Page 1

O

S

/

S

S

E

R

C

L

AFN

CH,

7

S

O

R

VI

E MANUA

M

DEL

: XV-N350B

XV-N352

DVD-VIDE

PLAYE

MODELS : XV-N350B/XV-N352

P/NO :

31629394MAR

200

Page 2

CONTENTS

SECTION 1.........SUMMARY

SECTION 2.........CABINET & MAIN CHASSIS

SECTION 3.........ELECTRICAL

SECTION 4.........MECHANISM (DP-11)

SECTION 5.........REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD PRODUCTS..................................1-3

SERVICING PRECAUTIONS....................................................................................................................1-4

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

SERVICE INFORMATION FOR EEPROM ...........................................................................................1-5

SPECIFICATIONS ........................................................................................................................................1-6

1-2

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from JVC. All components should be replaced

only with types identical to those in the original circuit and their physical location, wiring

and lead dress must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by LG Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into the

set are not delayed until the new service literature is printed.

CAUTION

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage or user

injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

GRAPHIC SYMBOLS

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After

the original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

2. Verify that all protective devices such as insulators, barriers, covers, shields, strain

3. Soldering must be inspected to discover possible cold solder joints, solder

4. Check for physical evidence of damage or deterioration to parts and components,

5. No lead or component should touch a high current device or a resistor rated at 1

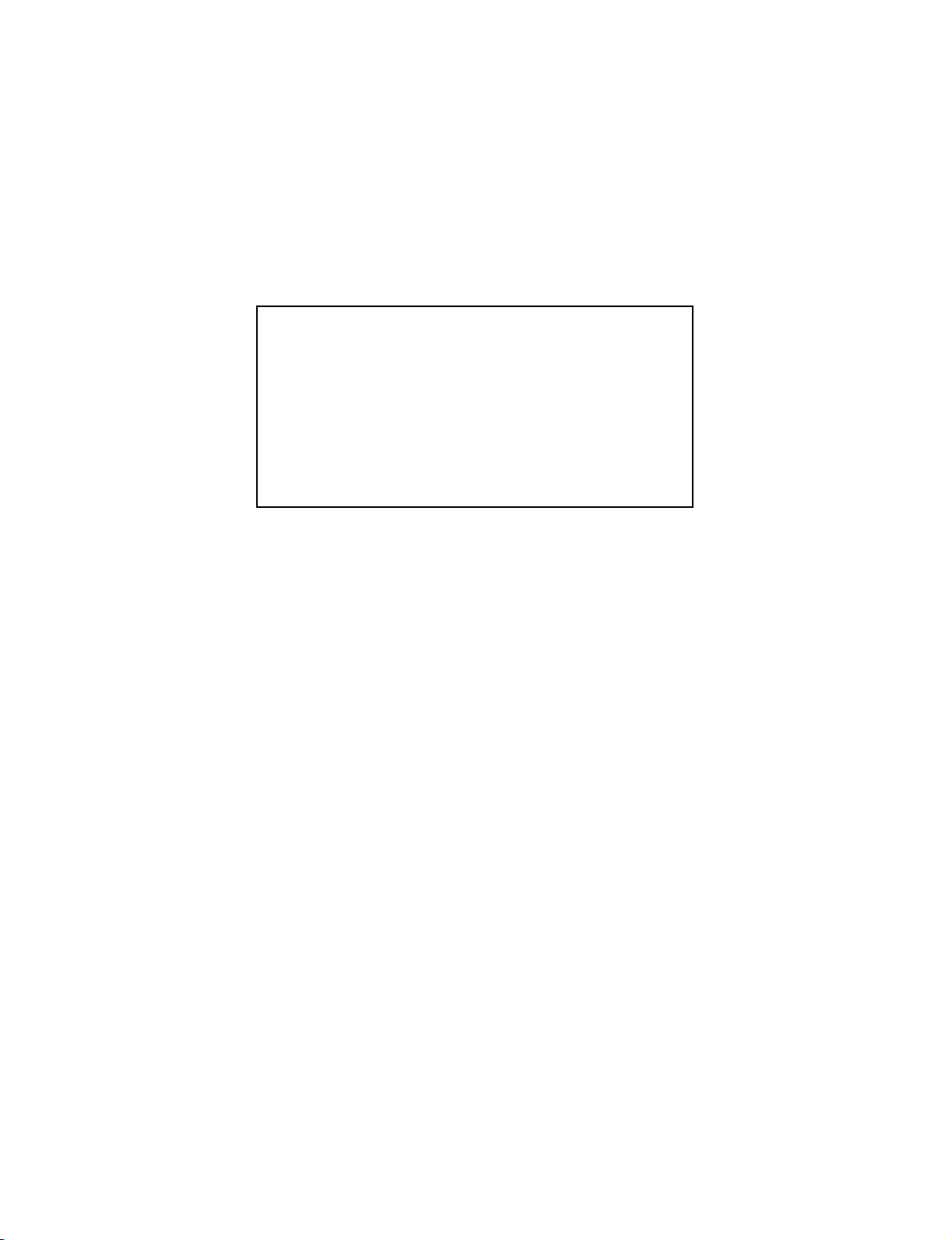

6. After reassembly of the set, always perform an AC leakage test on all exposed

: Do not attempt to modify this product in any way. Never perform

The exclamation point within an equilateral triangle is intended to alert

the service personnel to important safety information in the service

literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence of

noninsulated “dangerous voltage” that may be of sufficient magnitude

to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral

triangle is intended to convey to the service personnel the following

fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF

FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

component shorts. This is especially important on items trans-ported to and from

the repair shop.

reliefs, power supply cords, and other hardware have been reinstalled per the

original design. Be sure that the safety purpose of the polarized line plug has not

been defeated.

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

for frayed leads or damaged insulation (including the AC cord), and replace if

necessary.

watt or more. Lead tension around protruding metal surfaces must be avoided.

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING

THIS TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity

in the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by a .15

mfd 150V AC type capacitor between a known good earth ground water pipe,

conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC

voltage across the combination of 1500 ohm resistor and .15 mfd capacitor.

Reverse the AC plug by using a non-polarized adaptor and repeat AC voltage

measurements for each exposed metallic part. Voltage measured must not

exceed 0.75 volts RMS. This corresponds to 0.5 milliamp AC. Any value

exceeding this limit constitutes a potential shock hazard and must be corrected

immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew

is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should also

avoid the use of decorative scarves or other coverings that might obstruct

ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must follow

the factory-approved mounting instructions. A product mounted to a shelf or

platform must retain its original feet (or the equivalent thickness in spacers) to

provide adequate air flow across the bottom. Bolts or screws used for fasteners

must not touch any parts or wiring. Perform leakage tests on customized

installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

1-3

Page 5

SERVICING PRECAUTIONS

CAUTION: Before servicing the DVD covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE: if unforeseen circumstances

create conflict between the following servicing precautions

and any of the safety precautions in this publication, always

follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1.Always unplug the DVD AC power cord from the AC power

source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor.

Caution: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2.Do not spray chemicals on or near this DVD or any of its

assemblies.

3.Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4.Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might

be equipped.

5.Do not apply AC power to this DVD and / or any of its

electrical assemblies unless all solid state device heat

sinks are correctly installed.

6.Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation

resistance between each blade of the attachment plug and

accessible conductive parts (Note 1) should be more than

1Mohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1.Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons prior

to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6.Do not remove a replacement ES device from its

protective package until immediately before you are ready

to install it. (Most replacement ES devices are packaged

with leads electrically shorted together by conductive

foam, aluminum foil, or comparable conductive material).

7.Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

1-4

Page 6

SERVICE INFORMATION FOR EEPROM

POWER ON

DVD LOGO Status (NO Disk status)

Remotecontrol

Pause key-->1-->4-->7-->2 in order.

Press number 0~8, Press charater

A~F (1~6 for a while)

Use arrow key (F D G E) to move

to approprite position and make

changes

Press pause key once

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

MODEL: XV-N350B/XV-N352S

NAME HEX

OPT 1 00

OPT 2 00

OPT 3 00

OPT 4 00

OPT 5 00

OPT 6 00

OPT 7 00

OPT 8 00

Change will be applied when power

OFF-->ON.

1-5

Page 7

SPECIFICATIONS

• GENERAL

Power requirements : AC 200 ~ 240V, 50/60Hz

Power consumption : 8W

Dimensions (Approx.) : 430 x 35 x 202mm (17 x 1.4 x 7.9inches)

(W x H x D) without foot

Net Weight (Approx.) : 1.6kg (3.5lbs)

Operating temperature : 5°C to 35°C (41°F to 95°F)

Operating humidity : 5% to 90%

• OUTPUTS

VIDEO OUT : 1.0V(p-p), 75Ω, sync negative, RCA jack x 1 / SCART (TO TV)

AUDIO OUT : 2.0Vrms (1KHz, 0dB), 600Ω, RCA jack (L, R) x 1 / SCART (TO TV)

DIGITAL OUT (COAXIAL) : 0.5V(p-p), 75Ω, RCA jack x 1

SCART Model only

• SYSTEM

Laser : Semiconductor laser, wavelength 650nm

Signal system : PAL / NTSC

Frequency response : DVD (PCM 96 kHz) : 8Hz to 44kHz

DVD (PCM 48 kHz) : 8Hz to 22kHz

CD : 8Hz to 20kHz

Signal-to-noise ratio : More than 90dB (ANALOG OUT connectors only)

Harmonic distortion : Less than 0.02%

Dynamic range : More than 95dB (DVD/CD)

Accessories : Video cable (1), Audio cable (1), Remote control (1), Batteries (2)

1-6

Page 8

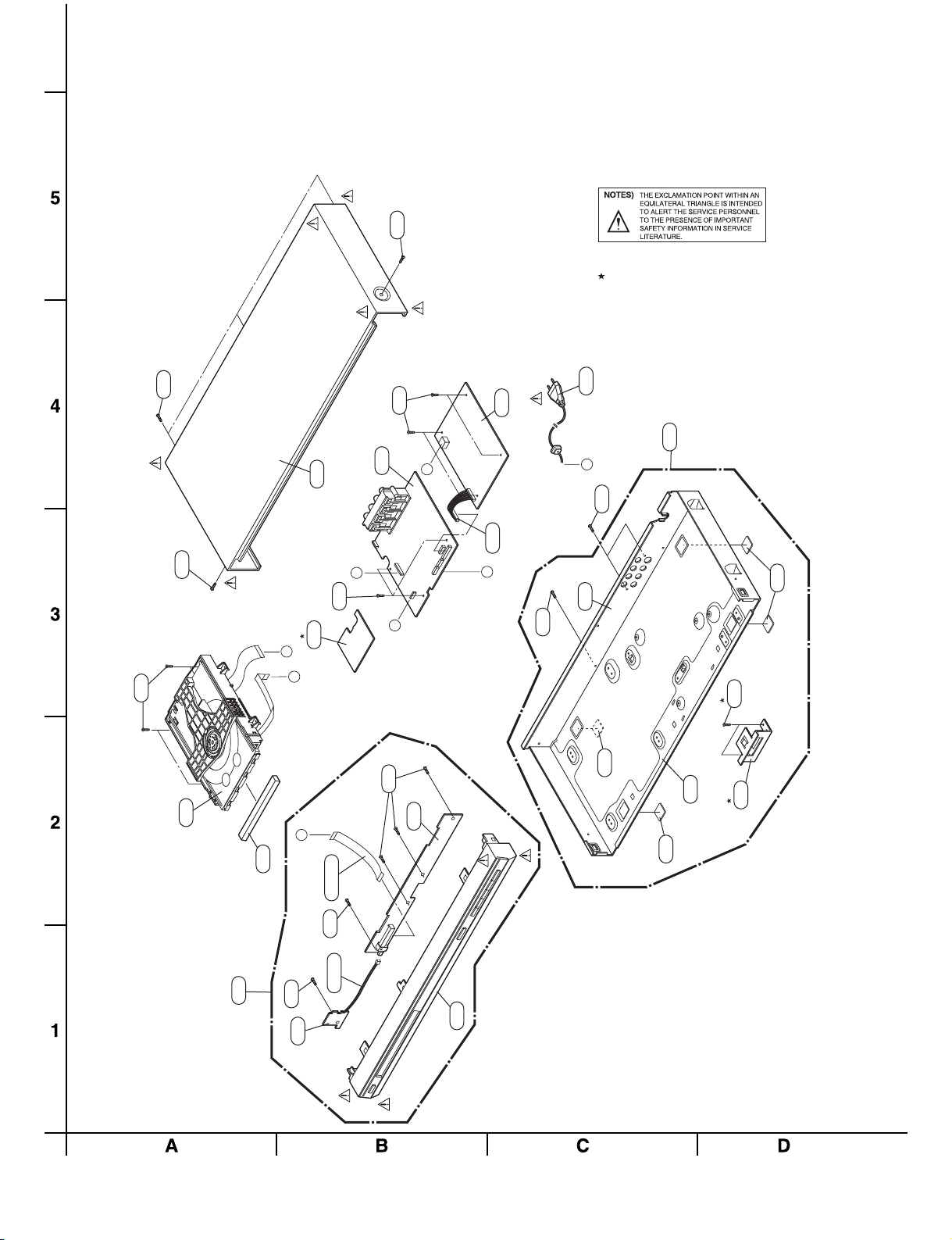

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS .....................................................................................................................................2-2

1. CABINET AND MAIN FRAME SECTION ..................................................................................................2-2

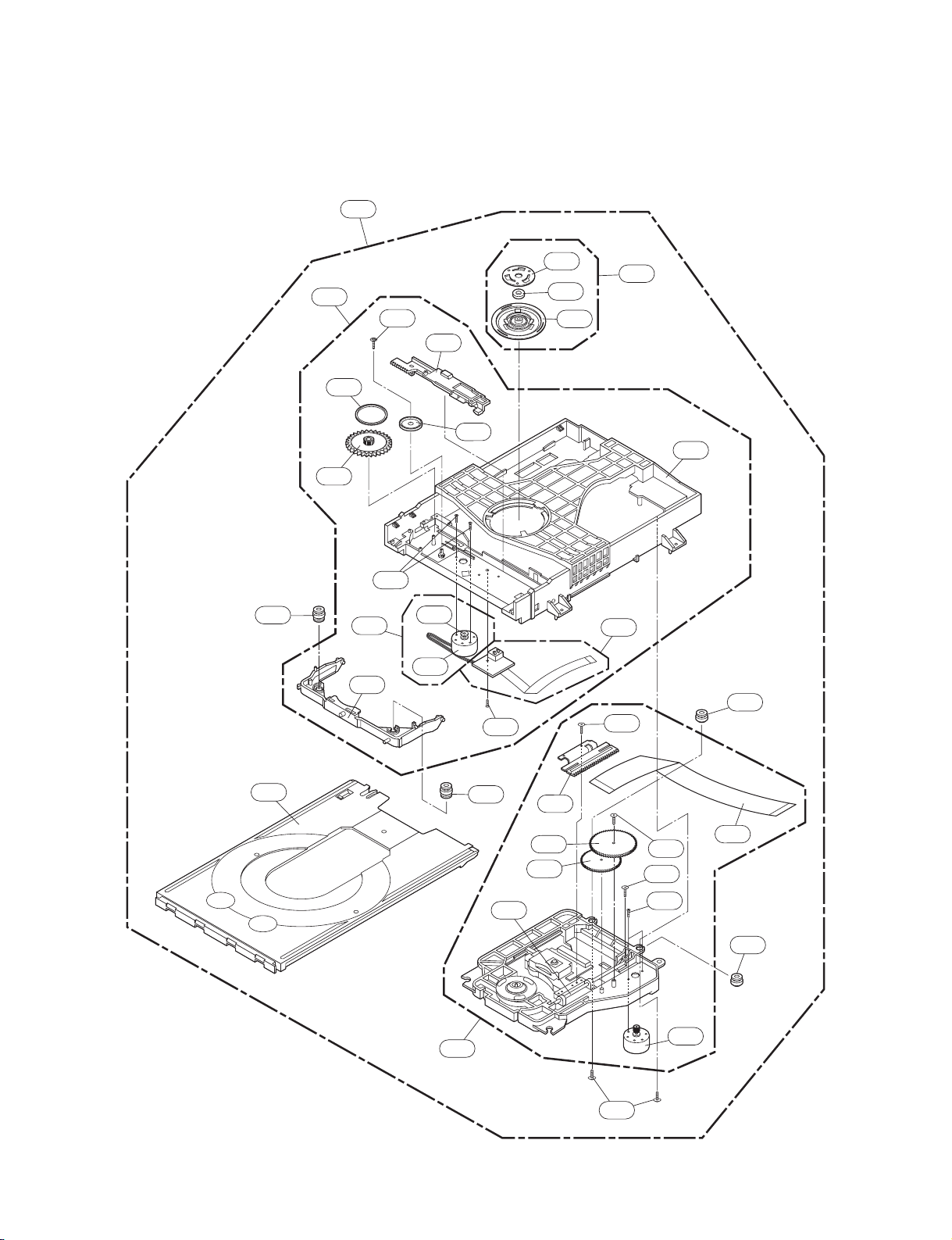

2. DECK MECHANISM SECTION (DP-11) ...................................................................................................2-3

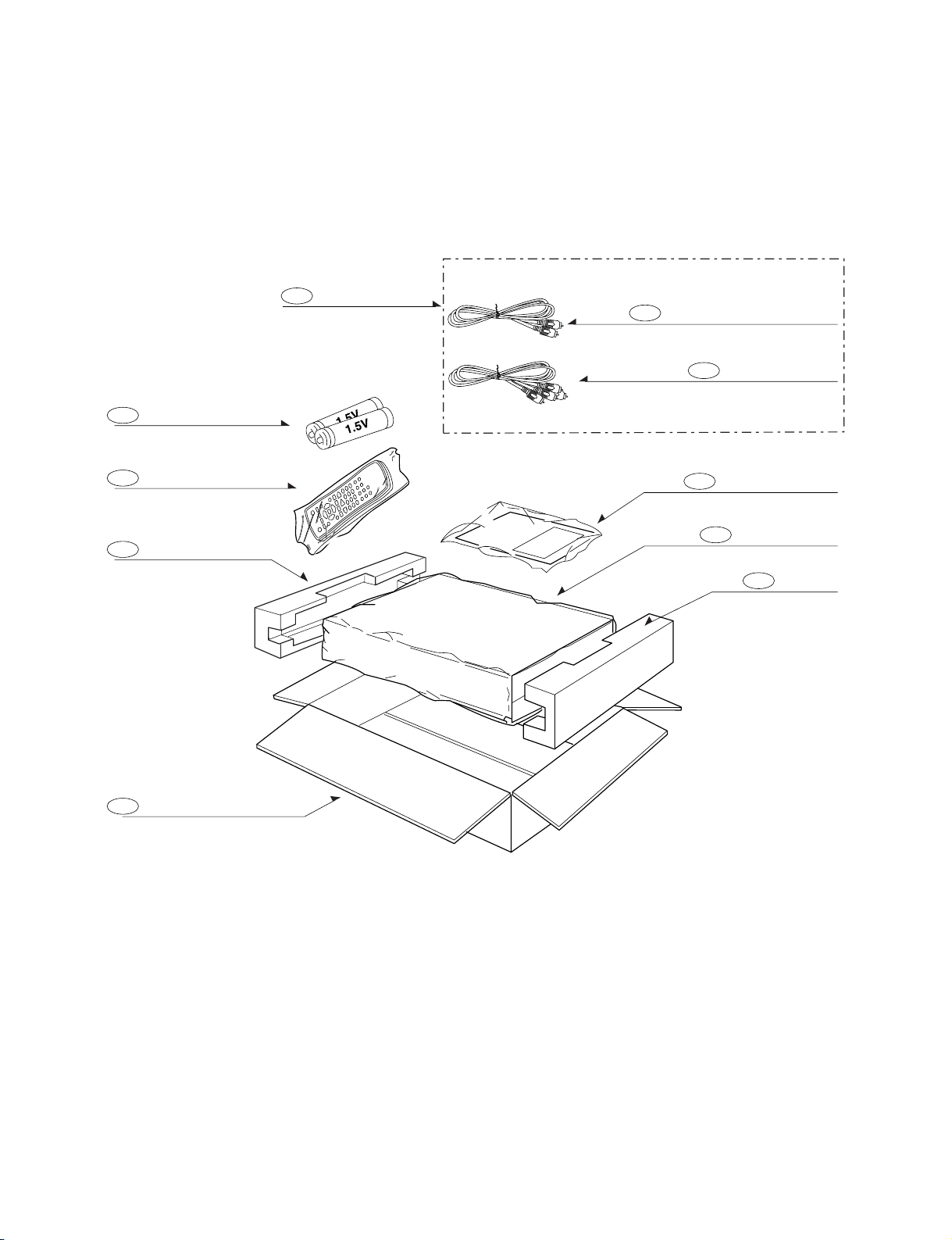

3. PACKING ACCESSORY SECTION...........................................................................................................2-4

2-1

Page 9

OPTIONAL PART

C

B

462

460

460

460

250

462

A44

A

300

A26

283

261

261

260

262

320

467

465

261

D

A

C

B

462

462

A48

A46

P101

A47

MAIN

SMPS

5.1CH

SCART

452

D

A43

A49

CABLE1

CN903

452

280

KEY

TIMER

452

A42

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

2-2

Page 10

2. DECK MECHANISM SECTION (DP-11)

A26

A02

439

018

013

017

014

001

002

003

020

016

015B

015A

435

015

019

440

432

012A

010

439

431

435

030

024

025

036

A03

430

021

012A

012

012

026

A01

2-3

Page 11

3. PACKING ACCESSORY SECTION

808 BATTERY

810 CABLE SET ASS’Y

811 PLUG ASS’Y 1WAY(YELLOW)

812 PLUG ASS’Y 2WAY

801 OWNER’S MANUAL

804 PACKING SHEET

803 PACKING

900 REMOCON

803 PACKING

802 BOX CARTON

2-4

Page 12

SECTION 3

ELECTRICAL

CONTENTS

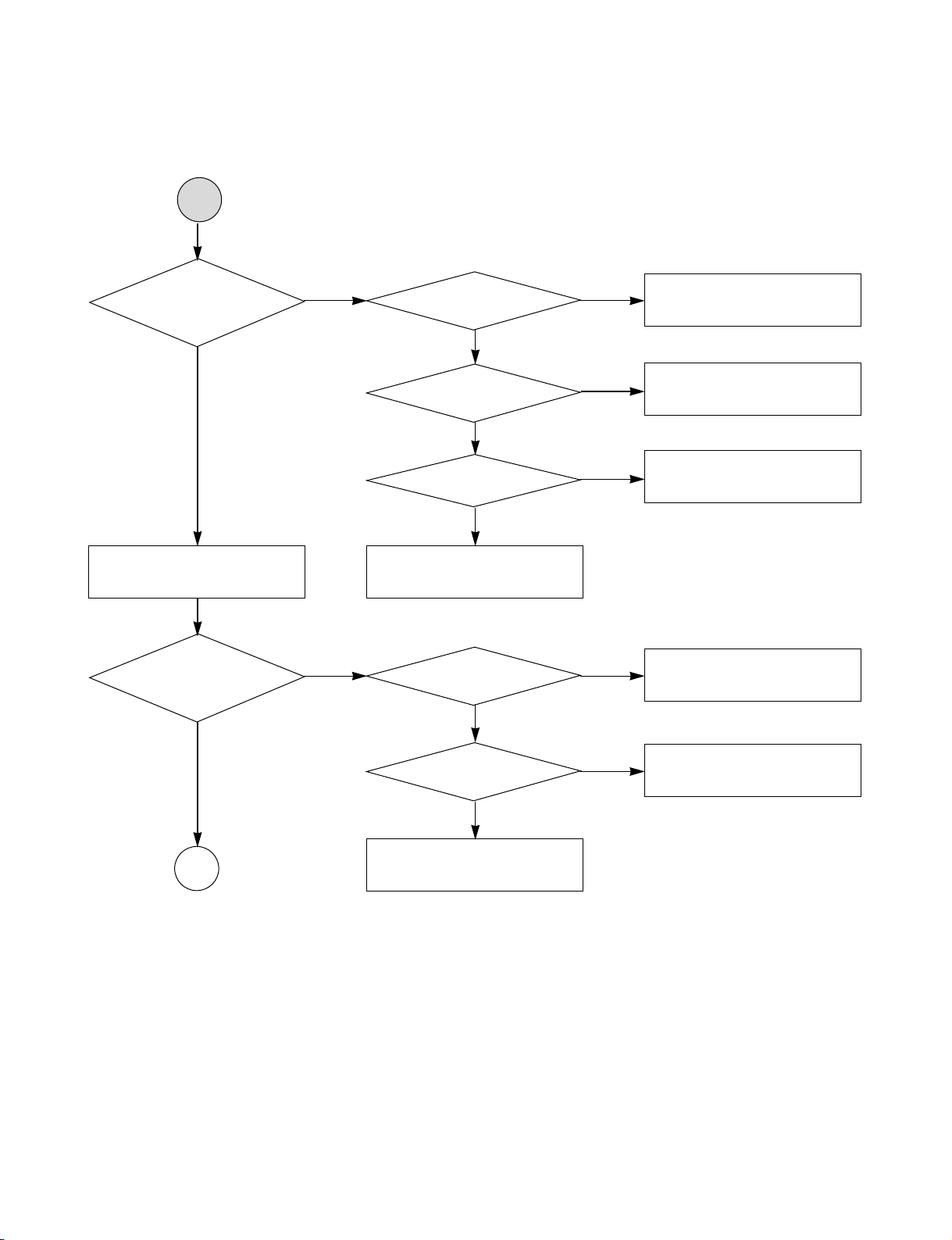

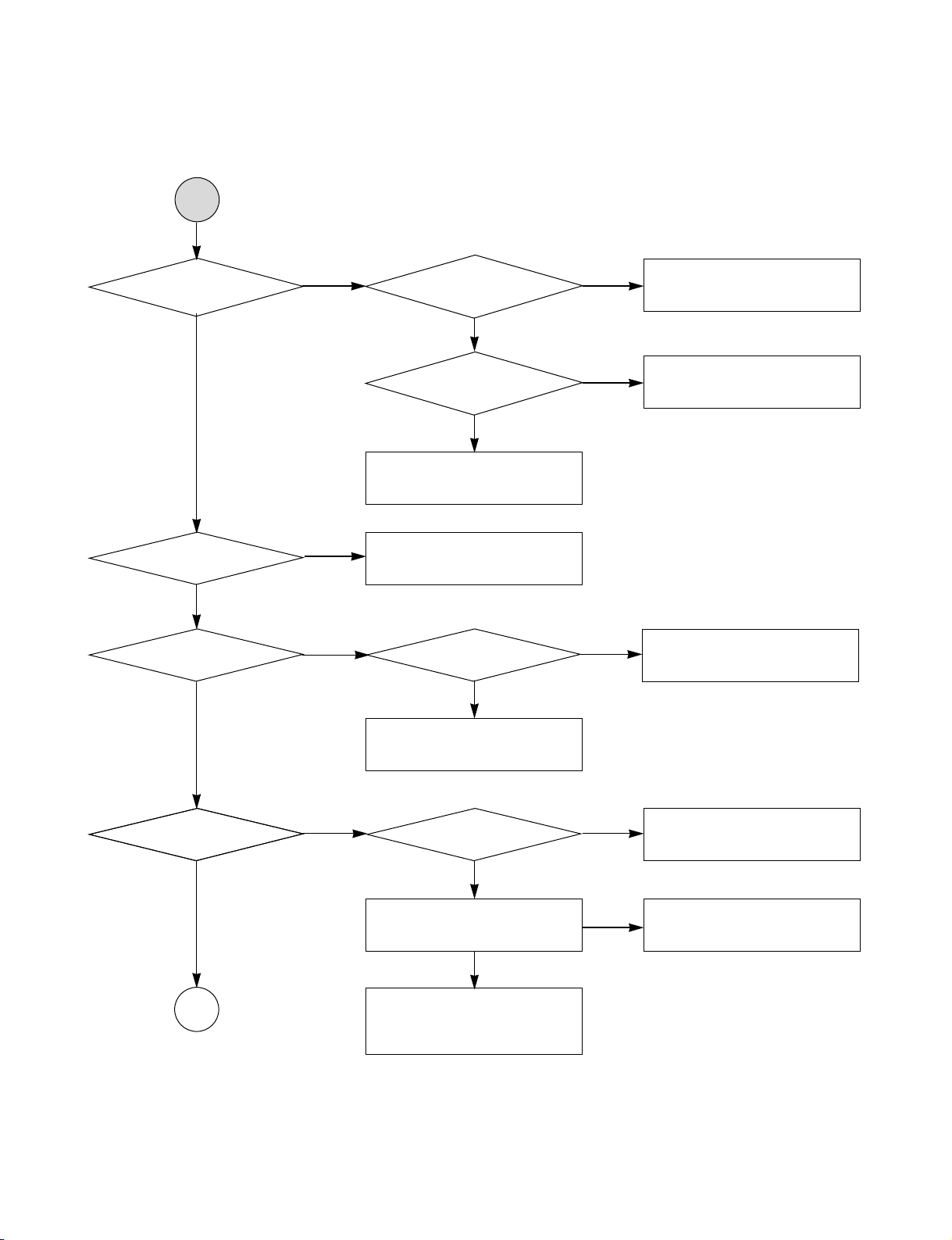

ELECTRICAL TROUBLESHOOTING GUIDE.....................................................................................3-2

1. POWER CHECK FLOW ..........................................................................................................................3-2

2. SYSTEM OPERATION FLOW.................................................................................................................3-3

3. SYSTEM TEST FLOW.............................................................................................................................3-4

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 27MHZ CLOCK, RESET, FLASH R/W SIGNAL....................................................................3-10

2. SDRAM CLOCK.....................................................................................................................................3-12

3. TRAY OPEN/CLOSE SIGNAL ...............................................................................................................3-12

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)............................................................3-13

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION) ..........................................................3-13

6. LASER POWER CONTROL RELATED SIGNAL (NO DISC CONDITION) ..........................................3-14

7. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION) ...............................................................3-14

8. FOCUS ON WAVEFORM......................................................................................................................3-15

9. RACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING) ......................................................3-16

10. ZR966 AUDIO COAXIAL OUTPUT (SPDIF) .........................................................................................3-17

11. ZR966 VIDEO OUTPUT WAVEFORM...................................................................................................3-17

12. AUDIO OUTPUT FROM ZR966 ............................................................................................................3-18

CONNECTOR PICTURE ..........................................................................................................................3-19

1. ALL CONNECTOR PICTURE ................................................................................................................3-19

2. P2201 CONNECTOR PICTURE............................................................................................................3-20

3. P2202 CONNECTOR PICTURE............................................................................................................3-20

4. PW6101 CONNECTOR PICTURE ........................................................................................................3-21

5. P6501 CONNECTOR PICTURE............................................................................................................3-21

6. P6602 CONNECTOR PICTURE............................................................................................................3-22

7. P6901 CONNECTOR PICTURE............................................................................................................3-22

8. P7301 CONNECTOR PICTURE............................................................................................................3-23

BLOCK DIAGRAMS ..................................................................................................................................3-24

1. OVERALL BLOCK DIAGRAM ...............................................................................................................3-24

2. POWER SUPPLY BLOCK DIAGRAM ...................................................................................................3-25

3. SERVO BLOCK DIAGRAM ...................................................................................................................3-26

4. MPEG & MEMORY BLOCK DIAGRAM.................................................................................................3-27

5. VIDEO BLOCK DIAGRAM.....................................................................................................................3-28

6. AUDIO BLOCK DIAGRAM.....................................................................................................................3-29

CIRCUIT DIAGRAMS................................................................................................................................3-31

1. POWER (SMPS) CIRCUIT DIAGRAM ..................................................................................................3-31

2. SYSTEM (MPEG) CIRCUIT DIAGRAM.................................................................................................3-33

3. SERVO CIRCUIT DIAGRAM.................................................................................................................3-35

4. AV/JACK CIRCUIT DIAGRAM ...............................................................................................................3-37

5. TIMER/KEY CIRCUIT DIAGRAM ..........................................................................................................3-39

CIRCUIT VOLTAGE CHART...................................................................................................................3-41

PRINTED CIRCUIT BOARD DIAGRAMS...........................................................................................3-43

1. MAIN P.C.BOARD..................................................................................................................................3-43

2. KEY P.C.BOARD ...................................................................................................................................3-45

3. TIMER P.C.BOARD ...............................................................................................................................3-45

4. SMPS P.C.BOARD ................................................................................................................................3-47

5. SCART P.C.BOARD (SCART MODEL ONLY).......................................................................................3-47

.........................................3-10

3-1

Page 13

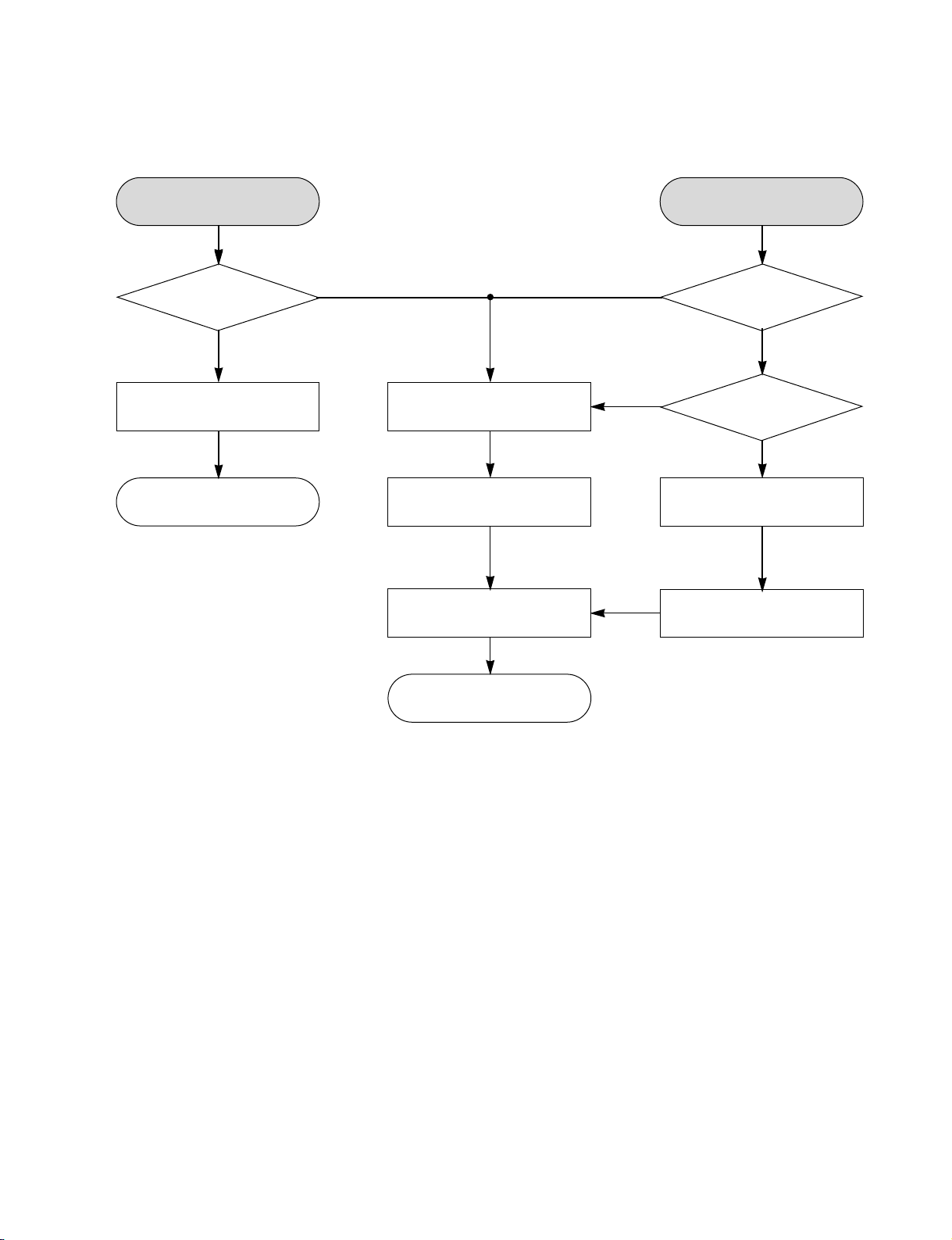

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER CHECK FLOW

A. B.

No 5V No 3.3VA.

Is 3.3VA

section working?

YES

Is 5.6V present at

collector of Q126?

YES

Replace Q126. Check FR101 Replace Q121.

NO

No 3.3VA

Is there a DC voltage at

cathode of D105 or D107?

NO

NO

NO

Is 3.3VA

section working?

YES

Is 3.3V

present at emitter

of Q121?

YES

YES

Check D105/D106/D107/

D108 and replace.

YES

Replace IC101.

3-2

Page 14

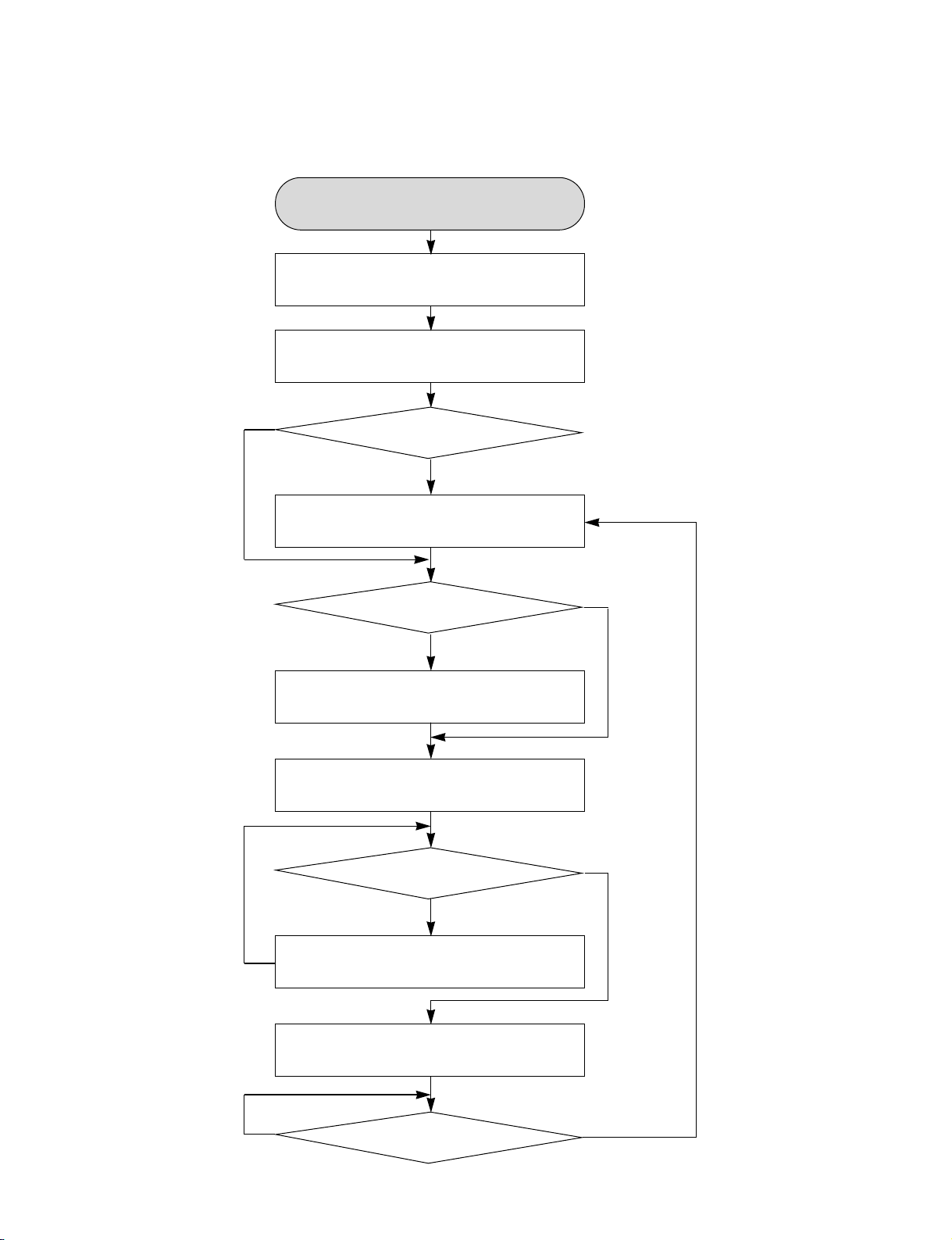

ELECTRICAL TROUBLESHOOTING GUIDE

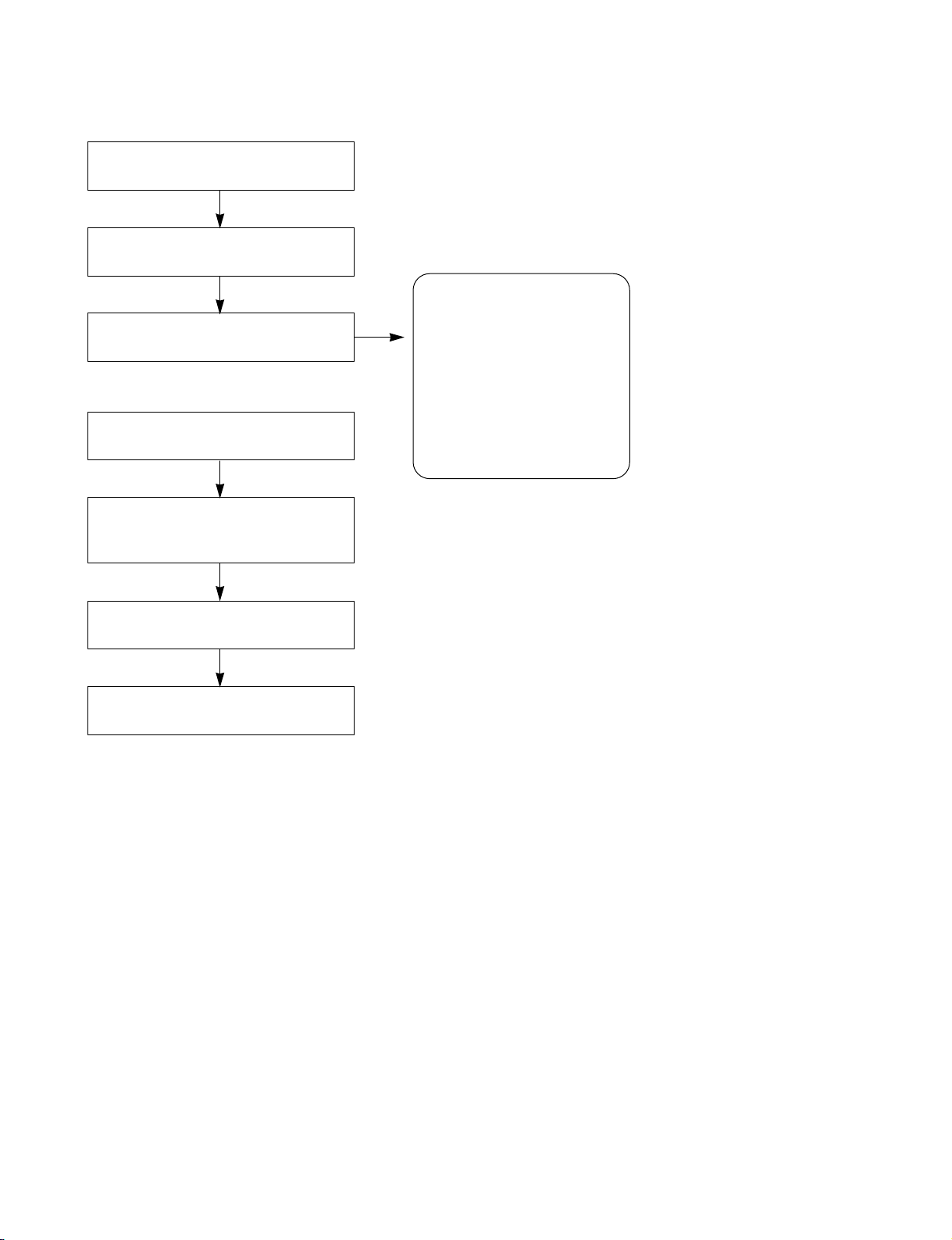

2. SYSTEM OPERATION FLOW

Power on

1. 8032 initializes SERVO,DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

YES

Tray close to closed position

SLED moves to inner position

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Recieve OPEN/CLOSE Key?

Tray closed ?

NO

SLED at inner side ?

NO

YES

YES

NO

1. Execute pressed Key & IR key

2. System operation routine loop

1. Stop playback & open Tray

2. Display tray open message & LOGO

NO

Receive CLOSE Key?

YES

3-3

Page 15

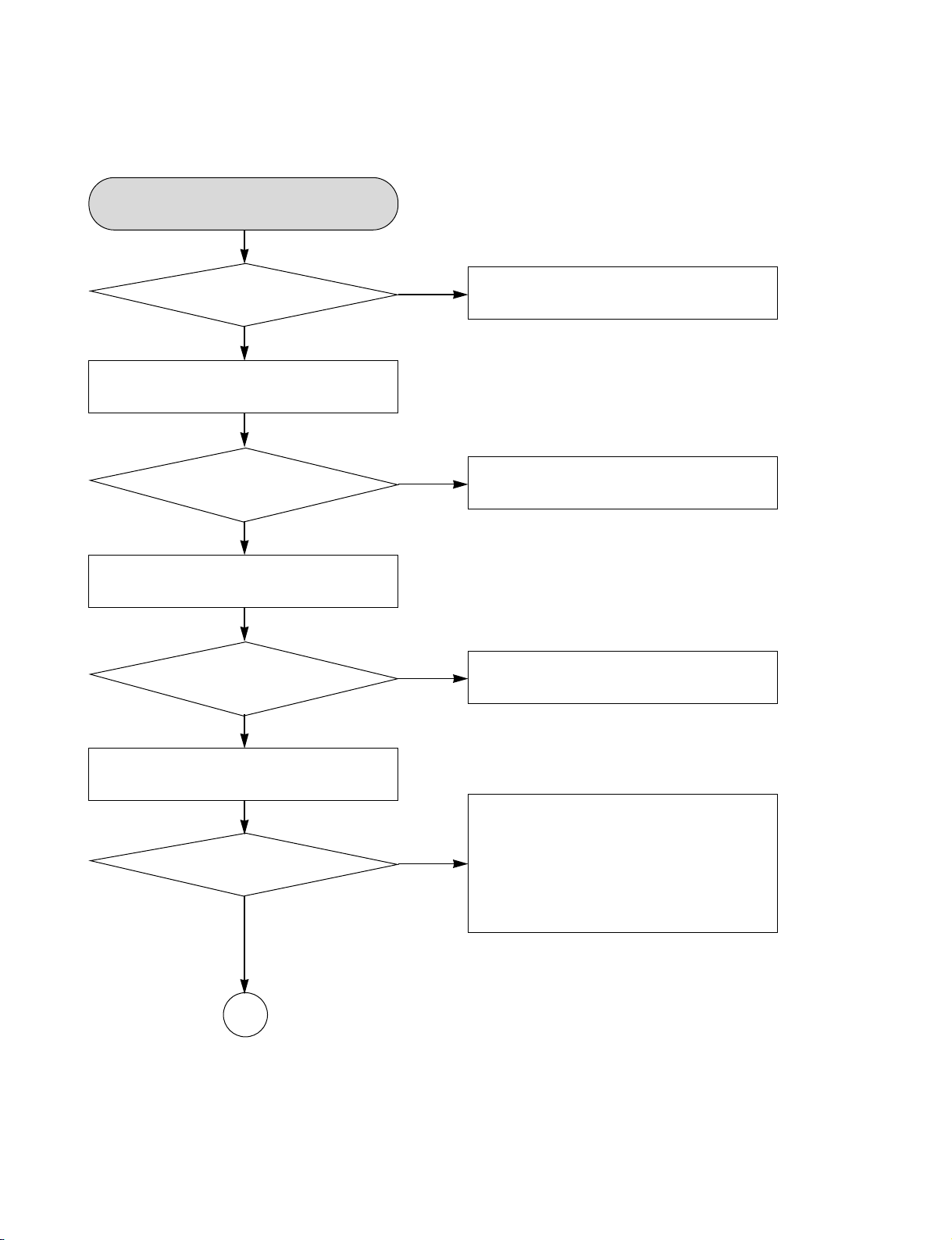

ELECTRICAL TROUBLESHOOTING GUIDE

3. SYSTEM TEST FLOW

TEST

Check the AC

Voltage Power PCBA (110V

or 220V)

YES

Switch on the power PCBA

Is the DC

voltage outputs OK?

(5V, 3.3V, 12V, 5.6V

MOTOR)

YES

Make sure the main PCBA don't

short on VCCs and switch it on.

YES

Is 3.3V

and 1.8V DC outputs normal

on main PCBA?

YES

NO

NO

NO

Replace power PCBA or AC transformer.

Repair or Replace power PCBA

Check the regulators or related diodes.

Connect to PC RS232 cable and

update the FLASH memory code.

Update FLASH

successfully?

YES

A

NO

1. Check 27MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,

RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

3-4

Page 16

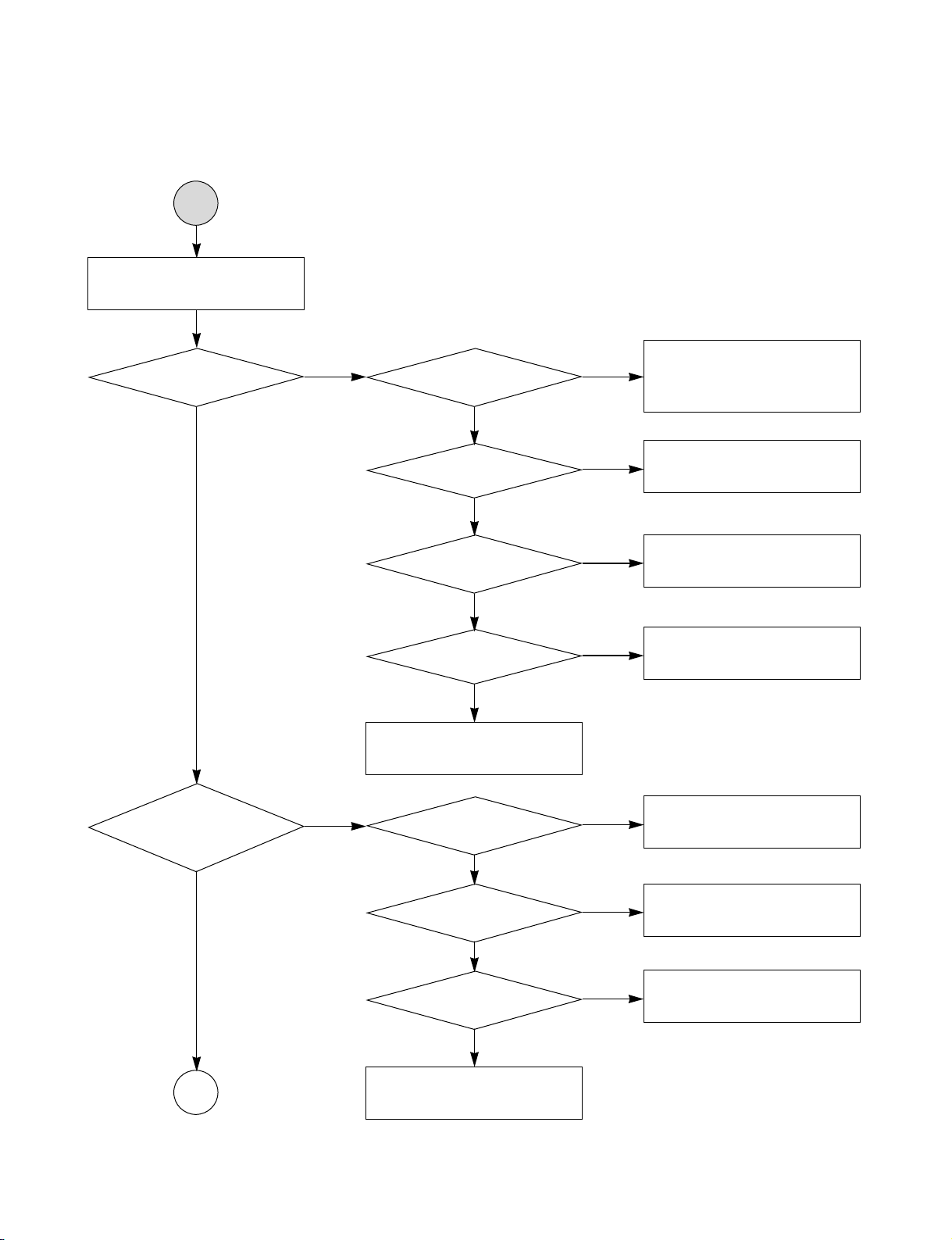

ELECTRICAL TROUBLESHOOTING GUIDE

A

RESET or power on.

Show LOGO?

YES

Does

Tray move inside

when it is not at closed

position?

NO NO

Flash

memory operates

properly?

YES

SDRAM

NO

works properly?

YES

ZR966

VIDEO outputs

NO

properly?

YES

Have TV

NO

signal output?

YES

Check AV cable

connection to TV set.

NO

Normal

TROUT & TRIN

NO

signals?

YES

Check connection lines

between FLASH & ZR966

and the FLASH access time

whether is suitable or not.

Check connection lines

between SDRAM & ZR966

and the SDRAM is damaged.

Check the related

circuit of ZR966.

Check the filtering and amp

circuit of TV signal.

Check the load OPEN &

CLOSE switch

B

YES

Normal

TRCLOSE & TROPEN

signal?

YES

Normal LOAD+ &

LOAD signal?

YES

Check the cable connection

between main PCBA and loader.

3-5

NO

NO

Check the Tray control IO

pins on ZR966 & AM5890S.

Check the Tray control

amplifying circuit on motor driver.

Page 17

ELECTRICAL TROUBLESHOOTING GUIDE

B

Does

the SLED move

to inner side when it is

at outter position?

YES

Do not put in disc and

tray close.

Optical Lens has

movements for searching

focus?

Motor

Driver DRVSB Pin

is high?

YES

Is sled_s

DC Level higher than

1.4V?

YES

SL+ and

SL- output properly?

YES

Check the cable connection

with MECHA.

Proper

focus_s outputs to motor

driver?

YES

NONO

NO

NO

NONO

Check the connection line

of DRVSB signal.

Check the related

circuit of Sled_s.

Check the amp circuit on

motor driver.

Check focus_s connection

on ZR966 and motor dirver.

C

YES

Proper F+ &

F- outputs?

YES

Check cable connect on

with pick-up head.

3-6

NO

Check the amp circuit on

motor dirver.

Page 18

ELECTRICAL TROUBLESHOOTING GUIDE

C

Laser

turns on when reading

disc?

YES

Put disc in?

YES

Disc ID is correct?

NO NO

DVD_LD,

CD_LD output properly?

YES

Collector

NO

voltage of power transistor

is OK?

YES

Check cable connection

between transistor ouput

and pick-up head.

NO

Laser off

NO

Proper RF signal

NO

on OPU

YES

Check the laser power circuit

on ZR966 and connecting to

power transistor.

Check the related circuit on

laser power transistor

Check the related circuit

on RF signal.

YES

Does spindle rotate?Does spindle rotate?

YES

D

Check DVD_LD &

CD_LD signal

NO NO

Proper spindle_s

signal on ZR966

YES

SP+ & SP- output properly?

YES

NO

Check the cable connection

between spindle and main

PCBA.

3-7

Check spindle_s related

circuit on ZR966.

Check the spindle control

amp circuit of motor driver.

Page 19

ELECTRICAL TROUBLESHOOTING GUIDE

D

Focus on OK?

YES

Track on OK?

NO NO

Proper signals on

A,B,C,D of ZR966

YES

Check focus_s

NO

signal on ZR966

YES

F+ & F- output

properly?

YES

Check cable connection on

pick-up head.

NO NO

Properly track_s

signal on ZR966?

YES

Check connections between

ZR966 and pick-up head.

Check the focus_s connection

on ZR966 and motor driver.

Check the focus control

amp circuit on motor driver.

Check the track_s connection

on ZR966 and motor dirver.

YES

Disc is play?

YES

E

NO

T+ & T- output

properly?

YES

Check cable connection on

pick-up head.

Check RF signal waveform.

3-8

NO

Check the tracking control

amp circuit on motor driver.

Page 20

ELECTRICAL TROUBLESHOOTING GUIDE

E

Normal

Audio output when disc

playback?

YES

Normal

IR.VFD & Front

pannel key

functions?

YES

NO

DAC received correct

Audio

NO

data stream?

YES

Normal Audio

NO

DAC out?

YES

Check Audio filter,

amplify, mute circuit.

Commu-

NO NO

nications between

IR.VFD Front pannel

key & ZR966 is

normally?

YES

Check connection between

ZR966 & Audio DAC.

Check the related

circuit of Audio DAC.

Check communication

lines on ZR966.

TEST END

Check the cable connection

on Front pannel.

3-9

Page 21

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 27MHz CLOCK, RESET, FLASH R/W SIGNAL

1) ZR966 main clock is at 27MHz (X601)

1

1

2) ZR966 reset is active high.

2

3

4

FIG 1-1

3.3VA

2

3

PWR_CTL

RESET

4

FIG 1-2

3-10

Page 22

3) RS232 waveform during procedure (Downloading)

5

5

6

TXD

RXD

FIG 1-3

4) Flash R/W enable signal during download (Downloading)

7

7

PRD

6

IC602

8

PWR

8

FIG 1-4

3-11

Page 23

2. SDRAM CLOCK

DCLK = 128MHz, Vp-p=2.2, Vmax=2.7V

9

3. TRAY OPEN/CLOSE SIGNAL

IC603

9

FIG 2-1

10

11

12

13

11

INSW

OUTSW

10

IC201

CLOSE

13

OPEN

12

FIG 3-1

3-12

Page 24

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

15

SLED_S(1.9V/1.4V/1.1V)

18

14

14

DRVSB(3.3V)

15

16

SLED+(4.2V/2.8V/1.2V)

16

17

SLED-(4.2V/2.8V/1.5V)

17

20

19

FIG 4-1

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION)

18

19

20

FOCUS_S(1.5V/1.4V/1.3V)

FACT+(3.2V/2.7V/2.2V)

FACT-(3.2V/2.7V/2.2V)

FIG 5-1

3-13

Page 25

6. LASER POWER CONTROL RELATED SIGNAL (NO DISC CONDITION)

CN201

MDI1(0V/180mV)

21

21

22

23

CD_LD(3.3V//2.3V)

22

DVD_LD(3.3V/2.3V)

23

FIG 6-1

7. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

SPINDLE_S(1.4V/1.8V)

24

25

SP-(3.6V/2.4V)

26

SP+(3.6V/4.8V)

FIG 7-1

3-14

24

25

26

Page 26

8. FOCUS ON WAVEFORM

27

28

29

27

FOCUS_S

FF+

FF-

IC201

27

FIG 8-1 (DVD)

28

FOCUS_S

29

28

29

FF+

FF-

FIG 8-2 (CD)

3-15

Page 27

9. RACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING)

TRACK_S

30

30

31

32

30

Tracking+

Tracking-

FIG 9-1 (DVD)

TRACK_S

P2201

31

31

32

Tracking+

Tracking-

FIG 9-2 (CD)

3-16

32

Page 28

10. ZR966 AUDIO COAXIAL OUTPUT (SPDIF)

33

FIG 10-1

33

11. ZR966 VIDEO OUTPUT WAVEFORM

1) 100% COLOR BAR

FIG 11-1

3-17

Page 29

2) COMPOSITE VIDEO SIGNAL

FIG 11-2

12. AUDIO OUTPUT FROM ZR966

FIG 12-1

3-18

Page 30

CONNECTOR PICTURE

1. ALL CONNECTOR PICTURE

3-19

Page 31

2. P2201 CONNECTOR PICTURE

P2201 (MD 23PIN)

3. P2202 CONNECTOR PICTURE

P2202 (MD 9PIN)

3-20

Page 32

4. PW6101 CONNECTOR PICTURE

PW6101 (POWER 10PIN)

5. P6501 CONNECTOR PICTURE

P6501 (USB 4PIN) Not used currently

3-21

Page 33

6. P6602 CONNECTOR PICTURE

P6602 (DOWN LOAD 4PIN)

P6602 (HYPER TEAMINAL 4PIN)

7. P6901 CONNECTOR PICTURE

P6901 (TIMER 12PIN)

3-22

Page 34

8. P7301 CONNECTOR PICTURE

P7301 (SCART 12PIN)

3-23

Page 35

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

3-24

Page 36

2. POWER SUPPLY BLOCK DIAGRAM

3-25

Page 37

3. SERVO BLOCK DIAGRAM

3-26

Page 38

4. MPEG & MEMORY BLOCK DIAGRAM

3-27

Page 39

5. VIDEO BLOCK DIAGRAM

3-28

Page 40

6. AUDIO BLOCK DIAGRAM

3-29

Page 41

MEMO

3-30

Page 42

No Power

D105~D108 are Defective

12V No Power

Q123 is Defective

5V No Power

Q126 is Defective

Switching Error

IC102, IC103 are Defective

No Power

FR101 is Defective

Switching Error

IC101 is Defective

3.3V No Power

Q121 is Defective

CIRCUIT DIAGRAMS

1. POWER (SMPS) CIRCUIT DIAGRAM

IMPORTANT SAFETY NOTE :

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN

BE MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE JVC. ALL COMPONENTS SHOULD BE

REPLACED ONLY WITH TYPES IDENTICAL TO

THOSE IN THE ORIGINAL CIRCUIT. SPECIAL

COMPONENTS ARE SHADED ON THE SCHEMATIC

FOR EASY IDENTIFICATION. THIS CIRCUIT DIAGRAM

MAY OCCASIONALLY DIFFER FROM THE ACTUAL

CIRCUIT USED. THIS WAY, IMPLEMENTATION OF THE

LATEST SAFETY AND PERFORMANCE

IMPROVEMENT CHANGES INTO THE SET IS NOT

DELAYED UNTIL THE NEW SERVICE LITERATURE IS

PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

3-31 3-32

Page 43

2. SYSTEM (MPEG) CIRCUIT DIAGRAM

3-33 3-34

Page 44

3. SERVO CIRCUIT DIAGRAM

3-35 3-36

Page 45

4. AV/JACK CIRCUIT DIAGRAM

3-37 3-38

Page 46

5. TIMER/KEY CIRCUIT DIAGRAM

3-39 3-40

Page 47

• CIRCUIT VOLTAGE CHART

PIN No Disc Play

IC201

1 1.33 1.66

2 1.84 1.83

3 2.76 3

4 1.28 1.65

5 1.25 1.24

6 3.28 3.24

7 0.0003 0.0003

8 4.89 4.97

9 0.53 0.435

10 3.83 3.99

11 2.29 2.47

12 2.29 2.45

13 2.34 2.27

14 2.34 2.54

15 2.32 2.4

16 2.32 2.41

17 1.34 3.32

18 1.34 1.49

19 4.87 4.97

20 0.92 1.03

21 4.87 4.99

22 0.0007 0.001

23 1.01 1.94

24 0.435 0.4

25 4.81 4.93

26 1.35 1.64

27 1.65 1.64

28 0.004 3.17

IC601

1 1.91 1.97

2 1.56 2.109

3 1.32 2.117

4 2.61 2.328

5 0.64 1.51

6 1.32 1.46

7 1.51 1.61

8 1.64 1.08

9 0.97 2.31

10 0.72 1.49

11 0.0002 0.0003

12 1.71 1.13

13 1.77 1.966

14 1.756 0.278

15 3.28 0.281

16 0.23 0.36

17 3.28 0.297

18 3.23 0.293

19 3.21 0.279

20 0.03 1.09

21 2.45 2.21

22 0.78 1.04

23 1.45 1.75

24 1.18 1.68

25 1.6 1.72

26 3.28 3.25

27 0.001 0.36

28 1.61 2.35

29 1.13 1.03

PIN No Disc Play

30 3.28 1.51

31 0.0001 0.001

32 1.83 2.15

33 0.31 1.83

34 0.72 0.32

35 3.28 0.35

36 0.87 0.62

37 2.56 0.24

38 0.002 0.31

39 3.28 0.3

40 0.003 0.31

41 0.004 0.31

42 0.003 0.003

43 1.67 0.24

44 1.86 0.25

45 1.69 0.28

46 3.28 3.25

47 0.0001 0.0001

48 0.92 1.31

49 1.63 1.57

50 1.57 1.68

51 1.62 1.57

52 1.75 1.74

53 1.58 1.21

54 0.015 0.015

55 0.003 0.007

56 3.28 3.28

57 0.0001 0.0001

58 0.004 3.28

59 0.004 0.005

60 3.24 3.21

61 0.035 0.035

62 3.2 3.16

63 3.2 3.23

64 3.26 3.18

65 3.28 3.28

66 0.0001 0.0001

67 3.22 3.24

68 2.9 2.83

69 0.0001 0.0004

70 3.25 0.26

71 3.29 3.24

72 1.51 0.07

73 0.04 1.24

74 1.87 1.67

75 2.68 1.54

76 3.28 3.249

77 0.0001 0.0001

78 1.56 1.22

79 1.87 1.64

80 1.51 1.61

81 1.69 2.13

82 1.78 0.07

83 1.49 1.52

84 3.32 3.247

85 0.001 0.001

86 0.67 0.98

87 1.86 1.13

88 3.32 1.742

PIN No Disc Play

89 1.61 0.93

90 1.59 1.91

91 1.15 1.87

92 1.42 1.93

93 3.32 3.249

94 0.002 3.24

95 0.0005 0.0005

96 0.45 0.51

97 0.002 0.003

98 0 0.0001

99 0 0.0001

100 0.0001 0.001

101 3.28 3.24

102 0.0005 0.001

103 0.001 0.001

104 3.26 3.21

105 3.281 3.246

106 0.001 0.0008

107 0.0005 0.0009

108 0.0008 0.0008

109 0.0006 0.0006

110 0.0001 0.0002

111 0.0005 0.0006

112 0.0005 0.0006

113 1.642 1.62

114 1.642 1.62

115 1.642 1.62

116 1.642 1.62

117 0.0005 0.0005

118 0.0001 0.0009

119 0.0008 0.0007

120 0.005 0.005

121 3.286 3.247

122 1.635 1.617

123 0.005 0.005

124 0.047 0.053

125 0.005 0.005

126 0.005 0.005

127 0.005 0.005

128 3.27 3.22

129 4.31 4.18

130 3.82 3.72

131 0.013 0.015

132 0.005 0.005

133 3.62 3.32

134 3.295 3.72

135 3.286 3.252

136 3.284 3.22

137 3.281 3.25

138 3.284 3.25

139 3.281 3.25

140 1.75 1.747

141 0.0003 0.0003

142 3.286 3.248

143 0.0003 0.0005

144 1.751 1.745

145 1.59 1.57

146 1.63 1.61

147 1.35 1.57

PIN No Disc Play

148 0.0002 0.0005

149 0.0003 0.0005

150 3.279 3.24

151 0.93 1.166

152 0.0001 0.0003

153 3.278 3.242

154 0.0002 0.0003

155 1.233 1.235

156 0.0002 0.0003

157 0.0003 1.67

158 0.0003 1.67

159 3.29 3.23

160 0.69 2.26

161 0.21 2.24

162 3.29 3.24

163 0.22 2.254

164 0.68 2.257

165 1.75 1.75

166 0.81 2.37

167 0.436 0.397

168 0.812 2.36

169 0.0001 0.003

170 0.256 1.726

171 1.598 1.694

172 0.0001 0.003

173 0.806 2.097

174 0.001 1.647

175 0.002 0.93

176 0.0001 0.003

177 3.29 3.24

178 0.0001 0.199

179 0.0001 0.006

180 3.29 2.36

181 3.29 3.22

182 0.0001 1.733

183 3.29 3.25

184 0.0015 1.612

185 0.0001 0.0002

186 0.0029 2.484

187 0.0018 1.697

188 3.28 3.24

189 0.0003 0.0005

190 1.754 1.749

191 0.0002 0.0003

192 0.003 0.003

193 3.37 3.37

194 0.0003 0.0003

195 3.27 0.0003

196 0.029 0.067

197 3.19 3.21

198 3.09 3.08

199 0.003 0.003

200 3.29 3.262

201 1.88 2.49

202 3.22 2.87

203 3.23 2.81

204 1.52 2.65

205 1.65 2.6

206 1.68 2.75

PIN No Disc Play

207 1.61 2.47

208 3.28 3.25

IC603

1 3.31 3.3

2 1.42 1.93

3 3.31 3.3

4 1.59 1.91

5 1.86 1.13

6 0.0002 0.0003

7 1.49 1.52

8 1.69 2.13

9 3.31 3.3

10 1.87 1.64

11 2.68 1.54

12 0.0001 0.0002

13 0.04 1.24

14 3.31 3.3

15 2.9 2.83

16 3.22 3.24

17 3.26 3.18

18 3.2 3.23

19 3.2 3.16

20 0.035 0.035

21 3.24 3.21

22 0.003 0.008

23 1.5 1.28

24 1.51 1.71

25 0.95 1.31

26 1.87 1.6

27 3.31 3.3

28 0.0002 0.0003

29 1.66 1.6

30 1.7 1.61

31 1.6 1.58

32 1.62 1.58

33 0.016 0.013

34 0.004 0.021

35 0.003 0.004

36 0.0002 0.005

37 0.45 0.51

28 0.227 0.24

39 2.9 2.82

40 0.004 0.004

41 0.0001 0.005

42 1.51 0.07

43 3.31 3.29

44 1.87 1.67

45 1.56 1.22

46 0.0002 0.0001

47 1.51 1.61

48 1.78 0.07

49 3.31 3.29

50 0.67 0.98

51 1.61 0.93

52 0.0002 0.0003

53 1.15 1.87

54 0.0002 0.0003

IC604

1 3.21 2.56

PIN No Disc Play

2 3.22 2.16

3 0.16 0.97

4 2.48 2.31

5 0.85 1.05

6 1.8 1.71

7 1.25 1.75

8 1.32 1.65

9 0.001 0.002

10 3.28 3.28

11 3.28 3.28

12 3.31 3.29

13 3.31 3.29

14 3.31 3.29

15 1.76 1.71

16 0.001 0.31

17 1.88 2.49

18 1.32 1.13

19 1.8 1.53

20 1.8 1.68

21 0.28 1.78

22 0.8 1.59

23 0.95 1.56

24 2.75 2.93

25 3.19 2.93

26 3.23 2.79

27 0.002 0.0005

28 3.23 2.81

29 1.52 2.65

30 1.65 2.6

31 1.68 2.75

32 1.61 2.47

33 1.68 2.59

34 1.55 2.57

35 1.65 2.67

36 2.79 2.69

37 3.3 3.29

38 0.53 1.91

39 1.37 2.03

40 1.37 2.31

41 1.76 0.81

42 0.91 2.21

43 0.76 2.4

44 1.71 1.95

45 1.91 1.59

46 0.017 0.005

47 3.3 3.29

48 0.15 0.51

IC702

1 7.21 7.32

2 4.3 4.34

3 4.29 4.32

4 0.002 0.004

5 4.28 4.31

6 4.29 4.32

7 7.24 7.32

811.84 11.98

DC VOLTMETER MEASUREMENT METHOD

condenser Capacitor Compressive(V)

C617 100uF 16V 3.25 0.00

C623 100uF 16V 1.75 0.00

C624 100uF 16V 3.25 0.00

C627 220uF 6.3V 3.242 0.00

C640 100uF 16V NC NC

C644 47uF 6.3V 3.25 0.00

C646 47uF 6.3V 1.76 0.00

C649 47uF 6.3V 3.30 0.00

C661 10uF 16V 3.25 0.00

C678 33uF 16V 2.42 0.00

C155 220uF 16 12.01 3.99V

C156 330uF 10 4.98 5.02V

C6C9 220uF 6.3V 3.29 0.00

C201 100uF 16V 4.94 0.00

C208 47uF 6.3V 3.29 3.23

C209 47uF 6.3V 3.29 2.41

C214 470uF 6.3V 4.94 0.00

C221 47uF 16V NC NC

C223 47uF 6.3V 3.29 0.00

C716 22uF 16V 6.63 0.00

C717 22uF 16V 6.66 0.00

C727 22uF 16V 0.37 0.00

C728 470uF 16V 11.98 0.00

C729 220uF 16V NC NC

C741 47uF 6.3V NC NC

C787 47uF 6.3V 0.17 0.00

TR

Q201 3.29 0.05 3.23

Q202 3.11 2.04 2.41

Q203 2.50 1.78 1.85

Q701 0.00 0.00 2.41

Q702 0.00 0.00 3.25

Q703 3.24 -2.73 3.31

Q711 0.00 0.00 0.07

Q712 0.00 0.00 0.07

Q713 0.00 0.00 0.07

Q714 3.02 4.96 0.07

E/S C/D B/G

PLAY

Playback

+/A -/K

3-41 3-42

Page 48

PRINTED CIRCUIT BOARD DIAGRAMS

1. MAIN P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3-43 3-44

Page 49

2. KEY P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3. TIMER P.C.BOARD

(TOP VIEW)

(BOTTOM VIEW)

3-45 3-46

Page 50

4. SMPS P.C.BOARD

5. SCART P.C.BOARD (SCART MODEL ONLY)

(TOP VIEW) (BOTTOM VIEW)

3-47 3-48

Page 51

MEMO MEMO

3-49 3-50

Page 52

4-1

SECTION 4

MECHANISM (DP-11)

CONTENTS

DECK MECHANISM PARTS LOCATIONS

• TOP VIEW....................................................................................................................................4-2

• TOP VIEW (WITHOUT TRAY DISC) ...........................................................................................4-2

• BOTTOM VIEW ...........................................................................................................................4-2

DECK MECHANISM DISASSEMBLY

1. MAIN BASE ...............................................................................................................................4-3

1-1. Clamp Assembly Disc .........................................................................................................4-3

1-1-1. Plate Clamp ..............................................................................................................4-3

1-1-2. Magnet Clamp ..........................................................................................................4-3

1-1-3. Clamp Upper ............................................................................................................4-3

2. TRAY DISC ................................................................................................................................4-3

3. BASE ASSEMBLY SLED ..........................................................................................................4-4

3-1. Gear Feed...........................................................................................................................4-4

3-2. Gear Middle ........................................................................................................................4-4

3-3. Gear Rack...........................................................................................................................4-4

4. RUBBER REAR.........................................................................................................................4-4

5. FRAME ASSEMBLY UP/DOWN................................................................................................4-5

6. BELT LOADING.........................................................................................................................4-5

7. GEAR PULLEY..........................................................................................................................4-5

8. GEAR LOADING .......................................................................................................................4-5

9. GUIDE UP/DOWN .....................................................................................................................4-5

10. PWB ASSEMBLY LOADING...................................................................................................4-5

11. BASE MAIN .............................................................................................................................4-5

EXPLODED VIEW

1. DECK MECHANISM EXPLODED VIEW...................................................................................4-7

Page 53

4-2

DECK MECHANISM PARTS LOCATION

• TOP VIEW (WITHOUT TRAY)

Procedure

Parts Fixing Type

Disass Fig-

Starting No.

embly ure

1 Main Base 4-1

12

Clamp Assembly

4-1

Disc

1, 2 3 Plate Clamp 4-1

1, 2, 3 4 Magnet Clamp 4-1

1, 2, 3, 4 5 Clamp Upper 4-1

16Tray Disc 4-2

1, 6 7 Base Assembly Sled 4-3

4 Screws,

1, 2, 6 8 Gear Feed 1 Connector 4-3

1 Locking Tabs

1, 2, 6, 8 9 Gear Middle

1, 2, 6, 8,

10 Gear Rack 1 Screw 4-3

9

1, 2, 7 11 Rubber Rear 4-3

1, 2, 7 12

Frame Assembly

1 Screw Bottom 4-4

Up/Down

1, 2 13 Belt Loading 1 Locking Tab 4-4

1, 2 ,13 14 Gear Pulley 4-4

1, 2, 13, 14 15 Gear Loading 1 Locking Tab 4-4

1, 2, 7, 12,

16 Guide Up/Down 4-4

13, 14

1, 2, 13 17 PWB Assembly

1 Locking Tab

Bottom 4-4

Loading

1 Hook

2Screw

1, 2, 7, 12,

13, 14, 15, 18 Base Main 2 Locking Tabs 4-4

16, 17

• TOP VIEW (WITH TRAY)

• BOTTOM VIEW

Note

When reassembling, perform the procedure in

reverse order.

The “Bottom” on Disassembly column of above

Table indicates the part should be disassembled

at the Bottom side.

Page 54

4-3

1. MAIN BASE (FIG. 4-1)

1-1. Clamp Assembly Disc

1) Place the Clamp Assembly Disc as Fig. (A)

2) Lift up the Clamp Assembly Disc in direction of

arrow(A).

3) Separate the Clamp Assembly Disc from the

Holder Clamp.

1-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise

direction and then lift up the Plate Clamp.

1-1-2. Magnet Clamp

1-1-3. Clamp Upper

2. TRAY DISC (FIG. 4-2)

1) Insert and push a Driver in the emergency eject

hole(A) at the right side, or put the Driver on the

Lever(B) of the Gear Emergency and pull the

Lever(B) in direction of arrow so that the Tray

Disc is ejected about 15~20mm.

2) Pull the Tray Disc until it is separated from the

Base Main completely.

DECK MECHANISM DISASSEMBLY

FIG. 4-1 FIG. 4-2

Page 55

4-4

3. BASE ASSEMBLY SLED (FIG. 4-3)

1) Release 4 Screw (S2).

2) Disconnect the FFC Connector (C1)

3-1. Gear Feed

3-2. Gear Middle

3-3. Gear Rack

1) Release the Scerw (S3)

4. RUBBER REAR (FIG. 4-3)

FIG. 4-3

Page 56

4-5

5. FRAME ASSEMBLY UP/DOWN (FIG. 4-4)

Note

Put the Base Main face down (Bottom Side)

1) Release the screw (S4)

2) Unlock the Locking Tab (L3) in direction of arrow

and then lift up the Frame Assembly Up/Down to

separate it from the Base Main.

Note

• When reassembling move the Guide Up/Down in

direction of arrow(C) until it is positioned as

Fig.(C).

• When reassembling insert (A) portion of the

Frame Assembly Up/Down in the (B) portion of

the Guide Up/Down as Fig.(B)

6. BELT LOADING(FIG. 4-4)

Note

Put the Base Main on original position(Top Side)

7. GEAR PULLEY (FIG. 4-4)

1) Unlock the Locking Tab(L4) in direction of

arrow(B) and then separate the Gear Pulley from

the Base Main

8. GEAR LOADING (FIG. 4-4)

9. GUIDE UP/DOWN (FIG. 4-4)

1) Move the Guide Up/Down in direction of

arrow(A) as Fig.(A)

2) Push the Locking Tab(L5) down and then lift up

the Guide Up/Down to separate it from the Base

Main.

Note

When reassembling place the Guide Up/Down as

Fig.(C) and move it in direction arrow(B) until it is

locked by the Locking Tab(L5). And confirm the Guide

Up/Down as Fig.(A)

10. PWB ASSEMBLY LOADING (FIG. 4-4)

Note

Put the Base Main face down(Bottom Side)

1) Release 1 Screws(S5)

2) Unlock the Loading Motor (C2) from the Hook

(H1) on the Base Main.

3) Unlock 2 Locking Tabs(L6) and separate the

PWB Assembly Loading from the Base Main.

11. BASE MAIN (FIG. 4-4)

FIG. 4-4

Page 57

4-6

MEMO

Page 58

001

002

003

020

439

018

013

017

015B

015A

440

019

012

015

012

432

030

010

439

431

435

021

430

024

025

036

012A

012A

026

016

435

014

A01

A02

A03

A00

4-7 4-8

EXPLODED VIEW

1. DECK MECHANISM EXPLODED VIEW

DP-11

Page 59

4-9 4-10

MEMO MEMO

Loading...

Loading...