SCAN-650

Scanning Sonar

OPERATION MANUAL

JW FISHERS MFG INC

rev 811

JW FISHERS MFG INC

1953 COUNTY ST.

E. TAUNTON, MA 02718 USA

(508) 822-7330; (800) 822-4744; FAX (508) 880-8949

Email: jwfishers@aol.com WEB: www.jwfishers.com

1

SCAN-650

Scanning Sonar

OPERATION

AND

MAINTENANCE

MANUAL

Surface Sonar Processor Included

(508) 822-7330; (800) 822-4744; FAX (508) 880-8949

Email: jwfishers@aol.com WEB: www.jwfishers.com

2

JW FISHERS MFG INC

1953 COUNTY ST.

E. TAUNTON, MA 02718 USA

TABLE OF CONTENTS

• CAUTIONS............................................................................................................. 4

• SPECIFICATIONS AND OPTIONS........................................................................ 5

• MINIMUM SYSTEM REQUIREMENTS................................................................. 6

• INTRODUCTION.................................................................................................... 7

• SYSTEM COMPONENTS ..................................................................................... 9

• THEORY OF OPERATION .................................................................................. 11

• OPERATOR SWITCHES AND CONTROLS ....................................................... 16

• INSTALLING HARDWARE AND SOFTWARE .................................................... 27

• CABLING THE SYSTEM ..................................................................................... 31

• ATTACHING TO ROV .......................................................................................... 32

• OPERATION ........................................................................................................ 35

• SAMPLE PLAYBACK ........................................................................................... 36

• SAMPLE RECORDING ....................................................................................... 37

• FAQs .................................................................................................................... 39

• TROUBLESHOOTING......................................................................................... 4 1

• APPENDIX A (configuring GPS) .......................................................................... 44

• APPENDIX B (USB to Serial Adaptor) ................................................................. 45

• MAINTENANCE................................................................................................... 47

• WARRANTY......................................................................................................... 47

3

CAUTIONS:

• Do not allow the SCAN-650 to be exposed to excessive heat by leaving it in direct

sunlight or inside of a closed vehicle on a hot day. Excessive heat can buildup

inside the housing which can damage the electronics and/or destroy the waterproof

seals.

• Take special care of the black flexible boot located on the top of the scanning head.

The black flexible boot is an acoustic window that should be keep clean (soap and

water) and protected from damage.

• Do not remove the (6) screws that hold the black flexible boot in place on the scanning head in-place. The scanning head contains a liquid that will drain out if the

screws are loosened.

• Do not remove the black hex head bolt on the scanning head (this is only on the 2

piece SCAN-650).

• When mounting the scanning head, be sure the arrow on top of the scanning head is

pointing forward, this will be the top of the screen on the PC.

4

SPECIFICATIONS

PERFORMANCE/DESCRIPTION:

• Frequency............................................................................................................ 650 kHz.

• Beamwidth - horizontal x vertical .......................................................... 2.4 deg by 40 deg.

• Ranges: ........................................................................................ 5, 10, 20, 40, 60 meters

. .................................................................................................. 16.5, 33, 66,132,198 feet

• Max depth ............................................................................................... 300 m / 1,000 ft .

• Input voltage

- Sonar Processor .......................................................... 9-12 vdc or 120/220 vac (5 watt).

- Scanning Head................................................ from Sonar Processor or 9-36 from ROV.

• Cable ..................................................................................................... 2 or 4 conductor.

DIMENSIONS/WEIGHT:

• Sonar Processor..................................... 8”Wx9"Dx2.5"H ......................... 2 lbs / 0.9 Kg.

650A:

• Scanning Head and housing ................... 3.5"Dia x 10.5"L ................. 3.6 lbs 1.6 Kg (air).

............................. 0 lbs / 0 Kg (water).

650B:

• Scanning Head ......................................... 3.5"Dia x 4"L ................... 1.4 lbs / .6 Kg. (air).

.......... .375 lbs / .17 Kg. (water).

• Housing ..................................................... 3.5”Dia x 9"L ..................... 2.8 lbs 1.2 Kg (air).

..................... 0 lbs / 0 Kg (water).

Note:

If 180° sweep, cut times in half; if 90° sweep, cut times by four, etc.

• up to 600 meters / 2,000 feet of cable

• Carrying case

OPTIONS

5

SCAN-650 MINIMUM SYSTEM REQUIREMENTS

CPU: Intel or AMD. 500MHz

System memory: 64 Mb RAM

(Faster CPU and more RAM will allow faster scanning)

One available USB port

Windows 98 or later

15 Mb of free disk space for program installation

Disk space for file recording:

5 Meter Range

.5 deg step ............... 52 meg/hr ............ 13 hrs/CD, 90 hrs/DVD

2 deg step ................ 30 meg/hr ............ 23 hrs/CD, 200 hrs/DVD

10 Meter Range

.5 deg step ............... 27 meg/hr ............ 25 hrs/CD, 170 hrs/DVD

2 deg step ................ 17 meg/hr ............ 39 hrs/CD, 270 hrs/DVD

60 Meter Range

.5 deg step ............... 14 meg/hr ............ 50 hrs/CD,345 hr/DVD

2 deg step ................ 11.5 meg/hr ......... 60 hr/CD, 400 hr/DVD

Video Card capable of:

16 bit color

Screen Area of 800 x 600 pixels (minimum)

Optional:

CD or DVD burner for archiving files

Note: For the fastest scanning capability, shut down all other programs (including

virus scan).

6

INTRODUCTION

The SCAN-650 is a high performance imaging sonar system available in two different package

configurations which enables it be used on large or small ROVs. It can also be pole-mounted and

used from a small boat in shallow water.

The SCAN-650A configuration is used with

larger ROVs, or when the main application is

boat deploying the unit on a pole (see photo next page).

The black scanning head is connected permanently to

the electronics module. A cable (not shown) comes out

of the bottom of the electronics module and connects

to the Sonar Processor.

The SCAN-650B configuration is used with

smaller ROVs. The black scanning head is mounted

to the front of the ROV and a short cable connects the

head to the electronics module which is mounted on the

side or under the ROV. Cabling options include a hardwired

version where a cable comes out of the bottom of the of the

electronics module and connects directly to the Sonar Processor or a set of short wires equipped with under water connectors and a hull penetrator. This option allows the wiring from

the scanning head to enter the ROV. The scannin head can

draw power from the ROV and utilize (2) spare wires in the ROV

umbilical cable for communication with the Sonar Processor.

The Sonar Processor is located in the boat and

allows fine tuning of the signal from the electronics

module prior to being displayed and recorded on

the PC display. It is used with both of the above

models. The Sonar Processor also includes an

interface for a GPS receiver.

7

Mounting the scanning

3

3

4

4

head on a pole allows

it to be deployed from

a boat in shallow

water .

23

23

SCAN-650

When operating in shallow water, the

scanning head can taped or clamped to

a pole and deployed over the side of a

boat or off a dock. Pole must be held very

steady (and no waves if deployed from a

boat) to insure a clear picture. If the surface conditions are too rough, the scanning head can be attached to a tripod and

lowered to the bottom (2’ off bottom for

small targets) to provide clear images.

There are times when it is advantages to

deploy the scanning head inverted (upside down). This might occur when deploying on a pole. The software allows

inverted scanning (see “Settings” Menu

pg 18 .)

Pole

SCAN-650

2

2

Transducer (black end) is

positioned downward when

operating with a pole. Be

sure transducer is below

bottom of pole (so pole

does not interfere with

signal).

Tripod deployment

The target below is a pickup truck (note large

black shadow) located in 18 feet of water. The

scanning head was mounted on a pole which

was deployed from a small boat (see top photo).

The most common application is mounting the scanning head

on an ROV. The ROV can rest on the bottom or hover just off the

bottom and the sonar scans 360 degrees looking for targets.

SCAN-650 scanning head

mounted on Fishers SeaLion

ROV.

8

SYSTEM COMPONENTS

5

5

Signals from the scanning head travel up the cable to the Sonar Processor on the surface. The

signals are processed and sent to the PC where the signal is displayed and recorded. The boat’s GPS

receiver can also be connected to the Sonar Processor. If connected, the boat’s Latitude and

Longitude will be displayed and recorded by the PC.

Transducer Head and

Electronics

234

234

cable to surface

Sonar

Processor

PC (customer supplied)

USB Port

Boat’s

GPS

The Sonar Processor connect to any available USB port on the PC. (Note: It is best to use the

same physical USB port every time you operate)

The Sonar Processor can be powered by 9 - 12 vdc. A 120/220 vac to 12 vdc wall transformer is

supplied to power the system from a 120/220 ac voltage supply . A cable with battery clips is

supplied to power the sonar from a 12 volt battery .

Wall Transformer

Cable for 12 v battery

9

LEFT

BLANK

10

THEORY OF OPERATION

SONAR BASICS

Sonar is the bouncing of an acoustic signal off a target and then measuring the time it takes to

return - thus giving us distance, and measuring the size or amplitude of the returned signal - thus

giving us hardness of the target. Since the speed of sound in water is known (1500 meters per

second), it is easy to determine the distance to a target by simply measuring the time it takes to

make the round-trip and dividing by two. If we examine the size of the returned signal (amplitude),

we can determine if the sonar signal hit a soft object (mud bottom) or a hard object (rocky bottom).

The muddy bottom will absorb much of the signal with very little signal (echo) being returned. The

rocky bottom produces a large echo which is called a hard return.

The acoustic signal is produced by a transducer. In operation, the transmitter generates an

electrical pulse which is applied to the transducer . The transducer converts this pulse to a mechanical vibration which produces an oscillating pressure wave in the water thus forming a sound pulse.

The pulse then travels away from the transducer until it strikes an object at which point some portion

of the pulse is reflected back to the transducer as an echo.

When the echo returns to the transducer , the transducer is mechanically excited by the sound

pressure and converts the vibration into an electrical signal. This signal is then detected and amplified by the receiver.

The control/display unit regulates the precise timing between the transmitters, receiver and display elements.

DEPTH SOUNDER

Depth sounders are a simple form of sonar. They send out a conical shape energy pulse toward

the bottom, listen for the return, calculate the time it took, and displays the answer in feet (of depth).

If your depth sounder has a display or a printout, a line will be drawn representing the bottom. Because the beam is so wide (15 to 30 deg), the beam will be on the object for a long time as you pass

over it. As a result, even smaller objects appear to be quite large on the printout. Fish show up as

large arcs on the display. Depth sounders typical operate at a frequency of between 50kHz and

200kHz. Good for long range but not for detecting small targets

SCANNING SONAR

Scanning sonar refines the process by decreasing the beam width to a very narrow 2 deg (2 deg

by 40 deg fan shaped beam) and dramatically increasing the frequency of the signal (typically 600kHz

range). The very narrow fan shaped beam and high frequency dramatically improves the detail of the

objects on the bottom. The fact that scanning sonar sweeps the beam back and forth across the

bottom gives a major improvement over the depth sounder printout for bottom detail. Not only can

very small targets be detected but the details of the target can be seen.

Signal

SCAN-650

SCAN-650

Signal

Side View (fan shaped signal)

T op View (very narrow signal)

11

THEORY OF OPERATION (continued)

The JW Fishers SCAN-650 scanning sonar operates by transmitting a short, high energy,

narrow width acoustic wave. This high energy acoustic wave hits directly below the transducer

Fish

Transducer

first (as shown below)

100 m Range Switch

25 meter range

100 m

Target #2

3 meters

10 m

Acoustic Wave

Target #1

As the pulse continues to sweep across the bottom, away from the transducer, echoes

continuously return to the transducer (see below). The returning echos strike the transducer

which produce the return electrical signals.

Fish

Transducer

100 m Range Switch

A look at returning echoes

Hard Return

No Return Echos (Shadow)

#1

3 meters

10m

Returning Echos

Light Return

Medium Return

25 meter range

100 m

Acoustic

Wave

Hard Return

#2

The harder the object (rocks, metal, etc ), the larger the returned echo. The angle of the

bottom surface and target angles also impact the amplitude of the return signal. The left

side of target #1 and #2 will produce a larger (harder) return echo than the top area. When

the acoustic wave hits the top of the target, some of the echo is reflected away from the

fish. When the bottom slopes away and down from the fish, only light echo’s return from the

bottom. When the bottom slopes upward, medium echo returns are received. If a hard

target is positioned on a down or on a up-sloping bottom, a hard return will result from the

target. If a target is up “off the bottom”, as is target #1 and #2, then there will be an area

directly behind the target that will be blocked from the acoustic wave. No echo returns will

be received from that area by the fish. When displaying this area, the display will show a no

signal color . This area on the display is called the target’s “shadow”.

The return electrical signals are amplified by the preamp and sent up the cable to be

processed by the “time variable gain” (TVG) circuit in the Sonar Processor . (Refer to

page 15 for a more details on the TVG circuit.)

12

THEORY OF OPERATION (continued)

After the return signals are processed by the TVG, the Sonar Processor takes evenly spaced

samples of the echo returns which are processed and displayed on the PC screen as a very narrow

sector that changes color along it’s length depending on the intensity of the reflected signal.The

amplitude of the returned echo samples, during one line, determines the color for each point along

the line. The larger the amplitude of the return, the greater the change of color on the display. Every

one pulse out of the transducer fills one “degrees per step” sector.

0 deg

Screen

View

Single line displayed

270 deg

on the screen.

The width of this

sector is determined

by the “Degrees per

Step” setting.

SCAN-650

90 deg

Continuous 360 degree

180 deg

sweep or any portion of

360 degrees.

After the line is displayed, the transducer head (scanning head) rotates (steps) slightly to the right

and the sequence is repeated. The smaller the step (1/2, 1, 1 1/2, or 2 degree) the higher the resolution

of the picture. The transducer’s continuous stepping fills the display with the sonar image. The

sequence is repeated, and if nothing moves (targets or sonar), then the identical picture will be

overlaid over the previous picture (one line at a time). If a 360 degree continuous sweep is selected,

at 1 degree steps, then 360 steps will make up a complete picture (720 steps for 1/2 degree).

13

TIME VARIABLE GAIN (TVG)

The Sonar Processor contains a TVG circuit on the PC board that receives the echo signals from the

fish preamplifier boards. The TVG circuit amplifies and makes time variable gain adjustments to the

signal to make up for signal losses

which occur when the echoes are traveling through the water; the greater the range, the greater the

losses. TheTVG circuit has its own set of operator controls which are located of the Sonar Processor’s

top panel. The controls are NEAR GAIN, FAR GAIN, and OVERALL GAIN.

The signal return (Fig 2) to the Sonar Processor is the signal that we would expect to see at the output

of the fish preamps. The amplitude of the signal that reaches the Computer determines the color of

the image. If the TVG circuit did not modify the signal shown below (Fig 2), then the display would start

out good, but the bottom return would quickly turn to a color indicating no return. If the return from target

#2 was real strong, it might "pop out" of the light background and print a light image.

Fish

Transducer

Fig 1

Acoustic Wave

100 m Range Switch

Target #1

3 meters

10 m

25 meter range

100 m

A

m

p

l

i

t

u

d

e

Transmit pulse

#1

Fig 2

Signal to Sonar Processor

before TVG

Shadow

8"

Target #2

#2

Shadow

Next transmit pulse

The signal (Fig 2 ) feeds the input of the TVG amp. The TVG amp has been adjusted, by the operator,

to automatically increase the gain over time. The next drawing below (Fig 3) shows the gain increase

(called the ramp). The last drawing below (fig 4)shows the output of the TVG amp with the “ramp”

applied to the input. When this signal is displayed, there will be a even color across the paper with two

light colors representing the two targets.

G

a

i

Low Gain

n

A

m

p

l

i

t

u

d

e

#1 #2

Fig 3

Fig 4

Shadow

High Gain

Next transmit pulseTransmit pulse

Signal with TVG ”ramp” applied

Shadow

Next transmit pulseTransmit pulse

14

The TVG amplifier has three operator controls. They are located on the top panel of the Sonar

Processor. Recommended settings for the TVG controls are provided in the Operation Section of this

manual. Final TVG adjustments are made by the operator while the unit is running. The function of these

controls is to adjust the amplifiers to compensate for losses that occur when the signal travels through

the water. When they are adjusted properly, a reasonably even color is displayed across the screen

during side scanning. The even color is the result of reflections off the bottom.

LEFT CHANNEL GAIN

TVG ADJUSTMENTS

546

7

3

8

546

7

3

8

546

7

3

8

2

1

OVERALL GAIN

NEAR GAIN FAR GAIN OVERALL GAIN

9

10

2

1

FAR GAIN

9

10

2

1

NEAR GAIN

9

10

Near Gain - Adjusts the TVG gain at the start of the sweep (objects close to the scanning head).

Far Gain - Adjusts the TVG gain at the finish (objects furthest from the scanning head). Operator

adjusts for even color of the displayed line.

Overall Gain - Adjusts the gain of the complete line up or down. It adjusts overall darkness or lightness.

Near

A

Gain

m

p

l

i

t

u

d

e

Overall gain adjusts the overall amplitude

of the signal (increases or decreases it).

Overall Gain Increases Or

Decreases The Overall Gain

(Amplitude) Of The Complete Line

Far

Gain

15

OPERATOR SWITCHES AND CONTROLS

THE HARDWARE

Scanning Head(transducer module):

The scanning head does not contain any operator switches or controls. The scanning head is

factory calibrated and should not be opened.

Sonar Processor:

The Sonar Processor amplifies and conditions the signal from the scanning head. The amplifier

in the Sonar Processor is called a Time Variable Gain (TVG) amplifier. The gain of the amplifier

increases over time for each returning signal. The operator has very precise control of the TVG

amplifier using the three gain controls.

The Near Gain, Far Gain, and Overall Gain controls on the front of the Sonar Processor are adjustments for the T ime Variable Gain (TVG) amplifier. The goal of these adjustments is to adjust the

amplifiers to compensate for signal losses that occur when the signal travels through the water.

When they are adjusted properly , a reasonably even color will represent the ocean floor from the

center to the outer edge of the scanned area. (See page 15 for a detailed description of the TVG)

SONAR PROCESSOR

Computer:

The system will run on a Laptop, Desktop, or on JW Fishers optional “Splash Proof” computer. The

“Splash Proof” is a computer system that is built into a Underwater Kinetics case. It utilizes a 10” Ultra

Bright” display which is much easier to read in a open boat.The Sonar Processor has an integrated

interface board that converts the analog signals to digital, and inputs the signal to the computer. The

computer takes the digital signal, displays it, and stores it for future reference. The software has

numerous toolbars and pull down menus for controlling the display. There is also communications

from the computer to the transdcucer which allow the operator to control different functions within the

Fish.

16

OPERA T OR SWITCHES AND CONTROLS (continued)

SONAR PROCESSOR

•

POWER INPUT - The power input for the Sonar Processor can be any voltage between 9 and

12 volts dc. A wall transformer is also supplied with the SCAN-650 which allows the

Sonar Processor to be powered from 120/220 volts ac. The wall transformer converts

120/220 volts ac to 12 volts dc. A dc power cable with red and black alligator clip s on the

end is also supplied with the system; the dc cable can be connected to any high capacity

9 to 12 volt battery (such as a 12v automobile battery).

• POWER SWITCH - When switched to the ON position power is applied to the processor’s

electronics and the green LED is illuminated. If the cable to the scanning head is connected (it should be before power is turned on) then power is also sent to the “downstairs”

electronics.

• PC INTERFACE - A USB cable connects the Sonar Processor to the PC

• GPS/LORAN INPUT connector - Your GPS plugs into this connector. The Sonar Processor

requires a NMEA 0183 input. It may be necessary to select this type of input from a menu

in the GPS or LORAN unit (see page 34 Appendix A for more det ail).

• CABLE LENGTH COMPENSA TION switch – Adjusts the gain of an amplifier to compensate

for the various lengths and qualities of signal cables that can be used with the system.

Switch position 1 is used for shorter cables (such as a 150ft cable). Switch position 5 is

used for long cables (such as a 2000ft cable).

• TRANSDUCER HEAD (SCANNING HEAD) connector - The cable from the Scanning Head

Electronics attaches to this connector .

• NEAR GAIN CONTROL - Adjust s the gain for objects close to the scanning head.

• FAR GAIN CONTROL - Adjusts the gain of TVG amplifier so that the reflected signal from

objects farthest from the Head can be amplified sufficiently to produce an image on the

monitor.

• OVERALL GAIN CONTROL - Adjusts the darkness of the sonar image in the selected color .

17

OPERATOR SWITCHES AND CONTROLS (Continued) -

THE SOFTWARE

The majority of operator controls are located in toolbars on the screen. The number of tools in each

toolbar, and therefor the number of toolbars, will depend on the resolution setting on your computer

display. The resolution setting for the display below was 1024 by 768.

File Position T oolbar

T op T oolbar

Mode/Screen

Toolbar

Settings

Playback Speed Bar

or

Sweep Speed Bar

Toolbar

Sweep origin

(scanning head)

Sweep progress

indicator

Range mark rings on the display make it

easy to determine the distance from the

sonar head to the target.

SOFTWARE MENUS:

There are 5 pulldown menus available: FILE, VIEW , ACTIONS, SETTINGS and HELP. The

selections available under each heading:

File:

• Record new file - This is used to record a new sonar file.

• Open file - Use this to open an existing sonar file for playback.

• Save screen as a picture - Saves the image on the sonar screen

as a Bitmap file.

• Print screen - Prints the image shown on the screen.

• Exit - closes the SCAN-650 program.

18

OPERATOR SWITCHES AND CONTROLS (continued)

View:

The number of toolbars available under VIEW depends on the

display resolution selected for the monitor . The higher resolution

settings permit a single large toolbar (Mode/Screen Toolbar),

where a lower resolution setting (640 by 480) requires three

toolbars (Standard/Playback/Screen Position) to show the same

number of icons. Details for each of these toolbars is covered later

in the manual.

• Mode/Screen Toolbar - Displays icons for various tools on left

side of screen.

• Playback Slider bar - Active in Playback mode. Allows the

operator to control the playback speed of recorded files. The speed can be adjusted from

very slow to very fast.

• File Position T oolbar - Used when Playback is selected. Displays the approximate location

in the file for the present image being displayed. Operator can instantly move anywhere in the file by moving the slider .

• Screen Position - Moves the origin of the sweep display giving

the operator a larger viewing area.

Center , Left, Right, T op, Bottom can be selected.

• Show Range Rings - Makes the range rings visible in the sector

the sonar is sweeping. This can assist the operator in determining

the distance to a target. The default command is not to show the

range rings.

• Display GPS - The GPS position is shown in the BOAT LOCATION section of the Righthand T oolbar .

• Settings T oolbar - Show or hide the right hand settings toolbar

Actions:

The commands shown under the ACTION pulldown menu duplicate many of the commands shown on the Playback and Mode/

Screen T oolbars.

• Record - Selecting this command operates the sonar and saves

the data to a file.

• Monitor Mode - This command is for real time viewing of sonar

images without recording data.

• Playback - Used to playback a previously recorded file.

• Playback with Continuous Loop - Continuously repeats the playback of a recorded file.

• Rewind - Rewind a recorded file.

• Fast Forward - Views the recorded file in fast motion.

• Stop - Stops the recording or playing back of a file.

• Record Highlights - Records select parts (edits) of a previously recorded sonar record to a

19

OPERATOR SWITCHES AND CONTROLS (continued)

separate file (see page 24 for details).

Settings:

• Set Serial Port number - The Sonar Processor has an integrated

USB to Serial communications port. The operator must select the

Sonar Processor com port for proper operation.

Note: Use the same physical USB port on the PC every time.

• Set Head Orientation - The choices are normal or inverted. The sonar operator must identify

whether the scanning head is mounted right side up (normal) as would be if mounted on top of a

ROV , or upside down (inverted) as if it was pole mounted and deployed over the side of a boat.

If the orientation is set incorrectly , targets that should be displayed on the left side of the screen

will be displayed on the right side.

• Set Date Format - The operator can choose either: month/ day/ year or day/month/year . The

date is displayed in the Settings Toolbar.

• Set Time Format - The operator can choose either a 12 hour or 24 hour time format. The time

is displayed in the Settings T oolbar .

• Restore Default Settings - Returns settings to the original factory default settings.

Help:

• Help T opics - Refers you to Operators Manual for help. Comp any contact information is pro-

vided.

• About Sonar - Revision information and Comp any contact information is provide

20

OPERATOR SWITCHES AND CONTROLS (continued)

TOOL BARS:

Mode/Screen Toolbar-

The Mode/Screen toolbar allows for easy 1-click access to many software functions. A “Tooltip” stating

the name of a button will appear when the mouse cursor hovers over the button . These controls are

duplicates of “Menu” functions, please refer to the “Software Menus” section of this manual starting on

page 19 for a detailed explanation of the commands below.

- Removes tool bar from screen.

- Record new file.

- Monitor Mode, only real time viewing of the sonar image with no recording of data.

- Playback

- Fast forward

- Rewind

- Rewind to beginning of file.

- Stop playing file,

- Open a file for playback,

- Save screen as Bitmap picture.

- Clear the screen.

- Print creen.

- Center of the screen.

- T op center of the screen.

- Down center of the screen.

- Left center of the screen.

- Right center of the screen.

- Upper left corner

- Upper right

- Lower left corner

These Screen Position

commands move the center of

the scanned area to best

match the display to the sector

being scanned.

- Lower right corner

- Zooms in on sonar image.

File Position Toolbar - Used when Playback is selected. Dis-

plays the approximate location in the file for the present image

being displayed. Operator can instantly move anywhere in the

file by moving the slider.

21

OPERATOR SWITCHES AND CONTROLS (continued)

TOOL BARS: (CONTINUED)

Playback Slider bar - Active in Playback mode. Allows the operator to control the

playback speed of recorded files. The speed can be adjusted from very slow to

very fast.

Sweep speed bar - Only needed if your SCAN-650 Sonar Processor connects to

your PC using a PC-CARD. If your Sonar Processor connects to your PC using a

USB port, the Sweep Speed Bar is not used [speed adjustment is automatic].

Active in Recording and Monitor mode. Allows the operator to optimize sweep

speed to match the speed of the computer. T o set the optimum speed, move the

slider toward “F AST” until the data is only shown in half of the screen sector ( a

mirror image is shown in each half of the chosen sector). Now move the slider

slightly toward “SLOW” until data is shown in the full chosen sector . Note: Slider

adjustments only take effect the beginning of the next sweep.

Note: The sweep speed must be optimized for each combination of Range and

Step. The software will save the user optimized setting for each combination.

22

OPERATOR SWITCHES AND CONTROLS (continued)

TOOLBARS: (CONTINUED)

Settings Toolbar

Displayed on the right side of the screen. Information and pull down

menus are:

- Range - The range setting sets the radius of area to be scanned. Range

settings of: 5, 10, 20, 40, or 60 meters are available. A 360° sweep

with a range setting of 10 meters would result in a total scan diameter

of 20 meters.

- Steps -The steps setting sets the number of degrees the transducer rotates between the individual “pings” of a sweep. The smaller the step,

the higher the image resolution. Larger steps reduce the time it takes

to scan a sector, but trade image quality. Step degrees of 1/2, 1.0,

1.5, or 2.0 degrees are available.

- Start of Sweep, End of Sweep - Allows the user to select the sector that

will be scanned. The angle can be selected from the pulldown menus

or can be typed into the box. Please refer to page 25 for more details.

- Sector - When depressed, the sweep rotates between the “S tart of Sweep”

angle and the “End of Sweep” angle. Scans perfomed using the

Sector setting will start in a clockwise direction and reverse direction

at the end of each sweep.

- 360 SCAN - When depressed the sweep rotates continuously (360 deg), always clockwise.

- Zoom - Sets the magnification of the displayed image. Available Zoom settings are:

50%, 100%. 150%, and 200%. 100% is normal. The Zoom setting can also be changed

by pressing the ‘+’ and ‘-’ keys on the keyboard.

- Color Bar - Displays the colors for the sonar image being displayed. Zero or weak echo

returns are represented by the colors on the left side of the bar and strong returns are

the colors on the right side of the color bar.

- Color - Selects the colors for the color bar . There are numerous color choices. The color

combinations allow the sonar image to be displayed in various shades of both colors.

The best color is a matter of operator preference although at times a sonar image can

appear to be more distinct in one particular color . Clicking repeatedly on the COLOR

button scrolls through the color choices, or the color can be selected by clicking on the

down arrow on the right hand side of the box showing the color name.

- Invert Color - Clicking the invert color button inverts the color bar. The colors on the left

are now on the right and the colors on the right are now on the left. At times a sonar

image can appear to be more distinct by vewing it in an inverted color set.

- Gain - The software gain control should be used only during playback to compensate for

images recorded with improper TVG control settings. The gain can be adjusted from

-5 to +5 in one digit increments. Clicking repeatedly on the GAIN button scrolls through

the 1 1 gain settings. The gain can also be set by clicking on the down arrow on the

right hand side of the box showing the gain number . Positive numbers increase the

gain, negative numbers decrease the gain. The Gain should be set to 0 during recording.

23

OPERATOR SWITCHES AND CONTROLS (continued)

TOOLBARS: (CONTINUED)

Settings T oolbar (continued)

- Threshold - Adds an offset to the sonar return signal so that even the smallest

signal is visible on the monitor. Clicking repeatedly on the Threshold button

scrolls through the 256 settings (0 - 255) or the threshold can be selected by

clicking on the up or down arrows on the right hand side of the box showing

the threshold number. A threshold setting of 25 is commonly used.

- Sweep# - Shows the number of sweeps that have occurred. Each time the

scanning head completes a sweep in either direction it is counted as one

sweep and the number in the Sweep# box increments by one. This information is useful when a target is seen on the sonar. The operator can make

note of the sweep number and easily return to the part of the file showing the

target by forwarding to the appropriate sweep number .

- Run Time - Shows the running time of the sonar. This is the time from when the

SCAN-650 application is opened, or a new recording is started.

- Time - Shows the time of day (gets the info from the computer). Under Settings

(top toolbar), 12 hr or 24 hr clock can be selected.

- Date - Shows today’s date (gets info from computer). Under Settings (top toolbar),

Month-Day -Y ear or Day-Month-Y ear can be selected.

- Size - Allows the operator to measure the size of any object shown on the sonar

display. The measured target size is shown in the window to the right of the Size

button. Please see page 26 for details on how to use the sizing tool.

BOA T LOCA TION (information is from your GPS):

- Latitude and Longitude - Show the GPS position of the boat.

RECORD HIGHLIGHTS (under the Action Menu)

Allows the operator to create a new , smaller file containing any size portion of another previously

recorded file.

1. Select “Record Highlights” from the “Actions” pull down menu. The “Save Highlights as

File” box opens.

2. Select the destination in the “Save In:” box and enter a file name. Click Save.

3. A “Record Highlights” box containing “Record” and “S top” buttons opens.

4. Open and start the playback of the previously recorded file.

5. When the portion of the file that you want to save to the Highlights file begins playing,

rewind slightly and click on “Record” in the Record Highlights box.

6. Allow the file to play. When the file reaches the end of the portion you want to save in the

Highlights file, click “S top” in the Record Highlights box.

7. The new Highlight file can now be played.

24

OPERATOR SWITCHES AND CONTROLS (continued)

SCREEN POSITION (under the View Menu and Mode/Screen Toolbar)

The operator can move the origin point (center) of the sweep to any position on the screen to

give a large viewing area. Moving the origin point and increasing the zoom extends the image

from the top to the bottom of the screen. The origin point can also be moved to the corners of the

screen when it is advantageous to do so. The screen position can be moved from the “View”

menu, from the Mode/Screen toolbar, or by dragging the origin with the mouse. To drag the

origin with the mouse, position the mouse cursor over the origin. The mouse cursor will change

from an arrow to a set of crosshairs (+). Press and hold the left mouse button down while dragging the origin to the desired location. As the origin is dragged away from the center of the

screen, the Zoom level changes, magnifying the sonar image to a maximum of 200%

Start of Sweep, End of Sweep -

Allows the user to select the sector that will be scanned. The angle can be selected from the

pulldown menus or can be typed into the box. Alternately, the operator can set the “Start of

Sweep” angle by following these steps.

1. Move the mouse cursor to the “S tart of Sweep” arm on the sonar display .

2. Press and hold down the right mouse button.

3. Drag the arm to the desired “S tart of Sweep”position.

4. Release the right mouse button.

The “End of Sweep” angle can be set in the same maner , but requires the “Shift” key on the

keyboard to be pressed and held before pressing the right mouse button and released only after

the measurement is complete.

With a “Start of Sweep” angle of 300 degrees and an “End of Sweep” angle of 60 degrees

selected, the resulting sweep would cover a total sector of 120 degrees( as shown below).

“Start of Sweep” angle

“End of Sweep” angle

300° 60°

“Start of Sweep” arm “End of Sweep” arm

origin point

25

Size (Located in the Settings T oolbar)

Allows the operator to measure the size of any object shown on the sonar display , measure the

distance between objects or the distance between the object tnd the tranducer . A “Size” can be

measured by:

1. Left mouse click on the “SIZE” button in the Right Toolbar

2. Move the mouse pointer to one end of the target

3. Press and hold down the left mouse button

4. While holding the left mouse button down, drag the cursor to the other end of the target.

5. Release the left mouse button. The size of the target (in meters) will be displayed in the

window to the right of the Size button

Alternately , the Size can be measured by:

1. Press and hold the Shift key on the keyboard

2. Move the mouse pointer to one end of the target

3. Press and hold down the left mouse button

4. While holding the left mouse button down, drag the cursor to the other end of the target.

5. Release the left mouse button. The size of the target (in meters) will be displayed in the

window to the right of the Size button

When measuring the distance of an object from the origin (transducer), alway start measuring

at the object and end at the origin.

26

SCAN-650 SOFTWARE INSTALLATION

Operation of the SCAN-650 software requires three software programs to be installed on the

PC. The installation CD will automatically launch the hardware driver and sonar software installation

programs. The first program, InstaCal, is required for the PC to calibrate and control the integrated

Interface board (analog to digital board). The second program is a USB to Serial Driver . This program is required for the PC to control the Sonar Processor Settings. The third program, SCAN-650,

is the actual operating software. All Software must be installed before the Sonar Processor is connected to the computer with the included USB cable.

1.S tart PC

2.Insert

3.The JW Fishers

4.If the

SCAN-650

SCAN-650

Installation CD into CD or DVD drive.

SCAN-650

banner should appear. If it does, Skip to step 5

banner box does not open within 60 seconds, the installation

can be performed from Windows Explorer.

A. Open Windows Explorer from the Start / Programs menu.

B. Select Jwf –

SCAN-650

. Click on Setup.exe. This will start the installation

program.

5. The ‘Welcome to the InstalShield Wizard for InstaCal for Windows’ box opens.

Click next to continue.

6. The “Destination Folder’ window will appear. Click Next to continue.

7. Click ‘Install’ to begin the installation. The driver will install, then the ‘InstalShield

Wizard Complete’ message box will show. Click ‘Finish’ to complete this step.

8. The’ Welcome to the InstalShield Wizard for PL-2303 USB to Serial’ box opens.

Click ‘Next’ to continue

9. The driver will install, then the ‘InstalShield Wizard Complete’ message box will

show. Click ‘Finish’ to complete this step.

10. The ‘Welcome to JW Fishers

to continue.

11.The customer information box opens “Enter your name, and organization, then

Click ‘Next’.

12.Click ‘Next’.

SCAN-650

27

Setup Wizard’ box opens. Click ‘Next’

INSTALLING HARDWARE AND SOFTWARE (continued)

10. The “Select Installation Folder’ box opens. The default folder is C:\ Program Files\.

This should only be changed if either the Windows or Program Files folder is not

located on the C:\ drive. Click ‘Next’.

11. The ‘Confirm Installation’ box opens. Click ‘Next’.

12. The SCAN-650 software installation will complete. Click ‘Close’ in the ‘Installation

Complete’ box.

13. A messagebox will appear stating ‘You must restart your computer for the configuration changes made by JW Fishers SCAN-650 to take effect. Click on ‘Yes, I

want to restart my computer now’ and ‘OK’ to complete the InstaCal installation.

14. Remove the Installation CD from the drive now.

SCAN-650 SOFTWARE INSTALLATION CONTINUED ON NEXT PAGE

28

INSTALLING HARDWARE AND SOFTWARE (continued)

If you have purchased a complete system (including the computer ) from JW Fishers then the hardware and SCAN-650 Software have already been installed and tested. You can go directly to

CONNECTING THECABLES on page 31.

If you are using your own computer system then proceed below .

(If your SCAN-650 connects to your PC using a PC-CARD or PCI board (desktop PC) skip to page 26)

When you first connect the Sonar Processor SP to PC Interface (USB Cable), the Windows “Found

New Hardware Wizard will launch.

1. The first message box will state: ‘Can Windows Connect to Windows update to search for

software?’ Select ‘No, not this time.’ then click ‘Next’ to continue.

2.The next screen states: ‘If your hardware came with an installation CD of Floppy , insert it now The

drivers have already been installed on the PC. It is not necessary to insert the CD. Select ‘Install the

software automatically (Recommended)’, then click ‘Next’ to continue.

InstaCal program - Interface board configuration and calibration

Before the SCAN-650 can be used for the first time, this program must be run to configure the

Interface board which is integrated into the Sonar Processor. This program must also be run

whenever the Sonar Processor is used with a different PC. The SP to PC interface (USB Cable)

must be connected before running this program.

1. From the Start menu select Programs / Measurement Computing / InstaCal.

2. The InstaCal software starts.

3. A ‘Plug and PlayBoard Detection’ window should open. USB-1208HS should show in the

window. Click ‘OK’

4. ‘Board #0 - USB-1208HS’ should show in the board list window.

5. From the ‘Install’ pull-down menu click on ‘Configure’. The ‘Board Configuration’ box opens.

6. • Next to ‘Number of Channels’, select ‘8 Single Ended’. from the drop down list.

• Click ‘OK’ to continue.

7. Exit the InstaCal program.

29

INSTALLING HARDWARE AND SOFTWARE (PC-CARD or PCI board)

Skip to page 31 if your SCAN-650 Sonar Processor connects to the PC using a USB cable

For PC-CARD on Laptop PC:

Before the SCAN-650 can be used for the first time, this program must be run to

configure and calibrate the Interface board. This program must also be run whenever the Inter-

face board is installed in a different Laptop PC. The Interface board must be installed before

running this program.

1. From the Start menu select Programs / Measurement Computing / InstaCal.

2. The InstaCal software starts.

3. In the ‘PC Board list’ click on ‘PC-CARD-DAS16/330’ to highlight it.

4. From the ‘Install’ pull-down menu click on ‘Configure’. The ‘Board Configuration’ box opens.

5. • Next to ‘Clock 0 Source’, select ‘External’.

• Next to ‘Clock Speed’, select ‘10MHz’.

• Next to ‘ADC External Pacer Edge’, select ‘Rising’.

• Click ‘OK’ to continue.

6. From the ‘Calibrate’ pull-down menu click on ‘A/D’. The automatic calibration will begin.

Allow the calibration to complete. When calibration is complete, click ‘OK’.

7. Exit the InstaCal program.

For PCI board (Desktop PC)

Before the SCAN-650 can be used for the first time, this program must be run to configure and

calibrate the Interface board. This program will also need to be run if the Interface board has

been removed and replaced in the PC or moved to a different slot on the motherboard. The

Interface board must be installed before running this program.

1. From the Start menu select Programs / Measurement Computing / InstaCal.

2. The InstaCal software starts.

3. If the Interface board is properly installed, the ‘Plug and Play Board Detection’ box will

open. Be sure there is a checkmark in the box next to ‘PCI-DAS1200Jr’. Click ‘OK‘ to continue.

4. In the ‘PC Board list’ click on ‘PCI-DAS1200Jr’ to highlight it.

5. From the ‘Install’ pull-down menu click on ‘Configure’. The ‘Board Configuration’ box opens.

6. • Next to ‘No. of Channels’, select ’16 Single Ended’.

• Next to ‘ADC Ext Pacer Edge’, select ‘Rising’.

• Next to ‘Counter 4 Source’, select ‘External’.

• Click ‘OK’ to continue.

7. From the ‘Calibrate’ pull-down menu click on ‘A/D’. The automatic calibration will begin.

Allow the calibration to complete. When calibration is complete, click ‘OK’.

8. Exit the InstaCal program.

30

INSTALLING HARDWARE AND SOFTWARE (continued)

When you run the SCAN-650 software for the first time it will be necessary to configure the

SCAN-650 software to open the correct COM (serial) port for communications. To select the

COM (serial)port number that the software will use:

1. Follow the instruction on the Sonar Processor Box cover to cable and power up the

SCAN-650 system. Do not launch the SCAN-650 Application at this time.

2. Select the windows ‘Start’ menu and single right mouse click on ‘(My )Computer’.

3. A pop-up menu will appear . Left mouse click on ‘Manage’

4. Left mouse click on ‘Device Manager’ (found in the left hand list).

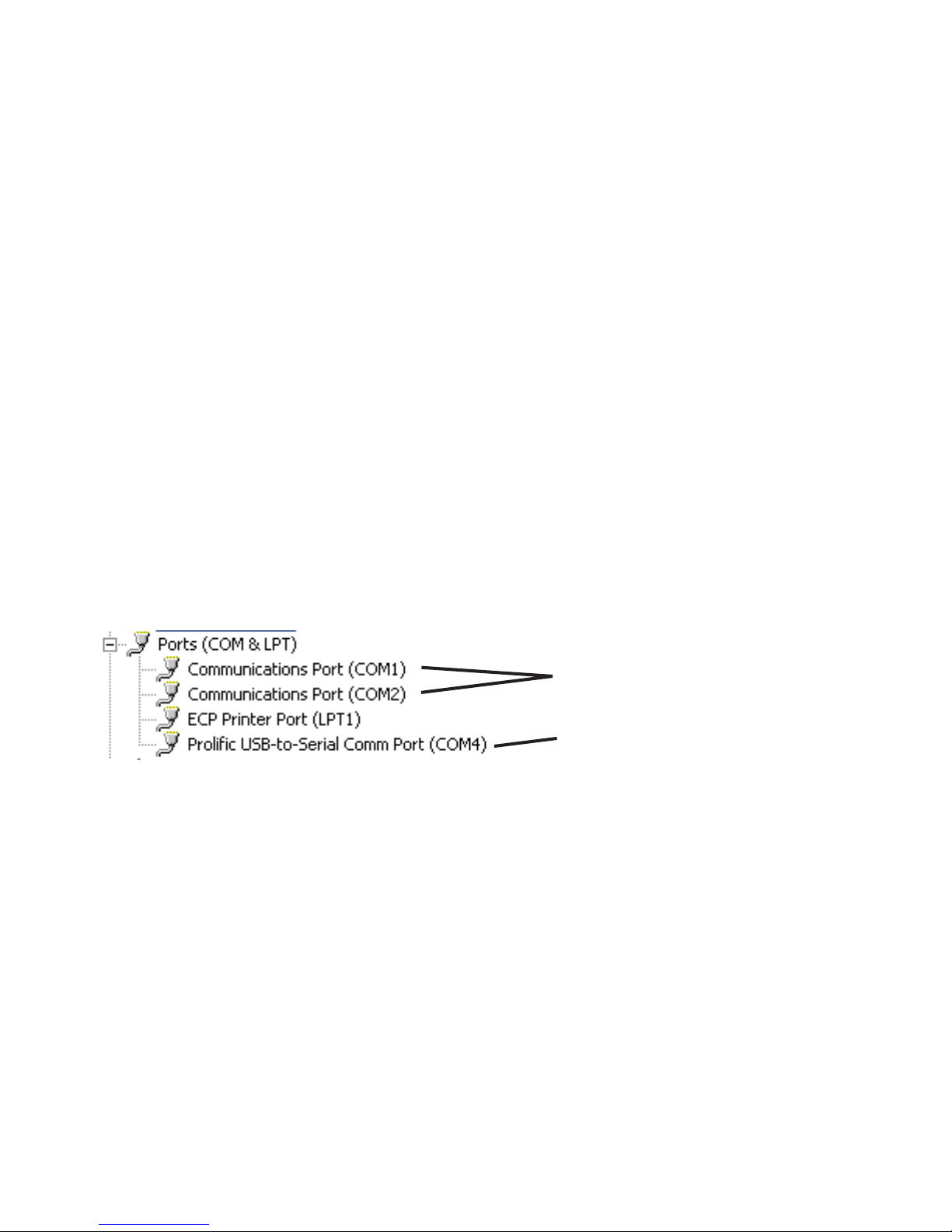

5. In the Device Manager window a list of your computers hardware will be shown.

Click on ‘Ports (Com & LPT)’. If this is not shown, make sure the Sonar Processor power

is ON and the Sonar Processor is connected to the PC with a USB Cable.

6. After clicking on ‘Ports (Com & LPT), one or more items will be shown. Look for the item

that refers to your USB to Serial Adapter, it will be something like ‘Prolific USB to Serial

Com Port (COM4)’ or ‘Belkin Serial Port (COM6)’. Note which COM port number has

been assigned to the USB to Serial Adapter.

7. Close all open windows.

8. Launch the SCAN-650 application

9. A message box will appear stating “Unable to Open Serial Port. Select Cancel to work

Offline”. Select “Cancel”.

10.Open the “Settings” Menu and select “Select Serial Port Number”

1 1.Select the COM port number that matches the COM port number assigned to the USB

to Serial Adaptor

The SCAN-650 COM settings are now configured.

*Note:

If the USB to Serial Adaptor is installed in a different (physical) USB port, the COM port

number changes and you will have to repeat these steps to reconfigure the COM settings.

The hardware and software installation is now complete.

31

CONNECTING THE CABLES (USB)

5

The drawing below shows the cable connections between the T ransducer Head,

the Sonar Processor, the boat’s GPS system, and the PC See pages 9 and 10 of this

maual for a description and picture of each of the cables.

Transducer Head and

Electronics

234

cable to surface

Processor

1.) Attach the long cable that connects the

Sonar

Boat’s

GPS

Transducer Head

PC

USB Port

to the Sonar Processor.

2.) Connect either the 12vdc battery power cable or the 120/220 vac to 12vdc power supply to

the “+12vdc Input” jack on the Sonar Processor Panel

3.) If available: Connect the data cable from the GPS to the “GPS Input” jack on the Sonar

Processor Panel

4.) Boot you PC into Windows. Wait until Windows is fully loaded before proceeding.

5.) Switch the Sonar Processor Power Switch ‘ON’

6.) Att ach the (USB) interface cable that connects the Sonar Processor to the PC

7.) Launch the SCAN-650 Application

USB Interface Cable

32

CONNECTING THE CABLES (PC-CARD or PCI for Desktop PC)

5

The drawing below shows the cable connections between the Scanning Head,

the Sonar Processor, the boat’s GPS system, and the PC. See pages 9 and 10 of this

maual for a description and picture of each of the cables.

Scanning Head

and

Electronics

234

cable to surface

Sonar

Processor

Boat’s

GPS

Interface

Board

PC (customer supplied)

Serial

or

USB Port

Step 1.

Attach the long cable that connects the

Make sure the O-ring is inside the submersible connectors on the

Scanning Head

to the Sonar Processor . CAUTION:

Scanning Head

cable.

Step 2.

Attach the interface cable that connects the Sonar Processor to the Interface board (see page 21

of this manual for instructions on installing the interface board).

Interface Cable for Laptop PC Interface Cable for Desktop PC

Step 3.

Attach the cable that connects the Sonar Processor to the Serial or USB port of the computer .

See picture below. If your computer has a Serial port then only the leftmost cable is used. If your

computer has USB ports (no serial ports), then the cables are plugged together and both cables

are used. The rightmost cable converts the Serial cable to a USB cable. If using this cable see

the Appendix in the back of this manual for instructions on using the Serial to USB adapter .

33

28

Step 3.

If the data cable for your GPS has a 9 pin “D” connector on the end (for a PC serial port), then you can

connect the GPS directly to the GPS INPUT jack on the Sonar Processor panel. If the data cable for

your GPS has bare wire leads on the end, you will need to splice the appropriate wires to the cable

(shown below). If your GPS did not come with a data cable, one can be obtained from the GPS retailer

or manufacturer. There are usually a variety of cables available, many also include connections for an

external power source for the GPS. We recommend using an external power source as using the GPS

with the data output consumes a set of small batteries in a few hours.

T o Sonar Processor

red wire for Signal (Data Out)

SOLDER WIRES TO

GPS DA T A CABLE

black wire for Return (Data Ground)

A TT ACH THE SCANNING HEAD TO ROV OR POLE HANDLE

After attaching the SCAN-650 cables to the appropriate system components, the Scanning Head can

be attached to the ROV or mounted on a pole handle for operation from a boat. When attaching the

Scanning Head to an ROV , if the Head and Electronics are in one unit, mount the unit on the top of the

ROV. If the Head and Electronics are separate units, mount the head on the top of the ROV and the

Electronics in a protected position on the side, or bottom, of the ROV .

Note: Be sure the arrow on top of the Scanning Head is pointing forward. The arrow points to the area

that will be displayed at the top of the PC screen.

Scanning electronics

strapped to ROV skid

Scanning Head

mounted uptop and

forward

Mount Scanning Head arrow facing

forward, this will be the top of the

display on the PC

34

OPERATION

1. Connect all cables as described above.

2. Connect the appropriate power supply to Sonar Processor unit and turn on the

power switch. If the Scanning Head is receiving power from an ROV, turn on

power to the ROV.

3. Turn on the GPS and obtain a position fix. See “Installing hardware and software

section of this manual for instructions on connecting and configuring your GPS.

4. Turn on the PC. If the SCAN-650 is being operated for the first time, the Interface

board must be installed into the computer and the SCAN-650 software loaded

onto the hard disk. See “Installing Hardware and Software” section of this manual.

NOTE: The minimum recommended resolution setting for the PC is 1024 x 768.

5. Open the SCAN-650 program on the PC.

6. Select the operating parameters from the Right Hand Toolbar (range, step, de-

grees, sector, zoom, etc.). See “Operator Switches and Controls” and “sample

Recording” section of this manual for a complete description of each of these

functions.

7. Choose the proper selections in the Settings menu for your system - see “Set-

tings” section of this manual for complete information on settings. This step is

primarily for first time setup of the system.

8. Choose the operating mode, either Monitor or Record. In the Monitor mode the

sonar image is displayed on the monitor, but is not saved. In the Record mode the

sonar image is displayed on the monitor and saved to disk or hard drive. The

Monitor mode can be selected by clicking on the green arrow on the toolbar. The

Record mode can be selected by clicking on the red button on the toolbar.

The SCAN-650 is now ready to operate. Recorded files can be played back at any

time by clicking the playback arrow on the toolbar. If the operator does not select a file

from the file menu, the last recorded file will automatically be played back.

35

SAMPLE PLAYBACK

It is recommended that before beginning use of the SCAN-650, the operator practice playing

back the sample files in the program. This will help familiarize the operator with some of the system

features. T o playback a sample file follow the step s below.

1. Open the SCAN-650 program. Under the File heading on the toolbar click Open. Select the

sample file from the sample file stored on the hard disk. The default location of the sample files

is: C:\Program Files\JW Fishers\SCAN-650\Sample Data Files

2. Click the Playback button on the toolbar on the left of the screen. The Playback button is the

single blue arrow pointing to the right. The saved file will begin to play .

3. Using the toolbar on the right of the screen, click on the invert color button and note how the sonar

image changes.

4. Change the selection on the colors menu next to the COLOR button, and note how the sonar

image changes.

5. Click the Stop button on the toolbar on the left of the screen. The S top button is the black square.

6. Click the Rewind button on the toolbar on the left of the screen. The Rewind button is the double

blue arrowhead pointing to the left. The double blue arrowhead with the line in front is the Rewind

to beginning of file button. Using the Rewind button the operator can rewind the file being played

to any point on the recorded file. Click the Stop button when the file is rewound to the desired

place. Click the Playback button to continue playing the file.

7. Click the Fast Forward button on the toolbar on the left of the screen. The Fast Forward button is

the double blue arrowheads pointing to the right. When the file is advanced to the desired place,

click the Stop button and then the Playback button to continue reviewing the file.

8. When playing back files the File Position T oolbar appears on the screen. Using the mouse the

operator can move the slider on the toolbar to quickly move to any point in the file.

9. T o measure a target on the screen, hold the shift key and click the mouse arrow on one end the

target. Holding both the shift key and the mouse button down, move the mouse arrow to the other

end of the target and release the mouse button. The size of the target (in meters) will be displayed in the size box.

10.Try using other buttons on the toolbar and note their effect on the sonar image. Some buttons

cannot be used with recorded files such as the Range, Step, and Sector buttons. These p arameters were set when the file was originally recorded and can not be changed during playback

mode.

36

SAMPLE RECORDING

The procedure below provides an example on how to record a file and will step you through some

of the recording options. The complete system needs to be cabled up and ready to go with the

SCAN-650 deployed on an ROV or on a pole over the side of a boat (3-4 ft off the bottom).

1. Open the Scan-650 application.

2. Select a scan range under “Range” on the right side toolbar. The choices are 5, 10, 20, 40, and

60 meters. Longer range settings allow a larger area to be scanned, but the resolution of the

scan is lower . Shorter range settings produce higher resolution images and are recommended

when searching for small or “soft” targets. For this exercise select 10 meters.

3. Select a step degree setting under “Step” on the right side toolbar . The choices are .5, 1, 1.5,

and 2. Larger steps allow the sonar beam to scan the area more quickly , however , resolution is

lower . The smaller the step, the higher the resolution of the sonar image. For this exercise

select a step of 0.5. This setting provides the highest resolution.

4. Select a sector to be scanned in the right side toolbar. The sector selected represents the

portion of a circle that will be scanned. The choices for the “S tart” (left menu) and “S top” (right

menu) angle are 0, 30, 45, 60, 90, 120, 150, 180, 210, 240, 270, 300, 315, and 330. The larger

the sector , the longer it takes the sonar beam to sweep the area. If Sector is selected the sonar

beam will rotate right to left, then left to right in a motion similar to a windshield wiper . If “360

Scan” is selected, the sonar beam will continuously rotate 360 degrees, refreshing the sonar

image with each subsequent pass of the beam. For this exercise select 360 Scan.

5. Under “Zoom” on the right side toolbar select 100%. This is the normal operating setting. When

an image of interest is appears on the screen the operator can select one of the other zoom

settings - 150%, or 200% to enlarge the image. The operator can also choose which portion of

the scanned area to display by selecting one of the screen positions in the Mode/Screen T oolbar

on the left side of the screen the repositions the origin point.

6. Select a screen color under “Colors” on the right side toolbar. The color combinations allow the

sonar image to be displayed in various shades of both colors. The best color is a matter of

operator preference although at times a sonar image can appear to be more distinct in one

particular color . For this exercise select red-yellow for the Colors list.

7. Select a gain value under “Gain” on the right side toolbar. The choices are -5, -4, -3, -2, -1, 0,1,

2, 3, 4, and 5. The gain settings are used to lighten or darken the sonar image. The lower the

number the lighter the image. A zero gain setting is recommended when recording files as this

setting will allow the gain to be adjusted up or down when the file is played back. When recording files the gain can be adjusted on the Sonar Processor to produce the desired sonar image.

8. Select “0” under “Threshold” on the right side toolbar. The choices range from 0 - 255. Threshold is similar to gain in that it adjust the lightness and darkness of the sonar image, however ,

threshold allows much finer adjustment because of the broader range. A setting of “0” is recommended when recording files. This will allow the threshold to be varied widely when playing back

recorded files. Small details in the sonar image may become visible as the threshold is increased. If a high threshold setting is selected when recording a file, the sonar reflections from

hard targets will be so high on the threshold scale that all detail will be lost. This data can not be

recaptured when playing back the file even if the threshold is lowered to the minimum setting.

37

9. The SCAN-650 is now ready to begin displaying and recording sonar data. T o record a new file

click the red button at the top of the left side toolbar or click ”Actions” on the top toolbar and

select “Record”. Before the recording begins, you will be asked to name the file and select a

location for the storage. The sonar data will be displayed on the PC monitor and recorded to the

hard drive.

10. Set the Gain Controls on the Sonar Processor. The Sonar Processor amplifies and conditions

the signal from the scanning head. The amplifier in the Sonar Processor is called a T ime

V ariable Gain (TVG) amplifier. Adjusting the TVG:

a) Start with all three gain controls at their mid-point.

b) Set the CABLE LENGTH COMPENSATION switch. Select the switch position that gives the

best picture with the three GAIN controls set at their mid-point. This is a one time adjustment,

once the best switch setting is found, it is not necessary to change it unless a different cable

is used. Switch position 1 is used for shorter cables (such as a 150ft cable). Switch position

5 is used for long cables (such as a 2000ft cable).

c) Adjust the Far Gain up or down for an even background color .

d) If an even color cannot be obtained by adjusting the Far Gain, adjust the Near Gain up or

down then readjust the Far Gain. The Near Gain usually requires little or no adjustment.

e) Adjust the Overall Gain so that only the very strongest returns (from “hard” objects) cause the

highest color on the color chart to be displayed.

f) If, once the desired picture is displayed, you find that the GAIN controls are set near their

minimum settings, lower the setting of the CABLE LENGTH COMPENSA TION switch by

one position and readjust the GAIN controls. Conversely , if you find that the GAIN controls

are set near their maximum settings, increase the setting of the CABLE LENGTH COMPENSA TION switch by one position and readjust the GAIN controls.

Note: When recording, it is important to have the Gains properly adjusted. If a file is recorded

with the Gains set too high, causing the signal to “saturate” the amplifier , detail lost in the saturated portion of the image cannot be recovered in playback. It would be preferable to have the

Overall Gains set slightly too low; the Gains can be increased by the on-screen Gain Control

during playback, with most of the detail retained.

While the sonar data is being recorded the settings can be changed at any time. Select a new

Range setting, Sector scan angle, Step, color scheme, etc. and note the change in the sonar image.

In most cases the change will not take place until after completion of the present sweep. Once the file

has been recorded, play it back to view the results. Experiment with the file by changing the settings

and noting the results on the displayed image.

38

FAQs

Operation

Q) What would you consider a good place to start with the gain Controls?

A) I start with the Near Gain 5, the Far Gain 7, and the Overall Gain 7. If the image produced

with the TVG controls at these settings is much too light, increase the Cable Compensation switch

setting by 1. The Cable Compensation switch is located on the SCAN-650 Sonar Processor box.

This switch is used to adjust the gain to compensate for various lengths of cable. Switch position 1

is used for shorter cables (such as a 150ft cable); switch position 5 is used for long cables (such

as a 2000ft cable). Fine tune the Near Gain so objects close to the scanning head look good.

Next, adjust the Far Gain so objects farthest from the scanning head look good. Finally , use the

Overall Gain to adjust the overall darkness or lightness of the image.

Q) How do I adjust to compensate for a bottom that slopes away or towards the scanner

head?

A) The SCAN-650 produces a fan shaped beam that is 40 degrees in the vertical plane. This

allows the SCAN-650 to scan gently sloped bottoms without altering the orientation of the scanning head. For bottoms that slope gently away from the scanning head, you can compensate by

raising the far gain. For bottoms that slope gently up towards the scanning head, you can compensate by lowering the far gain. Steeper slopes would require you to adjust the head to be perpendicular to the slope. This would ensure complete coverage of the surface of the slope.

Q) Some of the images are clearly vehicles, while others only show a large, undefined shape.

A) This is normal. When performing a search, it is important to remember that objects will not

always be displayed as you would expect. The orientation of the target in relation to the scanning

head can make a big difference in the how the sonar “sees” the target. Changing the orientation

of the scanning head in relation to the target will change how it appears on the display .

Q) Why is a lot of detail lost farther out in the scan?

A) The sonar beam produced by the SCAN-650 is a fan shaped beam.

The farther the beam travels away from the transducer, the more the spread out the beam becomes. Since the beam spreads as it travels, the images produced at long ranges are not as

detailed as images of close objects. (Echoes from all portions of this fan shaped beam are combined to draw the image on the screen)

Q) Will I still be able to see small objects on the larger scans?

A) The 40 meter plus ranges are best when searching for large objects such as vehicles.

Small objects are often overlooked due to their small size when drawn on the screen. On a 21",

monitor, with the screen positioned so the a 270-90 degrees sweep is shown at maximum size, a

3ft length measures only ¼”, which is very easy to overlook. To thoroughly search an area for a

(Continued)

39

FAQs (continued)

small target (body), you will need to perform several shorter range scans. The 5 meter and 10

meter ranges are best for small target searches.

Q) How do I get the update of JW Fishers SCAN-650 Software?

A) Contact JW Fishers for information on software updates.

PH (800) 822-4744

PH (508) 822-7330

E-MAIL: jwfishers@aol.com or info@jwfishers.com

Q) What is the optimum height off the bottom for the scanning head?

A) For small targets, the SCAN-650 transducer should be approximately 2 feet from the

bottom.

Q) If used on a pole, does the motion of the boat affect the scan?

A) Y es, the motion of the boat will affect the scan. Acceptable images can be captured when

pole mounting the SCAN-650, however, the transducer must be stationary to produce the highest

quality images. Horizontal motion affects the scan more than vertical.

Q) Most tripods I have seen have a self leveling function. Would that make it hard to see the

contour of the bottom or would a fixed head better keep it on the right plane?

A) A self leveling tripod is ideal for many situations. Gently sloped bottom contours do not

affect the performance of the SCAN-650. Lowering the

SCAN-650 to the bottom of a lake or pond on a self leveling tripod ensures the scanning head is

perpendicular to the bottom and in the proper position for scanning a fairly level bottom (as is

common in most ponds). As long as the scanning head is perpendicular to a surface, the contour

of that surface will be clear . The SCAN-650 does not know the difference between a level bottom

and a sloped bottom.

40

Troubleshooting

Problem: “Unable to Open Serial Port” message

The JW Fishers Sonar requires a COM (serial) port to pass operation parameters from the

PC to the Sonar . It will be necessary to configure the JW Fishers Sonar software to open the

correct COM (serial) port for communications. Below are instructions for configuring the COM

(serial) port.

T o select the COM (serial) port number that the sof tware will use:

1. Cable and power up the JW Fishers Sonar system. Do not launch the JW Fishers

Sonar application at this time.

2. Select the Windows ‘Start’ menu and single right mouse click on ‘My Computer’.

3. A pop-up menu will appear . Left mouse click on ‘Manage’

4. Left mouse click on ‘Device Manager’ (found in the left hand list).

5. In the Device Manager window a list of your computers hardware will be shown. Click on

the ‘+’ symbol next to ‘Ports (Com & LPT)’. If this is not shown, make sure the Sonar

Processor power is ON and the Sonar Processor is connected to the PC with a USB

Cable.

6. After clicking on ‘Ports (Com & LPT), one or more items will be shown. Look for the item

that refers to your USB to Serial Adapter, it will be something like ‘Prolific USB to Serial

Com Port (COM4)’ or ‘Belkin Serial Port (COM6)’. Note which COM port number has

been assigned to the USB to Serial Adapter .

Hardware COM Ports

USB to Serial Adaptor

(USE THIS ONE)

7. Close all open windows.

8. Launch the JW Fishers Sonar application

9. A message box will appear stating “Unable to Open Serial Port. Select Cancel to work

Offline”. Select “Cancel”.

10.Open the “Settings” Menu and select “Select Serial Port Number”

1 1.Select the COM port number that matches the COM port number found in step 6. (If

more than one COM port was listed, try each one until you find the one that works.)

The JW Fishers Sonar COM settings are now configured.

*Note:

If the USB to Serial Adaptor is inst alled in a different (physical) USB port, the COM port

number changes and you will have to repeat these steps to reconfigure the COM settings.

41

Troubleshooting (continued)

Problem: “A Required Interface Board Was Not Found” message

JW Fishers Sonar systems use an interface board to capture the analog sonar signal and

convert it to digital data which the software can then process. The driver software for this interface

board is installed as part of the JW Fishers Sonar application installation process. After the JW

Fishers Sonar application installation process is completed and before the sonar system is run for

the first time, a program to configure the interface board must be run. This program must also be

run whenever the Sonar Processor is used with a different PC.

USB Systems:

The SP to PC Interface (USB) Cable must be connected to the Sonar Processor and PC

1. From the Start menu select Programs / Measurement Computing / InstaCal.

2. The InstaCal software starts.

3. A ‘Plug and Play Board Detection’ window should open. USB-1208HS should show in the

window. Click ‘OK’

4. ‘Board #0 - USB-1208HS’ should show in the board list window .

5. From the ‘Install’ pull-down menu click on ‘Configure’. The ‘Board Configuration’ box opens.

6. Next to ‘Number of Channels’, select ‘8 Single Ended’. From the drop down list.

7. Click ‘OK’ to continue.

8. Exit the InstaCal program.

PC-CARD (older) systems

The PC-CARD Interface Board must be Installed in the PC

1. From the Start menu select Programs / Measurement Computing / InstaCal.

2. The InstaCal software starts.

3. In the ‘PC Board list’ click on ‘PC-CARD-DAS16/330’ to highlight it.

4. From the ‘Install’ pull-down menu click on ‘Configure’. The ‘Board Configuration’ box opens.

• Next to ‘Clock 0 Source’, select ‘Internal’.

• Next to ‘Clock Speed’, select ‘10MHz’.

• Next to ‘ADC External Pacer Edge’, select ‘Rising’.

• Click ‘OK’ to continue.

5. From the ‘Calibrate’ pull-down menu click on ‘A/D’. The automatic calibration will begin.

Allow the calibration to complete. When calibration is complete, click ‘OK’.

6. Exit the InstaCal program.

The interface board is now configured.

42

Troubleshooting (continued)

PC-CARD (older) systems only

Problem: On certain range settings the monitor seems to show a mirror image in a split

screen. Why does it do this?

The SCAN-650 software allows the operator to optimize sweep speed to match the speed

of the computer. This is accomplished using the Sweep Speed slider . If the sweep speed setting

is too fast, Sonar pings are not recorded by the PC. This will result in the mirror image. Slowing

down the sweep speed will correct this problem. Please note this adjustment must be made for

each Range setting / degrees per Step combination.

Problem: Sometimes my sweep speed had to be all the way down to get a full screen on

step setting 0.5. Is this normal?

The latest version of software has improved performance and should allow faster sweep

speeds. A new version of the SCAN-650 software is available for download. The latest version of

software offers improved performance and fixes several minor bugs found in earlier revisions.

Contact JW Fishers for information on software updates.

PH (800) 822-4744

PH (508) 822-7330