JW Faircloth & Son Faircloth Skimmer Installation Manual

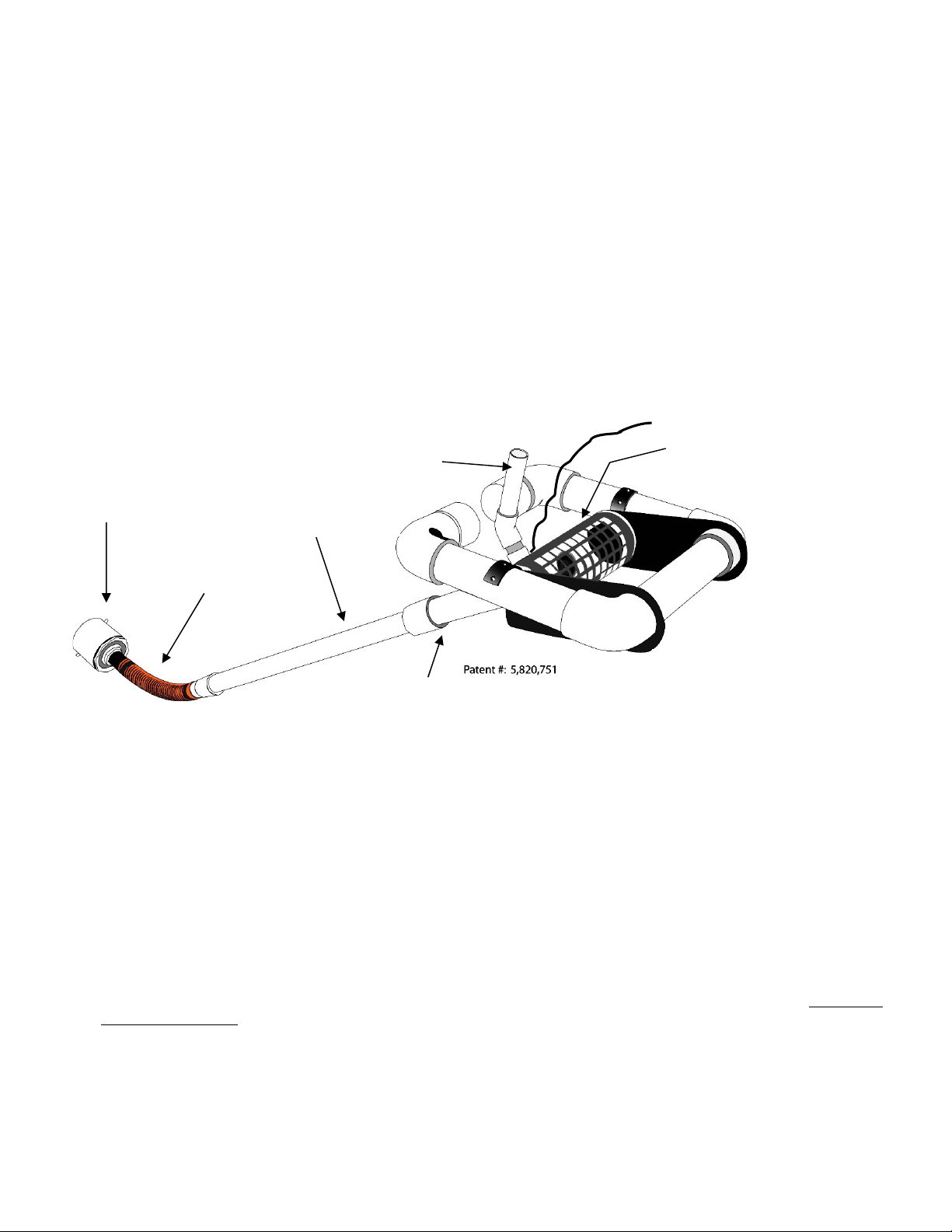

2½” Faircloth Skimmer®

1½” hose

Rope

Surface Drain

Instructions for Assembly, Use and Maintenance

You Will Need:

6 feet or more of 1½” Sch 40 PVC pipe SOLID

Primer and glue for PVC pipe

Phillips screw driver, maybe a knife

Assembly and Installation Directions.

1. Glue on the 2½” inlet extension to the Tee on the inlet. Install the vent.

Details Prime and glue the 2½” inlet extension (with the coupling, 1½” bushing and screw on one end) into the

2½” end of the Tee on the side of the Inlet (5" horizontal tube suspended between the sides of the float with the

aluminum screen door).

Install the vent into the socket in the Tee: back the screw out, insert the short end of the vent, point the long end

toward the door on the inlet, and tighten the screw. Use a little grease so it can be removed later.

Vent

With Green

Tip

Inlet

4” Sch 40

coupling

connection

1½” Sch 40 SOLID pvc

barrel or “arm”

SUPPLIED BY USER

2½” inlet

extension

Skimmer shown in

floating position

2. Glue the 6’ long 1½” sch 40 barrel to the 1½” grey coupling on the hose.

Details You will need 1½” Sch 40 PVC pipe (solid, not foam core) for the barrel (or "arm") between the float

assembly and the 1½” hose. The length of the pipe should be about 1.4 times the depth of the basin so the

surface drain floats properly when the basin fills with a minimum length of 6' so the surface drain can be pulled

to the side of the basin for maintenance.

If barrel is longer than 8’ weight may have to be added to the inlet so it sits at the right depth.

3. Put the other end of the barrel into the socket on the inlet extension and tighten the screw.

Details Make sure the screw point is not protruding into the 1½” bushing on the outlet end of the inlet extension

you glued onto the Tee.

WITHOUT GLUE OR PRIMER, but with a little grease, insert the other end of the pipe into the bushing all the way

in until it hits bottom. It may be easier to do this in the basin after you have connected the hose to the pipe, riser or

outlet structure. Tighten the screw so the point enters the pipe to secure it; it does not have to go all the way in.

This connection is not glued to allow disassembly and possible reuse of the surface drain later.

4. Cut the orifice in the disk (size shown on the erosion control plans), put the disk in adaptor, and install the

adaptor on the inlet, and tighten the screw. Close the door.

2-5inchInstr 9-23-19 1 © J. W. Faircloth & Son, Inc. 2019

Details Refer to the erosion control plans for the orifice size. Open the door on the inlet and remove the 2½”

disk in the inlet. Follow the instructions below for cutting the

ORIFICE. Put the orifice in the adaptor, install the adaptor on the

inlet, secure it with the screw (through the hole in the top of the

inlet) and close the door and secure it with the screw eye. If you do

not know the size of the orifice, refer to the instructions on the next

page.

5. Cut a trench in the bottom of the basin 1’ to 2’ deep under where

the surface drain will be placed. If required, place a support under

the surface drain inlet.

Details If the surface drain will settle to the bottom when the basin

drains it is recommended that a 1' - 2' deep trench a backhoe

bucket wide should be excavated under the surface drain to catch sediment that will settle under the surface drain.

If a pool of water is to be provided, install the support under the surface drain inlet as shown on the erosion control

plans. It is recommended that the hose connection to the pipe through the dam be low enough that the whole pond

can be drained using the surface drain even if a pool of water is to be provided. Doing this will avoid using a pump

to drain the very bottom of the pond.

If ice is expected during winter place the surface drain near the dam or side of the basin where the ice will be the

thinnest and you can get to the inlet to break the ice and keep water flowing through the surface drain. But do not

put it so close to the side that the surface drain cannot settle to the bottom and drain the whole basin.

6. Attach the 4” coupling on the hose to the pipe through the dam or the outlet structure.

Details Make sure the screw points are not protruding into the 4" coupling on the hose and attach it to the pipe

through the dam.Tighten the screws just so the points go into the plastic to secure it. Greasing the pipe is

recommended so the hose can be removed later.

If the connection pipe is larger than 4” you will need a coupling for that pipe, a bushing for that couping with a 4”

socket, and about 10” of 4” pipe to create an attachment.

If attaching to a metal pipe you will need a rubber coupling (Fernco) and a short piece of 4” pvc pipe to make the

connection.

OR The 4” coupling can be removed and the hose connected using the 2” threaded fitting. If attaching to a

concrete structure with a hole or orifice at the bottom, either: 1) grout a 4” PVC pipe into the hole and connect the

hose: or 2) a more secure way is to use a steel plate with a hole cut in it and 2” coupling welded to it that will fit

over the hole in the concrete and bolt the plate to the structure with sealant to make it water tight.

7. Attach the rope to the Tee and the other end to a stake on the side of the basin.

Details Tie one end of the rope around the Tee between the vent socket and the 5" tube on the inlet. Secure the

other end to a stake or post on the dam or side of the basin where it can be used to pull the surface drain to the

side if necessary to remove trash and debris.

8. Put a fence post, 1 not 2, on the opposite side of the barrel from where the rope is tied to a stake to keep the

surface drain in place.

Details Put the surface drain where you want it to settle to the bottom and drive a metal fence post into the

ground on the outside of the barrel (away from the side) 2’ from the float to hold the surface drain in that place.

Posts on both sides of the barrel are not recommended because it will prevent pulling the surface drain to the side

for maintenance.

9. Take a break.

Maintenance

2-5inchInstr 9-23-19 2 © J. W. Faircloth & Son, Inc. 2019

Loading...

Loading...