JVL MAC50, MAC95, MAC140 service manual

MAC50

MAC95

MAC140

Integrated Servo Motors

Technical Manual

TT0940GB

JVL Industri Elektronik A/S

LB0048-05GB Revised 14.10.2002

Copyright 1998-2002, JVL Industri Elektronik A/S. All rights reserved.

This user manual must not be reproduced in any form without prior written

permission of JVL Industri Elektronik A/S.

JVL Industri Elektronik A/S reserves the right to make changes to information contained in this manual without prior notice.

Similarly JVL Industri Elektronik A/S assumes no liability for printing errors

or other omissions or discrepancies in this user manual.

MotoWare is a registered trademark

JVL Industri Elektronik A/S

Blokken 42

DK-3460 Birkerød

Denmark

Tlf. +45 45 82 44 40

Fax. +45 45 82 55 50

e-mail: jvl@jvl.dk

Internet: http://www.jvl.dk

Contents

1 Introduction .................................................................................................................... 5

1.1 Introduction .........................................................................................................................................6

1.2 Sampled Systems .................................................................................................................................7

2 MacRegIO ........................................................................................................................ 9

2.1 Installation ..........................................................................................................................................10

2.2 Description of MacRegIO Windows ..................................................................................................11

2.3 Operation ..........................................................................................................................................13

3 Parameter and Data Description ................................................................................. 15

3.1 Description of Data Formats ............................................................................................................. 16

3.2 Parameter and Data Registers ........................................................................................................... 17

4 Program/Function Description ..................................................................................... 49

4.1 Function blocks (Profile Generation) ................................................................................................. 50

4.2 Speed Regulator .................................................................................................................................55

4.3 Current Regulator .............................................................................................................................56

4.4 Modes ................................................................................................................................................57

4.5 Monitoring Functions ......................................................................................................................... 68

5 Interface Description .................................................................................................... 71

5.1 MacTalk Protocol ..............................................................................................................................72

5.2 FastMAC / FlexMAC ..........................................................................................................................74

6 Index............................................................................................................................... 85

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 3

4 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

1 Introduction

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 5

1.1 Introduction

This Technical Manual describes advanced use of the MAC motor.

The Manual describes the functions of the MAC-motor, its data registers and interfaces

in greater detail than is necessary for normal operation of the MAC motor.

Chapter 2 describes the MacRegIO software, which provides direct access for changing

and reading operational parameters and data.

Chapter 3 describes all registers containing operational parameters and data.

Chapter 4 describes the function of the MAC motor in detail.

Chapter 5 describes the MAC motor’s interfaces to its surroundings, i.e. RS232 and

RS422 communication interfaces, and their associated protocols.

It is recommended that section 1.2 “Sampled Systems” is read. This section explains certain terminology used in sampled systems.

6 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

1.2 Sampled Systems

In contrast to analogue regulation systems, in which analogue control signals continuously

flow through regulation filters, output stages, etc., the control signals in a sampled system

only appear in filters and other circuitry at discrete times.

These discrete times are called the sampling times. The time interval between two sampling times is called a sampling interval. The number of samples per second is denoted as

the sampling frequency.

At each sampling point (each sample), relevant measurement values are read, such as:

• Phase current

• Motor position

• Reference input

Values that cannot be read directly are calculated. For example:

Velocity = Delta_P / sampling interval

where Delta_P is the difference in position from the preceding sample.

At each sample, all outputs are updated, including the three phase voltages.

The MAC motor contains 3 regulation loops with a sampling frequency of 7812 Hz for

regulation of the motor’s 3 phase currents, and 1 regulation loop with a sampling frequency of 521 Hz for regulation of velocity / position.

The MAC motor’s regulation loops contain digital filters, corresponding to the analogue

filters of an analogue regulator. These digital filters are defined by and calculated in the

MAC motor using the Z-transform of their transfer function.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 7

8 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

2MacRegIO

MacRegIO.exe is a program for directly writing to and reading the storage registers in

the MAC motor. In addition, the program provides facilities for real-time acquisition of

data in a data-buffer, for writing parameter set-ups to flash memory, and for resetting the

MAC motor.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 9

2.1 Installation

MacRegIO.exe uses two data files:

• MacReg.dat: This file describes the register names and register formats for various

registers.

• MacBit.dat: Certain registers contain single bits or groups of bits. This file describes

the names of these bits as well as explantory names of their status.

All three files must be installed in the same folder (directory).

10 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

2.2 Description of MacRegIO Windows

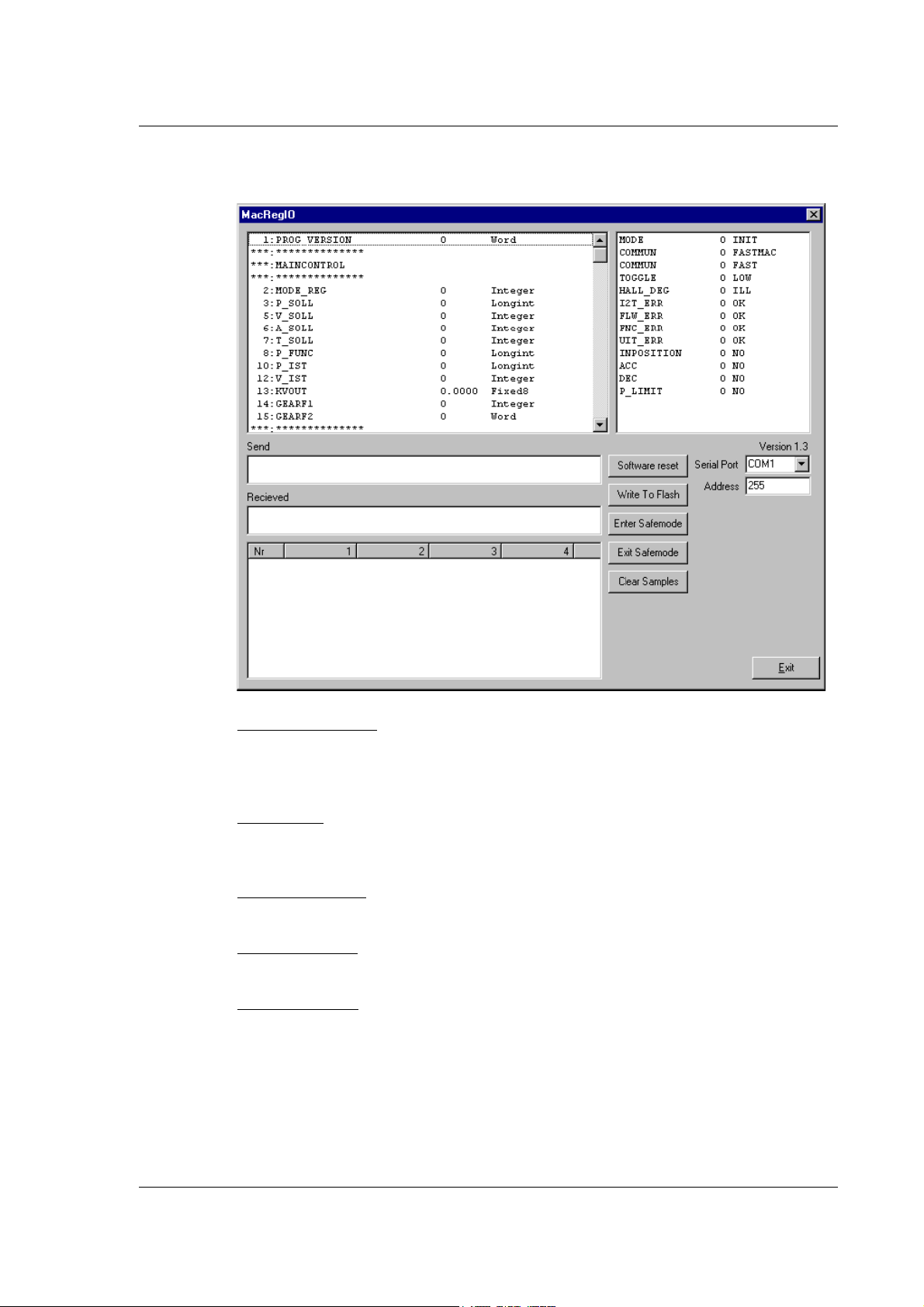

The screen of the MacRegIO software consists of 5 windows and 5 buttons, as illustrated

below.

Parameter Window:

This window displays parameter numbers, parameter names, parameter values and parameter formats. See "Description of Data Formats", page 16 for a description of the parameter formats.

Bit Window:

This window displays the names of bits/bit groups, their numerical values and explanatory texts of the values.

Transmit Window:

This window displays the last transmitted message, byte-by-byte, in decimal format.

Receive Window:

This window displays the last received message, byte-by-byte, in decimal format.

Sample Window:

During operation, data can be gathered in real-time in a sample buffer. The number designations of the registers to be sampled are specified in registers SAMPLE1 ... SAMPLE4.

Four fields are displayed at the top of the window indicating the names of the sampled

registers. The register values are displayed in four columns, sample by sample. See

"SAMPLE1 - Register 112", page 41.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 11

2.2 Description of MacRegIO Windows

Software Reset Button:

This button is used to reset the MAC motor. The MAC motor can only be reset in Init

Mode. See "Init Mode", page 57.

Write to Flash Button:

This button is used to save the setup of the MAC motor to the motor’s FlashMemory.

After writing the setup to Flash Memory, the MAC motor is reset.

Clear Samples Button:

This button is used to erase the contents of the Sample Window. It has no effect on the

MAC motor.

Enter Safe Mode:

The MAC Motor can be equipped with various optional modules. Some of these are programmable and can control the motion of the MAC motor. If a control program is to be

changed, the MAC Motor must be brought to a safe mode in which commands from the

extension modules are not accepted. This button is used to set the MAC motor to Safe

Mode. See "SAFE_MODE ( MODE = 15 )", page 67.

Exit Safe Mode:

This button is used to exit Safe Mode.

12 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

2.3 Operation

The Parameter Window is activated by clicking in the window. When the Parameter

Window is active, a selected register will be highlighted.

To read the selected (highlighted) register, either the ”r” or ”R” key is used. In this way,

the register contents are updated and displayed in the Parameter Window.

To write to the selected register, either the ”w” or ”W” is used. A dialogue box is then

displayed and the new parameter value can be specified. Immediately after writing to

a register, the register value will be read back and updated in the parameter

window. If the register is continuously updated by the MAC motor, a value other than that entered may be shown in the parameter window.

The cursor position, i.e. selected parameter, can be changed using the arrow keys, PgUp

or PgDn keys, or using the mouse.

To display the sampled register values in the Sample Window, either the ”s” or ”S” key

is used. The values of the sampled registers for the first/next sample is displayed.

Note that using the ”Write to Flash” button causes the MAC motor to be reset.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 13

14 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3 Parameter and Data Description

The following sections describe the data formats, parameter and data registers.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 15

3.1 Description of Data Formats

The MAC motor uses 5 different data formats:

• Word

• Integer

• LongInt

• Fixed4

• Fixed8

16 bit unsigned.

Word:

Range: 0 ... 65535

Integer:

Range: -32767 ... +32767

LongInt:

Range: -2.147E9 ... +2.147E9

Fixed4:

Range: -7.999756 ... +7.999756

Unit: 1 / 4096.

Fixed8:

Range: -127.996 ... 127.996

Unit: 1 / 256

16 bit signed.

32 bit signed.

16 bit signed fixed point.

16 bit signed fixed point.

16 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3.2 Parameter and Data Registers

The following subsections described all of the available parameter and data registers.

Each register has its own unique register number. The following subsections of this manual are structured such that register number N is described in section 3.2.N.

Note that registers of the format LongInt take up two register numbers, corresponding

to two words.

The Parameter and Data Registers can be categorised into the following groups:

• Main Control: Registers 1 ... 15. Primarily operational parameters.

• Error handling: Registers 16 ... 35. Parameters and data for error handling.

• Power on: Registers 36 ... 42. Parameters for setup and reset.

• Register mode: Registers 43 ... 88. Parameters for operation via registers.

• Filters: Registers 89 ... 111. Coefficients for various filters.

• Data acquisition: Registers 112 ... 116. Parameters for real-time data acquisition.

• Position / velocity-loop: Registers 117 ... 123 Various parameters for position- and

velocity loops.

• Current-loops: Registers 124 ... 152.

• Diverse: Registers 153 ... 156.

3.2.1 PROG_VERSION - Register 1

Data format: word.

Indicates the MAC motor’s program version. Can be changed by the user, but cannot be

written to Flash Memory. Example: Version is read as 78 = 4Eh = version 4.14.

3.2.2 MODE_REG - Register 2

Data format: word.

Range: 0 ... 15.

This register determines the mode in which the MAC motor will be operated:

Value: Operation mode:

0Init mode. See "Init Mode", page 57.

1 Velocity mode, V_MODE. See "Velocity Mode", page 58.

2 Position mode, P_MODE. See "Position Mode", page 58.

3 Gear mode, G_MODE. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

4 Analog Torque mode, AT_MODE. See

"Analog Torque Mode ( AT_MODE, MODE = 4 )", page 60.

5 Analog Velocity mode, AV_MODE. See "Analog Velocity Mode", page 61.

6 Analog Velocity Gear mode, AVG_MODE. See

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

7 Manual current mode, MANI_MODE. See

"Manual Mode ( MANI_MODE, MODE = 7 )", page 62.

8 Voltage test mode, TESTU_MODE. See

"TESTU_MODE ( MODE = 8 )", page 62.

9 Acceleration test mode, TESTA_MODE. See

"TESTA_MODE ( MODE = 9 )", page 63.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 17

3.2 Parameter and Data Registers

10 Break mode, BREAK_MODE. See

"BREAK_MODE ( MODE = 10 )", page 64.

11 Stop mode, STOP_MODE. See "STOP_MODE ( MODE = 11 )", page 64.

12 Home 1 mode, HOME1_MODE. See "HOME1_MODE ( MODE = 12 )", page 64.

13 Home 2 mode, HOME2_MODE. See "HOME2_MODE ( MODE = 13 )", page 65.

14 Home 3 mode, HOME3_MODE. See "HOME3_MODE ( MODE = 14 )", page 66.

15 SAFE_MODE. See "SAFE_MODE ( MODE = 15 )", page 67.

3.2.3 P_SOLL - Register 3

Data format: LongInt.

Range: +/-67E6.

This register indicates the absolute position to which the motor will move. See

"CNTRL_BITS - Register 36", page 31, RELPOSBIT.

The register is used in Position mode, P_MODE, where the specified value indicates the

desired position, measured in encoder counts. See the following sections: "Position

Mode", page 58, "P_IST - Register 10", page 21, and "P_FNC - Register 8", page 21.

Unit: Encoder counts.

3.2.4 P_SOLL - Register 3

18 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3.2 Parameter and Data Registers

S

B

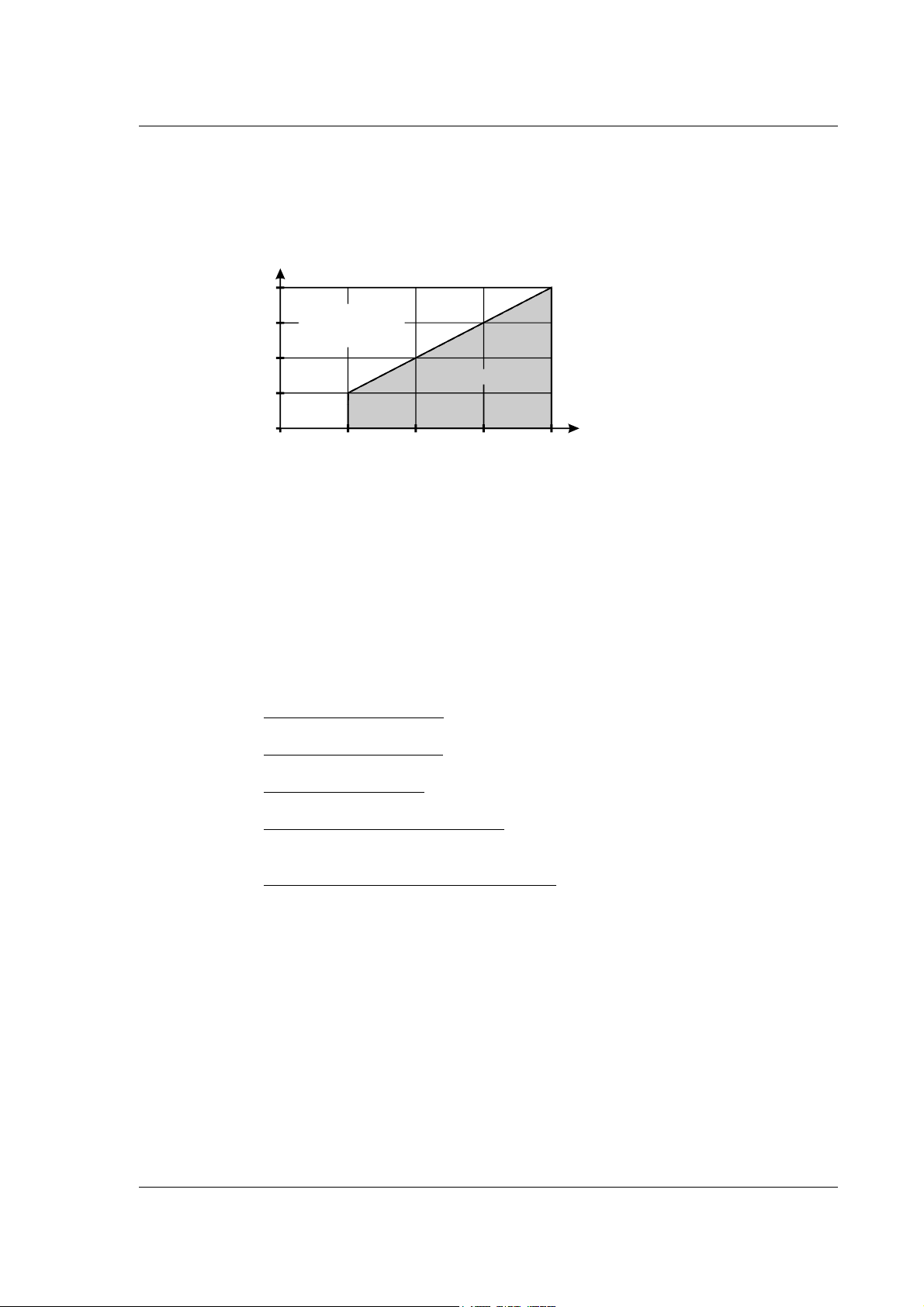

3.2.5 V_SOLL - Register 5

Data format: Integer.

Recommended range: See illustration.

peed in RPM

4000

3000

2000

1000

This register specifies a velocity measured in 1/16 encoder counts/sample. The sampling

frequency is 520.8 Hz. The number of encoder counts per revolution = 4096.

Restricted area

motor losses will

be too high

Safe operation area

0

0 12243648

Operation below 12V is not recommended

Supply

Volta ge (VDC)

TT0925G

i.e. if V_SOLL is specified as 1600, the angular velocity will be:

1600 520.8

------- * ----------- = 12.715 rev/sec = 762.9 rpm

16 4096

V_SOLL is used differently in different operating modes:

• Velocity mode, V_MODE:

V_SOLL specifies the required velocity. See

"Velocity Mode", page 58.

• Position mode, P_MODE:

V_SOLL specifies the maximum velocity during

positioning. See "Position Mode", page 58.

• Gear mode, G_MODE:

V_SOLL specifies the maximum velocity during positioning.

See "Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog Velocity mode, AV_MODE:

In this mode, the motor velocity is controlled by

an analogue input signal ( +/- 10V ). V_SOLL specifies the maximum velocity

corresponding to +/- 10V. See "Analog Velocity Mode", page 61.

• Analog Velocity Gear mode, AVG_MODE:

In this mode, the motor velocity is

controlled by signals at the pulse input, with a bias velocity that is controlled by the

signal at the analogue input. V_SOLL specifies the total maximum velocity. See

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

Unit: 0.4768 rpm.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 19

3.2 Parameter and Data Registers

3.2.6 A_SOLL - Register 6

Data format: Word.

Recommended range: 1 ... 1000.

This register specifies an acceleration measured in 1/16 encoder counts/sample

sampling frequency is 520.8 Hz. The number of encoder counts per revolution = 4096.

i.e. if A_SOLL is specified as 160, the acceleration will be:

160 520.8

------ * ----------- = 662.2 rev/sec2 = 39731 rpm/sec

16 4096

A_SOLL specifies the maximum acceleration/deceleration in the following modes:

• Velocity mode, V_MODE. See "Velocity Mode", page 58.

• Position mode, P_MODE. See "Position Mode", page 58.

• Gear mode, G_MODE. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog Velocity mode, AV_MODE. See "Analog Velocity Mode", page 61.

• Analog Velocity Gear mode, AVG_MODE.

See "Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

• Homing mode 1 ... 3. See "HOME1_MODE ( MODE = 12 )", page 64,

"HOME2_MODE ( MODE = 13 )", page 65, and

"HOME3_MODE ( MODE = 14 )", page 66.

Unit: 248.3 rpm/sec.

2

2

. The

3.2.7 T_SOLL - Register 7

Format: Word.

Range: 0 ... 1023

This register specifies the maximum allowable torque in the following modes:

• Velocity mode, V_MODE. See "Velocity Mode", page 58.

• Position mode, P_MODE. See "Position Mode", page 58.

• Gear mode, G_MODE. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog Velocity mode, AV_MODE. See "Analog Velocity Mode", page 61.

• Analog Velocity Gear mode, AVG_MODE. See

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

• TESTA_MODE. See "TESTA_MODE ( MODE = 9 )", page 63.

• HOME2_MODE. See "HOME2_MODE ( MODE = 13 )", page 65.

• HOME3_MODE. See "HOME3_MODE ( MODE = 14 )", page 66.

Full torque corresponds to a value of 1023.

20 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3.2 Parameter and Data Registers

3.2.8 P_FNC - Register 8

Data format: Longint.

Range: +/-2147483647

This register is updated by a function generator in the following modes:

• Velocity mode, V_MODE. See "Velocity function block", page 50 and

"Velocity Mode", page 58.

• Position mode, P_MODE. See "Position function block", page 50 and

"Position Mode", page 58.

• Analog velocity mode, AV_MODE. See "AV function block", page 53 and

"Analog Velocity Mode", page 61.

• Gear mode, G_MODE. See "Gear function block", page 52 and

"Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog velocity gear mode, AVG_MODE. See "AVG function block", page 54 and

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

Unit: 1/16 encoder counts.

P_FNC specifies the position that a given function generator has reached. The value of

P_FNC is only used in P_MODE. The fact that the value is updated in other modes of

operation enables the start position to be found when switched to P_MODE.

Example (flying saw):

1. The motor (saw) is stationary at its start position in P_MODE, while a target job passes.

2. At a given signal, the operating mode is switched to G_MODE. The motor (saw) synchronises velocity with the object. During this operation, P_FNC is updated.

3. The object is sawn.

4. The mode of operation is switched to P_MODE. Since the value of P_FNC has

changed, the position function block will generate a velocity that moves the motor

(saw) back to its starting point.

P_FNC can be used to perform relative positioning. See "Position function block", page 50.

3.2.9 P_FNC - Register 8

3.2.10 P_IST - Register 10

Data format: LongInt.

Range: +/-2147483647.

This register indicates the motor’s current position.

Unit: Encoder counts

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 21

3.2 Parameter and Data Registers

The register can be freely overwritten by a user. This will not influence control of the

motor since the register contents are not used by the control program. This gives the

user the facility to reset P_IST at a given position and thereafter measure the distance to

another position, e.g. in conjunction with a linear guide.

Software position limits refer to this register. See "Software end-of-travel limits", page 68.

The register is updated in all modes of operation.

3.2.11 P_IST - Register 10

3.2.12 V_IST - Register 12

Data format: Integer.

Range: +/-32767.

This register indicates the motor velocity measured in encoder counts per sample. the

sampling frequency is 520.8 Hz. The number of encoder counts per revolution = 4096.

If V_IST = 100, this corresponds to a motor velocity of:

100 * 520.8

----------------- = 12.715 rev/sec = 762.9 rpm.

4096

The register should not be overwritten by the user since this will result in a positioning

error.

The register is updated in all modes of operation.

Note:

The resolution of the measured velocity stored in this register is approximately 8

rpm. Reading this register will therefore involve measurement noise (quantisation noise)

amounting to +/- 8 rpm. In the context of control, this error is of no consequence since

it is only valid for 1/520.8 sec = 1.92 ms.

Unit: 7.629 rpm.

22 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3.2 Parameter and Data Registers

3.2.13 KVOUT - Register 13

Data format: Fixed8

Recommended range: 1.0 ... 10.0

This register is used to determine a relative, inertial motor load, seen in relation to the

motor’s nominal inertial load. The calculation of KVOUT incorporates the motor’s own

inertia.

Example: Let a motor’s own inertia be 17.3E-6 kgm2, (nominal load). The motor is loaded with an inertial load = 50E-6 kgm2.

KVOUT is calculated as:

17.3E-6 + 50E-6

-------------------- = 3.9

17.3E-6

During control, the calculated nominal torque will be multiplied by KVOUT, thus maintaining the motor acceleration.

KVOUT is used in the following modes of operation:

• Velocity mode. See "Velocity Mode", page 58.

• Position mode. See "Position Mode", page 58.

• Gear mode. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog Velocity mode. See "Analog Velocity Mode", page 61.

• Analog Velocity Gear mode. See

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

• Stop mode. See "STOP_MODE ( MODE = 11 )", page 64.

• HOME1 mode. See "HOME1_MODE ( MODE = 12 )", page 64.

• HOME2 mode. See "HOME2_MODE ( MODE = 13 )", page 65.

• HOME3 mode. See "HOME3_MODE ( MODE = 14 )", page 66.

See "Speed Regulator", page 55.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 23

3.2 Parameter and Data Registers

3.2.14 GEARF1 - Register 14

3.2.15 GEARF2 - Register 15

Data format, GEARF1: Integer.

Data format, GEARF2: Word.

These registers are used for electronic gearing of the signal at the pulse input.

Conversion ratio:

Output GEARF1

--------- = -------------- Input GEARF2

The direction of rotation of the motor can be reversed by changing the sign of GEARF1.

GEARF1 and GEARF2 are used in the following modes of operation:

• Gear mode, G_MODE. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog Velocity Gear mode, AVG_MODE. See

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

It is recommended that the gearing ratio, ( fraction ), is reduced:

Output 15500 31

--------- = ------------- = ----------- Input 10000 20

24 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3.2 Parameter and Data Registers

3.2.16 I2T - Register 16

3.2.17 I2TLIM - Register 17

Data format: Word.

These registers are used for monitoring thermal overload of the motor as a result of current heat dissipation in the coils.

In principle, I2T carries out a partial integration of the current heat loss:

2

+ Ib2 + Ic

Ia

where Ia, Ib and Ic are the measured phase currents.

When the value of I2T exceeds I2TLIM the following occurs:

• I2T_ERR bit is set. See "ERR_STAT - Register 35", page 30.

• MODE_REG = INIT_MODE. See "STOP_MODE ( MODE = 11 )", page 64 and

"Init Mode", page 57.

Register I2T is updated in all modes of operation.

3.2.18 UIT - Register 18

3.2.19 UITLIM - Register 19

Data format: Word.

These registers are used for monitoring thermal overload of the motor’s internal power

dump as a consequence of regenerative energy from the motor during deceleration.

In principle a partial integration of the regenerative power is carried out:

Preg = - ( Ia*Ua + Ib*Ub + Ic*Uc )

2

where Ia, Ib and Ic are the measured phase currents, and Ua, Ub and Uc are the applied

voltages to the three phases.

If Preg is calculated to be < 0, Preg is set = 0.

When the value of UIT exceeds UITLIM, and the supply voltage > 52V, the following occurs:

• UIT_ERR bit is set. See "ERR_STAT - Register 35", page 30.

• MODE_REG = INIT_MODE. See "STOP_MODE ( MODE = 11 )", page 64 and

"Init Mode", page 57.

Register UIT is updated in all modes of operation.

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 25

3.2 Parameter and Data Registers

3.2.20 FLWERR - Register 20

3.2.21 FLWERR - Register 20

3.2.22 FLWERRMAX - Register 22

(Follow Error)

Data format: LongInt.

Range, FLWERR: +/-67E6.

Range, FLWERRMAX: 0 ... 67E6.

These registers are used in the following modes of operation:

• Velocity mode, V_MODE. See "Velocity Mode", page 58.

• Position mode, P_MODE. See "Position Mode", page 58.

• Gear mode, G_MODE. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

• Analog Velocity mode, AV_MODE. See "Analog Velocity Mode", page 61.

• Analog Velocity Gear mode, AVG_MODE. See

"Analog Velocity Gear mode ( AVG_MODE, MODE = 6 )", page 61.

In the above modes, FLWERR is calculated. In all other modes of operation FLWERR is

set to 0.

3.2.23

V, AV, AVG_MODE:

velocity errors that are in part due to the dynamic characteristics of the velocity regulator, and in part can be due to the fact that the motor is torque overloaded, which results

in the expected position cannot be maintained. FLWERR is thus used here to detect abnormal loading of the motor or blockages.

P, G_MODE:

noted however that in these modes the function generator will correct/adjust the velocity profile so that the motor is not significantly overloaded. The value of FLWERR will

therefore be limited automatically. The user can however still use FLWERR, FLWERRMAX in applications in which the maximum motor torque is expected to be so small

that a correction of the velocity profile will not take place, and where the user wants to

use FLWERR as an indicator of an abnormal torque sequence.

If the absolute value of FLWERR exceeds FLWERRMAX, the following occurs:

• FLW_ERR bit is set. See "ERR_STAT - Register 35", page 30.

• MODE_REG = INIT_MODE. See "STOP_MODE ( MODE = 11 )", page 64 and

"Init Mode", page 57.

This monitoring function can be disabled by setting FLWERRMAX = 0.

See "Follow error", page 69.

FLWERR is calculated in the same way as described above. It should be

In these modes of operation FLWERR is calculated by accumulating

26 JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140

3.2 Parameter and Data Registers

3.2.24 FNCERR

3.2.25 FNCERR

3.2.26 FNCERRMAX

(Function Error).

Data format: LongInt.

Range, FNCERR: +/-134217727.

Range, FNCERRMAX: 0 ... 134217727.

These registers are used in the following modes of operation:

• Velocity mode, V_MODE. See "Velocity Mode", page 58.

• Position mode, P_MODE. See "Position Mode", page 58.

• Gear mode, G_MODE. See "Gear Mode (G_MODE, MODE = 3 )", page 59.

In the above modes FNCERR is calculated. In all other modes of operation FNCERR is

set to 0.

V_MODE, P_MODE:

that the function generator has applied to the velocity profile in order to maintain the

specified maximum torque.

It should be noted that the value of FNCERR in P_MODE is not an expression of a positioning error. If the motor is forced from its correct position and stays there, the function

generator will generate a velocity towards the correct position. Assume for example that

this velocity = 10. Since the motor is kept in this position, in principle the velocity profile

will be corrected by a value of -10 at each sample. The absolute value of FNCERR will

thus increase by 10 for each sample, despite the fact that the positioning error is constant.

G_MODE:

tion generator has applied to the velocity profile in order to maintain the specified maximum torque, maximum acceleration and maximum velocity.

In G_MODE, FNCERR represents a positioning error.

If the absolute value of FNCERR exceeds FNCERRMAX, the following occurs:

• FNC_ERR bit is set. See "ERR_STAT - Register 35", page 30.

• MODE_REG = INIT_MODE. See "STOP_MODE ( MODE = 11 )", page 64 and

"Init Mode", page 57.

This monitoring function can be disabled by setting FNCERRMAX = 0.

FNCERR is calculated by accumulating the velocity corrections that the func-

FNCERR is calculated by accumulating the velocity corrections

In P_MODE especially, it is normally unacceptable that FNCERR deviates from 0. The

specified maximum torque, T_SOLL, and maximum acceleration, A_SOLL, should be

corrected by the user.

See "Function Error", page 69.

3.2.27 FNCERRMAX

JVL Industri Elektronik A/S - Technical Manual - Integrated Servo Motors MAC50, 95 and 140 27

Loading...

Loading...