JVM Antriebe JV, JVA OPERATING MANUAL

OPERATING MANUAL

JV/JVA 10-27

2 of 19

Table of content

1. SAFETY ............................................................................................................................3

1.1. W

1.2. 'A

1.3. G

2. GENERAL NOTES ...........................................................................................................4

3. DESIGN AND OPERATION.............................................................................................4

3.1. G

3.2. D

3.3. O

3.4. N

3.5. R

4. STORAGE.........................................................................................................................6

5. HANDLING .......................................................................................................................6

6. INSTALLATION................................................................................................................7

7. ELECTRICAL CONNECTION.......................................................................................... 8

8. SETTING THE CENTRIFUGAL FORCE........................................................................13

8.1. S

8.2. S

ORK SAFETY SYMBOL

TTENTION' NOTICE

ENERAL WORK SAFETY AND 'ATTENTION' INSTRUCTIONS FOR UNBALANCE VIBRATORS

ENERAL

ESIGN OF AN UNBALANCE VIBRATOR

PERATIONAL CHARACTERISTICS

OISE INFORMATION (ACCORDING TO 3.

ATING PLATES

AFETY NOTE

ETTING INSTRUCTIONS

.....................................................................................................................4

............................................................................................................5

.............................................................................................................13

.................................................................................................3

.....................................................................................................3

............................................................................4

..................................................................................5

GSGV)............................................................5

..............................................................................................13

....3

9. MAINTENANCE.............................................................................................................. 15

9.1. I

9.2. L

9.3. O

10. SPARE PARTS........................................................................................................... 17

10.1. I

10.2. S

11. SPECIAL DESIGNS....................................................................................................18

11.1. PTC

11.2. P

12. DATA FOR NORMALS MAINS CONNECTION AND CONNECTION

13. DATA SHEET..............................................................................................................19

MPORTANT NOTES

UBRICATION

THER MAINTENANCE / INSPECTION OPERATIONS

MPORTANT NOTES

PARE PARTS DRAWING/PARTS LIST

RESISTOR AS ADDITIONAL PROTECTION

OLE REVERSING UNBALANCE VIBRATOR

UNDER EMC CONDITIONS....................................................................................... 18

.....................................................................................................15

.............................................................................................................15

.........................................................16

..................................................................................................17

.........................................................................17

............................................................17

..................................................................18

ATTENTION

OPERATING MANUAL

1. Safety

1.1. Work safety symbol

This symbol is in this operating manual allocated to those safety instructions which

deal with danger to the health and life of persons.

These instructions must be strictly observed. Please pass this document to,the

operators of the unbalance vibrator.

Apart from the work safety instructions in this operating manual, the general as well

as the local safety and accident prevention regulations must be observed.

1.2. 'Attention' notice

This symbol is in this operating manual allocated to those notes, regulations and

guidelines which deal with damage to or destruction of the unbalance vibrator as a

result of inexpert operation.

1.3. General work safety and 'attention' instructions for unbalance

vibrators

It must be ensured that every person charged with the installation, operation and

maintenance of the unbalance vibrator has read and understood this operating

manual before commencing work.

The unbalance vibrator has been built in accordance with the latest state of

technology and is safe and reliable. If, however, it is inexpertly operated by

uninstructed persons, it may cause grave injury and damage.

The unbalance vibrator ist intended exclusively for the application agreed with the

manufacturer. If this is not observed, the manufacturer will not accept liability for any

resulting damage or injury.

For the installation, electrical connection, setting of centrifugal force and

maintenance, it must be made clear which person is responsible for the work, so that

safety is not impaired when working with the unbalance vibrator.

The unbalance vibrator must only be operated in its original condition, except for the

setting of centrifugal force. If changes from the original condition are found, these

must be reported by the operator to the appropriate office.

Conversions and alterations of the unbalance vibrator on the operator's own

initiative, which could impair the safety, are not permitted.

JV/JVA 10-27

3 of 19

OPERATING MANUAL

All maintenance and setting work on the unbalance vibrator must in principle only be

carried at rest. Before starting work, ensure that the unbalance vibrator cannot be

switched on accidentally or by unauthorized persons.

The unbalance vibrator must never be operated without the covers of the centrifugal

weights. Danger of injury!

The electrical connection of the unbalance vibrator must be adequately fused..

If the insulation of the connection cable is damaged or if the cover of the terminal

box is missing, there is a life-threatening danger of electrocution! Such defects must

be corrected immediately!

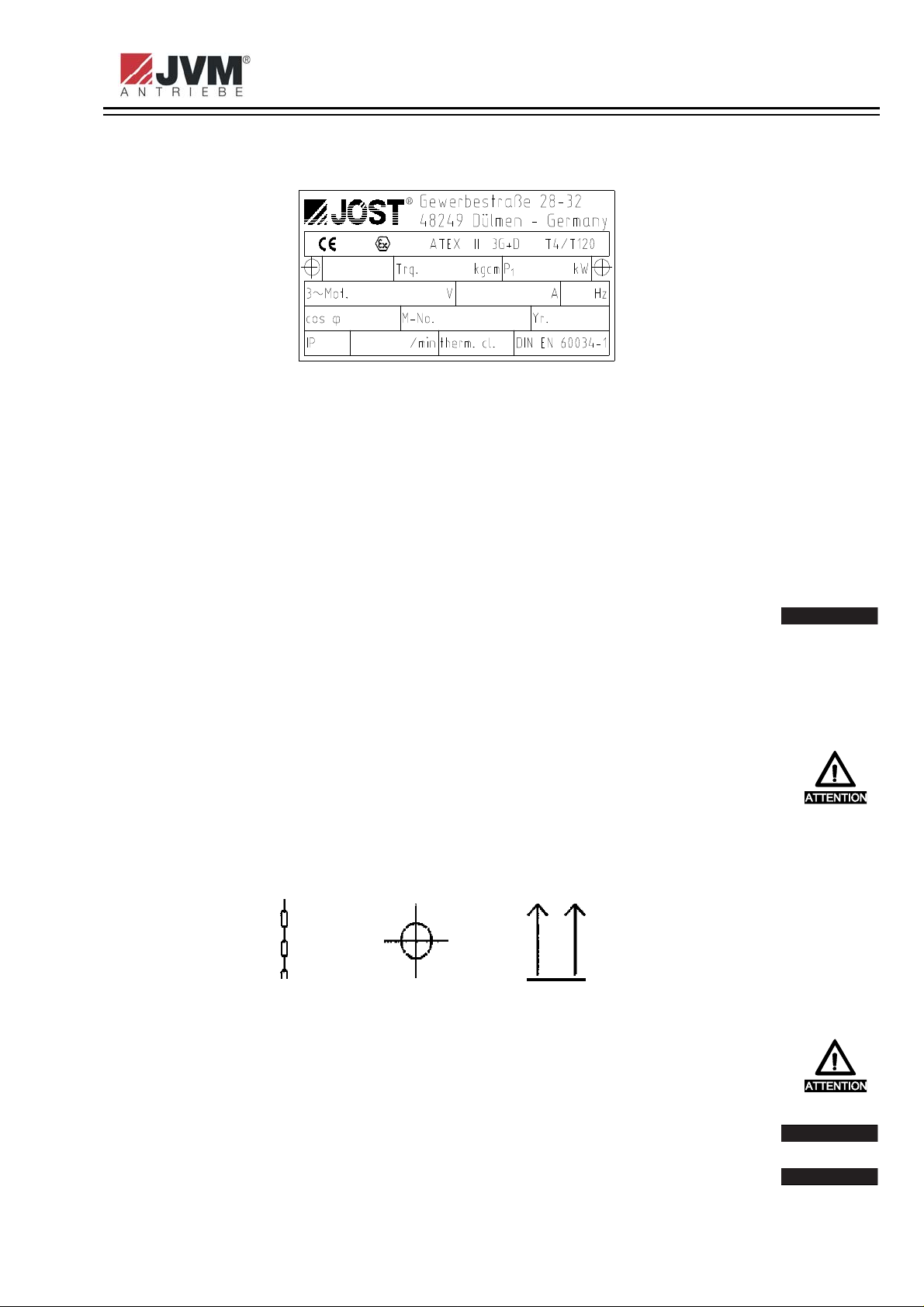

In areas which are subject to explosion risk, only explosion-proof unbalance

vibrators must be used. This is indicated as such by the type of explosion-proof

enclosure shown in the rating plate as well as by the EX symbol on the housing of

the unbalance vibrator. In addition, the special requirements of this operating manual

for save use must be observed.

JV/JVA 10-27

4 of 19

2. General notes

Only with the aid of this operating manual it is possible to install, set, operate and

maintain the unbalance vibrator properly and safely.

The manufacturer recommends that the operating manual is read through carefully,

since he does notaccept liability fordamage resulting from non-observance of this

operating manual.

The operating manual should always be kept ready to hand for the operator.

Changes in design and construction, for the purpose of improving the unbalance

vibrator, are reserved.

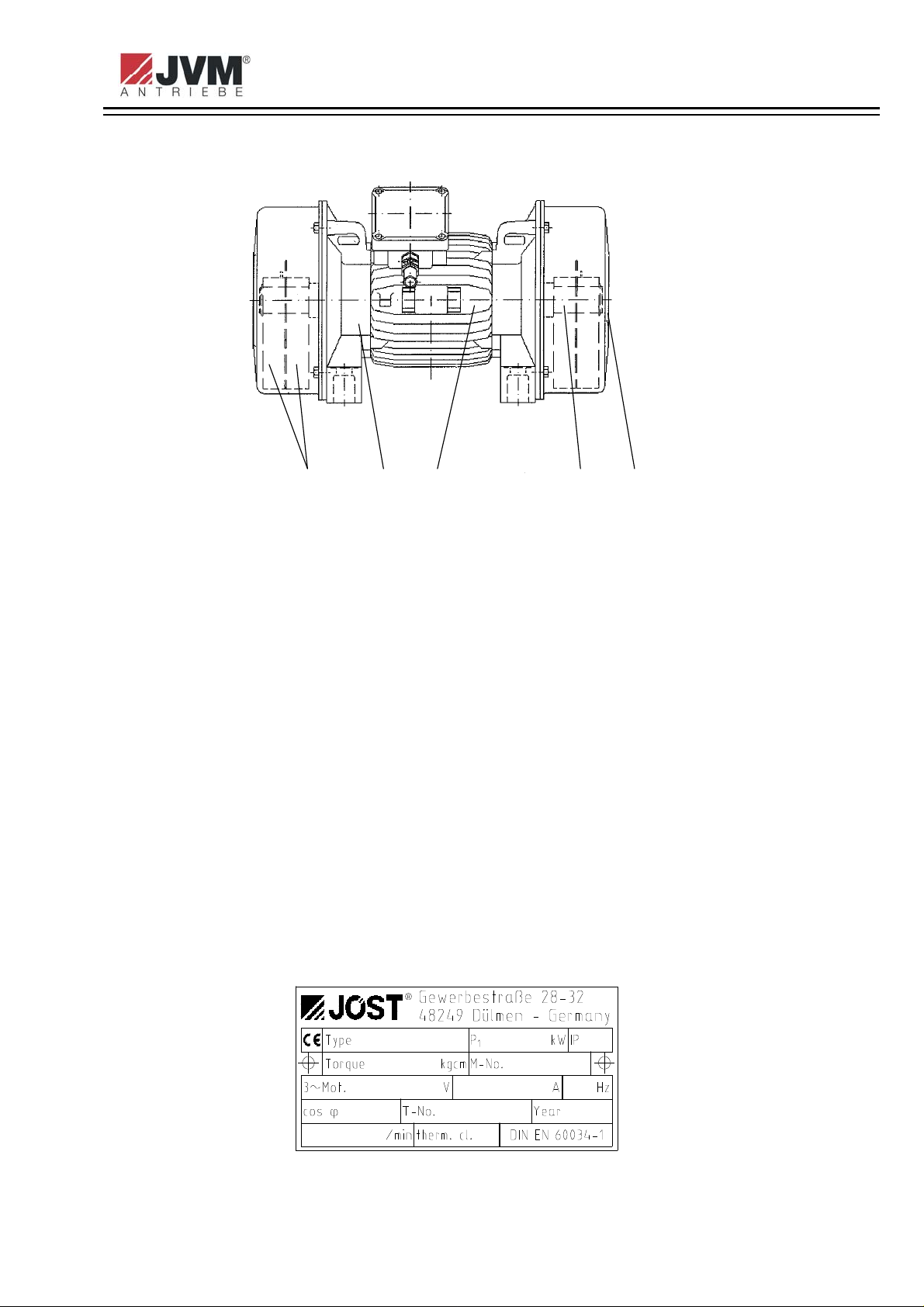

The characteristics power consumption [kW], rated current [A], rated voltage

[V], working moment [kgcm] and rated speed [1/min] are given on the rating

plate or type plate of the d rive.

3. Design and operation

3.1. General

The unbalance vibrator generates the vibratory motions by means of rotary

centrifugal weights.

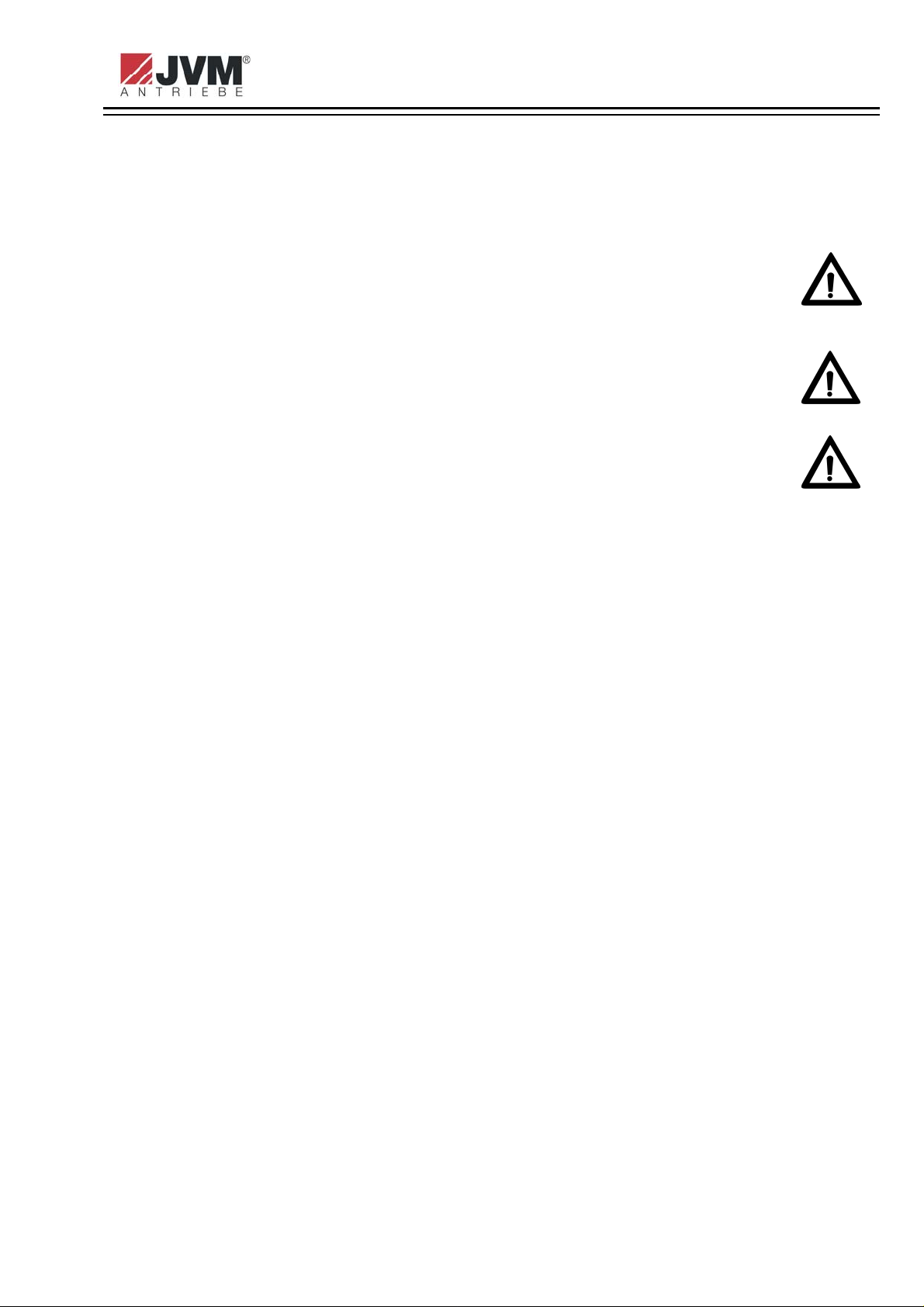

3.2. Design of an unbalance vibrator

A type JVJVA unbalance vibrator type 10 - 27 consists of the following main

elements:

1. Stator

2. Endshield with bearing

3. Rotor

4. Centrifugal weights

5. Cover

OPERATING MANUAL

JV/JVA 10-27

5 of 19

12345

3.3. Operational characteristics

The unbalance vibrator is a three-phase squirrel-cage motor. The two shaft

extensions of the rotor, which is mounted in antifriction bearings, carry adjustable

centrifugal weights.

With the unbalance vibrator switched on, the rotary motion of the rotor and its

centrifugal weights generates a centrifugal force. This causes the machine

connected to the unbalance vibrator to vibrate.

Type N unbalance vibrators are in principle designed for continuous duty in

accordance with S1 to VDE 0530.

3.4. Noise information (according to 3. GSGV)

The sound pressure level can be taken from the data sheet of the unbalance motor.

The sound pressure level - at nominal speed and operating temperature has been

determined on a testing stand by the manufacturer.

3.5. Rating plates

The unbalance vibrator JV is identified by the following rating plate:

ATTENTION

ATTENTION

ATTENTION

The unbalance vibrator JVA is identified by the following rating plate:

4. Storage

Until its final installation, the unbalance vibrator should as far as possible be stored

in closed rooms.

If the unbalance vibrator is stored in the open, it must be covered with tarpaulins

open underneath, so that any condensate can drain off. In the case seaworthy

packing of the unbalance vibrator, this packing must not be damaged or opened

during transit and storage

The unbalance vibrator must be placed on a suitable base to counteract ground

moisture or it must be stored in shelves.

The unbalance vibrator must only be placed on its foot surfaces!

To protect against corrosion, the foot surfaces are greased before dispatch from the

works. This grease coating must only be removed immediately before installation..

OPERATING MANUAL

JV/JVA 10-27

6 of 19

5. Handling

To avoid danger to persons and damage of the unbalance vibrator, the unbalance

vibrator must be handled with proper care! Apart from the instructions below, the

general as well as the local safety and accident prevention regulations must be

observed.

If the unbalance vibrator is packaged, the handling gear must only be attached at the

points marked. The symbols for handling - if any - have to be observed:

The unbalance vibrator itself must only be carried at the hitching eyes provided at

the stator. Small unbalance vibrators must be carried by using a rope fixed at the

stator.

The unbalance vibrator must only be placed on its foot surfaces!

Transit damage must always be reported to the manufacturer. Care has to be taken

that the foot surfaces and covers are in a non-damaged condition.

Hitch here! Centre of gravity! UP!

ATTENTION

ATTENTION

ATTENTION

ATTENTION

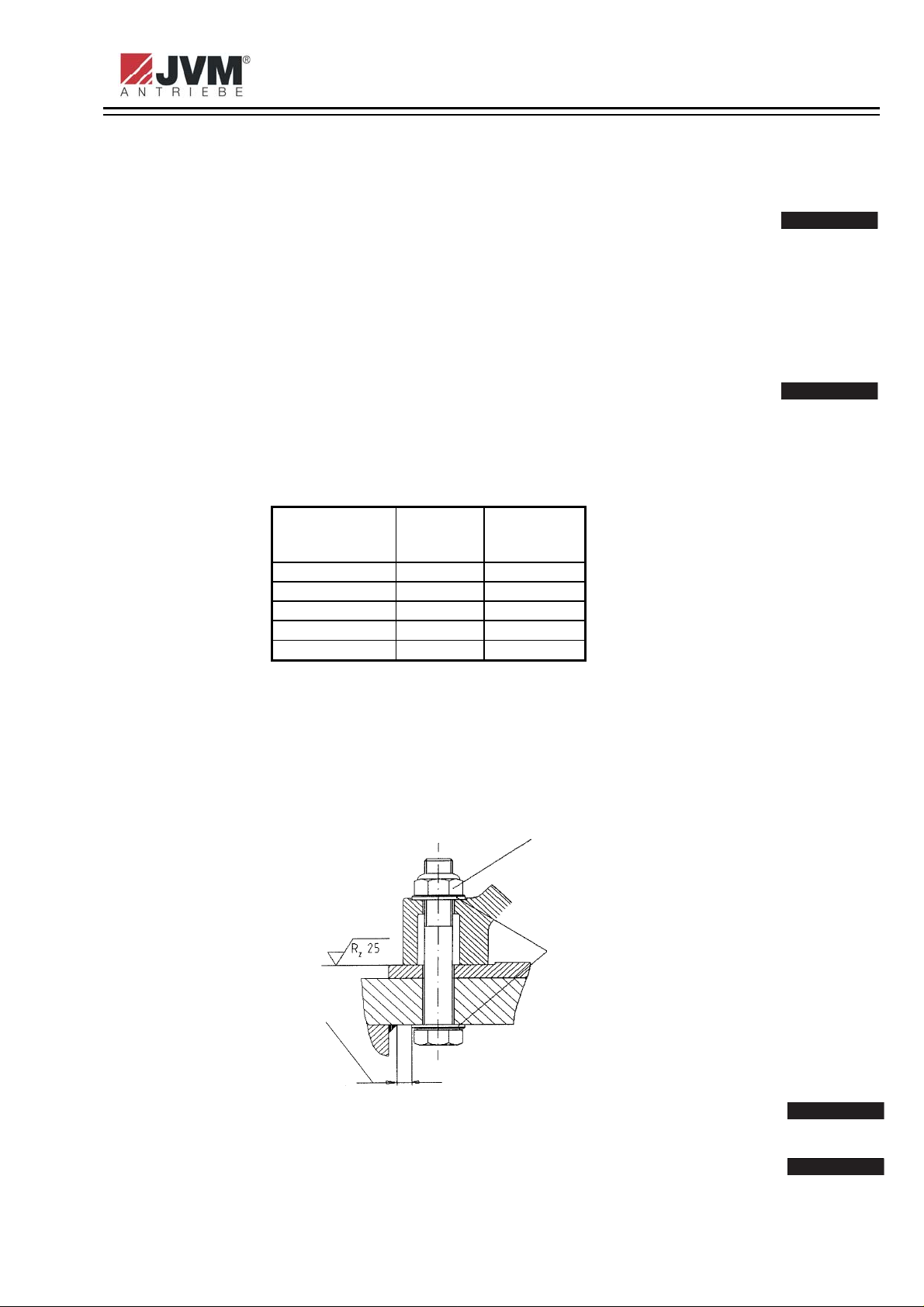

6. Installation

The unbalance vibrator must be installed by qualified personnel. The manufacturer

does not accept any responsibility for faulty installation!

The foot support surfaces of the unbalance vibrator must be metallically bright and

free from grease, paint or other impurities.

The support surfaces for the unbalance vibrator on the machine must be plane

parallel, have a maximum peak-to-valley height of R

bright as well as being free from dirt and grease.

The machine part on which the unbalance motor is mounted (e. g. motor crossmember, motor base plate), must be sufficiently strong, to eliminate the possibility of

deformation (bending, torsion) between the foot contact surfaces of the unbalance

vibrator as a result of the occuring centrifugal forces. The unbalance vibrator is not a

load-bearing component!

JV/ JVA 10 M 10 49

JV/ JVA 13 M 16 210

JV/ JVA 15 M 20 410

JV/ JVA 17/ 20 M 24 710

JV/ JVA 24/ 27 M 30 1450

Thre thread size of the fixing screws, of quality class 8.8, and the required tightening

torques are given in the above table. Self-locking nuts of quality class 8 must be

used. One washer according to DIN 125, made at least of St-50, must be placed

under the screw head and nut.

OPERATING MANUAL

Unbalanced

mass vibration

generator

25 µm and be metallically

z

Thread Torque MA

(Nm)

JV/JVA 10-27

7 of 19

Self-locking nut quality class

8, Springstop- nut or

Cleveloc-nut

Type JV/JVA 10 - 20: washer DIN

125, St 50 Type JV/JVA 24 + 27:

washer dia. 50/31 x 10, St 50

A minimum distance

must be bemaintained!

After the first 50 hours of operation the unbalance vibrator, the fixing screws must be

retightened to the correct tightening torque.

The centrifugal weights of an unbalance vibrator must be set identically at both

sides. The setting can be read off with % - scales provided on the centrifugal

weights.

Loading...

Loading...