Page 1

Reference Manual

SERIES 8000

ENCLOSURES

Copyright © 2000 Kaman Aerospace Corporation

PART NO: 860093-001 Measuring & Memory Systems

Last Revised: 3/16/01 217 Smith Street

Middletown, CT 06457

www.kamansensors.com or 860-632-4442

Page 2

Page 3

Series 8000 Enclosures

Reference Manual

1/2 Rack Instrumentation Case (3U/42HP)

3/4 Rack Instrumentation Case (3U/63HP)

Full 19" Subrack (3U/84HP)

Kaman Measuring Systems

P/N 860093-001, Revised 3/16/01

Page 4

4

Series 8000 Systems

The Series 8000 is a modular packaging system for Kaman Instrumentations line of inductive

displacement transducer electronics. The Series 8000 enclosures integrate various measuring

channels, function cards, power supplies, and displays into a coherent application specific

industrial package. Sensors for the measuring channels are available that measure

displacements in the microinch/nanometer ranges as well as sensors that can make accurate

displacement measurements at up to 1000oF. Function cards are available that can take the

displacement measurement and process the signal to measure ID, OD,runout, or out of

tolerance conditions. The versatility and flexibility of the 8000 system is virtually endless.

This manual is designed to help put it all together for the specific system you have purchased.

features: Eurocard/Eurorack format

Up to 12 channel systems

Integral rear mounted power supplies

Terminal block I/O

Optional 1/8 DIN display modules

Multi-channel Scalable displays

Inductive sensing technology

Plug-in function modules for:

Dynamic signal measurement

Set point window comparators

Summation for thickness/ID/OD measurement

4-20 mA outputs

Page 5

5

Table of Contents Page

Getting Started Quickly 7

Series 8000 Enclosures 8

Subracks 8

Instrument Enclosure 13

NEMA 17

Integral Power Supply 18

Input Voltage Selection (120VAC/240VAC) 19

The Internal Back Plane 23

Internal Back Plane Connectors 25

Adding Additional Modules 26

The Back Panel 29

Back Panel Power Input 29

Back Panel I/O and Labeling 30

Back Panel Sensor Inputs 31

The Front Panels 32

Module Side Panel Labeling 32

MCD-8000 and 1/8 DIN Panel Mounted Displays 33

Using the Multi-Inputs 35

Input wiring to the Display 36

0-10VDC Display Input Configuration 37

+/-5VDC Display Input Configuration 37

+/-10VDC Display Input Configuration 37

4-20mA Display Input Configuration 38

Calibration 39

Appendix A -- Measuring Channel Configuration 43

Basic Measuring Channel Configuration 44

Appendix B -- Function Card Configuration 45

VC8000 Voltage to Current Converter Configuration 46

SC8000 Summation/Comparator Configuration 47

DY8000 Dynamic Module Configuration 48

SP8000 Dual Set Point Configuration 49

Appendix C -- MCD-8000 Display Specifications 50

MCD 8000 Functional Specifications 50

MCD 8000 Performance Specifications 51

MCD 8000 Environmental/Physical Specifications 51

Appendix D -- Replacement or Expansion Parts 52

Appendix E – Warranty, Customer Service and Service/Repair 54

Page 6

6

List of Illustrations Page

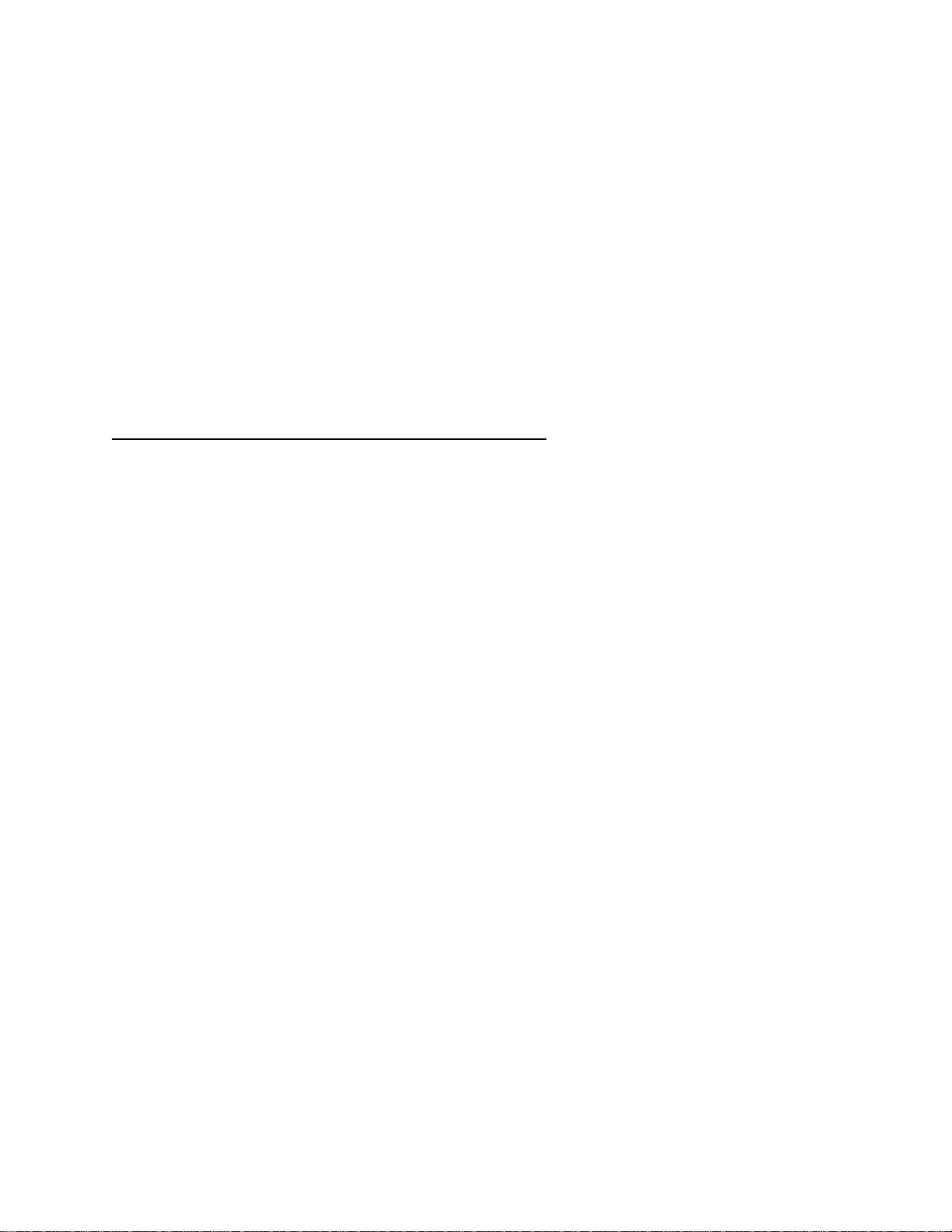

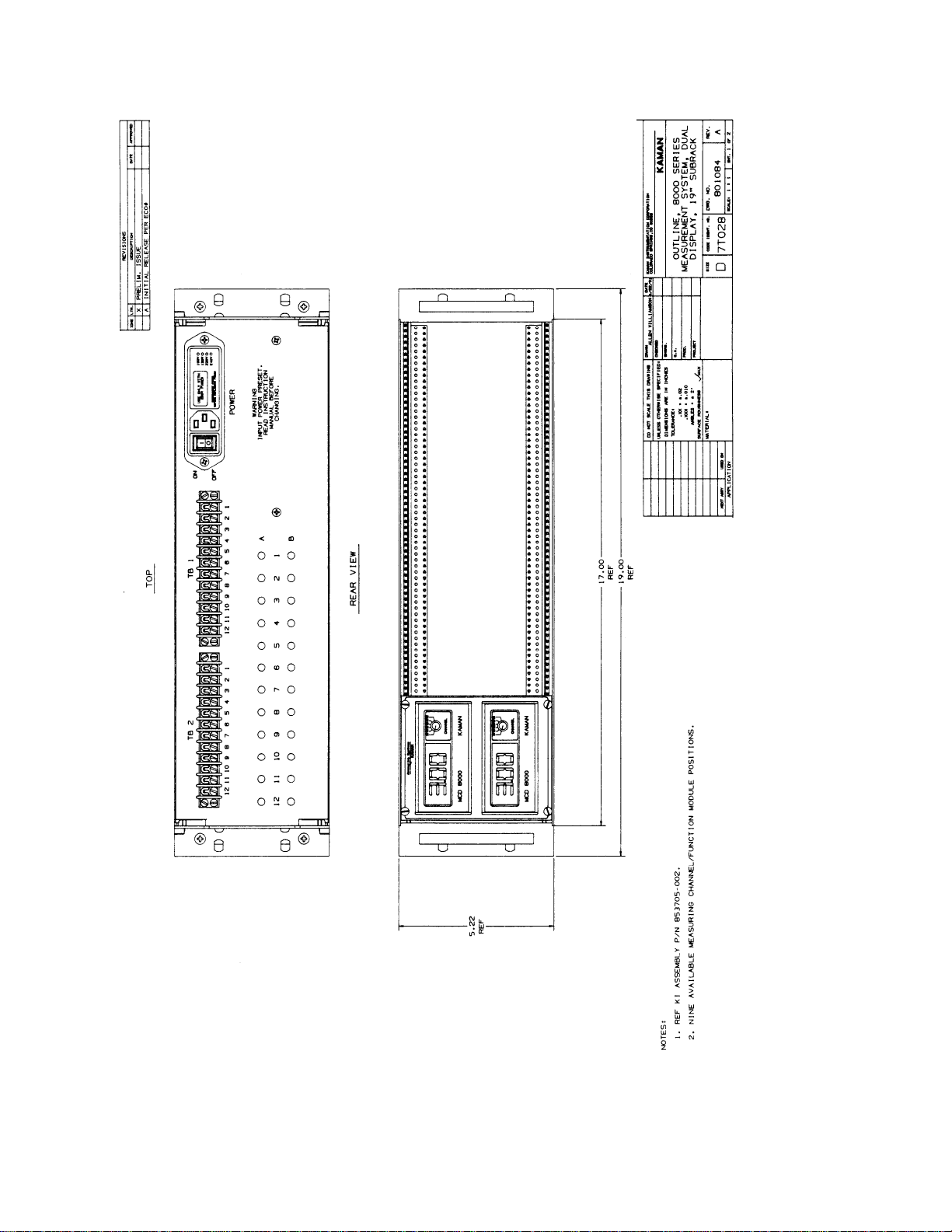

fig. 1 -- Full 19" Subrack Rear/Front Outline drawing 9

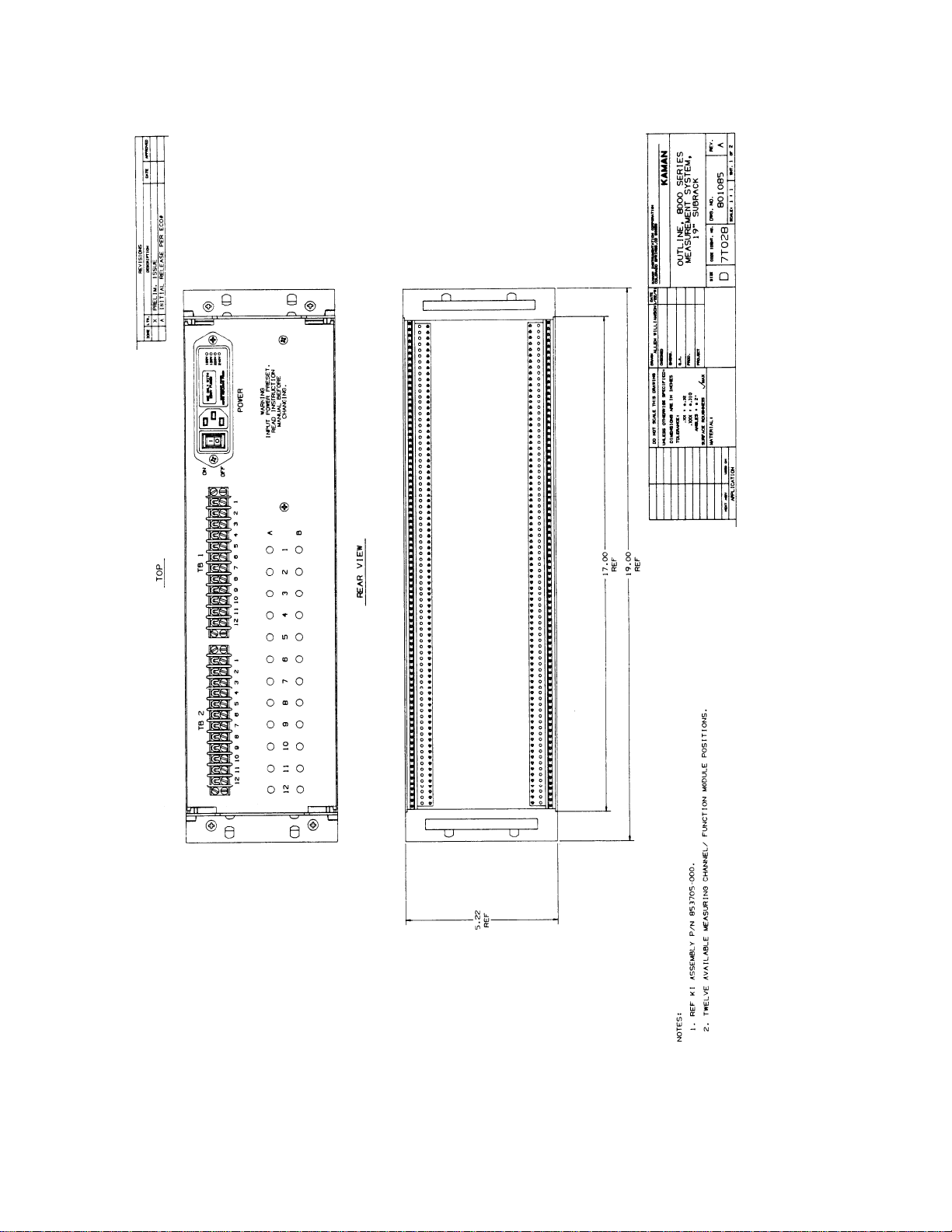

fig. 2 -- Full 19" Subrack Top View Outline Drawing 10

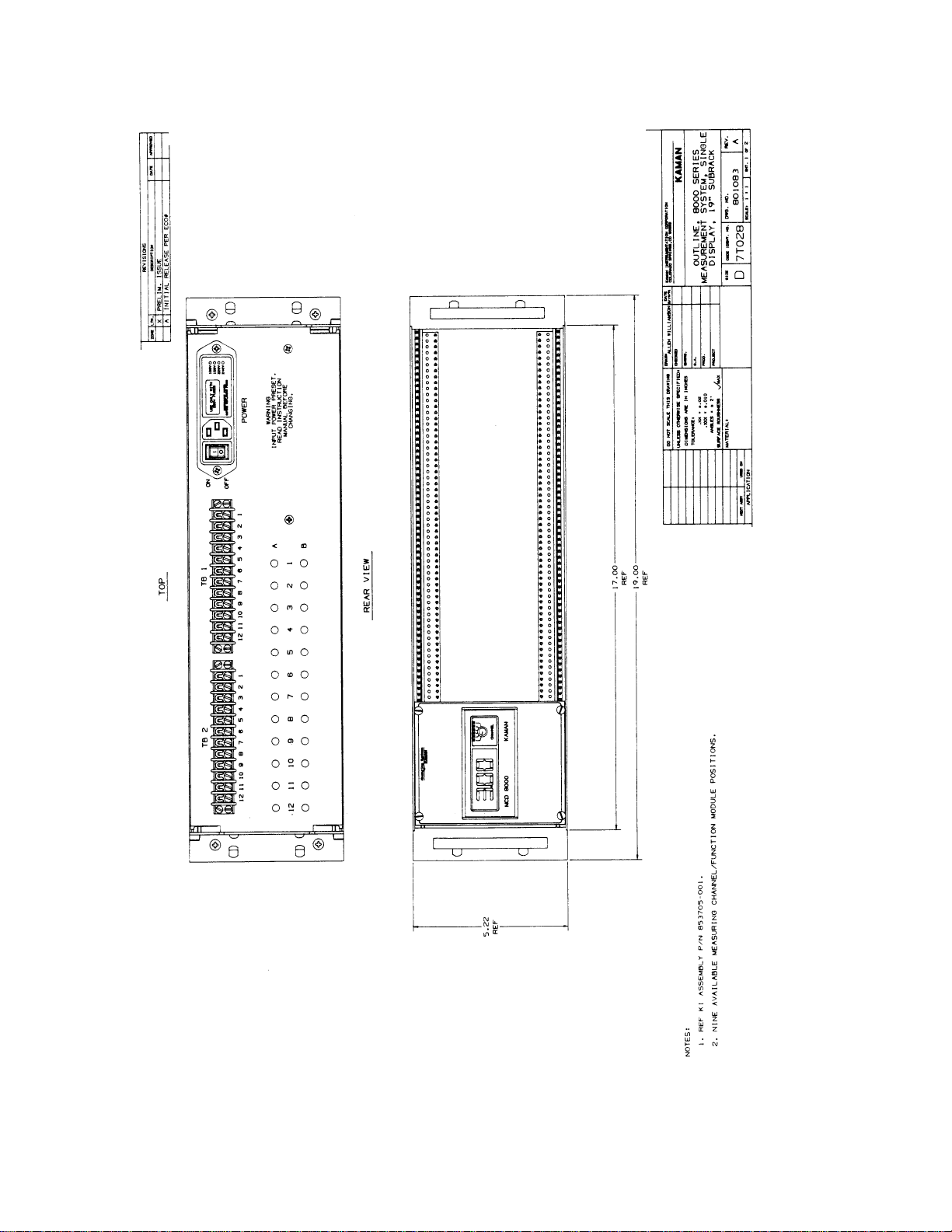

fig. 3 -- Full 19" Subrack Rear/Front with Display 11

fig. 4 -- Full 19" Subrack Rear/Front with Dual Display 12

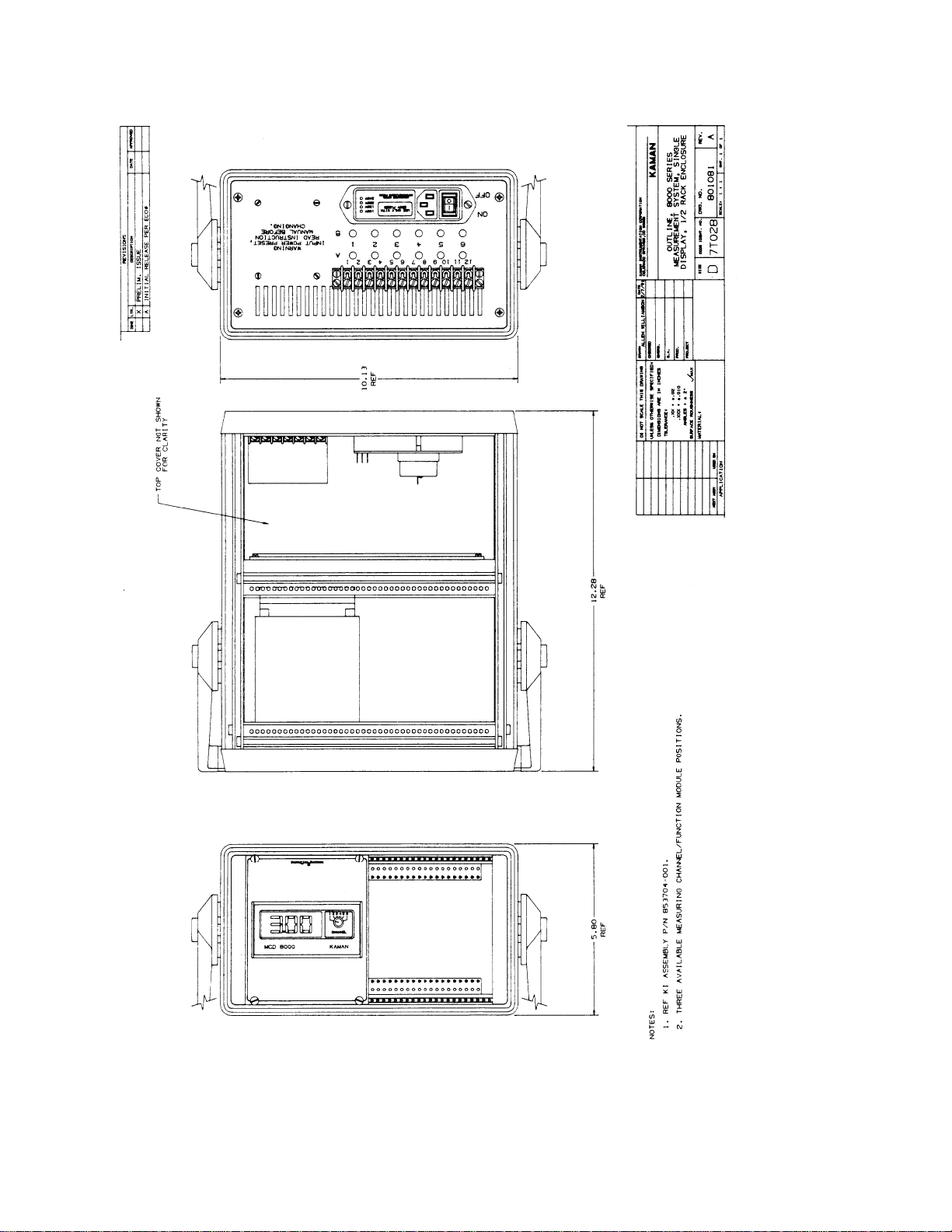

fig. 5 -- 1/2 Rack with Display Outline Drawing 14

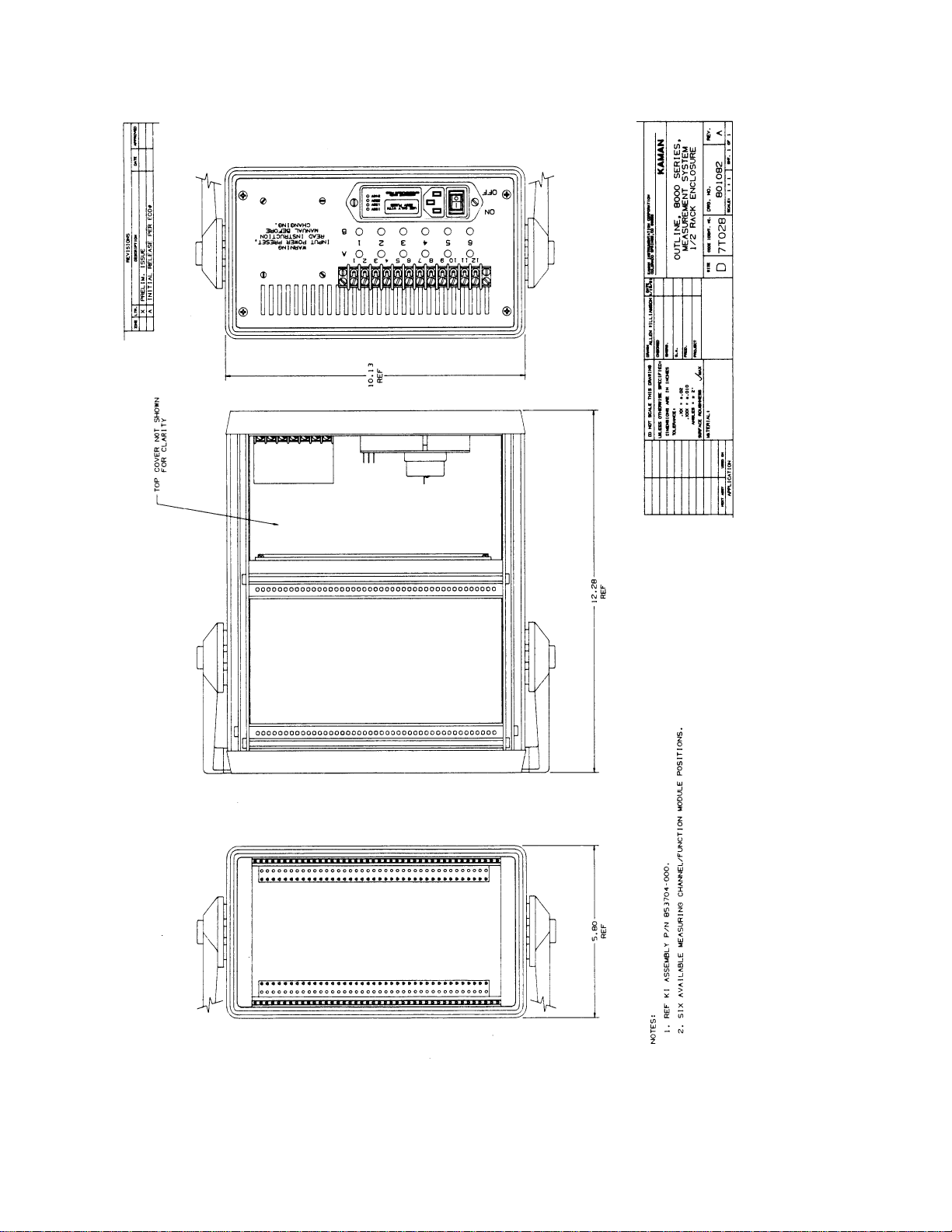

fig. 6 -- 1/2 Rack Outline Drawing 15

fig. 7 -- 3/4 Rack with Display Outline Drawing 16

Table 1 -- Power Supply Specifications 18

fig. 8 -- Power Entry Module 19

fig. 9 -- Accessing the Voltage Selector Card 19

fig. 10 -- Voltage Selector Card Orientation 20

fig. 11 -- Top View of Main board on display. 22

fig. 12 -- Physical Eurocard Pin Locations 23

Table 2 -- Electrical Standards for Pinout 24

fig. 13 -- Single Coil Coaxial 25

fig. 14 -- Dual Coil Coaxial 25

fig. 15 -- Back Plane Template 28

fig. 16 -- Power Entry Module 29

Table 3 -- Terminal Block Labeling 30

fig. 17 -- Back Panel Sensor Inputs 31

fig. 18 -- Typical Module Side Panel Labeling 32

fig. 19 -- Single 1/8 DIN Mounting Panel 814873-001 33

fig. 20 -- Dual 1/8 DIN Mounting Panel 814873-002 34

fig. 21 -- MCD 8000 Front Panel 35

Table 4 -- Displayed Outputs 35

fig. 22 -- MCD 8000 Input Wiring 36

fig. 23 -- MCD 8000 Power Wiring 36

fig. 24 -- Voltage/Current Input Dip Switch 38

fig. 25 -- Diodes For Loop Continuity in Current Mode 38

fig. 26 -- MCD 8000 Adjustment Switches 40

fig. 27 -- Process/Scaling Dip Switch 40

fig. 28 -- Button Function Legend 42

Table 5 -- MCD-8000 Error Message Table 42

Table 6 -- Series 8000 Sensor Family 43

fig. 29 -- Basic Measuring Channel 44

fig. 30 -- Module Reference Dimensions 45

fig. 31 -- VC8000 Voltage to Current Converter 46

fig. 32 -- SC8000 Summation/Comparator 47

fig. 33 -- DY8000 Dynamic Module 48

fig. 34 -- SP8000 Dual Set Point 49

Page 7

7

Getting Started Quickly

The Series 8000 rack systems are typically prewired and set up at the factory with all

measuring channels and function cards installed. To get started with the 8000 system you will

need to:

a Install the sensors in the application or cal fixture

b Connect the sensors to the enclosure (see page 30)

c Connect the power cord and turn on the unit

d If you have a display see page 32

e If you have no display see page 29 on back panel I/O

As with any complex electronics system you should thoroughly familiarize yourself with all

manuals dealing with the product. Included with the system are the appropriate manuals for

any measuring channels and function cards purchased. Please refer to these manuals for

specific information.

Warning: The integral power supply in racks utilize high voltage

(120 or 240VAC). Unplug the unit before servicing.

Page 8

8

Series 8000 Enclosures

Subracks

The subrack is a 19" wide frame having solid side panels and horizontal rails across the top

and bottom to hold the system modules in place. Use of a subrack enables you to install your

Series 8000 system into a standard 19" test equipment rack, or bolt it into a NEMA enclosure.

The subrack has a built in 120VAC/240VAC selectable power supply to provide +/-15VDC at 1

amp. The subrack also can be configured with either one or two MCD 8000 display modules

that have up to six selectable inputs. The display modules draw no current from the +/-15 volt

supply.

Full 19" Sub-Racks - 3U/84HP Instrumentation Subrack

Part Number Configuration

853705-000 No display meter, 12 available positions

853705-001 One display meter, 9 available positions

853705-002 Two display meters, 9 available positions

Page 9

9

fig.1 – Full 19” Subrack Rear/Front Outline Drawing

Page 10

10

Fig. 2 – Full 19” Subrack Top View Outline Drawing

Page 11

11

fig. 3 – Full 19” Subrack Rear/Front with Display

Page 12

12

fig. 4 – Full 19” Subrack Rear/Front with Dual Display

Page 13

13

Instrument Enclosure

The instrument case is a fully enclosed stand-alone enclosure for your series 8000 system with

a tilt bar to elevate the front of the case. The subrack has a built in 120VAC/240VAC

selectable power supply to provide +/-15VDC at 500 milliamp. The subrack also can be

configured with either one or two MCD 8000 display modules that have up to six

selectable inputs. The display modules draw no current from the +/-15DC volt supply.

1/2 rack enclosures - 3U/42HP Instrumentation enclosure

Part Number Configuration

853704-000 No display meter, 6 available positions

853704-001 One display meter, 3 available positions

3/4 rack enclosures - 3U/63HP Instrumentation enclosure

Part Number Configuration

853723-001 One display meter, 6 available positions

Page 14

14

fig.5 – ½ Rack with Display Outline Drawing

Page 15

15

fig. 6 – ½ Rack Outline Drawing

Page 16

16

fig. 7 – ¾ Rack with Display Outline Drawing

Page 17

17

NEMA

The NEMA 12 configuration is an 8"x8"x4" continuous hinge enclosure. It can contain either 1

or 2 synchronized measuring channels and an optional function card. An optional integral

power supply and/or display is available. In the NEMA the modules do not have separate

enclosures. This configuration is not described further in this manual, please refer to the NEMA

manual PN 860060 for further information on the NEMA enclosure.

PN Configuration

853638-001 Standard NEMA

853639-001 NEMA with internal 120VAC power supply

853640-001 NEMA with display

853641-001 NEMA with 120VAC PS and display

853639-001E NEMA with 240 VAC power supply

853641-001E NEMA with 240 VAC power supply and display

Page 18

18

Integral Power Supply

Warning: The integral power supply in racks utilize high voltage

(120 or 240VAC). Unplug the unit before servicing.

The power supply for the series 8000 rack enclosures are integral to the chassis and mounted

on the back panel for better heat dissipation. All of the Series 8000 power supplies provide a

+/-15VDC+/-.5V linear regulated output for low noise operation. The available current is

500mA per side in the 1/2 and 3/4 rack configurations and 1A per side in full rack

configurations. Most measuring channels and function cards from Kaman typically draw less

than 70mA per side. When adding additional function cards or measuring channels to the unit

you should check on the actual current amount by referring to the specifications on each module

and adding up the total current draw from the power supply. For example, if you had 10

measuring channels you should allow for the supply to be able to handle 700mA (full rack

configuration). The MCD-8000 or other 1/8 DIN display modules are powered directly off the

AC input and therefore draw no current from the integral supplies. The power supply

specifications are summarized in table 1 below:

Full 19" Sub-Racks - 3U/84HP Instrumentation Subrack

Input Power: 115VAC +/-10%, 50-60 Hz, .5A fuse

230 VAC +/-10%, 50-60Hz, .25A fuse

Output Voltage: +/-15VDC +/-.5V

Output Current: 1A per side

3/4 rack enclosures - 3U/63HP Instrumentation enclosure

Input Power: 115VAC +/-10%, 50-60 Hz, .5A fuse

230 VAC +/-10%, 50-60Hz, .25A fuse

Output Voltage: +/-15VDC +/-.5V

Output Current: .5A per side

1/2 rack enclosures - 3U/42HP Instrumentation enclosure

Input Power: 115VAC +/-10%, 50-60 Hz, .5A fuse

230 VAC +/-10%, 50-60Hz, .25A fuse

Output Voltage: +/-15VDC +/-.5V

Output Current: .5A per side

Table 1 -- Power Supply Specifications;

Page 19

19

Input Voltage Selection (120VAC/240VAC)

Warning: When you change the input voltage on the rear panel

you must also change the MCD 8000 input voltage

or you may damage the unit.

Warning: The integral power supply in racks utilize high voltage

(120 or 240VAC). Unplug the unit before servicing.

To change the input voltage you must first select the proper input voltage on the power entry

module on the unit. To change the selected voltage:

a Open the cover using a small blade screwdriver or similar tool. Set aside

the cover/fuse block assembly and pull the voltage selector card straight

out of the housing. See fig. 9 on accessing the voltage selector card.

fig. 8 -- Power Entry Module;

fig. 9 -- Accessing the Voltage Selector Card;

Page 20

20

b Using the indicator pin orient the selector card so that the desired

voltage is readable at the bottom. Orient the indicator pin to point up

when the desired voltage is readable at bottom ( note that when indicator

pin is fixed, successive voltages are selected by rotating the card 90o

clockwise). See fig. 10 for voltage selector orientation.

c Insert voltage selector card into housing with printed side of card facing

toward IEC connector and edge containing the desired voltage first.

Replace cover and verify that indicator pin shows the desired voltage.

fig. 10 -- Voltage Selector Card Orientation;

Page 21

21

If you have an MCD 8000 (for other 1/8 DIN panel meter configurations you will need to see

the specific manual on the meter for changing the input voltage) 110VAC or 220VAC is

selectable using a switch on the indicators main circuit board. Check the instruments tag for

the voltage range set at the factory. If you are changing the input voltage to the unit you will

need to set this switch appropriately. To change the input voltage on the MCD 8000 display

module perform the following steps:

Warning: When you change the input voltage on the rear panel

you must also change the MCD 8000 input voltage

or you may damage the unit.

Warning: The integral power supply in racks utilize high voltage

(120 or 240VAC). Unplug the unit before servicing.

a Remove the MCD-8000 unscrew the 4 screws holding the unit in the

chassis. You will need to very carefully pull this out of the enclosure to

get at the voltage selector switch. Be careful not to pull out any of the

wires attached to the terminal block of the MCD 8000.

b Remove the input selector knob and face plate and spread the black box

to remove the PC board. There is a plastic tab on the bottom side that

holds the PC board in place. Spreading the box slightly will allow the PC

board to slip over the top.

c On the main display board set the voltage switch for the appropriate

input voltage and replace the unit. See fig. 11 for a top view of the main

display board.

d Reinstall the display module in the unit.

Page 22

22

fig. 11 -- Top View of Main board on display.;

Warning: Dangerous voltages are exposed at the screw terminals.

Always remove power before working in this area

for rewiring, disassembly, and all other activities

that involve proximity to electrical circuitry.

Page 23

23

The Internal Back Plane

The back plane of the series 8000 rack system is typically hand wired at the factory. Channels

configured as blanks are normally left unconfigured because it is not always specified as to

what will be in a slot in the future. In designing the series 8000 modules some standards have

been adhered to accommodate expansion. The diagram in figure 12 details physical pin

locations for the standard Eurocard connector. Table 2 gives the electrical standards used for

designing compatible modules. Figure 15 is a template used for special wiring to the back

plane. See the section on Adding Additional Modules for information concerning expansion.

When connecting other 3rd party equipment to the Series 8000 you must take care to avoid

drawing to much power from the supply and/or adding additional noise to the output from the

system (especially with digital cards such as A/D, D/A, or CPU).

fig. 12 -- Physical Eurocard Pin Locations;

Page 24

24

Caution: Be careful when connecting power, incorrect connections may damage your system.

function Pin C Pin A function

+15VDCin 2 2 +15VDCin

SPL 4 4 SPL

-15VDCin 6 6 -15VDCin

SPL 8 8 SPL

Gnd 10 10 Gnd

I/O 12 12 I/O

I/O 14 14 I/O

I/O 16 16 I/O

I/O 18 18 I/O

I/O 20 20 I/O

I/O 22 22 I/O

Aux 24 24 Aux

Gnd 26 26 Gnd

I/O 28 28 I/O

Gnd 30 30 Gnd

I/O 32 32 I/O

Table 2 -- Electrical Standards for Pinout;

Pins labeled I/O are either input/output, pins labeled Gnd are always ground, pins labeled Aux

are generally reset type functions, pins labeled SPL are not normally used but may be

depending on the density required for pinout, the power supply input pins are obvious and the

function cards are always set up to allow a +/-15 volt input.

Page 25

25

Internal Back Plane Connectors

The bare chassis eurocard connector is available for expansion and is part number 826020002 for function cards. For most Kaman measuring systems use the SMA connector for coaxial

connection, two part numbers are available: 853503-001 for single coil systems or 853503002 for dual coil or differential systems. These connectors are prewired to the eurocard

connector with bulkhead SMA's.

fig. 13 -- Single Coil Coaxial; fig. 14 -- Dual Coil Coaxial;

Page 26

26

Adding Additional Modules

To add additional modules you will need to wire in additional Eurocard connectors to the back

panel. You must have a soldering iron and 24AWG bus wire as well as insulated wire to

connect any outputs that are required to the display or the back panel.

Warning: The integral power supply in racks utilize high voltage

(120 or 240VAC). Unplug the unit before servicing.

1) Using the back plane template provided in fig. 15 map out the wiring of the unit.

Power and ground connections from the power supply are shown in the diagram.

Measuring channel and function cards I/O is shown in tables at the top of the

template. You should refer to the specific manual on the module you are adding

for further pinout information. The measuring channel sensor SMA pigtail

connectors will already attached to the Eurocard connector.

2) Determine the connector required:

If you are adding a measuring channel:

you will need to have the 853503-001 or 853503-002 (depending on whether the

measuring channel has one or two coils) connector with the coaxial bulkhead

SMA connector (which comes with a measuring channel).

If you are adding a function card:

you will need to have the 826020-002 Eurocard connector which comes with a

function card.

3) Insure that the power cord is removed from the unit

4) Remove the back panel

On subracks:

you should only remove two screws and carefully flip the panel up to avoid

breaking any wires already connected.

On instrumentation cases:

you should remove the top panel and the back panel being careful not to put

any excess strain on connections already made.

5) Install the connector spaced the same number of holes as the rest of the

connectors in the unit (there should be 6 empty holes between connectors). The

2 M2.5x6 screws (supplied -- Kaman PN 826028-146) should be used to secure

the connector firmly in place. If you are installing a measuring channel and

have and SMA pigtail it is best to wait until later to secure the SMA to the back

panel.

Page 27

27

6) Install the guide rails. Be sure to space as other guide rails in the unit are

spaced (there should be 5 empty holes between guide rails). The guide rails

snap into place in the upper and lower horizontal parts of the rack.

7) Solder in the power and ground connections. You will need to use 24AWG bus

wire to connect the power and ground of any Kaman supplied module. The back

plane template (fig. 15) shows the power and ground connections.

8) Solder in connections with insulated bus wire to the display and/or back panel

as required for the application. The wiring template in fig. 15 gives the basic

pinout for measuring channels and function cards. For third party modules

you will have to refer to the specific information provided by the manufacturer.

Typical connections are from the measuring channel out+ (C14/A14) and out-

(A16/C16) to the display module (see the section on Input Wiring to the

Display) or to an available pin on the back panel terminal block. If you are

wiring in a function card you will need to use the measuring channel outputs as

inputs to the function card. Typical function cards have inputs located on

A12/C12 for channel 1 input and A16/C16 for channel 2 input. The location of

the outputs vary depending on the type of output required.

9) Once you have carefully checked the wiring of outputs and inputs connect the

SMA to the back panel and carefully reassemble the unit.

Page 28

28

fig. 15 – Back Plane Template

Page 29

29

The Back Panel

The exact back panel configuration will depend on the specific enclosure, measuring channels,

and function cards to build a system. Figures 3, 5, and 7 show the back panel configurations

for the 3 standard rack mounted enclosure types. Exact terminal block outputs depend on the

measuring channel/function module configuration of the specific rack. See the section on

Back Panel I/O and Labeling for specific information on terminal block outputs.

Back Panel Power Input

The back panel has a universal IEC AC power input jack with on/off switch. The units can be

configured for either 120VAC or 240VAC use (Note: If you switch power input to the unit and

you have a display you must

AC input -- failure to do so will damage the unit). See the section on Input Voltage Selection

for switching the AC input. The power switch for the unit is located on the power entry

module.

also switch the display power input as it is powered directly off the

fig. 16 -- Power Entry Module

Page 30

30

Back Panel I/O and Labeling

Each back panel has terminal blocks used for I/O with special laser markings depending on

the cards installed in the rack. The half rack has one 12 position terminal block, the 3/4 and

full racks have two 12 position terminal blocks. The outputs are labeled to be consistent with

the table below where `x' refers to the channel number. Unfortunately, because of the density

of the outputs on the back plane vs. the available outputs on the terminal blocks all outputs

will not always be available on the terminal block. If you need a specific output not provided

on the back panel terminal block please call the factory for information. If you have a function

card not listed here please refer to the manual for the specific function card on terminal block

labeling information.

TB

Module label Function

8200 CHx Signal out of measuring channel

GND Ground from measuring channel

8200HT CHx Signal out of measuring channel

GND Ground from measuring channel

VC8000 +Ix Hi side current out of measuring channel

-Ix Lo side current out of measuring channel

SP8000 SHx Hi set point OC output for CHx

SLx Lo set point OC output for CHx

CEx common emitter output for CHx setpoints

GHx Go set point high for CHx

GLx Go set point low for CHx

SC8000 x+/-x Summed Output

SHx Hi set point output for CHx

SLx Lo set point output for CHx

CEx common emitter output for CHx

DY8000 PPX Peak-to-Peak or Positive peak for CHx

NPX Negative Peak for CHx

RMx RMS for CHx

SHx Hi set point output for CHx

SLx Lo set point output for CHx

CEx common emitter output for CHx

Any GND Ground

+V +15 volt from internal supply or +15V input

-V -15 volt from internal supply or -15V input

Table 3 -- Terminal Block Labeling;

Page 31

31

Back Panel Sensor Inputs

The back panels are configured with holes for panel mounted SMA connectors for coaxial

sensor inputs. Depending on the number and type of measuring channels some of the holes

may be plugged. The two rows of sensor inputs are marked A (or `Active') and B (or

`Inactive')(for dual coil or differential sensor configurations) with a number between the A/B

sensor inputs corresponding to the particular measuring channel input. For example, when

installing the unit the sensor marked `A' or `Active' designated for channel 2 should be mated

with the SMA connector on the back panel in row A, column 2. If the sensor is a single coil

sensor, row B will be plugged. Figures 3, 5, and 7 show the back panel configurations for the 3

standard rack mounted enclosure types. If additional measuring channels are added in the

field you must use coaxial cables on the sensor inputs.

fig. 17 -- Back Panel Sensor Inputs;

Page 32

32

The Front Panels

The series 8000 enclosure front panels are essentially self configuring depending on the mix of

function card and measuring channels. You will need to refer to the manual on the specific

module for information on the front panel controls. See appendix A and B for some brief

information on measuring channels and function cards. Since the MCD-8000 is essentially an

integral part of the chassis, information on its operation and calibration is included in this

manual.

Module Side Panel Labeling

The modules are normally labeled on the side panel with special information concerning the

module such as part number, sensor type, and whether the module is a master or a slave.

With the measuring systems it is important to know whether the unit is a master or slave as

the chassis are configured such that the master is the leftmost measuring channel slot and all

other measuring channel slots ( on measuring channels with the same oscillator frequency) are

configured as slaves. On function cards the dash number on the part number may be

significant as to how the card was configured.

fig. 18 -- Typical Module Side Panel Labeling;

Page 33

33

MCD-8000 and 1/8 DIN Panel Mounted Displays

The MCD 8000 is a scalable 4 digit display module designed for accurate, reliable ,

measurement of voltage or milliamps from up to 6 inputs. The panel cutout for the MCD-8000

is a standard 1/8 DIN size. This allows flexibility in choosing an appropriate meter for a

particular application. For most applications the MCD-8000 with its multi-channel scalable

input is adequate. Information on the MCD-8000 is included in this manual. If another meter

is used please refer to the specific manual on it for usage information. See Appendix C for

specifications on the MCD-8000. 1/8 DIN panel cutouts are available in either single or dual

configurations. For the single configuration use PN 814873-001 and for the dual configuration

use PN 814873-002.

fig. 19 -- Single 1/8 DIN Mounting Panel 814873-001;

Page 34

34

fig. 20 -- Dual 1/8 DIN Mounting Panel 814873-002;

Page 35

35

Using the Multi-Inputs

Select the input you wish to display by turning the front panel selector switch. The knob's

index mark indicates the selected input as labeled on the front panel lens.

fig. 21 -- MCD 8000 Front Panel;

The display is normally configured to display the measuring channel output in the numbered

position starting to the right of the display. For example, if you wish to read the output from

channel 4 you will need to set the display switch to `4' which will read the output from the

module 4 positions to the right of the display. Some function card modules contain dual channel

outputs, these modules will count as 2 positions. For example, if you had 2 measuring

channels, a dual RMS->DC converter card (dynamic module -004), and a third measuring

channel in the fourth slot, when the display switch is on channel 4 you will read the RMS

output of channel 2 and if the switch is on channel 5 you will read the measuring channel in

the fourth position to the right of the display. Some modules have no outputs that go to the

display, these modules count as 0 positions. The following table gives the displayed outputs

and count. The channel numbers are relative to the modules to the left of the function card.

Dash Displayed 1st 2nd

Module number Outputs Position

8200 any 1 ---- ---8200HT any 1 ---- ---VC8000 any 0 ---- ---SP8000 any 0 ---- ---SC8000 any 1 Summed Output ---DY8000 -001 2 Ch 1 P-P Ch 1 RMS

DY8000 -002 2 Ch 1 +Peak Ch 2 +Peak

DY8000 -003 2 Ch 1 -Peak Ch 2 -Peak

DY8000 -004 2 Ch 1 RMS Ch 2 RMS

Table 4 -- Displayed Outputs;

Page 36

36

Input wiring to the Display

The display can come in several configurations depending on the rack requirements. The basic

connectors to the back of the module are from the measuring channels to the terminal block as

shown in fig. 22 with the measuring channel output wired to the (+) terminal and the GND

wired to the (-) terminal for a particular channel. If you have a bipolar meter please request

drawing 853727 for information on special wiring.

fig. 22 -- MCD 8000 Input Wiring;

Warning: Insure that the voltage label on the meter matches

the power source input. Failure to have the

display configured the same as the power input

can result in destruction of the unit.

Connect the input sensor and power wires to the screw terminals at the back of the meter as

shown below:

fig. 23 -- MCD 8000 Power Wiring;

Page 37

37

0-10VDC Display Input Configuration

The 0-10VDC input is by far the most common display configuration. It has differential inputs

to the meter. It has a maximum resolution of 200 microvolts per count.

+/-5VDC Display Input Configuration

The +/-5VDC input option is used where a high resolution bipolar input is required. It has a

maximum resolution of 200 microvolts per count with the inputs configured single ended. This

option requires the input conditioning board (Kaman PN 853737-002) to be wired to the

display. This display is limited to a display reading of +/-9.99 (999x2 counts) since the first

digit location is taken up by the sign.

+/-10VDC Display Input Configuration

The +/-10VDC input option is used where a bipolar input with a large voltage swing is

required. It has a maximum resolution of 400 microvolts per count with the inputs configured

single ended. This option requires the input conditioning board (Kaman PN 853737-001) to be

wired to the display. This display is limited to a display reading of +/-9.99 (999x2 counts)

since the first digit location is taken up by the sign.

Page 38

38

4-20mA Display Input Configuration

The MCD 8000 can take either voltage or current inputs. When configuring for current input

you need to snap off the front panel lens to gain access to the display board. Behind the

display is a DIP switch used to set the indicators input measuring mode. You will also need to

change the wiring on the display terminal block (see section on Input Wiring to the Display) to

go into the +I and -I terminals. This mode is not normally used but may be if there is a special

request to display the output from the VC8000 or other third party module that has 0-20mA or 420mA output. When configured for current input all

current.

channels will be configured to measure

fig. 24 -- Voltage/Current Input Dip Switch;

When using the current loop type inputs, it may be desirable to install diodes on each channel

to maintain loop continuity of disengaged channels. Use 1N4002 DIODES installed in the

terminal block screw terminals or soldered onto the multi-channel input circuit board (you

must take the display apart to do this, pads are provided on the board).

fig. 25 -- Diodes For Loop Continuity in Current Mode;

Page 39

39

Calibration

The MCD-8000 calibration consists of a 2 point calibration that adjusts the offset and slope of

the resulting display. The scale factor of the MCD-8000 can be adjusted for a minimum of 200

microvolts per count (400 microvolts per count with +/-10VDC input option). In order to

calibrate the unit the following steps should be followed:

1) Select the input channel with the maximum voltage range to calibrate from. The

selector switch only changes the input. Once calibrated to a particular input the

remaining 5 channels will have the same calibration (you cannot have a different

calibration for each separate input). You must have the ability to change the

input to the meter so that you have the 2 data points near the extreme ends of

the input range.

2) Determine the display values for the 2 data points. You must insure that the

display has a minimum of 200 microvolts per count (400 microvolts per count

with +/-10VDC input option) or you will get an error when you try to calibrate.

To determine number of counts available for display divide the maximum voltage

input by 10000 (2000 for bipolar inputs). The decimal point location is

inconsequential for determining the display counts. Keep in mind that the

meter has four digits and ignore the decimal point location when determining

the number of counts. For example if you have a 0-.4 VDC sensor output you

can display .4VDC/.0002=2000 counts. If you are calibrating for English units

and .4VDC=40 mils and want to display the result in English units you would

probably not want to display the result in inches because the maximum the

display would show for the range would be .0040 so you would be losing

resolution. If you display the result in mils you may be tempted to try 40.00 but

this won't work because it requires 4000 counts and you can only use 2000

counts. This means that the best compromise is display in mils because you

can display 40.0 (losing the first digit this gives you 400 counts which is less

than the 2000 count maximum). If you must have more display resolution you

will need to increase the voltage output so that the minimum voltage/count

requirement is met. Don't forget, if you have a bipolar option the first digit gets

used by the sign so you only have +/-999 counts to work with.

Page 40

40

3) Pull off the switch cap and pop off the front of the meter panel using a small flat

head screwdriver and twisting slightly in the slot near the bottom center of the

panel.

Note: The DIP switch may either be a rocker type (press down on

appropriate end) or a slider type (slide toward appropriate

end). The drawing in fig. 26 details the adjustment

activities.

fig. 26 -- MCD 8000 Adjustment Switches;

4) Actual calibration occurs in the SCALING mode. Push down or slide towards

the bottom the left most dip switch. This will put the unit in scaling mode and

the word "LO" will appear on the display.

fig. 27 -- Process/Scaling Dip Switch;

Page 41

41

a Position the sensor or simulated input so that it is

near the low scale point (e.g. 0 mils, 0 Volts, 4 mA)

push the "ENTER" button.

b Use the "SET" button to change the value of the

flashing digit. When the flashing digit is correct,

push the enter button. The flashing digit will now

move to the next right hand digit. Continue until

all digits are correct with the rightmost digit still

flashing. (e.g. OOOO-- still flashing)

c Push both "SET" and "ENTER" buttons at the same

time to program in this scale factor. In other

words, when the indicator receives a process input

signal identical to the simulated (calibration) one it

will display the same value shown now. (e.g. 4mA =

0000).

Note: While the indicator is calibrating itself "oo" will appear in the

display. After a few seconds it will return to display "HI" (go to

step 4d) or "ERR" (see error message table).

d with "HI displayed change the input to simulate

the +Full scale (High) (e.g. 20mA). Repeat steps as

shown in steps a,b, and c changing the digits to

represent the Full Scale desired display (e.g. 7500).

When complete the indicator will then go to the

decimal point position.

5) with the decimal points displayed

a push the "SET" button until desired position is

displayed.

b Push "SET" and "ENTER" buttons at the same time

to program into memory.

10) Return the "PROCESS/SCALING" dip switch to the PROCESS position. Replace

the front lens.

Page 42

42

Note: Pushing both the "SET" and "ENTER" button at the same

time always causes the indicator to recalibrate itself to the

given input and what is on the display at that moment.

As a protective measure, if scaling changes are made and

not terminated this way no recalibration will occur,

previous values will remain.

Note: As a further protective measure, the "SET" and "ENTER

buttons are not functional unless the PROCESS/SCALING

switch is in the SCALING position.

fig. 28 -- Button Function Legend;

Table 5 -- MCD-8000 Error Message Table;

Page 43

43

Appendix A -- Measuring Channel Configuration

The heart of the system is the measuring channel. Currently Kaman offers a wide variety of

signal conditioning modules and inductive sensors. The table below is a brief description of

ranges and display parameters for the standard line of sensors. Please refer to the KDM-8200

instruction manual for further information on calibration and usage of the inductive sensors.

Table 6 --

Series 8000 Sensor Family;

Page 44

44

Basic Measuring Channel Configuration

Most of the displacement measuring channels offered by Kaman have the same pinout and

front panel configuration. They utilize inductive bridge technology which has a high sensitivity

and is generally insensitive to contaminants such as dust, dirt, and oil. If adding additional

measuring channels to an existing unit you will need to be careful to wire the `Sync out' pin

from a master modules to the `Sync in' pin on all other module which must be configured as

slaves to avoid beat note interference problems. Please see a Kaman 8200 user manual (PN

860059), 8200 differential supplement (PN 860067), or 8200 High Temp manual (PN 860064)

for more specific information on the particular sensor system that you have.

Page 45

45

Appendix B -- Function Card Configuration

Any series 8000 enclosure can be configured with optional function cards. Function cards

available include Voltage to Current conversion (for 4-20mA outputs), dual set points,

summation/comparator (for thickness applications), dynamic measurement (RMS->DC

conversion or Peak measurements), and a prototyping card. Each function card will have its

own manual describing pinouts and usage. Please refer to the appropriate function card

manual for specific questions.

Caution: Be careful when connecting power, incorrect connections may damage your system.

The following pages briefly describe some of the function cards available along with the pinout

for reference.

fig. 30 -- Module Reference Dimensions;

Note: All dimensions are

in inches

Page 46

46

VC8000 Voltage to Current Converter Configuration

The VC8000 was designed to convert a 0-5 volt DC input to either a 0-20mA or 4-20mA

output. The isolated loop supply and current output make it ideal for noisy industrial

environments. Please see the VC8000 user manual (PN 860061) for more specific information.

Page 47

47

SC8000 Summation/Comparator Configuration

The SC8000 Summation/Comparator module was designed for use when a direct reading of ID,

OD, or thickness was desirable. The module performs an analog summation on the inputs and

has an integral window comparator for monitoring out of tolerance conditions. Please see the

SC8000 user manual (PN 860062) for more specific information.

Page 48

48

DY8000 Dynamic Module Configuration

The DY8000 Dynamic Module was designed to take dynamic inputs such as shaft runout,

vibration or ultrasonic weldhorn amplitude and convert them to a DC voltage easily readable

and quantifiable on the display module. The DY8000 can perform either single peak-to-peak,

dual positive peak, dual negative peak, or dual RMS measurements. Integral progressive

comparators allow for easy monitoring of out of tolerance conditions. Please see the DY8000

user manual (PN 860048) for more specific information.

Page 49

49

SP8000 Dual Set Point Configuration

The Dual Set Point module was designed with two separate channels of either window or

progressive comparator operation. The configuration allows for alarm and shutdown with Hi,

Lo, or Go outputs. Please see the SP8000 user manual (PN 860090) for more specific

information.

Page 50

Appendix C -- MCD-8000 Display Specifications

MCD 8000 Functional Specifications

Input Range: 0-10VDC or 0-20mA

Note: Kaman Special input module (PN 853727) allows either a

+/-5VDC or +/-10VDC input to the meter but changes it

to be a single ended input.

Sensitivity: 200 microvolts/count or 0.4microamps per count

Note: on units with the Kaman input module (PN 853727) with a

+/-10VDC input, the display will only have 400 microvolt

per count sensitivity.

Input Impedance: Voltage mode >=1 Megohm

Current mode 5 ohms

Note: on units with the Kaman input module (PN 853727) with a

+/-10VDC input, the display will have a 20k ohm input

impedance.

A/D read rate: 2 per second nominal

Power: 115VAC +/-10%, 50-60 Hz; 230 VAC +/-10%, 50-60Hz

switch selectable

50

Page 51

MCD 8000 Performance Specifications

Reference Operating Conditions (ROC):

+/-10% line voltage

23+/-2oC ambient temperature

<80% RH non-condensing

Accuracy (at ROC): 0.02% of reading +/-1 count

Noise Rejection:

NMRR: >-60dB @ 50/60Hz, +/-.1Hz

CMRR: >-120dB @ 50/60Hz, +/-.1Hz with 250 ohm unbalanced

Overload Protection:

Power lead to ground: 1500VDC or ACRMS

Across inputs: Voltage up to 250VDC or VAC for 1 min., +V to -V

Current up to 150mADC or mAAC for 1 min., +I to -I

Stability with Temperature: Zero 1uV/oC, Span 0.01% reading/oC

Stability with Time: 10 counts per year maximum

Repeatability: +/- 1 count

MCD 8000 Environmental/Physical Specifications

Operating Range:

Temperature: 5 to 45oC

Relative Humidity: 10-80% RH non-condensing

Storage Range: -40 to 65oC

Power:

115VAC +/-10%, 50-60 Hz

230VAC +/-10%, 50-60 Hz

51

Page 52

Appendix D -- Replacement or Expansion Parts

Rack Parts:

PN Description

814873-001 Single meter 1/8 DIN 21T Wide Front Panel

814873-002 Dual meter 1/8 DIN 21T Wide Front Panel

853737-001 MCD-8000 1/8 DIN Replacement Meter (1-6 label)

853737-002 MCD-8000 1/8 DIN Replacement Meter (7-12 label)

822238-C001 Power Cord 110V

814639-001 Single Slot Blank Front Panel

814639-002 Dual Slot Blank Front Panel

826029-001 Thumbscrews (4 per panel required)

853503-001 Rack Side Euroconnector with single SMA connector

853503-002 Rack Side Euroconnector with dual SMA connectors

826020-002 Euroconnector for function cards

826019-001 Guide Rails (2 per slot required)

850643-004 Accessory Kit with Feeler Gauge

850643-005 Accessory Kit without Feeler Gauge

820222-001 Hole Plugs (for unused sensor inputs)

853727-001 Bipolar Meter Conversion Kit

Function Card Modules:

PN Description

853557-001 SC8000 Summation/Comparator Module (C-(A+B) operation

853558-001 VC8000 Single Voltage to Current Module (4-20mA output)

853558-002 VC8000 Dual Voltage to Current Module (4-20mA output)

853717-001 SP8000 Dual Set Point Module

853669-001 DY8000 Dynamic Module Single Channel PP/RMS

853669-002 DY8000 Dynamic Module Dual Channel Positive Peak

853669-003 DY8000 Dynamic Module Dual Channel Negative Peak

853669-004 DY8000 Dynamic Module Dual Channel RMS

Note: There is a wide variety of measuring channels please

see a Kaman Sales Brochure for replacement

measuring channels. Be sure to specify if unit is

to be a master or a slave module.

52

Page 53

53

Series 8000 Sensor Family

SENSOR MEASURING TYPICAL ANALOG DISPLACEMENT FULL

SCALE

MODELS RANGE OFFSET VOLTAGE SENSITIVITY MCD8000

Inch (mm) Inch (mm) Inch (mm) mV/mil (mV/mm)

English (Metric)

.5SU/.5U2 .020 (0.5) .002 (0.05) 2.00 (0.5) 100 (1000) 20.00 (_.500)

1U1/1U2 .040 (1.0) .006 (0.13) 0.40 (1.0) 10 (1000) _40.0 (1.000)

2S1 .080 (2.0) .015 (0.38) 0.80 (2.0) 10 (1000) _80.0 (2.000)

2UB1 .080 (2.0) .015 (0.38) 0.80 (2.0) 10 (1000) _80.0 (2.000)

2U2 .100 (2.5) .025 (0.63) 1.00 (2.5) 10 (1000) 100.0 (2.500)

3U1 .120 (3.0) .020 (0.51) 1.20 (3.0) 10 (1000) 120.0 (3.000)

4S1 .160 (4.0) .020 (0.51) 1.60 (4.0) 10 (1000) 160.0 (4.000)

6U1/6U2 .240 (6.0) .035 (0.89) 2.40 (0.6) 10 (100) 240.0

(_6.00)

15U1/15U2 .600 (15) .150 (3.81) 0.60 (1.5) 1 (100) _600.

(15.00)

30U1/30U2 1.20 (30) .300 (7.5) 1.20 (3.0) 1 (100) 1200.

(30.00)

60U1 2.40 (60) .600 (15) 2.40 (.60) 1 (10) 2400.

(_60.0)

15N (diff) +/-.009 (.25) .006 (.15) +/-9.0 (9.0) 1000 (36000) +/-

9.00. (+/-.250)

20N (diff) +/-.009 (.25) .006 (.15) +/-9.0 (9.0) 1000 (36000) +/-

9.00. (+/-.250)

1925(HT) .050 (1.27) .005 (.127) 2.50 (2.5) 50 (2) _50.0

(_1.27)

1925M(HT) .040 (1.0) .002 (.05) 2.00 (2.0) 50 (2) _40.0

(_1.00)

1950(HT) .150 (3.81) .01 (.254) 1.50 (1.50) 10 (400) 100.0

(_3.81)

1950M(HT) .100 (2.54) .005 (.127) 1.00 (1.00) 10 (400) 100.0

(_2.54)

1975(HT) .200 (5.00) .010 (.254) 2.00 (2.00) 10 (400) 200.0

(_5.00)

1975M(HT) .100 (2.54) .005 (.127) 1.00 (1.00) 10 (400) 100.0

(_2.54)

Note: "_xx.x" indicates that the left most meter display character (for higher

resolution) is not available at the scale factor selected due to limitations

of the meter. The meter has a minimum input requirement of 200

microvolts per count with a 10V total range except in bipolar +/-10V

input systems where the minimum input requirement is 400 microvolts

per count.

Page 54

Appendix E -- Warranty and Repair

Kaman Instrumentation Operations

Products

Standard Limited Warranty

Products of Kaman Instrumentation are warranted to be free from defects in materials

and workmanship when installed and operated in accord with instructions outlined in

the instruction manual.

Kaman Instrumentation's obligation under this warranty shall be limited to repair or

replacement (at the discretion of Kaman Instrumentation) of the defective goods

returned to Kaman's plant within one (1) year from date of shipment. Extreme

environment sensors are limited to the maximum operating temperature as specified

within the most current Kaman Measuring Systems Extreme Environment Systems

data sheets.

This warranty is valid except when the products have been subject to misuse, accident,

negligent damage in transit or handling, or operation outside the conditions prescribed

in the data sheet or instruction manual. This will be determined by Kaman

Instrumentation personnel.

In no event shall Kaman be liable for incidental or consequential damages, including

commercial loss, resulting from any article sold under this Agreement.

In the event Buyer fails to limit to Kaman's warranty set forth above, any express or

implied warranty Buyer may make with respect to any product of which any article

sold thereunder is a component, Buyer shall indemnify and hold Kaman harmless

from any and all liability, costs and expenses to which Kaman may be subjected as a

result of Buyer's failure to so limit its express or implied warranties.

THIS WARRANTY IS EXCLUSIVE AND IS MADE IN LIEU OF ALL OTHER

WARRANTIES; AND THOSE IMPLIED WARRANTIES, INCLUDING SPECIFICALLY THE

WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY EXPRESSLY LIMITED TO ONE (1) YEAR DURATION.

NO MODIFICATION OR ALTERATION OF THE FOREGOING WARRANTY AND

LIMITATION OR REMEDIES PROVISIONS SHALL BE VALID OR ENFORCEABLE

UNLESS SET FORTH IN A WRITTEN AGREEMENT SIGNED BY KAMAN AND THE

BUYER.

Kaman Instrumentation Warranty No. 7A

54

Page 55

55

Customer Service Information

Should you have any questions regarding this product, please contact an applications

engineer at Kaman Measuring Systems 800-552-6267. You may also contact us

through our web site at: www.kamansensors.com.

Service/Repair Information

In the event of a malfunction, please call for return authorization:

Customer Service/Repair Kaman Measuring Systems:

860-632-4442

Loading...

Loading...