Page 1

SERVICE MANUAL

DVD VIDEO PLAYER

XA00220035

XV-N30BK[MK2],

XV-N33SL[MK2]

Area Suffix

J -------------------------- U.S.A.

C --------------------- Canada

B -------------------------- U.K.

E ------ Continental Europe

EN ------- Northern Europe

EV --------- Eastern Europe

DISPLAY

TITLE/

3D PHONIC

GROUP RETURN CANCEL

213

5

4

8

7

010 +10

ANGLE

SUB TITLE AUDIO ZOOM

TOP MENU MENU

CHOICE

SLOW

PREVIOUS SELECT

CLEAR

STANDBY/ON

6

9

ENTER

VFP ON SCREEN

NEXT

For only Europe

EE ---- Russian Federation

This illustration is XV-N30BK for U.S.A.

This service manual is a service manual of the model which

changes a part of specification of the above-mentioned model

which has already been put on the market.

Please refer to the following page for details.

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED.

No.XA002

2003/5

Page 2

For this service manual

This service manual is a service manual of the model which changes a part of specification of the above-mentioned model

which has already been put on the market.

<When the label in figure is pasted in the main body>

The specification is different from what the label of the same model does not paste because of the specification improvement,

and refer to this service manual, please. Please already refer to the issued service manual when the label is not pasted.

* Please refer to this service manual for the model to which this label is pasted.

* Please refer to the service manual which has already been issued for the

model to which this label is not pasted.

(one that there is no description named [MK2] in cover of service manual. )

0478

The surface of a rear panel

inside

or

Used only service dealer

Please refer to service manual of an applicable model [MK2]

GN30080-001A

1-2 (No.XA002)

Page 3

SPECIFICATION

(For U.S.A.)

General

Readable discs DVD VIDEO, DVD-R (Video format), DVD-RW (Video format), +RW (Video format), SVCD, Video CD,

Audio CD (CD-DA), MP3 format, CD-R/RW (CD-DA, SVCD, Video CD, MP3 format)

Video format NTSC

Other

Power requirements AC 120 V, 60 Hz

Power consumption 10 W (POWER ON) 0.7 W (STANDBY mode)

Mass 2.1 kg (4.7 lbs)

Dimensions (W x H x D) 435mm x 53mm x 248.4mm (17-3/16 inch x 2-1/8 inc x 9-13/16 inch)

Video outputs

COMPONENT (pin jacks) Y Output: 1.0 Vp-p (75 ohm)

Pb/Pr Output: 0.7Vp-p (75 ohm)

VIDEO OUT (pin jack) 1.0 Vp-p (75 ohm)

S-VIDEO OUT (S jack) Y Output: 1.0 Vp-p (75 ohm)

C Output: 286 mVp-p (75 ohm)

Horizontal resolution 500 lines or more

Audio outputs

ANALOG OUT (pin jack) 2.0 Vrms (10 kohm)

DIGITAL OUT (COAXIAL) 0.5 Vp-p (75 ohm termination)

DIGITAL OUT (OPTICAL) -21 dBm to -15 dBm (peak)

Audio characteristics

Frequency response CD (sampling frequency 44.1 kHz):2 Hz to 20 kHz

DVD (sampling frequency 48 kHz):2 Hz to 22 kHz

(4 Hz to 20 kHz for DTS and Dolby Digital bitstream signals)

DVD (sampling frequency 96 kHz):2 Hz to 44 kHz

Dynamic range 16 bit: More than 98 dB

20 bit: More than 100 dB

24 bit: More than 100 dB

Wow and flutter Unmeasurable (less than + 0.002%)

Total harmonic distortion less than 0.006%

• Specifications and appearance are subject to change without prior notice.

• Manufactured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarkes of Dolby Laboratories.

• Manufactured under license from Digital Theater Systems, Inc. "DTS" and "DTS Digital Surround" are registered trademarks of Digital Theater Systems, Inc.

(No.XA002)1-3

Page 4

SECTION 1

Important Safety Precautions

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

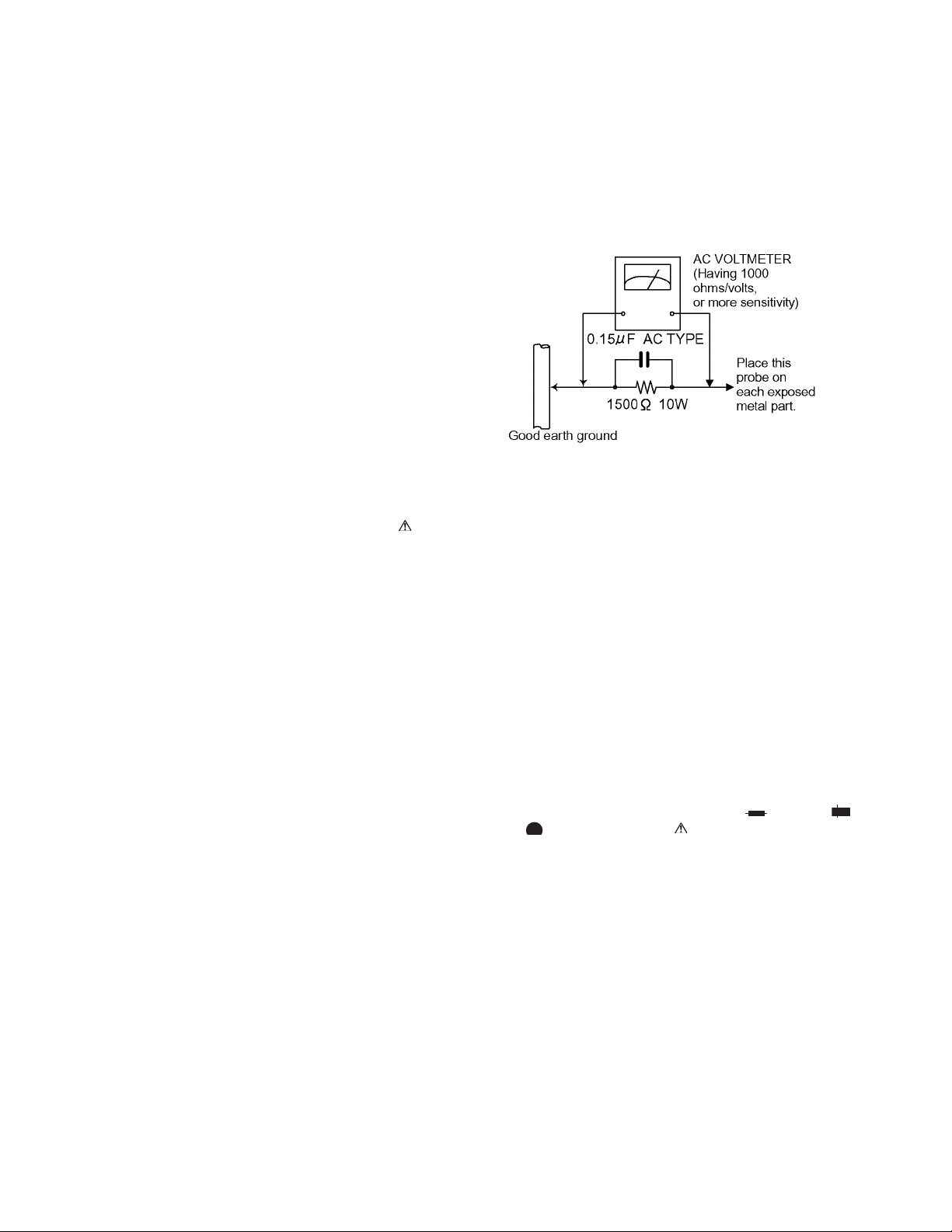

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000 ohms per volt or more sensitivity in the following manner. Connect a 1,500 ohm 10W

resistor paralleled by a 0.15 F AC-type capacitor between an exposed metal part and a known good earth

ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

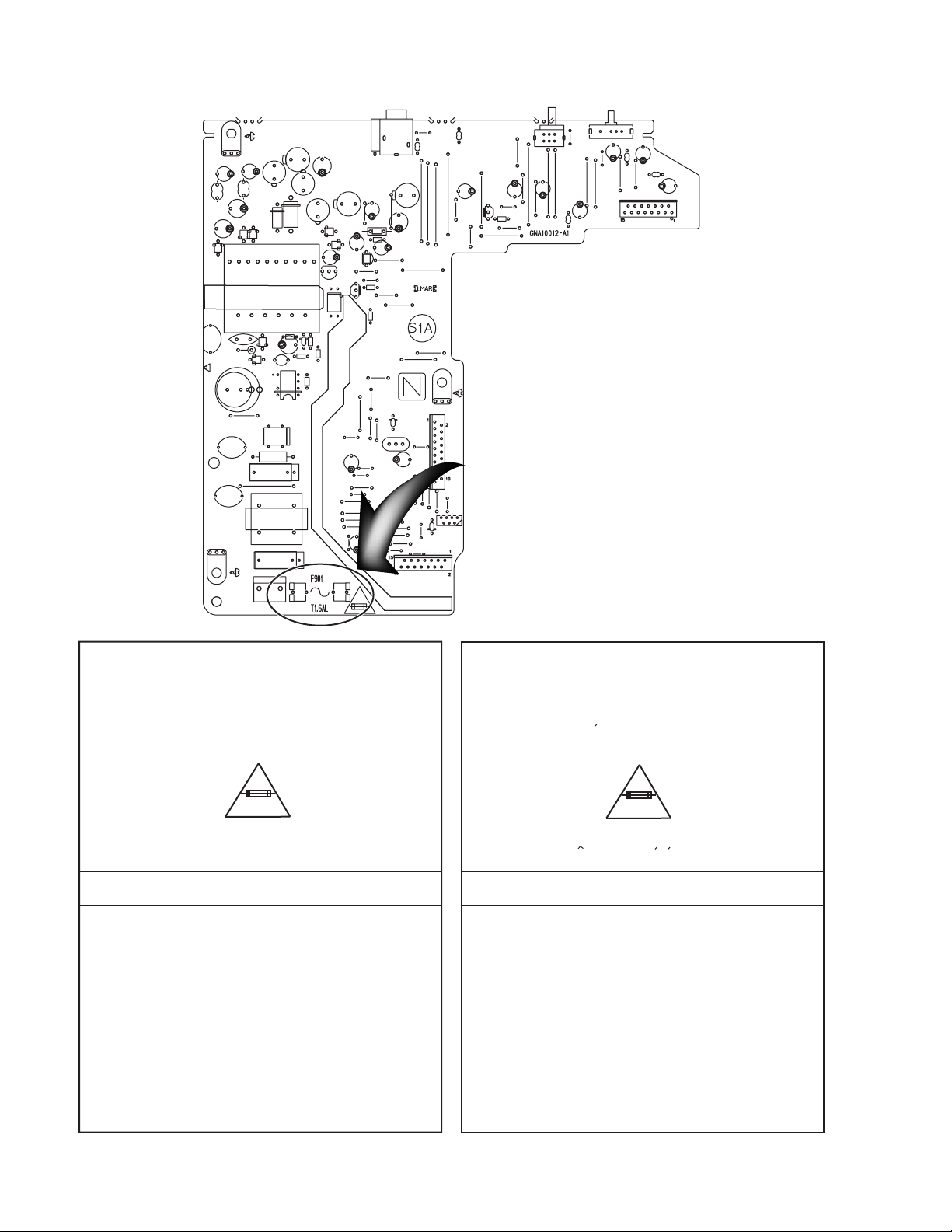

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical for

safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer. (Except

the JC version)

1-4 (No.XA002)

Page 5

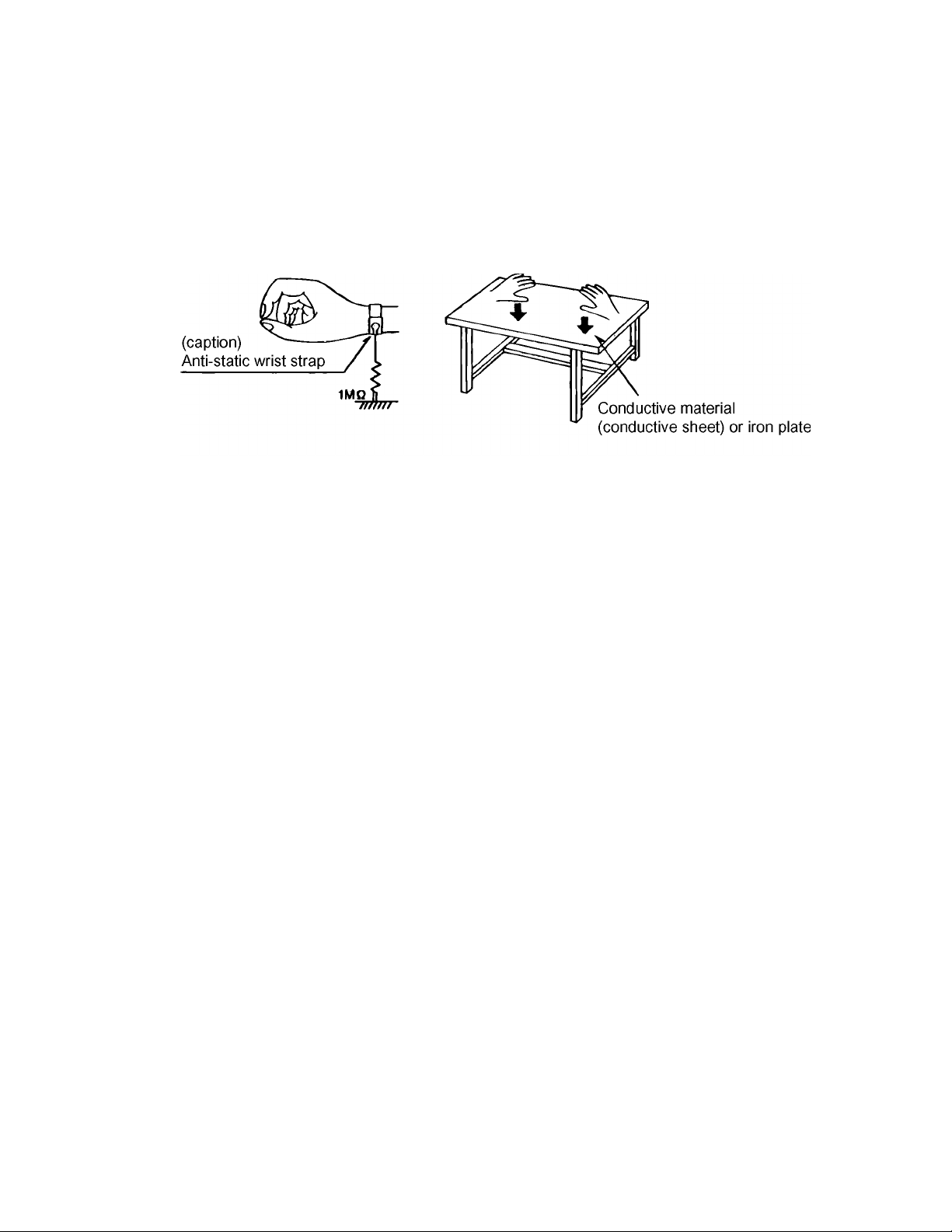

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Precautions of the safe use of battery (Only XV-N30BK for U.S.A.)

• Store the battery in a place where children cannot reach.If a child accidentally swallows the battery, consult a doctorimmediately.

• Do not recharge, short, disassemble or heat the battery or dispose of it in a fire.

Doing any of these things may cause the battery to give off heat, crack, or start a fire.

• Do not leave the battery with other metallic materials.Doing this may cause the battery to give off heat, crack, or start a fire.

• When throwing away or saving the battery, wrap it in tape and insulate; otherwise, the battery may start to give off heat, crack, or

start a fire.

• Do not poke the battery with tweezers or similar tools.Doing this may cause the battery to give off heat, crack, or start a fire.

• Dispose of batteries in the proper manner, according to federal, state, and local regulations.

(No.XA002)1-5

Page 6

1.8 Importance admistering point on the safety

J702

EP953

C966

C965

L954

L953

C963

D957

D956

T901

C908

R901

C906

C907

B234

R910

C904

C918

C905

L901

C902

EP951

P901

L955

C988

C967

C964

D954

D903

D901

B631

C958

D953

D955

R912

D902

C914

R915

C913

IC901

FC901

L951

C952

D951

R903

D904

R906

C955

B141

D952

PC901

R913

R954

C950

C970

CP951

B137

IC952

B34

Q951

R953

R951

B116

B135

B303

B133

B134

B37

C701

B38

B39

B132

B40

B202

B231

B233

B105

C808

C802

B45

FC902

B4

L710

L709

L952

B331

C953

R969

C951

B236

B136

B271

B347

D701

X701

C706

B201

B142

B143

B170

B203

B102

B16

C959

B140

B852

B871

B874

B872

B166

B403

B237

EP952

CN904

B36

B103

B101

B171

B44

P704

B2

D702

B41

CN901

S901

B273

B873

C973

B601

Q953

B32

R966

B272

B139

B138

,,

B17

B772

B771

C957

B332

B532

C977

L959

S902

C975

C976

L957

B15

B533

L956

B276

B333

C974

CN902

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : 1.6 A / 125 V F901 : 1.6 A / 125 V

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

1-6 (No.XA002)

Page 7

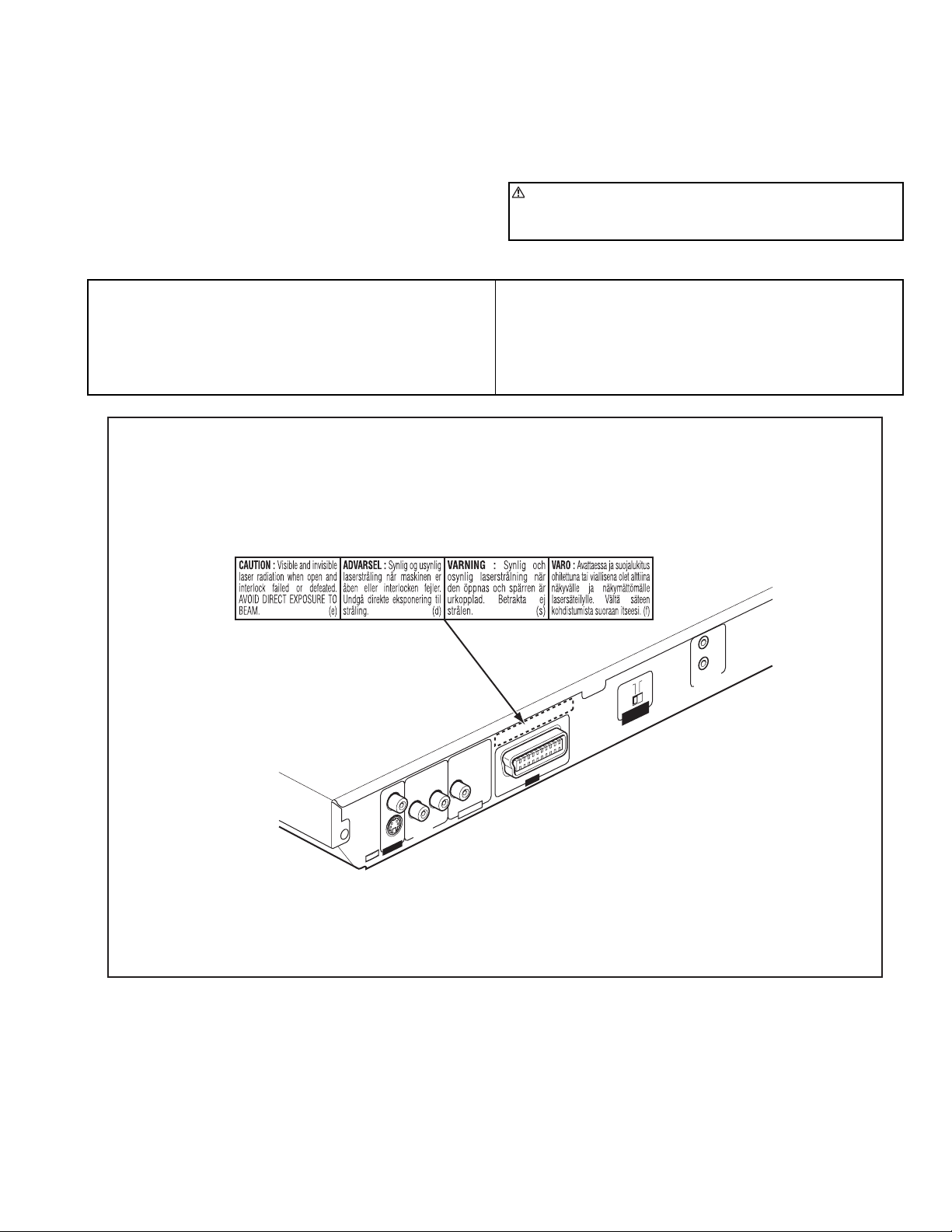

1.9 Important for laser products

(1) CLASS 1 LASER PRODUCT

(2) DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

(3) CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace the

complete Laser Unit if it malfunctions.

(4) CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are de feated.

It is dangerous to defeat the safety switches.

VARNING

Osynlig laserstrålning är denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen.

VARO

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen.

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er

ude af funktion. Undgå udsasttelse for stråling.

ADVARSEL

Usynlig laserstråling ved åpning, når sikkerhetsbryteren er avslott. unngå utsettelse for stråling.

REPRODUCTION AND POSITION OF LABEL and PRINT

WARNING LABEL and PRINT

(5) CAUTION : If safety switches malfunction, the laser is able

to function.

(6) CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

Please use enough caution not to see the beam directly

or touch it in case of anadjustment or operation check.

The inside of a rear panel

M

A

PCM/STRE

COAXIAL

LEFT

VIDEO

S-VIDEO

ID

V

EO O

RIGHT

U

O

IO

D

AU

T

U

UT

O

AL

IT

DIG

T

/C

Y

.

P

COM

B

G

/R

SIGNAL

OR

VIDEO

SELECT

T

U

O

V

A

COMPU LINK

AV

(No.XA002)1-7

Page 8

1.10 Precautions for Service

1.10.1 Handling of Traverse Unit and Laser Pickup

(1) Do not touch any peripheral element of the pickup or the actuator.

(2) The traverse unit and the pickup are precision devices and therefore must not be subjected to strong shock.

(3) Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the internal power supply of the tester.)

(4) To replace the traverse unit, pull out the metal short pin for protection from charging.

(5) When replacing the pickup, after mounting a new pickup, remove the solder on the short land which is provided at the center of

the flexible wire to open the circuit.

(6) Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

1.10.2 Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothingor the human body. Before repairing peripheral elements of

the traverse unit or pickup, be sure to take the following electrostatic protection:

(1) Wear an antistatic wrist wrap.

(2) With a conductive sheet or a steel plate on the workbench on which the traverse unit or the pick up is to be repaired, ground the

sheet or the plate.

(3) It solders to two short circuit sections on the substrate of a pick-up.

(4) After removing the flexible wire from the connector (CN101), short-circuit the flexible wire by the metal clip.

(5) Short-circuit the laser diode by soldering the land which is provided at the center of the flexible wire for the pickup.

After completing the repair, remove the solder to open the circuit.

Pick-up

Short circuit

* Please refer to the disassembly method for details.

CN101

Servo control board

1-8 (No.XA002)

Page 9

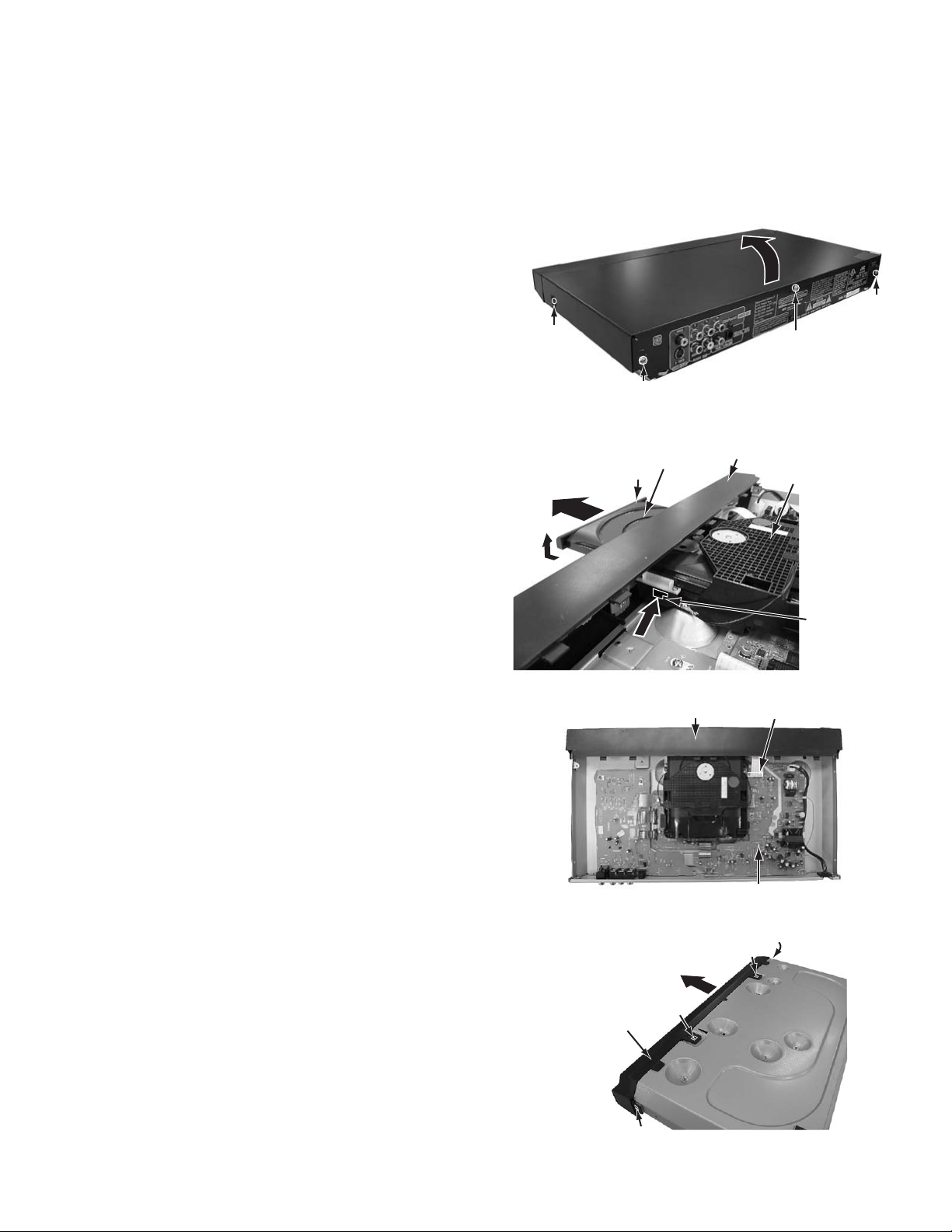

SECTION 2

TOP COVER

r

Push

Disassembly method

There is a part different from the photograph according to the model and the destination though explains this disassembly method

by using XV-N30BK for U.S.A.

2.1 Main body section

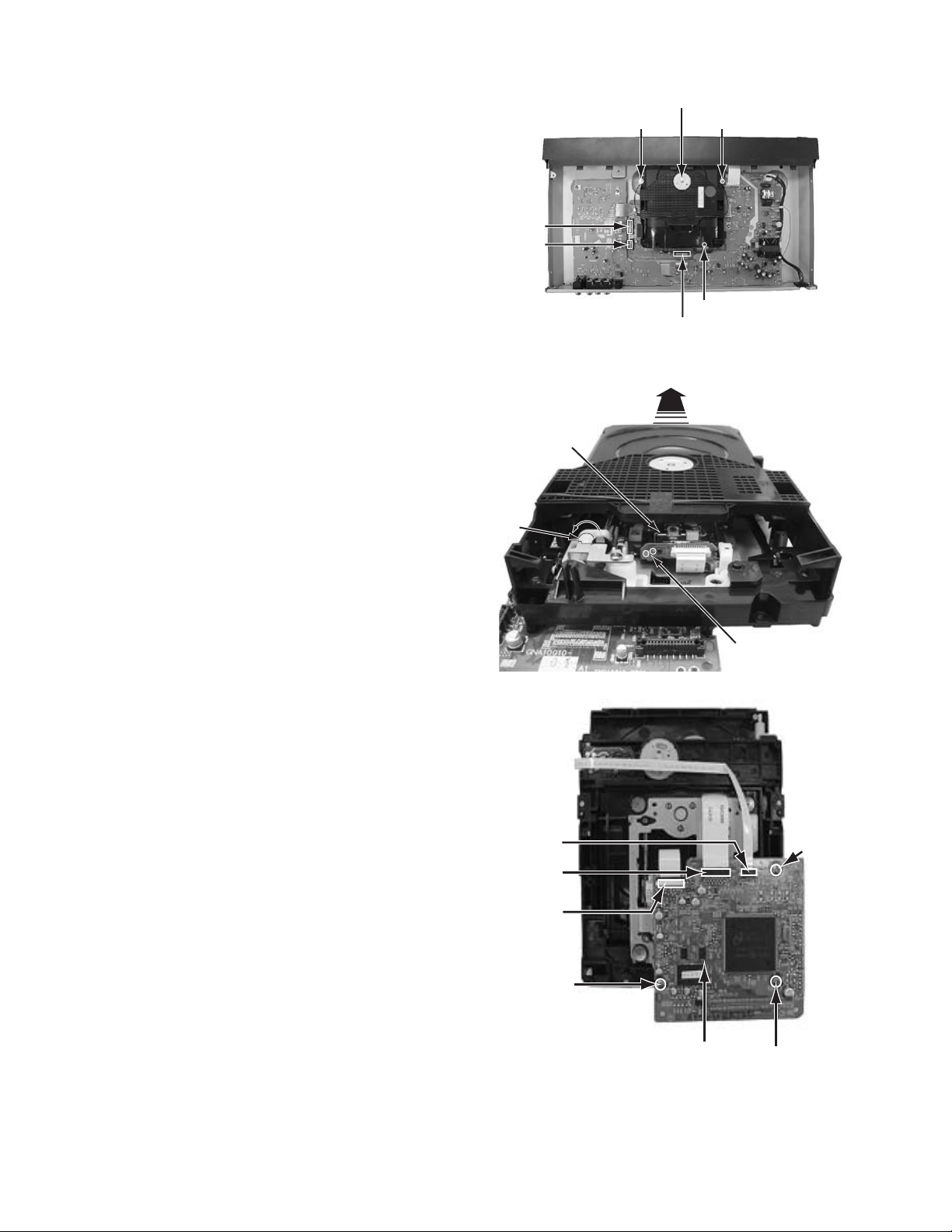

2.1.1 Removing the top cover (See Figure 1)

(1) Remove the two screws A attaching the top cover on both

sides of the main body.

(2) Remove the three screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

2.1.2 Removing the front panel assembly (See Figure 2, Figure 3, Figure 4)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the mechanism assembly.

(1) Insert a kind of screwdriver in a hole located in the right

side of mechanism assembly, and push a lever until it cannot be inserted any further.

(2) And then, a tray will come out. Remove the tray in an upper

direction, with slightly opening the lower part of fitting in an

outward direction.

(3) Disconnect the card wire from connector CN901 on the

power supply board.

(4) Hook a and b are removed respectively, and the front panel

assembly is removed.

A

x

2

Fitting

B

Push

TOP COVER

TOP COVER

Fig.1

Tray

B

Front panel assembly

Mechanism assembly

Hole and leve

B

Fig.2

Front panel assembly

Power supply board

Fig.3

Hook b

Front panel

assembly

Hook b

Hook a

Fig.4

CN901

Hook a

(No.XA002)1-9

Page 10

2.1.3 Removing the mechanism assembly (See Figure 2, Figure 5)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the front panel assembly.

(1) Insert a kind of screwdriver in a hole located in the right

side of mechanism assembly, and push a lever until it cannot be inserted any further.

(2) And then, a tray will come out. Remove the tray in an upper

direction, with slightly opening the lower part of fitting in an

outward direction.

(3) Remove the three screws C attaching the mechanism as-

sembly.

(4) Disconnect the wire from connector CN501,CN502,CN503

on the servo control board respectively.

(5) Remove the mechanism assembly by lifting the rear part of

the mechanism assembly.

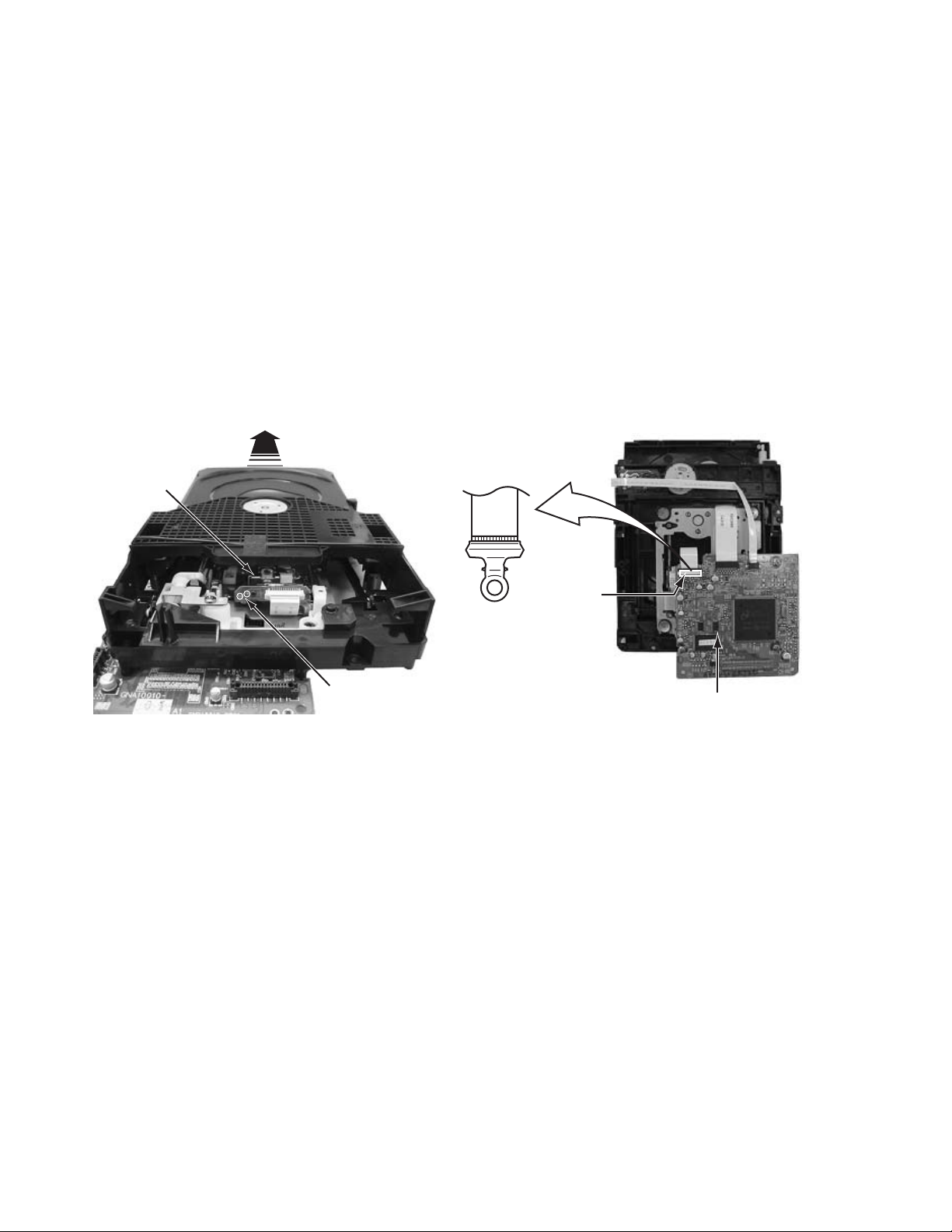

2.1.4 Removing the servo control board (See Figure 6, Figure 7)

• Prior to performing the following procedure, remove the mechanism assembly.

(1) A tray is made to slide ahead.

(2) A gear 1 is turned counterclockwise. Then, a pick-up unit

moves back.

(3) It solders to two c sections on the pick-up unit.

(4) Remove the three screws D attaching the servo control

board.

(5) Disconnect the card wire from connector CN201,CN202 on

the servo control board.

(6) Disconnect the flexible wire from connector CN101 on the

servo control board from pick-up unit.

ATTENTION:

Please extract the wire after short-circuited of two places

on the wire in part c with solder. Please remove the solder two places of part c after connecting the wire with

CN101 when reassembling.

CAUTION:

Be sure to solder the short land sections “c” on the pickup unit before disconnecting the card wire from connector CN101 on the DVD servo control board.

If the card wire is disconnected without attaching solder,

the pick-up unit may be destroyed by static electricity.

CN502

CN503

Gear1

Pick-up

Mechanism assembly

C

CN501

Fig.5

Fig.6

C

C

Part c

1-10 (No.XA002)

CN202

CN201

CN101

D

Servo control board

Fig.7

D

D

Page 11

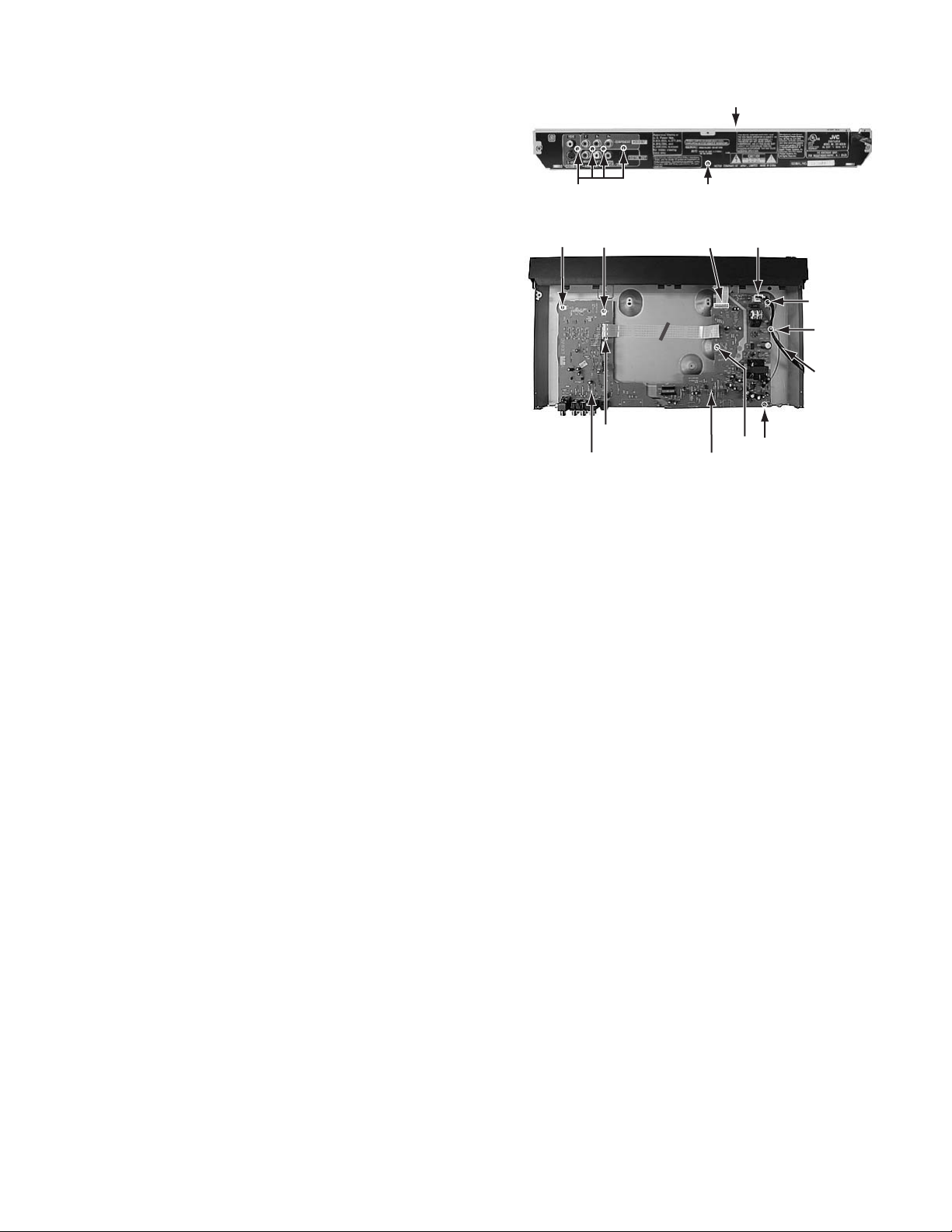

2.1.5 Removing the rear panel (See Figure 8, Figure 9)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the five screws E attaching the rear panel.

(2) Disconnect the power cord from connector P901 on the

power supply board

(3) Remove tie band.

Rear panel

E

E

Fig.8

G G

CN702

2.1.6 Removing the output terminal board and power supply board. (See Figure 9)

• Prior to performing the following procedure, remove the top

cover/mechanism assembly/rear panel.

(1) Remove the two screws G attaching the output terminal

board.

(2) Disconnect the card wire from connector CN702 on the

output terminal board.

(3) Remove the three screws H attaching the power supply

board.

(4) Disconnect the card wire from connector CN901 on the

power supply board.

CN901 P901

H

Power supply boardOutput terminal board

Fig.9

H

Tie band

Power cord

H

(No.XA002)1-11

Page 12

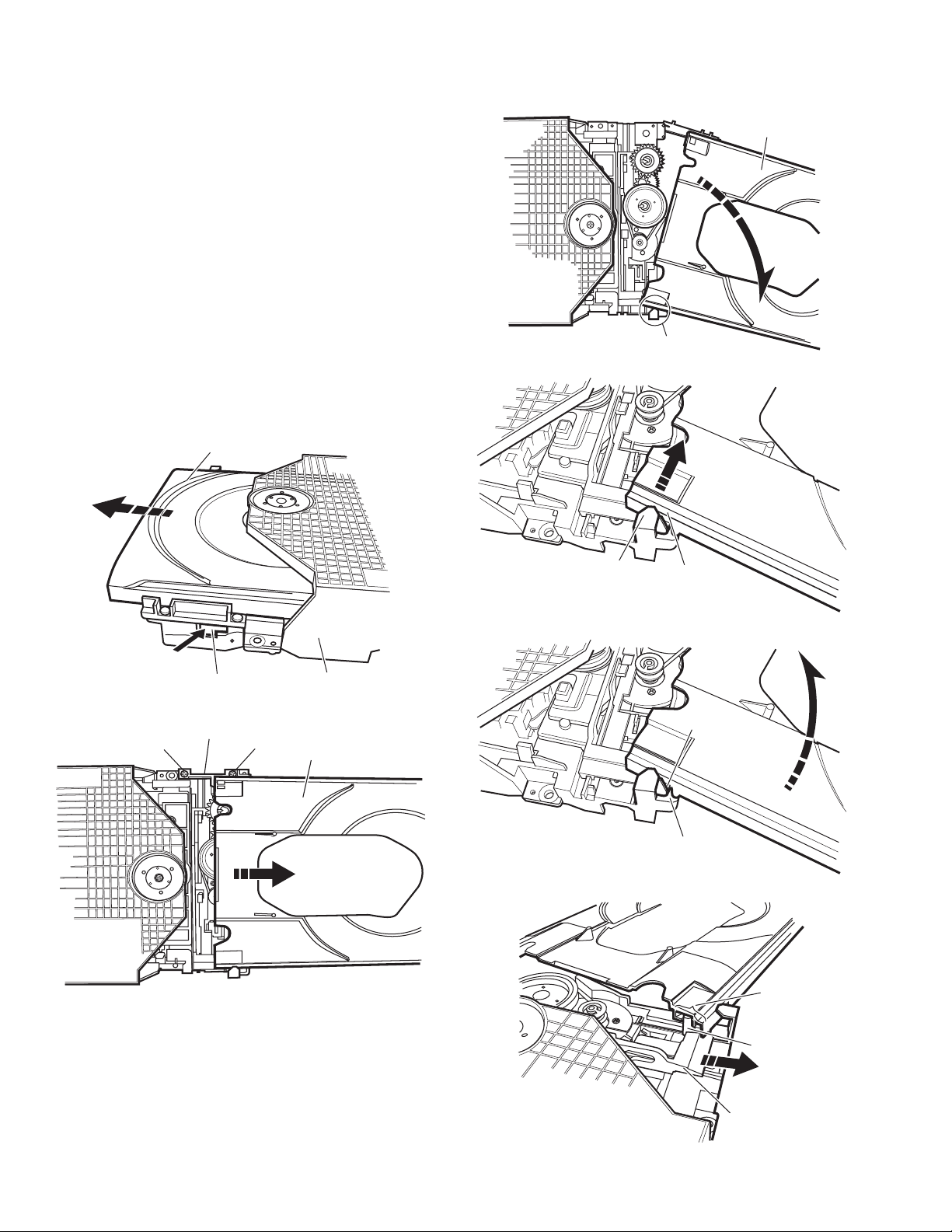

2.2 Loading mechanism assembly

Projection of the tray

2.2.1 Removing the tray (See Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6)

(1) Push a of the slide cam on the hole in the right side of the

loading base by using a driver until it stops. (See Figure 1.)

(2) The tray comes out. Pull the tray in a front direction until it

stops.

(3) Remove the two screws A attaching the slide bracket. (See

Figure 2.)

(4) Tilt the tray in a direction of the arrow around the point in

the left rear part of the tray. (See Figure 3.)

(5) The rail of the tray is removed from b of the loading base.

Then, remove the tray upward. (See Figure 4.)

Attaching the tray:

Engage c of the loading base to the projection of the tray while

tilting the tray to the left. Turn the tray in a direction of the arrow, and attach the slide bracket. (See Figure 5.)

Note:

Prior to the procedure above, move the slide cam in a direction

of the arrow so that d of the slide cam can be inserted in e of

the tray. (See Figure 6.)

Tray

The point in the left rear part

Tray

Fig.3

Push

Slide cam part a

Slide bracket

A

Fig.1

Fig.2

A

Loading base

Tray

Loading base part b

Rail of the tray

Fig.4

Projection of the tray

Loading base part c

Fig.5

Part e

1-12 (No.XA002)

Part d

Slide cam

Fig.6

Page 13

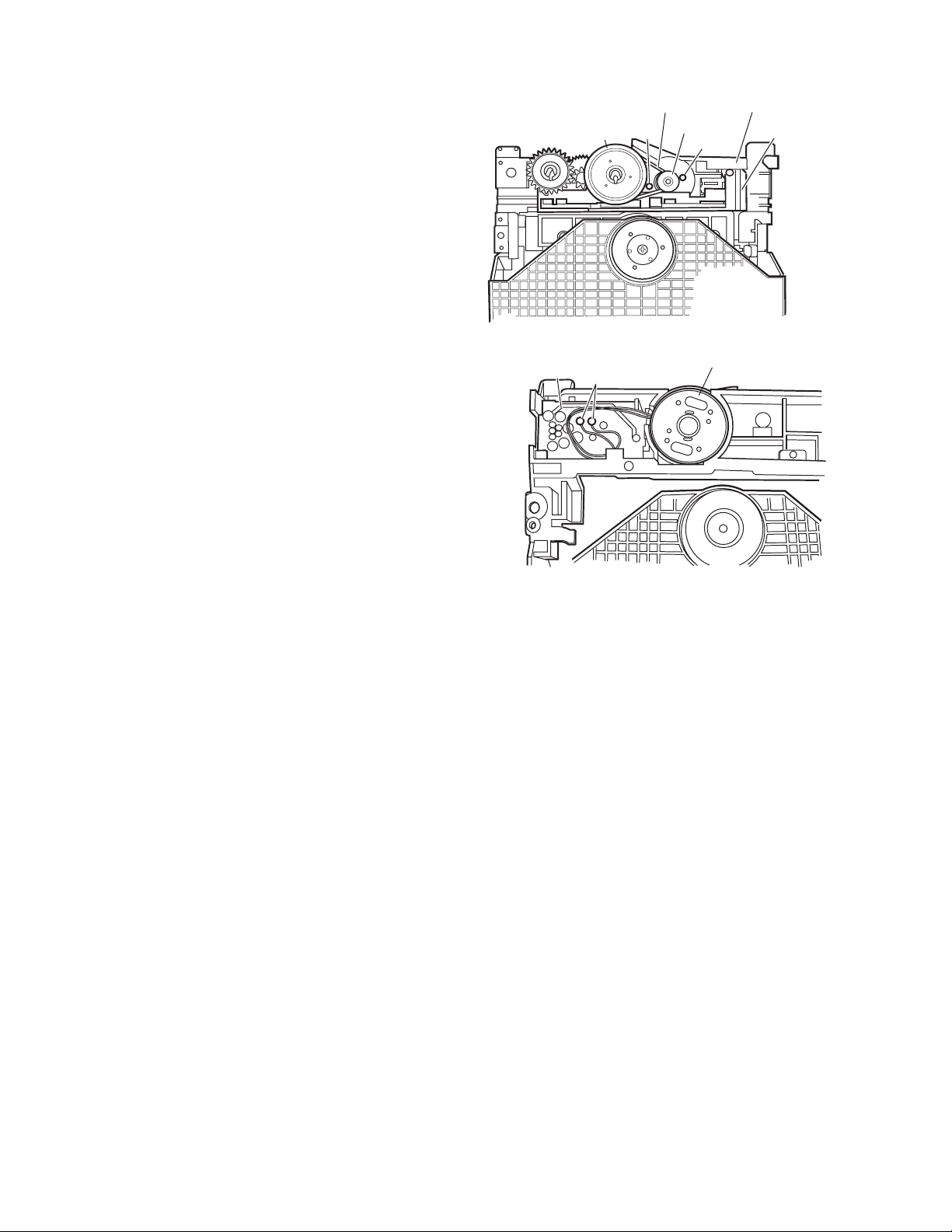

2.2.2 Removing the traverse mechanism assembly (See Figure 7)

f

Shaft

Reverse the loading mechanism assembly. Remove the four

screws B attaching the traverse mechanism assembly. Remove

the traverse mechanism assembly upward.

Loading mechanism assembly

2.2.3 Removing the elevator (See Figure 8 and Figure 9)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove the two arms of the elevator from the two parts f

by moving the arms in a direction of the arrow.

(2) Pull out the elevator in a rear direction.

Attaching the elevator:

Engage the two holes g to the two shafts on the front part of

the elevator. And then, attach the elevator.

B

B

B

B

Traverse mechanism assembly

Fig.7

Elevator

Part f

Fig.8

g

Slide cam

Elevator

Shaft

Fig.9

(No.XA002)1-13

Part

g

Page 14

2.2.4 Removing the loading motor (See Figure 10 and Figure 11)

• Prior to the following procedure, remove the tray, the traverse

mechanism assembly, and the elevator.

(1) Remove the belt from the pulley.

(2) Remove two screws C attaching the loading motor.

(3) Remove two solders h on the switch board.

Pulley

Belt

C

Fig.10

Pulley

C

Loading base

Slide cam

Switch board

Loading motor

Part h

Fig.11

1-14 (No.XA002)

Page 15

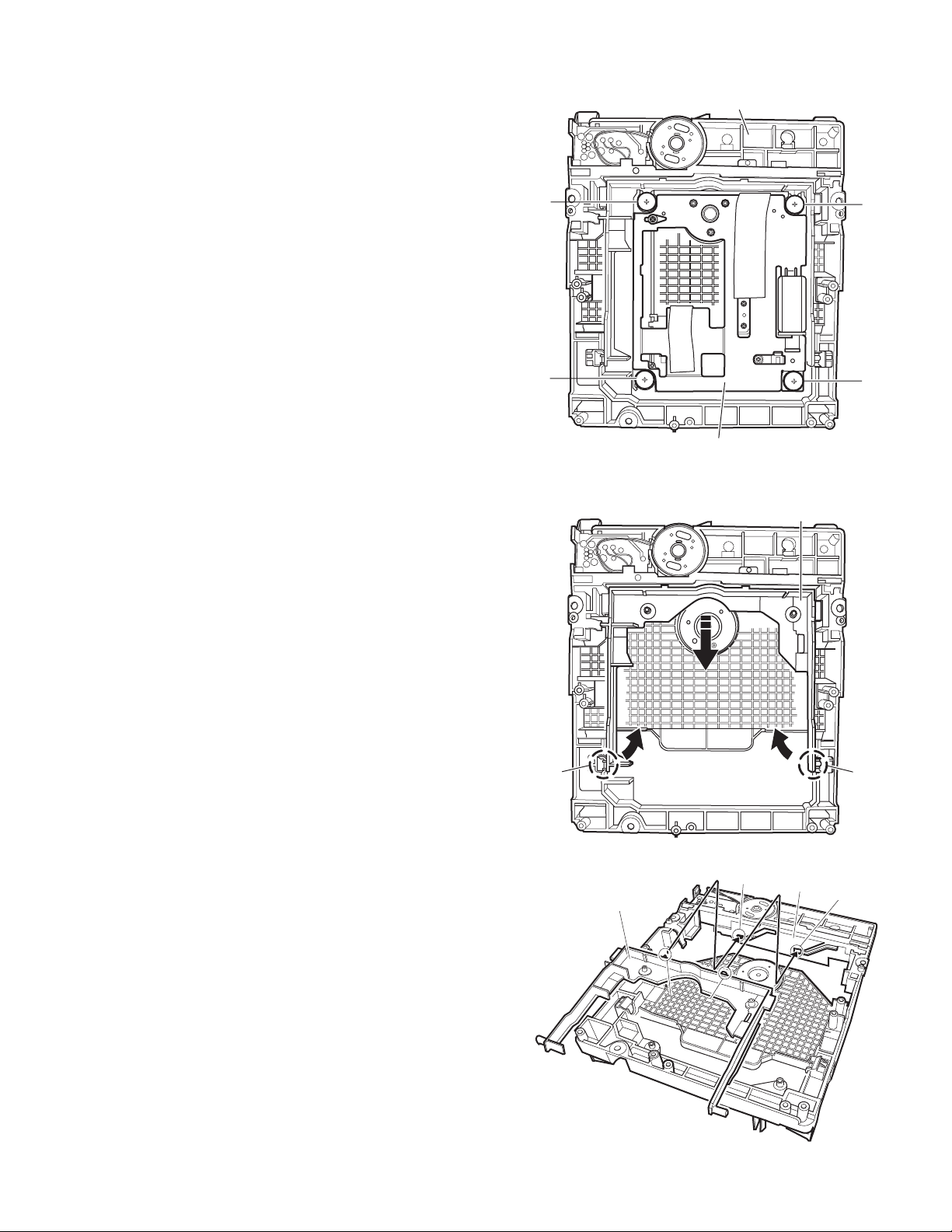

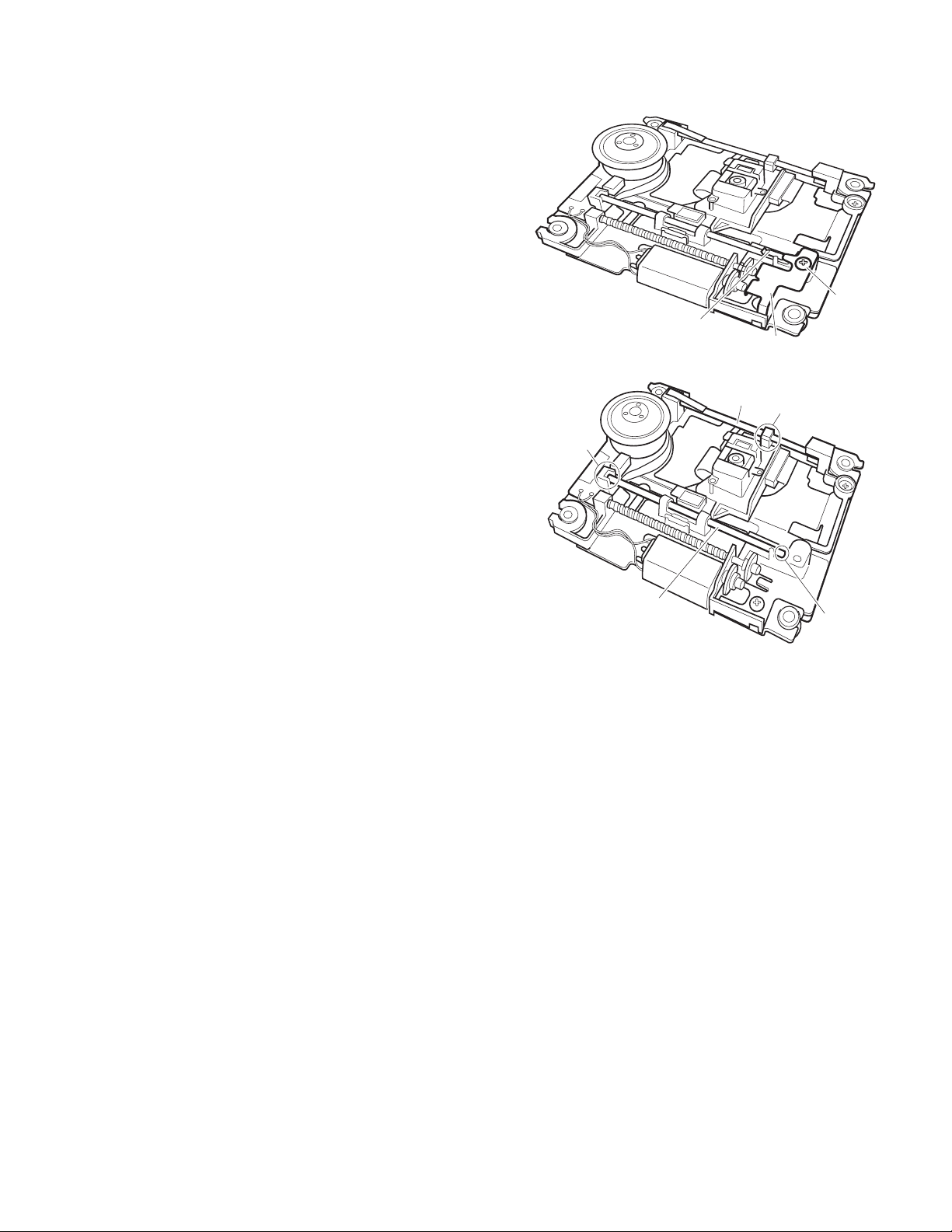

2.3 Traverse mechanism assembly

2.3.1 Removing the pickup (See Figure 12, Figure 13)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove one screw D attaching the plate.

(2) Remove the plate and the leaf spring.

(3) Lift i of the shaft 1, and pull out the shaft 1 from j.

(4) Remove k of the pickup from the shaft 2.

Attaching the pickup:

(1) Engage k of the pickup to the shaft 2.

(2) Insert the shaft 1 in j, and attach the shaft 1 to i.

(3) Attach the leaf spring, and then attach the plate. Fix the

leaf spring and the plate by using the screw D.

D

Leaf spring

Plate

Fig.12

Part j

Shaft 2

Part k

Shaft 1

Part i

Fig.13

(No.XA002)1-15

Page 16

SECTION 3

Adjustment

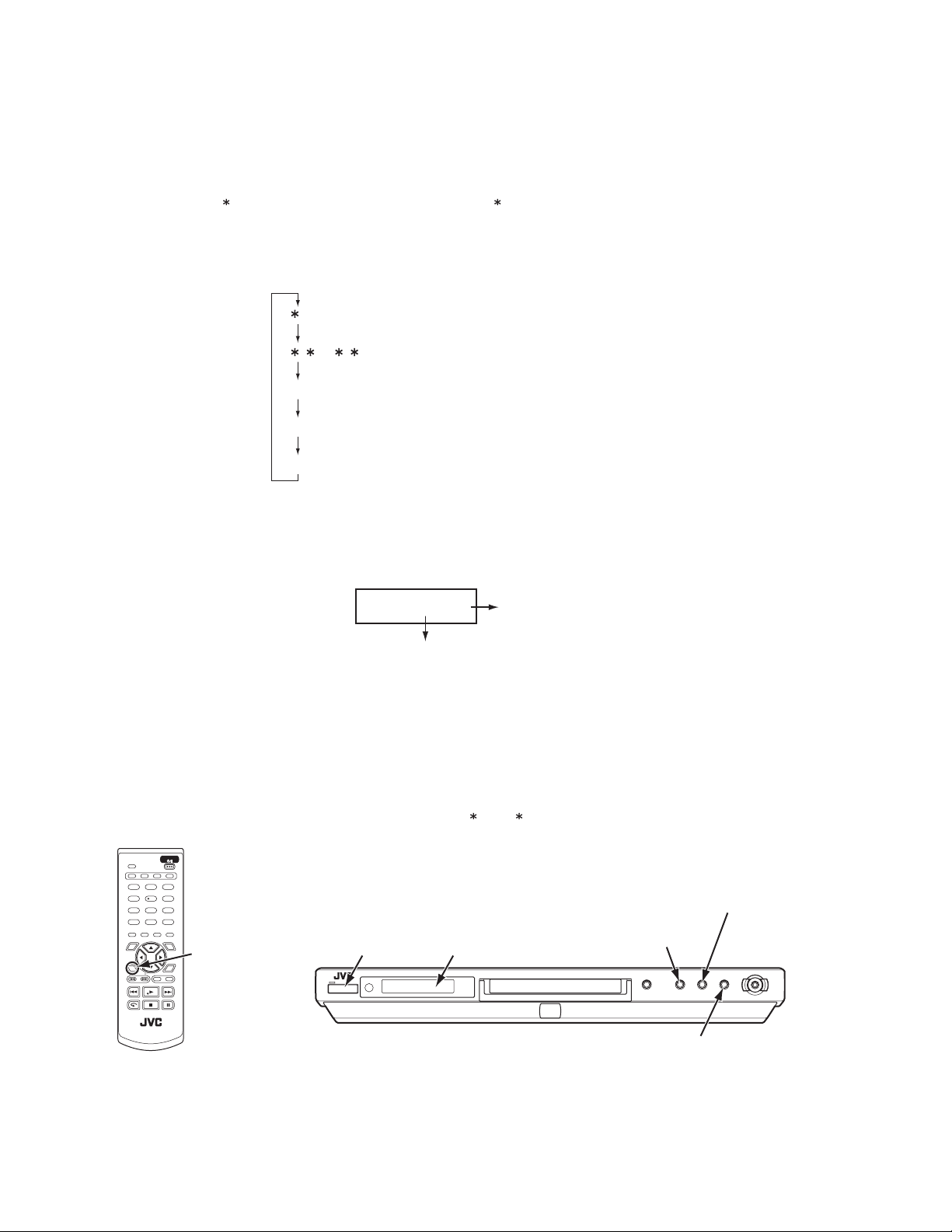

3.1 Test mode setting method

(1) Unplug the power plug.

(2) Insert power plug into outlet while pressing both "PLAY" key and "STOP" key of the main body.

(3) The FL display shows " 0", and the main body turns to test mode. " " means the destination, and "0" means parameter adjust-

ment status.

(4) To release test mode, press "POWER" key of the main body.

NOTE:

Each pressing of "CHOICE" key of the remote controller in test mode changes the mode as follows.

0 ------------------------------

_ ----------------------

Becames test mode

Version of firmware

FL Display becames all lighting

CK --------------------------------

EP -------------------------------

3.2 Method of displaying version of firmware

(1) Set the main body at test mode.

(2) Press "CHOICE" key of the remote controller once. Then, version number and alphabetical letter of the system controller and

the back end are displayed in the FL display as follows:

Check mode

Not used

FL Display (Example)

19_16

System controller

3.3 Initialization method

Please initialize according to the following procedures in the following case:

• Just after you upgrade the firmware.

• After you confirm the symptoms that a customer points out. First Initialize, and then confirm whether the symptoms are improved or

not.

• After servicing, before returning the main body to a customer. (Initialized main body should be returned to a customer.)

(1) Set the main body at test mode.

(2) Press "PAUSE" key of the main body.

(3) When initialization is completed, the FL display changes from " 0" to " 00".(The left "0" of "00" is not always "0". It shows pa-

rameter adjustment status.)

STANDBY/ON

DISPLAY

TITLE/

3D PHONIC

GROUP RETURN CANCEL

213

5

6

4

8

9

7

010 +10

ANGLE

SUB TITLE AUDIO ZOOM

TOP MENU MENU

CHOICE

SLOW

VFP ON SCREEN

PREVIOUS SELECT

CLEAR

CHOICE key

ENTER

(switch of mode)

NEXT

POWER key

FL Display

Back end

PLAY key

(for test mode)

STOP key

(for test mode)

1-16 (No.XA002)

PAUSE key

(for initialize)

Page 17

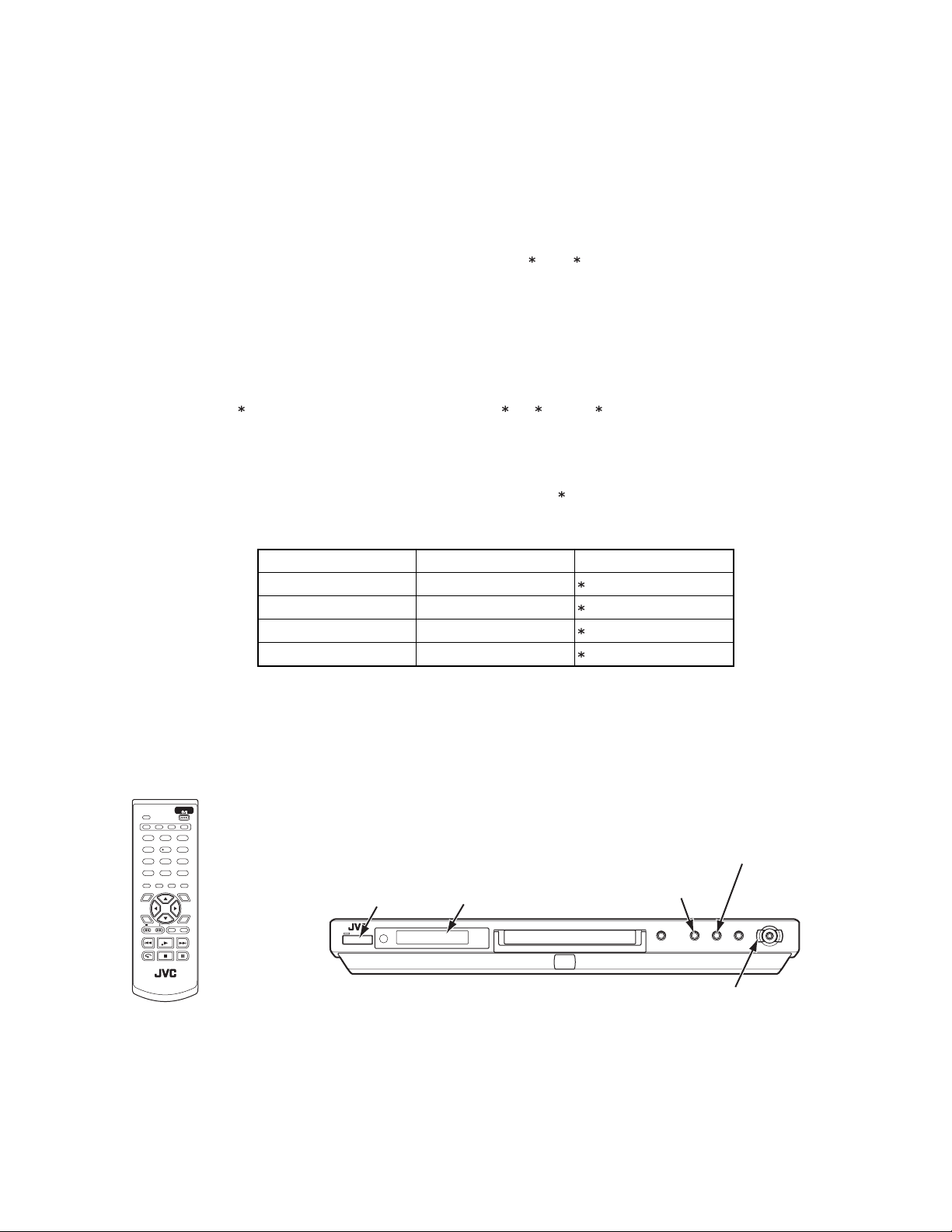

3.4 All-initialization method

Please perform all-initialization according to the following procedures in the following case:

• Just after you exchange the pick-up.

• Just after you exchange the spindle motor.

• Just after you exchange the traverse mechanism base.

NOTE:

Please perform all-initialization when you exchange the parts above and also when you remove the parts above.

• Just after the flap adjustment of the pick-up guide shaft

(1) Set the main body at test mode.

(2) Press and hold "BACKWARD SKIP" key of the main body for more than 2 seconds.

(3) When all-initialization is completed, the FL display changes from " 0" to " 33".

NOTE:

After all-initialization, be sure to perform optimization adjustment of Front End parameter.

3.5 Optimization adjustment of Front End parameter

Adjustment to optimize Front End parameter must be performed in each mechanism assembly of this model for high-speed starting.Please perform optimization according to the following procedures just after all-initialization is completed and when FL display

shows anything except " 0" (For example when FL display shows " 1", " 2", and " 3") at test mode.

(1) Press "POWER" key of the main body to turn the main body on (not to set the main body at test mode).

(2) Insert the test disc VT-501 or commercial dual-layer DVD software.

(3) Remove the disc when the FL display changes from "READ" to disc information.

(4) Perform the same procedures as in (2) and (3) above by using the test disc CTS-1000 or commercial CD-DA software.

(5) Set the main body at test mode, and check that the FL display shows " 0".

NOTE:

Status of this adjustment can be judged by the number displayed at test mode as follows:

DVD adjustment CD adjustment FL display at test mode

Adjusted Adjusted 0

Not adjusted Adjusted 1

Adjusted Not adjusted 2

Not adjusted Not adjusted 3

NOTE:

As for a disc used for adjustment,

• Disc should be mounted. ("Mounting" means to display "READ" after the disc is inserted and then display the disc information.) Disc need not be played.

• If you do not have test disc either VT-501 (DVD) or CTS-1000 (CD-DA), use a commercial disc (for DVD, dual-layer software) after seeing and checking that the disc is neither curved nor foreseen that it may shake at the time of playback.If you

use a disc with bad features, starting time may be slow or disc may not be read.

STANDBY/ON

DISPLAY

TITLE/

3D PHONIC

GROUP RETURN CANCEL

213

5

4

8

7

010 +10

ANGLE

SUB TITLE AUDIO ZOOM

TOP MENU MENU

CHOICE

SLOW

VFP ON SCREEN

PREVIOUS SELECT

CLEAR

6

9

STOP key

ENTER

POWER key

NEXT

FL Display

(for test mode)

BACKWARD SKIP key

(for All initialize : It pushes 2 seconds or more.)

PLAY key

(for test mode)

(No.XA002)1-17

Page 18

3.6 Display of current value of laser

(1) Set the main body at test mode.

(2) Press "CHOICE" key of the remote controller three times. Then, FL display is displayed "CK".

(3) The laser current value can be switched between the value of CD and that of DVD by pressing the following key of the remote

controller.

FL Display (Example)

2530

The number shown in the FL display shows mA of current value of laser.

The first two numbers ("25" in "2530") shows current value of laser at the time of adjustment after the latest all-initialization, 25mA

in this example.

The last two numbers ("30" in "2530") shows the present current value of laser, 30mA in this example.

The first two numbers ("25" in "2530") usually shows current value of laser at the time of shipment, so you can see how the product has been deteriorated by comparing the first two numbers ("25" in "2530") and the last two numbers ("30" in "2530").

CD and DVD:

The laser current value of 80 mA or less is normal.The laser current value of over 81 mA is n ot normal. Laser diode of the

pickup has been deteriorated.

To return to test mode, press "STOP" key of the main body.

3.7 Flap adjustment of the pick-up guide shaft

Please perform flap adjustment of the pick-up guide shaft in the following case:

• Just after you exchange the pick-up.

• Just after you exchange the spindle motor.

• Just after you exchange the traverse mechanism base.

NOTE:

Please perform flap adjustment of the pick-up guide shaft when you exchange the parts above and also when you remove the

parts above.

• When the reading accuracy of the signal is bad (There is a b lock noise in the screen, Screen stops in the outer circumference of a

disc, etc.)

4 key (laser of CD)

5 key (laser of DVD)

STANDBY/ON

DISPLAY

TITLE/

GROUP RETURN CANCEL

3D PHONIC

213

5

6

4

7

SUB TITLE AUDIO ZOOM

ANGLE

TOP MENU MENU

CHOICE

SLOW

PREVIOUS SELECT

CLEAR

6 key

8

9

(display of jitter value)

010 +10

CHOICE key

ENTER

(switch of mode)

VFP ON SCREEN

NEXT

POWER key

Remote controller "4" key --- Laser of CD

Remote controller "5" key --- Laser of DVD

(for test mode and jitter value)

STOP key

FL Display

(for test mode)

PLAY key

1-18 (No.XA002)

Page 19

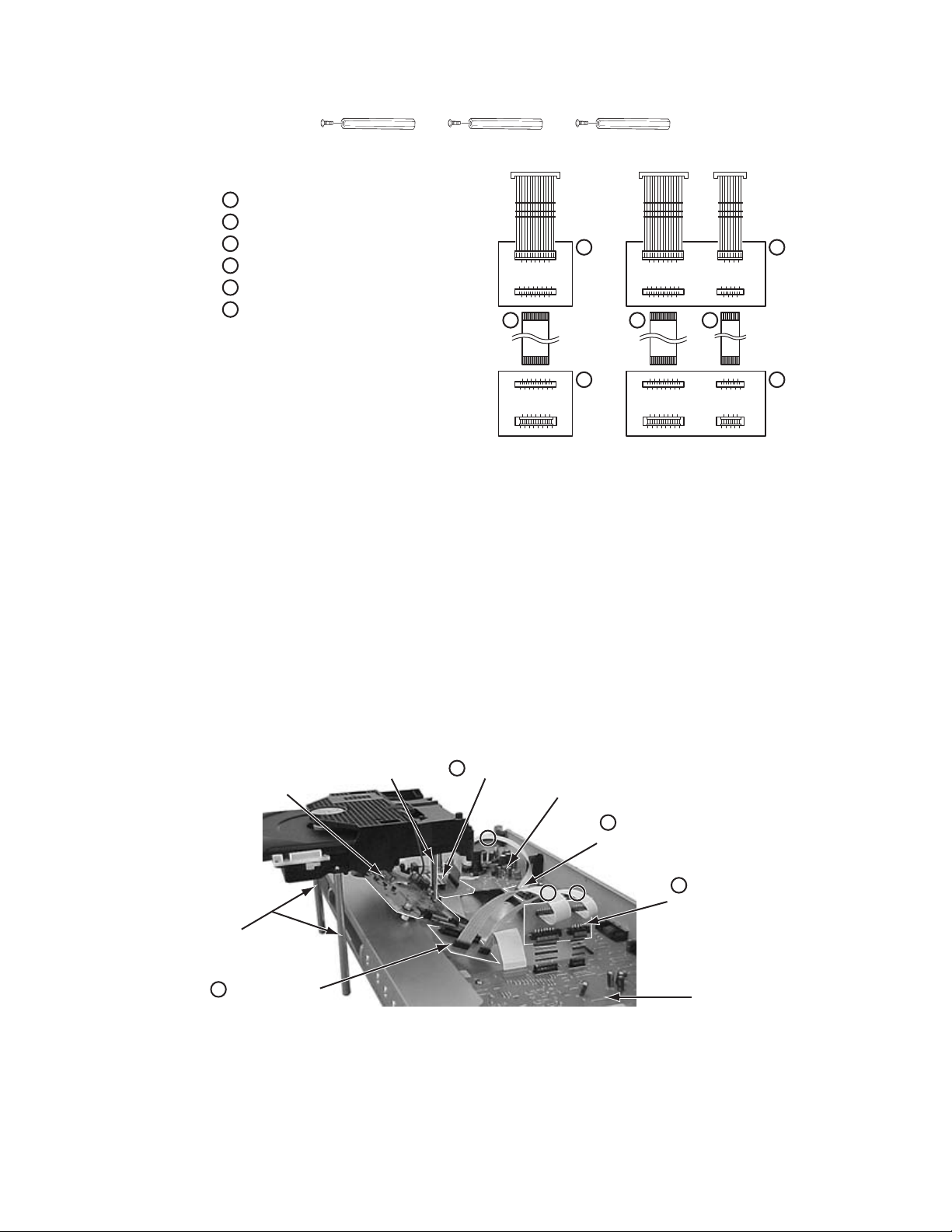

3.7.1 Tool for adjustment

*Stud: One set (four studs), Part number: JIGXVS40 (Note: One of the four studs is not used here.)

* Relay board and extension cord (One set) --- Parts number : EXTXVN30CB

-- Items --

1

Relay board 1 : EXTXVN30CB-1

2

Relay board 2 : EXTXVN30CB-2

3

Relay board 3 : EXTXVN30CB-3

4

Relay board 4 : EXTXVN30CB-4

5

Card wire : 15 pins 15 cm 2 pcs

6

Card wire : 9 pins 15 cm 1 pcs

5 5 6

3

1

4

2

*The phillips screwdriver for adjustment --- goods on the market

*Test disc ---- Parts number : VT-501

3.7.2 Preparation for adjustment

(1) A mechanism assembly is removed with reference to the disassembly method of a service manual.

(2) When the card wire which has connected the power supply board and the output terminal board is extracted at this time, please

connect again.

(3) Three stud is attached in a mechanism assembly, respectively.

(4) Remove the servo control board attached the mechanism assembly.

(If you disconnect the wires connected to the servo control board, connect them again.)

(5) The relay board 2 is connected to the connectors CN601 and CN701 on the output terminal board.

(6) The relay board 4 is connected to the connectors CN902 on the power supply board.

(7) The relay board 1 is connected to the connectors CN502 and CN503 on the servo control board.

(8) The relay board 3 is connected to the connectors CN501 on the servo control board.

(9) Between relay boards, an extension code is inserted, respectively and it connects.

(Be careful of direction of a card wire at this time.)

3

Servo control board

Stud

Relay board 3

55

Power supply board

4

Relay board 4

Stud

1

Relay board 1

55 66

2

Relay board 2

Output terminal

board

(No.XA002)1-19

Page 20

3.7.3 Adjustment

A

(1) Set the main body at test mode.

(2) Press the "CHOICE" key of the remote controller three times, and the FL display is displayed "CK".

(3) Insert a test disc (VT-501), and press the "PLAY" key of the main body.

(4) After a few seconds, press the numeric key "6" of the remote controller. Then, the FL display is displays a jitter value.

(5) Turn the adjustment screws on the underside of the traverse mechanism with phillips screw driver until the maximum jitter value

is displayed on the FL display. (In this model, a bigger jitter value means a better result.)

NOTE:

• Reference values to judge whether the jitter is allowable or not are displayed, instead of actual jitter values.

• Please be sure to perform "all-initialization" and "optimization adjustment of front end parameter" after adjusting.

Traverse mechanism assembly

Loading mechanism assembly

Screw c

POINT:

Turn the adjustment screws a and b to the

same angle in the right direction. And turn

the adjustment screws a and b to the

same angle in the left direction. Then, turn

the screws a and b in either the right or

the left direction to increase the number of

jitter. Don't turn the adjustment screw c.

Screw a

Screw b

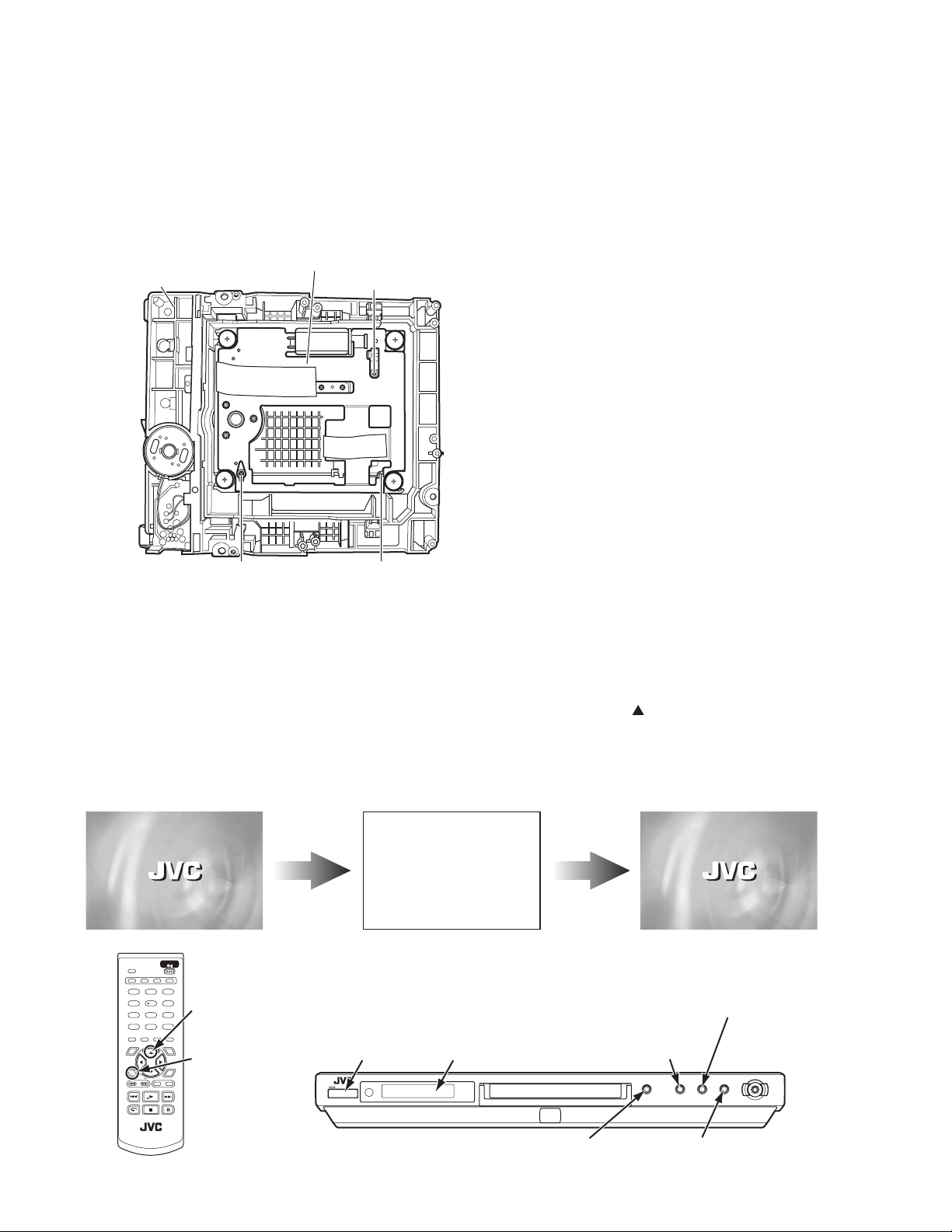

3.8 Upgrading of firmware

The latest firmware for upgrading is updated in "Optical disc CSG" page in JS-net.At the time of service, compare the version of the

product and the latest version, and upgrade the old version into the latest version.

(1) Press "POWER" key of the main body to turn the main body on

(2) Insert the upgrade disc.

(3) When FL display of the main body changes from "READ" to "UP", press "cursor UP" key ( ) of the remote controller.

(4) The entire screen becomes blue, and upgrading starts.

(5) The tray opens automatically. Remove the upgrade disc.

(6) The screen returns to the normal screen. Then, press "POWER" key of the main body. When the stand-by indicator is lighted,

upgrading is completed.

(7) Set the main body at test mode, and perform initialization. Then, confirm the version of the firmware.

Firmware upgrade Disc ... press UP

fter inserting the up-grade disc

STANDBY/ON

DISPLAY

TITLE/

3D PHONIC

GROUP RETURN CANCEL

213

UP key

5

6

4

7

ANGLE

SUB TITLE AUDIO ZOOM

TOP MENU MENU

CHOICE

SLOW

PREVIOUS SELECT

CLEAR

(for firmware upgrade)

8

9

010 +10

CHOICE key

ENTER

(switch of mode)

VFP ON SCREEN

NEXT

Upgrade application initializing...

While upgrading (blue screen)

POWER key

FL Display

NO DISC

When up-grade is completed

PLAY key

(for test mode)

STOP key

(for test mode)

1-20 (No.XA002)

OPEN/CLOSE key

PAUSE key

(for initialize)

Page 21

3.9 Confirm method of operation

Please confirm the operation of the undermentioned item after doing the repair and the upgrade of the firmware.

Initialize Refer to the initialization method.

All-initialize Refer to the All-initialization method.

Parameter adjustment status Set the main body at test mode, and check that the FL display shows " 0".

Opening picture check (Power ON) It should be display "JVC"

Muting working The noise must not be had to the performance beginning when you push "PLAY" button or

at ON/STANDBY.

FL Display The mark and the logo, etc. displayed by each operation must be displayed correctly.

FL Display should light correctly without any unevenness.

All Function button All function buttons should worked correctly with moderate click feeling.

Open and close movement of tray When press OPEN/CLOSE button the tray should move smoothly without any noise.

Remote controller unit working Check the correctly operation in use of remote controller unit.

Reading of TOC Be not long in the malfunction.

Search Both forward-searches and backward-searches should be able to be done.Do not stop be

searching or after the search.

Skip Both forward-skip and backward-skip should be able to be done.Do not stop be after the skip.

Playback Do not find abnormality etc. of tone quality and the picture quality.

Most outside TITLE playback check Play VT-501 TITLE 59 CHAPTER 1 , check normal playback.

(No.XA002)1-21

Page 22

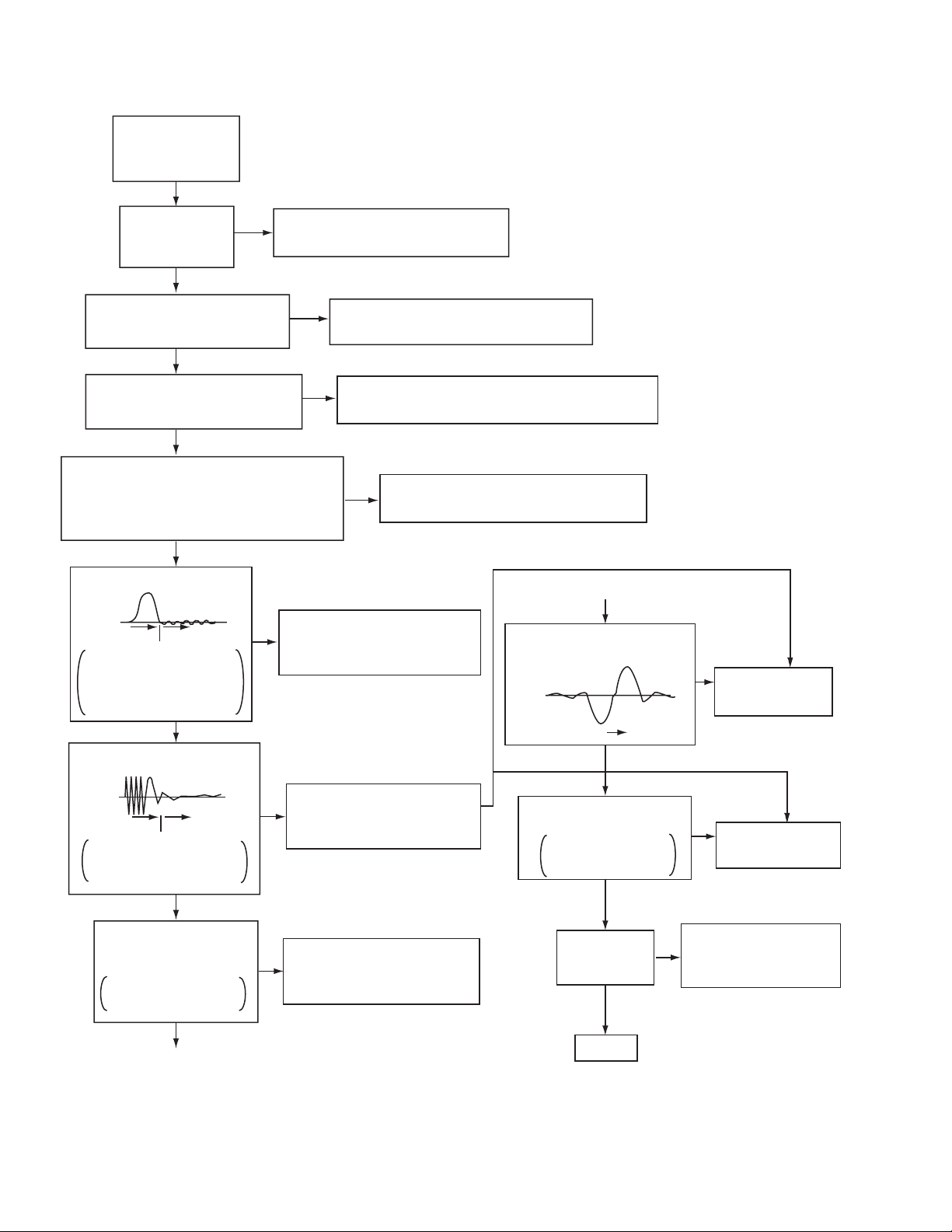

3.10 Troubleshooting

3.10.1 Servo volume

Press OPEN

/CLOSE key

Is tray

operation

Confirmation of tray drive circuit

N

and circuit in surrounding

correct?

Y

Is the traverse moving

along the innermost

N

perimeter for SW detection?

Y

"NO DISC" message appears

Y

immediately after vertical

movement of the pick-up lens

N

The state that DISC does not rotate continues for

several seconds, and becomes NO DISC or an

error display afterwards.

The rotation of DISC becomes high-speed and

abnormal, and becomes NO DISC or an error

display afterwards.

N

Is focus retraction OK?

FE

OFF

Even when it retracts

correctly, if it is out of focus

and makes repeated retries

with a clicking sound, it is

in error.

ON

See "(4) Focus ON error"

N

in "Check points for

individual errors"

Y

Is tracking retraction OK?

See "(3) Traverse movement error"

in "Check points for individual errors"

See "(2) Disk detection, distinction error"

in "Check points for individual errors"

Y

See "(1) Spindle startup error"

in "Check points for individual errors"

Is the inter-layer jump OK?

FE

LO LI

A

Two layers of DVD only.

N

(8) Inter-layer

jump error

Y

TE

OFF

If TE waveform reappears

or fails to converge after the

TE retraction, it is in error.

Is the spindle servo

locked correctly?

Is the RF OUT waveform

locked correctly?

1-22 (No.XA002)

A

ON

See "(5) Tracking ON error"

N

in "Check points for

individual errors"

Has the disc information

been collected?

Stop will result

N

(7) Address read

error

Y

Y

Check (9),(10),(11), and

See "(6) Spindle CLV error"

N

in "Check points for

individual errors"

Is playback

possible?

Y

N

(12) items in "Check points

for individual errors"

Y

OK !

Fig.1

Page 23

3.11 Check points for each error

3.11.1 Spindle start error

(1) Defective spindle motor

• Are there several ohms resistance between each pin of CN201 "1-2","2-3","1-3"?

(The power supply is turned off and measured.)

• Is the sign wave of about 100mVp-p in the voltage had from each terminal?

[ CN201"10"(H1+),"11"(H1-),"7"(H2+),"8"(H2-),"5"(H3+),"6"(H3-) ]

(2) Defective spindle motor driver (IC251)

• Has motor drive voltage of a sine wave or a rectangular wave gone out to each terminal(SM1~3)

of CN201"1,2,3" and IC251"2,4,7"?

• Is FG pulse output from the terminal of IC251"24"(FG) according to the rotation of the motor?

• Is it "L(about 0.9V)" while terminal of IC251"15"(VH) is rotating the motor?

(3) Has the control signal come from servo IC or the microcomputer?

• Is it "L" while the terminal of IC251"18"(SBRK) is operating?

Is it "H" while the terminal of IC251"23"(/SPMUTE) is operating?

• Is the control signal input to the terminal of IC251"22"(EC)?

(changes from VHALF voltage while the motor is working.)

• Is the VHALF voltage input to the terminal of IC251"21"(ECR)?

(4) Is the FG signal input to the servo IC?

• Is FG pulse input to the terminal of IC301"69"(FG) according to the rotation of the motor?

3.11.2 Disc Detection, Distinction error (no disc, no RFENV)

• Laser is defective.

• Front End Processor is defective (IC101).

• APC circuit is defective. --- Q101,Q102.

• Pattern is defective. --- Lines for CN101 - All patterns which relate to pick-up and patterns between IC101

• IC101 --- For signal from IC101 to IC301, is signal output from IC101 "20" (ASOUT) and IC101 "41"(RFENV) and IC101 "22"

(FEOUT)?

3.11.3 Traverse movement NG

(1) Defective traverse driver

• Has the voltage come between terminal of CN101 "2" and "4" ?

(2) Defective BTL driver (IC201)

• Has the motor drive voltage gone out to IC201"17" or "18"?

(3) Has the control signal come from servo IC or the microcomputer?

• Is it "H" while the terminal of IC201"9"(STBY1) ?

• TRSDRV Is the signal input? (IC301 "67")

(4) TRVSW is the signal input from microcomputer? (IC301 "56")

3.11.4 Focus ON NG

• Is FE output ? --- Pattern, IC101

• Is FODRV signal sent ? (R209) --- Pattern, IC301 "115"

• Is driving voltage sent ?IC201 "13", "14" --- If NG, pattern, driver, mechanical unit .

• Mechanical unit is defective.

3.11.5 Tracking ON NG

• When the tracking loop cannot be drawn in, TE shape of waves does not settle.

• Mechanical unit is defective.

Because the self adjustment cannot be normally adjusted, the thing which cannot be normally drawn in is thought.

• Periphery of driver (IC201)

Constant or IC it self is defective.

• Servo IC (IC301)

When improperly adjusted due to defective IC.

(No.XA002)1-23

Page 24

3.11.6 Spindle CLV NG

• IC101 -- "30"(ARF-), "31(ARF+).

• Does not the input or the output of driver's spindle signal do the grip?

• Has the tracking been turned on?

• Spindle motor and driver is defective.

• Additionally, "IC101 and IC301" and "Mechanism is defective(jitter)", etc. are thought.

3.11.7 Address read NG

• Besides, the undermentioned cause is thought though specific of the cause is difficult because various factors are thought.

Mechanism is defective. (jitter)

IC301

The disc is dirty or the wound has adhered.

3.11.8 Between layers jump NG (double-layer disc only)

Mechanism defective

Defect of driver's IC(IC201)

Defect of servo control IC(IC301)

3.11.9 Neither picture nor sound is output

(1) It is not possible search

• Has the tracking been turned on?

• To "(5) Tracking ON NG" in "Check points for each error" when the tracking is not normal.

• Is the feed operation normal?

To "(3) traverse movement NG" in "Check points for each error" when it is not normal.Are not there caught of the feeding mechanism etc?

3.11.10 Picture is distorted or abnormal sound occurs at intervals of several seconds.

Is the feed operation normal?

Are not there caught of the feeding mechanism etc?

3.11.11Others

• The image is sometimes blocked, and the image stops.

• The image is blocked when going to outer though it is normal in suroundings in the disk and the stopping sympton increases.

There is a possibility with bad jitter value for such a symptom.

3.11.12CD During normal playback operation

(1) Is TOC reading normal?

• Displays total time for CD-DA.

• Shifts to double-speed mode for V-CD

(2) Is playback afterwards possible?

(3) When can not do a normal playback

• --:-- is displayed during FL search.

According to [It is not possible to search ] for DVD(9), check the feed and tracking systems.

• No sound is output although the time is displayed.(CA-DA)

DAC, etc, other than servo.

• The passage of time is not stable, or picture is abnormal.(V-CD)

• The wound of the disc and dirt are confirmed.

1-24 (No.XA002)

Page 25

SECTION 4

Description of major ICs

4.1 74LCX373MTC-X (IC512,IC513) : Octal D-type latch

•Pin layout

1OE

2Q0

3D0

4D1

5Q1

6Q2

7

8D3

9Q3

10GND

(TOP VIEW)

20

19

18

17

16

15

14D2

13

12

11

VCC

Q7

D7

D6

Q6

Q5

D5

D4

Q4

LE

• Truth table

INPUTS OUTPUT

LE OE Dn Qn

XHXZ

HLLL

HLHH

LLXQ0

H = HIGH Voltage levelL = LOW Voltage levelZ = High impedanceX = ImmaterialQ0 = Previous Q0 before HIGH to LOW

transition of latch enable

• Pin function

Symbol Description

D0~D7 Data inputs

LE Latch enable input

OE Output enable input

Q0~Q7 3-State latch outputs

• Block diagram

D0

3

D

Q

L

2

Q0

OE

11

LE

1

D1

D2

D3

D4

D5

D6

4

7

8

13

14

D

D

D

D

Q

Q

L

L

5

Q1

Q

L

L

6

9

Q3

12

Q2

17

D

Q

Q

L

15

Q4

Q5

D7

18

D

D

Q

L

Q

L

16

19

Q6

Q7

(No.XA002)1-25

Page 26

4.2 AN8703FH-V (IC101) : Frontend processor

• Pin layout

48 33~

• Block diagram

AGOFST

AGCBAL

DFLTOP

AGCLVL

DCFLT

DCFLT

RFENV

BOTTOM

PEAK

49

~

64

116

23

19

30

31

25

32

41

42

43

32

17

~

Level

Cont.

+-

+-

HOLD EQ

+-+-

~

UDO

40 39 45 44 29 27 56 36 36 28 55 26 61

Level

Cont.

Vol. Adg

VGA

OFTR

Det.

BDO

Det.

OFTR

AGC Cont.

Boost

Cont.

FC

Cont.

AGCO

AGCG

VHALP

VREF2

VREF1

VCC3

VCC2

VCC1

GND3

REG SIF

GND2

GND1

LPC AMP

+-

DTRD

9

10

IDGT

11

STANBY

12

SEN

13

SCK

14

STDI

64

HDTYPE

1

LPC1

2

LPCO1

LPC2

3

LPCO2

4

18

TEOUT

RFINP

RFINN

TESTSG

VFOSHORT

DCRF

RFOUT

RFC

FEOUT

FEN

FBAL

ASOUT

47

48

46

38

35

37

22

21

20

TEN

+-

S-line

J-line

17

TBAL

6

8

POFLT

MON

24

34

RFDIFO

15

RSCL

JLINE

16

+-

+-

VIN8

SW

+-

VIN9

VIN10

AMP

Differential

Phase

TBAL

Det.

EQ EQ EQ EQ

63 57 58 59 60

VIN1

VIN11

VIN12

TBAL

VIN2

VIN3

VIN4

5

+-

+-

FBAL

ADD ADD ADD

7

49 50 51 52 53 54 62

VIN5

VIN6

VIN7

Micro

Det.

ADD

+-

ADD

1-26 (No.XA002)

Page 27

• Pin function

Pin No. Symbol Function

1 LPC1 Laser pin input (DVD head)

2 LPCO1 Laser drive output (DVD head)

3 LPC2 Laser in input (CD head)

4 LPCO2 Laser drive output (CD head)

5 VFOSHORT VFOSHORT control

6 TBAL Tracking balance control

7 FBAL Focus balance control

8 POFLT Track detection threshold level

9 DTRD Data slice data read signal input (for RAM)

10 IDGT Data slice address gate signal input (for RAM)

11 STANBY Standby mode control

12 SEN SEN (serial data input)

13 SCK SCK(serial data input)

14 STDI STDI(serial data I/O)

15 RSCL Reference current setting

16 JLINE J-line vurrent setting

17 TEN Tracking error amplifier inverted input

18 TEOUT Tracking error signal output

19 AGCBAL Offset adjustment for DRC-1

20 ASOUT Full addition signal output

21 FEN Focus error amplifier inverted input

22 FEOUT Focus error signal output

23 AGCOFST Offeset adjustment for DRC-2

24 MON Monitor

25 AGCLVL Output amplitude adjustment for DRC

26 GND2 Ground 2

27 VREF2 VREF2 voltage output

28 VCC2 Power supply 2 (5V)

29 VHALF VHALF voltage output

30 DFLTON Filter amplifier inverted output

31 DFLTOP Filter amplifier positive output

32 DCFLT Filter output capacitance connection

33 GND3 Groud 3

34 RFDIFO Raidal differntial output

35 RFOUT RF full-addition amplifier output

36 VCC3 Power supply 3 (3.3V)

37 RFC Filter for RF-group delay correction amplifier

38 DCRF DC-cut filter for RF full-addition amplifier

39 OFTR OFTR output

40 BDO BDO output

41 RFENV RF envelope output

42 BOTTOM Bottom envelope detection filter

43 PEAK Peak envelope detection filter

44 AGCG AGC amplifier again control

45 AGCO AGC amplifier level control

(No.XA002)1-27

Page 28

Pin No. Symbol Function

46 TESTSG TEST signal input

47 REFINP RF signal positive input

48 RFINN RE signal inverterd input

49 VIN5 Internal four-partition (CD) RF input 1

50 VIN6 Internal four-partition (CD) RF input 2

51 VIN7 Internal four-partition (CD) RF input 3

52 VIN8 Internal four-partition (CD) RF input 4

53 VIN9 Internal four-partition (DVD) RF input 2

54 VIN10 Internal four-partition (DVD) RF input 1

55 VCC1 Power supply 1 (5V)

56 VREF1 VREF1 voltage output

57 VIN1 Internal four-partition (DVD) RF input 1

58 VIN2 Internal four-partition (DVD) RF input 2

59 VIN3 Internal four-partition (DVD) RF input 3

60 VIN4 Internal four-partition (DVD) RF input 4

61 GND1 Groud 1

62 VIN11 3-deam sub (CD) input 2

63 VIN12 3-deam sub (CD) input 1

64 HDTYPE HD type selection

1-28 (No.XA002)

Page 29

4.3 AK4381VT-X (IC402) : 2ch DAC

•Pin layout

• Block diagram

MCLK

BICK

SDTI

LRCK

PDN

CSN

CCLK

CDTI

CSN

CCLK

CDTI

LRCK

BICK

SDTI

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

DZFL

DZFR

VDD

VSS

AOUTL+

AOUTLAOUTR+

AOUTR-

MCLK

VDD

VSS

DZFL

uP

Interface

De-emphasis

Control

Clock

Divider

DZFR

AOUTL+

AOUTL-

Audio

8X

Interpolator

Modulator

SCF

Data

Interface

8X

Interpolator

Modulator

SCF

AOUTR+

AOUTR-

PDN

• Pin functions

Pin No. Symbol I/O Description

1 MCLK I Master clock input terminal

2 BICK I Audio serial data clock terminal

3 SDTI I Audio serial data input terminal

4 LRCK I L/R Clock terminal

5 PDN I Power down mode terminal

6 CSN I Chip select

7 CCLK I Control data input terminal

8 CDTI I Control data input terminal

9 AOUTR- O Rch negative analog output terminal

10 AOUTR+ O Rch positive analog output terminal

11 AOUTL- O Lch negative analog output terminal

12 AOUTL+ O Lch positive analog output terminal

13 VSS - Connect to ground

14 VDD - Power supply terminal

15 DZFR O Rch data zero input detection terminal

16 DZFL O Lch data zero input detection terminal

(No.XA002)1-29

Page 30

4.4 BA6664FM-X (IC251) : Spindle motor driver

• Pin layout

NC

A3

NC

A2

NC

NC

A1

GND

H1+

H1-

H2+

H2-

H3+

H3-

1

2

3

4

5

6

7

29 30

8

9

10

11

12

13

14

RNF

28

VM

27

GSW

26

Vcc

25

FG

24

PS

23

EC

22

ECR

21

FR

20

FG2

19

SB

18

CNF

17

BR

16

VH-

15

• Block diagram

A3

2

A2

4

A1

TL

7

9

10

11

12

13

8

HALL AMP

+

-

+

-

+

-

+

-

+

-

+

-

GND

H1+

H1-

H2+

H2-

H3+

H3-

14

DRIVER

GAIN

CONTROL

CURRENT

SENSE AMP

R

D Q

CK Q

TSD

+ -

SENSE AMP

SHORT BRAKE

BRAKE MODE

PS

TOROUE

VCC

Hall Bias

GAIN

SWITCH

VCC

+

-

VCC

28

27

26

25

24

23

22

21

20

19

18

17

16

15

R

NF

VM

GSW

VCC

FG

PS

EC

ECR

FR

FG2

SB

CNF

BR

VH

1-30 (No.XA002)

Page 31

• Pin function (BA6664FM-X)

Pin No. Symbol I/O Description

1 NC - Non connect

2 A3 O Output 3 for spindle motor

3 NC - Non connect

4 A2 O Output 2 for spindle motor

5 NC - Non connect

6 NC - Non connect

7 A1 O Output 1 for spindle motor

8 GND - Connect to ground

9 H1+ I Positive input for hall input AMP 1

10 H1- I Negative input for hall input AMP 1

11 H2+ I Positive input for hall input AMP 2

12 H2- I Negative input for hall input AMP 2

13 H3+ I Positive input for hall input AMP 3

14 H3- I Negative input for hall input AMP 3

15 VH I Hall bias terminal

16 BR - Non connect

17 CNF - Capacitor connection pin for phase compensation

18 SB I Short brake terminal

19 FG2 - Non connect

20 FR - Non connect

21 ECR I Torque control standard voltage input terminal

22 EC I Torque control voltage input terminal

23 PS O Start/stop switch (power save terminal)

24 FG O FG signal output terminal

25 VCC - Power supply for signal division

26 GSW O Gain switch

27 VM - Power supply for driver division

28 RNF O Resistance connection pin for output current sense

29 - Connect to ground

30 - Connect to ground

(No.XA002)1-31

Page 32

4.5 BA5983FM-X (IC201) : 4-channel driver

• Block diagram

27

26

25

28

Vcc

10k

24

20k

23 22 30

10k

20k

21

STAND BY

CH4

20

Vcc

19

18

10k

10k

17 16

10k

10k

Level Shift

10k

10k

15

10k

10k

Level Shift

10k

10k

1

2

3

5

4

10k

6

• Pin function

Pin No. Symbol I/O Description

1 BIAS IN I Input for Bias-amplifier

2 OPIN1(+) I Non inverting input for CH1 OP-AMP

3 OPIN1(-) I Inverting input for CH1 OP-AMP

4 OPOUT1 O Output for CH1 OP-AMP

5 OPIN2(+) I Non inverting input for CH2 OP-AMP

6 OPIN2(-) I Inverting input for CH2 OP-AMP

7 OPOUT2 O Output for CH2 OP-AMP

8 GND - Substrate ground

9 STBY1 I Input for CH1/2/3 stand by control

10 PowVcc1 - Vcc for CH1/2 power block

11 VO2(-) O Inverted output of CH2

12 VO2(+) O Non inverted output of CH2

13 VO1(-) O Inverted output of CH1

14 VO1(+) O Non inverted output of CH1

15 VO4(+) O Non inverted output of CH4

Level Shift

10k

10k

Level Shift

10k

10k

10k

10k

10k

10k

10k

STAND BY

CH1/2/3

729 891011121314

Vcc

Pin No. Symbol I/O Description

16 VO4(-) O Inverted output of CH4

17 VO3(+) O Non inverted output of CH3

18 VO3(-) O Inverted output of CH3

19 PowVcc2 - Vcc for CH3/4 power block

20 STBY2 I Input for Ch4 stand by control

21 GND - Substrate ground

22 OPOUT3 O Output for CH3 OP-AMP

23 OPIN3(-) I Inverting input for CH3 OP-AMP

24 OPIN3(+) I Non inverting input for CH3 OP-AMP

25 OPOUT4 O Output for CH4 OP-AMP

26 OPIN4(-) I Inverting input for CH4 OP-AMP

27 OPIN4(+) I Non inverting input for CH4 OP-AMP

28 PreVcc - Vcc for pre block

29 - Connect to ground

30 - Connect to ground

1-32 (No.XA002)

Page 33

4.6 SST39VF160-7DD (IC509) : 16M EEPROM

A

•Pin layout

• Block diagram

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

/WE

/RST

NC

NC

R/B

A18

A17

A7

A6

A5

A4

A3

A2

A1

19~A0

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

48

A16

47

/BYTE

46

Vss

45

D15

44

D7

43

D14

42

D6

41

D13

40

D5

39

D12

38

D4

37

VCC

36

D11

35

D3

34

D10

33

D2

32

D9

31

D1

30

D8

29

D0

28

/OE

27

Vss

26

/CE

25

A0

16,777,216Bit

X-Decoder

EEPROM

Cell Array

Address Buffer & Latches

Y-Decoder

/CE

/OE

Control Logic

I/O Buffers & Data Latches

/WE

DQ15~DQ0

• Pin function

Symbol Pin name Function

A19~A0 Address Inputs To provide memory addresses. During sector erase A19~A11 address lines will select the

sector. During block erase A19~A15 address lines will select the block.

DQ15~DQ0 Data Input/Output To output data during read cycles and receive input data during write cycles. Data is

internally latched during a write cycle. The outputs are in tri-state when /OE or /CE is high.

/CE Chip Enable To activate the device when /CE is low.

/OE Output Enable To gate the data output buffers.

/WE Write Enable To control the write operations.

VCC Power Supply To provide 3-volt supply ( 2.7V-3.6V ).

Vss Ground Connect to ground

NC No Connection

(No.XA002)1-33

Page 34

4.7 JCE8044 (IC501) : AV Decoder

• Pin layout

240 181

1

180

• Block diagram

digital audio

serial

peripherals

DVD data

60

61 120

Serial

controller

121

audio DAC

port

digital audio

Audio

output

processor

DVD

A/V

+

CSS

Audio

DSP

Demux

engine

MPEG

Video

decoder

SDRAM

controller

Video I/O port

Video

output

processor

RISC

uProcessor

+ cache

NTSC

PAL

SCART

encoder

XBUS

controller

Video

XBUS

SDRAM

• Pin function

Pin No. Symbol I/O Description

1 VDDio - Power supply terminal 3.3V

2,3 MD10,11 I/O SDRAM Data bus terminal

4 VDD - Power supply terminal 1.8V

5 MD12 I/O SDRAM Data bus terminal

6 VSSio - Connect to ground

7~9 MD13~15 I/O SDRAM Data bus terminal

10 VDDio - Power supply terminal 3.3V

11 DQM1 O SDRAM Data byte enable

12,13 MA9,8 O SDRAM Address bus terminal

14 VSSio - Connect to ground

15,16 MA7,6 O SDRAM Address bus terminal

17 VSS - Connect to ground

18 MA5 O SDRAM Address bus terminal

19 VDDio - Power supply terminal 3.3V

20,21 MA4,3 O SDRAM Address bus terminal

22 MCLK O SDRAM Clock output

23 VSSio - Connect to ground

24 CKE O SDRAM Clock enable output

1-34 (No.XA002)

Page 35

Pin No. Symbol I/O Description

25,26 MA2,1 O SDRAM Address bus terminal

27 VDDio - Power supply terminal 3.3V

28 MA0 O SDRAM Address bus terminal

29 MA10 O SDRAM Address bus terminal

30 MA11 - Non connect

31 VSSio - Connect to ground

32,33 MA12,13 O SDRAM Address bus, reserved for terminal compatibility with 64Mb SDRAM

34 VDD - Power supply terminal 1.8V

35 CS0 O SDRAM Primary bank chip select

36 VDDio - Power supply terminal 3.3V

37 RAS O SDRAM Command bit

38 CAS O SDRAM Command bit

39 WE O SDRAM Command bit

40 VSSio - Connect to ground

41 DQM0 O SDRAM Data byte enable

42 DQM2 O SDRAM Data byte enable

43 MD16 I/O SDRAM Data bus terminal

44 VDDio - Power supply terminal 3.3V

45,46 MD17,18 I/O SDRAM Data bus terminal

47 VSS - Connect to ground

48 MD19 I/O SDRAM Data bus terminal

49 VSSio - Connect to ground

50~52 MD20~22 I/O SDRAM Data bus terminal

53 VDDio - Power supply terminal 3.3V

54~56 MD23~25 I/O SDRAM Data bus terminal

57 VSSio - Connect to ground

58~61 MD26~29 I/O SDRAM Data bus terminal

62 VDDio - Power supply terminal 3.3V

63,64 MD30,31 I/O SDRAM Data bus terminal

65 DQM3 O SDRAM Data byte enable

66 CS1 O SDRAM Extension bank chip select

67 VSSD - Connect to ground

68 SPDIF O S/PDIF Digital audio output terminal

69 VSSio - Connect to ground

70 ADC I Digital audio input for digital micro; can be used as GPIO

71 AOUT3 O Serial audio output data to audio DAC for left and right channels for down-mix

72 AOUT2 O Serial audio output data to audio DAC for surround left and right channels

73 AOUT1 O Serial audio output data to audio DAC for center and LFE channels

74 AOUT0 O Serial audio output data to audio DAC for left and right channels

75 VDDio - Power supply terminal 3.3V

76 PCMCLK O Audio DAC PCM sampling clock frequency, common clock for DACs and ADC

77 VDD - Power supply terminal 1.8V

78 ACLK O Audio interface serial data clock, common clock for DACs and AD converter

79 LRCLK O Left / right channel clock, common clock for DACs and ADC

80 SRST O Active low RESET signal for peripheral reset

81 RSTP I RESET_Power : from system, used to reset frequency synthesizer and rest of chip

(No.XA002)1-35

Page 36

Pin No. Symbol I/O Description

82 VSSio - Connect to ground

83 RXD1 I UART1 Serial data input from external serial device, used for IR receiver

84 SSPIN1 I/O SSP1 Data in or 16X clock for USART function in UART1

85 VSS - Connect to ground

86 SSPOUT1 I/O SSP1 Data out or UART1 data-terminal-ready signal

87 SSPCLK1 I/O SSP1 Clock or UART1 clear-to -send signal

88 SSPCLK0 I/O SSP0 Clock or request-to-send function in UART1

89 VDD - Power supply terminal 1.8V

90 SSPIN0 I/O SSP0 Data in or 16X clock for USART function in UART0

91 VDDio - Power supply terminal 3.3V

92 SSPOUT0 I/O SSP0 Data out or UART0 data-terminal-ready signal

93 TXD0 I/O UART0 Serial data output to an external serial device

94 RXD0 I UART0 Serial data input from external serial device

95 CTS0 I/O UART0 Clear-to-send signal

96 RTS0 I/O UART0 Request-to-send signal

97 VSSio - Connect to ground

98 CXI I Crystal input terminal for on-chip oscillator or system input clock

99 CXO O Crystal output terminal for on-chip oscillator

100 OSCVSS - Connect to ground for oscillator

101 OSCVDD - Power supply terminal for oscillator 1.8V

102 MVCKVDD - Power supply terminal for main and video clock PLL 3.3V

103 SCEN I Scan chain test enable

104 MVCKVSS - Connect to ground for main and video clock PLL

105 ACLKVSS - Connect to ground for audio clock PLL

106 SCMD I Scan chain test mode

107 ACLKVDD - Power supply terminal for audio clock PLL 3.3V

108 VDDDAK - Power supply terminal for DAC digital 1.8V

109 VSSDAC - Connect to ground for DAC digital

110 Cr/R O Video signal output (Cr output : composite/component Red output)

111 IOM O Cascaded DAC differential output used to dump current into external resistor for power

112 C/Cb/B O Video signal output (Chrominance output for NTSC/PAL S-Video Cb output for

component Blue output)

113 VAA3 - Power supply terminal for DAC analog 3.3V

114 Y/G O Video signal output (Luminance for S-Video and component Green output)

115 VSSA - Connect to ground for DAC analog

116 VREF - Non connect

117 VAA 118 CVBS/C O Video signal output (Composite video Chrominance output for S-Video)

119 RSET O Current setting resistor of output DACs

120 COMP O Compensation capacitor connection

121 VSS - Connect to ground

122 VCLK - Non connect

123 DISCSTP - Non connect

124 DISCSET - Non connect

125 VDDio - Power supply terminal 3.3V

126 SLEEP - Non connect

1-36 (No.XA002)

Page 37

Pin No. Symbol I/O Description

127 TRVSW - Non connect

128 HFMON - Non connect

129 SBAK - Non connect

130 HAGUP - Non connect

131 VI02 - Non connect

132 VSSio - Connect to ground

133 DRVMUTE - Non connect

134 SPMUTE - Non connect

135 VDD - Power supply terminal 1.8V

136~139 AD31~28 I/O Multiplexed address / data bus terminal

140 VDDio - Power supply terminal

141~144 AD27~24 I/O Multiplexed address / data bus terminal

145 PWE3 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

146 AD23 I/O Multiplexed address / data bus terminal

147 VSSio - Connect to ground

148~153 AD22~17 I/O Multiplexed address / data bus terminal

154 VDDio - Power supply terminal 3.3V

155 AD16 I/O Multiplexed address / data bus terminal

156 PWE2 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

157158 AD15,14 I/O Multiplexed address / data bus terminal

159 VDD - Power supply terminal 1.8V

160 SCLK O External bus clock used for programmable host peripherals

161 ACK I/O Programmable WAIT/ACK/RDY control

162 VSSio - Connect to ground

163~168 AD13~8 I/O Multiplexed address / data bus terminal

169 VDDio - Power supply terminal 3.3V

170 PWE1 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

171 VSS - Connect to ground

172~176 AD7~3 I/O Multiplexed address / data bus terminal

177 VSSio - Connect to ground

178~180 AD2~0 I/O Multiplexed address / data bus terminal

181 VDDio - Power supply terminal 3.3V

182 PWE0 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

183 ALE I/O Address latch enable

184~187 LA0~3 I/O Latched address 0~3

188 VSSio - Connect to ground

189 RD I/O Read terminal

190 LHLDA O Bus hold acknowledge in slave mode

191 LHLD I Bus hold request from external master in slave mode

192 VDD - Power supply terminal 1.8V

193 PCS0 O Peripheral chip select 0, generally used for enabling the program store ROM/FLASH

194195 XI01,02 I/O Programmable general purpose external input/output

196 VDDio - Power supply terminal 3.3V

197~200 XI03~06 I/O Programmable general purpose external input/output

201 VSS - Connect to ground

202 SODCCS I SODC Chip select

(No.XA002)1-37

Page 38

Pin No. Symbol I/O Description

203 ADSCIRQ I Interrupt input

204 VSSio - Connect to ground

205 XI09 I/O Programmable general purpose external input/output

206~208 XID10~12 I/O Programmable general purpose external input/output

209 ODCIRQ I Interrupt input

210 VDDio - Power supply terminal 3.3V

211 ODCIRQ2 I Interrupt input

212 VDD - Power supply terminal 1.8V

213 DSYNC I DVD Parallel mode sector sync

214 ODCIRQ2 I Interrupt input

215 DCLK I Data sampling clock

216 DSTB I Parallel mode data valid, serial mode left/right clock

217 DVD0 I DVD Drive parallel data port

218 VSSio - Connect to ground

219~223 DVD1~5 I DVD Drive parallel data port

224 VDDio - Power supply terminal 3.3V

225226 DVD6,7 I DVD Drive parallel data port

227 MD0 I/O SDRAM Data bus terminal

228 VSSio - Connect to ground

229 MD1 I/O SDRAM Data bus terminal

230 VSS - Connect to ground

231232 MD2,3 I/O SDRAM Data bus terminal

233 VDDio - Power supply terminal 3.3V

234~236 MD4~6 I/O SDRAM Data bus terminal

237 VSSio - Connect to ground

238~240 MD7~9 I/O SDRAM Data bus terminal

1-38 (No.XA002)

Page 39

4.8 UPD789074MC-024 (IC701) : System controller

•Pin layout

NTB

S/COMP

VPP

RESET

X2

X1

VSS

VDD

TCLOSE

TOPEN

AVCI

REMO

SWCLOSE

SWOPEN

RXD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GAINCNT

30

FASTPLAY

29

NC

28

E/OTHER

27

LMUTE

26

AVCO

25

P.ON/STANDB

24

CPURST

23

MUTE

22

FLDIN

21

FLDOUT

20

FLCLK

19

FLSTB

18

INTP

17

TXD

16

• Pin function

Pin No. Symbol I/O Description

1 NTB I NTSC(L)/PAL(H) switching signal input

2 S/COMP I S(L)/COMPORNENT(H) output switching signal input

3 VPP - The power supply for on board to writing

4 RESET I Reset input (L:reset)

5 X2 - Clock (5MHz)

6 X1 - Clock (5MHz)

7 VSS - Connect to ground

8 VDD - Power supply terminal +3.3V

9 TCLOSE O PWM signal output for tray close

10 TOPEN O PWM signal output for tray open

11 AVCI I AV Compulink control data input

12 REMO I Remote control signal input

13 SWCLOSE I Tray switch signal input 1 L:Full open L:Movement H:Full close

14 SWOPEN I Tray switch signal input 2 L:Full open H:Movement H:Full close

15 RXD I Decoder serial communication data input

16 TXD O Decoder serial communication data output

17 INTP O Decoder serial communication interruption signal output

18 FLSTB O FL Driver strobe output

19 FLCLK O FL Driver clock output

20 FLDOUT I Data input from FL Driver

21 FLDIN O Data output to FL Driver

22 MUTE O Audio muting output H:muting

23 CPURST O LSI Reset output L:reset

24 P.ON/STANDB O Power ON output

25 AVCO O AV Compulink control data output

26 LMUTE O Motor driver muting output H:mute

27 E/OTHER I Europe specification (H)/except Europe specification switching signal input

28 NC O Not use

29 FASTPLAY O Quick playback LED (green) signal output

30 GAINCNT O The signal output for KARAOKE switching L:At normal H:At KARAOKE

(No.XA002)1-39

Page 40

4.9 MN103S26EDC-H (IC301) : Super optical disc controller

• Terminal layout

176 133

1

132

• Block diagram

44

45 88

Analog

Servo I/O

(core 1 I/O)

Servo core

(core 2)

RAM

89

DVD-ROM

Formatter

CGEN

MODE

CD-PRE

Instruction

memory

(40KB)

Data

memory

(6KB)

General purpose IO bus

DMA

I/F

High speed IO bus

32 bit

CPU core

ECC

Host I/F

MPEG I/F

DMA

BCU

DRAMC

ATAPI

2Mbit