Page 1

_

DIT-5200L

Non-Contact Displacement

Differential Measuring System

User’s Manual

This apparatus, when installed and operated per the manufacturer’s recommendations,

.

conforms with the protection requirements of EC Council Directive 89/336/EEC on the

approximation of the laws of the member states relating to Electromagnetic Compatibility.

Refer to the DIT-5200L Declaration of Conformity or contact Kaman Measuring Systems for

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 1 -

Last Revised 11/16/2012

Page 2

_

Table of Contents

PART 1 - INTRODUCTION..........................................................................................................3

PART 2 – CONNECTING THE DIT-5200L...................................................................................4

2.1 What’s Included ................................................................................................................. 4

2.2 Cautions and Safeguards................................................................................................. 4

2.3 Pin out and Connector Assignments.............................................................................. 4

PART 3 – APPLICATION INFORMATION ...................................................................................6

3.1 Fixturing............................................................................................................................... 6

3.2 Sensor Mounting and Installation.................................................................................... 7

3.3 Electrical Nulling Procedure............................................................................................. 7

3.4 Optimizing Performance................................................................................................... 8

3.5 Factors That May Degrade Performance...................................................................... 8

3.6 Target Characteristics....................................................................................................... 9

PART 4 – CALIBRATION ...........................................................................................................11

PART 5 – GENERAL SPECIFICATIONS & TYPICAL PERFORMANCE...................................13

PART 6 - TROUBLESHOOTING................................................................................................15

APPENDIX A DIT-5200L SENSOR DIMENSIONS ..................................................................16

APPENDIX B DIT-5200L ENCLOSURE DIMENSIONS ...........................................................17

APPENDIX C TERMINOLOGY..................................................................................................18

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 2 -

Last Revised 11/16/2012

Page 3

_

PART 1 - INTRODUCTION

The DIT-5200L Non-Contact Displacement Measuring System is an advance in precision

measurement technology. It provides exceptional resolution, repeatability, and nulling accuracy

for detecting the aligned / centered position of a conductive target relative to a pair of noncontacting sensors.

The DIT-5200L is identical in form to Kaman’s previous DIT-5200 product. Enhancements have

resulted in lower noise (better resolution) and CE Marking.

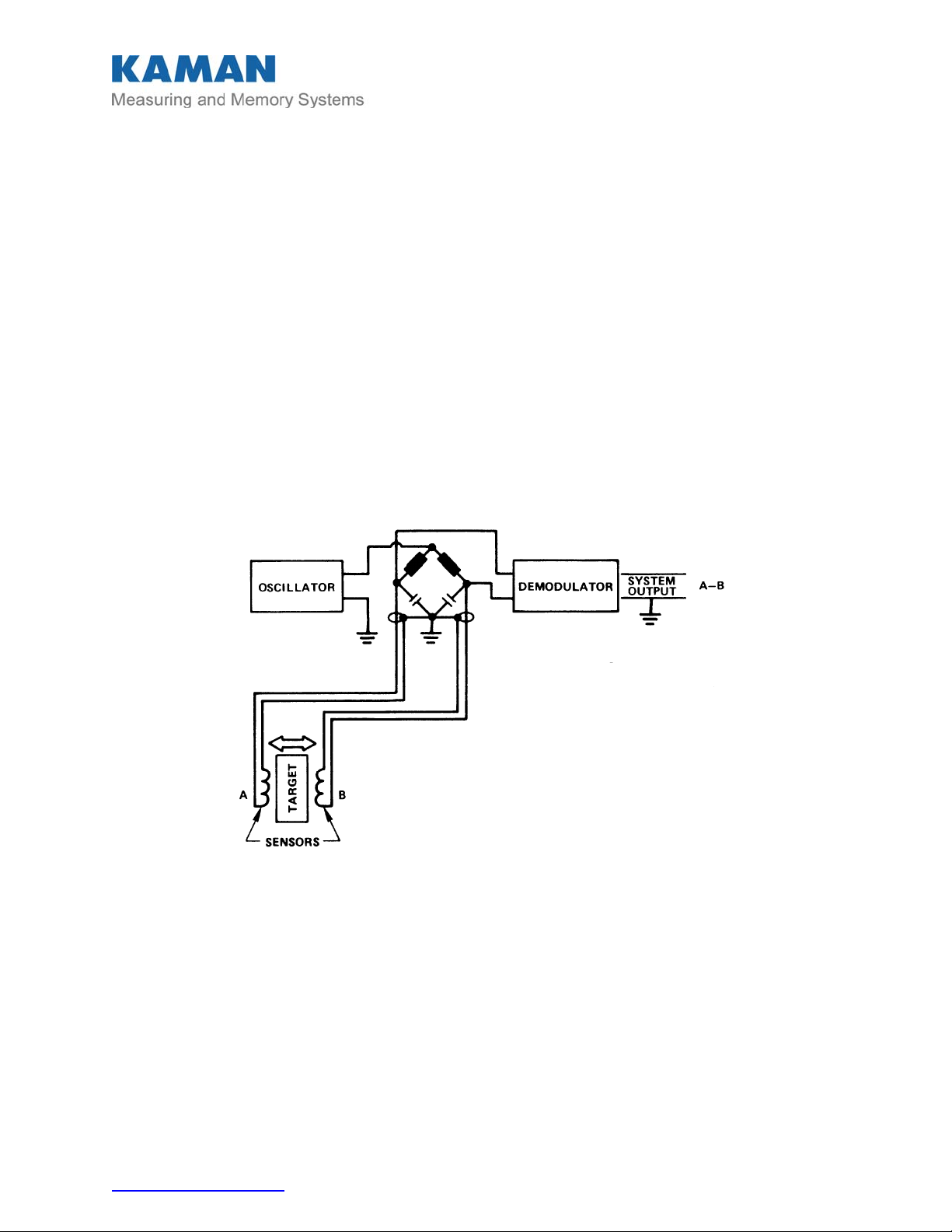

The DIT-5200L uses advanced inductive measurement technology to detect the aligned or

centered position of a conductive target. For differential measurement applications, two precisely

matched sensors per channel are positioned on opposite sides or ends of a target. In this sensorto-target relationship, as the target moves away from one sensor, it moves toward the other

sensor an equal amount. Output is differential and bipolar. Electrically matched sensors on

opposing legs of the same bridge provide exceptional thermal stability

Figure 1 DIT-5200L Circuit

The DIT-5200L signal conditioning electronics is packaged in is a die cast aluminum box with

MCX style sensor connections. The I/O is on a 9 pin mini-D connector. Input power connections

are reverse voltage protected.

The electronics can also be supplied as a bare PCB for installation inside the user’s enclosure.

Custom configurations can also be designed for OEM application requirements

The DIT5200L is CE Marked when purchased in the original enclosure. To maintain the CE

Marking, a ferrite must be installed over the input power wires only on the I/O cable.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 3 -

Last Revised 11/16/2012

Page 4

_

PART 2 – CONNECTING THE DIT-5200L

2.1 What’s Included

DIT-5200L Signal Conditioning Electronics

2 or 4 sensors (Typically 15N or 20N)

18” Input/Output Cable

2.2 Cautions and Safeguards

The sensor faces may be damaged if allowed to strike the target or other hard surface. Protective

plastic caps should remain in place until the sensors are ready for installation.

The maximum input voltage to the DIT-5200L is +/-15.5V, exceeding this input voltage will cause

damage to the DIT-5200L.

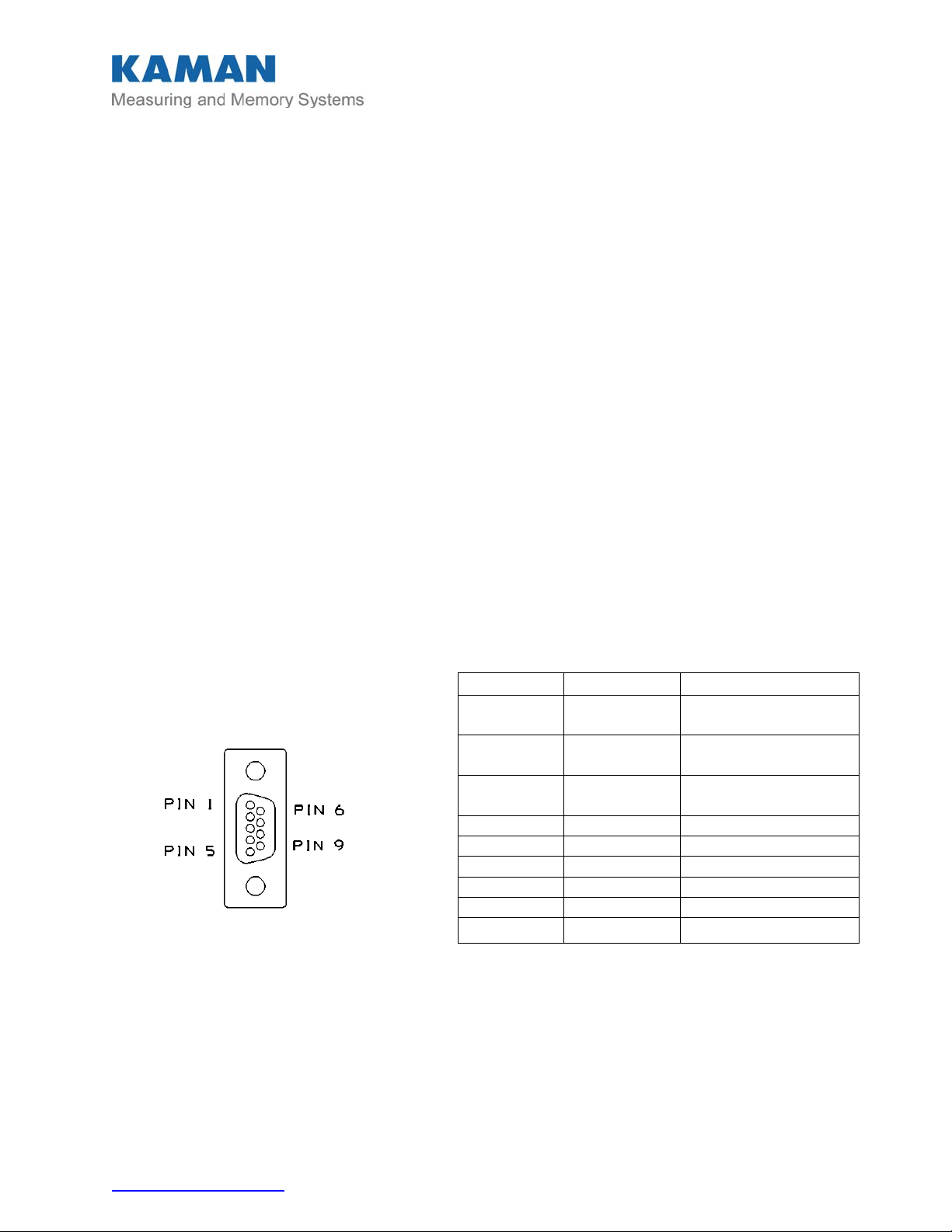

2.3 Pin out and Connector Assignments

The DIT-5200L I/O connections are via an ITT Cannon model MDM-9SL2P connector on the

enclosure. A mating connector with 18 inch leads is provided as part of the system. Connection

information is detailed below.

Sensor connections are the same for both the enclosure style and the OEM DIT-5200L. On the

OEM DIT-5200L orient the box so the I/O connector is on the right and the sensor connections

are on the left.

Pin Color Function

1 Black +15V @ 40 mA

(typical).

2 Brown -15V @ 40 mA

(typical)

3 Red Power Supply

Common

4 Orange +X Output

5 Yellow -X (Gnd)

6 Green +Y Output

7 Blue -Y(Gnd)

8 Violet N/C

9 Gray N/C

Figure 2 I/O Connector

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 4 -

Last Revised 11/16/2012

Page 5

_

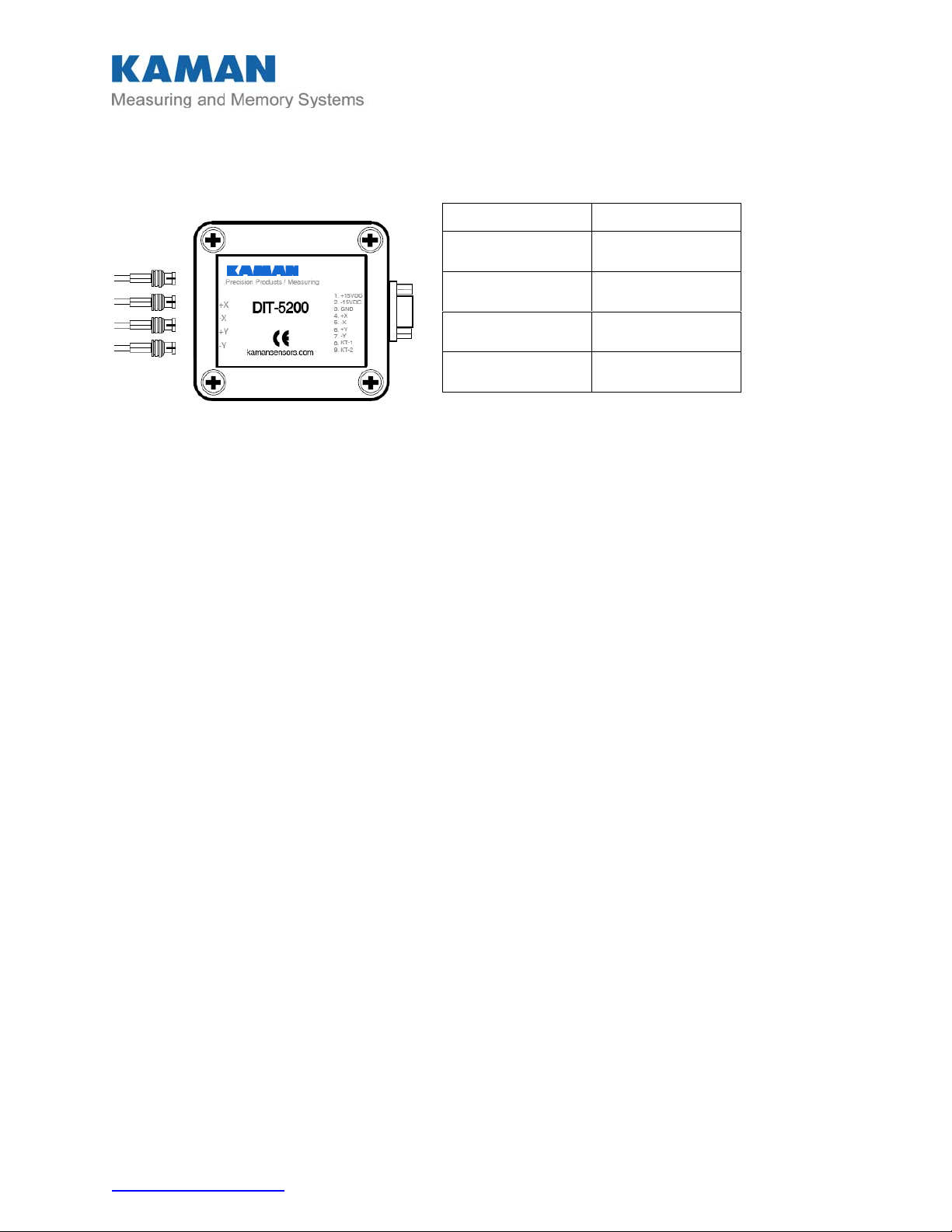

Function Sensor Label

Axis 1 Positive

Sensor

Axis 1 Negative

Sensor

Axis 2 Positive

Sensor

Axis 2 Negative

Sensor

+X

-X

+Y

-Y

Figure 3 Sensor Connections

The output on the channel will become more positive with movement toward the positive (+)

sensor. The output on the channel will become more negative with movement toward the

negative (-) sensor.

On single channel systems only the Axis 1 (X channel) is used.

The system is set up with the sensors as marked. Sensors are supplied as matched pairs for

optimum performance. Swapping sensors will result in degraded performance without factory

recalibration.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 5 -

Last Revised 11/16/2012

Page 6

_

PART 3 – APPLICATION INFORMATION

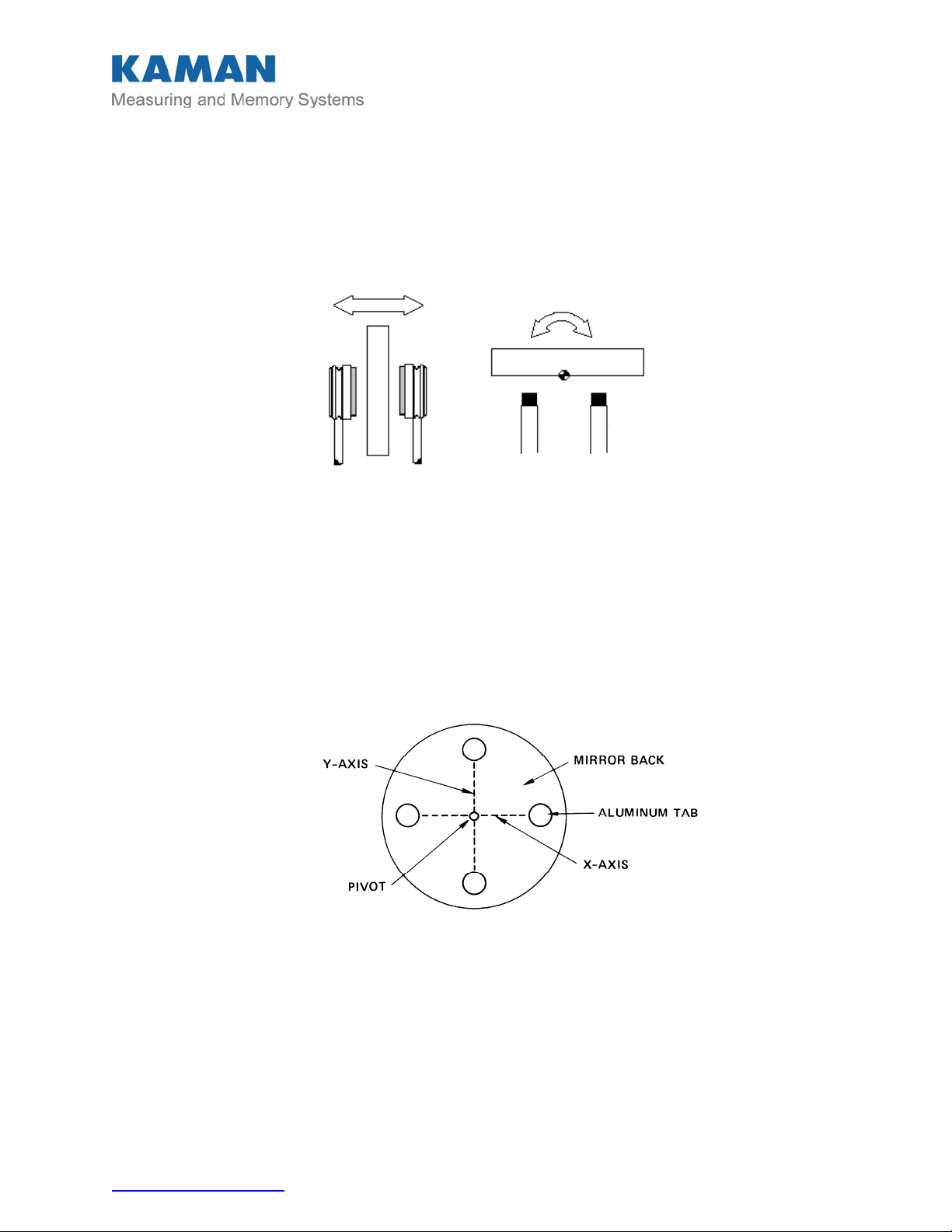

For differential measurement applications, the two electronically matched sensors are positioned

on opposite sides or ends of the target. The sensor to target relationship is such that as the target

moves away from one sensor, it moves toward the other an equal amount.

Figure 4 Sensor/Target Relationship

Standard systems come with two measurement axes (four sensors; two per axis) and can

therefore be fixtured a number of ways to provided precise x-y alignment. The figure below

illustrates target configuration for x-y alignment of an image stabilization mirror for an electrooptical application.

Figure 5 Sensor Position on a Stabilization Mirror

3.1 Fixturing

The user provides fixturing for the DIT-5200L electronics and sensors. The following information

establishes fixturing requirements for optimum system performance. Both the sensor and target

fixturing must be structurally sound and repeatable

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 6 -

Last Revised 11/16/2012

Page 7

_

3.2 Sensor Mounting and Installation

The sensors must be securely clamped. A collet type fixture is the best. It is best to clamp the

fixture as close to the sensor face as possible (without causing additional loading on the sensor) –

this is to minimize expansion differences between the two sensor housings. To insure that the

fixturing does not load the sensor and cause performance errors you should have any metal parts

approximately 3 sensor diameters away from the tip.

The target must not strike the sensor face. The sensor should have a null gap and measuring

range specified on the calibration record. As an example a 15N sensor may have a null gap of 15

mils (0.015” / 0.381mm) and a range of +/-10 mils (+/-0.010” / +/-0.254 mm). The difference

between the null gap and measuring range is the offset distance for the sensors. In this example

the offset would be 15-10=5 mils for an offset. The offset is the closest distance the sensor gets

to the target during normal operation. This offset is necessary both to optimize performance and

to keep the target from contacting and possibly damaging the coils in the sensor face.

Install the sensors so that only the target interacts with the sensor’s field. No conductive material

other than the target should be present within the sensor’s field. Because the sensor field

radiates in all directions, excessive back loading can also be a problem.

3.3 Electrical Nulling Procedure

Note: Although both sensors may appear to be positioned mechanically, this can cause a

cumulative error. By electrically positioning the second sensor using the system output, the error

is minimized.

The sensor coil is mounted at the face of both sensors. For purposes of mechanical nulling,

measure distance from the sensor face. (Use care not to damage the sensor coil)

1. Sensor position relative to the target is critical. Make sure the target is in the null position.

Install the first sensor of a pair (start with X-) in the application fixture. Using a dimensional

standard, precisely locate the sensor at the null gap. Secure the sensor and recheck its

position.

2. Now install the second sensor of the pair (X+) in the fixture and position it to within a few mils

(10’s of microns) of the required null gap. Connect the Power/Signal line and apply power to

the system. The system must be energized for a minimum of 30 minutes for best results. Use

the output from the system as a guide in the final positioning of this sensor (electrical nulling).

Slowly move the second sensor toward or away from the target as necessary until the system

output reads 0VDC (typically +/-10mV). Secure the sensor and recheck that the output is

0VDC. This output indicates the sensor is positioned correctly.

3. Repeat steps 1 and 2 for sensor Y- and Y+.

The system is now ready for use.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 7 -

Last Revised 11/16/2012

Page 8

_

3.4 Optimizing Performance

There are several things to be aware of when using the DIT-5200L in order to optimize the

performance of the system.

Insure that there are no ‘incidental targets’ – i.e. targets that the sensor may see that are

not to be measured.

Insure that the sensor is not tilted with respect to the target as this will cause additional

non-linearity.

Make sure that the system is set up with the proper null gap – electrical nulling of the

second sensor in a pair is best.

Insure you are using the specified calibration material (aluminum is the standard).

Make certain that you are using stable fixturing and mounting of the sensors.

Ensure the target is 3 sensor diameters in size and is thick enough to prevent penetration

of the magnetic field. (reference section 3.6 on Targets)

The system will perform the best if both sensors are in a similar thermal environment –

avoid temperature differentials between the sensor pairs.

3.5 Factors That May Degrade Performance

Unequal Loading

This refers to an unequal amount of conductive material within the field of one sensor as opposed

to the other sensor in the pair (the sensor’s field is approximately three times its diameter).

Unequal loading causes asymmetrical output from the sensors which induces non-linearity in the

system output. Ideally, no conductive material other than the target should be in the sensor’s

field. Some loading may be acceptable if it is equal and the sensors are calibrated in place. Even

then, sensor loading may cause non-linearity. If unable to calibrate, then loading is too great.

Unequal Displacement

For targets using pivot point mount, the system should “see” equal displacement: i.e., the pivot

point of the target is perfectly centered between the sensors. If the pivot point is a fraction of a

centimeter off, it can introduce non-linearity into the system.

The pivot point must be on a common line between the centerline of a pair of sensors.

The axis of tilt must be a perpendicular bisector of a line between the centerlines of a sensor

pair.

The pivot point must be positioned on the target so as not to introduce a translation error.

This error, a function of angle, is caused by slight changes in the effective null gap as the

target moves about the pivot. This results in non-linearity.

The pivot point must not move or change with time.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 8 -

Last Revised 11/16/2012

Page 9

_

3.6 Target Characteristics

Target Material

Aluminum is the preferred target material for the DIT-5200L. Aluminum targets may be mounted

on materials with more stable temperature characteristics such as Invar or other substrates as

long as the target thickness guidelines are observed. Invar is an excellent target substrate as it

has a very low expansion coefficient with temperature. The figure below shows aluminum tabs

(which give optimal performance from the DIT-5200L) mounted on and Invar fixture.

Iron, nickel, and many of their alloys (ferro-magnetic targets) can be used with the DIT-5200L.

Performance to these materials may not meet standard performance specifications.

Refer to the DIT-5200L data sheet for performance specifications to aluminum

.

Figure 6 Attachment of Aluminum Targets

If the system was purchased for use with a target material other than aluminum, it has been precalibrated (with pre-selected component values) at the factory using that specific material.

Changing the target material may require re-calibration or cause the DIT-5200L to malfunction.

The effect of target material is due to the resistivity and mainly affects the sensitivity of the

system. Expect about twice as much noise and drift on a system set up for a stainless steel target

as compared to one set up for aluminum.

Target Thickness

The RF field produced by the sensor is maximum on the target surface, but it also penetrates

below the surface. The depth of penetration depends on the target material used. For example,

the RF field will penetrate aluminum 0.022”. To avoid variations caused by temperature changes

of the target, use the recommended minimum target thickness in the table below:

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 9 -

Last Revised 11/16/2012

Page 10

_

Material Thickness, mils (mm)

Silver and Copper

22 ( 0.56 )

Gold and Aluminum 22 ( 0.56 )

Beryllium 25 ( 0.64 )

Magnesium, Brass, Bronze,

58 ( 1.5 )

Lead

300 Series Stainless Steel 110 ( 2.8 )

Inconel 110 ( 2.8 )

In applications where the sensors oppose each other with the target between them, the minimum

thickness should be at least double those listed above to prevent sensor interaction

Target Size

The minimum target size must be 1½ to 2 times the sensor diameter. It is preferred that the target

size be 3 times the sensor diameter for optimum performance.

Figure 7 Sensor Field Size

Additional recommendations and guidelines can be found in Kaman’s Inductive Technology

Handbook. The latest copy of this reference guide is located on our website.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 10 -

Last Revised 11/16/2012

Page 11

_

PART 4 – CALIBRATION

The DIT-5200L systems are shipped from the factory pre-calibrated for a user specified

measuring range, sensitivity, and target material. They do not normally require calibration or recalibration. Potentiometer locations for the OEM and enclosure version are the same relative to

the sensor and I/O connector positions.

The system must be positioned to the null gap by first adjusting one sensor to the null gap and

adjusting the opposing sensor for a zero volt output. Reference section 3.2.

Figure 8 Sensor Positioning for Calibration

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 11 -

Last Revised 11/16/2012

Page 12

_

R117 Offset Ch X

R112 Gain Ch X

R

R212 Gain Ch Y

217 Offset Ch Y

Figure 9 Potentiometer Locations

Note:

included in this calibration sequence.

1. Position the target at Null

2. Adjust the offset control for the measuring channel being calibrated to 0+/-0.001V (unless

3. Position the target at –FS (negative full scale)

4. Adjust the gain control for the measuring channel being calibrated to the full scale voltage +/-

5. Position the target at Null

6. Adjust the offset control for the measuring channel being calibrated to 0+/-0.001V (unless

7. Position the target at –FS (negative full scale)

8. Adjust the gain control for the measuring channel being calibrated to the full scale voltage +/-

9. Repeat steps 1-8 as necessary

Offset (zero) potentiometers R117 and R217 are not normally installed and are not

otherwise specified).

0.005mV (unless otherwise specified)

otherwise specified). (See above note if there is no offset control)

0.005mV (unless otherwise specified).

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 12 -

Last Revised 11/16/2012

Page 13

_

PART 5 – GENERAL SPECIFICATIONS & TYPICAL

PERFORMANCE

Parameter Value Units Comments

Target Material Aluminum is

preferred

Most conductive materials can be

considered

Null Gap See Data

Sheet

Range See Data

Sheet

Output Voltage +/-10 Volts Typical

Non-Linearity <0.5 %FSO Typical

Resolution at Null

(p-p at 1kHz BW)

Resolution at FSO

(p-p @ 1kHz BW)

TempCo at Null <0.005 %FSO/oC Typical

TempCo at FSO <0.02 %FSO/oC Typical

Power Dissipation at 15N

Sensor Head

Power Dissipation at 20N

Sensor Head

Power Dissipation

(Electronics)

<0.004 %FSO Typical

<0.015 %FSO Typical

< 0.5 mW/sensor Typical

< 2 mW/sensor Typical

<1.35 Watts

Range and sensor dependant.

See Data Sheet.

See Data Sheet

Frequency Response 0 - 20 kHz

Input Voltage +/-15 Volts

Output Impedance <1 Ohm

Weight <8 oz Enclosure Version (Typical)

Operating Temperature

Electronics: +32to +140oF (0C to +60oC)

Sensors: -62

Cryogenic 20N Sensor: +4

o

F to +220oF (-52oC to +105oC)

o

K to +220oF (+105oC)

Storage Temperature Range

Electronics: -26oF to +180oF (-32oC to +82oC)

Sensors: -62

Cryogenic 20N Sensor: +4

o

F to +220oF (-52oC to +105oC)

o

K to +220oF (+105oC)

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 13 -

Last Revised 11/16/2012

Page 14

_

Sensor/Range Specific Performance

Range,

+/-mil

10 0.25 15 0.40 x 0.15% 0.30% 0.02% 2E-5% 2E-5%

10 0.25 20 0.50 x 0.10% 0.20% 0.02% 2E-5% 2E-5%

20 0.50 25 0.65 x 0.25% 0.50% 0.03% 2E-5% 2E-5%

20 0.50 40 1.0 x 0.15% 0.30% 0.02% 2E-5% 2E-5%

35 0.90 40 1.0 x 0.50% 1.00% 0.03% 2E-5% 1E-5%

50 1.25 60 1.5 x 0.25% 0.50% 0.03% 2E-5% 1E-5%

75 1.90 85 2.2 x 0.50% 1.00% 0.03% 1.5E-5% 1E-5%

Note: Full Range (FR) is considered as twice the +/- Range

Rang

e

+/-

mm

Null,

mil

Null,

mm

15N 20N Typical

Non-

Linearity,

%FR

Max.

Non-

Linearity,

%FR

Typical

Sensor

TempCO

, %FR/

o

Equivalent

RMS Input

Noise,

C

%FR/Hz @

FR

Equivalent

RMS Input

Noise,

%FR/Hz @

Null

Calculating Effective Resolution

To calculate the effective resolution, take the Equivalent RMS Input Noise and multiply it by the

square root of the measurement bandwidth. Peak-to-peak noise is normally 6.6 times higher than

the RMS noise assuming gaussian (randomly distributed) noise.

For Example, to calculate the worst case noise of a 15N system with a +/-0.5 mm (+/- 500

micron) range at a 20 kHz bandwidth:

Step 1) Calculate the full range of the system:

FR (Full Range) = 2 x 500 microns = 1,000 microns

Step 2) Calculate the Equivalent RMS Input Noise in measurement units by multiplying by the Full

Range (don't forget to divide by 100 to take into account the percent).

Resolution at Full Scale is 2E-5%FR/Hz x 1,000 microns / 100 = 2E-4 microns/Hz

Step 3) Multiply by the square root of the measurement bandwidth to calculate the effective

resolution.

Effective RMS Resolution @ 20kHz = 2E-5%FR/Hz x 1,000 microns x 20 kHz = 0.028

microns

Step 4

Note: Output filtering on the DIT-5200L is set to 20 kHz. External filtering is assumed when

calculating resolutions at lower bandwidths.

) To approximate the peak-to-peak resolution multiply by 6.6

Effective peak-to-peak resolution @ 20 kHz = 0.028 x 6.6 = 0.185 microns

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 14 -

Last Revised 11/16/2012

Page 15

_

PART 6 - TROUBLESHOOTING

5.1 Insufficient Gain

If attempting to recalibrate for a specific sensitivity, measuring range, or for a target different from

factory calibration specifications, there may be insufficient gain control to do this. You may need

to decrease the desired output in order to calibrate the system.

Another cause for insufficient gain could be excessive loading of the sensors by conductive

material (other than the target) within the field of the sensors. The sensor’s field is approximately

three times its diameter.

5.2 Unable to Zero

The DIT-5200L is an exceptionally stable measuring system. Long term drift is less than 2 microinches per month. If the unit does not work, this would most likely be discovered during the

functional test. If you are unable to calibrate your system in no more than two iterations, the

problem is most likely poor mechanical repeatability in the fixturing or actuating mechanisms. To

determine this:

1. Do not make any adjustments to the calibration controls. (Record how much time the next

step takes).

2. Do at least 12 to 15 iterations of moving the target from null to full range and back to null.

Record the output at null each time. If successive readings of the output at null consistently

vary with no clear trend (drift) in one direction or the other, the problem is mechanical

repeatability.

3. Stabilize the target at null and record the output. Leave the target at null for the same length

of time it took to accomplish step two and monitor the output.

4. If the output remains constant, this confirms the problem is mechanical repeatability.

If the output drifts, the problem could be drift in the fixturing, drift in the target positioning servos,

or drift in the DIT-5200L.

If you can positively eliminate all other variables as the source of the problem, consult Kaman

Precision Products.

5.3 Poor Non-Linearity

Poor non-linearity is typically the result of additional loading on the sensor or the sensor head

being slightly tilted.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 15 -

Last Revised 11/16/2012

Page 16

_

APPENDIX A DIT-5200L SENSOR DIMENSIONS

15N Sensor Versions 20N Sensor

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 16 -

Last Revised 11/16/2012

Page 17

_

APPENDIX B DIT-5200L ENCLOSURE DIMENSIONS

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 17 -

Last Revised 11/16/2012

Page 18

_

APPENDIX C TERMINOLOGY

Null Gap

The point at which a target is equidistant from each sensor of a differential pair. The system

output at null = 0VDC. The actual gap is measured from the sensor face to the corresponding

target face and includes a required offset (null gap = offset plus maximum measuring range).

Offset

The minimum distance between the sensor face and the target. Offset is necessary to both

prevent the target from striking the sensor face and to optimize performance (offset = null gap

minus max range).

Measuring Range

The full range of target motion over which the various specifications such as resolution, linearity,

and sensitivity can be met. The differential sensor arrangement yields a bipolar output and

measuring range is expressed as + and – value either side of the null position (measuring range =

null gap minus the offset).

Sensitivity (scale/gage factor)

Output voltage per unit of displacement. Usually expressed as millivolts per mil (0.001”) or per

millimeter.

Linearity (or non-linearity)

The maximum deviation of any point of a calibrated system’s output from a best fit straight line.

Expressed in actual units, e.g., micro-inches or as a percentage of the full range (the full scale

output times 2).

Equivalent RMS Input Noise

A figure of merit used to quantify the noise contributed by a system component. It incorporates

into a single value, several factors that influence a noise specification such as signal-to-noise

ratio, noise floor, and system bandwidth. Given a measuring systems sensitivity/scale factor and

the level of “white” noise in the system, Equivalent RMS Input Noise can be expressed using

actual measurement units.

Effective Resolution

An application dependent value determined by multiplying the Equivalent RMS Input Noise

specification by the square root of the measurement bandwidth.

Example: an application with a 100 Hz bandwidth using a DIT-5200 with an Equivalent RMS Input

Noise level of 0.2nm/ Hz results in a system with an effective resolution of 0.2nm/ Hz x 100 Hz

or 2nm

.

_____________________________________________________________________________

Kaman Precision Products PART NO: 860522-001

www.kamansensors.com

- 18 -

Last Revised 11/16/2012

Loading...

Loading...