Page 1

SERVICE MANUAL

DVD AUDIO/VIDEO PLAYER

XV-D721BK

XV-D721BK

XV-D721BK

XV-D723GD

XV-D723GD

XV-D723GD

Area Suffix

XV-D721BK

J

C

EG

ES

EN

EE

Area Suffix

XV-D723GD

A

J

EG

ES

EN

UF

U.S.A

Canada

Germany

Spain

Northern Europe

Russian Federation

US Minitary

Australia

U.S.A

Germany

Singapore

Northern Europe

China

Brazil,Mexico,Peru

Contents

Safety Precautions

Preventing static electricity

Important for laser products

Importance Admistering

point on the Safety

This service manual is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

1-2

1-3

1-4

1-5

Disassembly method

Adjustment method

Description of major ICs

1-6

1-11

1-18

No.A0002

Nov. 2000

1-1

Page 2

XV-D721BK

XV-D723GD

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alter ations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or proper ty

damage resulting therefrom.

3. Many electrical and mechanical par ts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement par ts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When ser vice is required, the or iginal lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

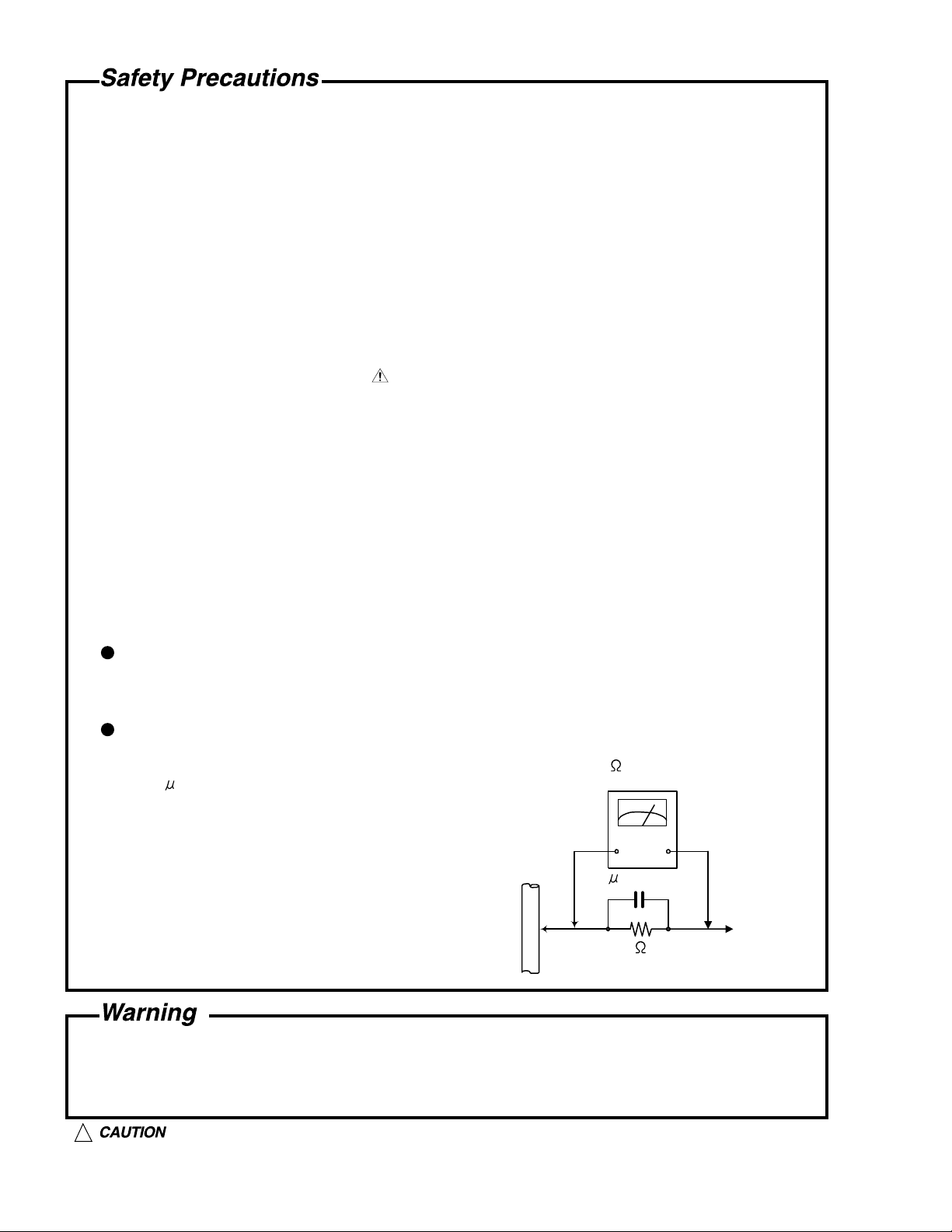

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Move the resistor connection to eachexposed metal

part, par ticularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Place this

probe on

each exposed

metal part.

This corresponds to 0.5 mA AC (r.m.s.).

Good earth ground

1-2

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

XV-D721BK

XV-D723GD

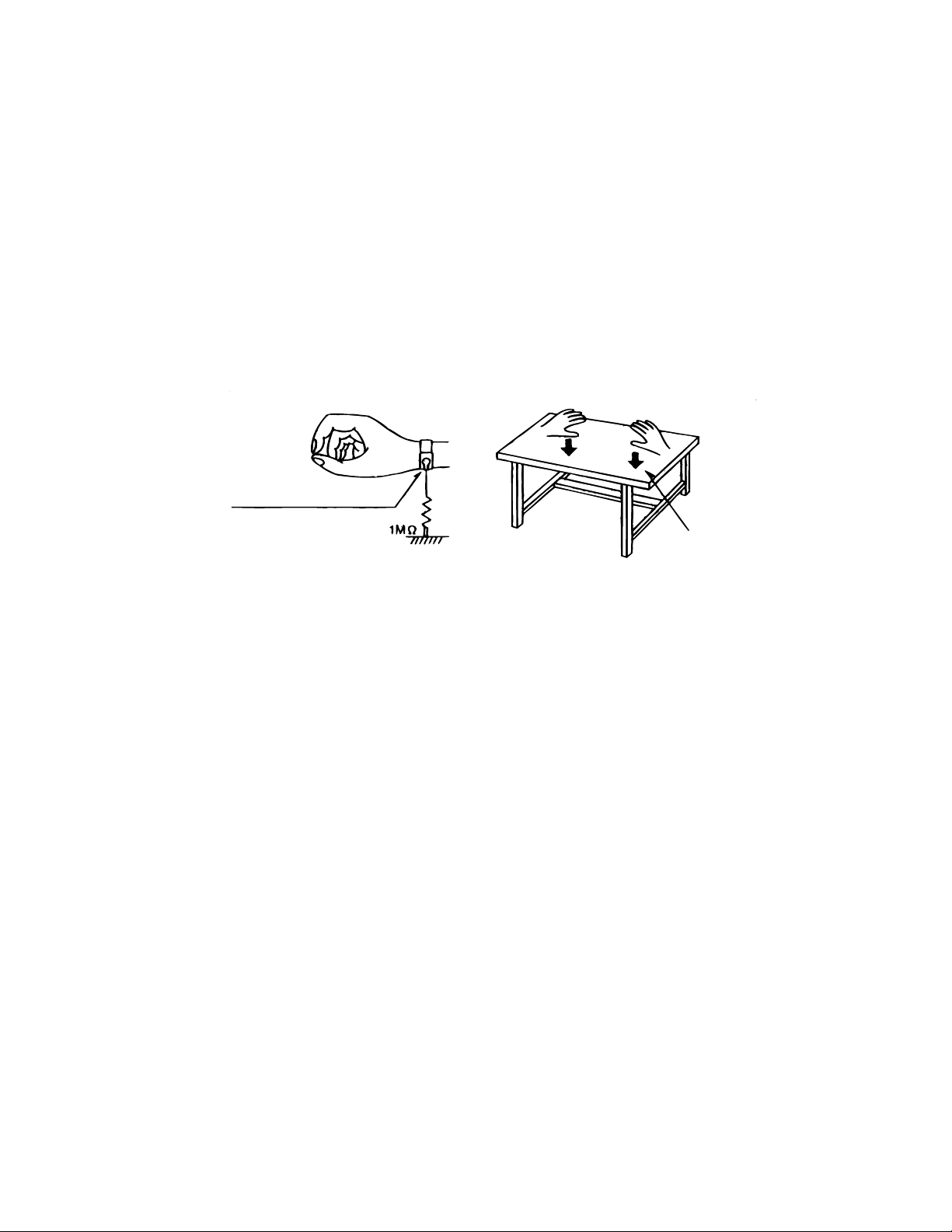

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-3

Page 4

XV-D721BK

XV-D723GD

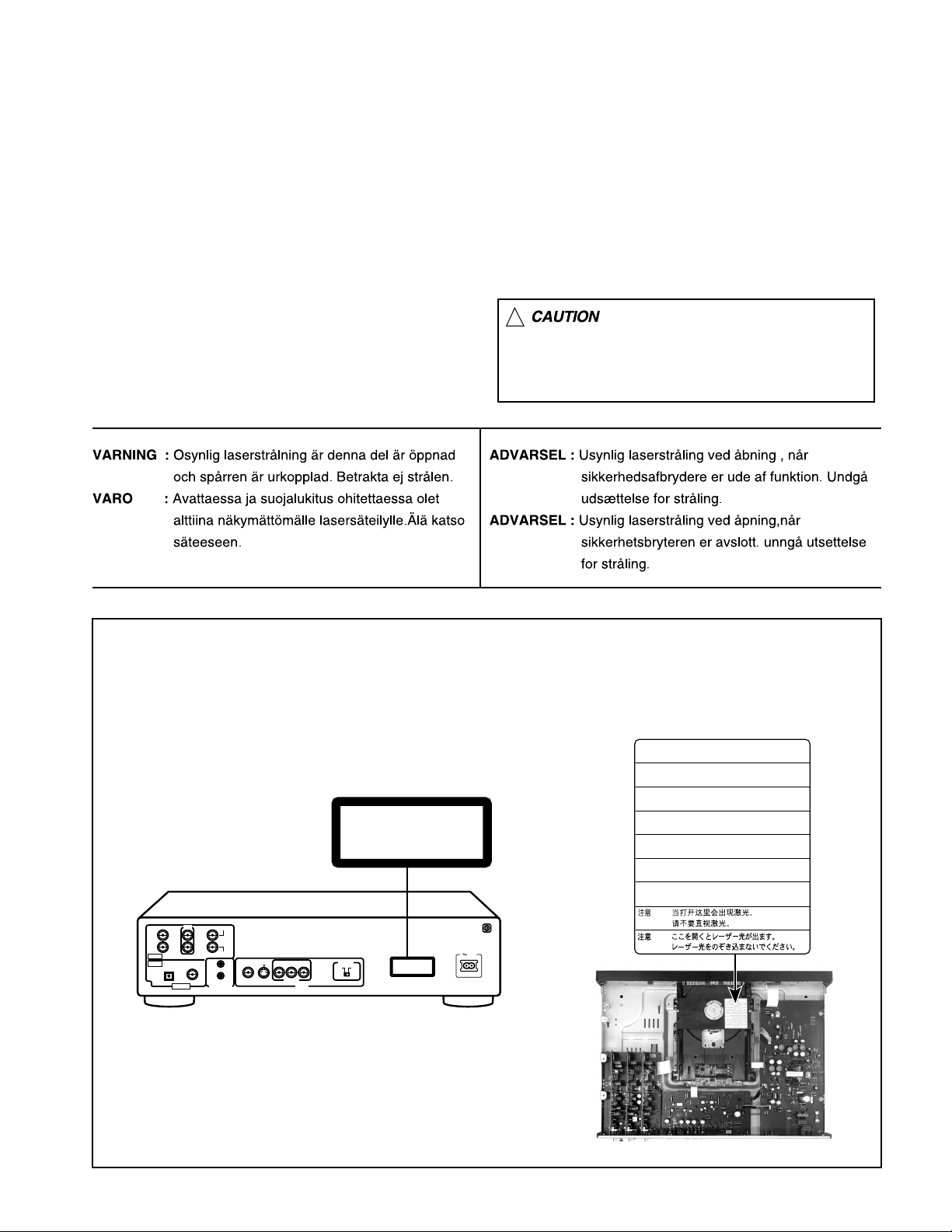

Important for Laser Products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

REAR

FRONT CENTER

LEFT

LEFT

RIGHT

RIGHT

ANALOG

PCM/STREAM

DIGITAL

COAXIAL

OPTICAL

AUDIO OUT AV COMPU LINK

SUBWOOFER

VIDEO S-VIDEO

YPBP

COMPONENT

VIDEO OUT

SCAN MODE

R

525p 525i

CLASS 1

LASER PRODUCT

1

AC IN

CAUTION - - LASER RADIATION WHEN OPEN.

DO NOT STARE INTO BEAM.

ATTENTION RAYONNEMENT LASER EN CAS D’OUVERTURE.

NE PAS REGARDER DANS LE FAISCEAU.

- VORSICHT LASERSTRAHLUNG, WENN ABDECKUNG GEÖFFENET.

NICHT IN DEN STRAHL BLICKEN.

- ADVARSEL LASERSTRÅ LING VED Å BNING.

SE IKKE IND I STRÅ LEN.

- ADVARSEL LASERSTRÅ LING NÅ R DEKSEL Å PNES.

STIRR IKKE INN I STRÅ LEN.

-

VARNING LASERSTRÅ LNING NÄR DENNA DEL ÄR ÖPPNAD.

STRRA EJ IN I STRÅ LEN.

VARO! AVATTAESSA OLET ALTTIINA LASERSÄTEILYLLE.

ÄLÄ TUIJOTA SÄTEESEEN.

-

-

1-4

Page 5

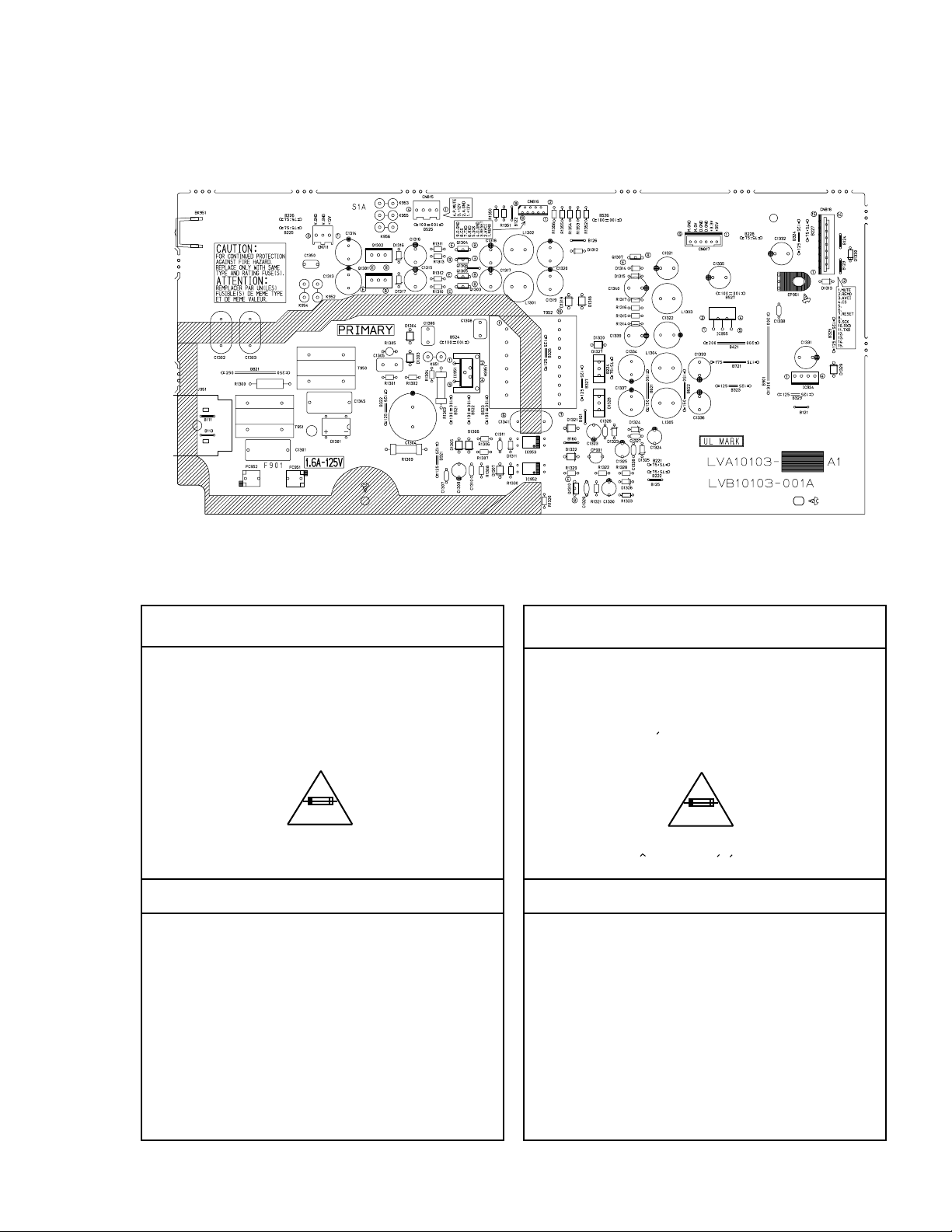

Importance Admistering point on the Safety

XV-D721BK

XV-D723GD

Note : It's means "J" for U.S.A. market model and "C" for canada market model.

XV-D721BK/XV-D723GD C/J ONLY

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : 1.6 A / 125 V

XV-721BK/XV-723GD C/J SEULEMENT

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

F901 : 1.6 A / 125 V

1-5

Page 6

XV-D721BK

XV-D723GD

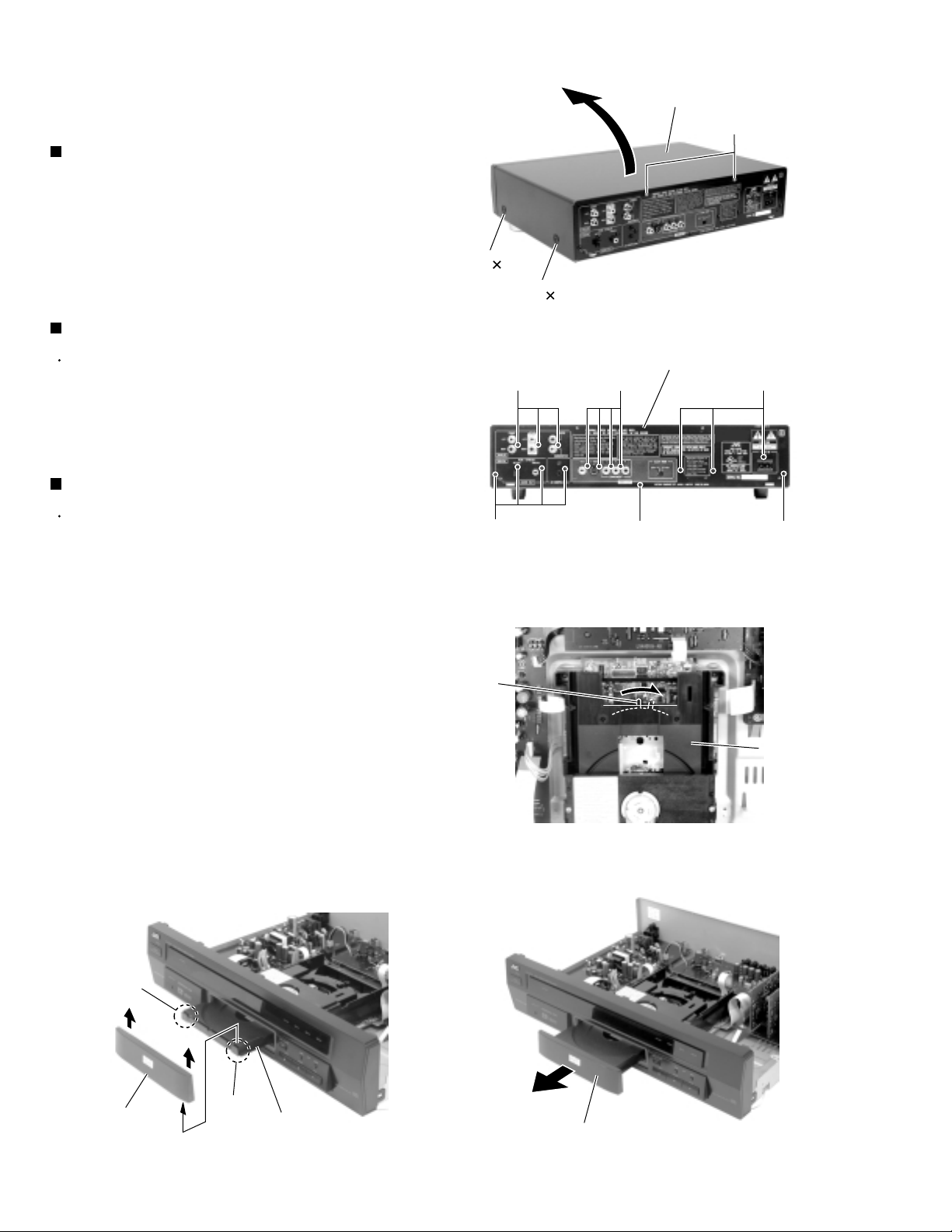

Disassembly method

< Main body>

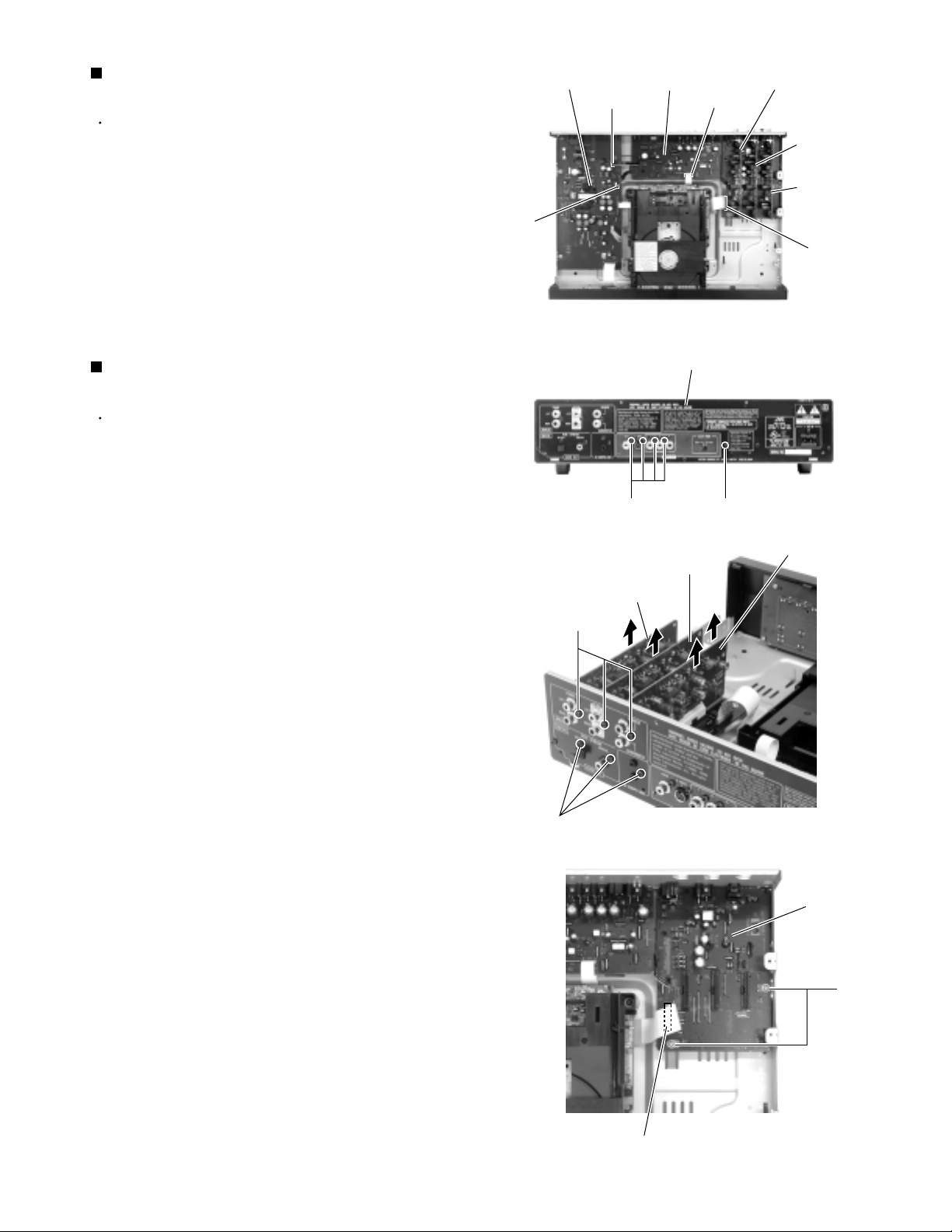

Removing the top cover (See Fig.1)

1.

Remove the four screws A on each side of the body.

2.

Remove the two screws B on the back of the body.

3.

Remove the top cover from behind in the direction of

the arrow while pulling the lower part of the sides.

Removing the rear panel (See Fig.2)

A

2

A 2

Top cover

B

Fig.1

Prior to performing the following procedure, remove

the top cover.

1.

Remove the sixteen screws C on the back of the

body.

Removing the fitting (See Fig.3 to 5)

Prior to performing the following procedure, remove

the top cover.

ATTENTION:

1.

Lower the mechanism by moving the lever marked a

in the direction of the arrow from the upside of the

body (Refer to Fig.3).

2.

Manually eject the loading tray toward the front.

3.

Remove the fitting from the loading tray by releasing

the joints b on the both sides of the fitting.

4.

Push and return the loading tray.

To remove the front panel assembly and

the DVD mechanism assembly, remove

the fitting in advance.

Lever a

CC

CC

Fig.2

Rear panel

C

C

Loading tray

1-6

Joint b

Fitting

Joint b

Loading tray

Fig.3

Loading tray

Fig.4Fig.5

Page 7

XV-D721BK

XV-D723GD

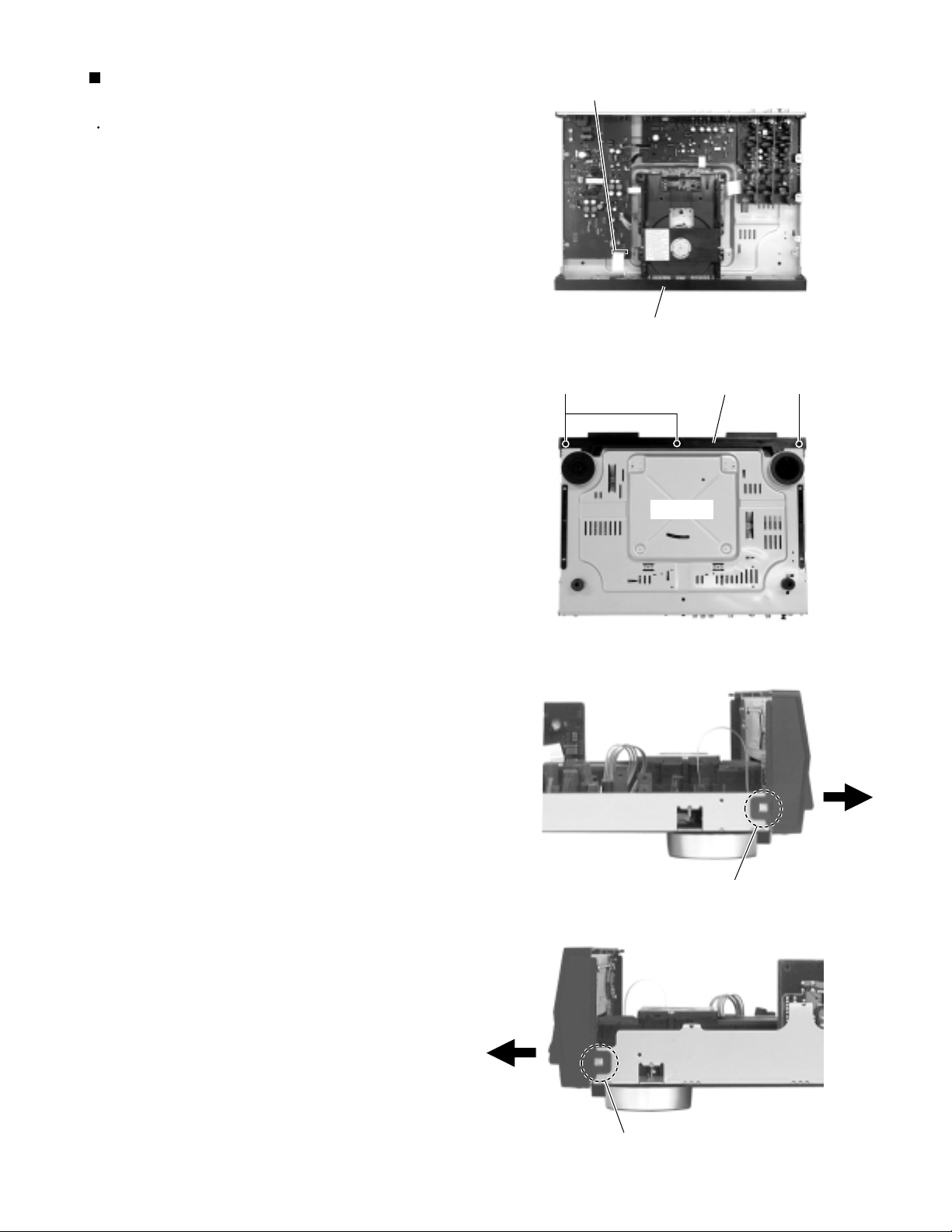

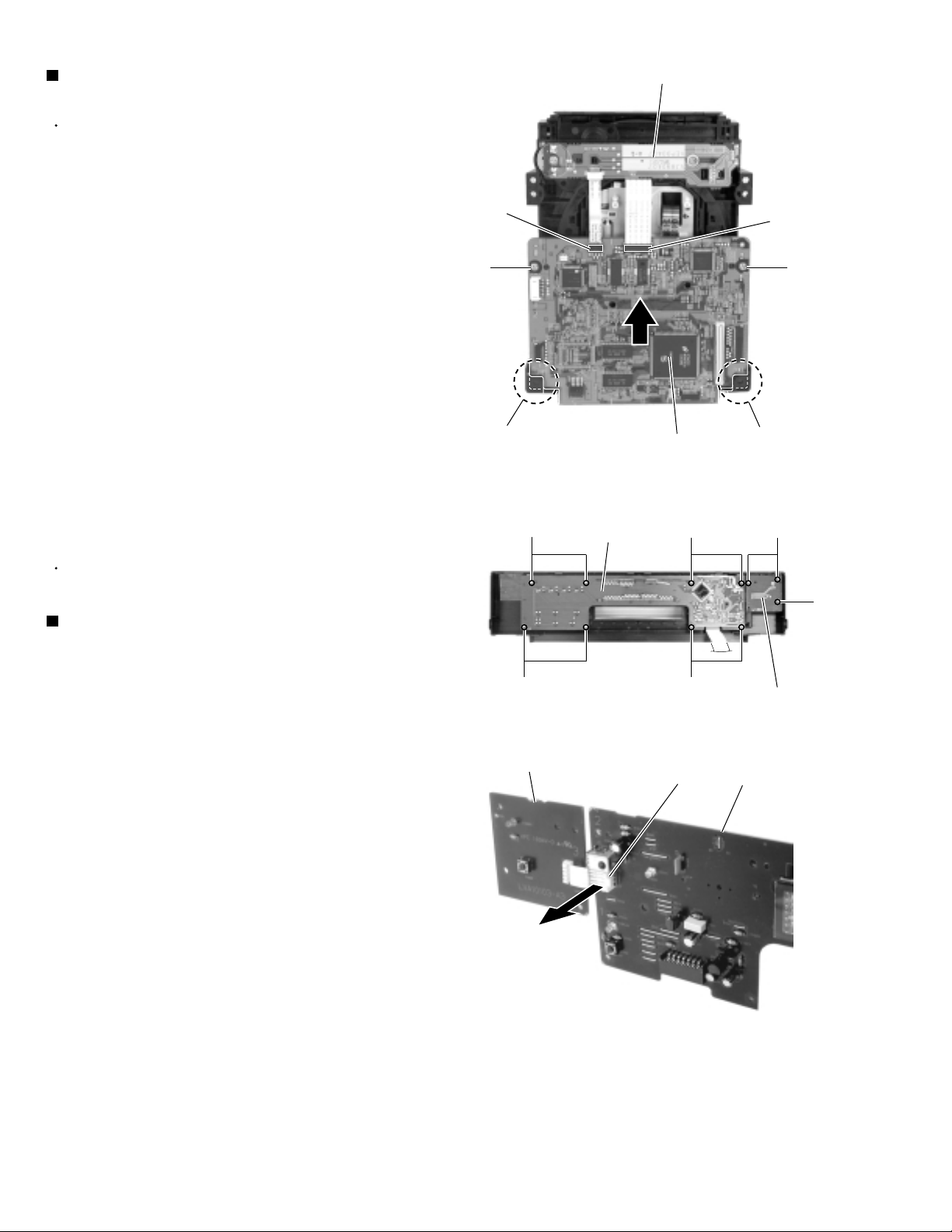

Removing the front panel assembly

(See Fig.6 to 9)

Prior to performing the following procedure, remove

the top cover and the fitting.

1.

Disconnect the card wire from connector CN818 on

the regulator board.

2.

Turn back the body and remove the three screws D

fixing the front panel assembly.

3.

Release the two joints c on both sides of the body

and remove the front panel assembly toward the

front.

Regulator board

CN818

Front panel assembly

Fig.6

DD

Front panel assembly

(Bottom)

Fig.7

Fig.8

Joint c

Joint c

Fig.9

1-7

Page 8

XV-D721BK

XV-D723GD

Removing the DVD mechanism

(See Fig.10)

Prior to performing the following procedure, remove

the top cover and the fitting.

It is not necessary to remove the front panel

assembly.

1.

Disconnect the card wire from connector CN816 and

the harness from CN817 on the regulator board.

2.

Disconnect the card wire from connector CN701 on

the video board.

3.

Disconnect the card wire from CN831 on the DSP

board.

4.

Remove the four screws E and the DVD mechanism

assembly by pulling out from the front panel

assembly backward.

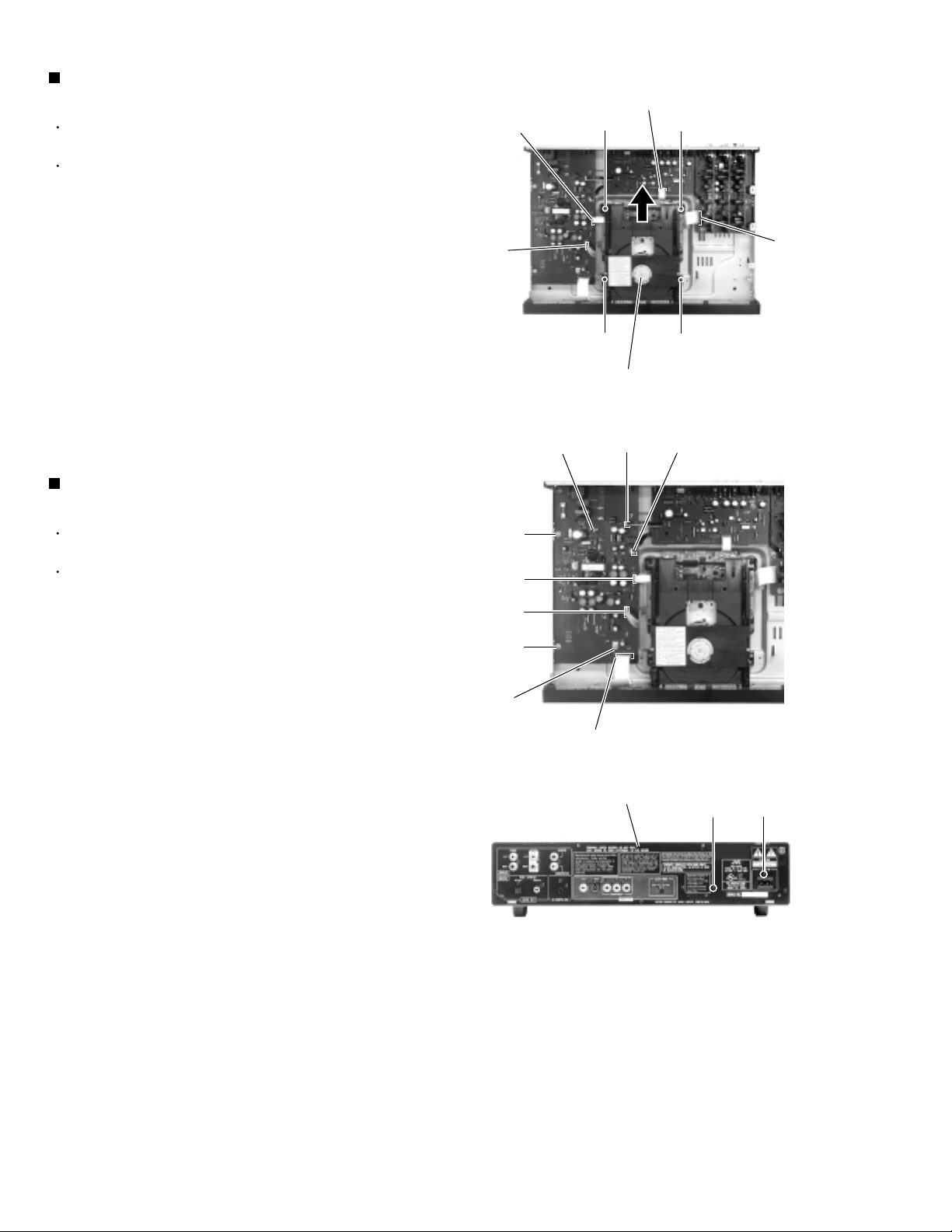

Removing the regulator board

(See Fig.11 and 12)

Regulator board

CN816

CN817

Regulator board

Video board

CN701

E

E

DVD mechanism assembly

Fig.10

CN711 CN815

E

E

DSP board

CN831

Prior to performing the following procedure, remove

the top cover.

It is not necessary to remove the rear panel.

1.

Disconnect the card wire from connector CN816 and

CN818 and the harnesses from CN815,CN817 and

CN711 on the regulator board.

2.

Remove the three screws F attaching the regulator

board.

3.

Remove the two screws C on the rear panel.

F

CN816

CN817

F

F

CN818

Rear panel

Fig.11

CC

Fig.12

1-8

Page 9

XV-D721BK

XV-D723GD

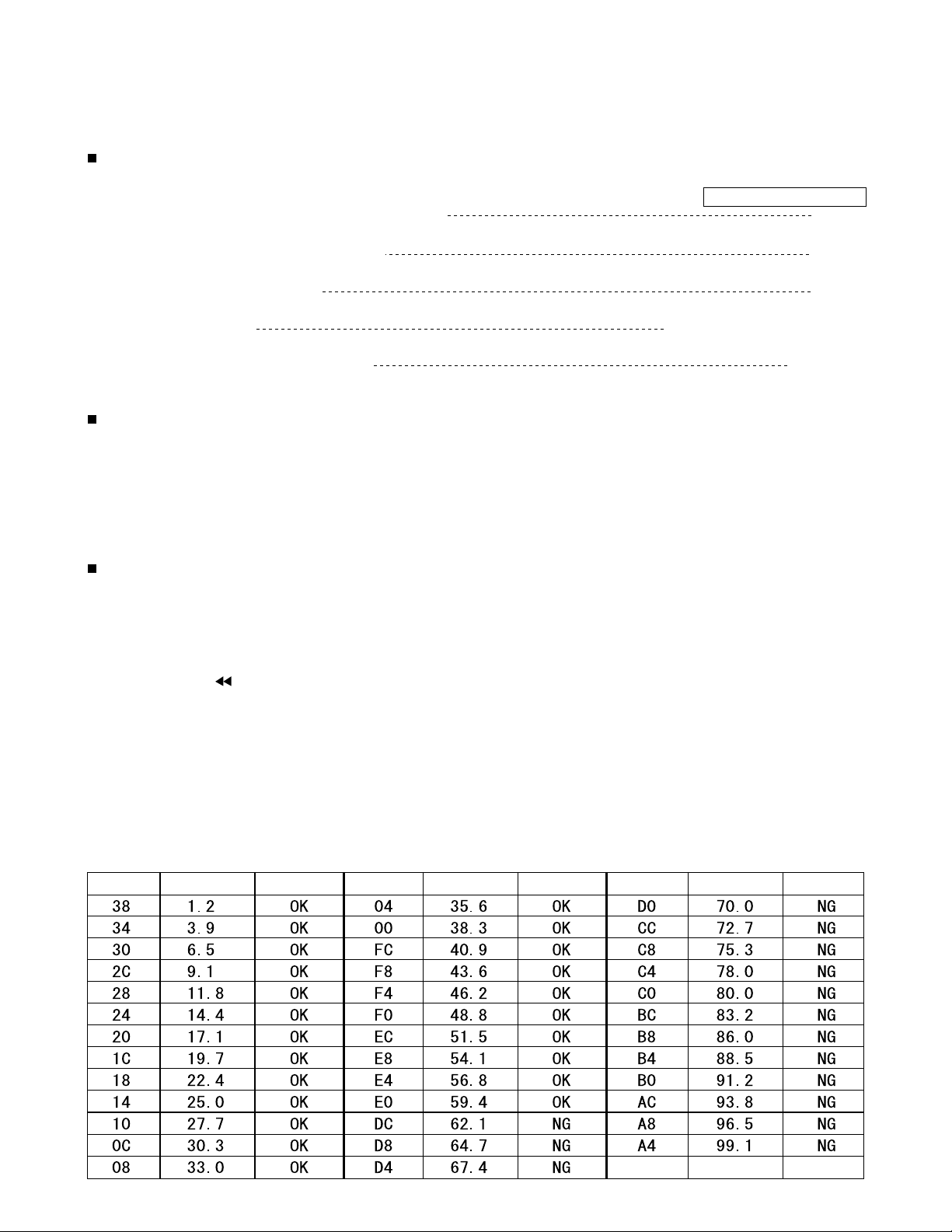

Removing the video board

(See Fig.13 and 14)

Prior to performing the following procedure, remove

the top cover.

Ref. :

It is not necessary to remove the rear panel.

1.

Disconnect the harnesses from the connector CN711

on the regulator board.

2.

Disconnect the card wire from connector CN701 on

the video board.

3.

Remove the five screws C on the rear panel.

Removing the Audio board 1,2 and 3 / the

Audio board (See Fig.13,15 and 16)

Prior to performing the following procedure, remove

the top cover and rear panel.

1.

Remove the three screws C attaching the audio

board 1,2 and 3.

Regulator board

CN815

CN711

C

Video board

Fig.13

Rear panel

Fig.14

Audio board 3

CN701

Audio board 2

Audio board 1

Audio board

CN831

C

2.

Disconnect the audio board 1,2 and 3 from the audio

board respectively.

3.

Disconnect the harnesses from connector CN815 on

the regulator board.

4.

Disconnect the card wire from connector CN831 on

the audio board.

5.

Remove the two screws G attaching the audio

board.

Audio board 1

C

C

Audio board 3

Audio board 2

Fig.15

Audio board

G

CN831

Fig.16

1-9

Page 10

XV-D721BK

XV-D723GD

Removing the DVD servo board

(See Fig.17)

Prior to performing the following procedure, remove

the top cover and the DVD mechanism assembly.

1.

Turn over the DVD mechanism assembly and

disconnect the card wire from connector CN102 and

CN103 on the DVD servo board.

2.

Remove the two screws H attaching the DVD servo

board. Move the DVD servo board in the direction of

the arrow to release the two corner joints d.

DVD mechanism board

CN103

H

Joint d Joint d

DVD servo board

Fig.17

CN102

H

<Front panel assembly>

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

Removing the FL board / the power

switch board (See Fig.18 and 19)

1.

Remove the eight screws I and three screws J on

the back of the front panel assembly. Remove the FL

board and the power switch board at the same time.

Disconnect the harness from connector CN903 on

2.

the FL board.

FL board

II

Power switch board

Fig.18

II

Power switch board

CN903 FL board

J

J

1-10

Fig.19

Page 11

XV-D721BK

XV-D723GD

Adjustment method

This model has the TEST mode for simple diagnosis of the internal function. Use the TEST mode for diagnosing and checking

the set as mentioned below.

Details of the TEST mode

The TEST mode comprises the five modes of the following.

FL indication (*: numeral)

1.DVD AUDIO copyright protection key serial indication

Indicates the content of the DVD AUDIO copyright at shipment. Use this mode for checking it.

2.Microcomputer's version number indication

Indicates the initial version number of the microcomputer at shipment. Use this mode for checking it.

3.Servo signal system check mode CHECK

Use this mode for checking the laser pickup status.

4.Indication check mode The FL and LED's go on in full.

The LED's and FL of the set go on in full. Use this mode for checking indications.

5.Microcomputer software upgrading mode UPGRADE

Use this mode for upgrading the microcomputer software.

How to set the TEST mode

1.While pressing the STOP key and PLAY key of the set together, plug in the power cord.

*Continue to pressing both the STOP key and PLAY key until reading of disk data completes (until the "NOW READING"

message changes into a DVD logo).

2."TEST *" message appears on the FL. (* In the part of the sign, the sign is different according to the destination.)

3.The five modes of the TEST mode change one after another each time the DISPLAY OFF key of the set is pressed.

4.To recover the usual operation mode, turn off the set by pressing the POWER ON/OFF key.

********

**_**_**

How to check the laser pickup

Since the laser pickup of the set is easily affected by static electricity, heat, etc., it may be damaged depending on use

condition. If the set shows such a symptom as it fails in reading disk data, check the laser pickup as follows.

* Checking laser current

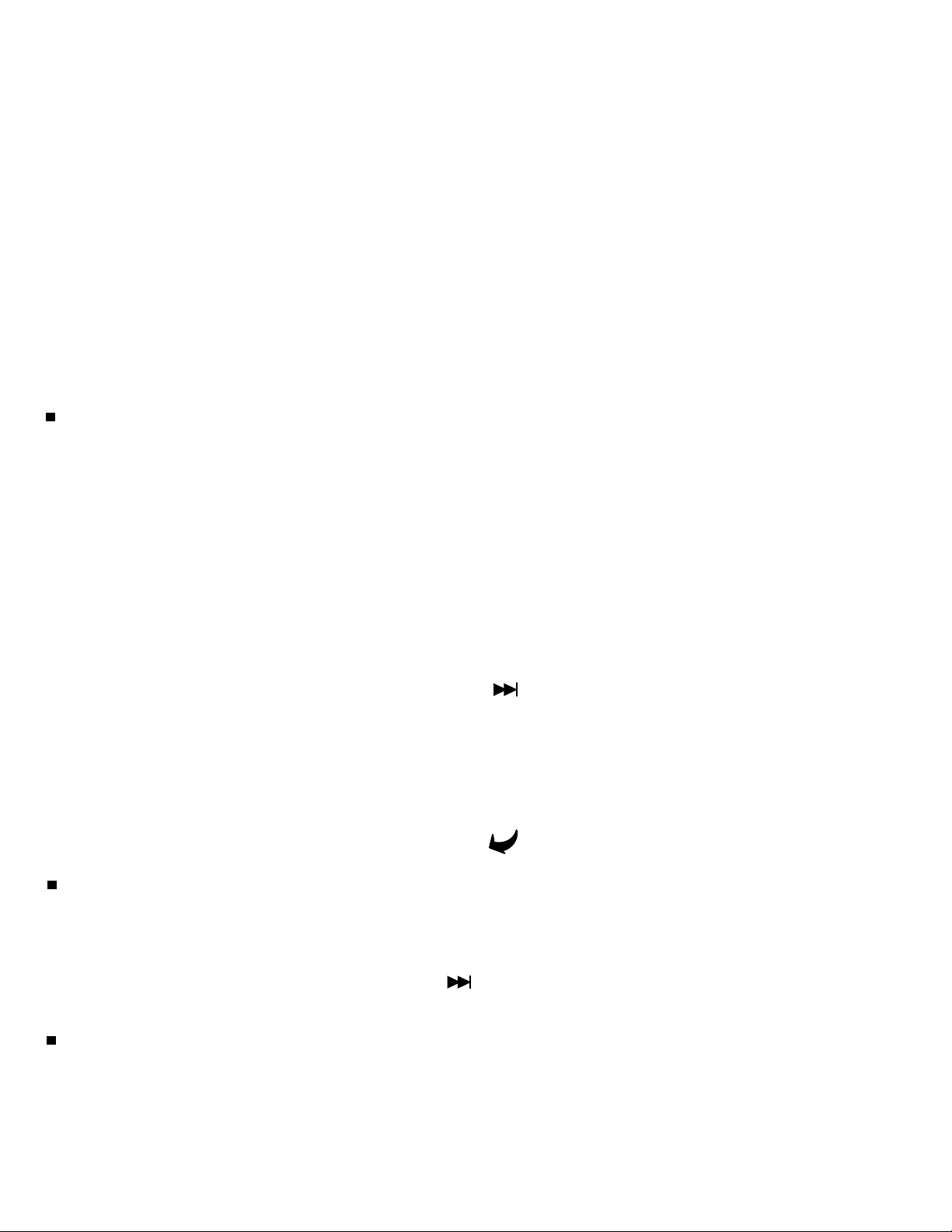

1.Enter the set into the "servo signal system check mode" of the TEST mode.

2.Press the SKIP | key of the set.

The laser is turned on and the LAS **** message appears on the FL display. **** in the message indicates the current

in code. For knowing the actual laser current, read the first two figures (omitting the last two figures) and convert the

number into the current (mA) referring to the following conversion table, because the FL indication is a hexadecimal

number. Since the FL indication varies because of self-heating of the set, read the indication value about 20 seconds

after the set was turned on. If the indicated value is the OK level (see the conversion table), the laser is judged to be

normal in the initial status by this simple checking method.

3. Press the STOP key to set back the check mode to the initial status.

Laser current conversion table

FL indication

Current (mA)

Judgment

FL indication

Current (mA)

Judgment

FL indication

Current (mA)

Judgment

1-11

Page 12

XV-D721BK

XV-D723GD

* Automatic adjustment/Jitter value indication

1.Enter the set into the "servo signal system check mode" of the TEST mode.

2.Open the tray with the OPEN key of the set. Set the TEST disk VT-501 on the tray and put back the tray with

the CLOSE key. Then, press the PAUSE key.

The TEST disk starts rotation to execute automatic adjustment. If the set is in the normal condition, the

"CHECK OK" message appears. If there is something abnormal in the adjustment values, an error message

appears and it mostly comes from a failure in the servo system (including the mechanism and pickup). In

such the event, refer to the check points by errors.

When using the TEST disk VT-501, carefully check to see if there is neither damage nor dirt on the read

surface of the disk beforehand.

3.Press the STOP key to return the check mode to the initial status.

4.After the automatic adjustment with the TEST disk completes, press the PLAY key.

The disk starts rotation and a jitter value (signal read precision in percentage) appears on the FL display (JIT

0***). If the indication value (in *** places) is 110 (11 %) or less, it can be judged by this simple checking

method that the signal read precision of the set is satisfactory.

Before using the TEST disk VT-501, carefully check it if there is neither damage nor dirt on the read surface.

5.Press the STOP key to return the mode to the initial status.

Upgrading microcomputer software

The internally incorporated microcomputer software of this set can be revised in part for the reason that the set

is designed to conform to new standards and to be capable of playing disks to be put on the market by other

manufacturers. To upgrade the internal microcomputer software, use the upgrade disk and follow the procedure

mentioned below.

* How to upgrade the microcomputer software

1.Set the upgrade disk in the set and enter it into the TEST mode.

2.After confirming that the set completes reading of the upgrade disk data while looking at the indication on the

monitor screen, change the TEST mode to the microcomputer software upgrading mode and then press the

PLAY key.

3.The set completes writing of the upgrade disk data approximately 1 minute later and it is automatically reset

by the self-resetting function. Then the set again reads the upgrade disk and stops automatically.

4.Take the upgrade disk out of the set and turn it off with the POWER ON/OFF key.

5.Again enter the set into the TEST mode, and press the SKIP key and then the PAUSE key.

6.Make sure that the DVD AUDIO indicator goes on a few seconds after the above-mentioned operation, check

the version number of the microcomputer software in the microcomputer software version number indication

mode.

*Carefully carry out the above procedure. If data write is interrupted in the middle of course by power failure

or careless shutdown operation, not only the data of the internal software may be damaged but the set may

fail in resetting. The version number of the internal microcomputer software is shown as follows.

FL indication: ** ** **

[IC901] [IC401] [IC508/IC509] Symbol number of microcomputer IC

Initializing the set

Initialization of the set returns it to the initial status at shipment.

Be sure to initialize the set after repair service.

* How to initialize the set

1.Enter the set into the TEST mode and press the SKIP key first and the PAUSE key second.

2.Make sure that the DVD AUDIO indicator goes on a few seconds later.

DVD AUDIO copyright protection

To protect the DVD AUDIO copyright from infringement, a number proper to each DVD AUDIO set called a

device key is assigned to each set. If a proper device key is not set for a set, it fails in playing a copyrighted

disk.

The management number of the device key of a set can be checked by the DVD AUDIO copyright protection

key serial indication in the TEST mode. If the "???...." message appears in this check mode, the set has a

failure in the device key. If it occurs, inquire at the Service Section of the Audio and Communication Division,

JVC.

1-12

Page 13

Check points for each error

(1) Spindle start error

*Defective spindle motor

Are there 10ohms resistance between each pin of CN102 "1~4"?

(The power supply is turned off and measured.)

*Hall element: Is sine wave output between CN102 "10" and "11", between "12" and "13",

and between "14" and "15" during rotation?

In either case, replace the mechanical unit.

*Defective spindle driver (IC251)

Is a driving wave output from CN102 "1~4" ?

During

rotation

Is IC251 "9" at "H" level (START)?

Servo IC --- Is control signal sent to the motor driver ?

IC201 "95" : Duty is 50% during stop, but varies during rotation (greatly varies at start).

--- If not sent, pattern or servo IC (IC201) is defective.

XV-D721BK

XV-D723GD

R259 : approx 2.5V during stop, but varies during rotation (greatly varies at start).

--- of not sent, pattern or servo IC (IC201) is defective.

Is FG input to servo IC ?

Observe FG wave from IC201 "89". --- If not output, pattern, IC251 or IC201 is defective.

(2) Disc Detection, Distinction error (no disc, no REFNV)

* Laser is defective.

* Front End Processor is defective (IC101).

* APC circuit is defective. --- Q101.

* Pattern is defective. --- Lines for CN101 "15" and "17".

Lines for between IC201 "2" and IC101 "2"(LDONA),

between IC201 "3" and IC101 "1" (LDONB).

* Servo IC is defective (IC201).

* Is signal sent to IC201(servo)"71" AS2 ?

* IC101 --- For signal from IC101 to IC301, is signal output from IC101 "88" (RFAS1) and

IC101 "69" REENV ?

1-13

Page 14

XV-D721BK

XV-D723GD

(3) Traverse movement NG

* For automatic adjustment, traverse movement occurs only when the position is changed to retry

judging the disc type after the 1st judgment resulted in an error. Therefore, traverse movement

rarely occurs because, in most cases, disc judgment at the current position (1st time judgment)

is executed successfully. (Of course, NG rarely occurs in this step.)

Note: 1st time judgment of disc type resulted in NG. --- The re-judgment of disc type may not be

successful. Therefore, after removing the cause of traverse movement, re-execute automatic

adjustment and confirm that no problem exists.

* Check point

a) During stop

Whether 50% duty pulse is output to R273

Whether between R274 and C271 is at approx. 2.5VDC

Offset voltage between CN102 "1" and "2" (scores mV if exists)

b) When tray is opened or closed

Check by oscilloscope whether a rectangular wave signal is output from CN102 "1" or "2".

50msec

2.5V

Approx.

500mV

GND

If checking a) or b) resulted in NG, IC201 maybe defective.

(4) Focus ON NG

* Is FE output ? --- Pattern, IC101

* Is FCDRV signal sent ? (R286) --- Pattern, IC301

* Is driving voltage sent ?

CN101 "1", "3" --- If NG, pattern, driver, mechanical unit (with the power turned off, measure the

resistance between CN101 "20" and "21").

* Does CN101 "8" become "H" and is the focus drawing in done?

--- Mechanical unit (laser power too low), IC101(defective gain)

--- Moreover, It is thought that abnormality is found in the disk.

* Mechanical unit is defective.

(5) Tracking ON NG

* When the tracking loop cannot be drawn in, IC201 "58" (/TRON) does not become "L".

* Mechanical unit is defective.

Because the undermentioned adjustment value is abnormal, it is not possible to draw in normally.

* Periphery of driver (IC271)

Constant or IC it self is defective.

(When passing without becoming abnormal while adjusting the following.)

* Servo IC (IC201)

When improperly adjusted due to defective IC.

1-14

[Focus position rough adjustment]

[Phase difference cancellation rough adjustment]

[Tracking balance adjustment]

Page 15

XV-D721BK

XV-D723GD

(6) Spindle CLV NG

* When the spindle cannot be shifted to CLV Servo, does not become "H" between IC201 "18"

and IC301"88".

* IC201 Is signal output from IC101 "87" (RFOP)?

* IC201 Is signal output from IC201 "60" to "64" (binary-coded clock and data)?

* IC201 Is "58" (/TRON) at "L" level ?

* IC301 "74" to "76" --- Is signal output to IC201 "24", "25", "28" (In case of only CD).

(Serial communication of rotation information)

* Spindle motor driver is defective.

Even when one of the three phases is defective, item (1) may be passed.

--- Check the second item in (1) above.

* C260 to C263 Defective soldering

If noise eliminating capacitors are not properly soldered, noise may ride on the waveform.

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various

factors are thought.

Mechanism is defective.(jitter)

IC101, IC201.

(7) Address read NG

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various

factors are thought.

Mechanism is defective. (jitter)

IC201, IC301, IC401.

The disc is dirty or the wound has adhered.

(8) Between layers jump NG (double-layer disc only)

* When the focus flight is generated when jumps between layers.

Because all adjustments for L1 layer must be successful, this error may rarely be due to a

circuit defect.

* Crosstalk might occur from tracking to focus system. (See (11) ) --- Replace the mechanical unit.

* Driver surroundings.

* Defect of constant and IC.

* For double-layer discs, after checking CLV on layer L1, jumps to layer L0 after mode changes to FG.

Then tracking is turned off, and adjustments are executed from the focus position coarse adjustment

in order.

* When the jump between layers is done on the single-layer disk, the disk distinction error is thought.

--- The laser power is low (RF level is confirmed by IC101"87" (RFOP)).

--- AS1, AS2, REFNV Is the signal sent to between IC101 and IC201 ?

1-15

Page 16

XV-D721BK

XV-D723GD

(9) Neither picture nor sound is output

* Cannot search

a) Can the feed system be driven?

Check the waveform of TRSDRV signal (R273). --- Waveform between R274 and C271.

Search results in a change of duty

(three values with 2.5V at the center)

(The figure is exaggerated.)

Check the waveform of CN101 "1" and "2". --- After the driver (IC271)

b) Is kick available?

Check the TRDRV signal waveform from R289.

Check the waveform of CN101 "2" and "4" --- After the driver (IC271)

Although differs in amplitude and DC offset, the waveform is similar to that of R289

Kick pulse

Approx.

2.5V

Long-distance seek

Acceleration pulse at start;

deceleration pulse at stop

(each one)

(In the direction of search,

opposite to this figure)

For short-distance search, the waveform

becomes roundish, not trapezoidal, and

voltage is low.

Feed

Tracking

Kick pulse (fine seek) is

inserted after longdistance seek.

(Not one)

1-16

Hold (DC) during feed

Page 17

(10) Picture is distorted or abnormal sound occurs at intervals of several seconds.

XV-D721BK

XV-D723GD

Does JITOUT

change periodically?

(2V or more in peak

value, except

during kick)

YES

Feed system is defective (drive gain is defective: too large).

Check the waveform according to a) in (9).

Play back a simple disc with no angle change.

OK when the following waveform appears at intervals

of several seconds.

5~10Sec.

1~1.2V

Some system other

NO

than servo may be

defective.

If this voltage is too

high (2V or more, for

example), feed motor

may be defective, or

the mechanical unit

has seized.

(11) Others (unusual events experienced to date)

* Problem occurs with double-layer discs although no problem occurs with single-layer DVD.

(Error occurs, or search becomes unstable and takes longer.)

Crosstalk might occur from tracking to focus system.

--- When FE was observed during search (skip, etc.), it was found that a wave resembling TE

with an amplitude of 200mVp-p was riding on FE.

--- Mechanical unit was replaced.

* Error frequently occurred in the outer part of discs although no error occurred in the inner part.

--- Mechanical unit was replaced because tilt seemed to be defective.

(12) CD During normal playback operation

a) Is TOC reading normal?

NO

Please refer to "Servo Volume" flow.

Displays total time

for CD-DA.

Shifts to double-speed

mode for V-CD.

YES

b)Playback possible?

NO

*--:-- is displayed during FL serch.

According to [*Cannot serch ] for DVD(9), check the feed

and tracking systems.

*No sound is output although the time is displayed.(CA-DA)

*DAC, etc, other than servo.

*The passage of time is not stable, or picture is abnormal.(V-CD)

*The wound of the disc and dirt are confirmed.

(13) Others

V-CD : Frequent occurrence of error in inside and outer.

(Even the disk without the wound : when generated.)

Waveform observation

--- Is the oscillation frequency of about 700~900Hz output?

(Borrow a pertinent disk for the complaint for the combination with the disk.)

--- Exchanges mechanism for the mechanism resonance.

1-17

Page 18

XV-D721BK

XV-D723GD

Description of major ICs

AN8706FHQ (IC101) : Front end processor

1.Pin layout

CBDOSL

CSAG

DCAGC

AGCG

PEAK

BOTTOM

RFENVFCBOOST

OFTR

BDO

75747372717069686766656463626160595857565554535251

RBCA

RFINP

RFINN

VCC2

GND2

VREF2

RFON

RFOP

TS

DCRF

FS

VIN6

VIN5

VCC1

VIN1

VIN2

VIN3

VIN4

VREF4

DIFP

DIFN

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

AN8706FHQ

CBDOFS

TESTSG

COFTFS

COFTSL

JITOUT

GND3

FUPDN

ITDLI

VCOIN

PLFLT

PLFLT2

FCPO

PCPO

VCC3

CAPA

DTRD

IDGT

VCC5

50

RDCKP

49

RDCKN

48

RDTP

47

RDTN

46

GND5

45

GND4

44

VCC4

43

DTMONN

42

DTMONP

41

DSLFLT

40

DSLO

39

FLTOUT

38

DCFLT

37

VREF3

36

VPWBDO

35

VPWOFT

34

IDDLY

33

DBAL

32

GND1

31

VREF1

30

TKCNT

29

TKCFLT

28

TEOUT

27

TEI

26

RSCL

2.Block diagram

Head Amp.

SSD Signal

Head Amp.

DPD Signal

12345678910111213141516171819202122232425

TG

LPCOA

LDONB

LDONA

LPC1

VHARF

RFOUT

FS/TS

POFLT

TGBAL

PTH

TBAL

FBAL

FGCTL

FEN

FEOUT

VREFL

VREFC

TGTETKCNTTBALFBALFE

SEN

PULIN

VREFH

SCK

STDI

FC/Boost

AGC Cont

TKCNT

FE(SSD)

FE BAL

AGC

MU

TE(DPD)

TE BAL

STNBY

XTRON

RFIN

MTRON

ROMRAM

EQ

RF ENV

DSL

BDO Det

OFTR Det

DFLTOP/NRFENV

PLL

JITTER Det

SYNC

JITOUT

CLK

DATA

DSLOUT

BDO

OFTR

1-18

TG(DPD)

LPC(Amp)

OPTICAL HEAD

(650nm)

INTERFACE

VREF reg

TGBAL CPU STNBY MTRON

SERVO PROCESSOR

Head Amp.

Page 19

XV-D721BK

XV-D723GD

3.Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

LDONB

LDONA

LPCOA

LPC1

VHARF

TGBAL

POFLT

PTH

TBAL

TG

FGCTL

FBAL

FEOUT

FEN

VREFL

VREFC

VREFH

PULIN

SEN

SCK

STDI

STNBY

XTRON

MTRON

ROMRAM

RSCL

TEI

TEOUT

TKCFLT

TKCNT

VREF1

GND1

DBAL

IDDLY

VPWOFT

VPWBDO

VREF3

DCFLT

FLTOUT

DSLO

DSLFLT

DTMONP

DTMONN

VCC4

GND4

GND5

RDTN

RDTP

RDCKN

RDCKP

Functions

I

Laser ON (CD Head) terminal

I

Laser ON (DVD Head) terminal

O

Laser drive output terminal

I

Laser PIN input terminal

O

VHALF voltage output terminal

I

Tangential phase balance control terminal

O

Track detection Threshold value level terminal

I

Track detection Threshold value level terminal

I

Tracking balance control terminal

O

Tangential phase error signal output terminal

I

Focus amplifier Gain control terminal

I

Focus balance control terminal

O

Focus error signal output terminal

I

Focus error output amplifier reversing input terminal

O

VREFL voltage output terminal

O

VREFC voltage output terminal

O

VREFH voltage output terminal

I

DSL,PLL drawing mode switch terminal

I

SEN(Cereal data input terminal)

I

SCK(Cereal data input terminal)

I

STDI(Cereal data input terminal)

I

Standby mode control terminal

I

Tracking OFF holding input terminal

I

Monitor output ON/OFF switch terminal

I

O

I

O

O

O

O

O

I

I

I

I

O

O

O

O

O

O

O

I

O

O

O

O

O

O

RAM switch terminal

ROM

Standard current source terminal

Tracking error output Amp reversing input terminal

Tracking error signal output terminal

Track count detection filter terminal

Track count output terminal

VREF1 voltage output terminal

Earth terminal 1

Data slice offset adjustment terminal

Data slice delay adjustment terminal

OFTR detection level setting terminal

BDO detection level setting terminal

VREF3 voltage output terminal

Capacity connection terminal for data slice input filter

Filter amplifier output terminal

Data slice single data output terminal

Constant filter terminal when data is sliceddelly

PLL differential motion 2 making to value edge signal moniter output (+)

PLL differential motion 2 making to value edge signal moniter output (-)

Power terminal 4 (5V)

Earth terminal 4

Earth terminal 5

PLL differential motion making to synchronization RF signal reversing output

PLL differential motion making to synchronization RF signal rotation output

PLL differential motion making synchronization clock reversing output

PLL differential motion making synchronization clock rotation output

AN8706FHQ (1/2)

1-19

Page 20

XV-D721BK

XV-D723GD

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VCC5

IDGT

DTRD

CAPA

VCC3

PCPO

FCPO

PLFLT2

PLFLT

VCOIN

ITDLI

FUPDN

GND3

JITOUT

BDO

OFTR

BOOST

FC

RFENV

BOTTOM

PEAK

AGCG

DCAGC

CSAG

CBDOSL

CBDOFS

RBCA

TESTSG

RFINP

RFINN

VCC2

GND2

VREF2

COFTFS

COFTFL

RFON

RFOP

TS

DCRF

FS

VIN6

VIN5

VCC1

VIN1

VIN2

VIN3

VIN4

VREF4

DIFP

DIFN

I/OPin No. Symbol Functions

Power terminal 5 (3.3V)

I

Data slice part address part gate signal input terminal (For RAM)

I

Data slice data read signal input terminal(For RAM)

I

Data slice CAPA(Address)signal input terminal (For RAM)

I

Power terminal 3 (5V)

I

PLL phase gain set terminal

O

PLL frequency gain set terminal

O

PLL low region filter terminal

O

PLL high region filter terminal

O

PLL VCO input terminal

I

PLL jitter free current ripple removal filter terminal

O

PLL frequency control input terminal

I

Earth terminal 3

O

Detection signal output of jitter

O

BDO output terminal

O

OFTR output terminal

O

Booth control terminal for filter

I

FC control terminal for filter

I

RF enve output terminal

O

Bottom enve detection filter terminal

O

Peak enve detection filter terminal

O

AGC amplifier gain control terminal

O

AGC amp filter terminal

O

Sag cancellation circuit filter terminal

O

BDO detection capacitor terminal

O

BDO detection capacitor terminal

O

BCA detection level setting terminal

O

TEST signal input terminal

I

RF signal positive moving input terminal

I

RF signal reversing input terminal

I

Power terminal 2 (5V)

I

Earth terminal 2

O

VREF2 voltage output terminal

O

OFTR detection capacitor terminal

O

OFTR detection capacitor terminal

O

RF signal output terminal P

O

RF signal output terminal N

O

All addition amplifier (DVD) output terminal

O

All addition amplifier capacitor terminal

O

All addition amplifier (CD) output terminal

O

Focus input of external division into two terminal

I

Focus input of external division into two terminal

I

Power terminal 1 (5V)

I

External division into four (DVD/CD) RF input terminal 1

I

External division into four (DVD/CD) RF input terminal 2

I

External division into four (DVD/CD) RF input terminal 3

I

External division into four (DVD/CD) RF input terminal 4

I

VREF4 voltage output terminal

O

RF signal (RAM) output terminal P

O

RF signal (RAM) output terminal N

O

AN8706FHQ(2/2)

1-20

Page 21

MN103007BGA (IC301) : Optical disc controller

1.Terminal layout

DMARQ

NIOWR

VSS

NIORD

IORDY

NDMACK

5VDD

INTRQ

IOCS16

DA1

VSS

NPDIAG

DA0

DA2

VDD

NCS1FX

NCS3FX

NDASP

NTRYCL

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

HDD15

HDD0

HDD14

5VDD

HDD1

HDD13

HDD2

VSS

HDD12

VDD

HDD3

HDD11

HDD4

HDD10

5VDD

HDD5

HDD9

VSS

HDD6

HDD8

HDD7

5VDD

NRESET

MASTER

NINT0

NINT1

WAITOOC

NMRST

DASPST

VDD

OSCO2

OSCI2

UATASEL

VSS

PVSSDRAM

PVDDDAM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

3738394041424344454647484950515253545556575859606162636465666768697071

MN103007BGA

126

5VDD

125

NEJECT

VSS

MONI0

124

123

122

MONI1

MONI2

121

120

MONI3

SDATA

119

118

SCLOCK

VDD

FAT0

117

116

115

DAT1

114

DAT2

113

DAT3

112

CHCK4

XCLDCK

111

110

72

SUBC

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

SBCK

VSS

P0

P1

PVDD

PVSS

VDD

OSC01

OSCI1

VSS

LRCK

BLKCK

IPFLAG

DACCLK

DACLRCK

DACDATA

NTRON

LG

JMPINH

IDDHOLD

PLLOK

CLKOUT2

VDD

NRST

MMOD

VSS

CPDET1

CPDET2

BDO

IDGT

DTRO

TEHLD

VDD

CLKOUT1

CPUDT0

CPUDT1

XV-D721BK

XV-D723GD

2.Block diagram

DVD-ROM

Formatter

CGEN

MODE

VSS

CPUASR15

CPUNDA17

CPUADR16

CD-PRE

Instruction

memory

(40KB)

DATA

MEMORY

(6KB)

VDD

CPUADR9

CPUADR8

CPUADR11

CPUADR10

CPUADR7

CPUADR14

CPUADR13

CPUADR12

Formatter

General purpose IO bus

CPUADR6

CPUADR5

CPUADR4

CPUADR3

CPUADR2

i /t

High speed IO bus

32 bit

CPU core

GCAL

CPUADR1

VSS

NCS

CPUADR0

ECC

NWR

NRD

VDD

CPUDT17

CPUDT16

PVPODRAM

PTESTORAM

Host i / f

MPEG i / t

DMA

BCU

DRAMC

CPUDT15

CPUDT14

PVSSDRAM

OVDDDRAM

VSS

CPUDT2

CPUDT13

ATAPI

4Mbit

DRAM

WDT

16 bit

timer x 2

SYSTEM

i / f

INTC

1-21

Page 22

XV-D721BK

XV-D723GD

3.Function

Pin NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

Symbol

HDD15

HDD0

HDD14

5VDD

HDD1

HDD13

HDD2

VSS

HDD12

VDD

HDD3

HDD11

HDD4

HDD10

5VDD

HDD5

HDD9

VSS

HDD6

HDD8

HDD7

5VDD

NRESET

MASTER

NINT0

NINT1

WAITODC

NMRST

DASPST

VDD

OSCO2

OSCI2

UATASEL

VSS

PVSSDRAM

PVDODRAM

CPUADR17

CPUADR18

VSS

CPUADR15

CPUADR14

CPUADR13

CPUADR12

VDD

CPUADR11

CPUADR10

CPUADR9

I/O

Function

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I/O

ATAPI data

I

ATAPI reset

I/O

ATAPI master / slave selection

O

System control interruption 0

O

System control interruption 1

O

System control weight control

O

System control reset

I

DASP signal initializing

I,O

VSS connection,OPEN

I,O

VSS connection, OPEN

I

VSS connection

I

System control address

I

System control address

I

System control address

I

System control address

I

System control address

I

System control address

System control address

I

System control address

I

System control address

I

System control address

Pin NO.

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Symbol

CPUADR8

CPUADR7

CPUADR6

CPUADR5

CPUADR4

CPUADR3

CPUADR2

CPUADR1

VSS

CPUADR0

NCS

NWR

NRD

VDD

CPUDT7

CPUDT6

PVPPDRAM

PTESTDRAM

OVDDDRAM

PVSSDRAM

CPUDT5

CPUDT4

CPUDT3

VSS

CPUDT2

CPUDT1

CPUDT0

CLKOUT1

VDD

TEHLD

DTRO

IDGT

BDO

CPDET2

CPDET1

VSS

MMOD

NRST

VDD

CLKOUT2

PLLOK

IDOHOLD

JMPINH

MN103007BGA(1/2)

I/O

Function

System control address

I

System control address

I

System control address

I

System control address

I

System control address

I

System control address

I

System control address

I

System control address

I

GND

System control address

I

System control chip selection

I

System control wright

I

System control lead

I

Apply 3V

System control data

System control data

C=10000PF is connected

O

between VSS

VSS connected

I

System control data

System control data

System control data

GND

System control data

System control data

I/O

System control data

I/O

16.9/11.2/8.45MHz clock

O

Apply 3V

-

Mirror gate

O

Data part frequency control

O

switch

Part CAPA switch

O

RF dropout / BCA data of

I

making to binary

Outer side CAPA detection

I

Side of surroundings on inside

I

GND

VSS connected

I

System reset

I

Apply 3V

-

16.9MHz clock

O

Frame mark detection

O

ID gate for tracking holding

O

Jump prohibition

O

1-22

Page 23

MN103007BGA(2/2)

XV-D721BK

XV-D723GD

Pin NO.

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119~122

123

124

125

126

127

128

129

130

131

132

Symbol I/O Function

LG

NTRON

DACDATA

DACLRCK

DACCLK

IPFLAG

BLKCK

LRCK

VSS

OSCI1

OSCO1

VDD

PVSS

PVDD

P1

P0

VSS

SBCK

SUBC

XCLDCK

CHCK4

DA T3

DA T2

DA T1

DA T0

VDD

SCLOCK

SDATA

MONI3~0

VSS

NEJECT

5VDD

NTRYCL

NDASP

NCS3FX

NCS1FX

VDD

DA2

DA0

O

Land / group switch

I

Tracking ON

O

Cereal output

O

L and R identification output

I

Clock for cereal output

I

Interpolation flag input

I

Sub-code,Block clock input

I

L and R identification signal output

I,O

16.9MHz oscillation

I,O

16.9MHz oscillation

I/O

Terminal MASTER polarity switch

input

I/O

CIRC-RAM OVER/UNDER

Interruption signal input

O

Sub-code, Clock output for serial input

I

Sub-code, Cereal input

I

Sub-code, Frame clock input

I

Read clock to DAT3~0(Output of

dividing frequency four from ADSC)

I

Read data from DISC

I

(PAralle output from ADSC)

I

I

I/O

Debugging cereal clock

(270 pull up)

I/O

Debugging cereal data

(270 pull up)

O

Internal goods title monitor

I

Eject detection

I

Tray close detection

I/O

ATAPI Drive active/

Sulave connection I/O

I

ATAPI host chip selection

I

ATAPI host chip selection

I/O

ATAPI host address

I/O

ATAPI host address

Pin NO.

133

134

135

136

137

138

139

140

141

142

143

144

Symbol I/O Function

ATAPI slave master diagnosis input

NPDIAG

VSS

DA1

IOCS16

INTRQ

5VDD

NDMACK

IORDY

NIORD

VSS

NIOWR

DMARQ

I/O

ATAPI host address

I/O

ATAPI output of selection of width

O

of host data bus

ATAPI host interruption output

O

ATAPI host DMA response

I

ATAPI host ready output

O

ATAPI host read

I

ATAPI host writes

I/O

ATAPI host DMA demand

O

1-23

Page 24

XV-D721BK

XV-D723GD

MN67705EA (IC201) : Digital servo controller

1.Terminal layout

FEPNTRON

N.C.

N.C.

CDDVD

N.C.

N.C.

N.C.

ECR(PWM3B)

EC(PWM3A)

DVSS

SYSCLK

VCOF1

DVSS

128

127

126

125

124

123

122

121

120

119

118

117

116

FGC

1

LDONA

2

LDONB

3

PULIN

4

SRF

5

DVSS

DVDD

TRVSW

ST/SP

HFMON

BRK

DVSS

PLLOK

N.C.

N.C.

N.C.

N.C.

DVSS

DVDD

TSTSG

FUPDN

MONA

MONB

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33343536373839404142434445464748495051525354555657585960616263

CPSEN

CPCEN

CPUIRQ

CPUCLK

CPUDTIN

MN67705

BDO

SDAT-

CHK4I

SCLK-

SDAT+

SCLK+

CPUDTOUT

SBCK

TRAYSET1

TRAYSET2

DRVMUTE

TRAY-CLOSE

TRAY-OPEN

TBAL(PWMDA1)

GBAL(PWMDA2)

BDOLVL(PWMDA3)

OFTLVL(PWMDA4)

IREF1

XRESET

115

114

N.C.

N.C.

TEST

MINTESTFGDSLO

113

112

111

N.C.

N.C.

DVSS

TKCRS2

110

109

DVSS

DVDD

TKCRS1

OFTR

DVDD

108

107

106

SUBC

MONC

BLKCLK

TRSDRVB(DA8)

TRSDRVA(DA7)

TRDRV(DA6)

105

104

103

LRCK

NTRON

NCLDCK

FODRV(DA5)

102

DVSS

DBAL(DA4)

101

DAT0

BOOST(DA3)

100

DAT1

FC(DA2)

FBAL(DA1)

999897

DAT2

DAT3

AVDD

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

CHCK4

AVSS

TS(AD1)

FS(AD2)

FE(AD3)

TROFS(AD4)

TE(AD5)

VREFLDA

VREFMDA

VREFHDA

TG(AD6)

N.C.(AD7)

N.C.(AD8)

RFENV(AD9)

VREFOP

LDCUR(AD10)

JITOUT(AD11)

VREFC

AVDD(AD12)

VREFHAD

VREFMAD

VREFLAD

AVSS

DVDD

DVSS

TX

MOND

IPFLAG

CIRCIRQ

N.C.

N.C.

N.C

DVSS

2.Block diagram

The signal of the error

of the servo input

from FEP.

Driver

ODC

A/Dconverter

Track crossing

counter

Phese

comparison

Line speed

detection

Detection at

FG cycle

CIRC core

Focus servo

Tracking servo

Traverse servo

Spindle servo

SERVO

DSP core

Serial port

CPU I/F

PLL

A/D converter

(Analog control)

PWM

Standard

clock

generation

PLL

FEP I/F

PLL

Focus tracking

driving value output

Spindre / traverse

driving value output

Crystal

33.8MHz

FEP

1-24

CPU

ADSC function block of the second generation.

Page 25

XV-D721BK

XV-D723GD

3.Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

FGC

LDONA

LDONB

PULIN

SRF

DVSS

TRAYSET1

TRAYSET2

DRVMUTE

DVDD

TRVSW

TRAY-CLOSE

TRAY-OPEN

ST/SP

HFMON

BRK

DVSS

PLLOK

N.C.

TBAL(PWMDA1)

GBAL(PWMDA2)

BDOL VL(PWMDA3 )

OFTL VL(PWMDA4 )

N.C.

N.C.

N.C.

DVSS

DVDD

TSTSG

FUPDN

MONA

MONB

CPSEN

CPCEN

CPUIRQ

CPUCLK

CPUDTIN

CPUDTOUT

CHK4I

SCLK+

SCLK-

SDAT+

SDAT-

BDO

SBCK

IREF2

Function

0

H fixation

O

Laser drive controlA (ON / OFF)

O

Laser drive controlB (ON / OFF)

O

DSL and PLL high boost signal (FEP)

O

Head amplifier gain H/L selection

Ground for digital circuit

O

Tray drive ON/OFF and direction control

O

Tray drive ON/OFF and direction control

O

Drive IC mute control

Power supply for digital circuit

I

Surroundings position detection in traverse

I

Tray close detection SW

I

Tray opening detection SW

O

Spindle motor drive switch (START /STOP)

O

High cycle module control

O

Spindle motor IC short brake control

Ground for digital circuit

I

SYNC detection (DVD : 18T / CD : 22T)

O

O

Tracking balance (FEP)

O

Tangential balance (FEP)

O

BDO slice level (FEP)

O

Off-track error slice level (FEP)

O

O

O

Ground for digital circuit

Power supply for digital circuit

O

Self calibration signal (FEP)

O

Signal of frequency UP/DOWN of PLL (FEP)

O

Monitor terminal A

O

Monitor terminal B

I

Servo DSP cereal I/F chip selection (SYSCOM)

I

CIRC cereal I/F chip selection (SYSCOM)

O

Interrupt request to silicon (SYSCOM)

I

Silicon cereal I/F clock (SYSCOM)

I

Silicon cereal I/F data input (SYSCOM)

O

Silicon cereal I/F data output (SYSCOM)

I

Connects with unused DVSS

I

Lead channel clock differential motion signal (positive)

I

Lead channel clock differential motion signal (negative)

I

Lead channel data differential motion signal (positive)

I

Lead channel data differential motion signal (negative)

I

BDO + BCA (FEP)

I

CD sub-code data shift clock (ODC)

Connects with unused DVSS

MN67705EA (1/3)

1-25

Page 26

XV-D721BK

XV-D723GD

Pin No. Symbol I/O

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

IREF3

VCOF2

DVSS

VCOE3

DVSS

DVDD

SUBC

BLKCLK

MONC

NCLDCK

LRCK

NTRON

DVSS

DA T0

DA T1

DA T2

DA T3

CHCK4

DVSS

DACCLK

DACLRCK

DACDATA

CIRCIRQ

IPFLAG

MOND

TX

DVSS

DVDD

AVSS

VREFLAD

VREFMAD

VREFHAD

AVDD

VREFC(AD12)

JIOUT(AD11)

LDCUR(AD10)

VREFOP

RFENV(AD9)

N.C.(AD8)

N.C.(AD7)

TG(AD6)

VREFHDA

VREFMDA

VREFLDA

TE(AD5)

TROFS(AD4)

FE(AD3)

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Function

Connects with unused DVSS

Connects with unused DVSS

Ground for digital circuit

Connects with unused DVSS

Ground for digital cirucuit

Power supply for digital cirucuit

CD sub-code (ODC)

CD sub-code synchronous signal (ODC)/Jump output of one at DVD

Monitor terminal C

Sub-code data freme clock (ODC)

LR channnel data strove circCIRC(ODC)

L: Tracking ON (ODC)

Ground for digital cirucuit

CIRC / Binary making DVD data output

CIRC / Binary making DVD data output

CIRC / Binary making DVD data output

CIRC / Binary making DVD data output

Synchronous clock of DAT0

Ground for digital circuit

Connects with unused DVSS

I

Connects with unused DVSS

I

RAM with built-in CIRC exceeds / Underflow interrupt

CIRC error flag

Monitor terminal D

Digital audio interface

Ground for digital cirucuit

Power supply for digital cirucuit

Ground for analog cirucuit

AD subordinate position standard voltage (0.6 0.1v)

It is a place standard voltage in AD (1.4 0.1V)

High-ranking AD standard voltage (2.2 0.1V)

Power supply for analog circuit

I

Jitter signal(FEP)

I

Laser drive current signal

I

Operation amplifier standard voltage(VREFC)

RFENV(FEP)

I

Connects with VREFC

I

Connects with VREFC

I

Tangential Phase difference (FEP)

I

High-ranking AD standard voltage (2.2 0.1V)

It is a place standard voltage in AD (1.4 0.1V)

AD subordinate position standard voltage (0.6 0.1v)

Tracking error (FEP)

I

Tracking drive IC input offset

I

Focus error (FEP)

I

3

MN67705EA (2/3)

1-26

Page 27

Pin No. Symbol I/O

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

FS(AD2)

TS(AD1)

AVSS

AVDD

FBAL(DA1)

FC(DA2)

BOOST(DA3)

TBAL(DA4)

FODRV(DA5)

TRDRV(DA6)

TRSDRVA(DA7)

TRSDRVB(DA8)

DVDD

OFTR

TKCRS1

TKCRS2

DSLO

FG

MINTEST

TEST

XRESET

IREF1

DVSS

VCOF1

SYSCLK

DVSS

EC(PWM3A)

ECR(PWM3B)

N.C.(PWM3A)

N.C.(PWM2B)

N.C.(PWM1A)

CDDVD

N.C.(PWM0A)

N.C.(PWM0B)

FEPNTRON

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Function

FS (FEP)

I

TS (FEP)

I

Ground for analog cirucuit

Power supply for analog circuit

Focus balance(FEP)

Cutting off frequency (FEP)

Amount of boost (FEP)

DSL offset balance (FEP)

Focus drive

Tracking drive

Traverse drive A aspect

Traverse drive B aspect

Power supply for digital cirucuit

I

Off-track error signal (FEP)

I

Track crossing signal 1 (FEP)

I

Track crossing signal 2 (FEP)

I

Binary making data slice signal (FEP)

I

FG signal input (spindle motor driver)

Connects with DVSS

Connects with DVSS

I

Reset L : Reset

VCO reference current 1( for SYSCLK)

Ground for digital circuit)

VCO control voltage 1 (for SYSCLK)

I

33.8MHz system clock input

Ground for digital circuit

Spindle motor drive

CD/DVD control signal (FEP) CD : H DVD : L

Tracking ON (FEP)

XV-D721BK

XV-D723GD

MN67705EA(3/3)

TK15400(IC701):Video AMP.

1.Pin layout 2.Block diagram

VCC

Y-INPUT

GND

GND

STANDBY

C-INPUT

1

2

3

4

5

6

12

Y-OUTPUT

11

Y-SAG

10

CVBS-OUTPUT

9

CVBS-SAG

8

C-OUTPUT

7

GND

Y-INPUT

STANDBY

C-INPUT

VCC

1

driver

75

2

Clamp

1.25V

Reference

5

6

&

Standby

logic

Bias

2.0V

100k

Camp

1.25V

5k 5k

347

GND

6dB

1.5

5k5k

driver

75

6dB

1.5

driver

75

6dB

12

Y-OUTPUT

Y-SAG

11

CVBS

10

-OUTPUT

9

CVBS-SAG

C-OUTPUT

8

1-27

Page 28

XV-D721BK

XV-D723GD

1. Block diagram

BA5983FM-X(IC271):4CH driver

27

26

10k

25

20k

28

Vcc

24

23 22

10k

20k

21

20

19

Vcc

STAND BY

CH4

10k

10k

18

Level Shift

17 16

10k

10k

10k

10k

15

10k

10k

Level Shift

10k

10k

1

2

3

5

4

10k

10k

6

7

2. Pin function

Pin No. Pin No.

Symbol Symbol

1

BLAS IN

OPIN1(+)

2

OPIN1(-)

3

OPOUT1

4

OPIN2(+)

5

OPIN2(-)

6

OPOUT2

7

8

9

10

11

12

13

14

GND

STBY1

PowVcc1

VO2(-)

VO2(+)

VO1(-)

VO1(+)

I/O I/O

Amplifier input

I

CH1 amplifier input (+)

I

CH1 amplifier input (-)

I

CH1 amplifier output

O

CH2 amplifier input (+)

I

CH2 amplifier input (-)

I

CH2 amplifier output

O

Ground

CH1/2/3 input control

I

CH1/2 power supply

CH2 output (-)

O

CH2 output (+)

O

CH1 output (-)

O

CH1 output (+)

O

Function

15

16

17

18

19

20

21

22

23

24

25

26

27

28

TK15401(IC702):Video AMP.

1.Pin layout 2.Block diagram

VCC

R-INPUT

GND

G-INPUT

STANDBY

B-INPUT

1

2

3

4

5

6

12

R-OUTPUT

11

VCC

10

G-OUTPUT

9

VCC

8

B-OUTPUT

7

GND

R-INPUT

G-INPUT

B-INPUT

STAND BY

CH1/2/3

89

VO4(+)

VO4(-)

VO3(+)

VO3(-)

PowVcc2

STBY2

GND

OPOUT3

OPIN3(-)

OPIN3(+)

OPOUT4

OPIN4(-)

OPIN4(+)

PreVcc

2

BIAS

4

BIAS

6

100k

100k

100k

Level Shift

10k

Vcc

10k

11

10

O

CH4 output (+)

O

CH4 output (-)

O

CH3 output (+)

O

CH3 output (-)

-

CH3/4 power supply

I

CH4 input

-

Ground

O

CH3 amplifier output

I

CH3 amplifier input (-)

I

CH3 amplifier input (+)

O

CH4 amplifier output

I

CH4 amplifier input (-)

I

CH4 amplifier input (+)

-

Power supply pin

VCC

9 11

1

driver

75

6dB

5k5k

driver

6dB

75

5k5k

driver

75

6dB

10k

10k

12

Level Shift

10k

10k

13

Function

12

10

8

10k

10k

14

R-OUTPUT

G-OUTPUT

B-OUTPUT

1-28

BIAS

STANDBY

5k5k

357

GND

Page 29

MN101C23DBP3 (IC810) : System controller

XV-D721BK

XV-D723GD

Pin No.

1

2

3

4

5

6

7

8

9,10

11

12,13

14

15

16~19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42~44

45,46

47

48

49

50

51~59

60~89

90

91

92

93

94

95

96

97

98

99

100

Symbol I/O Descriptions

KCMND

MSTAT

KCLK

DATAOUT

DATAIN

CK

BEAT

VDD

OSC2,1

VSS

XI,XO

MMOD

VREF-

KEY1~4

SLCKEY1

SLCKEY2

SLCKEY3

SPIDTI

VREF+

MRDY

RESET

PANEL OP

PANEL CL

LOAD DET

MSI

PROSACK

PROSADA

REMIN

PHOTOA

PHOTOB

INH

RDSCLK

PRT

RDS DATA

SPICSB

OSDCLK

SPIC~A

VOL+/-

MPX

FVOLDA

SLCCE

RVOLDA

G9~1

P1~30

SABCE

PROCE

DSPCE

EXTCE

VOLCK

SMUTE

OSDCE

POUT

TUCE

VC3RESET

VPP

O

I

I

O

I

O

O

-

I/O

-

I/O

-

-

I

I

I

I

I

-

I

I

I

I

I

I

O

I

I

I

I

I

I

I

I

O

-

O

I

I

O

O

O

O

O

O

O

O

O

O

O

O

O

O

-

VC3 Serial data output

VC3 Status data input

VC3 Serial clock input

SLC/TUNER data output

SLC/TUNER data input

SLC/TUNER clock signal output

BEAT Cut signal output of TUNER

Power supply +5V

Oscillation terminal (8MHz)

Connect to GND

Sub clock (32.768kHz)

Connect to GND

Connect to GND

Key matrix input 1~4

Tape A playback detect switch

Tape B playback detect switch

Tape B playback/recording detect switch

SPI data input

Power supply +5V

VC3 ready input

Reset signal input

Moving panel open detection signal input

Moving panel close detection signal input

Overload detect signal input

MS Detector signal input

Clock signal output to IC406

Data input from IC406

Remote control signal input

Tape A mechanism running detection signal input

Tape B mechanism running detection signal input

Inhibit signal input

Clock signal input from IC4

Protector input

RDS data input from IC4

SPI Chip select signal output

Not used

SPI-C~A Data output to IC542

Volume rotary encoder input (+/-)

Stereo detect

Front volume data output

SLC Chip enable signal output to IC303,IC304

Rear volume data output

FL grid control signal output

FL segment control signal output

SA BASS Chip enable signal output

ProLogic Chip enable signal output

DSP Chip enable signal output

EXT Chip enable signal output

Clock signal output to IC401

System mute control signal output

Not used

Power ON/OFF

TUNER Chip enable signal output

VC3 Reset output

Power supply

1-29

Page 30

XV-D721BK

XV-D723GD

MN102LP25GGB(IC401):UNIT CPU

Pin No. Pin No.

Symbol Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

WAIT

RE

MUTE

WEM

CS0

CS1

CS2

CS3

TCLOSE

TOPEN

LSIRST

WORD

A0

A1

A2

A3

VDD

SYSCLK

VSS

XI

XO

VDD

OSCI

OSCO

MODE

A4

A5

A6

A7

A8

A9

A10

A11

VDD

A12

A13

A14

A15

A16

A17

A18

A19

VSS

A20

-

STOP

ADPD

-

-

TRVSW

I/O I/O

Micon wait signal input

I

Read enable

O

Driver mute

O

Write enable

O

Non connect

O

Chip select for ODC

O

Chip select for ZIVA

O

Chip select for outer ROM

O

Tray close signal output

O

Tray open signal output

O

LSI reset

I

Bus selection input

O

Address bus 0 for CPU

O

Address bus 1 for CPU

O

Address bus 2 for CPU

O

Address bus 3 for CPU

O

Power supply

System clock signal output

O

Power supply

Non connect

Non connect

Power supply

Clock signal input(13.5MHz)

I

Non connect

CPU Mode selection input

I

Address bus 4 for CPU

O

Address bus 5 for CPU

O

Address bus 6 for CPU

O

Address bus 7 for CPU

O

Address bus 8 for CPU

O

Address bus 9 for CPU

O

Address bus 10 for CPU

O

Address bus 11 for CPU

O

Power supply

Address bus 12 for CPU

O

Address bus 13 for CPU

O

Address bus 14 for CPU

O

Address bus 15 for CPU

O

Address bus 16 for CPU

O

Address bus 17 for CPU

O

Address bus 18 for CPU

O

Address bus 19 for CPU

O

Power supply

Address bus 20 for CPU