Page 1

SERVICE MANUAL

DVD VIDEO PLAYER

XV-M50BK

TV DVD

STANDBY/ON

DISC

SELECT

TV DVD

PLAY

3D

TV/VIDEO

MODE

PHONIC

CANCEL

RETURN

TV1 TV2 TV3

123

TV4 TV5 TV6

4

56

TV7 TV8 TV9

89

7

TV

-/-- TV0 MUTING

0+1010

THEATER

POSITION

SUBTITLEANGLE

AUDIO

DIGEST

S

U

IO

V

E

R

P

SELECT

R

A

E

L

C

–

W

O

L

S

E

L

T

I

T

+

CH

VOL

-

ENTER

C

-

CH

H

O

I

C

E

RM-SXVM50J REMOTE CONTROL

ZOOM

N

E

X

T

S

T

R

O

B

E

S

L

O

W

+

M

E

N

U

VOL

+

Y

A

L

P

S

I

D

STANDBY

STANDBY/ON

PLAY & EXCHANGE

DVD / VIDEO CD / CD

10-bit/27MHz VIDEO D/A CONVERTER

DOLBY

D I G I T A L

3

DISC

2

DISC

1

DISC

XV-M50 DVD/CD PLAYER

DISC TITLE CHAP RESUME THEATER

DVD

EACH

SKIP

DISC 3

3

DISC 2

2

DISC 1

1

PAUSEPLAYSTOP

XV-M50BK

Contents

Safety precautions ------------------------ 1-2

Preventing static electricity ------------- 1-3

Precautions for Service ------------------ 1-4

Importance admistering point

on the safety ----- 1-5

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

Area Suffix

J ------------- U.S.A.

C ---------- Canada

Disassembly method -------------------- 1-6

Adjustment method ----------------------- 1-21

Description of major ICs ---------------- 1-25

No.A0008

Jun. 2001

Page 2

XV-M50BK

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the warranty

and will further relieve the manufacture of responsibility for personal injury or property damage

resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after reassembling.

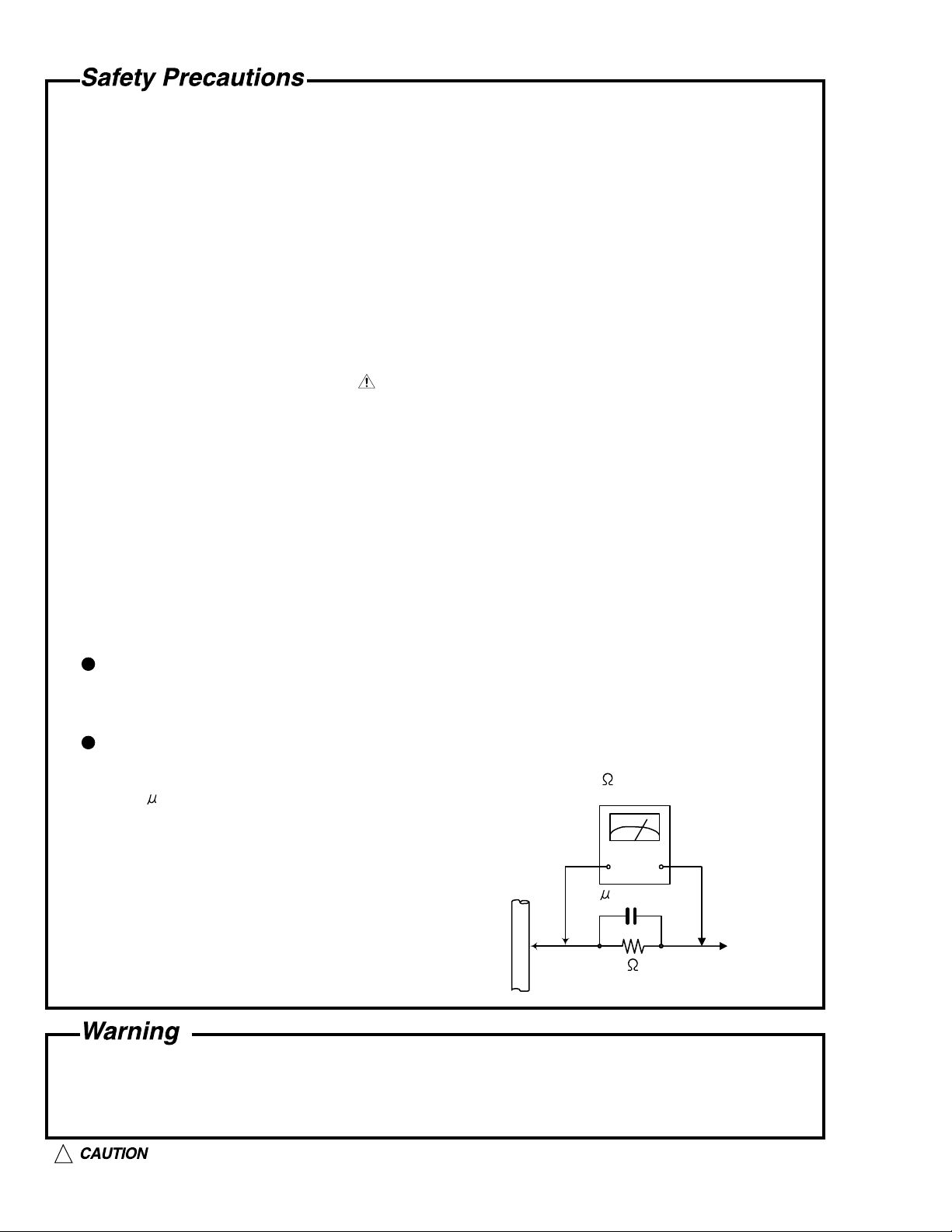

5. Leakage current check (Electrical shock hazard testing)

After reassembling the product, always perform an isolation check on the exposed metal parts of

the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Move the resistor connection to each exposed

metal part, particularly any exposed metal part

having a return path to the chassis, and measure

the AC voltage across the resistor. Now, reverse

the plug in the AC outlet and repeat each

measurement. voltage measured Any must not

0.15 F AC TYPE

1500 10W

Place this

probe on

each exposed

metal part.

exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

Good earth ground

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

XV-M50BK

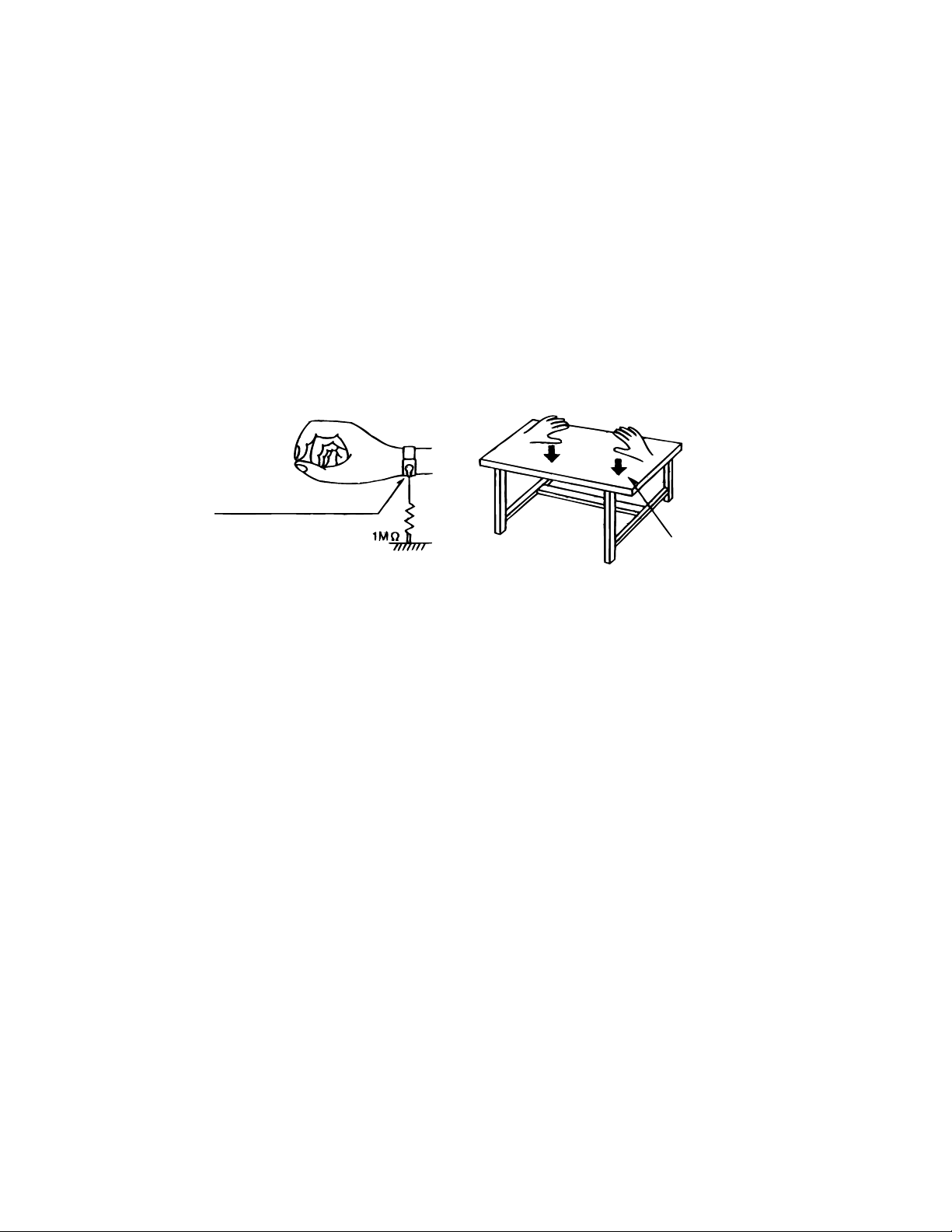

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the next page.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. For specific details, refer to the replacement procedure in the text. Be careful not to take too long a time

when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-3

Page 4

XV-M50BK

Precautions for Service

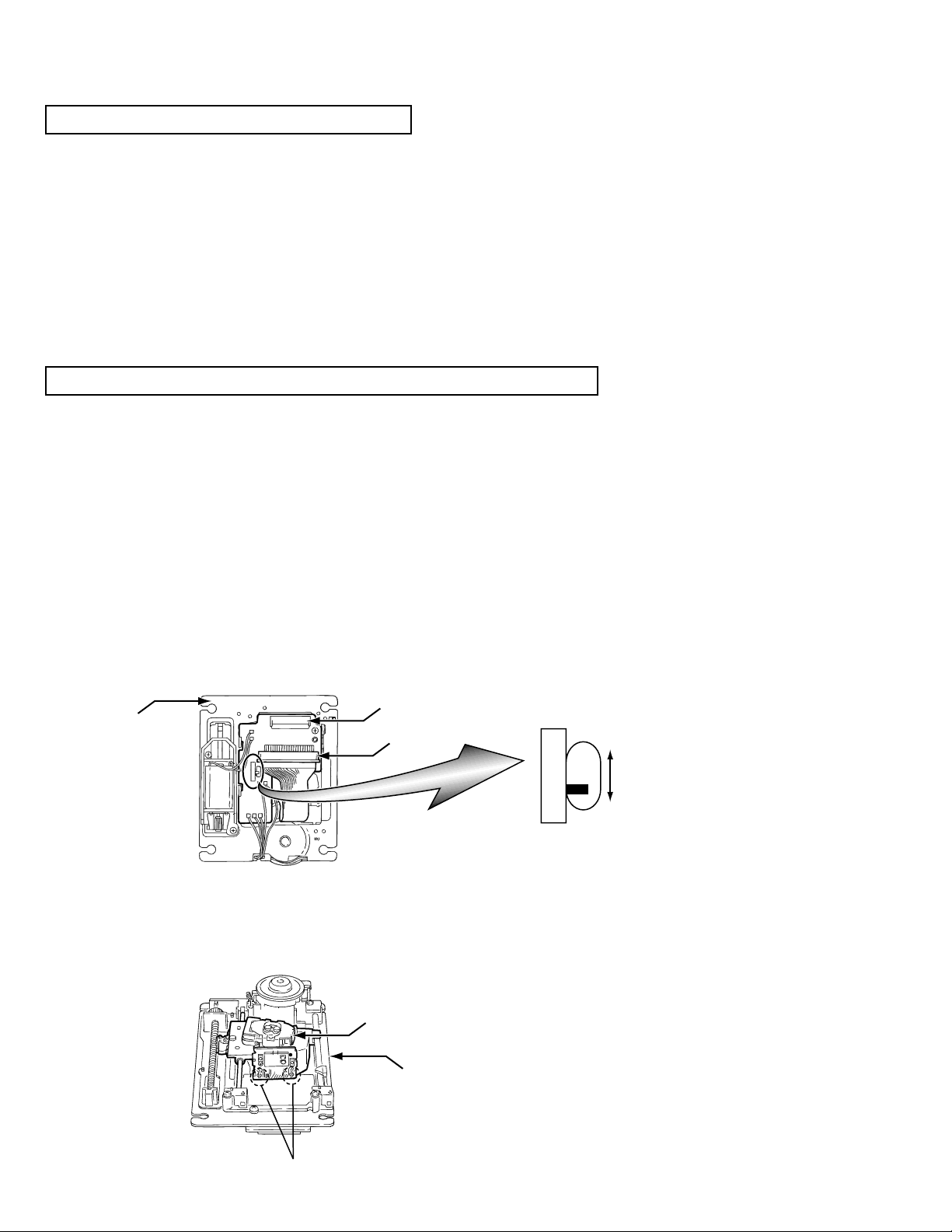

Handling of Traverse Unit and Laser Pickup

1. Do not touch any peripheral element of the pickup or the actuator.

2. The traverse unit and the pickup are precision devices and therefore must not be subjected to

strong shock.

3. Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the

internal power supply of the tester.)

4. When replacing the pickup, after mounting a new pickup, remove the solder on the short land

which is provided at the center of the flexible wire to open the circuit.

5. Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the

characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body. Before repairing peripheral elements of the traverse

unit or pickup, be sure to take the following electrostatic protection:

1. Wear an antistatic wrist wrap.

2. With a conductive sheet or a steel plate on the workbench on which

the traverse unit or the pick up is to be repaired, ground the sheet

or the plate.

When you remove the traverse mechanism from the servo control substrate

The laser diode of pick-up might be destroyed by static electricity and set switch (S11) on the pick-up board

on "SHORT" side, please before removing the card wire from connector (CN10).

Moreover, please set switch (S11) on "OPEN" side after assembling and inserting the card wire in

connector (CN10) without fail at times.

Traverse

mechanism

CN10

CN12

SWITCH S11

SHORT

OPEN

When you remove the pick-up from the traverse mechanism

The laser diode of the pick-up might be destroyed by static electricity, and solder with part a, please before

extracting a flexible wire from connector (CN12).

Moreover, please remove solder in part a after inserting a flexible wire in connector (CN12).

1-4

Pick-up

Traverse

mechanism

Soldering part

Page 5

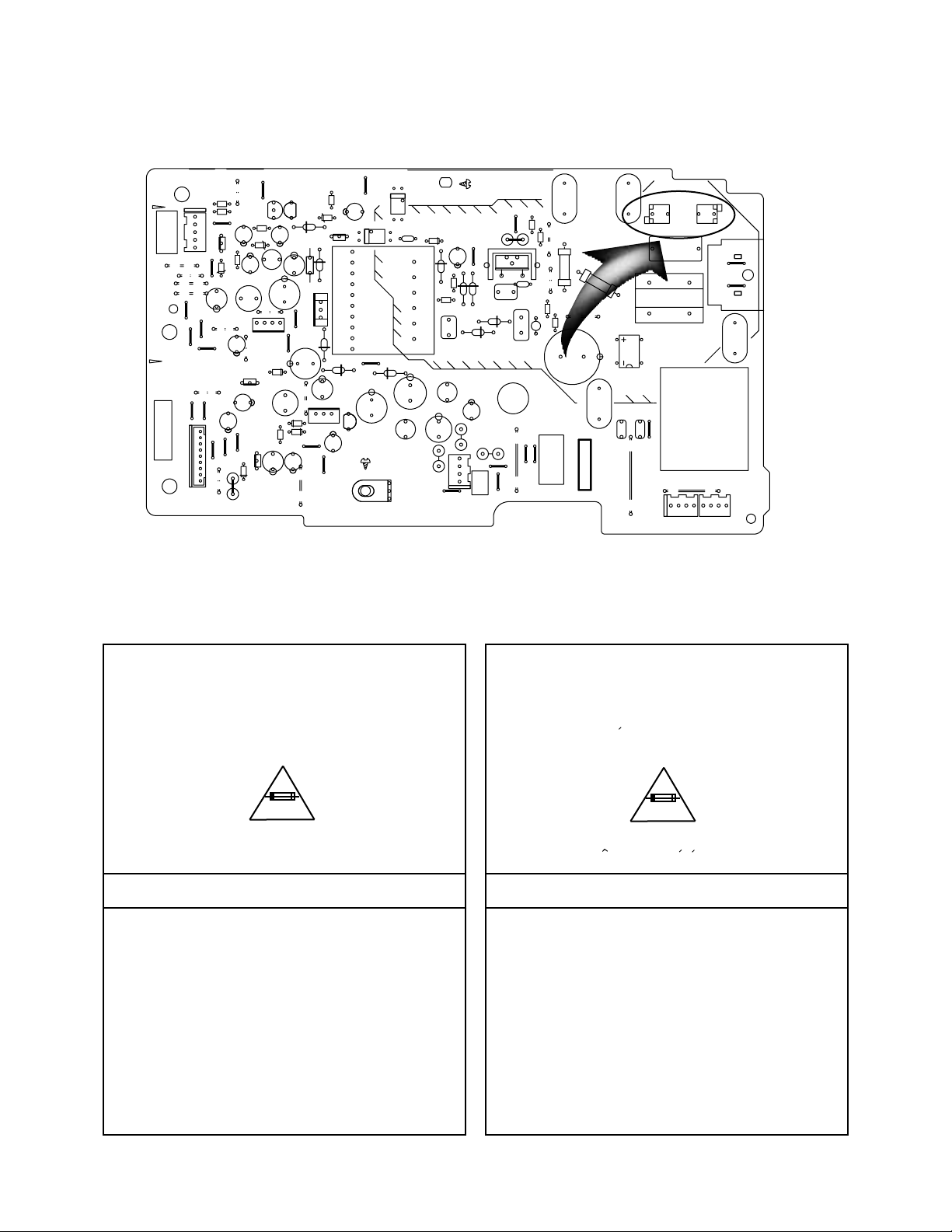

Importance Admistering point on the Safety

F901

D954

D991

IC953

R960

D952

T901

B9015

Q991

D956

C978

C992

CP952

EP951

B9016

B9017

PC901

C982

PC902

L957

D957

C918

C987

L959

C984

K952

D911

C909

D910

R903

K953

CN981

B9018

C914

R904

C989

D908

D902

D904

B9030

C913

D903

K951

K902

B9024

HS901

B9019

B9020

B9023

IC901

C908

S1B

B9601

R908

C915

B9021

R906

R901

LEA10018-

B9022

A1

C906

B9111

B9206

R907

R910

R911

C907

B9207

C916

C905

C912

1.6A/125V

FC902

C902

L901

D901

C911

B9025

B9801

B9501

B9201

B9102

B9202

B9203

CN971

B9031

B9005

B9008

B9004

B9006

B9113

CN961

B9003

C966

B9007

B9029

R957

B9002

Q953

D950

B9104

B9107

C969

B9001

B9013

B9101

R956

C962

R980

B9028

K954

L952

C974

C964

C973

D974

B9106

Q965

B9010

R953

D960

IC951

Q966

Q951

C965

B9105

D970

L955

R976

C995

L951

C979

CP951

C960

B9011

B9012

D973

D972

C963

R954

B9204

C996

B9301

D951

D953

C997

B9014

F901

FC901

XV-M50BK

P901

B9026

B9027

C904

CN952 CN951

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : 1.6 A / 125 V

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

F901 : 1.6 A / 125 V

1-5

Page 6

XV-M50BK

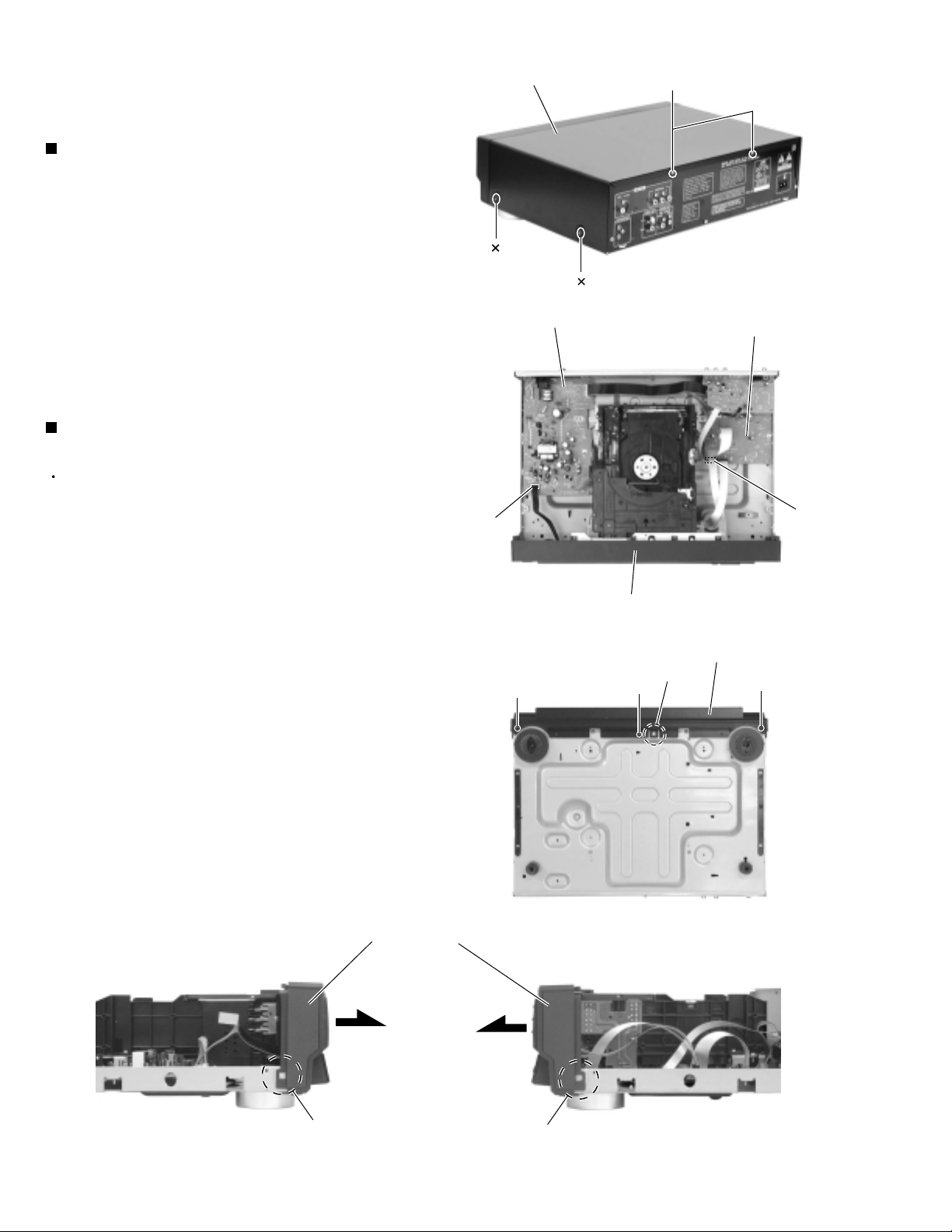

Disassembly method

<

Main body

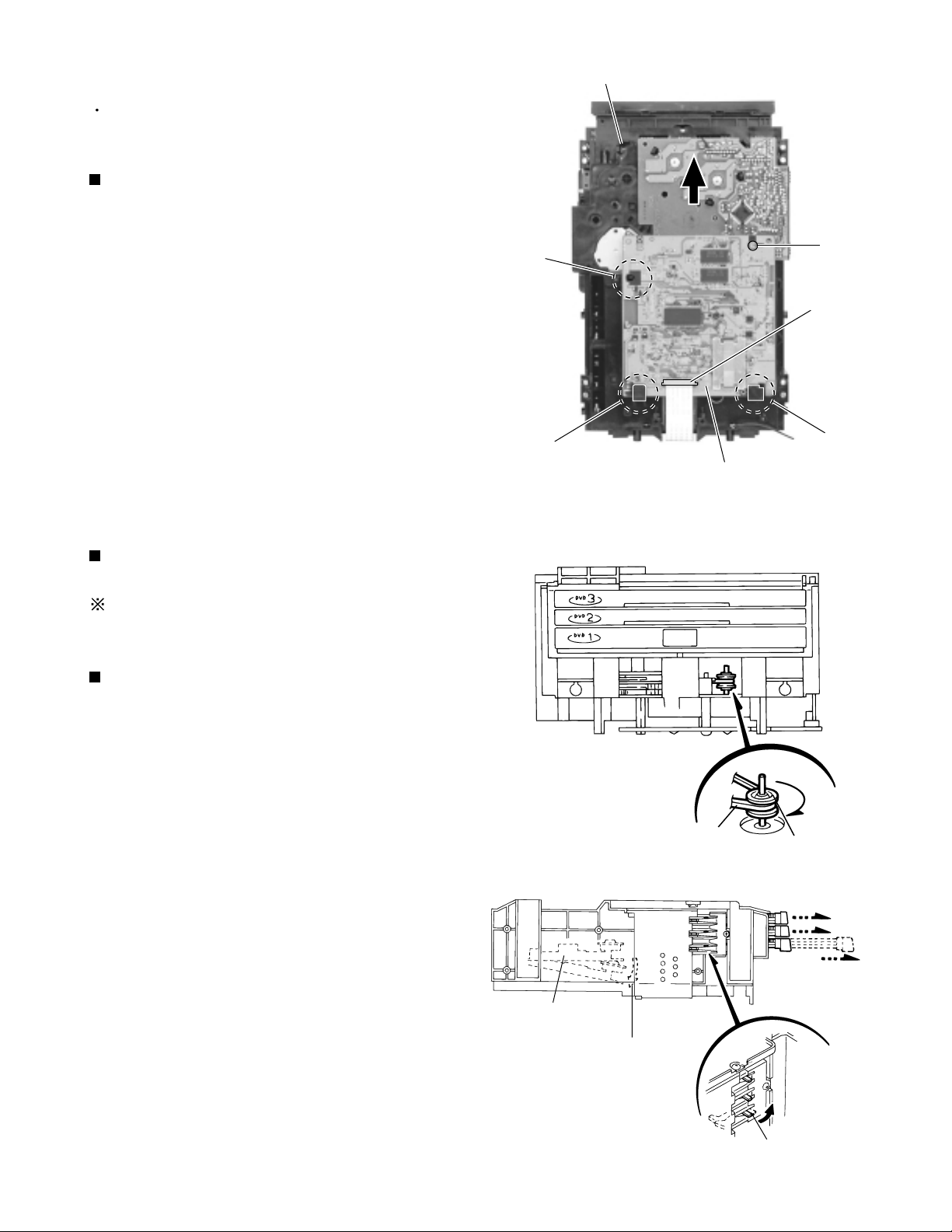

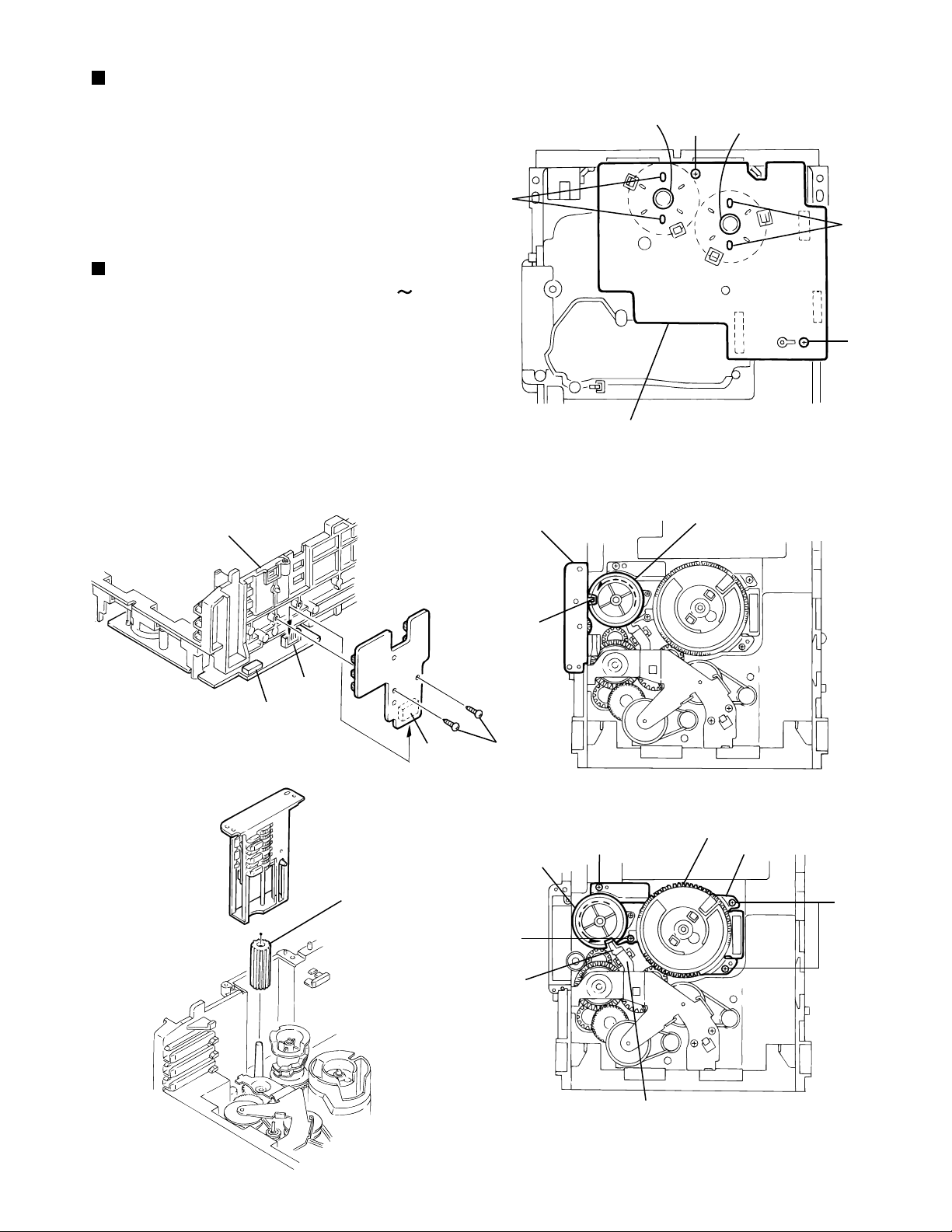

Removing the top cover (See Fig.1)

1.

Remove the two screws A attaching the top cover

on the back of the body.

2.

Remove the four screws B attaching the top cover

on both sides of the body.

3.

Pull the lower parts of the top cover sides and

remove the top cover in the direction of the arrow.

Removing the front panel assembly

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the wire from connector CN971 on the

power supply board.

>

(See Fig.2 to 5)

Top cover

B

2

Power supply board

CN971

B

A

2

Fig.1

System control board

CN703

2.

Disconnect the card wire from connector CN703 on

the system control board.

3.

Remove the three screws C attaching the front

panel assembly on the bottom of the body.

4.

Release the joint a on the bottom and the two joints

b on both sides of the body. Remove the front panel

assembly toward the front.

Front panel assembly

C

Front panel assembly

Fig.2

Joint a

C

Fig.3

Front panel assembly

C

1-6

Joint b

Joint b

Fig.5Fig.4

Page 7

XV-M50BK

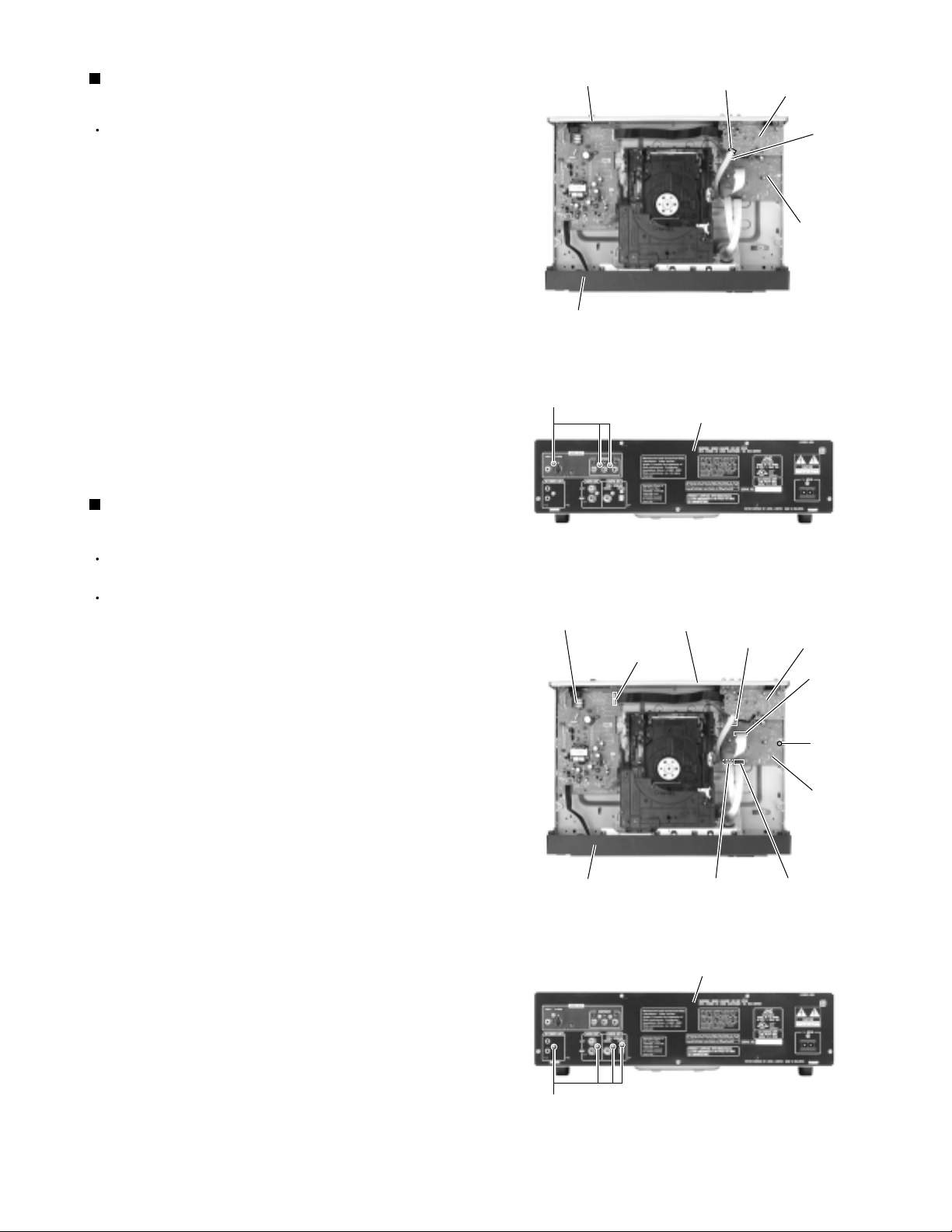

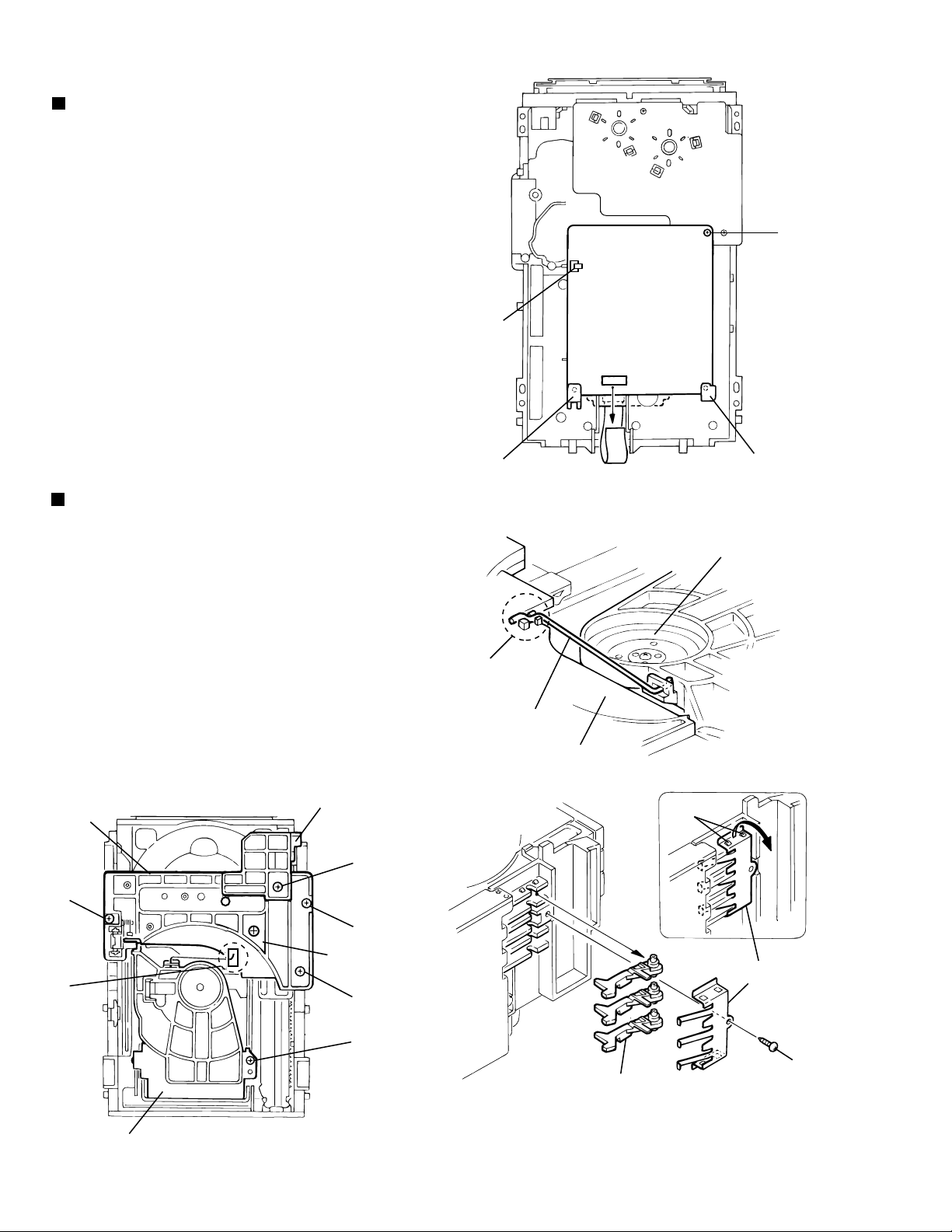

Removing the rear panel (See Fig.6)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the eleven screws D attaching the rear

panel on the back of the body and detach the rear

panel.

Removing the DVD changer mechanism assembly

(See Fig.7)

Prior to performing the following procedure, remove

the top cover and front panel assembly.

1.

Remove the one screw E.

2.

Disconnect the 9 pin wire from connector CN961 on

the power supply board.

D

D

Power supply board

F

Fig.6

F

E

Rear panel

D

Video board

CN601

CN701

System control

board

3.

Disconnect the card wire from connector CN601 on

the video board.

4.

Disconnect the card wires from connector CN701

and CN702 on the system control board.

5.

Remove the four screws F attaching the DVD

changer mechanism assembly.

It is easy for removing the front panel assembly to

remove the mechanism assembly though the

mechanism assembly can be removed even in the

state that the front panel assembly adheres.

CN961

F

DVD changer mechanism assembly

F

Fig.7

CN702

1-7

Page 8

XV-M50BK

Removing the power supply board

(See Fig.8 and 9)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the wire from connector CN971 on the

power supply board (The wire is extending from the

front panel assembly).

2.

Disconnect the 9 pin wire from connector CN961 on

the power supply board (The wire is extending from

the DVD changer mechanism assembly).

3.

Disconnect the wire from connector CN951 and

CN952 on the power supply board (The wire is

extending from the system control board).

4.

Remove the screw D attaching the AC jack on the

rear panel.

5.

Remove the two screws G attaching the power

supply board and detach the power supply board.

Power supply board

G

CN971

CN961

Rear panel

CN951,CN952

Front panel assembly

Fig.8

Rear panel

Fig.9

D

1-8

Page 9

XV-M50BK

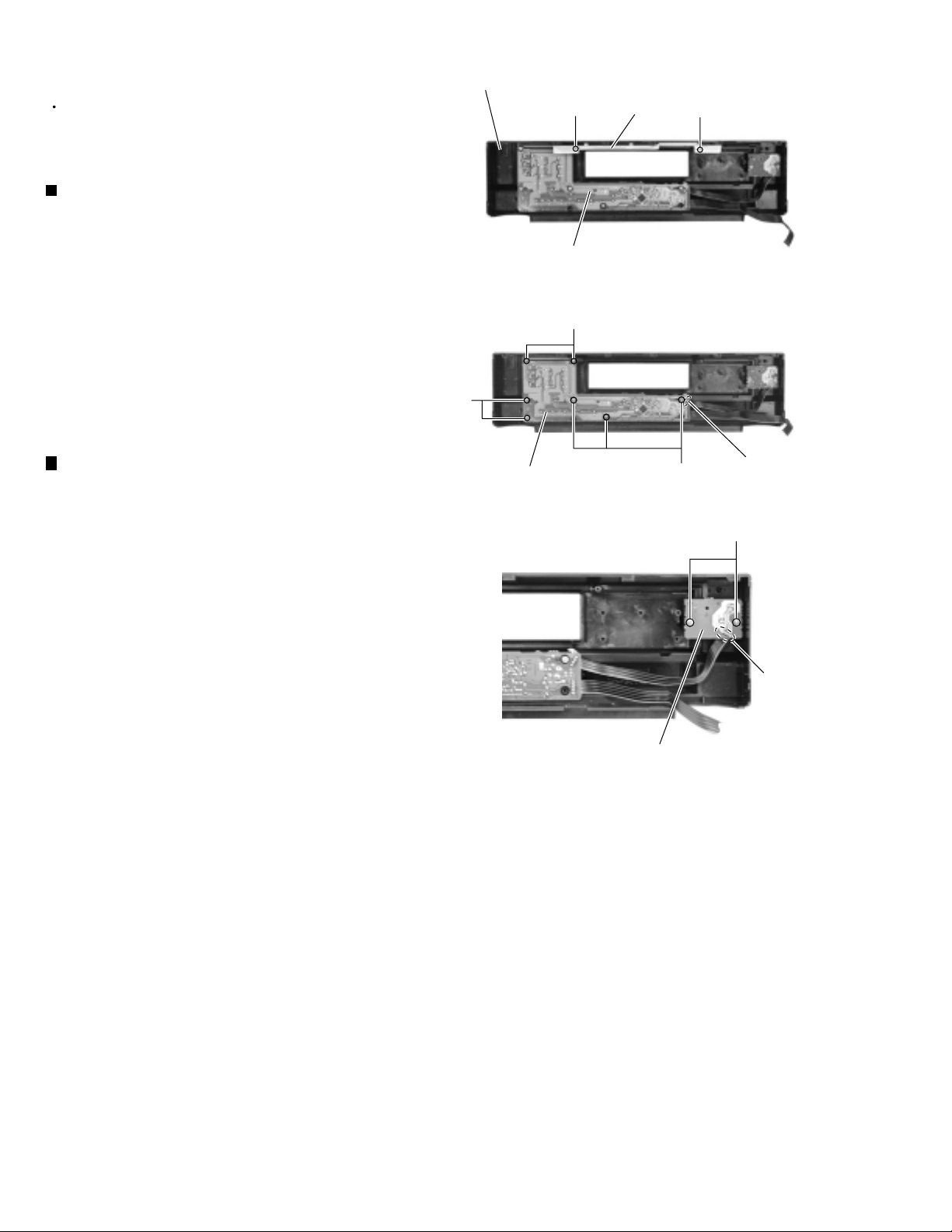

Removing the video board

(See Fig.10 and 11)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the card wire from connector CN601 on

the video board (The card wire is extending from the

DVD changer mechanism assembly).

2.

Disconnect the wire from connector CN704 on the

system control board (The wire is extending from the

video board).

3.

Remove the three screws D attaching the video

board on the rear panel. Pull out the video board

from the rear panel.

Removing the system control board

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the top cover.

The system control board can be removed even if

the video board is attached.

1.

Disconnect the card wire from connector CN703 on

the system control board (The card wire is extending

from the front panel assembly).

Rear panel

Front panel assembly

D

Power supply board

CN951,CN952

Fig.10

Rear panel

Fig.11

Rear panel

CN601

CN704

Video board

CN704

System control

board

Video board

CN701

2.

Disconnect the card wire from connector CN701 and

CN702 on the audio board (The card wires are

extending from the DVD changer mechanism

assembly).

3.

Disconnect the wire from connector CN704 on the

system control board (The wire is extending from the

video board).

4.

Disconnect the wire from connector CN951 and

CN952 on the power supply board (The wire is

extending from the system control board).

5.

Remove the screw H attaching the system control

board.

6.

Remove the four screws D attaching the system

control board on the rear panel. Pull out the system

control board toward the front.

Front panel assembly

D

Fig.12

Rear panel

Fig.13

CN703

H

System control

board

CN702

1-9

Page 10

XV-M50BK

<

Front panel assembly

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

>

Removing the front board

(See Fig.14 and 15)

1.

Remove the two screws I on the back of the front

panel assembly and remove the bracket from the

front panel assembly.

2.

Remove the seven screws J attaching the front

board.

If necessary, unsolder FW803 and disconnect the

wire.

Removing the STANDBY switch board

(See Fig.16)

1.

Remove the two screws K on the back of the front

panel assembly.

Front panel assembly

Front board

J

Front board

Bracket

I

Fig.14

I

J

J

FW803

Fig.15

K

If necessary, unsolder FW803 and disconnect the

wire.

FW803

STANDBY switch board

Fig.16

1-10

Page 11

XV-M50BK

<

DVD changer mechanism assembly

Prior to performing the following procedure, remove

the top cover and the DVD changer mechanism

assembly.

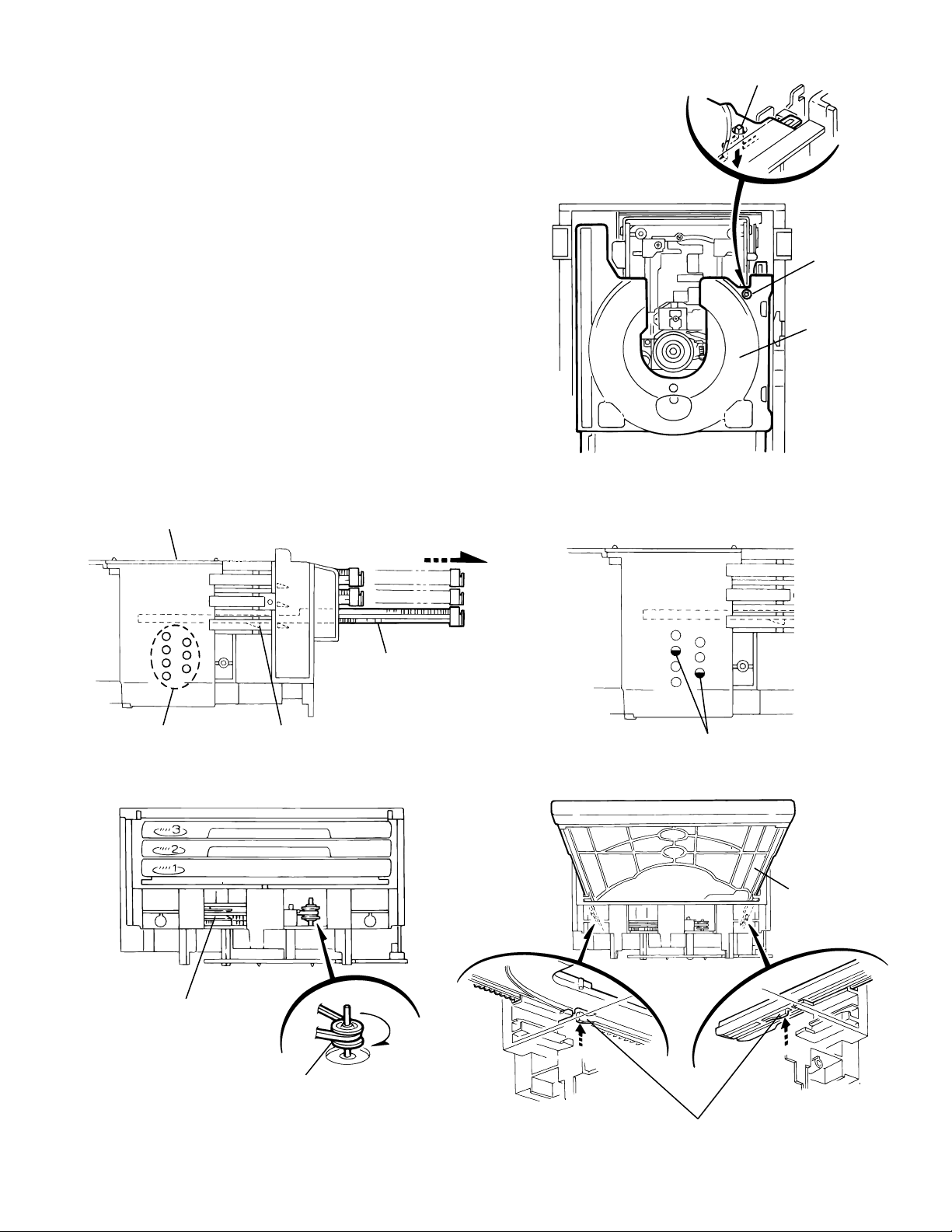

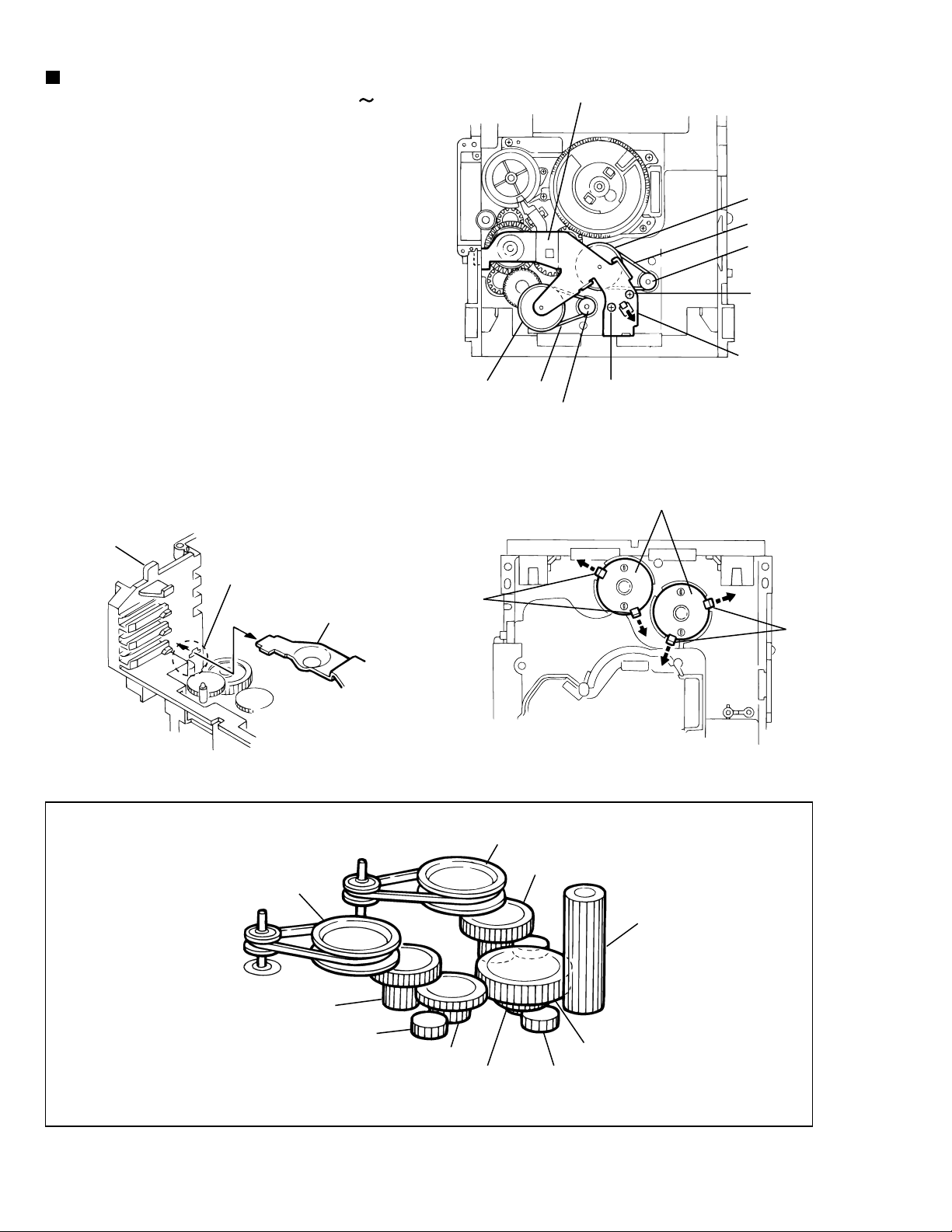

Removing the traverse mechanism

control board (See Fig.17)

1.

Disconnect the card wire from connector CN101 on

the traverse mechanism control board on the bottom

of the DVD changer mechanism assembly.

2.

Remove the screw L attaching the traverse

mechanism control board. Release the three parts e,

f and g and remove the traverse mechanism control

board.

Ejecting the DVD (See Fig.18 and 19)

DVD changer mechanism assembly

>

Par t

e

Par t

f

Fig.17

L

CN101

Par t

DVD traverse

mechanism control board

g

When the DVD is set or the traverse

mechanism is up.

The DVD tray can not be ejected when the traverse

mechanism is up.

Bringing down the traverse mechanism

as shown in the Fig.20

1.

The motor pulley and the belt can be seen on the

front side of the changer. Turn the motor pulley

clockwise until the belt stops.

2.

Pull the tray lock lever on the left side of the changer

and draw the DVD tray.

3.

Draw the DVD tray 1 to 3 as above.

Fig.18

Belt

Motor pulley

Draw the DVD tray.

Traverse mechanism

As the motor pulley is

turned, the traverse

mechanism lowers.

Fig.19

Tray stopper

Tray lock lever

1-11

Page 12

XV-M50BK

<

DVD Changer Mechanism Section

Removing the DVD mechanism board

(See Fig.1)

1.

Remove the DVD changer mechanism assembly.

2.

From bottom side the DVD changer mechanism

assembly, remove the one screw A retaining the DVD

servo control board.

Disconnect the card wire from the connector CN101 on

3.

the DVD servo control board.

Disengage the one engagement a and two

4.

engagements b , remove the DVD servo control board.

ATTENTION !

The laser diode of pick-up might be destroyed by static

electricity and set switch (S11) on the pick-up board on

"SHORT" side, please before removing the card wire from

connector (CN101).

Moreover, please set switch (S11) on "OPEN" side after

assembling and inserting the card wire in connector (CN101)

without fail at times.

Please refer to page 1-4 for a detailed content.

>

A

DVD servo

control board

a

CN101

bb

Removing the DVD tray assembly

(See Fig.2~4)

Remove the screw B retaining the Disc stopper

1.

(See Fig.3).

Remove the three screws C retaining the T.bracket

2.

(See Fig.3).

From the clamper base section c, remove both of the

3.

edges fixing the rod(See Fig.2 and 3).

Remove the screw D retaining the clamper assembly

4.

(See Fig.3).

From the left side face of the chassis assembly, remove

5.

the one screw E retaining both of the return spring and

lock lever(See Fig. 4).

By removing the pawl at the section d fixing the return

6.

spring, dismount the return spring(See Fig.4).

Remove the three lock levers(See Fig.4).

7.

Disc stopper

T.Bracket

B

C

C

Lod stopper

(C/J version only)

c

C

Fig.1

Clamper base

c

Rod

T.Bracket

Fig.2

d

Return spring

Clamper assembly

1-12

D

E

Lock lever

Fig.4

Fig.3

Page 13

XV-M50BK

8.9.Check whether the lifter unit stopper has been caught

into the hole at the section e of DVD tray assembly as

shown in Fig.5.

Make sure that the driver unit elevator is positioned as

shown in Fig.6 from to the second or fifth hole on the

left side face of the DVD Traverse mechanism

assembly.

[Caution]

10.

11.

12.

Chassis assembly

In case the driver unit elevator is not at above

position, set the elevator to the position as

shown in Fig.7 by manually turning the pulley

gear as shown in Fig.8.

Manually turn the motor pulley in the clockwise

direction until the lifter unit stopper is lowered from the

section e of DVD tray assembly(See Fig.8).

Pull out all of the three stages of DVD tray assembly in

the arrow direction f until these stages stop

(See Fig.6).

At the position where the DVD tray assembly has

stopped, pull out the DVD tray assembly while

pressing the two pawls g and g' on the back side of

DVD tray assembly(See Fig.9). In this case, it is easy

to pull out the assembly when it is pulled out first from

the stage DVD tray assembly.

Stopper

e

DVD tray

assembly

Fig.5

Refer to Fig.7

Pulley gear

Pawl

DVD tray assembly

g

f

Drive unit of elevator

Fig.7Fig.6

DVD tray assembly

Fig.8

Motor pulley

Fig.9

Pawl ,

g

g'

1-13

Page 14

XV-M50BK

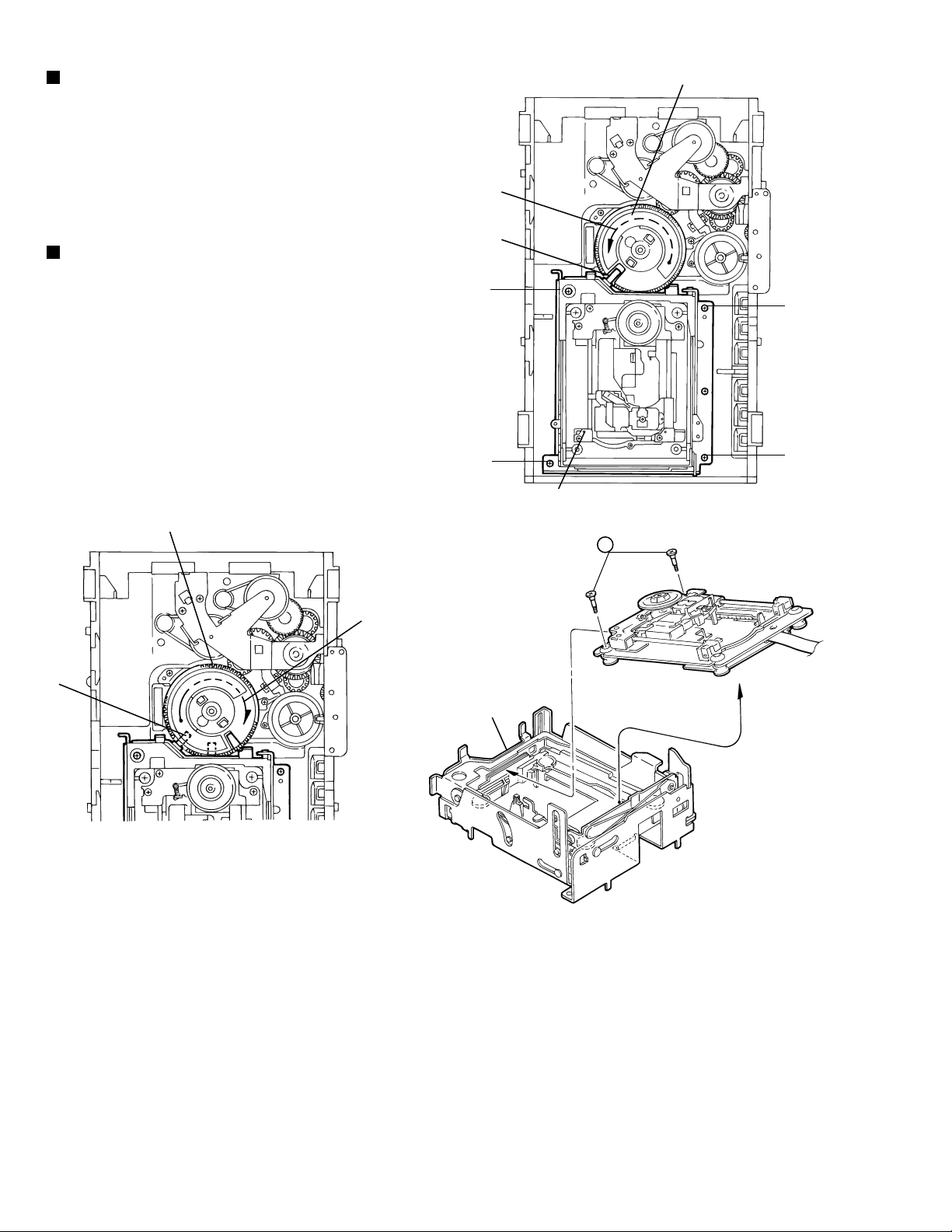

Removing the DVD mechanism

Cams R1, R2 assembly

assembly(See Fig.10)

1.2.While turning the cams R1 and R2 assembly in the

arrow direction h , align the shaft i of the DVD

mechanism assembly to the position shown in Fig.10.

Remove the four screw F retaining the DVD

mechanism assembly.

Arrow

h

i

Removing the DVD traverse mechanism

assembly (See Fig.11 and 12 )

F

For dismounting only the DVD mechanism without

1.

removing the DVD mechanism assembly, align the shaft

j of the DVD mechanism assembly to the position

shown Fig.11 while turning the cam R1 and R2

assembly in the arrow direction k.

Remove the two screws G raising the DVD mechanism

2.

assembly.

Remove the DVD traverse mechanism assembly in the

3.

arrow direction I from the lifter unit (See Fig. 12)

F

DVD mechanism assembly

Cam R1, R2 assembly

Fig.10

G

F

F

DVD traverse

mechanism

assembly

Arrow

k

j

Lifter unit

Fig.11

Fig.12

Arrow

l

1-14

Page 15

Removing the mechanism control

board (See Fig.14, 15)

1.

Absorb the four soldered positions m of the right and

left motors with a soldering absorber(See Fig.14).

2.

Remove the two screws H retaining the mechanism

control board(See Fig.14).

Remove the two screws I retaining the tray select

3.

switch board(See Fig.15).

Removing the cam unit

(See Fig.15 18 )

1.

Remove the DVD mechanism assembly.

2.

While turning the cam gear L, align the pawl n position

of the drive unit to the notch position(Fig.15) on the cam

gear L.

Pull out the drive unit and cylinder gear(See Fig.17).

3.

While turning the cam gear L, align the pawl o position

4.

of the select lever to the notch position(Fig.18) on the

cam gear L.

Remove the four screws J retaining the cam unit(cam

5.

gear L and cams R1/R2 assembly)(See Fig.18).

m

Motor L

Mechanism control board

H

Fig.14

XV-M50BK

Motor R

m

H

Chassis assembly

CN801

Fig.15

CN802

Drive unit

CD Tray

switch board

Cylinder gear

CN804

Drive unit

n

I

Cam gear L

J

Cam gear L

Fig.16

Cams R1, R2 assembly

J

Cam unit

J

Fig.17

o

Select lever

Fig.18

1-15

Page 16

XV-M50BK

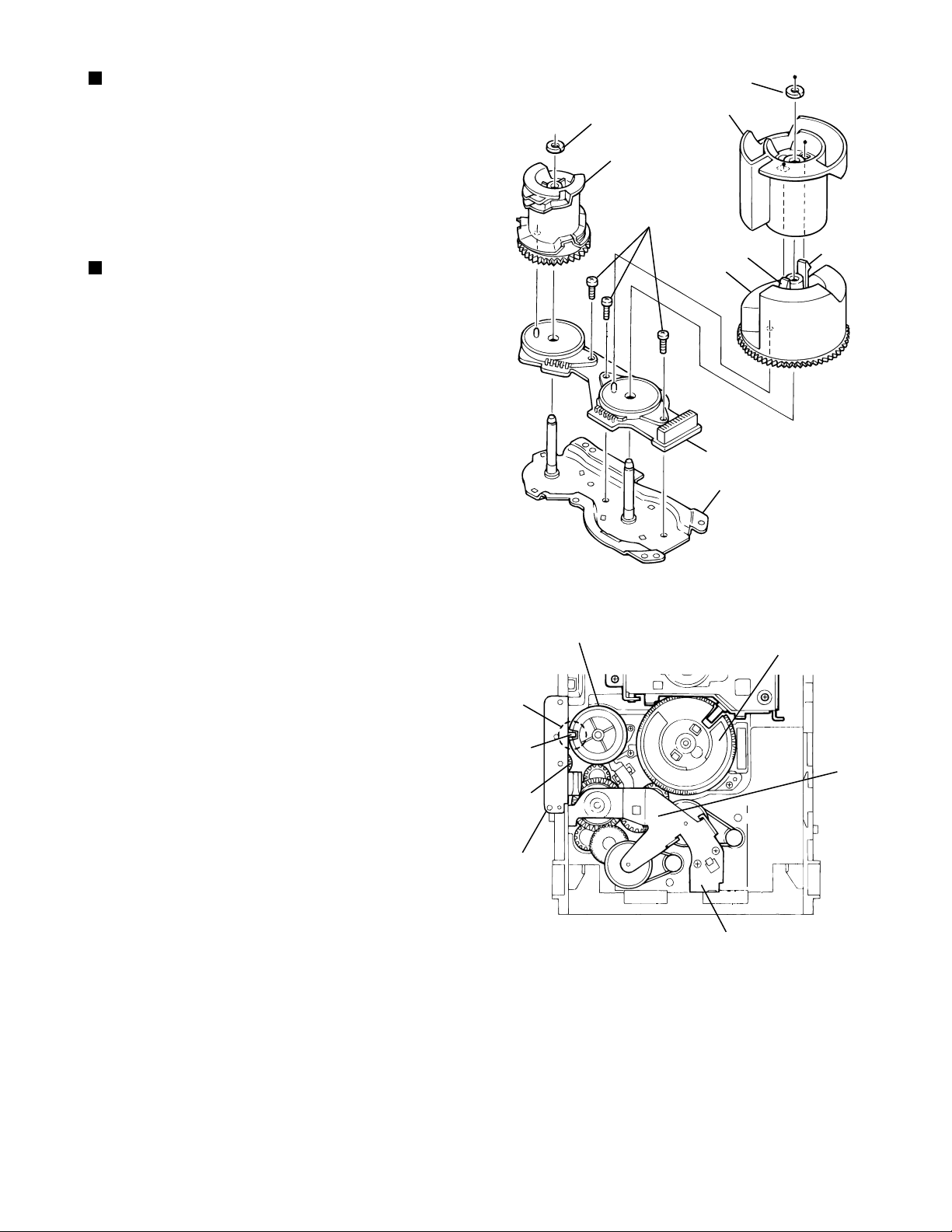

Removing the actuator motor and belt

(See Fig.19 22)

1.

Remove the two screws K retaining the gear bracket

(See Fig.19).

2.

While pressing the pawl p fixing the gear bracket in the

arrow direction, remove the gear bracket

(See Fig.19).

From the notch q section on the chassis assembly fixing

3.

the edge of gear bracket, remove and take out the gear

bracket(See Fig. 20).

Remove the belts respectively from the right and left

4.

actuator motor pulleys and pulley gears(See Fig. 19).

After turning over the chassis assembly, remove the

5.

actuator motor while spreading the four pawls r fixing

the right and left actuator motors in the arrow

direction(See Fig. 21).

[Note]

When the chassis assembly is turned over under

the conditions wherein the gear bracket and belt

have been removed, then the pulley gear as well

as the gear, etc. constituting the gear unit can

possibly be separated to pieces. In such a case,

assemble these parts by referring to the assembly

and configuration diagram in Fig. 22.

Pulley gear

Gear bracket

Belt

Motor pulley

K

Fig.19

Actuator motor

Pulley gear

Belt

Motor pulley

K

Pawl

p

Chassis assembly

q

Gear bracket

Fig.20

Assembly and Configuration Diagram

Pulley gear

r

r

Fig.21

Pulley gear

Gear B

Cylinder gear

1-16

Gear B

Gear C

Select gear

Gross gear L

Fig.22

Gross gear U

Gear C

Page 17

XV-M50BK

Removing the cams R1/R2 assembly

and cam gear L (See Fig.23)

Remove the slit washer fixing the cams R1 and R2

1.

assembly.

By removing the two pawls s fixing the cam R1,

2.

separate R2 from R1.

Remove the slit washer fixing the cam gear L.

3.

Pull out the cam gear L from the C.G. base assembly.

4.

Removing the C.G. base assembly

(See Fig.23 and 24)

Remove the three screws L retaining the C.G. base

assembly.

[Caution]

To reassemble the cylinder gear, etc.with the

R1/R2

cam unit (cam gear and cams

gear unit and drive unit, align the position of the

pawl n on the drive unit to that of the notch on

the cam gear L. Then, make sure that the gear

unit is engaged by turning the cam gear L

(See Fig. 24).

assembly),

Slit washer

Cam gear L

L

Slit washer

Cam R2

s

Pawl

Cam R1

Cam switch board

C.G. base assembly

Pawl

s

Notch

Pawl

n

Cylinder

gear

Drive unit

Fig.23

Cam gear L

Cam R1, R2 assembly

Gear unit

Gear bracket

Fig.24

1-17

Page 18

XV-M50BK

< DVD Traverse mechanism section>

Removing the pickup (See Fig.1 to 5)

1.

Solder soldering a on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN12 on the pickup

board.

ATTENTION

The laser diode of the pick-up might be destroyed by

static electricity, and solder with part a, please before

extracting a flexible wire from connector (CN12).

Moreover, please remove solder in part a after

inserting a flexible wire in connector (CN12).

Please refer to page 1-4 for a detailed content.

3.

Remove the screw A attaching the shaft stopper (R)

on the upper side of the traverse mechanism unit.

Pull the side of the shaft stopper (R) outward to

release the joint b and remove it upward. Remove

the skew spring at the same time.

Pickup unit

Flexible board

a

Fig.1

Pickup board

CN12

Flexible wire

4.

Move the shaft in the direction of the arrow to release

it from the part c.

5.

Release the joint d with the shaft and remove the

pickup with the shaft.

6.

Pull out the shaft.

7.

Remove the screw B attaching the switch actuator.

Shaft

Pickup

B

Pickup unit

Shaft

Joint d

Shaft stopper (R)

Fig.2

Shaft stopper (R)

Fig.3

A

A

Part c

Shaft

Shaft stopper (R)

Joint b

1-18

Switch actuator

Skew spring

Shaft

Fig.4Fig.5

Page 19

Removing the pickup board

(See Fig.1 and 6)

1.

Solder soldering a on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN12 on the pickup

board.

ATTENTION

The laser diode of the pick-up might be destroyed by

static electricity, and solder with part a, please before

extracting a flexible wire from connector (CN12).

Moreover, please remove solder in part a after

inserting a flexible wire in connector (CN12).

Please refer to page 1-4 for a detailed content.

3.

Unsolder soldering e, f and g of each harness on the

pickup board.

XV-M50BK

Pickup unit

Flexible board

a

Fig.1

e

Pickup board

4.

Remove the screw C attaching the pickup board and

release the two joints h.

Removing the feed motor assembly

(See Fig.1, 6 and 7)

1.

Solder soldering a on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN12 on the pickup

board.

ATTENTION

The laser diode of the pick-up might be destroyed by

static electricity, and solder with part a, please before

extracting a flexible wire from connector (CN12).

Moreover, please remove solder in part a after

inserting a flexible wire in connector (CN12).

Please refer to page 1-4 for a detailed content.

3.

Unsolder soldering e of the motor harness on the

pickup board.

Joint h

Joint h

Feed motor assembly

C

CN12

f

g

Fig.6

Feed motor assembly

Thrust spring

D

D

4.

Remove the two screws D attaching the feed motor

assembly and remove the thrust spring. Move the

feed motor assembly in the direction of the arrow to

pull it out from the feed holder.

Feed holder assembly

Fig.7

1-19

Page 20

XV-M50BK

Removing the turn table assembly

(See Fig.1, 6, 8 and 9)

1.

Solder soldering a on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN12 on the pickup

board.

ATTENTION

The laser diode of the pick-up might be destroyed by

static electricity, and solder with part a, please before

extracting a flexible wire from connector (CN12).

Moreover, please remove solder in part a after

inserting a flexible wire in connector (CN12).

Please refer to page 1-4 for a detailed content.

3.

Unsolder soldering f and g of the harness extending

from the turn table assembly to the pickup board.

4.

Remove the screw E attaching the shaft stopper (F)

on the upper side of the traverse mechanism unit.

Pull the side of the shaft stopper (F) outward to

release the joint i and remove it upward. Remove the

spring at the same time.

5.

Remove the screw F attaching the turn table

assembly.

Joint h

Joint h

Feed motor assembly

Pickup unit

Flexible board

a

Fig.1

e

Pickup board

C

CN12

f

g

Fig.6

6.

Move the turn table assembly outward and pull out

from the shaft. Then remove it from the base chassis.

Shaft stopper (F)

Shaft stopper (F)

Joint i

E

Turn table assembly

E

Shaft stopper (F)

F

Fig.8

E

F

1-20

Shaft

Shaft

Turn table assembly

Fig.9

Page 21

Adjustment method

(1) Initialization method

If microprocessor (IC401,IC402,IC403) or pick-up is replaces, initialize the

DVD player in the following matter

1)Take out the disc and close the tray.

2)Unplug the power plug.

3)Insert power plug into outlet while pressing both PLAY button and DISC 1 OPEN/CLOSE button.

4)FL Display indicate "tESt " . :Version, :Region code

5)Press 3D-PHONIC key button of remote controller. and EEPROM initialize start.

6)When indicate "V.REPLACE" on the display, initialize finishes.

7)The power is turned OFF, and Unplug the power plug.

(2) Display of "Laser current value" and "Jitter value"

"Laser current value" and "Jitter value" are displayed on the FL display by the undermentioned

method. Please refer to the failure diagnosis.

1)Take out the disc and close the tray.

2)Unplug the power plug.

3)Insert power plug into outlet while pressing both PLAY button and DISC 1 OPEN/CLOSE button.

4)FL Display indicate "tESt " . :Version, :Region code

5)Press the "OPEN/CLOSE" button to move the tray outward.

Put the test disc (VT-501) on the tray and press "OPEN/CLOSE" button.

The tray should move inward (Note:Don't push to close the tray directly by hand etc.)

6)Press the "PLAY" button.

7)The laser current value and the jitter value is displayed on the FL indicator as follows.

XV-M50BK

FL Display

* The test mode is canceled when

0 0 4 0 3 9 7 8

Laser current value Jitter value

the power is turned off.

For Laser current value

The laser current value becomes 40mA for the above-mentioned.

Becomes a test mode by doing above-mentioned procedure 1) - 4). Afterwards, the laser current value can

be switched by pushing the key to remote control without turning on the disk.

Remote control "4" key --- Laser of CD

Remote control "5" key --- Laser of DVD

If the laser current value is 64mA or less, it is roughly good. There is a possibility to which pick-up is

deteriorated, and exchange pick-up, please when there are 65mA or more laser current value.

*Returns to a usual test mode by the

thing to push the stop button of

remote control.

1-21

Page 22

XV-M50BK

For Jitter value

The jitter value is displayed by the hexadecimal number and refer to the conversion table of following,please.

If the indication value is 11% or less, it can be judged by this simple checking method that the signal

read precision of the set is satisfactory.

Before using the TEST disc VT-501, careful check it if there is neither damage nor dirt on the read surface.

STANDBY/ON

DISC

SELECT

TV DVD

PLAY

3D

TV/VIDEO

MODE

PHONIC

CANCEL

TV1 TV2 TV3

123

TV4 TV5 TV6

4

56

TV7 TV8 TV9

89

7

TV

-/-- TV0 MUTING

0+1010

SUBTITLEANGLE

AUDIO

DIGEST

S

U

O

I

V

E

R

P

SELECT

R

A

E

L

C

S

–

W

O

L

S

E

L

IT

T

+

CH

VOL

-

ENTER

C

-

CH

H

O

IC

E

RM-SXVM50J REMOTE CONTROL

TV DVD

RETURN

THEATER

POSITION

ZOOM

N

E

X

S

T

R

O

L

O

W

+

M

E

S

I

D

T

B

E

N

U

VOL

+

A

L

P

3D PHONIC

BUTTON

5 BUTTON

(LASER OF DVD)

4 BUTTON

(LASER OF CD)

Y

POWER BUTTON

Jitter value

FL display FL display

3818

3828

3838

3848

3858

3868

3878

3888

3898

38A8

38b8

38c8

38d8

38E8

38F8

3918

3928

3938

3948

3958

3968

3978

3988

Conversion

value(&)

4.7

4.8

4.9

5.1

5.2

5.3

5.4

5.5

5.7

5.8

5.9

6.0

6.1

6.3

6.4

6.6

6.7

6.9

7.0

7.1

7.2

7.3

7.5

3998

39A8

39B8

39C8

39D8

39E8

39F8

3A18

3A28

3A38

3A48

3A58

3A68

3A78

3A88

3A98

3AA8

3AB8

3AC8

3AD8

3AE8

3AF8

STANDBY

STANDBY/ON

Conversion

value(&)

7.6

7.7

7.8

7.9

8.1

8.2

8.3

8.5

8.7

8.8

8.9

9.0

9.1

9.3

9.4

9.5

9.6

9.7

9.9

10.0

10.1

10.2

PLAY & EXCHANGE

DVD / VIDEO CD / CD

10-bit/27MHz VIDEO D/A CONVERTER

DOLBY

D I G I T A L

OPEN/CLOSE

BUTTON

V.REPLACE display part

PLAY BUTTON

3

DISC

2

DISC

1

DISC

FL display FL display

3B18

3B28

3B38

3B48

3B58

3B68

3B78

3B88

3B98

3BA8

3BB8

3BC8

3BD8

3BE8

3BF8

3C18

3C28

3C38

3C48

3C58

3C68

3C78

3C88

XV-M50 DVD/CD PLAYER

3D-PHONIC

DISC TITLE CHAP.

TRACK

PROGRAM

DVD VCD

EACH

REMAIN

RANDOM

REPEAT 1A-B

RESUME

THEATER

Conversion

value(&)

10.5

10.6

10.7

10.8

10.9

11.1

11.2

11.3

11.4

11.5

11.7

11.8

11.9

12.0

12.1

12.4

12.5

12.7

12.7

12.9

13.0

13.1

13.2

SKIP

DISC 3

DISC 2

DISC 1

3C98

3CA8

3CB8

3CC8

3CD8

3CE8

3CF8

3D18

3D28

3D38

3D48

3D58

3D68

3D78

3D88

3D98

3DA8

3DB8

3DC8

3DD8

3DE8

3DF8

3

2

1

PAUSEPLAYSTOP

Conversion

value(&)

13.3

13.5

13.6

13.7

13.8

13.9

14.1

14.3

14.4

14.5

14.7

14.8

14.9

15.0

15.1

15.3

15.4

15.5

15.6

15.7

15.9

16.0

1-22

Page 23

When replacing a pickup etc., execute the following

adjustments:

XV-M50BK

Pickup replacement

1. When removing the traverse mechanism from the

changer mechanism unit, move the pickup to the

innermost diameter of the disc and set switch (S11)

on the pick-up board on "SHORT" side, please before

removing the card wire from connector (CN10)

2. Take out the traverse mechanism.

3. First short-circuit the pickup circuit before removing

the pickup. Then carry out the replacement.

Pick-up

Soldering part

Adjustment

Jig setup

1. Remove the rubber cushion from each of the four

corners of the traverse mechanism.

(When installing be sure not to make a mistake with

the cushion colors).

2. Install the jig stud.

3. Make a jig clamp. (Remove the clamp from the set

and assemble it as shown in the diagram below.

mechanism

Traverse

mechanism

Green rubber

cushion

CN10

Traverse

CN12

SWITCH S11

SHORT

OPEN

Blue rubber

cushion

Note:

How to handle the pickup

To protect the pickup from electro-static damage,

make sure to hold it by the die-cast chassis (optical

base). And make sure that pickup lens do not touch

the top cover.

How to prepare a clamp

Remove the claws

from the 3 locations

Jig stud

Disassemble the clamp

and holder

Installing the

4 jig studs

Blue rubber

cushion

Combine the clamp

and holder to become

a jig clamp.

1-23

Page 24

XV-M50BK

Integrated wiring for adjustment

1. Place a board on top of the unit and put the

changer on it. Then carry out the wiring of the

main unit.

2. Connect a extension cable to the traverse

mechanism for adjustment and then connect

them to the changer.

3. Remove the solder of the short-circuited

flexible wire. Then remove the short-circuited

pin from the traverse mechanism

4. Connection is completed.

Adjustment preparation

1. The 3 adjustment locations

2. 1.4 mm hexagonal wrench

3. Set the VT-501 or the VT502 test disc.

FL jitter display

1. Connect the power cable while pressing the

(OPEN/CLOSE) button of DISC1 and

(PLAY) button simultaneously.

--- The DISC no. " " is displayed on

the FL indicator.

2. Press the 3D-PHONIC key button of remote

controller to commence initialization.

3. When the key (PLAY) is pressed the jitter

value is displayed.

4. Adjust the jitter value to minimum by using the

adjust screw.

a). Turn the adjustment screw ( A and B )

clockwise half.

b). Return the adjustment screw ( A and B ) to

former position.

c). Turn the adjustment screw ( A and B )

counterclockwise half.

d). Set the adjustment screw ( A and B ) to the

position of best jitter at three positions.

Next, do it similar to the above-mentioned in

adjustment screw A and C.

Extension cord

QUQ605-4040AJ

Adjustment location

(Adjust screw C )

Adjustment location

(Adjust screw A )

Stud

JIGXVM555

Hexagonal wrench

(Adjust screw B )

Jig ass'y clamp adjustment

Test disc

1-24

3 locations

for adjustment

Adjust by using

a hexagonal

wrench

Page 25

Description of major ICs

AN8706FHQ (IC101) : Front end processor

1.Pin layout

CBDOSL

CSAG

DCAGC

AGCG

PEAK

BOTTOM

RFENVFCBOOST

OFTR

BDO

JITOUT

GND3

FUPDN

ITDLI

75747372717069686766656463626160595857565554535251

RBCA

RFINP

RFINN

VCC2

GND2

VREF2

RFON

RFOP

TS

DCRF

FS

VIN6

VIN5

VCC1

VIN1

VIN2

VIN3

VIN4

VREF4

DIFP

DIFN

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

AN8706FHQ

CBDOFS

TESTSG

COFTFS

COFTFL

VCOIN

PLFLT

PLFLT2

FCPO

PCPO

VCC3

CAPA

DTRD

IDGT

VCC5

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

XV-M50BK

RDCKP

RDCKN

RDTP

RDTN

GND5

GND4

VCC4

DTMONN

DTMONP

DSLFLT

DSLO

FLTOUT

DCFLT

VREF3

VPWBDO

VPWOFT

IDDLY

DBAL

GND1

VREF1

TKCNT

TKCFLT

TEOUT

TEI

RSCL

2.Block diagram

Head Amp.

SSD Signal

Head Amp.

DPD Signal

12345678910111213141516171819202122232425

TG

LPCOA

LDONB

LDONA

LPC1

VHARF

RFOUT

FS/TS

POFLT

TGBAL

PTH

TBAL

FBAL

FGCTL

FEOUT

FEN

VREFL

VREFC

SEN

PULIN

VREFH

TGTETKCNTTBALFBALFE

SCK

STDI

FC/Boost

AGC Cont

TKCNT

FE(SSD)

FE BAL

AGC EQ

MU

TE(DPD)

TE BAL

TG(DPD)

STNBY

XTRON

MTRON

RFIN

ROMRAM

RF ENV

DFLTOP/NRFENV

DSL

BDO Det

OFTR Det

PLL

JITTER Det

SYNC

JITOUT

CLK

DATA

DSLOUT

BDO

OFTR

LPC(Amp)

OPTICAL HEAD

(650nm)

INTERFACE

VREF reg

TGBAL CPU STNBY MTRON

SERVO PROCESSOR

Head Amp.

1-25

Page 26

XV-M50BK

3.Pin function

Pin No. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

LDONB

LDONA

LPCOA

LPC1

VHARF

TGBAL

POFLT

PTH

TBAL

TG

FGCTL

FBAL

FEOUT

FEN

VREFL

VREFC

VREFH

PULIN

SEN

SCK

STDI

STNBY

XTRON

MTRON

ROMRAM

RSCL

TEI

TEOUT

TKCFLT

TKCNT

VREF1

GND1

DBAL

IDDLY

VPWOFT

VPWBDO

VREF3

DCFLT

FLTOUT

DSLO

DSLFLT

DTMONP

DTMONN

VCC4

GND4

GND5

RDTN

RDTP

RDCKN

RDCKP

I/O

I

Laser ON (CD Head) terminal

I

Laser ON (DVD Head) terminal

O

Laser drive output terminal

I

Laser PIN input terminal

O

VHALF voltage output terminal

I

Tangential phase balance control terminal

O

Track detection Threshold value level terminal

I

Track detection Threshold value level terminal

I

Tracking balance control terminal

O

Tangential phase error signal output terminal

I

Focus amplifier Gain control terminal

I

Focus balance control terminal

O

Focus error signal output terminal

I

Focus error output amplifier reversing input terminal

O

VREFL voltage output terminal

O

VREFC voltage output terminal

O

VREFH voltage output terminal

I

DSL,PLL drawing mode switch terminal

I

SEN(Cereal data input terminal)

I

SCK(Cereal data input terminal)

I

STDI(Cereal data input terminal)

I

Standby mode control terminal

I

Tracking OFF holding input terminal

I

Monitor output ON/OFF switch terminal

I

ROM RAM switch terminal

O

Standard current source terminal

I

Tracking error output amplifier reversing input terminal

O

Tracking error signal output terminal

O

Track count detection filter terminal

O

Track count output terminal

O

VREF1 voltage output terminal

O

Earth terminal 1

I

Data slice offset adjustment terminal

I

Data slice delay adjustment terminal

I

OFTR detection level setting terminal

I

BDO detection level setting terminal

O

VREF3 voltage output terminal

O

Capacity connection terminal for data slice input filter

O

Filter amplifier output terminal

O

Data slice single data output terminal

O

Data slice time constant filter terminal

O

PLL differential motion 2 making to value edge signal moniter output (+)

O

PLL differential motion 2 making to value edge signal moniter output (-)

I

Power terminal 4 (5V)

O

Earth terminal 4

O

Earth terminal 5

O

PLL differential motion making to synchronization RF signal reversing output

O

PLL differential motion making to synchronization RF signal rotation output

O

PLL differential motion making synchronization clock reversing output

O

PLL differential motion making synchronization clock rotation output

Functions

AN8706FHQ (1/2)

1-26

Page 27

Pin No. Symbol

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VCC5

IDGT

DTRD

CAPA

VCC3

PCPO

FCPO

PLFLT2

PLFLT

VCOIN

ITDLI

FUPDN

GND3

JITOUT

BDO

OFTR

BOOST

FC

RFENV

BOTTOM

PEAK

AGCG

DCAGC

CSAG

CBDOSL

CBDOFS

RBCA

TESTSG

RFINP

RFINN

VCC2

GND2

VREF2

COFTFS

COFTFL

RFON

RFOP

TS

DCRF

FS

VIN6

VIN5

VCC1

VIN1

VIN2

VIN3

VIN4

VREF4

DIFP

DIFN

I/O

I

Power terminal 5 (3.3V)

I

Data slice address part gate signal input terminal (For RAM)

I

Data slice data read signal input terminal(For RAM)

I

Data slice CAPA(Address)signal input terminal (For RAM)

I

Power terminal 3 (5V)

O

PLL phase gain set terminal

O

PLL frequency gain set terminal

O

PLL low-pass filter terminal

O

PLL high-pass filter terminal

I

PLL VCO input terminal

O

PLL jitter free current ripple removal filter terminal

I

PLL frequency control input terminal

O

Earth terminal 3

O

Detection signal output of jitter

O

BDO output terminal

O

OFTR output terminal

I

Boost control terminal for filter

I

FC control terminal for filter

O

RF envelope output terminal

O

Bottom envelope detection filter terminal

O

Peak envelope detection filter terminal

O

AGC amplifier gain control terminal

O

AGC amplifier filter terminal

O

Sag cancellation circuit filter terminal

O

BDO detection capacitor terminal

O

BDO detection capacitor terminal

O

BCA detection level setting terminal

I

TEST signal input terminal

I

RF signal positive input terminal

I

RF signal negative input terminal

I

Power terminal 2 (5V)

O

Earth terminal 2

O

VREF2 voltage output terminal

O

OFTR detection capacitor terminal

O

OFTR detection capacitor terminal

O

RF signal output terminal N

O

RF signal output terminal P

O

Full adder amplifier (DVD) output terminal

O

Full adder amplifier capacitor terminal

O

Full adder amplifier (CD) output terminal

I

Focus input of external division into two terminal

I

Focus input of external division into two terminal

I

Power terminal 1 (5V)

I

External division into four (DVD/CD) RF input terminal 1

I

External division into four (DVD/CD) RF input terminal 2

I

External division into four (DVD/CD) RF input terminal 3

I

External division into four (DVD/CD) RF input terminal 4

O

VREF4 voltage output terminal

O

RF signal (RAM) output terminal P

O

RF signal (RAM) output terminal N

Functions

XV-M50BK

AN8706FHQ(2/2)

1-27

Page 28

XV-M50BK

MN67705EA (IC201) : Digital servo controller

1.Terminal layout

FEPNTRON

N.C.

N.C.

CDDVD

N.C.

N.C.

N.C.

ECR(PWM3B)

EC(PWM3A)

DVS S

128

127

126

125

124

123

122

121

120

119

FGC

1

LDONA

2

LDONB

3

PULIN

4

SRF

5

6

DVS S

DVDD

TRVSW

ST/SP

HFMON

BRK

DVS S

PLLOK

N.C.

N.C.

N.C.

N.C.

DVS S

DVD D

TSTSG

FUPDN

MONA

MONB

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33343536373839404142434445464748495051525354555657585960616263

MN67705

TRAYSET1

TRAYSET2

DRVMUTE

TRAY-CLOSE

TRAY-OPEN

TBAL(PWMDA1)

GBAL(PWMDA2)

BDOLVL(PWMDA3)

OFTLVL(PWMDA4)

SYSCLK

VCOF1

DVS S

118

117

116

IREF1

XRESET

115

114

TEST

MINTESTFGDSLO

113

112

111

TKCRS2

110

109

TKCRS1

OFTR

DVDD

108

107

106

TRSDRVB(DA8)

105

TRSDRVA(DA7)

104

TRDRV(DA6)

103

FODRV(DA5)

102

DBAL(DA4)

101

BOOST(DA3)

100

FC(DA2)

FBAL(DA1)

999897

AVDD

64

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

AVS S

TS(AD1)

FS(AD2)

FE(AD3)

TROFS(AD4)

TE(AD5)

VREFLDA

VREFMDA

VREFHDA

TG(AD6)

N.C.(AD7)

N.C.(AD8)

RFENV(AD9)

VREFOP

LDCUR(AD10)

JITOUT(AD11)

VREFC

AVDD(AD12)

VREFHAD

VREFMAD

VREFLAD

AVS S

DVDD

DVS S

TX

MOND

IPFLAG

CIRCIRQ

DA C DATA

DACLRCK

DACCLK

DVS S

2.Block diagram

The signal of the error

of the servo input

from FEP.

Driver

CPSEN

CPCEN

CPUIRQ

A/Dconverter

Track crossing

counter

Phase

comparison

Line speed

detection

Detection at

FG cycle

CPUCLK

CPUDTIN

CPUDTOUT

CHK4I

SCLK+

SCLK-

SDAT+

BDO

SDAT-

SBCK

IREF2

DVSS

DVSS

DVDD

VCOF3

SUBC

IREF3

VCOF2

Focus servo

Tracking servo

Traverse servo

Spindle servo

SERVO

DSP core

Serial port

CPU I/F

MONC

BLKCLK

NCLDCK

LRCK

NTRON

DVSS

DAT0

DAT1

DAT2

DAT3

CHCK4

(Analog control)

A/D converter

PWM

Standard

clock

generation

PLL

Focus tracking

driving value output

Spindre / traverse

driving value output

Crystal

33.8MHz

1-28

ODC

CIRC core

PLL

CPU

FEP I/F

FEP

PLL

ADSC function block of the second generation.

Page 29

XV-M50BK

3.Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

FGC

LDONA

LDONB

PULIN

SRF

DVSS

TRAYSET1

TRAYSET2

DRVMUTE

DVDD

TRVSW

TRAY-CLOSE

TRAY-OPEN

ST/SP

HFMON

BRK

DVSS

PLLOK

N.C.

TBAL(PWMDA1)

GBAL(P WMDA2)

BDOLVL(PWMDA3)

OFTLVL(PWMDA4)

N.C.

N.C.

N.C.

DVSS

DVDD

TSTSG

FUPDN

MONA

MONB

CPSEN

CPCEN

CPUIRQ

CPUCLK

CPUDTIN

CPUDTOUT

CHK4I

SCLK+

SCLK-

SDAT+

SDAT-

BDO

SBCK

IREF2

Function

0

H fixation

Laser drive controlA (ON / OFF)

O

Laser drive controlB (ON / OFF)

O

DSL and PLL high boost signal (FEP)

O

Head amplifier gain H/L selection

O

Ground for digital circuit

Tray drive ON/OFF and direction control

O

Tray drive ON/OFF and direction control

O

Drive IC mute control

O

Power supply for digital circuit

Surroundings position detection in traverse

I

Tray close detection SW

I

Tray opening detection SW

I

Spindle motor drive switch (START /STOP)

O

High cycle module control

O

Spindle motor IC short brake control

O

Ground for digital circuit

SYNC detection (DVD : 18T / CD : 22T)

I

O

Tracking balance (FEP)

O

Tangential balance (FEP)

O

BDO slice level (FEP)

O

Off-track error slice level (FEP)

O

O

O

O

Ground for digital circuit

Power supply for digital circuit

Self calibration signal (FEP)

O

Signal of frequency UP/DOWN of PLL (FEP)

O

Monitor terminal A

O

Monitor terminal B

O

Servo DSP serial I/F chip selection (SYSCOM)

I

CIRC serial I/F chip selection (SYSCOM)

I

Interrupt request to silicon (SYSCOM)

O

Silicon serial I/F clock (SYSCOM)

I

Silicon serial I/F data input (SYSCOM)

I

Silicon serial I/F data output (SYSCOM)

O

Connects with unused DVSS

I

Lead channel clock differential motion signal (positive)

I

Lead channel clock differential motion signal (negative)

I

Lead channel data differential motion signal (positive)

I

Lead channel data differential motion signal (negative)

I

BDO + BCA (FEP)

I

CD sub-code data shift clock (ODC)

I

Connects with unused DVSS

MN67705EA (1/3)

1-29

Page 30

XV-M50BK

Pin No. Symbol I/O

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

IREF3

VCOF2

DVSS

VCOE3

DVSS

DVDD

SUBC

BLKCLK

MONC

NCLDCK

LRCK

NTRON

DVSS

DAT0

DAT1

DAT2

DAT3

CHCK4

DVSS

DACCLK

DACLRCK

DAC D ATA

CIRCIRQ

IPFLAG

MOND

TX

DVSS

DVDD

AVSS

VREFLAD

VREFMAD

VREFHAD

AVDD

VREFC(AD12)

JITOUT(AD11)

LDCUR(AD10)

VREFOP

RFENV(AD9)

N.C.(AD8)

N.C.(AD7)

TG(AD6)

VREFHDA

VREFMDA

VREFLDA

TE(AD5)

TROFS(AD4)

FE(AD3)

Function

Connects with unused DVSS

Connects with unused DVSS

Ground for digital circuit

Connects with unused DVSS

Ground for digital cirucuit

Power supply for digital cirucuit

CD sub-code (ODC)

O

CD sub-code synchronous signal (ODC)/Jump output of one at DVD

O

Monitor terminal C

O

Sub-code data frame clock (ODC)

O

LR channnel data strove CIRC(ODC)

O

L: Tracking ON (ODC)

O

Ground for digital cirucuit

CIRC / Binary making DVD data output

O

CIRC / Binary making DVD data output

O

CIRC / Binary making DVD data output

O

CIRC / Binary making DVD data output

O

Synchronous clock of DAT0 3

O

Ground for digital circuit

O

Connects with unused DVSS

I

Connects with unused DVSS

I

RAM with built-in CIRC exceeds / Underflow interrupt

O

CIRC error flag

O

Monitor terminal D

O

Digital audio interface

O

Ground for digital cirucuit

Power supply for digital cirucuit

Ground for analog cirucuit

AD subordinate position standard voltage (0.6 0.1v)

It is a place standard voltage in AD (1.4 0.1V)

High-ranking AD standard voltage (2.2 0.1V)

Power supply for analog circuit

I

Jitter

I

I

signal(FEP)

Laser drive current signal

Operation amplifier standard voltage(VREFC)

RFENV(FEP)

I

Connects with VREFC

I

Connects with VREFC

I

Tangential Phase difference (FEP)

I

High-ranking AD standard voltage (2.2 0.1V)

It is a place standard voltage in AD (1.4 0.1V)

AD subordinate position standard voltage (0.6 0.1v)

Tracking error (FEP)

I

Tracking drive IC input offset

I

Focus error (FEP)

I

MN67705EA (2/3)

1-30

Page 31

Pin No. Symbol I/O

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

IREF3

VCOF2

DVSS

VCOE3

DVSS

DVDD

SUBC

BLKCLK

MONC

NCLDCK

LRCK

NTRON

DVSS

DAT0

DAT1

DAT2

DAT3

CHCK4

DVSS

DACCLK

DACLRCK

DAC D ATA

CIRCIRQ

IPFLAG

MOND

TX

DVSS

DVDD

AVSS

VREFLAD

VREFMAD

VREFHAD

AVDD

VREFC(AD12)

JITOUT(AD11)

LDCUR(AD10)

VREFOP

RFENV(AD9)

N.C.(AD8)

N.C.(AD7)

TG(AD6)

VREFHDA

VREFMDA

VREFLDA

TE(AD5)

TROFS(AD4)

FE(AD3)

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Function

Connects with unused DVSS

Connects with unused DVSS

Ground for digital circuit

Connects with unused DVSS

Ground for digital cirucuit

Power supply for digital cirucuit

CD sub-code (ODC)

CD sub-code synchronous signal (ODC)/Jump output of one at DVD

Monitor terminal C

Sub-code data frame clock (ODC)

LR channnel data strove CIRC(ODC)

L: Tracking ON (ODC)

Ground for digital cirucuit

CIRC / Binary making DVD data output

CIRC / Binary making DVD data output

CIRC / Binary making DVD data output

CIRC / Binary making DVD data output

Synchronous clock of DAT0 3

Ground for digital circuit

Connects with unused DVSS

I

Connects with unused DVSS

I

RAM with built-in CIRC exceeds / Underflow interrupt

CIRC error flag

Monitor terminal D

Digital audio interface

Ground for digital cirucuit

Power supply for digital cirucuit

Ground for analog cirucuit

AD subordinate position standard voltage (0.6 0.1v)

It is a place standard voltage in AD (1.4 0.1V)

High-ranking AD standard voltage (2.2 0.1V)

Power supply for analog circuit

I

Jitter

I

I

signal(FEP)

Laser drive current signal

Operation amplifier standard voltage(VREFC)

RFENV(FEP)

I

Connects with VREFC

I

Connects with VREFC

I

Tangential Phase difference (FEP)

I

High-ranking AD standard voltage (2.2 0.1V)

It is a place standard voltage in AD (1.4 0.1V)

AD subordinate position standard voltage (0.6 0.1v)

Tracking error (FEP)

I

Tracking drive IC input offset

I

Focus error (FEP)

I

XV-M50BK

MN67705EA (2/3)

1-31

Page 32

XV-M50BK

Pin No. Symbol I/O

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

FS(AD2)

TS(AD1)

AVSS

AVDD

FBAL(DA1)

FC(DA2)

BOOST(DA3)

DBAL(DA4)

FODRV(DA5)

TRDRV(DA6)

TRSDRVA(DA7)

TRSDRVB(DA8)

DVDD

OFTR

TKCRS1

TKCRS2

DSLO

FG

MINTEST

TEST

XRESET

IREF1

DVSS

VCOF1

SYSCLK

DVSS

EC(PWM3A)

ECR(PWM3B)

N.C.(PWM3A)

N.C.(PWM2B)

N.C.(PWM1A)

CDDVD

N.C.(PWM0A)

N.C.(PWM0B)

FEPNTRON

Function

FS (FEP)

I

TS (FEP)

I

Ground for analog cirucuit

Power supply for analog circuit

Focus balance(FEP)

O

Cutting off frequency (FEP)

O

Amount of boost (FEP)

O

O

DSL offset balance (FEP)

O

Focus drive

O

Tracking drive

Traverse drive A aspect

O

Traverse drive B aspect

O

Power supply for digital cirucuit

Off-track error signal (FEP)

I

Track crossing signal 1 (FEP)

I

Track crossing signal 2 (FEP)

I

Binary making data slice signal (FEP)

I

FG signal input (spindle motor driver)

I

Connects with DVSS

Connects with DVSS

Reset L : Reset

I

VCO reference current 1( for SYSCLK)

Ground for digital circuit)

VCO control voltage 1 (for SYSCLK)

33.8MHz system clock input

I

Ground for digital circuit

Spindle motor drive

O

O

O

O

O

CD/DVD control signal (FEP) CD : H DVD : L

O

O

O

Tracking ON (FEP)

O

MN67705EA(3/3)

1-32

Page 33

M56788FP-W (IC271) : Traverse mechanism driver

1.Terminal layout

CH3IN

OUT3

IN3-

VBS2

Vm2

N.C

GND

IN3+

VM3-

VM3+

GND

VM4+

VM4-

VM5+

VM5-

OUT5

IN5-

IN5+

IN4+

IN4-

OUT4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

XV-M50BK

REG+

REGB

IN1+

VBS1

Vm1

IN1-

OUT1

VM1-

VM1+

GND

VM2+

VM2-

OUT2

GND

IN2-

IN2+

MUTE1

MUTE2

SS.GND

VREF

VERFO

2.Block diagram

Vm1

IN1+

IN1-

OUT1

VM1(+)

VM1(-)

VM2(+)

VM2(-)

OUT2

IN2-

IN2+

VREF0

VREF

REGB

REG+

VREG

VBS2

CH1

X5

CH2

X5

VBS1

VREF

E1

E2

VBS1

VBS1

VBS1

VBS1

VBS1 VBS2

R

RR

Vrefm1 Vrefm2

BIAS

Vm1 Vm2

Low, Open

MUTE ON

1~4

CH

VBS1

1.25V

VREF0

Hi:Sleep

SLEEP

5CH

TSD

Vm2

VBS2

R

E3

VBS2

CH3

X8

VBS2

CH4

X8

VBS2

E4

VBS2

CH5

X8

VBS2

E5

IN3IN3+

OUT3

CH3IN

VM3(+)

VM3(-)

VM4(+)

VM4(-)

IN4IN4+

OUT4

VM5(+)

VM5(-)

IN5IN5+

OUT5

SS.GND

MUTE1 MUTE2

GND (4PIN)

1-33

Page 34

XV-M50BK

MN103007BGA (IC301) : Optical disc controller

1.Terminal layout

HDD15

HDD0

HDD14

5VDD

HDD1

HDD13

HDD2

VSS

HDD12

VDD

HDD3

HDD11

HDD4

HDD10

5VDD

HDD5

HDD9

VSS

HDD6

HDD8

HDD7

5VDD

NRESET

MASTER

NINT0

NINT1

WAITODC

NMRST

DASPST

VDD

OSCO2

OSCI2

UATASEL

VSS

PVSSDRAM

PVDDDRAM

DMARQ

NIOWR

VSS

NIORD

IORDY

NDMACK

5VDD

INTRQ

NIOCS16

DA1

VSS

NPDIAG

DA0

DA2

VDD

NCS1FX

NCS3FX

NDASP

NTRYCL

5VDD

NEJECT

VSS

MONI0

MONI1

MONI2

MONI3

SDATA

SCLOCK

VDD

DAT0

DAT1

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

3738394041424344454647484950515253545556575859606162636465666768697071

MN103007BGA

114

DAT2

113

DAT3

112

CHCK4

XCLDCK

111

110

72

SUBC

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

SBCK

VSS

P0

P1

PVDD

PVSS

VDD

OSCO1

OSCI1

VSS

LRCK

BLKCK

IPFLAG

DACCLK

DACLRCK

DA C DATA

NTRON

LG

JMPINH

IDHOLD

PLLOK

CLKOUT2

VDD

NRST

MMOD

VSS

CPDET1

CPDET2

BDO

IDGT

DTRO

TEHLD

VDD

CLKOUT1

CPUDT0

CPUDT1

2.Block diagram

DVD-ROM

Formatter

CGEN

MODE

VSS

CPUADR17

CPUADR16

CPUADR15

CD-PRE

Instruction

memory

(40KB)

DATA MEMORY

(6KB)

VDD

CPUADR14

CPUADR13

CPUADR12

CPUADR11

General purpose IO bus

CPUADR9

CPUADR10

CPUADR8

CPUADR7

CPUADR6

CPUADR5

Formatter

i /t

High speed IO bus

CPUADR4

CPUADR3

CPUADR2

CPUADR1

32 bit

CPU core

GCAL

VSS

CPUADR0

ECC

NCS

NWR

NRD

VDD

CPUDT7

CPUDT6

PVPPDRAM

PTESTDRAM

Host i / f

MPEG i / t

DMA

BCU

DRAMC

CPUDT5

CPUDT4

PVSSDRAM

PVDDDRAM

VSS

CPUDT3

CPUDT2

ATAPI

4Mbit

DRAM

1-34

WDT

16 bit

timer x 2

SYSTEM i / f

INTC

Page 35

3.Pin function

XV-M50BK

MN103007BGA(1/4)

Pin NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Symbol

HDD15

HDD0

HDD14

5VDD

HDD1

HDD13

HDD2

VSS

HDD12

VDD

HDD3