INSTALLER USER

&

MANUAL

For

Denia 14 - 14D & Mia 16 - 16D

29

GB

Dear Customer,

We thank you for having chosen one of our products, the fruit of technological experience and of continual research for

a superior quality product in terms of safety, dependability, and service.

In this manual you will nd all the information and useful suggestions to use your product with the maximum safety

and efciency.

• Incorrect installation, incorrectly performed maintenance, improper use of the product release the manufacturer from

every eventual damage derived from the use of the stove.

• The unit cannot be used as an incinerator. Do not use fuels other than pellets.

• This manual has been realized by the manufacturer and constitutes an integral part of the product and must remain

with it during its entire lifetime. If the product is sold or transferred, be sure that the booklet is present since the

information contained in it are addressed to the buyer, and to all those persons of various titles who complete the

installation, use and maintenance.

• Carefully read the instructions and the technical information contained in this manual, before proceeding with the

installation, use, and any operation on the product.

• The observance of the indications contained in the present manual guarantees the safety of people and the product,

the economy of use and a longer functioning lifetime.

• Although the carefully studied design and the risk analysis done by our company has permitted the realization of a

safe product, in any case, before effecting any operation on the stove, it is recommended to keep said manual available and pay scrupulous attention to the instructions written therein.

• Be very careful when moving the ceramic details where present.

• Check the precise atness of the pavement where the product will be installed

• The wall where the product will be placed must not be constructed in wood, or in any case, made of an inammable

material, and in addition it is necessary to maintain a safety distance.

• While the stove is in operation, several parts of the stove (door, handle, sides) can reach high temperatures. Therefore pay attention and use the proper precautions, above all in the presence of children, elderly or disabled persons,

and animals.

• Assembly must be performed by authorized persons (Authorized Assistance Center).

• Diagrams and drawings are furnished for the purpose of illustration; the manufacturer, with the intent of pursuing a

policy of constant development and renewal of the product can, without any notice, make any modications that

are believed opportune.

• When the stove is working at its maximum speed, it is strongly suggested to wear gloves while handling with the

door for pellets loading and the door handle.

• It is prohibited to install in bedrooms or in explosive environments.

• Only use replacement parts recommended by the supplier.

In the event of a fire, disconnect the power supply, use an extinguisher and call the fire fighters if necessary.

After that contact the Authorized Assistance Center.

Never cover the body of the stove in any way or obstruct the openings placed on the upper side

when the device is operating. All our stoves are trial lighted on the construction line.

This instruction booklet is an integral part of the product: make sure that it always accompanies the appliance, even in

case of transfer to another owner or in the case of transfer to another place. In the event of damage or loss, request a

copy from the area technician.

These symbols indicate specific messages in this booklet:

ATTENTION:

This warning sign indicates that the message to which it refers should be carefully read and understood,

because failure to comply with what these notices say can cause serious damage to the stove and

put the user’s safety at risk.

INFORMATION:

This symbol is used to highlight information which is important for proper stove operation. Failure to

comply with these provision will compromise use of the stove and its operation will not be satisfactory.

eniaD tovesS 6D16-ia14D_M14-1

Cod. 001122

We highly recommend to turn to our Authorized Service Centre for the installation and the first

ignition of the device as it not only carries out the installation perfectly but also verifies the

regular operation of it.

30

GB

Our company declares that the stove conforms to the

following norms for the EC European Directive labelling:

• 2014/30 UE (regulation EMCD) and following

amendments;

• 2014/35 UE (Low Voltage Directive) and following

amendments;

• 2011/65 EU (RoHS 2 directive);

• The New Rules of Construction Products (CPRConstruction Products Regulation) No. 305/2011

regarding the construction world;

• For installations in Italy, please refer to UNI 10683/98

or following changes. For the water-thermo-sanitary

equipment, let the installer give you the conformity

declaration in compliance with L. 37/2008. While

installing the unit respect the local, national and Europen

rules;

• EN 55014-1; EN 55014-2; EN 61000-3-2; EN 61000-3-3;

EN 60335-1; EN 60335-2-102; EN 62233, EN 50581.

Safety information

Please carefully read this use and maintenance manual

before installing and operating the stove!

If clarication is needed, please contact the dealer or the

Authorized Assistance Center.

• The pellet stove must only be operated in living

environments. This stove, being controlled by an

electronic board, permits a completely automatic and

controlled combustion; the exchange, in fact, regulates

the lighting phase, 5 power levels and the shut down

stage, guaranteeing the safe operation of the stove.

• The basket used for combustion allows most of the ash

produced by the combustion of the pellets to fall into

the collection compartment. Nevertheless, check the

basket daily, given that not all pellets have high quality

standards (use only quality pellets recommended by the

manufacturer).

Responsibility

With the delivery of the present manual, we decline all

responsibility, both civil and penal, for accidents deriving

from the partial or total lack of observance of the

instructions contained herein.

We decline every responsibility derived from improper

use of the stove, from incorrect use by the user, from

unauthorized modications and/or repairs, from the use

of replacement parts that are not original for this model.

The manufacturer declines every civil or penal, direct or

indirect responsibility due to:

• Lack of maintenance;

• Failure to observe the instructions contained in the

manual;

• Use in non-conformity with the safety directives;

• Installation in non-conformity with the norms in force in

the country;

• Installation by unqualied or untrained personnel;

• Modications and repairs not authorized by the manu-

facturer;

• Use of non-original replacement parts;

• Exceptional events.

Norms and declarations of conformity

• Use only wood pellets;

• Keep / store the pellets in a cool

dry place;

• Never pour pellets directly on the hearth;

• The stove must be fueled only with quality

pellets with a diameter of 6 mm and a maximum

length of 30 mm of the type recommended by

the manufacturer.

• Before making the electrical connection of the

stove the discharge tubes must be connected

with the flue;

• The protective grill placed inside the pellet

container must never be removed;

• The environment where the stove is installed

must have a sufficient exchange of air;

• It is forbidden to operate the stove with the

door open or the glass broken;

• Do not use the stove as an incinerator; the stove

should be used only for the intended purpose;

• Any other use is considered improper and

therefore dangerous. Do not put in the hopper

other than wood pellets;

• When the stove is operating, the surfaces,

glass, handle and tubes become very hot:

during operation do not touch these parts

without adequate protection;

• Keep the fuel and other inflammable materials

off the stove.

31

GB

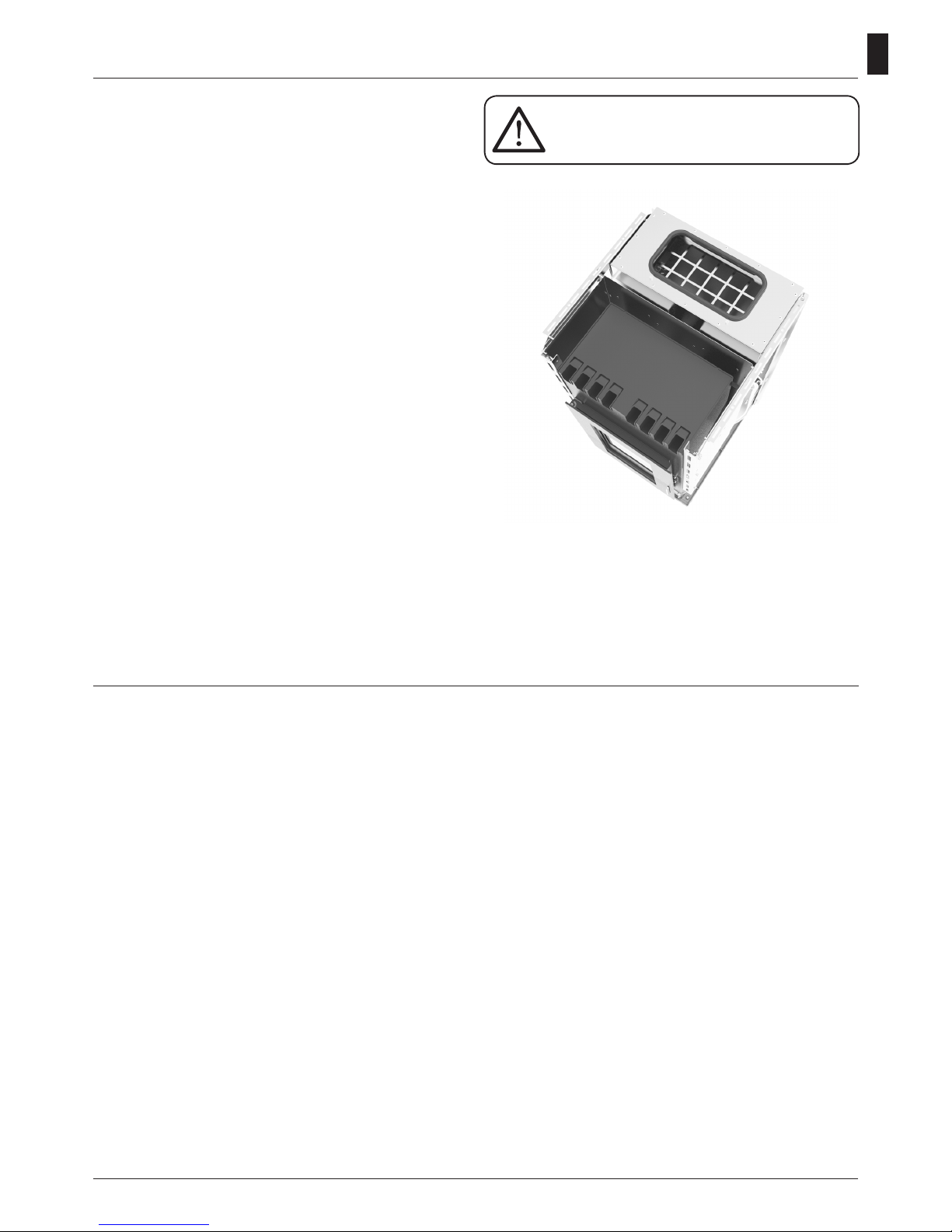

Charge pellet

Fuel is loaded from the upper part of the stove by opening

a door.

Pour the pellets in the hopper; vacuum contains about 23

kg of pellets. This is easier if performed in two steps:

• Pour half of the contents of the bag into the hopper and

wait for the fuel to settle on the bottom.

• Then pour in the second half;

• Keep the cover closed , after loading the pellets , the lid

of the fuel tank;

• Before closing the door load-pellet make sure that there

are no residues of pellets around the seal. If carefully

cleaned to avoid compromising the seals.

The stove is a product by heating, presents the external

surfaces particularly hot. For this reason, we recommend

extreme caution when operating in particular:

• Do not touch the stove body and the various components, do not approach the door , it could cause burns;

• Do not touch the exhaust fumes;

• Do not perform any type of cleaning;

• Do not dump the ashes;

• Do not open the ash tray;

• Be careful that children do not come near;

• The appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capacities , or lack of experience or knowledge,

unless they have been given through the intermediary

of a person responsible for their safety, supervision or

instruction concerning use of the appliance;

• Do not use the stove as a ladder or scaffold;

• Do not put clothes to dry on the stove. Any clothes

hangers and suchlike must be kept a suitable distance

from the stove. - Risk of re

• Carefully explain that the stove is made from material

subjected to high temperatures for the elderly , the

disabled, and in particular for all children, keeping them

away from the stove during operation

• Do not touch the stove with wet hands: the stove has

electrical components that could produce sparks if

handled incorrectly.

• Never open the glass door of the pellet stove while the

stove is in operation.

• The stove must be connected to an electrical system

equipped with an earthing conductor in accordance with

regulations 73/23 and 93/98 EEC;

• The system must be of adequate electrical power

declared the stove;

• Do not wash the inside of the stove with water.

The water could damage the electrical insulation, causing

electric shock;

• Do not expose your body to hot air for a long time. Do

not overheat the room you are in and where the stove is

installed.

This can damage the physical conditions and cause

health problems;

• Do not expose to direct the ow of hot air plants or

animals;

• The pellet stove is not a cooking element;

• External surfaces during operation can become very

hot. Do not touch them except with the appropriate

protection.

Instructions for safe and efficient use

Never remove the protection grille in the

hopper. When filling, do not let the sack

of pellets touch any hot surfaces.

32

GB

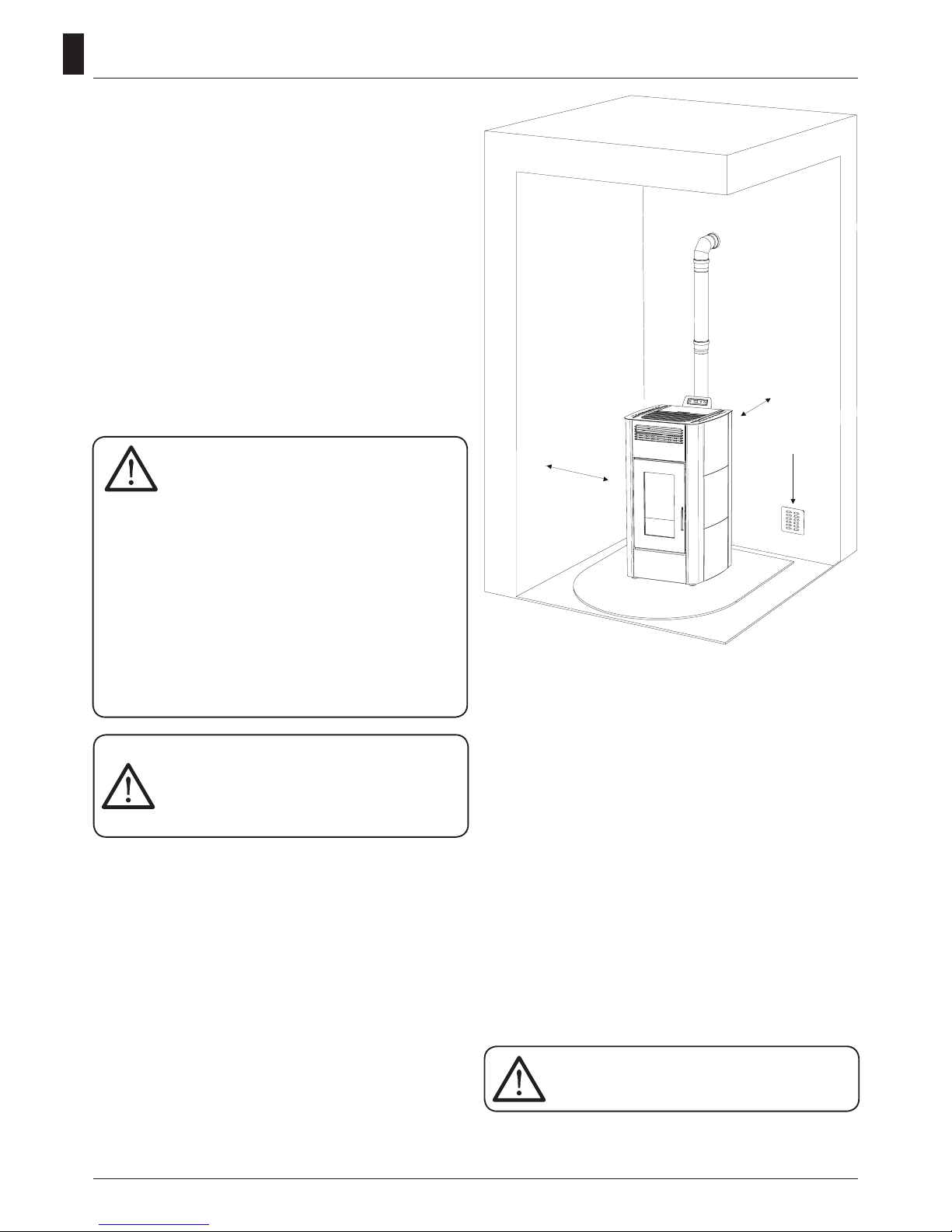

For proper functioning and a good temperature distribution,

the stove shoul be positioned in a location where it is able

to take in the air necessary for combustion of the pellet

(about 40 m3/h must be available, as laid down in the

standard governing the installation and in accordance with

local national standards).

The volume of the room must not be less than 30 m3.

The air must come in through permanent openings made

in walls (in proximity to the stove) which give onto the

outside, with a minimum cross-section area of 100 cm2.

These openings must be made in such a way that it is not

possible for then to be obstructed in any way. Alternatively,

the air can be taken from rooms adjacent to the one which

needs ventilating, as long as they are provided with an air

intake from the outside, and are not used as bedrooms or

bathrooms, and provided there is no re risk such as there

is for example in garages, woodsheds, and storerooms,

with particular reference to what is laid down in current

standards.

It is not permissible to install the stove in

bedrooms, bathrooms, or in a room where

another heating appliance is installed

(fireplace, stove etc.) which does not have its own

independent air intake.

Locating the stove in a room with an explosive

atmosphere is prohibited.

The floor of the room where the stove is to be

installed must be strong enough to take its weight. If

walls are flammable, maintain a minimum distance

of 20 cm at the rear (A), of 30 cm at the side (B) and

100 cm at the front. If the room contains objects

which are believed to be particularly delicate, such

as drapes, sofas and other furniture, their distance

from the stove should be considerably increased.

In the presence of wood floors, install a

floor protection surface in compliance

with the rules in force in the country

Operating area

30 cm

(B)

Min.

100 cm

2

20 cm (A)

Connection to the external air intake

It is essential that at least as much air must be able to ow

into the room where the stove is installed as is required for

proper combustion in the appliance and for the ventilation

of the room. This can be effected by means of permanent

openings in the walls of the room to be ventilated, which

give onto the outside, or by single or collective ventilation

ducts.

For this purpose, on the external wall near the stove, a

hole must be made with a minimum free cross-section of

100 cm2. (equivalent to a round hole of 10 cm diameter or

a square hole 10x10 cm) protected by a grille on the inside

and the outside.

The air intake must also:

•

communicate directly with the room where the stove is

installed

•

be protected by a grille, metal mesh or suitable guard, as

long as this does not reduce the area below the minimum.

•

positioned in such a way as to be impossible to obstruct.

If the stove is installed on a flammable

floor it must be interposed with a slab of

insulating material to heat it protrudes at

least 20 cm on the sides and 40 cm on the

front.

33

GB

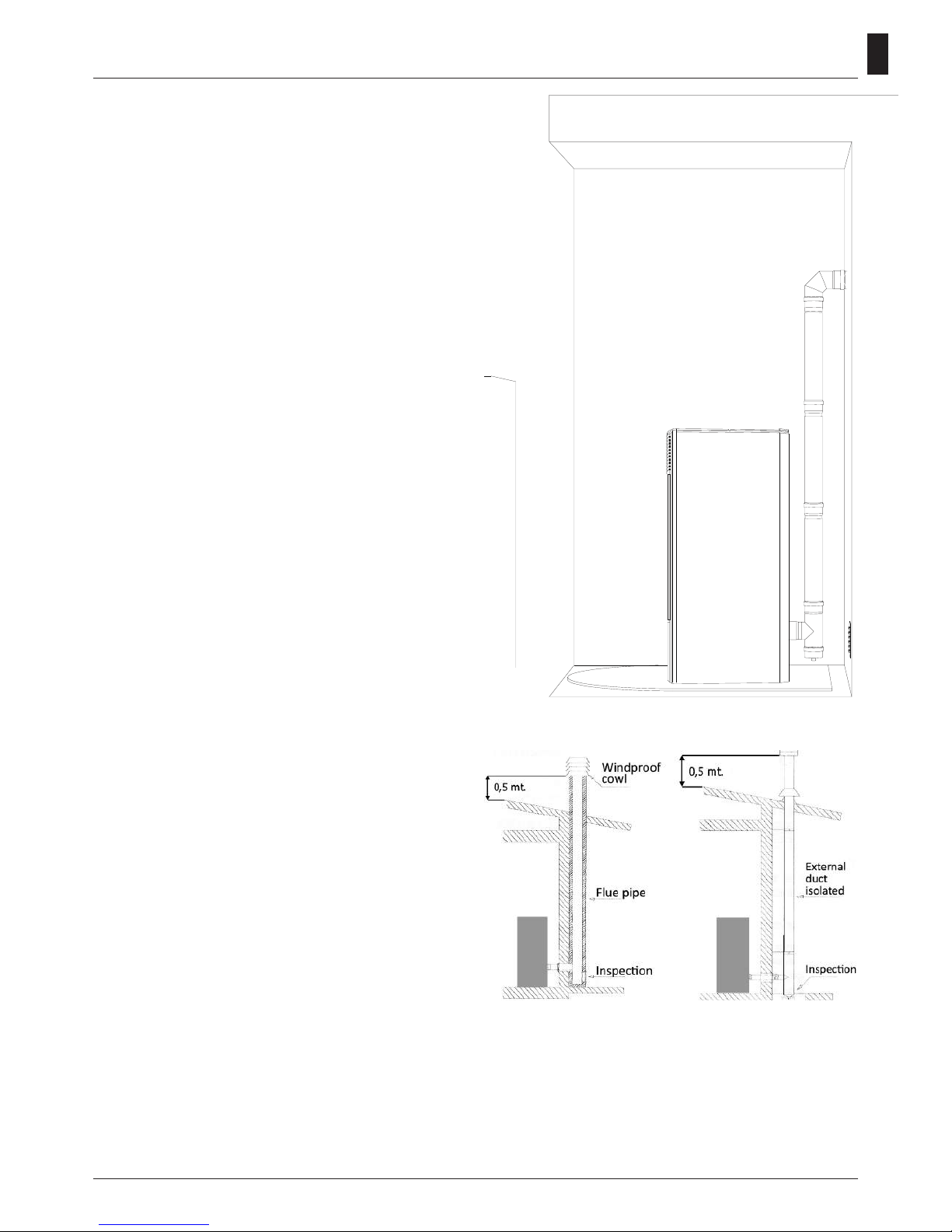

Connection to the flue pipe

The ue pipe must have internal dimensions not larger

than 20x20 cm, or diameter 20 cm. In the event of larger

dimensions, or of the ue pipe being in poor condition ( for

example cracks, poor insulation, etc.), it is advisable to t

a stainless steel pipe of suitable diameter inside the ue

pipe throughout its length, right up to the top.

Check with suitable instruments that there is a draught

between 3 Pa and 10 Pa. This type of connection ensures

the evacuation of the fumes even in the event of a

temporary power cut.

At the bottom of the ue pipe, provide an inspection cap

to allow periodic checking and cleaning, which must be

done annually. Make a gas-tight connection to the ue

pipe, using pipes and connectors as recommended by us.

You must ensure that a windproof cowl should be tted

which complies with the standards in force

Connection to an external flue with insulated or

double-wall pipe

The only type of pipe which is permissible is insulated

(double-walled) stainless steel, smooth on the inside,

xed to the wall. Flexible stainless steel pipe must not be

used. At the bottom of the ue pipe, provide an inspection

cap to allow periodic checking and cleaning, which must

be done annually. Make a gas-tight connection to the ue

pipe, using pipes and connectors as recommended by us.

You must ensure that a windproof cowl should be tted

which complies with the standards in force.

Check with suitable instruments that there is a draught

between 3 Pa and 10 Pa.

Connection to the flue pipe

For proper functioning, the connecting pipe between the

stove and the chimney or ue duct must have a slope of

not less than 3% in the horizontal stretches, the length of

which must not exceed 2 metres and the vertical distance

between one tee connector and another (change of

direction) must not be less than 1,5 m.

Check with suitable instruments that there is a draught

between 3 Pa and 10 Pa. At the botton of the ue pipe,

provide an inspection cap to allow periodic checking and

cleaning, which must be done annually.

Make a gas-tight connection to the ue pipe, using pipes

and connectors as recommended by us. You must ensure

that a windproof cowl should be tted which complies

with the standards in force.

Fig. 3: connection to an

external ue with insulated

or double-wall pipe.

Fig. 2: connection to the

ue pipe.

34

GB

Fireplace flue gas

Avoid contact with combustible materials (example:

wooden beams) and in any case provide for their insulation

with ame retardant material. In case of pipe penetrations

through roofs or walls is recommended to use special

kits crossing, certicates, are available commercially. In

the event of a chimney re, turn off the stove, disconnect

from the network and never open the door. Then call the

authorities.

The chimney cap

The chimney cap must respect the following requirements:

• It must have the equivalent diameter and internal form

of the ue.

• It must have a useful outlet diameter of not less than

double that of the ue.

• The chimney cap on the roof or that remains in contact

with the outside (for example, in case of open lofts or attics), must be covered with elements in brick or tile and

must, in any case, be well insulated.

• It must be constructed to prevent rain, snow, and extraneous bodies from entering the ue and so that the

discharge of the products of combustion is not inhibited

by wind from any quarter or strength (wind-proof chimney cap).

• The chimney cap must be positioned in such a way as

to guarantee the adequate dispersion and dilution of the

products of combustion and in any case, must be out of

the reux zone. This zone has different dimensions and

forms according to the angle of inclination of the roof so

it is necessary to adopt minimum heights (Fig. 2).

• The chimney cap must be a wind-proof type and must

be above the ridge.

• Eventual structures or other obstacles that are higher

than the chimney cap must not be too close to the

chimney cap itself.

• The device should not be installed in the ue shared.

Fig. 5: Characteristics of chimney

YES NO

REMARKS:

- the appliance must be installed by a qualied technician in

possession of the technical and professional requirements

according to the DM37/2008 that, under its responsibility,

to ensure compliance with the rules of good technique.

- you need to keep in mind all laws and national, regional,

provincial and municipal laws of the country in which you

installed the device

- check that the oor is not ammable: if necessary use a

suitable platform

- in the room where the generator must be installed to

heat must not pre-exist or be installed with an extractor

hood or ventilation ducts of the collective type.

Should these devices be located in adjacent rooms

communicating with the installation, and ‘prohibited the

simultaneous use of the heat generator, where there is a

risk that one of the two rooms being placed in depression

than the other

- it is not permissible to install in bedrooms or bathrooms.

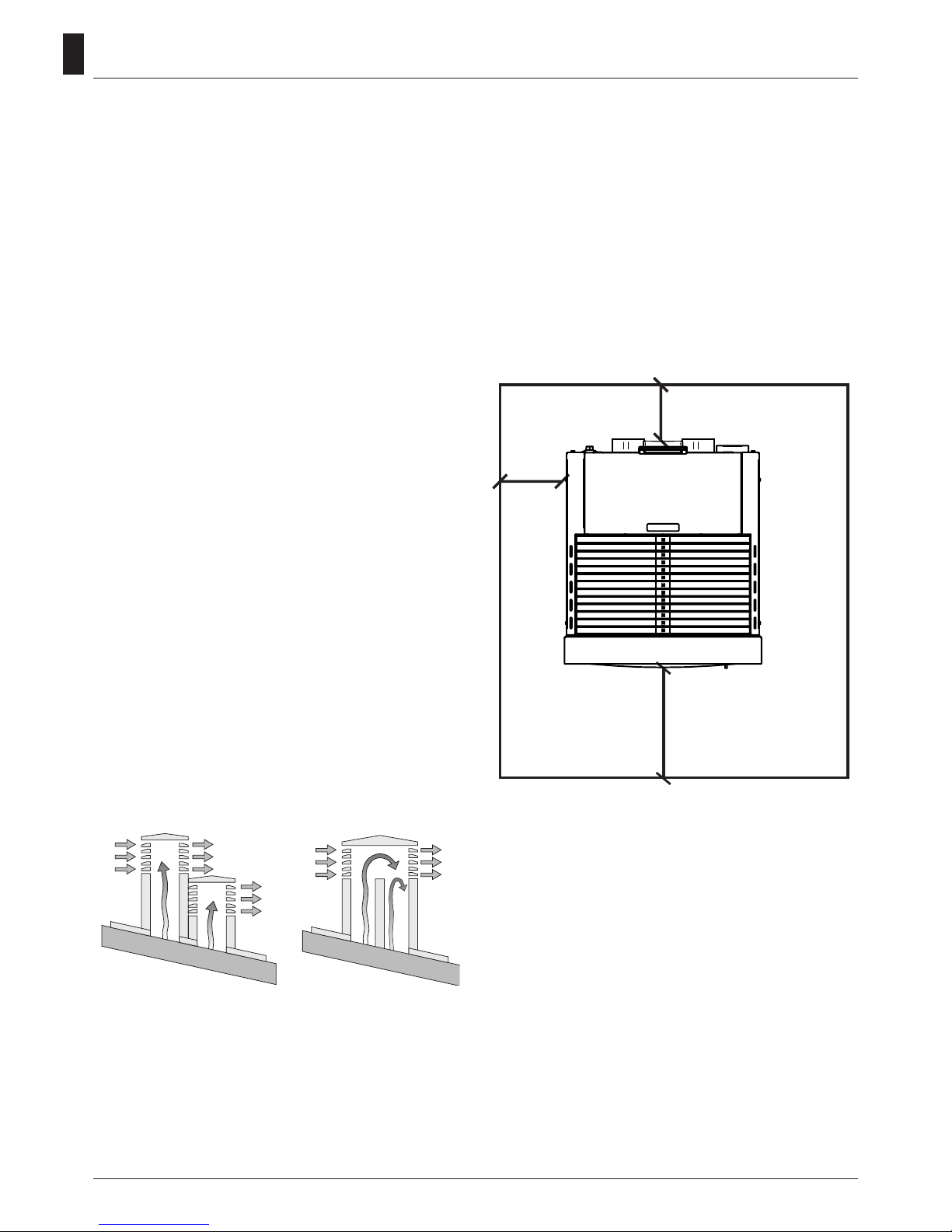

Connection of the canalization pipe

The two air outputs placed on the back of the stove

only one tube of 80mm diameter and 8 linear meters of

maximum length.

You have to consider a loss around 1 meter of the linear

tract for each bend of 45° (ex.: maximal distance without

bends: 8 meters; maximal distance with one bend 8-1=7

meters).

Distance to objects

It is also recommended to keep the pellets and all

ammable materials at a suitable distance from the stove.

30 cm

100 cm

20 cm

35

GB

How to change the operating power

You can change the operating power from a min. value of

1 to a max. value of 5. You can also choose the “Auto”.

Press the key 6 (6) to increase or press

5

6

(5) to

reduce it.

When you stop working on the power menu for a while,

the stove will automatically leave the menu itself.

Functional keys

1. Temperature increase: using this key you can increase

the wished temperature from a min. value of 7°C to a max.

value of 40°C.

2. Temperature decrease: using this key you can reduce

the wished temperature from a max. value of 40° C to a

min. value of 7°C.

3. Key SET: push this button to enter the programming

menu of the stove.

4. Key on/off: keep this button pushed for two seconds

to switch the stove on or off.

5. Operating power decrease: using this key you can

reduce the working power from a max. value of 5 to a min.

value of 1.

6. Operating power increase: using this key you can

increase the working power from a min. value of 1 to a

max. value of 5.

Function indicators

Chronothermostat

This signalises that the automatic single or daily switching

on or off of the stove is on. The automatic programming

can be set only using the remote control.

Resistance indicator

This works only when the stove is lighting up to indicate

that the resistance is warming the air to burn pellets.

Endless screw

6

This switches on every time pellets are being loaded in

the stove.

Smokes extractor 6

This signalises the smokes ventilator is working.

Exchanger

6

This indicates the room ventilator is working.

Control board

1. Temperature increase

2. Temperature decrease

3. Key SET

4. Key on/off

5. Operating power decrease

6. Operating power increase

Alarm indicator

4

5

6

This lights up in the event of an alarm or functioning defect.

You can read the kind of signalised alarm on the display.

Remote control reception

Stove setting

How to change the wished room temperature

You can change the temperature whenever you want.

Press the keys

1

6

1

6

(1) and

1

6

1

2

3

SET

4

5

6

(2) to modify the wished

value. When you stop working on the Set temperature

menu for a while, the stove will automatically leave the

menu itself.

36

GB

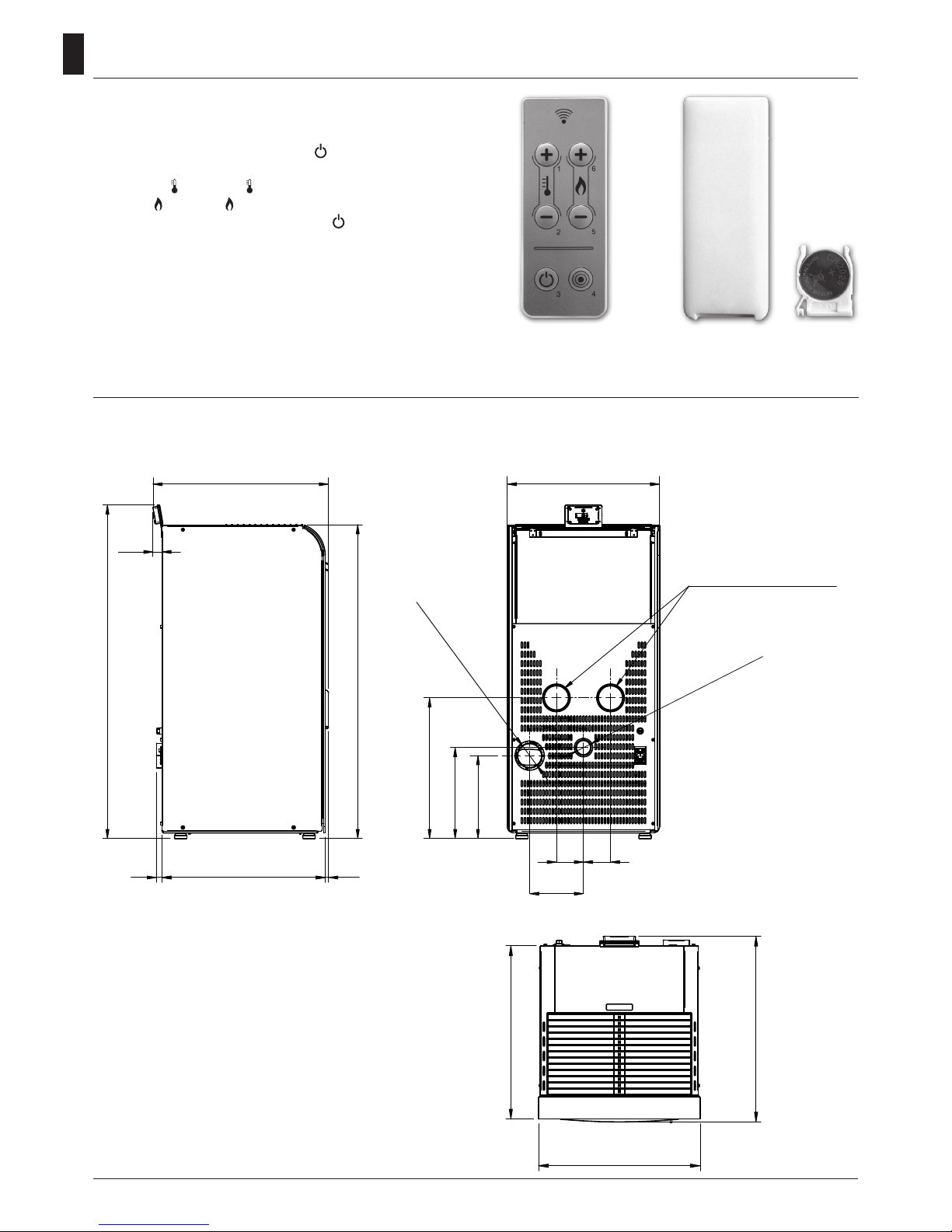

530 1020

570

8888

175

495

Ø 50 Air Intake

Ø 80 Smoke Outlet

Ø 80 Channeling (If Any)

1020

1084

269

296

457

30

The remote control (Fig. 3) used to adjust water temperature

power and the on/off functions for the pellet stove.

To start the stove, press key and the stove will

automatically enter the starting phase.

Press keys + (1) and - (2) to adjust temperature, and

use keys + (6) and - (5) to adjust operating power.

To turn off the stove, hold down key .

To replace the 3 volt battery located on the back of the

remote control, pull the centre of the cover and the lever

on the side of the same, replace the battery observing the

correct polarity (Fig. 4)

Fig. 3 Fig. 4

Technical Specification

Remote Control

REMARKS:

- measurements are approximate and may vary

based on to the aesthetics of the stove

- the positions of the tubes in the rear view are

indicative and tolerance of +/- 10 mm

- measures with a tolerance of about 10 mm

Mod. 14 - 14 C

TOLLERANZE GENERALI D I LAVORAZIONE

DIMENSIONI LINEARI

PRECISIONE

12

GRADO DI

FINO A

± 0,15

± 0,1

6

± 0,3

± 0,25

120

± 0,2

± 0,15

60

6

60

4000

± 0,8

± 0,6

1000

400

± 0,5

± 0,4

400

120

± 2

± 1,5

4000

2000

± 1

± 1,2

2000

1000 DA

A

± 2.5

± 3,5

OLTRE

AAAAA

DADADADADA

Spessore

Peso

Materiale

F

G

7488850 g

H

I

495

1020

530 1020

570

570

495

8888

175

495

Ø

50 Aspirazione Aria

Ø

80 Uscita Fumi

Ø80 Canalizzazione

(ove presente)

1020

1084

269

296

457

530

30

37

GB

REMARKS:

- measurements are approximate and may

vary based on to the aesthetics of the stove

- the positions of the tubes in the rear view

are indicative and tolerance of +/- 10 mm

- measures with a tolerance of about 10 mm

Mod. 16 - 16 C

TOLLERANZE GENERALI DI LAVORAZIONE

DIMENSIONI LINEARI

PRECISIONE

12

GRADO DI

FINO A

± 0,15

± 0,1

6

± 0,3

± 0,25

120

± 0,2

± 0,15

60

6

60

4000

± 0,8

± 0,6

1000

400

± 0,5

± 0,4

400

120

± 2

± 1,5

4000

2000

± 1

± 1,2

2000

1000 DA

A

± 2.5

± 3,5

OLTRE

AAAAA

DADADADADA

Spessore

Peso

Materiale

7488850 g

495

1080

530 1020

570

570

495

8888

175

495

Ø

50 Aspirazione Aria

Ø 80 Uscita Fumi

Ø80 Canalizzazione

(ove presente)

1080

1144

329

356

517

530

30

530 1020

570

8888

175

495

Ø 50 Air Intake

Ø 80 Smoke Outlet

Ø 80 Channeling

(if Any)

1080

1144

329

356

517

30

38

GB

PARAMETER

UNIT OF

MEASURE

CAYENNE 14 - 14 C CAYENNE 16 - 16 C

Heat input kW 13,2 16,3

Nominal heat output kW 12,5 15,2

Reduced heat output kW 3,7 3,7

CO concentration at nominal

reference (13% O2)

mg/m

3

104,82 94,85

CO concentration at reduced

reference (13% O2)

mg/m

3

409,5 409,5

Nominal efciency % 94,76 93,48

Reduced efciency % 98 98

Pellet consumption (min-max) Kg/h 0,78 - 2,72 0,78 - 3,44

Heated surface mc 340 400

Flue gas ow rate (min-max) g/s 2,83 - 7,29 2,83 - 8,53

Draft advised (min-max) Pa 3 - 12 3 - 12

Flue gas temperature (min-max) °C 46 - 112 46 - 139

Tank capacity Kg 23 23

Recommended fuel

(ø x H)

mm

pellet 6 x 30 pellet 6 x 30

Diameter smoke outlet tube mm 80 80

Diametro canalizzazione mm 80 80

Diameter air intake mm 50 50

Nominal voltage V 230 230

Nominal frequency Hz 50 50

Power consumption max W 400 400

Stove weight Kg 135 - 140 140 - 145

N° Test Report K19052016T1

The pellets are cylinders of compressed wood, produced from sawdust and wood processing (chips and

sawdust), generally produced by sawmills and carpenters. The binding capacity of the lignin contained

in wood, allows to obtain a compact product without adding additives and foreign chemicals to the

wood, is therefore obtained a natural fuel with high yield.

The use of expired pellets or any other unsuitable material can damage parts of

the stove and impair proper operation: this can lead to the termination of the

guarantee, and its producer responsibility.

For our stoves use pellets diameter 6 mm, length 30 mm and a maximum

of 8% moisture. Store the pellets away from heat sources and not in

humid environments or with explosive atmospheres.

Pellet

It is recommended that the control of emissions after installation.

39

GB

Charge pellet

Fuel is loaded from the upper part of the stove by opening

a door. Pour the pellets in the hopper. When empty, it will

hold slightly more than 23 kg.

This is easier if performed in two steps:

•

Pour half of the contents of the bag into the hopper and

wait for the fuel to settle on the bottom.

•

Then pour in the rest.

The brazier should be cleaned before each

starting.

Never remove the protection grille in the

hopper. When filling, do not let the sack of

pellets touch any hot surfaces.

Remove any components which might

burn from the firebox and from the glass

(various instructions and adhesive labels).

First lighting of the stove

• Before switching on, make sure that the grate is clean and

empty of any pellet residues from previous combustions.

Otherwise make sure you empty and clean it

• Fill the container 3/4 full with the pellets recommended

by the manufacturer

• Connect the stove to an electrical outlet with the cable

that has been supplied

• Press the lighting switch located on the back part of the

stove

• The upper display will read “OFF”

• Press the button for 2 seconds. After a few moments

the smoke extractor and the lighting resistor will start

and the display will read “START”; The led resistance is

switched on

• After 1 minute the display will read “LOAD PELLET”, the

stove will load the pellets and continue lighting the resistor

• Once the appropriate temperature has been reached

the display will read “FLAME LIGHT”: this means that the

stove has begun the last phase in lighting, at the end of

which the stove will be completely operational; The led

resistence is switched off

• After some minutes the display will show the words

“WORK” alternating room temperature and current working

power. The stove is now completely on

• When the stove reaches the set temperature, the display

will show “MODULATION”.

Stove start up

We highly recommend to turn to our

Authorized Service Centre for the

installation and the first ignition of the

device as it not only carries out the installation

perfectly but also verifies the regular operation of it.

During the first lighting the environment should

be well ventilated since during the first hours of

operation unpleasant odours could develop due to

the physical stabilizing of the paint and from the

grease in the tube bundle.

Before lighting a small amount of smoke

may fill the combustion chamber.

Stove switching off

To switch off the stove, press the key on the control

board until you read “CLEANING FINAL” on the display.

After the stove has been switched off, the fan continues

working for a set time in order to grant a fast smokes

exhaust from the combustion chamber.

If you have a model with remote control, you just need to

switch the remote control off keeping the key pressed for

2 seconds and conrming the selection pressing the key

SEND.

If you try to switch on the stove during this phase, the

display will show “waiting cooling” (that means wait for

cooling) in order to inform you a switching off phase is

running. Wait until the cooling phase is completely off and

the display shows “OFF” before staring a new light up.

REMARKS:

• Do not continuously turn the stove on and off as this

could provoke sparks that could shorten the life of the

electrical components.

• Do not touch the stove with wet hands: the stove

has electrical components that could produce sparks

if handled incorrectly. Only authorized technicians can

resolve possible problems.

• Do not remove any screws from the re chamber without

rst lubricating them well.

• Never open the glass door of the pellet stove while the

stove is in operation.

• Be sure that the brazier basket is positioned correctly.

• The ue system must be suitable for inspecion. If it cannot

be removed, it must have some holes for inspection and

cleaning.

40

GB

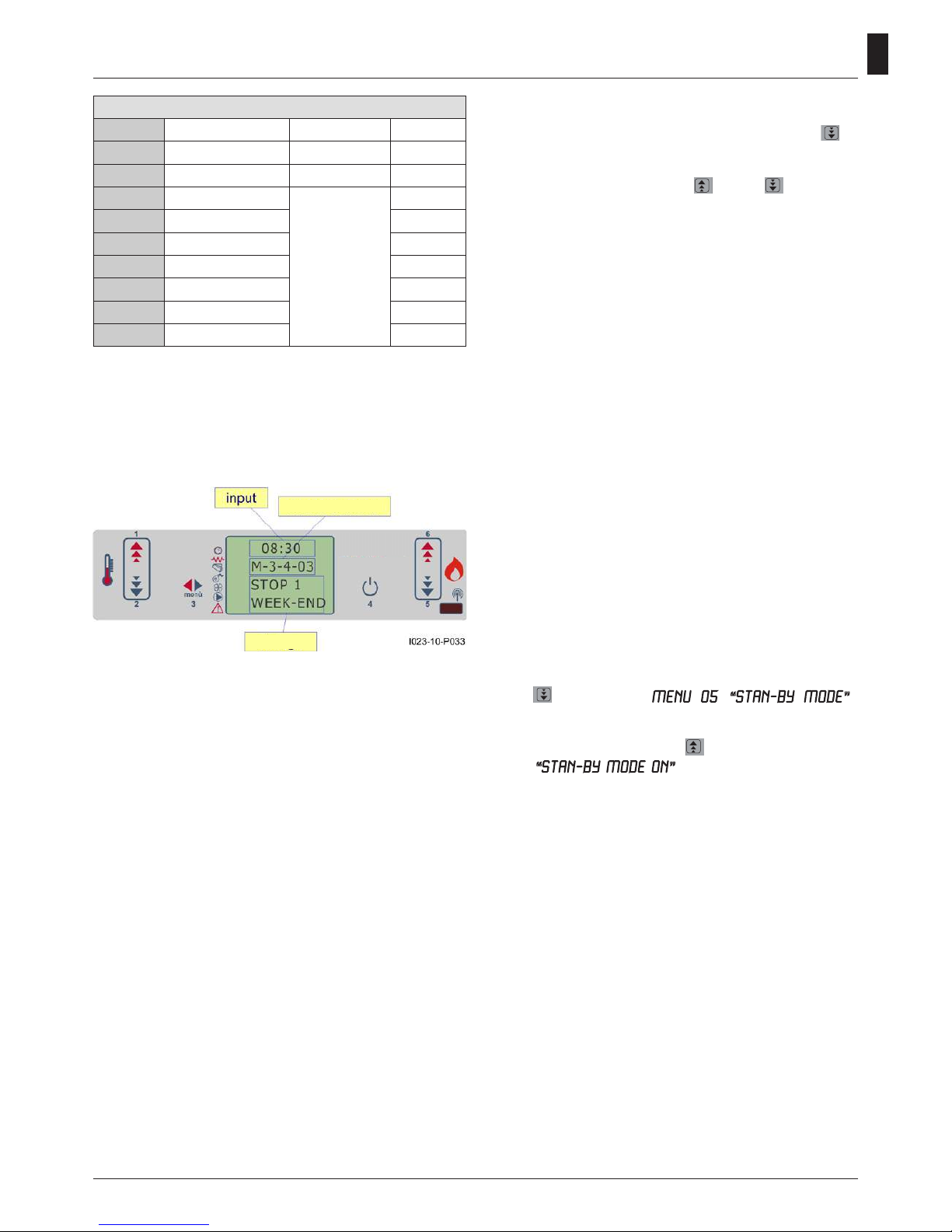

Programming menu

Menu 02 SET CLOCK

To access the set clock option, press the “SET” button (3), with the button - (5) scroll through the submenus until MENU

02 - SET CLOCK and with buttons 1 and 2 select the current day. Press the “SET” button (3) to conrm.

Then use buttons 1 and 2 to set the time and press “SET” (3) to advance to the minutes setting by pressing buttons 1

and 2. By pressing set again it’s possible to access various submenus in order to set the date, day, month, and year.

To do so, repeat the steps indicated above, using buttons 1, 2, and 3.

The following table briey describes the structure of the menu, focusing only on those selections which are available

to the user.

Set the current time and date. The device comes equipped

with a lithium battery that allows the internal clock to

operate autonomously for over 3-5 years.

Menu 03 SET CHRONO

Press the “SET” button (3) and then button 5 to arrive at the desired menu; press “SET” (3) to enter.

Enter menu M-3-1 and with buttons 1 and 2 select whether or not to activate the thermostat (on/off), which allows you

to program the automatic ignition of the stove.

Once the thermostat is activated/deactivated, press button “4” (OFF) and continue scrolling though the submenus

using button 5. Select which submenu you wish to enter in order to access the daily, weekly, and weekend programmes.

To set the ignition times and days repeat the previous steps:

- access the submenu using “SET” (3)

- adjust the days, times, and activation status (on/off) with buttons 1 and 2

- conrm by pressing the “SET” button (3)

- exit from the submenu/menu with button 4 to turn it off

The following table briey describes the structure of the menu, focusing only on those selections which are available

to the user.

level 1 level 2 level 3 level 4 value

02 - set clock

01 - day day of the week

02 - hour hour

03 - minutes minutes

04 - day day of the month

05 - month month

06 - year year

level 1 level 2 level 3 level 4 value

03 - set thermostat

01 -

activate thermos.

01 -

activate thermos.

on/off

02 -

day programme

01 -

daily thermostat

on/off

02 - start 1 day hour

03 - stop 1 day hour

04 - start 2 day hour

05 - stop 2 day hour

menu level

dialogue

MENU

CLOCK

41

GB

level 1 level 2 level 3 level 4 value

03 - set thermostat

03 - week program.

01 - week thermostat on/off

02 - start program. 1 hour

03 - stop program. 1 hour

04 - monday progr. 1 on/off

05 - tuesday progr. 1 on/off

06 -

wednesday prog. 1

on/off

07 - thursday prog 1 on/off

08 - friday prog 1 on/off

09 - saturday prog 1 on/off

10 - sunday prog 1 on/off

11 - start program. 2 hour

12 - stop program. 2 hour

13 - monday progr. 2 on/off

14 - tuesday progr. 2 on/off

15 -

wednesday prog. 2

on/off

16 - thursday prog 2 on/off

17 - friday prog 2 on/off

18 - saturday prog 2 on/off

19 - sunday prog 2 on/off

20 - start program. 3 hour

21 - stop program. 3 hour

22 - monday progr. 3 on/off

23 - tuesday progr. 3 on/off

24 -

wednesday prog. 3

on/off

25 - thursday prog 3 on/off

26 - friday prog 3 on/off

27 - saturday prog 3 on/off

28 - sunday prog 3 on/off

29 - start program. 4 hour

30 - stop program. 4 hour

31 - monday progr. 4 on/off

32 - tuesday progr. 4 on/off

33 -

wednesday prog. 4

on/off

34 - thursday prog. 4 on/off

35 - friday prog. 4 on/off

36 - saturday prog. 4 on/off

37 - sunday prog. 4 on/off

04 -

week-end program.

01 - therm. week-end

02 - start 1

03 - stop 1

04 - start 2

05 - stop 2

42

GB

selection meaning possible values

START 1 activation time time - OFF

STOP 1 shut-off time time - OFF

START 2 activation time time - OFF

STOP 2 shut-off time time - OFF

Menu 03 SET CHRONO

Submenu 03 - 01 - activate thermostat

This allows you to activate and deactivate all of the

functions of the thermostat

Submenu 03 - 02 - daily programme

This allows you to enable, disable, and set the daily

functions of the thermostat.

Submenu 03 - 03 - weekly programme

This allows you to enable, disable, and set the weekly

functions of the thermostat.

It’s possible to set two operating ranges delimited by the

times set according to the following table where the OFF

setting tells the clock to ignore the command:

The weekly programmer has 4 independent programmes

whose nal effect is composed of the combination of the

4 individual programmes.

The weekly programmer can be activated or deactivated.

Additionally, by setting OFF in the time eld, the clock

ignores the corresponding command.

Plan programming carefully in order to

avoid overlapping activation/deactivation

times in a single day in different

programmes.

PROGRAMME 1

menu level selection meaning

possible values

02-03-02 START PROGRAM 1 activation time time - OFF

02-03-03 STOP PROGRAM 1 shut-off time time - OFF

02-03-04 MONDAY PROGRAM 1

reference day

on/off

02-03-05 TUESDAY PROG 1 on/off

02-03-06 WEDNESDAY PROG 1 on/off

02-03-07 THURSDAY PROGR 1 on/off

02-03-08 FRIDAY PROGRAM 1 on/off

02-03-09 SATURDAY PROGR 1 on/off

02-03-10 SUNDAY PROGR 1 on/off

PROGRAMME 2

menu level selection meaning

possible values

03-03-11 START PROGRAM 2 activation time time - OFF

03-03-12 STOP PROGRAM 2 shut-off time time - OFF

03-03-13 MONDAY PROGRAM 2

reference day

on/off

03-03-14 TUESDAY PROG 2 on/off

03-03-15 WEDNESDAY PROG 2 on/off

03-03-16 THURSDAY PROGR 2 on/off

03-03-17 FRIDAY PROGRAM 2 on/off

03-03-18 SATURDAY PROGR 2 on/off

03-03-19 SUNDAY PROGR 2 on/off

PROGRAMME 3

menu level selection meaning

possible values

03-03-20 START PROGRAM 3 activation time time - OFF

03-03-21 STOP PROGRAM 3 shut-off time time - OFF

03-03-22 MONDAY PROGRAM 3

reference day

on/off

03-03-23 TUESDAY PROG 3 on/off

03-03-24 WEDNESDAY PROG 3 on/off

03-03-25 THURSDAY PROGR 3 on/off

03-03-26 FRIDAY PROGRAM 3 on/off

03-03-27 SATURDAY PROGR 3 on/off

03-03-28 SUNDAY PROGR 3 on/off

menu level

dialogue

ENABLE

THERMOSTAT

menu level

dialogue

DAY

menu level

dialogue

43

GB

Submenu 03 - 04 - program week-end

This allows you to enable, disable, and set the weekend

functions of the thermostat (days 5 and 6, or Saturday and

Sunday).

REMARKS:

- in order to avoid confusion and unwanted start-ups or

shutdowns, activate only one programme at a time unless

you know exactly what you’d like to achieve

- deactivate the daily program if you want to use the

weekly program

- always leave the weekend programme deactivated if you

use weekly programmes 1, 2, 3, and 4.

- activate the weekend programme only after you have

deactivated the weekly programme.

PROGRAMME 4

menu level selection meaning

possible values

03-03-29 START PROGRAM 4 activation time time - OFF

03-03-30 STOP PROGRAM 4 shut-off time time - OFF

03-03-31 MONDAY PROGRAM 4

reference day

on/off

03-03-32 TUESDAY PROG 4 on/off

03-03-33 WEDNESDAY PROG 4 on/off

03-03-34 THURSDAY PROGR 4 on/off

03-03-35 FRIDAY PROGRAM 4 on/off

03-03-36 SATURDAY PROGR 4 on/off

03-03-37 SUNDAY PROGR 4 on/off

Menu 04 - select language

Press the SET button to access the menu and press

5

6

(5)

up to the MENU 04 - SELECT LANGUAGE.

Then press the SET button to access the menu. Select the

desired language using the keys

1

6

(1) and

1

2

3

SET

4

5

6

(2)

Stand-by mode

This mode allows the automatic shutdown of the stove

once it reaches the temperature set on SET.

When this happens, the stove will wait a few minutes

(factory setting), after which will turn off automatically if

the temperature of the room in the meantime has always

maintained above the set.

Once turned off as a result of this condition, the stove will

automatically turn on only when the ambient temperature

will drop to 2 °C below the set temperature in the oven

(example: SET=24 °C and ambient temperature = 21 °C).

If the stove is turned off for the sleep-mode, although

there is an ignition programmed this will be ignored and

the heater will turn back on only to lower the temperature

as explained above.

The sleep timer is instead always respected if the stove is

in STAND-BY and is turned off manually by pressing the

OFF button; doing so the stove will shut down permanently

rekindling not more, less than expected from the ignition

weekly programming.

Enabling stand-by mode

Press the SET (3) to access the menu and with the

button

5

6

(5) reach the MENU 05 (“STAN-BY MODE”).

Then press SET (3) to access it; STAND-BY function is set

by default to OFF.

To activate this feature, press

1

6

(1), on the display you

will see “STAN-BY MODE ON”.

Press SET (3) to conrm and then OFF (4) to leave.

The STAND-BY mode is now active.

menu level

dialogue

44

GB

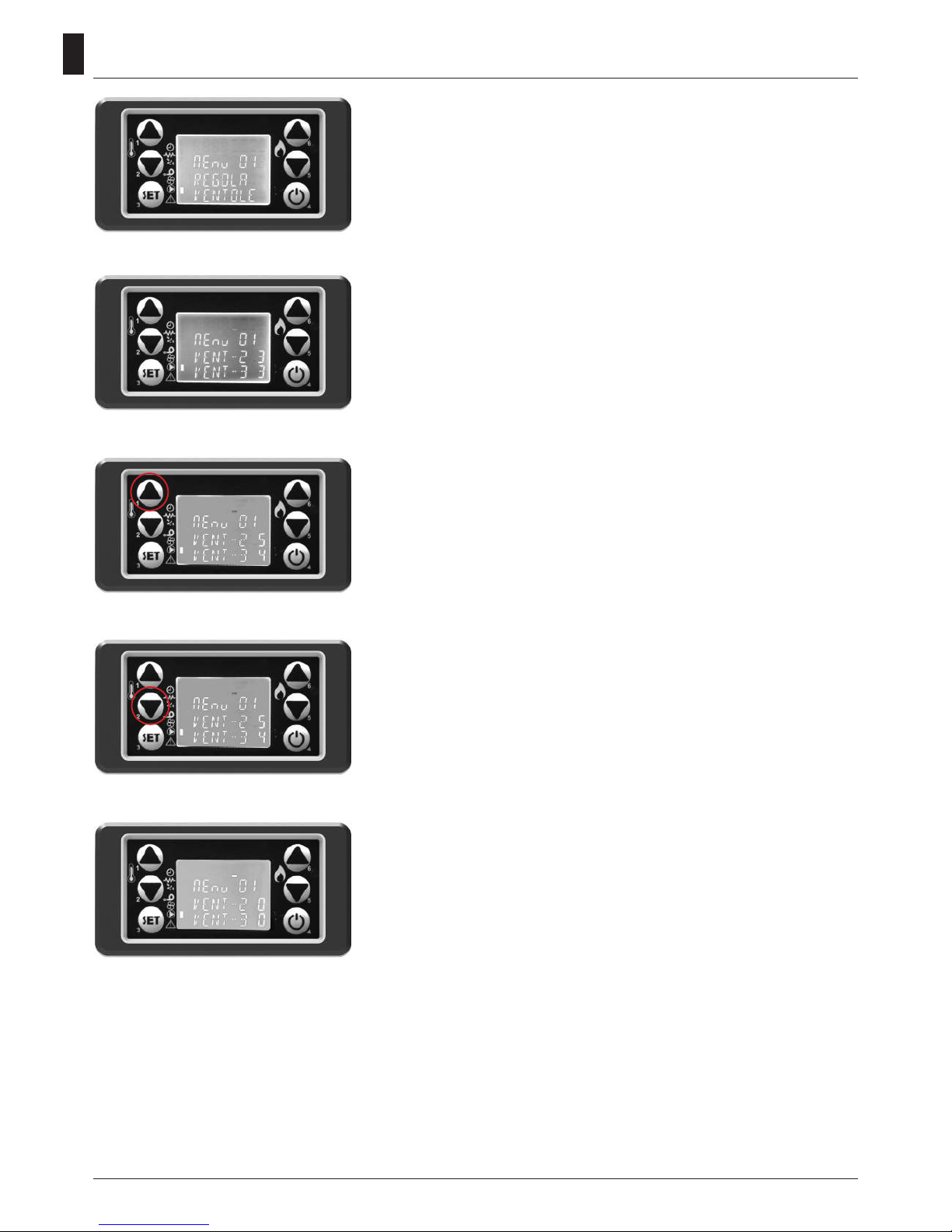

1. Press the SET button.

Will appear on the display MENU 01 SETTING FANS

2. Pressing the SET key to access the menu to set the speed of

your funnel fans

3. Set the speed using the buttons 1 and 2. With key 1 you set

the speed of the right fan, with key 2 you set the speed of the

left fan

4. To turn off the fans of the funnel, set the speed to 0

Fan speed adjustment channeling (if any)

45

GB

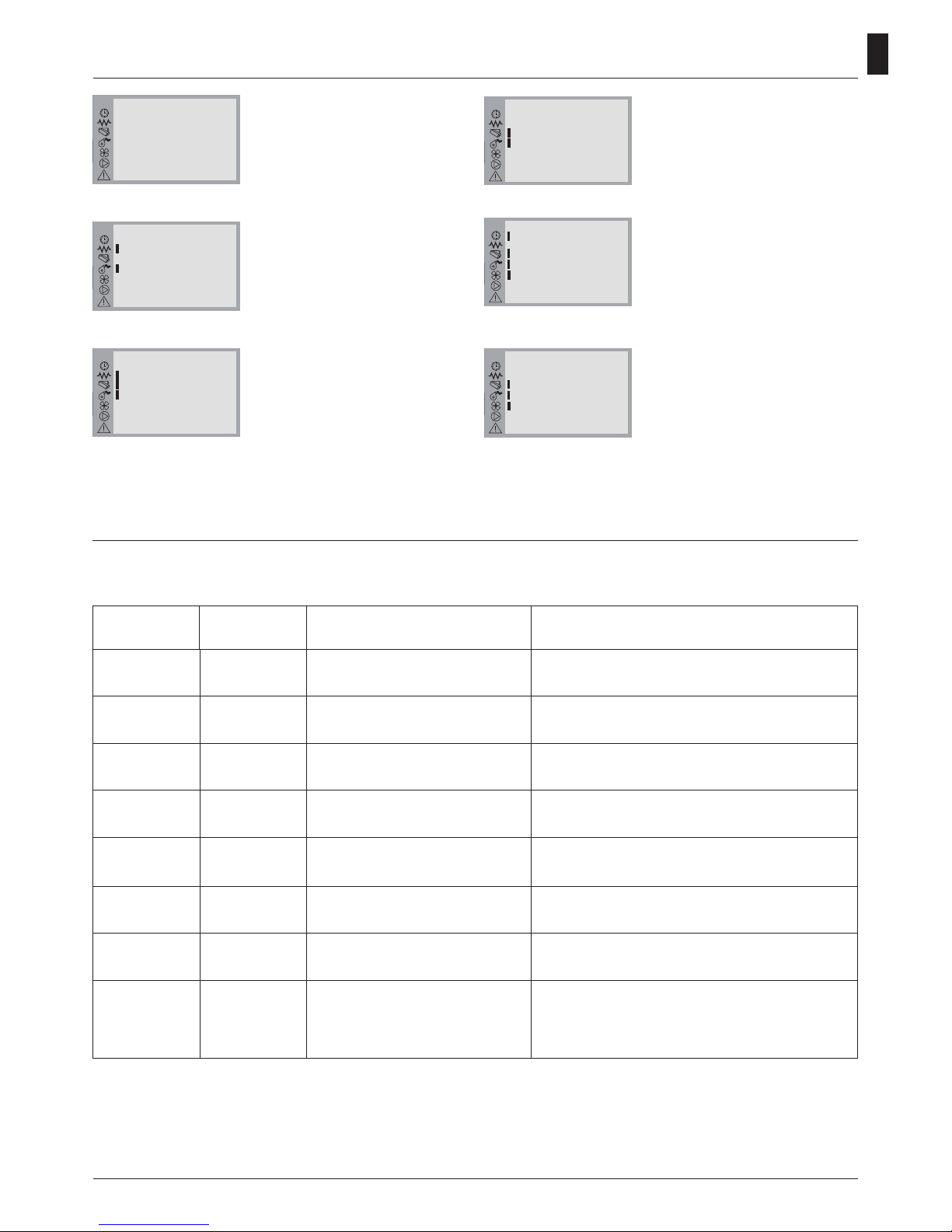

Display informations

Alarm signals

OFF

The stove is off.

21:10

22°C P-1

OFF

START

The stove is switching on.

Resistance and smokes extractor

are on.

21:10

22°C P-1

OFF

14:35

21°C P-2

START

LOAD PELLET

The stove starts loading pellets in

the brazier.

Resistance, smokes extractor and

gear motor are on.

21:10

22°C P-1

OFF

14:35

21°C P-2

START

14:35

21°C P-2

LOAD

pellet

FLAME LIGHT

The stove starts loading pellets in

the brazier.

Smokes extractor and gear mo-

tor are on.

21:10

22°C P-1

OFF

14:35

21°C P-2

START

14:35

21°C P-2

LOAD

pellet

14:35

21°C P-2

FLAME

LIGHT

CLEANING FIRE-POT

The stove is cleaning the brazier.

The smokes extractor is working

at its max. speed and the pellets

loading is minimal.

21:10

22°C P-1

OFF

14:35

21°C P-2

START

14:35

21°C P-2

LOAD

pellet

14:35

21°C P-2

FLAME

LIGHT

15:18

21°C P-3

WORK

(5)

16:40

22°C P-2

CLEANING

FIRE-POT

WORK

The stove is working, in this case

with working power 3. Detected

room temperature is 21°C. Smokes

ventilator, gear motor and room

ventilator are on during this phase.

21:10

22°C P-1

OFF

14:35

21°C P-2

START

14:35

21°C P-2

LOAD

pellet

14:35

21°C P-2

FLAME

LIGHT

15:18

21°C P-3

WORK

(5)

Regular checks should be carried out by the user, who should only contact the Authorized Assistance Center

if no solution is found.

In the event of a working defect, the system informs the user about the type of failure occurred.

The following table summarises the alarms, kind of problem and possible solution:

Upper

Display

Lower

Display

Kind of failure Solution

AL 5

The cannot start up

This is the rst light-up

Fill in the tank with pellets

Start up again

AL 6

NO

PELLET

The pellet stove switched off while work-

ing

Fill in the tank with pellets

AL 2

PROBE

EXHAUST

The smokes sensor is broken or not

connected to the pcb

Contact an Authorized Assistance Center

AL 7

SAFETY

THERMAL

The stove is overheated

Reset the thermostat manually. If the problem persists,

contact an Authorized Assistance Center.

COOL FIRE

There is no power supply

As soon as the power supply is back, the stove starts a cooling cycle. After completing the cycle it starts working automatically

AL 4

FAN

FAILURE

Smokes extractor blocked or broken Contact an Authorized Assistance Center

AL 8

FAILURE

DEPRESS

Obstructed ue

Clean the ue or check there are no obstructed grids near the

smokes exhaust

SERVICE

The stove has worked for 1300 hours.

Supplementary maintenance required

Contact an

Authorized Assistance Center

46

GB

Maintenance and cleaning of the stove

Before effecting any maintenance operation or cleaning

on the stove, take the following precautions:

• be sure that all parts of the stove are cold.

• be sure that the ashes are completely cold.

• be sure that the general switch is in the “OFF” position.

• be sure that the plug is pulled out of the socket to avoid

accidental contact.

• once the maintenance phase is completed check that

everything is in order as per before the intervention (the

brazier is placed correctly).

Follow carefully the following cleaning

instructions. Failure to follow these

instructions could create problems with

the operation of the stove.

Cleaning the glass

The glass is a self cleaning type, therefore, while the

stove is working, a veil of air is blown across its surface to

remove ash and dirt; nevertheless over a period of several

hours, a greyish patina tends to form which should be

cleaned when the stove is next shut down. How dirty the

glass becomes also depends on the quality and quantity

of pellets used.

Cleaning the glass should be done when the stove is cold

with products recommended and tested by our company.

When performing this operation, always check that the

grey seal around the glass is in a good state; failure to

check the efciency of this gasket can compromise the

function of the stove.

Poor quality pellets can, in any case, cause the glass to

become dirty.

If the glass is broken, do not attempt to

light the stove.

Cleaning the ceramic covering (if supplied)

The ceramic tiling must be cleaned with a soft dry cloth

before using a damp cloth. Use only neutral and delicate

detergents.

Do not wet and never clean the ceramic tiling with cold

water while it is hot as the thermal shock could cause

breakage!

Cleaning the brazier and brazier support

When the ame assumes a red colour or seems weak, and

is accompanied by black smoke, this means that there

are ash deposits or incrustations that do not permit the

correct functioning of the stove and that must be removed.

Remove the brazier every day by simply raising it from its

slot; then clean out the ashes and eventual incrustations

that may have formed, paying particular attention to

liberating the holes by using a pointed tool (not included

with the stove).

This operation is made particularly necessary before

every lighting the rst several times and above all if using

pellets that differ from those supplied by our company.

The frequency of this operation is determined by how

frequently the stove is used and the choice of pellets.

It is also a good idea to check the brazier support,

vacuuming the eventual ash present.

Ash box

Open the door and extract

the ash box. Use a vacuum

to remove all the ash deposited within.

This operation must be performed more or less frequently depending on the

quality of the pellets used.

Cleaning compartment exchanger

Under the ash drawer is the compartment exchanger;

make the cleaning by suction.

Be very careful because the ceramic

is very hot.

47

GB

1

CLEANING BY THE TECHNICAL

Check every year

Clean the combustion chamber

Cleaning the metal parts

To clean the metal parts of the stove, use a soft cloth

dampened with water.

Never clean the metal parts with alcohol, thinners,

petrol, acetone or other degreasing substances. If

such substances are used, our company declines any

responsibility.

Eventual variations in the colour of the metal parts can be

caused by an incorrect use of the stove.

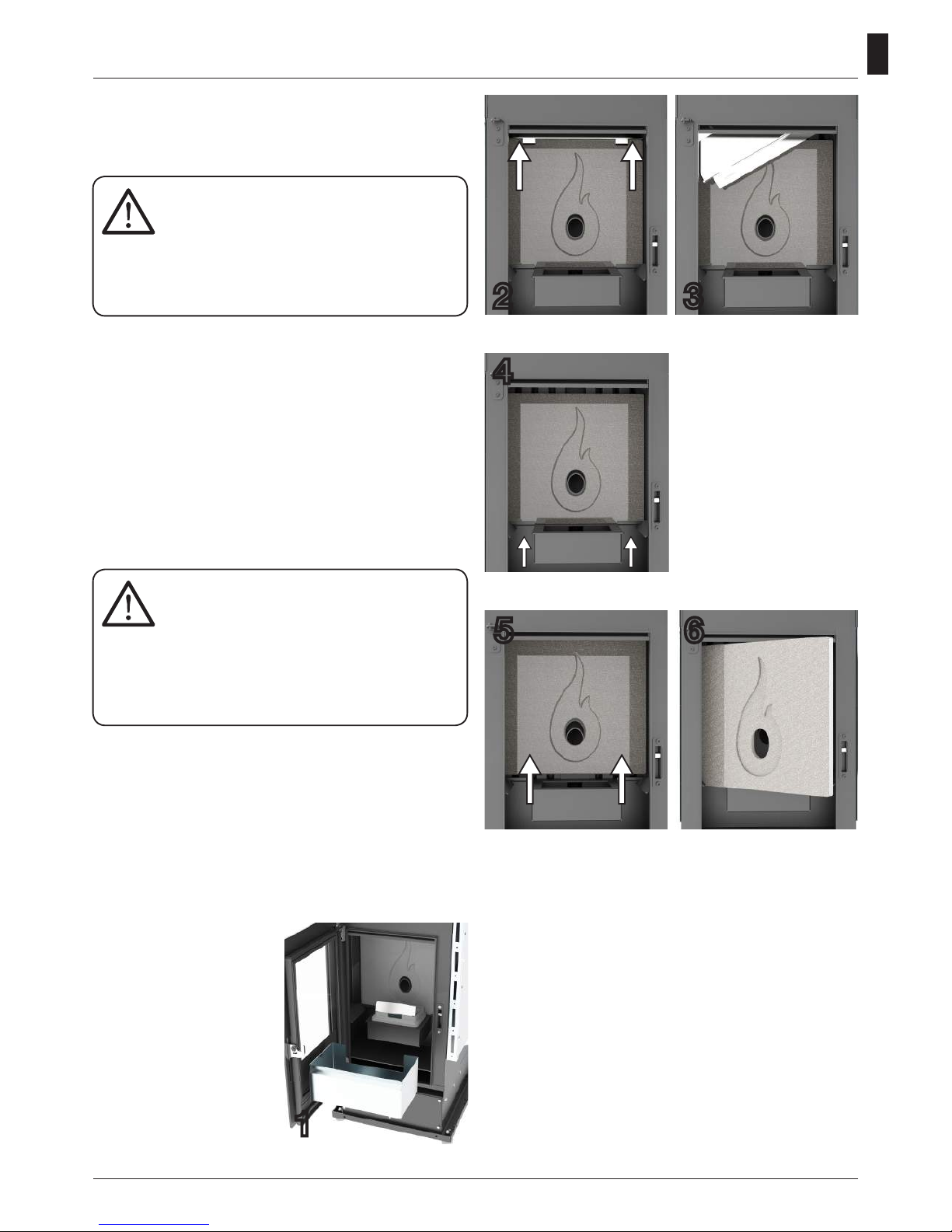

When the stove is cold,

please join the following

procedure: open the door

and pull the ash tray out and

remove the brazier. (photo 1)

Remove the mounting of

the refractory pushing it upwards and then pull it out

from the combustion chamber. (photo 2)

Turn and tilt it to remove it.

(photo 3)

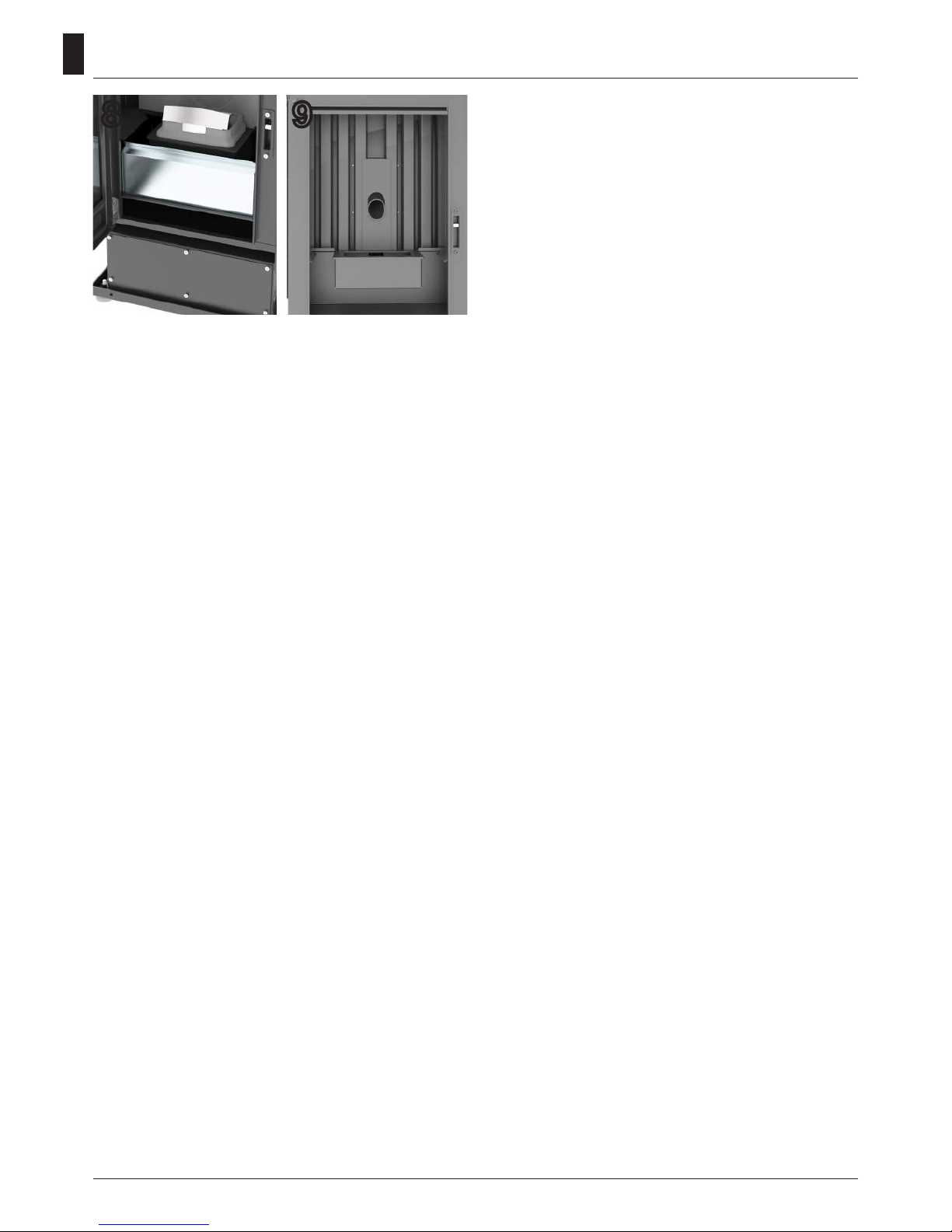

With a vacuum cleaner to clean the refractory material

and the walls of the combustion chamber, in particular the

front wall in which are located the heat exchanger pipes,

(photo 9) the bottom of the chamber combusione and the

compartment that is located below the ash box. (photo 8)

Also clean the brazier and the ash box.

After completing the cleaning, replace the refractory, its

attachment, the ash drawer and nally the brazier.

The use of aggressive detergents or thinners can damage the surfaces of the

stove.

Before using any detergent it is advisable to try it

on a small section out of sight or contact the Authorized Assistance Centre for information regarding the product.

It is necessary to daily clean the brazier

and often clean the ash box.

The lack of cleanliness can prevent the

starting of the stove, causing damages to the stove

itself and to the environment (possible emission of

unbrunt material and soot).

Do not re-use the pellet possibly remained in the

brazier due to no starting-up.

2 3

Now push the refractory upwards (photo 4 + photo 5),

rotate (photo 6) and remove

it from the combustion

chamber.

When handling the refractory take care not to break

it, it is very fragile.

4

5 6

Cleaning the surfaces

To clean the surfaces, use a rag dampened with water or

with water and a neutral detergent.

48

GB

9

8

Cleaning the clearing system

Until a reasonable experience is acquired regarding the

operating conditions, it is advisable to perform this maintenance on at least a monthly basis.

• remove the electrical feed cable;

• remove the cap from the T-joint and proceed with the

cleaning of the ducts. If necessary, at least for the rst few

times, call in qualied personnel;

• carefully clean the smoke discharge system: for this,

contact a professional chimney sweep;

• once a year clean the dust, cobwebs, etc. from the zone

behind the internal covering panels, paying particular attention to the fans.

Cleaning the fans

The stove is furnished with fans (environmental and

smoke) positioned at the rear and below the stove.

Eventual deposits of dust or ash on the blades of the fan

can cause an imbalance in the fans leading to noisy performance. It is, therefore, necessary to clean the fans at

least once a year.

Since said operation requires dismantling several parts of

the stove, have the fans cleaned only by our Technical Assistance Centre.

Season end cleaning

At the end of the season, when the stove will not be used

for some time, it is advisable to perform a thorough and

general cleaning:

• Remove all the pellets from the container and the screw

feeder;

• Carefully clean the brazier, the brazier support, the combustion chamber and the ash box.

Once the preceding points have been observed, it only

means that the state of the stove has been veried.

It is necessary to thoroughly clean the smoke discharge

tube or ue and check the condition of the basket. If necessary, order a new one from our Authorized Assistance

Centre.

If necessary, lubricate the hinges of the door and the han-

dle.

Also check the ceramic bre cord near the glass, on the

internal wall of the door; if it is worn or too dry, order a new

one from the Authorized Assistance Centre.

49

GB

Every 1200 hours of work the electronic board sends a warning signal and the display will show

“SERVICE”. This indicates the need for a thorough cleaning of the stove by a CAT. The lack of such

cleaning could result in failure of the stove and poor combustion, thereby resulting in a lower yield.

Maintenance and cleaning

Parts Everyday

Every 2-3

days

Every

week

Every 15

days

Every 30

days

Every 60-

90 days

Every year /

1200-1400 h

Brazier ◊

Cleaning ash collection compartment ◊

Cleaning ash tray ◊

Cleaning the door and glass ◊

Cleaning the interior heat exchanger /

smoke fan compartment

•

Cleaning complete exchanger •

Clean "T" to exhaust •

Flue •

Door gasket ash •

Internal parts •

Flue pipe •

Electromechanical components •

All cleaning of all parts must be carried out with the stove completely cold and unplugged to

avoid burns and thermal shock. The stove does not need much maintenance if used with certified

quality pellet. The need for maintenance varies depending on the conditions of use (switching on

and off repeatedly) and depending on the performance required.

◊ by the user

• by the authorised qualied technical assistance

50

GB

Safety devices

Pressure switch: monitors

depression in the smoke duct.

It is designed to shut down the

pellet feed screw in the event

of an obstructed ue or signicant back-pressure in the

presence of wind. At the time

of the pressure switch will

show “ALAR-DEP-FAIL”.

Pellets temperature safety:

In the rare event there is a too

high temperature in the tank,

the thermostat for pellets safety with manual reset creates an

alarm “ALAR-SIC-FAIL” stopping the pellet boiler stove.

You need to reset the system

working on the device placed

on the back of the stove.

RESTART

PELLET

Reduction motor: if the motor

stops, the stove continues to

function until the ame goes

out for lack of fuel, and until It

has cooled down to the mini-

mum level.

Flue gas temperature sensor: thermocouple that meas-

ures the temperature of the

fumes while keeping the operation or shuts the stove when

the ue gas temperature drops

below the preset value.

Electrical safety: the stove is

protected against violent surg-

es of current (ex. lightnings)

by the main fuse 4 A which is

located on the control panel

at the rear of the stove. Other

fuses to protect the electronic

boards are to be found on the

boards themselves.

Tampering with the safety devices is prohibited. It is only after eliminating the cause which gave

rise to the intervention of the safety system, that it is possible to relight the stove and thus reset

the automatic operation of the sensor. To understand which anomaly has occurred, consult this

manual at paragraph relating to alarms which explains what to do based on the alarm message the

stove display.

Room thermostat: the room

thermostat detects the present temperature in the room.

When it detects the set temperature on the display, the

stove will go into operation in

ECO ie hold function to save

fuel.

The room thermostat should

be spread so as not to be conditioned by the temperature of

the body stove.

51

GB

Any inconvenience and solutions

Given that all stoves are tested in their parts handling and work and therefore are delivered in perfect physical condition and operation, it should be remembered that the transport, unloading, handling, misuse or poor maintenance,

can be causes of drawbacks.

The main problems may be solved by reading the table below.

If after doing as hereinafter described the problem is not resolved, contact your authorized service center.

Problems and solutions

All repairs must be carried out exclusively by a specialised technician, with the stove completely

cold and the electric plug pulled out

. Is prohibited from any unauthorized modification to the

device and the replacement of parts with other non-original.

The operations marked in bold type

must be carried out by specialised personnel.

PROBLEM POSSIBLE CAUSE REMEDY

Display off and but-

tons are not working

1. Power failure in the network

2. Switch back off

3. Display defective

4. Fault in the connection of the

display with the card

5. Fuse board interrupted

6. Card defective

1. Check that the power cord is connected

2. Use the switch back to operate it

3. Unplug the stove from the power outlet for about

one minute and then turn on. If the problem persists,

contact an authorized service center

4. Check that the display and board are properly connected. Contact your authorized service

center

5. Contact an authorized service center

6. Contact an authorized service center

Remote inefcient

1. Too far from the stove

2. No batteries in the remote

3. The remote control is broken

1. Move closer to the stove

2. Check and change the batteries

3. Replace the remote control

Failure to ignite

the stove

1. Excessive accumulation of ash

in the grate

2. Incorrect ignition procedure

1. Clean the grate

2. Repeat the ignition procedure. If the problem

persists, contact your authorized service center

Smoke comes from

the grill

1. Accidental electrical blackout

1. In case of ignition phase interrupted and momentary interruption of the fan, can occur slight amount

of smoke

Hot air fan is not

working

1. The stove has not yet been

heated

1. Wait until the conclusion of the ignition cycle.

Arrived in temperature, the fan will start automatically.

If the problem persists, contact your authorized ser-

vice center.

52

GB

The stove does not

turn on automatically

1. The tank is empty.

2. The resistance does not reach

the temperature

3. Resistance damaged

4. The pellet drops

5. Screw motor defective

6. The grate is not in place or is

dirty

7. Obstruction of nests or foreign

bodies in the chimney or re-

place

8. Check operation of the glow

plug

9. The ash drawer is not closed

properly

10. Clogged ue and chimney

11. Smoke extractor not working

12. Temperature sensor defective

13. Pellet wet

1. Fill the tank with pellets

2. Check the electrical wiring and fuses, replace if

the resistance is broken

3. Replace the resistance

4. It is recommended to unplug the power supply

before:

- check that the pellet is not caught in the chute

- check that the cochlea is not blocked by dirt

- check the seal of the pellet-door

5. Contact an authorized service center

6. Check that the hole in the brazier matches the

glow plug, clean brazier

7. Remove any foreign body from the chimney or ue

pipe

8. Make sure that there is power. Replace the spark

plug if burned

9. Close the drawer ashtray

10. Perform periodic cleaning

11. Check the operation of the extractor flue

12. Contact an authorized service center

13. Make sure the place of stowage pellet and replace it with a handful of dry pellets

Lock the stove.

Pellets not being fed

into the combustion

chamber

1. The tank is empty

2. The cochlea is no pellet

3. Technical problem of the

cochlea

4. Reduction motor failure

5. Electronic board faulty

1. Load the pellets in the tank.

2. Fill the tank and proceed as instructed before igni-

tion stove

3. IT IS RECOMMENDED to unplug the power supply before:

- empty the thank and manually free the auger from

obstructions (sawdust)

- release the slide from obstructions

- remove the dust accumulation of pellets in the bottom of the tank

4. Replace the reduction motor

5. Replace the electronic board

The stove runs for a

few minutes and then

turn off

1. Lighting cycle not completed

2. Temporary failure of electricity

3. Probes fumes defective or

broken or not inserted

1. Re-run power

2. Re-run power

3. Check and replace sensors

Fume extraction fan

does not stop

1. The stove has not yet cooled

1. Allow the stove to cool. Only after cooling fan will

stop. If the problem persists, contact your authorized service center

53

GB

The stove is clogged

early in the brazier

with burning irregular,

door glass gets dirty,

the ame is long, reddish and weak

1. Flue with presence of stretch-

es too long or clogged

2. Too pellet

3. Excessive pellet or ash deposits in the brazier

4. The brazier is not found in its

slot

5. Wind contrary to the exhaust

ow

6. Insufcient combustion air

7. You changed the type of pel-

lets used

8. Smoke extractor motor broken

9. Door closed incorrectly

1. Perform periodic cleaning. See paragraph stove

installation in the user manual. Check chimney

cleaning

2. Decrease in the parameters the charge level of the

pellets

3. Clean the brazier after waiting for the total shutdown of the stove. If you repeat contact your

Authorized Service Center

4. Check that the hole in the brazier matches the

glow plug

5. Check the chimney cap windproof and / or possibly install it

6. Check the correct position of the brazier, its cleanliness and check that the air intake in both free environment, verify the status of the door seal, increase

the level in the parameter relative to the speed of

the fan exhaust fumes. Contact your Authorized

Service Center

7. Check the quality of the pellets. Contact your

Authorized Service Center

8. Increase the level in the parameters relating to the

speed of the fan exhaust fumes. Check and eventu-

ally replace motor

9. Check that the glass is sealed and the seal guarantees tightness

Smell of smoke in the

environment. Turning

off the stove.

1. Poor combustion

2. Malfunction of fan fumes

3. Installation of the ue performed incorrectly

4. Clogged chimney

1. Contact your Authorized Service Center

2. Contact your Authorized Service Center

3. Contact your Authorized Service Center

4. Contact your Authorized Service Center

In the automatic position the stove always

runs at full power

1. Room thermostat set to maxi-

mum

2. Signicant temperature sensor

failure

3. Control panel defective or

broken

1. Reset the thermostat temperature

2. Check the operation of the sensor and replace if

necessary

3. Check the control panel and replace if necessary

The engine smoke

extraction does not

work

1. The stove has no voltage

2. The motor is broken

3. The board is defective

4. The control panel has failed

1. Check the supply voltage and the protection fuse.

2. Check the motor and capacitor and replace if

necessary.

3. Replace the circuit board.

4. Replace the control panel.

54

GB

The manufacturer of the stove any liability and will void the warranty terms of the product for any

inconvenience caused by not following the rules described above. Any work of service center will

be borne by the applicant if they are not complied with these instructions.

The re goes out or

the stove stops automatically

1. The pellet tank is empty

2. No power

3. Pellets not being fed

4. Excessive deposit of ashes in

the grate

5. Intervention probe temperature

safety of the pellet

6. Cochlea blocked by dirt

7. The door is not closed properly or gaskets worn

8. Pellet inadequate

9. Low pellet

10. Chimney or drain clogged

with nests or foreign bodies

11. Pressure switch cuts

12. Smoke extraction motor

failure

13. Alarm active

1. Fill the tank with pellets

2. Check plug and presence electricity

3. Fill the tank with pellets

4. Clean the brazier

5. Let the stove cool down completely, reset the

manual reset and restart the stove. If the problem

persists, contact your authorized service representa-

tive

6. Pull the plug, empty the tank, remove any foreign

objects

7. Close the door or replace the gaskets with original

8. Change the type of pellet recommended by the

manufacturer. Sometimes, depending on the type,

the stage of adjustment of the parameters need

to vary the level relating to the loading of pellets

9. Increase the level in the parameter for the pellet feed. To check the flow of fuel from technical

authorized

10. Eliminate all foreign matter from the chimney

Clean the smoke duct. Perform periodic cleaning.

11. Verify potential smoke duct is blocked and if

the pressure switch is working properly

12. Check and replace the motor if necessary

13. See paragraph alarms

The air fan convention

(ambient air) never

stops

1. Temperature sensor tempera-

ture control defective or broken

2. Smoke probe fails

1. Check the operation of the sensor and replace if

necessary

2. Replace smoke probe

The stove does not

light.

1. Lack of electricity

2. Probe pellets in bulk

3. Fuse blown

4. Pressure switch broken (lockout indicated)

5. Smoke outlet or duct clogged

1. Check that the electrical outlet is plugged in and

the power switch to "I"

2. Lockout by resetting the rear thermostat, replace

the thermostat if it happens again

3. Replace the fuse

4. Replace the pressure

5. Clean the smoke outlet and / or smoke duct

55

GB

NOTES

56

GB

NOTES

Loading...

Loading...