Kuppersbusch KD 9660.0GE, KDUM 9660.0GE, KD 12660.0GE, KDUM 12660.0GE Instructions For Use And Installation Instructions

227954 R31

BEDIENUNGSANWEISUNG

mit Montageanweisungen

Instructions for use and installation instructions

Instructions d'utilisation et avis de montage

Gebruiksaanwijzing en montagehandleiding

Istruzioni di uso e di montaggio

Instrucciones de uso y de montaje

Instruções de uso e de montagem

KD 9660.0GE

KDUM 9660.0GE

KD 12660.0GE

KDUM 12660.0GE

18

GB

Disposing of the packaging

Please ensure the environmentally-friendly disposal of the packaging that came with your appliance. Recycling the packaging

material saves on resources and cuts down on waste.

Disposing of old appliances

The symbol on the product or on its packaging

indicates that this product may not be treated as

household waste. Instead it must be handed

over to a collection point for the recycling of

electrical and electronic equipment.

By ensuring that this product is disposed of cor-

rectly you will help to protect the environment

and human health, which could otherwise be harmed through the

inappropriate disposal of this product. For more detailed information about recycling this product, please contact your local city

office, your household waste disposal service or the shop where

you purchased the product.

Appropriate use

The hood is intended for extracting steam above electric and gas

cookers in households. It may not be used for any other purpose

and may only be used under supervision.

For your information...

Please read this manual carefully before using your hood. It contains important information on safety and on how to use and look

after your appliance so that it will provide you with many years of

reliable service.

Should your appliance develop a fault, please first consult the

section on “What to do if trouble occurs?”. You can often rectify

minor problems yourself, without having to call in a service engineer.

Please keep this manual in a safe place and pass it on to new

owners for their information and safety.

Contents

Safety instructions................................................................. 19

Connection and operation..................................................... 19

The hood in general.............................................................. 19

Concerning persons.............................................................. 19

Appliance description............................................................ 20

Operation................................................................................ 21

Instructions for using the hood.............................................. 21

Switching on the fan and selecting a fan setting................... 21

LED lamp.............................................................................. 21

Timer (automatic switch-off).................................................. 21

Maintenance and care............................................................ 22

Why maintenance? ............................................................... 22

Maintenance cycles .............................................................. 22

Cleaning the hood................................................................. 22

Opening the hood ................................................................. 23

Cleaning the inside of the hood ............................................ 23

Cleaning the metal grease filters .......................................... 24

Replacing the charcoal filters (recirculation air

operation only)...................................................................... 24

Cancelling the saturation display (LEDs 1 and 4) ................. 24

Cancelling the saturation display (LEDs 2 and 3) ................. 24

Replacing the LED lamp....................................................... 25

What to do if trouble occurs ................................................. 26

Assembly instructions........................................................... 27

Note ...................................................................................... 27

General information on outgoing air or recirculating air........ 27

Ordering a conversion kit...................................................... 27

Safety instructions for the extraction air mode...................... 27

Tips on the outgoing air duct................................................. 28

Exhaust air pipe.................................................................... 28

Electric connection................................................................ 28

Important information ............................................................ 28

Installation ........................................................................... 29

Start of operation .................................................................. 31

Technical data ..................................................................... 31

Safety instructions

GB

19

Safety instructions

Connection and operation

• The appliances are constructed in accordance with the relevant safety regulations.

• Repairing the appliances is a job that should be left to a qualified electrician according to valid safety regulations. For your

own safety, do not allow anyone other than a qualified service

technician to install, service or repair the product.

The hood in general

• In order to avoid damage and risks as a result of improper

operation, it is essential that these instructions for use be followed and be stored in a safe place.

• Should the appliance change hands, the instruction manual

should be passed on too.

• Cooking zones should always be covered with pots or pans to

prevent the strong heat from damaging the hood.

• Open flames are not permitted, since they damage the filters

and may start a fire. This does not include the proper use of a

gas cooker, i.e. the cooking zones must always be covered

with pots or pans.

• Constant supervision is essential when deep-frying or cooking

with oil or fat under the hood. There is a risk of fire if the frying

fat overheats or ignites itself. Avoid using fat which is not clean

or is old, since it is more likely to catch alight.

• Never flambé under the hood because of the risk of fire caused

by rising flames which could ignite the fat collected in the filter.

• It is essential to ensure a sufficient supply of fresh air in the

kitchen when the hood is in operation in the extraction air

mode and heating systems requiring a chimney are in operation.

• The hood may not be used without metal grease filters since it

will then be soiled on the inside.

• The air outlets may not be covered

during recirculation air operation in order

to enable the air to escape freely.

• The hood may not be cleaned with a

steam cleaner since safety can no longer be guaranteed due

to the steam.

• Do not look into the intensive source of light for too long!

• It is absolutely essential to observe maintenance and cleaning

cycles as failure to do so results in a risk of fire as fat deposits

may ignite.

• Disconnect the hood from the mains supply whenever it is

serviced or cleaned.

• When mounting the hood, the minimum clearance to cooking

zones must be 65 cm for electric cookers and 75 cm for gas

cookers. Smaller clearances are not permissible due to the risk

of fire.

• National building regulations stipulate certain restrictions when

cooker hoods and household furnaces connected to chimneys,

such as coal stoves, oil stoves and gas hot water boilers, are

operated in the same room.

The German regulation on firing heating systems only permits

a maximum negative pressure of 0.04 bars in such rooms.

Negative pressure occurs in a closed room as soon as an

extraction air system (cooker hood) is switched on.

Suitable measures must be taken in order to ensure that there

is a sufficient supply of fresh air for operation of the cooker

hood in the extraction air mode.

• Keep packaging material such as plastic bags away from children.

Concerning persons

• This appliance is not intended to be used by persons (including children) with physical, mental or sensory impairments or

by persons (including children) who lack the required experience or know-how, unless such persons are supervised by a

person responsible for their safety or have been given instructions on how to use the appliance by a person responsible for

their safety.

Children should be supervised in order to ensure that they do

not play with the appliance.

20

Appliance description

GB

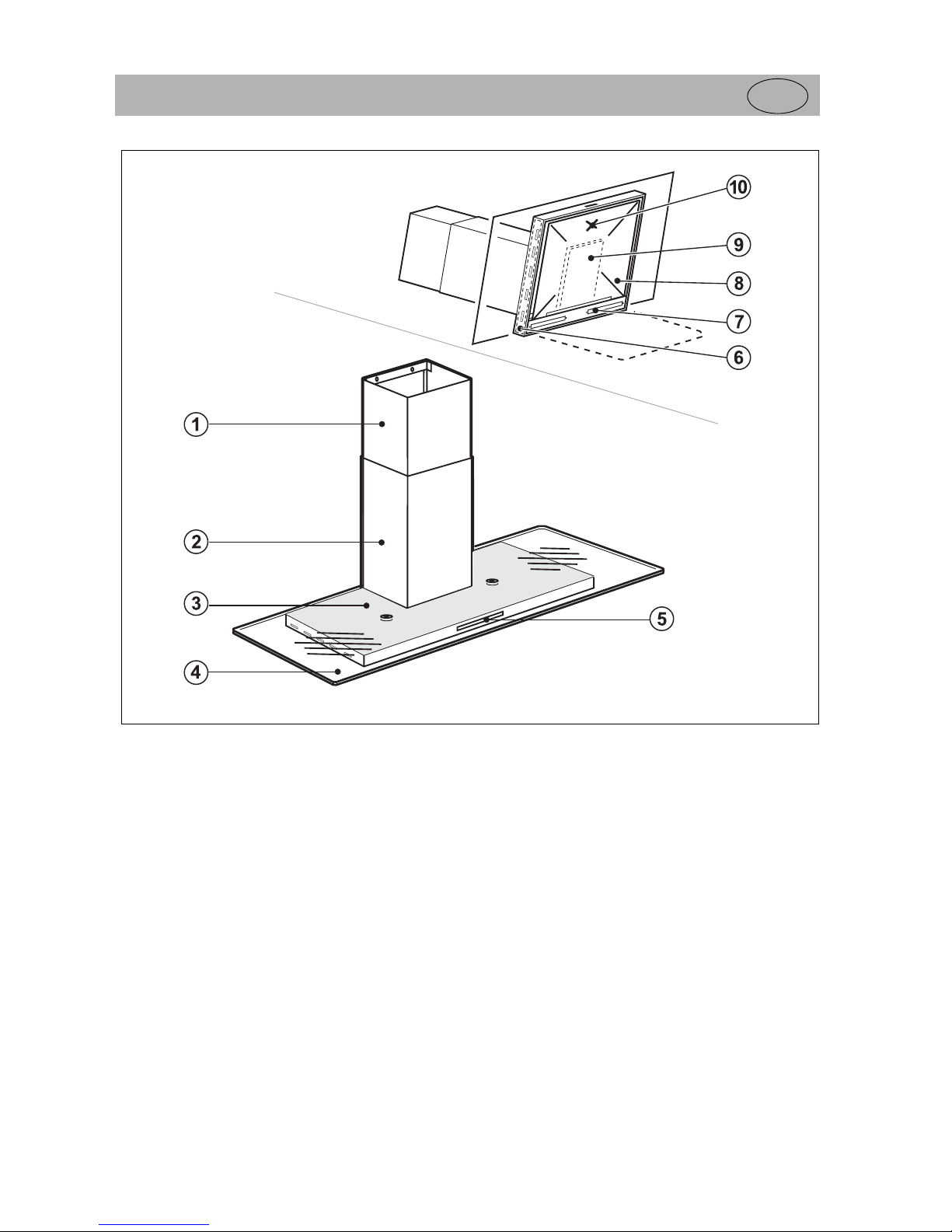

Appliance description

1. Chimney top

2. Chimney bottom

3. Canopy

4. Glass canopy (safety glass)

5. Control elements

6. Metal grease filters, both sides, 2 filters

7. LED lamp

8. Metal screen

9. Metal grease filter

10. Pressure point for opening (see p. 23)

Operation

GB

21

Operation

Instructions for using the hood

The power setting of the hood should be adapted to the occurrence of steam during cooking and frying, i.e. for little steam a

low setting should be chosen; the setting should be higher when

a lot of steam occurs.

Please ensure that the hood is switched on at the same time as

the hob so that an air current can build up. This has a positive

effect on the extraction rate. The hood should still run for a while

on completion of cooking so that remaining odours and residual

moisture can be extracted.

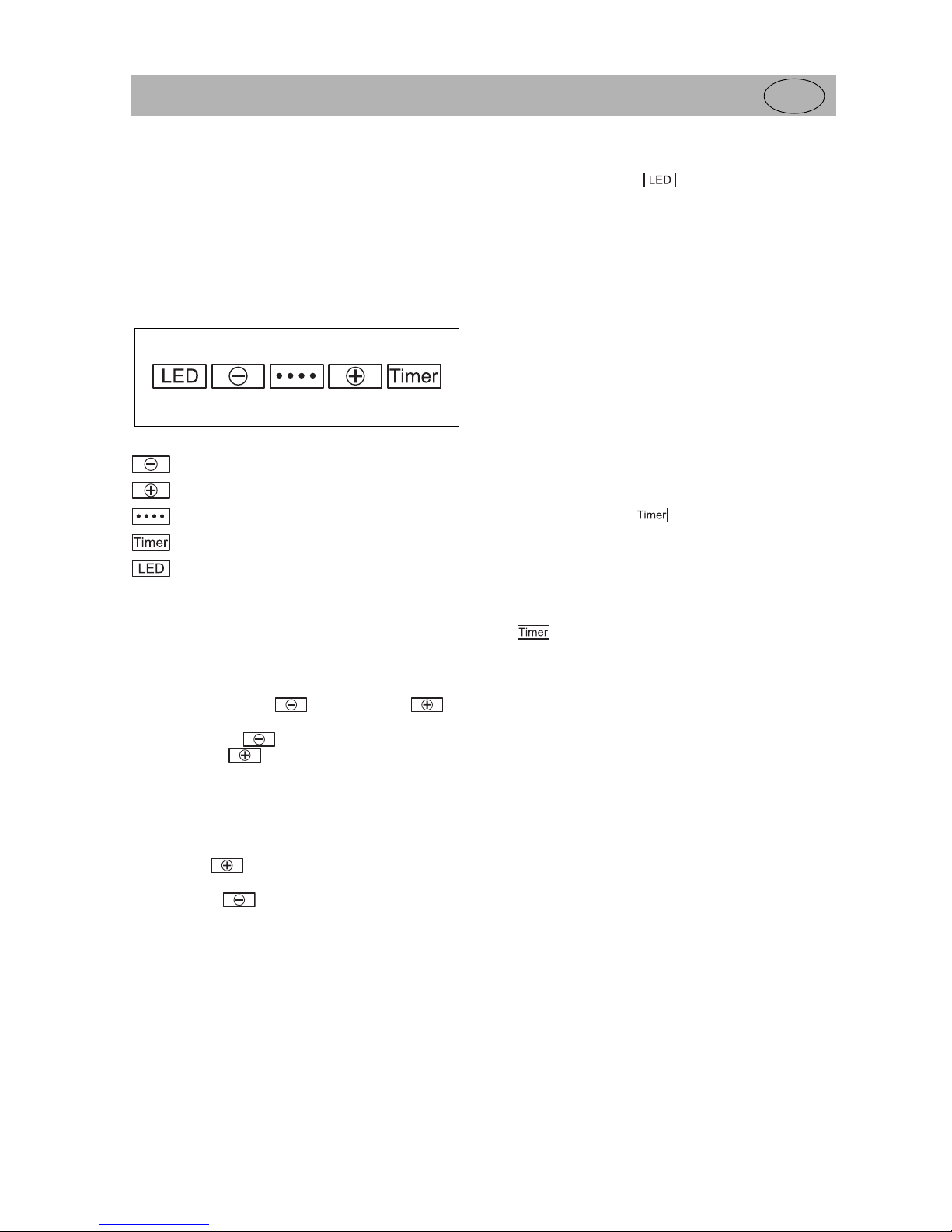

........... Minus button

(reduce the fan speed)

........... Plus button

(increase the fan speed)

........... Display

........... Timer button

........... Lamp button

Switching on the fan and selecting a

fan setting

The hood is equipped with a fan with several speed settings.

Pressing the

Minus button

or the

Plus button

will

switch the fan on.

Using the

Minus key

will immediately select fan setting 4;

using the Plus key will select the first fan setting.

The fan setting is shown by the lighting up of 4 LEDs in the dis-

play.

Switching off the fan

If the

Plus key

is pressed when the fan setting is at 4, the

hood will be switched off.

If the

Minus key

is pressed when the fan setting is at 1,

the hood will also be switched off.

LED lamp

Pressing the

Lamp button

will switch the lamp on and off.

Timer (automatic switch-off)

The hood is equipped with an automatic switch-off device which

can be used to programme switching off the hood after cooking.

Procedure

• Switch the hood on and select a fan setting from 1 – 4. The

delayed stop time depends on the fan setting selected:

Fan setting 1 - 20 min.

Fan setting 2 - 15 min.

Fan setting 3 - 10 min.

Fan setting 4 - 5 min.

•

Press the Timer key

once. The information blinks in

the display. The automatic switch-off device has been activated.

Please note:

• To deselect the programming mode, press the

Timer key

once in acknowledgement or switch the hood off manu-

ally. The display will no longer blink.

22

Maintenance and care

GB

Maintenance and care

The mains plug must be pulled out or the fuse

switched off or screwed out before maintenance or

cleaning work is carried out on the hood!

Why maintenance?

Carry out regular maintenance on your hood! Maintenance is

essential in order to ensure that the hood works properly and

effectively and that the risk of the grease filters catching alight

does not arise.

The metal grease filters should be regularly cleaned in good time

in order to ensure that they work properly and that the

performance of the hood is not impaired.

Maintenance cycles

Metal grease filter

The metal grease filter should be cleaned once a month in the

case of normal household use or alternatively whenever the

display lights up after approx. 40 hours of operation.

To cancel see the section “Saturation display”.

Charcoal filter (recirculation air operation only)

In the case of normal household use the charcoal filter can

absorb odorants for up to six months before it needs to be

replaced or alternatively, it must be replaced whenever the

display lights up after approx. 230 hours of operation.

To cancel see the section “Saturation display”.

The charcoal filter must be replaced sooner when the hood is

used more frequently and odours are not sufficiently reduced.

The metal filter should be cleaned in good time and the charcoal

filter replaced, in particular in the case of recirculation air

operation, in order to avoid undesirable deposits of greasy

vapours and condensate on kitchen units. Besides, a clogged

metal filter will no longer be able to absorb particles of fat and

these will then be unnecessarily deposited on the charcoal filter,

thus impairing the effect of the odour filter.

Cleaning the hood

The hood may only be cleaned when the mains plug

has been pulled out or the fuse switched off!

Use only a mild cleaning agent (e.g. detergent) to wipe

the outer surfaces of the hood and then dry it with a clean cloth.

No aggressive cleaning agents, scouring agents or sharp items

should be used. Stainless steel surfaces can be cleaned with a

commercially-available stainless steel cleaning agent and a soft,

non-abrasive sponge or cloth. When cleaning stainless steel

surfaces, wiping motions should always correspond with the

direction of the structure in order to avoid scratches.

Clean the glass surfaces with household glass cleaners only and

then rub the glass dry.

blink alternately

blink alternately

Maintenance and care

GB

23

Opening the hood

Disconnect the hood from the mains or switch off

the fuse!

Opening the metal screen

•

Press

in the middle of the metal screen, around 30 mm from

the front edge. The lock is released (soft

CLICK

).

Magnets will keep the metal screen in a horizontal position.

• To open put your hand into the edge suction from the side and

gently pull the metal screen so that it swings open.

Closing the metal screen

• Swing the metal screen upwards until the magnets hold it in a

horizontal position.

• Then press onto the same point used for removing the metal

screen so that the lock engages again (soft

CLICK

).

To ensure that the metal screen has engaged properly, put

your hand into the edge suction from the side and pull gently;

the metal screen must remain at the top.

Removing the metal screen

The metal screen can be removed to clean it. It must hang

downwards to remove it; the hood is open.

Caution – it could fall onto the hob, so please hold it firmly!

Protect the hob located below the hood with a thick blanket!

• To remove the metal screen, hold it and press the bolt on the

bearing inwards; this will release the metal screen on one side.

It can then easily be removed on the other side.

• Proceed in reverse order to replace the metal screen.

Cleaning the inside of the hood

Pull out the power plug or disconnect the fuse!

The metal screen must be removed for cleaning pur-

poses!

Deposits on easily accessible areas on the inside of the hood can

be wiped away carefully with a damp cloth and some detergent.

Please always work carefully as there is a risk of sharp

edges causing injury.

Clean the outer surface of the motor as well.

Ensure that no moisture gets into electrical parts.

Metal screen

press bolt

24

Maintenance and care

GB

Cleaning the metal grease filters

Disconnect the hood from the mains or switch off

the fuse!

Make sure that the grid is not damaged when you

clean the metal grease filter. Frequent cleaning may cause

the colour of the metal to change; this will not affect the

functioning of the filter.

Removing / installing metal grease filter (a)

The metal grease filter is located behind the metal screen and

can only be accessed when the hood is open.

• To remove the metal grease filter, disengage it on the bar rail

handle and remove it from its installation frame.

• Proceed in reverse order to replace the filter.

Removing / installing metal grease filters (b)

The two metal grease filters (b) are located on the left and right

inside the canopy.

• To remove the metal grease filter, first of all hold the back pin

and guide it along the side past the hinge. Then remove the

metal grease filter.

• To install the filter, proceed in reverse order, i.e. first of all

insert it in the frame at the front and then guide it along the

side next to the hinge. Finally press the metal grease filter

securely into the frame.

Cleaning by hand

• Soak the metal filter well in hot water with a detergent and then

rinse it off with hot water. Repeat the procedure if necessary,

depending on how greasy it is.

Rinsing in a dishwasher

• Lay the metal grease filter down flat in the dishwasher so that it

can be optimally cleaned. An intensive programme, at 65°C if

possible, should be selected in order to fully remove deposits

of fat.

Restore the mains power supply.

Replacing the charcoal filters

(recirculation air operation only)

The charcoal filter is located directly

behind the metal grease filter. The

metal grease filter will need to be

removed in order to replace the

charcoal filter.

• Put the charcoal filter onto the

inside of the metal grease filter.

• Clamp the fastening clamp on the

one side (1).

Then bend the two middle rods

slightly by hand (2) and clamp

them on the other side (3).

Also clamp the two individual rods

(4).

Proceed in reverse order to remove.

Cancelling the saturation display

(LEDs 1 and 4)

(metal grease filter)

After approx. 40 hours of operation LEDs 1 and 4 will blink

alternately for a few seconds when the hood is switched on.

The metal grease filter needs to be cleaned.

Pressing the

Minus button

and the

Plus button

simultaneously will clear the counter of the saturation display.

Cancelling the saturation display

(LEDs 2 and 3)

Charcoal filter (only present for recirculation air

operation)

After approx. 230 hours of operation LEDs 2 and 3 will blink

alternately for a few seconds when the hood is switched on.

The charcoal filter (recirculation air operation only) needs to be

replaced.

This saturation display is not significant for the

extraction mode.

Pressing the

Minus button

and the

Plus button

simultaneously will clear the counter of the saturation display.

Metal grease filters (b)

Metal grease filter (a)

Pin

Hinge

blink alternately

blink alternately

Maintenance and care

GB

25

Replacing the LED lamp

Disconnect the hood from the mains or switch off

the fuse before replacing the lamp.

Do not look into the intensive light source (LED) for

any length of time!

Only an original LED strip may be installed; these are only

available from Customer Service.

Recommendations

• Protect the hob located below the hood with a thick blanket!

• Please touch an earthed metal object (e.g. a heating element)

in order to prevent electrostatic charging.

Procedure

• Open the metal screen and remove it (see previous section)

• Remove the screws with a screw driver. Remove the coloured

plugs. This can be done carefully with your finger nail or a

kitchen knife.

• The light covering (plastic) and the metal screen will come lose

right across.

Caution – it could fall onto the hob, so please hold it

firmly!

• Remove the metal grease filter (possibly with the charcoal

filter). The plug contacts for the LED strip will be accessible.

Remove the plug contact.

• Remove the coloured plugs. This can be done carefully with

your finger nail or a kitchen knife.

The LED strip can be removed.

• Install the new LED strip in reverse order.

• Restore the mains power supply.

Metal screen

LED strip

Plugs

Screws

Metal grease filter

Plug contact

plugs

LED strip

26

What to do if trouble occurs

GB

What to do if trouble occurs

Interference with and repairs to the hood by

unqualified persons are dangerous as they can

result in electric shock, or short circuit. Do not

interfere with or try to repair the appliance; this

could cause injury to persons and damage to the appliance.

Therefore always have such work done by a qualified electrician, e.g. Customer Service.

Below are some tips for rectifying faults yourself.

The hood does not function at all.

• Is the plug in the socket?

• Has the fuse for the domestic wiring system tripped?

Has the hood developed a malfunction.

• Switch the hood off with the buttons and disconnect it from the

mains for a few seconds by removing the plug or switching off

the fuse.

The suction power is not strong enough.

• Has the right fan speed been set?

• Has the metal grease filter been cleaned?

• Was the charcoal filter replaced in good time?

• Is the air removed from the kitched replaced with a sufficient

supply of fresh air so that no negative pressure develops?

• Are the air outlets blocked?

• During installation, was the outlet air duct miscalculated or not

properly installed? (e.g. diameter too small, exhaust air pipe

too long or exhaust air duct too angled)?

The hood is suddenly much noisier during

operation.

• Does sufficient fresh air flow into the kitchen when the extraction air mode is operated?

Have operation noises become louder with time.

• Have the maintenance cycles of the filters been observed to

allow air to get in at all?

The LED lamp does not work.

• Has the fuse for the domestic wiring system tripped?

• Was the new LED lighting properly connected to the power

supply (plug connection)?

When the hood is switched on, two LEDs will

blink alternately for a few seconds (saturation

display).

Please clean the metal grease filter or replace the charcoal filter.

Pressing the

Minus button

and the

Plus button

simultaneously will clear the counter of the saturation display.

Assembly instructions

GB

27

Assembly instructions

Note

KÜPPERSBUSCH cooker hoods may only be built-in in

accordance with the instructions included in this manual. In

the case of failure to observe these instructions,

KÜPPERSBUSCH shall decline any liability and the

approved marks of conformity will become invalid!

General information on outgoing air

or recirculating air

The chimney hood may be operated in the recirculating air mode

or the extraction mode, depending on the model.

In the

recirculating air mode

air above the hob is extracted,

cleaned and returned to the kitchen. The polluted air is cleaned

by the metal grease filter, which absorbs residual fat, and the

charcoal filter, which filters out odorants.

In the

extraction mode,

residual fat is cleaned from the air which

has been extracted and lead outside through the exhaust air

pipe. The recirculating air mode should in principle only be used

when no air duct or outer wall is available.

Ordering a conversion kit

Please contact the Küppersbusch Customer Service to order a

conversion kit for the respective other operation mode.

You will find the address on page 2.

Safety instructions for the

extraction air mode

Operating the hood in the extraction air mode in

kitchens with household furnaces requiring a

chimney:

National building regulations stipulate certain restrictions when

cooker hoods and household furnaces connected to chimneys,

such as coal stoves, oil stoves and gas hot water boilers, are

operated in the same room.

The German regulation on firing heating systems only permits a

maximum negative pressure of 0.04 bars in such rooms. Negative pressure occurs in a closed room as soon as an extraction

air system (cooker hood) is switched on. Pressure may only be

equalised with an inflow of fresh air from outside and not by

means of the household furnace. It must be ensured that no carbon monoxide is extracted from the heating source.

Suitable measures must be taken in order to ensure that there is

a sufficient supply of fresh air for operation of the cooker hood in

the extraction air mode. A wall box ensures that fresh air flows

into the room.

When making an assessment, the entire ventilation system of the

home must be taken into consideration, since an insufficient

inflow of fresh air may cause exhaust gases from the household

furnace to flow into the home.

Your regional master chimney sweeper will give you relevant

information.

Operating the hood in the extraction air mode in

kitchens with no household furnace requiring a

chimney:

In rooms with no household furnace the rule is that the air inlets

must be at least as big as the air outlets in order to avoid impairing the functioning of the cooker hood. You can, for example,

leave the kitchen window ajar when the hood is in operation.

Connecting the hood to a chimney or a duct:

The hood may not be connected to:

- a smoke or exhaust gas flue which is in operation

- a shaft used for ventilating rooms with a household furnace.

Approval must also be granted by the regional master chimney

sweeper when the hood is to be connected to smoke or exhaust

gas flues which are not in operation!

Safety instructions on minimum clearances

For reasons of safety, the minimum

clearance between hobs and hoods

is

• 65 cm for electric cookers

• 75 cm for gas cookers

These clearances should not be significantly exceeded since the hood

output has been adapted accordingly.

Clearance

28

Assembly instructions

GB

Tips on the outgoing air duct

Only suitable materials which are as flame resistant as possible

may be used for connecting the hood with an extraction air system (e.g round pipe, square system, flexible aluminium hose,

etc.). The extraction rate of the hood also depends to a large

extent on the type, guide and length of the extraction air system.

The extraction rate will be optimal when resistance to the air flow

is maintained at a low level with the following properties:

• Smooth inner surfaces of the pipes

• Pipe diameters as large as possible

• Large pipe bends instead of narrow pointed bends

• Exhaust air pipes as short as possible (max. 5 m)

• As straight as possible instead of many changes in direction

• Avoiding reductions in cross-sections (e.g. connecting pieces)

or changes in the shape of cross sections (e.g. round - flat)

Serious deviations from the properties indicated may result in

drastic reductions in output.

Exhaust air pipe

The extraction air connection piece has an external diameter of

150 mm and the reducer (if included in the scope of delivery) is

125 mm in diameter.

No wider or narrower pipe diameters may be used as they are

unsuitable.

When laying the exhaust air pipe, it is essential to make sure that

all the connection points and transitions between pipe sections

are fitted tightly and are waterproof. This will prevent the used

exhaust air from escaping unintentionally.

Electric connection

The hood is fitted with a mains cable and a plug and can be connected to any shockproof socket supplying 230 volts of alternating current, 50 Hz which has been installed in accordance with

regulations.

If the mains cable of this appliance is damaged it will need to be

replaced with a special connection cable. In order to avoid any

risks, this must be carried out by the manufacturer or his Customer Service.

The shockproof socket must be accessible.

If, after installation of the hood, the shockproof socket or the

mains plug are no longer accessible behind the chimney cover,

an additional two-pole isolator must be installed to enable the

hood to be cut off from the power supply.

A qualified electrician must install an isolator in accordance with

EN 60664-1 overvoltage category III.

Important:

Permanent installations are always to be carried out by an

authorised electrician in accordance with currently valid regulations!

Important information

• Before installating the hood, please check to ensure that the

material for mounting (screws, dowels, etc.) is suitable for your

wall or ceiling.

• When drilling holes for dowels make sure that lines running in

the walls (electricity, gas and water) are not damaged.

• Switch off the safety fuse in the fuse box for the main socket so

that no injuries can result during installation.

Assembly instructions

GB

29

Installation

Mount the body of the hood at the required height in the centre

above the hob. Use the holder, screws and dowels supplied.

Insert a locking screw into the dowel. The hole for the locking

screw can be accessed from the inside of the hood. To access

the hole, open the metal screen and remove the grease filter. It is

located in the middle above the cross section on the back.

Use the M5x20 screws supplied to adjust the body of the hood

into a horizontal position.

Install the mounting bracket (1) for the top part of the chimney

underneath the ceiling with screws and dowels.

Install the mounting bracket (2) for the bottom part of the chimney

with screws and dowels.

Make the connection for extraction air (see the previous section).

Switch the safety fuse in the fuse box off and put in the mains

plug (if present) or make an electrical connection.

2

1

Dowel 6 mm

Dowel 6 mm

Dowel 8 mm

Dowel 8 mm

Locking screw

2

1

30

Assembly instructions

GB

Mount the air deflecting box and the mounting bracket (1) for the

top part of the shaft. Insert a pipe connection between the hood

and the air deflecting box (not included in delivery).

Install the two parts of the chimney that have been put together

onto the body of the hood.

Here the longer bottom chimney part is hung up onto the mounting bracket (2). Pressing it down a little will engage it properly into

the groove of the hood body.

Pull the top part of the chimney upwards until it reaches the ceiling.

Fasten the top chimney part with screws.

1

Recirculating air mode only

2

Assembly instructions

GB

31

Do not replace the glass canopy until the hood and the chimney

have been completely installed.

Fasten the glass canopy with screws. Do not use a battery-operated screw driver!

Start of operation

After installing the hood, check the functions (lighting and fan).

Technical data

KD 9660.0GE

KDUM 9660.0GE

Dimensions

Height/ Width/ Depth . . . . . . . mm 650 - 1000 x 900 x 520

Extraction air connection piece

Outer diameter. . . . . . . . . . . . mm 150

Weight

approx. . . . . . . . . . . . . . . . . . . kg 32

Electrical connection

2 lamps . . . . . . . . . . . . . . . . . . W

Motor . . . . . . . . . . . . . . . . . . . . W

230 V, 50Hz

4.5

75 - 195

Fan nominal output

. . . . . . m3/h 755

Hood maximum

extraction rate

. . . . . . . . . . m3/h 257 - 629

Max. noise

. . . . . . . . . . . . db (A) 48

KD 12660.0GE

KDUM 12660.0GE

Dimensions

Height/ Width/ Depth . . . . . . . mm 650 - 1000 x 1200 x 520

Extraction air connection piece

Outer diameter. . . . . . . . . . . . mm 150

Weight

approx. . . . . . . . . . . . . . . . . . . kg 39

Electrical connection

2 lamps . . . . . . . . . . . . . . . . . . W

Motor . . . . . . . . . . . . . . . . . . . . W

230 V, 50Hz

5.4

75 - 195

Fan nominal output

. . . . . . m3/h 755

Hood maximum

extraction rate

. . . . . . . . . . m3/h 257 - 629

Max. noise

. . . . . . . . . . . . db (A) 48

© Teka Küchentechnik GmbH

März 2010

Loading...

Loading...