Page 1

Home

Noncontact Displacement Measuring

System User’s Manual

This apparatus, when installed and operated per the manufacturer’s recommendations, conforms

with the protection requirements of EC Council Directive 89/336/EEC on the approximation of the

laws of the member states relating to Electromagnetic Compatibility. Please refer to the KD-2440

Declaration of Conformity or contact Kaman Precision Products for details.

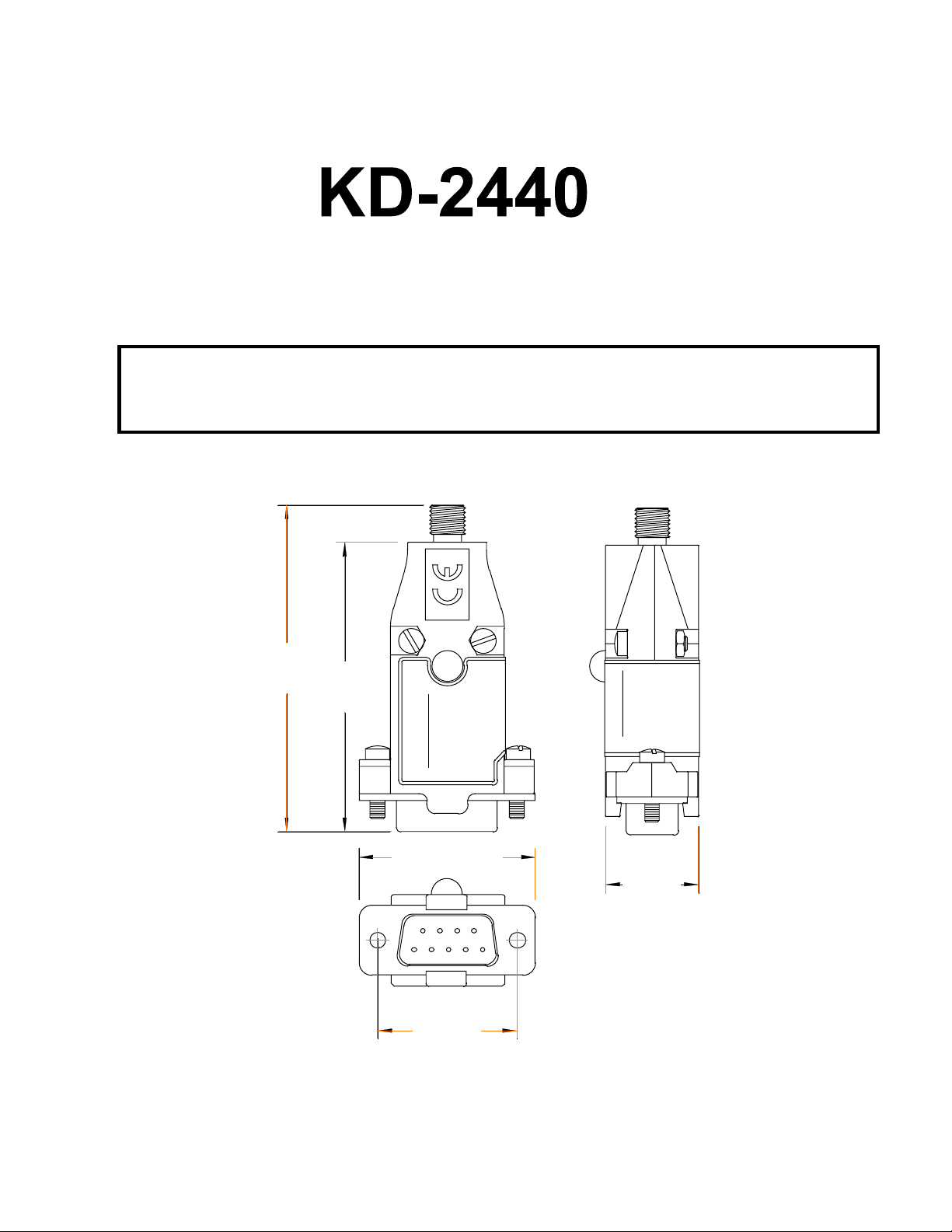

2.357

(59.9)

1.902

(48.3)

KD 2440

KAMAN

Instrumentation

1.23 (31.24)

.984

(24.99)

PIN SIGNAL

2 SWITCH

3 SWITCH

.610

(15.5)

4,7 V IN

5 COMM

9 V OUT

Page 2

Home

KD-2440

Kaman Precision Products’ Displacement Measuring

System Model KD-2440 is a noncontact linear proximity

measuring system. This low-cost, easy-to-use system

makes precision static and dynamic measurements of

metal targets, and thickness measurements of nonconductive material backed by metal. The system

includes a switching output that will track RPM

measurement to 10Khz.

Features Summary / Advantages

•••• Outstanding Precision: Static Resolution to 12

Microinches

•••• Easy to Adjust

•••• Excellent Performance with Ferrous Targets

•••• Variable Voltage Input from 12 to 24 Volts DC

•••• Adjustable Gain for up to 22 Volts Output with 24

Volts Input

•••• Compact Rugged Electronics and Sensors

•••• Temperature Tolerant Sensors (to 400°F)

•••• Level Adjustable Switched Output to 10Khz for

Process Control

•••• Drop in Replacement to Kaman’s KD-2400 with

Accessories Kit

KD-2440 Unit

The KD-2440 system consists of three subassemblies:

the sensor with integrated cable, the signal conditioning

electronics module, and the power and output cable.

The KD-2440 electronics uses a standard DB-9

connector to bring +12 Vdc to +24 Vdc into the

electronics and provide outputs for the analog voltage

and switch functions.

12345

6789

Electronics DB-9

Connector Face

54321

9876

I/O Cable DB-9

Connector Face

DB-9 Connections and Power I/O Cable

Color Chart:

Wire Color Pin Signal

1 N/C

BLU 2 SWITCH RX

WHT 3 SWITCH TX

GRN 4 VIN (ALTERNATE)

BLK 5 COMM

6 N/C

RED 7 VIN

8 N/C

ORN 9 VOUT

CLR - CABLE SHIELD

Electronics

The KD-2440 electronics has two potentiometers

accessible through openings in the enclosure for

adjusting the GAIN and SWITCH SET POINT level.

An LED indicates when the optically-isolated switch is in

the closed position. The KD-2440

electronics and sensors utilize SMA type coaxial

connectors: female on the electronics, and male on the

sensor cable. Two production-sensor configurations

are available, the 9C and the 5CM. Data for these two

sensors is shown on the following pages. The sensor

must be attached snugly (finger tight) to the electronics

assembly for the unit to function properly.

Mounting Instructions

Mounting the KD-2440 electronics module can be done

using either of the two holes in the enclosure, and an M3 or 4 screw. It is preferable not to remove both screws

from the case for mounting purposes. An easier

mounting method may be to use a cable tie wrap or zip

tie.

Positioning the electronics module so that it is not the

low point in the cable will keep liquids from running

down the cable and into the electronics. Take care to

route the sensor cable to avoid crushing or crimping it

during use. Damage to the sensor cable may affect the

desired set points and overall operation of the

electronics.

Theory of Operation

The KD-2440 system operates on a traditional Colpitts

oscillator circuit where the sensor acts as the resonating

coil for the oscillator. The proximity of the target to the

sensor face pulls

and amplitude of modulation, controlling a variable gain

oscillator section within the electronic circuit.

the oscillator, changing its frequency

5CM Sensor Response Data:

5CM Sensor Response Data:

2 7

Page 3

The signal is half-wave rectified and filtered to

Home

obtain an analog voltage proportional to the target

position or displacement. The analog voltage

output can be varied by adjustment of the gain. The

input power is diode protected and regulated to

provide a clean low-noise signal. The output is

short-circuit current protected.

Adjustment and Calibration

The KD-2440 is instrumented with a ten volt

regulator to provide a clean repeatable output

signal. The input voltage must be maintained at a

minimum of twelve volts for the regulator to

function.

The gain (ratio of output voltage to target

displacement) is used to adjust the output slope

(output per displacement). W hen changing types of

target materials or power supply voltages, it will be

necessary to readjust the gain for the desired

output voltage.

The KD-2440 can easily be adjusted or “calibrated”

to obtain maximum output per displacement,

maximum range, or any variation in between. Note

that when the KD-2440 is adjusted for maximum

output per displacement, it is at a minimum usable

range, whereas a minimum gain gives a voltage

change throughout the largest displacement for the

same sensor, target, and range as depicted in the

following graph:

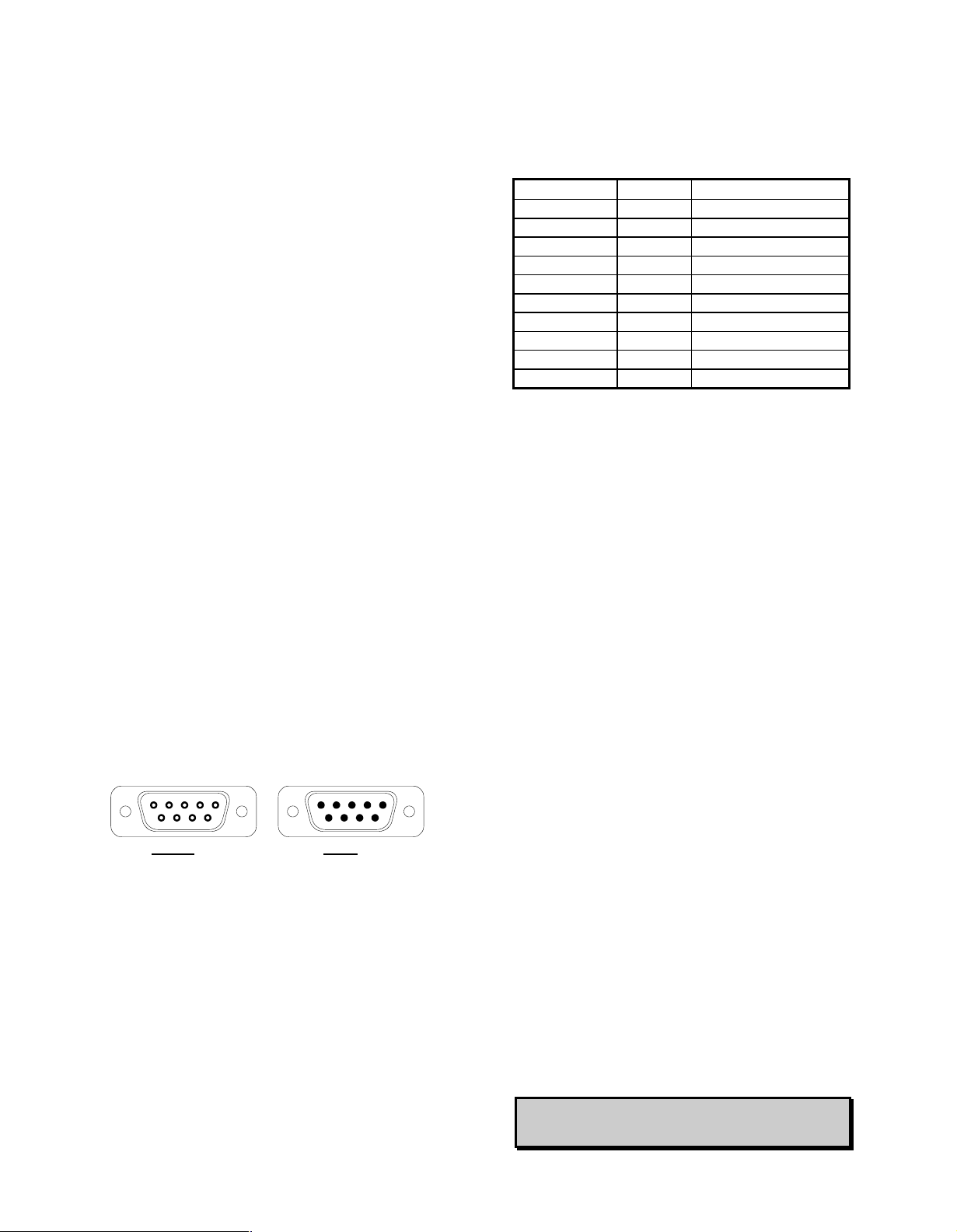

4130 Steel Output for 12 & 24 Volt Inputs

18

16

14

12

10

DC Output Voltage

The minimum gain is defined as being the lowest

gain obtainable without pulling the circuit into

saturation. Minimum gain can be obtained by

setting the sensor displacement to a point within

the usable

slowly decreasing the gain potentiometer

(clockwise) until the output saturates. At this point,

increase the gain slightly to a point just above

24 volt input w ith high gain

12 volt input w ith

high gain

8

6

4

2

0

0 50 100 150

Displacem ent, Mils

12 or 24 volt input

with low gain

range (preferably mid range), then

saturation (the output begins to change with a gain

increase).

Example Calibration

To maximize the output slope for an application using a

5CM sensor with a .010” offset and a range of .040”,

follow these steps:

1. Adjust the sensor / target to its maximum

displacement, plus the offset, plus approximately

20% of the range (.058”).

2. Adjust the gain potentiometer to its minimum point

(adjust clockwise until the analog output saturates)

3. Slowly increase the gain potentiometer (counter

clockwise) until it saturates at its maximum point.

this will be approximately two volts below the input

voltage.

4. At this point, the module is calibrated to a

maximum output per displacement condition. As

the sensor is moved toward the target from

approximately .058”, the output will decrease. If the

sensor / target displacement is increased beyond

.058”, the output will saturate at approximately two

volts below the input.

Switched Output Operation

The KD-2440’s switched output is a simple on / off

switch with a corresponding LED indicator lamp. The

switch is in a closed condition when the LED is

illuminated. The switch can be adjusted to trip

anywhere along the sensor range using the “Switch

Setpoint” potentiometer.

CLEANING

The KD-2440 is not designed to be immersed or

operated while immersed in liquids. Solvents may

damage electronics module, sensor, or power I/O

cable. Clean the unit with a damp cloth.

EMI PERFORMANCE

The KD-2440 conforms with the applicable standards

of Council Directive for Generic for Light Industrial and

Commercial Use. Under some EMI environments, at

specific frequencies, the KD-2440 unit may experience

a change in output voltage. In general, when exposed

to those environments covered by the EMC directive,

the user can expect less than 5% deviation of output.

Contact Kaman Instrumentation for

recommended solutions if you experience problems

with the KD-2440.

specific data or for

Page 4

Home

KD-2440

Specifications

ELECTRICAL

INPUT

Voltage: Regulated 12 VDC to 24 VDC

Current: Fuse limit input current from power source to 11 mA, .28W maximum at full load

ANALOG OUTPUT

Current (Full load): 4.2 mA maximum

Impedance: 50 ohms

Voltage: 0-22 VDC minimum with 24 VDC input

0-10 VDC minimum with 12 VDC input

SWITCHED OUTPUT

Opto-Isolated

Load Current: 100 mA maximum AC or DC

Load Voltage: 30V rms, 42.4V peak, or 60Vdc

On Resistance: 30 ohms minimum / 50 ohms maximum

Switch Point Hysterisis: 0.56% of full scale for 9C sensor, and 0.97% of full scale for 5CM sensor, using

24Vdc input on 4130 steel.

FREQUENCY RESPONSE

0-10 KHz (± 3db)

RESOLUTION

Better than 0.008% of measuring range using a 5CM sensor on a 4130 steel target at mid scale, and

12Vdc input

ENVIRONMENTAL

ENCLOSURE RATINGS

Sensor: IP 67

Electronics: IP 61

OPERATING TEMPERATURE RANGE

Sensor and cable: 0°F to 400°F (-18°C to 205°C)

Electronics: 32°F to 150°F (0°C to 66°C)

STORAGE TEMPERATURE RANGE

Sensor and cable: -60°F to 400°F (-52°C to 205°C)

Electronics: -58°F to 212°F (-50°C to 100°C)

THERMAL DRIFT

Less than 0.22% per °C of full scale for sensor, electronics or system.

4 5

Page 5

9C Sensor Specifications:

Home

RG179 coax cable

.320 Dia

3/8-24 THD

(8.13)

SMA Male Connector

96 (2438)

1.030 (26.16)

1.250 (31.75)

Target Material 9C Sensor Measuring Range

Non-Ferrous (Aluminum) 0 - 0.175 in. (0 - 4.45 mm)

Non-Magnetic Steels (304

0.025 - 0.200 in. (0.64 - 5.08 mm)

Stainless)

Magnetic Steels (4130) 0.040 - 0.275 in. (1.02 - 6.99 mm)

5CM Sensor Specifications:

RG179 coax cable

M5 x 0.8 THD

.160 Dia.

(4.1)

SMA Male Connector

120 (3048)

1.60 (40.6)

1.85 (47.0)

Target Material 5CM Sensor Measuring Range

Non-Ferrous (Aluminum) 0 - 0.100 in. (0 - 2.54 mm)

Non-Magnetic Steels (304

0.010 - 0.125 in. (0.254 - 3.18 mm)

Stainless)

Magnetic Steels (4130) 0.015 - 0.150 in. (0.38 - 3.8 mm)

Dimensions are in inches (millimeters)

Page 6

Home

9C Sensor Response Data:

Aluminum Output for 12 & 24 Volt Input

14

12

10

8

6

4

2

DC Output Voltage

0

0 50 100 150 200 250

Displacement, Mils

24 Vdc High Gain

12 Vdc High Gain

24 Vdc Low Gain

12 Vdc Low Gain

Outputs at Medium Gain & 12 Volt Input

12

10

8

6

4

2

DC Output Voltage

0

0 50 100 150 200 250

Displacement, Mils

12V in Aluminum

12V in 303 Stainless

12V in 4130 Steel

303 SS Output for 12 & 24 Volt Input

14

12

24 Vdc High Gain

10

12 Vdc High Gain

8

24 Vdc Low Gain

6

4

2

DC Output Voltage

12 Vdc Low Gain

0

0 50 100 150 200 250

Displacement, Mils

4130 Steel Output for 12 & 24 Volt Inputs

14

24 Vdc High Gain

12

10

12 Vdc High Gain

8

6

4

DC Output Voltage

2

24 Vdc Low Gain

12 Vdc Low Gain

0

0 50 100 150 200 250

Displacement, Mils

Outputs at Medium Gain & 24 Volt Input

12

10

8

6

4

2

DC Output Voltage

0

24V in Aluminum

24V in 303 Stainless

24V in 4130 Steel

0 50 100 150 200 250

Displacement, Mils

Example Output Noise @ 12Vdc Input, Mid

Gain, Medium Displacement

4.00

3.50

3.00

2.50

4130 Steel

304 Stainless

Aluminum

2.00

1.50

1.00

0.50

0.00

Differential Noise, mV p-p

100 1000 10000

Bandwidth, Hz

6 3

Page 7

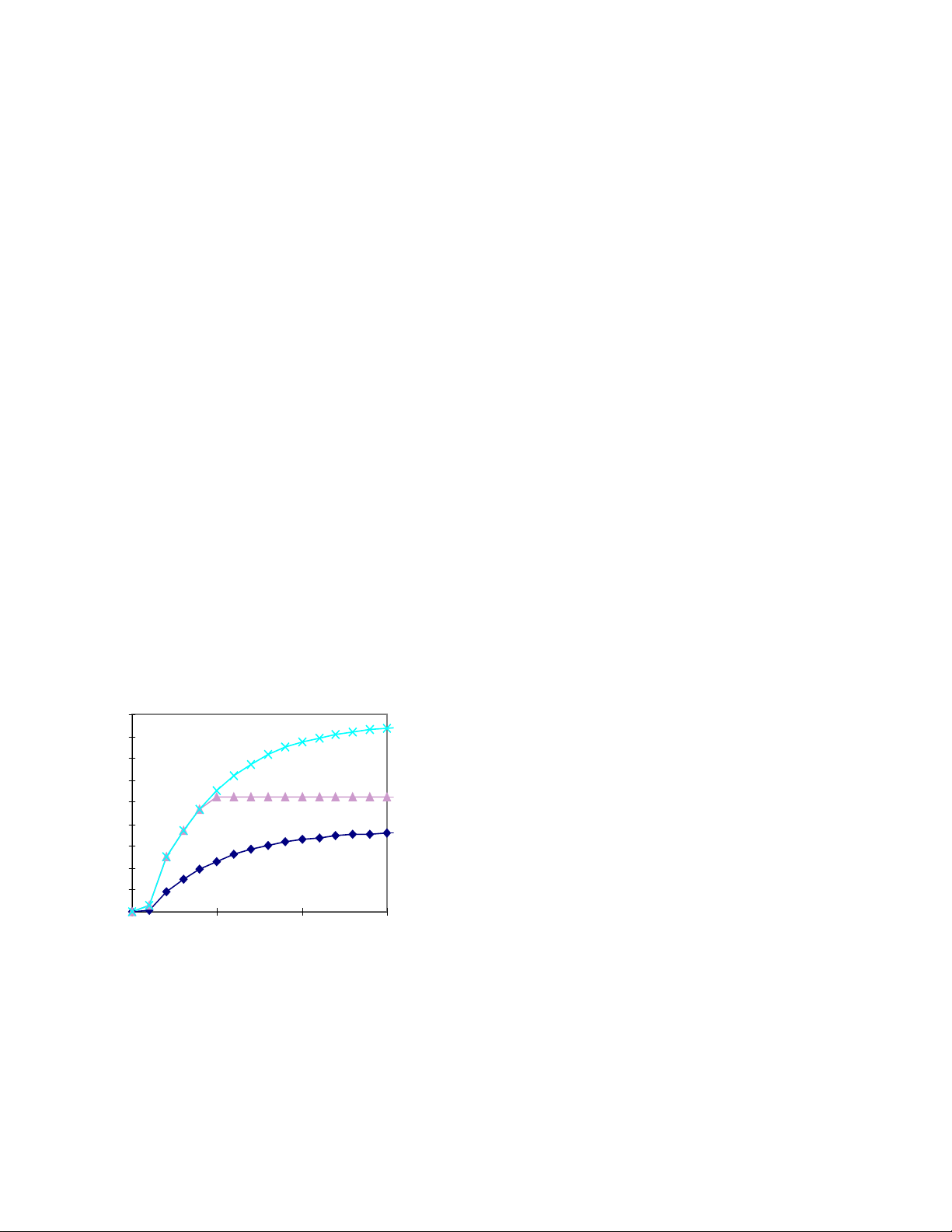

Aluminum Output for 12 & 24 Volt Inputs

Home

13

11

24Vdc High Gain

9

12Vdc High Gain

12Vdc Low Gain

7

24Vdc Low Gain

5

3

DC Output Voltage

1

0 50 100 150

Displacement, Mils

Outputs at Medium Gain & 12 Volt Input

12

10

8

6

4

2

DC Output Voltage

0

0 50 100 150

Displacement, Mils

Aluminum

303 Stainless

4130 Steel

303 SS Output for 12 & 24V Inputs

14

24 Vdc High Gain

12

10

8

12 Vdc High Gain

6

4

2

DC Output Voltage

24 Vdc Low Gain

12 Vdc Low Gain

0

0 50 100 150

Displacement, Mils

4130 Steel Output for 12 & 24 Volt Inputs

18

24 Vdc High Gain

16

14

12

12 Vdc High Gain

10

8

6

24 Vdc Low Gain

4

DC Output Voltage

2

12 Vdc Low Gain

0

0 50 100 150

Displacement, Mils

Outputs at Medium Gain & 24 Volt Input

14

12

10

8

6

4

2

DC Output Voltage

Aluminum

303 Stainles s

4130 Steel

0

0 50 100 150

Displacement, Mils

Example Output Noise @ 12Vdc Input, Mid

Gain, Medium Displacement

0.80

0.70

0.60

4130 Steel

Aluminum

304 Stainless

0.50

0.40

0.30

0.20

0.10

0.00

Differential Noise, mV p-p

100 1000 10000

Bandwidth, Hz

Loading...

Loading...