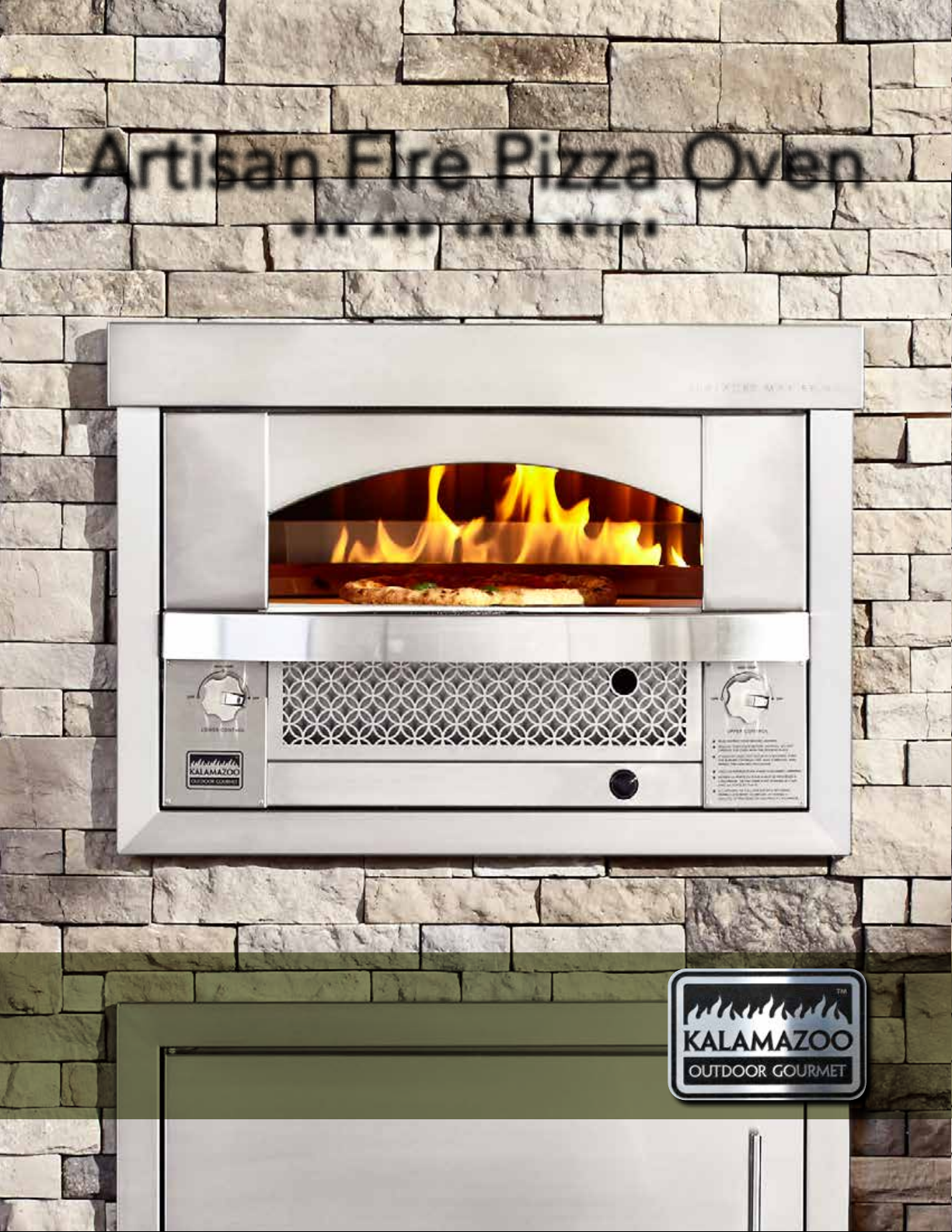

Artisan Fire Pizza Oven

USE AND CARE GUIDE

1.800.868.1699 1

KalamazooGourmet.com2

Important Safety Warnings

This appliance is FOR OUTDOOR USE ONLY. It is not to be used inside a garage, other building or

any type of enclosed area.

WARNING: Failure to follow the information in this Use and Care Guide exactly may result in fire

or explosion, causing property damage, personal injury or death. Read and follow all warnings and

instructions before assembling and using the appliance.

WARNING: This appliance is not intended to be installed in or on a boat or recreational vehicle.

DANGER: IF YOU SMELL GAS:

1. Shut-off gas to the appliance.

2. Extinguish any open flame.

3. Open grill hood.

4. If odor continues, keep away from the appliance and immediately call your gas

supplier or fire department.

Failure to follow these instructions could result in fire or explosion which could cause

property damage, personal injury or death.

WARNING: FOR YOUR SAFETY:

1. Do not store or use gasoline or other flammable liquids or vapors in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall not be stored in the vicinity of this or any

other appliance.

3. Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

IMPORTANT: Damage caused by a failure to heed the warnings or follow the

safety instructions and practices described in this Use and Care Guide is not

covered by the warranty.

1.800.868.1699 1

This Use and Care Guide contains

important information necessary

for the proper assembly and safe

use of the pizza oven.

Read and follow all warnings and

instructions before assembling and

using the pizza oven.

Follow all warnings and

instructions when using the

pizza oven.

Keep the Use and Care Guide for

future reference.

Thank you for choosing Kalamazoo Outdoor

Gourmet cooking equipment.

Because of the high performance nature

and unique design of the Artisan Fire Pizza

Oven, we recommend familiarizing yourself

with this book before using your pizza oven

for the first time. Your Use and Care Guide

contains important safety information as

well as helpful guidance for successful

cooking experiences and care. Following the

guidance of this book will help ensure many

years of outdoor cooking enjoyment.

Should you ever have any questions about cooking

with or caring for your Artisan Fire Pizza Oven, we are

here to help. Contact Kalamazoo Outdoor Gourmet

Customer Service at:

1.800.868.1699

or

customerservice@KalamazooGourmet.com

Please have your model number and serial number

ready or include it in your email.

Model Number

F AFPO-B-NG

F AFPO-B-LP20

F AFPO-B-LPBLK

Serial Number

Version 01.02.2018

KalamazooGourmet.com2

Table of Contents

Safe Operation 6

Liquid Propane Tank Safety 8

Liquid Propane Gas Requirements 10

Natural Gas Requirements 11

Bulk Propane Gas Requirements 12

Leak Testing 13

Locating the Pizza Oven 14

Required Clearances 15

Initial Assembly 18

Pizza Oven Controls 22

Lighting Your Pizza Oven 24

Burner Adjustments 25

Cooking with Your Pizza Oven 29

Recipes 35

Caring for Your Pizza Oven 64

Troubleshooting 67

Installation Checklist 70

Packing List 71

Dimensions 72

About Kalamazoo Outdoor Gourmet 75

1.800.868.1699 3

KalamazooGourmet.com4

Safety Information

1.800.868.1699 5

Safe Operation

WARNING: When in use, portions of your pizza oven get hot enough to cause severe

burns. Children and pets should never be left alone or unattended in the area where the

pizza oven is being used. Never allow children to sit, stand or play on or around the pizza

oven.

IMPORTANT: Improper use or installation is dangerous. Because this pizza oven produces

intense heat, the risk of accidents or potential injuries is increased. Extreme care must be

taken. Carefully follow all instructions, including the following:

To reduce the risk of fire, burns or other injury, read this Use and Care Guide thoroughly. Begin by ensuring

proper installation and servicing. Do not repair or replace any part of the pizza oven yourself unless it is

specifically recommended in this Use and Care Guide. All other service must be carried out by a qualified

gas technician.

Never allow children to operate the pizza oven. Do not store items of interest to children in or around the

pizza oven.

Do not heat unopened food containers in the pizza oven. The build up of pressure resulting from the heat

may cause the container to burst.

Never lean on any part of the pizza oven. When lighting the pizza oven, always pay close attention to what

you are doing. Make sure you are aware of which burner you are lighting and can see whether or not it is

lit. Make sure you have ready access to the ignition button and burner valves when you are lighting the

burner. Make sure you are pushing the ignition button when you attempt to light the burner.

When the burners are on or the oven is still hot, do not touch the cooking deck, any part of the oven’s

interior or any surface near the open front of the pizza oven. These areas become extremely hot and may

cause severe burns. The surfaces and trim above the oven door opening become particularly hot. Likewise,

do not touch any part of the pizza oven chimney.

Do not use any cleaner, including water, on a hot pizza oven. Never use any liquids when cleaning the

cooking deck.

Be sure all control knobs are in the OFF position and the pizza oven is cool before using any aerosol

cleaner on it or near it. The chemical used for aerosol propellant could ignite in the presence of heat.

Never use aerosol cleaner on the cooking deck.

Always use dry pot holders or gloves on hot surfaces or cooking tools: moist or damp pot holders or

gloves may cause steam burns. Never use a towel or bulky cloth in place of pot holders. Do not let pot

holders touch hot portions of the pizza oven or allow them to get near the open flame.

Pizza oven must be locked into position. (Figure 23)

Do not operate the pizza oven under an unprotected combustible construction. Use only in a well-

ventilated area. The oven is for outdoor use only.

KalamazooGourmet.com6

Safe Operation CONTINUED

Do not obstruct any of the openings on the pizza oven or otherwise obstruct the flow of combustion and

ventilation air. See installation clearances specifications for proper installation (Figure 10).

Keep all gas hoses away from the hot surfaces of the pizza oven, including all external surfaces of the unit.

Keep all electrical cords away from the hot surfaces of the pizza oven.

Ensure proper installation and servicing by following all instructions in this Use and Care Guide and any

other instructions or markings provided with this product. Have your pizza oven installed by a qualified

technician. Have the installer show you where the gas supply shut off valve is located and instruct you in its

operation so that you can shut off the gas to the pizza oven.

If you smell gas, there is likely a problem with the installation. If the connections are not perfectly sealed,

you can have a small leak resulting in the faint smell of gas -- even if the pizza oven appears to be working

properly. Close the gas supply shut off valve and call a qualified technician to locate and resolve the leak.

California Proposition 65 Warning:

The burning of gas cooking fuel generates some by-products that are on the

list of substances which are known by the State of California to cause cancer or

reproductive harm. California law requires business’s to warn customers of potential

exposure to such substances. To minimize exposure to these substances, always

operate the pizza oven according to this Use and Care Guide and ensure you provide

good ventilation when cooking with gas.

1.800.868.1699 7

Important LP Tank Safety Information

A liquid propane cylinder should never be “overfilled” beyond the cylinder filling capacity.

“Overfilling” may create a dangerous condition.

“Overfilled” tanks can build up excess pressure. The standard safety device on tanks is the

safety relief valve. This valve vents propane gas vapors to relieve excess pressure. These

vapors are combustible and can be ignited.

To avoid risk of fire or explosion, take the following safety precautions:

Never replace the liquid propane regulator or hose with a different type than the model supplied.

Never use a dented or rusty LP tank.

Never connect the pizza oven to anything other than the fuel source indicated on the serial plate. Factory

conversion kits are available for switching fuel sources. Contact Kalamazoo Outdoor Gourmet or an

authorized dealer for details. Conversion kit installation must be done by a qualified technician.

The LP-gas cylinder must include a collar to protect the cylinder valve from damage.

Ensure proper ventilation of the cylinder. The cylinder supply system must be arranged for vapor

withdrawal.

The LP-gas supply cylinder to be used must be constructed and marked in accordance with the

specifications for LP-gas cylinders, U.S. Department of Transportation (DOT) or the standard for Cylinders,

Spheres and Tubes for the Transportation of Dangerous Goods, CAN/CSA-B339.

When the pizza oven is not in use, the gas must be turned off at the supply cylinder.

The pizza oven may be stored indoors, but only if the cylinder is disconnected and removed from the oven.

An LP cylinder MUST NEVER BE STORED INDOORS.

Cylinders must be stored outdoors out of the reach of children and must not be stored in a building,

garage or any other enclosed area.

The pressure regulator and hose assembly supplied with the pizza oven must be used. Replacement

pressure regulators and hose assemblies must be the type specified by Kalamazoo Outdoor Gourmet. For

replacement parts, contact Kalamazoo Outdoor Gourmet customer service at 1.800.868.1699.

DANGER:

A. Do not store a spare LP-gas cylinder under or near this appliance;

B. Never fill the cylinder beyond 80 percent full; and

C. If instructions A and B are not followed exactly, a fire causing death or

serious injury may occur.

KalamazooGourmet.com8

LP Tank Safety Information CONTINUED

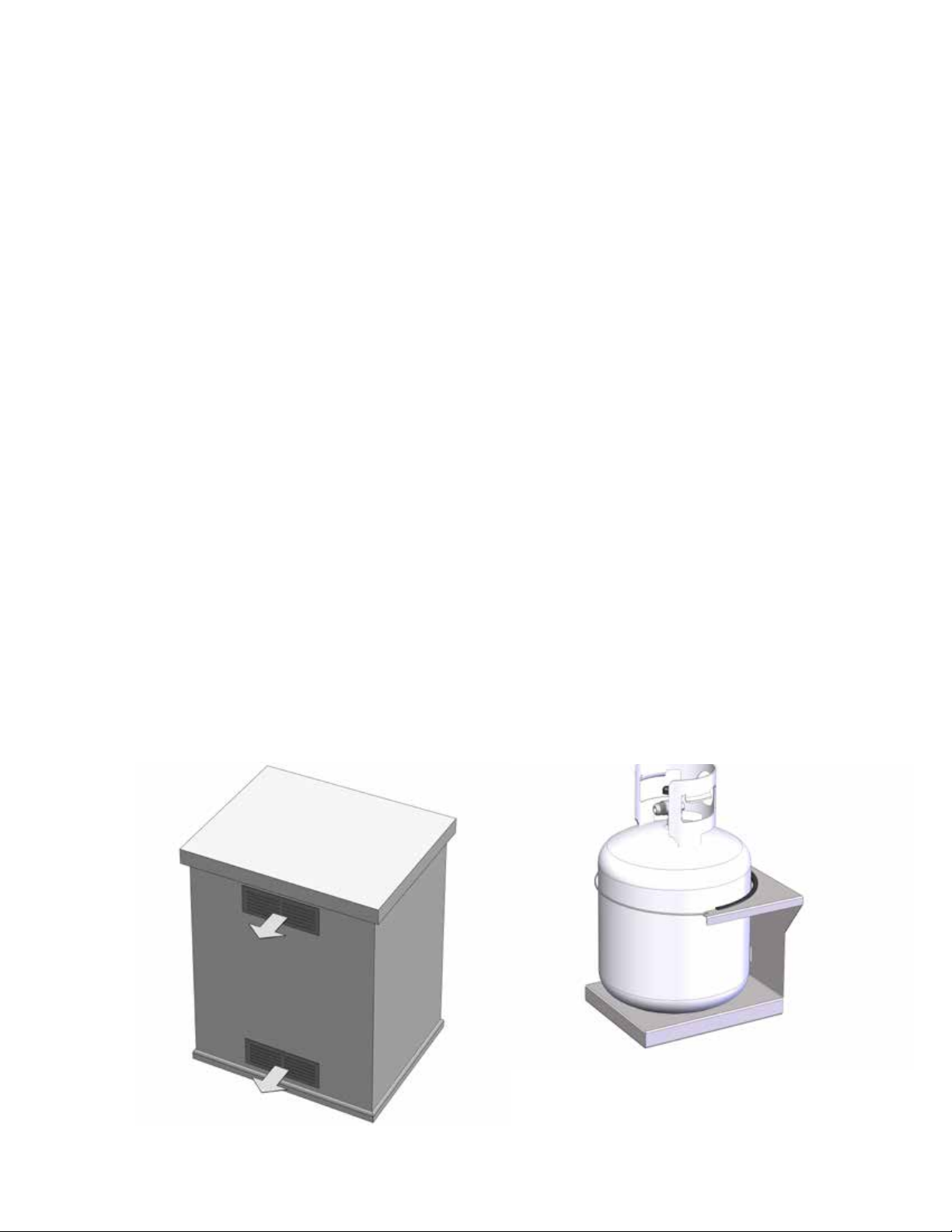

Required ventilation for built-in LP-gas cylinder structures:

An enclosure for an LP-gas cylinder shall be ventilated by openings at both the upper and lower levels of the

enclosure. The effectiveness of the opening(s) for purposes of ventilation shall be determined with the LP-gas

supply cylinder in place. This shall be accompanied by one of the following:

a. One side of the enclosure shall be completely open; or

b. For an enclosure having four sides, a top and a bottom (see Figure 1):

1. At least two ventilation openings shall be provided in the side walls of the enclosure, located within

5 in (217 mm) of the top of the enclosure, equally sized, spaced at a minimum of 90 degrees (1.57 rad),

and unobstructed. The opening(s) shall have a total free area of not less than 1 in2/lb (14.2 cm2/kg) of

stored fuel capacity.

2. Ventilation opening(s) shall be provided at floor level of the enclosure and shall have a total free area

of not less than 1/2 in2/lb (7.1 cm2/kg) of stored fuel capacity. If ventilation openings at floor level are

in a side wall, there shall be at least two openings. The bottom of the openings shall be 1 in (25.4 mm)

or less from the floor level and the upper edge no more than 5 in (127 mm) above the floor level. The

openings shall be equally sized, spaced at a minimum of 90 degrees and unobstructed.

3. Every opening shall be a minimum of a 1/8 in (3.2 mm) diameter.

4. Ventilation openings in side walls shall not communicate directly with other enclosures of the outdoor

cooking gas appliance.

Keep the ventilation openings of the cylinder enclosure free and clear from debrs.

In a built-in construction where an LP tank is going to be used, there MUST be some type of support

(braces, cutout, etc.) to prevent tank from moving within the installation. The support must also allow LP

tank to withstand a horizontal tipping force equal to the weight of the tank without tipping over. The tank

can not tip over or deflect more than 1” when a 20 lb. force is applied at the center of the tank.

FIGURE 1

Kalamazoo Outdoor Gourmet offers

an LP tank mounting bracket to meet

the cylinder install requirements.

1.800.868.1699 9

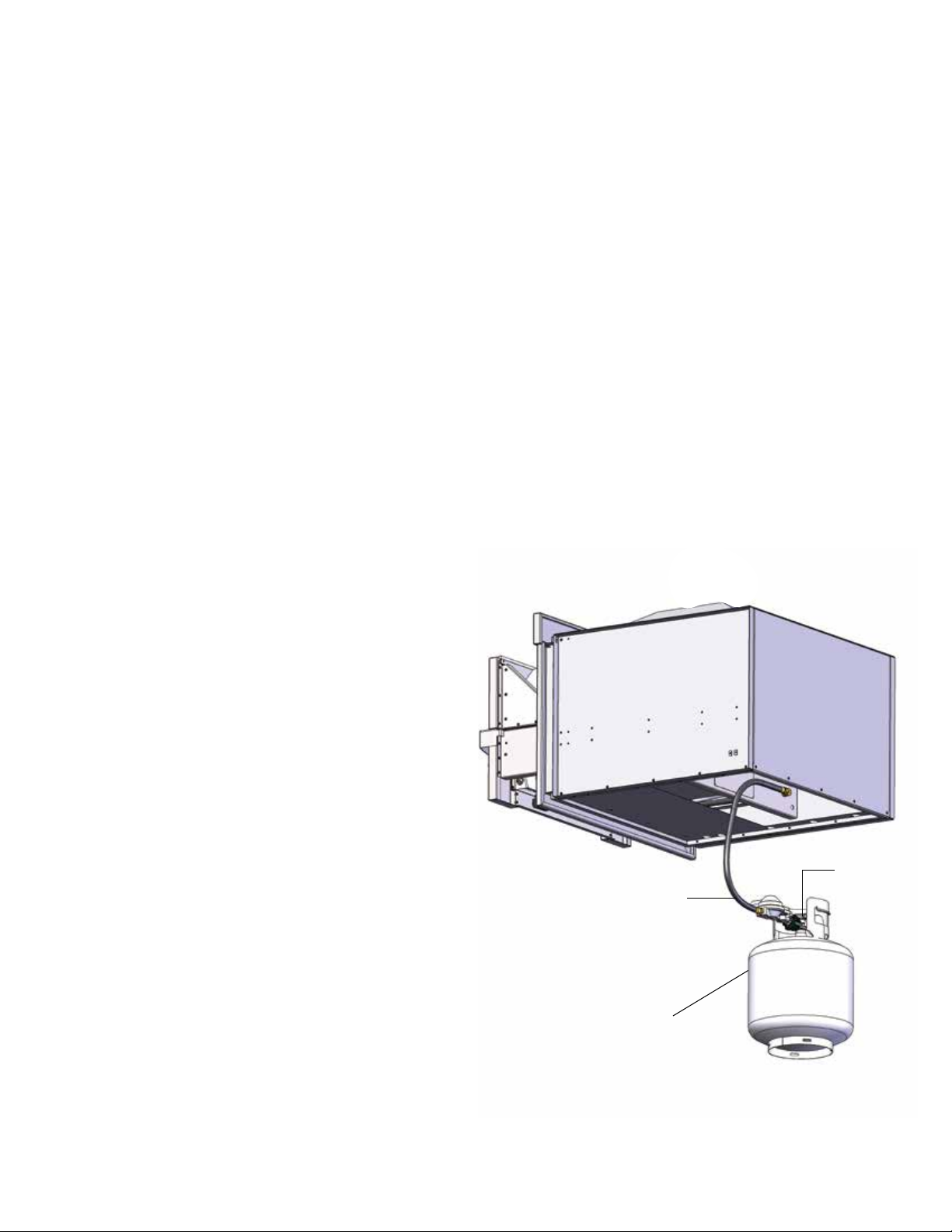

Liquid Propane Gas Requirements

(20-Pound Cylinder)

Verify the type of gas your pizza oven has been configured for by the factory by checking

the serial plate on the back of the oven. Pizza ovens configured for liquid propane (LP) gas

are orificed differently than ovens configured for natural gas (NG). Pizza ovens configured

for use with a standard 20-pound LP cylinders equipped with a Type 1, QCC-1 valve,

are shipped with an dual-stage LP regulator hose assembly. LP regulator hose assembly

(included) connects to the pizza oven via a 0.375" flare fitting.

Operating Pressure: 11.0" W.C.

To connect the LP regulator hose assembly to the LP tank, first make sure the main valve on the tank is

completely closed. Make sure also that the control valves on the front of the pizza oven are OFF.

Thread the regulator inlet over the tank valve. Use care to ensure proper alignment of the threaded coupler

and avoid cross-threading or damaging the coupler. Turn the black coupler clockwise until tightened up, but

do not over-tighten.

IMPORTANT: Always close the main valve on the

tank before disconnecting or transporting the tank.

IMPORTANT: After connecting a fresh LP tank,

you may need to purge air from the system. Before

lighting, open the main valve on the tank. Turn

the control valves on the pizza oven to the HIGH

position for about 15 seconds to purge air from the

system. Turn the control valves on the pizza oven

OFF and wait 5 minutes for any gas to clear. Finally,

continue with the normal lighting procedure.

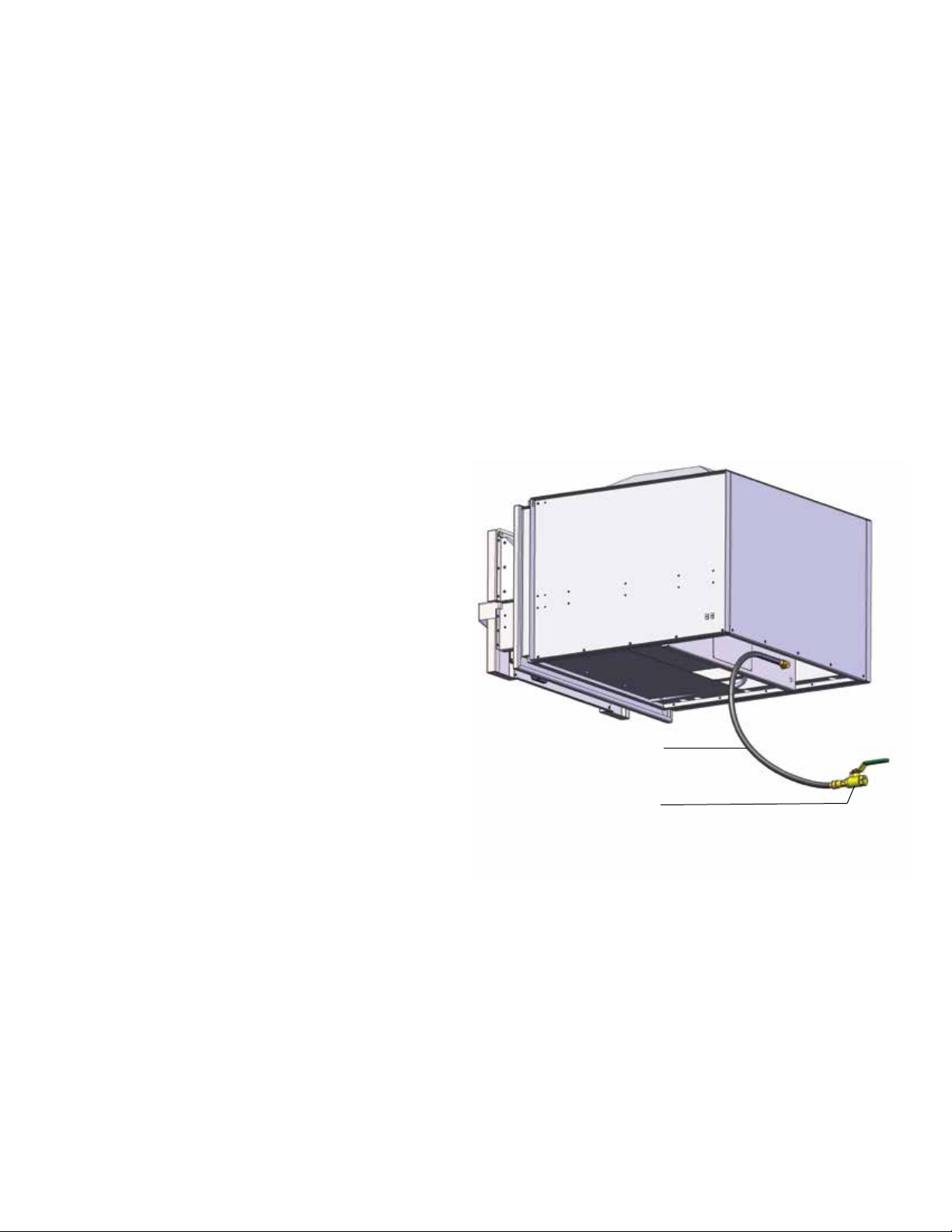

FIGURE 2

The installation must conform with local codes. In

the absence of local codes, the installation must

conform with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54; Storage and Handling of Liquefied

Petroleum Gases, ANSI/NFPA 58; Natural Gas and

Propane Installation Code, CSA B149.1; or Propane

Storage and Handling, CSA B149.2.

Cylinder Requirements: Never use a

dented or rusty LP tank. Never use a

cylinder with a damaged valve. Always

check for leaks after connecting an LP tank.

MAIN

VALVE

LP REGULATOR HOSE

ASSEMBLY PROVIDED

20-POUND LP TANK

(NOT INCLUDED)

KalamazooGourmet.com10

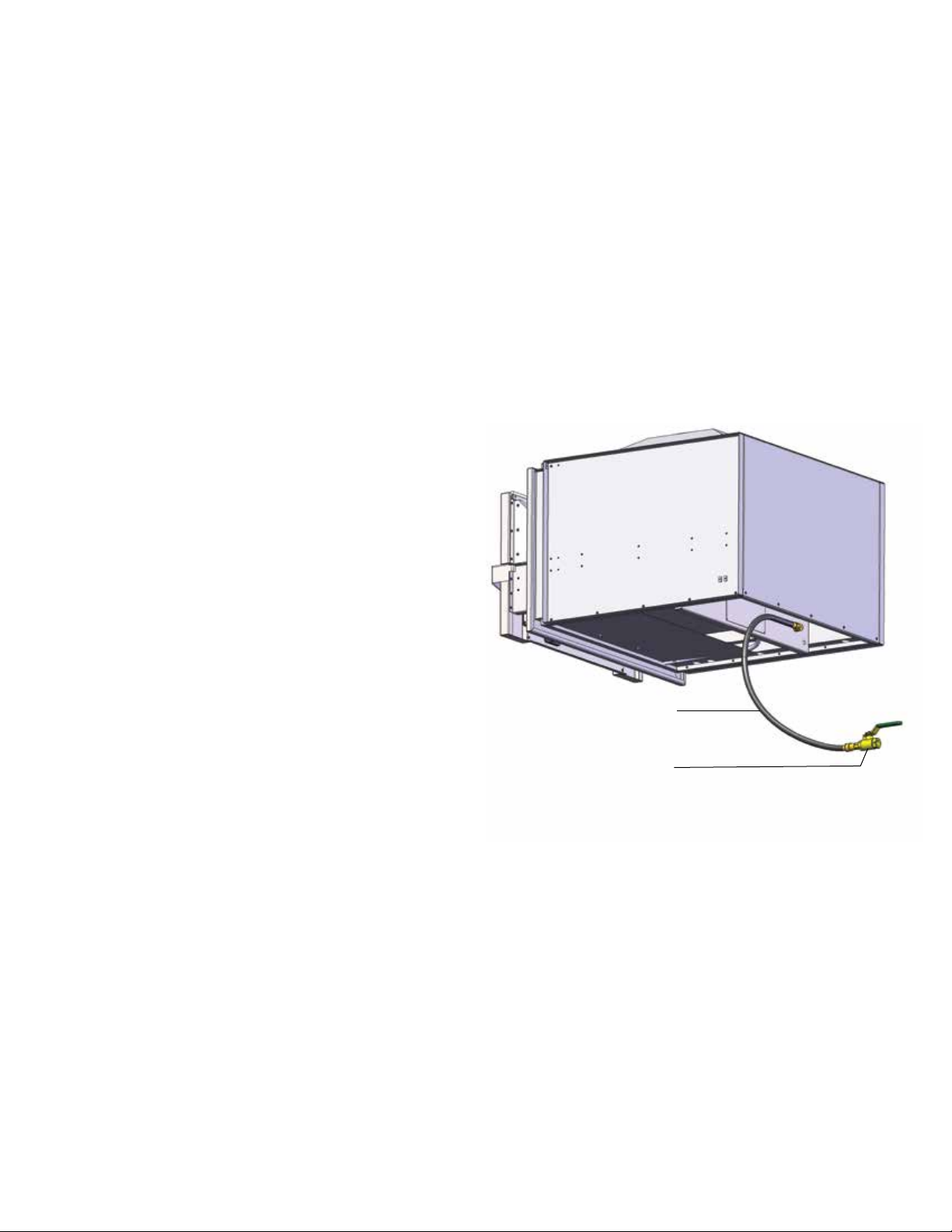

Natural Gas Requirements

Verify the type of gas your pizza oven has been configured for by the factory by checking the

serial plate on the back of the oven. Pizza ovens configured for natural gas (NG) are orificed

differently than ovens configured for liquid propane (LP) gas. Pizza ovens configured for use

with natural gas are shipped with a gray hose with a quick-connect fitting which connects to

the pizza oven via a .375” flare fitting.

Connection: 3/8” female NPT connection

Operating Pressure: normal 7.0” w.c., minimum 5” w.c., maximum 8” w.c.

IMPORTANT: Always close gas supply shutoff valve

before disconnecting the pizza oven gas supply hose.

IMPORTANT: An installer-supplied safety shutoff valve

MUST be installed on the natural gas supply line for the

pizza oven. The valve should be easily accessed and

located between 3 and 20 feet away from the oven.

All gas connections should be made by a qualified

technician. The installation and all installer-supplied

parts must conform to local codes. In the absence

of local codes, the installation and all parts should

conform to the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 or Natural Gas and Propane Installation Code,

CSA B149.1.

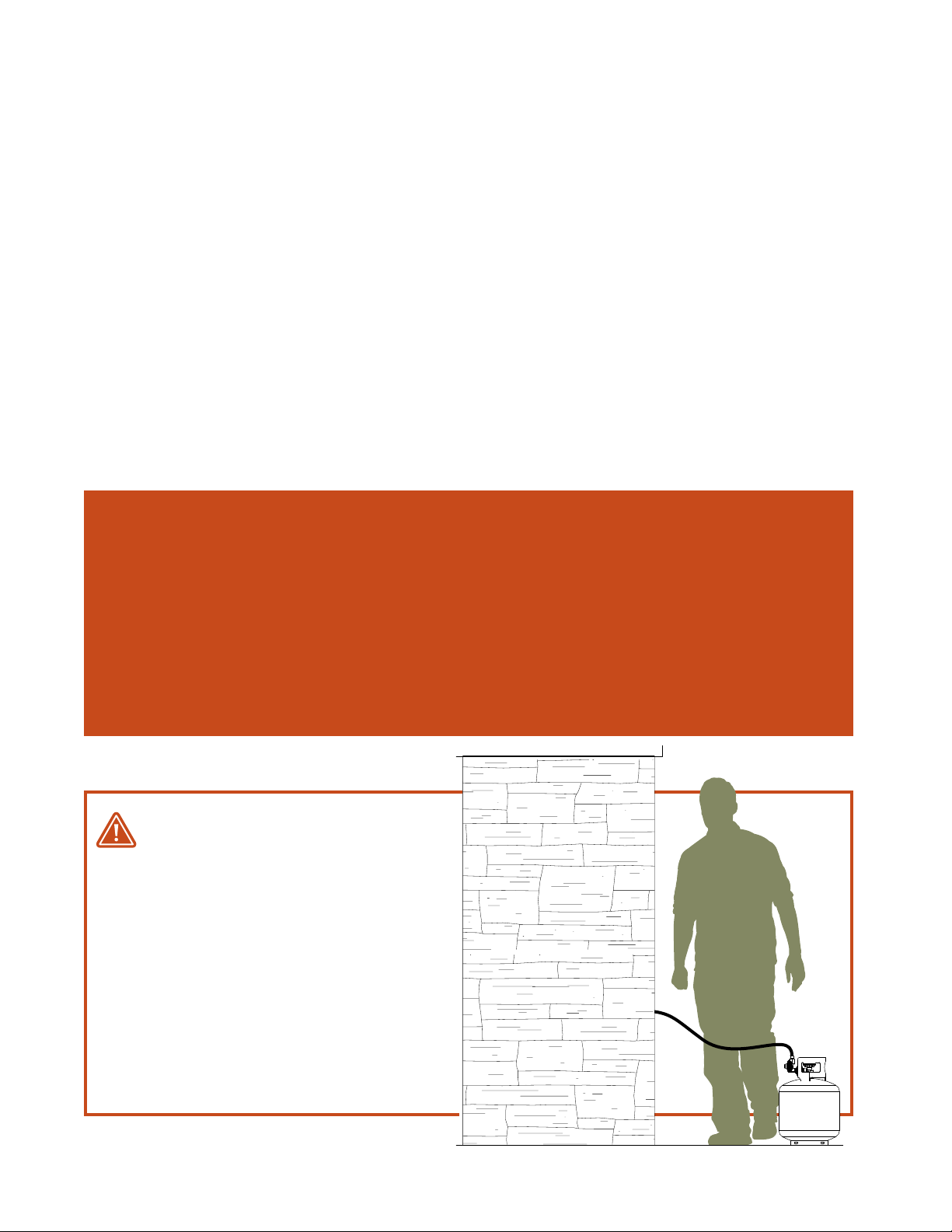

FIGURE 3

All pipe sealants must be an approved type.

IMPORTANT: Diameter and length of the gas supply

pipe may limit the pressure and BTU delivery of gas to

the oven. The installer must ensure proper delivery to

the pizza oven or it will not operate properly.

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at pressures in

excess of 1/2 psi (3.5 kPa).

During any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi

(3.5 kPa), the appliance must be isolated from the

system by closing its individual manual shutoff valve.

GAS HOSE ASSEMBLY

PROVIDED

INSTALLER-SUPPLIED

SHUTOFF VALVE MUST

BE EASILY ACCESSIBLE

(NOT INCLUDED)

1.800.868.1699 11

Bulk Supply Liquid Propane Gas Requirements

Verify the type of gas your pizza oven has been configured for by the factory by checking

the serial plate on the back of the oven. Pizza ovens configured for liquid propane (LP) gas

are orificed differently than ovens configured for natural gas (NG). Pizza ovens configured for

use with bulk LP tanks are shipped with a gray hose with a quick-connect fitting.

Connection: Quick-connect hose assembly (included) connects to the pizza oven via 0.5"

NPT male with a 0.375" flare adapter (included). The quick-connect fitting (included) threads

onto a 0.375” male NPT connection point (not included).

Operating Pressure: normal 11.0" w.c., minimum 10” w.c., maximum 12” w.c.

IMPORTANT: Always close gas supply shutoff valve before disconnecting the pizza oven gas supply hose.

IMPORTANT: An installer-supplied safety shutoff

valve MUST be installed on the gas supply line for

the pizza oven. The valve should be easily accessed

and located between 3 and 20 feet away from the

oven.

All gas connections should be made by a qualified

technician. The installation and all installer-supplied

parts must conform to local codes. In the absence

of local codes, the installation and all parts should

conform to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54; Storage and Handling of Liquefied

Petroleum Gases, ANSI/NFPA 58; Natural Gas and

Propane Installation Code, CSA B149.1; or Propane

Storage and Handling, CSA B149.2.

All pipe sealants must be an approved type.

FIGURE 4

GAS HOSE ASSEMBLY

PROVIDED

INSTALLER-SUPPLIED

SHUTOFF VALVE MUST

BE EASILY ACCESSIBLE

(NOT INCLUDED)

KalamazooGourmet.com12

Leak Testing

Although gas connections on the pizza oven are leak tested at the factory prior to shipment,

a complete test must be performed after installation due to possible mishandling during

shipping or installation.

Periodic checks are also recommended. Immediately check for leaks if you smell gas.

Never use an open flame to look for leaks.

Before Testing: Extinguish all open flames. Do not smoke.

You will need a spray bottle, a brush or a rag. For LP units using a 20-pound cylinder, a full cylinder should be

used.

IMPORTANT: Homeowners should only check for leaks on the gas connections that are external to the pizza

oven. If the valves or other internal connections need to be checked, please call a qualified technician or

Kalamazoo Outdoor Gourmet customer service at 1.800.868.1699.

To Conduct the Test:

Make a soap solution of one part liquid dish soap and one part water.

Make sure both pizza oven control valves are in the OFF position. Turn the gas supply ON. Use a spray bottle,

brush or rag to apply the mild soap solution to all connections from the supply line or LP cylinder to the

connection on the back of the pizza oven. Check all connections. Soap bubbles will appear at any connections

with a leak. Turn OFF the gas supply and tighten any leaky connections. Recheck, applying more mild soap

solution.

IMPORTANT: Do not use the pizza oven until all connections have been

checked and do not leak.

1.800.868.1699 13

Pizza Oven Location

The built-in version of the Artisan Fire Pizza Oven is designed for installation within a noncombustible outdoor structure.

Choosing a Location: This pizza oven is for outdoor use only.

Do not place the pizza oven in a location where the door opening is likely to be exposed to strong wind.

Do not place the pizza oven where it is likely to be bumped into or inadvertently touched by passers by. The

exterior surface of the pizza oven can become extremely hot.

Never locate the pizza oven in a building, breezeway, shed or other such enclosed areas.

The pizza oven is not intended to be installed in or on a boat or recreational vehicle.

For ease of use and safe operation, it is recommended the cooking deck height of the installed oven be not

less than 42 inches above the ground.

IMPORTANT: The built-in pizza oven requires clearance between the oven

and the interior of the non-combustible structure in which it is installed. 6

inches clearance is required around the sides and back. 24 inches clearance

is required above. The front face of the oven will be installed with zero

clearance to the front wall of the structure. Please note the top wall of the

front opening (the lintel) in the structure may not be more than 5 inches thick.

Access below the oven within the structure is required.

DANGER:

Do not route the gas supply hose

or locate a propane cylinder in a

way that may create a tripping

hazard. Tripping over, or getting

caught on, a gas supply hose may

cause serious risk of injury and

fire.

KalamazooGourmet.com14

Key Considerations for Installation

The non-combustible structure can be built using masonry techniques, or with steel framing

and cement board panels. Following are a few key considerations:

The oven liner is permanently installed in the structure and may be difficult, if not impossible, to

remove once the installation is complete.

The oven can be slid out of the oven liner for easy care and maintenance. No tools are required.

Access below the oven is required for connecting the gas, and for releasing the oven from the liner

to slide it out. An access door designed to match the oven is available from Kalamazoo Outdoor

Gourmet.

An installer-supplied gas shutoff valve is required for bulk gases at the connection point in the access

space below the oven.

Installer-supplied venting duct work is required. Duct attaches to the top of the oven liner. A

double-wall insulated grease duct is strongly recommended. Kalamazoo provides a mounting collar

designed for easy connection to Metal-Fab, Inc. G-Series 6-inch (inner diameter) Grease Duct system.

Connecting to other systems may require additional work by your installer. The duct should be topped

with an appropriate rain cap.

The oven liner is to sit on top of, and be screwed down into, a pair of supports that should run from

front-to-back in the non-combustible enclosure. See Figure 10 for dimensions.

The oven liner should NOT be screwed into the supports until the front fascia of the non-combustible

structure is completely finished. Once finished, slide the oven liner into position flush with the finished

face of the enclosure, then screw it securely into the supports.

The trim pieces cover the perimeter of the oven liner opening in the non-combustible structure. These

trim pieces look best when mounted over regular surfaces. Severely irregular surfaces may need

alteration for a clean appearance.

The lintel above the pizza oven opening in the non-combustible structure has a maximum depth of 5

inches from the finished face of the structure. See Figure 10.

Between the oven liner and the interior walls of the non-combustible structure, the following

clearances are required:

Front face opening is zero clearance.

Support structure below is zero clearance where the liner mounts to the supports.

Sides and back require 6 inches clearance.

Top requires 24 inches clearance.

Clearance to double-wall insulated grease duct is determined by duct manufacturer’s

specifications.

The front face of the oven, especially including the trim above the oven door opening, can

become very hot.

The finished wall of the non-combustible structure above the oven can also become hot.

Choose finish materials with this in mind. The finish, like the structure itself, must be non-

combustible.

1.800.868.1699 15

KalamazooGourmet.com16

Initial Assembly

1.800.868.1699 17

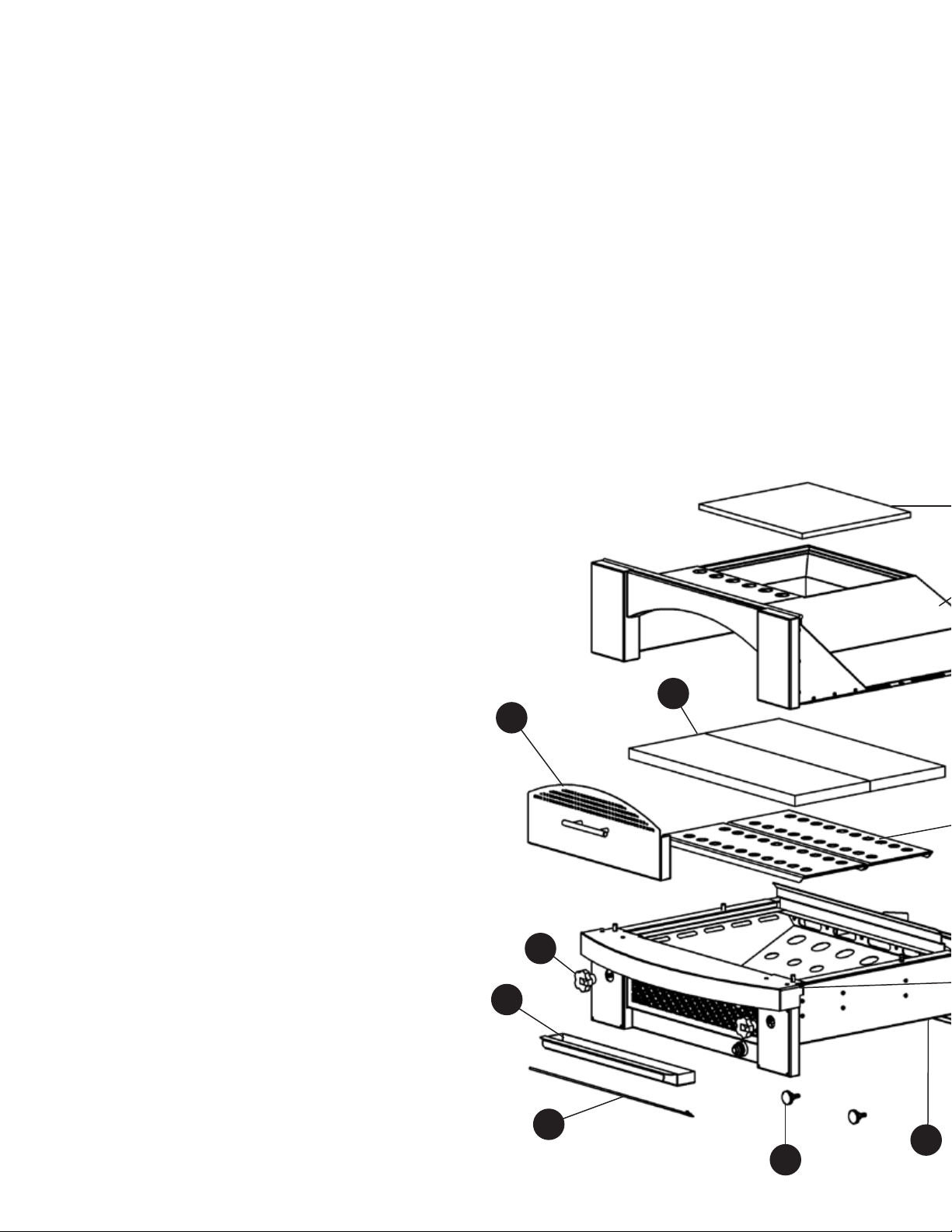

L

M

F

D

P

O

R

E

N

I

G

K

Q

J

C

G

H

Components and Initial Assembly

A. OVEN LINER A is installed within the custom installer-built non-combustible structure. See Installation

Instructions. IMPORTANT: the oven liner is larger than the finished opening in the non-combustible

structure, and it cannot be removed after the structure is complete (unless it can be removed from behind).

See Figure 16 for instructions on securing the liner within the non-combustible structure. The face of OVEN

LINER A should be installed flush with the finished face of the non-combustible structure. IMPORTANT: it

is highly recommended to finish the non-combustible structure with OVEN LINER A in place, but do not

secure OVEN LINER a to the non-combustible structure until the finished face of the structure is complete.

B. Kalamazoo-supplied DUCT COLLAR B can be secured to the top of OVEN LINER A using the

corresponding SUPPORT RING C underneath, #10 lock washers,10-24 X 0.75-inch screws, and

corresponding nuts supplied by Kalamazoo Outdoor Gourmet. An installer supplied 6-inch double-wall

insulated grease duct is to be secured to DUCT COLLAR B by the installer. Ensure all local codes are

followed for appropriate connection and ducting.

D. FACE FRAME D is secured to OVEN LINER A after the finished face of the non-combustible structure has

been completed. FACE FRAME D installs using 10-24 x 0.375in screws and #10 lock washers supplied by

Kalamazoo Outdoor Gourmet. See figure 17.

E. TOP TRIM E is secured to OVEN LINER A

after FACE FRAME D is installed. Secure with

10-24 X 0.375-inch screws and #10 lock washers

supplied by Kalamazoo Outdoor Gourmet. See

figure 18.

F. OVEN BASE F mounts to HEAVY DUTY SLIDES G.

See figure 19.

G. Extend HEAVY DUTY SLIDES G fully out of OVEN

LINER A.

H. CAUTION: Securing OVEN BASE F to HEAVY

DUTY SLIDES G requires at least two people

and extreme care. Set OVEN BASE F on top of

HEAVY DUTY SLIDES G such that it is temporarily

supported by OVEN BASE TABS H. Secure OVEN

BASE F to HEAVY DUTY SLIDES G using

8-32 X 0.375-inch screws and #8 lock washers

provided by Kalamazoo.

I. Attach GAS HOSE I to

OVEN BASE F. See Figure 22.

J. Install both DIFFUSERS J by setting

them in place in OVEN BASE F above

the lower burner.

K. Remove COOKING DECKS K from

the cardboard box. Remove any

stickers from the cooking deck.

Carefully insert the cooking decks

into OVEN BASE F by setting them

in place above the DIFFUSERS J.

Sudden impact will crack the cooking

decks, so use caution.

KalamazooGourmet.com18

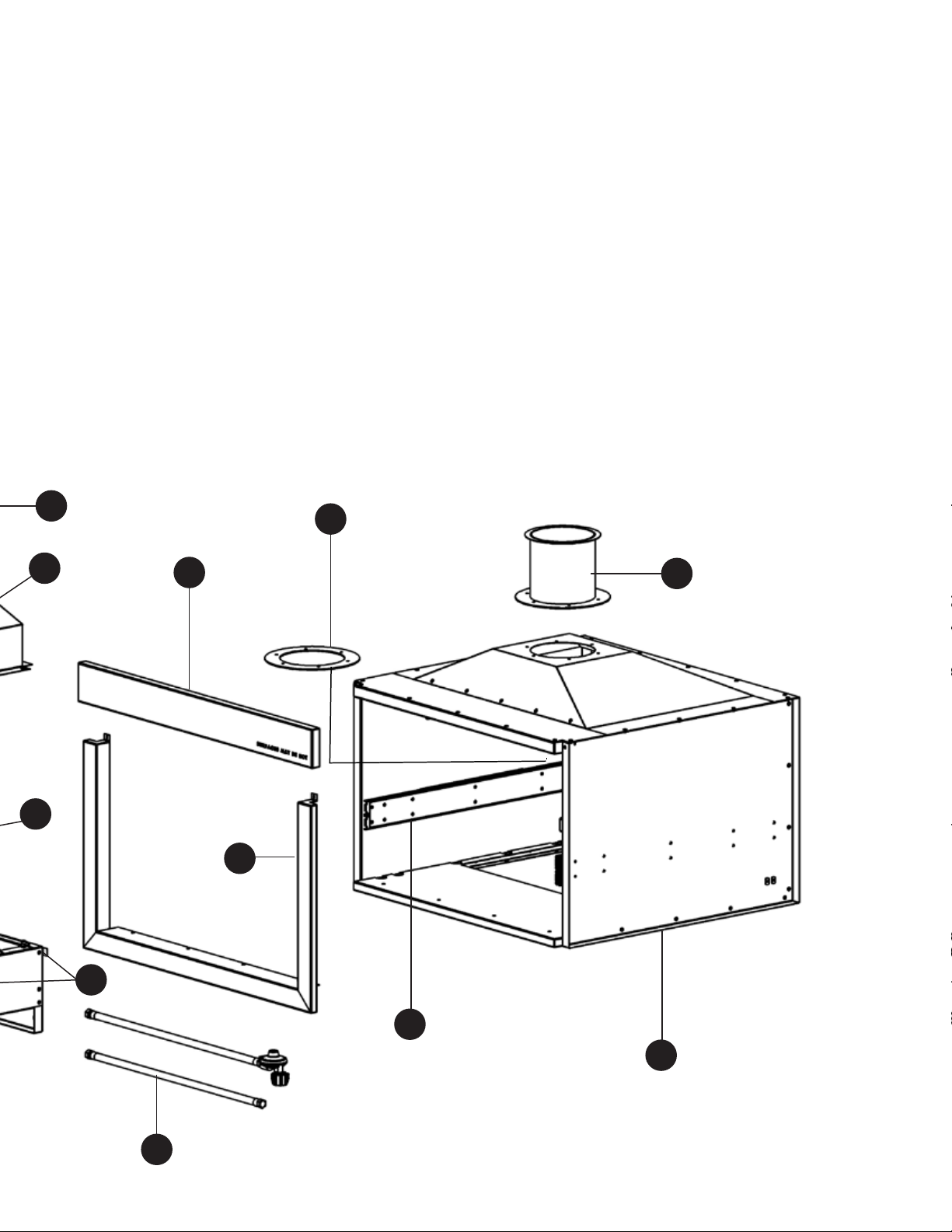

A

L

M

D

B

E

I

J

C

G

H

L. Place OVEN CHAMBER L onto OVEN BASE F, aligning the holes in the bottom of OVEN CHAMBER L with

the small posts on OVEN BASE F. OVEN CHAMBER L should sit flat and be positively located by the posts.

M. Insert CEILING STONE M into the top opening of MID BODY L. Remove any tape that may have been

used during shipping.

N. Once CEILING STONE M is installed, slide the entire oven rearward into OVEN LINER A. Use the two

KNURLED-HEAD SCREWS N to secure OVEN BASE F to the inside of OVEN LINER A.

O. Insert CRUMB TRAY O into the opening on the front of the unit below the main shelf. It sits on a ledge.

Crumbs can be brushed off the cooking deck down into the gap at the front of the stone, falling into the

crumb tray. WARNING: The crumb tray will become hot during operation. To avoid burns, be certain the

oven is cool before touching the tray, or use an appropriate cooking mitt.

P. If not already on the unit, mount CONTROL KNOBS P on the valve posts. Be sure the flat side of the

opening in the knob casting is aligned with the flat side of the valve stem.

Q. The pizza oven DOOR Q sits in the doorway. WARNING: Never operate the oven with the door in place.

R. MANUAL IGNITION WAND R is for use in manually igniting the oven. It should be stored near the oven.

FIGURE 5

1.800.868.1699 19

KalamazooGourmet.com20

Operation

1.800.868.1699 21

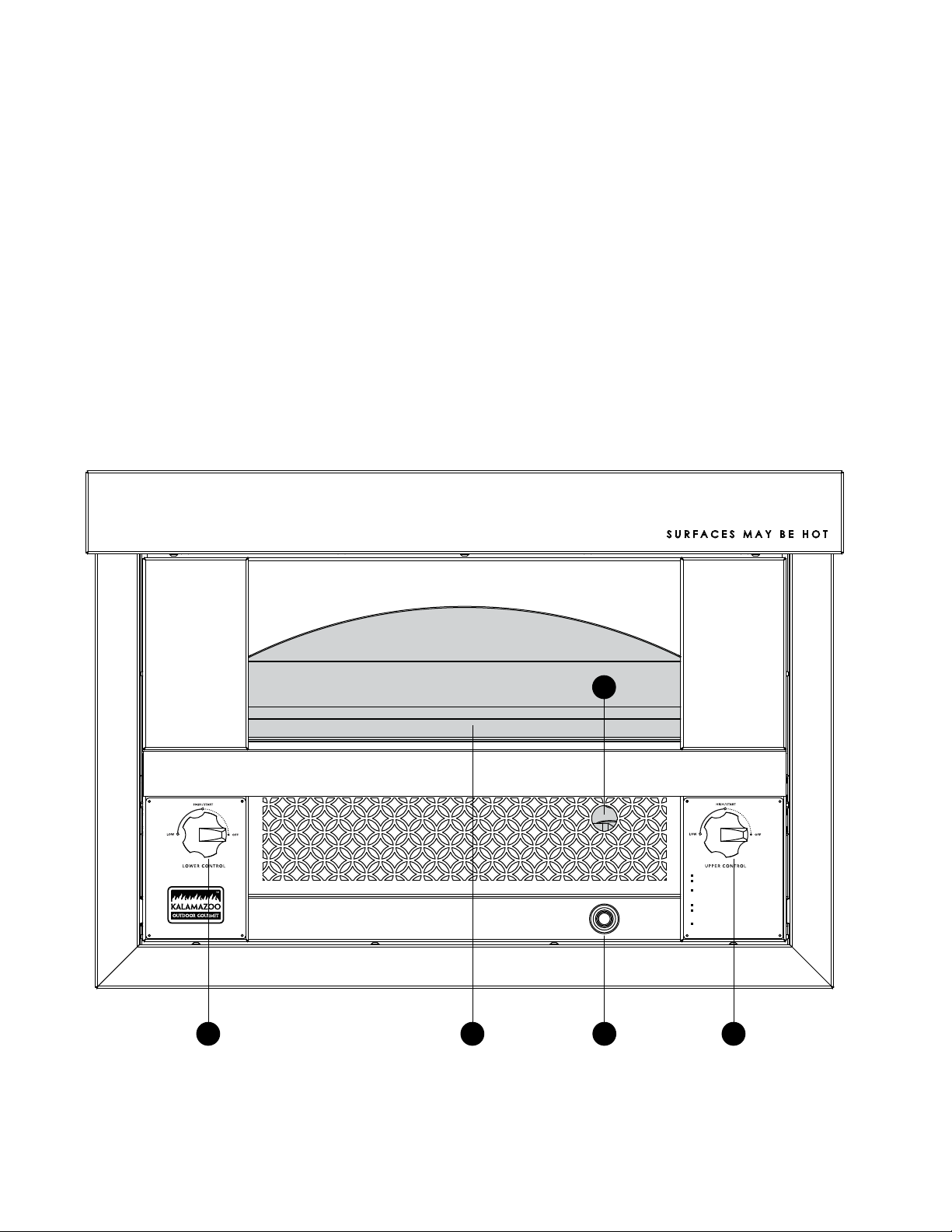

Pizza Oven Controls

A. Lower Burner Control: Controls the height of the flame on the burner below the cooking deck.

B. Upper Burner Control: Controls the height of the flame on the burner at the rear of the cooking deck. On

HIGH, this flame is visible above the Cooking Deck Backstop E.

C. Electronic Ignition Button: Depress to trigger the electronic ignition. Unscrew and remove to replace the

ignition system battery.

D. Lower Burner Viewport: Allows visual confirmation of lower burner status. Use as manual ignition port for

manual lighting procedure (SEE LIGHTING YOUR PIZZA OVEN).

E. Cooking Deck Backstop: Prevents pizzas from falling off the back of the cooking deck and into the upper

burner area. For manual lighting procedure, a match must be extended past this backstop to light the

upper burner (SEE LIGHTING YOUR PIZZA OVEN).

FIGURE 6

D

READ INSTRUCTIONS BEFORE LIGHTING.

REMOVE OVEN DOOR BEFORE LIGHTING. DO NOT

OPERATE THE OVEN WITH THE DOOR IN PLACE.

IF IGNITION DOES NOT OCCUR IN 5 SECONDS, TURN

THE BURNER CONTROLS OFF, WAIT 5 MINUTES, AND

REPEAT THE LIGHTING PROCEDURE.

LISEZ LES INSTRUCTIONS AVANT D'ALLUMER L'APPAREIL.

RETIRER LA PORTE DU FOUR AVANT DE PROCÉDER À

L'ALLUMAGE. NE PAS FAIRE FONCTIONNER LE FOUR

AVEC LA PORTE EN PLACE.

SI L'APPAREIL NE S'ALLUME PAS EN 5 SECONDES,

FERMEZ LE ROBINET DU BRÛLEUR, ATTENDEZ 5

MINUTES, ET PROCÉDEZ DE NOUVEAU À L'ALLUMAGE.

A B

E C

KalamazooGourmet.com22

Before You Cook

A quick safety check should be performed before each time you use the pizza oven.

1. Clean and inspect the gas hose. If there is evidence of abrasion, wear, cuts or leaks, do not use the

pizza oven. The hose must be replaced prior to using the pizza oven. Replace the hose assembly with

the exact type specified by Kalamazoo Outdoor Gourmet.

2. Ensure the gas hose is clear of the pizza oven. Keep the fuel supply hose away from any heated

surface(s).

3. Check that the area near the pizza oven is clear of combustible materials and vapors, including alcohol,

gasoline, aerosol containers and dry goods. Keep electrical cords from being in contact with the pizza

oven.

4. Check that nothing is interfering with the safe operation of the oven by obstructing the ventilation

around and under the unit. The pizza oven requires 6 inches of clearance to the left, right and back of

the unit with no obstructions above.

5. Do not use the oven with overly loose-fitting clothing, especially loose sleeves that may come in

contact with the hot surfaces inside the oven or near the door.

6. Have insulated gloves with long cuffs ready and available.

While You are Cooking

1. Never move the pizza oven while it is in use or when it is hot.

2. The use of alcohol, prescription or non-prescription drugs may impair your ability to properly assemble

or safely operate the pizza oven.

3. Do not touch the top of the pizza oven, the front shelf or any surfaces inside or near the door opening

while the oven is hot. These surfaces can cause serious burns.

4. Be very careful transporting hot pizzas. The toppings can cause serious burns to yourself or those

around you.

5. Only use a long-handled brass bristle brush to clean the cooking deck. The handle must be long

enough that your hands stay safely outside of the oven.

6. Never empty the crumb tray while the oven is hot. The tray and its contents become very hot while the

oven is in use.

Follow all warnings and instructions when using this appliance.

This appliance is not intended for and should never be used as a heater.

This appliance is not intended for commercial use.

1.800.868.1699 23

Lighting Your Pizza Oven

Before lighting your pizza oven, be sure you have followed the instructions in this Use and

Care Guide regarding proper setup, placement, gas connections, leak testing and safe

operation, all of which precede this page.

IMPORTANT: Do not use the pizza oven if the odor of gas is present at any time. Follow leak testing

procedures before using the pizza oven.

IMPORTANT: Your pizza oven is equipped with safety valves that prevent the flow of gas unless the integrated

sensors detect the heat of a flame. To light each burner, you must bypass the sensor by pressing in on the

control knob until the flame from the lit burner has sufficiently heated the sensor. The lower burner/control

knob and upper burner/control knob each has its own separate sensor.

Standard Lighting Procedure:

1. Remove the pizza oven door and set aside. DO NOT OPERATE THE PIZZA OVEN WITH THE DOOR INSTALLED.

2. Make sure the LOWER BURNER and UPPER BURNER control knobs are in the OFF position.

3. Turn the main gas supply on.

4. If lighting both burners, light the LOWER BURNER first. Keeping your face well away from the unit,

sight through the lower burner viewport (see Figure 6:D). Push inward on the LOWER BURNER

control knob (see Figure 6:A) and rotate to the HIGH/START position. While continuing to hold in the

control knob, press the ELECTRONIC IGNITION BUTTON (see Figure 6:C). You should hear clicking

and ignition should take place within 4 to 5 seconds. Watch through the lower burner viewport to

confirm ignition. If the burner does not light within this time, turn the knob to the OFF position and

wait 5 minutes for the gas to dissipate before trying again. If you do not hear clicking, refer to the

troubleshooting section of this Use and Care Guide. Once the burner is lit, continue pressing in the

control knob for at least 10 seconds until the safety valve sensor has detected the heat of the

flame.

5. To light the UPPER BURNER, you can look through the open door of the pizza oven, keeping your

face well away from the opening. Push inward on the UPPER BURNER control knob (see Figure 6:B)

and rotate to the HIGH/START position. While continuing to hold in the control knob, press the

ELECTRONIC IGNITION BUTTON. You should hear clicking and ignition should take place within

4 to 5 seconds. If the burner does not light within this time, turn the knob to the OFF position and

wait 5 minutes for the gas to dissipate before trying again. If you do not hear clicking, refer to the

troubleshooting section of this Use and Care Guide. Once the burner is lit, continue pressing in the

control knob for at least 10 seconds until the safety valve sensor has detected the heat of the flame.

Manual Lighting Procedure:

FOLLOW THE STANDARD LIGHTING PROCEDURE, but utilize a paper match inserted into the clip on the end

of the provided manual ignition wand rather than the electronic ignition.

To light the LOWER BURNER, insert the lit match and wand through the lower burner viewport (see Figure 6:D)

to a position above the lower burner. To light the UPPER BURNER, use the wand to hold the lit match at the

rear of the oven above the upper burner.

Light and position the match BEFORE turning on the corresponding control knob. If the burner does not light

immediately, turn the knob to the OFF position and wait 5 minutes for the gas to dissipate before trying again.

Once the burner is lit, continue pressing in the control knob for at least 10 seconds until the safety valve

sensor has detected the heat of the flame.

KalamazooGourmet.com24

Burner Adjustments

Every burner is tested and adjusted at the factory for proper performance. If a burner is

not operating properly, it may be due to variations in the local gas supply or because of an

obstructed air shutter or orifice. Flames should be stable without lifting from the burner. The

flames should burn cleanly without creating any sooty residue.

Upper Burner Flame Characteristics:

The flame should be predominantly orange and clearly visible at the back of the oven. The flame

diffuser on the burner is designed to create a more visually appealing flame for your oven. It diffuses

the gas coming out of the ports, making it so that there are not individual flames with individual cones.

The inner cone should be

approximately 3 inches high in

average.

The outer cone should not touch the

ceiling inside the pizza oven. If the

tips of the outer cone are making

contact with the ceiling, the flames

are too high.

FIGURE 7

OUTER CONE

AIR SHUTTER

LOCK SCREW

LOWER BURNER

Lower Burner Flame Characteristics:

The flame should be blue and stable with

only a small amount of orange, if any, at

the tips. There should be little noise and no

lifting.

The inner cone should be 1/4 inch high.

The outer cone should be 5/8 inch high.

UPPER BURNER

OUTER CONE

INNER CONE

LOCK SCREW

INNER CONE

AIR SHUTTER

Visually compare the flames in your pizza oven and adjust if necessary, using the instructions on the

following pages.

1.800.868.1699 25

Burner Adjustments CONTINUED

IMPORTANT: A sooty flame is usually caused by dirt, debris or spider nests blocking the air shutter or orifice.

This is a dangerous condition. The pizza oven should NOT be used until the problem is rectified. If you are not

comfortable addressing the issue yourself, please hire a qualified technician or contact Kalamazoo Outdoor

Gourmet Customer Service at 1.800.868.1699.

FIGURE 8 (BOTTOM VIEW)

H

D

A

B

C

E

F

G

A. Air shutter

B. Lock screw

C. Lower burner body

D. Brass orifice

E. Air shutter

F. Lock screw

G. Upper burner body

H. Brass orifice

IMPORTANT: Always ensure brass orifices (D and H above) are inserted into the

holes in the ends of the air shutters (A and E above) and centered.

KalamazooGourmet.com26

To Clean the Air Shutter:

It is possible to visually inspect the air shutter from below without dismantling the unit. The air shutter is

located directly behind the control valve for that burner (See figure 8, air shutters A and E).

Ensure the pizza oven control knobs are in the OFF position. Turn off the gas supply shutoff valve or close the

main valve on the LP cylinder. Disconnect the gas hose from the gas supply or cylinder.

From inside the access area below the oven, remove the knurled knobs that secure the oven to the liner (See

Figure 23). From outside the structure, carefully slide the oven out of the enclosure at least half way.

Use a flashlight to view the screened openings of the air shutter from below. Remove any obvious obstructions

from the screen protecting the air shutter.

To Adjust the Air Shutter:

It is possible to adjust the air shutter from below without dismantling the unit. The air shutter is located directly

behind the control valve for that burner (See figure 8).

Ensure the pizza oven control knobs are in the OFF position. Turn off the gas supply shutoff valve or close the

main valve on the LP cylinder. Disconnect the gas hose from the gas supply or cylinder.

From inside the access area below the oven, remove the knurled knobs that secure the oven to the liner See

Figure 23). From outside the structure, carefully slide the oven out of the enclosure at least half way.

Use a screwdriver to loosen the lock screw (Figure 8: B, F). Be careful not to remove the lock screw. Once

loose, you can rotate the air shutter to adjust the amount of air entering the venturi.

Visually inspect that the gas hose has not been stressed, dislodged or otherwise affected by moving the pizza

oven. If it is safe to do so, and with the pizza oven control knobs in the OFF position, reconnect the gas, turn

on the gas supply valve or open the main valve on the LP cylinder. Light the burner to be adjusted following

the lighting procedure on page 16. LIGHT ONLY THE BURNER TO BE ADJUSTED. Rotate the air shutter to

adjust the amount of air entering the venturi.

For a lifting flame, progressively close the air shutter until the flame no longer lifts from the burner. For a sooty

flame, progressively open the air shutter until the flame burns cleanly.

Once adjusted to a stable flame that burns cleanly and does not lift, turn the pizza oven control knob to the

OFF position. Tighten the lock screw. Re-light and confirm the adjustment is good. Turn the pizza oven control

knob to the OFF position. Turn off the gas supply shutoff valve or close the main valve on the LP cylinder.

Return the pizza oven to its normal position inside the liner. Re-secure the oven into the liner using the knurled

hand screws. Once again, visually inspect that the gas hose has not been stressed, dislodged or otherwise

affected by moving the pizza oven.

IMPORTANT: If the flame from the upper burner is contacting the ceiling inside the pizza oven, contact

Kalamazoo Outdoor Gourmet Customer Service. You may have higher than normal gas pressure and may need

a smaller orifice for this burner.

1.800.868.1699 27

KalamazooGourmet.com28

Cooking with Your Pizza Oven

IMPORTANT: The Artisan Fire Pizza Oven is a high-performance piece of equipment

that gets very hot. Use caution when working with the oven and do not leave the oven

unattended. Use insulated gloves with a long cuff to protect your hands and forearms from

heat.

Essential Equipment

Leather insulated gloves with long cuffs to protect your hands and forearms.

Long-handled brass brush, preferably “push broom” style, for cleaning the cooking deck

Heat-resistant pizza peels for transferring pizzas into the oven and rotating pizzas while cooking

Aluminum pizza screen to slow down the cooking of the crust when needed

Check out Kalamazoo’s Pizza Master’s Essentials Kit for the best pizza peels available.

Other Helpful Accessories

Dough divider/scraper

Large-diameter pizza cutting wheel

Heavy-gauge deep dish pizza pan

Cast iron skillet and/or fajita pans

Digital scale

Artisan Fire Pizza Oven Cover

IMPORTANT: Before cooking, become familiar with all the information in this

Use and Care Guide regarding safe operation of your pizza oven.

Preheating

The Artisan Fire Pizza Oven is ready to cook in as little as 20 minutes, however, we

recommend at least 45 minutes of preheating for optimum performance.

IMPORTANT: Always remove the door before operating the pizza oven. The

door is for use only when the pizza oven is OFF. It is not intended for cooking.

It is intended only for keeping foreign objects out of the oven when it is not

in use.

1.800.868.1699 29

General Operating Tips

Thin Crust Pizza

Crust formed to less than 1/8” thick

Upper burner on HIGH

Lower burner on LOW

Cook for approximately 3 minutes

Rotate pizza 3 to 4 times during cooking

Medium Crust Pizza

Crust formed to 1/4” thick

Upper burner on MEDIUM

Lower burner turned OFF a couple of

minutes before putting pizza in the oven

after preheating on LOW

Cook for approximately 8 minutes

Rotate pizza 3 to 4 times during cooking

Deep Dish Pizza

Use heavy-gauge aluminum pizza pan

Upper burner on MEDIUM

Lower burner MEDIUM

Cooling rack placed between pan and

cooking deck

Cook for approximately 40 minutes

Rotate pizza every 5 to 8 minutes

IMPORTANT: Never put greasy,

oily or buttery foods directly on

the cooking deck. For cookies,

meats and other items, use a pan

or cast iron skillet.

Temperature Range

When the oven is fully pre-heated, with both

burners on HIGH, the Artisan Fire Pizza Oven is

capable of intense heat in excess of 800ºF. The

heat is most intense at the rear of the cooking

deck and least intense at the front. Once you

are familiar with cooking in the oven, you will be

able to use this to your advantage in turning out

perfect pizzas. Only the thinnest of pizzas with a

reserved amount of toppings should be cooked

at the upper end of the temperature range.

Specialty flours may be needed to avoid burning

the dough.

When the upper burner is set to LOW and the

lower burner is LOW or OFF, the oven cooks at a

very low and slow speed. Temperatures can be as

low as 300ºF.

Calzones

Upper burner on MEDIUM

Lower burner turned OFF a couple of

minutes before putting calzones in the oven

after preheating on LOW

Cook for approximately 7 minutes

Rotate calzones once during cooking

Roasted Meats or Vegetables

Upper burner on HIGH

Lower burner LOW

Preheat cast iron skillet in the oven

Cook food in preheated skillet

Rotate skillet for even roasting

Why no Thermometer?

With the intense and dynamic heat characteristics

of the Artisan Fire Pizza Oven, we have found that

a thermometer is misleading at best, resulting in

poorly-cooked pizzas. After hundreds of tests, we

have developed the guide on the left for basic

burner settings. We recommend you learn to trust

your eyes and experiences to determine how

quickly a pizza is cooking and when it has reached

perfection.

Cook with your pizza oven a few

times to learn the ropes before

hosting your first pizza party.

KalamazooGourmet.com30

Additional Cooking Tips

Use corn meal or flour between the dough and the peel to help slide the pizza off the peel. Be sure the

dough is floured enough so that it is not sticky on the bottom.

Do not leave an assembled pizza on the countertop or the peel longer than absolutely necessary. This can

lead to the pizza sticking to the surface.

Cook thin to medium crust pizzas directly on the cooking deck.

Use multiple, smaller “flicking” gestures to coax the pizza off the peel into the oven. Trying to do it with

one, larger gesture is more likely to dislodge pizza toppings.

Do not overload a thin-crust or medium-crust pizza with too much toppings. This will most often lead to a

soggy center crust. When in doubt, less is more.

If the pizza sticks to the cooking deck, the deck was probably not hot enough before the pizza was put

onto the deck.

Do not put a frozen pizza on the cooking deck. It is almost certain to stick and to become burned before it

releases.

Rotate pizzas for even cooking. The oven is hottest at the back.

Brush burnt cornmeal or flour off the cooking deck and into the crumb tray before cooking the next pizza.

If you have any difficulty rotating the pizza inside the oven using a peel, try using a smaller pizza peel

designed for turning. Or try long-handled grill tongs to do the job. You can also use the tongs to lift the

edge of the pizza to check on the bottom of the crust.

Avoid letting the pizza contact the cooking deck backstop (Figure 6:E). This is a very hot surface that will

quickly burn the crust.

1.800.868.1699 31

KalamazooGourmet.com32

Recipes

1.800.868.1699 33

34

Recipes

Pizza making is the perfect opportunity for creative expression. It is relatively casual, so there

is less pressure, and follows a simple structure within which you can try a host of variations.

Pizza making is also great for communal cooking. People can gather to make a variety of

pizzas using their own toppings. The short cooking time offers instant gratification and

encourages experimentation.

Following are a selection of recipes we’ve created over the years. Sure, some of them are

pretty “out there,” but they are all delicious. We encourage you to give them a try — and

to come up with your own. We’d be especially grateful if you shoot us a note to share your

creations and experiences.

Two thoughts may help you on your way...

Use the freshest and best ingredients you can. Making your pizzas with seasonal ingredients

grown locally can be very rewarding. Try artisan cheeses. Keep a log of the ingredients you

like best and what you did with them.

And, keep your pizzas on the simple side, using only three or four main ingredients. Once

you establish a few combinations as your favorites, start riffing on those for new creations.

Most importantly of all, enjoy yourself and eat well!

Your pizza oven can cook more than just pizzas and bread. In this section, we

share quick recipes for roasted asparagus and a grilled cheese panini. You can

also roast meats — just be sure to do it in an appropriate roasting pan and

never directly on the cooking deck.

1.800.868.1699 35

36

White Wine Pizza Dough

Making pizza dough from scratch really isn’t a lot of work. You don’t need to dig out the

mixer and use the dough hook for kneading. Try kneading the dough by hand right in the

mixing bowl, and you may find yourself making dough from scratch more often.

This dough is easy to work with and appropriate for a wide variety of pizza styles and

calzones.

Yields 28 ounces of dough

¾ cup warm water

Pinch of sugar

3 teaspoons active dry yeast

1/4 cup white wine, at room

temperature

1¼ teaspoons kosher salt

2 tablespoons olive oil, plus extra for

coating

3 cups bread flour

2 teaspoons honey

Directions

Put 6 tablespoons of the lukewarm (100° to 110°F) water, sugar and

yeast in a small bowl, mix well and set aside for 5 minutes or until

frothy.

In a large bowl, whisk together the remaining water with the white

wine, salt and 2 tablespoons olive oil. Use a wooden spoon to stir in 1

cup of the flour, creating a batter. Stir the honey and the yeast mixture

into the batter.

Add the remaining flour and continue stirring with the wooden spoon

for a few minutes. Knead the mixture in the bowl until smooth and

relatively firm. Clean the sides of the bowl, oil the dough with a little

more olive oil and cover the bowl with a towel.

Let rise for 45 minutes. A good tip is to run a load of dishes in the

dishwasher while the dough rises right above the washer door. The

warm, moist air helps with the rising.

After 45 to 60 minutes, punch the dough down, split in half or

quarters, knead again briefly and let rest 15 minutes more before

rolling into pizza crusts. Unused dough may be frozen..

Makes enough dough for two 14-inch round pizzas or 4 individual

pizzas. For more pizzas, make the dough 1 batch at a time rather than

multiplying the recipe.

1.800.868.1699 37

38

Artisan Fire Pizza Dough

This Neapolitan-inspired pizza dough utilizes a blend of bread flour and Tipo '00 flour — the

Italian flour used by Neapolitan pizza restaurants because of its high burning point. We have

optimized this dough recipe for use in the Artisan Fire Pizza Oven when making Neapolitanstyle pizzas. The flour blend yields good overall color and the desired leapording.

This dough is a little more difficult to handle than the White Wine Pizza Dough and is

intended for use only with sparse toppings in the Neapolitan style.

Yields 7 10-ounce Dough Balls

(about 2kg dough)

50ml luke-warm tap water

2 teaspoons honey

5 grams active dry yeast

700ml cold tap water

450g Caputo Tipo 00 flour

800g unbleached bread flour

45g kosher salt

NOTES

For an interesting flavor and texture

alternative, try substituting 300g of

rye flour for 300g of bread flour.

All ingredients are measured by

weight. Metric measurements are

used for added precision (1 gram =

0.035 ounces) and to make it easier to

calculate the hydration (ratio of wet to

dry ingredients by weight).

Directions

Dissolve the honey in the warm water. Stir in the yeast. Let sit for 5

minutes to activate. It should become quite frothy.

Combine the yeast mixture with the cold water and ’00 flour in a large

bowl. Stir well to create a batter. Add half of the bread flour (400g)

and stir well to combine. Add the remaining half of the bread flour

and the salt. Work these into the dough, then remove from the bowl

onto a clean work surface. Knead until the dough is evenly combined

and has a consistent texture, about 8 minutes.

Return the dough to the mixing bowl and cover tightly. Let the dough

rest for 1 hour.

Divide the dough into 7 equal, 10-ounce (284g) parts, working each

part into a smooth ball and tucking in any corners or edges. Coat

each ball in olive oil and place them into covered dough boxes or on

baking sheets. Cover tightly and refrigerate for 12 to 24 hours.

Remove the dough boxes from the refrigerator and let the dough rest

at room temperature for 2 to 4 hours before making pizzas.

To form the pizza crusts, work the dough gently with your hands.

Never use a rolling pin or pinch the dough too firmly. This will “bruise”

the dough. Start with the dough ball on a floured work surface. Press

gently outward toward the edges with your fingers, rotating the dough

as you work your way around to create a disk. Lift the disk from the

surface and begin to gently stretch it. Once it is about 7 inches in

diameter, let gravity begin to help you shape the dough. Hold the disk

from the top with both hands. Try to use the flats of your fingers rather

than your fingertips. Sway the dough back and forth to stretch it, and

shuffle your hands along to rotate the dough as you sway back and

forth. You can also stretch the dough across the backs of your fists.

Combine these techniques in the manner that suits you best.

When the dough is ready for toppings, it should be about 1/8-inch

thick and roughly 12 inches in diameter. Do not create a lip for the

perimeter. The dough should be an even thickness from edge to

edge. The lip should rise around the edge in the oven (keep the

toppings ¾ inch from the edge).

1.800.868.1699 39

KalamazooGourmet.com40

Charcuterie Pizza

This pizza is amazing! Cheese and cured meats are not new to pizza (think pepperoni

pizza), but great cheese and great cured meats can elevate pizza to another level.

In particular, the buttery and nutty Campo de Montalban makes an incredible

contribution. The pork pate exterior becomes mouth-wateringly crisp from the high

heat of the pizza oven. You can follow these specific ingredients, or use the leftovers

from almost any meat and cheese board.

Yields a 10 inch pizza

1 Artisan Fire Pizza Dough ball,

10 ounces

Caputo '00 flour for dusting

1 ounce triple cream French cheese (I

used Délice de Bourgogne)

1 ounce Campo de Montalban,

cut into 1/2-inch cubes (this is a

Manchego-like cheese, but made

from a blend of sheeps’, cows’ and

goats’ milk)

1/2 ounce wild boar salami (I used

Creminelli brand)

1/2 ounce truffle sausage (I used

Charlito’s Cucina)

1 ounce pork pate

Extra virgin olive oil

Directions

Preheat the pizza oven for cooking with the upper burner control on

HIGH and the lower burner control on LOW.

Lightly dust the work surface and the dough ball with ‘00 flour.

Gently form the dough into a 10 inch crust about 1/8 inch thick.

Top the dough with dabs of the triple-cream cheese, plus the Campo

de Montalban and meats. Drizzle with olive oil.

Transfer the assembled pizza onto a pizza peel dusted with ‘00 flour.

Transfer to the pizza oven directly on the cooking deck and bake for 2

to 3 minutes until the crust is crisp and the cheese is browned. Rotate

several times for even baking.

Remove, let rest for a minute or two, slice and serve.

1.800.868.1699 41

42

Roasted Mushrooms and Bacon Pizza

Using wild mushrooms makes a remarkable difference in the taste of a pizza. We roast

shiitake, morel and chanterelle mushrooms before putting them on the pizza to concentrate

the earthy flavors and really make them the stars of this pie. Creamy, rich sottocenere cheese

adds the assertive and indulgent flavor of truffles while smoky bacon rounds things out.

Yields 2 10 inch pizzas

2 Artisan Fire Pizza Dough balls,

10 ounces

1/4 pound slab bacon, cut into 1/4

inch cubes (I used a bourbon maple

bacon made from Berkshire pork

belly)

1 ounce morel mushrooms

2 ounces chanterelle mushrooms, cut

in half

3 ounces shitake mushrooms

Extra virgin olive oil

Fine sea salt

Coarsely-ground black pepper

4 ounces sottocenere cheese

(a medium-soft Italian cheese laced

with truffles and with an ash rind), cut

into smallish pieces

4 ounces Quadrello di Bufala cheese

(similar to Taleggio but with a less

intense odor and more milky taste),

cut into smallish pieces

Directions

Preheat the pizza oven for cooking with the upper burner control on

HIGH and the lower burner control on LOW.

Cook the bacon in a skillet until done but not crisp. Reserve.

Toss the mushrooms in olive oil and season liberally with salt and

pepper. Either place them in the pizza oven on a fajita skillet and roast

until browned, about 5 minutes; or grill them directly over a hot fire

on the grill for about the same amount of time. Remove from heat and

reserve.

Form one dough ball to a 10- to 12-inch pizza crust. Depending

on your personal preference, place the dough on a pizza peel with

enough flour or corn meal beneath to allow the pizza to slide easily

— or assemble your pizza on the work surface and then slide the peel

underneath at the last minute. Either way, the less time the dough

spends on the peel, the less likely it is to stick.

Top the dough with half of each type of cheese, half the mushrooms

and half the bacon.

Transfer to the pizza oven directly on the cooking deck and bake for 2

to 3 minutes until the crust is crisp and the cheese is melted through.

Rotate several times for even baking.

Repeat for the second pizza.

1.800.868.1699 43

44

Zucchini Pizza Pinwheels

A lot like a calzone, but with a beautiful presentation, these pizza pinwheels are wonderful

starters for parties. Fresh zucchini melds with Spanish cheese and

sweetened tomatoes.

Yields 4 pinwheels

1 batch White Wine Pizza Dough,

about 28 ounces

1 cup grape tomatoes, quartered

1 tablespoon light brown sugar

1 cup shredded zucchini (1 fresh

zucchini should provide enough)

1 cup shredded manchego cheese

1/2 teaspoon fine sea salt

1 egg, beaten

Directions

Preheat the pizza oven for cooking with the upper burner control on

MEDIUM and the lower burner control on LOW.

Stir together the grape tomatoes with the brown sugar in a small bowl

and let sit for at least 15 minutes.

Spread the shredded zucchini out on a large cutting board and let it

air-dry for 15 minutes.

Discard the liquid in the tomato bowl and combine the tomatoes,

zucchini, cheese and salt in a large bowl.

Roll out the pizza dough into a square about 15 inches to a side. Trim

the large dough into four smaller, perfect squares, then roll those

thinner until they are each roughly 8 inches to a side.

Start with one square. Stretch the corners to elongate them, making

the dough into a four-pointed star. Transfer to a pizza prep peel

dusted with cornmeal. Spoon the zucchini filling onto the dough in

a square shape that is on a diagonal to the four-pointed star. Lift two

opposing corners of the star to the middle, folding over the filling and

firmly press them together between your fingers to join at the middle.

Repeat with the other two corners and then press the four corners

together at the middle.

Repeat to make a total of four pinwheels on your pizza prep peel.

Optionally, for more golden tops, lightly brush the top areas of the

dough with the beaten egg.

Turn the lower burner control to OFF.

Transfer the pinwheels to the pizza oven, directly onto the cooking

deck, and bake until golden brown on top and cooked through, about

7 minutes.

1.800.868.1699 45

46

Deep-Dish Three-Cheese Sausage Pizza

If you like lasagna, you’ll love this pizza.

Yields a 12 inch pizza

2 pounds fresh Roma tomatoes

4 cloves garlic

1/2 teaspoon kosher salt

1 batch White Wine Pizza Dough,

about 28 ounces

12 ounces scarmoza cheese,

shredded

8 ounces ricotta

1 teaspoon fresh thyme leaves

12 ounces fresh mozzarella (Ovolone),

drained and dried in a mesh strainer

2 pork sausages, casings removed

and broken into small pieces

You will also need a cooling rack and

a 12 inch heavy aluminum pizza pan, 2

inches deep. It should be made from

at least 14 gauge material.

Directions

Preheat the pizza oven for cooking with the upper burner control on

MEDIUM and the lower burner control on MEDIUM.

Combine the tomatoes, garlic and salt in a blender and puree until

very smooth. Transfer to a saucepan. Reduce over medium heat,

stirring frequently until thickened into a sauce.

Form the dough into a large circle, larger than the pizza pan and only

1/4 inch thick. The perimeter can be thicker. Place it over the pan and

let it sag into position. Coax it into the corners of the pan, leaving the

dough hanging over the edges.

Spread the scarmoza cheese into a bottom layer on the dough. Place

the cooling rack onto the cooking deck in the pizza oven. Place the

pizza pan with the dough and scarmoza onto the cooling rack. Cook,

rotating frequently until the cheese is fully-melted. This helps pre-crisp

the crust and the melted cheese forms a protective layer that helps

prevent the crust from becoming soggy. Remove from the pizza oven

using gloves or oven mitts.

Layer in the ricotta cheese, followed by the thyme leaves, and the

fresh mozzarella, keeping the layers as level as possible. Ladle on the

tomato sauce and then add the sausage. Use small pieces, evenlyspaced to help ensure the raw sausage will cook fully.

With all the ingredients in the pizza pan, the pan should be only

halfway full. The toppings will expand when cooking. Fold in the crust

that is hanging over the edge of the pan, getting it all inside the pan,

but keeping it high on the sides. If any pizza toppings overflow the

sides of the crust, the pizza will be soggy.

Put the pizza pan back into the oven on top of the cooling rack. The

cooling rack creates an air gap that helps keep the bottom crust from

burning. Cook for at least 40 minutes, rotating ever 5 to 8 minutes.

The toppings should be bubbling, the sausage should be fully-cooked

and the edges of the crust should be dark.

Remove from the oven and let rest 10 minutes before cutting and

serving.

1.800.868.1699 47

48

Grilled Cheese Panini

Your pizza oven makes excellent paninis. This recipe is intended only to give you the format.

Experiment and enjoy.

Yields 1 sandwich

2 slices Tuscan bread

1 slice provolone cheese

1 slice pepper jack cheese

1 slice mild cheddar cheese

Olive oil spray

Directions

Preheat the pizza oven for cooking with the upper burner control on

HIGH and the lower burner control on LOW.

Place the cheeses between the slices of bread to make a sandwich.

Spray the outside of the bread very lightly with olive oil spray. (The

reason we’re using spray is because we want far less oil than we could

ever brush on. If you want to make a panini using more oil, put it into

a skillet in the pizza oven).

Use long tongs to transfer the panini into the oven directly on the

cooking deck. Cook for 1 minute and then rotate. Cook for 1 minute

more and then flip it over. Cook for 2 minutes more, rotating once

until the bread is browned and the cheese is melted.

Remove, slice and enjoy.

1.800.868.1699 49

50

Roasted Asparagus Spears with Prosciutto and

Herbed Cheese

This dish makes a great appetizer or side. Crispy prosciutto wraps tender asparagus with a

cheesy surprise inside.

Serves 2

3 tablespoons Boursin garlic herb

cheese

Finely-grated lemon zest from 1/2

lemon

12 spears fresh asparagus, bases cut

off

1 tablespoon extra virgin olive oil

1 tablespoon lemon juice

4 slices prosciutto

You will also need a cast iron fajita

pan or skillet.

Directions

Preheat the pizza oven for cooking with the upper burner control on

HIGH and the lower burner control on LOW. Preheat a cast iron fajita

pan in the oven.

Combine the Boursin and the lemon zest.

Toss the asparagus in a bowl with the olive oil and lemon juice.

Lay out a slice of prosciutto on a clean work surface. Lay 2 asparagus

spears across one end of the prosciutto. Place a dollop of the Boursin

mixture on the center of the spears. Press a third spear into the top

of that. Roll tightly into the prosciutto slice to make the first bundle.

Repeat 3 more times.

Place the bundles in the preheated pan and put the pan into the oven.

Roast the bundles for about 4 minutes, turning once or twice with

tongs until the prosciutto is crisp. Use caution to avoid overcooking

the asparagus.

1.800.868.1699 51

KalamazooGourmet.com52

Installation and Construction

1.800.868.1699 53

38 3/8"

REQ'D TO SET

COOKING DECK

HEIGHT AT 48"

31 1/4" MIN./ 32" MAX.

OPENING WIDTH

20" MIN.

21 1/2"

MAX.

OPENING HEIGHT

29 1/4"

K-ACD-AFPO

ACCESS DOOR

OPENING WIDTH

23 1/2"

K-ACD-AFPO

ACCESS DOOR

OPENING HEIGHT

5"

MAX.

LINTEL DEPTH

26 1/2" MIN.

27 1/2"

MIN.

DISTANCE BETWEEN

SUPPORT LEDGES

OPEN ACCESS TO PIZZA OVEN

FOR GAS SUPPLY AND SERVICE

IS MANDATORY.

KALAMAZOO OUTDOOR GOURMET

ACCESS DOOR K-ACD-AFPO IS

INCLUDES REQ'D

CLEARANCES

Dimensions for Openings

Minimum and maximum heights for the front opening of the non-combustible structure within which the oven

will be installed are: 31.25 inches wide by 20 inches tall minimum; 32 inches wide by 21.5 inches tall maximum.

The cooking deck height can be set at any reasonable position. We recommend a cooking deck height of 48

inches from the ground for most people.

Access to the space below the oven is required. Dimensions for the access door opening described below are

to fit the optional Kalamazoo Outdoor Gourmet stainless steel access door.

FIGURE 9

KalamazooGourmet.com54

Structure Interior Dimensions & Clearances

The oven liner (see Figure 12) is mounted to a pair of support ledges that run from front-to-rear of the

structure. Maximum spacing between the two ledges is 27.5 inches. Minimum spacing is 26.5 inches. This

space must be open to access the bottom of the oven. The oven liner must be screwed down onto these

ledges for secure installation.

See the minimum dimensions below to allow for the required clearances between the oven liner and the

interior of the non-combustible structure.

FIGURE 10

1.800.868.1699 55

Installation Instructions

1. Review and understand the required clearances

and dimensions for openings (Figures 9 and 10).

2. Build the non-combustible structure without

fully closing in the front opening (Figure 11).

Ensure the support ledges are built to the proper

dimensions (Figure 10). Additional clearance is

required at the top of the front opening to install

the oven liner. The space can only be closed off

after the liner is in position.

3. Attach the chimney flange and support ring to the

oven liner (Figure 12) using 6 sets of 10-24 x 0.75-

inch screws, #10 lock washers and 10-24 flange

nuts.

4. Place the oven liner in the structure, resting on

the support ledges (Figure 13). Do not secure the

oven liner to the structure at this time.

5. Connect the installer-supplied chimney to the

chimney collar (Figure 14). Follow the chimney

manufacturer’s instructions and all local codes for

proper chimney length, clearances and installation

methods. A 6-inch inner diameter double-wall

insulated grease duct is strongly recommended.

The duct should be topped with an appropriate

rain cap.

FIGURE 11

FIGURE 13

FIGURE 12

FIGURE 14

KalamazooGourmet.com56

6. Finish building the non-combustible structure

around the oven liner (Figure 15). Apply the final

finish, if applicable) to the structure.

7. Align the front faces of the top and bottom

pieces of the oven liner flush with the finished

front face of the non-combustible structure

(Figure 15). Secure the oven liner to the support

ledges using at least eight installer-supplied

screws (Figure 16). When the oven and slides are

fully extended outside the oven liner (Figure 21),

the weight of the oven is secured only by these

screws. You must ensure a solid mounting to the

support ledges.

FIGURE 16

FIGURE 15

FIGURE 17

FIGURE 18

1.800.868.1699 57

8. Install the face frame utilizing 6 Kalamazoo-

supplied 10-24 x 0.375-inch button-head cap

screws and #10 lock washers (Figure 17).

9. Install the top trim piece utilizing 3 Kalamazoo-

supplied 10-24 x 0.375-inch button-head cap

screws and #10 lock washers (Figure 18).

10. Extend the heavy-duty slides fully out of the oven liner.

FIGURE 19

With assistance from another person, place the oven base (Figure 5:F) on top of the

extended slides (Figure 19), resting on the oven base tabs (Figure 5:H).

11. Secure the oven base to the slides 12 Kalamazoo-supplied 8-32 x 0.375-inch button-head cap screws and

#8 lock washers.

12. Place the two lower diffusers (Figure 5:J) inside the oven base above the lower burner.

13. Place the two baking deck sections in the oven base above the lower diffusers (Figure 5:K).

FIGURE 20

KalamazooGourmet.com58

FIGURE 22

FIGURE 21

14. Place the oven chamber section onto the oven

base using the posts (Figure 20) to locate its

position.

15. Place the ceiling stone in position on top of the

oven mid section (Figure 21).

16. Slide the assembled oven partially into the oven

liner. From inside the non-combustible structure,

install the gas hose onto the oven base flare

fitting (Figure 22).

17. Slide the oven the rest of the way into the

liner. Secure the oven in position using the 2

Kalamazoo-supplied knurled-head screws (Figure

23).

18. Connect the gas hose to the gas supply, and test

for leaks.

FIGURE 23

1.800.868.1699 59

Optional Access Door Installation Instructions

A companion stainless steel access door is available for the pizza oven. See Figure 9 for the

required opening dimensions. The optional door includes a trim piece to better match the

appearance of the oven.

1. First, install the trim piece into the opening. Align the trim so it is plumb and true, and the rear edge of

the trim is flush against the finished wall. Use 6 screws of the appropriate type for your non-combustible

construction materials. 3 screws are used on each side, driven through the rear-most holes of the flange

on the trim piece. See Figure 24. The other holes are clearance holes for the screws that secure the door

frame.

2. Second, place the door and frame into the opening. Loosely secure the door frame with 4 screws (2 per

side) in the oblong holes of your choice. See Figure 25.

3. Align the door so it is flush with the trim (Figure 26). Tighten the 4 screws fully, confirm alignment, then

finish securing the door frame with 8 more screws.

FIGURE 24 FIGURE 25

KalamazooGourmet.com60

FIGURE 27

29 1/4"

CUTOUT SIZE

29 1/8"

23 1/2"

27 1/4"

33"

4 3/16"

3/4"

23 3/8"

25 1/16"

19 13/16"

OPENING DIMENSIONS

1.800.868.1699 61

KalamazooGourmet.com62

Product Care

1.800.868.1699 63

Caring for Your Pizza Oven

The hand-built sheet metal parts of your Artisan Fire Pizza Oven are warranted for life

against structural deterioration or failure. With proper care, your pizza oven should last a

lifetime.

Stainless Steel Care:

The Artisan Fire Pizza Oven is built from 304 stainless steel, which is a high-quality, non-magnetic stainless steel

that is very corrosion resistant. It is also a highly-sanitary surface.

After usage, the stainless steel may discolor from the intense heat. This condition is normal.

Always clean your stainless steel pizza oven with a mild, food-safe, organic degreaser, followed by a stainless

steel polish. Always scrub with the grain, never across. Remove all cleaner residue before lighting the pizza

oven in order to avoid a build-up of film from the cleaner.

For stubborn stains, or to fix scratches, Kalamazoo Outdoor Gourmet recommends using a Scratch-B-Gone

kit, available from us by calling 1.800.868.1699. You may also use a product called Barkeeper’s Friend. This will

remove stains, but it is likely to alter the appearance of the brushed stainless steel finish.

Never use cleaners on the cooking deck.

SALT WATER ENVIRONMENTS: Stainless steel — even the high-quality stuff

used in Kalamazoo Outdoor Gourmet products — is not impervious to rust.

It is corrosion-resistant. Exposure to salt air and sea spray will eventually do it

in if you don’t care for your Artisan Fire Pizza Oven properly. The best thing

you can do to protect it is to clean it frequently. Don’t give the salt time to

establish a foot hold and the chemical reaction time to start getting nasty. In

salt air environments, we recommend cleaning all stainless steel surfaces at

least every two weeks to keep your oven in prime condition.

Cooking Deck Care:

Clean the cooking deck with a long-handled brass brush. It is best to do this while the cooking deck is hot.

Wear long, insulated gloves and use caution when doing so.

Never cook greasy, oily or buttery foods directly on the cooking deck.

Never use cleaners on the cooking deck.

Do not cook frozen pizza on the cooking deck.

Never drop the cooking deck or cause sudden impact. The deck will most likely crack.