Page 1

M-Bus

Technical Description

Kamstrup A/S

Industrivej 28, Stilling

DK-8660 Skanderborg

TEL: +45 89 93 10 00

FAX: +45 89 93 10 01

info@kamstrup.com

www.kamstrup.com

Page 2

Contents

1. Technical description M-Bus 3

Introduction 3

2. M-Bus System 4

M-Bus system components 4

Communication 4

Addresses of M-Bus Slave units 4

Primary addressing 4

Secondary addressing 4

Operation 5

3. M-Bus Master 6

®

4. M-Bus Slave for MULTICAL

5. M-Bus Slave for MULTICAL® Compact/MULTICAL® 401 8

6. M-Bus Slave for Kamstrup 162/382/351 Combi 9

7. M-Bus Cascade module 10

7

8. M-Bus Modem 12

Test 12

9. Installation of M-Bus 13

Cable length 13

Mounting 13

10. Data reading of M-Bus 15

Data reading of heat meters 15

®

M-Bus Slave for MULTICAL

III/MULTICAL® 15

M-Bus Slave for MULTICAL® Compact/MULTICAL® 401 16

Data reading of Kamstrup 162/382/351 Combi 16

M-Bus Slave for Kamstrup 162/382/351 Combi 16

Reading equipment 16

11. Protocol 17

Commands 17

The individual commands in detail 17

M-Bus Master to M-Bus Slave 17

M-Bus Slave to M-Bus Master 18

Communication process 19

Reading of fresh data through e.g. data logging 20

M-Bus Slave and foreign M-Bus masters 20

Appendix 20

Physical properties 26

5511-710 GB/12.2004/Rev. C1

2

Page 3

1. Technical description M-Bus

Introduction

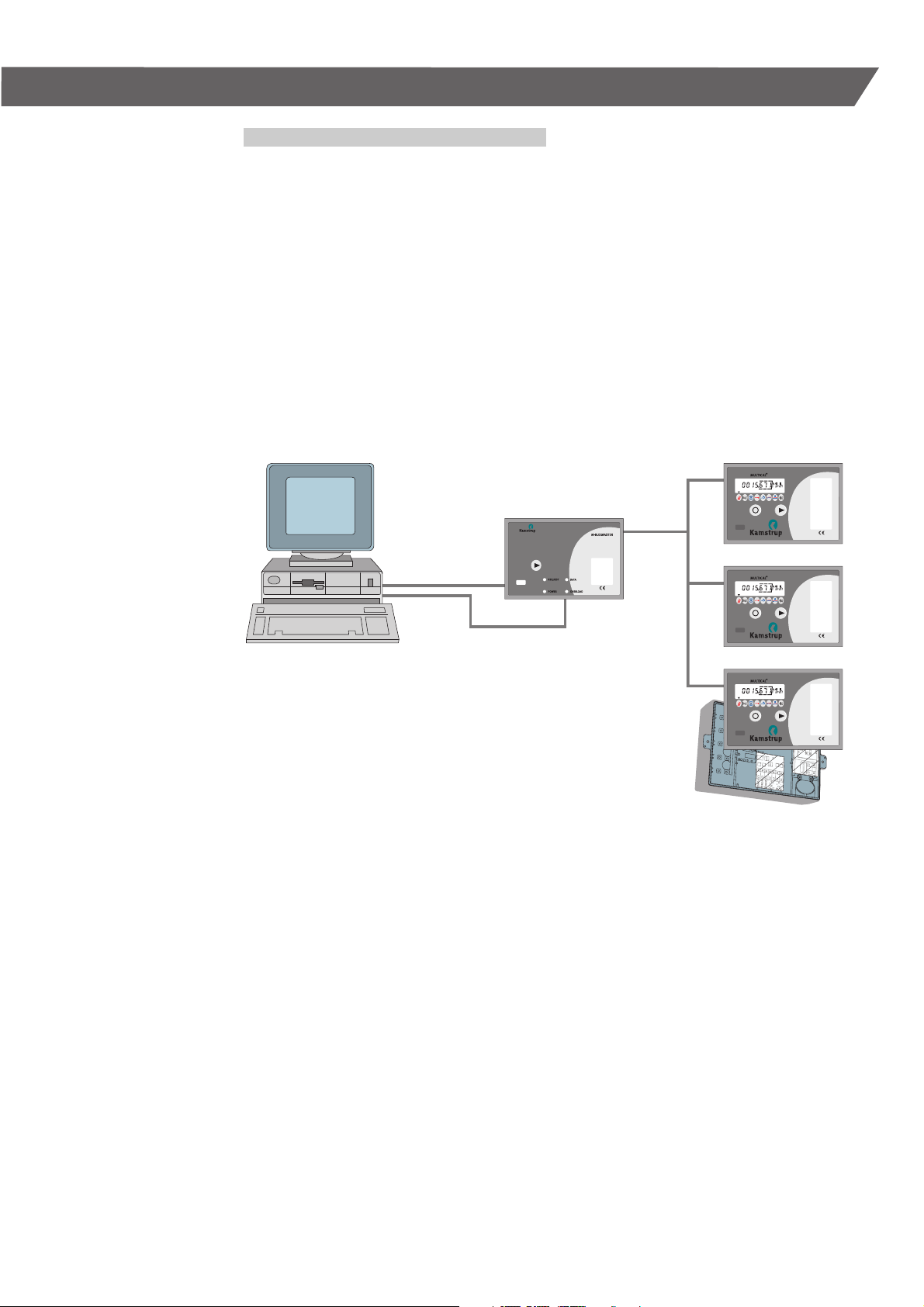

This document describes the use of Kamstrup’s

M-Bus system.

M-Bus is used for electronic reading of district heat

meters.

As the data route from meter to accounting

program is electronic, the data is secured against

errors. It is easy and simple to equip Kamstrup

energy meters with an M-Bus Slave, which is

inserted at the modular space in the energy meter.

It is unnecessary to program the integrating energy

meter or the M-Bus Slave as the system is selfconfiguring.

M-Bus Master

Computer placed

at the utility

5511-710 GB/12.2004/Rev. C1

Heat meters with

M-Bus Slave

3

Page 4

2. M-Bus System

M-Bus system components

The M-Bus system consists of the following

elements:

M-Bus Slave

■

M-Bus Master

■

M-Bus Cascade module

■

M-Bus Modem

■

Communication software PcM-Bus

■

Communication software PcModem

■

Communication software PcLink

■

IR head for reading

■

■

Data cabel for reading

The M-Bus Master is built-up as a repeater, which

converts signals from e.g. RS232 to M-Bus format

(18-30 V/0-20 mA). The M-Bus Master has been

constructed to function together with Kamstrup’s

M-Bus Slaves and Kamstrup’s reading software.

The M-Bus Master can supply up to 40 M-Bus

Slaves at the power consumption of 1.5 mA

(1 Unit Load) per M-Bus Slave.

One or more M-Bus Cascade modules can be installed, and can comprise up to 250 M-Bus Slaves.

Communication

The communication on the M-Bus consists of

vol-tage modulation from M-Bus Master to M-Bus

Slave (30 – 18 V) as well as current modulation

from M-Bus Slave to M-Bus Master (0 – 20 mA)

through an ordinary two-wire cable.

The M-Bus system has been constructed to observe

the regulations of the EN 1434-3.

The communication on the M-Bus system is asynchronous serial bit transmission (EN 60870-5-1)

in half duplex mode, i.e. the communication consists of 1 start bit, 8 data bits, 1 parity bit (even),

1 stop bit.

The transmission speeds are 300 baud or 2400

baud.

Addresses of M-Bus Slave units

If the M-Bus system is to function with a number

of connected M-Bus Slaves, each M-Bus Slave

must be given an identification number (address).

This is done via MULTICAL

®

, which contains a

unique customer number to the M-Bus Slave. The

unique address of the M-Bus Slave is equal to the

last 3–8 digits of the customer number, and thereby supports both primary and secondary addressing. The address applies to both types of addressing, and can be re-programmed either by means

of the hand-held terminal, MULTITERM, or the verification program of METERTOOL.

Primary addressing

The M-Bus Slave automatically reads the energy

meter’s costumer number in connection with start

or initialisation. The address must lie between 1

and 250.

If the last three digits of the customer number

exceed 250 (e.g. 345) the first digit will be ignored

and the ID number of the M-Bus Slave will only be

determined by the two last digits (e.g. 45).

If 3 systems are available each with 250 M-Bus

Slave modules, the number system is build up as

follows:

1st. system:

The energy meters are programmed with customer

numbers from 1001 to 1250.

2nd. system:

The energy meters are programmed with customer

numbers from 2001 to 2250.

3rd. system:

The energy meters are programmed with customer

numbers from 3001 to 3250.

Secondary addressing

The M-Bus Slave automatically reads the customer

number of the energy meter during start or initialization.

The M-Bus address consists of the last 3 – 8 digits

of the customer number, extending the address

possibility to 0000 0001 – 9999 9999.

Note: Kamstrup communication software,

PcM-Bus, and Kamstrup M-Bus Master

do not support secondary addressing.

The M-Bus module does not support extended

secondary address functions, e.g. enhanced secondary addressing, collision detection or wild-card

search.

Each M-Bus Slave must have its own addres

The M-Bus Master always sends a message on the

bus to a given address, which is encoded in the

message (the format). Only the M-Bus Slave in question will reply.

If several M-Bus Slaves have the same address a

collision will arise, when the M-Bus Slaves reply to

the M-Bus Master.

However, there are two special addresses, which

function as follows:

Address 254:

All M-Bus Slaves will answer to this address. The

address must solely be used in systems with only

one M-Bus Slave connected, e.g. for test.

Address 255:

No M-Bus Slave will answer to this address, but

all M-Bus Slaves will receive the message. This

message makes it possible e.g. to change the baud

rate of a whole system at a time, only by sending a

format from the M-Bus Master.

5511-710 GB/12.2004/Rev. C1

4

Page 5

Operation

It is optional whether the M-Bus Master is to be

permanently switched on, or the bus system is to

be switched off when not in operation (reading).

The M-Bus system cannot supply the MULTICAL

®

integrating units. Only the M-Bus Slaves are supplied from the M-Bus Master.

In connection with start-up the M-Bus Master will

have an initialization time of approx. 5 sec., and

the overload diode will light. After the 5 sec., the

diode will switch off and the M-Bus Master is ready.

In case the bus system is turned on constantly,

these initialization times will only appear in connection with installation. In addition, the initialization

time of M-Bus Slaves is approx. 9 sec., before data

can be acquired, and if mounted in MULTICAL

®

III.

However, if the M-Bus Slaves are installed in

®

MULTICAL

the initialization time is approx. 12 sec.

The initiation time for Kamstrup 162/382/351 Combi

is typically 7 seconds.

Rarely, a longer initiation time might be necessary

– see Appendix.

5511-710 GB/12.2004/Rev. C1

5

Page 6

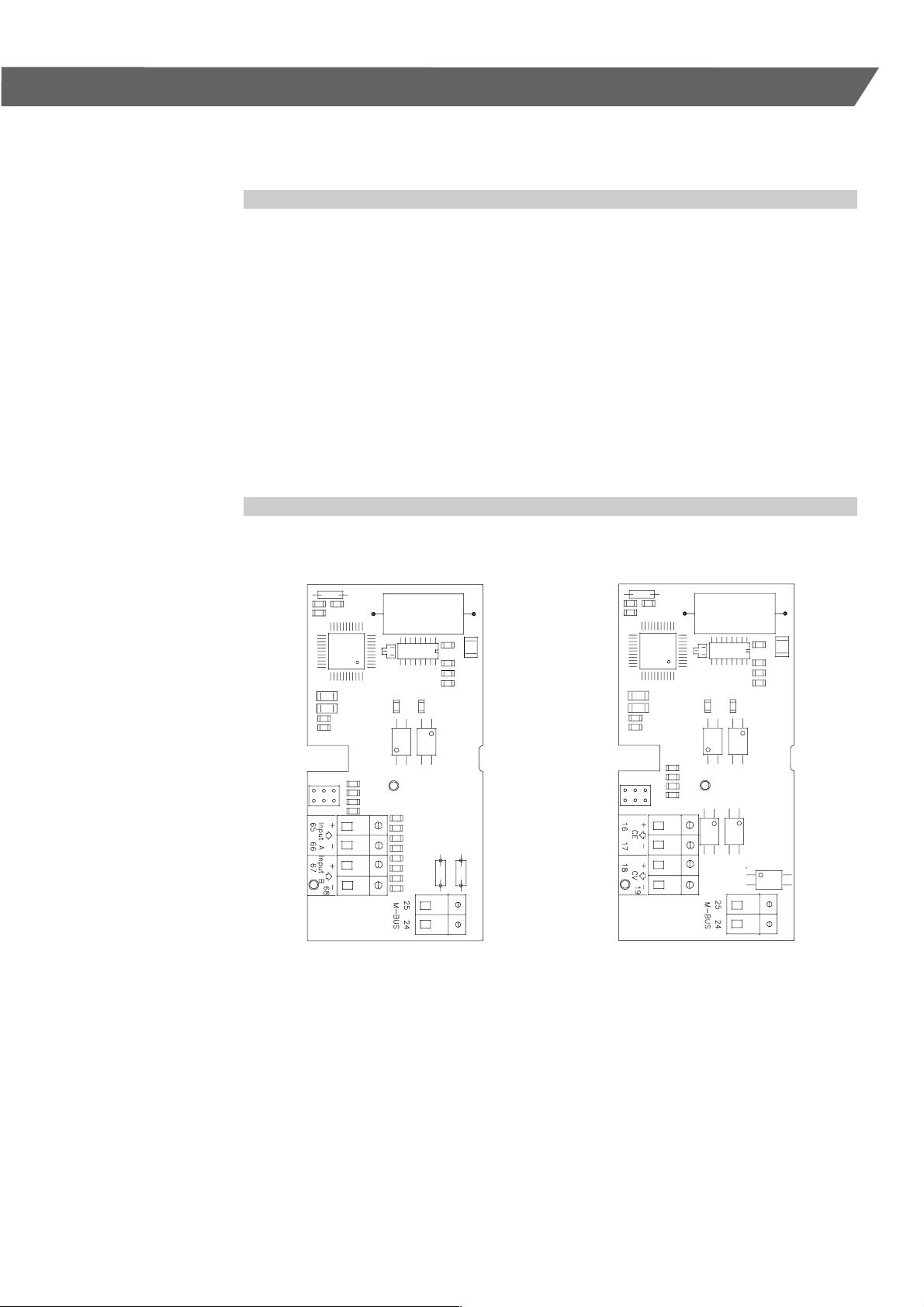

3. M-Bus Master

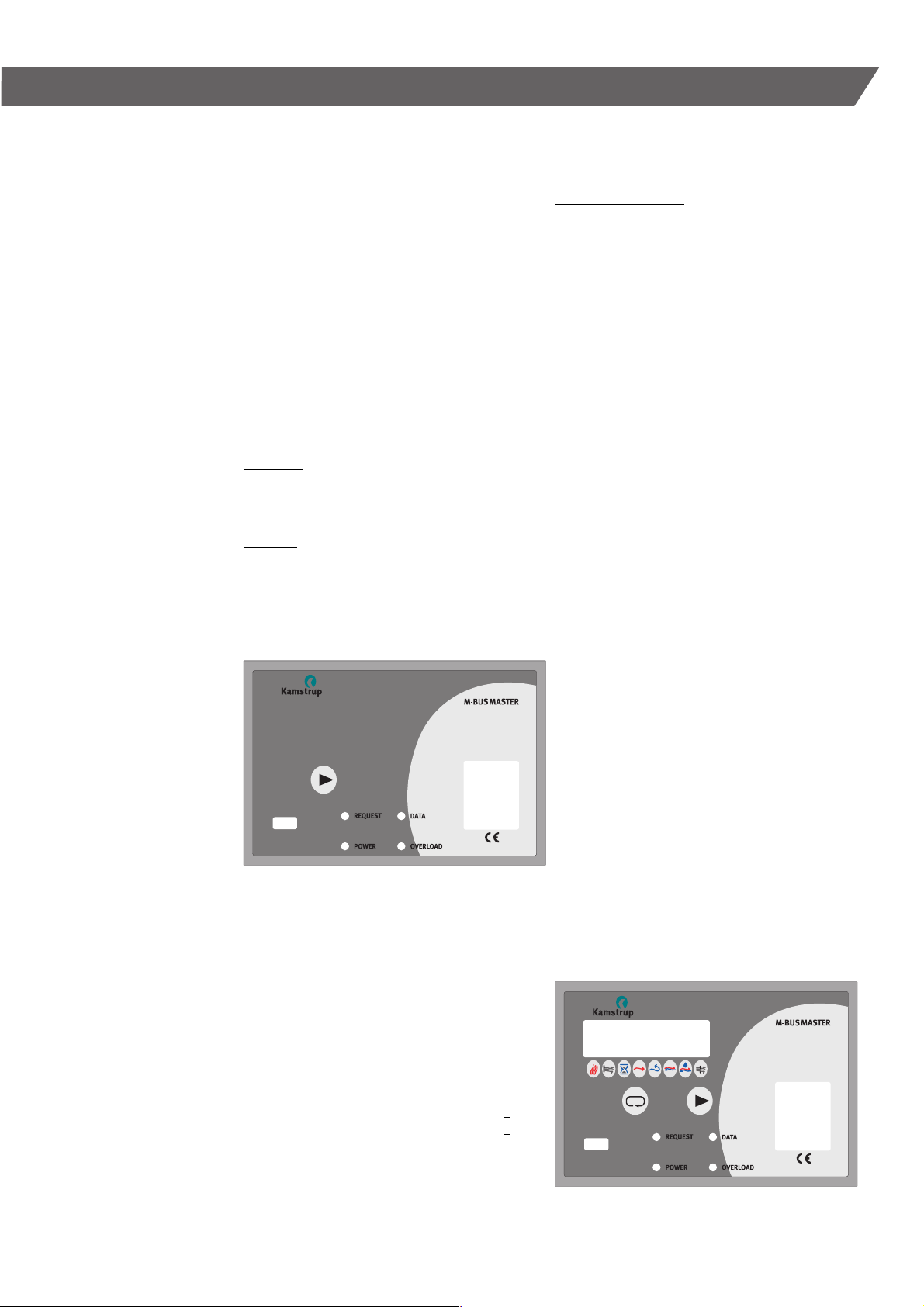

Two versions of the M-Bus Master are available.

One with a display and one without, however,

they function in the same way.

The M-Bus Master is built-up with supply print,

connection print and main print.

Furthermore the bracket has room for an extra

module – see paragraph 7 and 8.

The main print is placed at the top of the case,

and except from transformator, bridge connection

and connection terminals everything is mounted

on this print.

The front plate has four light emitting diodes

with the following indications:

Power:

Indicates that the M-Bus Master is supplied

with power.

Overload:

Indicates that too much power is drawn from the

bus. I.e. either a short-circuit or too many M-Bus

Slaves connected to the M-Bus Master.

Request:

Blinks when data are sent from M-Bus Master

to M-Bus Slave.

Data:

Blinks when the M-Bus Master receives data

from a M-Bus Slave.

M-Bus Master without display

The M-Bus Master is no intelligent unit, but a

repeater, which converts a RS232 or an optical

format to the M-Bus format.

M-Bus format means:

From M-Bus Master to M-Bus Slave is:

mark » 30 V

space » 18 V

There has to be at least 12 VDC between mark

and space.

From M-Bus Slave to M-Bus Master is:

mark = closed current

space = closed current + approx. 17 mA.

The M-Bus Master can send and receive at 300 or

2400 baud both over the optical connection possibility and over the data output in the bracket which

can be connected direct to RS232 by means of an

adapter cable.

The only difference between the two M-Bus

Masters is that M-Bus Master with a display makes

it possible to read data from all MULTICAL

meters connected, and a computer for reading of

data is not necessary.

Following MULTICAL

on the display:

1. For all heat meters

- Info code

- Energy

- Volume

- In A

- In B

- Target date

2. For each individual heat meter

- Target energy

- Target volume

- Flow temperature

- Return temperature

- ∆t, power and flow

Kamstrup M-Bus Masters can only be used with

primary addressing.

For further information – see the M-Bus Master

manual.

®

heat meter data can be read

®

heat

5511-710 GB/12.2004/Rev. C1

Ordernumbers:

M-Bus Master without display 66-98-11x-xxx

M-Bus Master with display 66-98-A1x-xxx

M-Bus Master manual 5511-185

x = module options (see paragraph 7 and 8)

xxx = Country code – is filled in by

Kamstrup A/S.

M-Bus Master with display

6

Page 7

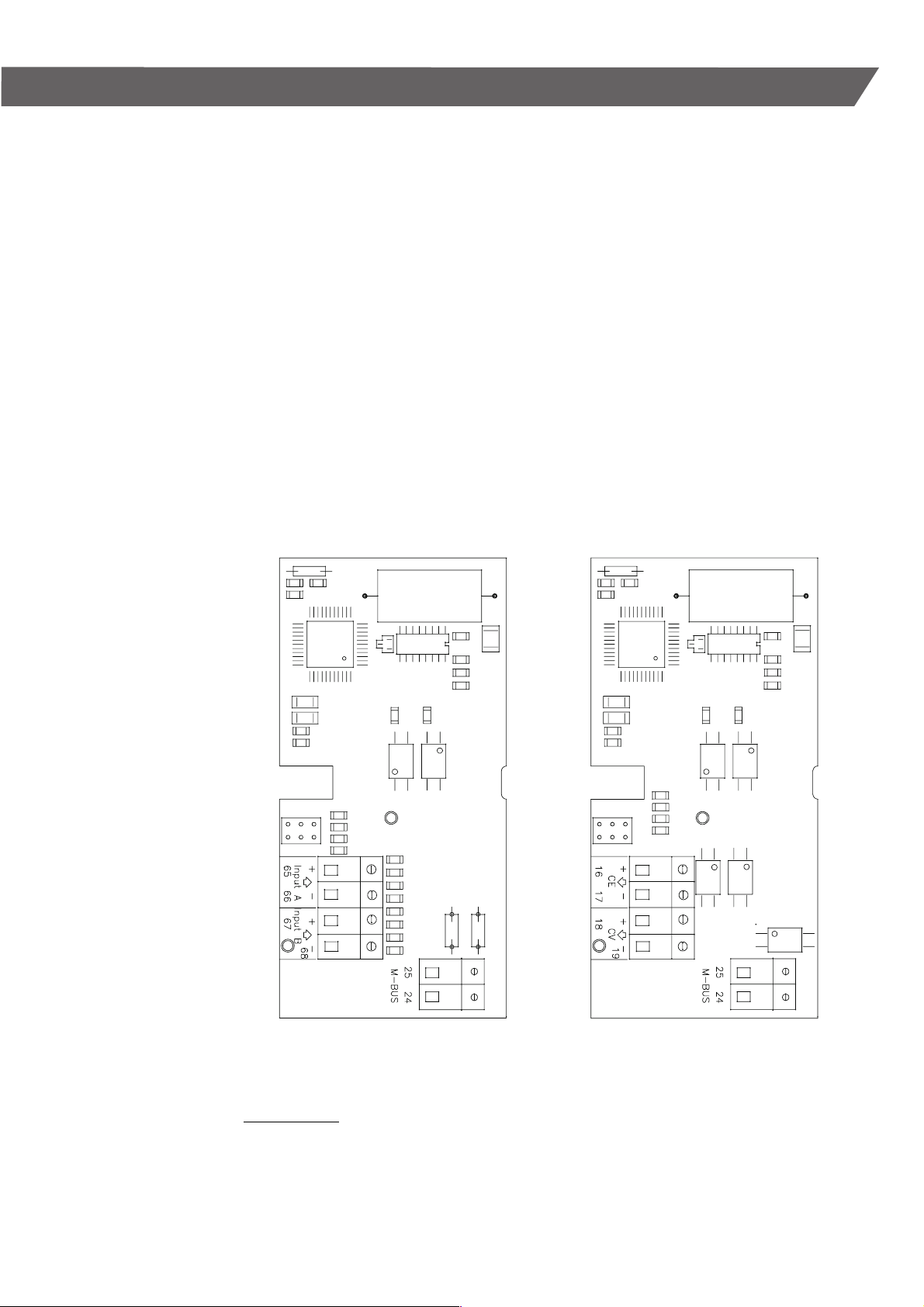

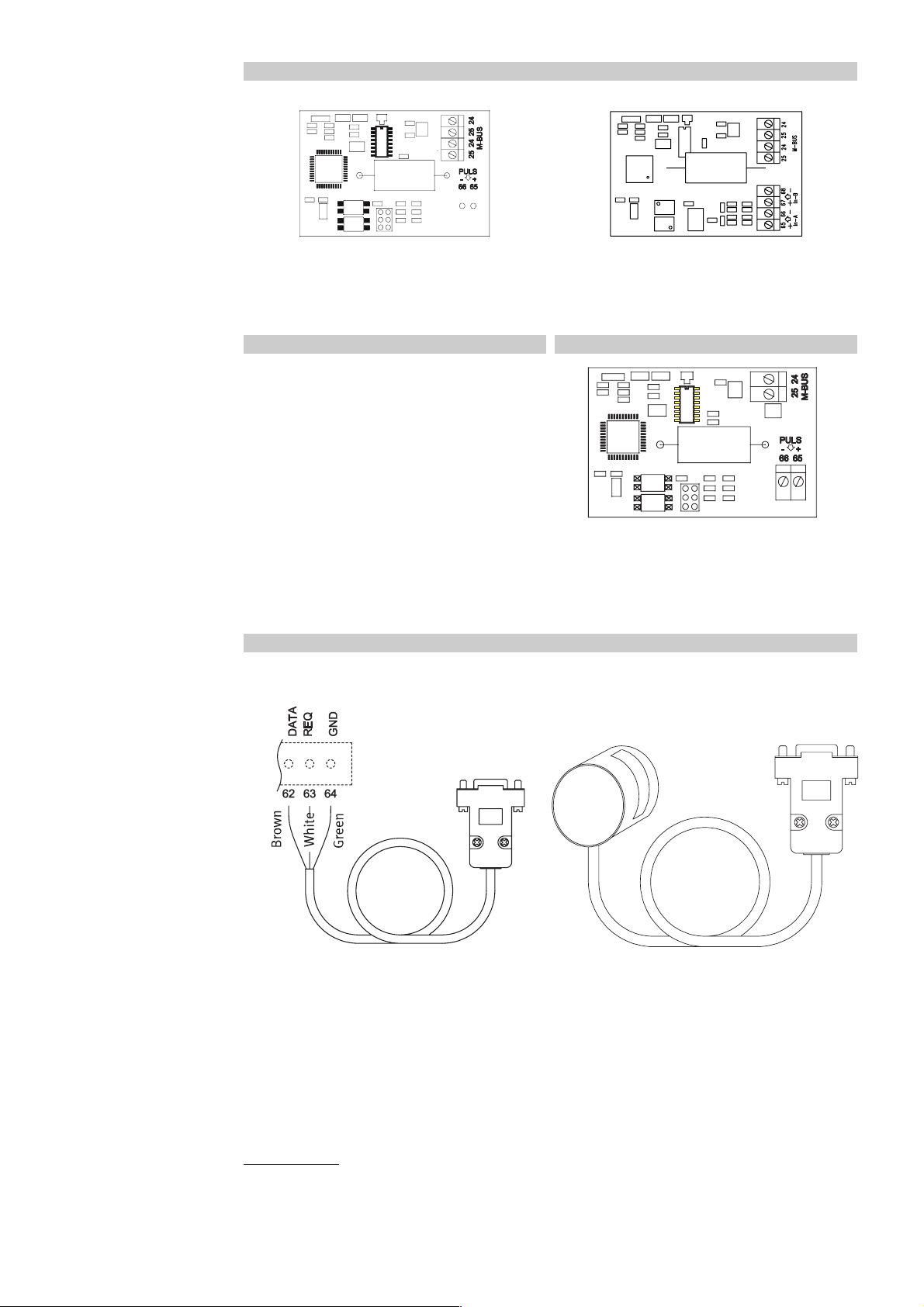

4. M-Bus Slave for MULTICAL

®

The M-Bus Slave is a module especially developed

for MULTICAL® and is easily installed in the modular space.

The M-Bus Slave is supplied via the M-Bus Master,

and there is a galvanic decoupling to MULTICAL

®

,

which cannot be supplied over the M-Bus Master.

The M-Bus Slave is equipped with either two

extra in- or outputs, to facilitate remote data

acquisition from other meters, e.g. water meter

or to read out the energy and volumes pulses

from the meter itself.

The M-Bus Slave is an intelligent unit with its own

processor and RAM.

The M-Bus Slave automatically collects data from

the heat meter every 12 hours. furthermore data is

collected during reset/start as well as when data

has been sent from M-Bus Slave to M-Bus Master.

Reset is produced by decoupling the supply power

to the M-Bus system for a while (at least 1 minute).

Pulse inputs Pulse outputs

The M-Bus Slave can also be initiated from the

M-Bus Master by sending the format SND_NKE.

Initiation means resetting the internal counters

and collecting data from the meter. When the M-Bus

Slave collects current data from the meter, communication to the M-Bus network is blocked. This interval is called the initiation time, for MULTICAL

®

III it

is typically 9 seconds, whereas the typical initiation

time of a MULTICAL

®

is 12 seconds.

For the creation of M-Bus data packs the M-Bus

Slave uses the codings of MULTICAL

®

(A-B-CCC).

If the coding cannot be found in the M-Bus Slave

an error message appears which means that the

decimal point will not be correctly placed in the

M-Bus data pack.

Each M-Bus Slave has a maximum current

consumption of 1 Unit Load (1.5 mA).

R

= 410 Ω, Cin = 0,5 nF.

in

Terminal 24-25 (M-Bus) M-Bus connection

Terminal 65-66 (input A) Pulse input A

Terminal 67-68 (Input B) Pulse input B

Terminal 24-25 (M-Bus) M-Bus connection

Terminal 16-17 (CE) Energy pulse

Terminal 67-68 (CV) Volume pulse

Order numbers:

M-Bus Slave for MULTICAL

M-Bus Slave for MULTICAL

M-Bus Slave for MULTICAL

M-Bus Slave for MULTICAL

®

III/MULTICAL® with pulse inputs 66-04-000-100

®

III/MULTICAL® with pulse outputs 66-07-000-100

®

with pulse inputs 66-08-000-100

®

with pulse outputs 66-09-000-100

There is a difference between the M-Bus Slaves for MULTICAL

MULTICAL

®

transmits a larger amount of data. Please refer to paragraph 10: Data acquisition of M-Bus.

®

III and MULTICAL®.

5511-710 GB/12.2004/Rev. C1

7

Page 8

5. M-Bus Slave for MULTICAL® Compact/MULTICAL® 401

M-Bus for MULTICAL

Terminal 24-25 (M-Bus) Connections

Terminal 65-66 (Pulse) Not in use

Display Battery

Module area

Module area in MULTICAL

Display Battery

®

Compact/MULTICAL® 401

®

Compact

The M-Bus Slave is a module especially developed

for MULTICAL® Compact/MULTICAL® 401, and is

easily installed in the module area.

The M-Bus Slave is an intelligent unit with a

processor and RAM of its own.

The M-Bus Slave for MULTICAL

MULTICAL

MULTICAL

®

401 is identical with the one for

®

III, except from the physical dimensions.

®

Compact/

There are two versions of the M-Bus module:

– without pulse inputs

– with pulse inputs

Both modules can be used in MULTICAL

as well as MULTICAL

®

401, however, the pulse in-

puts can only be used together with MULTICAL

®

Compact

®

401.

Each M-Bus Slave has a max. power consumption

of 1 Unit Load (1.5 mA)

R

= 410 Ω, Cin = 0,5 nF.

in

Data is automatically read every 12 hour, furthermore data is collected during reset/start as well

as when data has been sent from M-Bus Slave to

M-Bus Master. Reset is produced by decoupling

the supply power to the M-Bus system for a while

(at least 1 minute).

The M-Bus Slave can also be initiated from the

M-Bus Master by sending the format SND_NKE.

Initiation means resetting the internal counters

and collecting data from the meter.

When the M-Bus Slave collects current data from

the meter, communication to the M-Bus network

is blocked. This interval is called the initiation

time, for MULTICAL

®

Compact/MULTICAL® 401 it

is typically 9 seconds.

See Appendix for further information.

5511-710 GB/12.2004/Rev. C1

Module area

Module area in MULTICAL

Order numbers:

M-Bus Slave for MULTICAL

M-Bus Slave for MULTICAL

M-Bus, pulse inputs for

®

401

®

Compact/MULTICAL® 401 66-0S-000-100

®

Compact/MULTICAL® 401 with pulse inputs 66-0S-000-200

MULTICAL

®

Compact/MULTICAL® 401

8

Page 9

6. M-Bus Slave for Kamstrup 162/382/351 Combi

The M-Bus Slave is especially developed for

Kamstrup 162/382/351 Combi, and is easily

installed in the modular space of the electricity

meter.

The M-Bus Slave for electricity meters is equipped

with a pulse input.

Terminal 24-25 (M-Bus) Connections

Terminal 65-66 (Pulse) Pulse input

The physical dimensions are identical with those of

the M-Bus Slave for MULTICAL

it cannot be used for a MULTICAL

The M-Bus Slave is an intelligent unit with a processor and RAM of its own, and it automatically finds

out in which meter type it is placed.

Data is automatically read every hour, furthermore

data is collected during reset/start as well as when

data has been sent from M-Bus Slave to M-Bus

Master. Reset is produced by decoupling the supply

power to the M-Bus system for a while (at least 1

minute).

The M-Bus Slave can also be initiated from the

M-Bus Master by sending the format SND_NKE.

Initiation means resetting the internal counters

and collecting data from the meter.

When the M-Bus Slave collects current data from

the meter, communication to the M-Bus network

is blocked. This interval is called the initiation time,

and is for Kamstrup 162/382/351 COMbi typical

7 seconds.

See Appendix for further information.

The power consumption of each M-Bus Slave

is 1 Unit Load (1.5 mA).

R

= 410 Ω, Cin = 0,5 nF.

in

®

Compact, however,

®

Compact.

5511-710 GB/12.2004/Rev. C1

M-Bus Slave mounted

in an electricity meter

Order numbers:

M-Bus Slave for Kamstrup 162/382/351 Combi 6850-005

9

Page 10

7. M-Bus Cascade module

The M-Bus Cascade module can be used to increase

the number of M-Bus Slaves in an M-Bus network

from 40 to max. 250 M-Bus Slaves (primarily

addressing). Furthermore, the cable length can be

multiplied by six by using six M-Bus Cascade

modules mounted in M-Bus Master units.

The M-Bus Cascade module is mounted in an M-Bus

Master and needs neither set-up nor address.

The function of the M-Bus Cascade module is

to repeat communication to and from the M-Bus

Master.

A new M-Bus Master with M-Bus Cascade module

is to be connected to an already existing network

®

parallel to one of the connected MULTICAL

energy

meters with M-Bus Slave. From the new M-Bus

Master a new network with 38 energy meters and

1 M-Bus Cascade module or 40 M-Bus Slaves can

be established.

It is possible to connect up to 6 M-Bus Masters

and thereby increase the number of energy meters

in the network to a total of 250 meters (primarily

addressing).

Each M-Bus Cascade module has a power

consumption of 2 Unit Loads (3 mA).

R

= 410 Ω, Cin = 0,5 nF.

in

Extra cable length per unit:

Max. 1.800 m to the most remote

M-Bus Slave/0.8 mm

2

.

M-Bus interface

(53, 54)

To this the

M-Bus Slaves

are connected.

Input A (65, 66),

Input B (67, 68).

– Are not in use.

.

5511-710 GB/12.2004/Rev. C1

10

Page 11

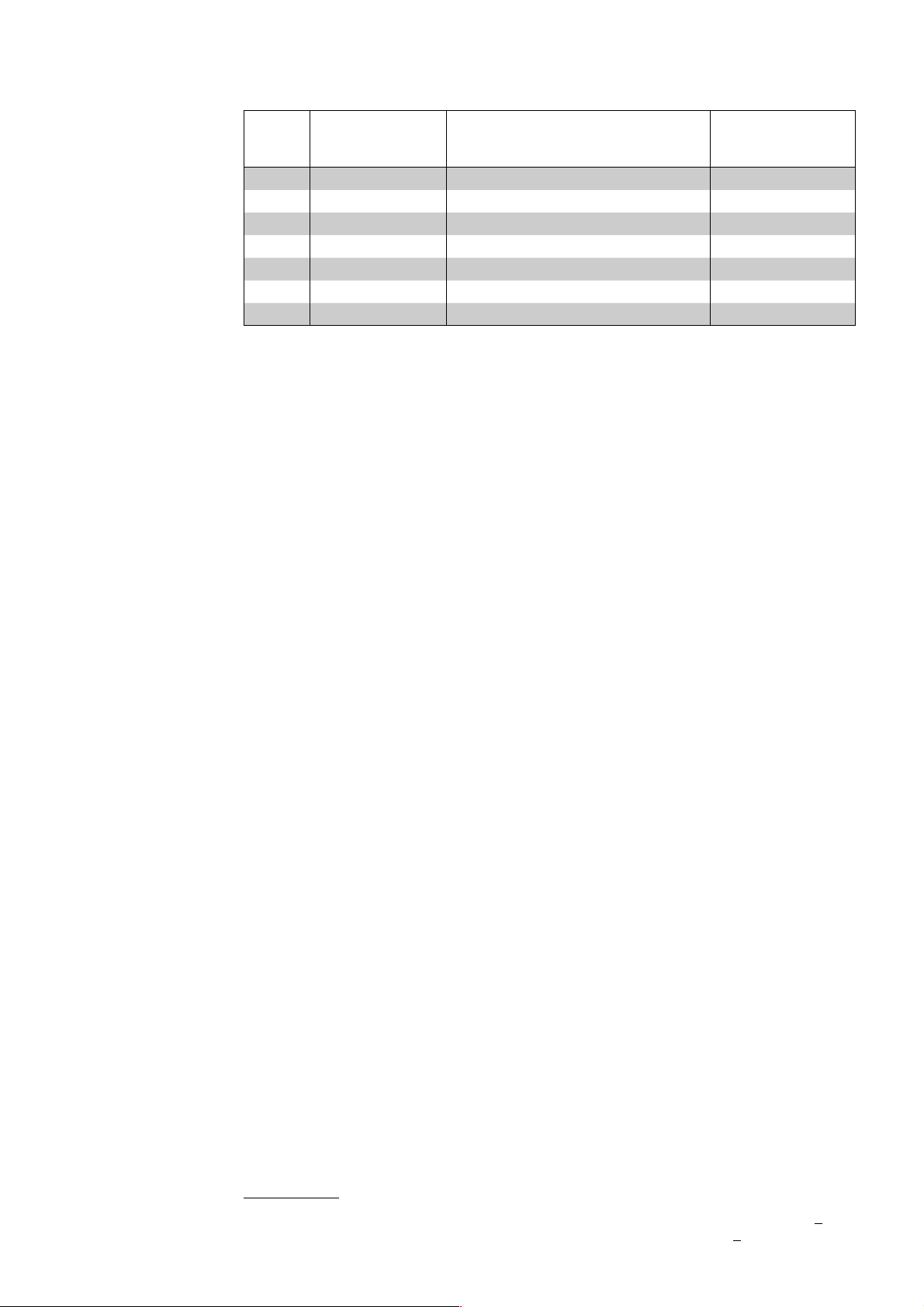

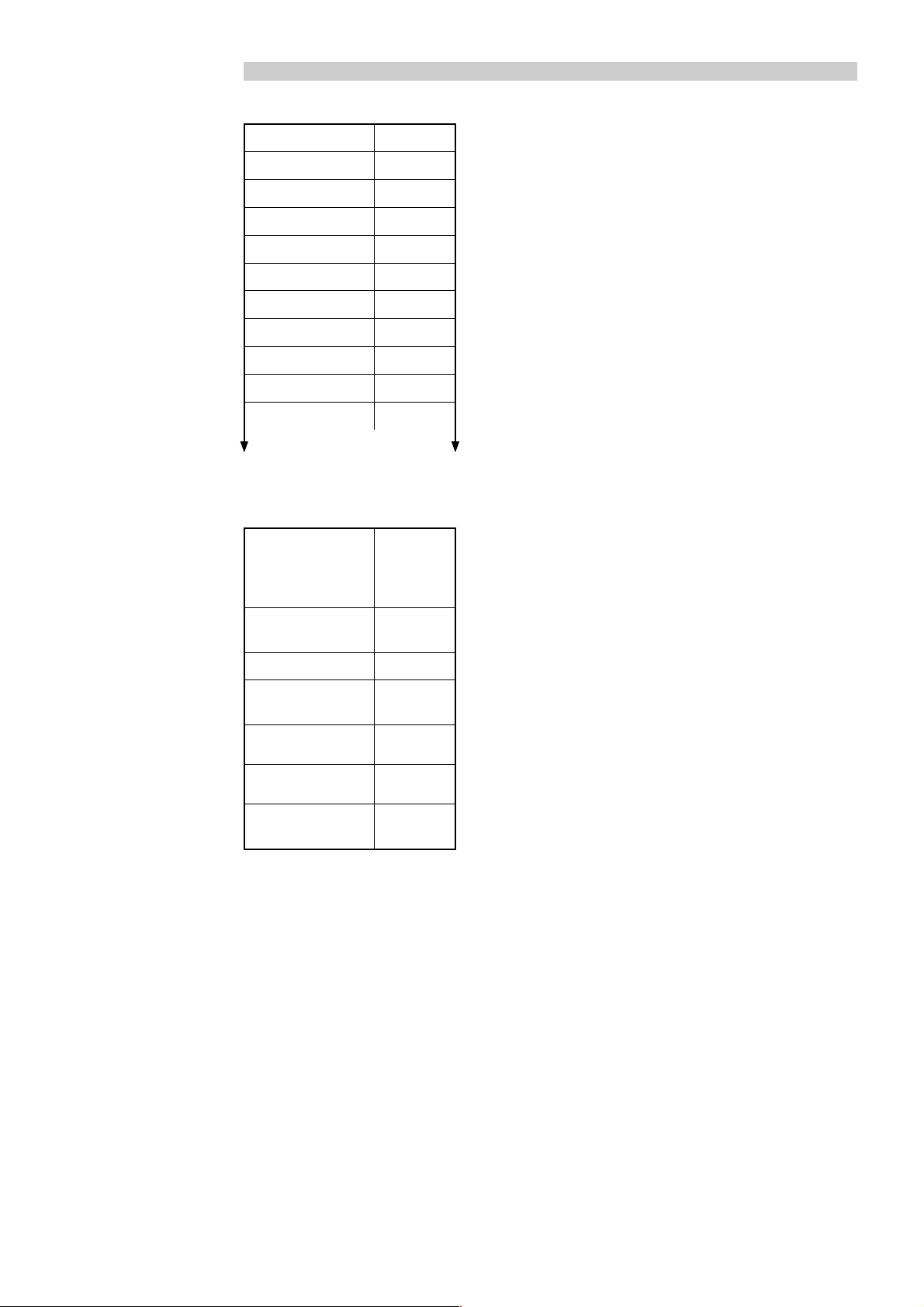

The number of M-Bus Slave modules/cable length as a function of the number of M-Bus Cascade units

in a Kamstrup M-Bus system.

M-Bus

Master

Cascade unit =

1 Cascade module

+ 1 M-Bus Master

Total numbers of M-Bus Slaves

Total cabel lenght

0,5/0,8 mm

1 0 40 1000/1800 m

1 38 + 40 = 78 2000/3600 m

2 38 + 38 + 40 = 116 3000/5400 m

3 38 + 38 + 38 + 40 = 154 4000/7200 m

4 38 + 38 + 38 + 38 + 40 = 192 5000/9000 m

5 38 + 38 + 38 + 38 + 38 + 40 = 230 6000/10800 m

6 38 + 38 + 38 + 38 + 38 + 38 + 22 = 250 7000/12600 m

2

5511-710 GB/12.2004/Rev. C1

Order numbers:

M-Bus Cascade module 66-98-001-100

1 = module number

11

Page 12

8. M-Bus Modem

An M-Bus system of up to 40 meters can be read

via the M-Bus Modem.

The M-Bus Modem can be mounted in both M-Bus

Master without a display and M-Bus Master with

a display.

The line voltage is measured here.

Test

1. When the modem has been installed, the line

voltage must be measured on clamps 70 and

71. It must be min. 24 VDC.

2. Remount the top of the M-Bus Master.

3. Make a forced call.

M-Bus Master without a display

Keep pressing the key for min. 10 seconds.

The modem module calls the utility at the

entered number.

M-Bus Master with display

Keep pressing both keys for min. 10 seconds,

until a “Call” appears in the display.

The modem module calls the utility at the entered number.

The M-Bus Modem is read via the communication

software PcModem, but uses the same database

as PcM-Bus.

When the call has been made, we recommend you

to call the utility to ensure that the call has been registered by the system software.

Two telephone numbers are entered into the

M-Bus Modem:

Telephone number 1: The data number for

■

remote reading.

Telephone number 2: An alternative data num-

■

ber for remote reading.

Each number can contain 24 digits.

The M-Bus Modem can be programmed to make

calls directly and not via a PABX switchboard according to the “0 - Pause - dialling tone” method.

For further information please refer to:

The M-Bus Master manual

■

The M-Bus Modem installation guide

■

The PcModem manual

■

5511-710 GB/12.2004/Rev. C1

Order numbers:

M-Bus Modem module 66-98-002-319

2 = module number

12

Page 13

9. Installation of M-Bus

An M-Bus system is mounted with bus topology,

which means that all M-Bus Slaves are coupled to

the M-Bus system in parallel. You start from the

M-Bus Master, into the first M-Bus Slave, from the

first M-Bus Slave and on to the next one etc.

The M-Bus Master has two sets of parallel terminals, which makes it possible to divide the M-Bus

in two halves in order to facilitate later error detection.

The M-Bus terminals have the numbers 24 and 25.

The M-Bus is independent of polarity i.e. it is at no

consequence how the M-Bus wires are connected

to terminals 24 or 25.

®

A M-Bus Slave is mounted in MULTICAL

ting the M-Bus Slave at the module place and

mounting the M-Bus cables. Before the identification number can be entered in the M-Bus Slave,

the M-Bus Slave must be either reset or initiated.

We recommend that the whole M-Bus system is

switched off when mounting new M-Bus Slaves.

When all M-Bus Slaves have been connected,

the M-Bus system is started (the current to the

M-Bus Master is switched on). This start will reset

all M-Bus Slaves.

by inser-

M-Bus Slaves can also be mounted without the

M-Bus system being switched off. This means that

SND_NKE must be sent to address 255 when all

M-Bus Slaves have been mounted in order to initiate them. Failing to do so, the connected M-Bus

Slaves will not collect their ID-numbers, so that

the M-Bus Master can contact them, until 12 hours

later.

Cable length

The cable length depends on the cable resistance

and capacity. The cable resistance depends on the

cable type and above all the cross section.

General demands:

The resistance R must be less

than 29 Ω/km.

The capacity C must be less

than 180 nF/km.

If e.g. a cable of 2 x 0.8 mm

approx 1.800 m cable is used in total in the M-Bus

system based on 40 M-Bus Slaves.

In addition – see tabel on page 11

2

is used, in practice

Mounting

M-Bus connection

Supply

Modular space for M-Bus Modem

or M-Bus Cascade module

5511-710 GB/12.2004/Rev. C1

Introduction of M-Bus

and data cable

Serial data output line 230 VAC Introduction of 230 VAC

Botton of the M-Bus Master

13

Page 14

230 VAC is connected on terminals 27 and 28.

Power supply is connected on terminals 60 (+)

and 61 (-).

M-Bus is connected on terminals 24 and 25,

independent on polarity.

Serial data output:

- terminal 62 = DATA: Brown

- terminal 63 = REQUEST: White

- terminal 64 = GND: Green

For correct communication between M-Bus Master

and PC, IR head type 66-99-102 or data cable type

66-99-106 from Kamstrup must be used.

The M-Bus Slave is connected to M-Bus on terminals 24 and 25. It is possible to loop the terminals.

After mounting we recommend to check the voltage on terminals 60 and 61, it should be between

36 and 62 VDC. Then mount the M-Bus Master top

part, the light emitting diode designated POWER

should be constantly lighted and OVERLOAD will

be lighted for approx. 5 sec.

Now the M-Bus power can be checked on terminals

24 and 25. It is not possible, however, to do this in

the bracket itself, cables on which to measure must

be mounted and drawn through the bracket.

The control can possibly be made on a M-Bus Slave

in a MULTICAL

®

. The power must be between 30 and

36 VDC, if communication is made on the M-Bus.

When the M-Bus Master reads a M-Bus Slave,

REQUEST will be lighted briefly and the light emitting diode DATA will be lighted short-term when

the M-Bus Slave answers.

Extra pulse inputs M-Bus connection

M-Bus Slave for MULTICAL

®

III/MULTICAL

®

M-Bus connection Supply Serial data output

M-Bus cable

2-wire

E.g.: 2 x 0.8 mm

Max. 1800 m

Max. 40 M-Bus

Slave modules.

M-Bus Master

5511-710 GB/12.2004/Rev. C1

Holes 230 VAC

for cables

2

MULTICAL

M-Bus connection

M-Bus Slave

®

bottom

M-Bus connection

M-Bus Slave

MULTICAL

M-Bus installation

®

bottom

14

Page 15

10. Data reading of M-Bus

A Kamstrup M-Bus system is read by means of a

PcM-Bus reading programme installed on a PC.

Data reading of heat meters

Following data message can be read:

®

66-04-000-100 pulse inputs MULTICAL

66-07-000-100 pulse outputs MULTICAL

66-0S-000-100 MULTICAL

66-0S-000-200

pulse inputs MULTICAL® Compact/401:

®

Compact/401:

III/CDE

®

III/CDE

- Customer ID No., TA2, TL2, TA3, TL3, InA, InB,

Prog No., Config. No., Date, Energy, Volume,

Hour counter, t

forward

, t

, ∆t, Power, Flow,

return

Peak power or peak flow, Info Code, Target

date, Energy*, Volume*.

NB.: M-Bus Slave modules for MULTICAL

be used in MULTICAL

®

but in such cases it will only

®

III can

tranfer above data telegram. InA and InB are not

used in 66-07-000-100 or in 66-0S-000-100.

M-Bus Slave for MULTICAL® III/MULTICAL

®

Pulse inputs

66-04-000-100

66-08-000-100

Data is read via the M-Bus Master through the

IR-head, or via a data cable mounted in the bottom

of the M-Bus Master.

Following data message can be read:

6608-000-100 pulse inputs MULTICAL

66-09-000-100 pulse outputs MULTICAL

®

,

®

:

- Customer ID No., TA2, TL2, TA3, TL3, InA, InB,

Prog. No., Config. No., Date, Energy, Volume,

Hour counter, t

Peak power or peak flow, Info Code, m

3

m

x t

, Cooling energy, Yearly peak power,

return

forward

, t

, ∆t, Power, Flow,

return

3

x t

forward

Target date, Energy*, Volume*.

NB.: Can only be used in MULTICAL

®

.

InA and InB are not used in 66-09-000-100.

* Target date data

Pulse outputs

66-07-000-100

66-09-000-100

,

Terminal 24-25 (M-Bus) M-Bus connection

Terminal 65-66 (Input A) Pulse input A

Terminal 67-68 (Input B) Pulse input B

5511-710 GB/12.2004/Rev. C1

Terminal 24-25 (M-Bus) M-Bus connection

Terminal 16-17 (CE) Energy pulse

Terminal 18-19 (CV) Volume pulse

15

Page 16

M-Bus Slave for MULTICAL® Compact/MULTICAL® 401

Without pulse inputs With pulse inputs

Terminal 24-25 (M-Bus) M-Bus connection

Terminal 65-66 (In A) Pulse input A Not in use for MULTICAL

Terminal 67–68 (In B) Pulse input B Not in use for MULTICAL

Data reading of Kamstrup 162/382/351 Combi

M-Bus Slave for Kamstrup 162/382/351 Combi

Following data telegram can be read:

162/282/382:

- Energy, Power, Operating hours, Counter value,

Peak power, Customer number, Pulse input,

Spec. data, Info Code.

351 Combi:

- Customer number, Operating hours, True

energy, Power, Peak power, Pulse input,

Spec. data, Info Code.

Terminal 24-25 (M-Bus) M-Bus connection

Terminal 65-66 (Pulse) Pulse input

See the PcM-Bus manual for further information.

Reading equipment

Data cable for reading IR head for reading

®

Compact

®

Compact

Data cable or IR head must be used for correct transmission of meter data between M-Bus Master and PC.

Order numbers:

M-Bus Software PcM-Bus S75-30-007

PcM-Bus manual 5511-722

IR head for reading 66-99-102

Cable for reading 66-99-106

5511-710 GB/12.2004/Rev. C1

16

Page 17

11. Protocol

Commands

The M-Bus concept includes the possibility of

various commands from M-Bus Master to M-Bus

Slave and from M-Bus Slave to M-Bus Master.

For the Kamstrup M-Bus system certain commands

which are relevant for the communication with a

district heat meter have been chosen.

M-Bus Master to M-Bus Slave:

REQ_UD2 Collects data from

the M-Bus Slave

SND_NKE Initiates the M-Bus Slave

SND_UD1 Send data to M-Bus Slave,

e.g. new baudrate

M-Bus Master to M-Bus Slave

REQ_UD2: Collect data from M-Bus Slave

STARTCHARACTER 10H

C-FIELD 5BH

A-FIELD XXH

CHECKSUM XXH

STOPCHARACTER 16H

Startcharacter: 10H = short format

C-field: 5BH/7BH = REQ_UD2

A-field: Address of M-Bus Slave modules

Checksum: Sum of A and C field, the two least significant

Stopcharacter: Always 16H

M-Bus Slave to M-Bus Master:

RSP_UD1 Sends data to M-Bus Master

CON_ACK Acknowledgement of the receipt

of data from the M-Bus Master

The individual commands in detail

The Appendix describes all command formats.

Hex digits

SND_NKE: Initiate M-Bus Slave.

STARTCHARACTER 10H

C-FIELD 40H

A-FIELD XXH

CHECKSUM XXH

STOPCHARACTER 16H

SND_UD1: Data to M-Bus Slave (e.g. new baudrate).

STARTCHARACTER 68H

L-FIELD 03H

L-FIELD 03H

STARTCHARACTER 68H

C-FIELD 53H

A-FIELD XXH

CI-FIELD XXH

CHECKSUM XXH

STOPCHARACTER 16H

Startcharacter: 10H = short format

C-field: 40H = SND_NKE

A-field: Address of M-Bus Slave modules

Checksum: Sum of A and C field, the two least significant

Hex digits

Stopcharacter: Always 16H

Startcharacter: 68H = long format

L-field: Desribes the lenght of long format

Startcharacter: 68H = long format

C-field: 53H = SND_UD1

A-field: Address of M-Bus Slave modules

CI-field: Data field, B8H = 300 baud, BBH = 2400 baud

Checksum: Sum of A, C and CI field, the two least significant

Hex digits

Stopcharacter: Always 16H

5511-710 GB/12.2004/Rev. C1

CON_ACK: Data format from M-Bus.

Master received and accepted.

SINGLECHARACTER

E5H

17

Page 18

M-Bus Slave to M-Bus Master

RSP_UD1: Data from heat meter to M-Bus Master.

STARTCHARACTER

68H

L-FIELD 82 or 92H

L-FIELD 82 or 92H

STARTCHARACTER

68H

C-FIELD 08H

A-FIELD XXH

CI-FIELD XXH

DATA HEAD

RECORD ENERGY

RECORD WATER

RECORD

DATA HEAD

ID - No

ID - No

ID - No

ID - No

TYPE A

TYPE A

TYPE A

TYPE A

Startcharacter: 68H = long format

L-field: Describes the lenght of long format

Startcharacter: 68H = long format

C-field: 08H = RSP_UD1

A-field: Address of M-Bus Slave module

CI-field: Data field, answer in variable structure

Checksum: Sum from C-field to last data record,

the two least significant Hex digits

ID-no, type A

Indicates the 8 least significant digits of the

®

MULTICAL

number, is not used by Kamstrup.

MANUFAC.

MANUFAC.

00101101

00101100

GEN. METER XXH

MEDIA HEAT

04H

eller 0CH

ACCESS XXH

STATUS 00H

SIGNATURE

SIGNATURE

00H

00H

MANUFAC: M-Bus coded manufacturer code for “KAM”.

Gen. meter: Generation of the heat meter.

Media (heat): Code for district heat meter. 04H for returnn

flow meter and 0CH for flow meter.

Access: Counts 1 every time data is sent to the

M-Bus Master.

Status: Is set by the M-Bus Slave, must be 00H for correct

data – should be checked. See also page 26.

Signature: Not used by Kamstrup.

5511-710 GB/12.2004/Rev. C1

18

Page 19

RSP_UD1: Data to the M-Bus Master from

Kamstrup 162/382/351 Combi.

STARTCHARACTER 68H

L-FIELD 46H

L-FIELD 46H

STARTCHARACTER 68H

C-FIELD 08H

A-FIELD XXH

CI-FIELD XXH

Data head

ID - No

ID - No

ID - No

ID - No

MANUFAC.

MANUFAC.

GEN. METER XXH

MEDIA ELEC. 02H

ACCESS XXH

STATUS 00H

SIGNATURE

SIGNATURE

63 BDC

21 BDC

67 BDC

31 BDC

2DH

2CH

00H

00H

Startcharacter: 68H = long format

L-field: Describes the lenght of long format

Startcharacter: 68H = long format

C-field: Code for RSP_UD1

A-field: Address of M-Bus Slave module

CI-field: Data field, answer in variable structure

ID-no, type A

As e.g.: costumer no. 31672163

Manufac: M-Bus coded manufacturer code for “KAM”.

Gen. meter: Generation of electricity meter

Media (el.): Code for electricity

Access: Counts 1 every time data is sent to the

M-Bus Master.

Status: Is set by M-Bus Slave. 00H for correct data.

See also page 26.

Signature: Not used by Kamstrup.

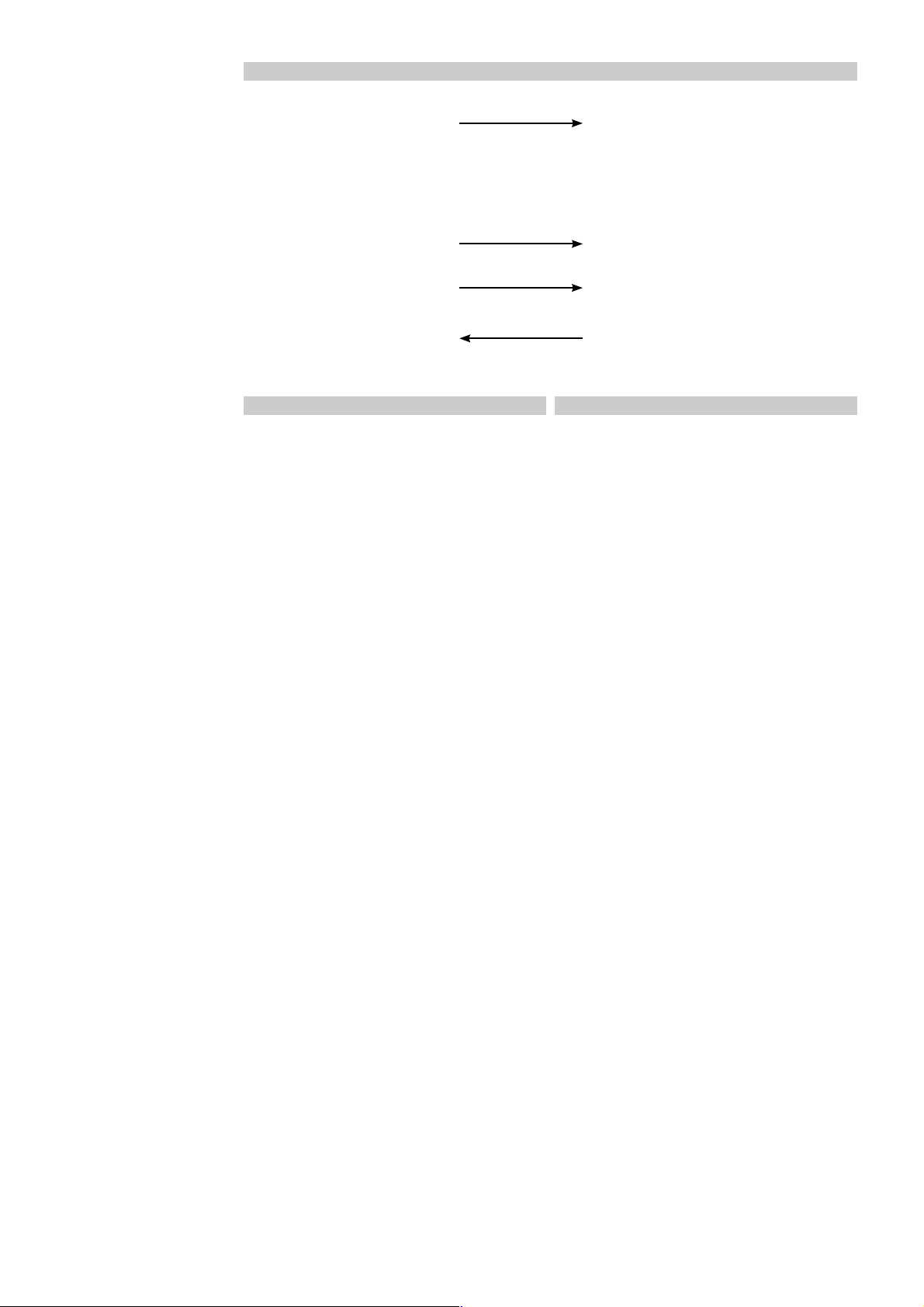

Communication process

Initialization of M-Bus network

M-Bus Master M-Bus Slave

1. SND_NKE (255), 300 baud

or 2400 baud.

2. SND_UD1 (255) 300 baud

CI = BBH (change to 2400 baud).

3. REQ_UD2 (adr) 2400 baud.

4. M-Bus Master (software)

stores no data.

All M-Bus Slaves collect new data.

No acknowledgement is sent.

The M-Bus Slave changes to 2400 baud.

No acknowledgement is sent.

Relevant M-Bus Slave answers with data.

Enters new data.

RSP_UD1 2400 baud.

The M-Bus Slave answers with data.

5. The next M-Bus Slave receives a requestes

until all M-Bus Slaves have answered

Reading of data, can be up to 12 hours old:

The M-Bus network is supposed to have been initiated.

M-Bus Master M-Bus Slave

1. SND_UD1 (255) 300 baud

CI = BBH (change to 2400 baud)

The M-Bus Slave changes to 2400 baud.

No acknowledgement is sent.

2. REQ_UD2 (adr) 2400 baud. Request sendes til M-Bus Slave module.

5511-710 GB/12.2004/Rev. C1

3. M-Bus Master (software)

stores no data.

4. The next M-Bus Slave receives a requestes

until all M-Bus Slaves have answered

RSP_UD1 2400 baud.

The M-Bus Slave answers with data.

19

Page 20

Reading of fresh data through e.g. data logging

M-Bus Master M-Bus Slave

1. SND_NKE (255), 300 baud

or 2400 baud.

All M-Bus Slave collect new data.

No acknowledgement is sent.

Data ready in MULTICAL

9 sec. MULTICAL

In Kamstrup 162/382/351 Combi data

is ready typically after 7 sec.

2.

SND_UD1 (255) 300 baud

CI = BBH (change to 2400 baud).

3.

REQ_UD2 (adr) 2400 baud.

4.

The next M-Bus Slave

receives a request until

all slaves have answered.

M-Bus Slave changes to 2400 baud.

No acknowledgement is sent.

Relevant M-Bus Slave answers with data.

Enters new data.

RSP_UD1 2400 baud.

The M-Bus Slave answers with data.

®

®

III typically after

typically after 12 sec.

M-Bus Slave and foreign M-Bus masters

When using foreign masters and/or foreign

software, the same commands are to be used.

The M-Bus Slave only supports the abovementioned commands.

Is the command SND_NKE (address) used,

the M-Bus Slave will answer CON_ACK.

Is the command SND_UD1 (address) used,

the M-Bus Slave also answers CON_ACK.

Kamstrup software always uses the address 255,

which does not require an acknowledgement from

the M-Bus Slave.

The data telegram is in M-Bus format until the

“END” character 0FH, see Appendix.

The data which follows is in Kamstrup format,

which can not be decoded by foreign software/

M-Bus Masters.

The M-Bus Slave will identify itself by the manufacturer code “KAM”.

Appendix

1. REQ_UD2 (adr.) ¨ RSP_UD1

In order to collect heat meter data from a M-Bus

Slave REQ_UD1 must be sent from the M-Bus

Master. The M-Bus Slave checks the message,

and if it is o.k., the M-Bus Slave answers

RSP_UD1 – heat meter data packed according

to the CEN standard. The collected data will always be at least 12 hours old. When RSP_UD1

has been sent from the M-Bus Slave, new data

will be collected from the heat meter. I.e. you

can acquire completely fresh data by sending

REQ_UD1 twice to the same M-Bus Slave.

As data acquisition from MULTICAL

MULTICAL

®

means that the bus communication

®

III or

is blocked, an interval of min. 9 sec. between

two REQ_UD1 to the same M-Bus Slave is required. MULTICAL

®

requires an interval of 12

sec. However, at rare intervals bus communication may be blocked for up to 25–30 sec.

while measurings of energy, power, flow, temperature etc. are being made.

The initiation time of the electricity meter is

typically 7 sec., but at rare intervals the communication may be blocked for up to 20 sec.

2. SND_NKE (adr.) ¨ CON_ACK

The M-Bus Master is initiated by means of

SND_NKE, and the M-Bus Slave acknowledges

receipt of the message by means of CON_ACK.

3. SND_UD1 (adr.) ¨ CON_ACK

The M-Bus Master wants to change the baud

rate of the M-Bus Slave. SND_ UD1 is sent,

and the M-Bus Slave accepts with CON_ACK.

It should be mentioned that the baud rate

cannot be changed until CON_ACK has been

transmitted.

In Rev. C1 and onwards for type 66-04-00-100

this feature is unnecessary, as the M-Bus Slave

is furnished with a built-in auto detect of the

baud rate, however, nevertheless it is implemented in the M-Bus Slave. The feature is not

necessary for 66-07-000-100, 66-08-000-100,

66-09-000-100, 66-0S-000-100 and

66-0S-000-200, but is nevertheless implemented.

5511-710 GB/12.2004/Rev. C1

20

Page 21

RSP_UD1 MULTICAL® III/MULTICAL® Compact/MULTICAL® 401

STARTCHARACTER 68H

L-FIELD 82H

L-FIELD 82H

STARTCHARACTER 68H

C-FIELD 08H

A-FIELD XXH

CI-FIELD XXH

DATA HEAD

¨

Data head ¨

RECORD ENERGY

RECORD WATER

RECORD HOUR COUNTER

RECORD FORWARD TEMPERATURE

Data record

RECORD RETURNN TEMPERATURE

RECORD F-R TEMPERATURE

RECORD POWER

RECORD FLOW

RECORD READ ENERGY

RECORD READ WATER

RECORD READ DATE

END OFH

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

PEAK POWER 10

PEAK POWER 10

PEAK POWER 10

PEAK POWER 10

INFO 10

INFO 10

INFO 10

INFO 10

TAR2 10

TAR2 10

TAR2 10

TAR2 10

TL2 10

TL2 10

TL2 10

TL2 10

TAR3 10

TAR3 10

TAR3 10

TAR3 10

1

3

5

7

9

11

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

0

2

4

6

8

10

TL3 10

0

TL3 10

2

TL3 10

4

TL3 10

6

In A* 10

0

In A* 10

2

In A* 10

4

In A* 10

6

In B* 10

0

In B* 10

2

In B* 10

4

In B* 10

6

0

2

4

6

0

2

4

6

PROGRAM NO. 10

PROGRAM NO. 10

PROGRAM NO. 10

PROGRAM NO. 10

CONFIGURATION 10

CONFIGURATION 10

CONFIGURATION 10

CONFIGURATION 10

DATE 10

DATE 10

,

InA and InB are not used in MULTICAL® Compact.

A “dummy string” is transmitted including the “0”

digit.

DATE 10

DATE 10

CHECKSUM

STOPCHARACTER 16H

ID - No. TYPE A

ID - No. TYPE A

ID - No. TYPE A

ID - No. TYPE A

MANUFAC 00101101

MANUFAC 00101100

GEN. METER XXH

MEDIA (HEAT) XXH

ACCESS XXH

STATUS 00H

SIGNATURE 00H

SIGNATURE 00H

DIF DATA

VIF VALUE

10

10

10

10

1

3

5

7

10

10

10

10

DIF DATA

VIF VALUE

TYPE G

TYPE G

0

2

4

6

BCD

BCD

BCD

BCD

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

5511-710 GB/12.2004/Rev. C1

21

Page 22

RSP_UD1 MULTICAL

®

STARTCHARACTER 68H

L-FIELD 92H

L-FIELD 92H

STARTCHARACTER 68H

C-FIELD 08H

A-FIELD XXH

CI-FIELD XXH

DATA HEAD

RECORD ENERGY

RECORD WATER

RECORD HOUR COUNTER

RECORD FORWARD TEMPERATURE

RECORD ReturnN TEMPERATURE

RECORD F-R TEMPERATURE

RECORD POWER

RECORD FLOW

RECORD READ ENERGY

RECORD READ WATER

RECORD READ DATE

END OFH

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

COSTUMER NO. 10

PEAK POWER 10

PEAK POWER 10

PEAK POWER 10

PEAK POWER 10

INFO 10

INFO 10

INFO 10

INFO 10

TAR2 10

TAR2 10

TAR2 10

TAR2 10

TL2 10

TL2 10

TL2 10

TL2 10

TAR3 10

TAR3 10

TAR3 10

TAR3 10

TL3 10

TL3 10

TL3 10

TL3 10

In A 10

In A 10

In A 10

In A 10

In B 10

In B 10

In B 10

1

3

5

7

9

11

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

¨

0

2

4

6

8

10

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

ID - NO. (e.g.) 06BCD

ID - NO. 21BCD

ID - NO. 67BCD

ID - NO. 31BCD

MANUFAC. 2DH

MANUFAC. 2CH

GEN. METER 01H

DATA HEAD ¨

MEDIA (HEAT) XXH

ACCESS XXH

STATUS XXH

Data record

SIGNATURE 00H

SIGNATURE 00H

DIF DATA

VIF VALUE

10

10

10

10

1

3

5

7

10

10

10

10

0

2

4

6

DIF DATA

VIF VALUE

TYPE G

TYPE G

10

10

10

10

10

10

10

10

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

4

7

In B 10

PROGRAM NO. 10

PROGRAM NO. 10

PROGRAM NO. 10

PROGRAM NO. 10

CONFIGURATION 10

CONFIGURATION 10

CONFIGURATION 10

CONFIGURATION 10

DATE 10

DATE 10

DATE 10

DATE 10

m x T

forward

m3 x T

forward

m3 x T

forward

m3 x T

forward

m3 x T

return

m3 x T

return

m3 x T

return

m3 x T

return

COOLING ENERGY 10

COOLING ENERGY 10

COOLING ENERGY 10

COOLING ENERGY 10

YEARS PEAK POWER 10

YEARS PEAK POWER 10

YEARS PEAK POWER 10

YEARS PEAK POWER 10

CHECKSUM

STOPCHARACTER 16H

BCD

BCD

BCD

BCD

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

5511-710 GB/12.2004/Rev. C1

22

Page 23

RSP_UD1 Kamstrup 162/382/351 Combi

STARTCHARACTER 68H

L-FIELD 46H

L-FIELD 46H

STARTCHARACTER 68H

C-FIELD 08H

A-FIELD XXH

CI-FIELD XXH

DATA HEAD

RECORD ENERGY*

RECORD HOUR COUNTER

RECORD POWER

RECORD PEAK POWER

RECORD TARIF 1

RECORD TARIF 2

END OFH

TRIP COUNTER VALUE 10

TRIP COUNTER VALUE 10

TRIP COUNTER VALUE 10

TRIP COUNTER VALUE 10

PULSE IN 10

PULSE IN 10

PULSE IN 10

PULSE IN 10

SPEC. DATA 10

SPEC. DATA 10

SPEC. DATA 10

SPEC. DATA 10

INFO 10

INFO 10

INFO 10

INFO 10

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

CHECKSUM

STOPCHARACTER 16H

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

¨

0

2

4

6

0

2

4

6

0

2

4

6

0

2

4

6

DATA HEAD ¨

Data record

10

10

10

10

ID - NO. XXBCD

ID - NO. XXBCD

ID - NO. XXBCD

ID - NO. XXBCD

MANUFAC. 2DH

MANUFAC. 2CH

GEN. METER 00H

MEDIA (EL.) 02H

ACCESS 00H

STATUS 00H

SIGNATURE 00H

SIGNATURE 00H

DIF DATA

VIF VALUE

1

3

5

7

10

10

10

10

0

2

4

6

32 bit integer

32 bit integer

32 bit integer

32 bit integer

5511-710 GB/12.2004/Rev. C1

* Kamstrup 351 Combi: Reel energy

23

Page 24

VIF: Value Information Field MULTICAL

®

HEX CODING THEME UNIT SIZE FACTOR

0F 00001111 Energy GJ J x 10

0E 00001110 Energy GJ J x 10

7

6

05 00000101 Energy kWh Wh x 10

06 00000110 Energy kWh Wh x 10

07 00000111 Energy MWh Wh x 10

3

17 00010111 Volume m

16 00010110 Water m

15 00010101 Water m

14 00010100 Water m

13 00010101 Volume m

x 10 m3 x 10 1

3

3

x 10

3

x 10

3

x 10

-1

-2

-3

m3 x 10

m3 x 10

m3 x 10

m3 x 10

2

3

4

0

-1

-2

-3

1000/100/10/1

1

1

1

100/10/1

1

1

1

1

22 00100010 Hour counter Hours Hours 1

3

3E 00111110 Flow m

3D 00111101 Flow m

3C 00111100 Flow m

3B 00111011 Flow l/h m

/h m3/h x 10

3

3

/h x 10

/h x 10

-1

-2

m3/h x 10

m3/h x 10

3

59 01011001 Temp. forward C° C° x 10

5D 01011101 Temp. return C° C° x 10

61 01100001

∆t

2D 00101101 Power kW x 10

2E 00101110 Power MW x 10

2F 00101111 Power MW x 10

K K x 10

-1

-3

-2

W x 10

W x 10

W x 10

/h x 10

-2

-2

-2

2

3

4

0

-1

-2

-3

1

1

1

1

1

1

1

1

1

1/10

6C 01101100 Date G-type Date 1

CODING: Coding of the VIF of the data pack

THEME: Subject of record

UNIT: Wanted unit

SIZE: Unit entered in the VIF

FACTOR: The factor, by which the values of the software

are multiplied, in order to comply with the units

required – see next page.

5511-710 GB/12.2004/Rev. C1

24

Page 25

If multiplied with 10, 100 or 1000 the info field and the prog_NO. field change.

INFO FIELD

7

10

x3x2x1x0 x3x2x1x

10

6

0

5

10

x3x2x1x

4

10

0

x3x2x1x

0

3

10

x3x2x1x

2

10

0

x3x2x1x

0

Reserved for info codes from heat meter

0

= The factor method is used

x

1

x

2

x

x3 = Power x 10

0

x

= Energy x 10

1

x

= Energy x 100, Reading Energy x 100

2

x

= Energy x 1000, Reading Energy x 1000

3

x

The 2 most significant bits in “Energy”

PROGRAM NUMBER

10

x3x2x1x

7

0

10

x3x2x1x

6

0

5

10

x3x2x1x

4

10

0

x3x2x1x

0

3

10

x3x2x1x

2

10

0

x3x2x1x

0

Reserved for the program number from the heat meter

10

x3x2x1x

10

x3x2x1x

1

0

1

0

10

x3x2x1x

10

x3x2x1x

0

0

0

0

The 2 most significant bits in “Reading Energy”

DIF: Data Value Field

EMNE VÆRDI HEX BESKRIVELSE

DATE_AFL 01000010 42H 16 Integer, Historic Value, Type G

Energy_AFL 01001100 4CH 8 Digit BCD, Historic Value, Type A

Water_AFL 01001100 4CH 8 Digit BCD, Historic Value, Type A

RESTEN 00001100 0CH 8 Digit BCD, Current Value, Type A

5511-710 GB/12.2004/Rev. C1

25

Page 26

DATA HEAD

DATA VÆRDI TYPE BESKRIVELSE

1

ID-NO. XXH A Customer number x 10

/customer number x 10

ID-NO. XXH A Customer number x 103/customer number x 10

ID.NO. XXH A Customer number x 105/customer number x 10

ID.NO. XXH A Customer number x 107/customer number x 10

0

2

4

6

MANUFAC. 00101101 C [ascii “K” – 64] x 32 x 32 + 1 [ascii “A” – 64] x 32+

MANUFAC. 00101100 C [ascii “M” – 64] ISO 60870 Standard

GEN. METER 00H C Heat meter generation

MEDIA (HEAT) 04H* el. 0CH** D Code for heat

ACCESS XXH C Counts 1 after each data transfer to the M-Bus Master

STATUS XXH*** D Error code – see below

SIGNATURE 00H C Not in use

SIGNATURE 00H C Not in use

* 04H is used when data is acquired from a return meter

** 0CH is used when data is acquired from a flow meter

*** Error code: 80H ¨ Error during the last collection of heat meter data, data incorrect or too old.

40H ¨ Error in prog_No., e.g. number unknown. I.e. data not correctly encoded.

The error code should be checked when data is received – only apply to “old” M-Bus Slaves.

Heat meter M-Bus Slaves supplied after 15 April 2003 automatically check the STATUS field, and do not

send data on the M-Bus if the field is different from “0”.

The M-Bus Slave makes up to three attempts, at intervals of 5 seconds, to collect correct data from the

meter. If the STATUS field remains different from “0”, automatic data update, or the next user effected

reading will be awaited.

Physical properties

Bus independent of polarity

■

Dynamic impedance = 35 Ω

■

Galvanical isolation from data wires to earth

■

Short-circuit proof

■

Symmetric around earth

■

Transmission speed 300 or 2400 baud

■

Maximum resistance in cable = 29 Ω/180 nF per pair

■

Connection of 230 VAC (M-Bus Master)

■

Current consumption: 10 mA + 1.5 mA per M-Bus Slave.

■

5511-710 GB/12.2004/Rev. C1

26

Loading...

Loading...