KAEL Mühendislik Elektronik

Tic. ve San. Ltd.Şti.

Reactive Power Control Relay

√ Industrial Facilities

√ Markets

√ Oil Stations

√ Schools

√ Workshops

√ Hotels

12 Step

VARkombi-12-PC-TFT-OG

Connection type selective

V

A

R

k

o

m

b

i

-

1

2

-

P

C

-

T

F

T

-

O

G

Contents

Introduction .......................................

Warnings ...........................................

Specifications......................................

General ..............................................

Step Panel ..........................................

Making the Connections .......................

Connections .......................................

Alerts .................................................

Commisioning .....................................

Main Screens ......................................

% Instant Consumption........................

CosФ ..................................................

PF Power Factor .................................

Σ Accumulated Energy Ratios................

Steps ..................................................

1. MENU ................................................

1.1 Harmonics ..........................................

1.2 Step Indicator .....................................

1.3 Voltage, Current, Frequency.................

1.4 Power ................................................

1.5 Energy ...............................................

1.6 Counter Index ....................................

1.7 Settings .............................................

1.7.1 Measurement Types .........................

1.7.2 Target CosФ .......................................

1.7.3 Switch on(decharge) Time ...................

1.7.4 Switch off Time ...................................

1.7.5 Switch min. Time ...............................

1.7.6 Limit of Inductive Penalty.....................

1.7.7 Limit of Capacitive Penalty....................

1.7.8 Current Transformer (Primary) Value ...

1.7.9 Number of Steps .................................

1.7.10 Advanced Set-up Menu.........................

1.7.10.1 ΔT on Transition(Delay) Time...............

1.7.10.2 ΔT off Transition(Delay) Time..............

1.7.10.3 Current Flow Direction Detection ..........

1.7.10.4 Fast Step Mode....................................

1.7.10.5 Step Parameters..................................

1.7.10.5.1 Continuous Step Power Detection ........

1.7.10.5.2 Constant Step Function ......................

1.7.10.5.3 Step Synch. Time Sharing ....................

1.7.10.5.4 Enter Step Powers ..............................

1.7.10.5.5 Delete Step Powers ............................

1.7.10.5.6 Step Change Control ...........................

1.7.10.6 Alarm & Protection ..............................

1.7.10.6.1 Alarm Control .....................................

1.7.10.6.1.1 Phase Alarms .....................................

1.7.9.10.1.1.1 Over Voltage.......................................

1.7.9.10.1.1.2 Under Voltage ....................................

1

1

2

3

3

3

4

4

5

6

6

7

7

7

8

8

8

8

8

9

9

9

10

12

12

13

13

14

14

14

14

15

15

15

15

16

16

16

16

16

17

17

18

18

18

19

19

19

6

Contents

1.7.10.6.1.1.3 Over Current.......................................

1.7.10.6.1.1.4 Over Compensation.............................

1.7.10.6.1.1.5 Under Compensation ..........................

1.7.10.6.1.1.6 No Phase ...........................................

1.7.10.6.1.1.7 THD on Voltage...................................

1.7.10.6.1.1.8 HD on Voltage.....................................

1.7.10.6.1.1.9 THD on Current...................................

1.7.10.6.1.1.10 HD on Current...................................

1.7.10.6.1.2 General Alarms........................................

1.7.10.6.1.2.1 Connector Failure(1)............................

1.7.10.6.1.2.2 Connector Failure(2)............................

1.7.10.6.1.2.4 Total Over Compensation.....................

1.7.10.6.1.2.5 Total Under Compensation...................

1.7.10.6.1.2.6 System Error.....................................

1.7.10.6.1.2.7 Over Temperature...............................

1.7.10.6.1.2.8 Voltage Connection Failure...................

1.7.10.6.1.2.9 Step Change ......................................

1.7.10.6.1.2.10 Step Zero..........................................

1.7.10.6.1.2.11 Modbus Security Failure.....................

1.7.10.6.2 Alarm Setting Values. ..........................

1.7.10.6.2.1 Over Voltage Setting ...........................

1.7.10.6.2.2 Low Voltage Setting ............................

1.7.10.6.2.3 Over Temperature .............................

1.7.10.6.2.4 Voltage THD Setting ............................

1.7.10.6.2.5 Voltage HD Setting ..............................

1.7.10.6.2.6 Current THD Setting ............................

1.7.10.6.2.7 Current HD Setting ..............................

1.7.10.6.3 Fan Settings .......................................

1.7.10.6.3.1 Fan Temperature Value .......................

1.7.10.6.3.2 Fan Output .........................................

1.7.10.6.4 Step Protection Function......................

1.7.10.6.4.1 Temperature Protection.......................

1.7.10.6.4.2 Voltage Protection...............................

1.7.10.6.4.3 Harmonic Protection............................

1.7.10.7 Password Settings................................

1.7.10.7.1 Password Enable/Disable......................

1.7.10.7.2 Change Password ................................

1.7.10.8 Generator Parameters.. .......................

1.7.10.8.1 TanΦ2-CosΦ2 Target...........................

1.7.10.8.2 Generator Input Enable/Disable............

1.7.10.9 MODBUS RTU Settings ........................

1.7.10.9.1 Data Write Protection...........................

1.7.10.9.2 Data Read Protection...........................

1.7.10.9.3 Data Write Password............................

1.7.10.9.4 Data Read Password............................

1.7.10.9.5 Port Settings .......................................

1.7.10.10 Connection Settings ............................

1.8 Factory Defaults ..................................

19

19

19

19

19

19

19

19

20

20

20

20

20

20

20

20

20

20

20

21

21

21

21

22

22

22

22

23

23

23

23

23

23

24

24

24

24

25

25

25

25

25

25

25

25

26

26

27

Introduction

Warnings

All the information you need to know and the warnings regarding 3 Phase controlled VARkombi12-PC-TFT-OG reactive power control relay are described in the user manual.

Prior to taking the circuit for the device read this booklet carefully for your system and your own

safety. Do not act without getting touch with our company for the issues that can not be

understood.

Tel: 0090.232.877 14 84 (pbx) Fax: 0090.232.877 14 49

Factory: Atatürk mah. 78 sok. No:10 Ulucak köyü, Kemalpaşa - İZMİR

1- The device should be commisioned and programmed by the authorized and certificated

personels. If necessary, checks should be made by that person again.

2- As compensation is a complex system, subscriber' s system are advised to keep under

control by licensed - professional electrical engineers and technicians that company owned or

agreed.

3- Do not open the device and not let it open. There are not any parts in the device that the

user or someone can cut in.

4- Prior to making electrical connections to the terminals of the device, make sure that there is

no energy in the cable and terminals. There shouldn' t be energy at the control panel.

5- Do not use the device for different purposes other than compensation system.

6- Fix the device tightly on the control panel with the apparatus given on the device without

hanging around.

7- Do not interfere to the keys on the front panel with an object other than your fingers.

8- Wipe your device with dry cloth being sure to disconnect the power. Water or chemicals used

for cleaning damage to the device.

9- Make sure that the terminal connections are made in accordance with the connection

scheme and without causing contact problem (loose binding or multiple copper cables touching

to each other, etc.), prior to commissioning (supplying energy) of your device.

10- Use compensation contactors compatible to the power of the capacitor in your compensation

system. Select the fuses in the power line of the capacitor compatible to the current of the

capacitor.

11- Select the current value of the fuses connected to the C1, C2 and C3 terminals which are

input of contact phase considering the sum of the current drawn by the coils of connectors in

each group (senary). In case of using connectors with high current coil, auxiliary relay must be

used to prevent damage to the contact outputs of the device.

12- The alerts and the warnings above are just for your security. In case of not applied, KAEL

Elektronik Ltd. or its seller is not responsible for undesirable conditions.

1

Specifications

√ Easy to use with English menu

√ Advanced dynamic software

√ Easy to commissioning

√ Large color LCD screen ( 320 x 240 pixel 3,2” )

√ Enough number of steps needed ( 18 steps )

√ Quickly and accurately detection power of capacitors

√ Normal or fast operation mode selection

√ Connecting triphase, double-phase and single-phase capacitor

√ Connecting shunt reactors

√ Displaying the current and voltage up to the 31. harmonic simultaneously with the

graphics

√ Total current and voltage harmonics

√ Displaying the phase or phases to which connected capacitors in color on the screen

√ Making compensation even at low currents (min. 10 mA)

√ 40 ms measurement, calculation and response time

√ Making compensation for the generator according to the second Cos Φ2 set-up

√ Displaying many guiding screens

√ operating system is used in the micro-processor

√ Computer communicated (RS485 MODBUS RTU)

√ Password protected

√ For balance or unbalance operatings

√ Ensuring equal-aging of the capacitors in the same power

√ Informing the user for the capacitors losing power

√ Measuring temperature

√ Following electrical parameters of three phases at the same time

■ Voltage of phases V( L1,2,3 – N)

■ Current of phases I( L1,2,3 – N)

■ CosΦ value of phases CosΦ(1,2,3)

■ TanΦ value of phases TanΦ(1,2,3)

■ Power factor value of phases PF(1,2,3)

■ Active powers ΣP,P1,P2,P3

■ Inductive reactive powers ΣQ(ind),Q1(ind),Q2(ind),Q3(ind)

■ Capacitive reactive powers ΣQ(Cap),Q1(Cap),Q2(Cap),Q3(Cap)

■ Apparent powers ΣS,S1,S2,S3

■ Total active energy ΣWh

■ Total inductive reactive energy ΣVARh(ind)

■ Total capacitive reactive energy ΣVARh(Cap)

2

General

Electricity networks are gradually overloaded as a result of increasing use and demand of

emerging technologies In all sectors. While the compensation becomes a nightmare for the

companies having unstable load, even the companies having stable load in the past have now

difficulties to provide reactive compensation. Therefore, the period of reactive power relays

measured by single-phase will be over in the close future. KAEL Elektronik has incorporated a

brand-new device to the electricity sector having much more steps, quite good equipped in terms

of function means and software with improved running algorithms, by combining the achievements

and experiences coming along with VARkombi-12-PC-TFT-OG regarding the reactive power

compensation.

Facilities are provided to the users with many graphics and animation by using large 3.2 " color

LCD screen on the device. Moreover, the microprocessor in the device is running very fast and an

operating system is used. This provides to reach all transactions running simultaneously.

In case the blue led on the lower left corner of the front panel of the device flashes, this

means it is close to the value of penalty % and authorized persons should be informed as

soon as possible. This is also useful in terms of taking the attention of the end-user in

case of penalty who does not know this functional issue.

■ The connections of the device should be made while the system is energy-free.

■ VARkombi-12-PC-TFT-OG should be connected as shown in the connection diagram.

■ Three phase and neutral connections should be made to the voltage input. Phase should not

be given instead of neutral. Otherwise the device can be damaged.

■ Current connections should be made as to match the same phase with the same current

transformer. Scheme should be followed.

■ The value of the selected current transformers should not be under the real load values but

should be X/5 amper. It is also advised to choose 0.5 class.

■ Connect the “C1, C2, C3” common phase inputs to the same phase with FF type fuses

seperately. Select the fuses to be used according to the specified current value.

■ The outputs of the steps are not needed to be made in any order. However, the first 6 steps

can consist of triple-phase capacitor groups. It is recomended to connect single-phase

capacitors to the second and third 6 steps and, to connect capacitors or reactors to the third 6

steps in terms of accepting the statements in this manual.

■ Make the connections to the generator if it is used.

■ Make RS485 connection. (Not applicable in VARkombi-12-TFT-OG)

■ Do not energize the device without ensuring the connections checked by measurement

instruments.

Making the Connections

1 2 3

4

5 6 789 11

10 12

30

Temperature (ºC)

1. step

Capacitor step not

activated

Capacitor step

activated (blue)

1

R

S

T

Step Indicator

The powers and the phases they are belonging to are

not yet informed

A step indicator made by symbols that can be easily realized by the user, is located on the upper

part of the screen of VARkombi-12-PC-TFT-OG. No matter which part of the user in, this panel is

always located on the top of the screen. Step numbers, the phase or the phases they are

connected, whether these are informed or not, whether they are capacitors or reactors, whether

the steps and the generators are activated or not and control panel temperature value can all be

observed on this panel at the same time.

LCD screen is used in VARkombi-12-PC-TFT-OG to provide it to be more easier in use

and be intelligible. In case the keys are not pressed for a long time, the device switch to the

screen saver mode to extend the life of the display, and only the step indicator shown on the the

top scrolls down step by step from the top to the bottom of the screen. Thus, the condition of the

steps can be continued to be monitored. In case of pressing on any key, the main screen image

appears again.

Compensation normal

Fast mode activated

The following symbols can be seen on this part of the

display.

Manual control

3

!

H

F

I V

I V

I

V

I V

Measurement: Current from

medium volt age side – voltage from

low voltage side(non-insulated)

I

V

Measurement: Current from

medium volt age side – voltage from

medium volt age side

Measurement: Current from low

voltage side – vol tage from low

voltage side (insulated)

Measurement: Current from low

voltage side – vol tage from low

voltage side (non-insulated)

Current direction

~

230Vac

50/60 Hz

Connections

2 3 5 6 8 9 11 12 18741 10

30

ALARMS

R

S

T

Over voltage

Under voltage

Over current

T. over comp.

Under comp.

Exit▲▼Select

2 3 5 6 8 9 11 12741 10

30

Exit

- capacitors and the devices in the system

can be damaged.

- capacitors are recommended to be

disabled.

Over Voltage

Alarms

In case of alarm in the device, an exclamation mark appears

under the main screen. Pressing the exclamation key, the alert

page shown on the right side can be displayed on the screen as

well as a warning page can only be displayed. In case of more

than one alert, they are ranked one under the other according to

the priority.

Meanwhile, the phase in which the alarm is given displayed on the

screen. Arrow keys can move between the alarms. In case

“Select” key is pressed during on any alarm (format is blue colour),

warning page of that alert comes to screen. The essential

corrections should be made by taking into consideration the

recommendations made therebefore. Alarm page is back by

pressing the “Exit” key.

L3 (T)

L2 (S)

L1 (R)

N

N

L1 (R)

L2 (S)

L3 (T)

Gnd

B

A

TR

Power

Supply

I1

k1

I2

k2

I3

k3

Voltage inputs

Current Transformer Inputs

Load

AB

Transformer

CON-2

RS485 - Ethernet

4

connections are shown at

pages 10 and 11

connections are shown at

pages 10 and 11.

6A

K7

6A

ALR

C1

K1

K2

K3

K4

K5

K6

C2

K7

K8

K9

K10

K11

K12

ALR

(Alarm output)

*

*

*

*

Fuse compatible

to the capacitor

power

FAN

(Fan output)

FAN

2A

2A

K1

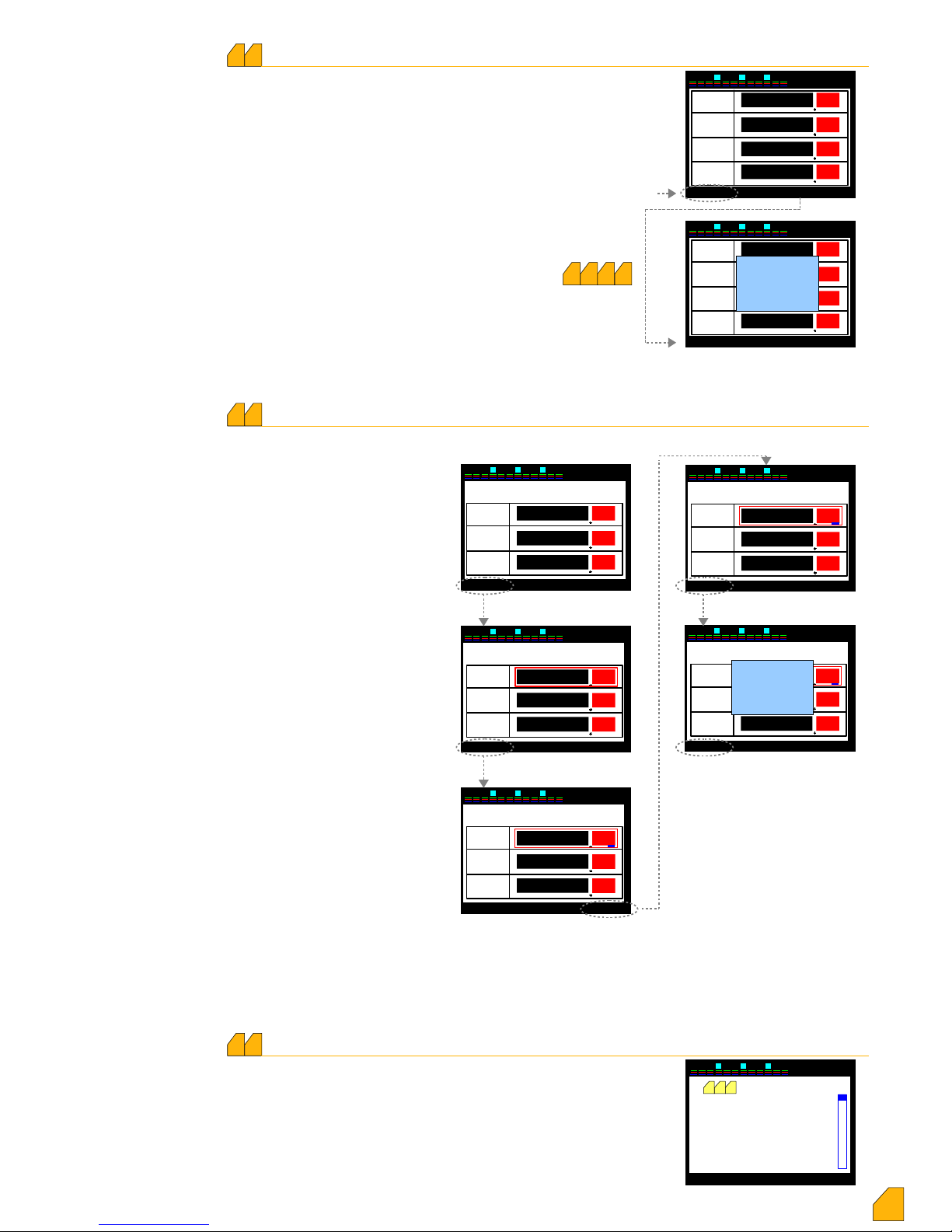

Commisioning

Device requires to enter the number of steps.

In this case, the screen on the right side will be

displayed. The number of step is set-up to the

required value by the direction keys and

“Apply” is selected. In case “Okay” key is

pressed, saves the change. Or, in case no key

is pressed, when the time is over on the

screen, it switches to the section in which the

current transformer ratio is inserted by taking

12 steps in the memory.

The line on which the blue bar locates, is setup to the required value by using the direction

keys and switch to the next side by pressing

the left direction key. Inserting the complete

primary value, “Apply” key is pressed. In case

of pressing “Okay” key, the change is saved.

The device automatically switches to the

internalization of current polarity directions

mode. In this case, it is required to draw

enough current from each phase. If enough

current can not be drawn from any phase, the

device warns as “current flow directions not

detected” and shows the phase or phases

which are not internalized by ??? marks. When

the total of current polarity directions are

internalized, the device switches to the

automatic capacitor power internalization

mode.

P.S.: There is no need to press on the main

screen key normally.

2. Step : Number of Steps

3. Step : Current Transformer Ratio

4. Step : Determine of Current Transformer

Directions

Device tries to identify capacitor powers and

the phases to which they connected, by

activating and then removing the steps in

sequence. It is recommended the closure of

variable loads in the system to ensure instant

internalization during this process. If required,

the user presses the “Make the steps

internalize” key and can make the system

internalize by himself. The automatic

internalization is put on hold in the meantime.

The step is not internalized automatically as

long as the user is in the “Make the steps

internalize” menu.

P.S.1: There is no need to press on the main

screen key normally.

P.S.2: Despite of the variable loads are

disabled, the connections of the device should

be checked again in case any power of the

steps and their connections are not intenalized

for a long time.

5. Step : Learning of step powers

For more info

When all the steps are internalized, the main

screen page comes up and the device starts

operating in automatic mode.

P.S.1: It' s required to enter the Menu for the

parameters the user need to set-up. It' s

recommended to see the specifications of the

device by navigating in the menu.

P.S.2: Unless the user disable the password

protection, some transactions (eg. set-up,

deleting the energy) will be password

protection.

6. Step (Main Screen)

5

1

Akım Polarite Yönleri Bulunamıyor

Ana Ekran

1 7 9 5 4

Current from M.V / Voltage from M.V (insulated)

Current from M.V / Voltage from L.V (non-insulated)

1

2 345 6 789 11

10 12

30

Menu %-Cos-PF-Σ Steps

.0

R

-50

-30 -10 10

30 50

cap.

ind..

0

N

+

%

2

.0

S

-50

-30 -10 10 30 50

cap.

ind.

0

N

+

%

9

.0

T

-50

-30 -10 10 30 50

cap.

ind..

0

+

%

5

.0

N

1 2 3 4 5 6 7 8 91011 12

30

Kvar

Make internalizeMain Screen

R S T

Detecting step powers... 10:00

Please close the vari able loads in the system.

K1 -1.0 -1.0 -1.0

1 2 3 4 5 6 7 8 91011 12

30

Main MenuPlease wait

R

S

T

detected

detected

detected

T

S

searching for current

transformer directions ... 5

R

1 2 3 4 5 6 7 8 91011 12

30

Seaeching for current

transformer directions...

Main Menu

Current Flow dir. not Detected

R

S

T

????????

????????

????????

- Make sure all

phases have loads

- Check voltage and

current inputs

!

1 2 3 4 5 6 7 8 9 10 11 12

30

searching for current

transformer directions ... 5

Main MenuPlease wait

R

S

T

????????

????????

????????

Please commision

Load on each phase

1 2 3 4 5 6 7 8 91011 12

30

Enter current transformer ratio

seconds

30

00500 / 5A

Apply▲ + ▼ - ◄

1 2 3 4 5 6 7 8 9 10 11 12

30

Insert current transformer ratio

seconds

20

CancelOkay Back

00500 / 5A

Save

Changes?

1 2 3 4 5 6 7 8 9 10 11 12

30

Enter number of step

seconds

20

12

Apply▲ + ▼ - ◄

1 2 3 4 5 6 7 8 9 10 11 12

30

Enter number of step

seconds

20

18

CancelOkay Exit

Save

Changes?

Current from L.V / Voltage from L.V (insulated)

Current from L.V / Voltage from L.V (non-insulated)

1. Step : Number of Steps

When commissioning the first time,

measurement type must be selected ( 4 types).

The device waits for the user to select one of

these types. These are also described in detail

on pages 10 and 11.

select ▼ ▲

2 3 5 6 8 9 11 12741 10 14

30

1 2 345 6 789 11

10 12

30

Menu %-Cos-PF-Σ Steps

.0

R

-50

-30 -10 10 30 50

kap.

ind..

0

N

+

%

2

.0

S

-50

-30 -10 10 30 50

kap.

ind.

0

O

-

%

9

.12

T

-50

-30 -10 10

30 50

kap.

ind..

0

+

%

5

.16

U

Main Screens

VARkombi-12-PC-OG has color 3.2 "TFT screen. The switch between pages and the key terms

are provided on the bottom line of the display. The keys have different meanings in different

pages.

Steps, to which phase or phases they are connected, whether they are capacitors and/or

reactors, temperature value, whether the fan and the generator are activated or not, all these can

be observed on all main screens.

Temperature (ºC)

Of R phase

Q

P

Normal

%

% Over

consumption

Shows the system within the

normal limits

Steps

%

cos (cosΦ)

(Instant Consumptions)

Instant consumption % values of each phase and their scaled representation, the normal, under

and over compensation of the phases, their inductive-capacitive characterized loads and whether

the system is normal or not according to the accumulated energy can be observed on

consumptions page.

Instant cosΦ value of each phase, angular representation on triple-phase vector diagram, the

angle (Φ) values, the normal, under and over compensation condition of the phases, their

inductive-capacitive characterized loads and whether the system is normal or not according to the

accumulated energy can be observed on this page.

Every time pressing this key,

switches next to the right menu

1 2 345 6 7

8

9 11

10 12

30

Menu %-Cos-PF-Σ Steps

.0

R

N

+

0

. 0

S

N

+

T

-

N

01

0

. 0

01

9

. 990

“ Φ “ angle on R phase

Current vector of T phase

Voltage point on R phase

Inductive

capacitive

R

1º0º

-1º

S

T

% Under

consumption

Over

Under

6

PF Power Factor

The instant reactive power value (Q), active force values (P), power factor values (PF) calculated

from their ratios (Q / P), vectoral representation of these forces, inductive - capacitive

characterized loads, whether the systems is normal or not as per the accumulated energy can be

monitored.

Σ

Ratios of Accumulated Energy

Accumulated energy ratios of each phase, total energy ratios and their scaled respresentation can

be monitored. This screen is very useful in terms of realizing the characters of loads connected to

the phases and enabling the user to take the necessary actions and make the corrections.

Whether the system is under penalty according to the total energy ratios can also be monitored.

Steps

This is the section used to see the conditions (activated-deactivated-holding)of steps more clearly,

to examine the reactive power of the system or for commissioning and disabling the steps

manually.

You must exit this menu for automatic mode as soon as you complete with

manual control. Otherwise, the device remains in manual control continuously.

1 2 3

4

5 6 789 11

10 12

30

Menu %-Cos-PF-Σ Steps

.0

R

S T

.0

ind

cap

ind

cap

ind

cap

S T

Q

1,763

K

P 21,44

K

PF 0,991

- 0,155

K

14,66

K

- 0,999

- 1,454

K

10,87

K

- 0,990

Reactive powers

Active powers

Power factors

1

2 345 6 789 11

10 12

30

Menu %-Cos-PF-Σ Steps

.

R

N

%

.

S

T

82

2.5

5

Cap.

İnd.

0 0

1015202530

354045

50

5 10 15 20 25 30

35 40 45

50

N

%

.

53

%

Normal

2.4

%

Normal

3.8

%

Normal

R

S

T

3.5

%

Normal

3.3

%

Normal

3.9

%

Normal

Total capacitive % Total inducitive %

Capacitive % of R phase

Inducitive % of R phase

Capacitive % of S phase

Inducitive % of S phase

Capacitive % of T phase

Inducitive % of T phase

2 3 5 6 8 9 11 12

30

Step

Status

Manual Mode

R

S

T

-0.346 KVAR

Exit VAR-W-VA

0.143 KVAR

0.345 KVAR

1

2

3

4

5

6

8

9

10

11

12

16

17

18

13

14

15

7

Switches to the section enabling the

commision and cut off the steps by

manual control.

741 10

Can change the power

representation from

this menu

4,7,10,13,14. steps activated (greenl)

1,2,3,5,6,8,9. steps deactivated (white)

11 and 12. steps holding for decharge period (yellow)

2 3 5 6 8 9 11 12

30

Manual

Mode

on-off

R

S

T

-0.346 KVAR

Exit

0.143 KVAR

0.345 KVAR

1

2

3

4

5

6

8

9

10

11

12

16

17

18

13

14

15

7

741 10

▲▼

7

2 3 5 6 8 9 11 12

30

Step info.

1

2

3

4

5

6

8

9

10

11

12

16

17

18

13

14

15

7

741 10

Operation Time

34 hours

Number of switching

663 times

-1.000 KVar

R S T

Total power

Select ▼ Exit▲

Current

Voltage

2 3 5 6 8 9 11 12

30

741 10 14

Exit◄ ► Setting

THD = 27.0 THD = 29.0 THD = 29.0

R S T

30

10

3

3 5 7 9 11 13 15 17 19 21 23 25 27 29 31T

1. MENU

This is the section in which many of the electrical measurements

are monitored and set-up are made. The parameters are

accessed by direction keys in the menu, parameters are inserted

by “Select” key and exit from the parameters by “Exit” key.

P.S.: Set-up section can only be accessed by password.

Harmonics

Displays the harmonic amplitude and %

values of voltage as well as current of three

phases up to 31.harmonic in terms of linear or

logarithmic on colour graphics screen.

Total harmonic

column(for three phase)

R S T

Allows to switch between

the harmonics

The section in which;

- current or voltage,

- % or amplitude

- linear or logarithmic

selections of harmonics are made.

Amplitude or %

values of

harmonic

distortion

Step Monitoring

All steps can be accessed by up and down keys. Step

information of the step with red frame ( ) among the step

boxes is displayed on the left side of the screen while moving

with directon keys.

The information regarding the runtime of all steps, number of

switching, phase or phase to which they are connected, total

power values and whether they are capacitor or reactor can

all be accessed.

These values can be deleted when you make a change in

step. “Select” key is pressed for deleting on the related step.

Selecting the required type of deleting from the sub-screens

shown on the right side, operation can be realized.

Voltage, Current, Frequency

This is the section in which the current, voltage and frequency

drawn from the system are monitored.

Power

This is the section in which active, reactive and apparent

powers drawn from each phase and, total active, reactive and

apparent powers are monitored.

These values can be observed by selecting “Powers” or

“Total” at the bottom of the screen.

1 1

1 3

1 4

100

%f

A

A

A

V

Select ▼ Exit▲

1 1

MENU

►

Harmonics

Step Monitoring

Voltage,Current,Frequency

Power

Energy

2 3 5 6 8 9 11 12741 10

30

ExitAmp-Volt %-Ampl. Log-Lin

ExitDelete all Delete ▲

CancelYes No

2 3 5 6 8 9 11 12

30

V

741 10

R

S T

Exit

219.8

219.2 220.2

A

60.48 71.32 43.29

f

49.9 Hz

2 3 5 6 8 9 11 12

30

Q

Var

741 10

R

S

T

Exit

0.864 KVar

Total

P

W

R

S

T

33.17 KW

S

VA

R

S

T

33.18 KVA

Powers Total

8

1 2

Energy

This is the section in which the actice, reactive (ind. and cap.)

and apparent energies consumed one by one in each phase

and, the total active, reactive (ind. and cap.) and apparent

energy consumed in total of the system are monitored.

If required, “Reset” selection is pressed (eg.when the counter

is read for invoicing purpose). Entering the password, “Delete

counters ?” question appears on the screen. In case of

pressing “Yes”, all the counters are deleted.

P.S.: Password process is described in this section.

Counter Index

The index value of electrical counter

connected to the plant is entered in

this section. Thus, the energies

recorded by electrical counter are

compared.

P.S.: VARkombi-12-PC-TFT-OG

does not use these values for

compensation.

Press “Setings” selection first

inorder to enter energy values.

Sub-screen will change and red

frame will appear on the index line.

Red frame is moved to the line of

which value will be entered by using

direction keys and, “Select” key is

pressed.

An underline in blue colour appears

in the line with red frame. The value

of number in the digit under which

the blue line is, is entered by using

up and down keys. Then, move to

the next digit by left key. When all

the digits are changed with the same

figures in the counter, “Apply” key is

pressed. When the values of all

lines are entered, “Okay” key is

pressed and, when “Save Changes”

appears on the screen, the data are

kept in the memory by pressing

“Okay” key.

Settings

This is the section in which you can find all set-up regarding

the device. Password is entered. After commissioning of

VARkombi-12-PC-TFT-OG, any change of parameters is not

required normally. However, it may be necessary for the

users requring to create special conditions or make some

adjustments.

1 7

1 6

1 5

2 3 5 6 8 9 11 12

30

KWh

(Active)

741 10

Exit

Σ-L1-L2-L3

Reset

KVARh

(ind.)

KVARh

(cap.)

KVAh

(apparent)

000003035 137

000000108

131

000000087 291

000003058

151

Total

Select ▼ ESC▲

1 7

SET-UP

►

Target TanΦ - CosΦ

Switch On Time

Switch Off Time

Min. Step Time

2 3 5 6 8 9 11 12741 10

30

1

2 3 5 6 8 9 11 12

30

KWh

(Active)

741 10 14

ExitSettings

KVARh

(ind.)

KVARh

(cap.)

000000056 321

000000001

031

000000000 291

2 3 5 6 8 9 11 12

30

KWh

(Active)

741 10

Cancel

Yes

KVARh

(ind.)

KVARh

(cap.)

KVAh

(apparent)

000003035 137

000000108

131

000000087 291

000003058

151

Delete

Counters?

No

Counter Index

2 3 5 6 8 9 11 12

30

KWh

(Active)

741 10

KVARh

(ind.)

KVARh

(cap.)

000000056 321

000000001

031

000000000 291

Counter Index

2 3 5 6 8 9 11 12

30

KWh

(Active)

741 10

ExitSelect

KVARh

(ind.)

KVARh

(cap.)

000000056 321

000000001

031

000000000 291

Counter Index

▼ ▲

Apply▲ + ▼ - ◄

2 3 5 6 8 9 11 12

30

KWh

(Active)

741 10

KVARh

(ind.)

KVARh

(cap.)

000000056 321

000000001

031

000000000 291

Counter Index

CancelOkay Exit

2 3 5 6 8 9 11 12

30

KWh

(Active)

74 10

KVARh

(ind.)

KVARh

(cap.)

000000056

321

000000001

031

000000000 291

Counter Index

CancelOkay Exit

Save

changes

1

1 7 9 7

Measurement Types

9

1 7

Settings – Measurement Type

1

The device offers the possibility of 4 types , according to the

connection.

Current Inputs

N

L1

Voltage Inputs

L2 L3

I3

I2

I1

L3

L2

L1

N

~~~

I3

k3

I2

k2

I1

k1

select ▼ exit▲

2 3 5 6 8 9 11 12741 10

30

X/5A

X/5A

X/5A

MEDIUM VOLTAGE LOW VOLTAGE

Current from M.V / Voltage from L.V (without voltage transformer)

There are two settings

1) MV – LV Ratio : The ratio of medium voltage to the low voltage

value (phase to phase). Forexample ; 33.000V / 400V = 82,5

2) Transformer Type : DYN-11 or DYN-5

NOTE: The current transformer ratio must be entered in the section

from the menu 1.7.8

select ▼ exit▲

1 7

Measurement types

►

MV – LV ratio

Transformer Type

2 3 5 6 8 9 11 12741 10

30

1 1

Enter MV – LV ratio

2 3 5 6 8 9 11 12741 10

30

apply▼ - ◄

0001.000

“Apply” key is pressed to take the target value into memory. “Save

Changes” message will appear on the screen. When “Okay” key is

pressed, the value is taken into the memory.

cancelokay back

▲ +

Medium Voltage

(VOLT)

Low Voltage

(VOLT)

select ▼ exit▲

1 7

2 3 5 6 8 9 11 12741 10

30

1 2

Enter Transformer Type

2 3 5 6 8 9 11 12741 10

30

apply▼ -

DYN - 11

cancelokay back

▲ +

DYN – 11

or

DYN – 5

Connection :

2A 2A 2A

10

►

MV – LV ratio

Transformer Type

Measurement types

L1 L2 L3

I3

I2

I1

L3

L2

L1

~~~

I3

k3

I2

k2

I1

k1

X/5A

X/5A

X/5A

select ▼ exit▲

2 3 5 6 8 9 11 12741 10

30

Current from L.V / Voltage from L.V (with voltage transformer)

Current from M.V / Voltage from M.V (with voltage transformer)

NOTE: The current transformer ratio must be entered in the section

from the menu 1.7.8

Enter Voltage Trans. Value

2 3 5 6 8 9 11 12741 10

30

apply▼ - ◄

0001.000

cancelokay back

▲ +

Current Inputs

L1

Voltage Inputs

L2 L3

I3

I2

I1

L3

L2

L1

~~~

I3

k3

I2

k2

I1

k1

X/5A

X/5A

X/5A

select ▼ exit▲

2 3 5 6 8 9 11 12741 10

30

Connection:

MEDIUM VOLTAGE LOW VOLTAGE

Voltage become isolated. The value of the voltage transformer must

be entered.

NOTE: The current transformer ratio must be entered in the section from the menu 1.7.8

Enter Voltage Trans. Value

2 3 5 6 8 9 11 12741 10

30

apply▼ - ◄

0001.000

cancelokay back

▲ +

2A2A2A

2A2A2A

11

MEDIUM VOLTAGE LOW VOLTAGE

Connection:

Current Inputs Voltage Inputs

L1 L2 L3

I3

I2

I1

L3

L2

L1

~~~

I3

k3

I2

k2

I1

k1

X/5A

X/5A

X/5A

N

N

select ▼ exit▲

2 3 5 6 8 9 11 12741 10

30

Current from L.V / Voltage from L.V (without voltage transformer)

NOTE: The current

transformer ratio must

be entered in the

section from the menu

1.7.7

2A2A2A

MEDIUM VOLTAGE LOW VOLTAGE

Connection:

Current Inputs Voltage Inputs

2 3 5 6 8 9 11 12741 10

30

1 7

Settings – Switch on Time (decharge) (1 – 600 sec)

3

Enter Step Switch On (Dis.)

Time

2 3 5 6 8 9 11741 10

30

Apply▲ + ▼ - ◄

020

sec

CancelOkay Exit

This is the enterance section of the value of decharge period (sec) holded for preventing the

capacitor to activate again without decharging in the same step in case of requirement, after

release of the activated step. The value is setup to the required step starting from the digit under

which the blue line is, by using up and down keys. Then left key is pressed and the blue line

moves next to left digit. All the values are entered in the same way by using up and down keys.

Press “Apply” key inorder to take the period of step activating into memory. “Save changes”

message will appear on the screen. When “Okay” key is pressed, the value is taken into memory.

Period of activating line is subjected to a function with the % value obtained from the ratio of

energies. In case % value is getting close to the inductive penalty line value, the time is reduced

automatically by the device. If necessasy, compensation speeds up; and if not, it slows down by

means of dynamic control of step activating, and continously do not make fast moves

unnecessarily.

P.S.: Step activating time counts only for capacitor released newly. If necessary and a close

solution is found in another step, device activates the other option on time and the compensation

is not delayed.

If it' s not required the device to respond so quickly, holding period between the steps can be

extended to delay receiving process by increasing the value of ΔT on switching time described in

the next chapter.

P.S.3:

In case of selecting the switch on

time less than min.step time,

device accepts the switch on time

as constant time value.

1 7 10 1

Other Relays : They proceed the step activating transaction with constant time adjusted. If the

time is not over, they will wait for the deadline. This causes delays in the compensation.

VARkombi-12-PC-TFT-OG : It collects the energies (ind., cap., active) consumed. Step activating

and de-activating periods are decreased or increased automatically by the device according to the

consumed enerygy.

P.S.: The energies consumed in VARkombi-12-PC-TFT-OG and the % values are calculated

separately for each phase. Therefore, step activating and de-activating periods of each phase can

vary. For instance, while the step activating time for R-phase down to 2 seconds, the one for Sphase can be 7 sec. VARkombi-12-PC-TFT-OG analyze the system phase by phase and set-up

the compensation rate for each phase seperately.

The most simple explanation

regarding the ratio of energy

of step activating period has

been given below.

In fact the function consists of

much more complicated and an

array of fuzzy logic. Step subperiod (min) determines the

lowest time value of level activating

time which can be reduced by the device.

This parameter can be specified by the user.

% ind.

Switch on time

0

Min. Switch Time

% ind.penalty line

t(sec)

12

Enter Step Switch On (Dis.)

Time

020

sn

Save

changes

1 7

Settings - Target TanΦ ( % ±75 ) – CosΦ ( ± 0,800 )

2

This is the section in which the required % value of the system is entered. CosΦ value

corresponding to the % value is displayed automatically on the other side. The value is setup to

the required step by using up and down keys starting from the digit where the blue line is. Then,

left key is pressed and the blue line moves next to left digit. All values are entered in the same

way by using the up and down keys. Moving the blue sub-line to the digit where the sign is by

using left key, the sign can be changed by pressing upwards key. (+) expresses inductive, (-)

expresses capacitive sections..

Enter target TanΦ value

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

CosΦ

1.000

%

+00

Enter target TanΦ value

2 3 5 6 8 9 11 12741 10

30

CancelOkay Exit

CosΦ

1.000

%

+00

Save

changes

“Apply” key is pressed to take the

target value into memory. “Save

Changes” message will appear on

the screen. When “Okay” key is

pressed, the value is taken into the

memory.

2 3 5 6 8 9 11 12741 10

30

002

sn

1 7

Settings – Min. Switch Time (1 – 600 sec)

5

Enter Min.SwitchTime

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

002

Save

changes

sec

CancelOkay Back

This is the section in which the value of step sub-period (min) is entered (sec). The value is setup

to the required step by using up and down keys starting from the digit where the blue line is. Then,

left key is pressed and the blue line moves next to left digit. All values are entered in the same

way by using the up and down keys.

Press “Apply” key inorder to take the step sub-period (min) time into memory. “Save changes”

message will appear on the screen. When “Okay” key is pressed, the value is taken into memory.

Period of activating line is subjected to a function with the % value obtained from the ratio of

energies. It represents the minimum value of both step activating and de-activating time which can

be changed by the device.

Step sub-period is not taken into

account during fast mode.

2 3 5 6 8 9 11 12741 10

30

020

sn

1 7

Settings – Switch Off time (1 – 600 sec)

4

Enter Step Switch Off Time

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

020

Save

changes

sec

CancelOkay Back

This is the section in which the value of switch off time is entered (sec). The value is setup to the

required step by using up and down keys starting from the digit where the blue line is. Then, left

key is pressed and the blue line moves next to left digit. All values are entered in the same way by

using the up and down keys.

Press “Apply” key in order to take the switch off time into memory. “Save changes” message will

appear on the screen. When “Okay” key is pressed, the value is taken into memory.

Period of activating line is subjected to a function with the % value obtained from the ratio of

energies. In case % value is getting close to the capactive penalty line value, the time is reduced

automatically by the device. If necessasy, compensation speeds up; and if not, it slows down by

means of dynamic control of switch off time, and continously do not make fast moves

unnecessarily.

P.S.1: Switch off time counts only for capacitor activated newly. If necessary and a close solution

is found in another step, device deactivates the other option on time and the compensation is not

delayed.

If it' s not required the device to respond so quickly, holding period between the steps can be

extended to delay releasing process by increasing the value of ΔT off switching time described in

the next chapter.

P.S.2: In case fast operating mode

is selected, switch off time of the

device is 200 msec.

It' s independent from switch off

time which is set-up.

P.S.3: In case of selecting the

switch off time less than min.step

time, device accepts the switch off

time as constant time value.

1 7 10 2

Other Relays : They proceed the step de-activating transaction with constant time adjusted. If the

time is not over, they will wait for the deadline. This causes delays in the compensation.

VARkombi-12-PC-TFT-OG : It collects the energies (ind., cap., active) consumed. Step activating

and de-activating periods are decreased or increased automatically by the device according to the

consumed enerygy.

P.S.: The energies consumed in VARkombi-12-PC-TFT-OG and the % values are calculated

separately for each phase. Therefore, step activating and de-activating periods of each phase can

vary. For instance, while the step de-activating time for R-phase down to 2 seconds, the one for

S-phase can be 7 sec. VARkombi-12-PC-TFT-OG analyze the system phase by phase and setup the compensation rate for each phase seperately.

The most simple explanation

regarding the ratio of energy

of step de-activating period has

been given below.

In fact the function consists of

much more complicated and an

array of fuzzy logic. Level subperiod (min) determines the

lowest time value of step de-activating

time which can be reduced by the device.

This parameter can be specified by the user.

% cap.

Switch Off time

0

Min. Step Time

% cap.penalty line value

t(sec)

13

200 msec

Fast Mode

Normal Mode

Enter Step Switch Off Time

Enter Min.Switch Time

1 7

Settings – Inductive penalty limit ( % 3 – 50 )

6

This is the section in which the limit value of inductive/active % acceptable in compensation, is

entered. This value is determined by electric distribution company and is recommended to setup a

value slightly lower than requested to avoid penalty. The value is setup to the required step by

using up and down keys starting from the digit where the blue line is. Then, left key is pressed

and the blue line moves next to left digit. All values are entered in the same way by using the up

and down keys.

Press “Apply” key inorder to take the inductive penalty line into memory. “Save changes” message

will appear on the screen. When “Okay” key is pressed, the value is taken into memory.

Enter inductive penalty limit

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

%

20

Enter inductive penalty limit

2 3 5 6 8 9 11 12741 10

30

CancelOkay Exit

%

20

Save

changes

1 7

Settings – Capacitive penalty limit ( % 3 – 50 )

7

This is the section in which the limit value of capacitive/active % acceptable in compensation, is

entered. This value is determined by electric distribution company and is recommended to setup a

value slightly lower than requested to avoid penalty. The value is setup to the required step by

using up and down keys starting from the digit where the blue line is. Then, left key is pressed

and the blue line moves next to left digit. All values are entered in the same way by using the up

and down keys.

Press “Apply” key inorder to take the capacitive penalty line into memory. “Save changes”

message will appear on the screen. When “Okay” key is pressed, the value is taken into memory.

Enter cap.penalty limit

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

%

10

Enter cap.penalty limit

2 3 5 6 8 9 11 12741 10

30

CancelOkay Exit

%

10

Save

changes

1 7

Settings – Current Transformer (Primary) value ( 5.......10000 / 5A )

8

Enter current transformer value

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

00500 / 5A

Enter current transformer value

2 3 5 6 8 9 11 12741 10

30

CancelOkay Exit

This is the section in which the primary value of current transformers in compensation system, is

entered. The value is setup to the required step by using up and down keys starting from the digit

where the blue line is. Then, left key is pressed and the blue line moves next to left digit. All

values are entered in the same way by using the up and down keys. Press “Apply” key inorder to

take the current transformer (primary) value into memory. “Save changes” message will appear

on the screen. When “Okay” key is pressed, the value is taken into memory.

00500 / 5A

Save

changes

1 7

Settings – Number of Steps ( 3 – 12 )

9

Enter number of steps

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

2 3 5 6 8 9 11 12741 10

30

CancelOkay Exit

This is the section in which the number of steps will be used for compensation, is entered. The

value is setup to the required step by using up and down keys starting from the digit where the

blue line is. Then, left key is pressed and the blue line moves next to left digit. All values are

entered in the same way by using the up and down keys. Press “Apply” key inorder to take the

number of steps into memory. “Save changes” message will appear on the screen. When “Okay”

key is pressed, the value is taken into memory.

12 12

Save

changes

14

Enter number of steps

1 7

Settings – Advanced Setting Menu

10

This is the section in which the parameters are not used very often.

1 7 10

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

0000

2 3 5 6 8 9 11 12741 10

30

CancelOK ESC

Enter ΔT On Delay time Enter ΔT On Delay time

0000

Save

changes

1

This is the section in which the holding time between steps during step activating, is entered. The

value is setup to the required step by using up and down keys starting from the digit where the

blue line is. Then, left key is pressed and the blue line moves next to left digit. All values are

entered in the same way by using the up and down keys. Press “Apply” key inorder to take ΔT on

switching time into memory. “Save changes” message will appear on the screen. When “OK” key

is pressed, the value is taken into memory.

In case at least one of ΔT on

or ΔT off time is setup to any

value rather than zero and the

device runs in quick mode, quick

mode is canceled automatically.

1 7

Settings – Advanced Setting Menu - ΔT off Delay Time (0 – 3600 sec)

10

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ - ◄

0000

2 3 5 6 8 9 11 12741 10

30

CancelOkay Exit

Enter ΔT Off time Enter ΔT Off time

0000

Save

changes

This is the section in which the holding time between steps during step de-activating, is entered.

The value is setup to the required step by using up and down keys starting from the digit where

the blue line is. Then, left key is pressed and the blue line moves next to left digit. All values are

entered in the same way by using the up and down keys. Press “Apply” key inorder to take ΔT off

switching time into memory. “Save changes” message will appear on the screen. When “Okay”

key is pressed, the value is taken into memory.

sec

sec

2

1 7

Settings - Advanced Setting Menu – current flow direction detection

10 3

This is the section in which the function of searching of current transformer polarity directions are

activated or de-activated. In case “Activated” is selected, internalization of current transformer

direction is always “On”, and only checks the directions when the device is powered. If “Off” is

selected, then the device internalize the current transformer directions at once and do not change

it. The “Off” choice should be selected for some loads (producing negative active load).

The required status for function is selected by using the up

and down keys. Press “Apply” key inorder to take this parameter

into memory. “Save changes” message will appear on the screen.

When “Okay” key is pressed, the value is taken into memory.

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ -

Enable

Direction Detection Status

Settings – Advanced Setting Menu - ΔT on Delay Time (0 – 3600 sec)

ΔT on

2

ΔT off

1 2

1

15

In case at least one of ΔT on

or ΔT off time is setup to any

value rather than zero and the

device runs in fast mode, quick

mode is canceled automatically.

In case internalization of direction is activated, internalization of

current transformer direction is always “On”, and only checks the

directions when the device is powered. In case the ends of

current are changed while the device is running, it can not detect

this. It' s needed to turn off and on again.

1 7

Settings – Advanced Setting Menu – Fast Step Mode

10 4

This is the section in which the fast step mode is enable or disable. In case “enable” is selected,

the device can activate many steps at the same time as well as de-activate them. If “Off” is

selected, then the device makes only one step attempt at each time.

The required status for function is selected by using the up

and down keys. Press “Apply” key in order to take this parameter

into memory. “Save changes” message will appear on the screen.

When “Okay” key is pressed, the value is taken into memory.

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ -

Enable

Fast Step Mode Status

In case fast step mode is activated, the device set ΔT on and

ΔT off times to zero automatically.

If fast step mode is selected, then the contactors which will be

used, must be absolutely compensation contactors, and the step

activating time (discharge) that the producers recommend, should

be entered.

1 7

Settings – Advanced Setting Menu – Step Parameters – Continuos Step Power Detecting

10 5

This is the section in which the continous internalization of step power is activated or de-activated.

In case “Activated” is selected, the device checks the step power at each step activating and deactivating operation. In case of a change in power, then the device determine it and start to use

this value. If the last value of the capacitor is decreased by 50% than the power value of the initial

internalization, the device warns the user about the decrease in power of capacitor. It continues to

make compensation with the value internalized finally. In case “Off” is selected, the device can

only internalize the capacitor powers on the first

commissioning. It determines the change, but continues to

compensation with the values of initial internalization.

P.S.: It can be necessary to disable the function of step power

İnternalization in some plants (especially, the plants in which the

loads are changing very quickly).

The required status for function is selected by using the up

and down keys. Press “Apply” key inorder to take this parameter

into memory. “Save changes” message will appear on the screen.

When “Okay” key is pressed, the value is taken into memory.

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ -

Enable

Contn. Step Power Detecting

1 7

Settings – Advanced Setting Menu – Step parameters – Constant Step Function

10 5

This is the section in which the constant step function is activated or de-activated.First step

switch on and stay at this position if this function is enable . This function is only used in activating

constant capacitor to meet the loss of transformers in the counters measure the medium voltage.

This capacitor must be connected ahead from the current transformers. Using the step of the

device for constant capacitor is not recommended actually. Much more steps are required for

compensation.

Consequently, constant capacitor can be connected to switch

input with a on-off switch. In case “Off” is selected, the device starts

to use this step.

The required status for function is selected by using the up

and down keys. Press “Apply” key inorder to take this parameter

into memory. “Save changes” message will appear on the screen.

When “Okay” key is pressed, the value is taken into memory.

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ -

Disable

Constant Step function

1 7

Settings – Advanced Setting Menu – Step Parameters – Step Sync.Time Sharing

10 5

This is the section of activating or de-activating the simultaneous use of levels in the same power.

In case “Activated” is selected, device tries to make the used hours of capacitors in the same

power equal.

The required status for function is selected by using the up

and down keys. Press “Apply” key inorder to take this parameter

into memory. “Save changes” message will appear on the screen.

When “Okay” key is pressed, the value is taken into memory.

2 3 5 6 8 9 11 12741 10

30

Apply▲ + ▼ -

Disable

Step Sync.Time Sharing

1

2

3

16

1 7

Settings – Advanced Setting Menu – Step Parameters – Enter Step Powers

10 5

This is the section in which the step powers are entered. The

device directs the user with subcommand display

continuously. It is moved on the step of which the power is

required to be entered by using the up and down keys. In the

meantime, that line are in red colour. Select key is pressed.

The selected step number comes to screen. The selection of

triple-phase or single-phase of capacitor or reactor should be

made on this screen.

The position of red frame changes when up and down keys

are used. In case the reactive load on the step is triple-phase,

the frame is moved on triple-phase and “Select” key is

pressed. Triple-phase option becomes red in this case. If up or

down direction key is pressed, the red frame moves to total

value digit. The “Select” key is pressed and a blue underline

appears on the last digit inside of the frame. The value is

setup by using the up and down keys starting from the digit

where the blue line is. Then, left key is pressed and the blue

underline moves next to the left digit. All the values are

entered in the same way by using up and down keys. The

“Apply” key is pressed to take them into memory. The subcommand screen changes and “Okay”, then “Exit” key is

pressed. “Save Changes” will appear on the screen. When

“Okay” key is pressed, the value is taken into memory.

If the reactive load on the step is single-phase, frame is

moved onto single-phase and “Select” key is pressed. Singlephase option becomes red in this case. In case of pressing up

or down direction key is pressed, the red frame moves on the

lines of R, S and T-phases including total value. In case of

which phase the reactive load on the step is connected to,

“Select” key is pressed during on that line. Entering the value

and taking it into memory is the same as described above.

P.S.: Moving the blue underline to the digit on which the sign is

by using the left key, the sign can be changed by pressing

upwards key. (+) represents the reactor, (-) represents the

capacitor.

2 3 5 6 8 9 11 12741 10

30

Exit▲▼

Kvar

4

Select

R S T

K1 --------- --------- ---------

K2 --------- --------- --------K3 --------- --------- --------K4 --------- --------- --------K5 --------- --------- ---------

Step powers are adjusted manually...

2 3 5 6 8 9 11 12741 10 14

30

Exit▲▼

3-phase

Select

R

S

T

1.Step

1-phase

Σ

0.000

KVAr

0.000 KVAr

0.000 KVAr

0.000 KVAr

2 3 5 6 8 9 11 12741 10

30

3-phase

R

S

T

1.Step

1-phase

Σ

0.000 KVAr

0.000

KVAr

0.000 KVAr

0.000 KVAr

Apply▲ + ▼ - ◄

CancelOkay Exit

Exit▲▼Select

2 3 5 6 8 9 11 12741 10

30

3-phase

R

S

T

1.Step

1-phase

Σ

0.000 KVAr

0.000 KVAr

0.000

KVAr

0.000 KVAr

CancelOkay Exit

Save

changes

1 7

Settings – Advanced Setting Menu – Step Parameters – Delete Step Powers

10 5

2 3 5 6 8 9 11 12741 10

30

Exit▼

Kvar

5

Delete

R

S

T

K1 -0,500 -0,500 -0,500

K2 -1,000 -1,000 -1,000

K3 -1,500 -1,500 -1,500

K4 -2,500 -2,500 -2,500

K5 -3,330 -3,330 -3,330

2 3 5 6 8 9 11 12741 10

30

Kvar

R S T

K1 -0,500 -0,500 -0,500

K2 -1,000 -1,000 -1,000

K3 -1,500 -1,500 -1,500

K4 -2,500 -2,500 -2,500

K5 -3,330 -3,330 -3,330

2 3 5 6 8 9 11 12741 10

30

Kvar

R S T

K1 -0,500 -0,500 -0,500

K2 -1,000 -1,000 -1,000

K3 -1,500 -1,500 -1,500

K4 -2,500 -2,500 -2,500

K5 -3,330 -3,330 -3,330

2 3 5 6 8 9 11 12741 10

30

Kvar

R

S

T

K1 -0,500 -0,500 -0,500

K2 -1,000 -1,000 -1,000

K3 -1,500 -1,500 -1,500

K4 --------- --------- ---------

K5 -3,330 -3,330 -3,330

2 3 5 6 8 9 11 12741 10

30

Kvar

R

S

T

K1 --------- --------- ---------

K2 --------- --------- --------K3 --------- --------- --------K4 --------- --------- --------K5 --------- --------- ---------

CancelOkay ExitCancelOkay Exit

Step

Delete ?

Step

Delete ?

Exit▼ Delete Delete AllExit▼ Delete Delete All

This is the section in which the step parameters are deleted

one by one, or all. In case the reactive load is changed in any

step, the power of that step must be deleted to let the device

internalize the the power of new step. The device fowards the

user continuously by sub-command screen. Moving onto the

step of which power required to be deleted, the up or down

key is pressed. The line is in red colour in the meantime. In

case of deleting only that step, “Delete” key is pressed; in case

of deleting all steps (if a device used in somewhere

else is connected to a new plant),

“Delete All” key is pressed.

If “Delete” key is pressed, “Step Delete?”

warning appears on the screen. When

“Okay” key is pressed, the power of

that step would be deleted. The device

will automatically try to internalize the

power of that step again. You can exit

the menu by “Exit” key. In case “Delete

All?” key is pressed, “Steps Delete?”

warning appears on the screen. When

“Okay” key is pressed, the power of all

steps would be deleted. The device

will automatically try to internalize the

power of that step again. You can exit

the menu by “Exit” key.

17

Delete All

1 7

Settings – Advanced Setting Menu – Step Parameters – Step Change Control

10 5

It' a useful function in terms of warning the user. First, it' s

better to clarify some definitions step alteration control page:

Old value : The first internalized power of step.

New value: The power alterated minimum ± 15% with respect

to the past value.

This page has been designed to identify and enter the real

value of steps whose powers are not internalized, even though

the powers are alterated over time or replaced with the past

one by the user.

In case the new value of any step is alterated ± 50% with

respect to the first value, the device warns the user as

“Change in the power of capacitor”. If the capacitor in which

alert is given has really alterated, then the new value should

be loaded instead of the past one. The alteration in step power

appears on the screen as a warning

In case internalization of step power is activated, the device

controls the capacitor power at every step activation and deactivation process. In case of a change in the power, the

device determines it and continue to compensate with the final

value internalized. If “Off” is selected, the device internalize

capacitor powers only at the first activation. It determines the

alteration, however continues the compensation with the first

internalized values.

The device directs the user with sub-command screen

continuously. The red frame is moved on the step whose

power decreased (box in blue colour) by using up and down

keys and “Select” key is pressed.

Sub-command screen is alterated. In case of which value will

be used, past or new value key is pressed and then load key is

presse. “Load selected value to step?” question appears on

the screen. If “Yes” key is pressed, load will be completed.

6

2 3 5 6 8 9 11 12741 10

30

Exit▲▼

Old value

Select

R

S

T

Σ

0.000 K

0.000 K

0.000 K

0.000 K

Step Change

2

3

4

5

6

8

9

10

11

12

16

17

14

15

1 7 13

2 3 5 6 8 9 11 12741 10

30

ExitLoadNew value

Old value

Old value

R

S

T

Σ

0.000

K

0.000 K

0.000 K

0.000 K

Step Change

2

3

4

5

6

8

9

10

11

12

16

17

14

15

1 7 13

2 3 5 6 8 9 11 12741 10

30

CancelNoYes

R

S

T

Σ

0.000 K

0.000 K

0.000 K

0.000

K

2

3

4

5

6

8

9

10

11

12

16

17

14

15

1 7 13

1 7 10 6

This is the section in which the alerts are set and the value of

protection parameters are entered. It consists of nested

menus. You can move between the parameters which

generate the menu by direction keys, and can enter the next

sub-menu or into the parameter by pressing “Select” key on

the sub-command screen.

The device directs the user with sub-command screen

continuously. In case of entering into the parameter, the

commands on the sub-screen are alterated as shown on the

right side. In this case blue line appears under the first digit of

the parameter. The value is alterated by using the up and

down key starting from the digit where the blue line is. Then

left key is pressed and the blue underline moves next to the

left digit. All values are entered in the same way by using up

and downkeys. “Select” key is pressed to take them into the

memory.

“Save changes?” message will appear on the screen. Pressing

“Okay” key, the value is taken into the memory.

CancelOkay Exit

Exit▲▼Select

Apply▲ + ▼ - ◄

1 7 10 6 1

1 7 10 6 1

Phase alarms

1 7 10 6 1

General Alarms

1 2

Over voltage

Under voltage

Over current

Over compensation

Under compensation

No phase

THD on voltage

HD on voltage

THD on current

HD on current

1st Connector Error

2st Connector Error

3st Connector Error

Total over compensation

Total under compensation

System Error

Over temperature

Voltage connection

Step Change

Step Zero

Modbus security Error

Settings – Improved Setup Menu – Alert & Protection

This is the section in which the

activation or de-activation

process of alerts are performed.

18

Settings – Advanced Setting Menu – Alarm & Protection – Alarm Control

18

18

18

Old value

Step Change

Load

Selected value

to Step ?

1 7 10 6 1

Phase Alarms – Over Voltage (enable)

1 1

In case of over voltage during the activation of alert, alert is given and device warns the user.

In this case;

- capacitors and devices in the system may be damaged.

- “Voltage protection activated” may be preferred in the step protection function(Chapter 1710642)

1 7 10 6 1

Phase Alarms – Under Voltage (enable)

1 2

In case of under voltage during the activation of alert, alert is given and device warns the user.

In this case;

- capacitors and devices in the system may be damaged or may not be operated properly.

- “Voltage protection activated” may be preferred in the step protection function(Chapter 1710642)

1 7 10 6 1

Phase Alarms – Over Current (enable)

1 3

In case over current is drawn from the system during the activation of alert, alert is given and

device warns the user. In this case;

- Inputs of the device may be damaged any moment. This case is out of warranty.

- Please stop the system and replace the current transformers with the larger ones.

1 7 10 6 1

Phase Alarms – Over Compensation (enable)

1 4

In case the system falls into over compensation in any phase during the activation of alert, device

warns the user. In this case;

- Review the capacitor power distribution in the steps, especially in the phase where the alert is

given.

- Please allow less powerful capacitors which can reach buffer power values.

1 7 10 6 1

Phase Alarms – Under Compensation (enable)

1 5

In case the system falls into under compensation in any phase during the activation of alert,

device warns the user.

In this case;

- Review the capacitor power distribution in the steps, especially in the phase where the alert is

given.

- Please insert the capacitors which the phase or the phases need.

1 7 10 6 1

Phase Alarms – No Phase (enable)

1 6

In case any phase in the system cut down during the activation of alert, device warns the user.

In this case;

- At least one of the phases is not in the system..

- Measure the voltage at the voltage input terminals, control the terminals. You should read 220V

between phase-neutral.

1 7 10 6 1

Phase Alarms – THD on Voltage (enable)

1 7

In case total harmonic failure in the phase voltage exceeds the set value during the activation of

alert, device warns the user.

In this case;

- You should install harmonic filter to protect your devices.

1 7 10 6 1

Phase Alarms – HD on Voltage (enable)

1 8

In case the failure of any harmonics between 3...31 in the phase voltage exceeds the set value

during the activation of alert, device warns the user.

In this case;

- You should install harmonic filter to protect your devices.

1 7 10 6 1

Phase Alarms – THD on Current (enable)

1 9

In case total harmonic failure in the phase of system exceeds the set value during the activation of

alert, device warns the user.

In this case;

- You should install harmonic filter to protect your devices.

1 7 10 6 1

Phase Alarms – HD on Current (enable)

1 10

In case the failure of any harmonics between 3...31 in the phase voltage exceeds the set value

during the activation of alert, device warns the user.

In this case;

- You should install harmonic filter to protect your devices.

19

20

1 7 10 6 1

General Alarms – 1. connector failure (K1...K6) (enable)

2 1

In case of this alarm;

- (C1) common phase input may not be connected.

- The fuse of (C1) common phase input may blowed out.

- Compensation connection may be made prior to current transformers.

- Removing the failure, steps internalized zero should be internalized again.

1 7 10 6 1

General Alarms – 2. connector failure (K7...K12) (enable)

2 2

In case of this alarm;

- (C2) common phase input may not be connected.

- The fuse of (C2) common phase input may blowed out.