HMI connection manual

|

CATALOG |

|

1 SERIAL PORT OF HMI .................................................................................................................... |

1 |

|

1.1 |

Download port .......................................................................................................................... |

1 |

1.2 |

PLC port ................................................................................................................................... |

3 |

1.3 |

Expand port.............................................................................................................................. |

3 |

1.4 |

Ethernet port ............................................................................................................................ |

5 |

2 THE CONNECTION OF PLC AND HMI............................................................................................ |

8 |

|

2.1 |

XINJE FC series PLC .............................................................................................................. |

8 |

|

2.1.1Model .............................................................................................................................. |

8 |

|

2.1.2 Parameters .................................................................................................................... |

8 |

|

2.1.3 Cable making................................................................................................................. |

8 |

|

2.1.4 Device address .............................................................................................................. |

9 |

2.2 |

XINJE XC series PLC ............................................................................................................ |

10 |

|

2.2.1 Model ........................................................................................................................... |

10 |

|

2.2.2 Parameters .................................................................................................................. |

10 |

|

2.2.3 Cable making................................................................................................................ |

11 |

|

2.2.4 Device address ............................................................................................................ |

12 |

2.3 |

Mitsubishi FXseries PLC........................................................................................................ |

14 |

|

2.3.1Model ............................................................................................................................ |

14 |

|

2.3.2 Parameters .................................................................................................................. |

14 |

|

2.3.3 Cable making............................................................................................................... |

15 |

|

2.3.4 Device address ............................................................................................................ |

16 |

2.4 |

Mitsubishi FX3U/G series PLC .............................................................................................. |

17 |

|

2.4 .1 Model .......................................................................................................................... |

17 |

|

2.4 .2 Parameters ................................................................................................................. |

17 |

|

2.4 .3 Cable making.............................................................................................................. |

18 |

|

2.4 .4 Device address ........................................................................................................... |

18 |

2.5 |

Mitsubishi FX BD series PLC (RS232/485) ........................................................................... |

20 |

|

2.5.1 Device type .................................................................................................................. |

20 |

|

2.5.2 Parameters .................................................................................................................. |

20 |

|

2.5.3 Cable making............................................................................................................... |

21 |

|

2.5.3 Device address ............................................................................................................ |

22 |

2.6 |

Mitsubishi Q series PLC......................................................................................................... |

23 |

|

2.6 .1 Model .......................................................................................................................... |

23 |

|

2.6.2 Parameters .................................................................................................................. |

23 |

|

2.6.3 Cable making............................................................................................................... |

26 |

|

2.6.4 Device address ............................................................................................................ |

27 |

2.7 |

Siemens S7-200 series PLC ............................................................................................... |

29 |

|

2.7.1Model ............................................................................................................................ |

29 |

|

2.7.2 Parameters .................................................................................................................. |

29 |

|

2.7.3 Cable making............................................................................................................... |

30 |

|

2.7.4 Device address ............................................................................................................ |

30 |

|

ii |

|

2.8 Siemens S7-300/400 series PLC........................................................................................... |

32 |

2.8.1 Model ........................................................................................................................... |

32 |

2.8.2 Parameters .................................................................................................................. |

32 |

2.8.3 Cable making............................................................................................................... |

34 |

2.8.4 Device address ............................................................................................................ |

35 |

2.9 OMRON SYSMAC series PLC............................................................................................ |

36 |

2.9.1 Device model ............................................................................................................... |

36 |

2.9.2 Parameters .................................................................................................................. |

37 |

2.9.3 Cable making............................................................................................................... |

38 |

2.9.4 Device address ............................................................................................................ |

39 |

2.10 Koyo S series PLC............................................................................................................... |

41 |

2.10.1 Device model ............................................................................................................. |

41 |

2.10.2 Parameters ................................................................................................................ |

42 |

2.10.3 Cable making............................................................................................................. |

43 |

2.10.4 Device address .......................................................................................................... |

44 |

2.11 Koyo DL series PLC ............................................................................................................. |

45 |

2.11.1 Device type ................................................................................................................ |

45 |

2.11.2 Parameters................................................................................................................. |

45 |

2.11.3 Cable making ............................................................................................................. |

45 |

2.11.4 Device address .......................................................................................................... |

46 |

2.12 Delta DVP series PLC.......................................................................................................... |

47 |

2.12.1Model .......................................................................................................................... |

47 |

2.12.2 Parameters ................................................................................................................ |

47 |

2.12.3 Cable making............................................................................................................. |

47 |

2.12.4 Device address .......................................................................................................... |

48 |

2.13 LG Master-K(CPU Direct) series PLC ................................................................................. |

49 |

2.13.1 Device model ............................................................................................................. |

49 |

2.13.2 Parameters ................................................................................................................ |

49 |

2.13.3 Cable making............................................................................................................. |

50 |

2.13.4 Device address .......................................................................................................... |

50 |

2.14 LG Master-K(Cnet) series PLC............................................................................................ |

52 |

2.14.1 Device model ............................................................................................................. |

52 |

2.14.2 Parameters ................................................................................................................ |

52 |

2.14.3 Cable making............................................................................................................. |

53 |

2.14.4 Device address .......................................................................................................... |

54 |

2.15 LG Glofa(Cnet) series PLC.................................................................................................. |

55 |

2.15.1 Device model ............................................................................................................. |

55 |

2.15.2 Parameters ................................................................................................................ |

55 |

2.15.3 Cable making............................................................................................................. |

57 |

2.15.4 Device address .......................................................................................................... |

58 |

2.16 LG XGT(CPU Direct) series PLC......................................................................................... |

60 |

2.16.1 Device model ............................................................................................................. |

60 |

2.16.2 Parameters ................................................................................................................ |

60 |

2.16.3 Cable making............................................................................................................. |

60 |

|

iii |

2.16.4 Device address .......................................................................................................... |

61 |

2.17 Matsushita MEWNET FP series PLC .................................................................................. |

62 |

2.17.1Device model .............................................................................................................. |

62 |

2.17.2 Parameters ................................................................................................................ |

63 |

2.17.3 Cable making............................................................................................................. |

64 |

2.17.4 Device address .......................................................................................................... |

65 |

2.18 Schneider PLC .................................................................................................................. |

67 |

2.18.1Device model .............................................................................................................. |

67 |

2.18.2 Parameters ................................................................................................................ |

67 |

2.18.3 Cable making............................................................................................................. |

69 |

2.18.4 Device address .......................................................................................................... |

69 |

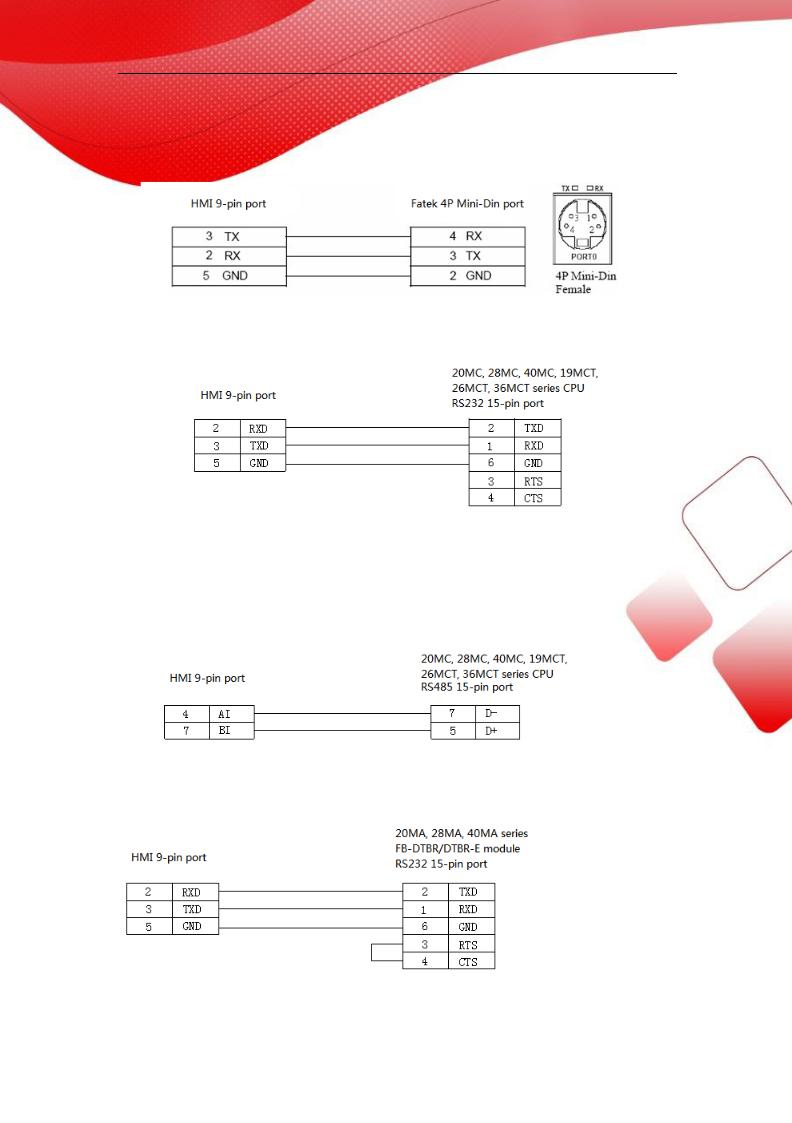

2.19 Fatek FB series PLC............................................................................................................ |

70 |

2.19.1 Device model ............................................................................................................. |

70 |

2.19.2 Parameters ................................................................................................................ |

70 |

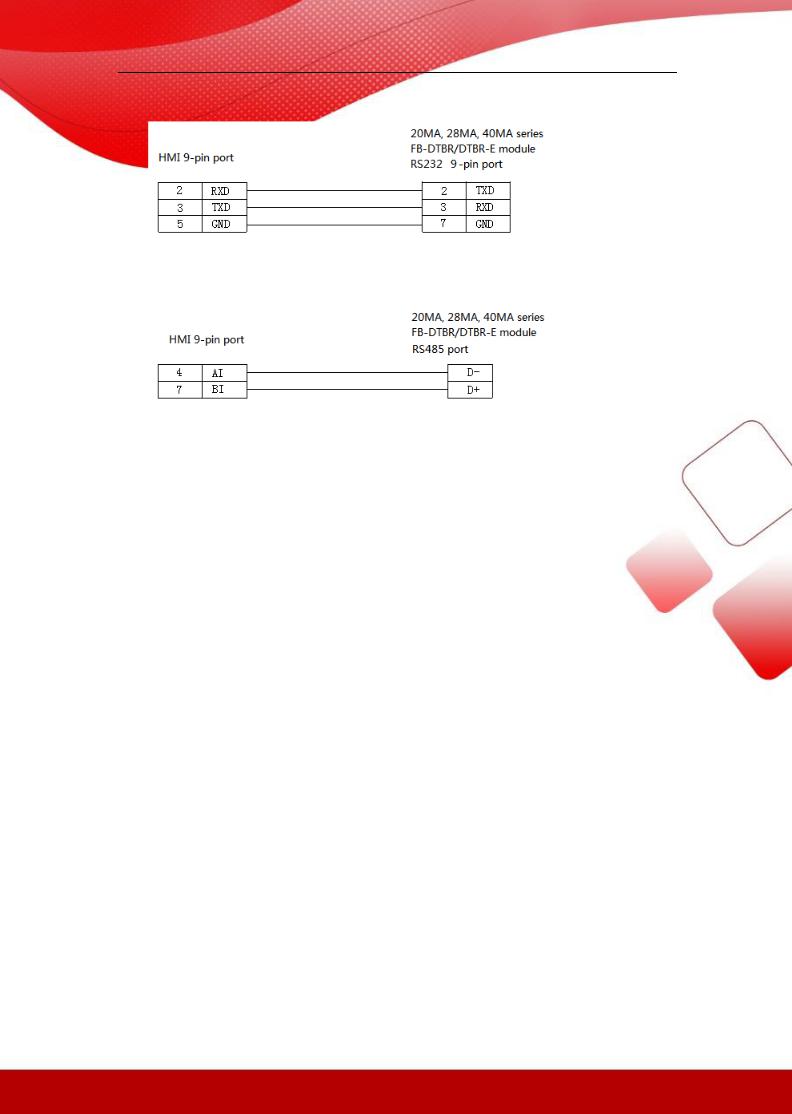

2.19.3 Cable making............................................................................................................. |

71 |

2.19.4 Device address .......................................................................................................... |

72 |

2.20 Vigor VIGOR PLC ................................................................................................................ |

73 |

2.20.1 Device model ............................................................................................................. |

73 |

2.20.2 Parameters ................................................................................................................ |

73 |

2.20.3 Cable making............................................................................................................. |

73 |

2.20.4 Device address .......................................................................................................... |

75 |

2.21 Fuji SPB series PLC ............................................................................................................ |

76 |

2.21.1 Device model ............................................................................................................. |

76 |

2.21.2 Parameters ................................................................................................................ |

76 |

2.21.3 Cable making............................................................................................................. |

76 |

2.21.4 Device address .......................................................................................................... |

77 |

2.22 Keyence KV series PLC....................................................................................................... |

79 |

2.22.1Device model .............................................................................................................. |

79 |

2.22.2 Parameters ................................................................................................................ |

79 |

2.22.3 Cable making............................................................................................................. |

79 |

2.22.4 Device address .......................................................................................................... |

81 |

2.23 Emerson EC20 series PLC.................................................................................................. |

82 |

2.23.1Device model .............................................................................................................. |

82 |

2.23.2 Parameters ................................................................................................................ |

82 |

2.23.3 Cable making............................................................................................................. |

82 |

2.23.4 Device address .......................................................................................................... |

83 |

2.24 OEMax NX7 series PLC ...................................................................................................... |

84 |

2.24.1 Device model ............................................................................................................. |

84 |

2.24.2 Device address .......................................................................................................... |

84 |

2.24.3 Cable making............................................................................................................. |

84 |

2.24.4 Device address .......................................................................................................... |

86 |

2.25 Bosch Rexroth IndraControl L40 series PLC....................................................................... |

87 |

2.25.1 Device model ............................................................................................................. |

87 |

2.25.2 Parameters ................................................................................................................ |

87 |

iv |

|

2.25.3 Cable making............................................................................................................. |

87 |

2.25.4 Device address .......................................................................................................... |

88 |

2.26 OPTO 22 SNAP series PLC ................................................................................................ |

89 |

2.26.1 Device model ............................................................................................................. |

89 |

2.26.2 Parameters ................................................................................................................ |

89 |

2.26.3 Cable making............................................................................................................. |

89 |

2.26.4 Device address .......................................................................................................... |

90 |

2.27 SAIA-Burgess PCD series PLC ........................................................................................... |

91 |

2.27.1 Device model ............................................................................................................. |

91 |

2.27.2 Parameters ................................................................................................................ |

92 |

2.27.3 Cable making............................................................................................................. |

92 |

2.27.4 Device address .......................................................................................................... |

96 |

2.28 Allen-Bradley series PLC ..................................................................................................... |

96 |

2.28.1 Device model ............................................................................................................. |

96 |

2.28.2 Parameters ................................................................................................................ |

96 |

2.28.3 Cable making............................................................................................................. |

99 |

2.28.4 Device address .......................................................................................................... |

99 |

2.29 Xinje V5 series inverter ...................................................................................................... |

101 |

2.29.1 Device model ........................................................................................................... |

101 |

2.29.2 Parameters .............................................................................................................. |

101 |

2.29.3 Cable making........................................................................................................... |

102 |

2.30 SHIMADEN ........................................................................................................................ |

103 |

2.30.1 Device model ........................................................................................................... |

103 |

2.30.2 Parameters .............................................................................................................. |

103 |

2.30.3 Cable making........................................................................................................... |

103 |

2.30.4 Device address ........................................................................................................ |

104 |

2.31 Modbus RTU (panel is Master).......................................................................................... |

105 |

2.31.1 Device model ........................................................................................................... |

105 |

2.31.2 Parameters .............................................................................................................. |

105 |

2.31.3 Cable making........................................................................................................... |

105 |

2.31.4 Device address ........................................................................................................ |

106 |

2.32 Modbus ASCII (Panel is Master)........................................................................................ |

107 |

2.32.1Device model ............................................................................................................ |

107 |

2.32.2 Parameters .............................................................................................................. |

107 |

2.32.3 Cable making........................................................................................................... |

107 |

2.32.4 Device address ........................................................................................................ |

108 |

2.33 Modbus slave (panel is Slave)........................................................................................... |

109 |

2.33.1Device model ............................................................................................................ |

109 |

2.33.2 Parameters .............................................................................................................. |

109 |

2.33.3 Cable making........................................................................................................... |

109 |

2.33.4 Device address ......................................................................................................... |

110 |

2.34 ABB PLC ............................................................................................................................. |

111 |

2.34.1Device model ............................................................................................................. |

111 |

2.34.2 Parameters ............................................................................................................... |

111 |

|

v |

|

2.34.3 Cable making............................................................................................................ |

112 |

|

2.34.4 Device address ......................................................................................................... |

113 |

2.35 IDEC.................................................................................................................................... |

114 |

|

|

2.35.1 Device type ............................................................................................................... |

114 |

|

2.35.2 Parameters ............................................................................................................... |

114 |

|

2.35.3 Cable making............................................................................................................ |

114 |

|

2.35.4 Device address ......................................................................................................... |

115 |

2.36 TAIAN .................................................................................................................................. |

116 |

|

|

2.36.1 Device type ............................................................................................................... |

116 |

|

2.36.2 Parameters ............................................................................................................... |

117 |

|

2.36.3 Cable making............................................................................................................ |

117 |

|

2.36.4 Device address ......................................................................................................... |

118 |

2.37 YuDian AI ............................................................................................................................ |

119 |

|

|

2.37.1 Device address ......................................................................................................... |

119 |

|

2.37.2 Parameters ............................................................................................................... |

119 |

|

2.37.3 Cable making............................................................................................................ |

119 |

|

2.37.4 Device address ........................................................................................................ |

120 |

2.38 Inovance PLC..................................................................................................................... |

121 |

|

|

2.38.1 Device type .............................................................................................................. |

121 |

|

2.38.2 Parameter ................................................................................................................ |

121 |

|

2.38.3 Cable making........................................................................................................... |

122 |

|

2.38.4 Device address ........................................................................................................ |

122 |

2.39 |

HaiWell PLC .................................................................................................................... |

124 |

|

2.39.1 Device type .............................................................................................................. |

124 |

|

2.39.2 Parameters .............................................................................................................. |

124 |

|

2.39.3 Cable making........................................................................................................... |

124 |

|

2.39.4 Device address ........................................................................................................ |

125 |

2.40 |

Hollias PLC...................................................................................................................... |

126 |

|

2.40.1 Device type .............................................................................................................. |

126 |

|

2.40.2 Parameters .............................................................................................................. |

126 |

|

2.40.3 Cable making........................................................................................................... |

126 |

|

2.40.4 Device address ........................................................................................................ |

127 |

2.41 |

Delta (temperature controller) ......................................................................................... |

128 |

|

2.41.1 Device type .............................................................................................................. |

128 |

|

2.41.2 Parameters .............................................................................................................. |

128 |

|

2.41.3 Cable making........................................................................................................... |

128 |

|

2.41.4 Device address ........................................................................................................ |

129 |

2.42 |

Siemens S7-1200............................................................................................................ |

130 |

|

2.42.1 Device type .............................................................................................................. |

130 |

|

2.42.2 Parameters .............................................................................................................. |

130 |

|

2.42.3 Cable making........................................................................................................... |

135 |

|

2.42.4 Device address ........................................................................................................ |

136 |

2.43 Mitsubishi FR series inverter ............................................................................................. |

137 |

|

|

2.43.1 Device type .............................................................................................................. |

137 |

|

|

vi |

2.43.2 Parameters .............................................................................................................. |

137 |

2.43.3 Cable making........................................................................................................... |

140 |

2.44 Sanken VM06 inverter ....................................................................................................... |

141 |

2.44.1 Device type .............................................................................................................. |

141 |

2.44.2 Parameters .............................................................................................................. |

141 |

2.44.3 Cable making........................................................................................................... |

143 |

2.44.4 Device address ........................................................................................................ |

143 |

2.45 XINJE XD/XE series .......................................................................................................... |

145 |

2.45.1 Device type .............................................................................................................. |

145 |

2.45.2 Parameters .............................................................................................................. |

145 |

2.45.3 Cable making........................................................................................................... |

146 |

2.45.4 Device address ........................................................................................................ |

147 |

2.46 LG XGB series PLC ........................................................................................................... |

149 |

2.46.1 Device type .............................................................................................................. |

149 |

2.46.2 Parameters .............................................................................................................. |

149 |

2.46.3 Cable making........................................................................................................... |

153 |

2.46.4 Device address ........................................................................................................ |

154 |

2.47 Koyo Click series ............................................................................................................... |

155 |

2.47.1 Device type .............................................................................................................. |

155 |

2.47.2 Parameter setting .................................................................................................... |

155 |

2.47.3 Cable making........................................................................................................... |

156 |

2.47.4 Device address ........................................................................................................ |

156 |

2.48 Mitsubishi Melsec protocol................................................................................................. |

157 |

2.48.1 Device type .............................................................................................................. |

157 |

2.48.2 Parameter settings................................................................................................... |

158 |

2.48.3 Cable making........................................................................................................... |

161 |

2.48.4 Device address ........................................................................................................ |

162 |

2.49 Free type (panel is slave)................................................................................................... |

162 |

2.49.1 Device type .............................................................................................................. |

162 |

2.49.2 Parameter setting .................................................................................................... |

163 |

2.49.3 Cable making........................................................................................................... |

165 |

2.49.4 Device address ........................................................................................................ |

166 |

2.50 Modbus-TCP device .......................................................................................................... |

166 |

2.50.1 Device type .............................................................................................................. |

166 |

2.50.2 Parameter setting .................................................................................................... |

166 |

2.50.3 Cable making........................................................................................................... |

172 |

2.50.4 Device address ........................................................................................................ |

173 |

2.51 Mitsubishi FX5U series ...................................................................................................... |

173 |

2.51.1 Device type .............................................................................................................. |

173 |

2.51.2 Parameter setting .................................................................................................... |

173 |

2.51.3 Cable making........................................................................................................... |

177 |

2.51.4 Device address ........................................................................................................ |

178 |

2.52 Siemens S7-200 smart series............................................................................................ |

179 |

2.52.1 Device type .............................................................................................................. |

179 |

|

vii |

2.52.2 Parameter setting .................................................................................................... |

179 |

2.52.3 Cable making........................................................................................................... |

182 |

2.52.4 Device address ........................................................................................................ |

184 |

2.53 Siemens S7-300 series...................................................................................................... |

185 |

2.53.1 Device type .............................................................................................................. |

185 |

2.53.2 Parameter setting .................................................................................................... |

185 |

2.53.3 Cable making........................................................................................................... |

188 |

2.53.4 Device address ........................................................................................................ |

190 |

2.54 X-NET communication ....................................................................................................... |

191 |

2.54.1 Device type .............................................................................................................. |

191 |

2.54.2 HMI setting............................................................................................................... |

191 |

2.54.3 XD series PLC setting (PLC hardware V3.2.2 and up) ........................................... |

197 |

2.54.4 Cable making........................................................................................................... |

200 |

2.54.5 Device address ........................................................................................................ |

202 |

2.55 Keyence KV5000 ............................................................................................................... |

204 |

2.55.1 Device type .............................................................................................................. |

204 |

2.55.2 Parameter setting .................................................................................................... |

204 |

2.55.3 Cable making........................................................................................................... |

207 |

2.55.4 Device address ........................................................................................................ |

208 |

2.56 LG XGT .............................................................................................................................. |

209 |

2.56.1 Device type .............................................................................................................. |

209 |

2.56.2 Parameter setting .................................................................................................... |

209 |

2.56.3 Cable making............................................................................................................ |

211 |

2.56.4 Device address ........................................................................................................ |

212 |

2.57 Haiwell................................................................................................................................ |

213 |

2.57.1 Device type .............................................................................................................. |

213 |

2.57.2 Parameters .............................................................................................................. |

213 |

2.57.3 Cable making........................................................................................................... |

215 |

2.57.4 Device address ........................................................................................................ |

216 |

viii

1 Serial port of HMI

This chapter will introduce the serial port of HMI.

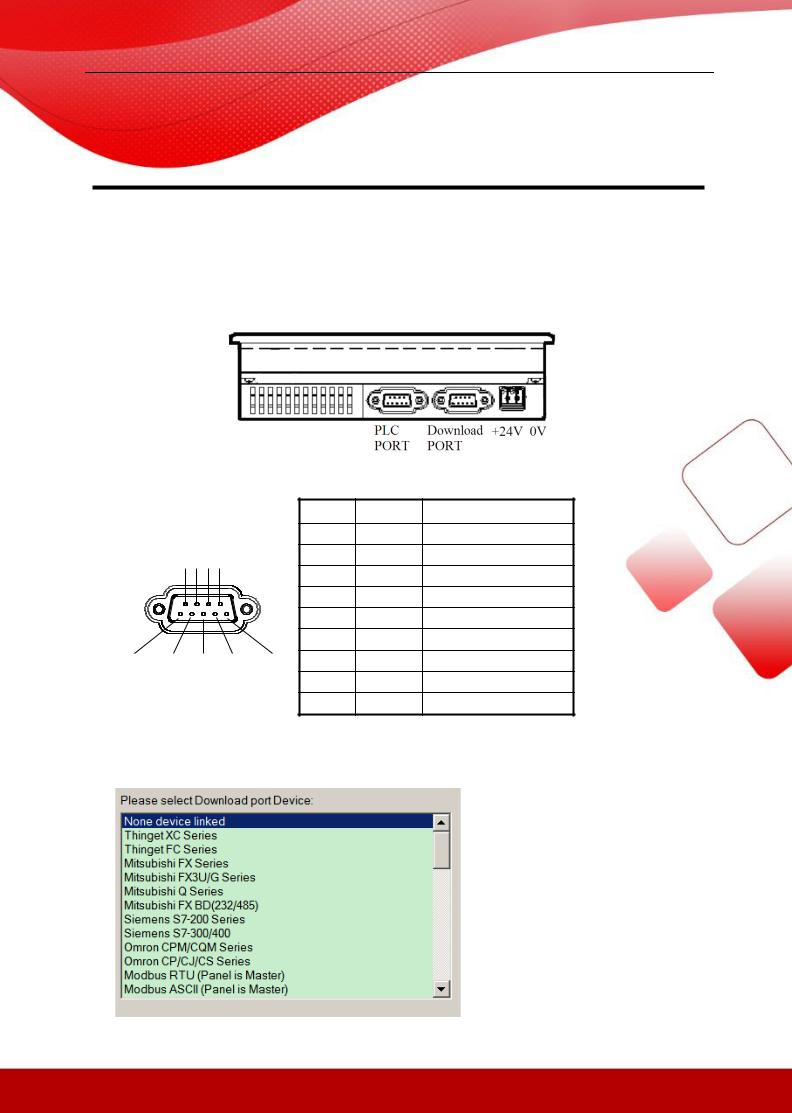

1.1 Download port

The HMI of XINJE TP and TH series are configured PLC port and download port. Next, it will introduce the port and function. The following diagram is the port of TP460-L.

Download port: |

|

|

|

|

|

||

|

|

|

|

|

Pin |

Name |

Explanation |

|

9 8 7 6 |

|

1 |

NC |

Vacant |

||

|

|

2 |

RXD |

RS232 receive |

|||

|

|

|

|

|

|||

|

|

|

|

|

3 |

TXD |

RS232 send |

|

|

|

|

|

4 |

A |

RS485 + |

|

|

|

|

|

5 |

GND |

Ground |

|

|

|

|

|

6 |

NC |

Vacant |

5 |

4 |

3 |

2 |

1 |

7 |

B |

RS485 - |

|

|

|

|

|

8 |

NC |

Vacant |

|

|

|

|

|

9 |

NC |

Vacant |

1. Choose the device to communicate with download port

(a) Build a new project in Touchwin software, choose download port device

1

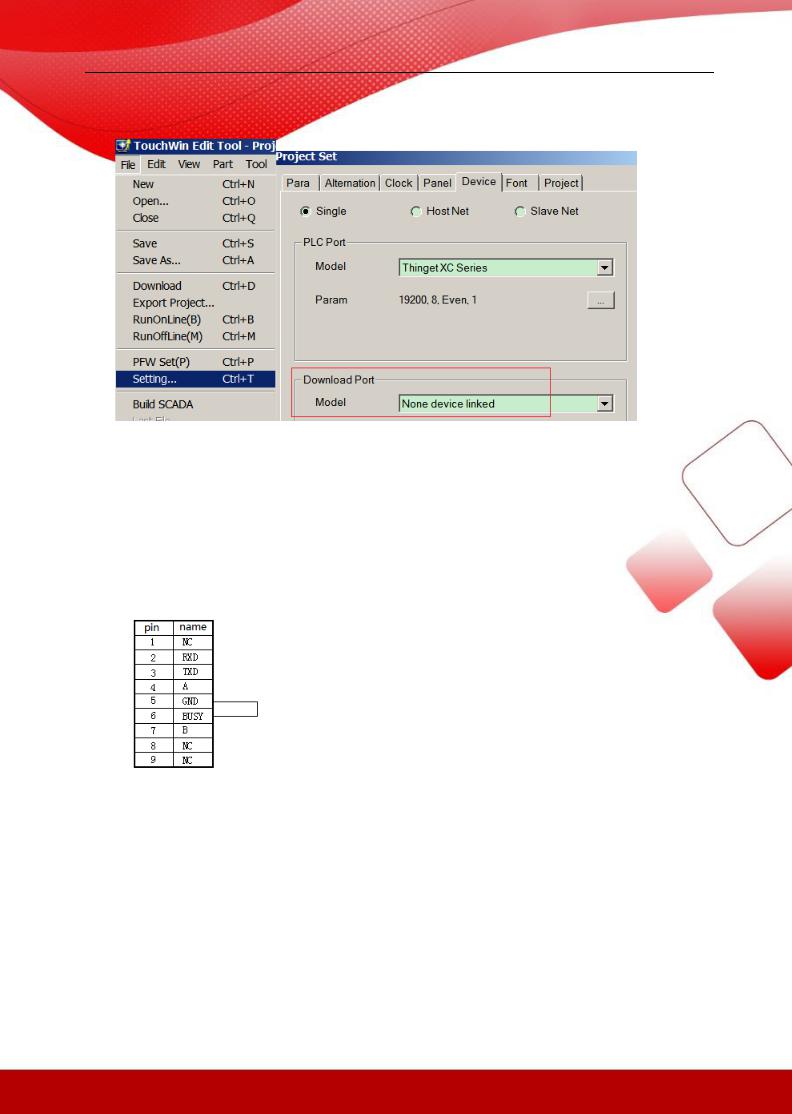

(b) For current project, please set it in the Touchwin software:

2. Mode switching for download port

The default mode of TH series download port is communication. But it is download mode for TP series. If the download port of TP series needs to switch to communication mode, two pins of the download port must be shorted. Please see the following diagram.

(1)Cut off the power of TP series HMI, connect pin5 and pin6 of TP download port.

(2)Power on the HMI, take away the connection cable, the download port will be in communication mode.

Note: 1. if the HMI needs to download program, please restart the HMI. 2. Please connect the pin 5 and 6 directly.

2

1.2 PLC port

PLC port: |

|

|

|

|

|

|

|

|

|

|

|

|

Pin |

Name |

Explanation |

|

9 8 7 6 |

|

1 |

TD+ |

RS422 send - |

||

|

|

2 |

RXD |

RS232 receive |

|||

|

|

|

|

|

|||

|

|

|

|

|

3 |

TXD |

RS232 send |

|

|

|

|

|

4 |

A |

RS485 + |

|

|

|

|

|

5 |

GND |

Ground |

|

|

|

|

|

6 |

TD- |

RS422 send - |

5 |

4 |

3 |

2 |

1 |

7 |

B |

RS485 - |

|

|

|

|||||

|

|

|

|

|

8 |

RDD- |

RS422 receive - |

|

|

|

|

|

9 |

RDD+ |

RS422 receive + |

For real application, pelase refer to chapter 2 for cable making. Refer to chapter 1.1 for

download port settings.

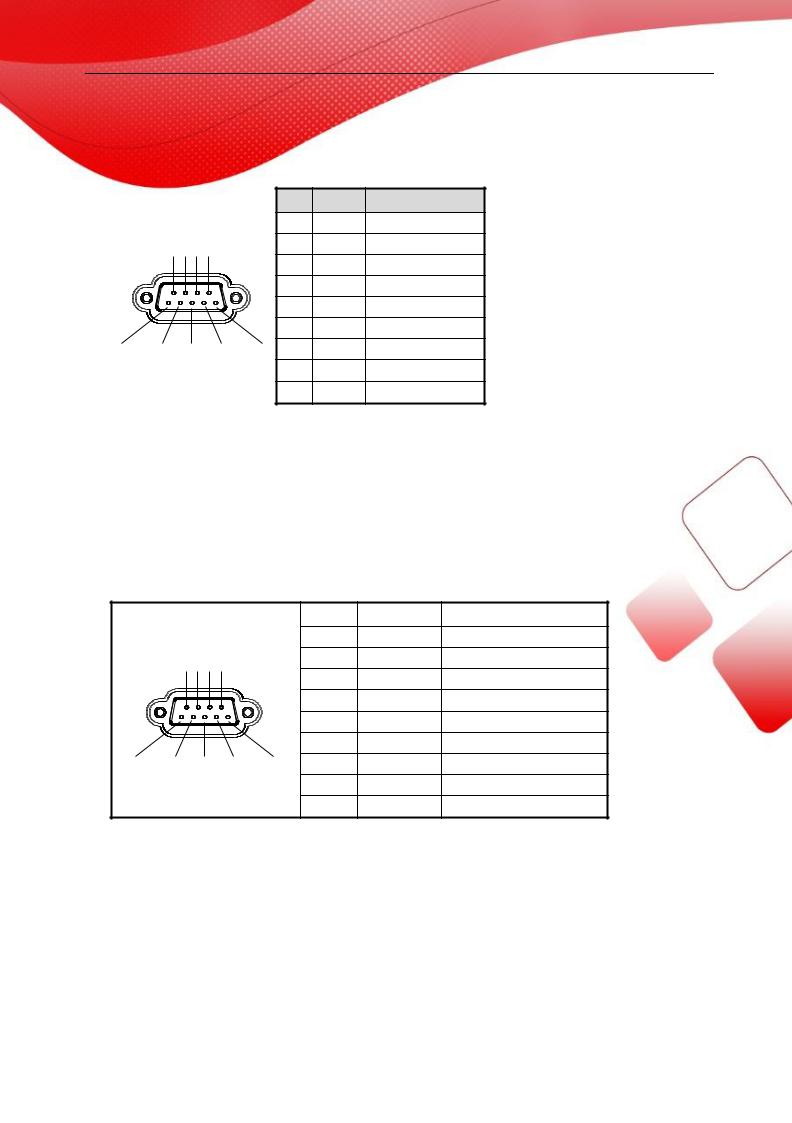

1.3 Expand port

Expand port:

|

|

|

|

|

Pin |

Definition |

Explanation |

|

9 8 7 6 |

|

1 |

A |

RS485 + |

||

|

|

2 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

6 |

B |

RS485 - |

5 |

4 |

3 |

2 |

1 |

7 |

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

9 |

|

|

Note: only TH765-NT3/NU3 has this expand port.

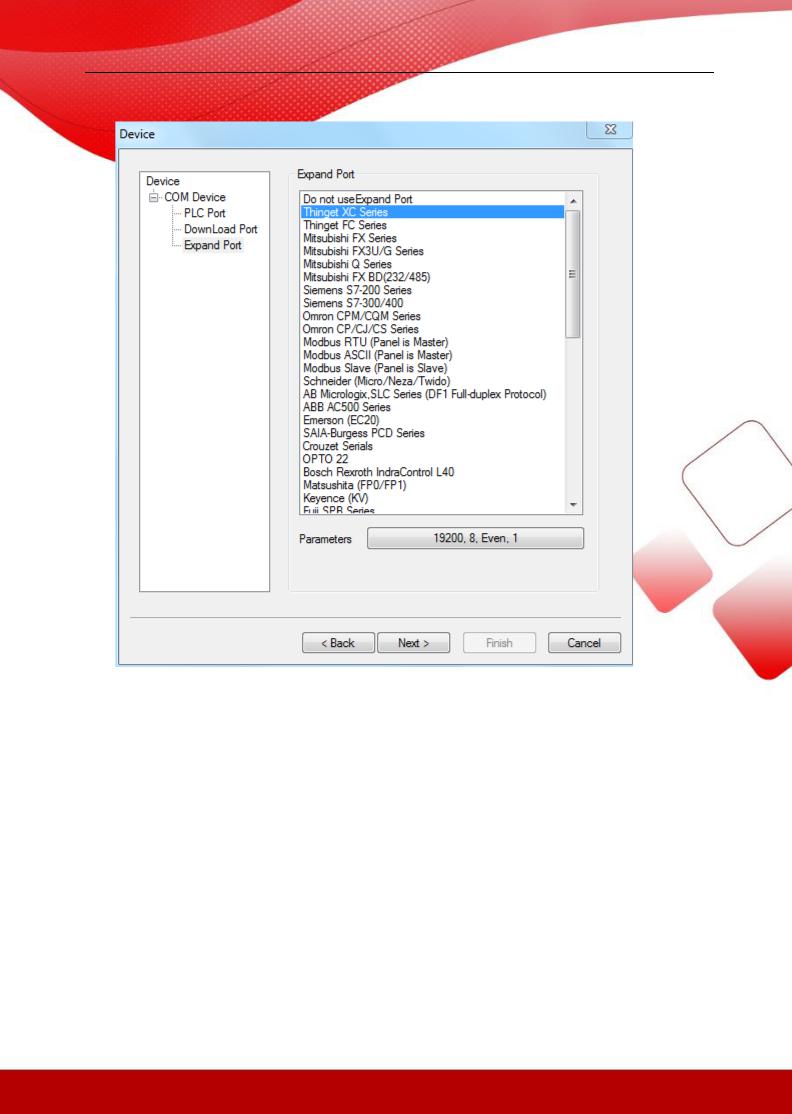

1. choose expand port device

(1) Build a new project, click expand port, and choose the device

3

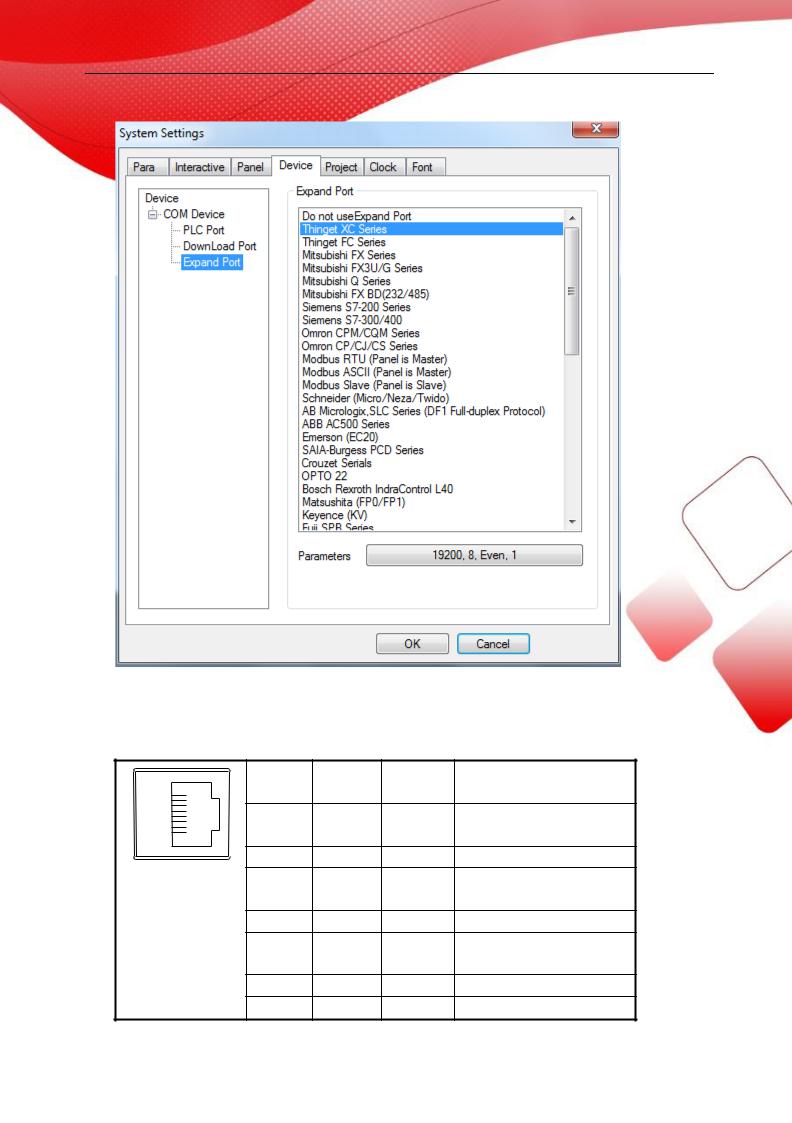

(2) For existed project, click File/setting/device/expand port to set the PLC model.

4

1.4 Ethernet port

RJ45 Ethernet port:

Pin |

Color |

Definitio |

Explanation |

|

8 |

|

n |

|

|

1 |

Orange |

TXD+ |

Data send + |

|

1 |

white |

|||

|

|

|||

|

|

|

||

2 |

Orange |

TXD- |

Data send - |

|

3 |

Green |

RXD+ |

Data receive + |

|

|

white |

|||

|

|

|

||

4 |

Blue |

- |

- |

|

5 |

Blue |

- |

- |

|

|

white |

|||

|

|

|

||

6 |

Green |

RXD- |

Data receive - |

|

7 |

Brown |

- |

- |

|

|

|

5 |

|

|

white |

|

|

8 |

Brown |

- |

- |

Note: only TG765-ET/TG865-ET/TGA62-ET/TGC65-ET has Ethernet port.

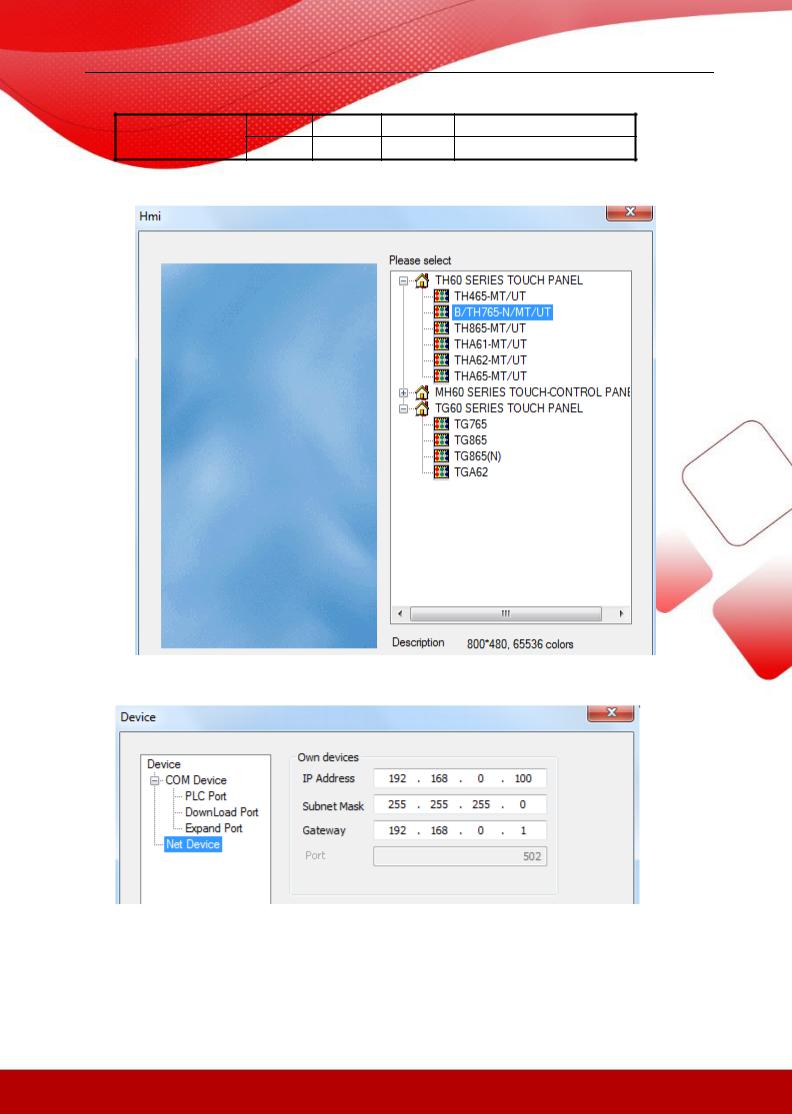

1.Build a new project, choose TG model in the list.

2. Click next, choose net device. Set the IP address of TG series HMI.

6

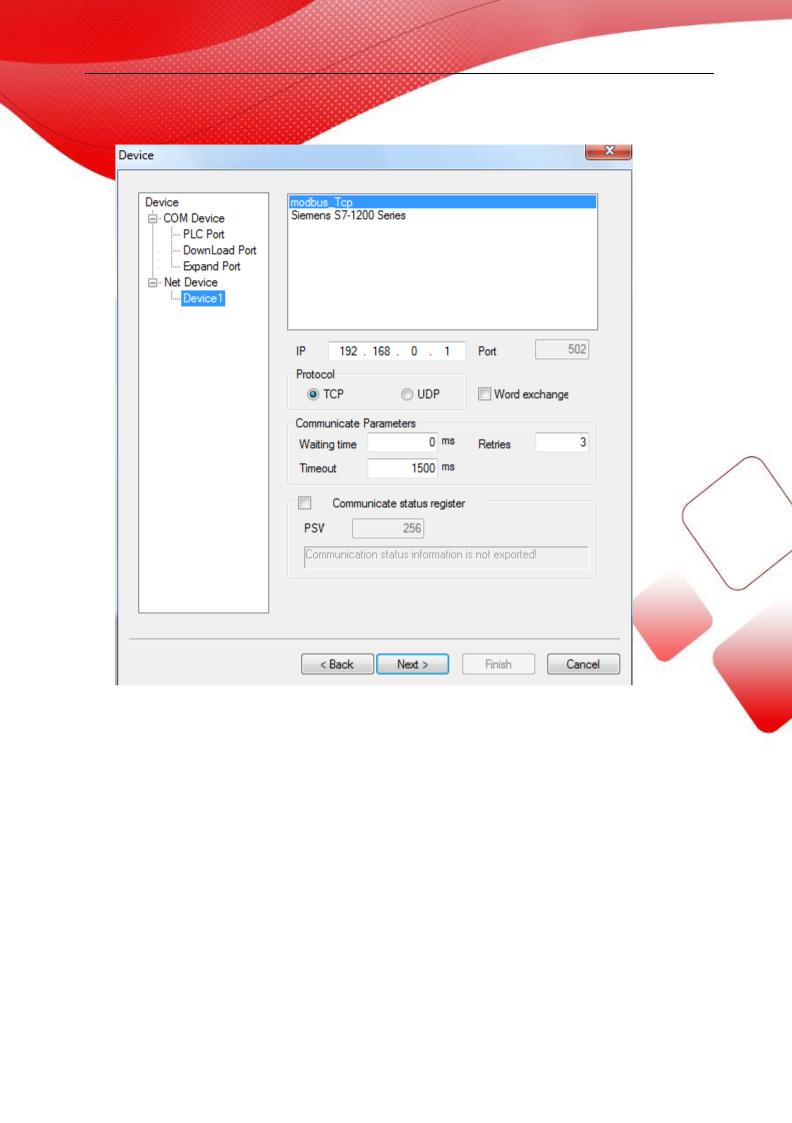

3. Right click net device, build a new Ethernet device.

Note: this function support local area network, but not support wide area network

7

2 The connection of PLC and HMI

This chapter will introduce the connection between PLC and HMI.

Please don’t pull out or plug the cable when power on, the serial port may be damaged.

2.1 XINJE FC series PLC

2.1.1Model

|

Serie |

|

|

CPU |

|

|

Connecte |

|

|

Port |

|

|

Cable |

|

|

Device |

|

|

s |

|

|

|

|

d module |

|

|

|

|

making |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

CPU |

|

RS232 |

|

Fig1 |

|

|

|

|||

|

|

|

|

XC32V2-CPU030427 |

|

|

direct |

|

|

|

|

|

|

Xinje FC |

|||

|

FC |

|

|

|

|

RS485 |

|

|

|

|

|||||||

|

|

-R5 |

|

|

connectio |

|

|

|

|

Fig2 |

|

series |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.1.2 Parameters

HMI parameters:

Parameters |

Settings |

Choices for settings |

Item |

PLC type |

FC series |

|

|

|

|

|

|

Port |

RS232 |

RS232or RS485 |

|

|

|

|

|

Data bit |

8 |

7 or 8 |

|

|

|

|

|

Stop bit |

1 |

1 or 2 |

|

|

|

|

|

Parity |

Odd parity |

Odd/even/no parity |

|

|

|

|

|

Baud rate |

9600 |

4800/38400/9600/115200/19200/187500 |

|

|

|

|

|

Station No. |

0 |

0~255 |

|

|

|

|

|

The default communication parameters of FC: 9600, 8, 1, odd parity, station No.0.

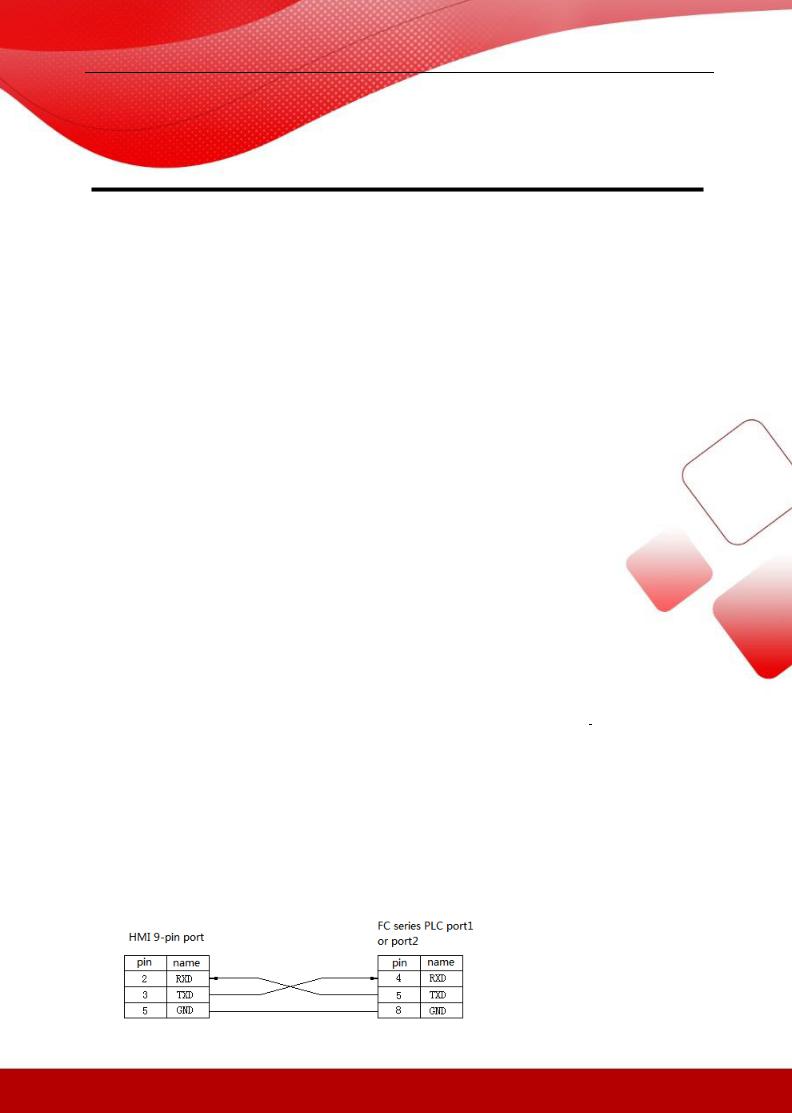

2.1.3 Cable making

(a) Connect to FC series CPU (RS232 port)

8

Fig1

(b) Connect to FC series PLC CPU (RS485 port)

Fig2

2.1.4 Device address

PLC address |

Range |

Data type |

Explanation |

X |

0~337 |

Bit |

External input coil |

|

|

|

|

Y |

0~337 |

Bit |

External output coil |

|

|

|

|

M |

0~383 |

Bit |

Internal coil |

|

|

|

|

SM |

0~96 |

Bit |

Special coil |

|

|

|

|

T |

0~128 |

Bit |

Timer |

|

|

|

|

C |

0~128 |

Bit |

Counter |

|

|

|

|

W |

0~2047 |

Word/DWord |

Data register |

|

|

|

|

FW |

0~191 |

Word/DWord |

FlashROM register |

|

|

|

|

TW |

0~127 |

Word/ |

Timer register |

|

|

|

|

CW |

0~127 |

Word/ |

Counter register |

|

|

|

|

SW |

0~111 |

Word//DWord |

Special register |

|

|

|

|

WX |

0~13 |

Word//DWord |

Input coil register |

|

|

|

|

WY |

0~13 |

Word//DWord |

Output coil register |

|

|

|

|

WM |

0~23 |

Word//DWord |

Interla coil register |

|

|

|

|

9

2.2 XINJE XC series PLC

2.2.1 Model

|

Series |

|

CPU |

|

Connected module |

|

Port |

|

Cable making |

|

Device |

|

|

|

|

|

|

CPU |

direct |

|

RS232 |

|

Fig1 |

|

|

|

|

|

|

|

connection |

|

|

|

|

|

|

|

|

|

|

XC1\XC2\ |

|

|

|

RS485 |

|

Fig 2 |

|

Xinje XC |

|

|

XC |

|

|

|

|

|

|

|

|

|

||

|

|

|

XC-RS485-BD |

|

RS232 |

|

Fig 3 |

|

||||

|

|

XC3\XC5 |

|

|

|

|

series |

|||||

|

|

|

|

(communication |

|

|

|

|

|

|||

|

|

|

|

|

RS485 |

|

Fig 4 |

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

extension board) |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

2.2.2 Parameters

HMI parameters:

Parameter |

Recommend settings |

Choices of settings |

Item |

PLC type |

XC series |

FC/XC series |

|

|

|

|

|

Port |

RS232 |

RS232 or RS485 |

|

|

|

|

|

Data bit |

8 |

7 or 8 |

|

|

|

|

|

Stop bit |

1 |

1 or 2 |

|

|

|

|

|

Parity |

Even parity |

Even/odd/no parity |

|

|

|

|

|

Baud rate |

19200 |

4800/38400/9600/115200/19200/187500 |

|

|

|

|

|

Station No. |

1 |

0~255 |

|

|

|

|

|

The default communication parameters of XC: 19200, 8, 1, even, station No.1.

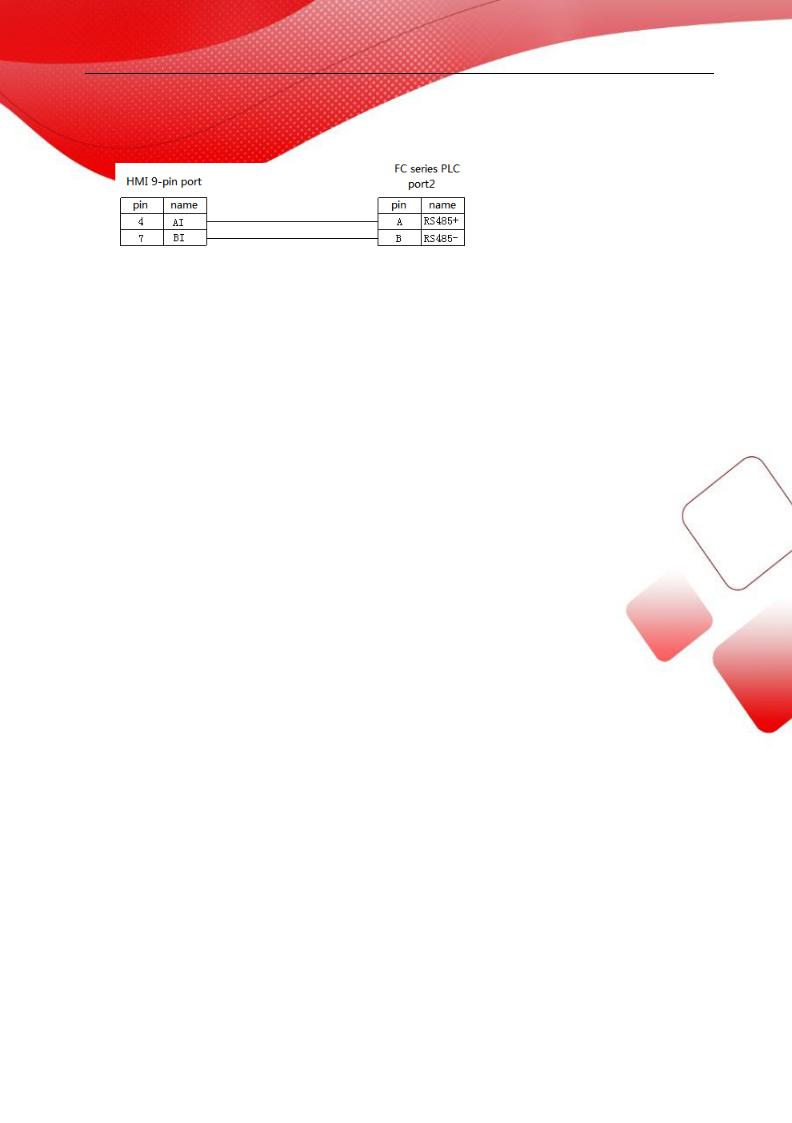

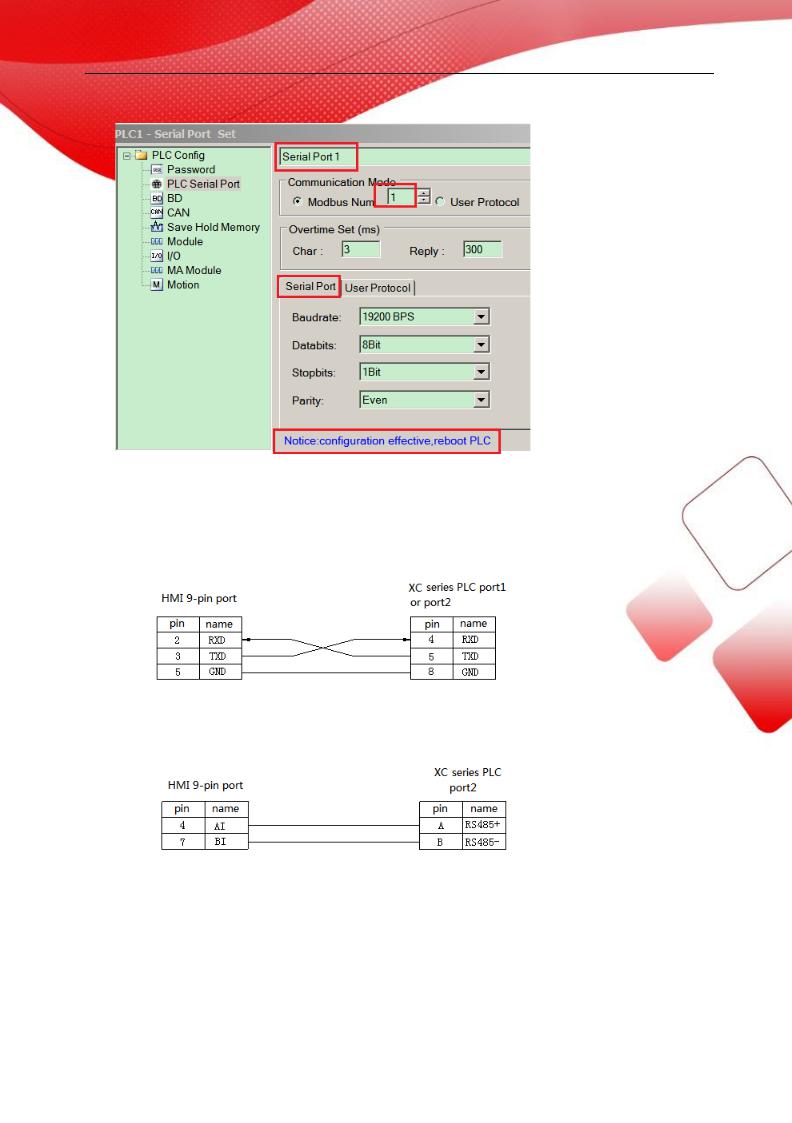

PLC settings:

Open XCPpro software:

10

2.2.3 Cable making

(a) Connect to XC series PLC CPU (RS232 port)

Fig1

(b) Connect to XC series PLC CPU (RS485 port)

Fig2

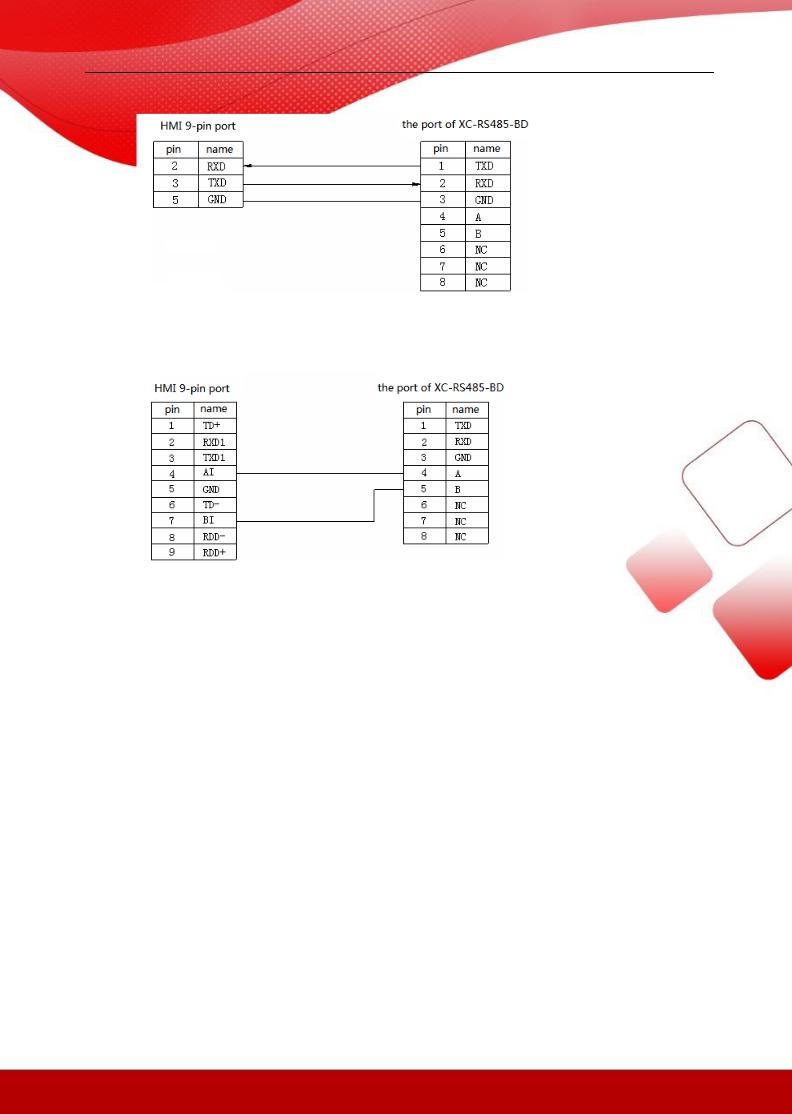

(c) Connect via XC-RS485-BD (RS232)

11

Fig3

(d) Connect via XC-RS485-BD (RS485)

Fig4

2.2.4 Device address

PLC address |

Range |

Data type |

Explanation |

X |

0~543 |

Bit |

External input coil |

|

|

|

|

Y |

0~543 |

Bit |

External input coil |

|

|

|

|

M |

0~7999 |

Bit |

Internal coil |

|

|

|

|

S |

0~1023 |

Bit |

Internal coil |

|

|

|

|

M8XXX |

0~511 |

Bit |

Internal special register |

|

|

|

|

T |

0~639 |

Bit |

Timer |

|

|

|

|

C |

0~639 |

Bit |

Counter |

|

|

|

|

D |

0~7999 |

Word//DWord |

Data register |

|

|

|

|

TD |

0~639 |

Word//DWord |

Timer register |

|

|

|

|

CD |

0~639 |

Word//DWord |

Counter register |

|

|

|

|

D8XXX |

0~511 |

Word//DWord |

Special register |

|

|

|

|

FD |

0~1535 |

Word//DWord |

FlashROM register |

|

|

|

|

FD8XXX |

0~511 |

Word//DWord |

Output register |

|

|

|

|

ED |

0~36862 |

Word//DWord |

Extend register |

|

|

|

|

DM |

7984 |

Word |

Data register |

|

|

|

|

|

|

12 |

|

DX |

0~52 |

Word |

Data register |

|

|

|

|

DY |

0~52 |

Word |

Data register |

|

|

|

|

DS |

0~1008 |

Word |

Data register |

|

|

|

|

DM8XXX |

0~496 |

Word |

Data register |

|

|

|

|

DT |

0~603 |

Word |

Data register |

|

|

|

|

DC |

0~619 |

Word |

Data register |

|

|

|

|

ID |

0~9999 |

Word//DWord |

Analog input |

|

|

|

|

QD |

0~9999 |

Word//DWord |

Analog output |

|

|

|

|

13

2.3 Mitsubishi FXseries PLC

2.3.1Model

|

Series |

|

|

CPU |

|

|

Connected |

|

|

Port |

|

|

Cable |

|

|

Device |

|

|

|

|

|

|

module |

|

|

|

|

making |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

FX0N |

|

CPU direct |

|

RS422 |

|

Fig1 |

|

Mitsubishi FX |

|||||

|

|

|

|

FX1N |

|

connection |

|

|

|

series PLC |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

FX2N |

|

RS232-BD |

|

RS232 |

|

Fig 2 |

|

Mitsubishi |

|||||

|

|

|

|

FX1S |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

RS485\422-B |

|

RS485 |

|

Fig 3 |

|

|||||||

|

|

|

|

|

|

|

|

FXBD(232\485) |

|||||||||

|

|

|

|

FX3U |

|

D |

|

|

|

|

|

|

|

||||

|

FX |

|

|

|

RS422 |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

FX3G |

|

CPU direct |

|

|

|

|

|

|

|

Mitsubishi FX |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

FX0 |

|

|

RS422 |

|

Fig 1 |

|

|||||||

|

|

|

|

|

connection |

|

|

|

series PLC |

||||||||

|

|

|

|

FX1 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

FX2 |

|

CPU direct |

|

RS422 |

|

Fig 4 |

|

Mitsubishi FX |

|||||

|

|

|

|

|

connection |

|

|

|

series PLC |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.3.2 Parameters

HMI settings:

Parameter |

Recommend |

Choices of settings |

Item |

|

settings |

|

|

PLC type |

FX series |

|

|

|

|

|

|

Dat bit |

7 |

7 or 8 |

|

|

|

|

|

Stop bit |

1 |

1 or 2 |

|

|

|

|

|

Parity |

Even parity |

Even/odd/no parity |

|

|

|

|

|

Baud rate |

9600 |

4800/9600/19200/38400/56000/57600/11 |

|

|

|

5200/187500 |

|

|

|

|

|

Station No. |

0 |

0~255 |

|

|

|

|

|

The default parameters of Mitsubishi FX series PLC: 9600, 7, 1, even, station No.0.

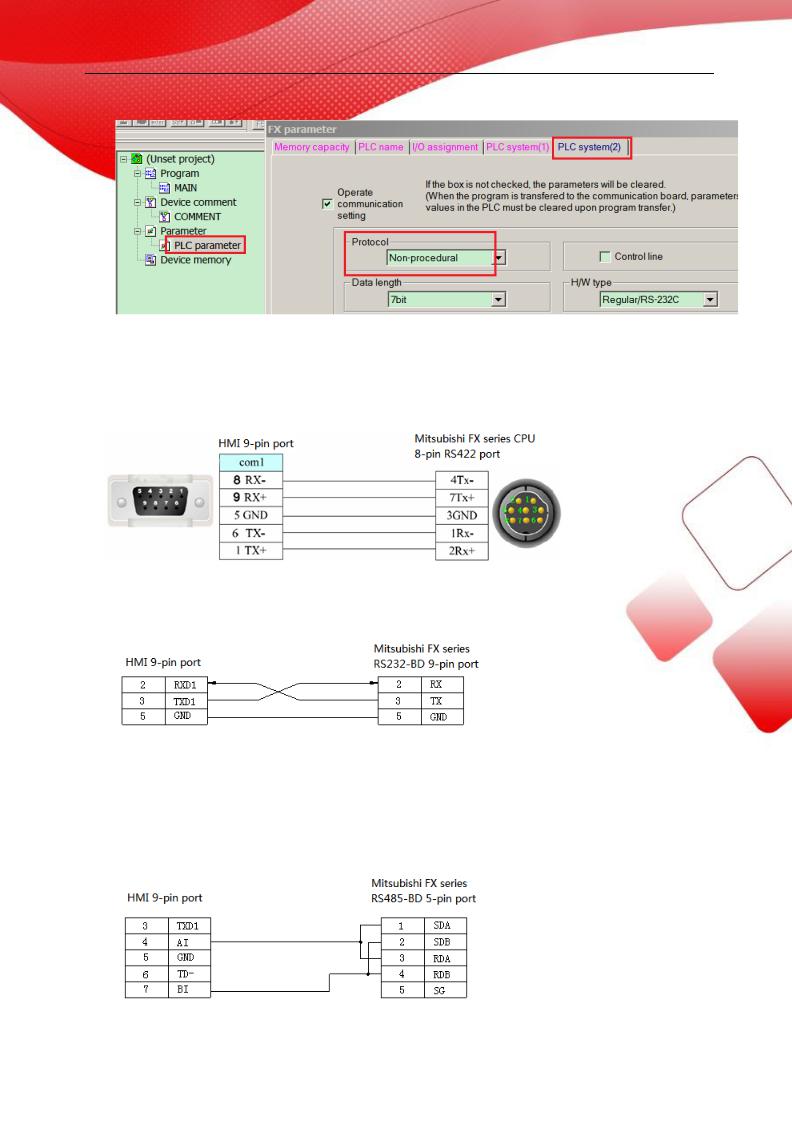

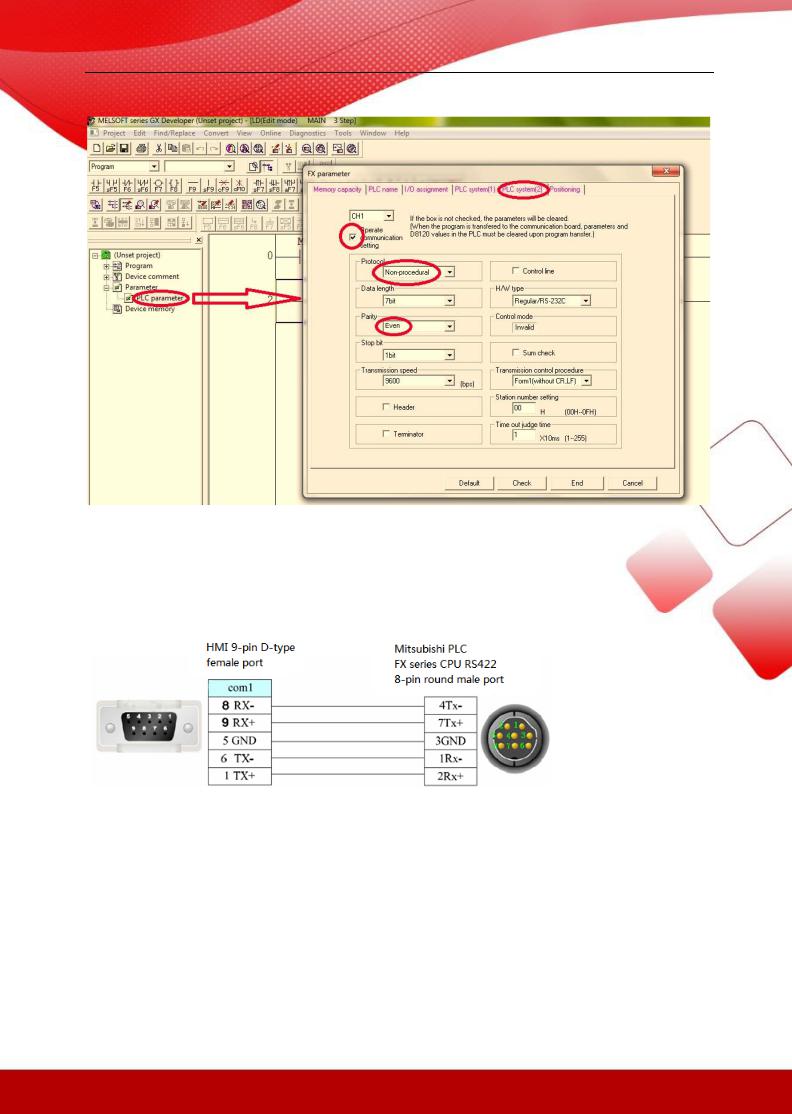

PLC settings:

14

2.3.3 Cable making

(a) FX1N\2N\3U\3G\1S series PLC, RS422 port:

Fig1

(b) FX series PLC uses RS232-BD:

Fig2

(c) FX series PLC uses RS485BD:

Fig3

15

(d) FX2 series PLC:

Fig4

2.3.4 Device address

PLC address |

Range |

Data type |

Explanation |

X |

0~177 |

Bit |

External input coil |

|

|

|

|

Y |

0~177 |

Bit |

External output coil |

|

|

|

|

M |

0~8255 |

Bit |

Internal coil |

|

|

|

|

S |

0~999 |

Bit |

Stepper coil |

|

|

|

|

T |

0~255 |

Bit |

Timer |

|

|

|

|

C |

0~255 |

Bit |

Counter |

|

|

|

|

C16 |

0~199 |

Word/DWord |

16-bit counter |

|

|

|

|

C32 |

200~255 |

DWord |

32-bit counter |

|

|

|

|

D |

0~8255 |

Word/DWord |

Data register |

|

|

|

|

T |

0~255 |

Word/DWord |

Current value |

|

|

|

|

X |

0~177 |

Word/DWord |

Data register |

|

|

|

|

Y |

0~177 |

Word/DWord |

Data register |

|

|

|

|

M |

0~8255 |

Word/DWord |

Data register |

|

|

|

|

S |

0~999 |

Word/DWord |

Data register |

|

|

|

|

16

2.4 Mitsubishi FX3U/G series PLC

2.4 .1 Model

|

|

|

|

|

|

|

Connected |

|

|

|

|

|

|

|

|

Choose PLC type |

|

|

Series |

|

|

CPU |

|

|

|

|

Port |

|

|

Cable |

|

|

in Touchwin |

|

|

|

|

|

|

|

module |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

software |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FX |

|

FX3U |

|

CPU |

|

RS422 |

|

Fig 1 |

|

Mitsubishi |

||||||

|

|

FX3G |

|

|

|

|

FX3U/G |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.4 .2 Parameters

HMI settings:

Parameter |

Recommended |

Choices of settings |

Notes |

|

settings |

|

|

PLC type |

Mitsubishi |

|

|

|

FX3U/G series |

|

|

|

|

|

|

Data bit |

7 |

|

|

|

|

|

|

Stop bit |

1 |

|

|

|

|

|

|

Parity |

Even parity |

|

|

|

|

|

|

Baud rate |

9600 |

4800/9600/19200/38400/56000/57600/115200/187500 |

|

|

|

|

|

Station |

0 |

|

|

no. |

|

|

|

|

|

|

|

The default parameters of Mitsubishi FX3U/G series PLC: 9600, 7, 1, even parity, station no.0 PLC settings:

17

2.4 .3 Cable making

(a) FX3U\3G series PLC RS422:

2.4 .4 Device address

PLC address |

Range |

Type |

Explanation |

X |

0~177 |

Bit |

External input terminal |

|

|

|

|

Y |

0~177 |

Bit |

External output terminal |

|

|

|

|

M |

0~8255 |

Bit |

Internal auxiliary coil |

|

|

|

|

|

|

18 |

|

S |

0~999 |

Bit |

Stepper coil |

|

|

|

|

T |

0~255 |

Bit |

Timer |

|

|

|

|

C |

0~255 |

Bit |

Counter |

|

|

|

|

C16 |

0~199 |

Word/DWord |

16-bit counter |

|

|

|

|

C32 |

200~255 |

DWord |

32-bit counter |

|

|

|

|

D |

0~8255 |

Word/DWord |

Data register |

|

|

|

|

T |

0~255 |

Word/DWord |

Timer current value |

|

|

|

|

X |

0~177 |

Word/DWord |

Used as data register |

|

|

|

|

Y |

0~177 |

Word/DWord |

Used as data register |

|

|

|

|

M |

0~8255 |

Word/DWord |

Used as data register |

|

|

|

|

S |

0~999 |

Word/DWord |

Used as data register |

|

|

|

|

19

2.5 Mitsubishi FX BD series PLC (RS232/485)

2.5.1 Device type

|

|

Series |

|

|

CPU |

|

|

Connected |

|

|

Port |

|

|

Cable |

|

|

PLC type in |

|

|

|

|

|

|

|

module |

|

|

|

|

|

|

Touchwin software |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

FX0N/1N/2 |

|

232-BD |

|

RS232 |

|

Fig1 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

FX |

|

N |

|

|

|

|

|

|

|

|

|

|

Mitsubishi FX |

|||

|

|

|

FX1S |

|

|

|

|

|

|

|

|

|

|

BD(232\485) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

FX3U/3G |

|

485-BD |

|

RS485 |

|

Fig2 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Note: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.Do not hot plug the device!

2.The driver of 485-BD supports multi-station.

2.5.2 Parameters

HMI settings:

Paramete |

Recommend settings |

Choices of settings |

Notes |

rs |

|

|

|

PLC type |

Mitsubishi FX BD(232\485) |

|

|

|

|

|

|

Data bit |

7 |

|

|

|

|

|

|

Stop bit |

1 |

|

|

|

|

|

|

Parity |

Even parity |

|

|

|

|

|

|

Baud rate |

9600 |

9600/19200/38400/56000/57600 |

|

|

|

/ |

|

|

|

115200/187500 |

|

|

|

|

|

Station |

0 |

0~255 |

|

no. |

|

|

|

|

|

|

|

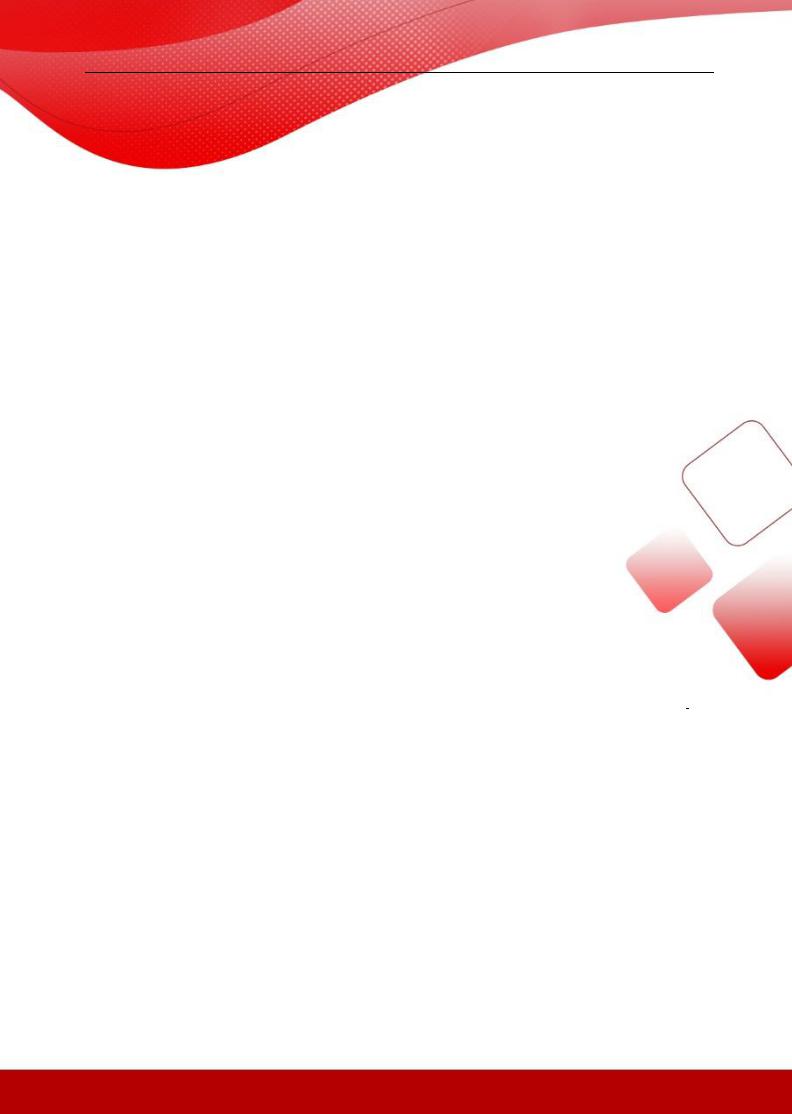

The default paramreters of Mitsubishi FX BD (232/485): 9600, 7, 1, even parity, station no.0 PLC settings:

20

Note:

1.Please choose RS232 as H/W type when using 232-BD.

2.Please re-power on the PLC after changing the parameters.

2.5.3Cable making

(a)FX series PLC RS232-BD:

Fig1

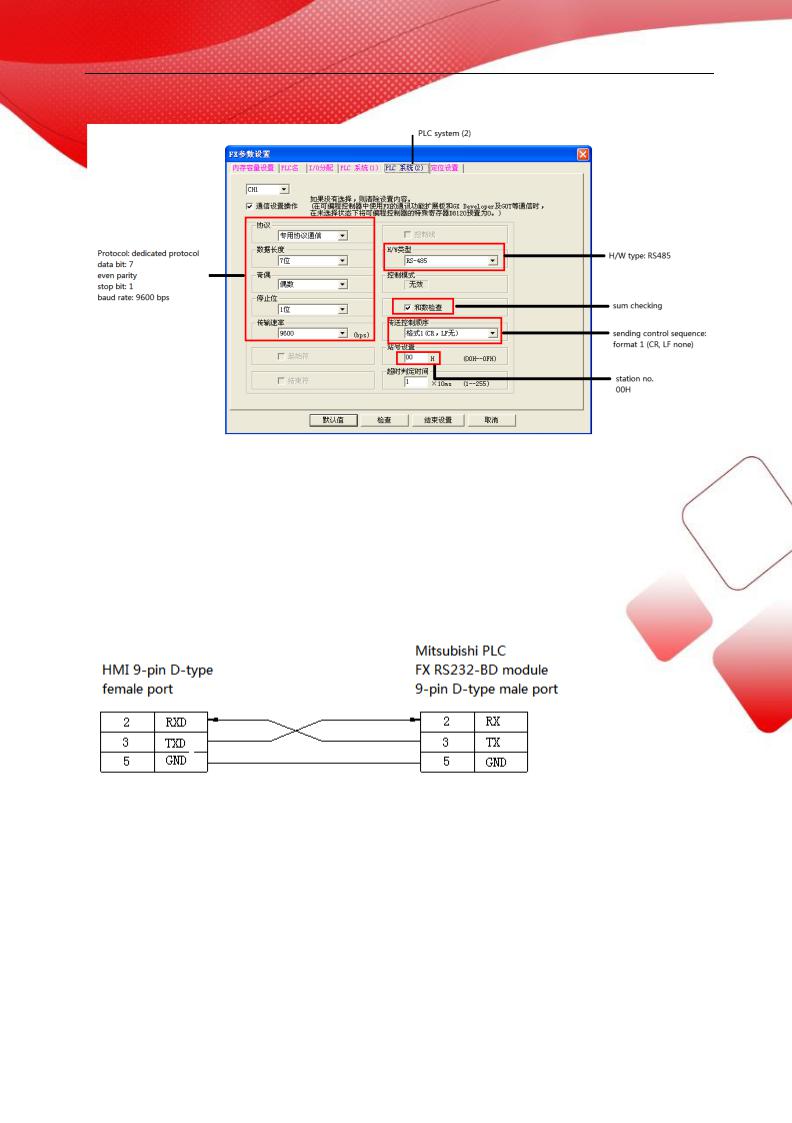

(b) FX series PLC RS485-BD:

21

Fig2

2.5.3 Device address

PLC |

Range |

Data type |

Explanation |

address |

|

|

|

X |

0~177 |

Bit |

External input terminal |

|

|

|

|

Y |

0~177 |

Bit |

External output terminal |

|

|

|

|

M |

0~8255 |

Bit |

Internal auxiliary coil |

|

|

|

|

S |

0~999 |

Bi |

Stepper coil |

|

|

|

|

T |

0~255 |

Bit |

Timer |

|

|

|

|

C |

0~255 |

Bit |

Counter |

|

|

|

|

C16 |

0~199 |

Word/DWord |

16-bit counter |

|

|

|

|

C32 |

200~255 |

DWord |

32-bit counter |

|

|

|

|

D |

0~8255 |

Word/DWord |

Data register |

|

|

|

|

T |

0~255 |

Word/DWord |

Current value |

|

|

|

|

X |

0~177 |

Word/DWord |

Used as data register |

|

|

|

|

Y |

0~177 |

Word/DWord |

Used as data register |

|

|

|

|

M |

0~8255 |

Word/DWord |

Used as data register |

|

|

|

|

S |

0~999 |

Word/DWord |

Used as data register |

|

|

|

|

22

2.6 Mitsubishi Q series PLC

2.6 .1 Model

MELSEC-Q series include the CPU unit of Q00, Q01, Q00U and so on. They can connect to the HMI via programmable port or communication module (QJ71C24N).

|

Series |

|

|

CPU |

|

|

Connected module |

|

|

Port |

|

|

Cable |

|

|

Device |

|

|

|

|

|

|

|

|

|

|

|

making |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q00 |

|

CPU |

direct |

|

|

|

|

|

|

|

Mitsubishi Q |

|||

|

|

|

|

Q01 |

|

|

RS232 |

|

Fig 1 |

|

||||||||

|

|

|

|

|

connection |

|

|

|

|

|

series |

|||||||

|

|

|

|

Q00U |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q |

|

Q00J Q00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Q01 Q02H |

|

|

|

|

|

RS232 |

|

Fig 2 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

Serial communication |

|

|

|

|

|

|

|

Mitsubishi Q |

|||||

|

|

|

|

Q06H Q12H |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

module QJ71C24 |

|

|

|

|

|

|

|

series |

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

Q25H Q12PH |

|

|

|

|

|

RS422 |

|

Fig 3 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Q25PH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.6.2 Parameters

HMI settings:

Parameter |

Recommend |

Choices of settings |

Item |

|

setting |

|

|

PLC type |

Q series |

|

|

|

|

|

|

Data bit |

8 |

7 or 8 |

|

|

|

|

|

Stop bit |

1 |

1 or 2 |

|

|

|

|

|

Parity |

Odd parity |

Even/odd/no parity |

|

|

|

|

|

Baud rate |

19200 |

4800/9600/19200/38400/56000/57600/115200/187500 |

|

|

|

|

|

Station |

0 |

0~255 |

|

No. |

|

|

|

|

|

|

|

The default parameter of Q series PLC: 19200, 8, 1, odd parity, station No.0.

PLC settings:

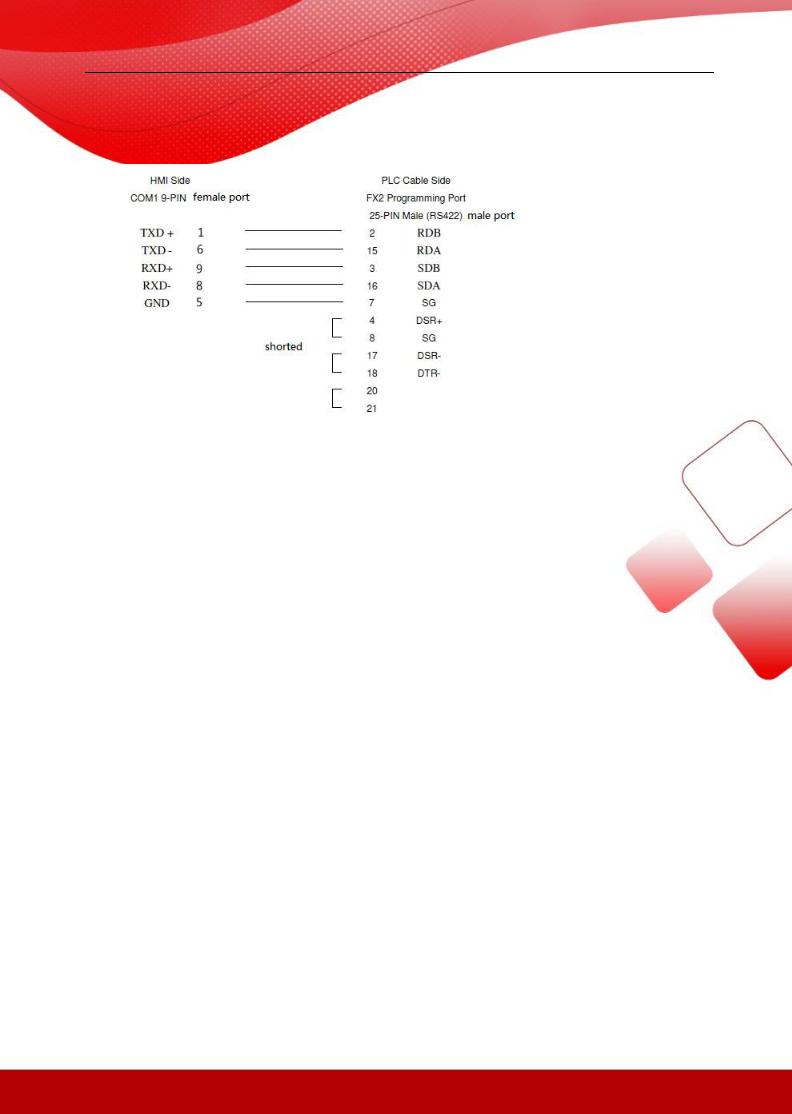

1. Q01\Q00 PLC:

23

2 QJ71C24N serial port module

QJ71C24N can connect to CPU and communicate with other devices. Such as Q02CPU, the settings are as the following:

PLC software version v8.26

(a) Double click PLC parameter, choose I/O assignment:

(b) Change the type of item1 to intelli.

(c) Click “switch setting” :

24

(d) Set the parameter as the following window: