Page 1

XV-FA900BK/XV-FA902SL

SERVICE MANUAL

DVD AUDIO/VIDEO PLAYER

XV-FA900BK/XV-FA902SL

Area Suffix

J ------------- U.S.A.

STANDBY/ON

OPEN/

DISC

TV DVD

CLOSE

SELECT

TV22TV11TV3

3

TV55TV44TV6

6

TV88TV77TV9

9

TV00TV-/--10MUTING

+10

TITLE/

TV/VIDEO

CANCEL

GROUP

RETURN

PAGE

U

M

N

E

E

CH

N

M

U

+

P

O

T

VOL

-

VOL+

C

H

O

I

C

E

SLOW

3D

PHONIC

REMOTE CONTROL

ENTER

CH

-

SELECT STROBECLEAR

-

ANGLEDIGEST

RM-SXV016J

N

E

E

R

C

S

N

O

NEXTPREVIOUS

SLOW+

VFPAUDIOSUB TITLEREPEAT

PROGRESSIVE

fs/Rate

SCAN

ZOOM

AMP VOL

STANDBY/ON

STANDBY/ON

DVD AUDIO

DISC 1 DISC 2 DISC 3 DISC 4 DISC 5 DISC 6 DISC 7 EXCHANGE DISC SKIP

DVD AUDIO/DVD VIDEO/SUPER VCD/VCD/CD PLAYER

PROGRESSIVE

PLAY & EXCHANGE

OPEN/CLOSE

PLAY

PAUSE

STOP

7

-

DISC

SKIP

Each difference point

Model

XV-FA900BK

XV-FA902SL

Body color

Black

Silver

< ATTENTION ! >

Please pull out the AC plug code after the standby indicator lights pushing the

power supply button without fail after completing the repair.

The mechanism becomes initialed position. There is a possibility to break when

carrying in not initialed position the mechanism but the state.

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.A0034

Aug. 2002

Page 2

XV-FA900BK/XV-FA902SL

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Critical parts for safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Preventing static electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 Handling the traverse unit (optical pickup) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7 Importance admistering point on the safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.8 Precautions for Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Main body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Front panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 chassis unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Traverse mechanism unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Main tray assembly unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Adjustment method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Test mode setting method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Initialization method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Method of displaying version of microcomputer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Method of displaying device key index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.5 Display of current value of laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6 Display of jitter value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.7 Flap adjustment of the pick-up guide shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8 Upgrading of firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.9 Display of region code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.10 Confirm method of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.12 Check points for each error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 Description of major ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1 AN8703FH-V (IC101) : Frontend processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 BA5983FM-X (IC201) : 4CH Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3 74LCX373MTC-X(IC512,IC513) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4 BA6664FM-X (IC251) : Spindle motor driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5 K4S643232E-TC60(IC505):DRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.6 MN102L62GLK(IC401):Unit CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.7 MN103S26EGA (IC301) : Super optical disc controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.8 NDV8611VWA(IC501):AV Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.9 SST39VF160-7CEK (IC509) : 16M EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.10 UPD780206GF-125(IC801):System controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.11 S-93C66AFJ-X (IC451, IC510) : EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.12 MN35505-X (IC753, IC763, IC773) : DAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.13 BA6287F-X(IC411,IC412):Motor driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.14 STR-G6651 (IC901) : Switch regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Glossary of term and abbreviations(for AV Decoder section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2

Page 3

SECTION 1

Important Safety Precautions

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes.

For continued protection, no changes should be made to the

original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be

performed by qualified personnel only.

(2) Alterations of the design or circu itry of the pro duct should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will vo id

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these specia l

safety characteristics are identified in the Parts List of Service

Manual. Electrical components having such features are

identified by shading on the schematics and by ( )

on the Parts List in the Service Manual. The use of a substitute replacement which does not have the same safety

characteristics as the recommended replacement parts

shown in the Parts List of Service Manual may create

shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

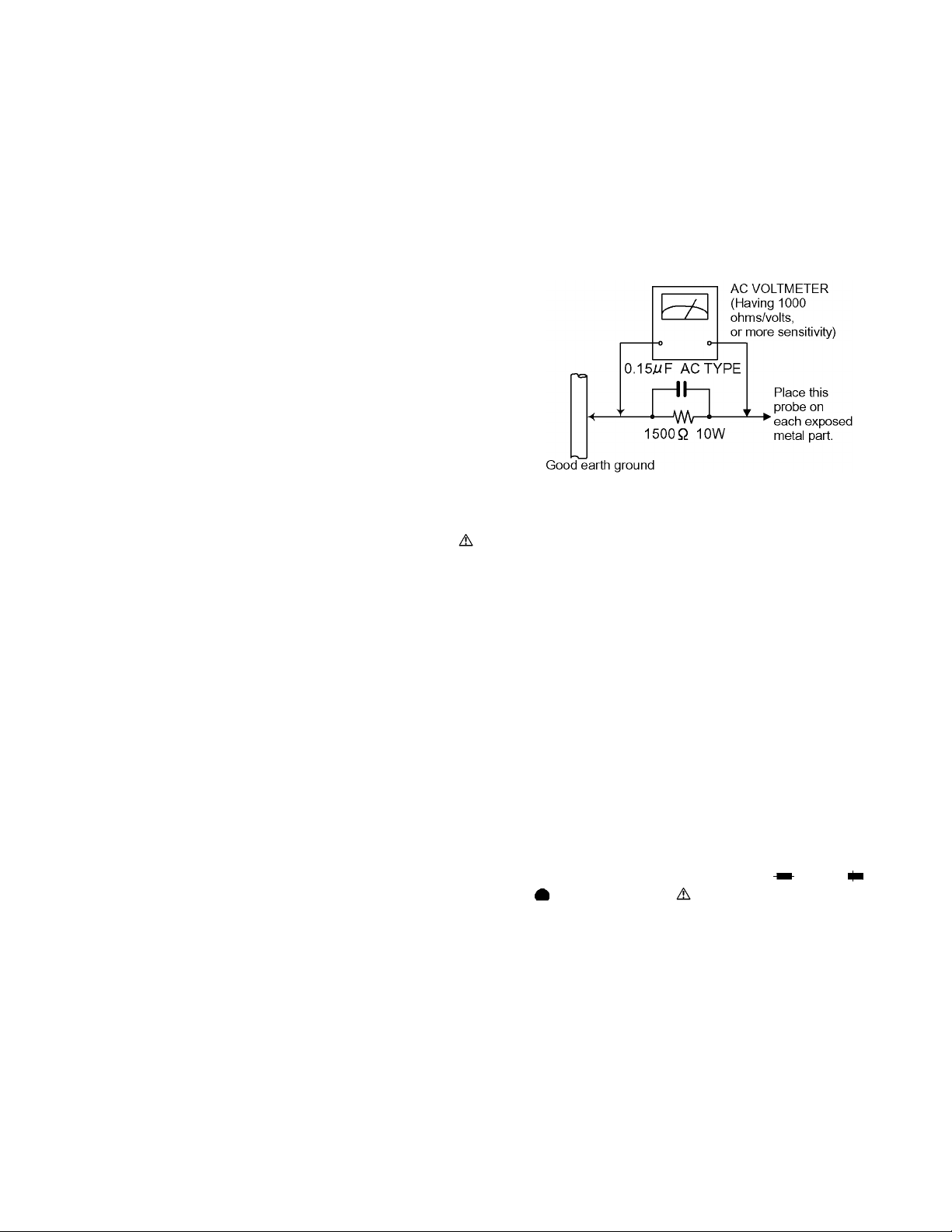

(5) Leakage shock hazard testin g)

After reassembling the product, always perform an isolation

check on the exposed metal parts of the product (antenna

terminals, knobs, metal cabinet, screw heads, headphone

jack, control shafts, etc.) to be sure the product is safe to

operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord direct ly into the AC outle t. Use a n AC

voltmeter having, 1,000 ohms per volt or more sensitivity in

the following manner. Connect a 1,500 ohm 10W resistor

paralleled by a 0.15 µF AC-type capacitor between an

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

XV-FA900BK/XV-FA902SL

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and repeat

each measurement. Voltage measured any must not

exceed 0.75 V AC (r.m.s.). This corresponds to 0.5 mA AC

(r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for lo-

cal voltage.

1.3 Caution

Burrs formed during molding may be left over on some

parts of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

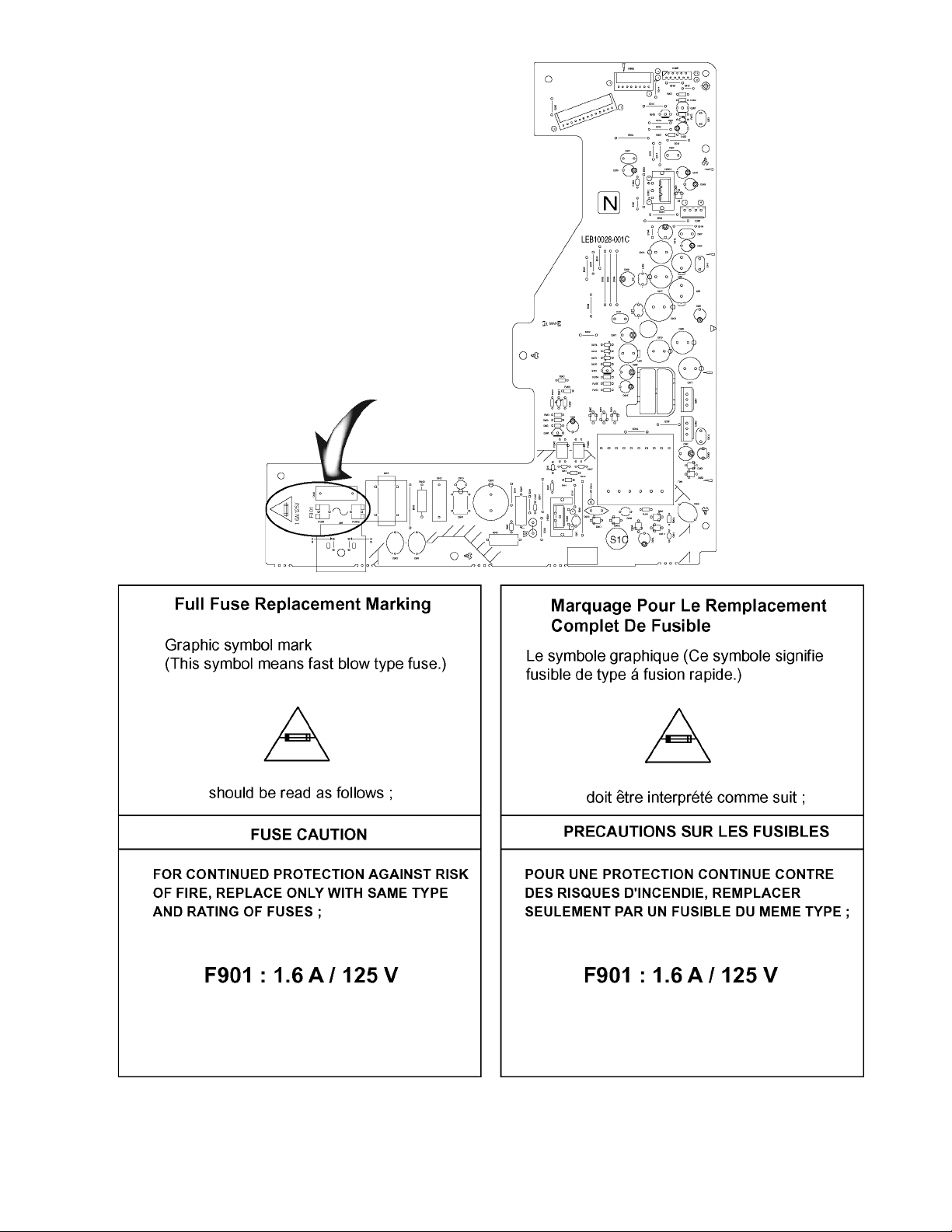

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( ) and

ICP ( ) or identified by the " " ma rk nearby are critical for safety.

When replacing them, be sure to use the parts of the same type

and rating as specified by the manufacturer. (Except the JC version)

3

Page 4

XV-FA900BK/XV-FA902SL

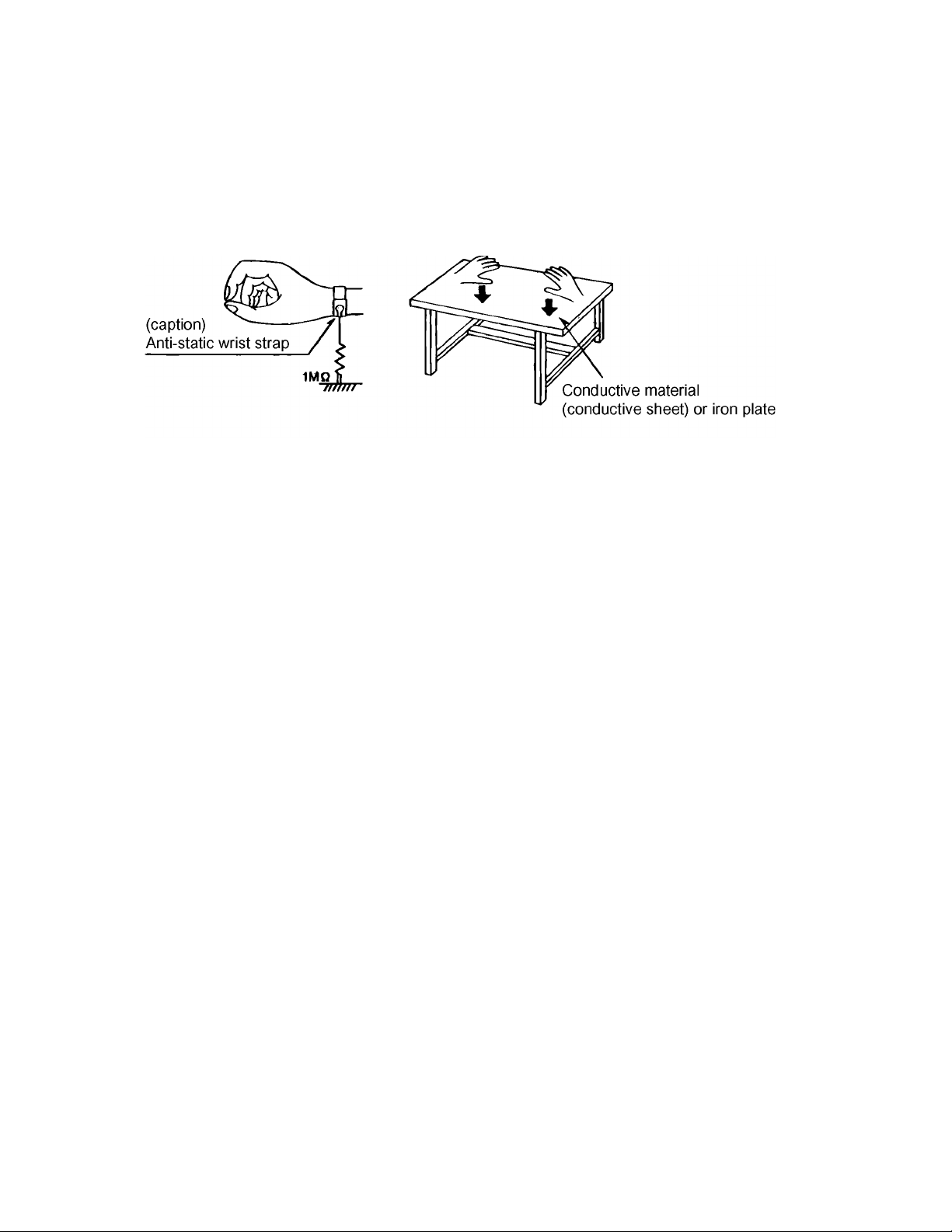

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron pl ate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diod e on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can

easily destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too

long a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4)I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

4

Page 5

1.7 Importance admistering point on the safety

XV-FA900BK/XV-FA902SL

5

Page 6

XV-FA900BK/XV-FA902SL

1.8 Precautions for Service

1.8.1 Handling of Traverse Unit and Laser Pickup

(1) Do not touch any peripheral element of the pickup or the actuator.

(2) The traverse unit and the pickup are precision devices and therefore must not be subjected to strong shock.

(3) Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the internal power supply of the tester.)

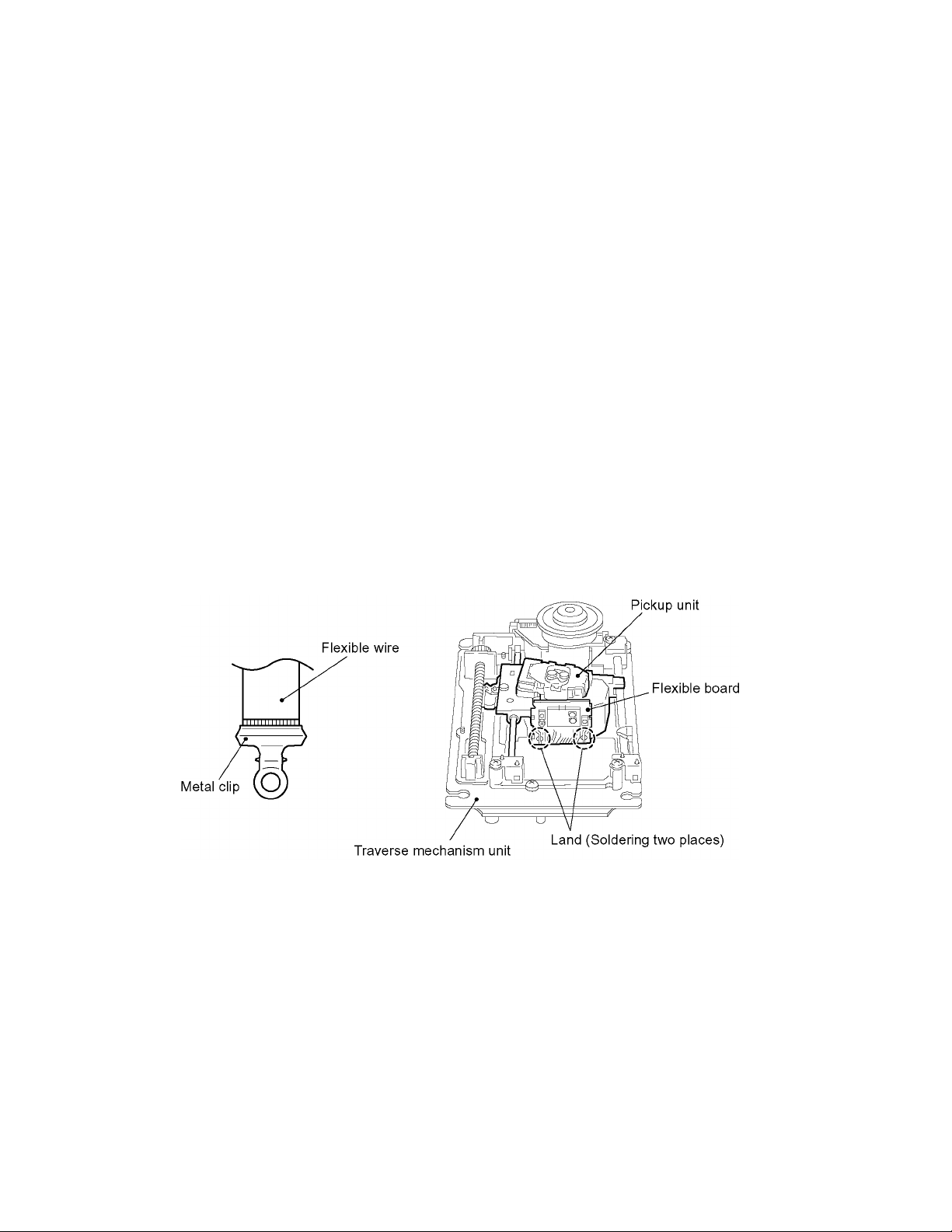

(4) To replace the traverse unit, pull out the metal short pin for protection from charging.

(5) When replacing the pickup, after mounting a new pickup, remove the solder on the short land which is pr ovided at the center

of the flexible wire to open the circuit.

(6) Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to mat ch the characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

1.8.2 Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body. Before repairing peripheral elements of the traverse unit or pickup, be sure to take the following electrostatic

protection:

(1) Wear an antistatic wrist wrap.

(2) With a conductive sheet or a stee l plate on the workben ch on which th e traverse unit or the pick up is to be repa ired, ground

the sheet or the plate.

(3) After removing the flexible wire from the connector (CN1), short-circuit the flexible wire by the metal clip.

(4) Short-circuit the laser diode by soldering the land which is provided at the center of the flexible wire for the pickup.

After completing the repair, remove the solder to open the circuit.

Please refer to "Fig.1 of 3.2" of "Disassembly

method" for details.

6

Page 7

SECTION 2

Disassembly method

2.1 Main body

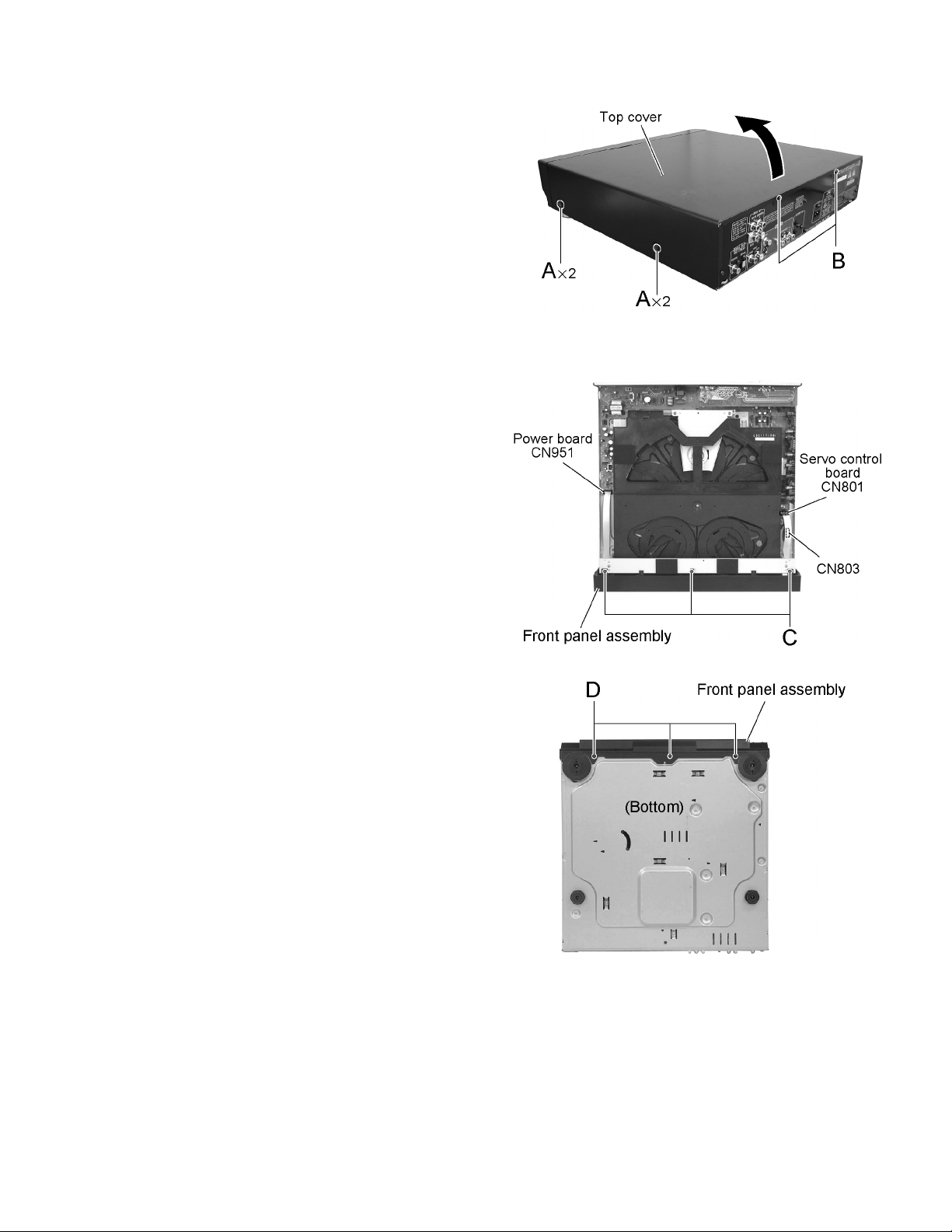

2.1.1 Removing the top cover

(See Fig.1)

(1) Remove the four screws A on each side of the body.

(2) Remove the two screws B on the back of the body.

(3) Lift the rear part of the top cover and remove in the direc-

tion of the arrow while pulling both sides of the top cover

outward.

2.1.2 Removing the front panel assembly

(See Fig.2 and 3)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connector CN801 and

CN803 on the servo control board, and CN951 on the

power board respectively.

(2) Remove the three screws C on the upper side of the body.

(3) Remove the three screws D on the bottom of the body.

Remove the front panel assembly toward the front.

XV-FA900BK/XV-FA902SL

Fig.1

Fig.2

Fig.3

7

Page 8

XV-FA900BK/XV-FA902SL

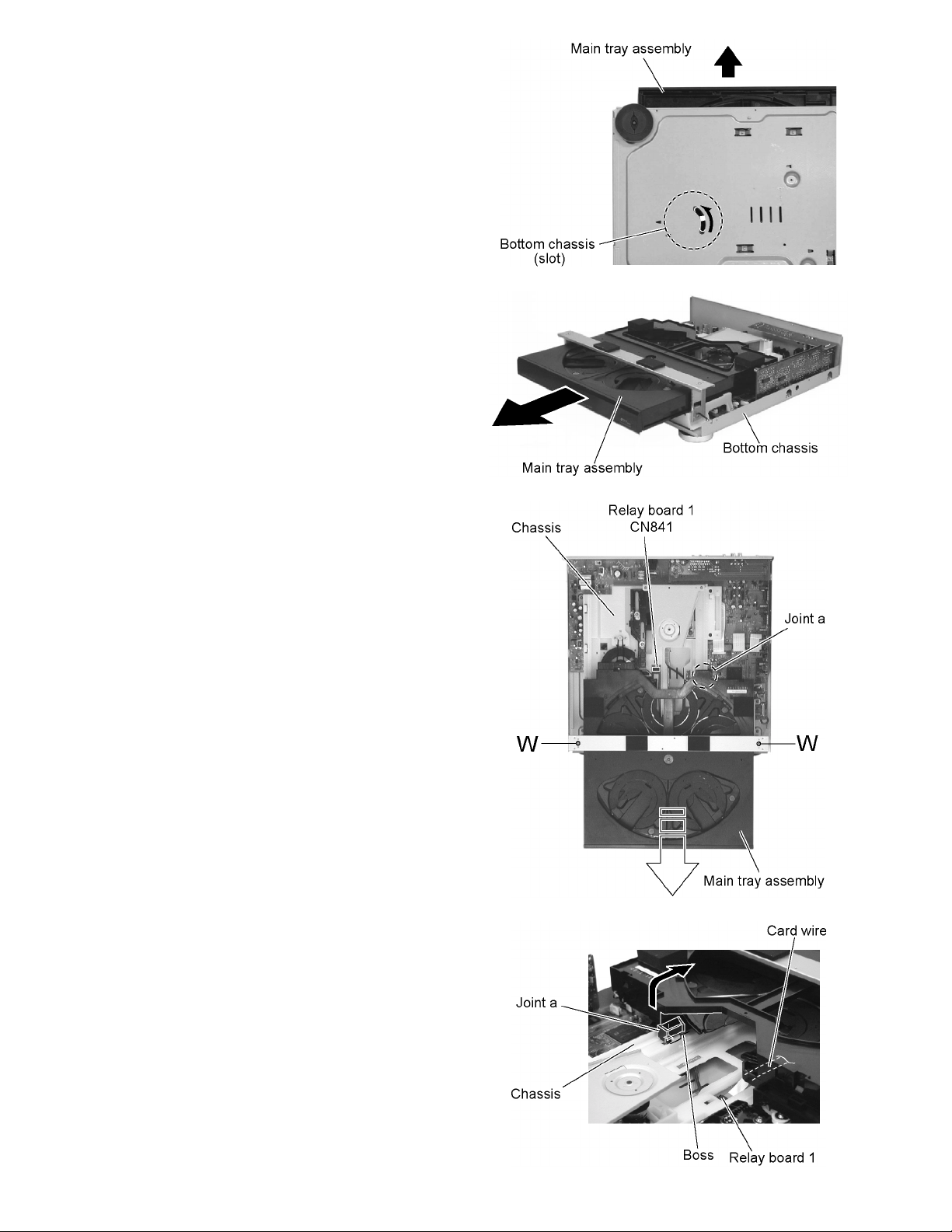

2.1.3 Removing the main tray assembly

(See Fig.4 to 7)

• Prior to performing the following procedure, remove the top

cover and the front panel assembly.

(1) Turn over the body and insert a screwdriver into the slot of

the bottom chassis, then move it in the direction of the ar-

row in Fig.4. The main tray assembly will move forward.

(2) Draw the main tray assembly toward the front manually.

(3) Bring up the joint a over the boss of the chassis, and re-

move the main tray assembly toward the front.

(4) Remove the two screws W attaching the front bracket.

(5) Disconnect the card wire, on the back of the main tray as-

sembly, from connector CN841 on the relay board 1.

Fig.4

Fig.5

Fig.6

Fig.7

8

Page 9

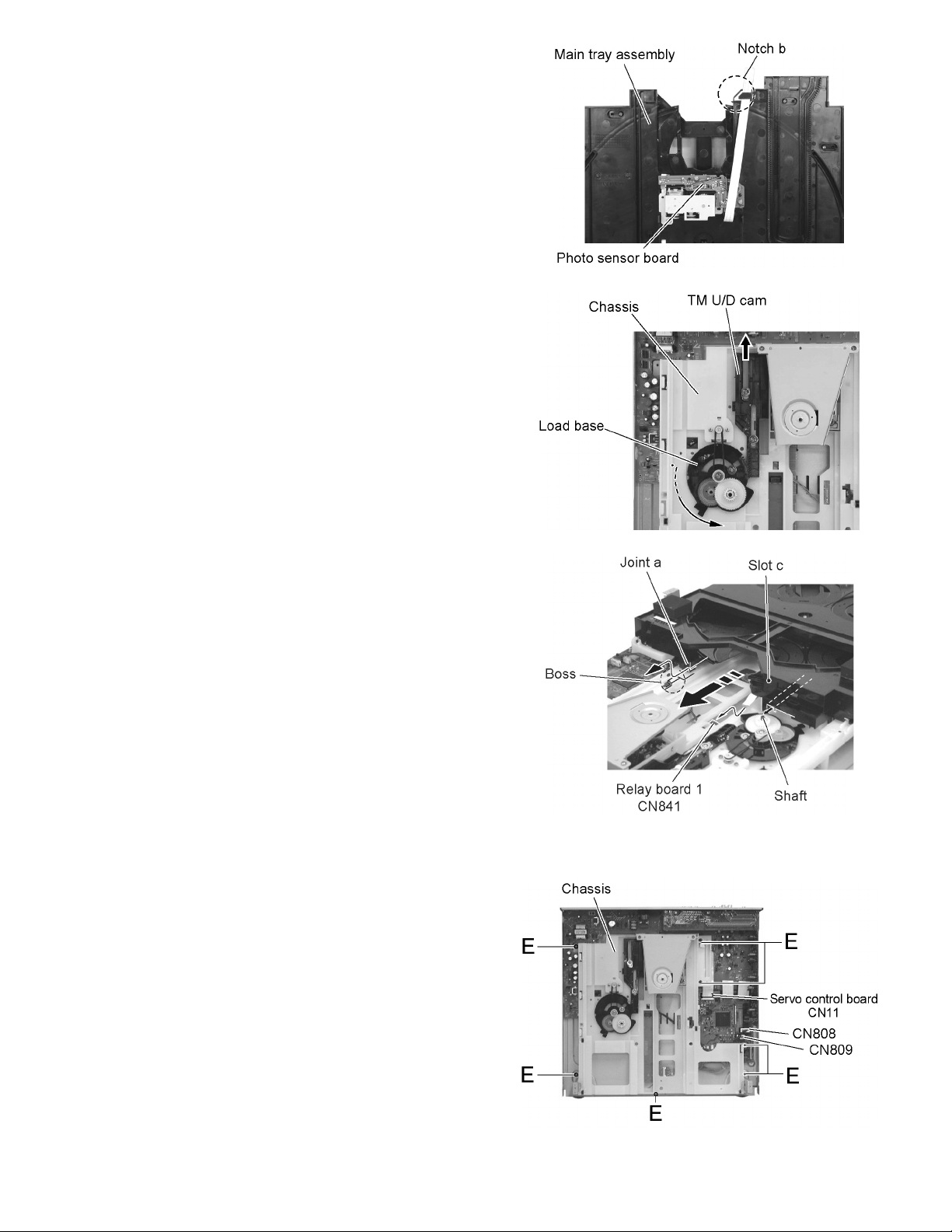

--Reattaching the main tray assembly -(See Fig.8 to 10)

(1) Turn over the main tray assembly and pass the card

wire extending from the photo sensor board through the

notch b, in advance (Fig.8).

(2) From above the chassis, turn the load base counter-

clockwise until the TM U/D cam stops at the back end

(Bring down the traverse mechanism assembly).

(3) Reattach the main tray assembly to the chassis while fit-

ting to the groove on the right and left sides of the chassis.

(4) Connect the card wire through the notch b to connector

CN841 on the relay board 1.

(5) Reattach the main tray assembly while fitting the slot c

to the shaft.

XV-FA900BK/XV-FA902SL

Fig.8

2.1.4 Removing the chassis

(See Fig.11)

• Prior to performing the following procedure, remove the top

cover, the front panel assembly and the main tray assembly.

(1) Disconnect the wire from connector CN808, CN 809 and

the card wire from CN11 on the servo control board respectively.

(2) Remove the seven screws E attaching the chassis.

Fig.9

Fig.10

Fig.11

9

Page 10

XV-FA900BK/XV-FA902SL

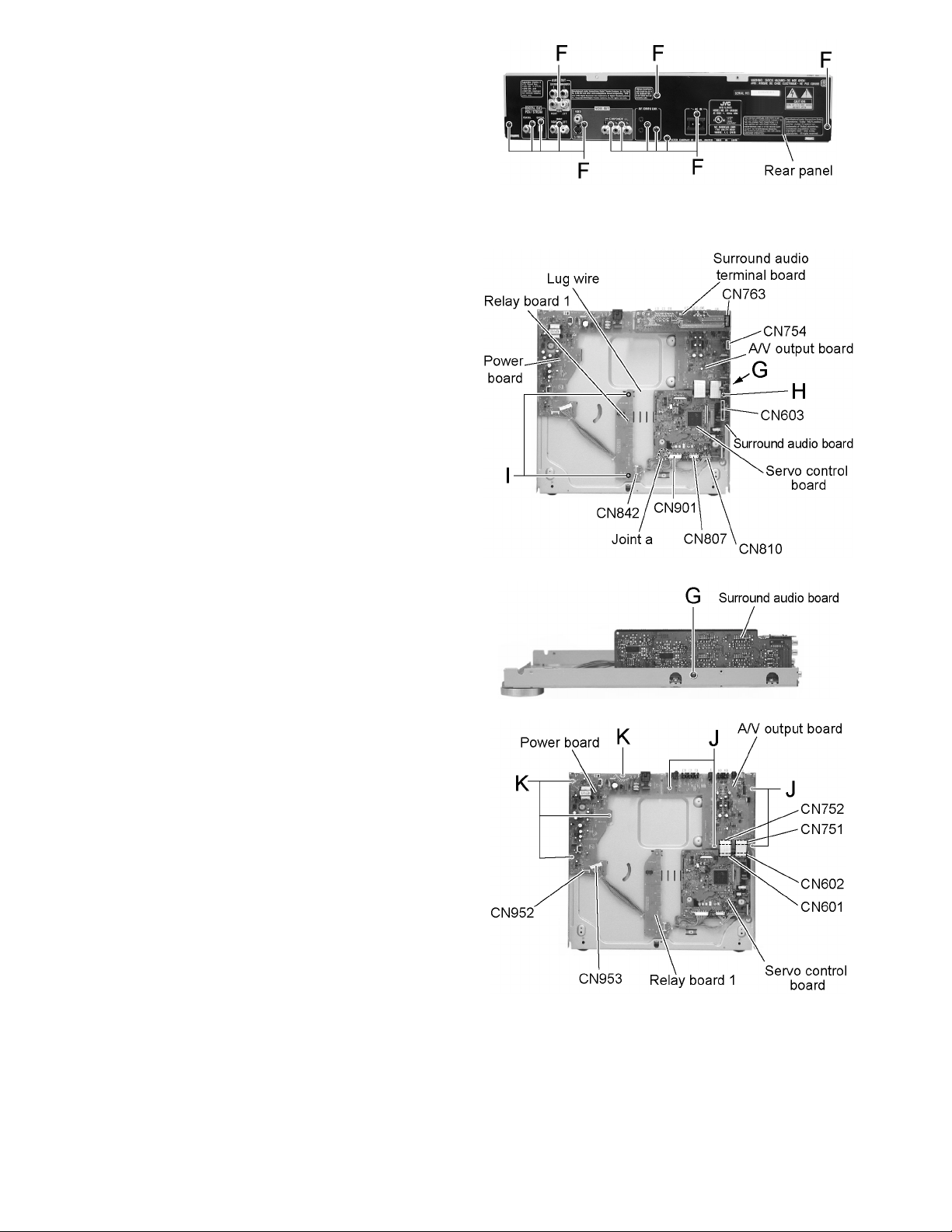

2.1.5 Removing the rear panel

(See Fig.12)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the fourteen screws F attaching the rear panel.

2.1.6 Removing each board

(See Fig.13 to 15)

• Prior to performing the following procedure, remove the top

cover, the front panel assembly, the main tray assembly, rear

panel and the chassis.

--Surround audio board--

(1) Pull out the surround audio terminal board from connec-

tor CN763.

(2) Remove the screw G attaching the surround audio

board.

(3) Pull out the surround audio board from connector

CN754 and CN603.

--Servo control board--

(1) Disconnect the card wire from connector CN601 and

CN602 on the servo control board.

(2) Disconnect the wire from connector CN807, CN810 and

CN901 on the servo control board respectively.

(3) Remove the screw H attaching the servo control board

and release the joint a.

--Relay board 1--

(1) Disconnect the wire from connector CN842 on the relay

board 1.

(2) Remove the two screws I attaching the relay board.

--A/V output board--

(1) Disconnect the card wire from connector CN751 and

CN752 on the A/V output board.

(2) Remove the four screws J attaching the A/V output

board.

--Power board--

(1) Disconnect the wire from connector CN952 and CN953

on the power board.

(2) Remove the four screws K on the upper side of the

body.

Fig.12

Fig.13

Fig.14

10

Fig.15

Page 11

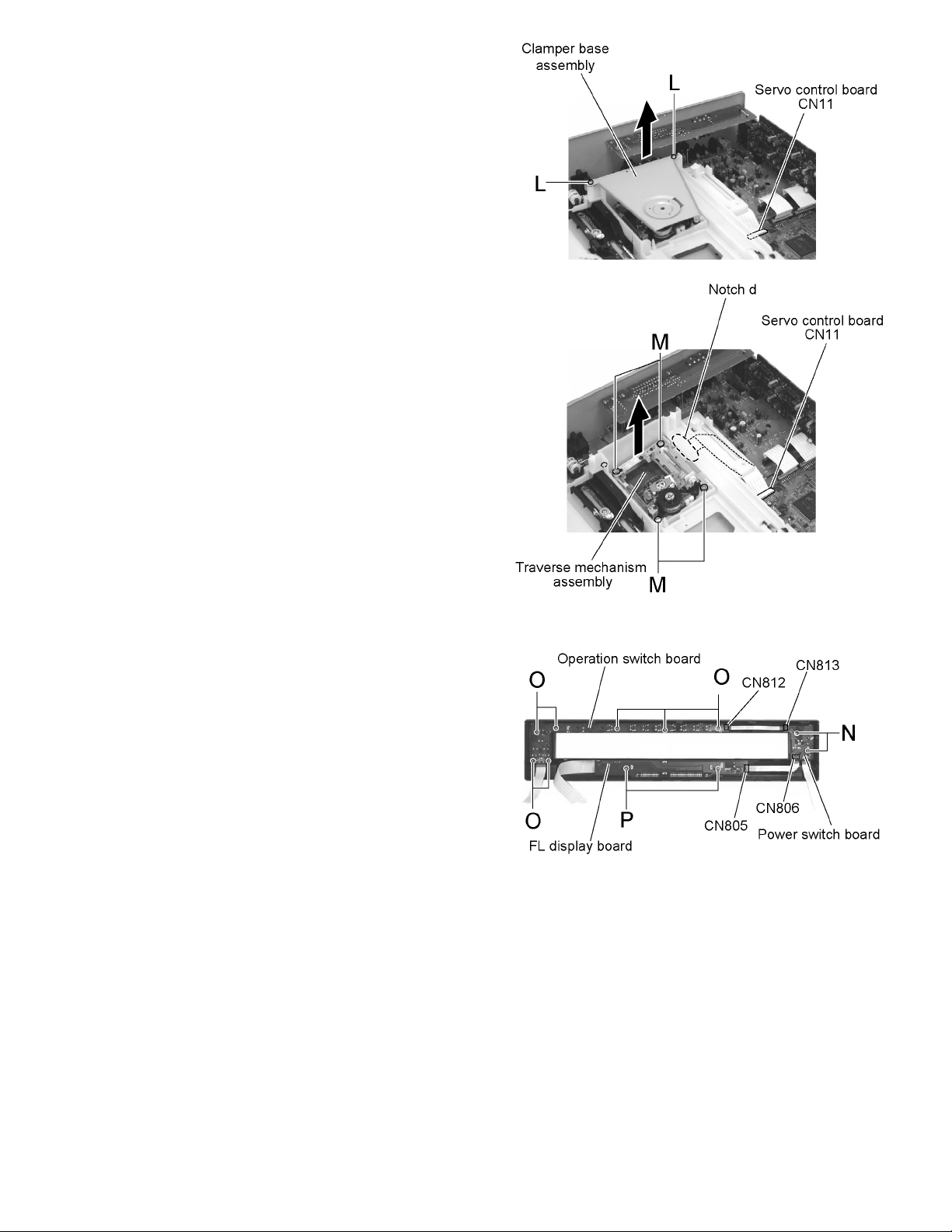

2.1.7 Removing the traverse mechanism assembly

(See Fig.16 and 17)

• Prior to performing the following procedure, remove the top

cover.

REFERENCE:

There is no need to remove the chassis.

(1) Eject the main tray assembly toward the front referri ng to

“Removing the main tray assembly”

(2) Remove the two screws L and pull out the clamper base

assembly upward.

(3) Disconnect the card wire from connector CN11 on the ser-

vo control board.

(4) Remove the four screws M and the traverse mechanism

assembly upward.

CAUTION:

When reattaching the traverse mechanism assembly, pass

the card wire extending from the traverse mechanism assembly through the notch d of the TM U/D base.

XV-FA900BK/XV-FA902SL

Fig.16

2.2 Front panel assembly

• Prior to performing the following procedure, remove the top

cover and the front panel assembly.

2.2.1 Removing the power switch board

(See Fig.18)

(1) Remove the two screws N on the back of the front panel

assembly.

(2) Disconnect the card wire from connector CN813 and

CN806 on the power switch board.

2.2.2 Removing the operation switch board

(See Fig.18)

(1) Remove the seven screws O on the back of the front pan-

el assembly.

(2) Disconnect the card wire from conn ector CN812 on the

operation switch board.

2.2.3 Removing the FL display board

(See Fig.18)

(1) Remove the two screws P on the back of the front panel

assembly.

(2) Disconnect the card wire from connector CN805 on the FL

display board.

Fig.17

Fig.18

11

Page 12

XV-FA900BK/XV-FA902SL

SECTION 3

MECHANISM

3.1 chassis unit

• Prior to p erforming the following p rocedures, remove the top

cover, the front panel assembly, the main tray assembly, the

chassis.

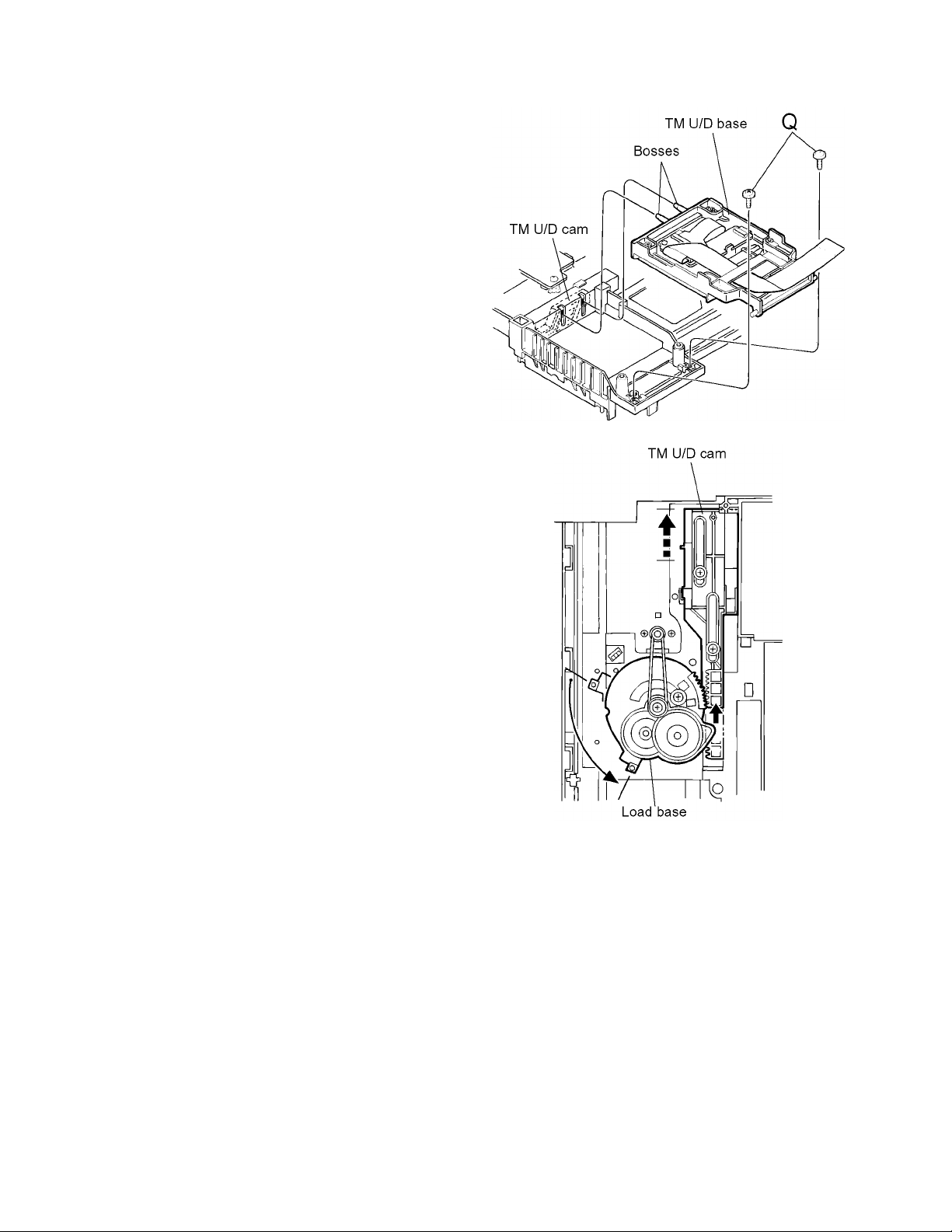

3.1.1 Removing the TM U/D base

(See Fig.1 and 2)

REFERENCE:

It is not necessary to remove the traverse mechanism assembly from the TM U/D base. As the removing procedure of the

traverse mechanism, please refer to “Removing the traverse

mechanism assembly”

(1) Turn over the chassis and remove the two screws Q.

(2) Remove the TM U/D base upward.

Reattaching the TM U/D base

REFERENCE:

From above the loading base, turn the load base counterclockwise until the TM U/D cam stops at the back end as

shown in

Fig.2.

Fig.1

(1) Reattach the TM U/D base to the chassis while fitting

the two Bosses on the side of the TM U/D base to the

grooves of the TM U/D cam.

(2) Reattach the two screws Q.

Fig.2

12

Page 13

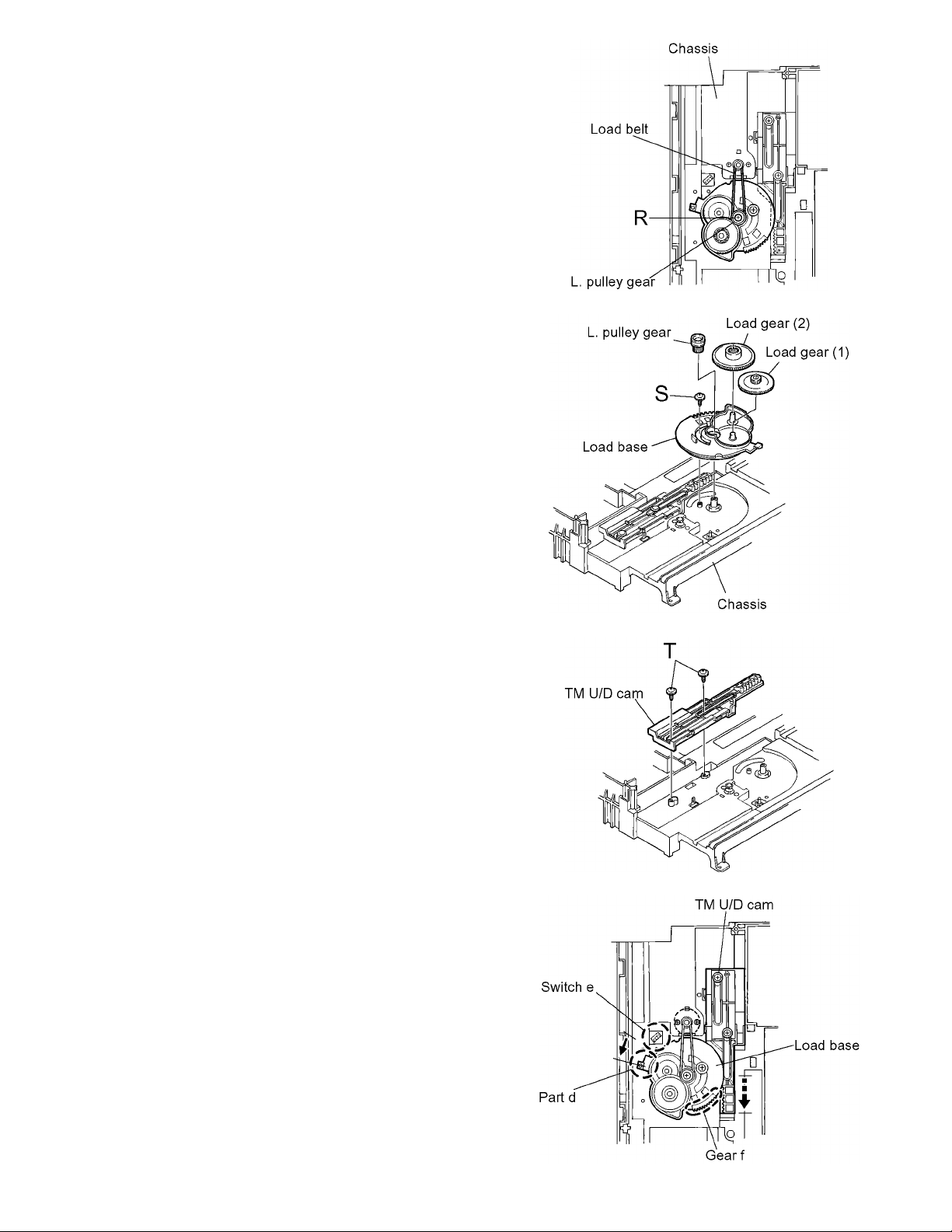

3.1.2 Removing the load belt / load base / TM U/D cam

(See Fig.3 to 6)

• Prior to performing the following procedures, remove the TM

U/D base.

(1) Remove the load belt on the upper side of the chassis.

(2) Remove the screw R attaching the L. pulley gear.

(3) Remove the L. pulley gear, the load gear (1), the load gear

(2) and the load belt respectively.

(4) Remove the screw S and the load base upward.

(5) Remove the two screws T and the TM U/D cam upward.

CAUTION:

When reattaching the TM U/D cam and the load base,

(1) Move the TM U/D cam toward the front until it stops

(Fig.6).

(2) Make sure that the part d of the load base is out of align-

ment with the switch e and that the gear f is disengaged

from the TM U/D cam.

XV-FA900BK/XV-FA902SL

Fig.3

Fig.4

Fig.5

Fig.6

13

Page 14

XV-FA900BK/XV-FA902SL

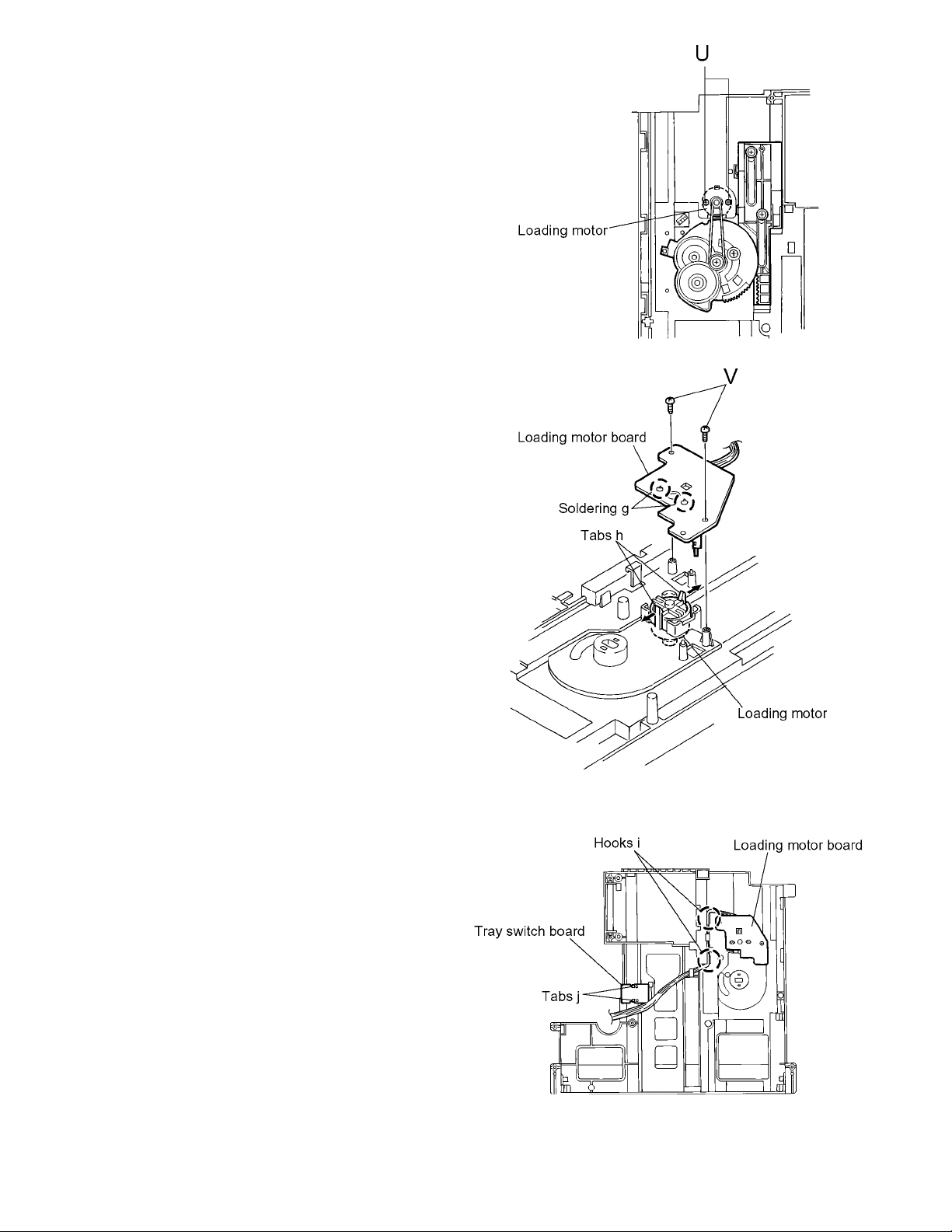

3.1.3 Removing the loading motor / loading motor board

(See Fig.7 and 8)

(1) Remove the two screws U attaching the loading motor on

the upper side of the chassis.

(2) Turn over the chassis and unsolder the two soldering g on

the loading motor board.

(3) Remove the two screws V attaching th e loading motor

board.

(4) Spread apart the two tabs h and pull out the loading motor.

CAUTION:

When reattaching the loading motor board, settle the wires on

the two hooks i on the chassis and draw the other end to the

left as shown in Fig.9.

Fig.7

3.1.4 Removing the tray switch board

(See Fig.9)

(1) Turn over the chassis, and remove the tray switch board

while spreading apart the two tabs j.

14

Fig.8

Fig.9

Page 15

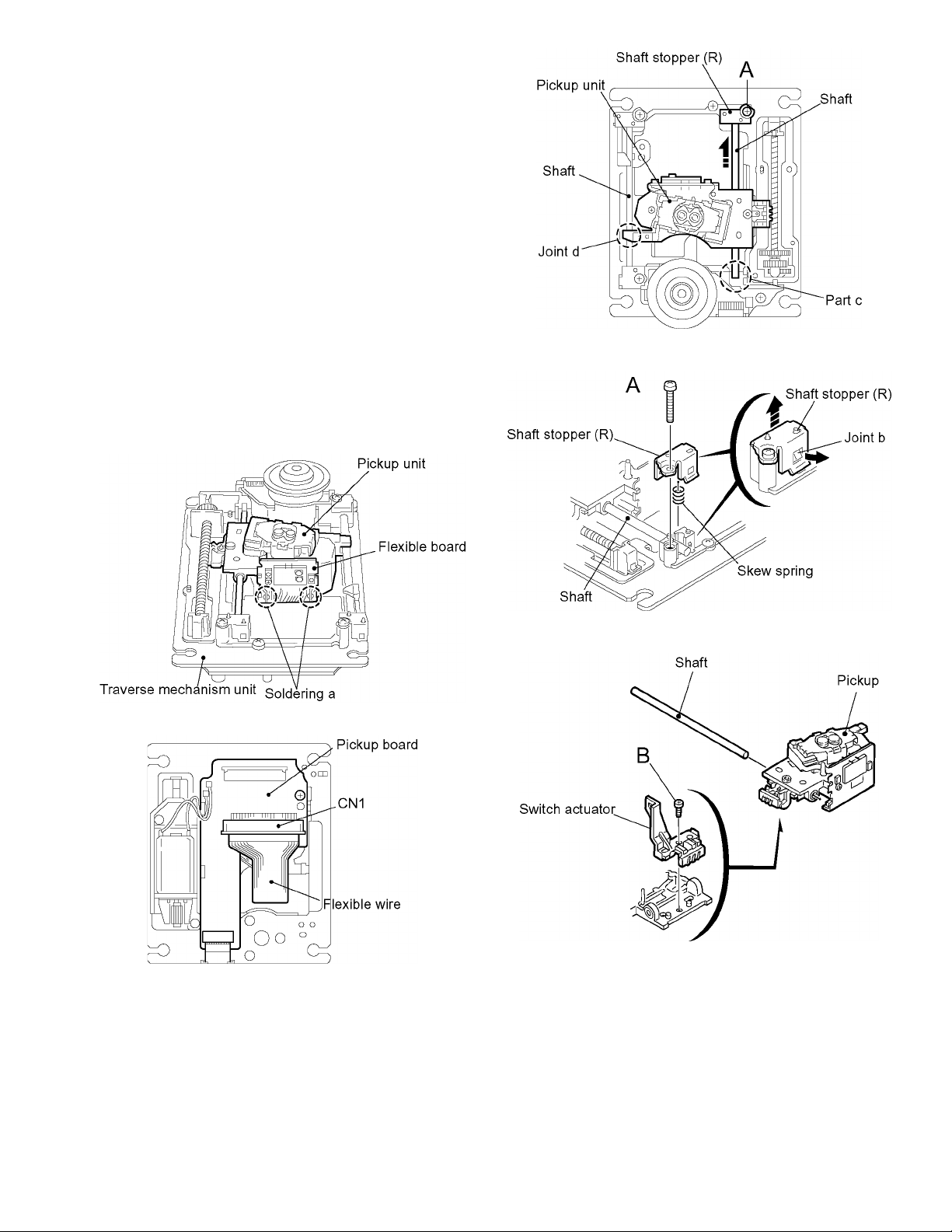

3.2 Traverse mechanism unit

3.2.1 Removing the pickup

(See Fig.1 to 5)

It is not necessary to remove the traverse mechanism unit.

(1) Solder soldering a on the flexible board next to the pickup

unit.

(2) From the bottom of the traverse mechanism unit, discon-

nect the flexible wire from CN1 on the pickup board.

ATTENTION:

Disconnecting the flexible wire without soldering may

cause damage to the pickup.

(3) Remove the screw A attaching the shaft stopper (R) on

the upper side of the traverse mechanism unit. Pull the

side of the shaft stopper (R) outward to release the joint b

and remove it upward. Remove the skew spring at the

same time.

(4) Move the shaft in the direction of the arrow to release it

from the part c.

(5) Release the joint d with the shaft and remove the pickup

with the shaft.

(6) Pull out the shaft.

(7) Remove the screw B attaching the switch actuator.

XV-FA900BK/XV-FA902SL

Fig.3

Fig.1

Fig.2

Fig.4

Fig.5

15

Page 16

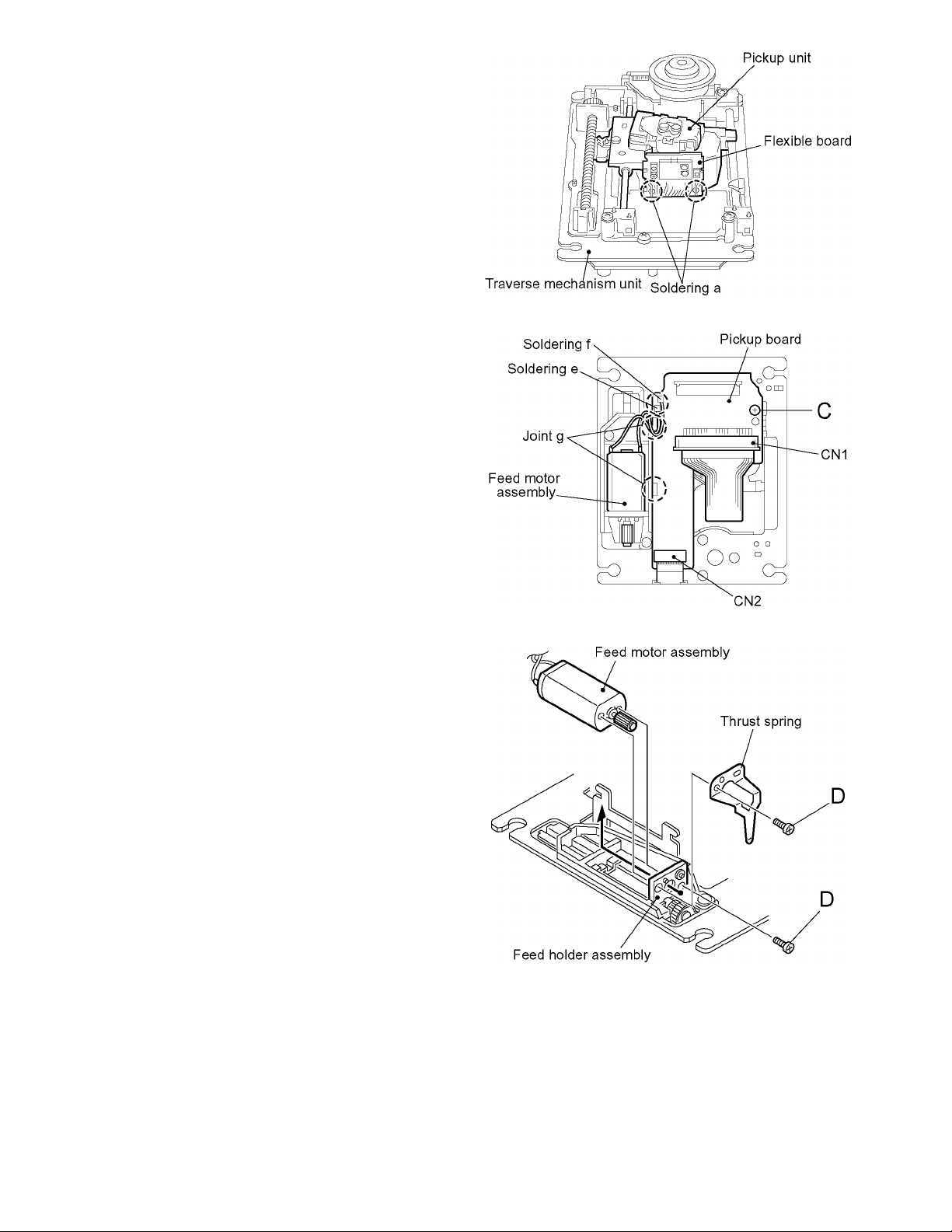

XV-FA900BK/XV-FA902SL

3.2.2 Removing the pickup board

(See Fig.1 and 6)

It is not necessary to remove the traverse mechanism unit.

(1) Solder soldering a on the flexible board next to the pickup

unit.

(2) From the bottom of the traverse mechanism unit, discon-

nect the flexible wire from CN1 on the pickup board.

ATTENTION:

Disconnecting the flexible wire without soldering may

cause damage to the pickup.

(3) Disconnect the card wire from connector CN2 on the pick-

up board and unsolder the soldering e and f on the harnesses

(4) Remove the screw C attaching the pickup board and re-

lease the two joints g.

3.2.3 Removing the feed motor assembly

(See Fig.1, 6 and 7)

• Prior to performing the following procedure, remove the

traverse mechanism unit.

(1) Solder soldering a on the flexible board next to the pickup

unit.

(2) From the bottom of the traverse mechanism unit, discon-

nect the flexible wire from CN1 on the pickup board.

ATTENTION:

Disconnecting the flexible wire without soldering may

cause damage to the pickup.

Fig.1

(3) Remove the pickup board.

(4) Remove the two screws D attaching the feed motor a s-

sembly and remove the thrust spring. Move the feed motor

assembly in the direction of the arrow to pull it out from the

feed holder.

Fig.6

Fig.7

16

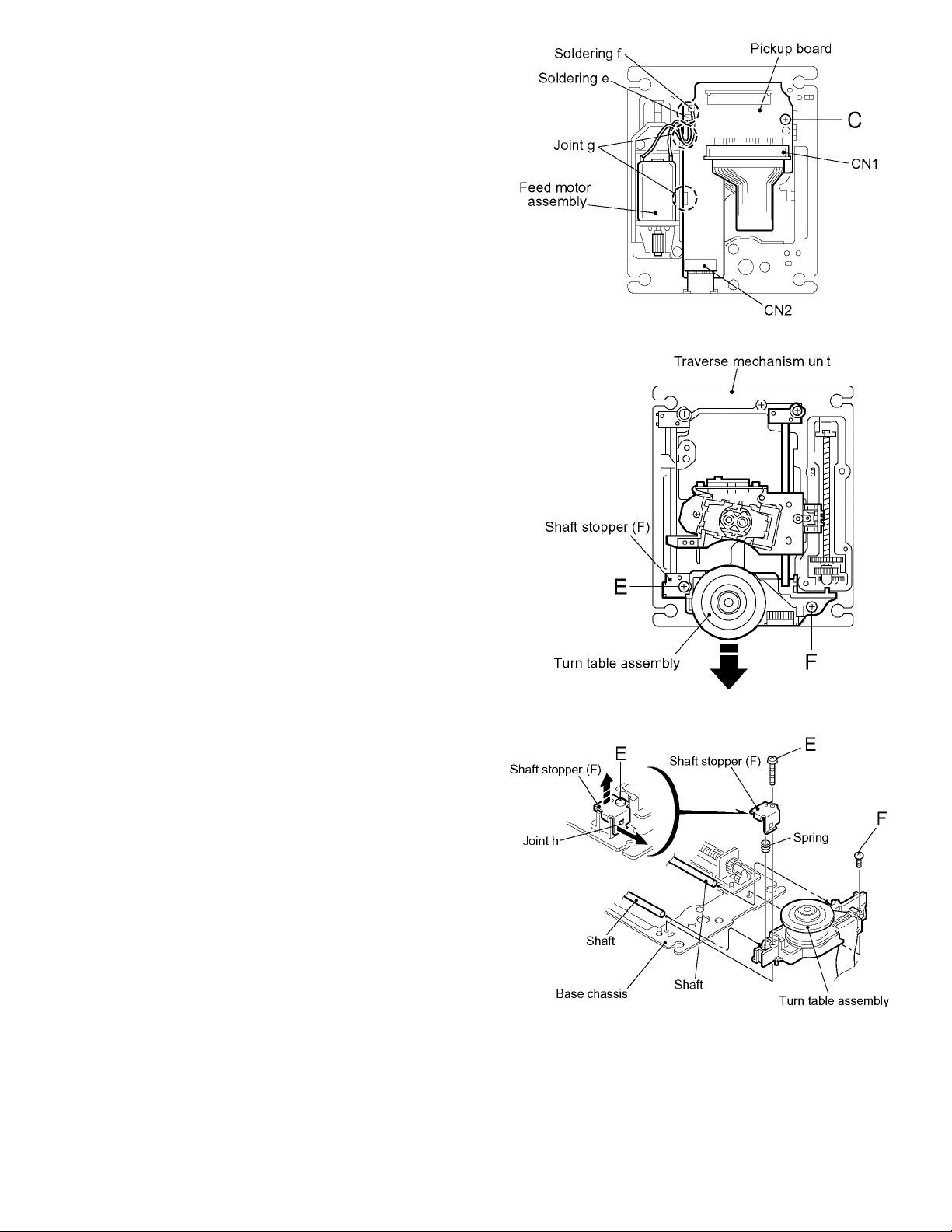

Page 17

3.2.4 Removing the turn table assembly

(See Fig.6, 8 and 9)

• Prior to performing the following procedure, remove the

traverse mechanism unit.

(1) Disconnect the card wire extending from the turn table as-

sembly, from connector CN2 on the pickup board.

(2) Remove the screw E attaching the shaft stopper (F) on the

upper side of the traverse mechanism unit. Pull the side of

the shaft stopper (F) outward to release the joint h and re-

move it upward. Remove the spring at the same time.

(3) Remove the screw F attaching the turn table assembly.

(4) Move the turn table assembly outward and pull out from

the shaft. Then remove it from the base chassis.

XV-FA900BK/XV-FA902SL

Fig.6

Fig.8

Fig.9

17

Page 18

XV-FA900BK/XV-FA902SL

3.3 Main tray assembly unit

• Prior to p erforming the following p rocedures, remove the top

cover, the front panel assembly and the main tray assembly.

3.3.1 Removing the fitting (See Fig.1)

(1) Remove the fitting on the front side of the main tray as-

sembly while releasing the four joints a upward.

3.3.2 Removing the main tray cover and the main tray

(See Fig.2 and 3)

• Prior to performing the following procedure, remove the fitting.

(1) Remove the six screws A attaching the main tray on the

under side of the main tray assembly.

(2) Remove the screw B attaching the main tray cover on the

upper side of the main tray assembly.

(3) Push the two joint tabs b on the back of the main tray as-

sembly to release the main tray cover from the tray bottom. Disengage the joint tabs c of the main tray from the

main tray cover.

Fig.1

18

Fig.2

Fig.3

Page 19

3.3.3 Removing the photo sensor board and the sub tr ay

drive motor assembly

(See Fig.4)

(1) Turn over the main tray assembly and remove the two

screws C attaching the photo sensor board.

(2) Disconnect the card wire from conn ector CN082 on the

photo sensor board.

REFERENCE:

Make sure to disconnect the card wire from the photo

sensor board. If the photo sensor board is pulled out

from the main tray without disconnecting the card wire,

the cam switch side inside of the main tray may be damaged.

(3) Remove the two screws D attaching the motor base unit.

--When reassembling,--

• Attach the two wires to the part d on the photo sensor

board, and before reattaching the photo sensor board, connect the card wire to connector CN082 and pass the card

wire extending from connector CN081 through the notch e

of the main tray.

XV-FA900BK/XV-FA902SL

Fig.4

19

Page 20

XV-FA900BK/XV-FA902SL

3.3.4 Sub tray position and operation check

(See Fig.5 and 6)

• Prior to performing the following procedures, remove the fit-

ting and the main tray cover.

CAUTION:

Make sure the sub trays are set as shown in Fig.5. When moving the sub trays, put the sub trays which come to the position

(4) and (5) forward in turn.

Prior to moving the sub trays by hand, the sub tray drive motor

assembly must be removed in advance referring to the preceding page.

Do not put the sub trays forward except at the position (4) and

(5).

3.3.5 Removing the U/D cam (U)

(See Fig.7)

• Prior to performin g the fo llo wing pr ocedure, re mo ve the main

tray cover.

(1) Remove the two screws E attach ing the U/D cam (U) on

the upper side of the main tray assembly.

Fig.5

20

Fig.6

Fig.7

Page 21

3.3.6 Removing the sub trays (See Fig.8 to 14)

• Prior to performing the following procedure, remove the main

tray cover and the U/D cam (U).

CAUTION:

Remove the sub tray assembly (4), (3), (2), (5), (6), (7) and (1)

in order. When reattaching, observe the following procedure

without fail.

(1) Remove the sub tray (4) and (3) from the main tray up-

ward.

(2) Remove the sub tray (2) upward.

(3) Similarly, remove the sub tray (5) , (6) and (7) upward.

(4) At last, remove the sub tray (1) upward.

--Reattaching the sub tray--

(1) Reattach the sub tray (1) while fitting the part f to the

groove of the ACT. gear (1) marked g.

(2) Reattach the sub tray (2) while inserting the shaft h into

the groove i of the main tray, and at the same ti me, fitting the part j to the groove of the ACT. gear (1) marked

k .

Move the sub tray (2) toward the tray (1).

(3) Similarly, reattach the sub tray (7).

XV-FA900BK/XV-FA902SL

Fig.8

Fig.9

Fig.10

21

Page 22

XV-FA900BK/XV-FA902SL

(4) Reattach the sub tray (3) while inserting the shaft l into

the groove m of the main tray, and at the same time,

putting the shaft n on the U/D cam (L). Then, move the

sub tray (3) toward the sub tray (2) until it stops.

REFERENCE:

At this point, the sub tray (3) is on top of the sub tray

(2).

(5) Reattach the sub tray (4) while fitting the part o to the

ACT.gear (2) on the main tray.

CAUTION:

Make sure the part o of the sub tray (4) engages with

the ACT. gear (2) correctly in the center of the main

tray.

REFERENCE:

At this point, the sub tray (4) is on top of the sub tray

(3).

(6) Reattach the sub tray (6) and (5) in the same way.

CAUTION:

Make sure that the trays are attached to the correct

position and that they can be moved. To move the sub

trays manually, the sub tray drive motor assembly

must be removed in advance.

Fig.11

Fig.12

Fig.13

22

Fig.14

Page 23

3.3.7 Removing the cam switch board assembly

(See Fig.15 to 17)

• Prior to performing the following procedure, remove the main

tray cover, the U/D cam (U) and the sub trays.

(1) Remove the screw F attaching the gear cover. Release

the two tabs marked p by pushing inward.

(2) Remove the cam gear (2) upward.

(3) Disconnect the card wire from conn ector CN083 on the

cam switch board assembly.

(4) Remove the two screws G attaching the cam switch board

assembly.

CAUTION:

When reattaching the cam gear (2), set the position of the

boss and the triangular mark and hole as shown in Fig.17.

XV-FA900BK/XV-FA902SL

Fig.15

Fig.16

Fig.17

23

Page 24

XV-FA900BK/XV-FA902SL

3.3.8 Removing the ACT. gear (1), U/D cam (L), cam gear

(1) and ACT.gear (2)

(See Fig.18 and 19)

• Prior to performin g the fo llo wing pr ocedure, re mo ve the main

tray cover, the U/D cam (U) and the sub trays.

(1) Draw out the U/D cam (L).

(2) Draw out the ACT. gear (1).

(3) Draw out the cam gear (1).

(4) Draw out the ACT. gear (2) while pushing the two inward.

CAUTION:

When reassembling, make sure the position of each gear referring to Fig.19 and reattach the ACT. gear (2) first.

Fig.18

24

Fig.19

Page 25

SECTION 4

Adjustment method

4.1 Tes t mode setting method

(1) Take out the disc and close the tray.

(2) Unplug the power plug.

(3) Insert power plug into outlet while pressing both "PLAY" button and "STOP" button of the main body.

(4) The player displays "TEST * * " on the FL display. keeps pushing the button until this is displayed.

" * * " means the player version.

(5) When the power supply is turned off, test mode is released.

The mode changes as follows whenever the "CHOICE" button of remote controller is pushed in test mode.

XV-FA900BK/XV-FA902SL

4.2 Initialization method

Please initialize according to the following procedures when mic roprocessor or pick-up is exchanged and wh en the up-

grade is done.

(1) Makes to test mode.

(2) After "FORWARD SKIP" button ( ) of the main body is pushed, "PAUSE" button is pushed.

(3) DVD AUDIO indicator lights when about ten seconds pass. Then, it is initialization comp letion.

4.3 Method of displaying version of microcomputer

(1) Makes to test mode and initializes

(2) When "CHOICE" button of remote controller is pushed once, the figure is displayed on the FL display as follows.

* Version number of decoder is displayed on the television screen.

* Last two digits are displayed on the FL display for the treble version number.

4.4 Method of displaying device key index

(1) Makes to test mode and initializes.

(2) When "CHOICE" button of remote controller is pushed twice, the device key index is displayed on the

FL display as follows.

25

Page 26

XV-FA900BK/XV-FA902SL

4.5 Display of current value of laser

(1) Makes to test mode and initializes.

(2) When "CHOICE" key of remote controller is pushed four times, It is displayed on the FL display, "CHECK".

(3) Afterwards, the laser current value can be switched by pushing the key to remote controller without turning on the disc.

Remote controller "4" key --- Laser of DVD

Remote controller "5" key --- Laser of CD

As for the current value of the laser, the figure displayed on

the FL display becomes a current value as it is by "mA" unit.

becomes 36 mA if displayed as 36.

(4) The laser output stops if the "STOP" key to remote controller is pushed.

It can be judged it is simply good if the displayed current value of the laser is smaller than that of the undermentioned value.

Moreover, there must be a deteriorated possibility and the pick-up must exchange the pick-up more than the

undermentioned value.

Laser current value of CD ------ 49 mA or less

Laser current value of DVD ---- 64 mA or less

4.6 Display of jitter value

(1) Makes to test mode and initializes.

(2) When "CHOICE" key of remote controller is pushed four times, It is displayed on the FL display, "CHECK".

(3) The test disk (VT-501) is inserted, and the "PLAY" key to the main body is pushed.

(4) The jitter value is displayed on the FL display as follows.

Values to judge whether the jitter is allowa ble or not is displayed, instead of actual

jitter values.The displayed values are expressed in hexadeci mal numbe rs.

In the following cases, please "Flap adjustment of the pick-up guide shaft" referring to the following page.

Before using the TEST disc VT-501, careful check it if there is neither damage nor dirt on the read surface.

< In the following cases, please adjustment >

• When you exchange the pick-up

• When you exchange the spindle motor

• When the reading accuracy of the signal is bad (There is a block noise in the screen etc..)

26

Page 27

XV-FA900BK/XV-FA902SL

4.7 Flap adju stment of the pick-up guide shaft

<Tool list for adjustment>

Stud (four pieces set)

Parts No. : JIGXVS40

Hex wrench for adjustment

Off-the-shelf (1.3mm)

Test disc

VT-501 or VT-502

<Adjustment preparation>

(1) The metal cover is detached, the "OPEN/CLOSE" button is pushed, and the tray is done in open.

(2) The AC plug code is pulled out once in the state.

(3) Remove the surround audio board and surround audio terminal board respectively.

(4) The traverse mechanism is detached, and the card wire is connected with CN11.

(5) The stud is installed in the traverse mechanism as shown in Figure.

The clamper is removed from the clamper base.

(6) The disk (Everything is good) is put on sub-tray 1, the test disk is put on the turntable in the traverse mechanism, and fixes by

the clamper.

(7) The card wire becomes under the main tray, and the main tray is closed by hand operated.

(8) The AC plug code is inserted, and the "DISC1" button is pushed

(Please push the "DISC1" button directly without pushing the power supply button).

(9) Because the playback of "DISC1" starts, stops and the AC plug code is pulled out.

<Adjustment method>

(10) The AC plug code is made insertion test mode while pu shing the "PLAY" button and the "STOP" button of the main body at

the same time.

(11) Please push the "PAUSE" button after pushing the "FORWARD SKIP" button of the main body, and confirm

DVD AUDIO indicator lights after a few seconds.

(12) When the "CHOICE" button of remote controller is pushed three times, it is displayed on the FL display as

"CHECK".

(13) The display of the FL display changes into "CHECK OK" after a few seconds if the "PAUSE" button of the main body is pushed

in the state.

When the "PLAY" button of the main body is pushed afterwards, the jitter value is displayed on the FL display.

<Adjustment>

(1) Puts into the state to display the jitter value on the FL display referring to "Displa y of jitter value" .

(2) The adjustment screw under the traverse mechanism is turned with hex wrench, and matches so that the jitter value dis-

played on the FL display may become maximum value.

<POINT>

(1) turns in the forward or the opposite direction, and

makes to the position where the jitter value is good

the half rotation of adjustment screw a and b(180 degrees) respectively.

(2) Afterwards, adjustment screw b and c are turned in

the same way, and makes to the best position.

* As this value is bigger, the jitter is more allowable in

this model.

27

Page 28

XV-FA900BK/XV-FA902SL

4.8 Upgrading of firmware

(1) The power supply is turned on pushing the "P OWER" key.

(2) The up-grade disc is inserted.

(3) When FL display of the main body changes from "READING" into "UPGRADE", cursor "UP" key ( ) of remote controller

is pushed.

(4) The up-grade starts if the entire screen becomes blue and it is displayed, "Upgrade progress".

(5) The tray opens automatically, the up-grade disc is removed.

(6) The up-grade ends if the tray closes automatically, and the screen returns to the normal screen.

(7) Please confirm the version of the microcomputer after makes to test mode and initializes.

4.9 Display of region code

(1) Makes to the stand-by state.

(2) The "POWER" key is pushed while pushing the "BACK SKIP" key and the "FORWARD SKIP" key to the main body.

(3) Region code is displayed on the FL display as follows.

< ATTENTION ! >

Please pull out the AC plug code after the standby indicator lights pushing the power supply button without fail after

completing the repair.

The mechanism becomes initialed position.

There is a possibility to break when carrying in not initialed position the mechanism but the state.

28

Page 29

4.10 Confirm method of operation

Please confirm the operation of the undermentioned item after doing the repair and

the upgrade of the firmware.

The EEPROM is initialized.

Refer to the initialization method.

Opening picture check (Power ON)

It should be display "JVC"

Muting working

The noise must not be had to the performance beginning when you push "PLAY" button or at ON/STANDBY.

FL Display

The mark and the logo, etc. displayed by each operation must be displayed correctly.

FL Display should light correctly without any unevenness.

All Function button

All function buttons should worked correctly with moderate click feeling.

Open and close movement of tray

When press OPEN/CLOSE button the tray should move smoothly without any noise.

XV-FA900BK/XV-FA902SL

Remote controller unit working

Check the correctly operation in use of remote controller unit.

Reading of TOC

Be not long in the malfunction.

Search

Both forward-searches and backward-searches should be able to be done.

Do not stop be searching or after the search.

Skip

Both forward-skip and backward-skip should be able to be done.

Do not stop be after the skip.

Playback

Do not find abnormality etc. of tone quality and the picture quality.

Most outside TITLE playback check

Play VT-501 TITLE 59 CHAPTER 1 , check normal playback.

29

Page 30

XV-FA900BK/XV-FA902SL

4.11 Troubleshooting

Servo volume

30

Page 31

XV-FA900BK/XV-FA902SL

4.12 Check points for each error

4.12.1 Spindle start error

(1) Defective spindle motor

*Are there several ohms resistance between each pin of CN11 "7-6","6-5","7-5"?

(The power supply is turned off and measured.)

*Is the sign wave of about 100mVp-p in the voltage had from each terminal?

[ CN11"10"(H1-),"9"(H1+),"12"(H2-),"11"(H2+),"14"(H3-),"13"(H3+) ]

(2) Defective spindle motor driver (IC251)

*Has motor drive voltage of a sine wave or a rectangular wave gone out to each terminal(SM1~3) of CN11"5,6,7" and

IC251"2,4,7"?

*Is FG pulse output from the terminal of IC251"24"(FG) according to the rotation of the motor?

*Is it "L(about 0.9V)" while terminal of IC251"15"(VH) is rotating the motor?

(3) Has the control signal come from servo IC or the microcomputer?

*Is it "L" while the terminal of IC251"18"(SBRK) is operating?

Is it "H" while the terminal of IC251"23"(/SPMUTE) is operating?

*Is the control signal input to the terminal of IC251"22"(EC)?

(changes from VHALF voltage while the motor is working.)

*Is the VHALF voltage input to the terminal of IC251"21"(ECR)?

(4) Is the FG signal input to the servo IC?

*Is FG pulse input to the terminal of IC301"69"(FG) according to the rotation of the motor?

4.12.2 Disc Detection, Distinction error (no disc, no RFENV)

<About frontend section>

* Laser is defective.

* Front End Processor is defective (IC101).

* APC circuit is defective. --- Q101,Q102.

* Pattern is defective. --- Lines for CN11 - All patterns which relate to pick-up and patterns between IC101

* Servo IC is defective (IC301). * IC101 --- For signal from IC101 to IC301, is signal output from IC101 "20" (ASOUT) and

IC101 "41"(RFENV) and IC101 "22" (FEOUT)?

<About loading mechanism section>

* The disc exists in a sub tray. However, a sub tray is sent as follows the turntable without rising.

(Especially, when the disk is CD-RW)

--- IC81 is defective. Exchanges for "GP2S28J" of the rank specification parts.

4.12.3 Traverse movement NG

(1) Defective traverse driver

*Has the voltage come between terminal of CN11 "28" and "30" ?

(2) Defective BTL driver (IC201)

*Has the motor drive voltage gone out to IC201"17" or "18"?

(3) Has the control signal come from servo IC or the microcomputer?

*Is it "H" while the terminal of IC201"9"(STBY1) ?

*TRSDRV Is the signal input? (IC301 "67")

(4) TRVSW is the signal input from microcomputer? (IC401 "50")

4.12.4 Focus ON NG

* Is FE output ? --- Pattern, IC101

* Is FODRV signal sent ? (R209) --- Pattern, IC301 "115"

* Is driving voltage sent ?

IC201 "13", "14" --- If NG, pattern, driver, mechanical unit .

* Mechanical unit is defective.

4.12.5 Tracking ON NG

* When the tracking loop cannot be drawn in, TE shape of waves does not settle.

* Mechanical unit is defective.

Because the self adjustment cannot be normally adjusted, the thing which cannot be normally drawn in is thought.

* Periphery of driver (IC201)

Constant or IC it self is defective.

* Servo IC (IC301)

When improperly adjusted due to defective IC.

4.12.6 Spindle CLV NG

* IC101 -- "35"(RF OUT), "30"(RF-), "31(RF+).

* Does not the input or the output of driver's spindle signal do the grip?

* Has the tracking been turned on?

* Spindle motor and driver is defective.

* Additionally, "IC101 and IC301" and "Mechanism is defective(jitter)", etc. are thought.

31

Page 32

XV-FA900BK/XV-FA902SL

4.12.7 Address read NG

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various factors are thought.

Mechanism is defective. (jitter)

IC301, IC401.

The disc is dirty or the wound has adhered.

4.12.8 Between layers jump NG (double-layer disc only)

Mechanism defective

Defect of driver's IC(IC201)

Defect of servo control IC(IC301)

4.12.9 Neither picture nor sound is output

(1) It is not possible to search

*Has the tracking been turned on?

*To "4.10.5 Tracking ON NG" in "Check points for each error" when the tracking is not normal.

*Is the feed operation normal?

To "4.10.3 traverse movement NG" in "Check points for each error" when it is not normal.

Are not there caught of the feeding mechanism etc?

4.12.10 Picture is distorted or abnormal sound occurs at intervals of several seconds.

Is the feed operation normal?

Are not there caught of the feeding mechanism etc?

4.12.11 Others

The image is sometimes blocked, and the imag e stop s.

The image is blocked when going to outer though it is normal in

surroundings in the disk and the stopping symptom increases.

4.12.12CD During normal playback operation

a) Is TOC reading normal?

Displays total time for CD-DA.

Shifts to double-speed mode for V-CD.

b) Playback possible? *--:-- is displayed during FL search.

According to [It is not possible to search ] for DVD, check the feed and

tracking systems.

*No sound is output although the time is displayed.(CA-DA)

DAC, etc, other than servo.

*The passage of time is not stable, or picture is abnormal.(V-CD)

*The wound of the disc and dirt are confirmed.

There is a possibility with bad jitter

value for such a symptom.

32

Page 33

Description of major ICs

5.1 AN870 3FH-V (IC101) : Frontend processor

• Pin layout

• Pin function

XV-FA900BK/XV-FA902SL

SECTION 5

Pin No.

10 IDGT I Data slice part address part gate signal in-

11 STANDBY I Standby mode control terminal 46 TESTSG I TEST signal input terminal

12 SEN I SEN(Serial data input terminal) 47 RFINP I RF signal positive input terminal

13 SCK I SCK(Serial data input terminal) 48 RFINN I RF signal negative input terminal

14 STDI I STDI(Serial data input terminal) 49 VIN5 I Internal four-partition (CD) RF input 1

15 RSCL I Standard electric current terminal 50 VIN6 I Internal four-partition (CD) RF input 2

16 JLINE I Electric current setting terminal of JLine 51 VIN7 - Internal four-partition (CD) RF input 3

17 TEN I Reversing input terminal of tracking error

18 TEOUT O Tracking error signal output terminal 53 VIN9 I External two-partition (DVD) RF input 2

19 AGCBAL I Offset adjusting terminal 1 54 VIN10 I External two-partition (DVD) RF input 1

20 ASOUT O Full adder signal output terminal 55 VCC1 - Power supply terminal 5V

21 FEN I Focus error output amplifier reversing input

22 FEOUT O Focus error signal output terminal 57 VIN1 I Internal four-partition (DVD) RF input 1

23 AGCOFST I Offset adjusting terminal 2

24 MON - Non connect 58 VIN2 I Internal four-partition (DVD) RF input 2

25 AGCLVL O Output amplitude adjustment for DRC

26 GND2 - Connect to GND 59 VIN3 I Internal four-partition (DVD) RF input 3

27 VREF2 O VREF2 voltage output terminal

28 VCC2 - Power supply terminal 5V 60 VIN4 I Internal four-partition (DVD) RF input 4

29 VHALF O VHALF voltage output terminal

30 DFLTON O Reversing output terminal of filter AMP. 61 GND1 - Connect to GND

31 DFLTOP O Filter AMP. output terminal 62 VIN11 I 3 beam sub input terminal 2 (CD)

32 DCFLT I Capacity connection terminal for filter out-

33 GND3 - Connect to GND 64 HDTYPE O HD Type selection

Symbol I/O Description

1 LPC1 I Laser input terminal (DVD) 34 RFDIFO - Non connect

2 LPC01 O Laser drive signal output terminal (DVD) 35 RFOUT - Connect to TP103

3 LPC2 I Laser input terminal (CD) 36 VCC3 - Power supply terminal 3.3V

4 LPC02 O Laser drive signal output terminal (CD) 37 RFC O Filter for RF delay correction AMP.

5

VFOSHORT

6 TBAL I Tracking balance control terminal 39 OFTR O OFTR output terminal

7 FBAL I Focus balance control terminal 40 BDO O BDO output terminal

8 POFLT O Track detection threshold level terminal 41 RFENV O RF envelope output terminal

9 DTRD I Data slice part data read signal input termi-

I VFOSHORT control terminal 38 DCRF O All addition amplifier capacitor terminal

nal(For RAM)

put terminal( For RAM)

output AMP.

terminal

put

Pin No.

42 BOTTOM O Bottom envelope detection filter terminal

43 PEAK O Peak envelope detection filter terminal

44 AGCG O AGC amplifier gain control terminal

45 AGCO O A GC amplifier level control terminal

52 VIN8 - Internal four-partition (CD) RF input 4

56 VREF1 O VREF1 voltage output terminal

63 VIN12 I 3 beam sub input terminal 1 (CD)

Symbol I/O Description

33

Page 34

XV-FA900BK/XV-FA902SL

5.2 BA5983FM-X (IC201) : 4CH Driver

• Block diagram

• Pin function

Pin No.

10 PowVcc1 - Vcc for CH1/2 power block 25 OPOUT4 O Output for CH4 OP-AMP

11 VO2(-) O Inverted output of CH2 26 OPIN4(-) I Inverting input for CH4 OP-AMP

12 VO2(+) O Non inverted output of CH2 27 OPIN4(+) I Non inverting input for CH4 OP-AMP

13 VO1(-) O Inverted output of CH1 28 PreVcc - Vcc for pre block

14 VO1(+) O Non inverted output of CH1 29 - Connect to ground

15 VO4(+) O Non inverted output of CH4 30 - Connect to ground

5.3 74LCX373MTC-X(IC512,IC513)

• Pin layout

Symbol I/O Description

1 BIAS IN I Input for Bias-amplifier 16 VO4(-) O Inverted output of CH4

2 OPIN1(+) I Non inverting input for CH1 OP-AMP 17 VO3(+) O Non inverted output of CH3

3 OPIN1(-) I Inverting input for CH1 OP-AMP 18 VO3(-) O Inverted output of CH3

4 OPOUT1 O Output for CH1 OP-AMP 19 PowVcc2 - Vcc for CH3/4 power block

5 OPIN2(+) I Non inverting input for CH2 OP-AMP 20 STBY2 I Input for Ch4 stand by control

6 OPIN2(-) I Inverting input for CH2 OP-AMP 21 GND - Substrate ground

7 OPOUT2 O Output for CH2 OP-AMP 22 OPOUT3 O Output for CH3 OP-AMP

8 GND - Substrate ground 23 OPIN3(-) I Inverting input for CH3 OP-AMP

9 STBY1 I Input for CH1/2/3 stand by control 24 OPIN3(+) I Non inverting input for CH3 OP-AMP

Pin No.

Symbol I/O Description

• Truth table

INPUTS OUTPUTS

LE

X

H

H

L

OE

H

L

L

L

Dn Qn

X

L

H

X

Q0

Z

L

H

• Pin function

Symbol

D0~D7

LE

OE

Q0~Q7

Description

Data inputs

Latch enable input

Output enable input

3-State latch outputs

34

H = HIGH Voltage level

L = LOW Voltage level

Z = High impedance

X = Immaterial

Q0 = Previous Q0 before HIGH to LOW transition of latch enable

Page 35

5.4 BA666 4FM-X (IC251) : Spindle motor driver

• Pin layout

• Pin function

Pin No. Symbol I/O Description

1 NC - Non connect

2 A3 O Output 3 for spindle motor

3 NC - Non connect

4 A2 O Output 2 for spindle motor

5 NC - Non connect

6 NC - Non connect

7 A1 O Output 1 for spindle motor

8 GND - Connect to ground

9 H1+ I Positive input for hall input AMP 1

10 H1- I Negative input for hall input AMP 1

11 H2+ I Positive input for hall input AMP 2

12 H2- I Negative input for hall input AMP 2

13 H3+ I Positive input for hall input AMP 3

14 H3- I Negative input for hall input AMP 3

15 VH I Hall bias terminal

16 BR - Non connect

17 CNF - Capacitor connection pin for phase compensation

18 SB I Short brake terminal

19 FG2 - Non connect

20 FR - Non connect

21 ECR I Torque control standard voltage input terminal

22 EC I Torque control voltage input terminal

23 PS O Start/stop switch (power save terminal)

24 FG O FG signal outpu t terminal

25 VCC - Power supply for signal division

26 GSW O Gain switch

27 VM - Power supply for driver division

28 RNF O Resistance connection pin for output current sense

29 - Connect to ground

30 - Connect to ground

XV-FA900BK/XV-FA902SL

35

Page 36

XV-FA900BK/XV-FA902SL

5.5 K4S643232E-TC60(IC505):DRAM

• Block diagram

• Pin function

Symbol Description Symbol Description

CLK System clock signal input DQM0~3 Data input/output mask

CS Chi p select input DQ0~31 Data input/output

CKE Clock enable VDD Power supply terminal

A0~A10 Address VSS Connect to ground

BA0,1 Bank select address VDDQ Power supply terminal

RAS Row address strobe VSSQ Connect to ground

CAS Column address strobe NC Non connect

WE Write enable

36

Page 37

XV-FA900BK/XV-FA902SL

5.6 MN102L62GLK(IC401):Unit CPU

• Pin function

Pin No. Symbol I/O Function Pin No. Symbol I/O Function

1 WAIT I Micon wait signal input 51 SWUPDN - Non connect

2 RE O Read enable 52 MECHA-H/V - Not use

3 SPMUTE O Spindle muting output to IC251 53 DISCSET I Mechanism state signal input

4 WEN O Write enable 54 VDD - Power supply

5 LMMUTE - Non connect 55 FEPEN O Serial enable signal for FEP

6 CS1 O Chip select for ODC 56 SLEEP O Standby signal for FEP

7 CS2 - Non connect 57 BUSY - Non connect

8 HDTYPE O HD Type selection 58 REQ O Communication Request

9 DRVMUTE O Driver mute 59 - - Connect to TP405

10 SBRK O Short breake terminal 60 - - Non connect

11 LSIRST O LSI reset 61 VSS - Ground

12 WORD O Bus selection input 62 EPCS O EEPROM chip select

13 A0 O Address bus 0 for CPU 63 EPSK O EEPROM clock

14 A1 O Address bus 1 for CPU 64 DPDI I EEPROM data input

15 A2 O Address bus 2 for CPU 65 EPDO O EEPROM data output

16 A3 O Address bus 3 for CPU 66 VDD - Power supply

17 VDD - Power supply 67 SCLKO I Communication clock

18 SYSCLK - Non connect 68 S2UDT I Communication input data

19 VSS - Ground 69 U2SDT O Communication output data

20 XI I Oscillation terminal 70 CPSCK O Clock for ADSC serial

21 XO - Non connect 71 P74/SBI1 I Not use(Pull up)

22 VDD - Power supply 72 SDOUT O ADSC serial data output

23 OSCI I Clock signal input 73 - - Not use(Pull up)

24 OSCO O Clock signal output 74 - - Not use(Pull up)

25 MODE I CPU Mode selection input 75 NMI I NMI Terminal

26 A4 O Address bus 4 for CPU 76 ADSCIRQ I Interrupt input of ADSC

27 A5 O Address bus 5 for CPU 77 ODCIRQ I Interrupt input of ODC

28 A6 O Address bus 6 for CPU 78 DECIRQ I Interrupt input of ZIVA

29 A7 O Address bus 7 for CPU 79 CSSIRQ - Not use

30 A8 O Address bus 8 for CPU 80 ODCIRQ2 I Interruption of system control

31 A9 O Address bus 9 for CPU 81 ADSEP I Address data selection input

32 A10 O Address bus 10 for CPU 82 RST I Reset input

33 A11 O Address bus 11 for CPU 83 VDD - Power supply

34 VDD - Power supply 84 TEST1 I Test signal 1 input

35 A12 O Address bus 12 for CPU 85 FA900-MODE I Test signal 2 input

36 A13 O Address bus 13 for CPU 86 TEST3 I Test signal 3 input

37 A14 O Address bus 14 for CPU 87 TEST4 I Test signal 4 input

38 A15 O Address bus 15 for CPU 88 TEST5 I Test signal 5 input

39 A16 O Address bus 16 for CPU 89 TEST6 I Test signal 6 input

40 A17 O Address bus 17 for CPU 90 TEST7 I Test signal 7 input

41 A18 - Non connect 91 TEST8 I Test signal 8 input

42 A19 - Non connect 92 VSS - Ground

43 VSS - Ground 93 D0 I/O Data bus 0 of CPU

44 A20 - Non connect 94 D1 I/O Data bus 1 of CPU

45 DISCSTP O Mechanism state signal output 95 D2 I/O Data bus 2 of CPU

46 HAGUP O Connect to pick-up unit 96 D3 I/O Data bus 3 of CPU

47 TCLOSE - Non connect 97 D4 I/O Data bus 4 of CPU

48 WOBBLEF1L O Wobble circuit filter switch 98 D5 I/O Data bus 5 of CPU

49 HFMON O HFM Control output to Q103 99 D6 I/O Data bus 6 of CPU

50 TRVSW I Detection switch of traverse inside 100 D7 I/O Data bus 7 of CPU

37

Page 38

XV-FA900BK/XV-FA902SL

5.7 MN103S26EGA (IC301) : Super optical disc controller

• Terminal layout

• Block diagram

• Pin function (1/4)

Pin No. Symbol I/O Description

1,2 NINT0,1 O Interruption of system control 0,1

3 VDD3 - Power supply termina l for I/O(3.3V)

4 VSS - Connect to ground

5 NINT2 O Interruption of system control 2

6 WAITDOC O Wait control of system control

7 NMPST O Reset of system control (Non connect)

8 DASPST I Setting of initial value of DASP signal

9~17 CPUADR17~9 I System control address

18 VDD18 - Power supply terminal for I/O (1.8V)

19 VSS - Connect to ground

20 DRAMVDD18 - Power supply terminal for DRAM (1.8V)

21 DRAMVSS - Connect to ground for DRAM

22~30 CPUADR8~0 I System control address

31 VDD3 - Power supply terminal for I/O (3.3V)

32 VSS - Connect to ground

33 DRAMVDD3 - Power supply termina l for DRAM (3.3V)

34 NCS I System control chip select

35 NWR I Writing system control

38

Page 39

• Pin function (MN103S28EGA : 2/4)

Pin No. Symbol I/O Description

36 NRD I Read signal input from system controller

37~44 CPUDT7~0 I/O System control data

45 CLKOUT1 - Non connect

46 MMOD I Test mode switch signal

47 NRST I System reset

48 MSTPOL I Master terminal polarity switch input

49 SCLOCK - Non connect

50 SDATA - Non connect

51 OFTR I Off track signal input

52 BDO I Drop out signal input

53~56 PWM1~4 - Non connect

57 VDD3 - Power supply terminal for I/O (3.3V)

58 DRAMVDD18 - Power supply terminal for DRAM (1.8V)

59 DRAMVSS - Connect to ground for DRAM

60 VSS - Connect to ground

61~64 PWM5~8 - Non connect

65 TBAL O Tracking balance adjustment output

66 FBAL O Focus balance ad justment output

67 TRSDRV O Traverse drive output

68 SPDRV O Spindle drive outpu t

69 FG I Motor FG input

70 TILTP - Non connect

71 TILT - Non connect

72 TILTN - Non connect

73 TX O Digital output signal

74 DTRD - Non conn ect

75 IDGT - Non connect

76 VDD18 - Power supply terminal for I/O (1.8V)

77 VSS - Connect to ground

78 VDD3 - Power supply terminal for I/O (3.3V)

79 OSCI1 I Oscillation input 16.9MHz

80 OSCO1 O Oscillation ou tput 16.9MHz

81 VSS - Connect to ground

82 TSTSG O Calibration signal

83 VFOSHORT O VFO short output

84 JLINE O J-line setting output

85 AVSSD - Connect to ground for analog circuit

86 ROUT - Non connect

87 LOUT - Non connect

88 AVDD - Power supply terminal for analog circuit (3.3V)

89 VCOF I JFVCO control voltage

90 TRCRS I Input signal for track cross formation

91 CMPIN - Non connect

92 LPFOUT - Non connect

93 LPFIN I Pull-up to VHALF

94 AVSS - Connect to ground for ana log circuit

95 HPFOUT - Non connect

96 FPFIN I HPF input

97 CSLFLT I Pull-up to VHALF

98 RFDIF - Non connect

99 AVDDC - Power supply terminal for analog circuit (3.3V)

100 PLFLT2 I Connect to capacitor 2 for PLL

XV-FA900BK/XV-FA902SL

39

Page 40

XV-FA900BK/XV-FA902SL

• Pin function (MN103S28EGA : 3/4)

Pin No. Symbol I/O Description

101 PLFLT1 I Connect to capacitor 1 for PLL

102 AVSS - Connect to ground for analog circuit

103 RVI I Connect to resistor for VREF reference current source

104 VREFH I Reference voltage input (2.2V)

105 PLPG - Non connect

106 VHALF I Reference voltage input (1.65V)

107,108 DSLF2,1 I Connect to capacitor 2,1 for DSL

109 AVDD - Power supply terminal for analog circuit (3.3V)

110 NARF I Equivalence RF111 ARF I Equivalence RF+

112 JITOUT O Output for jitter signal monitor

113 AVSS - Connect to ground for analog circuit

114 DAC0 O Tracking drive output

115 DAC1 O Focus drive output

116 AVDD - Power supply terminal for analog circuit (3.3V)

117 AD0 I Focus error input

118 AD1 I Phase difference/3 beams tracking error

119 AD2 I AS : Full adder signal

120 AD3 I RF envelope input

121 AD4 I DVD laser current control term inal

122 AD5 I Tracking driver monitor

123 AD6 I CD laser current control terminal

124 TECAPA - Non connect

125 VDD3 - Power supply terminal for I/O (3.3V)

126 VSS - Connect to ground

127 MONI0 - Connect to TP306

128 MONI1 - Connect to TP307

129 MONI2 - Connect to TP308

130 MONI3 - Connect to TP309

131 NEJECT I/O Eject detection

132 NTRYCTL I/O Tray close detection

133 NDASP I/O ATAPI drive active / slave connect I/O

134 NCS3FX I ATAPI host chip select

135 NCS1FX I ATAPI host chip select

136,137 DA2 I/O ATAPI host address 2,0

138 NPDIAG I/O ATAPI slave master diagnosis input

139 DA1 I/O ATAPI host address 1

140 NIOCS16 - Non connect

141 INTRQ O ATAPI ho st interruption output

142 NDMACK I ATAPI host DMA characteristic

143 VDD3 - Power supply terminal I/O (3.3V)

144 VSS - Connect to ground

145 IORDY - Non c onnect

146 NIORD I/O ATAPI host read

147 NIOWR - N on connect

148 DMARQ - Non connect

149 HDD15 I/O ATAPI host data 15

150 HDD0 I/O ATAPI host data 0

151 HDD14 I/O ATAPI host data 14

152 VDD18 - Power supply terminal for I/O (1.8V)

153 PO I Connect to ground

154 UATASEL I Connect to ground

40

Page 41

• Pin function (MN103S28EGA : 4/4)

Pin No. Symbol I/O Description

155 VSS - Connect to ground

156 VDD3 - Power supply terminal for I/O (3.3V)

157 HDD1 I/O ATAPI host data 1

158 HDD13 I/O ATAPI host data 13

159 HDD2 I/O ATAPI host data 2

160 HDD12 I/O ATAPI host data 12

161 HDD3 I/O ATAPI host data 3

162 VDD3 - Power supply terminal for I/O (3.3V)

163 VSS - Connect to ground

164 HDD11 I/O ATAPI host data 11

165 HDD4 I/O ATAPI host data 4

166 HDD10 I/O ATAPI host data 10

167 HDD5 I/O ATAPI host data 5

168 HDD9 I/O ATAPI host data 9

169 VDD3 - Power supply terminal for I/O (3.3V)

170 VSS - Connect to ground

171~173 HDD6~8 I/O ATAPI host data 6~8

174 VDDH - Reference power supply for ATAPI (5.0V)

175 NRESET I ATAPI host reset input

176 MASTER I ATAPI master / slave select

XV-FA900BK/XV-FA902SL

41

Page 42

XV-FA900BK/XV-FA902SL

5.8 NDV8611VWA(IC50 1):AV Deco der

• Pin layout

• Block diagram

• Pin function (1/4)

Pin No. Symbol Description

1 VDDio - Power supply terminal 3.3V

2,3 MD10,11 I/O SDRAM Data bus terminal

4 VDD - Power supply terminal 1.8V

5 MD12 I/O SDRAM Data bus terminal

6 VSSio - Connect to ground

7~9 MD13~15 I/O SDRAM Data bus terminal

10 VDDio - Power supply terminal 3.3V

11 DQM1 O SDRAM Data byte enable

12,13 MA9,8 O SDRAM Address bus terminal

14 VSSio - Connect to ground

15,16 MA7,6 O SDRAM Address bus terminal

17 VSS - Connect to ground

18 MA5 O SDRAM Address bus terminal

19 VDDio - Power supply terminal 3.3V

20,21 MA4,3 O SDRAM Address bus terminal

22 MCLK O SDRAM Clock output

23 VSSio - Connect to ground

24 CKE O SDRAM Clock enable output

25,26 MA2,1 O SDRAM Address bus terminal

27 VDDio - Power supply terminal 3.3V

28 MA0 O SDRAM Address bus terminal

29 MA10 O SDRAM Address bus terminal

42

Page 43

• Pin function (NDV8611VWA 2/4)

Pin No. Symbol I/O Description

30 MA11 - Non connect

31 VSSio - Connect to ground

32,33 MA12,13 O SDRAM Address bus, reserved for terminal compatibility with 64Mb SDRAM

34 VDD - Power supply terminal 1.8V

35 CS0 O SDRAM Primary bank chip select

36 VDDio - Power supply terminal 3.3V

37 RAS O SDRAM Command bit

38 CAS O SDRAM Command bit

39 WE O SDRAM Command bit

40 VSSio - Connect to ground

41 DQM0 O SDRAM Data byte enable

42 DQM2 O SDRAM Data byte enable

43 MD16 I/O SDRAM Data bus terminal

44 VDDio - Power supply terminal 3.3V

45,46 MD17,18 I/O SDRAM Data bus terminal

47 VSS - Connect to ground

48 MD19 I/O SDRAM Data bus terminal

49 VSSio - Connect to ground

50~52 MD20~22 I/O SDRAM Data bus terminal

53 VDDio - Power supply terminal 3.3V

54~56 MD23~25 I/O SDRAM Data bus terminal

57 VSSio - Connect to ground

58~61 MD26~29 I/O SDRAM Data bus terminal

62 VDDio - Power supply terminal 3.3V

63,64 MD30,31 I/O SDRAM Data bus terminal

65 DQM3 O SDRAM Data byte enable

66 CS1 O SDRAM Extension bank chip select

67 VSSD - Connect to ground

68 SPDIF O S/PDIF Digital audio output terminal

69 VSSio - Connect to ground

70 AIN I Digital audio input for digital micro; can be used as GPIO

71 AOUT3 O Serial audio output data to audio DAC for left and right channels for down-mix

72 AOUT2 O Serial audio output data to audio DAC for surround left and right channels

73 AOUT1 O Serial audio output data to audio DAC for center and LFE channels

74 AOUT0 O Serial audio output data to audio DAC for left and right channels

75 VDDio - Power supply terminal 3.3V

76 PCMCLK O Audio DAC PCM sampling clock frequency, common clock for DACs and ADC

77 VDD - Power supply terminal 1.8V

78 ACLK O Audio interface serial data clock, common clock for DACs and AD converter

79 LRCLK O Left / right channel clock, common clock for DACs and ADC

80 SRST O Active low RESET signal for peripheral reset

81 RSTP I RESET_Power : from system, used to reset frequency synthesizer and rest

of chip

82 VSSio - Connect to ground

83 RXD1 I UART1 Serial data input from external serial device, used for IR receiver

84 SSPIN1 I/O SSP1 Data in or 16X clock for USART function in UART1

85 VSS - Connect to ground

86 SSPOUT1 I/O SSP1 Data out or UART1 data-terminal-ready signal

87 SSPCLK1 I/O SSP1 Clock or UART1 clear-to -send signal

88 SSPCLK0 I/O SSP0 Clock or request-to-send function in UART1

89 VDD - Power supply terminal 1.8V

90 SSPIN0 I/O SSP0 Data in or 16X clock for USART function in UART0

XV-FA900BK/XV-FA902SL

43

Page 44

XV-FA900BK/XV-FA902SL

• Pin function (NDV8611VWA 3/4)

Pin No. Symbol I/O Description

91 VDDio - Power supply terminal 3.3V

92 SSPOUT0 I/O SSP0 Data out or UART0 data-terminal-ready signal

93 TXD0 I/O UART0 Serial data output to an external serial device

94 RXD0 I UART0 Serial data input from external seria l device

95 CTS0 I/O UART0 Clear-to-send signal

96 RTS0 I/O UART0 Request-to-send signal

97 VSSio - Connect to ground

98 CXI I Crystal input terminal for on-chip oscillator or system input clock

99 CXO O Crystal output terminal for on-chip oscillator

100 OSCVSS - Connect to ground for oscillator

101 OSCVDD - Power supply terminal for oscillator 1.8V

102 MVCKVDD - Power supply terminal for main and video clock PLL 3.3V

103 SCEN I Scan chain test enable

104 MVCKVSS - Connect to ground for main and video clock PLL

105 ACLKVSS - Connect to ground for audio clock PLL

106 SCMD I Scan chain test mode

107 ACLKVDD - Power supply terminal for audio clock PLL 3.3V

108 VDDDAK - Power supply terminal for DAC digital 1.8V

109 VSSDAC - Connect to ground for DAC digital

110 Cr/R O Video signal output (Cr output : composite/component Red output)

111 IOM O Cascaded DAC differential output used to dump current into external resistor

112 C/Cb/B O Video signal output (Chrominance output for NTSC/PAL S-Video

113 VAA3 - Cb output for component Blue output)

114 Y/G O Power supply terminal for DAC analog 3.3V

115 VSSA - Video signal output (Luminance for S-Video and component Green output)

116 VREF - Connect to ground for DAC analog

117 VAA - Non connect

118 CVBS/C O Video signal output (Composite video Chrominance output for S-Video)

119 RSET O Current setting resistor of output DACs

120 COMP O Compensation capacitor connection

121 VSS - Connect to ground

122 VCLK - Non connect

123 VSYNC - Non connect

124 HSYNC - Non connect

125 VDDio - Power supply terminal 3.3V

126~131 VI07~02 - Non connect

132 VSSio - Connect to ground

133,134 VI01,00 - Non connect

135 VDD - Power supply terminal 1.8V

136~139 AD31~28 I/O Multiplexed address / data bus terminal

140 VDDio - Power supply terminal

141~144 AD27~24 I/O Multiplexed address / data bus terminal

145 PWE3 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

146 AD23 I/O Multiplexed address / data bus terminal

147 VSSio - Connect to ground

148~153 AD22~17 I/O Multiplexed address / data bus terminal

154 VDDio - Power supply terminal 3.3V

155 AD16 I/O Multiplexed address / data bus terminal

156 PWE2 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

157,158 AD15,14 I/O Multiplexed address / data bus terminal

159 VDD - Power supply terminal 1.8V

for power

44

Page 45

• Pin function (NDV8611VWA 4/4)

Pin No. Symbol I/O Description

160 SCLK O Extern al bus clock used for programmable host peripherals

161 ACK I/O Programmable WAIT/ACK/RDY control

162 VSSio - Connect to ground

163~168 AD13~8 I/O Multiplexed address / data bus terminal

169 VDDio - Power supply terminal 3.3V

170 PWE1 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

171 VSS - Connect to ground

172~176 AD7~3 I/O Multiplexed address / data bus terminal

177 VSSio - Connect to ground

178~180 AD2~0 I/O Multiplexed address / data bus terminal

181 VDDio - Power supply terminal 3.3V

182 PWE0 I/O Byte write enable for FLASH,EEPROM,SRAM or peripherals terminal

183 ALE I/O Address latch enable

184~187 LA0~3 I/O Latched address 0~3

188 VSSio - Connect to ground

189 RD I/O Read terminal

190 LHLDA O Bus hold acknowledge in slave mode

191 LHLD I Bus hold request from external master in slave mode

192 VDD - Power supply terminal 1.8V

193 PCS0 O Peripheral chip select 0, generally used for enabling the program store

ROM/FLASH

194,195 XI01,02 I/O Programmable general purpose external input/output

196 VDDio - Power supply terminal 3.3V

197~200 XI03~06 I/O Programmable general purpose external input/output

201 VSS - Connect to ground

202,203 XI07,08 I/O Programmable general purpose external input/output

204 VSSio - Connect to ground

205 XI09 I/O Programmable general purpose external input/output

206~209 XID10~13 I/O Programmable general purpose external input/output

210 VDDio - Power supply terminal 3.3V

211 XID14 I/O Programmable general purpose external input/output

212 VDD - Power supply terminal 1.8V

213 DSYNC I DVD Parallel mode sector sync

214 DREQ O DVD Parallel mode data request

215 DCLK I Data sampling clock

216 DSTB I Parallel mode data valid, serial mode left/right clock

217 DVD0 I DVD Drive parallel data port

218 VSSio - Connect to ground

219~223 DVD1~5 I DVD Drive parallel data port

224 VDDio - Power supply terminal 3.3V

225,226 DVD6,7 I DVD Drive parallel data port

227 MD0 I/O SDRAM Data bus terminal

228 VSSio - Connect to ground

229 MD1 I/O SDRAM Data bus terminal

230 VSS - Connect to ground

231,232 MD2,3 I/O SDRAM Data bus terminal

233 VDDio - Power supply terminal 3.3V

234~236 M D4~6 I/O SDRAM Data bus terminal

237 VSSio - Connect to ground

238~240 M D7~9 I/O SDRAM Data bus terminal

XV-FA900BK/XV-FA902SL

45

Page 46

XV-FA900BK/XV-FA902SL

5.9 SST39VF160-7CEK (IC509) : 16M EEPROM

• Pin layout

• Block diagram

• Pin function