be delivered with MID approval

Table 4

5512-876 GB/04-2012/Rev. F1

9

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

0 (powered by MULTICAL

)

4.2.1 Ordering details of separate ULTRAFLOW® 54

Type number composition of separate ULTRAFLOW® 54

ULTRAFLOW® 54. Type no: 65-5

Dynamic range and flow

Connection and overall length

Output module

Supply module

Final assembly and marking

- XX XX - Y Z - XXX

In addition to the basic variants listed above in

Table 3

, you must select output module (Y), supply module (Z) as

well as pulse figure programming (CC) and pulse duration (E).

The variant with galvanically coupled output module (Y=1) is solely for use together with MULTICAL®.

The variant with galvanically separated output module (Y=2 or 3) is used in the following situations:

1) More than 10 m cable length between MULTICAL® and ULTRAFLOW® is required.

2) As flow sensor no. 2 in connection with MULTICAL®. If two flow sensors are used together with

MULTICAL®, one must include a galvanically separated output module (Y=2 or 3). For further details see

paragraph 7.8 Calculator with two flow sensors

.

3) Together with other equipment/foreign calculators.

Please note:

Flow info cannot be read if output module with galvanic separation is used.

4.2.2 Type numbers of output and supply modules

Type number overview of output modules (Y) and supply modules (Z) for separate ULTRAFLOW® 54.

Y Output module Corresponding supply module

1 Galvanically coupled module

2 Galvanically separated module 0, 7, 8

3 Galvanically separated module 0, 2, 7, 8

Z Supply module Corresponding output module

0 No supply 1, 2, 3

2 Battery, D-cell 3

7 230 VAC supply module 2, 3

8 24 VAC supply module 2, 3

Table 5. Output modules (Y) and supply modules (Z).

®

10

5512-876 GB/04-2012/Rev. F1

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

4.2.3 Programming variants of pulse figures and pulse durations

Overview of programming variants as to pulse figures (CC) and pulse durations (E) for separate ULTRAFLOW

q

p

[m³/h] [imp/l] [l/pulse] CC [ms] (E=1) [ms] (E=4) [ms] (E=5) [ms] (E=6)

150 1 33 3.9 - - - Default

150 10 34 - 20 - 150 25 64 - 20 - 150 100 35 - 20 50 100

150 250 65 - 20 50 100

150 1000 36 - 20 50 100

150 2500 66 - 20 50 100

Pulse figure

Pulse duration

250 0.6 43 3.9 - - - Default

250 10 34 - 20 - 250 25 64 - 20 - 250 100 35 - 20 50 100

250 250 65 - 20 50 100

250 1000 36 - 20 50 100

250 2500 66 - 20 50 100

400 0.4 63 3.9 - - - Default

400 100 35 - 20 50 400 250 65 - 20 50 100

400 1000 36 - 20 50 100

400 2500 66 - 20 50 100

600 0.25 14 3.9 - - - Default

600 100 35 - 20 50 600 250 65 - 20 50 600 1000 36 - 20 50 100

600 2500 66 - 20 50 100

1000 0.15 54 3.9 - - - Default

1000 (0.25) 4 14 3.9 - - - *)

1000 100 35 - 20 50 1000 250 65 - 20 50 1000 1000 36 - 20 50 100

1000 2500 66 - 20 50 100

*) Spare part for ULTRAFLOW® type 65-S/R/T. Configured 65-5-FGCR. No flow info.

®

Table 6. Pulse figures (CC) and pulse durations (E).

5512-876 GB/04-2012/Rev. F1

11

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

2

)

2

)

4.3 Accessories

Please note that not all article numbers mentioned in the table can be directly ordered, some must be ordered via

our service department.

Article number Description

65-000-000-2000 D-cell lithium battery with two-pole connector

3026-477 1) Fitting for D-cell battery

1650-157 1) Plug for cable connection

1)

Obligatory when changing from mains supply module to battery supply.

Article number

65-000-000-7000

65-000-000-8000

Description

230 VAC supply module

24 VAC supply module

5000-290 Cable between supply module and output module

Note

(when ordering ULTRAFLOW®)

Enclosed if battery

supply or “No supply” is

selected

Enclosed if battery

supply or “No supply” is

selected

Note

(when ordering ULTRAFLOW®)

Enclosed if supply

module is selected

5000-286 24/230 V AC power cable Optional

2)

Including 5000-290.

Article number

Description

5550-1061 Output module (Y=1), galvanically coupled

5550-1062 Output module (Y=2), galvanically separated

Output module (Y=3), galvanically separated,

5550-1219

“Low power”

Note

(when ordering ULTRAFLOW®)

12

5512-876 GB/04-2012/Rev. F1

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

Article number

Description

Note

(when ordering ULTRAFLOW®)

Default for ULTRAFLOW®

ordered with MULTICAL

5000-333 2.5 m silicone cable (3-wire)

Optional for separate

ULTRAFLOW®

5000-259 5 m silicone cable (3-wire) Optional

5000-270 10 m silicone cable (3-wire) Optional

3026-207 Mounting fitting for electronics box Enclosed (mounted)

6561-332 Short distance piece (article)

3026-507 Long distance piece Enclosed

1051-006 Collar band for short and long distance piece Enclosed

1150-140 Gasket, DN150 PN25 (1 pc) Enclosed (2 pcs.)

1150-139 Gasket, DN200 PN25 (1 pc) Enclosed (2 pcs.)

1150-141 Gasket, DN250 PN25 (1 pc) Enclosed (2 pcs.)

®

4.3.1 Cables

ULTRAFLOW® 54 DN150-250, when ordered with MULTICAL®, is delivered with 2.5 m signal cable, optionally 5 or

10 m. The cable is mounted in the ULTRAFLOW® 54 electronics box and in MULTICAL® 6xx. When ULTRAFLOW® 54

is ordered with MULTICAL® 8xx, the calculator is delivered separately. Hence the cable is only mounted in the

ULTRAFLOW® 54 electronics box.

ULTRAFLOW® 54 DN150-250, when ordered as a separate flow sensor, is optionally available with signal cable in

lengths of 2.5, 5 or 10 m. The cable is mounted in the ULTRAFLOW® 54 electronics box.

If 24/230 VAC supply module is selected, the sensor is optionally available with power supply cable. The cable is

mounted in the sensor's electronics box from the factory.

5512-876 GB/04-2012/Rev. F1

13

TECHNICAL DESCRIPTION ULTRAFLOW® 54 DN150-250

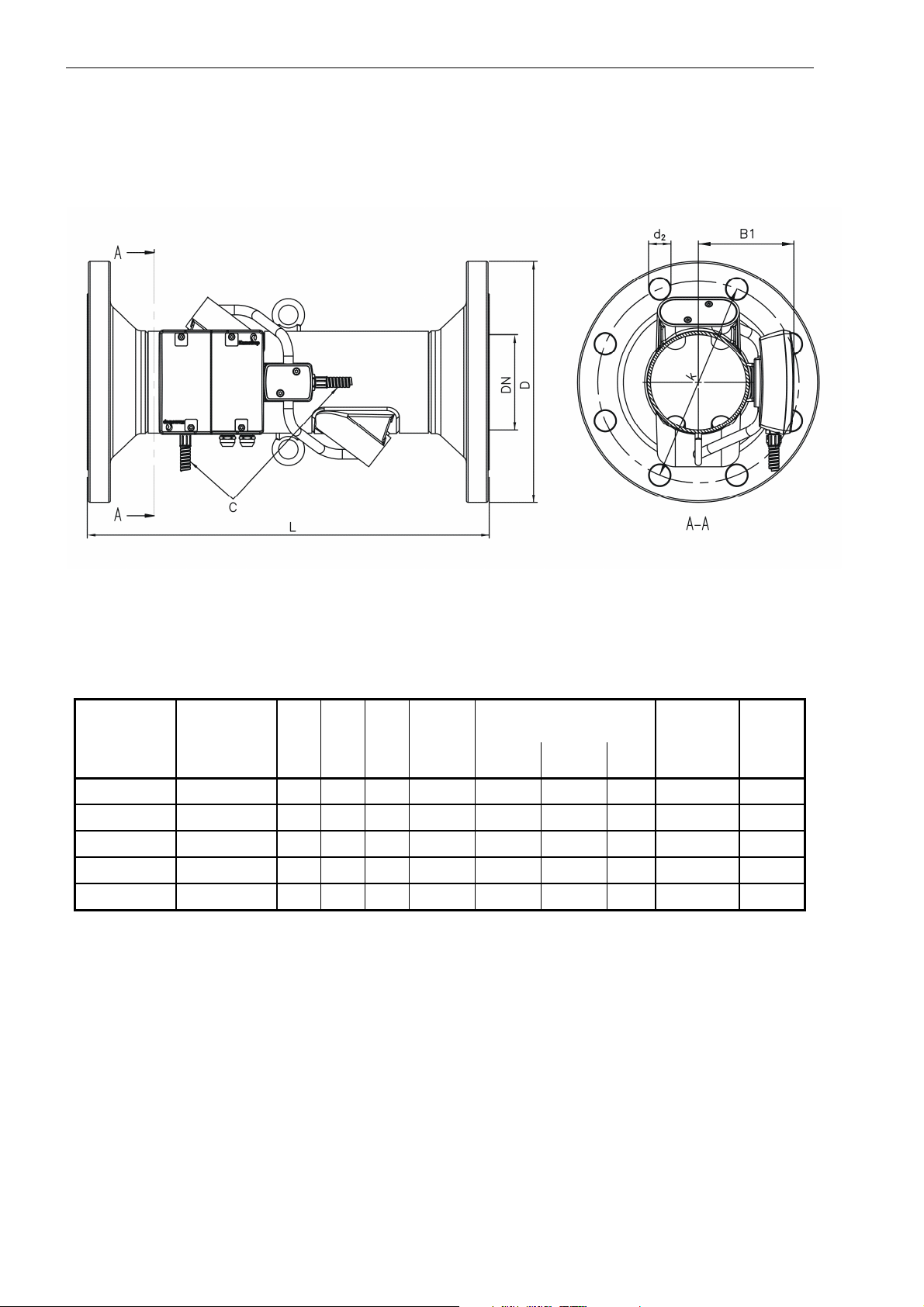

5 Dimensioned sketches

All measurements are in mm, unless otherwise stated.

Figure 1

Flange EN 1092-1, PN25

Nom.

diameter

Nom. flow q

L D k B1 Bolts

p

Steel tube

length

[m³/h] Quantity Thread d2 C [[