Industrial Ethernet

User Manual

MAC00-EC4/-EC41, MAC00-EI4/-EI41,

MAC00-EL4/-EL41, MAC00-EP4/-EP41,

MAC00-EM4/-EM41 , MAC00-ES4/-ES41

&

MIS and MILxxx (G2) motors

(Setup and functionality only. Some connector ID’s may differ)

JVL Industri Elektronik A/S

LB0056-22GB Revised 10.1.2019

Important

The MAC and MIS series of products are used to control electrical

and mechanical components of motion control systems.

You should test your motion system for safety under all potential

conditions. Failure to do so can result in damage to equipment

and/or serious injury to personnel.

!

!

Warning

User Information

Please contact your nearest JVL representative in case of technical assistance. Your nearest contact can be found on our web site www.jvl.dk

Copyright 2010-2019, JVL Industri Elektronik A/S. All rights reserved.

This user manual must not be reproduced in any form without prior written

permission of JVL Industri Elektronik A/S.

JVL Industri Elektronik A/S reserves the right to make changes to information contained in this manual without prior notice.

Similarly JVL Industri Elektronik A/S assumes no liability for printing errors

or other omissions or discrepancies in this user manual.

MacTalk and MotoWare are registered trademarks

JVL Industri Elektronik A/S

Bregnerødvej 127

DK-3460 Birkerød

Denmark

Tlf. +45 45 82 44 40

Fax. +45 45 82 55 50

e-mail: jvl@jvl.dk

Internet: http://www.jvl.dk

CANopen® Is a registered trademark of CAN in AUTOMATION - International Users and

Manufacturers Group e. V. (CiA), Nürnberg.

DeviceNet® Is a trademark of ODVA (Open DeviceNet Vendor Association, Inc).

EtherCAT® Is registered trademark and patented technology, licensed by Beckhoff Au-

tomation GmbH, Germany.

EtherNet/IP® Is a trademark of ODVA (Open DeviceNet Vendor Association, Inc).

Modbus TCP/IP® Is a registered trademark of Schneider Electric.

PROFINET IO® Is a registered trademark of PROFIBUS International, Karlsruhe.

SERCOS® Is a registered trademark of SERCOS International e.V., Suessen, Germany.

Contents

1 Introduction .................................................................................................................... 7

1.1 Introduction ........................................................................................................................................................ 8

1.2 Module types .................................................................................................................................................... 10

1.3 How to find FW/HW version at product .......................................................................................................... 13

2 General Hardware description ..................................................................................... 15

2.1 Hardware introduction ..................................................................................................................................... 16

2.2 I/O descriptions ................................................................................................................................................ 17

2.3 Connector description ...................................................................................................................................... 22

2.4 Cable accessories .............................................................................................................................................. 26

3 EtherCAT® Users Guide .............................................................................................. 33

3.1 Introduction to EtherCAT® ............................................................................................................................. 34

3.2 Protocol specifications ...................................................................................................................................... 36

3.3 Commisioning ................................................................................................................................................... 40

3.4 EtherCAT® objects .......................................................................................................................................... 45

3.5 CiA® DSP-402 drive profile ............................................................................................................................. 53

3.6 Examples ........................................................................................................................................................... 73

4 EthernetIP Users Guide ................................................................................................ 79

4.1 Introduction to EthernetIP ................................................................................................................................ 80

4.2 Using none cyclic messages .............................................................................................................................. 83

4.3 Using cyclic I/O-messages ................................................................................................................................. 88

4.4 Commissioning ................................................................................................................................................. 92

4.5 Implementation guidelines ................................................................................................................................ 99

4.6 Configuration with explicit messages .............................................................................................................. 102

4.7 Using and Selecting an Ethernet switch .......................................................................................................... 105

4.8 Examples ......................................................................................................................................................... 106

4.9 ODVA Conformance Certificate .................................................................................................................... 112

5 POWERLINK Users Guide .......................................................................................... 113

5.1 Introduction to POWERLINK ......................................................................................................................... 114

5.2 Protocol specifications .................................................................................................................................... 117

5.3 Commissioning ............................................................................................................................................... 121

5.4 Ethernet POWERLINK objects ....................................................................................................................... 124

5.5 Network Management Services ...................................................................................................................... 129

5.6 XML Device Description File ......................................................................................................................... 130

5.7 Examples ......................................................................................................................................................... 131

6 PROFINET Users Guide ............................................................................................. 137

6.1 Introduction to PROFINET IO .......................................................................................................................138

6.2 Commissioning ............................................................................................................................................... 140

6.3 PROFINET objects ......................................................................................................................................... 146

6.4 Ethernet switch ............................................................................................................................................... 153

6.5 Examples ......................................................................................................................................................... 154

7 ModbusTCP/IP® Users Guide .................................................................................... 159

7.1 Introduction to Modbus TCP/IP® .................................................................................................................. 160

7.2 Commissioning ............................................................................................................................................... 162

7.3 Register access ................................................................................................................................................ 170

7.4 Examples ......................................................................................................................................................... 171

8 Sercos® .......................................................................................................................177

8.1 Introduction to SERCOS ................................................................................................................................ 178

8.2 Commisioning ................................................................................................................................................. 180

8.3 Sercos Communication ................................................................................................................................... 196

8.4 FSP Drive profile ............................................................................................................................................. 207

8.5 FSP IO / JVL profile ......................................................................................................................................... 216

8.6 Examples ......................................................................................................................................................... 218

JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 5

9 Module Registers ........................................................................................................ 225

9.1 Register Overview ...........................................................................................................................................226

9.2 Register Descriptions. ......................................................................................................................................227

10 Using MacTalk over Ethernet .................................................................................... 239

10.1 Using MacTalk over Ethernet ..........................................................................................................................240

10.2 Setting up the Ethernet at the PC ...................................................................................................................243

10.3 Setting up MacTalk for Ethernet .....................................................................................................................249

11 Examples common to all protocols ............................................................................ 253

11.1 Using module I/O in embedded RxP ...............................................................................................................254

12 Appendix ..................................................................................................................... 257

12.1 Technical Data .................................................................................................................................................258

12.2 Motor registers MAC050 - 141 .......................................................................................................................264

12.3 Motor registers MAC400 - 4500 .....................................................................................................................273

12.4 Motor registers MISxxx ...................................................................................................................................292

6 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

1 Introduction

JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors 7

1.1 Introduction

TT3001-02GB

MAC family

Ethernet for servos

MIS family

Ethernet for steppers

Industrial Ethernet is becoming more and more

popular as it offers

• Very fast response time

• Predictable delay times (deterministic protocol)

• Safe transmission of data

Compared with most of the “classic” non Ethernet based protocols the indstrial Ethernet offers

state of the art performance.

The MAC00-Ex4/-Ex41 (Ethernet module for

MAC motors) and MIS/MILxxxxxxExxxxxx (MIS/

MIL motors with Ethernet option) can be config

ured by the end user to a number of different

Ethernet protocols, for instance

• EtherCAT

• EtherNetIP

• Ethernet POWERLINK

• PROFINET IO

• Modbus TCP/IP

• Sercos

®

®

®

®

®

®

• And more to come

Main Features:

• High speed communication - 100Mbits/sec.

• 2 individual ports on the module offers Daisy

chaining possibility.

• Standard M12 circular industrial connectors

• MAC motor module MAC00-Ex4: 1

input (24V) and 1 digital output (24V) for lo

cal use around the motor

• MAC motor module MAC00-Ex41: 4

input (24V) and 2 digital outputs (24V) for

local use around the motor

• MIS/MIL motor with Ethernet option offers 8

digital I/O’s. Each I/O terminal can also be an

-

analog input

• Multiple alternative I/O possibilities available

on request (OEM applications)

• LED’s for easy monitoring of operation status

• Optional encoder I/O

• Rough design

• Access to all internal motor parameters and

registers possible. No need of pre-setup of

the motor.

• RS232 connection available for monitoring

and setup use for the MAC00-Ex4/-Ex41

modules.

• RS485 connection available for monitoring

and setup use for the MIS/MILxxxxxxExxxx

motor.

Digital

-

Digital

8 JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors

MAC800 users important: Please notice that only MAC800 motors with a serial number newer than

85000 is compatible with the Ethernet modules MAC00-Exx.

JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors 9

1.2 Module types

1.2.1 Module types (Only applicable for MAC00-Ex4/-Ex41)

The MacMotor Ethernet modules are available for several Ethernet protocols.

The module used for each protocol has its own unique type number, but is based on the

exactly same hardware.

A neutral module where no protocol is installed however also exist.

• Neutral module - no protocol installed.

MAC00-Ex4/-Ex41 is a neutral module not setup-up for any particular protocol. The

final user can setup it up for any of the available protocols just by using the general

MacTalk windows software.

The visible LED marking, labels etc. only states that its a neutral MAC00-Ex4/-Ex41

module.

• Pre-loaded module - a specific protocol has been installed.

The modules MAC00-EC4/-EC41 (EtherCAT), MAC00-EI4/-EI41 (EtherNetIP), and

MAC00-EL4/-EL41 (POWERLINK), MAC00-EP (Profinet), MAC00-EM (Modbus

TCP) are setup at delivery with the relevant protocol and also the right LED marking.

The final user can setup it up for any of the available protocols just by using the general MacTalk windows software.

The visible LED marking, and type number is unique for each module type.

All modules (when not delivered mounted in a MacMotor) is followed by a little label

sheet containing labels for all the available standards and standards to come.

The overall idea is that any module can be changed to another protocol if desired, the

modules can stay neutral when it passes the distribution channel and be setup by the enduser simplifying the logistics.

MAC800 users important:

Please notice that only MAC800 motors with a serial number newer than 85000 is compatible with the Ethernet modules MAC00-Exx.

1.2.2 How to change the protocol type

Only 2 steps are needed in this process.

1. Install the intended protocol firmware in the module.

2. Apply or changing the label with LED marking and type number of the module.

The firmware can be setup as follows

(see next page)

10 JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors

1.2 Module types

TT3039-02GB

Step 1

Determine which Ethernet protocol you want to use.

Have in mind that your Ethernet module may

already be setup for a protocol.

How to setup the module for a different/new protocol

Step 2

As shown the module is setup as a module with

the Ethernet Powerlink protocol.

Choose the in the U

menu to setup the module with another protocol.

Update Firmware pdates

Step 3

Make sure that the checkbox

is checked.

Select the desired firmware such as EtherNet-IP.

Note that there may exist more than one

version. Choose the newest version.

Press S to download the selected firmware.

The status counter will now rise from 0

to 100%.

“Show all files”

tart

Step 4

When the download process is finished, the status

shows “ .

Also “ has changed to the actual

downloaded version meaning that the firmware in

the module is now changed permanently.

Done”

Current version”

Step 5

The module tab has now changed from

Powerlink (EL) to EthernetIP (EI).

Step 6

The firmware version, MAC address etc.

can be monitored on the module tab.

! When changing protocol the module

factory defaults are restored.

JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors 11

1.2 Module types

Only MAC

Sheet with type labels

for each Ethernet protocol

Peel off the relevant label from the sheet.

and place it in this area.

The existing typenumber and LED texts

will thereby be overwritten/replaced.

TT3040GB

Changing the label and typenumber (only MAC products)

This illustration show how to apply the appropriate label in order to change the LED

texts and also give the module its unique typenumber after the protocol firmware is load

ed.

-

Changing the label and typenumber (only MIS/MIL products)

No changes need to be done at the MIS/MIL motors. The LED at the rear is universal.

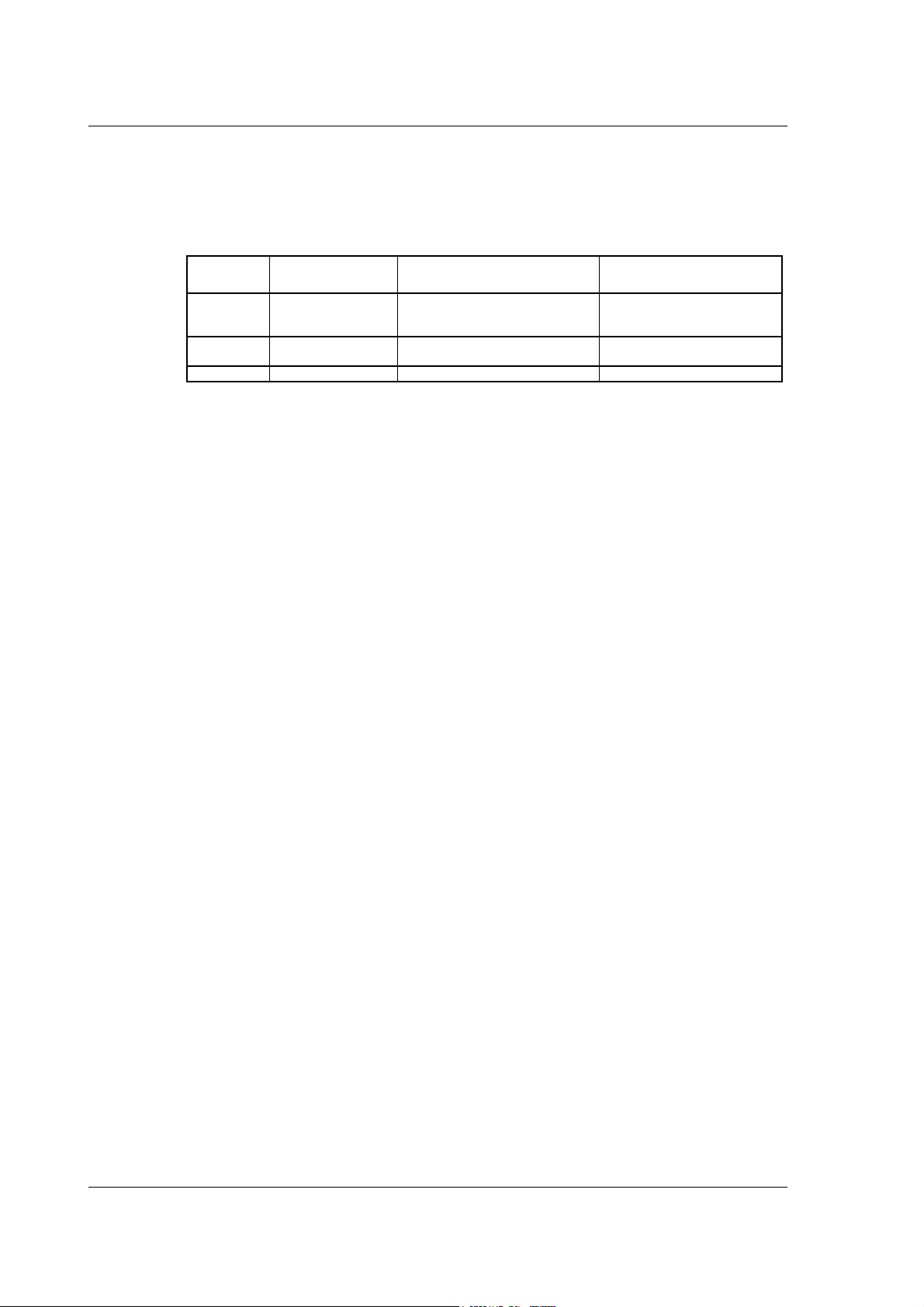

Typenumber overview for MAC and MIS/MIL:

MAC Type MIS Type Ethernet Protocol

12 JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors

MAC00-EC4/-EC41 MIS/MILxxxxxxECxxxxx EtherCAT

MAC00-EI4/-EI41 MIS/MILxxxxxxEIxxxxx EtherNET / IP

MAC00-EL4/-EL41 MIS/MILxxxxxxELxxxxx EtherNet POWERLINK

MAC00-EM4/-EM41 MIS/MILxxxxxxEMxxxxx Modbus TCP

MAC00-EP4/-EP41 MIS/MILxxxxxxEPxxxxx Profinet IO

MAC00-ES4/-ES41 MIS/MILxxxxxxESxxxxx Sercos III

1.3 How to find FW/HW version at product

TT3113-01GB

TT3114-01GB

HW version

FW version

1.3.1 Check Ethernet module version.

The firmware and hardware version of the Ethernet MAC module or the integrated

Ethernet module in the MIS/MIL motor can be checked from the MacTalk software when

connected to the motor. Select the tab for the Ethernet protocol in use, and check the

“Module info” frame. For some protocols and some motors is also the minimum capable

cycle time when using a drive profile (CiA402, FSP Drive etc.) listed.

1.3.2 Check motor version.

The hardware version of the motor can be found using MacTalk. Move the mouse curser

to the lower left corner and a pop-up box will show with all the relevant info.

The firmware version in the motor can be seen at the green text in the bottom of the

picture.

JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors 13

14 JVL Industri Elektronik A/S - User Manual - Ethernet expansion modules for MAC motors

2 General Hardware description

Only MAC

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 15

P+

CVI

P+

P-

P-

5V

O+

IN1

IO-O1

Rx1P

Rx0P

Rx1N

Rx0N

Tx1P

Tx0P

Tx1N

Tx0N

Tx

Rx

O1

Fx4

IO1 4-

Fx1 3-

RX

O2

A1/B1

A2/B2

TX

GND

GND

4 Inputs

4

3

4

2 Outputs

RS232

serial interface

Control

core

incl

8Mb RAM

4Mb Flash

Power supply for the module

“PWR”

Power supply

MAC400/800: +24V

“I/O”

Digital inputs and outputs

Voltage range 5-28 (32)V

“L/A IN”

Primary

EtherNet

Interface

M12 female

connector

“L/A OUT”

Secondary

EtherNet

Interface

M12 female

connector

TT3003GB

MAC00-Ex4 expansion module

Basic MAC motor

(MAC400 or 800)

Power supply

Internal power supply

(processor and encoder)

Multifunction I/O1

(setup as “serial data”)

Multifunction I/O2

High speed sync. 0/1

Optional I/O use

Internal COM

Status outputs

Asynchronous

interface (5V)

AIN1

AIN2

Analogue inputs

AIN1=Zero search input

±10V nom. or up to 32V

8

2

2

2

2

3

3

3

3

4

4

4

4

6

5

5

7

1

1

1

1

See note1

See note1

See note1

See note1

Note1: These signals are internally avilable. Custom hardware can be made

for OEM appl. with other connectors in order to make the signals available.

Contact your JVL representative for more information.

Optocoupler

Isolation zone 2

Each isolation zone do not have galvanic contact with any other circuitry.

Isolation zone 3

Isolation zone 4

2.1 Hardware introduction

2.1.1 Overall hardware description

All internal and external main connections can be seen in the illustration below.

Only MAC

16 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

2.2 I/O descriptions

Only MAC

Expansion module MAC00-Ex4 and Ex41 front plate

Neutral module for all the Ethernet protocols

L/AIN

PrimaryEthernet

channelM12‐4pin

female(D‐coded)

andLEDforshowing

activity.

L/AOUT

SecondaryEthernet

channelM12‐4pin

femaleEthernetcoded

(Dcoded)Usedwhen

moduleisdaisychained

MACAddress

Eachmoduleishavingitsown

uniqueMACaddressused

toidentifyitontheEthernet

network.TheMACaddresscanalsobereadelectronically

TT3038-02GB

PWR

Powersupplyconnector

M12‐5pinmaleand

GreenLEDforindicating

powerapplied

Modulestatusindicators.

(MAC00‐Ex4shown)

I/O

I/O’sandRS232interface

(basicversion)

M12‐8pinfemale

1

(ext.verison)

M12‐17pinfemale

4digitalinputsand2digital

outputs,2analogueinput

2RS422/RS485channels

MAC00‐Ex4

MAC00‐Ex41

digitalinputand1digital

output,1analogueinput

Serialnumber

Eeachmodulehaveitsown

uniqueserialnumberwhich

canbeusedfordetermine

hardwareversionetc.

2.2.1 Hardware overview

2.2.2 External signals available at the MAC00-Ex4 and Ex41.

Following signals are available.

• “L/A IN” and L/A OUT” connector.

- The Ethernet connection. L/A IN is connected to the upstream master and L/A

OUT can be used downstream for the next motors/units in the chain.

• “I/O” connector.

- AIN1 - analogue input +/-10V.

Can be used as input for the zero search sensor or as general analog input for

speed or torque control depending on the what the actual operation mode in the

motor has been setup for.

MAC00-Ex41 offers a second analogue input AIN2. Function similar to AIN1.

Please notice that AIN2 is not available if mounted in a MAC050-MAC141.

-O1 - user output 1

Can be used as or as general output control able over the Ethernet interface.

MAC00-Ex41 offers a second digital output (O2). Function similar to O2.

-RS232 Interface.

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 17

Serial unbalanced interface for connection to a PC or a controller. The protocol

is similar to the USB or RS485 interface, which means that all registers/parame

ters in the motor can be monitored or changed. RS232 is not recommended for

long distances (>10m).

-IN1 - User input 1.

Can be used as general input which can be read over the Ethernet interface.

MAC00-Ex41 offers in total 4 digital inputs (IN1, IN2, IN3 and IN4).

-

2.2 I/O descriptions

Only MAC

- I/O supply and gnd (IO- and O+).

Used as ground and supply for the user in/output (O1 and IN1).

- 2 RS422/RS485 Multifunction I/O channels

Only available at the MAC00-Ex41. Can be used for encoder input, full duplex

serial communication, encoder output etc.

Please notice that no multifunction I/O’s are available if mounted in a MAC050-

MAC141.

• “PWR” connector.

- 24V supply for the internal control circuitry in the motor.

18 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

2.2 I/O descriptions

Only MAC

TT3011GB

MAC400 Motor

with MAC00-Ex4

MAC400 Motor

with MAC00-Ex4

P+

P+

P-

P-

CVI

CVI

Power

Supply

Power

Supply

Control Volt.

Control Volt.

Mains 115 or 230VAC

Mains 115 or 230VAC

Main supply

Main supply

Max. 26VDC !

Max. 26VDC !

It is recommended

that a separate supply

line is used for each motor.

Power supply

Make sure that all

involved units are

connected to the same

potential

GND

+12-26VDC

(control voltage)

Power supply connections to a MAC400

mounted with a MAC00-Ex4 module.

2.2.3 General power supply description

The Ethernet modules can be used in the allmost all the MAC motors but please be

aware that to use the MAC50 to 141 they will need the special option : “A009” for ex

ample “MAC140-A1-AAAA-A009”

. The diagram below shows how to connect power to a MAC400 motor mounted with

a MAC00-Ex4/-Ex41 module. Please notice that the voltage connected to P+ and/or CVI

must stay in the range +12-26VDC. When using a MAC50 to 141 up to 48VDC is al

lowed.

See also the general power supply description in the MAC motor main manual LB0047.

For further information concerning physical connections, see the Expansion module

MAC00-Ex4 (basic version) connector description, page 22.

-

-

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 19

2.2 I/O descriptions

Only MAC

TT3012-02GB

MAC motor

+MAC00-Ex4

or MAC00-Ex41

MAC motor

+MAC00-Ex4

or MAC00-Ex41

MAC motor

+MAC00-Ex4

or MAC00-Ex41

Make sure that all

involved units are

connected to the same

potential

Make sure that all

involved units are

connected to the same

potential

Make sure that all

involved units are

connected to the same

potential

Analogue input connection at the MAC motor

mounted with a MAC00-Ex4 or Ex41 module.

Note ! : screen only

connected to signal source.

Note ! : screen only

connected to signal source.

±10V out

AIN1

(analogue input)

AIN1

(analogue input)

AIN1

(analogue input)

GND

(ground)

GND

(ground)

GND

(ground)

Position or

velocity

controller

Power supply

10-32VDC

Power supply

10VDC

Ground

Screen

Screen

Connected to a external controller

Connected to a potentiometer

Connected to a zero search switch

Zero search switch

Note: Do not apply voltages higher than 32V to the analogue input (AIN)

If only 24V supply is available

insert a 2.7k resistor here.

This example only covers 0-10V but other configurations do of course also exist, such as 0-5V or +/-10V.

2kOhm potentiometer

(JVL typeno. “POT2K”)

AIN2

(only MAC00-Ex41)

AIN2

(only MAC00-Ex41)

AIN2

(only MAC00-Ex41)

2.2.4 Using the analogue input 1 and 2 (AIN1 and AIN2).

When a MAC00-Ex4 or MAC00-Ex41 module is mounted in the MAC motor, the analogue input(s) is available in the same manner as in the basic motor itself.

The analogue input(s) can be used for several applications and the function of the analogue input is determined by the mode in which the motor is set to operate.

Typically the input(s) is used for controlling the velocity, torque or position of the motor

but the input is also used as digital input for zero search or in “Air Cylinder Mode” where

it is used as trigger input for the movement done by the motor.

For further information concerning physical connections, see the Expansion module

MAC00-Ex4 (basic version) connector description, page 22.

20 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

Please notice that analogue input 2 (AIN2) is only available at MAC00-Ex41. Please notice that AIN2 is not available if mounted in a MAC050-MAC141.

2.2 I/O descriptions

Only MAC

Central

Controller

(for example a PC)

MAC400 Motor

with MAC00-Ex4

RS232 connection between a PC or central controller

to MAC400 with a MAC00-Ex4 module.

Power supply

Tx

Rx

P+

Rx

Tx

P-

RS232

Interface

Screen connected

to GND in each end

Opto isolation *

Make sure that all

involved units are

connected to the same

potential

Power

Supply

Contr. Voltage

CVI

Mains 230VAC

IGND

GND

+12-32VDC

IGND

Main supply

Screen

Max. 32VDC !

* Opto isolation is recommended if connection is permanent.

TT3013GB

2.2.5 RS232 - General description.

The RS232 interface is considered the main interface to the

motor when the motor is set

up using the MacTalk win

dows software from a PC or

from any kind of controller us

ing a RS232 interface.

When connecting the RS232

interface to a PC or control

ler, the following rules must

be followed:

1 Only one motor can be

connected at the interface

line.

2 Use screened cable.

3 Ensure that GND (interface

ground) is also connected.

4 Ensure that all units have a

proper connection to safety

ground (earth) in order to

refer to the same potential.

5 The RS232 interface cable

length should not exceed 10

metres.

-

-

-

Connectors:

To see the specific connector pin-out please see the chapter Expansion module MAC00Ex4 (basic version) connector description, page 22 or Expansion module MAC00-Ex41 (extended IO) connector description, page 24

A finished RS232 cable also exist. Please see Cables for the MAC00-Ex4 (basic version),

page 26 or Cables for the MAC00-Ex41 (extended I/O version), page 27

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 21

2.3 Connector description

Only MAC

Expansion module MAC00-Ex4 front plate

L/AIN

PrimaryEthernet

channel

M12‐4pinfemale

Ethernetcoded

(Dcoded)

L/AOUT

SecondaryEthernet

channel

M12‐4pinfemale

Ethernetcoded

(Dcoded)

Usedwhenmodule

isdaisychained

TT3002GB

PWR

Powersupply

M12‐5pinmale

connectorincluding:

and

P+(primarysup ply),andCVI

(secondarysupply) P‐

I/O

I/O’sandRS232interface

M12‐8pinfemale

connectorincluding:

1digitalinputand1digital

output,1analogueinput

2.3.1 Expansion module MAC00-Ex4 (basic version) connector description

The MAC00-Ex4 offers IP65 protection and M12 connectors which makes it ideal for automation applications where no additional protection is desired. The M12 connectors offer solid mechanical protection and are easy to unplug.

The connector layout:

“PWR” - Power input. M12 - 5pin male connector

Signal name Description Pin no.

P+

P+ Main supply - Connect with pin 1 * 2 White 1

P- Main supply ground. Connect with pin 5 * 3 Blue 1

CVI

P- Main supply ground. Connect with pin 3 * 5 Grey 1

* Note: P+ and P- are each available at 2 terminals. Make sure that both terminals are connected in order to

split the supply current in 2 terminals and thereby avoid an overload of the connector.

(Continued next page)

Main supply - Connect with pin 2 *

When installed in MAC050 to 141 = 12-48VDC

When installed in MAC400-4500 = 18-30VDC

Control supply nominal +12-48VDC.

DO NOT connect >50V to this terminal !

A small leakage current may exist on this pin if

not used.

Connect this terminal to ground if not used.

1 Brown 1

4 Black 1

JVL Cable

WI1000M12F5T05N

Isolation

group

22 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

2.3 Connector description

Only MAC

(MAC00-Ex4 continued)

“I/O” - I/O’s and interface. M12 - 8pin female connector.

Signal name Description Pin no.

O1 Output 1 - PNP/Sourcing output 1 White 2

RS232: TX

RS232: RX

GND

AIN1 Analogue input1 ±10V or used for zero search 5 Grey 1

IN1 Digital input 1 - 12-32V tolerant. 6 Pink 2

IO-

O+

“L/A IN” - Ethernet port connector - M12 - 4pin female connector “D” coded

Signal name Description Pin no.

Tx0_P Ethernet Transmit channel 0 - positive terminal 1 Brown/White 3

Rx0_P Ethernet Receive channel 0 - positive terminal 2 Blue/White 3

Tx0_N Ethernet Transmit channel 0 - negative terminal 3 Brown 3

Rx0_N Ethernet Receive channel 0 - negative terminal 4 Blue 3

Shield Outside shield connected to connector housing Housing Shield 1

“L/A OUT” - Ethernet port connector. M12 - 4 pin female connector “D” coded

Signal name Description Pin no.

Tx1_P Ethernet Transmit channel 1 - positive terminal 1 Brown/White 4

Rx1_P Ethernet Receive channel 1 - positive terminal 2 Blue/White 4

Tx1_N Ethernet Transmit channel 1 - negative terminal 3 Brown 4

Rx1_N Ethernet Receive channel 1 - negative terminal 4 Blue 4

Shield Outside shield connected to connector housing Housing Shield 1

* Note: Isolation group indicate which terminals/circuits that a galvanic connected to each other. In other

words group 1, 2, 3 and 4 are all fully independently isolated from each other. Group 1 correspond to the hous

ing of the motor which may also be connected to earth via the DC or AC input supply.

RS232 interface. Transmit terminal

Leave open if unused.

RS232 interface. Receive terminal

Leave open if unused.

Interface ground to be used together with the

other signals in this connector. Also ground for

the analogue input (AIN1 - pin 5)

I/O ground to be used with the I/O terminals O1

and IN1.

Positive supply input to the output circuitry.

Connect 5-32VDC to this terminal if using the O1

output.

2 Brown 1

3 Green 1

4 Yellow 1

7 Blue 2

8 Red 2

JVL Cable

WI1000-M12

M8T05N

JVL Cable

WI1046M12M4S05R

JVL Cable

WI1046M12M4S05R

Isolation

group

(See note)

Isolation

group

(See note)

Isolation

group

(see note)

-

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 23

2.3 Connector description

Only MAC

Expansion module MAC00-Ex41 front plate

Extended I/O connections (MAC00-EC41 shown)

L/AIN

PrimaryEthernet

channel

M12‐4pinfemale

Ethernetcoded

(Dcoded)

L/AOUT

SecondaryEthernet

channel

M12‐4pinfemale

Ethernetcoded

(Dcoded)

Usedwhenmodule

isdaisychained

TT3087-02GB

PWR

Powersupply

M12‐5pinmale

connectorincluding:

and

P+(primarysupply),andCVI

(secondarysupply) P‐

I/O

I/O’sandRS232interface

M12‐17pinfemale

connectorincludes:

4digitalinputsand2digital

outputs,2analogueinputs

2RS422/RS485multifunction

channels

2.3.2 Expansion module MAC00-Ex41 (extended IO) connector description

The MAC00-Ex41 offers IP65 protection and M12 connectors which makes it ideal for

automation applications where no additional protection is desired. The M12 connectors

offer solid mechanical protection and are easy to unplug.

The connector layout:

“PWR” - Power input. M12 - 5pin male connector

Signal name Description Pin no.

P+

P+ Main supply - Connect with pin 1 * 2 White 1

P- Main supply ground. Connect with pin 5 * 3 Blue 1

CVI

P- Main supply ground. Connect with pin 3 * 5 Grey 1

* Note: P+ and P- are each available at 2 terminals. Make sure that both terminals are connected in order to

split the supply current in 2 terminals and thereby avoid an overload of the connector.

(Continued next page)

Main supply - Connect with pin 2 *

When installed in MAC050 to 141 = 12-48VDC

When installed in MAC400-4500 = 18-30VDC

Control supply nominal +12-48VDC.

DO NOT connect >50V to this terminal !

A small leakage current may exist on this pin if

not used.

Connect this terminal to ground if not used.

JVL Cable

WI1000M12F5T05N

1 Brown 1

4 Black 1

Isolation

group

24 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

2.3 Connector description

Only MAC

(MAC00-Ex41 continued)

“I/O” - I/O’s and interface. M12 - 17pin female connector.

Signal name Description Pin no.

IN1 Input channel 1. Can be used as digital input 1 Brown 2

GND

IN2 Input channel 2. Can be used as digital input 3 White 2

IN3 Input channel 3. Can be used as digital input 4 Green 2

B2- ** RS422/RS485 Multifunction I/O terminal B2- 5 Pink 1

IN4 Input channel 4. Can be used as digital input 6 Yellow 2

A2- ** RS422/RS485 Multifunction I/O terminal A2- 7 Black 1

B2+ ** RS422/RS485 Multifunction I/O terminal B2+ 8 Grey 1

OUT+ Output 1 and 2 supply input.

A2+ ** RS422/RS485 Multifunction I/O terminal A2+ 10 Violet 1

O1 Output 1. Can be used as digital output 11 Grey/pink 2

O2 Output 2. Can be used as digital output 12 Red/blue 2

AIN1

AIN2

RS232: RX

IO- Ground for IN1-4 and O1 and 2. Please notice

RS232: TX

“L/A IN” - Ethernet port connector - M12 - 4pin female connector “D” coded

Signal name Description Pin no.

Tx0_P Ethernet Transmit channel 0 - positive terminal 1 Brown/White 3

Rx0_P Ethernet Receive channel 0 - positive terminal 2 Blue/White 3

Tx0_N Ethernet Transmit channel 0 - negative terminal 3 Brown 3

Rx0_N Ethernet Receive channel 0 - negative terminal 4 Blue 3

Shield Outside shield connected to connector housing Housing Shield 1

“L/A OUT” - Ethernet port connector. M12 - 4 pin female connector “D” coded

Signal name Description Pin no.

Tx1_P Ethernet Transmit channel 1 - positive terminal 1 Brown/White 4

Rx1_P Ethernet Receive channel 1 - positive terminal 2 Blue/White 4

Tx1_N Ethernet Transmit channel 1 - negative terminal 3 Brown 4

Rx1_N Ethernet Receive channel 1 - negative terminal 4 Blue 4

Shield Outside shield connected to connector housing Housing Shield 1

* Note: Isolation group indicate which terminals/circuits that a galvanic connected to each other. In other

words group 1, 2, 3 and 4 are all fully independently isolated from each other. Group 1 correspond to the

housing of the motor which may also be connected to earth via the DC or AC input supply.

Ground intended to be used toghether with the

other signals related to isolation group 1 in this

connector

DO NOT connect >30V to this terminal !

Analog input 1.

Can be used as analog input ±10V.

Analog input 2.

Can be used as analog input ±10V.

RS232 interface. Receive terminal

Leave open if unused.

that this terminal is normally isolated from the

main ground and belongs to isolation group 2

RS232 interface. Transmit terminal

Leave open if unused.

2 Blue 1

9 Red 2

13 White/Green 1

14 Brown/Green 1

15 White/Yellow 1

16 Yellow/brown 2

17 White/grey 1

JVL Cable

WI1009M12

M17TxxN

JVL Cable

WI1046M12M4S05R

JVL Cable

WI1046M12M4S05R

Isolation

group

(see note)

Isolation

group

(See note)

Isolation

group

(see note)

** No connection when module is mounted in a MAC050-MAC141.

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 25

2.4 Cable accessories

Only MAC

2.4.1 Cables for the MAC00-Ex4 (basic version)

The following cables equipped with M12 connector can be supplied by JVL.

MAC00-Ex4 Connectors Description JVL Order no. Picture

“L/A IN”

4pin

male

“L/A OUT”

4pin

Female

“I/O”

8pin

Female

X

X

“PWR”

5pin

Male

RS232 Interface cable. Connects

directly from MAC00-Ex4 to a PC

Length: 5m (197 inch)

Cable with M12 male 8-pin

connector loose wire ends

0.22mm² (24AWG) and screen.

Length: 5m (197 inch)

RS232-M12-1-5-8

WI1000-M12M8T05N

X

X X

X X

X X

Same as above but 20m (787 inch)

Cable (Ø5.5mm) with M12 female

5-pin connector loose wire ends

X

0.35mm² (22AWG) and foil screen.

Length: 5m (197 inch)

Same as above but 20m (787 inch)

X

Ethernet cable with M12 male 4pin D

coded straight connector, and RJ45

connector (fits into std. Ethernetport)

Ethernet cable with M12 male 4pin D

coded straight connector, loose ends.

Same as above but 15m (590 inch)

WI1000-M12M8T20N

WI1000-M12F5T05N

WI1000-M12F5T20N

WI1046-M12M4S05NRJ45

WI1046-M12M4S05R

WI1046-M12M4S15R

Protection caps. Optional if connector is not used to protect from dust / liquids.

X X

IP67 protection cap for M12

female connector.

WI1000-M12FCAP1

Important: Please note that the cables are a standard type. They are not recommended for use in cable chains or where the cable is repeatedly bent. If this is required, use a special robot cable (2D or 3D

cable).

26 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

X X

IP67 protection cap for M12

male connector.

WI1000-M12MCAP1

2.4 Cable accessories

Only MAC

36.0mm

[1.42 inch]

54.0mm

[2.126 inch]

0

5.0mm

[0.197inch]

= Mounting holes

77.0mm

[3.031inch]

112.0mm

[4.409inch]

2 x

Ø4/8mm

[Ø0.16/0.32inch]

2 x

Ø4x8mm

[Ø0.16x0.32inch]

118.0mm

[4.646inch]

TT3088-01GB

2.4.2 Cables for the MAC00-Ex41 (extended I/O version)

The following cables equipped with M12 connector can be supplied by JVL.

MAC00-Ex41 Connectors Description JVL Order no. Picture

“L/A IN”

4pin

male

“L/A OUT”

4pin

Female

“I/O”

17pin

Female

(X)

X

“PWR”

5pin

Male

RS232 Interface cable. Connects

directly from MAC00-Ex4 to a PC

Length: 5m (197 inch)

IMPORTANT: Only valid if PA0190 is

used as adapter.

Cable with M12 male 17-pin

connector loose wire ends

0.22mm² (24AWG) and screen.

Length: 5m (197 inch)

RS232-M12-1-5-8

WI1009-M12M17T05N

X

X X

X X

X X

X

Same as above but 20m (787 inch)

Cable (Ø5.5mm) with M12 female

5-pin connector loose wire ends

X

0.35mm² (22AWG) and foil screen.

Length: 5m (197 inch)

Same as above but 20m (787 inch)

X

Ethernet cable with M12 male 4pin D

coded straight connector, and RJ45

connector (fits into std. Ethernetport)

Ethernet cable with M12 male 4pin D

coded straight connector, loose ends.

Same as above but 15m (590 inch)

Junction box for splitting the 17 pin I/O

connector into 4 independant connec

tors. Include also 9 LED’s for monitoring the I/O status and communication.

Cable length: 0,5m (20 inch)

WI1009-M12M17T20N

WI1000-M12F5T05N

WI1000-M12F5T20N

WI1046-M12M4S05NRJ45

WI1046-M12M4S05R

WI1046-M12M4S15R

-

PA0190

Protection caps. Optional if connector is not used to protect from dust / liq uids.

X X

IP67 protection cap for M12

female connector.

WI1000-M12FCAP1

X X

IP67 protection cap for M12

male connector.

WI1000-M12MCAP1

Important: Please note that the cables are a standard type. They are not recommended for use in cable chains or where the cable is repeatedly bent. If this is required, use a special robot cable (2D or 3D

cable).

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 27

2.4 Cable accessories

Only MAC

WI1000-M12F5T05N

M12 shl cable 5 m 5 pin Fem 0°

Power

Dat e: 04-07-13

JVL Industr i Elektronik A/S

Blo kk en 42 • DK-3460 Bir ker ød

Tel : +45 4582 4440

Fax: +45 4 582 5550

Ver s io n - 1.0

Appr ov ed by :

- BVJ

Dr a w n by :

PCR

LT0233-10

J1

Pi n n o . J1

Len g t h = 5 m

Text printed on green tube

Wh i t e

P-

Br o w n P+

P+

2

3

Co l o r

Si g n a l n a m e

Ty pe: WI1000- M12F5T05N

M12, 5 pi n f ema l e c on n ect o r

Scr een

Grey

4

(Opt io Ns)

1

Bl u e

Ho u s i n g

5

5

1

2

4

3

Vi ew f r o m f r o n t

Bl a c k

P-

Twisted pair

Twisted pair

WI1046-M12M4S05NRJ45

M12 shl cable 4 pin male 5m

Ethernet D-Coded RJ45

Date: 8-7-13

JVL Industri Elektronik A/S

Blokken 42 • DK-3460 Birkerød

Tel: +45 4582 4440

Fax: +45 4582 5550

Version - 1.2

Approved by:

- BVJ

Drawn by:

PCR/BVJ

LT0179-12

J1

Pin no. J1

Length = 5 m

Text printed on green tube

Cable data : Twisted with screen SFTP 24AWGx2 +AEB.

OrangeBrown

Rx+

Orange/WhiteBrown/White

Tx+

Tx-

2

3

Color (Type 2 Alt.)Color (Type 1 standard)

Please notice !: 2 versions of the cable type exist:

Type 1: This is the cable normally stocked

Type 2: This is the cable normally not stocked

standard

alternative

Alternative colors exist

Please see table below.

Alternative colors exist

Please see table below.

Signal name

Type: WI1046-M12M4S05NRJ45

M12, 4 pin male

connector Ethernet

D-Coded

ScreenScreen

GreenBlue

4

House

Rx-

GND

Connector type RJ45

with internal metal

housing/shield

J2

Pin 1

1

1

Pin 8

Pin no. J2

Housing

Flex

Pin1: Brown/White

Pin 2: Blue/White

Pin 3: Brown

Pin 4: Blue

Pin1: Brown/White

Pin 2: Brown

Pin 3: Blue/White

Pin 6: Blue

2

3Green/WhiteBlue/White

House

6

Housing

Below can be found drawings of the most typical cables used with the Ethernet modules.

2.4.3 Drawing WI1000-M12F5T05N

Cable for connecting power

2.4.4 Drawing WI1046-M12M4S05NRJ45

28 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

Cable that connects the Ethernet from M12 to RJ45 connectors

2.4 Cable accessories

Only MAC

RS232-M12-1-5-8

Interface cable

M12 to DSUB

Date: 27-9-06

JVL Industri Elektronik A/S

Blokken 42 • DK-3460 Birkerød

Tel:+45 4582 4440

Fax: +45 4582 5550

Version - 1.1

Approved by:

BVJ - 1.1

Drawn by:

JVJ

LT0082-11

J1

Cable

J1

Pin no.

DSUB Connector.

Female 9pin.

1

Brown

Green 3

2

5

Housing

White

Blue

Red

Pink

Yellow

Grey

J1J2The wires White, Grey, Pink, Blue and Red

are not connected and must be insulated

Pin 1, 4, 6, 7, 8, 9 must be left open

2

3

4

5

6

7

8

Screen

Pin no.Color

J2

J2

Finger screws (2 pcs)

RS232 communication cable for MAC expansion modules

5 metre

Cable, Black PVC, UL 24 AWG, 8 core screened.

M12, 8 pin male connector

Max.

15.6mm

1

2

3

4

5

6

7

8

9

Not connected

Ø6±0.2mm

36.0mm

[1.42 inch]

54.0mm

[2.126 inch]

0

5.0mm

[0.197inch]

= Mounting holes

77.0mm

[3.031inch]

112 .0m m

[4.409inch]

2 x

Ø4/8mm

[Ø0.16/0.32inch]

2 x

Ø4x8mm

[Ø0.16x0.32inch]

118 .0m m

[4.646inch]

TT3088-01GB

2.4.5 Drawing RS232-M12-1-5-8

Cable that connects the RS232 from M12 to DSUB connectors.

2.4.6 Drawing and description of PA0190

Junction box that splits the connects the signals in the MAC00-Ex41 “I/O” connector

into 4 individual connectors giving an easy and more flexible installation.

Usage hints: The LED's will only work with MIS/MIL or MAC motors where the OUT+

and IO- is supplied from the Ethernet module. See also the I/O description for the mod

ule.

If a cable is connected to the “BYPASS” then the Communication pins and GND must be

properly connected to valid signals (pins 2,15,17). AND “COM” must not be used. In

other words use EITHER the “BYPASS” OR the “COM” connector. Not both.

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 29

-

2.4 Cable accessories

Only MAC

«COM»

8 pin Female

«IO2»

8 pin Male

«BYPASS»

17 pin Female

Cable from Module

with 17 pin Male connector

«IO1»

8 pin Male

TT3089-01GB

1

11

1

1

2

2

2

2

2

3

3

3

3

3

7

99

7

7

7

7

8

10101616111112

12

8

8

Signals

and colors

like the

«BYPASS»

cable

The screen is

connected to

«GND»

(ground)

1717

8

8

4

4

4

4

4

5

66

1313

5

5

6

15

15

5

5

1414

6

6

B

Y

P

A

S

S

C

O

M

C

O

M

I

O

2

I

O

2

I

O

1

I

O

1

Pin no.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

Pin 13

Pin 14

Pin 15

Pin 16

Pin 17

Body

Color*

Brown

Blue

White

Green

Pink

Yellow

Black

Grey

Red

Violet

GY/PK

RD/BU

WH/GN

BN/GN

WH/YE

YE/BN

WH/GY

-

Funct.

IN1

GND

IN2

IN3

B2IN4

A2B2+

O+

A2+

O1

O2

AIN1

AIN2

RX

IOTX

GND

Pin no.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Body

Pin no.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Body

Pin no.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Body

Funct.

IN1

IN2

IN3

IOO2

O1

GND

O+

GND

Funct.

IN4

AIN1

AIN2

IOO2

O1

GND

O+

GND

Func.

IN4

TX

RX

GND

RX

TX

AIN1

AIN2

GND

Color*

White

Brown

Green

Yellow

Grey

Pink

Blue

Red

-

Color*

White

Brown

Green

Yellow

Grey

Pink

Blue

Red

-

* Notes.

COM

Colors shown are based on

the JVL standard cables type:

connection 8 Pin Male

cable

BYPASS

IO1

IO2

connect. 17 Pin Male

cable

connection 8 Pin Female

cable

connection 8 Pin Female

cable

WI1000-M12M8TxxN

WI1009-M12M17TxxN

WI1000-M12F8TxxN

WI1000-M12F8TxxN

Color*

White

Brown

Green

Yellow

Grey

Pink

Blue

Red

-

POWER

is lit if terminal

is supplied

«OUT+»

RX

is lit if data is rec-

eived at the RS232 line.

TX

is lit if data is trans-

mitted at the RS232 line.

IN3

is lit if input 3

is activated.

IN4

is lit if input 4

is activated.

O1

is lit if output 1

is activated

O2

is lit if output 2

is activated

IN1

is lit if input 1

is activated

IN2

is lit if input 2

is activated

Text in inverse is NOT

relevant when PA0190

is used with the

MAC00-Ex41 Ethernet

modules.

Text in NON-inverse must

be used when PA0190 is

used with the MAC00-Ex41

Ethernet modules.

LED explanations

Terminal and LED description of the PA0190 Junction box.

30 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

2.4 Cable accessories

Only MAC

TT3090-01GB

Diagram of the internal details in the PA0190 Junction Box.

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 31

32 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

3 EtherCAT® Users Guide

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 33

3.1 Introduction to EtherCAT®

TT3041-02GB

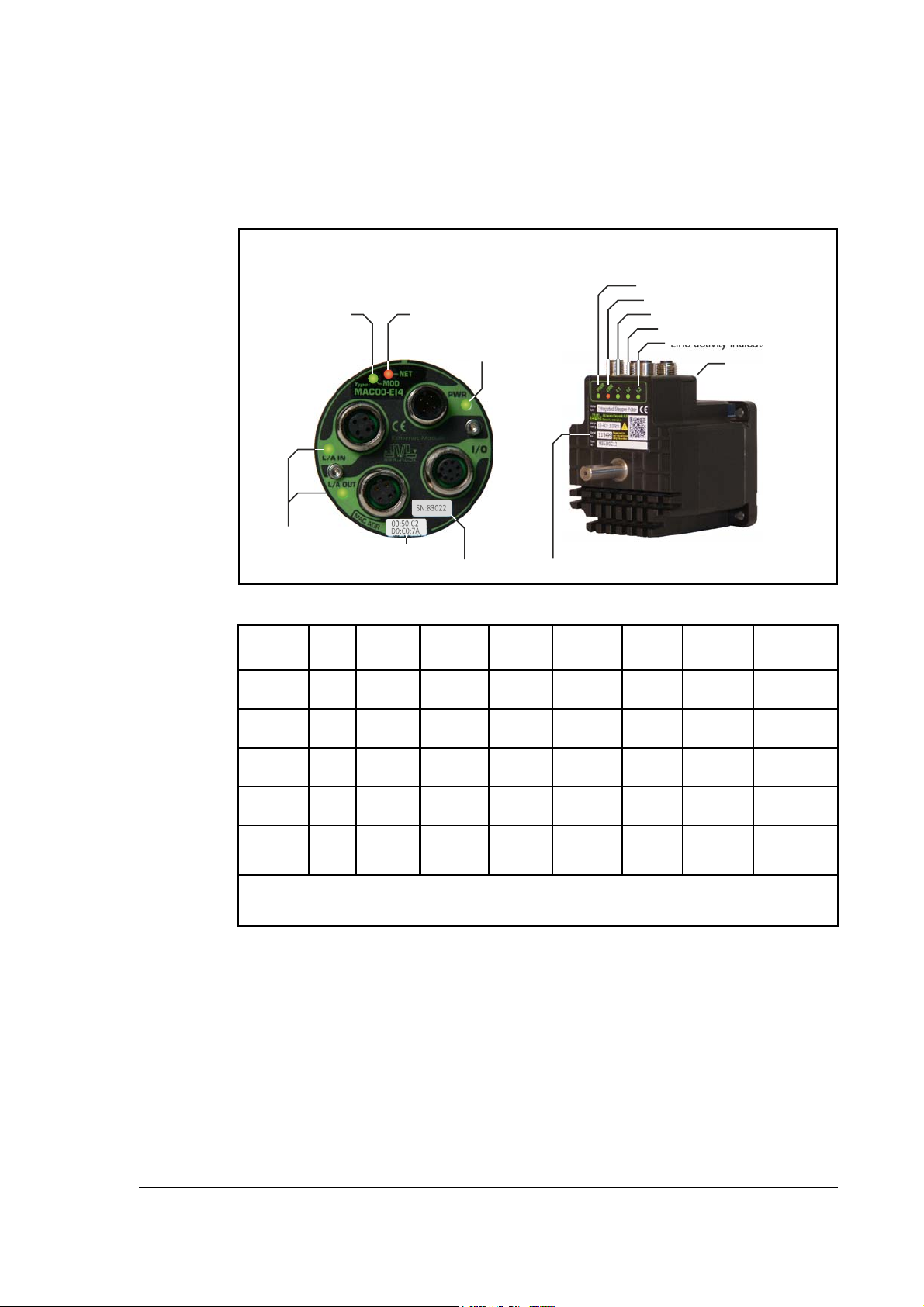

MAC EtherCAT® Module

Type:

MAC00- 4 (shown) or

MAC00- 41 (extended I/O)

To be used in following servo products:

MAC50, 095, 140 and 141

MAC400 and MAC402

MAC800

MAC1500 and MAC3000

EC

EC

MIS EtherCAT® motors.

Type:

MIS34xxx xx85 or

To be used in following stepper products:

- Integrated from factory

EC

MIS43xxx xx85

EC

3.1.1 Intro to EtherCAT®.

EtherCAT® is a Real Time Ethernet technology which aims to maximize the use of the

100 Mbit, full duplex Ethernet bandwidth. It overcomes the overhead normally associat

ed with Ethernet by employing "on the fly" processing hardware.

An EtherCAT® net consists of a master system and up to 65535 slave devices, connected together with standard Ethernet cabling.

The slave devices process the incoming Ethernet frames directly, extract or insert relevant data and transfer the frame to the next slave device, with a delay of approx. 4μs.

The last slave device in the bus segment sends the processed frame back, so that it is re

turned by the first slave to the master as a kind of response frame.

There are several protocols that can be used as the application layer. In the CANopen

over EtherCAT® (CoE) technology, the CANopen protocol is applied to EtherCAT®.

CANopen defines Service Data Objects (SDO), Process Data Objects (PDO) and the

Object Dictionary structure to manage the parameters. Further information about Eth

erCAT®, is available from the EtherCAT® technology group http://www.ethercat.org.

-

-

-

34 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

3.1 Introduction to EtherCAT®

3.1.2 Abbreviations

Following general used terms are usefull to know before reading the following chapters.

100Base-Tx 100 MBit Ethernet on twisted pairs

CAN Controller Area Network

CANopen Application layer protocol used in automation.

CoE CANopen over EtherCAT®.

DC Distributed Clock

EMCY Emergency Object.

EoE Ethernet over EtherCAT®.

ESI EtherCAT® Slave Information

ESC EtherCAT® Slave Controller

ETG EtherCAT® Technology Group

EtherCAT® Ethernet Control Automation Technologie

IP Internet Protocol - IP address ~ the logical address of the device, which is

user configurable (not used in EtherCAT®).

MAC Media Access Controller - MAC address ~ the hardware address of the

device (not used in EtherCAT®)

PDO Process Data Object (for cyclic data)

SDO Service Data Object (for acyclic data)

SII Slave Infirmation Interface

XML eXtensible Markup Language - used for the ESI file.

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 35

3.2 Protocol specifications

Preamble Ethernet header

8 bytes 14 bytes

Checksum4byte

s

EtherC AT

header

1'st Datagram

header

2 bytes 10 bytes

Data WKC

2bytes

n'thEtherCATdatagra

m

-44-1498bytes

-

TT3007GB

3.2.1 EtherCAT® - communication

The EtherCAT® fieldbus system is standardised by the EtherCAT® user organisation

(ETG). The driving force behind this is the german company, Beckhoff GmbH. Due to

the advanced Ethernet technology used for EtherCAT®, in the future, customers can

change from other fieldbus systems to EtherCAT® or generally equip new plant models

with EtherCAT®.

Communication on EtherCAT® is based on a master/slave operation. The update cycle

between master and slave depends on the number of EtherCAT® slaves, the amount of

process data of the individual slaves, and the set update time of the master. Due to the

ring topology, in every bus cycle only one telegram is sent on the bus. The bus cycle time

thus remains exactly the same in every cycle.

Slave addressing can be done in two ways:

• Auto increment addressing

• Fixed node addressing

With Auto increment addressing the master scans the net for slaves, and the slaves are

then addressed in the sequence they are physically present on the net. With fixed node

addressing, the addresses that each node has programmed, is used.

3.2.2 EtherCAT® frame structure

In EtherCAT®, the data between the master and the slaves is transmitted in Ethernet

frames. An EtherCAT® Ethernet frame consists of one or several EtherCAT® tele

grams, each addressing individual devices and/or memory areas. The telegrams can be

transported either directly in the data area of the Ethernet frame or within the data sec

tion of a UDP datagram transported via IP. The EtherCAT® frame structure is pictured

in the following figure. Each EtherCAT® telegram consists of an EtherCAT® header, the

data area and a working counter (WKC), which is incremented by all EtherCAT® nodes

that are addressed by the telegram and have exchanged associated data.

-

-

3.2.3 Sync managers

3.2.4 Sync manager watchdog

36 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

Sync managers control the access to the application memory. Each channel defines a consistent area of the application memory. The adapter module has four sync manager channels. The mailbox protocol (SDO's) and process data (PDO's) are described later in this

chapter.

The sync manager watchdog monitors the output sync managers. If the output data is not

updated by the EtherCAT® master within the configured time, the watchdog will acti

vate time out and change the state of the adapter module from Operational to Safe-Operational.

Note: EtherCAT® has been designed so that it provides no way for a slave to monitor

the connection to the master if the slave gets no output data.

Note: The drive reaction to a communication fault must be configured in the module

write flag register (object 2011 subindex 6 - motor set passive or motor set velocity =0).

-

3.2 Protocol specifications

Init

Operational

Pre-Operational

Safe-O

perationalBootstrap

(OI)

(OP)

(IP)

(PI)

(SO)

(SI)

(IB)

(BI

)

(OS)

(PS)

(SP)

TT3009GB

3.2.5 EtherCAT® - State machine

Both the master and the slaves have a state machine with the states shown below. After

boot the slaves are in INIT state, and then it's up to the master to request state transi

tions. The standardized EtherCAT® state machine is defined in the following figure. The

bootstrap state is not supported.

-

The module enters the Init state directly after start-up. After this, the module can be

switched to the Pre-Operational state. In the Pre-operational state the EtherCAT® mail

box communication is allowed and CoE objects can be accessed by SDOs. After the master has configured the slave, it can switch the module to the Safe-Operational state. In

this state input I/O data (PDOs) is sent from the adapter module to the EtherCAT® mas

ter, but there is no output I/O data from the master to the module. To communicate output I/O data the master must switch the adapter module to the Operational state.

State description table:

State Description

Init

Pre-operational SDO communication possible. No PDO communication.

Safe-operational Transmit PDO operational (drive sends data to master)

Operational Drive fully operational, responds to data via receive PDO

Boot-strap Not used.

State after device initialisation. No Application layer communication (no SDO and

PDO communication).

-

-

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 37

3.2 Protocol specifications

3.2.6 CANopen over EtherCAT®

The application layer communication protocol in EtherCAT® is based on the CANopen

DS 301 communication profile and is called CANopen over EtherCAT® (CoE). The pro

tocol specifies the Object Dictionary in the adapter module, in addition to communication objects for exchanging cyclic process data and acyclic messages. In addition to DS301

and the default JVL profile, the MAC00-ECx also supports the DSP402 drive profile

DSP-402 drive profile, page 53.

The EtherCAT® module uses the following message types:

• Process Data Object (PDO). The PDO is used for cyclic I/O communication,

in other words, process data.

• Service Data Object (SDO). The SDO is used for much slower acyclic

data transmission.

• Emergency Object (EMCY). The EMCY is used for error reporting when a fault has

occurred in the module or in the drive.

3.2.7 Drive synchronization (only applicable to MAC400+ & MIS/MILxxx)

Distributed clocks

The distributed clock is the primary mechanism built into the EtherCAT network protocol to allow synchronization between the master and slaves in the network. Not every

EtherCAT device supports the distributed clock protocol, but those that do can use this

mechanism to share a common clock domain across the network. MAC00-ECx supports

this when mounted in a MAC400+, and the MIS/MIL also supports this feature.

When the MAC00-ECx is mounted in a MAC050 - MAC141 DC is NOT supported.

-

CiA®

When the distributed clock protocol is being used, one clock on the network is selected

as the master clock, and all other devices are synchronized to it. The master controller

of the network determines which clock will be used as the master clock. The master

clock can either reside in the master controller itself, or in one of the slave devices on

the network. In many systems the slave devices are able to capture time stamps more

accurately than the master controller, so usually the first DC capable slave device in the

network is selected as the clock source.

Every EtherCAT slave device which supports the DC feature includes hardware which

allows a very accurate local time stamp to be captured when certain registers are written

over the network. These time stamps can then be used by the slave device to adjust its

local clock to remove the drift between it and the master clock on the network.

The EtherCAT master uses these time stamps to calculate the network delay between

devices on the network and to find an offset between each slave's local time and the sys

tem time.

Once this offset has been found for each slave, the master writes the offset to a register

on the slave's EtherCAT interface hardware. The result is a shared time base for every

device on the network which supports the distributed clock protocol.

-

38 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

3.2 Protocol specifications

Sync0 pulse

The distributed clock allows multiple devices on the network to share a common time

reference, but doesn't itself provide any real functional synchronization.

Additional hardware is provided on the DC enabled slave devices, which allows a pulse

to be generated on the slaves at a fixed period.

This pulse, known as the Sync0 pulse, is used by the slave device to synchronize its internal functions to the network.

The master is responsible for configuring the Sync0 pulse on each slave. Typically, the

master finds a sync period which is compatible with all slave devices, and configures the

Sync0 signal on all devices to occur simultaneously.

The acceptable sync periods for each slave device can be found in the documentation

provided by each device manufacturer. JVL MAC400+ servo motors have an internal po

sition loop with an update rate of 1kHz (1ms) - (alternatively 1.3 or 2.6mS), when used

with the MAC00-ECx.

For the synchronization to work, it is needed that the Sync0 period used is an integer

multiple of the 1ms position loop update rate. The JVL EtherCAT implementation sup

ports 1 and 2 ms sync0 pulse.The MIS/MIL motor do not have any internal position loop,

but nevertheless synchronizes its internal position update to the Sync0 pulse.

Once the Sync0 signal is configured by the master to a multiple of the motor's servo period, the motor will adjust its internal loop to align the start of a servo period with the

Sync0 signal.

Since the master typically configures the Sync0 signals of multiple drives on the network

to occur simultaneously, the result is simultaneous servo updates on multiple devices.

-

-

Synchronization specifications

When using synchronization the servo motor has to synchronize to the Distributed Clock

of the network. This is done with a PLL circuit which takes a little time to settle.

But when settled it has a maximum jitter of ±1μs.

Settle time of PLL:

Cycle time Typical settle time Max. settle time

1ms 2.4s 5s

2ms 2.6s 5s

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 39

3.3 Commisioning

TT3010-02GB

Error indicator

Hardware serial number

Hardware serial number

General status

indicator

MAC Module Indicators

and label overview

MIS Motor Indicators

and label overview

MAC address

Line activity

indicators

Error indicator

Power indicator

General status indicator

Line activity indicator (CN2)

Line activity indicator (CN3)

MAC address

(placed at front)

Power

indicator

3.3.1 Indicator LED’s - description.

The LED's are used for indicating states and faults of the Ethernet. There is one power

LED, two link/activity LED's (one for each Ethernet connector), and 2 status LED's.

LED indicator descriptions - Covers both MAC and MIS/MIL.

LED Text

MAC/ MIx

L/A IN /

L2

L/A OUT /

L3

RUN /

L1

ERROR /

ERR

PWR /

PWR

Notes:

Blinking: Flashing with equal on and off periods of 200ms (2.5Hz). Single flash: Repeating on for 200ms and

off for 1s. Double flash: Two flashes with a period of 200ms followed by 1s off period. Flickering: Rapid flash

ing with a period of approx. 50ms (10 Hz).

Colour Constant

off

No valid

Green

Green

Green

Red No error

Ethernet

connection.

No valid

Ethernet

connection.

Device

state = INIT

Green

Power is

not applied.

Constant onBlinking Single flash Double flash Flickering

Ethernet

is

connected.

Ethernet

is

connected.

Device state

= Operational

Critical communication

or controller

error

Power is applied to both

motor and

module.

- - -

- - -

Device

state = Preoperational

General

configura

tion error

Device state =

Safe-opera

tional

-

Local error

- - -

-

Process data

watchdog

timeout /

EtherCAT®

watchdog

timeout

- -

Activity on

line

Activity on

line

Booting

error

Power is

applied to

module but

no communi

cation with

motor.

-

-

40 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

3.3 Commisioning

TT3004GB

3.3.2 Quick start with TwinCAT (JVL Profile).

1. Copy the Ethernet slave information file (“JVL ECS V14.XML”) to the folder

“..\Twincat\IO\Ethernet\” on the master PC.

2. Apply power, and make sure the PWR (power) LED is lit.

3. Connect the Ethernet cable from Master to the L/A IN connector at the MAC mod-

ule or CN2 at the MIS/MILxxxxxxECxx motor.

Check that the corresponding LED is lit.

4. Start TwinCAT - system manager on the master, and make sure that a proper Ethernet I/O device is appended (consult your TwinCAT manual).

5. Right click the I/O device, and select "scan boxes".

Continued next page

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 41

3.3 Commisioning

TT3006GB

6. The device should now appear in the left side of the TwinCAT window, with a tiny

JVL logo.

7. Press F4 (Reload I/O devices), and select the JVL device on the left side of the window.

8. The "L/A IN" LED at the MAC module or "L2" at the MIS/MILxxxxxxECxx motor

should now be flashing and the process data should now appear on the bottom right

side of the TwinCAT window.

9. By pressing the "CoE online" tab, it's possibly to inspect the CANopen objects, and

modify motor and module parameters.

10. If DSP402 drive profile is selected the JVL device is named "Drive" instead of "Box" as

shown in the picture.

42 JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors

3.3 Commisioning

EtherCAT

master

Drive

with

EtherCAT

module

Drive

with

EtherC

A

T

modu

leDrivewithEtherCATmodule

L/A OUTL/AIN L/AOUTL/AIN L/A OU

T

L/A IN

OUT

IN

TT3007GB

TT3093-01GB

3.3.3 Mechanical installation

The network cables must be connected to the two M12 connectors (marked "L/A IN"

and "L/A OUT") on the module. (Corresponds to CN2 and CN3 at the MIS/MIL motors).

The cable from the EtherCAT® master is always connected to the "L/A IN" port. In the

line topology, if there are more slave devices in the same line, the next slave device is

connected to the port marked "L/A OUT". If there is a redundant ring, the right "L/A

OUT" port of the last slave device is connected to the second port of the EtherCAT®

master. See the figure below. Standard CAT 5 FTP or STP cables can be used. It is not

recommended to use UTP cables in industrial environments, which is typically very noisy.

3.3.4 Synchronization configuration

The MAC00-ECx and the MIS/MIL motors supports two different synchronization

modes for their process data sync managers. These modes are:

•Free run - No synchronization. (Requires motor cycle to be 1.0 or 1.3ms.)

• Synchron with Sync0 Event - Use Distributed Clock, and synchronize to Sync0.

Selection of synchronization mode is in TwinCAT done by selecting the drive and then

the DC tab, and there select the appropriate "Operation mode". Please see illustration

below.

The "Synchron with Sync0 Event" mode is only accessible in the MIS/MIL and in the

MAC00-ECx if mounted in a MAC400+ motor. The MAC050-141 only supports the

"Free run" mode.

JVL Industri Elektronik A/S - User Manual - Ethernet for MAC and MIS motors 43

3.3 Commisioning

Note ! Changes will only become effective after reconfiguring and restarting the Ether-

CAT master!

Precautions

In a typical EtherCAT system the master will periodically send process data to all devices

on the network. Ideally, this process data will be received by the slave devices with a

fixed delay relative to the Sync0 signal.

For example, the master may configure the Sync0 period on all slaves to 1 millisecond,

and time its communications so that the slaves receive updated process data every milli

second, exactly 50 microseconds before the Sync0 signal occurs.

It's very common in an EtherCAT system for the master to run on a complex PC operating system, and therefore not have the high degree of real time performance that the

slaves possess.

In such cases there can be a significant amount of timing jitter on the process data messages that the master sends. For example, if the master has +/- 100 microseconds of jitter on its message transmission timing, then the slave may receive the process data

update anywhere from 150 microseconds before Sync0 to 50 microseconds after Sync0.

This can cause system level problems such as incorrect trajectory interpolation in cyclic

synchronous position mode.

Configuring the process data sync managers to use Sync0 synchronization mode can resolve the problems caused by timing jitter in the master. In this mode the master can

compensate for its worst case timing jitter by transmitting the process data to the slaves

sufficiently early to ensure that the data will be received before the Sync0 signal. The

slaves will not use the process data received until the Sync0 time, so system can remain

well synchronized even with a significant amount of timing jitter in the master.

-

For example, in a system with a cycle time of 1ms and +/-100 microseconds of timing