Küppersbusch KD7580.0GE, KD9580.0GE, KD9970.0GE, KD9960.0GE Instructions For Assembly And Use

BEDIENUNGS- UND

MONTAGEANWEISUNG

GB INSTRUCTIONS FOR ASSEMBLY AND USE

GR

KD7580.0GE

KD9970.0GE

KD9960.0GE

KD9580.0GE

20

CONTENTS

General

Contents

Your appliance data

Safety Instructions

Installation

Assembly instructions

Electrical connection

Other assembly instructions and tips

Dimensioned drawings

Assembly instructions

Operation

Switching your appliance on / off

Power controls

Automatic delayed stop

Switching the lamp on / off

Dimmer function

Filter saturation display

Remote control

Maintenance, Cleaning and Care

Casing

Grease filter

Charcoal filter

29

32

32

32

32

32

33

33

34

35

36

20

21

22

24

24

25

26

21

Please note:

We require the following details for your request for customer service so that our

customer service technicians can be well-prepared to carry out repairs and have the

required spare parts available:

7. Your exact address

8. Your telephone number and, if available, fax number

9. When can customer service call?

10. An exact appliance designation:

model no. and fabric no. (refer to the nameplate and/or the receipt)

Model designation: ............................................................................................

E-number: ..........................................................................................................

F/N: ..............................................................................................................

11. Date of purchase

12. An exact description of the problem or the kind of service you require

Please also have your receipt available.

This will help us to avoid wasting time as well as cutting down on expenses and we

will be able to work more efficiently for you.

22

Safety Instructions

This appliance complies with valid safety regulations. Improper handling may cause

damage to property and injury to persons.

Please read these instructions carefully before installing your appliance and using it.

It contains important information and tips on assembly, safety and maintenance.

Information concerning structural requirements

The following instructions must be observed when cooker hoods are used in the

extraction mode:

- In kitchens/rooms with no open fireplace, the air supply must ensure that no

negative pressure occurs in the room and that the hood can function properly.

- Important! Kitchens / rooms with an open fireplace, e.g. tile stoves, coal

ovens, fireplaces, etc., must always be provided with a sufficient supply of

fresh air. This is best ensured with a wall box for inlet air and exhaust air or

with a flip switch for the window.

Contact your local chimney sweep for information before making your plans.

He will have to give his approval for the hood and the inlet air and exhaust air

pipes before you put your hood into operation.

- Under no circumstances may the hood be connected to a smoke or exhaust

gas chimney that is used for other appliances (hot water tanks, boilers,

furnaces, etc.). Chimneys used for ventilating rooms or fireplaces may not be

used for the hood.

- Your local chimney sweep must give his approval if the hood is connected to

smoke or exhaust gas chimneys which are no longer in use.

- Valid national building regulations must be observed.

23

Safety instructions for assembly and use

- The metal grease filters must always be in place when the cooker hood is in

operation. Greasy vapours may otherwise be deposited in the hood and in the

extraction air system.

- In the case of gas cookers it is important to ensure that the cooking zones are

not operated without any cookware. Uncovered gas flames may damage

components of the cooker hood as a result of rising heat.

- Never flambé under the cooker hood as there is a risk of fire. The rising flame

could ignite the fat that has been deposited in the filter.

- Constant supervision is essential when deep-frying or cooking with oil or fat

under the hood because of the risk of fire.

- No other work may be carried out with an open flame. A fire may result and

damage the metal grease filter or other parts of the hood. This does not

include the proper use of a gas cooker.

Safety instructions for maintenance, cleaning and care

- Pull the mains plug out of the socket or switch off the relevant safety fuse in

the fuse box for the building when carrying out any maintenance or cleaning

work.

- The cooker hood may not be cleaned with a steam cleaner.

- Grease deposits may cause a fire if the instructions for maintenance and

cleaning are not followed.

24

INSTALLATION

Depending on the model, a minimum clearance of 40-65 cm must be maintained

between an electric hob and the bottom of the cooker hood when installing the hood.

A minimum clearance of 55-70 cm must be maintained for gas hobs (Fig. 1).

Fig. 1

Electric hob 40-65

Gas hob 55 - 75

Assembly instructions

Extraction or recirculation mode

When the hood operates in the extraction mode, the air that is extracted is cleaned

in the grease filter and lead outside through an exhaust air duct.

In the recirculation mode, the air that is extracted is cleaned in the grease filter and

also in a charcoal filter (extra). The clean air is then lead back into the kitchen.

Hoods supplied from the factory have been fitted for the extraction mode. You can

order the extra part required for the recirculation mode from us (also see the section

on “maintenance, cleaning and care”).

Electrical connection

Before connecting the hood to the mains, check that the voltage stated on the type

plate corresponds to the local power supply. The type plate is located inside the

hood. You will see it next to the motor once you have removed the grease filter.

The hood is supplied from the factory fitted with a mains cable and a plug. It can be

connected to any 230 volt, 50 Hz alternating current shockproof socket which has

been installed in accordance with regulations.

The socket should be located behind the chimney so that it is not visible. The socket

will not be accessible once the chimney has been mounted, so it must be possible to

cut off the electric circuit to which the hood is connected when maintenance work

needs to be carried out.

The hood complies with protection class 1 standards.

25

Other important information

In order to make sure that ventilation is optimal and that the hood operates quietly,

the extraction air system, including the wall box, must be at least 150 mm in

diameter.

Please observe the following when installing the exhaust air pipe:

- Use short, straight exhaust air ducts

- Use as few pipe bends as possible

- Use only smooth pipes

- Exhaust air boxes and pipes with a diameter of 100 or 120 mm are not

suitable.

- Do not use a plastic flex exhaust air tube since this may make the operating

noise unpleasantly loud.

- When drilling holes for dowels make sure that lines running in the walls

(electricity, gas and water) are not damaged.

This cooker hood has been designed for mounting on a wall. Please follow the

drawings and instructions provided. We recommend that you always wear the gloves

that are supplied when mounting the hood in order to avoid fingerprints on the

stainless steel.

.

26

KD9580.0GE / KD7580.0GE dimensioned drawing

KD9580.0GE / KD7580.0GE dimensioned drawing of installation dimensions

(back view)

27

KD9970.0GE dimensioned drawing

KD9970.0GE dimensioned drawing of installation dimensions (back view)

28

KD9960.0GE dimensioned drawing

KD9970.0GE dimensioned drawing of installation dimensions (back view)

29

MOUNTING ON A WALL

Take the wall mounting bracket shown in Fig. 2 and place it on the wall so that you

have the height you want when you mount the cooker hood. Make sure that you

maintain a minimum clearance of 40-65 cm between the hob and the bottom of the

cooker hood for electric hobs and a minimum clearance of 55-70 cm for gas hobs.

See Fig. 2.1 for the exact dimensions of the wall mounting bracket.

Fig. 2 Fig. 2.1

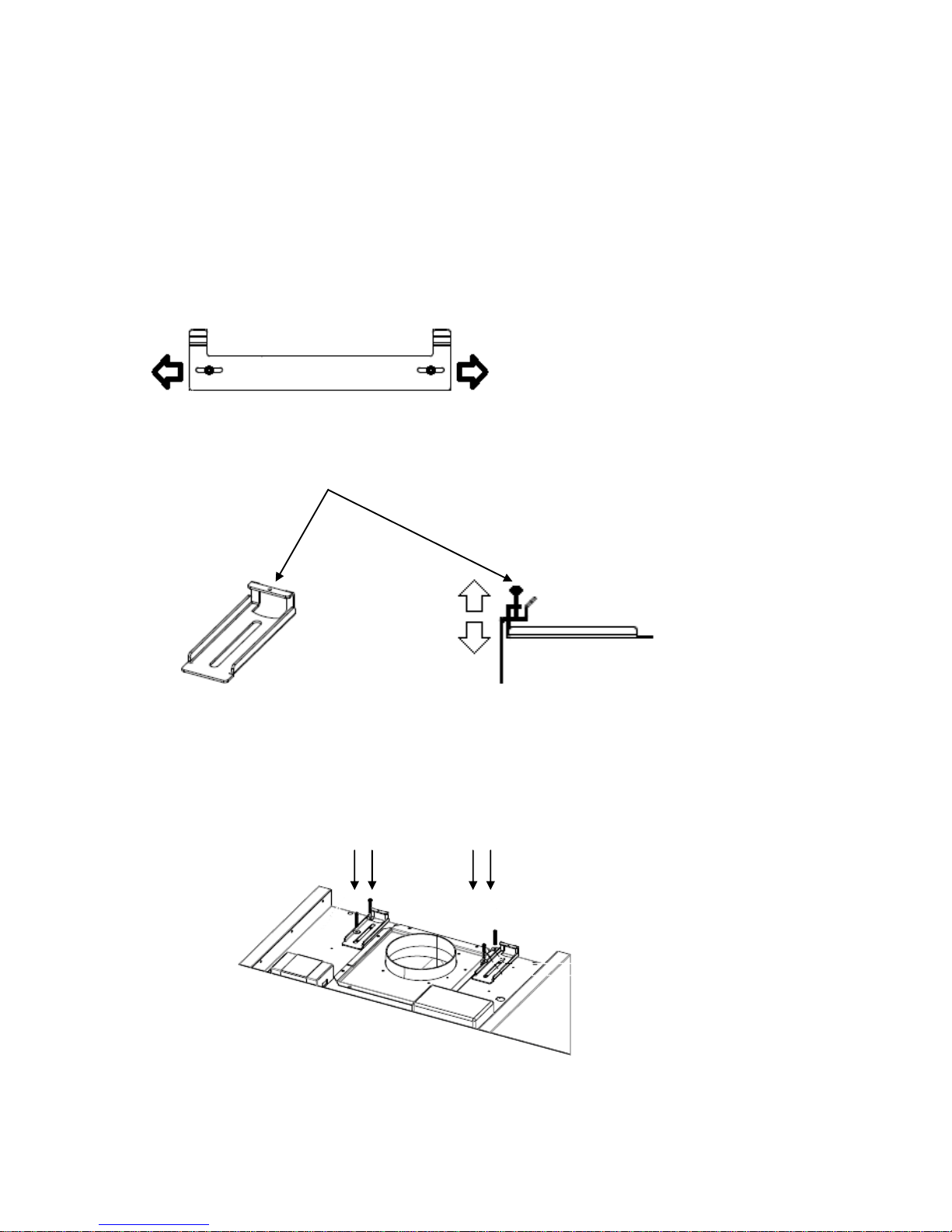

Now fasten the two mounting bars shown in Fig. 3 onto the holes that have been

provided on the top of the body / motor block of the cooker hood, on the right and left

next to the air exit of the fan motor and then hang the hood into the two clips on the

wall mounting bracket.

Fig. 3 Fig. 3.1

Fig. 4 shows the combination of the two steps for mounting the hood on the wall.

Fig. 4

30

You have several options for aligning the hood thanks to its multiaxial mounting

system.

To align the hood on the right and left hand side, you can either move the wall

mounting bracket to the left or right until it is in the ideal position by loosening the

screws and then fastening them again (if the hood needs to be moved by more than

0.5 cm) (Fig. 4.1). Or alternatively, if the hood only needs to be minimally moved, you

can hang the hood into the wall mounting bracket and then align and fasten it.

Fig. 4.1

To align the height of the hood when it has already been suspended, you will need to

unscrew and screw the two screws that go into the holes on the top clip of the

mounting bars evenly.

Fig. 4.2

If the cooker hood has not been horizontally mounted, the two screws will need to be

screwed in and out separately, until the hood is in the optimal / horizontal position.

If the cooker hood has not been mounted parallel to the wall, the clearance or

alignment of the hood to the wall can be adjusted or changed by loosening the two

fastening screws and pushing the mounting bars forwards and backwards (Fig. 4.3).

Fig. 4.3

31

To mount the chimney take the assembly clamp that has been provided (Fig. 5),

place it at the required height, generally right below the ceiling (Fig. 5) and then

fasten it. You will then need to make the connection for the extraction air and mount

the chimneys according to Fig. 5 and Fig. 5.1.

For the recirculation mode you will first of all need to follow the instructions given in

Fig. 5.2 before you mount the chimneys, also according to Fig. 5 and Fig. 5.1.

Please note:

Extraction mode: Telescopic part of the chimney with recirculation air

openings facing down

Recirculation mode: Telescopic part of the chimney with recirculation air

openings facing up

Pull the telescopic chimney (B) upwards and fasten it to the assembly clamp (C) with

the screws (do not use a battery-operated screw driver!)

Fig. 5 Fig. 5.1 Fig. 5.2

32

OPERATION

This cooker hood is regulated with touch-sensitive sensor controls located on the

front of the hood. The controls react when the corresponding symbol is touched

lightly.

You can regulate the power settings, the lamp, including the brightness level, as well

as the automatic delayed stop function with the sensor controls. A digital display

informs you about the setting that has been selected, the automatic delayed stop and

filter saturation.

Switching the cooker hood on / off

Touching this symbol will switch the cook hood on or off. When the hood is

switch on the fan will operate at power setting “2”.

Power controls

When the cooker hood is switched on, the power is controlled by pressing the

symbols “+” (to increase the power) and “-” (to reduce the power). Pressing

the symbol several times will increase or reduce the power setting from 1 – 4.

Automatic delayed stop

This cooker hood is equipped with an automatic delayed stop function which

automatically switches the hood motor off after 15 minutes. The automatic

delayed stop function should always be activated as soon as cooking has

been completed in order to remove the steam and odours that remain after

cooking. Touching the timer symbol lightly will switch on the automatic delayed

stop function. The power setting in the display will start flashing. The automatic

delayed stop function is switched off by touching the timer symbol or switching

off the cooker hood.

Switching the lamp on/off

The lamp is switched on and off by touching this symbol (LED module on / off).

Dimmer function

The display will how a horizontal bar for approx. 5 seconds without a break as

soon as this symbol is touched. When the symbol is touched again the display

will show the level of brightness. The lamp is pre-set at brightness level “9” in

the factory. Touching the “+” and “-” keys will set the brightness level of your

choice. Press the “lamp” symbol once again to save this setting.

33

Deleting the filter change display “C”

When the letter “C” is shown in the LED display, the charcoal filter will need to

be replaced (see also the section on “maintenance, cleaning and care”).

Hold the on/off key for approx. 5 seconds to reset the display. The function is

reset and the letter “C” will be deleted from the display.

IR remote control

An IR remote control (Fig. 6) is included with delivery. It can be used to

operate and regulate all the functions of the cooker hood from a distance of

several metres. To do so, point the remote control towards the cooker hood

and press the function of your choice on the remote control.

Fig. 6

On/off switch

Increase/reduce power setting

or the dimmer setting

Switch on the automatic

delayed stop function

Set the dimmer function and

switch the lamp

on and off

Timer

Dimmer

Lamp

34

Maintenance, Cleaning and Care

It is absolutely essential to have your cooker hood regularly serviced in order to

ensure that it operates efficiently for a long time. When the metal grease filter is

clogged with particles of grease and dirt it will not work properly.

The charcoal filter (only used for the circulation mode) cannot be rinsed or

regenerated and must therefore be replaced at regular intervals. You can order

replacement charcoal filters from your specialist dealer or from our spare-parts

service.

Important! Pull the mains plug out of the socket or switch of the relevant safety fuse

in the fuse box for the building when carrying out any maintenance or cleaning work.

The cooker hood may not be cleaned with a steam cleaner.

Housing

Only clean the surfaces and control elements with a sponge cloth and water as they

are very sensitive to scratches and cuts.

When you have removed the metal grease filter, clean the accessible metal surfaces

in the interior of the cooker hood. When doing so make sure that you only use a little

liquid when working on the interior of the cooker hood or when cleaning it.

Do not use any acidic cleaning agents, agents which contain solvents or abrasive

agents such as scouring powder or liquid scouring cleaner.

You can also remove and clean the insides of the two doors of model KD9970.0GE.

Use a soft cloth for cleaning. These doors are not suitable for rinsing in a dishwasher.

To remove the doors, first of all remove the two fastening screws (Fig. 7) and then

remove the inside of the door (Fig. 7.1).

Fig. 7 Fig. 7.1

35

Grease filter

To remove the grease filter press the bar rail handle of the filter down and remove

the grease filter from the hood (Fig. 8). Then remove the grease filter from the

stainless steel frame (Fig. 8.2).

To replace the grease filter, first of all replace it in the stainless steel frame and then

return it to the hood. To do so, replace the bottom of the filter in the frame of the

hood, making sure that the two bottom clips are fitted exactly into the two holes of the

filter frame (Fig. 8.1). Press the bar rail handle down until the top part of the grease

filter has been properly inserted into the filter frame and then let the frame go.

Fig. 8 Fig. 8.1

Some of the models have a metal grease filter that is covered with a removable

stainless steel grid. The metal grease filter will have to removed before you put it into

the dishwasher. To remove the stainless steel grid, press the bar rail handle down

until the two movable clips have been pulled right down (Fig. 8.2) and then press the

metal filter out of the stainless steel grid (Fig. 8.3). Now put the metal grease filter

(Fig. 8.4) into the dishwasher and clean the stainless steel grid with a soft cloth.

Fig. 8.2 Fig. 8.3 Fig. 8.4

Depending on how you cook and fry, the metal grease filters should be cleaned

approximately every two weeks.

Soak the metal grease filters and stainless steel frames well in hot soapy water,

clean them with a soft brush and then spray them thoroughly with hot water to rinse

them. Repeat the procedure if necessary.

36

The metal grease filters (not the stainless steel frames) may also be rinsed in the

dishwasher, using a standard 55 °C programme.

The metal grease filters should not be washed with dishes and glasses as grease

may be deposited on the dishes or scraps of food may collect on the metal grid.

Metal grease filters that are very clogged should be soaked well beforehand in hot

soapy water.

Please note! Make sure that the grid is not damaged when you clean the metal

grease filter. The metal surface may become discoloured as a result of frequent

cleaning or the use of aggressive detergents. This discolouration does not have any

effect on the functioning of the filter and gives no reason for complaint.

Replace the clean, dry metal grease filter in reverse order according to Fig. 8 ff.

Charcoal filter

To remove the charcoal filter (Fig. 9), pull the two front fastening clips in the filter

frame to the front. After you have removed the new charcoal filter from its packaging,

the filter should be shaken to distribute the granules evenly.

Make sure that the fastening clips on the filter point to the front when you insert the

new charcoal filter. First put the charcoal filter into the bottom of the frame and then

insert the front of the filter until it engages (Fig. 9.1).

Fig. 9 Fig. 9.1

The charcoal filter should be replaced after approximately three to six months.

The intervals for cleaning and replacement should generally be observed in order to

ensure that no greasy vapours are deposited on kitchen walls and units.

If the metal filter is not regularly cleaned when the hood is operated in the circulation

mode, the charcoal filter will also become clogged more quickly, impairing the

operation of the hood.

Loading...

Loading...