Easidew I.S.

Dew-Point Transmitter

User’s Manual

Kahn Instruments, Inc. 2015

This document is the property of Kahn Instruments and may not, either in part or whole, be copied or

otherwise reproduced, communicated in any way to third parties nor stored in any data processing

system, without the written authority of Kahn Instruments, Inc.

Easidew I.S.

For Kahn Instruments' contact information please go to

www.kahn.com

© 2015 Kahn Instruments

This document is the property of Kahn Instruments, Inc. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Kahn Instruments, Inc.

Easidew I.S. User’s Manual

Kahn Instruments 3

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Pressure Safety ............................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Calibration ...................................................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations ..................................................................................................................... vii

Warnings ...........................................................................................................................vii

1 INTRODUCTION ................................................................................................1

1.1 Features ............................................................................................................ 1

2 INSTALLATION ..................................................................................................2

2.1 Unpacking the Instrument ................................................................................... 2

2.2 Preparation of the Sensor Cable .......................................................................... 3

2.3 Cable Connection ............................................................................................... 5

2.4 Electrical Schematic ............................................................................................ 5

2.4.1 Electrical Boundaries ..................................................................................... 6

2.5 Transmitter Mounting .......................................................................................... 6

2.5.1 Transmitter Mounting - Sample Block (Optional) .............................................. 7

2.5.2 Transmitter Mounting - Direct Pipeline Connection ........................................... 8

2.5.3 Transmitter Mounting - With Additional Process Connection Adapter ................ 9

3 OPERATION ....................................................................................................10

4 MAINTENANCE ................................................................................................11

4.1 O-Ring Replacement ......................................................................................... 12

Figures

Figure 1 Transmitter Unpacking Method ....................................................................2

Figure 2 Connector Terminal Block Removal ..............................................................3

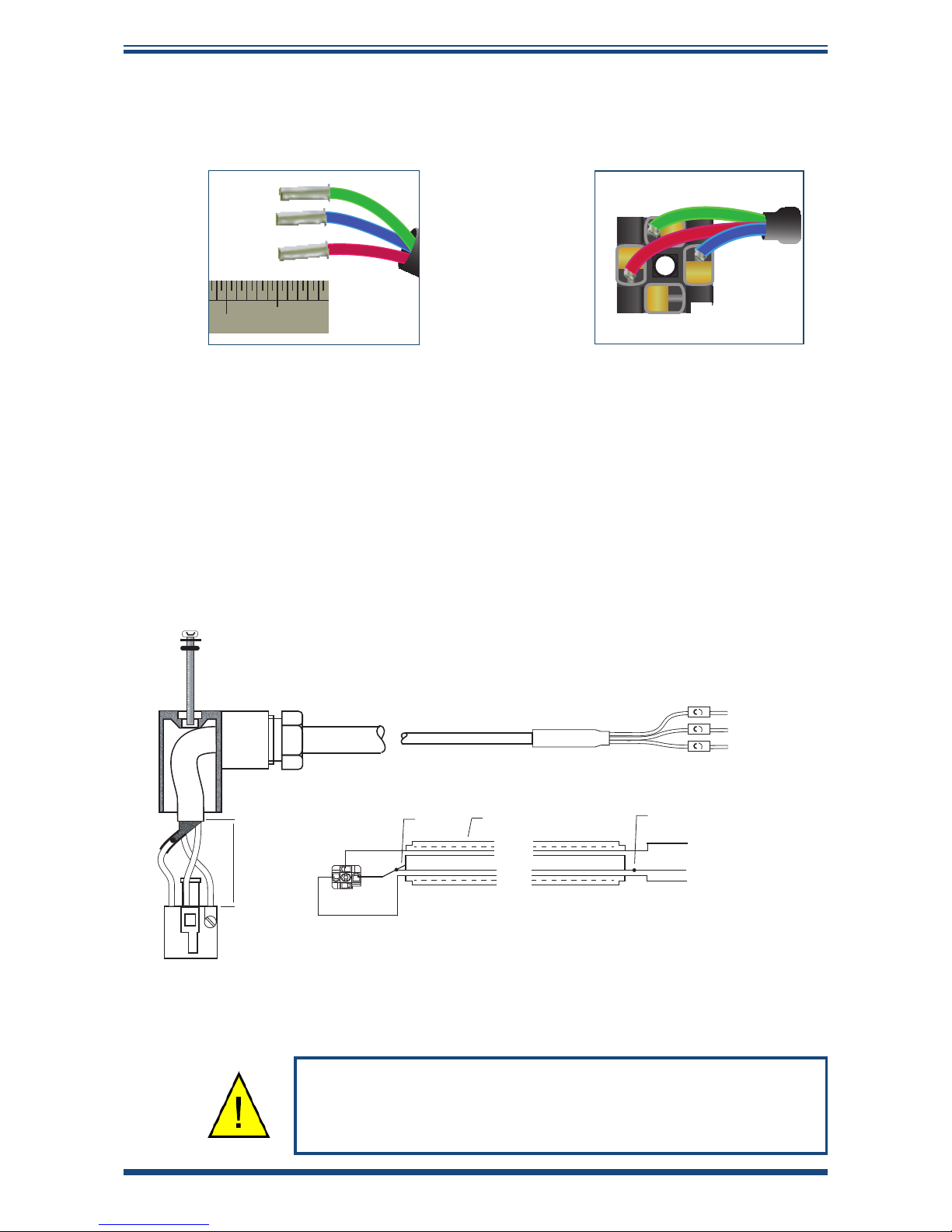

Figure 3 Bare Wires .................................................................................................3

Figure 4 Crimped Wires ...........................................................................................3

Figure 5 Cut to 5mm ...............................................................................................4

Figure 6 Connection to Connector Terminal Block .......................................................4

Figure 7 Wiring Connections .....................................................................................4

Figure 8 Connector Installation .................................................................................5

Figure 9 2-Wire Connection Diagram .........................................................................5

Figure 10 Electrical Connections .................................................................................5

Figure 11 Maximum Load of Easidew - Including Cable Resistance ................................6

Figure 12 Transmitter Mounting ..................................................................................7

Figure 13 Transmitter Mounting - Pipe or Duct.............................................................8

Figure 14 Transmitter Mounting with Adapter .............................................................9

Figure 15 Installation Location .................................................................................10

Figure 16 Indication of Dead Space ..........................................................................10

Figure 17 Replacement of HDPE Guard .....................................................................11

Figure 18 Dimensions .............................................................................................15

Easidew I.S. User’s Manual

4 97099 Issue 13.4, August 2015

Appendices

Appendix A Technical Specications ............................................................................. 14

A.1 Dimensions .................................................................................15

Appendix B System Drawings ....................................................................................... 17

B.1 Baseefa Approved System Drawing ...............................................17

B.2 FM Approved System Drawing ......................................................18

B.3 CSA Approved System Drawing .....................................................19

Appendix C Hazardous Area Certication ......................................................................21

C.1 Product Standards .......................................................................21

C.2 Product Certication ....................................................................21

C.3 Global Certicates/Approvals ........................................................21

C.4 Terminal Parameters ....................................................................21

C.5 Special Conditions of Use .............................................................22

C.6 Maintenance and Installation ........................................................ 22

Appendix D EC Declaration of Conformity ...................................................................... 24

Easidew I.S. User’s Manual

Kahn Instruments 5

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to insure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specied safe working pressure is 6500 psig (450 barg / 45 MPa). Refer to the Technical

Specications in Appendix A.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained by Kahn Instruments, Inc.. Refer to www.kahn.com for contact

details.

Calibration

The recommended calibration interval for this instrument is 12 months unless it is to be used in a

mission-critical application or in a dirty or contaminated environment in which case the calibration

interval should be reduced accordingly. The instrument should be returned to the manufacturer,

Kahn Instruments Inc., or one of their accredited service agents for re-calibration.

Safety Conformity

This product meets the essential protection requirements of the relevant US and European standards

and directives. Further details of applied standards may be found in the Technical Specications in

Appendix A.

Easidew I.S. User’s Manual

6 97099 Issue 13.4, August 2015

Abbreviations

The following abbreviations are used in this manual:

barg pressure unit (=100 kP or 0.987 atm) (bar gauge)

°C degrees Celsius

°F degrees Fahrenheit

DC direct current

dp dew point

fps feet per second

ft-lbs feet per pounds

g grams

lbs/in pounds per inch

µm micrometer

m/sec meters per second

mA milliampere

max maximum

mm millimetres

MPa megapascal

Nl/min normal liters per minute

Nm Newton meter

oz ounces

ppm

V

parts per million by volume

psig pounds per square inch

RH relative humidity

scfh standard cubic feet per hour

V Volts

Ω Ohms

ø diameter

“ inch(es)

Warnings

The following general warning listed below is applicable to this instrument. It is repeated

in the text in the appropriate locations.

Where this hazard warning symbol appears in the following

sections it is used to indicate areas where potentially hazardous

operations need to be carried out.

Easidew I.S. User’s Manual

Kahn Instruments 1

INTRODUCTION

1 INTRODUCTION

The Easidew I.S. dew-point transmitter has been manufactured, tested and calibrated

to the highest available standards and should be in perfect working order, ready for

installation into a gas measurement application. If, after reading this manual, there are

any questions about the instrument or how to install and operate it, please contact Kahn

Instruments. Inc. Refer to www.kahn.com for contact details.

This manual covers the following Easidew I.S. (Intrinsically Safe) dew-point products:

Easidew I.S. with 5/8” UNF thread

Easidew I.S. with 3/4” UNF thread

Easidew I.S. with G 1/2” BSP thread

1.1 Features

The Easidew I.S. dew-point transmitter is a continuous, on-line, 4-20 mA transmitter

for the measurement of dew-point temperature or moisture content in air and other

non-corrosive gases. It is designed specically for use within Zone 0, 1 and 2 hazardous

areas.

The key features are:

• IECEx, CSA, FM, ATEX certied transmitter for use in hazardous areas

• 5/8” or 3/4” UNF, G1/2” BSP, process connection

• Dew-point or ppmV moisture content

• 2-wire loop powered connection

• Rugged 316 stainless steel IP66 construction

• Measurement ranges -148 to +68°Fdp (-100 to +20°Cdp)

-166 to +68°Fdp (-110 to +20°Cdp)

• Accuracy ±2°Cdp

• Calibration Certicate (NPL, NIST)

Easidew I.S. User’s Manual

2 97099 Issue 13.4, August 2015

INSTALLATION

2 INSTALLATION

2.1 Unpacking the Instrument

On delivery, check that all the following standard components are in the packing tube:

• Easidew I.S. Transmitter

5/8” UNF and G 1/2” BSP version - Bonded seal tted over threaded part of

transmitter body

OR

3/4” UNF version - Recessed sensor O-ring seal

• Quantity 3 cable crimps

• Sensor connector

• Packing tube, and foam protectors (not needed for operation - save all

the packing materials for the purpose of returning the instrument for recalibration or any warranty claims)

• Certicate of calibration

NOTE: If any component is not present in the packing box, contact Kahn

Instruments immediately.

Unpack the dew-point transmitter packing tube as follows (see

Figure 1).

G 1/2“ BSP (black)

3/4” UNF (green)

5/8” UNF (blue)

98764 5321

Figure 1

Transmitter Unpacking Method

1. Unscrew the cap (1) from the packing tube (9).

2. Remove the bag containing 3 cable crimps (2).

3. Remove the foam block (4) containing the connector (3).

4. Pull out the transmitter (6) from the tube, complete with the two foam

covers (7) and (8) and the red protective cap (5).

5. Remove the foam covers from the transmitter but leave the green, blue or

black plastic protective cover (6) and the red cap (5) in place until ready

for installation.

NOTE: The transmitter sensing element is protected while in transit by a black,

green or blue cover containing a small desiccant capsule. The connection pins

are protected by a red plastic cap. None of these plastic items are required for

the operation of the transmitter.

NOTE: Keep the connector (3) in a safe place until the transmitter is ready

for wiring.

Easidew I.S. User’s Manual

Kahn Instruments 3

INSTALLATION

2.2 Preparation of the Sensor Cable

The sensor cable is NOT supplied as standard. A cable can be obtained by contacting

Kahn Instruments (see www.kahn.com for details).

The crimps supplied must be tted onto any cable installed

into the connector in order to comply with Hazardous Area

Certication of the product.

If making a cable assembly it is important that the cable is correctly terminated. See

Figures 3 to 6

.

Cable connection to the Easidew I.S. transmitter is made via the removable connector.

Removing the central screw enables the connector terminal block to be removed from

the outer housing by using a small screwdriver to pry it off.

O-ring

and washer

Figure 2

Connector Terminal Block Removal

Caution: When removing the central screw insure that the small

sealing O-ring and the washer are retained on the screw and

are present during re-installation.

NOTE:

Figure 3

to

Figure 6

shown below, should be followed in detail. The

crimps should be applied such that there is no possibility of a conductor

strand of a core becoming free (see

Figure 4)

.

Figure 3

Bare Wires

Figure 4

Crimped Wires

Easidew I.S. User’s Manual

4 97099 Issue 13.4, August 2015

INSTALLATION

When the crimp is made it should have a minimum of 2 positions of crimping. After the

crimp is made it should be trimmed to a length of 5mm (see

Figure 5)

. When the crimps

are installed into the connector terminal block insure they are fully inserted, as shown

in

Figure 6

, before tightening the terminal clamping screw.

10

mm

1

2

3 4

Figure 5

Cut to 5mm

Figure 6

Connection to Connector Terminal Block

When all wire connections are made, insure that there is a minimum clearance distance

and a minimum creepage distance in air of 0.8” (2mm) between each terminal.

For the transmitter to work properly, and to achieve maximum performance, the sensor

cable must be connected to the sensor connector as shown in the drawing below.

Note: The drawing below shows the identity of the connector terminals and

wiring connections of the cable supplied by Kahn Instruments.

SCALE 2:1

SHORT

AS POSSIBLE

1

3

2

4

BLUE

BRAID

BRAID

GREEN - 4-20 mA

(SOURCE)

SCREEN

RED

+POWER

GND

VIEW ON REAR

OF CONNECTOR

GREEN

SIGNAL (SOURCE)

GREEN

YELLOW

BLUE

RED

BLUE - SCREEN

RED + POWER

GREEN - 4-20 mA

BLUE - SCREEN

RED + POWER

GN

RD

BL

Figure 7

Wiring Connections

Always connect the 4-20 mA return signal to a suitable load

(see

Figure 7)

before the power is applied. Without this

connection, the transmitter may be damaged if allowed to

operate for prolonged periods.

Easidew I.S. User’s Manual

Kahn Instruments 5

INSTALLATION

2.3 Cable Connection

When installing the connector, and to insure that full ingress protection is achieved, the

securing screw (with the O-ring and washer) must be tightened to a minimum torque

setting of 3.4 Nm (2.5 ft-lbs). The sensor cable used must be a minimum diameter of

4.6mm (0.2”).

O-ring

and washer

Figure 8

Connector Installation

2.4 Electrical Schematic

NOTE: The screen/shield should be connected for maximum performance

and to avoid interference.

3

1

Max Load

250R @ 12V

500R @ 24V

Supply

12V Min

28V Max

+

Screen/

Shield

Figure 9

2-Wire Connection Diagram

DEW-POINT

TRANSMITTER

CERTIFICATION No’s:

Baseefa06ATEX0330X

IECEx BAS 06.0090X

TRANSMITTER VERSION

TERMINAL NUMBER

EASIDEW I.S.

3

1

(+)

(+)

(-)

(RETURN)

HAZARDOUS AREA

SAFE AREA

GALVANIC ISOLATION INTERFACE

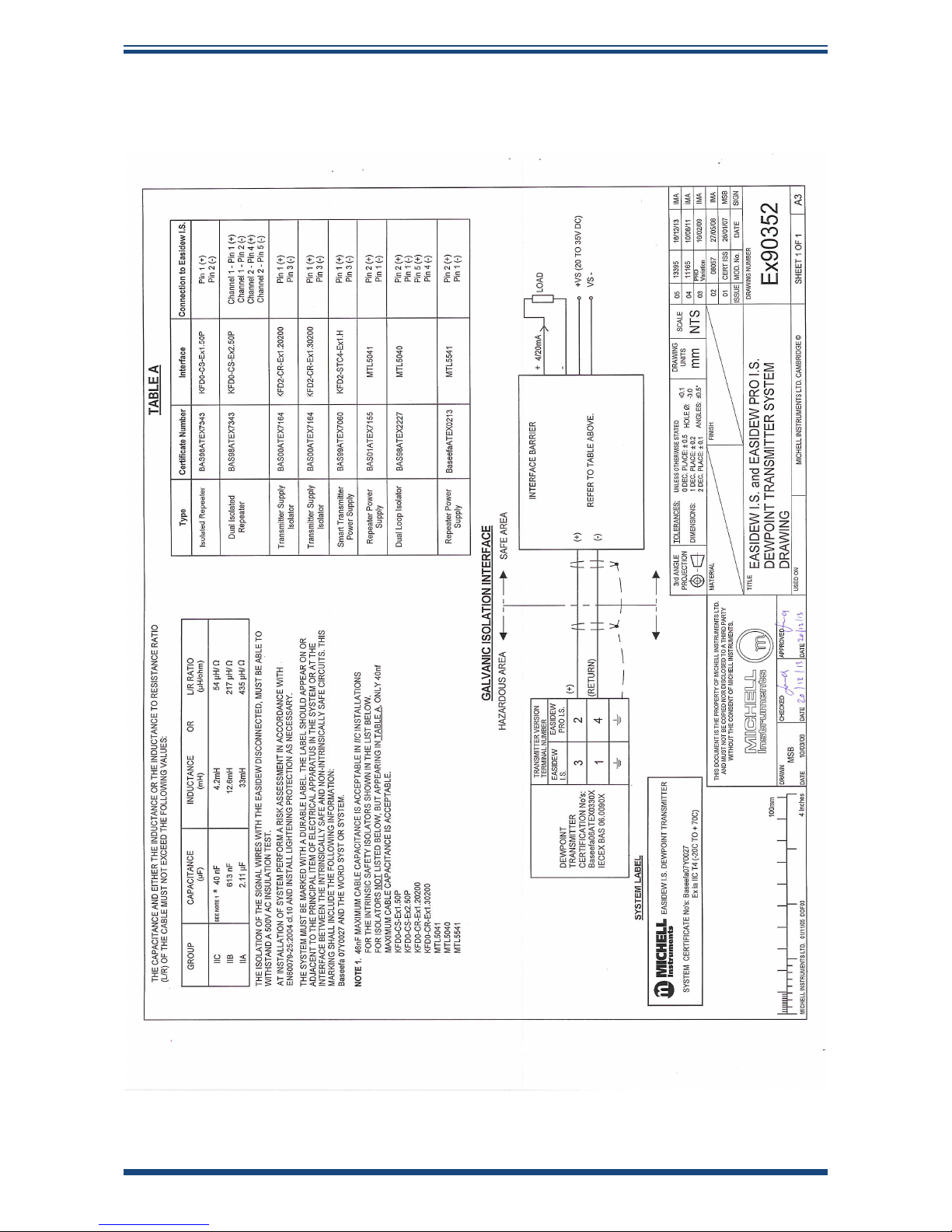

KFD2-STC4-Ex1 H

KFD0-CS-Ex2.50p

KFD2-CR-Ex1.20200

KFD2-CR-Ex1.30200

KFD0-CS-Ex1.50P

MTL5041

MTL5040

MTL5541

+

4-20 mA

LOAD

+VS (20 - 35 V DC)

VS -

-

Figure 10

Electrical Connections

Easidew I.S. User’s Manual

6 97099 Issue 13.4, August 2015

INSTALLATION

2.4.1 Electrical Boundaries

100

200

300

400

500

600

12 14 16 18 20 22 24 26 28

Resistance (ohms)

Supply Voltage

Figure 11

Maximum Load of Easidew - Including Cable Resistance

2.5 Transmitter Mounting

Prior to installation of the transmitter, unscrew and remove the black, green or blue

plastic cover and retain for future use. Take care to prevent any contamination of

the sensor before installation (handle the transmitter by the main body only,

avoiding contact with the sensor guard).

The Easidew I.S. can be mounted either into a ow-through sensor sampling block

(optional) or directly into a pipe or duct. It can be operated at pressures of up to 6500

psig (450 barg / 45 MPa) when tted with the bonded seal or O-ring provided.

The recommended gas ow rate, when mounted in the optional sampling block, is 2.1

to 10.6 scfh (1 to 5 Nl/min). However, for direct insertion applications, gas ow can be

from static to 32.8 fps (10 m/sec).

NOTE: Pass the seal over the mounting thread and assemble into the sampling

location, by hand, using the wrench ats only. DO NOT grip and twist the

sensor cover when installing the sensor.

When installed, fully tighten using a wrench until the seal is fully compressed and to the

following torque settings:

• 5/8” - 18 UNF 22.5 ft-lbs (30.5 Nm)

• 3/4” - 16 UNF 40 Nm (29.5 ft-lbs)

• G 1/2” BSP 56 Nm (41.3 ft-lbs)

Easidew I.S. User’s Manual

Kahn Instruments 7

INSTALLATION

2.5.1 Transmitter Mounting - Sample Block (Optional)

The following procedure must be carried out by a qualied

installation engineer.

To mount the transmitter into the sensor block (preferred method), proceed as follows,

refer to

Figure 12.

1. Insure that the green, blue or black protective cover (2), and its

desiccant capsule (2a), have been removed from the tip of the

transmitter.

2. G 1/2” and 5/8” Versions - Insure that the bonded seal (2) is over the

threaded part of the transmitter body.

3/4” Version - Insure the O-ring is fully seated in the recess.

Under no circumstances should the sensor guard be handled

with the ngers.

3. Screw the transmitter (1) into the sample block (3) and tighten to the

appropriate torque setting (see Section 2.5). NOTE: Use the ats of

the hexagonal nut and not the sensor body.

4. Fit the transmitter cable/connector assembly to the plug located on the

base of the transmitter and tighten the securing screw (see Section 2.3).

1

2

3

2a

4

4

Figure 12

Transmitter Mounting

Easidew I.S. User’s Manual

8 97099 Issue 13.4, August 2015

INSTALLATION

2.5.2 Transmitter Mounting - Direct Pipeline Connection

The transmitter may be directly mounted into a pipe or duct as shown in

Figure 13.

Caution: Do not mount the transmitter too close to the bottom

of a bend where any condensate in the pipeline might collect

and saturate the probe.

The pipe or duct will require a thread to match the transmitter body thread. Mounting

dimensions are shown in

Figure 13.

For circular pipework, to insure the integrity of

a gas tight seal, a mounting ange will be required on the pipe or tubing in order to

provide a at surface to seal against.

The following procedure must be carried out by competent

personnel.

1. Insure that the protective cover (and its desiccant capsule) has

been removed from the tip of the transmitter.

WARNING: Under no circumstances should the sensor guard

be handled with the ngers.

2. G 1/2” and 5/8” Versions - Insure that the bonded seal (2) is over the

threaded part of the transmitter body.

3/4” Version - Insure the O-ring is fully seated in the recess.

3. Screw the transmitter (3) into the pipe (1). Tighten enough to obtain a

gas tight seal. NOTE: Do not overtighten or the thread on the pipe

or tubing may be stripped.

14

15

16

17

18

18

20

21

22

23

2

3

4

5

6

7

8

9

10

11

(1.9”)

1

1

2

2

3

3

Optional

display

(available

on request)

Optional

cable

(available

on request)

48mm

Figure 13

Transmitter Mounting - Pipe or Duct

Easidew I.S. User’s Manual

Kahn Instruments 9

INSTALLATION

2.5.3 Transmitter Mounting - With Additional Process Connection Adapter

Applicable to the Easidew I.S. 5/8” Version ONLY

The following procedure must be carried out by a qualied

installation engineer.

To mount the adapter into the transmitter, proceed as follows (see

Figure 14)

:

1. Insure that the protective cover (2), and its desiccant capsule (2a), have

been removed from the tip of the transmitter.

2. Place the bonded seal (3) over the threaded part of the transmitter body.

3. Screw the adapter (4) onto the threaded part of the transmitter and tighten

to 22.5 ft-lbs (30.5 Nm). NOTE: Use the ats of the hexagonal nut and

not the sensor body.

WARNING: Under no circumstances should the sensor guard be

handled with the ngers.

4. Screw the transmitter (1) with its seal (3) and adapter (4) into the sample

block (see Section 2.5.1 or see Section 2.5.2) and fully tighten using a

wrench until the seal is fully compressed and to the following torque

settings:

G 1/2” BSP 41.3 ft-lbs (56 Nm)

3/4” - 16 UNF ` 29.5 ft-lbs (40 Nm)

1/2” NPT Use a suitable sealant e.g. PTFE tape using

correct taping procedures

NOTE: Use the ats of the hexagonal nut and not the sensor body.

1

2

3

4

2a

Figure 14

Transmitter Mounting with Adapter

Easidew I.S. User’s Manual

10 97099 Issue 13.4, August 2015

OPERATION

3 OPERATION

Operation is very simple, assuming the following installation techniques are adhered to:

Sampling Hints

Be Sure the Sample is Representative of the Gas Under Test:

The sample point should be as close to the critical measurement point as possible. Also,

never sample from the bottom of a pipe as entrained liquids may be drawn into the

sensing element.

Figure 15

Installation Location

Minimize Dead Space in Sample Lines:

Dead space causes moisture entrapment points, increased system response times and

measurement errors, as a result of the trapped moisture being released into the passing

sample gas and causing an increase in partial vapor pressure.

Deadspace

Figure 16

Indication of Dead Space

Remove Any Particulate Matter or Oil from the Gas Sample:

Particulate matter at high velocity can damage the sensing element and similarly, at

low velocity, they may ‘blind’ the sensing element and reduce its response speed. If

particulate, such as degraded desiccant, pipe scale or rust is present in the sample gas,

use an in-line lter, as a minimum level of protection. For more demanding applications

Kahn Instruments offers a range of sampling systems (for more information contact

www.kahn.com).

Use High Quality Sample Tube and Fittings:

Kahn Instruments recommends that, wherever possible, stainless steel tubing and

ttings should be used. This is particularly important at low dew points since other

materials have hygroscopic characteristics and adsorb moisture on the tube walls,

slowing down response and, in extreme circumstances, giving false readings. For

temporary applications, or where stainless steel tubing is not practical, use high quality

thick walled PTFE tubing.

Position Transmitter away from Heat Source:

It is recommended, as good instrumentation practice, that the transmitter is placed

away from any heat source to avoid adsorption/desorption.

Easidew I.S. User’s Manual

Kahn Instruments 11

MAINTENANCE

4 MAINTENANCE

Calibration

Routine maintenance of the Easidew I.S. is conned to regular re-calibration by exposure

of the transmitter to sample gases of known moisture content to insure that the stated

accuracy is maintained. Calibration services traceable to the US

National Institute of

Standards and Technology

(NIST) are provided by Kahn Instruments.

Kahn Instruments offers a variety of re-calibration and service exchange schemes to

suit specic needs. A Kahn representative can provide detailed, custom advice (refer to

www.kahn.com for details of Kahn Instruments’ contact information).

The following procedure must be carried out by a qualied

installation engineer.

Sensor Guard Replacement

The sensor is supplied with either a white HDPE or a stainless steel guard. The method

of replacement is the same for both types.

HDPE Guard

The HDPE guard provides <10μm protection to the dew-point sensor. It is designed

to show any contamination and the guard should be changed if the surface becomes

discolored.

When replacing the guard, care should be taken to handle the guard by the bottom part

only. Replacement guards (EA2-HDPE) - pack of 10 - can be obtained by contacting

Kahn Instruments (www.kahn.com) or your local distributor.

r

0

9

0

6

HANDLE,

USING

GLOVES, BY

BLACK PART

ON LY

Figure 17

Replacement of HDPE Guard

Stainless Steel Guard

The stainless steel guard provides <80μm protection to the dew-point sensor. It is

designed to show any contamination and the guard should be changed if the surface

becomes discolored.

When replacing the guard, care should be taken to handle the guard by the bottom

part only. A replacement guard (SSG) can be obtained by contacting Kahn Instruments

(www.kahn.com).

Easidew I.S. User’s Manual

12 97099 Issue 13.4, August 2015

MAINTENANCE

Bonded Seal

If the installed bonded seal gets damaged or lost, a pack of 5 replacement bonded seals

(1/2-BS (for G 1/2 -BSP) or 5/8-BS (for 5/8” -18 UNF)) can be obtained by contacting

Kahn Instruments, or your local distributor.

4.1 O-Ring Replacement

If the installed O-ring gets damaged or lost, a pack of 5 replacement O-rings (3/4OR (for 3/4” - 16 UNF)) can be obtained by contacting Kahn Instruments.

Do not touch the lter with bare hands

1. Identify the O-ring to be removed, as shown below.

BS116 (3/4” x 3/32”) viton,

75 shore

2. Carefully slide tweezers, thin bladed screwdriver or a blunt needle under

the outer edge of the O-ring. NOTE: Take care not to scratch any of

the surfaces of the surrounding metal component.

3. Move the tool around the circumference to assist the extraction process.

Slide the O-ring clear of the thread and lter.

4. Make sure the groove has no scratches and is free from grease, dirt

or debris. Slide the new O-ring over the lter and thread and into the

groove. NOTE: Do not touch the lter with bare hands.

Easidew I.S. User’s Manual

Kahn Instruments 13

APPENDIX A

Appendix A

Technical Specications

Easidew I.S. User’s Manual

14 97099 Issue 13.4, August 2015

APPENDIX A

Appendix A Technical Specications

Performance

Measurement Range

(dew point)

-148 to +68°Fdp (-100 to +20°Cdp)

-166 to +68°Fdp (-110 to +20°Cdp)

Accuracy (dew point) ±3.6°Fdp (±2°Cdp)

Repeatability 0.9°Fdp (0.5°Cdp)

Response Time 5 mins to T95 (dry to wet)

Calibration 13-point calibration with traceable 7-point calibration certicate

Electrical Specications

Output Signal

4-20 mA (2-wire connection current source)

User-congurable over range

Output Dew point or moisture content for ppm

V

Analog Output Scaled

Range

Dew point: -148 to +68ºF (-100 to +20ºC) OR

Moisture content in gas: 0 - 3000 ppm

V

Non-standard available upon request

Supply Voltage 12 to 28 V DC

Load Resistance

Max 250 Ω @ 12 V

(500 Ω @ 24 V)

Current Consumption 20 mA max

CE Marked Certied

Operating Specications

Operating Temperature -40 to +158ºF (-40 to +70ºC)

Operating Pressure

6500 psig (450 barg / 45 MPa) max

Qualied over-pressure rating: (2 x operating pressure)

13053 psig (900 barg / 90 MPa)

Flow Rate

2.1 to 10.6 scfh (1 to 5 Nl/min) mounted in standard sampling block

0 to 32.8 fps (0 to 10 m/sec) direct insertion

Temperature Coefcient Temperature compensated across operating temperature range

Mechanical Specications

Ingress Protection

NEMA 4 in protection accordance with standard NEMA 250-2003

IP66 in accordance with standard BS EN60529:1992

Housing Material 316 stainless steel

Dimensions Transmitter plus connector: L=5.19” x ø 1.77” (132mm x ø 45mm)

Sensor Guard

Standard: HDPE Guard < 10µm

Optional: 316 stainless steel sintered guard < 80µm

Process Connection &

Material

G 1/2” BSP; 3/4” - 16 UNF; 5/8” - 18 UNF

Material - 316 stainless steel

Weight 5.29oz (150g)

Interchangeability Fully interchangeable transmitter

Electrical Connection Hirschmann GDS series (DIN 4350-C)

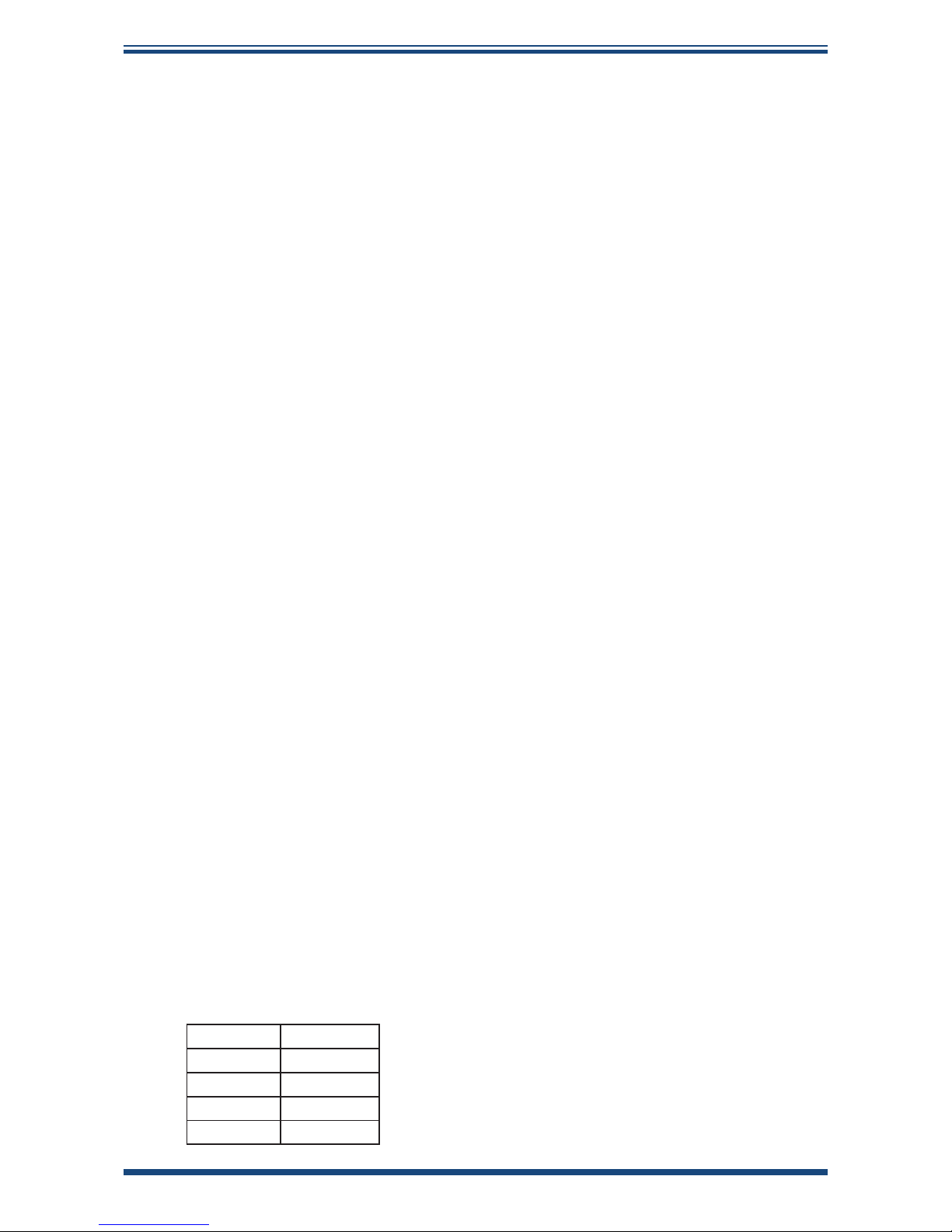

Diagnostic Conditions

(factory programmed)

Condition

Sensor fault

Under-range dew point

Over-range dew point

Output

23 mA

4 mA

20 mA

Easidew I.S. User’s Manual

Kahn Instruments 15

APPENDIX A

Approved Galvanic

Isolators

KFD2-CR-EX1.20200

KFD2-CR-EX1.30200

KFD0-CS-EX1.50P

KFD0-CS-EX2.50P

KFD2-STC4-EX1.H

MTL5041, MTL5040

Hazardous Area Certication

Certication Codes

ATEX II 1G Ex ia IIC T4 Ga (-20°C to +70°C)

IECEx Ex ia IIC T4 Ga (-20°C to +70°C)

TC TR Ex 0Ex ia IIC T4 Ga (-20°C to +70°C)

FM Class I, Division 1, Groups A B C D, T4

CSA Class I, Division 1, Groups A B C D, T4

A.1 Dimensions

132mm

(5.19”)

46mm

(1.81”)

10mm

(0.39”)

G1/2” BSP

10mm

(0.39”)

ø27mm

(1.06”)

SENSOR

132mm

(5.19”)

46mm

(1.81”)

10mm

(0.39”)

5/8” UNF

10mm

(0.39”)

ø27mm

(1.06”)

5/8” - 18 UNF Bonded Seal

ø25.4 x 2mm

(ø1 x 0.07”)

SENSOR

132mm

(5.19”)

46mm

(1.81”)

10mm

(0.39”)

10mm

(0.39”)

27mm

(1.06”)

A/F

45mm

(1.77”)

27mm

(1.06”)

A/F

45mm

(1.77”)

27mm

(1.06”)

A/F

45mm

(1.77”)

ø27mm

(1.06”)

3/4” UNF

3/4” - 16 UNF O-Ring

ø18.72 x 2.62mm

(ø0.75 x 0.09”)

SENSOR

G1/2” BSP Bonded Seal

ø28.65 x 2.61mm

(ø1.12 x 0.10”)

G1/2” Process Connection

3/4” Process Connection

5/8” Process Connection

Figure 18

Dimensions

Easidew I.S. User’s Manual

16 97099 Issue 13.4, August 2015

APPENDIX B

Appendix B

System Drawings

Easidew I.S. User’s Manual

Kahn Instruments 17

APPENDIX B

Appendix B System Drawings

B.1 Baseefa Approved System Drawing

Easidew I.S. User’s Manual

18 97099 Issue 13.4, August 2015

APPENDIX B

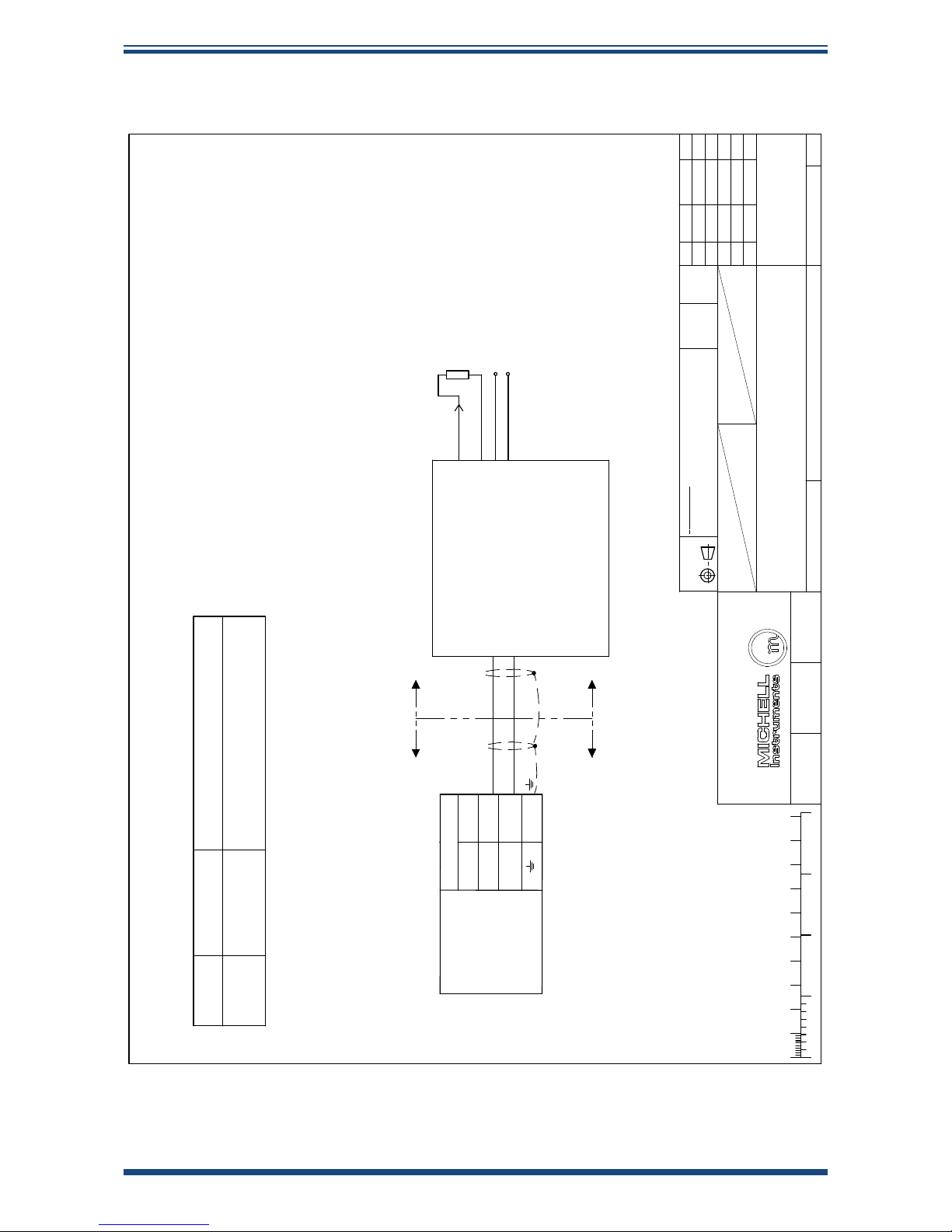

B.2 FM Approved System Drawing

10/03/06

MSB

Ex90385

SHEET 1 OF 1

NTS

SCALE

SIGN

A3

DATE

MOD. No.ISSUE

DRAWING NUMBER

TOLERANCES:

UNLESS OTHERWISE STATED

FINISH

DIMENSIONS:

MATERIAL

TITLE

USED ON

APPROVEDCHECKED

DATEDATE

DRAWN

DATE

MICHELL INSTRUMENT S LTD. 01/11/05 DOF03

mm

DRAWING

UNITS

THIS DOCUMENT IS THE PR OPERTY OF MICHELL INSTRUMENTS LTD.

AND MUST NOT BE COPIED NOR D ISCLOSED TO A THIRD PARTY

WITHOUT T HE CONSENT OF MICHELL INS TRUMENTS.

EASIDEW I.S. DEWPOINT TRANSMITTER

FM SYSTEM DRAWING

3rd ANGLE

PROJECTION

MICHELL INS TRUMENTS LTD. CAMBRIDGE ©

ANGLES: ±0.5°

HOLE Ø:

+0.1

-0.0

0 DEC. PLACE: ± 0.

5

1 DEC. PLACE: ± 0.2

2 DEC. PLACE: ± 0.1

01 CERT ISS 16/07/07 IMA

4 Inches

100mm

02 CERT ISS 23/12/08 IMA

03 CERT ISS 21/01/09 IMA

04 CERT ISS 24/03/09 IMA

05 11081 06/04/11 IMA

KFD2-CR-Ex1.20200

BAS 00 ATEX 7164

000

KFD2-CR-Ex1.30200

BAS 00 ATEX 7164

000

KFD0-CS-Ex1.50P

BAS 98 ATEX 7343

000

MTL5041

BAS 01 ATEX 7155

000

MTL5040

BAS 98 ATEX 2227

000

KFDO-CS-Ex2.50P

BAS98ATEX7343

HAZARDOUS LOCATION

CLASS 1, DIVISION 1, GROUPS A,B,C, & D

NON-HAZARDOUS LOCATION

+VS (20 TO 35V DC)

VS -

LOAD

4/20mA

+

-

(+)

(-)

(RETURN)

(+)

DEWPOINT

TRANSMITTER

CERTIFICATION No's:

Baseefa06ATEX0330X

IECEX BAS 06.0090X

3

1

TRANSMITTER VERSION

TERMINAL NUMBER

EASIDEW

I.S.

EASIDEW

PRO I.S.

2

4

3

THE CAPACITANCE AND EITHER THE INDUCTANCE OR THE INDUCTANCE TO RESISTANCE RATIO

(L/R) OF THE CABLE MUST NOT EXCEED THE FOLLOWING VALUES:

DCAB

33mH

12.6 mH

4.2mH

GROUP CAPACITANCE INDUCTANCE OR L/R RATIO

( F) ( mH) ( H/ohm)

THE ISOLATION OF THE SIGNAL WIRES WI TH THE EASIDEW DISCONNECTED, MUST BE ABLE TO

WITHSTAND A 500V AC INSULATION TEST.

THE INSTALLATION MUST COMPLY WITH THE INSTALLATION PRACTICES OF THE COUNTRY OF

USE, i.e. ANSI/ISARP12.6(INSTALLATION OF INTRINSICALLY SAFE SYSTEMS FOR HAZARDOUS

[CLASSIFIED] LOCATIONS) AND THE NATIONAL ELECTRICAL CODE ANSI/NFPA 70.

THE CAPACITANCE AND THE INDUCTANCE OF TEH HAZARDOUS AREA CABLES MUST NOT

EXCEED THE VALUES GIVEN IN TABLE 1.

2.11 F

613 nF

46 nF

435 H/

217 H/

54 H/

Easidew I.S. User’s Manual

Kahn Instruments 19

APPENDIX B

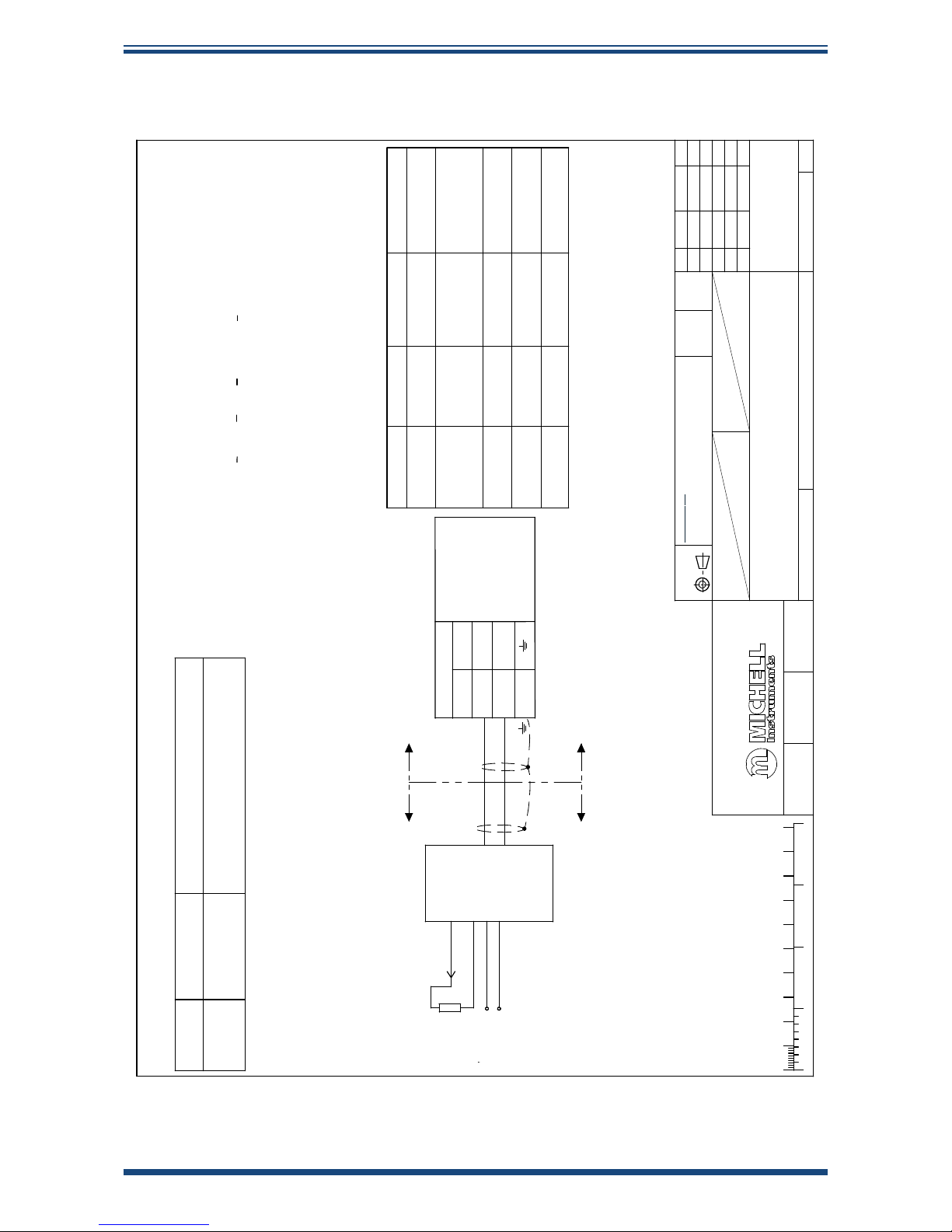

B.3 CSA Approved System Drawing

10/03/06

MSB

Ex90385CSA

SHEET 1 OF 1

NTS

SCALE

SIGN

A3

DATE

MOD. No.ISSUE

DRAWING NUMBER

TOLERANCES:

UNLESS OTHERWISE STATED

FINISH

DIMENSIONS:

MATERIAL

TITLE

USED ON

APPROVEDCHECKED

DATEDATE

DRAWN

DATE

MICHELL INSTRUMENTS LTD. 01/11/05 DOF0 3

mm

DRAWING

UNITS

THIS DOCUMENT IS THE PROPERTY OF MICHELL INSTRUMENTS LTD.

AND MUST NOT B E COPIED NOR DISCLO SED TO A THIRD PART Y

WITHOUT THE CONSENT OF MIC HELL INSTRUMENTS.

EASIDEW I.S. & EASIDEW PRO I.S.

DEWPOINT TRANSMITTER

SYSTEM DRAWIN. CSA

3rd ANGLE

PROJECTION

MICHELL INSTRUMENTS LTD. CAMBRIDGE ©

ANGLES: ±0.5°

HOLE Ø:

+0.1

-0.0

0 DEC. PLACE : ± 0.

5

1 DEC. PLACE: ± 0.2

2 DEC. PLACE: ± 0.1

02 CERT ISS 13/06/08 IMA

03 CERT ISS 16/06/08 IMA

4 Inches

100mm

04 CERT ISS 25/03/09 IMA

05 CERT ISS 15/06/09 IMA

06 11081 06/04/11 IMA

CSA Certified

Barrier

HAZARDOUS LOCATION

CLASS 1, DIVISION 1,

Gps A,B,C, & D

NON-HAZARDOUS LOCATION

S (20 TO 35V DC)

VS -

LOAD

4/20mA

+

-

(+)

(-)

EASIDEW I.S.

DEWPOINT

TRANSMITTE R

Vmax = 28V

Imax = 93mA

Pmax = 651mW

Ci = 37nf

Li = 0

(RETURN)

(+)

3

1

TRANSMITTER VERSION

TERMINAL NUMBER

EASIDEW

I.S.

EASIDEW

PRO I.S.

2

4

3

THE CAPACIT ANCE AND EITHER THE I NDUCTANCE OR THE IN

DUCTANCE TO RESISTANCE RATIO

(L/R) OF THE CABLE MUST NOT EXCEED THE FOLLOWING VA

LUES:

ABCD

4.2mH

12.6 mH

33mH

GROUP CAPACITANCE

INDUCTANCE OR L/R RATIO

(

F) (mH) ( H/ohm)

THE ISOLATION OF THE SIGNAL WIRES WITH THE EASIDEW

DISCONNECTED, MUST BE ABLE TO

WITHSTAND A 500V AC INSULATION TEST.

46 nF

613 nF

2.11 F

54 H/

217 H/

435 H/

THE INSTALLATION MUST COMPLY WITH THE INSTALLATION

PRACTICES OF THE COUNTRY OF

USE. i.e. ANSI/ISA RP12.6 (INSTALLATION OF INTRINSI

CALLY SAFE SYS TEMS FOR HAZARDOUS

[CLASSIFIED] LOCATIONS) AND THE NATIONAL ELECTRICAL

CODE ANSI/NFPA 70.

THE CAPACIT ANCE AND THE INDUCTANCE OF THE HAZARDOUS

AREA CABLES MUST NOT

EXCEED THE VALUES G IVEN IN TABLE 1

Intrinsically safe(entity), Class 1 , Div1, Group A,B,C,D

Hazardous Locat ion Installations

1) Control room equipment may not use or generate over 250Vrm

2) Wi re all circuits for pow er supply per CEC Part 1.

3) Use only e ntity approved safe ty barrier or other associ ated

equipment that satisfy the following conditions:

V

CG

<

V

max

, I

SC

<

I

MAX

, C

a

>

C

i

+ C

CABLE

, L

a

>

L

i

+ L

CABLE

Transmitter entity param eters are as follows:

V max < 2.8Vdc

I max < 93mA

Ci = 37nF

Li = 0uH

4) WARNING: SUBSTITUTION OF COMPONENTS MAY IMPARE

INTRINSIC SAFETY.

5) Ex ia is defined as Intrinsically Safe.

Type

Isolated Repeater

Dual Isolated

Repeater

Transmitter Supply

Isolator

Transmitter Supply

Isolator

Smart Transmitter

Power Supply

Certificate Number

BAS98ATEX7 343

UL Canada E106378CUL

BAS98ATEX7343

UL Canada

E106378CUL

BAS00ATEX7164

UL Canada E106378CUL

BAS00ATEX7164

UL Canada E106378CUL

BAS99ATEX7060

UL Canada E106378CUL

Interface

KFD0-CS-Ex1.50P

KFD0-CS-Ex2.50P

KFD2-CR-Ex1.20200

KFD2-CR-Ex1.30200

KFD2-STC4-Ex1.H

Connection t o Easidew I.S.

Pin 1 (+)

Pin 2 (-)

Channel 1 - Pin 1 (+)

Channel 1 - Pin 2 (-)

Channel 2 - Pin 4 (+)

Channel 2 - Pin 5 (-)

Pin 1 (+)

Pin 3 (-)

Pin 1 (+)

Pin 3 (-)

Pin 1 (+)

Pin 3 (-)

Easidew I.S. User’s Manual

20 97099 Issue 13.4, August 2015

APPENDIX C

Appendix C

Hazardous Area Certication

Easidew I.S. User’s Manual

97099 Issue 13.2, April 2015 21

APPENDIX C

Appendix C Hazardous Area Certication

The Easidew I.S is certied compliant to the ATEX Directive (94/9/EC), and IECEx for

use within Zone 0, 1 and 2 hazardous areas and has been assessed so by Baseefa Ltd

(Notied Body 1180).

The Easidew I.S is certied compliant to the North American Standards (USA and

Canada) for use within Class I, Division 1, Groups A, B, C & D hazardous locations and

has been assessed so by CSA and FM.

C.1 Product Standards

This product conforms to the Standards:

EN60079-0:2012 IEC60079-0:2011

EN60079-11:2012 IEC60079-11:2011

FM Class 3600:1998 CAN/CSA-C22.2 No. 0-10

FM Class 3610:2007 CAN/CSA-C22.2 No. 157-92

FM Class 3810:2005 C22.2 No. 142-M1987

C.2 Product Certication

This product is attributed with the product certication codes:

ATEX & IECEx

II 1G Ex ia IIC T4 Ga (-20°C to +70°C)

North American

IS, Class I, Division 1, Groups A, B, C & D, T4

C.3 Global Certicates/Approvals

ATEX Baseefa 06ATEX0330X

ATEX System Baseefa 07Y0027

IECEx IECEx BAS 06.0090X

CSA 2013218

FM 3030238

TC TR Ex RU C-GB. ГБ05.B.00229

These certicates can be viewed or downloaded from our website at:

http://www.kahn.com

C.4 Terminal Parameters

Ui

= 28 V

li

= 93 mA

Pi

= 651 mW

Ci

= 37 nF

Li

= 0

Easidew I.S. User’s Manual

22 97099 Issue 13.4, August 2015

APPENDIX C

C.5 Special Conditions of Use

1. The wiring connections to the free socket must be made via crimped

connectors in such a way that all the strands of the wire used are held

securely by the crimp.

2. The plastic plug and socket create a potential for electrostatic discharge

so must not be rubbed with a dry cloth or cleaned with solvents.

3. The Easidew I.S. Dew-Point Transmitter does not withstand the 500 V AC

insulation test to frame. This must be taken into account when installing

the equipment.

C.6 Maintenance and Installation

The Easidew I.S. must only be installed by suitably qualied personnel and in accordance

with the instructions provided and the terms of the applicable product certicates.

Maintenance and servicing of the product must only be carried out by suitably trained

personnel or returned to Kahn Instruments.

Easidew I.S. User’s Manual

Kahn Instruments 23

APPENDIX D

Appendix D

EC Declaration of Conformity

Easidew I.S. User’s Manual

24 97099 Issue 13.4, August 2015

APPENDIX D

Appendix D EC Declaration of Conformity

http://www.kahn.com

Loading...

Loading...