Technical description

Kamstrup 162M/382M

Kamstrup A/S

Industrivej 28, Stilling

DK-8660 Skanderborg

TEL: +45 89 93 10 00

FAX: +45 89 93 10 01

energi@kamstrup.com

www.kamstrup.com

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

3

Contents

1 Revision history ................................................................................................................ 6

2 General description .......................................................................................................... 7

2.1 Terms ................................................................................................................................................. 7

2.2 Construction ....................................................................................................................................... 8

2.2.1 Terminals ............................................................................................................................... 8

2.2.2 Measurement Construction ..................................................................................................... 8

2.3 Meter types ........................................................................................................................................ 9

3 Functions ........................................................................................................................ 10

3.1 Start-up of meter .............................................................................................................................. 10

3.1.1 Software revision .................................................................................................................. 10

3.1.2 ROM checksum ..................................................................................................................... 10

3.2 Registers .......................................................................................................................................... 10

3.2.1 Energy registers .................................................................................................................... 11

3.2.2 Energy calculation ................................................................................................................ 12

3.2.3 Verification registers ............................................................................................................. 13

3.2.4 Resettable counter registers ................................................................................................. 13

3.2.5 Power registers ..................................................................................................................... 14

3.2.6 Other registers ...................................................................................................................... 15

3.2.7 Meter status register ............................................................................................................. 15

3.3 Time management ............................................................................................................................ 15

3.3.1 Real-time clock (RTC) ............................................................................................................ 15

3.3.2 Backup ................................................................................................................................. 16

3.3.3 Hour counter ......................................................................................................................... 16

3.4 Tariffs ............................................................................................................................................... 16

3.5 Voltage quality measurement ........................................................................................................... 16

3.5.1 Voltage measurement ........................................................................................................... 17

3.5.2 Registration of overvoltage/undervoltage .............................................................................. 17

3.5.3 Registration of voltage failures .............................................................................................. 18

3.5.4 Time stamp with RTC ............................................................................................................. 18

3.6 Loggers ............................................................................................................................................ 18

3.6.1 Debiting logger ..................................................................................................................... 18

3.6.2 Debiting logger 2 .................................................................................................................. 19

3.6.3 Load profile logger ................................................................................................................ 19

3.6.4 Analysis logger ..................................................................................................................... 21

3.6.5 Event logger for status .......................................................................................................... 22

3.6.6 Event logger for RTC .............................................................................................................. 22

3.6.7 Event logger for voltage quality ............................................................................................. 23

3.6.8 Event logger for the load profile logger .................................................................................. 23

3.6.9 Event logger for Cut off .......................................................................................................... 23

3.6.10 Event logger for neutral fault ................................................................................................. 23

3.7 Pulse inputs/outputs ........................................................................................................................ 26

3.7.1 Pulse inputs in the module area ............................................................................................ 26

3.7.2 Water meters ........................................................................................................................ 26

3.7.3 Electricity meters .................................................................................................................. 27

3.7.4 Pulse outputs in module area ............................................................................................... 27

3.7.5 S0 output ............................................................................................................................. 27

3.8 Auxillary Power Supply ...................................................................................................................... 28

3.9 Alarm handling/Push alarms............................................................................................................. 29

3.10 Load control ..................................................................................................................................... 29

4 Display ........................................................................................................................... 30

4.1 Value field ........................................................................................................................................ 31

4.2 Unit field .......................................................................................................................................... 31

4.3 Text field .......................................................................................................................................... 31

4.4 Mains voltage reading ...................................................................................................................... 31

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

4

4.5 Phase current indication ................................................................................................................... 31

4.6 Tariff indication ................................................................................................................................ 32

4.7 Current quadrant reading .................................................................................................................. 32

4.8 Breaker status .................................................................................................................................. 32

4.9 Object identification field ................................................................................................................. 32

4.10 Display configuration ........................................................................................................................ 33

4.11 Display read-out of load profile logger ............................................................................................... 35

5 Integrated radio .............................................................................................................. 37

5.1 Communication via radio .................................................................................................................. 37

5.2 Software upload ............................................................................................................................... 37

6 Integrated disconnection ................................................................................................ 38

6.1 Disconnect function in the meter ...................................................................................................... 38

6.2 Manual disconnection and connection .............................................................................................. 39

6.3 Disconnection by means of communication commands .................................................................... 39

6.4 Smart disconnect .............................................................................................................................. 40

6.4.1 Delayed disconnection ......................................................................................................... 40

6.4.2 Overcurrent protection .......................................................................................................... 41

6.4.3 Current-controlled disconnection .......................................................................................... 41

6.4.4 Power-controlled disconnection ............................................................................................ 41

6.4.5 Reconnection ........................................................................................................................ 41

6.4.6 Disconnection basis ............................................................................................................. 41

6.4.7 Disconnection status ............................................................................................................ 41

6.5 Prepayment ...................................................................................................................................... 42

6.6 Status chart of the disconnect function ............................................................................................. 43

6.7 Disconnection on meters with APS .................................................................................................... 44

6.7.1 Using the push button .......................................................................................................... 44

6.7.2 Using commands (remote) .................................................................................................... 44

7 Meter communication ..................................................................................................... 45

7.1 Requirements for third party modules ............................................................................................... 45

7.2 KMP .................................................................................................................................................. 45

8 Technical specifications .................................................................................................. 46

8.1 Approvals and standards .................................................................................................................. 46

8.2 Technical data .................................................................................................................................. 46

8.2.1 Connections ......................................................................................................................... 48

8.2.2 2W module supply ................................................................................................................ 49

8.2.3 Module interface................................................................................................................... 49

8.3 Diagrams/charts ............................................................................................................................... 50

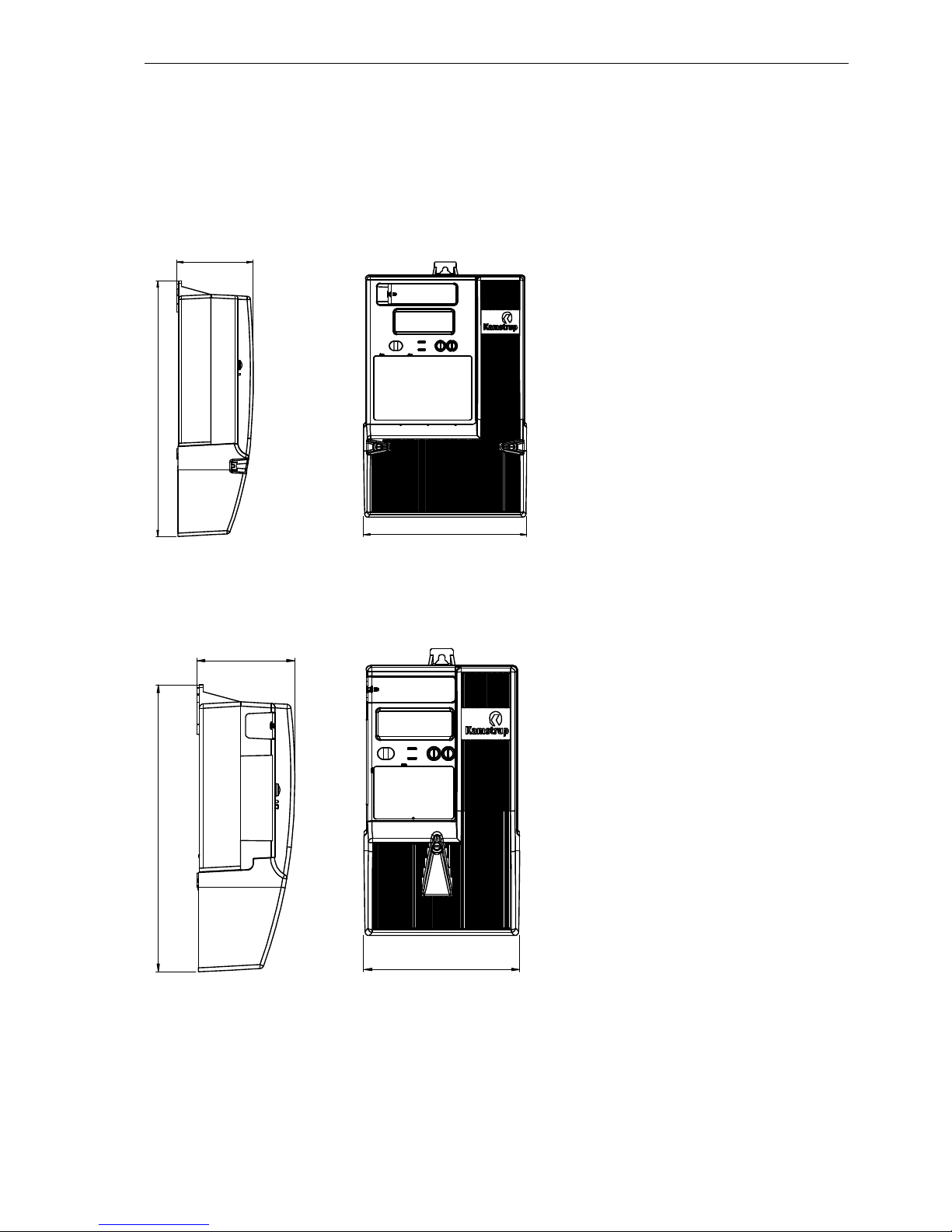

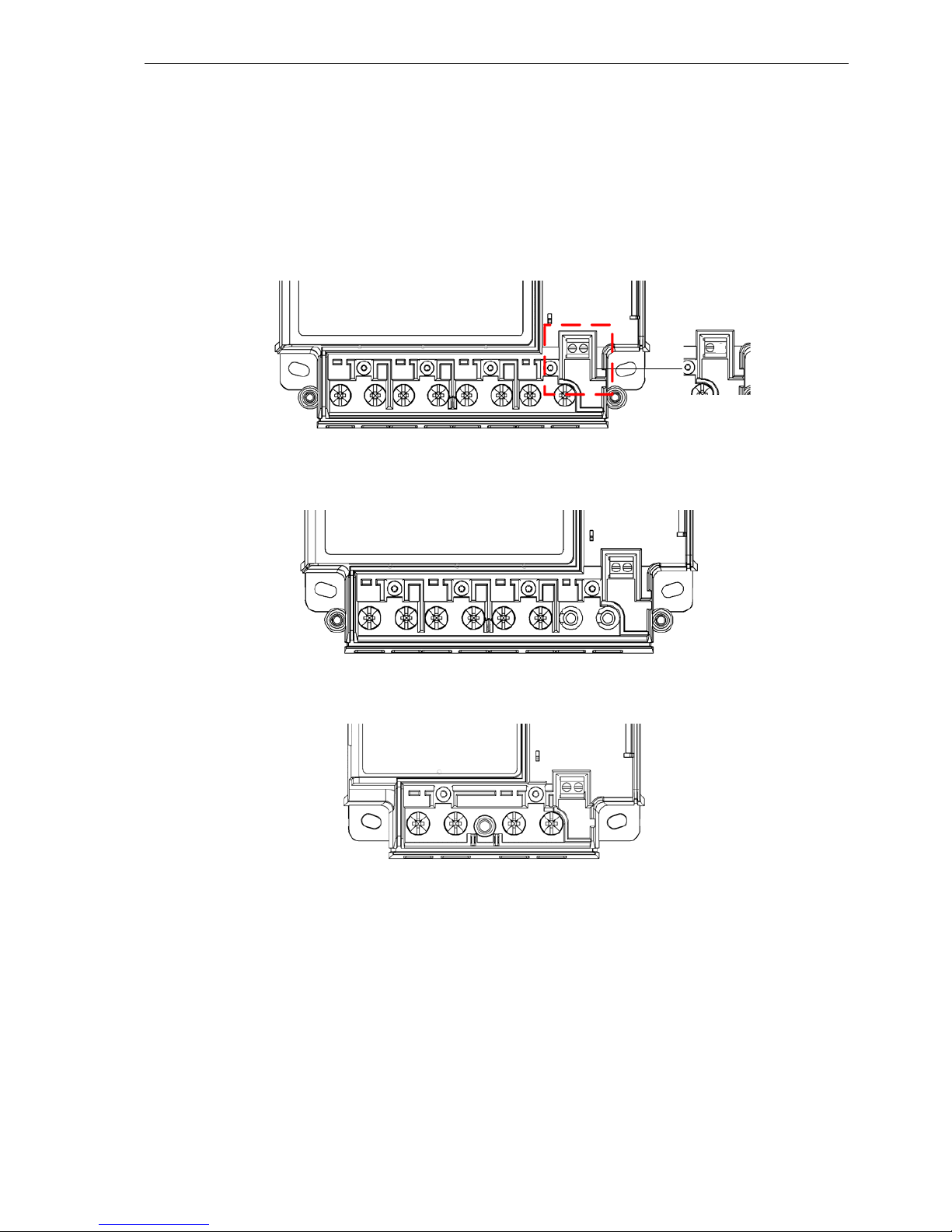

8.3.1 Dimensional sketch for 3-phase and Aron meter with/without breaker .................................. 50

8.3.2 Dimensional sketch for 1-phase meter with/without breaker ................................................. 50

9 Modules ......................................................................................................................... 51

9.1 Primary modules ............................................................................................................................... 51

9.2 Secondary communication modules ................................................................................................. 52

9.2.1 Variants of the secondary communication module ................................................................ 52

10 Ordering details ..................................................................................................... 53

10.1 Type number ..................................................................................................................................... 53

10.2 Configuration numbers ..................................................................................................................... 55

10.2.1 Configuration 1 ( A-B-CCC-DD-E ) ........................................................................................... 55

10.2.2 Configuration 2 ( FFF-GG-HH-I ) .............................................................................................. 57

10.2.3 Configuration 3 ( JJ-K-LL-M-NN ) ............................................................................................. 58

10.2.4 Configuration 4 ( OOO-PPP-QQ ) ............................................................................................ 59

10.2.5 Configuration 5 (RRR) ............................................................................................................ 59

10.3 Display readings ............................................................................................................................... 60

10.4 Period plan - Tariff and load control table .......................................................................................... 62

10.4.1 Setup working days and non-working days ............................................................................ 62

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

5

10.4.2 Setup period A and B and tariff switch for each period. ......................................................... 62

10.4.3 Setup plan for load control 1 and 2 ....................................................................................... 63

10.4.4 Setup calender for exception days ........................................................................................ 64

10.4.5 On Demand tariff .................................................................................................................. 64

10.4.6 Load control delay ................................................................................................................ 64

10.5 Daylight saving table ........................................................................................................................ 65

10.6 Label ................................................................................................................................................ 66

10.7 Display configuration ........................................................................................................................ 67

10.8 Disconnect configuration .................................................................................................................. 69

11 Installation manual ................................................................................................ 70

11.1 Terminal numbering .......................................................................................................................... 70

11.2 Connection diagrams ........................................................................................................................ 71

11.3 Guidelines for safety and installation ................................................................................................ 72

11.4 Sealing ............................................................................................................................................. 73

12 Test specifications ................................................................................................. 74

13 Packing .................................................................................................................. 75

14 Accessories ............................................................................................................ 75

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

6

1 Revision history

Revision Date Change

A1 2011-10-21 Document created

B1 2011-12-22 Figures are updated according to new mechanical design.

C1 2012-05-07 First release

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

7

2 General description

Kamstrup 162M and 382M are a generation of directly connected electricity meters for the measurement and

registration of electrical energy. The meters are full-electronic without movable parts. Thus, energy registration is

not affected by shock and impact during transportation and mounting. Furthermore, measurements are correct,

no matter the physical mounting direction. Using shunt as measuring principle, it is possible to obtain a good

linearity, a very large dynamic area and immunity to magnetism and DC currents.

The easily readable display scrolls automatically between readings, or readings can be changed manually by the

consumer activating a push button. The required display readings as well as their order are configurable. In

addition to being read from the display, data can be collected via the optical output or from the module area by

means of a suitable communication module. The unique module area also permits external monitoring of tariffs,

pulse inputs and outputs, and configuration as well as connection of AMR and AMM modules.

From the factory, the meter can be configured to measure both imported and exported energy. The meters are

constructed with independent and galvanically separated measuring systems (the number of measuring systems

depends on the meter type). This ensures a correct measurement irrespective of how many and which

measurement systems are used. The energy registration is saved in the integral data logger, which ensures good

data history.

The meter construction makes it immune to magnetic influence, and the measuring accuracy will not be

influenced by magnetism.

It is possible to supply the meter with battery backup for the integrated RTC (Real Time Clock) used for tariff

control and time stamping of data and events.

The tariff control permits up to 8 tariffs. The tariffs can be managed by the internal clock (RTC) on the basis of

preprogrammed time tables. The tariff shifts can also be effected by summer time/standard time and holidays.

The meter is configurable and can be supplied from the factory with required functions. This ensures a minimum

of configuration during installation. Furthermore, the meter can be configured to verification mode, which

improves the resolutions of the energy indications, thereby reducing the duration of test and verification.

The meter is approved according to current electricity meter standards.

Kamstrup electricity meters are supported by a Kamstrup configuration tool called METERTOOL.

2.1 Terms

Integration period: The integration period is the length of time over which the power is averaged in order

to find e.g. the peak power. For instance, it can be 15 min.

Load profile logger: A logger that contains a series of energy values A+, A-, R+, R- depending on meter type.

The interval between each values is defined by the integration period. As default the

logger contains the last 4 months of data.

Debiting period: The debiting period is a configurable length of time between each debiting entries

where the value of a number of predefined meter regsiters are logged. Usually the

debiting period is 1 month.

Debiting logger: Contains a series of predefined meter registers that are logged with a customer-

specific time interval defined as the debiting period. The depth of the logger is 36

entries.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

8

2.2 Construction

The meter is designed as a three-piece plastic construction, consisting of housing, verification and meter covers,

all parts made of fire resistant plastic. The verification cover protects the metrological functions. It is not possible

to open the verification cover without breaking the metrological seal.

The meter cover covers the module area. Various communication modules, input/output and control modules can

be connected without reverification. Furthermore, the meter cover can be ordered with different lenghts. A short

version allows premounted terminal-pins or wires to be mounted, while longer version covers the terminal in- and

outputs

2.2.1 Terminals

The current terminal is a combined terminal and shunt. The terminal is the elevating type with one screw per

terminal, which secures quick and simple mounting. The construction and design of the terminal protect the

connected cable from being damaged during tightening. Furthermore, a good contact area is provided, which

minimises the contact resistance and thereby heating at heavy currents.

2.2.2 Measurement Construction

The meter is provided with 1 shunt per system for current mesurement, and it measures the voltage through a

voltage divider. A switch mode supply feeds measuring circuits and main processor with voltage. Furthermore, the

switch mode supply in combination with varistors and power resistors functions as an excellent transcient

protection.

The use of shunt and switch mode supply also makes sure that the meter is immune to magnetic influence.

Magnetic influence will be detected by the integral sensors and be registered in the meter’s event logger.

Using shunt as measuring principle for the current measurement where a resistance stable metal provokes a

given drop of voltage at a given current, makes the energy measurement secure and reliable. Another important

advantage of the measuring principle shunt is a linear change of the voltage drop, which is an expression of the

current consumption.

The meters are constructed with independent and galvanically separated measuring systems (the number of

measuring systems depends on the meter type). This ensures a correct measurement irrespective of how many

and which measurement systems are used.

The meter’s main processor with corresponding data logger has its own supply, which means that data is well

secured against transients.

Like voltage drop, energy consumption is calculated as an expression of the current compared to the phase

voltage and time. The energy registration per measuring system is communicated to the meter’s legal processor

via the meter’s internal bus system. After correction, the energies are summed in the main energy register.

Measured and calculated data is safely stored in the memory (EEPROM) and can be read out either via the module

area’s unique interface, or through the optical interface by means of an optical head.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

9

2.3 Meter types

Kamstrup’s direct meters are available in different variants depending on the application for which they are used.

As default, in addition to many other functions, the meters are provided with debiting logger, event loggers,

voltage quality measurement, tamper detection, and the possibility of using up to 8 tariffs. Furthermore, the

meters can be supplied from the factory with internal disconnect function for disconnection and connection of the

consumer’s supply, configured for the measurement of energy types in all 4 quadrants, with integrated radio

transceiver, load profile logger, prepayment function, APS and smart disconnect.

The summary below provides an overview of which functions the meter types include.

The meter's type number consists of 13 characters that describe the meter's hardware and mechanics:

684-XXX-XX-XX-XXX for the 3-phase meter and 686-XXX-XX-XX-XXX for the 1-phase meter.

Kamstrup 3-phase Direct meter is a 3-phase 4-wire meter, 684-3XX-XX-XX-XXX.

Kamstrup Aron Direct meter is a 3-phase 3-wire meter, 684-2XX-XX-XX-XXX.

Kamstrup 1-phase Direct meter is a 1-phase 2-wire meter, 686-1XX-XX-XX-XXX.

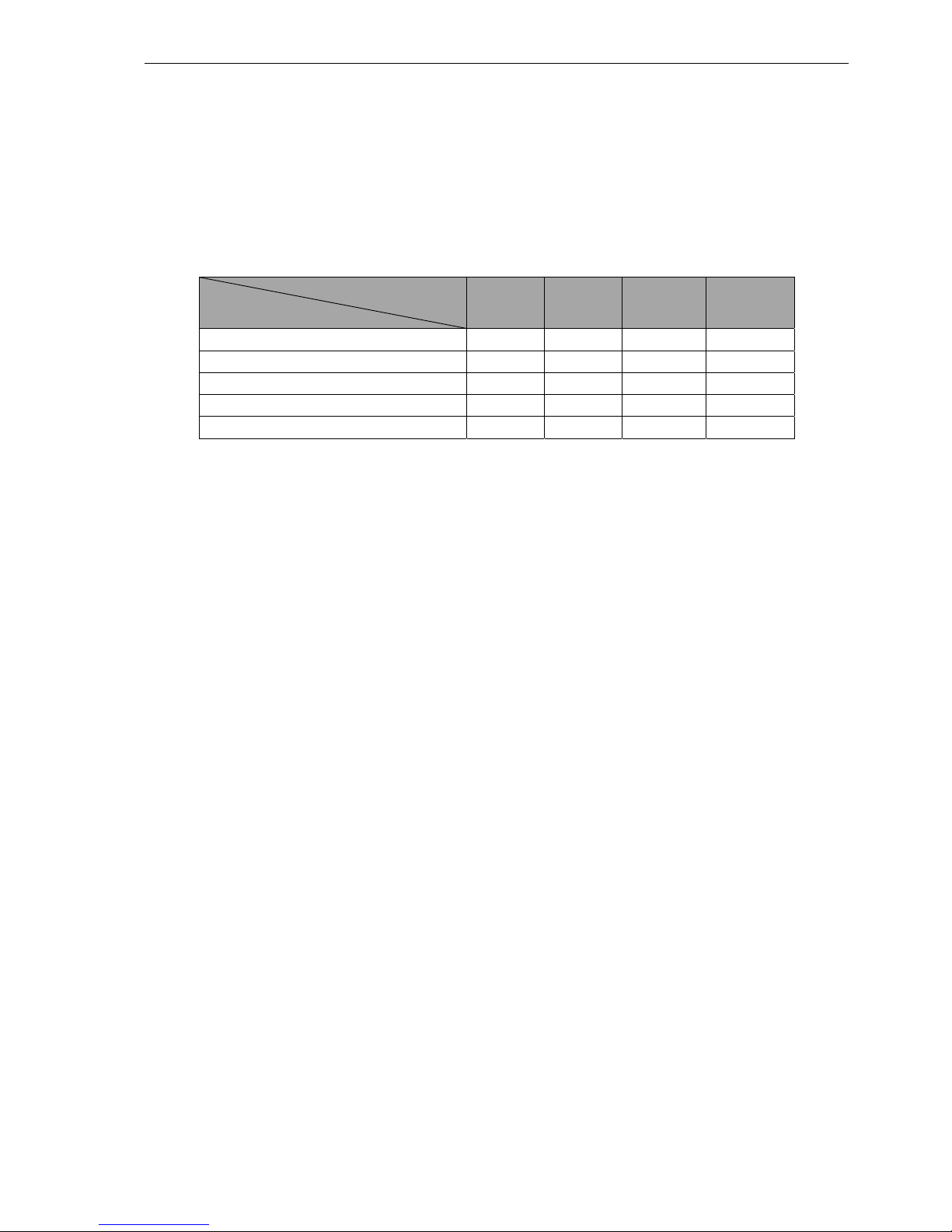

Meter Type 1-phase Aron 3-phase

Without

APS

Without

APS

With

APS

Without

APS

Without

Radio

Without breaker

With breaker

Kamstrup

Radio

Without breaker

With breaker

Table 1: Meter variants - hardware.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

10

3 Functions

3.1 Start-up of meter

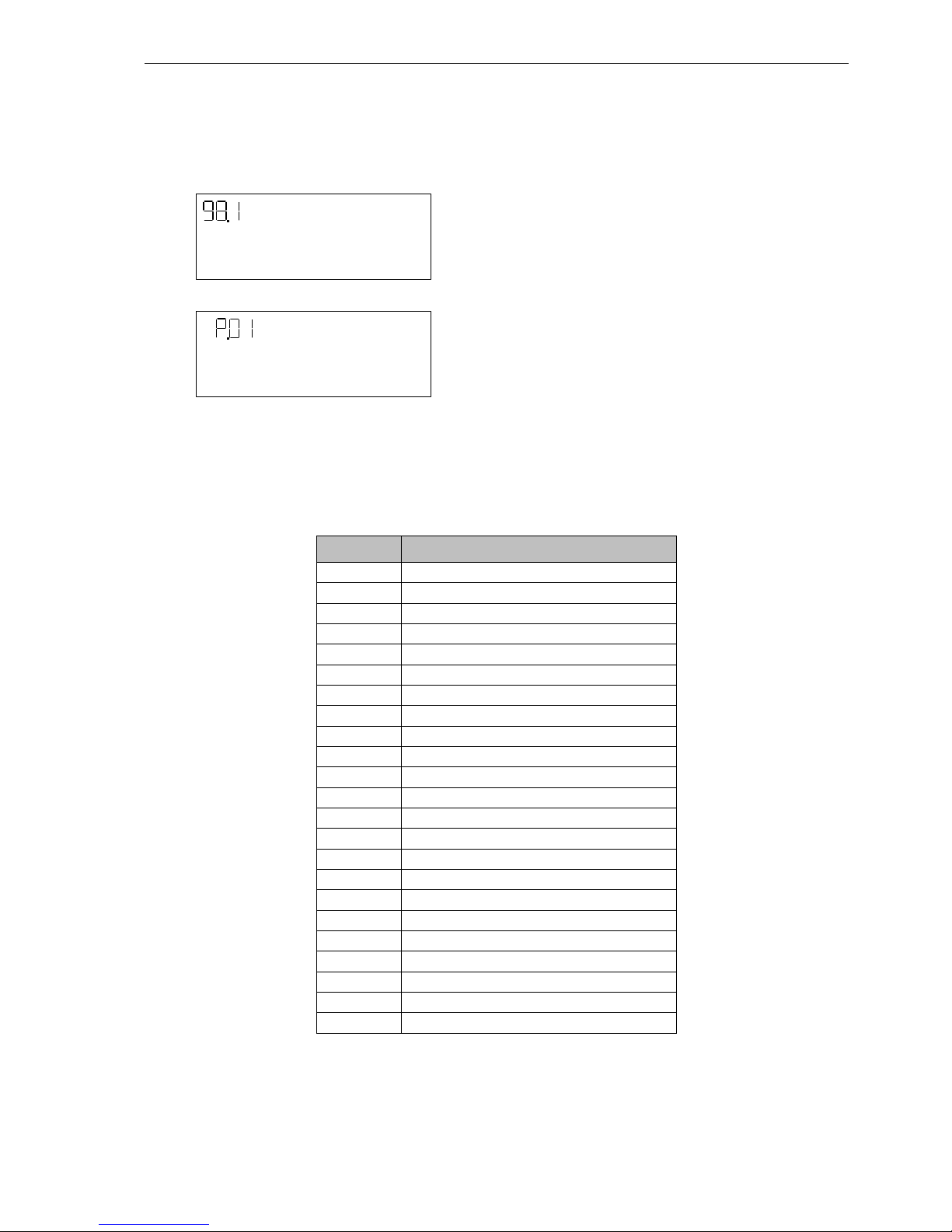

In the first five seconds after being connected to power, the meter will show its software type and revision

number. In the next five seconds, the ROM checksum will be displayed.

3.1.1 Software revision

The 8 digits in the value field describes the software type and revision is shown in the text field in the upper right

corner.

3.1.2 ROM checksum

The four or five digits of the ROM CRC appear as one number resulting from the checksum calculation.

3.2 Registers

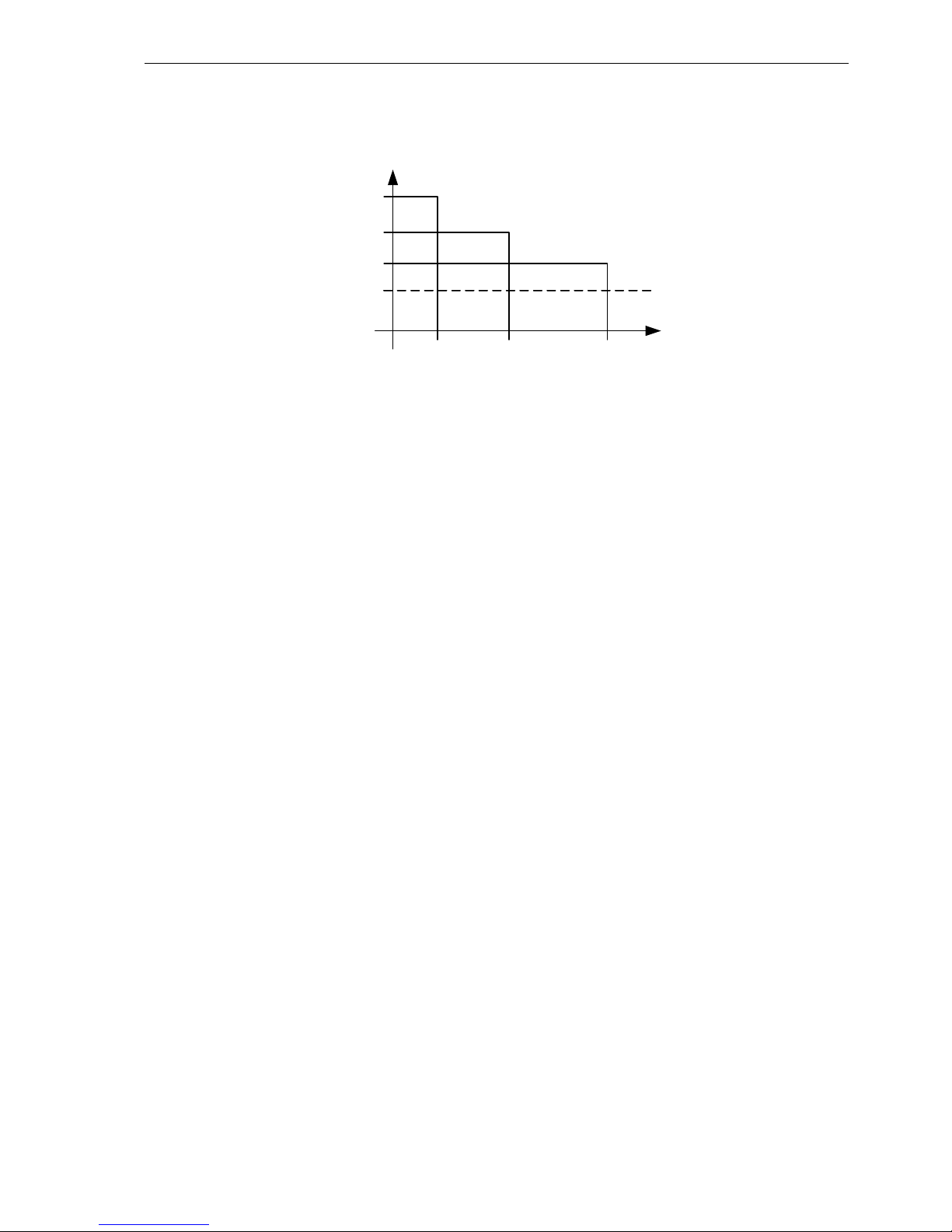

Kamstrup’s direct meters are constructed as 4-quadrant meters, which provide safe registration of various

measured data such as imported and exported energy for both active and reactive energy, tariffed energy, power,

voltage and current.

R+

kvarh

Rkvarh

A+

kWh

A-

kWh

1

2

3

4

+R

i

+R

c

-R

c

-R

i

Wvar

W

var

W

var

W

var

Figure 1: Energy and power measurement in 4 quadrants.

The basic meter is constructed as an import meter, but is available as an import/export meter for both active and

reactive energy. The possible energy registers are seen below. The OBIS code of each energy type is stated in

brackets according to EN 62056-61.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

11

A+ (1.8.0)

Active positive energy consists of active energy from quadrants 1 and 4.

A- (2.8.0)

Active negative energy consists of active energy from quadrants 2 and 3.

R+ (3.8.0)

Reactive positive energy consists of positive inductive energy from quadrant 1 and positive

capacitive energy from quadrant 2.

R- (4.8.0)

Reactive negative energy consists of negative inductive energy from quadrant 3 and

negative capacitive energy from quadrant 4.

R1 (5.8.0)

Positive inductive energy from quadrant 1.

R4 (8.8.0)

Negative inductive energy from quadrant 4.

3.2.1 Energy registers

The meter’s configuration determines the number of available registers.

The energy readings can be configured for display in format 7.0 (0000000) or format 6.1 (000000.0). Furthermore,

it is possible to select or deselect leading zeroes.

The meter’s main energy registers are:

A+ Active positive energy (consumption/import). Active energy from quadrants 1 and 4 is displayed in

kWh.

A- Active negative energy (production/export). Active energy from quadrants 2 and 3 is displayed in

kWh.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

12

R+ Reactive positive energy. Positive inductive energy from quadrant 1 and positive capacitive energy

from quadrant 2 are displayed in kvarh.

R- Reactive negative energy. Negative inductive energy from quadrant 3 and negative capacitive energy

from quadrant 4 are displayed in kvarh.

R1 Ri+ Reactive positive energy. Positive inductive energy from quadrant 1 is displayed in kvarh.

R4 Rc- Reactive negative energy. Negative capacitive energy from quadrant 4 is displayed in kvarh.

Furthermore, the above energy types are registered in tariffed registers T1, T2, T3, T4, T5, T6, T7 and T8.

For further information about tariff control, see section 3.4.

In addition, bidirectional positive registration in a register, i.e. active energy for import and export added

numerically, can be selected as a special register (control register). This register sums the energy positively

without considering whether the input and output terminals per system have been interchanged.

A1423 Numeric register for |A+| + |A-|. The value is displayed in kWh.

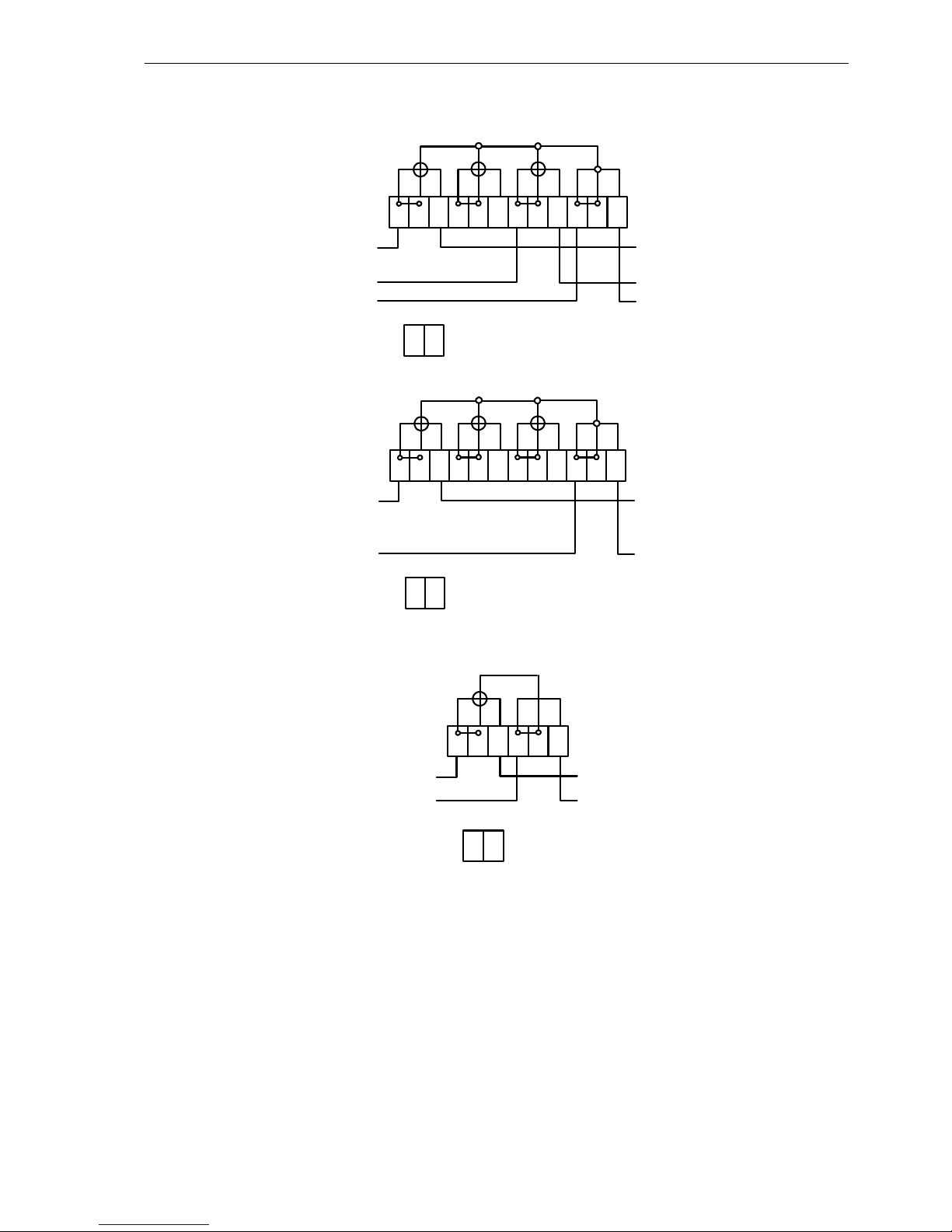

3.2.2 Energy calculation

There are several acceptable methods for calculating the energy in three-phase meters.

Three identical meters can obtain several different results for energy measurement dependent on the calculation

method.

If energy is imported on phases L1 and L2, and energy is exported on phase L3 as shown in Figure 2, the

calculation can be made according to the methods described below.

A- A+

L1

L3

L2

Figure 2: Example of energy consumption in a three-phase meter.

Figure 3 graphically shows the calculation of the total energy dependent on the applied calculation method. The

first method applies vector summation, which is known from the Ferraris meters where the energy is added in

consideration of sign. In the next example import and export are added individually, and finally is shown the

calculation with total summation where all contributions are added numerically is shown.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

13

A- A+

L1

L3

L2

A+

L1 L2

L3

A- A+

L1

L3

L2

A+

L1 L2

L3

A- A+

L1

L3

L2

A+

L1 L2

L3

A-

Vector summation Individually import/export Total summation

Figure 3: The three different calculation methods.

When using vector summation, the positive contributions are added and the negative contributions are

substracted in the same way as by electromechanical meters. Contributions from e.g. solar energy installations

will be set off in the total energy calculation. This calculation method is sensitive to incorrect installation and

manipulation.

Individually import/export calculation method has one register for the positive contributions and one for the

negative contributions.

Kamstrups 162M and 382M supports the individually import/export calculation method.

Note!

Total summation adds all contributions to the positive register whether one or all are negative. Kamstrup

Generation M meters doesn’t support this calculation method for the main energy registration, but have a

additional register for this called “A1423”.

3.2.3 Verification registers

For test purposes, the 4 main energy registers (A+, A-, R+, R-) can be displayed with higher resolution in format 3.4

(000.0000).

For test purpose it is possible to activate test mode. Test mode change the display setup to allow selection of

energy registers A+, A-, R+ and R- depending on the meter by activating the left push button. In test mode, the LED

blinks proportionally to the chosen energy type.

The meter changes automatically from test mode to normal mode 16 hours after the latest activation of the push

button, or if the meter is reset. METERTOOL can also be used for changing back to normal mode.

Finally, 6 seconds activation of the left push button can provoke a change to normal mode.

3.2.4 Resettable counter registers

The consumer can use a specific register (resettable counter) for monitoring the consumption in a given period,

e.g. every day or weekly.

In addition, the consumer can use another register (resettable counter) for monitoring the electricity production

that the consumer has delivered to the electricity grid, e.g. from a solar cell installation.

The resettable counters count with the same resolution as the main energy registers of the meter, but can be reset

by activating the push button for 6 seconds at the same time as the resettable counter reading is displayed.

No register values in the meter will decrease due to inverse current

flow, no matter of meter configuration.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

14

3.2.5 Power registers

The meter registers the current power (instantaneous power) in all four qudrants. Registration of active and

reactive Power in the meter use same individually Import/export calculation method as in the case of energy

measurements.

Actual power

Actual power shows the current three-phase power consumption. The actual power can be shown in the display

and is calculated and updated every second.

Peak Power

The peak power is the highest averagely determined power registered during the debiting period. The averagely

determined power is based on a period that corresponds to the integration period. The peak power is available for

P+

max

, P-

max

, Q+

max

and Q-

max

.

Furthermore, the meter can be configured to register the peak power P+

max

for T1 and T2. Thus, the biggest positive

active power during the debiting period is found for T1 and T2, respectively.

At the end of the debiting period, the peak power and the accumulated peak power are stored and a new period

starts. The accumulated peak power accumulates the values of each period and the accumulated peak power of

the previous period. The peak power, however, is reset after each period.

Below the power registers are described:

P+ Active positive instantaneous power of quadrants 1 and 4. The power is displayed in kW in format

4.3 (0000.000).

P- Active negative instantaneous power of quadrants 2 and 3. The power is displayed in kW in format

4.3 (0000.000).

Q+ Reactive positive instantaneous power of quadrants 1 and 2. The power is displayed in kvar in

format 4.3 (0000.000).

Q- Reactive negative instantaneous power of quadrants 3 and 4. The power is displayed in kvar in

format 4.3 (0000.000).

P+

max

Maximum active positive power during the debiting period measured over an integration period

deriving from quadrants 1 and 4. The power is displayed in kW in format 4.3 (0000.000).

P-

max

Maximum active negative power during the present debiting period measured over an integration

period deriving from quadrants 2 and 3. The power is displayed in kW in format 4.3 (0000.000).

Q+

max

Maximum reactive positive power during the present debiting period measured over an integration

period deriving from quadrants 1 and 2. The power is displayed in kvar in format 4.3 (0000.000).

Q-

max

Maximum reactive negative power during the present debiting period measured over an integration

period deriving from quadrants 3 and 4. The power is displayed in kvar in format 4.3 (0000.000).

P+

max akk

Accumulated maximum active positive power during the present debiting period. To calculate the

accumulated peak power, the peak power of the present debiting period is added to the

accumulated peak power of the last debiting period.

P+

max, daily

Max active power within the 24 hours in question.

P+

min, daily

Min. active power within the 24 hours in question.

Available power registers depend on the chosen energy type. E.g. a two-qudrant meter (A+, A-) only contains P+

and P- power registers.

Power threshold value

It is possible to let a counter register how many times a power threshold value is exceeded. The value only

applies to active positive power P+.

The threshold value can be configured between 0 and 99 kW. If the limit is exceeded within the integration period

(5, 15, 30 or 60 min.), the counting is made in the power threshold counter.

The power threshold counter is registered in the debiting logger of the meter, and is reset at every debiting stop.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

15

3.2.6 Other registers

Other registers that include measurement and registration of data and events are e.g:

RTC

Meter status

Magnetic influence

Access registration (Tamper)

Voltage quality

Meter number

Special data

Pulse input

3.2.7 Meter status register

The meter status register consists of 8 digit number where each number can either “0” or “1”. Each digit indicates

the actual status of following possible event: (The sequence is from right to left)

- 1

st

Number: Is not in use

- 2

nd

Number: Indicates an error in EEPROM access or a data backup error

- 3

rd

Number: Indicates Magnetic detection

- 4

th

Number: Ram error

- 5

th

Number: ROM checksum error

- 6

th

Number: External alarm input (Only relevant if the functionality is enabled)

- 7

th

Number: Indicates tamper of the meter cover.

- 8

th

Number: Is not use

The status indicators are reset when the source to the indication disappears. Errors in digit number 2, 4 and 5 will

in most cases be permanent and requires the meter to be returned to Kamstrup.

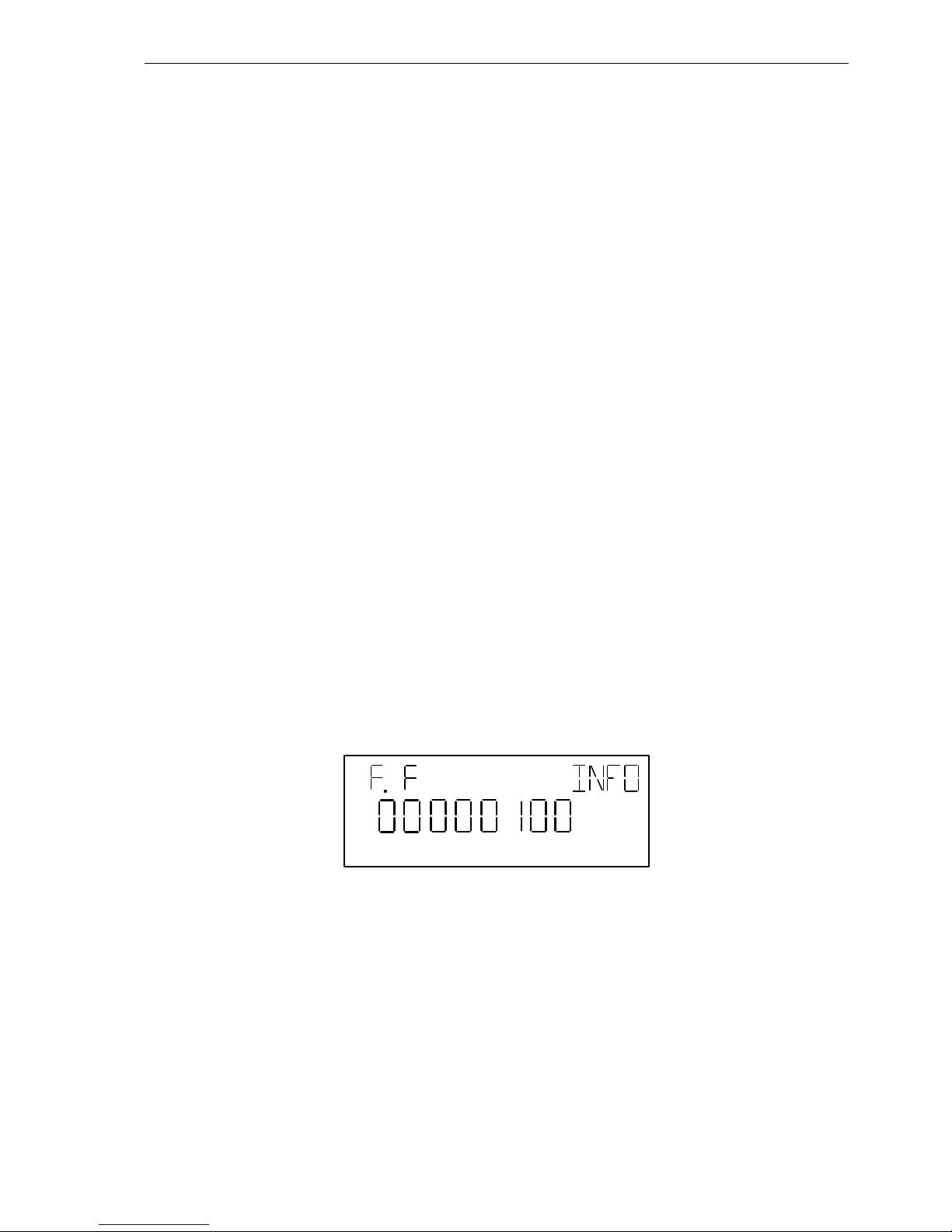

In Figure 4 an example of the register shown in the display is illustrated.

L1

L2 L3

Figure 4: Meter status register indicates magnetic detection.

3.3 Time management

The meter has an internal real-time clock (RTC) with either battery or rechargeable backup unit (supercap).

3.3.1 Real-time clock (RTC)

The real-time clock (RTC) makes it possible to provide measured data with an accurate time stamp (typically

5ppm at 23C).

The real-time clock time stamps load profile and event values, changes tariff etc. In addition to the tariffs, it is

associated with a calendar.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

16

The time is adjustable via the configuration program METERTOOL for kWh meter or via reading system. It is

possible to use daylight saving time with corresponding preprogramming of shifting dates, see more in section

10.2.4.

3.3.2 Backup

The meters can be supplied with either a non-rechargeable unit (battery) or a rechargeable type (supercap). The

backup time of the battery depends on the period of time the meter is without mains supply, and in addition, the

battery gives access to further functions such as display views despite lack of mains supply, see section 4.10 for

further information.

The lifetime of the backup unit also depends on the mains voltage supply to the meter and the ambient

temperature. For specifications, see also section 8.2.

3.3.3 Hour counter

As the RTC manage the date and time in the meter, an hour counter register manage the number of operating

hours of the meter, i.e. number of hours where main voltage are supplied to the meter.

3.4 Tariffs

The meter allows registration in eight tariffs for each energy type depending on configuration, see section 3.2.1.

The tariffs are active when at least one tariff-register has been selected in the display set-up. Do not forget to

select control type when activating tariffs.

The tariffs can be controlled in three different ways:

- Via communication commands, e.g. from a module or via METERTOOL, or

- Through the module’s I/O, or

- Internally by means of time control via the RTC.

Module I/O controlled tariffs use the ports of the module connector for changing the tariffs, e.g. if a tariff control

module prepared for 230 VAC is connected to 230 VAC. The inverted function can also be selected.

Port 1:

Terminals 13 and 15

Port 2:

Terminals 33 and 15

Active tariff Active tariff

inverted

0 VAC 0 VAC

T1

T4

230VAC 0 VAC

T2

T3

0 VAC 230VAC

T3

T2

230VAC 230VAC

T4

T1

Table 2: 230VAC - tariff control.

The tariff reading is updated in the display every 10 secs. The active tariff is displayed by readings T1..T8.

The time-controlled tariff is possible using the RTC to control the tariffs on the basis of a preprogrammed shifting

table.

The set-up of the meter’s configuration makes conflicts between control methods impossible as the choice of one

method automatically excludes the others.

3.5 Voltage quality measurement

The meter makes it possible to register/measure the voltage quality.

The voltage quality measurement consists of voltage measurement, registration of maximum and minimum

voltage, overvoltage and undervoltage as well as voltage failures. All registrations take place per phase.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

17

3.5.1 Voltage measurement

The RMS voltage measured per phase with average determination every second forms the basis of the registration

of overvoltage, undervoltage, and voltage failures. The voltage per phase can be displayed with an accuracy

corresponding to the meter’s class.

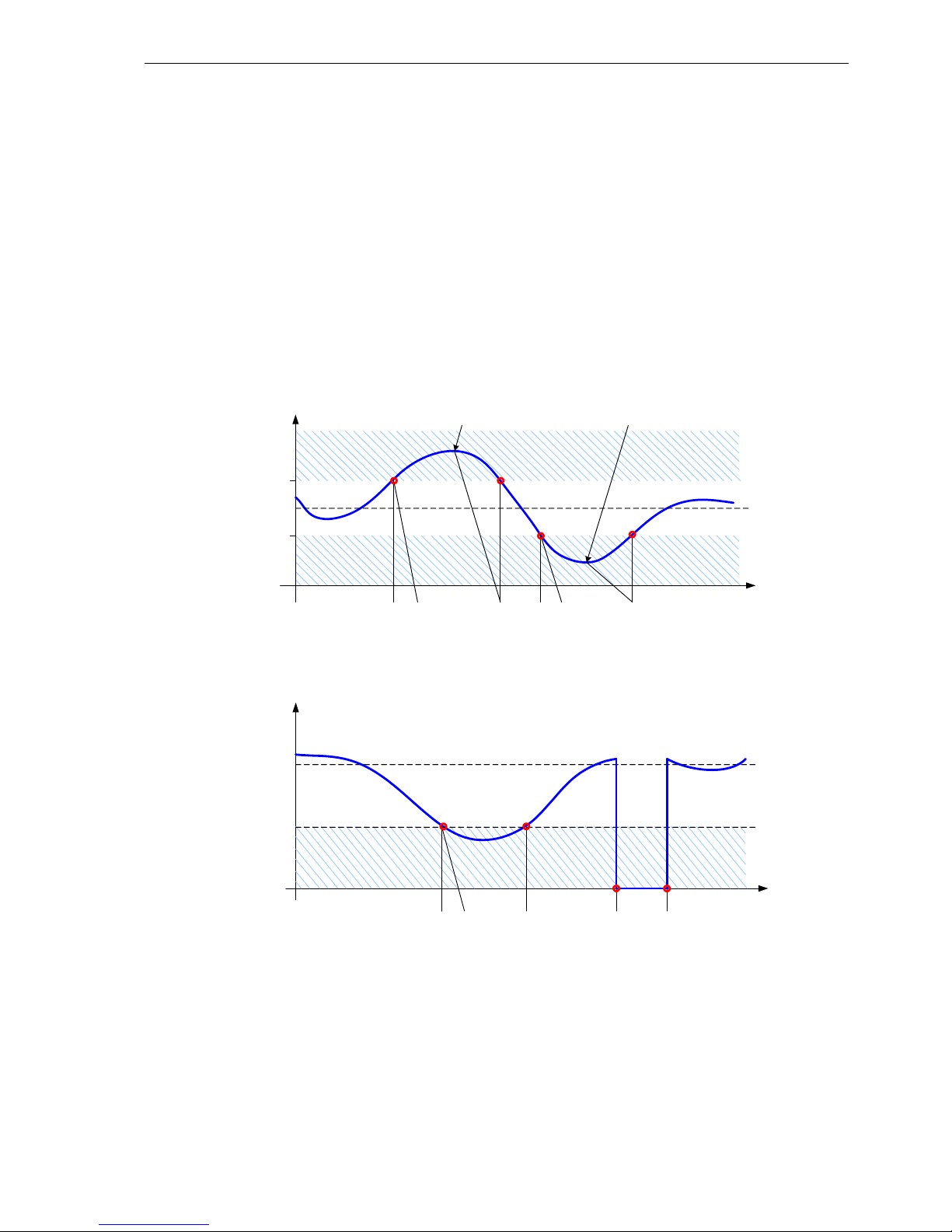

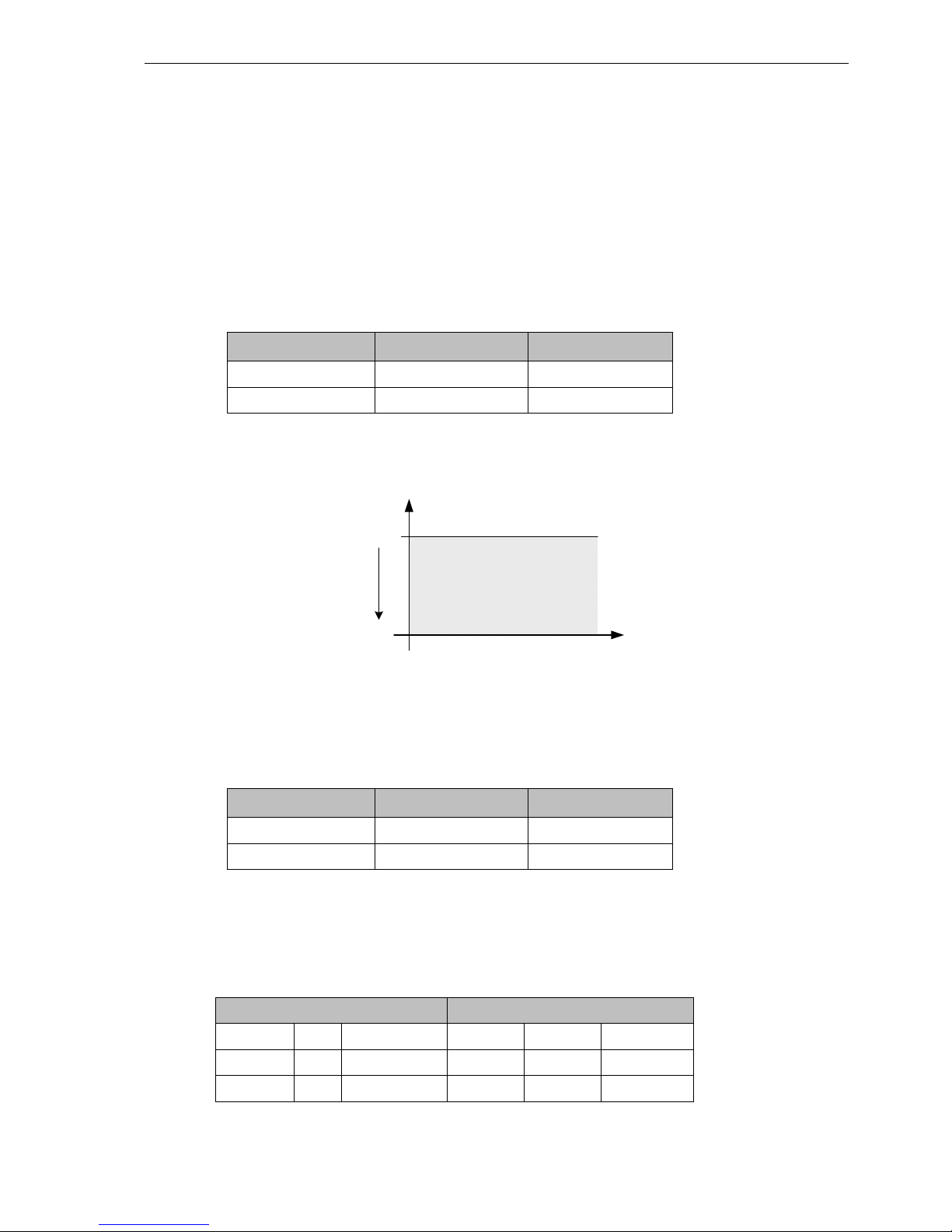

3.5.2 Registration of overvoltage/undervoltage

Registration of overvoltage/undervoltage for diagnosing the voltage situation of the individual consumer is an

important tool in connection with the evaluation of possible complaints from consumers as well as network

analysis.

If one or more phases has/have been outside a configurable overvoltage (U

High

) or undervoltage (U

Low

) limit for

some time (t

d

), this is registered in the meter's event logger for voltage quality. The registration includes date and

hour. The time period which triggers a registration can be configured between 10 secs. and 2550 secs.

The limits for registration of overvoltage and undervoltage are configurable from 0 to 20 %, i.e. from 230 VAC – 20

% (184 VAC) to 230 VAC + 20 % (276 VAC).

Time

Voltage

230 V

U

Low

U

High

t

1

t

2

t

3

t

4

t1+ t

d

t3+ t

d

U

Max

U

Min

Over voltage

Under voltage

Figure 5: Voltage quality measurements - under and over voltages.

Time

Voltage

230 V

t

1

t

2

t

3

t

4

t1+ t

d

U

Cutoff

= 160 V

Voltage cut off

Figure 6: Voltage quality measurements - voltage cut-off.

Figure explanation

U

High

is the configurable limit for overvoltage in %

U

Low

is the configurable limit for undervoltage in %

U

max

is the peak voltage in the overvoltage period (t1 – t2)

U

min

is the minimum voltage in the undervoltage period (t3 – t4)

U

Cutoff

is the voltage failure per phase (t3 – t4)

t

(1-4)

indicates RTC.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

18

3.5.3 Registration of voltage failures

Voltage failures on one or more phases lasting longer than the configurable time periode (t

d

) are registered in the

event logger with time stamps at voltage dropout (t

3

) and voltage recovery (t4) in Figure 6.

The time for the event is registered with date and hour.

The time for how long a voltage failure should last before it is registered in the voltage quality logger can be

configured in steps of 10 secs. The range is between 0 and 2550 seconds.

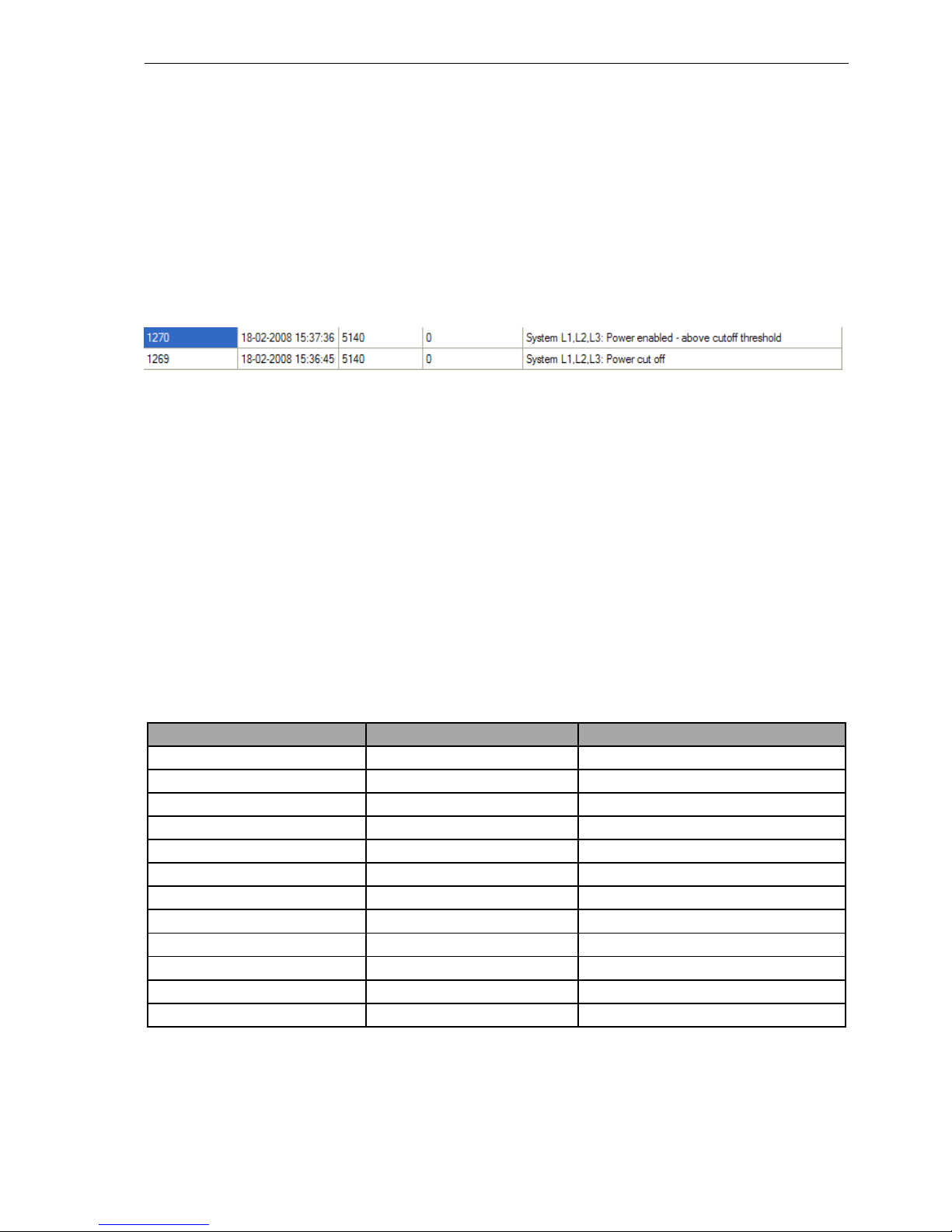

3.5.4 Time stamp with RTC

The time registration is made both at the the apperance of the voltage failure and at the return of voltage. An

example of this registration can be see in Figure 7, showing a read out from METERTOOL.

Figure 7: Logger registration of a voltage failure and re-power with correspondng log IDs and time stamps.

3.6 Loggers

The meter has several different loggers for registration of data and events, among others a debiting logger and

different loggers that secure the registration of events – as to internal errors, magnetic influence, access

registration (Tamper), clock, and voltage failure, load profile logger, andan analysis logger. The load profile and

analysis loggers share the same logging depth, which means that the depth of the analysis logger depends on the

logging depth of the load profile logger and thus the configuration of the meter.

3.6.1 Debiting logger

The debiting logger stores relevant data for a given period. The end of a debiting period is called debiting stop. A

debiting stop can be triggered by the meter’s internal clock or via a communication command.

With its logging depth of 36 loggings, the debiting logger makes it possible to store data for many purposes, e.g.

as a monthly logger controlled by either an internal RTC or an external unit. In the standard version, the loggings

are initiated by the meter’s time. The time for debiting stop has many options, e.g. monthly, every other month,

every six months or yearly.

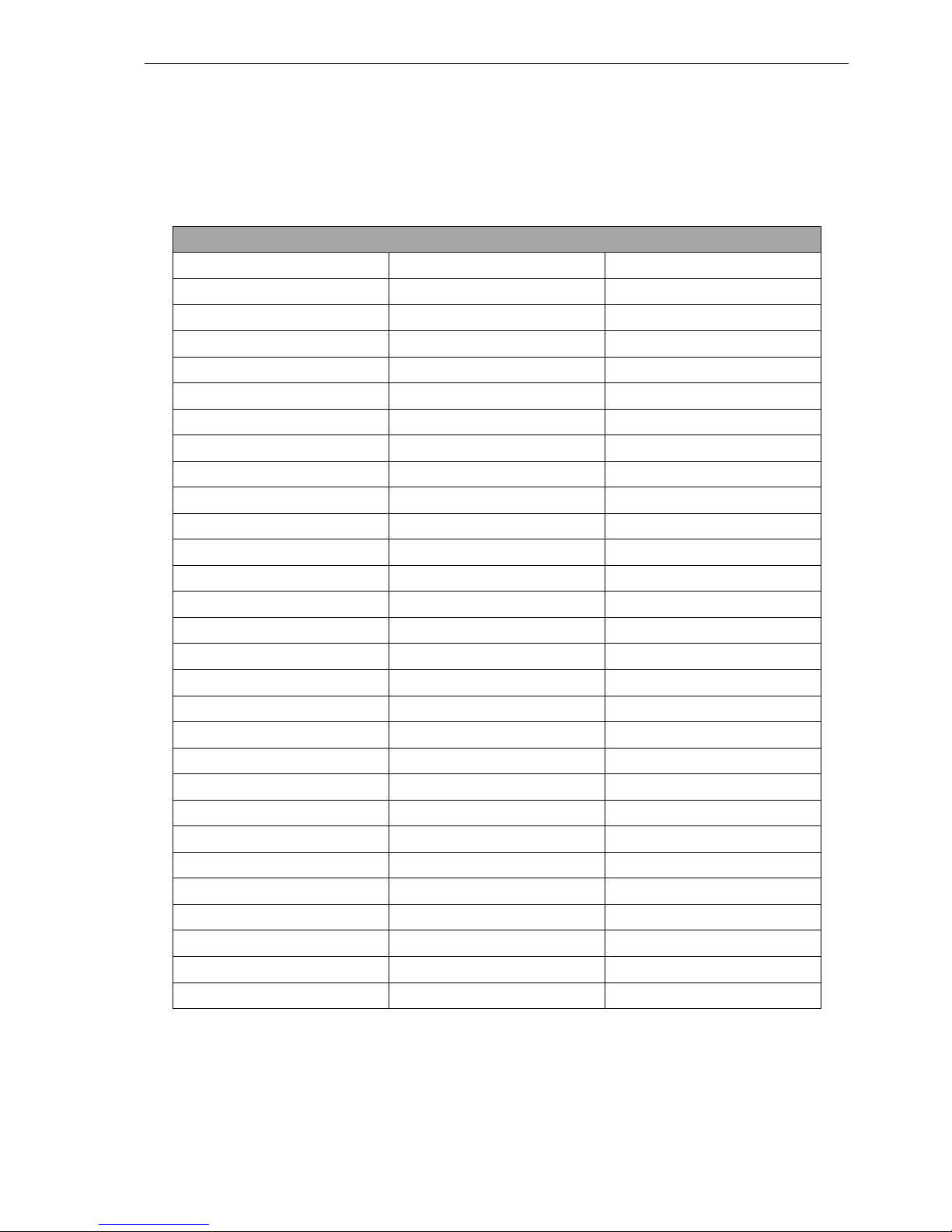

The debiting logger stores the following values at debiting stop depending on the meter’s configuration:

Various Energy registers Power registers

Date Active energy A+

Peak power P+

max acc

Time Active energy A-

Peak power P+

max

Date

Quality info Reactive energy R+

Peak power P+

max

Hour

Hour counter Reactive energy R-

Accumulated peak power P+

max acc

Number of debiting periods Active energy A+ Tariff 1

Peak power P+

max

Tariff 1

Power threshold counter

Active energy A+ Tariff 2

Peak power P+

max

Tariff 1 Hour

Pulse input Active energy A+ Tariff 3

Peak power P+

max

Tariff 1 Date

Active energy A+ Tariff 4

Peak power P+

max

Tariff 2

Reactive energy R+ Tariff 1

Peak power P+

max

Tariff 2 Hour

Reactive energy R+ Tariff 2

Peak power P+

max

Tariff 2 Date

Reactive energy R+ Tariff 3

Reactive energy R+ Tariff 4

Table 3: Registers stored in debiting logger.

A combined RTC/Quality stamp includes besides time and date, a data quality mark, that validates each

registration of eventually time adjustments and/or voltage quality events, i.e. over and under voltages and

voltage interrupts.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

19

3.6.2 Debiting logger 2

In addition, the meter has a debiting logger 2, which logs the following registers:

Various Energy registers

Date Active energy A+

Time Active energy A-

Quality info Reactive energy R+

Hour counter Reactive energy R-

Active energy A+ Tariff 1

Active energy A+ Tariff 2

Active energy A+ Tariff 3

Active energy A+ Tariff 4

Active energy A- Tariff 1

Active energy A- Tariff 2

Active energy A- Tariff 3

Active energy A- Tariff 4

Reactive energy R+ Tariff 1

Reactive energy R+ Tariff 2

Reactive energy R+ Tariff 3

Reactive energy R+ Tariff 4

Reactive energy R- Tariff 1

Reactive energy R- Tariff 2

Reactive energy R- Tariff 3

Reactive energy R- Tariff 4

Table 4: Registers stored in debiting logger 2.

The log interval can be configured to one day, one week or one month via METERTOOL. The logging depth is 45

loggings.

The log interval is Kamstrup factory standard which is one day.

3.6.3 Load profile logger

Kamstrup’s directly connected meters have an internal load profile logger that registers the energy with a

configurable interval, with the possibility of readouts, if required.

The meter enables the read-out of energy values in the load profile logger as both absolute and relative (delta)

values. Every data set includes log ID, RTC/Quality stamp and up to four energy registers.

The log ID is the meter’s identification of the data set and is only used in connection with readout. The RTC time

stamp indicates time of logging data in date and hour together with validation information. The number of register

values depends on the meter’s configuration of energy types.

The number of energy registers for which the meter is configured determines the number of registers for which the

load profile is logged.

The RTC/Quality stamp includes time, date and a data quality info, that validates each registration of eventually

time adjustments and/or voltage quality events, i.e. over and under voltages and voltage interrupts.

Readout can take place by means of the open standard DLMS or Kamstrup's own protocol KMP. The data format at

readout depends on whether absolute values or relative values are read out. The format of absolute values

follows the format in which data is registered (7.2), whereas the format of the relative values is [3.2] (XXX.XX)

kWh.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

20

The registration interval follows the integration period, and the integration period can be changed after the

commissioning.

IMPORTANT: If the integration period is changed, the load profile logger is deleted.

The logging depth of the load profile depends on the configuration of energy type and integration period for the

meter.

Integration period

Energy type

5 min.

Days

15 min.

Days

30 min.

Days

60 min.

Days

A+ 199

597

1194 2388

A+/A- 113

341

682 1364

A+/R+ 113

341

682 1364

A+/R1 113

341

682 1364

A+/A-/R+/R- 61

183

367 734

Table 5: Logging depth of load profile logger.

The logging depth of the load profile logger is pre-configured to 130 days when the integration period is 15, 30 or

60 min. The logging depth of 130 days is, however, a default setting which subsequently can be changed via

system upgrade. The remaining part of the memory is dedicated to an integrated analysis logger. Furthermore, the

load profile logger can be read out on the meter display as described in section 4.11.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

21

3.6.4 Analysis logger

The analysis logger allows the client to configure the registers to log and the log interval. Up to 16 simultaneous

registers can be chosen. The log interval can be configured to 5, 15, 30 or 60 min. or 1 day. The logging depth of

the analysis logger varies from 7 days to approx. 520 days, depending on the number of registers, which registers

to log and the chosen log interval. Table 6 shows the registers that can be chosen for the analysis logger.

Description

Active energy A+ Reactive energy R+ Tariff 7

RTC status

Active energy A- Reactive energy R+ Tariff 8

VCOPCO status

Active energy A1423

Reactive energy R- Tariff 1

Voltage L1

Reactive energy R+

Reactive energy R- Tariff 2

Voltage L2

Reactive energy R- Reactive energy R- Tariff 3

Voltage L3

Reactive energy R1

Reactive energy R- Tariff 4

Current L1

Reactive energy R4

Reactive energy R- Tariff 5

Current L2

Active energy A+ Tariff 1 Reactive energy R- Tariff 6

Current L3

Active energy A+ Tariff 2 Reactive energy R- Tariff 7

Actual power P+ L1

Active energy A+ Tariff 3 Reactive energy R- Tariff 8

Actual power P+ L2

Active energy A+ Tariff 4 Peak power P+

Actual power P+ L3

Active energy A+ Tariff 5 Peak power P-

Power extreme value

Active energy A+ Tariff 6 Peak power Q+

Power event

Active energy A+ Tariff 7 Peak power Q-

Logger status

Active energy A+ Tariff 8 Actual power P+

Cut-off state

Active energy A- Tariff 1 Actual power P-

P+ max

Active energy A- Tariff 2 Actual power Q+

P+

min.

Active energy A- Tariff 3 Actual power Q-

P+

max – Clock

Active energy A- Tariff 4 Acc. peak power P+

P+

max – Date

Active energy A- Tariff 5 Acc. peak power P-

P+

max – RTC

Active energy A- Tariff 6 Acc. peak power Q+

P-

min. – Clock

Active energy A- Tariff 7 Acc. peak power Q-

P-

min. – Date

Active energy A- Tariff 8 Pulse input

P-

min. – RTC

Reactive energy R+ Tariff 1 Hour counter

Average voltage L1

Reactive energy R+ Tariff 2 Active tariff

Average voltage L2

Reactive energy R+ Tariff 3 Peak power P+ Tariff 1

Average voltage L3

Reactive energy R+ Tariff 4 Peak power P+ Tariff 2

Average current L1

Reactive energy R+ Tariff 5 Power threshold value

Average current L2

Reactive energy R+ Tariff 6 Power threshold counter

Average current L3

Table 6: Registers available for analysis logger.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

22

The analysis logger can be configured and read out via METERTOOL. It is not possible to configure the analysis

logger from the factory. The meter is supplied with a default configuration as shown for each meter type in the

following table.

The log interval of the analysis logger is default set to 15 min. This can be changed via METERTOOL. The default

setup of the analysis logger can be seen in Table 7.

Meter Type Single-phase Poly-phase

Registers in the load

profile logger

Default

registers in the

analysis logger

1

register

2 registers

4 registers

1

register

2 registers 4 registers

A+ (A+, A-

)

(A+, R+) (A+, A-, R+, R-

)

A+

(A+, A-) (A+, R+) (A+, A-, R+, R-

)

Actual power P+

X X X X X X X X

Actual power P-

X X X X

Actual power Q+

X X X X

Actual powerQ-

X X

Average voltage L1

X X X X X X X X

Average voltage L2

X X X X

Average voltage L3

X X X X

Average current L1

X X X X X X X X

Average current L2

X X X X

Average current L3

X X X X

Logging depth of

analysis logger

1

*

[Days]

77 50 5o 17 41 29 29 11

Table 7: Default setup for analysis logger.

Average phase voltage and phase current are calculated as the mean value during the integration period

configured for the analysis logger.

Phase currents are show as abolute values, i.e. with no sign to indicate the direction of the current.

3.6.5 Event logger for status

The status logger registers internal errors and can thus be used as an analytical tool to show the meter’s

condition.

The RAM is tested during start-up writing and reading, and both EEPROM and ROM are tested by checksum

calculation. Internal errors are indicated by a warning triangle in the display and cannot be reset without the

meter being returned to Kamstrup A/S.

The status logger registers with time stamp whether the meter has been exposed to magnetic influence or the

meter over has been dismounted (access control).

The status logger has a depth of 200 loggings.

3.6.6 Event logger for RTC

A logger in the meter stores information about changes/adjustments of the clock in the form of date/time before

and date/time after adjustment. Only adjustments of a specific size will be registered in the lock. The minimum

time for an adjustment to be logged is configurable, and the default value is 7 seconds. The value range is

between 0 and 255 seconds.

The RTC logger has a depth of 200 loggings.

1

The logging depth of the analysis logger depends on the integration period of the load profile logger. The stated

logging depths are calculated on the basis of an integration period of 15 min.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

23

3.6.7 Event logger for voltage quality

Voltage failures are possible on one or two independent phases or on all three phases. The lmeter registers

voltage failures that last longer than minimum 1 second. No matter how many phases the voltage failure applies

to, the time of the voltage dropout will be registrered, and it will also be registered when the voltage returns, as

described in Figure 6. The logger stores the phases that the failure applies to and during which period.

Voltage failure is defined as voltage below 160 VAC 5 %. The voltage failure logger has a depth of 200 loggings.

3.6.8 Event logger for the load profile logger

The logger registers all changes in the legal logger. A change in the configuration of the legal logger will, as

mentioned in a previous section, mean that all data in this legal logger are deleted. Therefore, every change in the

legal logger is registered with a timestamp. The event logger has a logging depth of 10 loggings.

3.6.9 Event logger for Cut off

A meter with breaker includes a logger that registers all events related to the disconnect functionality. For each

event, that be a disconnection, a release or a reconnection, the meter logs an ID, a timestamp, the disconnect

state (according to Figure 18) and the connection feedback.

3.6.10 Event logger for neutral fault

The logger registers errors in the supply network. The purpose with this logger is to register if the attached

electronic equipment is exposed to overvoltage, which can damage the equipment and/or cause injury to person

due to fire.

In meters with build in breakers, there is furthermore a possibility to switch off the supply out of the meter in case

of neutral fault detection.

Neutral fault detection only applies to the three-phase, 4-wire metertype.

Figure 8 illustrates when a missing or faulty neutral is detected.

Figure 8: Neutral fault detection.

This means it is only possible to detect missing or faulty neutral before the meter(marked green), not after the

meter(marked red).

The neutral fault detection is based on voltage measurements and voltage thresholds.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

24

Figure 9: Neutral fault measurement principle.

Figure 9 shows a situation without neutral fault and one with neutral fault. When the netraul fault is present the

load is asymmetric and the neutral fault voltage VN occurs.

The green vectors indicate the phase voltages on the grid. The yellow vectors indicate the phase voltages

measured by the meter.

The neutral fault is detected, when the following conditions are present:

Two of the phase voltages VL1, VL2 and VL3 must be above the threshold voltage VLHiTh.

One of the phase voltages VL1, VL2 and VL3 must be below the threshold voltage VLLoTh.

Condition 1 and 2 must be present in a time period longer than the period Time.

VLLoTh = 230V - VNTh

Figure 10: Neutral fault detection range.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

25

In Figure 10 to the left, the yellow areas indicate when the neutral fault will detected.

Figure 10 to the right shows a situation where the neutral fault is detected, where the conditions are:

VL1 < VLLoTh

VL2 > VLHiTh

VL3 > VLHiTh

The parameters VNTh, VLHiTh and Time can be configured with the registers: (shown with default values)

NeutralFaultVNTh = 40 VAC

NeutralFaultVLHiTh = 253 VAC

NeutralFaultTime = 60 s

Under some conditions a neutral fault is not detected. In Figure 10, fault is not detected in the white areas.

In conditions with symmetric load the neutral fault voltage VN will theoretically be zero volts and neutral fault will

not be detected, even if the neutral is missing. Table 8 lists the parameters that are logged in the neutral fault

logger.

Various Event registers

Date and time

Neutral Fault

Hour counter

Table 8: Neutral fault detection parameters.

The Neutral Fault Logger has a depth of 45 loggings.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

26

3.7 Pulse inputs/outputs

As default the meter has an S0 pulse output (described in section 3.7.5) and two available I/O (input/output)

ports in the module interface. The use of one or both I/O ports in the module area requires that the meter is

equiped with a primary module that supports the wanted functionality.

The S0 output provides 1000 pulses/kWh permanently, whereas the I/O module is configurable as to length and

number of pulses. The S0 output always follows the blinks from the LED light-emitting diode.

3.7.1 Pulse inputs in the module area

The pulse inputs in the module area (module I/O) can be configured for the following functions depending on the

meter’s configuration:

- Tariff control, see also Table 2.

- Pulse input from other units.

- Alarm input for the registration of an external alarm.

The pulse input accumulates pulses in the pulse input register. If this reigister is shown in the display, it is

updated every 10 seconds. It is possible to scale the reading of the pulse input by a ”pulse division factor” in the

range from 0.100 to 1000.000 units per pulse. The maximum permissible frequency for input pulses is 25 Hz.

In connection with the pulse input register, the following units can be selected: kWh, m

3

, l,”none”.

3.7.2 Water meters

A water meter emits 1 imp/25 l. The required reading in the electricity meter’s display is m

3

without decimals.

1000 l = 1 m

3

, 1000 / 25 = 40 Pulse division factor to be set to 40.

The electricity meter count will be incremented by one every 40 pulses, i.e. indication in m3 without decimals.

The most frequently used pulse values appear from Table 9.

Pulse value

l/Imp

Pulse value

Imp/m3

Pulse division factor

Display indication in ”m3 ”

Pulse division factor

Display indication in ”l”

100 10 10

-

50 20 20

-

25 40 40

-

10 100 100

0.1

5.0 200 200

5

2.5 400 400

2.5

1.0 1000 1000

1

1000 1 1

1000

Table 9: Pulse values for water meters.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

27

3.7.3 Electricity meters

Table 10 shows a similar list of pulse values for electricity meters.

Pulse value

Wh/imp

Pulse value

Imp/kWh

Pulse division factor

Display indication in ”

kWh ”

100000 0,01

-

10000 0,1

0.1

1000 1

1

16.67 60

60

13.33 75

75

8.333 120

120

4.167 240

240

2.941 340

340

2.083 480

480

1.667 600

600

1.000 1000

1000

0.100 10000

-

Table 10: Pulse values for electricity meters.

3.7.4 Pulse outputs in module area

The pulse outputs in the module area can be configured for pulse outputs for both active and reactive energy.

As standard, the pulse outputs send 1000 pulses/kWh, but can be configured for a pulse division factor between

1 – 1000. In addition, the pulse width can be configured for 30 or 80 msecs.

When selecting pulse division factor and pulse width, please be aware that the number of pulses at max load is

not exceeding the number which the meter is able to send via the pulse output.

Pulse value

Imp/kWh, Imp/kvar

Pulse duration /

pulse pause

30 msecs. 80 msecs.

1 100A

100A

10

100A

100A

100

100A

100A

1000

86A

32A

10000

8.6A

3.2A

Table 11: Maximum load current at different pulse values.

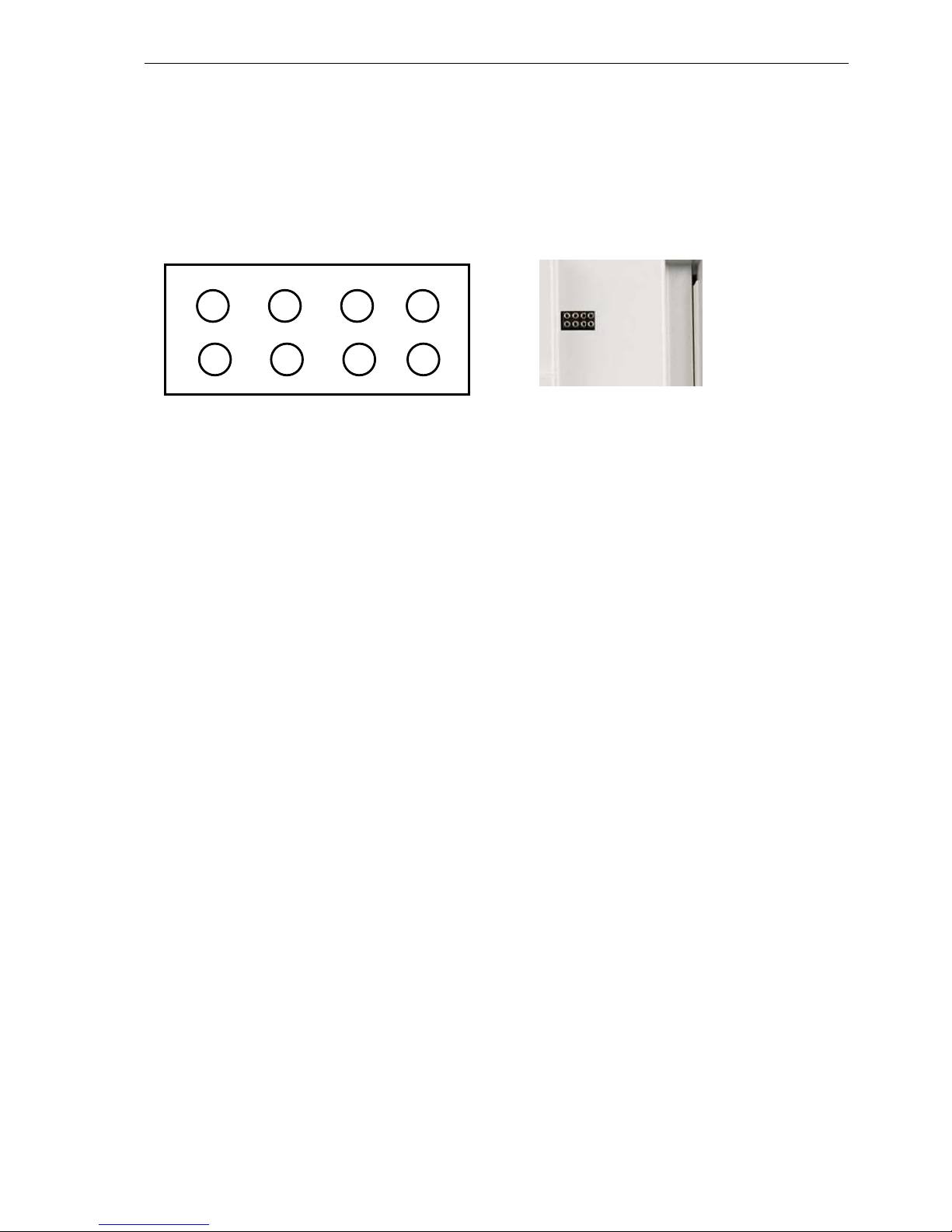

3.7.5 S0 output

The S0 output provides 1000 pulses/kWh permanently and the pulses are synchronized with the S0-LED.

The SO output is specified according to the standard DIN 43864 and Figure 11 shows the placement of the S0

ouput connector.

The maximum voltage that can be connected to the SO output is 27 V DC (at 1 k), and the maximum current

which can be drawn through the output is 27 mA.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

28

S0

S0-LED

Figure 11: The S0 output on a three-phase meter.

Table 12 lists the technical specification for the S0 output.

The status of

the pulse sensor

Test conditions Test data

Supply voltage

UB

Internal resistance

RV

Current through the

SO output

On (active) 18 V DC

1 k

i

> 10 mA

Off (inactive) 27 V DC

1 k

i

< 2 mA

Table 12: S0 technical specification.

On the three-phase meter with APS (Auxillary Power Supply) the S0-output is not available. S0 output can then

only be achieved as a module interface.

3.8 Auxillary Power Supply

The meter can optional be configured with an Auxillary Power Supply (APS) functionality. The function allows to

supply the meter with 230VAC on a separate input as shown in Figure 12. The functionality is usefull when a

external breaker is installed before the meter in an installation.

L1

L3

L2

N

APS

Figure 12: APS functionality.

When the meter is configured for APS functionality it doesn’t have a S0 output, as the connector is used for the

230 V APS input.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

29

3.9 Alarm handling/Push alarms

The meter can be configured to give alarms when specific events are registered by the meter. Events that can be

configured to generate push alarms are:

- Magnetic detection

- Tamper detection

- Internal meter error

- Under and over voltage detection

- Missing phase voltage detection

The alarms will be transmitted via Kamstrup radio communication (if the meter is with Radio) for use in Kamstrup

AMR systems, or on the module port. For further details about alarms and configuration, please contact Kamstrup.

3.10 Load control

As an option it is possible to mount a two relay load control module in the meter. The relays can be used to

control (On/Off) external installations. The control of the relays can be done by:

- Predefined (configurable) Load control tables - managed by the meter.

- By remote command – managed by system.

See more about configuration of the load control in section 10.4.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

30

4 Display

The display makes it possible to read out the meter’s registers. Which registers depends on the current

configuration. It is possible for customers to select individual display configurations.

The display is composed by segments as shown in Figure 13 and includes the following readings:

Value field

Unit field

Mains voltage readings of phases L1, L2 and L3

Phase current direction

Phase sequence (For future use)

Module indication (For future use)

Radio-symbol (For future use)

Readings of tariffs T1-T8

Quadrant reading, which states current quadrant(s) and thereby the actual power type P+, P-, Q+, Q-

Status reading

Breaker status

Tamper indication (For future use)

Prepayment indication (For future use)

7-digit identification field

4-digit text-field

The display function depends on the current configuration. The required configuration can be preprogrammed

from the factory or configured by means of the configuration tool METERTOOL for kWh meter. Display

configuration is described in section 4.10.

Quadrant

reading

7-digit identification field

OBIS-field

Value field

Unit

field

Text field

RF-

symbol

Breakersymbols

Tamper

symbol

Error-

symbol

prepayment-

symbol

Tariff

reading

Phase

sequence

symbol

Mains voltage

reading

Phase current

indication

Module

indication

Figure 13: Display layout.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

31

4.1 Value field

This field is used for displaying register values. The number of register values depends on the meter's

configuration. The value field reading depends on the value stated as well as the meter’s set-up. Meter numbers,

special data etc. are indicated by 8 digits, energy is stated in [6.1], or [7.0] format kWh/kvar, and power in [2.3]

format (00.000) kW/kvar. Date/time is stated according to the format YY:MM:DD and HH:MM:SS.

The value field can be configured to display leading zeroes of energy readings.

4.2 Unit field

The unit field is used for displaying the units of registers in the value field.

4.3 Text field

The text field can be used either for additional information to the unit field regarding values in the value field or

for text information. In the latter case, text messages are shown as sliding letters in the field.

4.4 Mains voltage reading

The mains voltage readings per phase L1, L2 and L3 indicates whether voltage is applied to the individually

phase input terminal or not.

Indications L1, L2, L3 Indicate

On The voltage is above minimum limit (160V).

Off The voltage is below minimum limit (160V).

Table 13: Main voltage indication.

The minimum voltage limit is 160 VAC 5 %. If the voltage remains below minimum limit for more than 1 second

in all phases, the meter is reset and the processor shuts down. Subsequently, the meter carries out a normal

start.

4.5 Phase current indication

The direction of the current for each phase is shown with these indicators. It can be useful when checking of

correct input/output installation.

Indications - + Indicate

On The load is above minimum limit (2.3W).

Off The load is below minimum limit (2.3W).

Table 14: Phase current indication.

The minimum load limit is approx. 10 mA. If the phase current is lower than this value, energy registration stops

and the phase current indication turn off in the display.

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

32

4.6 Tariff indication

The tariff indicator can show T1, T2, T3, T4, T5, T6, T7 and T8 to indicate the currently active tariff. The tariff

reading is updated every 10 sec., i.e. it may take up to 10 seconds from a tariff shift until the current reading is

displayed.

The tariff indication are switched off if a display configuration without tariff reading has been selected.

4.7 Current quadrant reading

The total load is indicated by the arrows for imported active power, exported active power, inductive reactive

power and capacitive reactive power, respectively.

The current quadrant reading is an instantaneous total value for all three phases. The reading is not active when

the load is below the minimum limit of 10 mA RMS.

This reading is On/Off-configurable.

4.8 Breaker status

If the meter is configured with an internal breaker, the position of the breaker is indicated as either connected or

disconnected.

4.9 Object identification field

Field for identification of the value in the value field. Uses OBIS codes in connection with identification.

This reading can be opted out.

The identification field is constructed as CC.DD.E.FF.

CC represents the quadrant in which the registration is made.

DD The physical size.

E Tariffings.

FF Debiting data (historical data).

The most frequently used values are stated in the table below.

CC (energy types) DD (physical sizes) E (tariffings) FF (debiting data)

1 – active + quadrants 1+4 _2 – accumulated peak

power

0 – No tariff

99 – latest

historical value

2 – active – quadrants 2+3 _6 – peak power

1 – Tariff 1

98 – latest

historical value + 1

3 – reactive + quadrants

1+2

_8 – Energy

2 – Tariff 2

4 – reactive – quadrants

3+4

3 – Tariff 3

4 – Tariff 4

Table 15: OBIS table.

Apart from these values, there are several others. For a complete list, see Error! Reference source not found. Error!

Reference source not found..

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

33

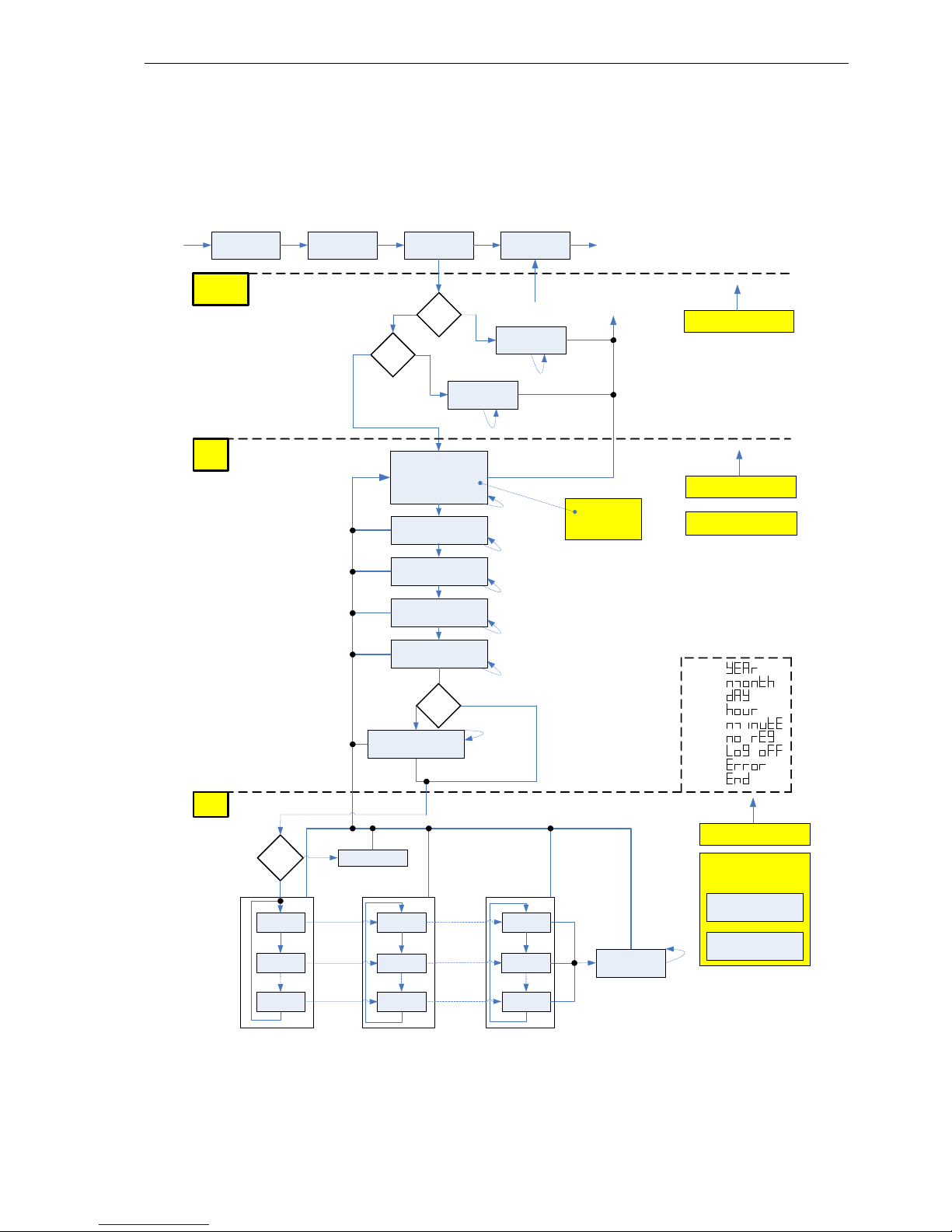

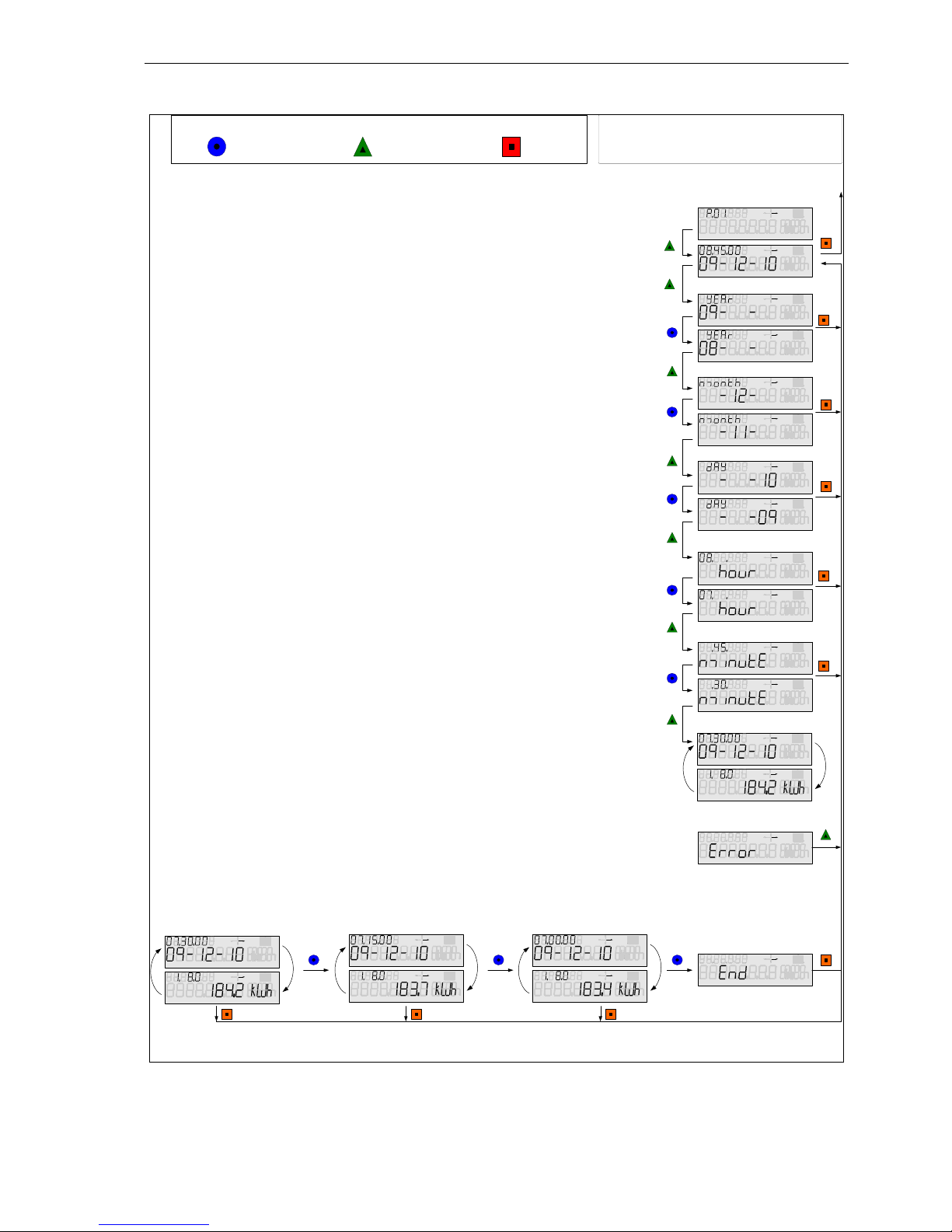

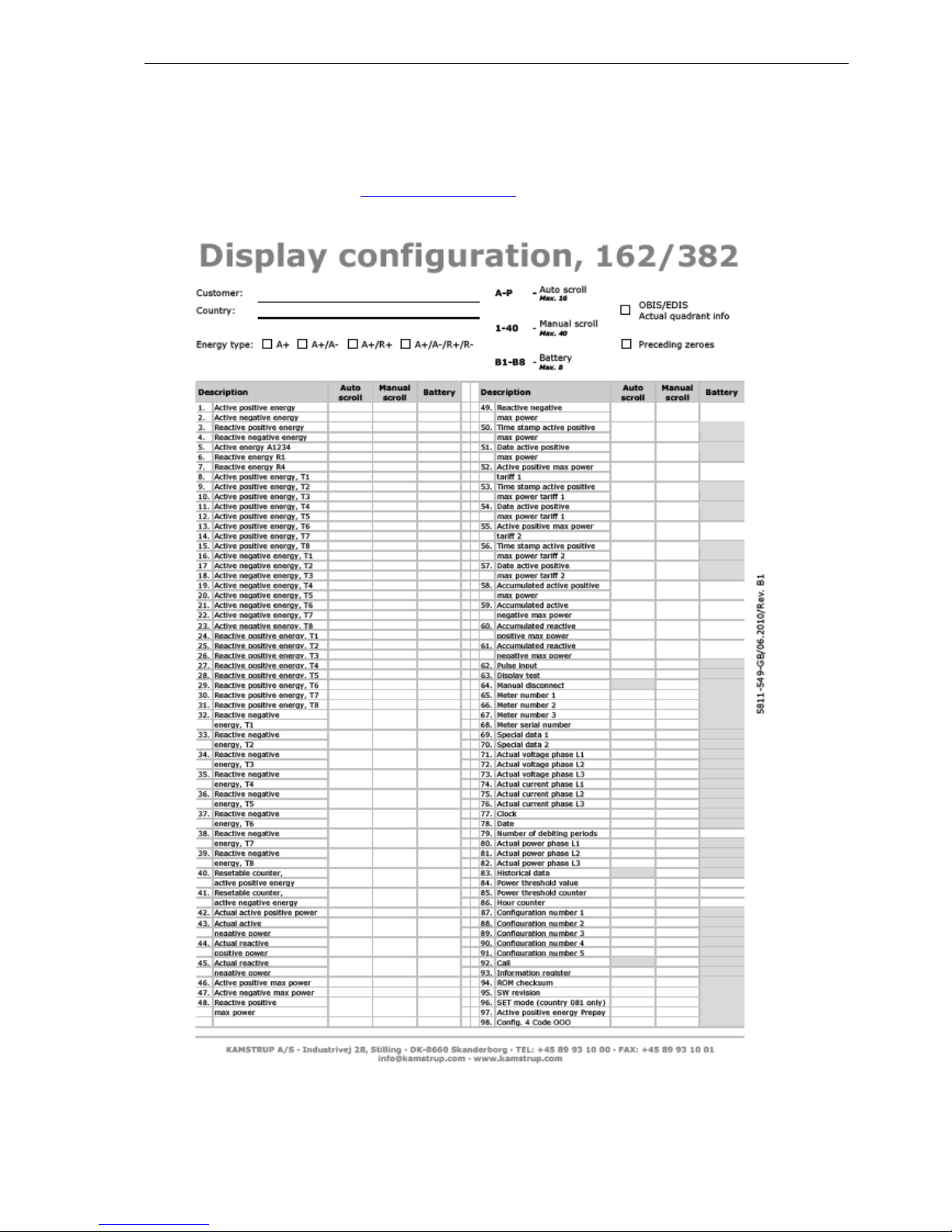

4.10 Display configuration

The display configuration is composed by three reading lists which can be configured as required. However, legal

readings are mandatory and cannot be deselected of the lists.

The automatic shift function (scroll) changes every 10 seconds between the selected readings in the required

order. Up to 16 readings can be selected.

At the manual shift function, the shift is effected when activating the push button. The shift is effected when you

release the push button. Again, the order is configurable and up to 30 readings can be selected.

If the meter is configured with battery backup unit, it is possible to select a battery-operated shift function, which

makes it possible to read the display without the meter being mains supplied. The shift is effected by activating

the push button. Up to 8 readings can be selected.

The meter automatically returns from manual shift function to automatic scroll function two minutes after the last

activation of the push button.

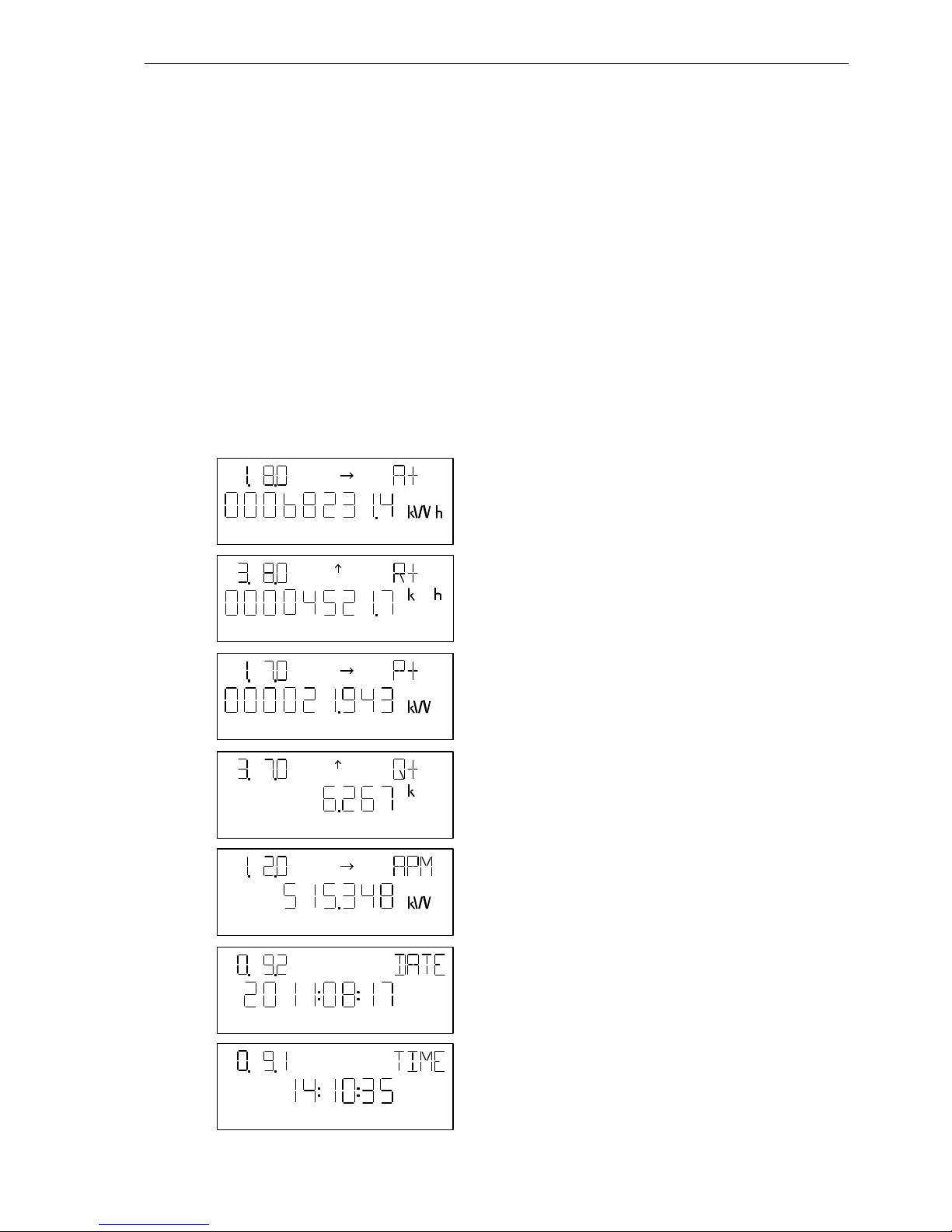

The display reading can be composed e.g. as shown in the example below. To view a complete list of possible

display readings, see 10.3 Display readings.

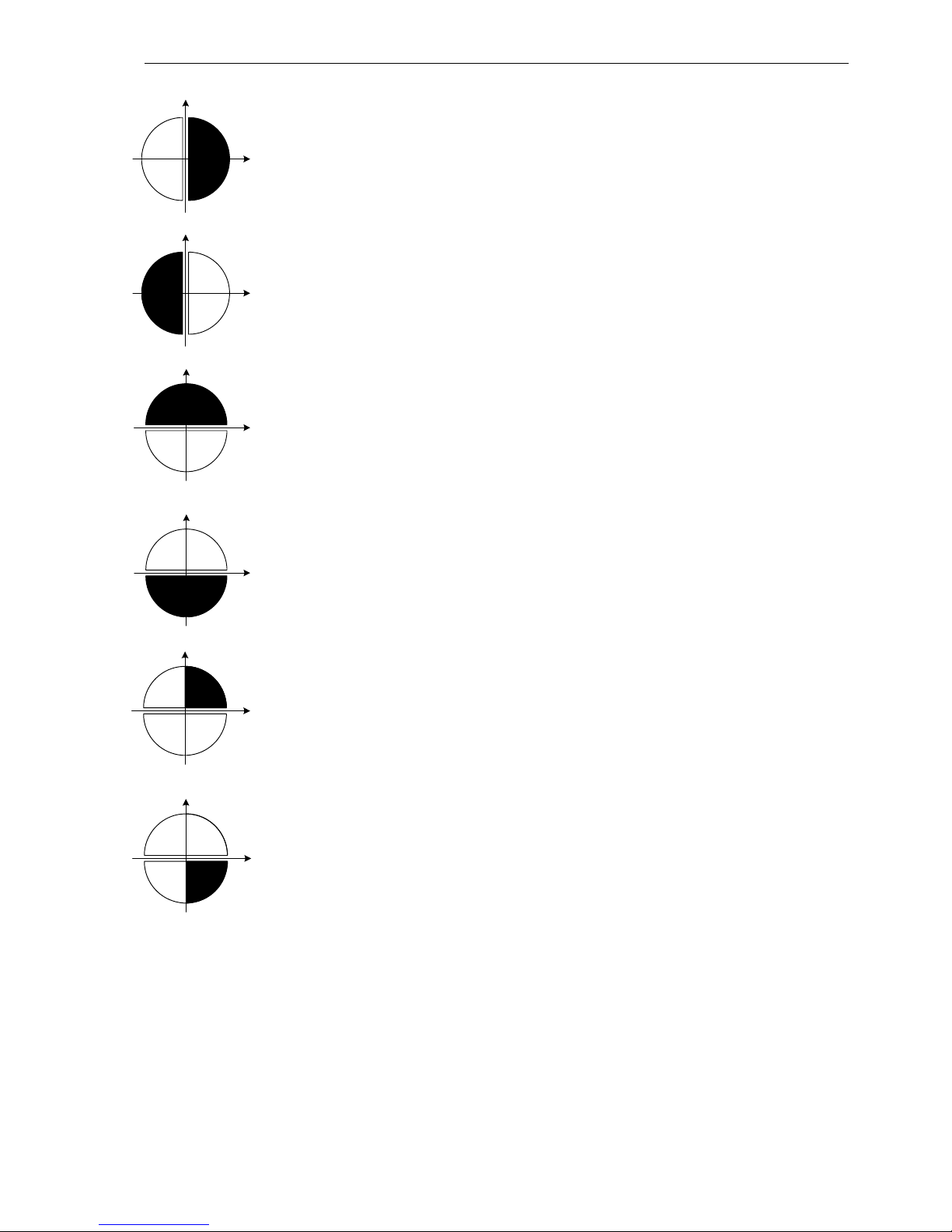

Automatic scroll

Active energy A+ in 6.1 format,

OBIS code/power arrow, leading zeros.

Reactive energy R+ in 6.1 format,

OBIS code/power arrow, leading zeros.

Active instantaneous power P+ , in 4.3 format,

OBIS code/power arrow, leading zeros.

Reactive instantaneous power Q+, in 4.3

format, OBIS code/power arrow.

Accumulated peak power P+ in 4.3 format,

OBIS code/power arrow.

Date, OBIS code.

Time, OBIS code.

+P

L1

L2 L3

+Q

var

+P

+Q

var

+P

L1

L2 L3

L1

L2

L3

L1

L2 L3

L1

L2 L3

L1

L2 L3

L1

L2 L3

TECHNICAL DESCRIPTION Kamstrup 162M/382M

5512-1040 GB/05.2012/Rev. C1

34

Manual scroll