Integrated Step Motors,

QuickStep,

MIS231, MIS232, MIS234,

MIS340, MIS341, MIS342,

MIS430, and MIS432

Including Step Motor Controller

SMC75, SMC85

User Manual

JVL Industri Elektronik A/S

LB0053-22GB Revised 25.th. January 2016

Important

User Information

!!

The MIS and SMC series of products are used to control electrical

and mechanical components of motion control systems.

You should test your motion system for safety under all potential

conditions. Failure to do so can result in damage to equipment

and/or serious injury to personnel.

Please contact your nearest JVL representative for technical assistance. Your

nearest contact can be found on our web site www.jvl.dk

Copyright 1998-2016, JVL Industri Elektronik A/S. All rights reserved.

This user manual must not be reproduced in any form without prior written

permission of JVL Industri Elektronik A/S.

JVL Industri Elektronik A/S reserves the right to make changes to information contained in this manual without prior notice.

Furthermore JVL Industri Elektronik A/S assumes no liability for printing errors or other omissions or discrepancies in this user manual.

Warning

MacTalk and MotoWare are registered trademarks

JVL Industri Elektronik A/S

Blokken 42

DK-3460 Birkerød

Denmark

Tlf. +45 45 82 44 40

Fax. +45 45 82 55 50

e-mail: jvl@jvl.dk

Internet: http://www.jvl.dk

`зенЙенл

1 Introduction .................................................................................................................... 7

1.1 Non-programmable motors ............................................................................................................................... 8

1.2 Programmable motors ...................................................................................................................................... 10

1.3 General description .......................................................................................................................................... 12

2 Hardware - Intelligent products .................................................................................. 13

2.1 Power Supply .................................................................................................................................................... 14

2.2 Inputs ................................................................................................................................................................ 18

2.3 Analogue Inputs ................................................................................................................................................ 21

2.4 User Outputs .................................................................................................................................................... 25

2.5 Serial interfaces overview ................................................................................................................................. 27

2.6 RS485 Interface ................................................................................................................................................. 28

2.7 Special Outputs ................................................................................................................................................. 30

2.8 Special Connections .......................................................................................................................................... 32

2.9 Handling noise in cables .................................................................................................................................... 33

2.10 How to connect MIS23x ................................................................................................................................... 35

2.11 How to connect MIS34x ................................................................................................................................... 37

2.12 LED indicators at the MIS34x ........................................................................................................................... 53

2.13 LED indicators at the MIS34x ........................................................................................................................... 54

2.14 LED indicators at the MIS34x ........................................................................................................................... 55

3 Hardware Non-intelligent products ............................................................................. 57

4 Using MacTalk ............................................................................................................... 59

4.1 Using the MacTalk software ............................................................................................................................. 60

4.2 How to update MacTalk ................................................................................................................................... 68

4.3 How to update the motor firmware ................................................................................................................. 69

4.4 How to update the encoder firmware ............................................................................................................. 70

5 Description of functions ................................................................................................ 71

5.1 Adjusting the motor current ............................................................................................................................. 72

5.2 Auto Correction ............................................................................................................................................... 73

5.3 Absolute position back-up ............................................................................................................................... 75

5.4 SSI encoder/sensor interface ............................................................................................................................. 78

5.5 Absolute Multi-turn Encoder ............................................................................................................................ 85

5.6 Position Limits ................................................................................................................................................... 91

5.7 Mechanical Zero search .................................................................................................................................... 96

6 Modes ............................................................................................................................ 97

6.1 Passive Mode .................................................................................................................................................... 98

6.2 Velocity Mode ................................................................................................................................................... 99

6.3 Positioning Mode ............................................................................................................................................ 100

6.4 Gear Mode ...................................................................................................................................................... 101

6.5 Zero search modes ......................................................................................................................................... 110

7 Error Handling ............................................................................................................ 115

8 Registers ......................................................................................................................117

8.1 Introduction to registers ................................................................................................................................. 118

8.2 MIS23x Registers ............................................................................................................................................. 119

8.3 MIS34x & MIS43x Registers ............................................................................................................................ 154

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 3

9 Building Sequential Programs .................................................................................... 189

9.1 Getting started with programming ..................................................................................................................190

9.2 Programming Main window ............................................................................................................................191

9.3 Programming menu .........................................................................................................................................192

9.4 How to build a program ..................................................................................................................................193

9.5 General programming hints .............................................................................................................................196

9.6 Command toolbox description ........................................................................................................................197

9.7 Graphic programming command reference ....................................................................................................198

10 CANopen Introduction ............................................................................................... 217

10.1 General information about CANopen .............................................................................................................218

10.2 Connection and setup of the CAN bus ...........................................................................................................222

10.3 Using CANopenExplorer ................................................................................................................................226

10.4 Objects in the DS301 standard ........................................................................................................................231

10.5 Objects used in the DSP-402 standard ............................................................................................................241

10.6 Flexible Register setup .....................................................................................................................................248

10.7 More details of CANopen Theory ..................................................................................................................249

11 Modbus interface ........................................................................................................ 261

11.1 Modbus in MIS34x and SMC85 ........................................................................................................................262

12 Stand alone electronics .............................................................................................. 265

12.1 Step motor drivers (SMDxx) ...........................................................................................................................266

12.2 Step motor controllers (SMCxx) .....................................................................................................................268

12.3 How to connect the motor .............................................................................................................................273

12.4 How to connect in general ..............................................................................................................................276

12.5 Quick Start (SMC75A1MxAA) .........................................................................................................................277

13 Technical Data ............................................................................................................ 278

13.1 MIS23x Technical Data ....................................................................................................................................279

13.2 MIS34x Technical Data ....................................................................................................................................280

13.3 SMC75 Technical Data ....................................................................................................................................281

13.4 Torque Curves ................................................................................................................................................282

13.5 Physical Dimensions ........................................................................................................................................284

13.6 Life time ...........................................................................................................................................................287

13.7 Trouble-shooting guide ...................................................................................................................................288

14 Connection to other Equipment ................................................................................ 289

14.1 Connecting SMI30/SMC35 to MIS/SMC75 ......................................................................................................290

14.2 Connecting MISxx/SMC75 to SMD73 .............................................................................................................291

14.3 Connecting MISxx/SMC75 to SMD41 .............................................................................................................292

14.4 Connecting MISxx/SMC75 to MAC00-Bx .......................................................................................................293

14.5 Connection to PLC/PC Boards .......................................................................................................................294

15 Accessories .................................................................................................................. 295

15.1 Cables ..............................................................................................................................................................296

15.2 Power Supplies ................................................................................................................................................297

15.3 Brakes and shaft reinforcement .......................................................................................................................298

15.4 Gear and brake mounting instruction ..............................................................................................................299

16 Appendix ..................................................................................................................... 301

16.1 MIS23x & SMC75 Registers detailed ...............................................................................................................302

16.2 MIS34/43/SMC85 Registers detailed ................................................................................................................312

16.3 Velocity accuracy .............................................................................................................................................322

16.4 Command timing .............................................................................................................................................323

16.5 More about program timing ............................................................................................................................324

16.6 Motor Connections .........................................................................................................................................325

16.7 Serial communication ......................................................................................................................................327

16.8 MIS Ordering Information ...............................................................................................................................332

4 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

16.9 SMC75/85 Ordering Information .................................................................................................................... 333

16.10 MST Motor Ordering Information .................................................................................................................. 334

17 Declarations ................................................................................................................ 336

17.1 CE Declaration of Conformity ........................................................................................................................ 337

17.2 Vibrationtest certificate MIS23x ...................................................................................................................... 339

17.3 Vibrationtest certificates MIS34x .................................................................................................................... 340

17.4 Index ............................................................................................................................................................... 342

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 5

6 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

1 Introduction

MIS34x family

(MIS340 shown)

This user manual describes the set-up and usage of the following products:

Complete motors with build-in controller or driver

• Types MIS231, MIS232 and MIS234 (NEMA23 sizes)

• Types MIS340, MIS341 and MIS342 (NEMA34 sizes)

• Types MIS43x (NEMA43 sizes) - only limited supported in this manual.

MIS23x family

(MIS232 shown)

TT2317-01GB

Stand-alone electronics without motor

• Types SMD73 and SMD74 drive PCB without intelligence (not programmable)

• Types SMC75 and SMC85 controller PCB with intelligence (fully programmable)

All the quickstep motors are available as a fully programmable product with a wide range

of features also covering a simple pulse and direction interface.

The smaller quickstep motors size MIS23x are also available as a “non-programmable”

and more simple version with pulse and direction inputs for applications which are price

sensitive.

Examples of motors and stand alone electronics.

MIS342 and MIS340

Standard version

MIS340

with Bluetooth

MIS232

with step and direction input

SMC85A1

Step motor controller

MIS230-234

Standard version

SMC75A1

Step motor controller

SMD73

Step motor driver

TT2319-01GB

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 5

1.1 Non-programmable motors

MIS231 Stepmotor

with pulse and direction input

TT2322-01GB

The QuickStep series of Stepper motors with integrated electronics represents a major step forward.

All the necessary electronics in a stepper system are integrated in the motor itself.

In the past, a traditional motor system has typically been

based on a central controller unit located remote from

the motor. This configuration however has the disad

vantage that installation costs are a major part of the total expense of building machinery.

The basic idea of the QuickStep motors is to minimize

these costs but also to make a component that is much

better protected against electrical noise, which can be a

typical problem when using long cables between the

controller and motor.

The stepper motor, encoder and electronics are specially developed by JVL so that together they form a

closed unit, in which the power driver and controller

are mounted inside the motor.

The advantages of this solution are:

• De-central intelligence.

• Simple installation. No cables between motor and

driver.

• EMC safe. Switching noise remains within

motor. (Noise can however be introduced in the

DI/DO).

• Compact. Does not take space in cabinet.

• Low-cost alternative to separate step or

servo motor and driver.

In the past decade, pulse/direction interfaces have become increasingly popular for the control of step and

servo motors. This is due to the fact that pulse/direction

signals provide a simple and reliable interface which is

100% digital, precise, and offers immediate response.

When a pulse is sent, the motor instantaneously moves

1 step forward.

For example, if the motor has a resolution of 200 steps/

revolution, it will move 1.8 degrees. By changing the

frequency of the applied pulse signal, it is possible to ac

celerate the motor.

-

By counting the number of pulses, the motor’s position can be determined without any error whatsoever. The direction input is used to determine

the motor’s direction of rotation. JVL’s QuickStep

motors with pulse/direction interface offer the fol

lowing advantages:

• Very simple technology that is easy to understand and apply.

• High stability and low cost because the technology is simple with few components.

• Only one cable with 4 wires is required, so

cabling costs are a minimum.

• No controller in the control cabinet.

• All positioning and control is performed by the

PLC, so there is no duplication of software or

cabling.

• Robust IP67 connector and IP55 motor housing

for applications in demanding environments.

• Thermally protected against current overload

and short-circuit.

• Reacts instantaneously. The motor starts within

microseconds.

• 5V or 24V PNP/NPN inputs ensure compatibility with any controller.

• Step resolution of 200, 400, 800, 1000 or 1600

pulses/revolution.

• Supply voltage 18-28VDC (based on SMD73).

• Supply voltage 18-48VDC (based on SMD74).

• Possibility for encoder feedback.

All the required electronics are integrated in the

motor itself in a single compact unit. The motor can

be supplied with the connector either on the back

or side of the housing. M12 connector is standard,

but cable glands or DSUB connector can be deliv

ered on request.

For further information on the pulse/direction

driver see also SMD73 Data-sheet and Tech

-

nical Note.

-

-

-

6 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

1.1 Non-programmable motors

1.1.1 Block diagram, Pulse/Direction Version

r

o

t

c

e

n

n

o

18-28VDC (SMD73)

c

18-48VDC (SMD74)

y

l

p

p

u

s

r

e

w

o

P

n

o

i

t

c

e

r

t

i

u

d

p

d

n

i

n

a

p

e

t

S

t

u

p

t

u

O

r

e

d

o

c

n

E

Bus Supply

Ground

Stepclock

Direction

SMD73 or SMD74 Driver

200, 400, 800,

1000, 1600 step

Driver

High speed

digital logic

array

5V to 24V

PNP/NPN

Selector

Encoder

A

B

Phase A

Phase B

Optional

Motor

2-phase

stepper

motor

Incremental

encoder

TT2178-02GB

1.1.2 Driver Connections

Versions with pulse and direction control:

Connections for versions with 1 M12 connector. (See also SMD73 data-sheet)

M12 5 pin male Description JVL cable WI1000M12 F5TxxN

1 P+ (18-28VDC) Brown

2 Pulse White

3 P- Blue

4 Direction Black

5 Signal Ground Grey

xx: 05 for 5 metre and 20 for 20 metre cable.

Versions with cable glands and 5 m cable

Colour Code Description

Red P+ (18-28VDC)

Black P-

Blue Direction

White Pulse

Shield Signal ground

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 7

1.2 Programmable motors

MIS232 with controller

The compact step motor controller SMC75

and SMC85 is designed for positioning and

speed control of stepper motors.

SMC75 is mounted directly in the housing of

the JVL QuickStep motors MIS 231, 232 and

234, and SMC85 is mounted in the MIS34x and

MIS43x, forming a complete integrated step

motor.

They may also be used with other types of step

motors according to customers requirements.

The basic features of the controller are:

• Serial RS485 or 5V serial position controller.

• Position controller with graphic programming.

• Option for CANbus, CANopen DS-301/

DSP-402 or DeviceNet (under develop

ment).

• A dual supply facility is available so that

position and parameters are maintained at

emergency stop.

• Gear mode.

• MACmotor protocol so MACmotor and

Quickstep motors can be connected on

the same RS485 bus.

• Command for easy PLC/PC setup and

communication.

• Power supply 12-48VDC.

• Fixed 1600 pulses/rev.

• Built-in 16Bit µprocessor (SMC75) and

32Bit µprocessor (SMC85) with 8 In/Out

that can be configured as inputs, PNP out

puts or analogue inputs. 5V serial and

RS485 interface for set up and program

ming.

•MODBUS interface.

• 9.6 to 1Mb communication.

-

-

• Driver technology is improved as compared to SMD73 and supply voltage is

12-48VDC.

When used with the QuickStep motor or

mounted on any other step motor the advantages of the controller are:

• De-central intelligence.

• Simple installation. No cables between

motor and driver.

• EMC safe. Switching noise remains

within motor.

• Compact. Does not take space in cabinet.

• Low-cost alternative to separate step

or servo motor and driver.

• Stall detect by means of magnetic

encoder with resolution of up to 1024

pulses/rev. (H2 option)

• Absolute multi turn encoder for keeping the position permanent also during

power down. (H3 option).

• Interface possibilities:

• From PC/PLC with serial commands via

5V serial or RS485.

• Pulse/direction input. Encoder output.

• CANopen, DeviceNet.

• 8 I/O, 5-28VDC that can be configured

as Inputs, Outputs or analogue inputs.

• Future option for Profibus DP, Ethernet,

Bluetooth and Zigbee wireless.

-

8 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

1.2 Programmable motors

S23

S

f

f

1.2.1 Block diagram, Positioning/Speed Control

MI

x, MIS34x, MIS43x Integrated Stepper Motor

Power supply

ace

erial inter

Field Bus

unction

Multi

Ethernet

connectorUser I/O connector

connector

connector

I/O Interface

connectors

P+

P+

Main supply

12-48V (SMC75)

12-80V (SMC85)

CVI

12-28V logic

(Ground)

P-

CVO

IO1

IO8

B+

CAN R

CAN L

A+

A-

B+

B-

IN

OUT

Fuse

750mA

Output

source

driver

IN1 Analog 1

Digital 1

IN8 Analog 8

Tx

Digital 8

Rx

A-

RS485

Driver

CAN

Tranciever

RS422

4

Ethernet

4

Interface

SMC75 or SMC85 Controller

Switchmode

Power

Supply

16Bit (SMC75)

32Bit (SMC85)

Microprocessor

Integrated Flash

Optional

Optional

Optional

MIS34x,

MIS43x

with

Wireless

Driver

High speed

digital logic

array

Optional

MIS34x,

MIS43x

Motor

Phase A

2-phase

stepper

Phase B

motor

Optional

Encoder

Magnetic

Incremental

Encoder

MIS23x:

H2 option - 1024 cpr

MIS34x and MIS43x

H2 option - 1024 cpr

H3 option - 65536 cpr

TT2140-02GB

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 9

1.3 General description

The QuickStep motors are currently available in 6 different models divided in 2 families.

NEMA23 covers: MIS231, MIS232 and MIS234, with holding torque ratings from 1.1 to

3.0 Nm and NEMA34 covers: MIS340, 341 and 342. The basic functions and I/O features

are the same for all models. MIS43x models up to 25.0 Nm are under development.

Motor Type MIS231 MIS232 MIS234 MIS340 MIS341 MIS342 Unit

Holding Torque 1.1 1.6 2.9 3.0 6.1 9.0 Nm

Inertia 0.3 0.48 0.96 1.4 2.7 4.0 kgcm

Flange NEMA23 (57x57 mm.) NEMA34 (87x87 mm) -

Length 96 118.5 154 9[3.74] 126[4.96] 156.0[6.14] mm [Inch]

Shaft Ø 6.35 6.35 10.0 9.53 14.0 14.0 mm

Shaft radial play Max. 0.02 (450g load) Max. 0.02 (450g load) mm

Shaft axial play Max. 0.08 (450g load) Max. 0.08 (450g load) mm

Max radial force 7.5 (20mm from flange) 22 (20mm from flange) kg

Max axial force 1.5 6 kg

Weight 0.9 1.2 1.8 2.7 4.2 5.8 kg

1.3.1 Basic modes/functions in the QuickStep motor

The QuickStep motor offers the following functions:

2

Mode Description

Passive

Velocity

Position

Gear

The motor will be in a completely passive state but communication is active and internal

registers can be setup. Motor shaft can be turned by hand.

The motor velocity can be controlled using MacTalk software or by setting register 5 (V_SOLL)

using serial or program commands.

The motor position can be controlled using MacTalk or by setting register 3 (P_SOLL) using

serial or program commands.

The motor position and velocity can be controlled by pulse and direction or encoder signals

at the inputs “IN1” and “IN2”.

The gear ratio can be set to a large ratio by using register 14 (GEAR1) and register 15

(GEAR2).

10 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2 Hardware - Intelligent products

This chapter ONLY covers intelligent products which are based on either the SMC75 or

SMC85 stepper controller.

The following pages explains how the I/O, Power supply, Interface etc. can be connected

and used.

Please notice that the SMC75 controller PCB is used in all the MIS23x motors and the

SMC85 controller PCB is used in all the MIS34x motors.

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 11

2.1 Power Supply

2.1.1 General Aspects of Power Supply - only MIS23x motors

Powering of the Controller is relatively simple.

To ensure that powering of the Controller is as simple as possible, only a driver and control voltage are connected to the Controller. Internal supply circuitry ensures the correct

supply voltages for the driver, control circuits, etc.

The motor can be operated with the same power supply if using 12 – 28VDC for both

Driver and control voltage. Often a higher voltage than 28VDC is desired as main supply

since the motor have a better torque performance at higher speed. In this case a separate

control supply (CVI) must be used with max. 28VDC.

Only MIS23x

MIS23x Power Supply

+

Main Power Supply

12-48VDC

Control Voltage

12-28 VDC

MIS23x Motor

P+

(Main supply)

CVI

P-

(GND)

NB: for actual connections, see drawing Step motor controllers (SMCxx), page 266

2.1.2 Main Power Supply (P+) - only MIS23x motors

The Driver section requires a supply voltage in the range 12-48VDC nominal. It is strongly recommended to use a voltage as high as possible since it will give the best torque performance of the motor at high speeds.

For optimum performance, it is recommended that a capacitance of minimum 1000µF is

connected to the power supply. It should be mounted as close as possible to the motor.

Similarly, it is recommended that 0.75mm cable is used to connect the power supply to

the Controller. If the Controller supply voltage falls below10V, the internal reset circuitry

will reset the driver. Provision should therefore be made to ensure that the supply volt

age is always maintained at a minimum of 12V, even in the event of a mains voltage drop.

The Controller is protected against incorrect polarity connection but not over-voltage.

(Control circuit supply)

TT2159GB

-

Warning: Power supply voltage higher than 50VDC will cause damages.

12 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.1 Power Supply

C

C

2.1.3 Control Voltage (CVI) - only MIS23x motors

The control voltage should be in the range 12-28VDC and is used to supply the microprocessor circuit, internal functions in general and the user output driver (O1-8).

To ensure that position and parameters are maintained after an emergency stop, the

control voltage should be maintained under a stop situation where the P+ (main power)

is disconnected.

Warning: Control voltage higher than 30VDC will damage the controller.

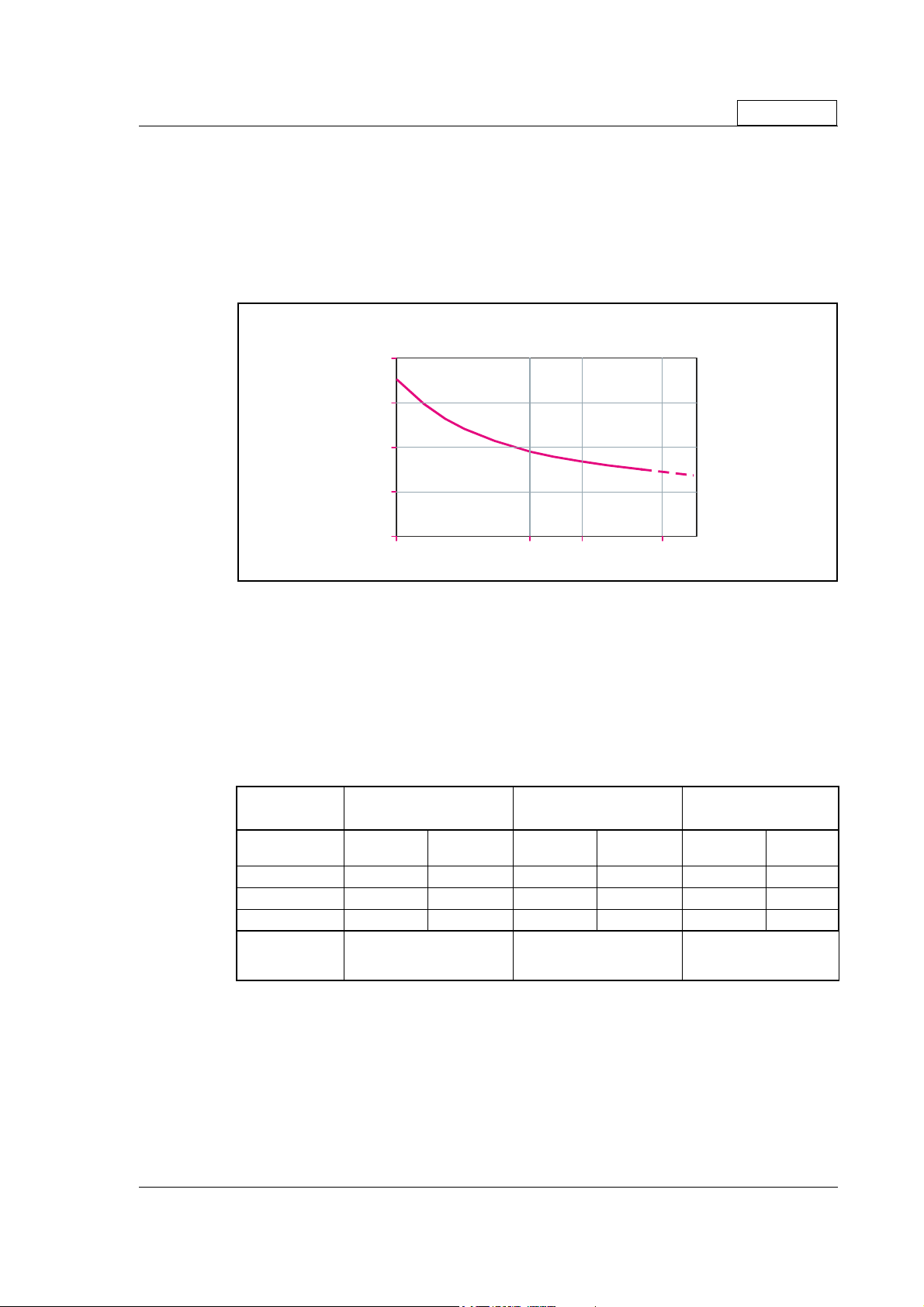

ontrol circuit supply current (CVI) versus voltage

mADC

200

150

100

50

Only MIS23x

0

10 20

TT2325-01GB

24

30

VD

2.1.4 Power Supply Grounding

It is recommended that the housing is connected to ground or common 0 VDC. The

overall earthing of the system must be done at a central point close to the power supply.

2.1.5 Dimensioning power supply and fuse - only MIS23x motors

The power supply must be dimensioned according to the actual motor size.

The size of the pre-fuse also depends on the actual model of the MIS motor.

Use the following table to select the power supply and fuse ratings.

Desired

voltage

-

12VDC 20W T4A 40W T6.3A 60W T10A

24VDC 40W T4A 80W T6.3A 160W T10A

48VDC 80W T4A 160W T6.3A 320W T10A

Recommended

power supply

Supply

rating

PSU24-075

PSU48-240

PSU40-4

MIS231 MIS232 MIS234

Fuse size Supply

rating

PSU24-240

PSU48-240

PSU40-4

Fuse size Supply

rating

PSU24-240

PSU48-240

PSU40-4

Fuse size

See also the appendix which shows the standard power supplies that JVL offers.

2.1.6 General power supply description

The supply voltage can be chosen in the range 12VDC to 48VDC. However the maximum torque is based on 48VDC. A lower voltage will decrease the speed/torque performance, and in general it is not recommended to run the motor at more than 300RPM if

for example 24VDC is used as supply.

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 13

2.1 Power Supply

Power supply connections to a MAC140 or a QuickStep motor

Only MIS23x

Make sure that all

involved units are

connected to the same

potential

Power supply

+12-48VDC

MAC140 Motor

with MAC00-B1,

B2 or B4

Power

Supply

Control voltage

Only MAC50-141 with

B2 or B4 (Optional)

P+

P-

O+

MIS23x QuickStep motor or

SMC75 Controller

Power

Supply

Control

Voltage

P+

P-

CVI

GND

(control voltage)

+12-28VDC

(Bus voltage)

Allways use shielded cables.

The screen must be connected

to common ground at

the power supply

2.1.7 Select Your Power Supply - only MIS23x motors

We recommend the use of 48VDC or the highest possible voltage to supply the motor.

As seen in the chart below, it is clear that the torque below 100 RPM is independent of

supply voltage. But above 300-500 RPM, the torque at 24VDC is half compared to the

torque at 48VDC.

Additionally, higher voltage gives better current and filter regulation and thereby better

performance. If there is a tendency for motor resonance, a lower supply voltage can be

a solution to the problem.

TT2220GB

14 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.1 Power Supply

2.1.8 Control Voltage (CVI) - only MIS34x motors

The control voltage should be in the range 12-28VDC and is used to supply the microprocessor circuit, internal functions in general and the user output driver (O1-8).

To ensure that position and parameters are maintained after an emergency stop, the

control voltage should be maintained under a stop situation where the P+ (main power)

is disconnected.

Warning: Control voltage higher than 30VDC will damage the controller.

2.1.9 Power Supply Grounding

It is recommended that the housing is connected to ground or common 0 VDC. The

overall earthing of the system must be done at a central point close to the power supply.

2.1.10 Dimensioning power supply and fuse - only MIS34x motors

The power supply must be dimensioned according to the actual motor size.

The size of the pre-fuse also depends on the actual model of the MIS motor.

Use the following table to select the power supply and fuse ratings.

Only MIS34x

Desired

MIS340 MIS341 MIS342

voltage

-

24VDC 120W T6.3A 200W T6.3A 250W T10A

48VDC 240W T6.3A 350W T6.3A 500W T10A

80VDC 450W T6.3A 600W T6.3A 700W T10A

Recommended

power supply

Supply

rating

PSU24-240

PSU48-240

PSU80-4

Fuse size Supply

Please notice that the specified wattage values are worst case values at maximum torque.

See also the appendix which shows the standard power supplies that JVL offers.

2.1.11 General power supply description

The supply voltage at the main power (P+ terminals) can be chosen in the range 12VDC

to 80VDC (nominal). However the maximum performance is based on a 80V DC supply.

A lower voltage will decrease the speed/torque performance.

See also the torque curves in the appendix Section 13.4, page 280.

rating

PSU24-240

PSU48-240

PSU80-4

Fuse size Supply

rating

PSU24-240

PSU80-4

Fuse size

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 15

2.2 Inputs

2.2.1 Inputs

The Quickstep motors has 8 inputs/outputs (IO’s) that each can be set individually to input, output or analogue input 0-5VDC via MacTalk or software commands. See Using

MacTalk, page 57, for setup.

This means for example that it is possible to have 4 inputs, 3 outputs and one analogue

input.

Please notice: The number of available IO terminals available may vary de-

!

Input/output functional diagram:

pending at which motor type you are using. Please the chapter Connector overview for the MIS23x, page 33 or Connector overview for the MIS34x, page 35

Internal µ-Processor

Digital output

Digital input

Analog input

TT2160-02GB

2.2.2 General Input features

• Inputs are TTL to 28VDC compliant.

• Over-current protection and thermal shut-down.

•10 kOhm input resistance.

• No galvanic isolation.

• Zero search input can be selected to any input 1 to 8.

• Digital filter can be enabled for each input selectable from 0 to 100ms. If disabled, the

response time is 100µs.

• Analogue filter can be selected for all analogue inputs.

Overcurrent protection

+5V

4k7

1nF

<1 Ohm

CVI

IO1 to IO8

10kOhm

Only MIS23x:

• High speed incremental counter on Input 1 and Input 2.

• High speed Pulse/direction on Input 1 and Input 2 for gear mode.

• Positive and negative limit can be selected to any input 1 to 8 (only MIS23x)

16 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.2 Inputs

Note that End-of-travel inputs,

I1-8 and HM share a

Se le ct exte rn a l

or inte rn a l p o w e r

sup p ly to s e n s o rs

or s imila r

comm on ground ( GN D).

All three ground terminals ( GND and P-)

are connected together.

PNP Output

Power Supply

+5-30VDC

This d iagra m is u s ed if a n NPN outp u t is c o nnec t e d

Power Supply

+5-30VDC

2.2.3 General

The Controller is equipped with a total of 8 digital inputs. Each input can be used for a

variety of purposes depending on the actual application. Each of the inputs can be detect

ed from the actual program that has been downloaded to the Controller or via serial

commands.

The Inputs are not optically isolated from other Controller circuitry. All of the Inputs

have a common ground terminal, denoted GND. Each Input can operate with voltages

in the range 5 to 30VDC. Note that the Inputs should normally be connected to a PNP

output since a positive current must be applied for an input to be activated.

Note that CVO is available as CVI on the I/O connectors. This provides the facility that

local sensors can be supplied directly from the controller.

+

Inductive

sensor

or similar

Inductive

sensor

+

or similar

NPN Output

R

CVO

User Inputs

cçê=~Åíì~ä=ÅçååÉÅíáçåë=

cçê=~Åíì~ä=ÅçååÉÅíáçåë=

ëÉÉ=Çê~ïáåÖ=é~ÖÉ=NN

ëÉÉ=Çê~ïáåÖ=é~ÖÉ=NN

TT2161GB

-

2.2.4 Connection of NPN Output

If an Input is connected to an NPN output, a Pull-Up resistor must be connected between the Input and the + supply. See the illustration above.

The value of the resistance used depends on the supply voltage. The following resistances

are recommended:

Supply Voltage Recommended Resistance R

5-12VDC 1kOhm / 0.25W

12-18VDC 2.2kOhm / 0.25W

18-24VDC 3.3kOhm / 0.25W

24-30VDC 4.7kOhm / 0.25W

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 17

2.2 Inputs

2.2.5 Digital inputs - features.

All of the eight I/O signals can be used as digital inputs. The sampled and possibly filtered

value of each input is stored in the Input’s register (reg. 18). Unlike the analogue inputs,

there is only one value for each digital input, so it must be configured to be either unfil

tered or filtered.

Unfiltered (high-speed) digital inputs are sampled every 100 µS (micro-seconds).

Filtered digital inputs are sampled every milli-second, and the filter value can be set in the

range 1 to100 mS, so the filtered input must be sampled to have the same logical value

for that number of samples in a row. Once an input has changed state after passing the

filtering, it will again take the same number of samples of the opposite logical level to

change it back. For example, if the filter is set to 5 mS and the start value is 0 (zero), the

input will remain at zero until three samples in succession have been read as 1 (one). If

the signal immediately drops down to 0 again, it will take three samples of zero in suc

cession before the register bit gets set to zero.

Note that filtering of the digital inputs does load the micro-controller, so if filtering of the

digital inputs is not needed, ALL the inputs can be selected as high-speed to reduce the

load.

-

-

18 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.3 Analogue Inputs

8

2.3.1 General

The 0-5V Analogue Inputs are used for example when the Controller is operated as a

stand-alone unit. In this kind of application it can be an advantage to use a potentiometer,

joystick or other device for adjusting speed, position, acceleration, etc.

In these modes of operation, the motor is controlled to produce a velocity or position,

etc., which is determined by, and proportional to, the voltage applied to the Analogue

Input.

The Analogue Inputs share a common internal supply with the GND and P- terminal and

are not optically isolated from all other inputs and outputs. The Analogue Inputs are pro

tected against voltage overload up to 30V peak and have a built-in filter which removes

input signal noise. See

Always use shielded cable to connect the source used to control an Analogue Input since

the motor, etc., can easily interfere with the analogue signal and cause instability.

The Controller is equipped with 8 analogue-to-digital converters (ADC) which convert

the detected analogue signal level. The ADCs have a resolution of 10bit.

In order to use the Analogue Inputs as 0-20 mA inputs, a 250 Ω, 1% resistor must be

connected between IO 1-8 and GND.

PC-card or

Poten tio m e ter

Ground

0-5V Out

TT2164GB

Note ! : screen only

connected to signal source.

Analogue inputs

0-5VDC Input

Screen

Analogue input filters, page 20.

-

0-20mA

250 Ohm

1%

0.25W

TT2186GB

IO 1 -

P-

Please notice: The number of available IO terminals available may vary depending at which motor type you are using. Please the chapter Connector over-

!

view for the MIS23x, page 33 or Connector overview for the MIS34x, page 35

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 19

2.3 Analogue Inputs

2.3.2 Analogue input filters

The Intelligent MIS motors have 8 general-purpose I/Os, that can be used as both digital

inputs, digital outputs and analogue inputs. When an I/O is configured to be an input, it

simultaneously has both a digital value (high or low) and an analogue value in the range

0.00 to 5.00 Volts. Input voltages higher than 5.0 Volts will be internally limited and read

as 5.00 Volts.

The inputs use a resolution of 10 bits, which means that in the raw motor units a value

of 5.00 Volts reads out as the value 1023. This gives a resolution of 5.00/1023 = 4.8876

mV per count.

The eight values from the analogue inputs are maintained by the SMC75 firmware in the

registers 89...96 as raw, unfiltered values with the fastest possible update frequency, and

additionally in the registers 81...88 as filtered values. The firmware does not use any of

the values for dedicated functions. It is always up to the program in the motor to read

and use the values.

The analogue filtered values are typically used to suppress general noise or to define how

quickly the input value is allowed to change, or in some cases to limit the input voltage

range. A typical example is an analogue input that is connected to a manually controlled

potentiometer, so an operator can regulate the speed of the machine by turning a knob.

In many environments, this setup is subject to noise, which could make the motor run

unevenly, and cause too sharp accelerations or decelerations when the knob is turned.

The filter functions supported in the SMC75 firmware always use three different steps.

Confidence check

First the raw input value is compared to two Confidence limits: Confidence Min and

Confidence Max. If the new value is either smaller than the Confidence Min limit or larger

then the Confidence Max limit, it is simply discarded (not used at all), and the value in its

associated register is unchanged. This is done to eliminate noise spikes. Confidence limits

can only be used if not all of the measurement range is used. Values of 0 for Confidence

Min and 1023 for Confidence Max will effectively disable the confidence limits.

Slope limitation

After a new sample has passed the Confidence limit checks, its value is compared with

the last filtered value in its associated register. If the difference between the old and the

new value is larger than the Max Slope Limit, the new value is modified to be exactly the

old value plus or minus the Max Slope Limit. This limits the speed of change on the signal.

Since the samples come at fixed intervals of 10 mS, it is easy to determine the number of

Volts per millisecond. A value of 1023 will effectively disable slope limitation.

Filtering

After a new sample has both passed the confidence limits checks and has been validated

with respect to the slope limitation, it is combined with the last filtered value by taking a

part of the new sample and a part of the old filtered value, adding them together and

writing the result back to the final destination register – one of the registers 81...88. For

instance a filter value of 14 would take 14/64 of the new sample plus 50/64 of the old

value. A filter of 64 would simply copy the new sample to the rule, thus disabling the fil

tering. This completes the filtering of the analogue inputs.

-

20 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.3 Analogue Inputs

Confidence alarms

If either of the Confidence Min or Confidence Max limits is used, it may be possible that

no new samples are accepted, which means that the filtered value will never change even

though there is a change in the input voltage. For instance, if the Confidence Min limit is

set to 2.0 V, and the actual input voltage is 1.50 V, the filtered value may continue to read

out 0.00 V (or the last value it had before exceeding the confidence limits).

To help troubleshooting in cases like this, each input has a status bit that is set if at least

half of the new samples during the last second lie outside either confidence limit. It is not

possible to see which of the confidence limits is violated. The status bits are updated once

per second.

Slope alarms

If the Max Slope limit is used (by setting its value lower than 1023), it may be possible

that many samples have their value limited. This is not necessarily an error in itself, but

can be a sign of a fault causing a noisy signal, or it can be a sign that the Max Slope limit is

set too low, which can have implications if the analogue voltage is used to control the mo

tor speed, torque, etc.

To help troubleshooting in cases like this, each input has a status bit that is set if at least

half of the new samples during the last second were limited by the Max Slope setting. The

status bits are updated once per second.

Example of analogue input filter operation:

Note that even though the examples use units rather than Volts, decimal values are used,

since the motor uses a much higher resolution internally to store the units.

Also note that as long as the slope limitation is in effect, the result will keep a constant

slope even when using a filter. When the slope limitation is no longer in effect, the filter

will cause the value to approach the final result more slowly as it approaches the result.

-

Confidence Min = 0, Confidence Max = 500, Max Slope = 10, Filter = 8, Old filtered

value = 0.

Sample 1 = 100 Confidence OK, slope limit to 0 + 10 = 10,

result = 10*(8/64)+0*(56/64) = 1.25 units.

Sample 2 = 100 Confidence OK, slope limit to 1.25 + 10 = 11.25,

result = 11.25*(8/64)+1.25*(56/64) = 2.5 units.

Sample 3 = 100 Confidence OK, slope limit to 2.5 + 10 = 12.5,

result = 12.5*(8/64)+2.5*(56/64) = 3.75 units.

Sample 4 = 800 Confidence error, keep old value, result = 3.75 units.

…and so on until the result gets ~= 95.0 units…

Sample 78 = 100 Confidence OK, no slope limitation needed,

result = 100*(8/64)+95*(56/64) = 95.625 units.

Sample 79 = 100 Confidence OK, no slope limitation needed,

result = 100*(8/64)+95.625*(56/64) ~= 96.171875 units.

Sample 80 = 100 Confidence OK, no slope limitation needed,

result = 100*(8/64)+96.171875*(56/64) ~= 96.65 units.

Sample 81 = 100 Confidence OK, no slope limitation needed,

result = 100*(8/64)+96.65*(56/64) ~= 97.07 units.

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 21

2.3 Analogue Inputs

Sample 82 = 100 Confidence OK, no slope limitation needed,

result = 100*(8/64)+97.07*(56/64) ~= 97.44 units.

Sample 83 = 100 Confidence OK, no slope limitation needed,

result = 100*(8/64)+97.44*(56/64) ~= 97.76 units.

... The following samples produce the following results ending up with the input value

(100.0).

98.04, 98.28, 98.49, 98.68, 98.85, 99.00, 99.12, 99.23, 99.33, 99.41, 99.48, 99.55, 99.60,

99.65, 99.70, 99.74, 99.77, 99.80, 99.82, 99.84, 99.86, 99.88, 99.90, 99.91, 99.92, 99.93,

99.94, 99.95, 99.95, 99.96, 99.96, 99.97, 99.97, 99.98, 99.98, 99.98, 99.98, 99.99, 99.99,

99.99, …….100.0

22 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.4 User Outputs

8

312

)

0

2.4.1 User outputs

The MIS motors has 8 inputs/outputs (IO’s) that each can be set individually to input, output or analogue input 0-5V via MacTalk or software commands.This means that it for example is possible to have 4 inputs, 3 outputs and one analogue input.

Please notice: The number of available IO terminals available may vary depending at which motor type you are using. Please the chapter Connector over-

!

view for the MIS23x, page 33 or Connector overview for the MIS34x, page 35

Input/output functional diagram:

Internal µ-Processor

Overcurrent protection

<1 Ohm

CVI

Digital output

+5V

4k7

TT2160-02GB

Digital input

Analog input

1nF

10kOhm

IO1 to IO

• Outputs are Source (PNP) outputs and 5-28VDC compliant

• No galvanic isolation

• Short-circuit to ground protected that shuts down all outputs and sets Error bit in

software

• In Position and Error signal can be selected to be on any outputs 1 to 8

• Optional Encoder outputs

• 75 to 350 mA output current that depends on number of outputs activated and on

duty cycle. (See diagram)

• Internal ground clamp diodes

Allowable output current as a function of duty cycle

Number of output s conducting si multaneousl y

273

234

)

A

m

(

t

195

n

e

r

r

u

C

156

r

o

t

c

e

l

l

117

o

C

78

39

0

0

10

8

20

30

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 23

76

40

Duty Cycle (%

5

4

3

50

70

60

80

90

TT2180GB

2

10

2.4 User Outputs

C

Output circuit (PNP output)

O8

O7

O6

O5

O4

O3

O2

O1

O-

CVI

Load

TT2165GB

NB: For actual SMC75 connections, see Step motor controllers (SMCxx), page 266.

2.4.2 General

The Controller is equipped with a total of 8 digital outputs. Each output can be used for

a variety of purposes depending on the Controller’s basic mode of operation. The Out

puts are not optically isolated from other Controller circuitry. The output circuitry is

powered from the internal power supply CVI. The output circuitry operates with volt

ages in the range 5-28VDC. Each output can supply a continuous current up to 350mA.

The outputs are all source drivers, i.e. if a given output is activated, contact is made be

tween the control voltage (CVI) and the respective output terminal. See above illustration.

2.4.3 Overload of User Outputs

All of the outputs are short-circuit protected, which means that the program and the motor is stopped and the output is automatically disconnected in the event of a short circuit.

The output will first function normally again when the short-circuit has been removed.

User Outputs

Max. 350mA

CVI

+

8-28VD

-

-

-

Note: Do not connect a voltage greater than 30VDC to the CVI terminal as the output

circuitry may be seriously damaged and the unit will require factory repair.

If one or more outputs are short circuited, MacTalk will show Error “Output Driver” and

Bit2 will be set in Err_Bits

24 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

Section 8.2.26, page 129.

2.5 Serial interfaces overview

2.5.1 Serial interfaces

The Controller has 2 serial interfaces:

• RS485 (A and B) balanced for up to 32 units in multi-axis applications and MODBUS

communication. (Standard)

• CANbus -CANopen DS-301/DSP-402,

• DeviceNet under development

CANbus and RS485 can be used at the same time.

Please notice: The number of available IO terminals available may vary depending at which motor type you are using. Please the chapter Connector over-

!

view for the MIS23x, page 33 or Connector overview for the MIS34x, page 35

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 25

2.6 RS485 Interface

0

2.6.1 RS485 - General description when using a QuickStep motor

The RS485 interface offers

more noise immune commu

nication compared to a USB

or RS232 interface

. Up to 32

motors can be connected to

the same interface bus.

When connecting the RS485

interface to a central control

ler, the following rules must

be followed:

1 Use twisted pair cable.

2 Use shielded cable.

3 Make sure that the GND is

also connected.

-

RS485 network with 1 x QuickStep, 1 x MAC140 and 1 x MAC80

mounted with MAC00-B1, B2 or B4 modules.

Central

Controller

(for example a PC)

Opto isolation *

**

B

-

A

GND

Screen connected

to GND in each end

Make sure that all

involved units are

connected to the same

potential

Power supply

GND

+12-32VDC

QuickStep motor or

SMC75 Controller

*** Address=1

A

RS485

B

Interface

GND

Power

Supply

Control voltage

P+

P-

CVI

(control voltage)

+12-48VDC

(Bus voltage)

4 Ensure that all units have a

proper connection to safety

ground (earth) in order to

refer to the same potential.

5 The last unit in each end of

the network must be termi

nated with a 120 Ohm resistor between A and B.

6 Ensure that the supply lines

are made individually in or

der to reduce the voltage

drop between the motors.

7Central Controller RS485

interface:

If available, it is strongly recommended a type with optical isolation is used.

The default configuration:

Databits = 8

Baud rate = 19200

Stop bit = 1

Parity = None

ScreenScreen Screen

MAC50-141

Motor

*** Address=2

A

RS485

B

-

-

Interface

GND

Power

Supply

Control voltage

Only MAC50-141 with

B2 or B4 (Optional)

P+

O+

P-

MAC800

Motor

*** Address=3

A

**

RS485

B

Interface

GND

Power

Supply

Up to 32

Motors

* Opto isolation is recommended.

** The last unit in each end of the line must be terminated. The MAC00-B1, B2

and B4 contain this feature. See the individual module descriptions.

The QuickStep motor does not have a resistor built-in, the resistor

has to be mounted externally, for instance in the M12 connector.

*** Each unit connected must be setup with an address via The MacTalk program.

If only one unit is connected no address is needed.

Main supply

P+

P-

Max. 32VDC !

Mains 230VAC

TT2181GB

26 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 27

2.7 Special Outputs

A

2.7.1 Error Output

Error output can be selected as one of the 8 outputs. This selection is done in MacTalk

or by setting a bit in register Error_Mask,

The Driver’s Error Output enables a PLC or other equipment in a motion control system

to verify that the Driver is functioning correctly.

Under normal operation, the Error Output has a status of logic “1”, but if the Driver is

short-circuited or the temperature exceeds 85 degrees Centigrade, the Output is

switched to logic “0”.

2.7.2 In Position Output

In Position Output can be selected as one of the 8 outputs.

This selection is done in MacTalk or by setting a bit in register 137 (bit 0-7) InPos_Mask,

Section 8.2.73, page 143.

When the motor is running, the output will be inactive. When the motor is at stand-still,

the output will be active.

2.7.3 In Physical Position Output”

In physical position can be selected as one of the 8 outputs.

This selection is done in MacTalk or by setting a bit in register 137 (bit 8 – 15)

InPos_Mask,

Section 8.2.73, page 143.

Section 8.2.74, page 143

This signal is used together with MIS motors with an internal or external encoder for positioning.

This signal can be selected to be continuously updated and will then indicate if the motor

is inside the “In Position Window” all the time.

If continuous update of the “In Physical Position” is not selected and the autocorrection

is used, this signal is changed after a move and when a check has been made of the posi

tion after the “settling time between retries” if the motor is inside the “In Position Window”.

In Physical Position Example

Requested

Pos i t i on

ctual

Pos i t i on

In Position

In Phys.Position:

w. o. update

w. U pda te

IPW=1

IPW=50

IPW=5

Settling time

TT2206GB

-

See also Cable WG1005 for MIS231A1C2N075 and mounted cable on MIS231a1C1N075

(Power Cable), page 30.

28 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.7 Special Outputs

2.7.4 Pulse/Direction Outputs

Any number of the outputs can be configured to follow the pulse and direction signals

used internally in the motor. This can be used for accurate synchronization of two or

more motors.

SMC75

TT2230-02GB

O1-O2

O3-O4

O5-O6

O7-O8

See the register description for registers 108 and 109 in PulseDirMask, page 136 and PulseDirMod, page 136

2.7.5 Encoder Outputs (only from version 2.0)

If the motor is equipped with a built-in encoder, it is possible to obtain the incremental

signal and the index pulse out on the user outputs. Please note that the voltage typically

is 24VDC PNP. Therefore a resistor to ground should be connected.

A 2 channel encoder with 256 pulses/revolution will give a total of1024 pulses/revolution.

SMC75

06

A

Driver

PLC

Motor

N

07

B

S

08

If a magnet is mounted on the rear end of the motor shaft and this is placed in close distance to the SMC75 PCB, a 1023 pulses/rev. incremental A, B, index signal will be available on 3 of the output pins. Encoder position will also be available at an internal register

and can be used in a PLC program.

Index

TT2232GB

Output Encoder designation

06 A

07 B

08 Index

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 29

2.8 Special Connections

QuickStep motor MIS231A1C1N075.

Motor with 2 cable glands PG12 out of the side for low cost applications where a short

total length is required.

Can also be delivered with 5m cables as MIS231A1C2N075. Option for IP65.

Cable WG0905 for MIS231A1C2N075 and mounted cable on MIS231A1C1HN075

Connector J3

Pin no. Function Colour

1 IO1 White

2 IO2 Brown

3 IO3 Green

4 IO4 Yellow

5 CVO Red

6 A- Grey

7 B+ Pink

8 GND Black

9-10 Not used

Connector J4

Pin no. Function Colour

1 IO5 Blue

2 IO6 Violet

3 IO7 Grey/Pink

4 IO8 Red/Blue

5-10 Not used

Connector J5

Pin no. Function Colour

1-2 Not used

3 CAN_H White/Green

4 CAN_L Brown/Green

5 V+ White/Yellow

6 GND Yellow/Brown

Connector J8

Screen

Cable WG1005 for MIS231A1C2N075 and mounted cable on MIS231a1C1N075 (Power

Cable

)

Connector J2

Pin no. Function Colour

1 P+ Red

2 CVI Blue

3 P-/GND Black/Screen

30 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.9 Handling noise in cables

2.9.1 About noise problems

The MIS family of motors eliminates the traditional problems with noise from long motor

cables that emit noise and feedback cables that are sensitive to noise from external

sources.

However, it is still necessary to be aware of noise problems with communications cables

and the 8 general-purpose inputs and outputs.

Whenever a digital signal changes level quickly, a noise spike is generated, and is transferred to the other wires in the same cable, and to a lesser degree to wires in other cables located close to the cable with the switching signal. A typical example is when a

digital output from the MIS motor changes from low to high to drive a relay. If this digital

output signal is transmitted in a multi-wire cable together with the RS-485 signals, there

is a high risk that the RS-485 signal will be affected to the extent that the communication

will fail, and require software retries.

If communication is used during operation, and operation includes either digital input signals or digital output signals, some precautions must be taken to avoid noise problems.

The following sections describe a number of measures which can be taken to solve noise

problems. In most installations, no special measures will be required, but if noise prob

lems are experienced – and/or must be avoided – it is highly recommended the instructions below are followed.

2.9.2 Use short cables

The shorter a cable is, the less noise problems it will induce. Be sure to keep the cables

as short as possible. Instead of curling up the cables, cut them off at the minimum re

quired length.

-

-

2.9.3 Use separate cables

Avoid running digital signals in the same multi-wire cables as RS-485 communication signals.

On some models of the MIS motors, the same connector contains both RS-485 signals

and I/O signals – typically the I/Os 1-4.

In many applications, far from all inputs and outputs are used. If only up to four I/Os are

required, consider using only I/Os 5-8 which are typically available via another connector

on the motor.

2.9.4 Use filters

If more than 4 I/Os are needed, consider using I/Os 1-4 for inputs and I/Os 5-8 for outputs. It is normally possible to install a hardware filter on the digital input signals before

they enter the cable. With such a (good) filter, noise on the RS-485 signals will not be a

problem.

It is also possible to use filters on the outputs, but it is more difficult. It can be done by

using short cables from the motor to the filters, and then using longer cables from the

filters to the output targets. It may be easier to use a short cable from the motor to a

splitter box, and then split the I/Os in one cable and the RS-485 signals in another cable.

2.9.5 Use termination (resistors) on the RS-485 signals

RS-485 is typically used to connect a single master PC or PLC to one or more motors in

a chain. Both ends of the chain must have a 120 Ohms termination resistor connected

between the A- and B+ signals. There is typically a terminating resistor in the master PC

or PLC, but there is no termination inside the motors. Therefore an external resistor

must be connected at the end of the cable out of the last motor in the chain. If the last

motor has no connection cable, a connector with a resistor soldered between the A- and

B+ pins should be used.

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 31

2.9 Handling noise in cables

As an alternative, a connector with a short cable can be used with the resistor soldered

between the two wires carrying A- and B+.

Use individually shielded cables.

In some installations, it will be necessary to have RS-485 signals in the same multi-wire

cables as fast-switching digital signals. In addition to keeping cable lengths to a minimum

and using termination resistors, high-quality cables, where each wire is shielded from the

other wires in the cable, should be used. This is typically done using a metal foil wrapped

around each wire. These types of cables are more expensive, but the overall cost and

noise immunity requirements may justify the solution instead of splitting cables.

2.9.6 Use simple shielding

Using cables with only a single shield shared by all the signal wires will also improve noise

problems to some degree, but will not guarantee completely stable operation for mixed

signal cables. If a cable carries only RS-485 or only digital I/O, this simple and inexpensive

form of shielding is recommended.

32 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

2.10 How to connect MIS23x

e

2.10.1 Connector overview for the MIS23x

Only MIS23x

# MIS23xAz yy75

RS485 serial communicati on

and few local I/O.

MIS23xAz yy75

RS485 serial communicati on in

network. Up to 32 MAC and QuickStep

on the same network . Many local I /O.

I/O5-8

PWR: RS485: CAN: I/O1-4: I/O5-8: SSI:

5 pin male 5 pin female 5 pin male 8 pin female 8pin female 8 pin mal

PWR

I/O1-4

RS485

PWR

I/O1-4

RS485

M2

M5

RS485

TT2259GB

MIS23xAz yy75

RS485 serial communicat ion in

network. Up to 32 MAC and QuickStep

on the same network. Few local I/ O.

MIS 23x Az y y75

MIS 23x Az y y75

RS485 and CANopen/Devicenet

operati on. Many local IO.

CAN

PWR

I/O1-4

RS485

PWR

I/O1-4

RS485

M3

RS485

M6

M7

I/O5-8

# MIS23xAz yy75

RS485 serial communicat ion

and many local I/O.

MIS23xAz yy75

RS485 and SSI encoder Few local I/O.

SSI

PWR

I/O1-4

RS485

PWR

I/O1-4

RS485

M4

I/O5-8

M9

RS485

Versions with positioning and speed control

Quick Step M12

Connector

overview

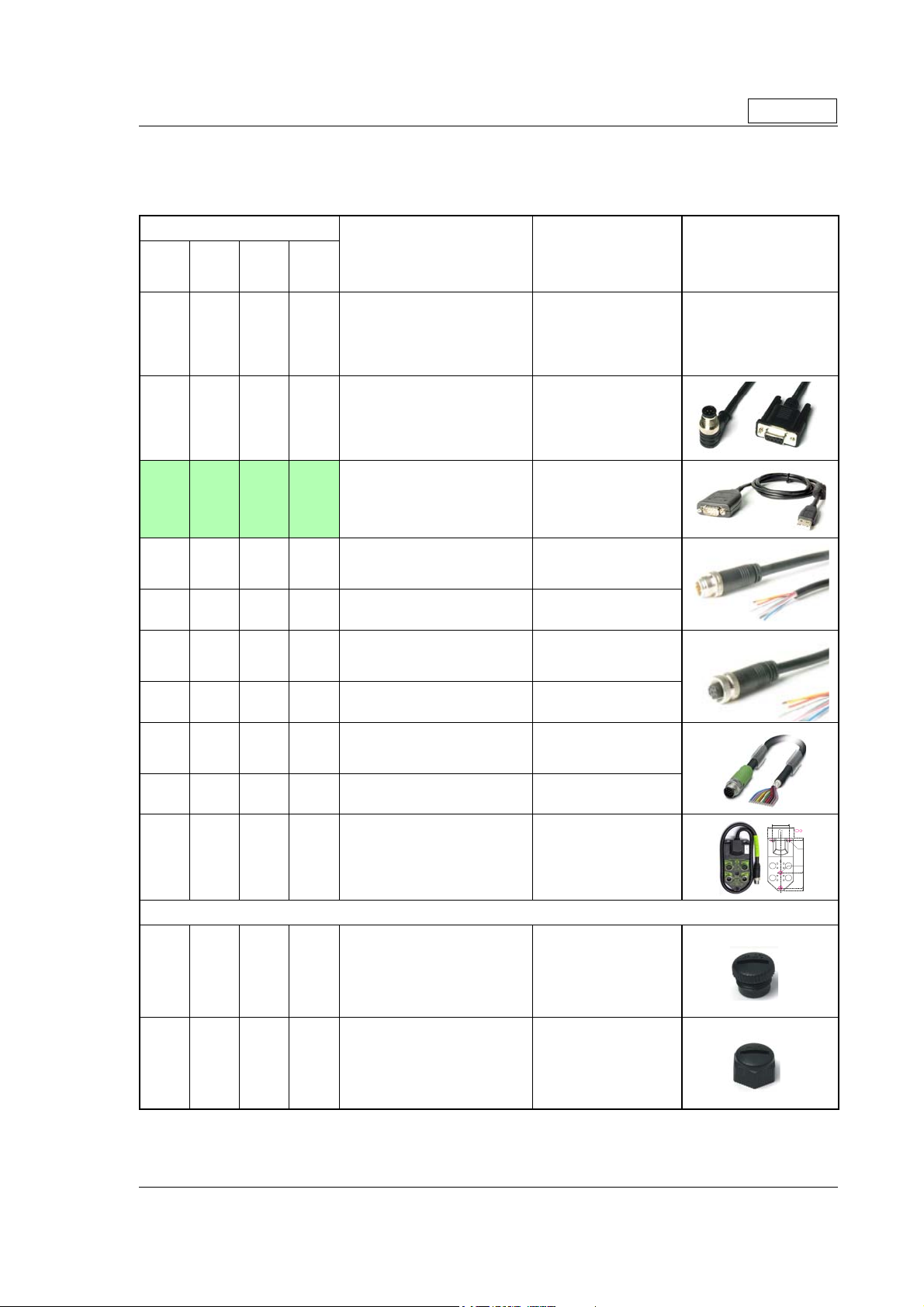

#MIS23xAzM2yy75 X X RS485, 4IO

MIS23xAzM3yy75 X X X 2xRS485, 4IO

#MIS23xAzM4yy75 X X X RS485, 8IO

MIS23xAzM5yy75 X X X X 2xRS485, 8IO

MIS23xAzM6yy75

MIS23xAzM7yy75

MIS23xAzM9yy75 X X X X SSI, 6IO

M12 Pin 1 P+ (12-

M12 Pin 2 P+ (12-

M12 Pin 3 P- (GND) IO3 IO7 B+ (RS485) CAN_GND A+ (Clock+)

M12 Pin 4 CVI+ (12-

M12 Pin 5 P- (GND) B+ (RS485) Not used GND CAN_L B- (Data in-)

M12 Pin 6 - A- (RS485) Not used - - B+ (Data in+)

M12 Pin 7 - IO4 IO8 - - A- (Clock-)

M12 Pin 8 - CVO+ (Out) CVO+ (Out) - - CVO+ (Out)

M12 connector

solder terminals

M12 cables 5m. WI1000-

Power

Male 5pin

IO1-4

RS485

Female 8pin

IO5-8

Female 8pin

RS485

Female 5pin

CANopen/

DeviceNet

Male 5pin

SSI Encoder

Male 8pin

X X X X

X X X X

48VDC) IO1 IO5 B+ (RS485) CAN_SHLD

48VDC IO2 IO6 A- (RS485) CAN_V+

IO5 Zero

setting

IO6 Counting

Direction

28VDC) GND IO- GND IO- A- (RS485) CAN_H GND

WI1008M12F5SS1

M12F5T05N

WI1008M12M8SS1

WI1000M12M8T05N

WI1008M12M8SS1

WI1000M12M8T05N

WI1008M12M5SS1

WI1000M12M5T05N

WI1008M12F5SS1

WI1006M12F5S05R

WI1008M12M8SSI

WI1000M12M8T05N

Function

CANopen,

RS485, 8IO

DeviceNet,

RS485, 8IO

#: Only >50pcs order. x : 1~1Nm, 2~1.6Nm, 3~2.5Nm.

z : 1~6.35mm shaft, 3~10.0mm shaft (only if x=3)

yy : NO~No encoder. H2~built-in encoder

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 33

2.10 How to connect MIS23x

2.10.2 M12 connectors

M12 connectors layout and pin locations.

Only MIS23x

1

4

1

7

6

2

5

3

2

8

3

4

5

2

3

2

3

4

1

5

4

1

7

6

5

TT2143GB

34 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

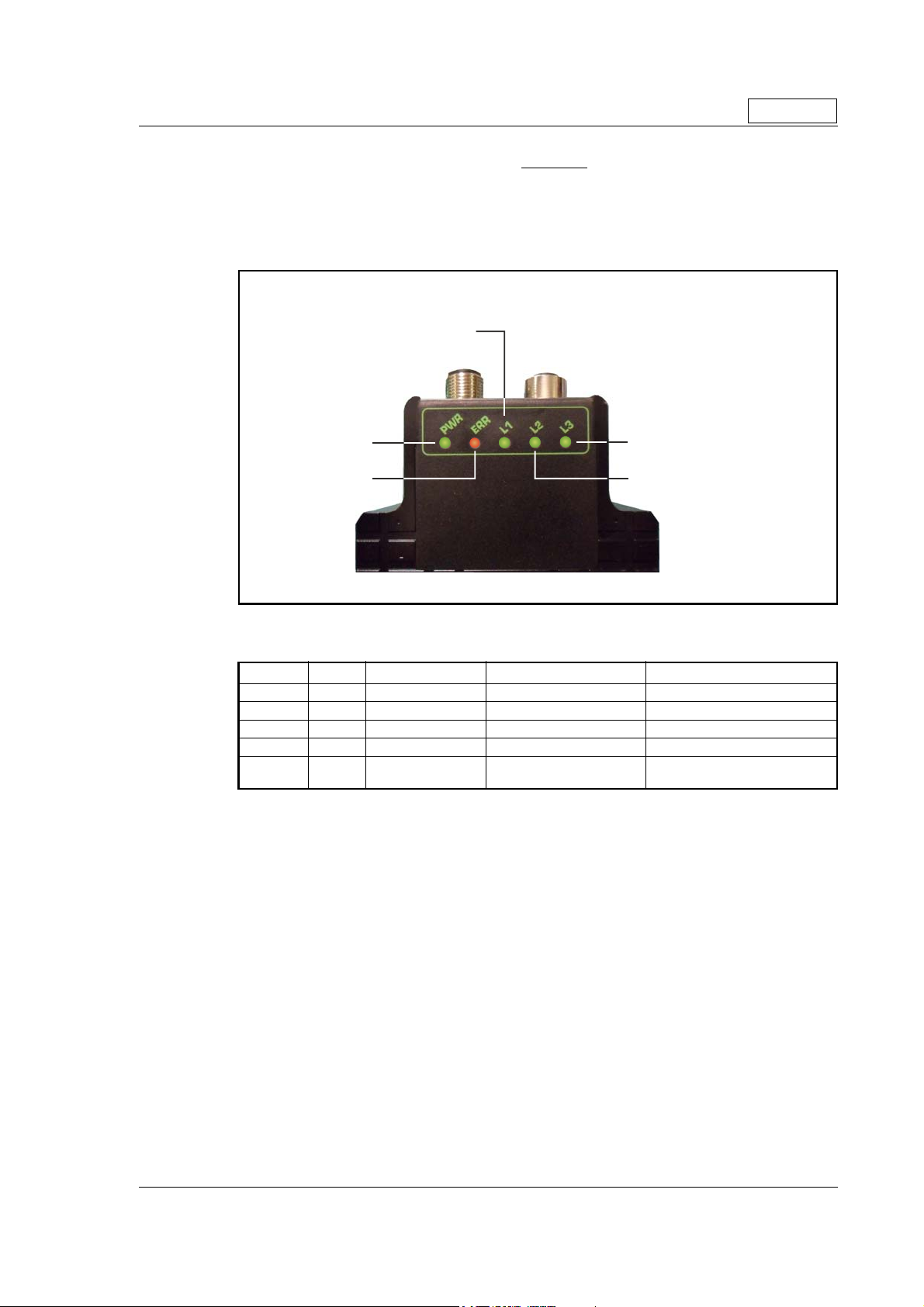

2.11 How to connect MIS34x

4

2.11.1 Connector overview for the MIS34x

QUICKSTEP

Connector

Overview

Connector ID

MIS34xCyyQ5zz85

(8IOA) Prefered type

MIS34xCyyP6zz85

(CAN-open)

MIS34xCyyQ9zz85

(SSI input)

MIS34xCyyExzz85

(Ethernet)

MIS34xCyyFBzz85

(Bluetooth)

MIS34xCyyFPzz85

(Profibus)

M12 Pin1

M12 Pin2

M12 Pin3

M12 Pin4

M12 Pin5

M12 Pin6

M12 Pin7

M12 Pin8

M12 Pin9

M12 Pin10

M12 Pin11

M12 Pin12

M12 Pin13

M12 Pin14

M12 Pin15

M12 Pin16

M12 Pin17

M12 Connector

solder terminals

M12 Cables 5m

Power

Male

5Pin

PWR (CN1) CN4 CN2 CN3 CN2 CN2 & CN3 CN3 CN2 & CN3 CN2 & CN3

P+ (12-80VDC) IO1 B0+ (RS485) IO1 IO1 CAN_SHLD IO5 Zero Set 5VDC TX0_P

P+ (12-80VDC) GND A0- (RS485) IO2 IO2 Unused IO6 CNTDIR A- RX0_P

P- (GND) IO2 B0+ (RS485) IO3 IO3 CAN_GND A+ (Clock+) DGND TX0_N

CVI (12-28VDC) IO3 A0- (RS485) GND GND CAN_H GND B+ RX0_N

P- (GND) B1- (RS422) GND B0-(RS485) B0-(RS485) CAN_L B- (Data In-) SHIELD -

- IO4 - A0+(RS485) A0+(RS485) - B+ (Data In+) - -

- A1- (RS422) - IO4 IO4 - A- (Clock -) - -

- B1+ (RS422) - CVO (out) CVO (out) - CVO (out) - -

- CVO (out) - - - - - - -

- A1+ (RS422) - - - - - - -

- IO5 - - - - - - -

- IO6 - - - - - - -

- IO7 - - - - - - -

- IO8 - - - - - - -

- A0+(RS485) - - - - - - -

- GND - - - - - - -

- B0-(RS485) - - - - - - -

WI1008M12F5SS1

WI1000M12F5T05N

IO1-8,

RS485,MFIO

Female

17Pin

x x x x

x x x

x x x x

x x x

x x x x

x x x

(not available) WI1008-

WI1009M12M17T05N

RS485

Female

5Pin

M12M5SS1

WI1005M12M8V

M5V03N

RS485 +

IO1-4

Female

8Pin

WI1008M12M8SS1

WI1009M12M8V05N

RS485 +

IO1-4

Female

8Pin

WI1008M12M8SS1

WI1009M12M8V05N

CANopen

Female

5Pin

WI1008M12M5SS1

WI1006M12F5

TM5T05N

SSI Encoder

Male 8Pin

WI1008M12F8SS1

WI1000M12F8T05N

Only MIS34x

Profibus

Male 5Pin

WI1028M12F5SS1

WI1026M12-F5S0R

Ethernet

Female

4Pin

(not available)

WI1046M12M4S05R

Connector layout

CN3

TT2323-01GB

CN4

PWR (CN1)

CN2

5 pin Female

1

4

8 pin Female

1

8

7

6

12 pin Female

1

10

9

8

12

7

17 pin Female

1

11

10

16

9

17

8

15

7

pin Female

2

3

2

4

5

2

4

11

5

6

2

12

4

13

5

14

6

2

5

3

5 pin Male

2

3

3

8 pin Male

2

3