Page 1

KAM® E-IAS™

ELECTRIC ISOKINETIC AUTOMATIC SAMPLER

PER API 8.2, ASTM D4177

AND ISO 3171

User Manual

EIASMANUAL0719

TEL +1 713 784-0000

FAX +1 713 784-0001

Email Sales@Kam.com

KAM CONTROLS, INC.

3939 Ann Arbor Drive

Houston, Texas 77063 USA

www.KAM.com

An ISO 9001 certified company

Page 2

TABLE OF CONTENTS

SECTION TITLE PAGE

1 Introduction 2

•Available Models and Mounting Options 2

2 Specifications 3

3 Installation 4

•Installation Considerations 4

• Fixed Insertion Installation 4

• Insertable Models Installation 5

• Wiring Diagram 10

4 Maintenance 11

•Parts List 11

•Replacing Seals and O-rings 12

CAUTION:

When installing the E-IAS™ sampler in a pipeline containing petroleum products,

petro-chemicals, waste waters with the presence of pressure & temperature, and high-pressure

steam refer to the Pipeline Operators’ “Health, Safety and Environmental Policy Procedures” to

ensure safe installation.

KAM CONTROLS, INC. reserves the right to make changes to this document without notice.

EIASMANUAL 0918

1

KAM CONTROLS, INC.

Page 3

INTRODUCTION

AVAILABLE MODELS and MOUNTING OPTIONS

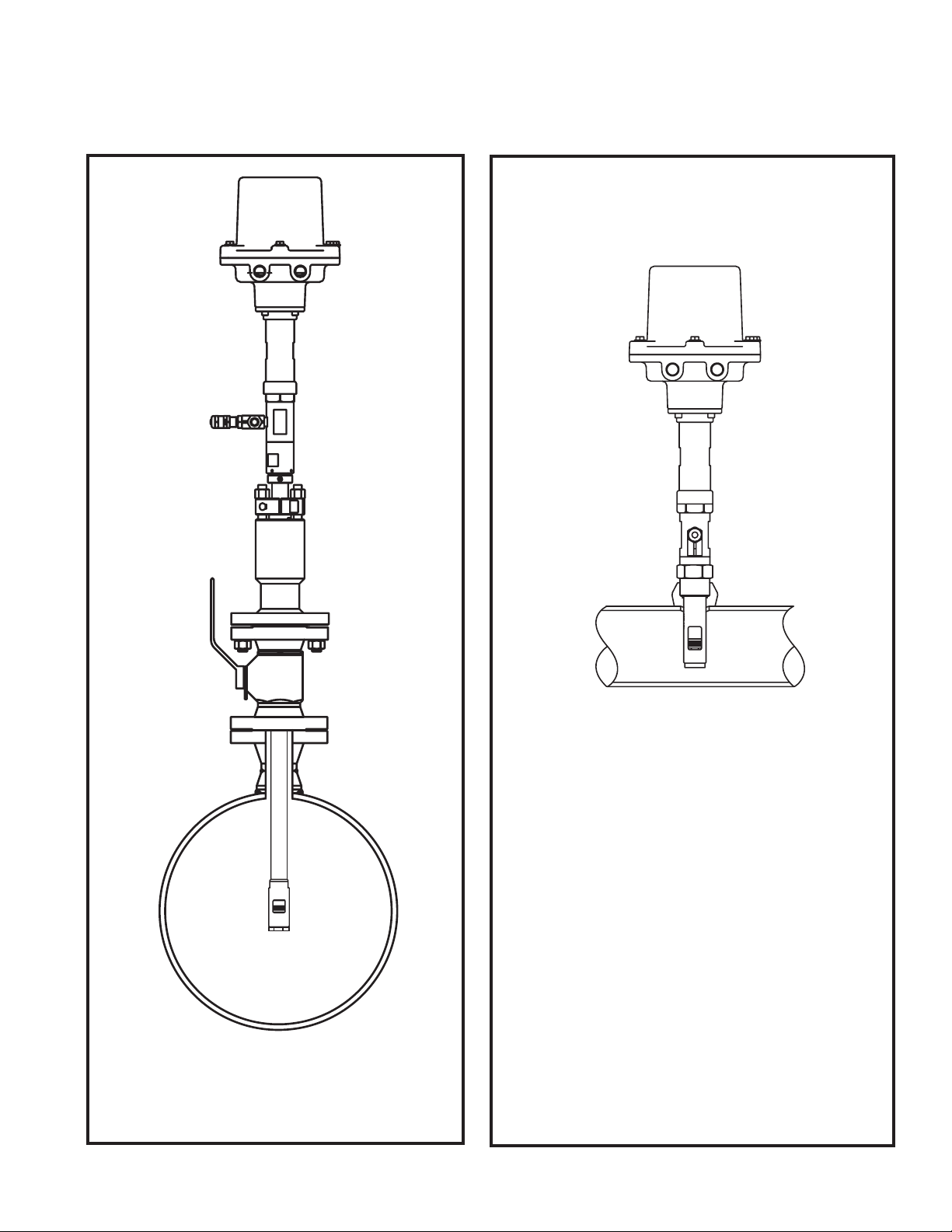

FIG. 1-2FIG. 1-1

Full-opening

Ball Valve

Option 1: Insertable/retractable E-IAS™

with 2”, 3”, or 4” flanged seal housing or 2" MNPT

Option 2: Fixed insertion E-IAS with 1.25" NPT

or 2", 3" or 4" flange

EIASMANUAL 0918

2

KAM CONTROLS, INC.

Page 4

SPECIFICATIONS

Media: Liquid hydrocarbons, including crude oil and condensate

Materials: Wetted parts SS316, Peek

Standard O-rings Viton

Bite size: 0.5, 1, 1.5 or 2 cc

Sample rate: 20 samples/minute max

Viscosity: 1-500 cSt

Pipe size: 1 – 36”

Max pressure: 285 psi

Temperature: -40º to 350ºF (-40º to 177ºC)

Electrical

Requirements: 120 VAC 2.0A RMS

50/60 Hz single phase

-20 ºC to +45 ºC

Motor: High-torque stepper motor

EIASMANUAL 0918

3

KAM CONTROLS, INC.

Page 5

INSTALLATION

PRIOR TO INSTALLATION

Before installing the E-IAS™ Sampler, thoroughly inspect to ensure that unit was not damaged during transit.

KAM CONTROLS recommends that the E-IAS™ Sampler be installed 2 to 4 pipe diameters downstream of a

KAM® static mixer and in conjunction with a KAM® ML™ Measurement Loop. At the time of installation the

pipeline pressure needs to be reduced to under 100 psi in order to safely install the E-IAS™ Sampler.

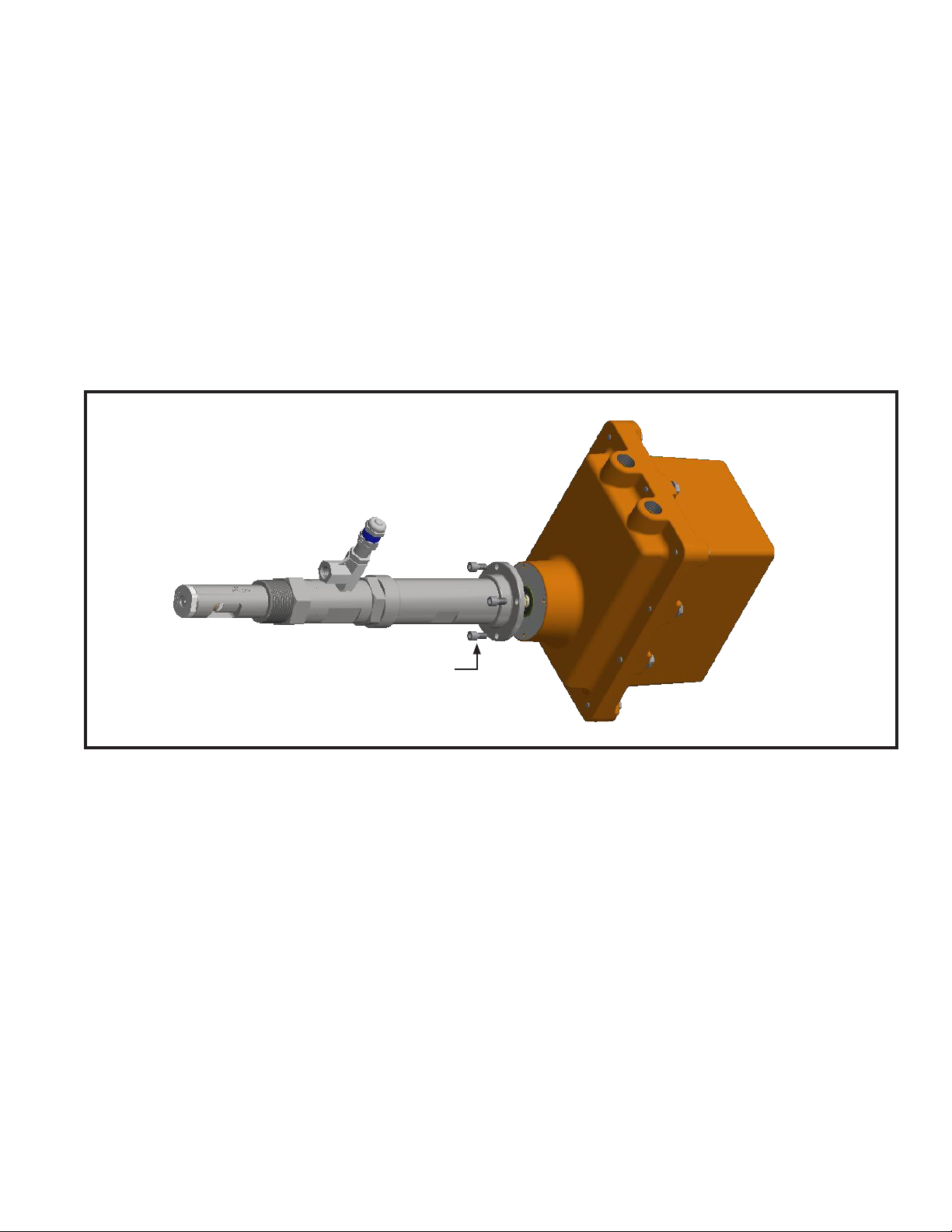

The KAM® E-IAS is shipped with the motor and housing separate from the probe body. KAM recommends full

installation of probe (including insertion on insertable models) prior to attaching motor housing to probe body. If

motor housing is attached at time of installation, detach prior to installation by removing the (4) hex screws at the

bottom of the housing with a 3/16 Allen wrench. (Fig. 3-1)

FIG. 3-1

Prior to installation,

remove hex screws with a 3/16 Allen wrench

FIXED INSERTION MODELS INSTALLATION

In horizontal lines, the E-IAS™ Sampler should be installed with the probe horizontally oriented at 3 or 9 o’clock.

KAM recommends using liquid pipe sealant rather than Teflon tape on all threaded connections.

Insertion distance/shaft length is set at factory. After installation of probe body on the line, attach the motor housing

to probe body using four hex screws and a 3/16 Allen wrench. (Fig. 3-1).

Follow wiring instructions on page 10 of this manual.

EIASMANUAL 0918

4

KAM CONTROLS, INC.

Page 6

INSTALLATION

INSERTABLE/RETRACTABLE MODELS INSTALLATION

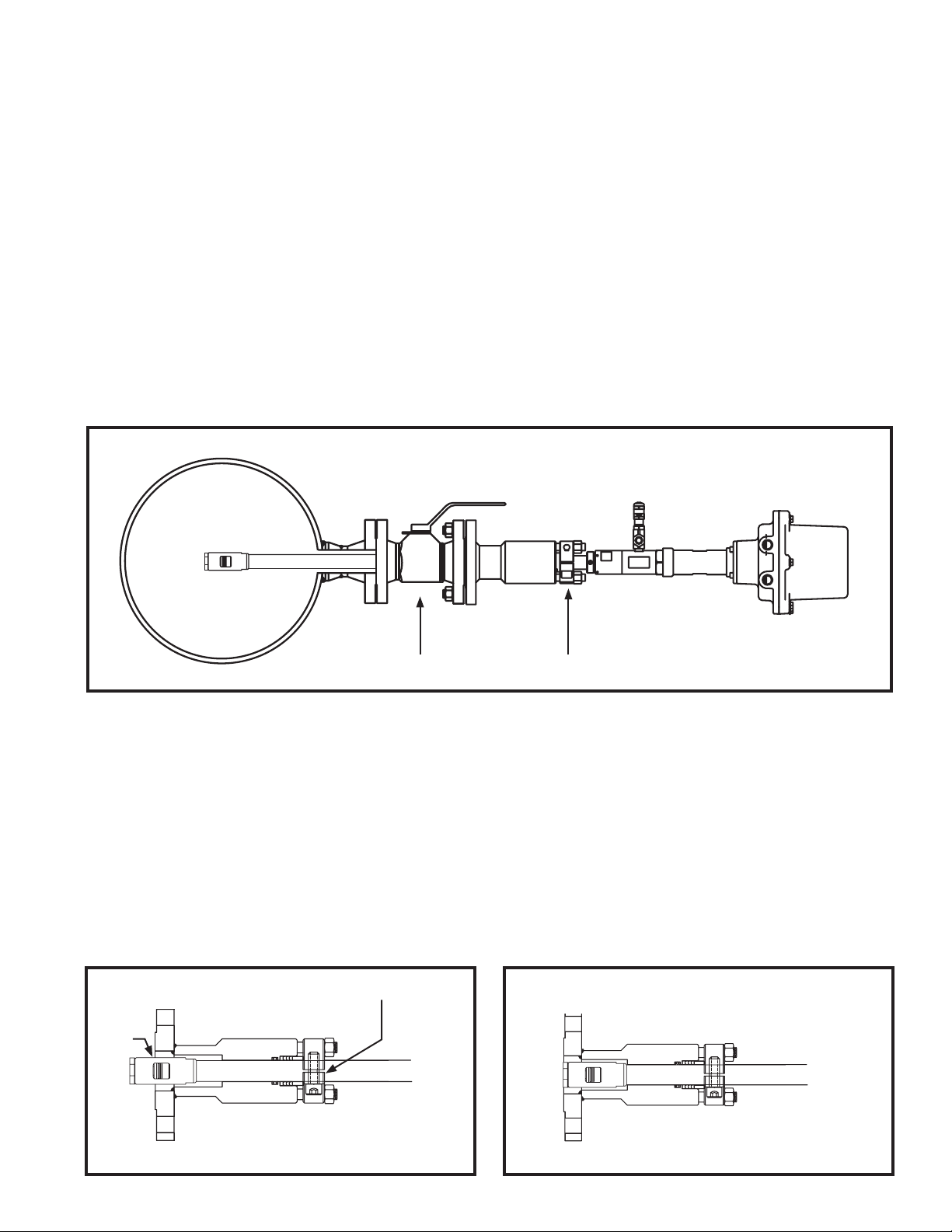

In horizontal lines, the E-IAS™ Sampler should be installed with the probe horizontally oriented at 3 or 9 o’clock.

Fig. 3-2.

The E-IAS™ Sampler Probe should be inserted so that the middle of the sampling window is in the 20% center area

of the pipe. Fig. 3-2. It is the user’s responsibility to ensure that the E-IAS™ Sampler is placed in the most representative point in the flow profile.

Insertable models of the E-IAS™ Sampler should be installed according to Fig. 3-2. The Full-Opening Ball Valve is

used to isolate the E-IAS™ Sampler from the pipeline during installation or removal. The Seal Housing of the E-IAS™

Sampler allows the Sampler Probe to be inserted in and out of the pipe under pressure and flow conditions up to 100

psi.

FIG. 3-2

Full-opening

Ball Valve

Hex socket cap screws

Before mounting the E-IAS™ Sampler on the Full-Opening Ball Valve, determine the insertion length required.

1.

Lay the E-IAS™ Sampler on the ground or a table.

Loosen Hex Socket Cap Screws on the Locking Collar using a 3/8" Allen wrench. Fig. 3-2. This will allow the E-

2.

IAS™ Sampler Shaft to slide through the Seal Housing.

3.

Push the E-IAS™ Sampler Shaft though the Seal Housing until the middle of the sampler window chamber is

aligned with the end of the Seal Housing. Fig. 3-3.

4.

Use a Sharpie or other permanent marker to mark the shaft at the edge of the Locking Collar. (Do not use anything sharp to mark the shaft. This will create grooves that will damage the O-rings in the Seal Housing.)

FIG. 3-3 FIG. 3-4

Align

here

Mark Here

EIASMANUAL 0918

5

KAM CONTROLS, INC.

Page 7

INSTALLATION CONTINUED

Pull Shaft back until the Probe is all the way within the Seal Housing and tighten the Hex Socket Cap Screws on

5.

the Locking Collar. This will prevent the E-IAS™ Sampler Shaft from sliding and the Probe will be protected inside

the Seal Housing until and during installation. Fig. 3-4.

6.

Measure the distance (D1) from the top of the main pipe to the end of the connection where the E-IAS™ Sampler

is going to be installed. Fig. 3-5.

FIG. 3-5

D1 D1

Calculate the insertion distance using the following formula:

7.

TID – Total Insertion Distance

D1 – Distance from the top of the valve to the pipe

WT – Pipe Wall Thickness

TD – Threaded Depth

ID – Inside Diameter

For Flanged Seal Housing

Total Insertion Distance (TID)= D1 + WT + (Pipe ID x 7/16) + Seal Thickness

Example: D1= 14"

WT= .25"

ID = 8.125"

Seal Thickness=1/8"

TID=14 + .25 + (8.125 x 7/16) + 1/8

14 + .25 + 3.55 + .125=17.93

EIASMANUAL 0918

6

KAM CONTROLS, INC.

Page 8

INSTALLATION CONTINUED

For 2" MNPT Seal Housing

TID cannot be calculated until the Seal Housing is screwed into place. Bolt or Screw the E-IAS™ Sampler to the

Valve or designated installation location. (KAM CONTROLS recommends liquid thread sealant and not teflon tape

for the threaded E-IAS™ Sampler.)

You must then measure the Threaded Depth (TD) into the Valve or connection in order to calculate TID. You can do

this by measuring the distance from the edge of the Valve or female connection to the top of the Seal Housing

body and subtracting that distance from 5.25". Fig 3-6.

FIG. 3-6

Threaded Depth

Measuring Points

Total Insertion Distance (TID)= D1 + WT + 7/16 Pipe ID -Threaded Depth (TD)

For example: If the measured distance from the top of the Valve and the top of the Seal Housing body is 4.65"

you should calculate the threaded depth (TD) by subtracting 4.65" from 5.25". (5.25-4.65=0.6)

8.

You are now ready to calculate the TID.

TID= D1 + WT + (Pipe ID x 7/16) - TD (from page 8)

Example: D1= 14"

WT= .25"

ID = 8.125"

TD=.6"

TID=14 + .25 + 3.55 - .6=17.2

EIASMANUAL 0918

7

KAM CONTROLS, INC.

Page 9

INSTALLATION CONTINUED

9.

For all insertable models, use the calculated TID and make another mark on the shaft, measuring from

First Mark. Fig 3-7.

FIG. 3-7

TID

First Mark Second Mark

If you have an E-IAS™ Sampler with a Flanged Seal Housing, you may now attach it to the Valve on the pipeline.

10.

Slowly open Full Opening Valve and check for leaks.

11.

Loosen Hex Socket Cap Screw on the Locking Collar.

12.

13.

Align Window of the E-IAS™ Sampler to face the flowing stream. This can be done by aligning the Flow

Indicators in parallel with the main pipe. The Flow Indicators are located at the bottom of the Actuator

Housing.

Push the E-IAS™ Sampler in until the Second Mark is at the top edge of the Locking Collar. Fig. 3-8.

14.

FIG. 3-8

Second Mark

EIASMANUAL 0918

8

KAM CONTROLS, INC.

Page 10

INSTALLATION CONTINUED

Re-tighten the Hex Socket Cap Screw.

15.

16.

Tighten the Hex Nuts holding the Locking Collar from ¼ to ½ of a turn. The Hex Nuts holding down the Locking

Collar should never be over tightened. Their major function is to apply light pressure on the Chevron Packing to

ensure a secondary seal between the Seal Housing Body and the Insertion Shaft. Fig. 3-9.

FIG. 3-9

PRV

Locking Collar

Hex Nuts

Hex Socket Cap Screw

The PRV arrives set at the maximum cracking pressure for the spring installed (normally a yellow spring for 750

1 7.

psi). If the maximum pressure does not exceed 350 psi, set the cracking pressure to the lowest cracking pressure for the PRV by twisting the cap 8 turns counter-clockwise. The PRV is going to have the highest

cracking pressure when the cap is screwed all the way in and the lowest cracking pressure when the cap is

almost all the way out. If your line pressure is within the range of the cracking pressure of the PRV, take the following steps to set the correct cracking pressure:

a) Slowly turn the cap counter-clockwise until liquid starts to come out of the PRV outlet.

b) Turn the cap two turns clockwise to stop the leak and set the PRV cracking pressure 200psi above the

current pressure.

c) Tighten lock nut against the cap.

d) Lock wire cap and body together to maintain set pressure.

EIASMANUAL 0918

9

KAM CONTROLS, INC.

Page 11

INSTALLATION CONTINUED

*

Th

Th

unles

begining of the previous pulse

WIRING DIAGRAM

FIG. 3-10

Supply Voltage

94-135VAC 3Amps

6A fast acting fuse

recomended.

Sampler

Controller

or

PLC

NOTE: the pulse duration should be between

The pulse duration should be between 200 ms and 1000ms.

200 ms and 1000 ms. The minimum time between

e minum time between pulses is 3 seconds.

e E-IAS will start the actuation to take a sample with every pulse

pulses is 3 seconds.

s it receivea a pulse before 3 seconds have passed from the

L

N

GND

GND

+ 5-24V DC Pulse *

L

N

GND

D2 (-)

D2 (+)

D1 (-)

D1 (+)

EIASMANUAL 0918

10

KAM CONTROLS, INC.

Page 12

MAINTENANCE

1

2

REVISION HISTORY

REV DESCRIPTION DATE

A

New Drawing

During normal operation of the KAM® E-IAS™ Sampler, some seals will wear. In order to ensure continuous

accurate sampling, KAM CONTROLS recommends replacing the seals on your E-IAS™ Sampler every six months.

A complete kit with all the E-IAS™ Sampler O-rings, seals, etc. can be ordered by contacting KAM CONTROLS at

sales@kam.com and requesting Seal Kit 361300 or by calling +1 713-784-0000 or faxing your request to

+1 713-784-0001.

FIG. 4-1 KAM® E-IAS™ SEAL KIT PART NUMBER 361300

1

3

5

9

8

4

7

6

ITEM QTY PART NUMBER DESCRIPTION

1 1 361150 Seal Bushing Assembly #1(2 internal O-rings)

2 1 361192 Seal Bushing Assembly #2 (3 internal O-rings)

3 1 360411 3/4" Plunger Piston Seal

4 1 360425 Check Spring

5 1 360390 Suction Spring

6 2 150022 2-022 O-ring 75 Durometer

7 1 150026 2-026 O-ring 75 Durometer

8 1 150013 2-013 Viton O-ring 75 Durometer

9 1 150004 2-004 Viton O-ring 75 Durometer

6

2

EIASMANUAL 0918

11

KAM CONTROLS, INC.

Page 13

MAINTENANCE CONTINUED

REPLACING SEALS AND O-RINGS

The seal/O-ring replacement process requires the following

materials:

FIG. 4-3

• 3/16" Allen wrench

• 9/16", 11/16", 1 1/2", 1 3/4" wrenches, or (2) adjustable

wrenches. Do not use pipe wrenches on the E-IAS.

• Pick or hook to removed old O-rings

• Solvent/part washer

• Grease for O-ring lubrication

• Loctite 242

Prior to removing the probe from the pipeline,

1.

disconnect the probe body from the motor assembly.

Socket

Cap Screws

Using a 3/16" Allen wrench, remove the (4) socket cap

screws connecting the probe to the motor assembly.

(Fig. 4-3.) Pull the probe free of the motor assembly.

2.

Remove the E-IAS™ probe body from the pipeline.

Once you’ve removed your E-IAS™ Sampler from the

3.

Probe

Body

pipeline, clean all surfaces as much as possible.

Remove the sampling section of the probe by placing a 1-1/2" wrench on the wrench Flats of the sample chamber

4.

and turning the bottom section of the probe counterclockwise using a 1-3/4" wrench on the 1-3/4" hex section

of the probe. (Fig. 4-4)

Motor

Assy.

FIG. 4-4

Sampling Section

1 3/4" Hex

Sample Chamber Wrench Flat

EIASMANUAL 0918

12

KAM CONTROLS, INC.

Page 14

MAINTENANCE CONTINUED

Hold the sample shaft using a 9/16" wrench, while unscrewing the sample piston using an 11/16" wrench. Be

5.

careful not to lose the small check valve and spring located inside the sample piston. They are not fixed in place.

FIG. 4-5

Sample Piston

9/16" Wrench Flat

Spring and Check Valve

11/16" Wrench Flat

6.

Using a 1 1/2" wrench, remove the Sample Chamber by turning it counterclockwise while holding the Linear

Actuator with a 1 3/4" wrench. (Fig. 4-6)

NOTE: There are (2) Seal Bushing Assemblies in either end of the Sample Chamber. These may come loose or

stick to the shaft when Sample Chamber is removed.

FIG. 4-6

Linear Actuator

Sample Chamber

1 1/2" Wrench Flat

7.

Remove Seal Bushing Assemblies from both sides of the Sample Chamber using a small hook or pick. (Fig. 4-7)

Remove internal 2-022 O-rings inside both sides of the sample chamber.

8.

Clean Chamber with a solvent to remove any oil.

9.

FIG. 4-7

Seal Bushing Assemblies

1 3/4" Wrench Flat

2-022 O-rings

EIASMANUAL 0918

13

KAM CONTROLS, INC.

Page 15

MAINTENANCE CONTINUED

10.

Install new 2-022 O-rings inside both sides of the Sample Chamber.

Apply a small amount of grease around the inside of the installed 2-022 O-rings.

11.

12.

Install new Seal Bushing Assemblies inside both sides of the Sample Chamber.

Apply grease around the inside of the new Seal Bushing Assemblies.

13.

14.

Insert the Linear Actuator back through the Sample Chamber. (Fig. 4-8) The fit should be tight and may require

some force. Ensure that both Seal Bushing Assemblies are in place inside the Sample Chamber when done.

15.

Apply Loctite 242 to the threads and tighten in place using 1 1/2" wrench and 1 3/4" wrench.

FIG. 4-8

1 3/4" Wrench Flat

1 1/2" Wrench Flat

Loctite 242

16.

Replace 2-013 O-ring from the sample shaft. (Fig. 4-9)

Replace 2-004 O-ring on the sample check valve.

1 7.

18.

Replace spring if necessary.

19.

Insert check and spring back into the sample piston.

Clean the sample shaft threads.

20.

21.

Screw the sample piston on to the sample shaft by holding the shaft with a 9/16" wrench and using an 11/16"

wrench to turn the sample piston.

FIG. 4-9

EIASMANUAL 0918

2004 O-ring

Spring

14

2013 O-ring

Sample Shaft Threads

KAM CONTROLS, INC.

Page 16

MAINTENANCE CONTINUED

22.

On the remaining sampling section, remove the Bottom Seal Holder by using a 1 1/8" wrench. (Fig. 4-10)

FIG. 4-10

Bottom Seal Holder

1 1/8" Wrench Flat

23.

Using a 5/32" Allen wrench remove the Cover holding the plunger seal. (Fig. 4-11)

24.

Inspect the Spring and Check Valve for damage and

replace if necessary.

25.

Using solvent clean the inside threads of the Cover.

26.

Place Check Valve and Spring back in place.

Install a new Plunger Seal.

2 7.

28.

Clean the outside Cover threads and apply a small

amount of blue Loctite 242 or equivalent.

FIG. 4-11

Cover

Plunger Seal

Spring and

Check Valve

29.

Screw the cover back in place using 5/32" Allen

wrench

NOTE: Do not alter small set screw on flat of Bottom Seal Holder threads. This determines sample

bite volume. To change, please consult factory.

Bottom

Seal Holder

EIASMANUAL 0918

15

KAM CONTROLS, INC.

Page 17

MAINTENANCE CONTINUED

30.

Replace the 2-026 O-ring located inside sampling section of the probe, at the same level as the hex section.

(Fig. 4-12)

Apply grease to the 2-026 O-ring previously installed.

31.

32.

Apply Loctite 242 to the Sample Chamber thread.

33.

Screw the sampling section back on to the sample chamber by holding the sample chamber with 1 1/2" wrench

and turning the bottom section of the probe clockwise using a 1 3/4" wrench.

FIG. 4-12

2-026 O-ring

Sample

Chamber

34. Install probe body on pipeline and then attach the motor assembly using a 3/16" Allen wrench and the (4) 1/4" x

1/2" socket cap screws. (Fig. 4-13)

FIG. 4-13

Socket Cap

Screws

EIASMANUAL 0918

16

KAM CONTROLS, INC.

Loading...

Loading...