Page 1

SERVICE MANUAL

DVD PLAYER

XV-521BK/523GD

XV-525BK/421BK

J

C

XV-521BK/523GD

XV-525BK/421BK

Area Suffix

XV-421BK

U.S.A

Canada

Contents

Safety precautions

Importance administering

point on the safety

Dismantling and assembling

the traverse unit

Instructions

Disassembly method

Main adjustment

1-2

1-3

1-4

1-5

1-15

Check points for each error

Precautions for service

Description of major ICs

Block diagram

Standard schematic diagrams

Printed circuit boards

Parts list

XV-525BK/523GD

J U.S.A

C Canada

Area Suffix

Area Suffix

XV-521BK

1-18

1-23

1-24

2-1

2-5

2-12

3-1~

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No.20836

Jun. 2000

Page 2

XV-521BK/523GD/525BK/421BK

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

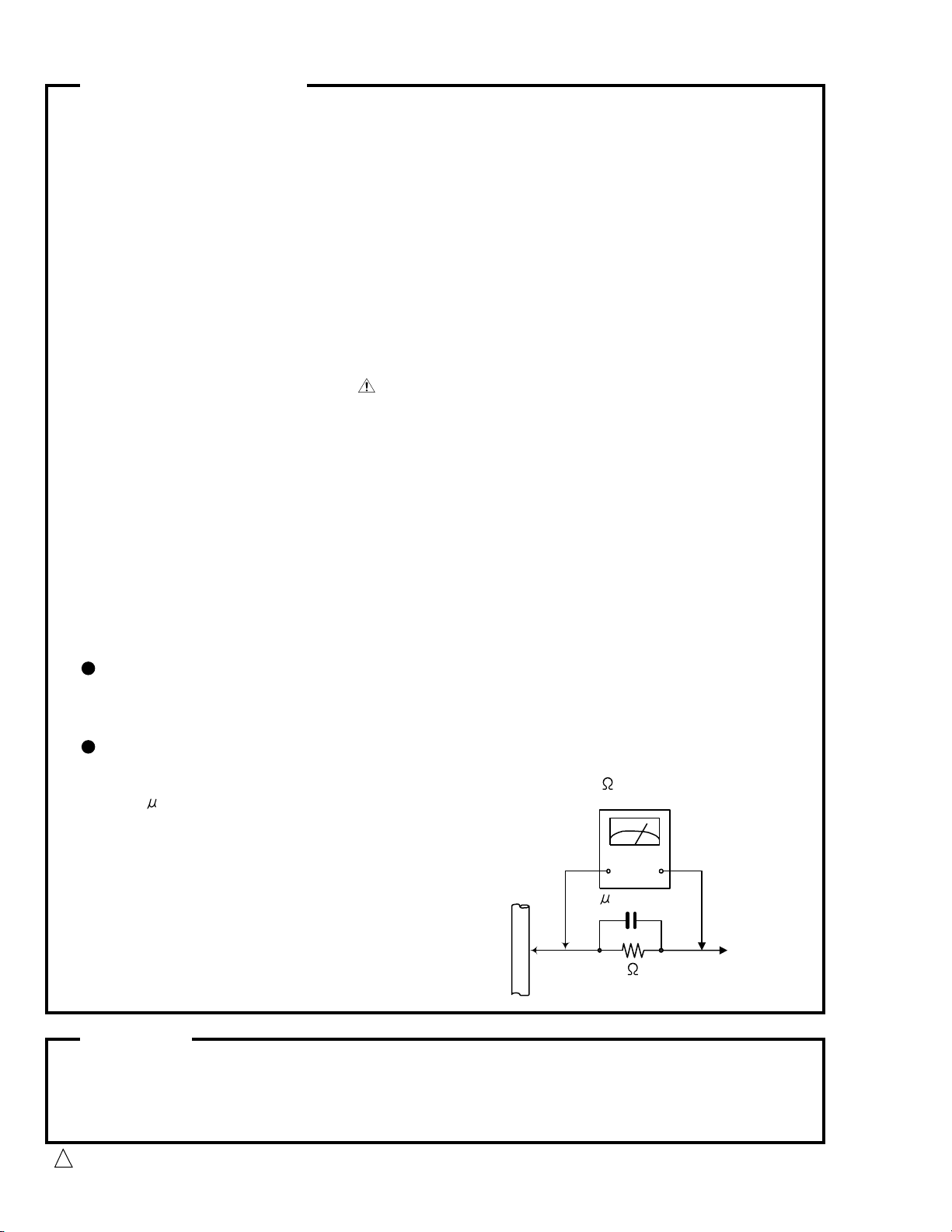

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to eachexposed metal

part, particularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

CAUTION

!

Page 3

XV-521BK/523GD/525BK/421BK

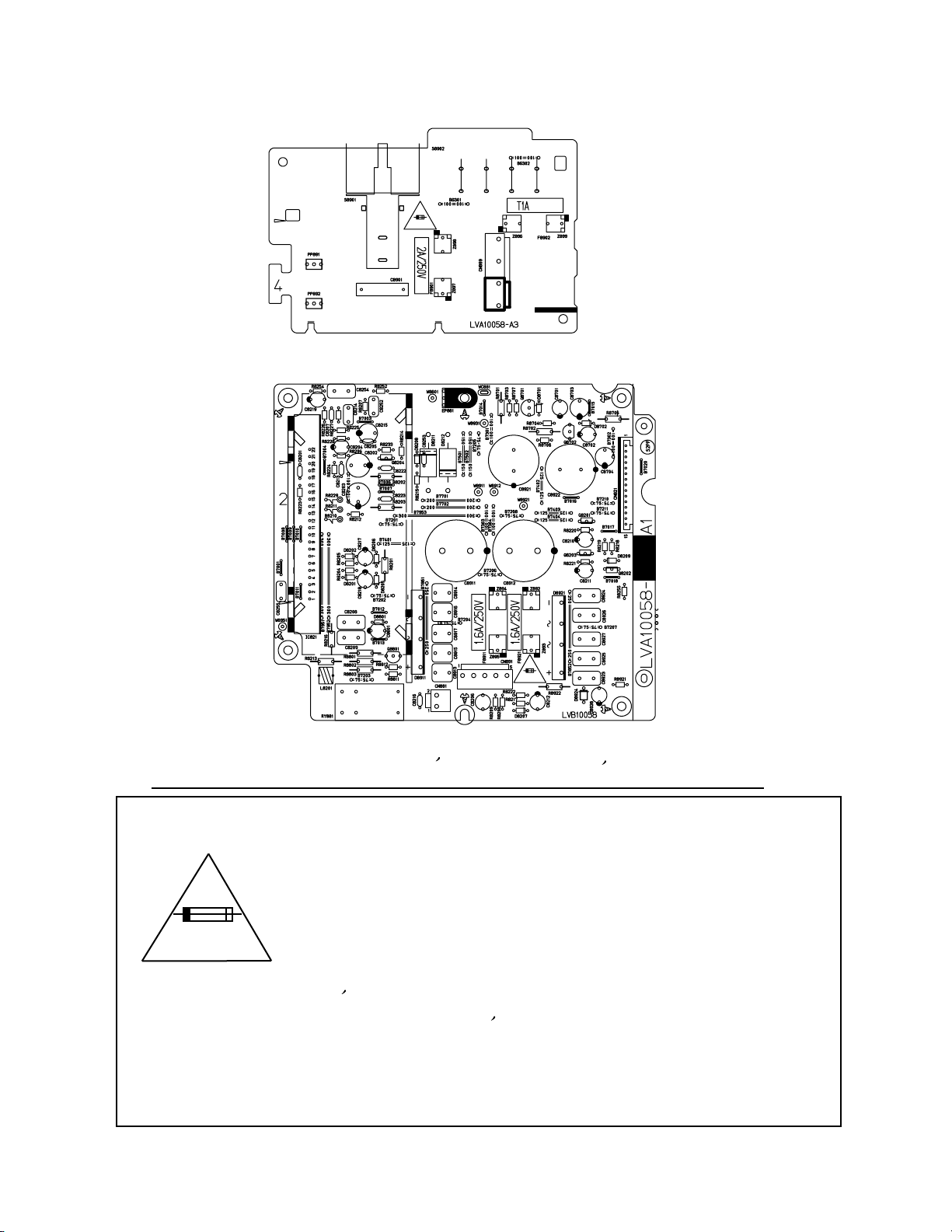

Importance administering point on the safety

For USA and Canada / pour Etats - Unis d' Amerique et Canada

Caution: For continued protection against risk of

fire, replace only with same type 2A/250V for

F8901, 1.6A/250V for F8911 and F8921. This symbol

specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F8901 comme le meme type

que 2A/250V, et 1.6A/250V pour F8911 et F8921.

Ce sont des fusibles suretes qui functionnes rapide.

^

1-3

Page 4

XV-521BK/523GD/525BK/421BK

Dismantling and assembling the traverse unit

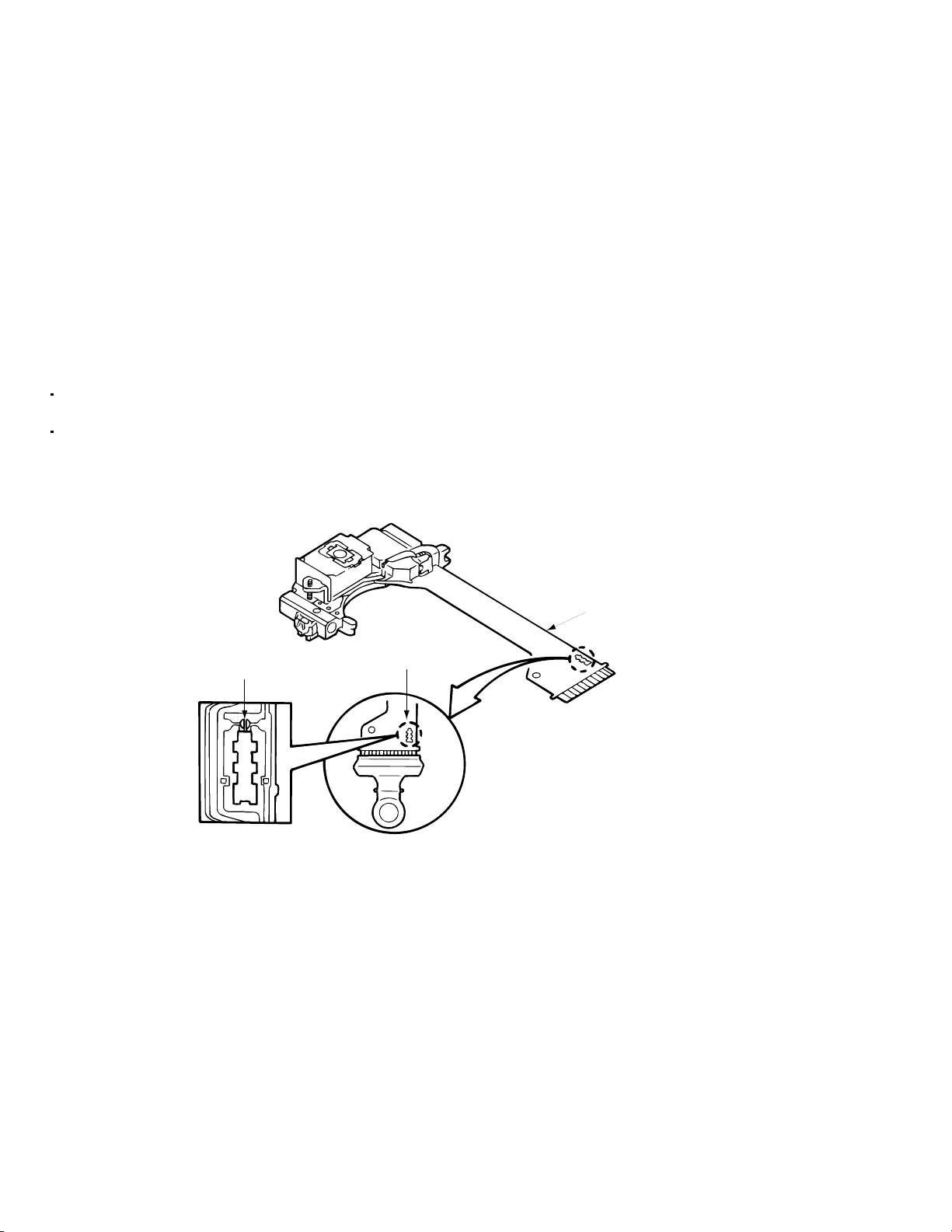

1. Notice regarding replacement of optical pickup

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing

repairs to the optical pickup or connected devices.

(Refer to the section regarding anti-static measures.)

1. Do not touch the area around the laser diode and actuator.

2. Do not check the laser diode using a tester, as the diode may easily be destroyed.

3. It is recommended that you use a grounded soldering iron when shorting or removing the laser diode.

Recommended soldering iron: HAKKO ESD-compatible product

4. Solder the land on the optical pickup's flexible cable.

Note : Short the land after shorting the terminal on the flexible cable using a clip, etc., when using an

ungrounded soldering iron.

Note : After shorting the laser diode according to the procedure above, remove the solder according

to the text explanation.

Short circuit land

Laser pick-up unit

Flexible cable

Shorting

Shot with the rclip

1-4

Page 5

Disassembly method

XV-521BK/523GD/525BK/421BK

< Main body>

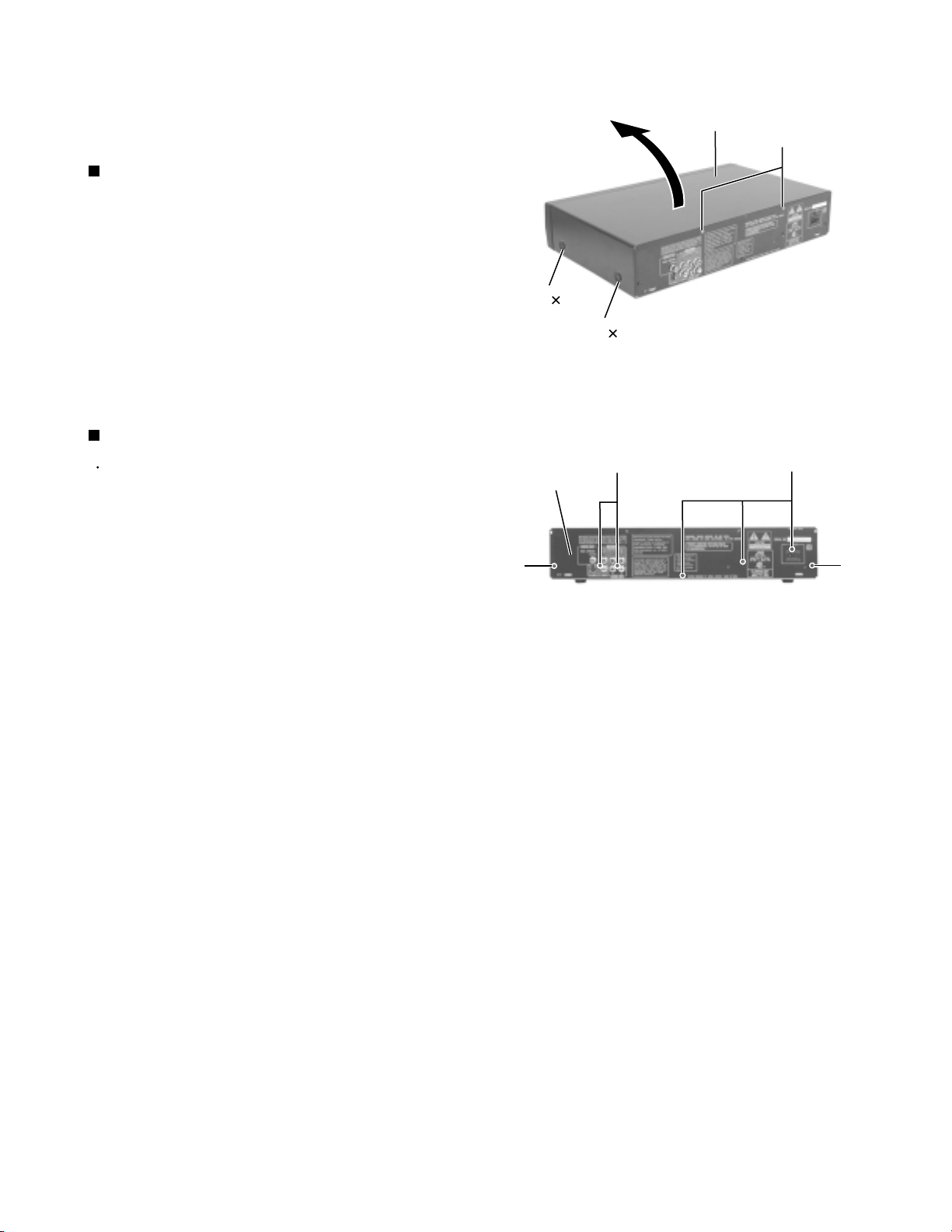

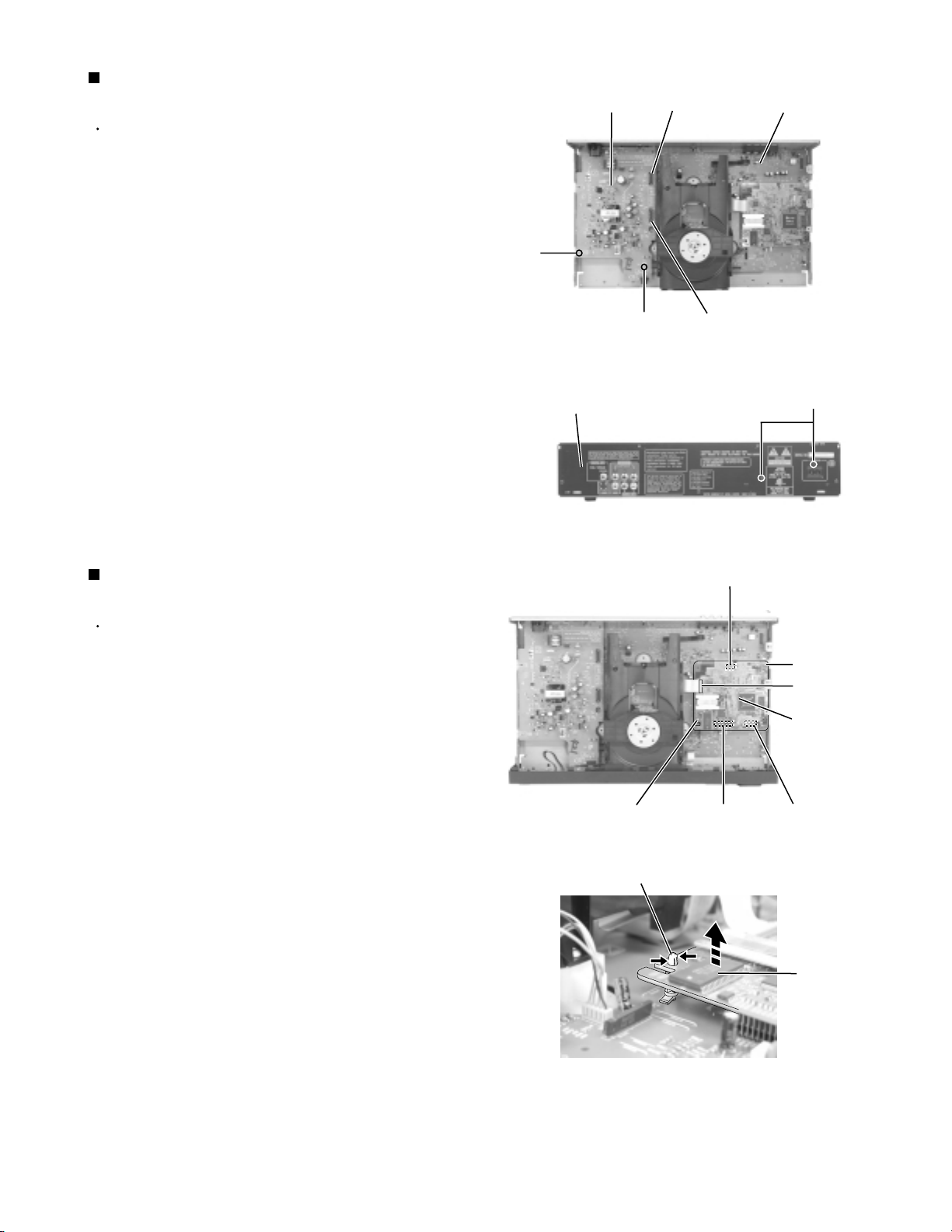

Removing the top cover (See Fig.1)

1.

Remove the four screws A on both side of the body.

2.

Remove the two screws B on the back of the body.

3.

Lift up the rear part of the top cover while pulling the

lower part of the sides, then detach upward.

Removing the rear panel (See Fig.2)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the seven screws C on the back of the

body.

A

2

Rear panel

C

A

2

C

Top cover

B

Fig.1

C

C

Fig.2

1-5

Page 6

XV-521BK/523GD/525BK/421BK

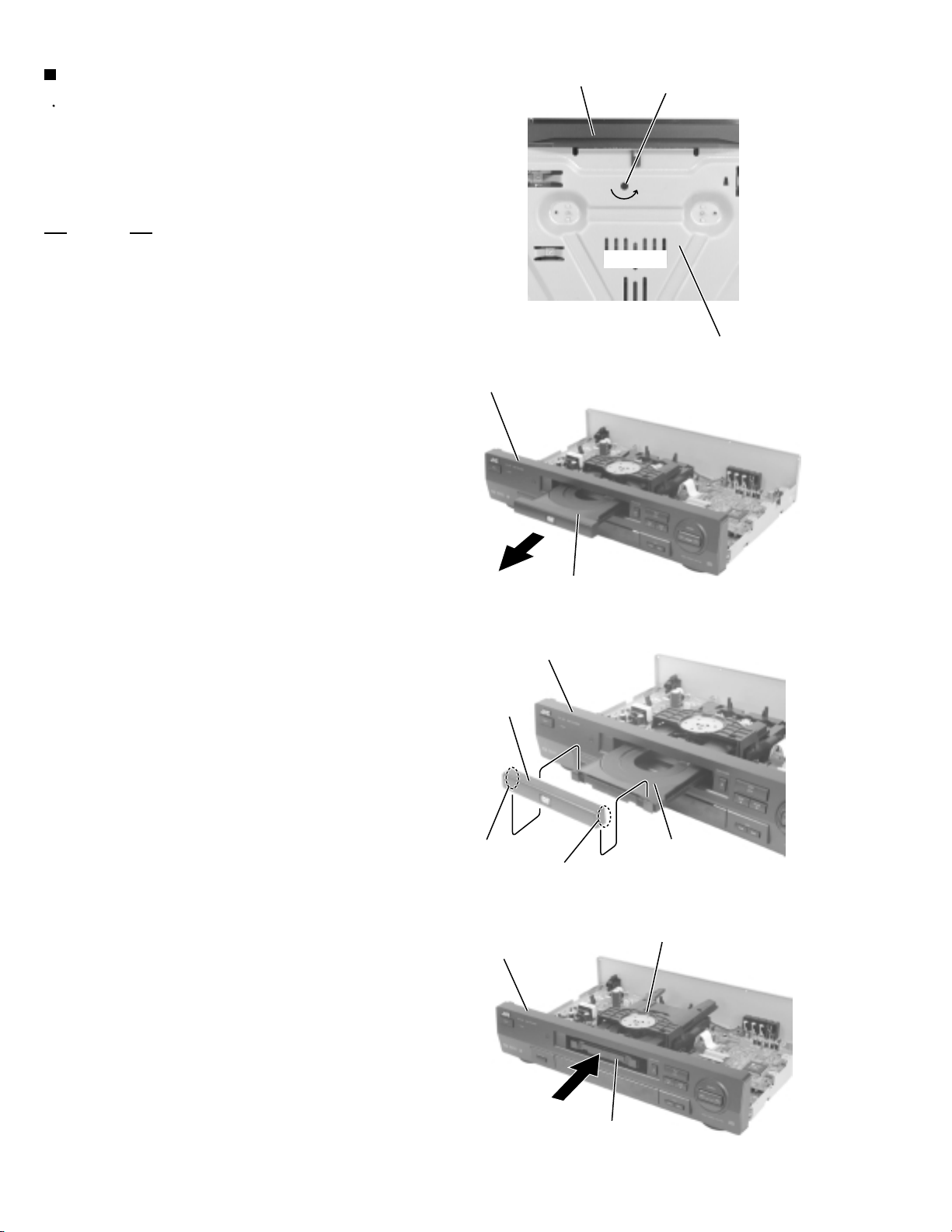

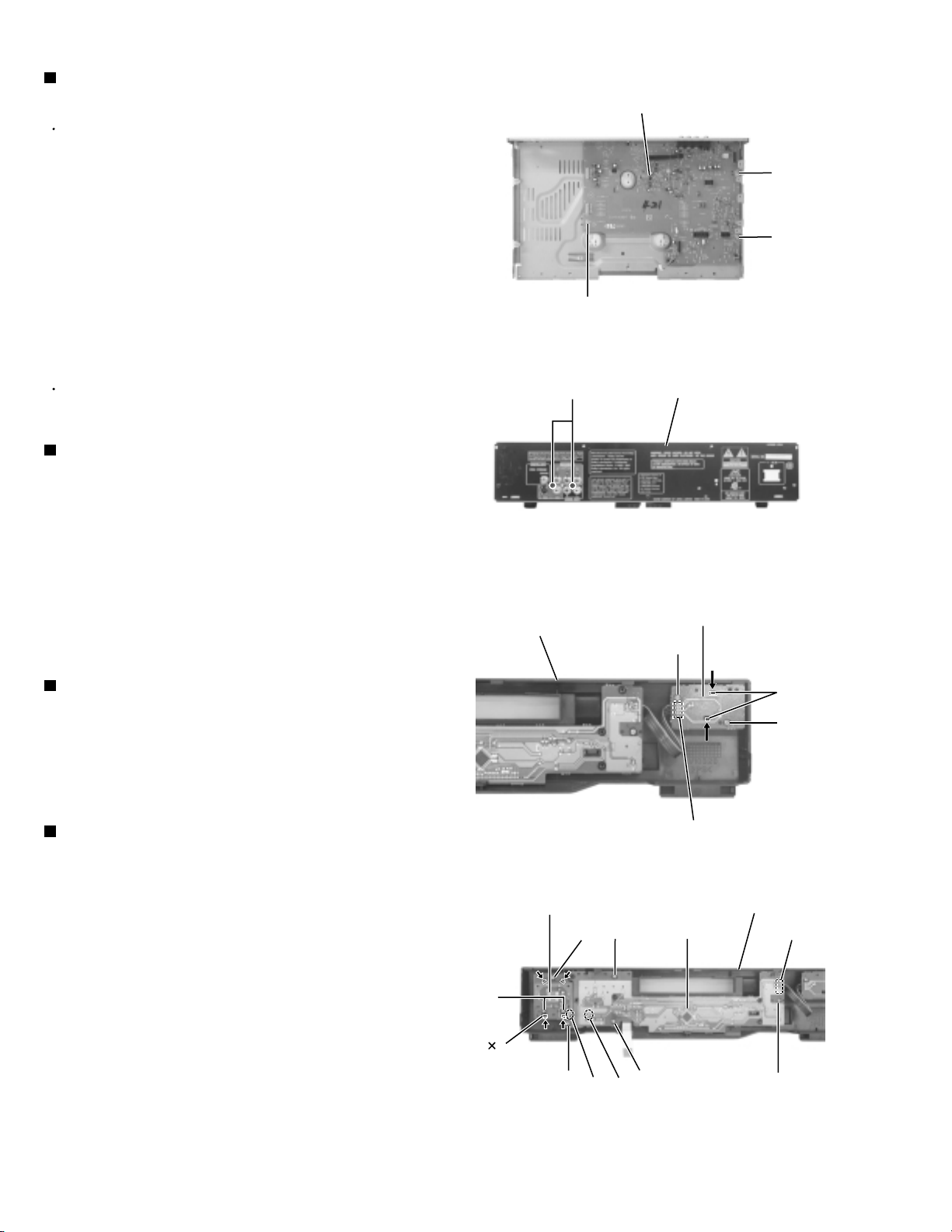

Removing the fitting (See Fig.3 to 6)

Prior to performing the following procedure, remove

the top cover.

ATTENTION:

by hand

1.

Turn over the body. Insert a screwdriver into the hole

of the bottom chassis and turnit. The loading tray will

be ejected out of the front panel assembly.

2.

Pull the loading tray toward the front.

3.

Remove the fitting upward from the loading tray at

the joints b.

4.

Push and return the loading tray.

To remove the front panel assembly

and the DVD mechanism assembly,

remove the fitting in advance.

Front panel

Front panel assembly

TRAY OPEN

(Bottom)

Fig.3

Hole

Bottom chassis

Loading tray

Front panel assembly

Fitting

Joint b

Joint b

Front panel assembly

Fig.4

Loading tray

Fig.5

DVD mechanism assembly

1-6

Loading tray

Fig.6

Page 7

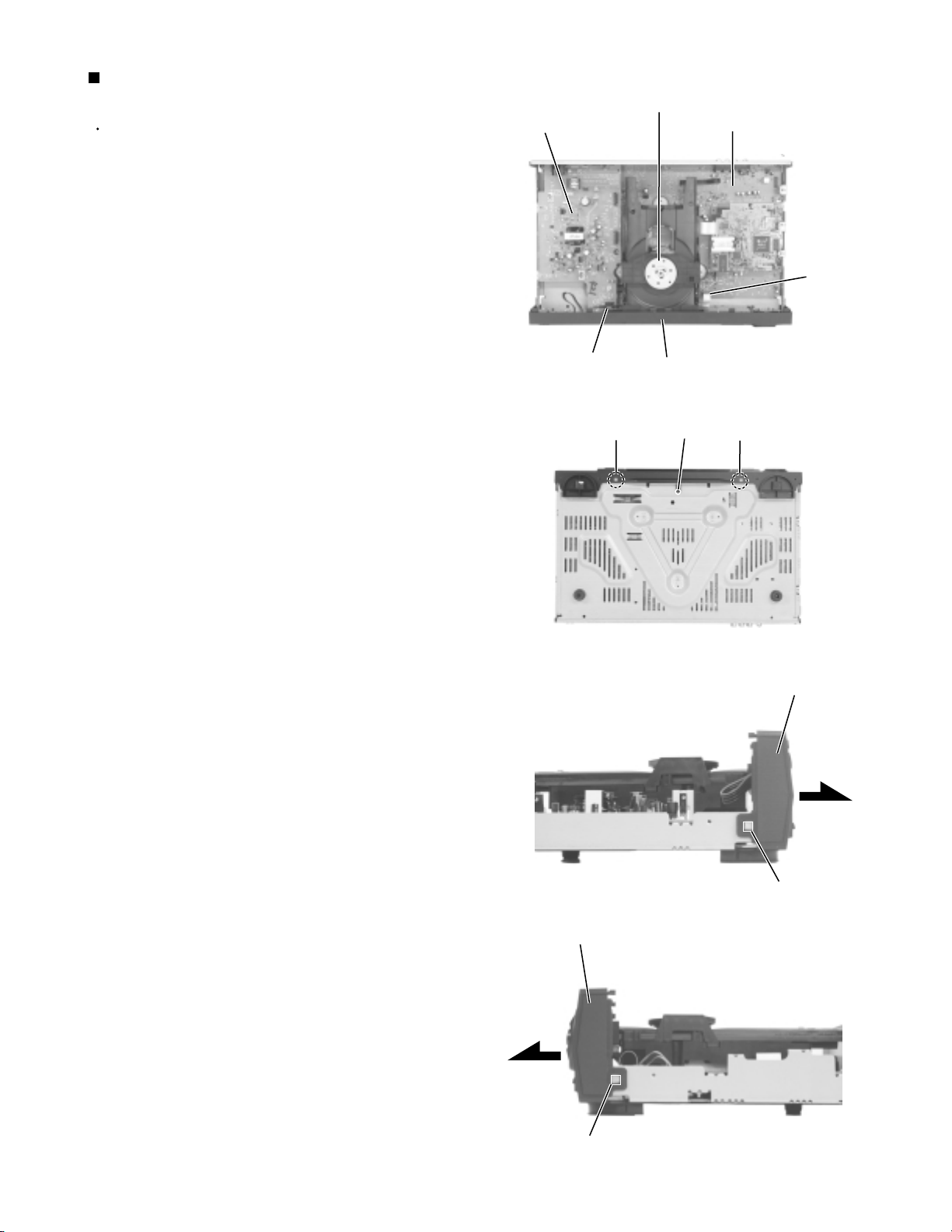

Removing the front panel assembly

(See Fig.7 to 10)

Prior to performing the following procedure, remove

the top cover and the fitting.

1.

Disconnect the card wire from connector CN703 on

the main board.

2.

Turn over the body and remove the screw D

attaching the front panel assembly.

3.

Release the five joints c on both sides and bottom of

the body and remove the front panel assembly

toward the front.

ATTENTION:

The connector CN832 on the front

panel assembly and CN971 on the AC

jack board will be disconnected at the

same time.

AC jack board

CN971

XV-521BK/523GD/525BK/421BK

DC mechanism assembly

Main board

Front panel assembly

Fig.7

Joint c Joint c

D

CN703

Front panel assembly

Fig.8

Fig.9

Front panel assembly

Joint c

Joint c

Fig.10

1-7

Page 8

XV-521BK/523GD/525BK/421BK

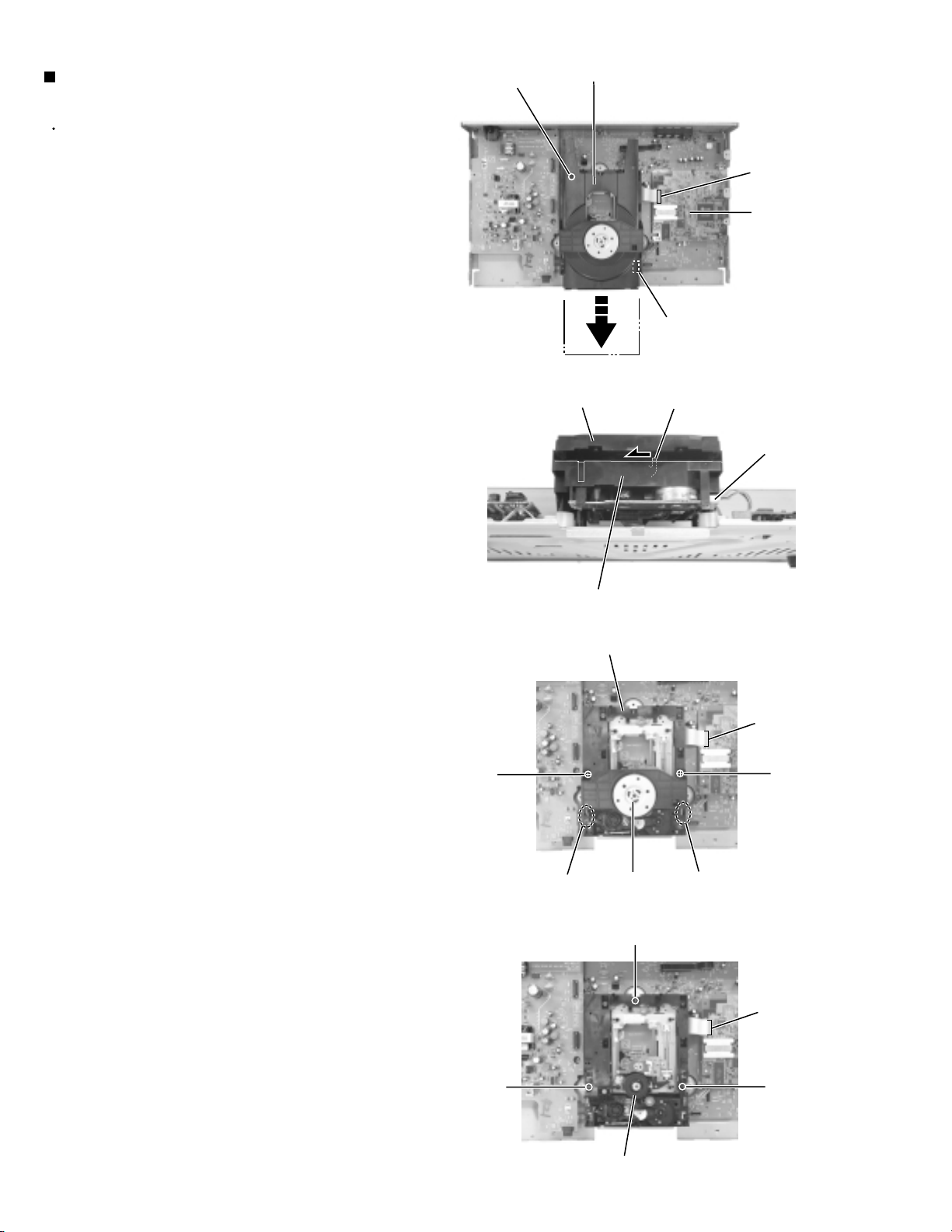

Removing the DVD mechanism assembly

(See Fig.11 to 14)

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

1.

Disconnect the card wire from connector CN101 on

the DVD Servo.

2.

Disconnect the harness from connector CN031 on

the DVD mechanism assembly.

3.

Remove the screw E on the rear left part of the

loading tray.

3.

From the front side of the DVD mechanism

assembly, move the lever d in the direction of the

arrow and pull out the loading tray.

4.

Remove the two screws F on the upper side of the

DVD mechanism assembly. Then release the two

joints e and detach the clamper base back-upward.

5.

Remove the three screws G attaching the DVD

mechanism assembly.

E

Loading tray

Fig.11

Loading tray

CN101

DVD Servo

DVD mechanism assembly

P031

Lever d

P031

F

DVD mechanism assembly

Fig.12

DVD mechanism assembly

CN101

F

Joint e Joint eClamper base

Fig.13

G

CN101

1-8

G

G

DVD mechanism assembly

Fig.14

Page 9

Removing the AC jack board

(See Fig.15 and 16)

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

1.

Remove the two screws H attaching the AC jack

board.

2.

Remove the two screws C on the rear panel.

3.

Disconnect connector CN951 and CN961 on the AC

jack board from CN704 and CN705 on the main

board respectively.

H

XV-521BK/523GD/525BK/421BK

CN951 / CN705

H

CN961 / CN704

Fig.15

Main boardAC jack board

Removing the DVD Servo

(See Fig.17 and 18)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the screw I attaching the DVD Servo.

2.

Pull out the DVD Servo from the fix f while pinching

the fix f.

3.

Disconnect connector CN501, CN502 and CN503 on

the DVD Servo from CN601, CN701 and CN706 on

the main board respectively.

Rear panel

Fix f

C

Fig.16

CN501 / CN706

I

CN101

DVD Servo

CN503 / CN701CN502 / CN701

Fig.17

Fix f

Main board

Fig.18

DVD Servo

1-9

Page 10

XV-521BK/523GD/525BK/421BK

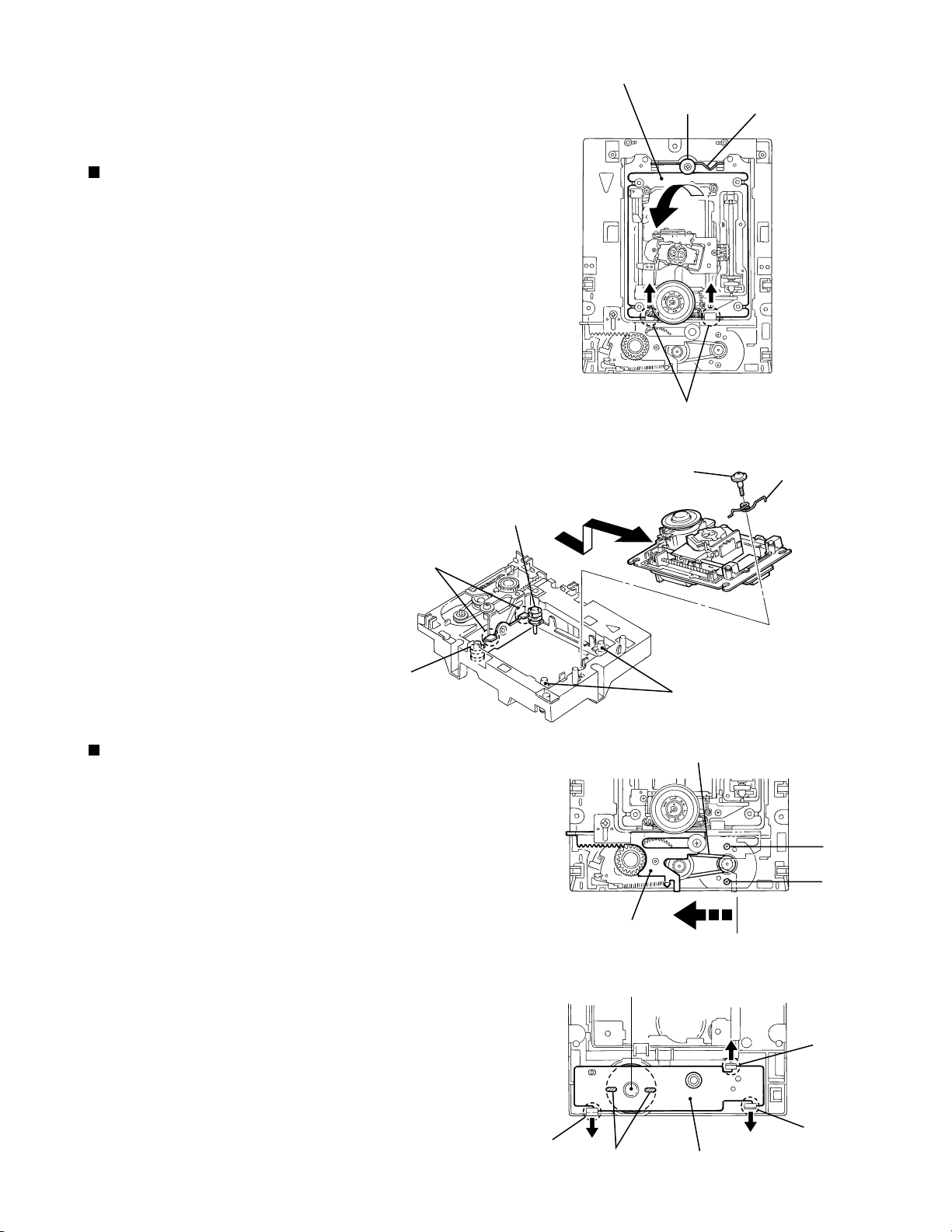

Removing the main board

(See Fig.19 and 20)

Prior to performing the following procedure, remove

the top cover, the front panel assembly, the DVD

mechanism assembly, the AC jack board and the

DVD Servo

1.

Remove the three screws J attaching the main

board.

2.

Remove the two screws C on the rear panel.

.

<Front panel assembly>

Main board

J

J

J

Fig.19

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

Removing the power switch board

(See Fig.21)

1.

Unsolder connector FW841 on the power switch

board on the back of the front panel assembly.

2.

Remove the two screws K attaching the power

switch board.

3.

Push the two tabs g in the direction of the arrow and

remove the power switch board.

Removing the LCD board (See Fig.22)

1.

Unsolder connector FW802 and soldering h on the

LCD board.

2.

Remove the four screws L attaching the LCD board.

Removing the search switch board

(See Fig.20)

C

Fig.20

Front panel assembly

Fig.21

Rear panel

Power switch board

K

Tabs g

K

FW841

1.

Unsolder soldering i on the search switch board.

2.

Remove the three screws M.

3.

Release the four tabs j in the direction of the arrow

and remove the search switch board.

1-10

M

Tabs j 4

M

L

hi

Fig.22

Front panel assemblySearch switch board

LCD board

FW802

LLL

Page 11

XV-521BK/523GD/525BK/421BK

Disassembly method

<DVD mechanism>

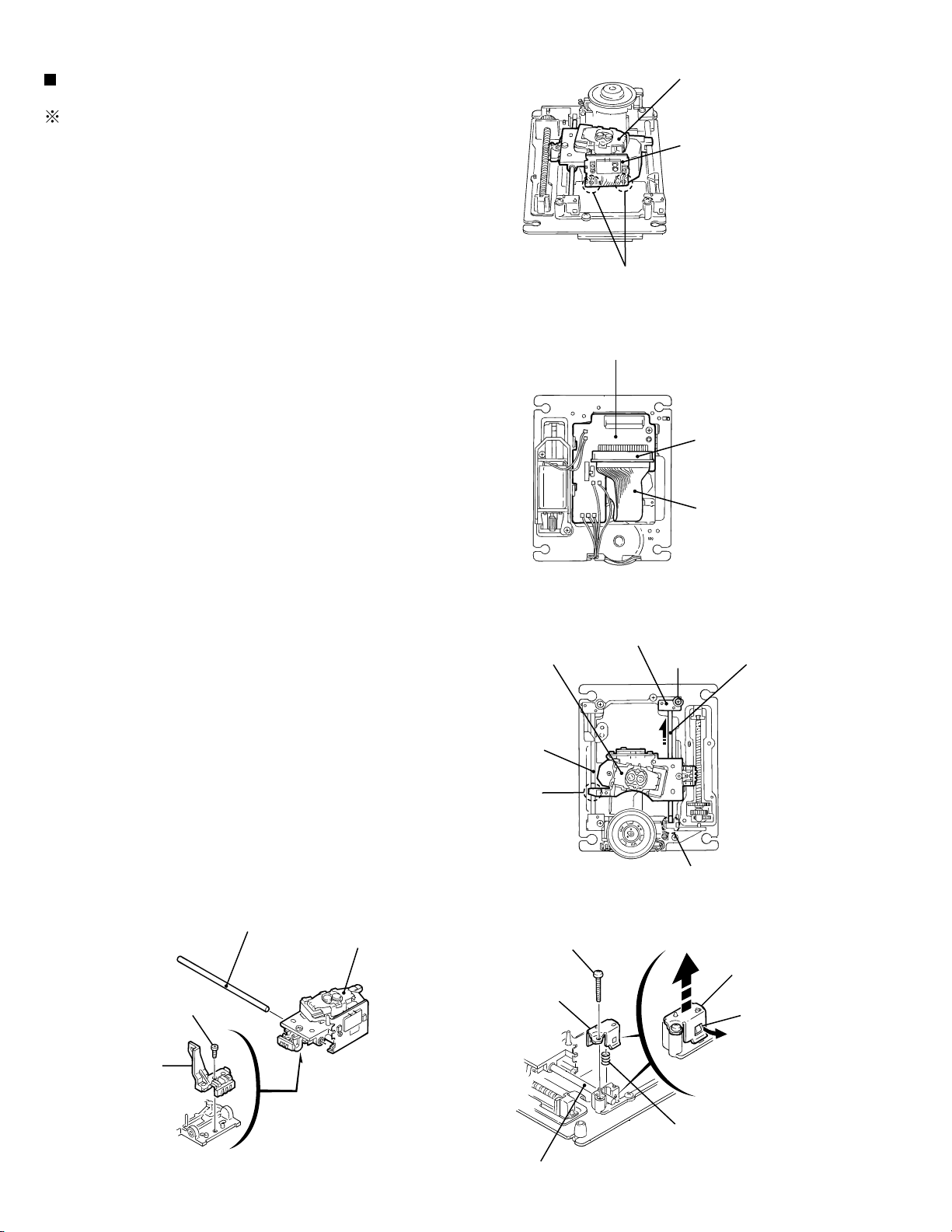

Removing the traverse mechanism unit

(See Fig.1 and 2)

1.

Remove the screw A and the spring on the upper

side of the loading base assembly.

2.

Move the rear part of the traverse mechanism unit

upward and pull backward to release the two joints a

with the base chassis.

ATTENTION:

When reattaching, engage the two

joints a and make sure the front

springs and the four insulators of the

traverse mechanism unit are correctly

attached.

Spring and Insulator

Traverse mechanism unit

A

Joints a

Fig.1

A

Spring

Spring

Joints a

Spring and Insulator

Removing the loading motor / loading

motor board (See Fig.3 and 4)

1.

Move the cam plate on the upper side of the loading

base assembly in the direction of the arrow.

2.

Remove the belt from the motor pulley.

3.

Remove the two screws B attaching the loading

motor.

4.

Turn over the loading base assembly and release the

loading motor board from the three tabs b while

spreading them outward. The loading motor board

will be detached with the loading motor.

Insulator

Fig.2

Belt

B

B

Cam plate

Fig.3

Loading motor

5.

Unsolder soldering c on the loading motor board and

remove the loading motor.

Ref.:

To remove the loading motor board only,

unsolder soldering c on the loading motor and

release the three tabs b.

Tab b

Tab b

Tab b

c

Loading motor board

Fig.4

1-11

Page 12

XV-521BK/523GD/525BK/421BK

Removing the pickup (See Fig.5 to 9)

It is not necessary to remove the traverse

mechanism unit.

1.

Solder soldering d on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN10 on the pickup

board.

ATTENTION:

3.

Remove the screw C attaching the shaft stopper (R)

on the upper side of the traverse mechanism unit.

Pull the side of the shaft stopper (R) outward to

release the joint e and remove it upward. Remove

the skew spring at the same time.

4.

Move the shaft in the direction of the arrow to release

it from the part f.

Disconnecting the flexible wire without

soldering may cause damage to the

pickup.

Pickup unit

Flexible board

d

Fig.5

Pickup board

CN10

Flexible wire

5.

Release the joint g with the shaft and remove the

pickup with the shaft.

6.

Pull out the shaft.

7.

Remove the screw D attaching the switch actuator.

Shaft

Pickup

D

Pickup unit

Shaft

Joint g

Shaft stopper (R)

Fig.6

Shaft stopper (R)

Fig.7

C

C

Shaft

Part f

Shaft stopper (R)

Joint e

1-12

Switch actuator

Skew spring

Shaft

Fig.8Fig.9

Page 13

Removing the pickup board

(See Fig.5 and 10)

It is not necessary to remove the traverse

mechanism unit.

1.

Solder soldering d on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN10 on the pickup

board.

ATTENTION:

3.

Unsolder soldering h, i and j of each harness on the

pickup board.

4.

Remove the screw E attaching the pickup board and

release the two joints k.

Disconnecting the flexible wire without

soldering may cause damage to the

pickup.

Joint k

XV-521BK/523GD/525BK/421BK

Pickup unit

Flexible board

d

Fig.5

h

Pickup board

E

Removing the feed motor assembly

(See Fig.5, 10 and 11)

Prior to performing the following procedure, remove

the traverse mechanism unit.

1.

Solder soldering d on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN10 on the pickup

board.

ATTENTION:

3.

Unsolder soldering h of the motor harness on the

pickup board.

4.

Remove the two screws F attaching the feed motor

assembly and remove the thrust spring. Move the

feed motor assembly in the direction of the arrow to

pull it out from the feed holder.

Disconnecting the flexible wire without

soldering may cause damage to the

pickup.

Joint k

Feed motor assembly

Feed holder assembly

CN10

i

j

Fig.10

Feed motor assembly

Thrust spring

F

F

Fig.11

1-13

Page 14

XV-521BK/523GD/525BK/421BK

Removing the turn table assembly

(See Fig.5, 10, 12 and 13)

Prior to performing the following procedure, remove

the traverse mechanism unit.

1.

Solder soldering d on the flexible board next to the

pickup unit.

2.

From the bottom of the traverse mechanism unit,

disconnect the flexible wire from CN10 on the pickup

board.

ATTENTION:

3.

Unsolder soldering i and j of the harness extending

from the turning table assembly to the pickup board.

4.

Remove the screw G attaching the shaft stopper (F)

on the upper side of the traverse mechanism unit.

Pull the side of the shaft stopper (F) outward to

release the joint l and remove it upward. Remove the

spring at the same time.

Disconnecting the flexible wire without

soldering may cause damage to the

pickup.

Joint k

Joint k

Pickup unit

Flexible board

d

Fig.5

h

Pickup board

E

CN10

i

5.

Remove the screw H attaching the turn table

assembly.

6.

Move the turn table assembly outward and pull out

from the shaft. Then remove it from the base chassis.

Feed motor assembly

Shaft stopper (F)

Shaft stopper (F)

Joint l

G

Turn table assembly

G

Shaft stopper (F)

j

Fig.10

H

Fig.12

G

H

1-14

Shaft

Shaft

Turn table assembly

Fig.13

Page 15

XV-521BK/523GD/525BK/421BK

Main adjustment

Adjustment and confirmation matter

(1) Auto adjustment method

If microprocessor (IC401, IC402, IC714, IC716) or pick up is replaced, initialize

the DVD player in the following matter:

1. Initialize the DVD player in the following matter:

1) Make sure that no disc is on the tray.

2) Insert the power pulag to the outret while pressing "PLAY" and "OPEN/CLOSE" button at the

same time.

FL Display indicate "TEST ; Version.

3) Press Enter button. And EEPROM initialize start.

4) When indicate "96kHz EEPROM" on the display , initialize finished.

Note : During the EEPROM initialization the keys may not be operated.

Press the "POWER" key to initiate the STAND-BY mode and the test mode will then

be cancelled.

(2) Confirmation of DVD RF level

1.The oscilloscope is connected between "1"(RFOP) of

CN104 and "2"(GND).

2.Reproduction of the test disc ( VT-502)

made by JVC.

3.It is confirmed that RF LEVEL is 350mVp-p 150mVp-p.

4.When there is disorder in the waveform road cuts etc,

test disk is exchanged and measured.

(3) Confirmation of CD jitter level and RF level

1. The CD jitter meter is connected between "11"(GND)

of CN104 and "12"(FLTOUT).

The RF level is observed at the same time.

2. The first test disk(CTS-1000) made of JVC is reproduced.

3. It is confirmed that RF LEVEL is 360 100mVp-p.

5. When there is disorder in the waveform road cuts

etc, test disk is exchanged and measured.

GNDGNDFLTOUT

12 ~ 1

CN104

DVD SERVO CONTROL PWB

"1""2""11""12"

RFOP

FRONT SIDE

1-15

Page 16

XV-521BK/523GD/525BK/421BK

(4)Flap adjustment of the Pick-up guide shaft

1) Make sure that there is no disc on the tray.

2) Press both the "PLAY" and "OPEN/CLOSE" keys of the main unit to activate the primary

power and "TEST 2 D2" will be displayed on the FL indicator.

Note: If the FL indicator display stops and remains at "TEST 0", unplug the power

cord from the outlet and after waiting at least 1 second, plug it in again. After

the tray open/close procedure has completed, unplug it again and then

perform the initialization procedure again.

3) Press the "OPEN/CLOSE" key of the main unit to draw the tray out.

*Place the test disk (VT-501) on the tray and then press the "OPEN/CLOSE" key.

(Note: Pushing the tray to close it is not possible.)

4) Press the "PLAY" key of the main unit.

5) The "JIT 0000" is displayed on the FL indicator.

Set the FL indicator figure value to its minimum by adjusting the pickup guide shaft flap.

* The test mode is cancelled when the power is turned off.

Measurement

FL Display

Measurement machine

No need

General tool : Hex-head wrench(2mm)

Adjustment point

Refer to Fig.2

connections

Refer to Fig.1

Mode

Reproduction

part

Extension cord No.

QUQ605-4040AJ

Disc

VT-501

"Flap adjustment" of the Pick-up guide shaft adjusts

"Tangential adjustment machine screw" A and

"Tilt adjustment machine screw" B from the

DVD Mechanism A'ssy bottom.

1. The part at the center on the DVD test disc is

reproduced.

2.The flap adjustment screws is turned alternately

and adjusted like clearly seeing the waveform of

CN104"1" to the way.

Note

1.The tangential adjustment is done finish and,

then, tilt is adjusted.

2.The repeat the adjustment 2-3 times,for best

result.

3.The final adjustment should be tilt adjustment.

Extension Cord

DVD Mechanism A'ssy

CN11 of

Stand

Connection PWB

CN101 of DVD Servo Control PWB

DVD player

Stand

200mm

Fig.1

1-16

Page 17

XV-521BK/523GD/525BK/421BK

Confirmation after adjustment.

Confirm to reproduce video CD and CD after

the DVD test disc is adjusted and to find abnormality.

B

Fig.2

A

A

(5) About keeping the disc

As for the DVD test disc, plane accuracy is demanded.Please note the keeping place on the disc.

1. Please do not put the disc directly on the work desk etc. after uses .

2.To keep the planarity of the disc, politely handle ,and please put in a special case and keep

the disc vertically after uses .

Please keep keeping the disc in a cool place where direct sunshine and the air-conditioning

wind do not drive.

3.When the disc curves,an accurate adjustment cannot be done.

Please exchange for a new test disc and adjust optics.

4 Other discs might not be able to be reproduced when adjusting on a curved disc.

Point of adjustment

* Please execute the static electricity protection measures before starting the

adjustment.

* When the following parts are exchanged,optical adjustment "Adjust the flap of the disc motor"

is necessary.

1.The disc motor was exchanged.

2.The laser pick up was exchanged.

3.The traverse motor unit was exchanged.

Note

Additionally, please adjust the flap of the disc motor when the picture quality deterioration is

seen .The basic adjustment though, is unnecessary for part exchange in the traverse.

An optical adjustment in the laser pick up cannot be done.

Please adjust the flap of the disc motor after exchanging the laser pick up.

* When the traverse unit is exchanged, the adjustment is basically unnecessary.

1-17

Page 18

XV-521BK/523GD/525BK/421BK

Check points for each error

(1) Spindle start error

*Defective spindle motor

Are there 10ohms resistance between each pin of CN101 "29~31"?

(The power supply is turned off and measured.)

*Hall element: Is sine wave output between CN101 "23" and "24", between "25" and "26",

and between "27" and "28" during rotation?

In either case, replace the mechanical unit.

*Defective spindle driver (IC251)

Is a driving wave output from CN101 "29~31" ?

During

rotation

Is IC251 "9" at "H" level (START)?

Servo IC --- Is control signal sent to the motor driver ?

IC201 "95" : Duty is 50% during stop, but varies during rotation (greatly varies at start).

--- If not sent, pattern or servo IC (IC201) is defective.

R259 : approx 2.5V during stop, but varies during rotation (greatly varies at start).

--- of not sent, pattern or servo IC (IC201) is defective.

Is FG input to servo IC ?

Observe FG wave from IC201 "89". --- If not output, pattern, IC251 or IC201 is defective.

(2) Disc Detection, Distinction error (no disc, no REFNV)

* Laser is defective.

* Front End Processor is defective (IC101).

* APC circuit is defective. --- Q101.

* Pattern is defective. --- Lines for CN101 "15" and "17".

Lines for between IC201 "2" and IC101 "2"(LDONA),

between IC201 "3" and IC101 "1" (LDONB).

* Servo IC is defective (IC201).

* Is signal sent to IC201(servo)"71" AS2 ?

* IC101 --- For signal from IC101 to IC301, is signal output from IC101 "88" (RFAS1) and

IC101 "69" REENV ?

1-18

Page 19

XV-521BK/523GD/525BK/421BK

(3) Traverse movement NG

* For automatic adjustment, traverse movement occurs only when the position is changed to retry

judging the disc type after the 1st judgment resulted in an error. Therefore, traverse movement

rarely occurs because, in most cases, disc judgment at the current position (1st time judgment)

is executed successfully. (Of course, NG rarely occurs in this step.)

Note: 1st time judgment of disc type resulted in NG. --- The re-judgment of disc type may not be

successful. Therefore, after removing the cause of traverse movement, re-execute automatic

adjustment and confirm that no problem exists.

* Check point

a) During stop

Whether 50% duty pulse is output to R273

Whether between R274 and C271 is at approx. 2.5VDC

Offset voltage between CN101 "34" and "35" (scores mV if exists)

b) When tray is opened or closed

Check by oscilloscope whether a rectangular wave signal is output from CN101 "34" or "35".

50msec

2.5V

Approx.

500mV

GND

If checking a) or b) resulted in NG, IC201 maybe defective.

(4) Focus ON NG

* Is FE output ? --- Pattern, IC101

* Is FCDRV signal sent ? (R286) --- Pattern, IC301

* Is driving voltage sent ?

CN101 "20", "21" --- If NG, pattern, driver, mechanical unit (with the power turned off, measure the

resistance between CN101 "20" and "21").

* Does CN101 "7"(SRF1) become "H" and is the focus drawing in done?

--- Mechanical unit (laser power too low), IC101(defective gain)

--- Moreover, It is thought that abnormality is found in the disk.

* Mechanical unit is defective.

(5) Tracking ON NG

* When the tracking loop cannot be drawn in, IC201 "39" (/TRON) does not become "L".

* Mechanical unit is defective.

Because the undermentioned adjustment value is abnormal, it is not possible to draw in normally.

* Periphery of driver (IC271)

Constant or IC it self is defective.

(When passing without becoming abnormal while adjusting the following.)

* Servo IC (IC201)

When improperly adjusted due to defective IC.

[Focus position rough adjustment]

[Phase difference cancellation rough adjustment]

[Tracking balance adjustment]

1-19

Page 20

XV-521BK/523GD/525BK/421BK

(6) Spindle CLV NG

* When the spindle cannot be shifted to CLV Servo, does not become "H" between IC301 "69"

and IC201"37".

* IC201 Is signal output from CN103 "1" (RFOP)?

* IC201 Is signal output from CN103 "11" (DSLIP)?

* IC201 Is signal output from CN103 "6" to "9" (binary-coded clock and data)?

* IC201 Is "39" (/TRON) at "L" level ?

* IC301 "74" to "76" --- Is signal output to IC201 "24", "25", "28" (In case of only CD).

(Serial communication of rotation information)

* Spindle motor driver is defective.

Even when one of the three phases is defective, item (1) may be passed.

--- Check the second item in (1) above.

* C260 to C263 Defective soldering

If noise eliminating capacitors are not properly soldered, noise may ride on the waveform.

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various

factors are thought.

Mechanism is defective.(jitter)

IC101, IC201.

(7) Address read NG

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various

factors are thought.

Mechanism is defective. (jitter)

IC201, IC301, IC401.

The disc is dirty or the wound has adhered.

(8) Between layers jump NG (double-layer disc only)

* When the focus flight is generated when jumps between layers.

Because all adjustments for L1 layer must be successful, this error may rarely be due to a

circuit defect.

* Crosstalk might occur from tracking to focus system. (See (11) ) --- Replace the mechanical unit.

* Driver surroundings.

* Defect of constant and IC.

* For double-layer discs, after checking CLV on layer L1, jumps to layer L0 after mode changes to FG.

Then tracking is turned off, and adjustments are executed from the focus position coarse adjustment

in order.

* When the jump between layers is done on the single-layer disk, the disk distinction error is thought.

--- The laser power is low (RF level is confirmed by CN102 "1" (RFOP)).

--- AS1, AS2, REFNV Is the signal sent to between IC101 and IC201 ?

1-20

Page 21

(9) Neither picture nor sound is output

* Cannot search

a) Can the feed system be driven?

Check the waveform of TRSDRV signal (R273). --- Waveform between R274 and C271.

Search results in a change of duty

(three values with 2.5V at the center)

(The figure is exaggerated.)

Check the waveform of CN101 "1" and "2". --- After the driver (IC271)

XV-521BK/523GD/525BK/421BK

b) Is kick available?

Check the TRDRV signal waveform from R289.

Check the waveform of CN101 "22" and "23" --- After the driver (IC271)

Although differs in amplitude and DC offset, the waveform is similar to that of R289

Kick pulse

Approx.

2.5V

Long-distance seek

Acceleration pulse at start;

deceleration pulse at stop

(each one)

(In the direction of search,

opposite to this figure)

For short-distance search, the waveform

becomes roundish, not trapezoidal, and

voltage is low.

Feed

Tracking

Kick pulse (fine seek) is

inserted after longdistance seek.

(Not one)

Hold (DC) during feed

1-21

Page 22

XV-521BK/523GD/525BK/421BK

(10) Picture is distorted or abnormal sound occurs at intervals of several seconds.

Does JITOUT

change periodically?

(2V or more in peak

value, except

during kick)

YES

Feed system is defective (drive gain is defective: too large).

Check the waveform according to a) in (9).

Play back a simple disc with no angle change.

OK when the following waveform appears at intervals

of several seconds.

5~10Sec.

1~1.2V

Some system other

NO

than servo may be

defective.

If this voltage is too

high (2V or more, for

example), feed motor

may be defective, or

the mechanical unit

has seized.

(11) Others (unusual events experienced to date)

* Problem occurs with double-layer discs although no problem occurs with single-layer DVD.

(Error occurs, or search becomes unstable and takes longer.)

Crosstalk might occur from tracking to focus system.

--- When FE was observed during search (skip, etc.), it was found that a wave resembling TE

with an amplitude of 200mVp-p was riding on FE.

--- Mechanical unit was replaced.

* Error frequently occurred in the outer part of discs although no error occurred in the inner part.

--- Mechanical unit was replaced because tilt seemed to be defective.

(12) CD During normal playback operation

a) Is TOC reading normal?

NO

Please refer to "Servo Volume" flow.

Displays total time

for CD-DA.

Shifts to double-speed

mode for V-CD.

YES

NO

b)Playback possible?

*--:-- is displayed during FL serch.

According to [*Cannot serch ] for DVD(9), check the feed

and tracking systems.

*No sound is output although the time is displayed.(CA-DA)

*DAC, etc, other than servo.

*The passage of time is not stable, or picture is abnormal.(V-CD)

*The wound of the disc and dirt are confirmed.

(13) Others

V-CD : Frequent occurrence of error in inside and outer.

(Even the disk without the wound : when generated.)

Waveform observation

--- Is the oscillation frequency of about 700~900Hz output?

(Borrow a pertinent disk for the complaint for the combination with the disk.)

--- Exchanges mechanism for the mechanism resonance.

1-22

Page 23

XV-521BK/523GD/525BK/421BK

Precautions for Service

Handling of Traverse Unit and Laser Pickup

1. Do not touch any peripheral element of the pickup or the actuator.

2. The traverse unit and the pickup are precision devices and therefore must not be subjected to

strong shock.

3. Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the

internal power supply of the tester.)

4. To replace the traverse unit, pull out the metal short pin for protection from charging.

5. When replacing the pickup, after mounting a new pickup, remove the solder on the short land

which is provided at the center of the flexible wire to open the circuit.

6. Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the

characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body. Before repairing peripheral elements of the traverse

unit or pickup, be sure to take the following electrostatic protection:

1. Wear an antistatic wrist wrap.

2. With a conductive sheet or a steel plate on the workbench on which

the traverse unit or the pick up is to be repaired, ground the sheet

or the plate.

3. After removing the flexible wire from the connector (CN101),

short-circuit the flexible wire by the metal clip.

4. Short-circuit the laser diode by soldering the land which is provided

at the center of the flexible wire for the pickup.

After completing the repair, remove the solder

to open the circuit.

Short-circuit

1-23

Page 24

XV-521BK/523GD/525BK/421BK

Description of major ICs

AK93C45AF-W (IC791) : CMOS EEPROM

1.Pin Layout

AK93C45AF

NC

YCC

CS

SK

1

2

3

4

2.Pin Functions

Symbol

CS

SK

DI

DO

Vcc

GND

NC

NC

8

GND

7

DO

6

DI

5

Function

Chip Select

Serial Clock Input

Serial Data Input

Serial Data Output

Power Supply

Ground

Non connection

3.Block Diagram

DI

INSTRUCTION

REGISTER

CS

SK

INSTRUCTION

DECODE.

CONTROL

AND

CLOCK

GENERATION

DATA

REGISTER

ADD.

BUFFERS

16

VREF

R/W AMPS

AND

AUTO ERASE

DECODER

VPP SW

GENERATOR

VPP

16

DO

EEPROM

1024bit

64 X 16

1-24

Page 25

AK93C65AF-X (IC403) : EEPROM

1.Terminal layout

XV-521BK/523GD/525BK/421BK

PE

VCC

CS

SK

2.Block diagram

DI

CS

INSTRUCTION

1

2

3

4

8 PIN SOP

REGISTER

8

7

6

5

INSTRUCTION

GENERATION

NC

GND

DO

DI

DECODE,

CONTROL

AND

CLOCK

DATA

REGISTER

ADD.

BUFFERS

16

R/W AMPS

AND

AUTO ERASE

DECODER

DO

16

EEPROM

4096bit

256 x 16

SK

PE

3.Pin function

Pin no. Symbol

1 PE

2 VCC

3 CS

4 SK

5 DI

6 DO

7 GND

8 NC

Function

Program enable (With built-in pull-up resistor)

Power supply

Chip selection

Cereal clock input

Cereal data input

Cereal data output

Ground

No connection

NOTE : The pull-up resistor of the PE pin is about 2.5M (VCC=5V)

VREF

VPP SW

VPP

GENERATOR

1-25

Page 26

XV-521BK/523GD/525BK/421BK

HY57V161610DTC8 or KM416S1120DT-G8 (IC504,IC505) : 16MB SDRAM

1.Block diagram

CLK

CKE

Address

CS

RAS

CAS

WE

Clock

Generator

Mode

register

Command decoder

Control logic

Row

address

buffer &

Refresh

counter

Column

address

buffer &

burst

counter

Bank B

Bank A

Row decoder

Sense amplifier

Column decoder

& latch circuit

Data counter

Input & output

Latch circuit

DQM

DQ

buffer

2.Pin function

Pin No. Symbol Description Pin No. Symbol Description

1

2,3

4

5,6

7

8,9

10

11,12

13

14

15

16

17

18

19,20

21~24

25

VCC

DQ0,1

VSS

DQ2,3

VDD

DQ4,5

VSS

DQ6,7

VCC

LDQM

WE

CAS

RAS

CS

A11,10

A0~3

VCC

Power supply

Data input/output

Connect to GND

Data input/output

Power supply

Data input/output

Connect to GND

Data input/output

Power supply

Lower DQ mask enable

Write enable

Column address strobe

Row address strobe

Chip enable

Address inputs

Address inputs

Power supply

26

27~32

33

34

35

36

37

38

39,40

41

42,43

44

45,46

47

48,49

50

VSS

A4~9

NC

CKE

CLK

UDQM

NC

VCC

DQ8,9

VSS

DQ10,11

VDD

DQ12,13

VSS

DQ14,15

VSS

Connect to GND

Address inputs

Non connect

Clock enable

System clock input

Upper DQ mask enable

Non connect

Power supply

Data input/output

Connect to GND

Data input/output

Power supply

Data input/output

Connect to GND

Data input/output

Connect to GND

1-26

Page 27

XV-521BK/523GD/525BK/421BK

MC44724AVFU (IC554) : VIDEO ENCODER

1.Terminal layout 2.Block diagrams

1

~

16

17 ~ 32

3.Pin function

No. Symbol

1

CVBS/Cb/B1

2

CVBS/Cb/B1

3

CVBS/Cb/B1Vdd

4

Y/G1

5

Y/G1

6

Y/G1/Vdd

7

C/Cr/R1

8

C/Cr/R1

9

C/Cr/R1Vdd

10

DAVss

11

TBIAS1

12

Vref1

13

DAVdd

14

Vref2

15

TBIAS2

16

NC

17

CVBS/Cb/B2

18

CVBS/Cb/B2

19

CVBS/Cb/B2Vdd

20

Y/G2

21

Y/G2

22

Y/GVdd

23

C/Cr/R2

24

C/Cr/R2

25

C/Cr/R2Vdd

26

ChipA

27

TEST

28

DVdd

29

CLOCK

30

DVss

31

Reset

32

PAL/NTSC

64 ~ 49

I/O

48

~

33

O

Analog composite drive signal (+)

O

Analog composite drive signal (-)

-

Power supply for CVBS/Cb/B DAC1

O

Analog brightness signal/G drive signal (+)

O

Analog brightness signal/G drive signal (-)

-

Power supply for Y/G DAC

O

Analog chroma signal (+)

O

Analog chroma signal (-)

-

Power supply for C/Cr/RDAC

-

Connect to ground for DAC

O

Standard BIAS for DAC1

-

Standard voltage for DAC1

-

Power supply for DAC

-

Standard voltage for DAC2

O

Standard BIAS for DAC2

-

Non connect

O

Analog composite drive signal (+)

O

Analog composite drive signal (-)

-

Power supply for CVBS/Cb/B DAC2

O

Analog brightness signal/G drive signal (+)

O

Analog brightness signal/G drive signal (-)

-

Power supply for Y/G DAC

O

Analog chroma signal (+)

O

Analog chroma signal (-)

-

Power supply for C/Cr/RDAC2

-

Chip address selection

I

Connect to test pin

-

Digital ground

I

Clock signal input (27MHz)

-

Power supply for digital circuit

I

Reset signal input L:ON

I

Selection NTSC/PAL NTSC:L PAL:H

ChipA

DVdd

DVdd

DVss

DVss

DVIN[7:0]

TP[8:1]

TVIN

TP[0]IN

Clock

Reset

PAL/NTSC

Function

H.V

DEMAX

Y

cb

cr

12C / SPI

SO

SDA/SI

EXT

Sync_ generator

CGMS,

wss gen

0

off_set

0

0

sub carrier

SEL

SCL/SCK

No. Symbol

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

F/Vsync

CCwss gen

Modulator

gen

SO

SDA/SI

SCL/SCK

SEL

DVdd

DVss

DVIN7

DVIN6

DVIN5

DVIN4

DVIN3

DVIN2

DVIN1

DVIN0

TVIN

EXT

F/Vsyac

Chsyac

DATST

TP-8

TP7

TP6

TP5

DVss

DVdd

TP4

TP3

TP2

TP1

TP0

DLVdd

DLVss

Hsync

RGB

matrix

Y/G2Vdd

C/Cr/R2Vdd

CVBS/Cb/B2Vdd

Copy,

protection

bus

0

+

0

+

0

0

0

0

DAC BIAS DAC DAC DAC

DAC

Output Selector

DAC

BIAS

TEST

TEST

I/O

-

Non connect

I

SPI Mode : Serial data input

I

Serial clock input

I

Power supply for serial data,chip select,digital

--

Power supply for digital circuit

--

Digital ground

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I/O

Y data input / test data I/O

I

VIDEO mute on Reset(0:nomal, 1:mute)

I/O

Frame output / VBI information input

I/O

Frame / Vertical, synchronous I/O

I/O

The horizontal, synchronous I/O

I

Data input

I/O

Multiplex data input

I/O

Multiplex data input

I/O

Multiplex data input

I/O

Multiplex data input

-

Ground for digital circuit

-

Power supply for digital circuit

I/O

Data input / Test data I/O

I/O

Data input / Test data I/O

I/O

Data input / Test data I/O

I/O

Data input / Test data I/O

I/O

Data input / Test data I/O

-

Power supply for D/A converter

-

Ground for D/A converter

DLVss

DLVdd

Function

Y/G1Vdd

CVBS/Cb/B1Vdd

C/Cr/R1Vdd

Y/G1

Y/G1

CVBS/Cb/B1

CVBS/Cb/B1

C/Cr/R1

C/Cr/R1

Vref1

iBIAS1

Y/G2

Y/G2

CVBS/Cb/B2

CVBS/Cb/B2

C/Cr/R2

C/Cr/R2

Vref2

Ibias

DAVdd

DAVss

1-27

Page 28

XV-521BK/523GD/525BK/421BK

MN101C12GCS3 (IC701) : System micom

1.Terminal layout

100 ~ 76

25

2.Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

1

~

26 ~ 50

GND

CS0

CS1

CS2

NTSEL

POWER SW

SHUT1

KEY1-5

KEY6-10

VREF

VDD

OSC2

OSC1

VSS

XI

XO

MMOD

OSDCS3

RSTE

OSDDO

S2UDT

U2SDT

SCLK

BUSY

CPURST

REQ

REMO

CS3

-

-

NC

RESET

NC

NC

VDD

OSDCK

NT

75

~

51

-

-

-

O

-

O

O

O

O

O

O

O

O

O

O

O

O

GND

I

A set bit0 (It is effective in the U.E version)

I

A set bit1 (It is effective in the U.E version)

I

A set bit2 (It is effective in the U.E version)

I

NTSC/PAL switch SW input

I

Power key input

I

JOG shuttle inout (AD)

I

10 Key input (1~5)

I

10 Key input (6~10, +10)

+B (Apply 5V)

+B (Apply 5V)

10MHz OSC

I

10MHz OSC

GND

I

Unused, Connects with GND

Unused

I

Connects with GND

VENCODER chip selection

V.ENCOSER reset

V.ENCODER communication DATA

Communication between unit microcomputers DATA OUT

I

Communication between unit microcomputers DATA IN

Communication between unit microcomputers CLK

Communication between unit microcomputers BUSY

Unit microcomputer reset

I

Communication between unit microcomputers REQ

I

Remote control interruption

I

Set password change judgment bit(H:Change, L:Usual)

I

GND

I

H:Checkers mode, L:Normal mode

I

H:Running mode, L:Normal mode

I

Un used

I

Reset input

Un uesd

Un used

Un used

V.ENCODER communication CK

1-28

Page 29

Pin No. Symbol I/O Function

XV-521BK/523GD/525BK/421BK

MN101C12GCS3 (2/2)

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66~76

77

78

79

80

81~85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

FS2

CHREQ

CHST

CHDATAIO

NC

CHCK

FLDATAO

FLDATAI

FLCK

FLCS

FLRST

EEDO

EEDI

EECK

EECS

VS1

VS3

DMUT1

DMUT2

PDB2

PDB1

DEMP2

DEMP1

DENA

KARAOKE

POWERON

VS2

NC

AVC I

AVC O

NC

STANBYIND

NC

CS4

MA

MB

M1M3

MD

MC

GAIN2

GAIN1

HPMUT

DAVSS

LMUTE

CMUTE

SMUTE

MUTE

DAVDD

O

O

O

O

O

I

O

O

O

O

I

O

O

O

O

-

-

-

-

-

-

O

O

O

O

I

O

O

O

O

O

O

O

O

O

O

-

-

O

O

O

O

O

-

48kHz, 96kHz switch

I

Changer communication REQUEST

Changer communication STROBE

Changer communication DATAI/O

Changer communication CLOCK

FL driver communication DATAO

FL driver communication DATAI

FL driver communication CLOCK

FL driver communication CS

FL reset output

EEPROM communication DATAO

EEPROM communication DATAI

EEPROM communication CLOCK

EEPROM communication CS

S1 control

S3 control(STBY:H, P.ON:L)

Un used

Un used

Un used

Un used

Un used

Un used

Un used

KARAOKE gain control(At KARAOKE : H)

Power ON output

S2 control

Un used

AV COMPULINK input

AV COMPULINK output

Un used

Standby LED output

Un used

Un used

DAC control MA

DAC control MB

DAC control M1M3

DAC control MD

DAC control MC

Un used

Un used

Un used

Un used

Un used

Un used

Un used

Front mute output

Apply 5V

1-29

Page 30

XV-521BK/523GD/525BK/421BK

NJM4580D (IC672) : LPF, Mic and H.phone Amp.

1.Terminal layout

2.Block diagram

+

V

INPUT

+

A OUT

A -IN

A +IN

V

1

2

A

3

-

4

(TOP VIEW)

B

8

7

6

5

+

V

B OUT

B -IN

B +IN

-

V

IC-PST9140-T (IC717) : Reset IC

1. Block diagram

CO1

OUTPUT

VCC

2

OUT

1

OP1

1-30

GND

3

Page 31

NJM78M05FA (IC718) : Regulator

1. Terminal layout

2. Block diagram

XV-521BK/523GD/525BK/421BK

1-31

Page 32

XV-521BK/523GD/525BK/421BK

STR-G6651 (IC901) : Switch regulator

VIN

4

D

START

REG

T. S. D

O.V.P

LATCH

O.S.C

Comp.2

Vth(2)

DRIVE

Comp.1

2

S

Vth(1)

5

O.C.P/F.B

3

GND

1-32

Page 33

TC74VHC00FT-X (IC503) : Wright timing control

1

5

4

2

3

VCC

OUT Y

IN B

IN A

GND

TC7SH08FU-X (IC311) : Timing control

1.Terminal layout

1.Terminal layout

2.Block diagram

1

2

3

4

8

7

6

5

VCC

PR

CLR

Q

CK

D

Q

GND

TC7WH74FU-X (IC374) : Clock buffer

1.Terminal layout / Block diagram

Vcc 4B 4A 4Y 3B 3A 3Y

14 13

12

11 10 9 8

XV-521BK/523GD/525BK/421BK

2

1

1A 1B 1Y 2A 2B 2Y GND

6

543

7

TC7SH32FU-X (IC312) : Timing control

1.Terminal layout

IN B

IN A

GND

1

2

3

5

4

VCC

OUT Y

1-33

Page 34

XV-521BK/523GD/525BK/421BK

ZIVA3-PE0 (IC501) : AV Decoder

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Symbol

PIO0

H DATA 0

H DATA 1

H DATA 2

VDD-3.3

H DATA 3

VSS

H DATA 4

H DATA 5

H DATA 6

H DATA 7

VDD-2.5

RESET

VSS

WAIT/DTACK

INT

VDD-3.3

NC

VSS

NC

PIO11

PIO12

PIO13

PIO14

PIO15

PIO16

VDD-3.3

PIO17

VSS

PIO18

PIO19

PIO20

PIO21

PIO22

PIO23

VDD-3.3

PIO24

VSS

PIO25

VDD-2.5

PIO26

VSS

I/O

I/O

I/O

I/O

I/O

O

O

O

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Programmable I/O pins.Input mode after reset.

8-bit bi-derectional host data bus. writes data to the decoder Code FIFO via HDATA.

MSB of the 32-bit word is written first. The host also reads and writes the decoder

internal registers and local SDRAM via HDATA.

3.3-V supply voltage for I/O signals.

8-bit bi-derectional host data bus. writes data to the decoder Code FIFO via HDATA.

MSB of the 32-bit word is written first. The host also reads and writes the decoder

internal registers and local SDRAM via HDATA.

Ground for core logic and I/O signals.

8-bit bi-derectional host data bus. writes data to the decoder Code FIFO via HDATA.

MSB of the 32-bit word is written first. The host also reads and writes the decoder

internal registers and local SDRAM via HDATA.

2.5-V supply voltage for core logic.

Hardware reset. An external device asserts RESET(active LOW) to execute a decoder

I

hardware reset. To ensure proper initialization after power is stable,assert RESET for at

least 20 ms.

Ground for core logic and I/O signals.

Transfer not complate / data acknowledge. Active LOW to indicate host initiated transfer

is not complate.WAIT is asserted after the falling edge of CS and reasserted when

decoder is ready to complate transfer cycle. Open drain signal, must be pulled-up via

1kW to 3.3 volts. Driven high for 10 ns before tristate.

Host interrupt. Open drain signal, must be pulled-up via 4.7kW to 3.3 volts.

Driven high for 10 ns before tristate.

3.3-V supply voltage for I/O signals.

No Connection

Ground for core logic and I/O signals.

No Connection

Programmable I/O pins. Input mode after reset

3.3-V supply voltage for I/O signals.

Programmable I/O pins. Input mode after reset

Ground for core logic and I/O signals.

Programmable I/O pins. Input mode after reset

Programmable I/O pins. Output mode after reset

3.3-V supply voltage for I/O signals.

Programmable I/O pins. Output mode after reset

Ground for core logic and I/O signals.

Programmable I/O pins. Output mode after reset

2.5-V supply voltage for core logic.

Programmable I/O pins. Output mode after reset

Ground for core logic and I/O signals.

-

ZIVA3-PEO (1/5)

Function

1-34

Page 35

Pin No.

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

Symbol

PIO28

PIO29

PIO30

VDD-3.3

PIO31

VSS

NC

PIO1

MDATA15

M DATA 0

VDD-3.3

MDATA14

VSS

M DATA 1

MDATA13

M DATA 2

VDD-3.3

MDATA12

VSS

M DATA 3

VDD-2.5

MDATA11

VSS

M DATA 4

VDD-3.3

MDATA10

VSS

M DATA 5

M DATA 9

M DATA 6

VDD-3.3

M DATA 8

VSS

M DATA 7

LDQM

UDQM

VDD-3.3

MWE

VSS

SD-CLK

SD-CAS

SD-RAS

VDD-3.3

SD-CS1

VSS

SD-CS0

VDD-2.5

NC

VSS

NC

VDD-3.3

MADDR9

VSS

MADDR11

XV-521BK/523GD/525BK/421BK

I/O

I/O

Programmable I/O pins. Output mode after reset

-

3.3-V supply voltage for I/O signals.

I/O

Programmable I/O pins. Output mode after reset

-

Ground for core logic and I/O signals.

O

No Connection

Programmable I/O pins. Input mode after reset

I/O

Memory data

I/O

Memory data

I/O

3.3-V supply voltage for I/O signals.

Memory data.

I/O

Ground for core logic and I/O signals.

-

Memory data.

I/O

3.3-V supply voltage for I/O signals.

Memory data.

I/O

Ground for core logic and I/O signals.

Memory data.

I/O

2.5-V supply voltage for core logic.

Memory data.

I/O

Ground for core logic and I/O signals.

Memory data.

I/O

3.3-V supply voltage for I/O signals.

Memory data.

I/O

Ground for core logic and I/O signals.

-

Memory data.

I/O

3.3-V supply voltage for I/O signals.

Memory data.

I/O

Ground for core logic and I/O signals.

Memory data.

I/O

SDRAM LDQM.

O

SDRAM UDQM.

O

3.3-V supply voltage for I/O signals.

SDRAM write enable. Decoder asserts active LOW to request a write operation to the

O

SDRAM array.

Ground for core logic and I/O signals.

SDRAM system clock.

O

Active LOW SDRAM column address.

O

Active LOW SDRAM row address.

O

3.3-V supply voltage for I/o signals.

Active LOW SDRAM bank select.

O

Ground for core logic and I/O signals.

Active LOW SDRAM bank select.

O

2.5-V supply voltage for core logic.

No Connection.

O

Ground for core logic and I/O signals.

No Connection.

O

3.3-V supply voltage for I/O signals.

Memory address.

O

Ground for core logic and I/O signals.

Memory address.

O

Function

ZIVA3-PEO (2/5)

1-35

Page 36

XV-521BK/523GD/525BK/421BK

Pin No.

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

Symbol

MADDR8

MADDR10

VDD-3.3

MADDR7

VSS

MADDR0

MADDR6

MADDR1

VDD-3.3

MADDR5

VSS

MADDR2

MADDR4

MADDR3

VDD-3.3

NC

VSS

NC

VDD-2.5

NC

VSS

NC

VDD-3.3

NC

VSS

NC

RESERVED

PIO2

NC

RESERVED

PIO3

VDD-3.3

RESERVED

VSS

RESERVED

PIO4

RESERVED

PIO5

V DATA 0

V DATA 1

VDD-2.5

V DATA 2

VSS

PIO6

V DATA 3

I/O

O

-

O

-

O

-

O

-

O

-

O

-

O

-

O

-

O

-

O

-

O

O

I/O

O

I

I/O

I

I

I/O

I

I/O

O

-

O

-

I/O

O

Memory address.

3.3-V supply voltage for I/O signals.

Memory address.

Ground for core logic and I/O signals.

Memory address.

3.3-V supply voltage for I/O signals.

Memory address.

Ground for core logic and I/O signals.

Memory address.

3.3-V supply voltage for I/O signals.

No Connection

Ground for core logic and I/O signals.

No Connection

2.5-V supply voltage for core logic.

No Connection

Ground for core logic and I/O signals.

No Connection

3.3-V supply voltage for I/O signals.

No Connection

Ground for core logic and I/O signals.

No Connection

Open drain signal, must be pulled-up via 4.7kW to 3.3 volts.

Programmable I/O pins. Input mode after reset.

No Connection

Tie to VSS or VDD-3.3

Programmable I/O pins. Input mode after reset.

3.3-V supply voltage for I/O signals.

Tie to VSS or VDD-3.3

Ground for core logic and I/O signals.

Tie to VSS or VDD-3.3

Programmable I/O pins. Input mode after reset.

Tie to VSS or VDD-3.3

Programmable I/O pins.Input mode after reset.

Video data bus. Byte serial CbYCrY data synchronous with VCLK. At power-up,

the decoder does not drive VDATA. During boot-up, the decoder uses configuration

parameters to drive or 3-state VDATA

2.5-V supply voltage for core logic.

Video data bus. Byte serial CbYCrY data synchronous with VCLK. At power-up,

the decoder does not drive VDATA. During boot-up, the decoder uses configuration

parameters to drive or 3-state VDATA

Ground for core logic and I/O signals.

Programmable I/O pins. Input mode after reset.

Video data bus. Byte serial CbYCrY data synchronous with VCLK. At power-up,

the decoder does not drive VDATA. During boot-up, the decoder uses configuration

parameters to drive or 3-state VDATA

ZIVA3-PEO (3/5)

Function

1-36

Page 37

Pin No.

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

Symbol

VDD-3.3

V DATA 4

VSS

V DATA 5

PIO7

V DATA 6

V DATA 7

PIO8

HSYNC

VSYNC

DA-IEC

VDD-3.3

DA-DATA0

VSS

DA-DATA1

DA-DATA2

DA-DATA3

DA-LRCK

DA-BCK

VDD-2.5

DA-XCK

VSS

DAI-DATA

DAI-LRCK

DAI-BCK

PIO9

CLKSEL

A-VDD

VCLK

SYSCLK

A-VSS

DVD-DATA0

/CD-DATA

VDD-3.3

DVD-DATA1

/CD-LRCK

VSS

DVD-DATA2

/CD-BCK

DVD-DATA3

/CD-C2PO

XV-521BK/523GD/525BK/421BK

ZIVA3-PEO (4/5)

I/O

3.3-V supply voltage for I/O signals.

Video data buses for byte sequential CbYCrY data.

O

The decoder does not run VDATA during the power up procedure. However,

during booting the decoder uses operational configuration parameters or 3-state VDATA.

Ground for core logic and I/O signals.

Video data buses for byte sequential CbYCrY data.

O

The decoder does not run VDATA during the power up procedure. However,

during booting the decoder uses operational configuration parameters or 3-state VDATA.

Programmable I/O pin. Input mode after resetting.

I/O

Video data buses for byte sequential CbYCrY data.

O

The decoder does not run VDATA during the power up procedure. However,

during booting the decoder uses operational configuration parameters or 3-state VDATA.

Programmable I/O.

I/O

pins. Input mode after reset.

I/O

Horizontal sync. The decoder begins outputting pixel data for a new horizontal line

after the falling (active) edge of HSYNC.

I/O

Vertical sync.Bi-directional, the decoder outputs the top border of a new field on the

first HSYNC aftre the falling edge of VSYNC. VSYNC can accept vertical

synchronization or top/bottom field notification from an external source.

(VSYNC HIGH = bottom field. VSYNC LOW = Top field)

O

Bistream data in IEC-1937 or PCM data out in IEC-958 format.

-

3.3-V supply voltage for I/O signals.

O

PCM data out, eight channels. Serial audio samples relative to DA-BCK clock.

Ground for core logic and I/O signals.

O

PCM data out, eight channels. Serial audio samples relative to DA-BCK clock.

O

PCM left-right clock. Identifies the channel for each audio sample. the polarity is

programmable.

O

PCM bit clock. Divided by 8 from DA-XCK can be either 48 or 32 times the sampling

clock.

-

2.5-V supply voltage for core logic.

I/O

Audio master frequency clock. Used to generate DA-BCK and DA-LRCK. DA-XCK can

be eigher 384 or 256 times the sampling frequency.

Ground for core logic and I/O signals.

I

PCM input data. two channels. Serial audio samples relative to DAI-BCK clock.

I

PCM input left-right clock.

I

PCM input bit clock.

I/O

Programmable I/O pins. Input mode after reset.

I

Clock Select: Internal = VDD, External = VSS

-

3.3-V analog supply voltage.

I

Video clock. Clocks out data on input. VDATA7.Clock is typically 27 MHz.

I

System clock.Decoder requires external 27 MHz TTL oscilator.

Drive with the same 27-MHz as VCK.

Analog ground for PLL

I

Serial CD data. This pin is shared with DVD compressed data DVD-DATA0.

-

3.3-V supply voltage for I/O signals.

I

Programmable polarity 16-bit word synchronization to the decoder

(right channel HIGH). This pin is shared with DVD compressed data DVD-DATA1.

Ground for core logic and I/O signals.

I

CD bit clock. Decoder accept multiple BCK rates. This pin is shared with DVD

compressed data DVD-DATA2.

I

Asserted HIGH indicates a corrupted byte.Decoder keeps the previous valid picture

on-screen unit the next valid picture is decoded. This pin is shares with DVD

compressed data DVD-DATA3.

Function

1-37

Page 38

XV-521BK/523GD/525BK/421BK

Pin No.

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

Symbol

DVD-DATA7

/CDG-SCLK

DVD-DATA6

/CDG-SOS1

DVD-DATA5

/CDG-VFSY

DVD-DATA4

/CDG-SDATA

PIO10

VREQUEST

VSTROBE

VDD-3.3

NC

VSS

V-DACK

VDD-2.5

RESERVED

VSS

ERROR

HOST8SEL

HADDR0

HADDR1

HADDR2

DTACKSEL

CS

R/W

RD

I/O

DVD parallel compressed data from DVD DSP. When DVD DSP sends 32-bit words, it must write

I

the MSB first.

CDG-SDATA:CD+G (Subcode) Data.Indicates serial subcode data input.

CDG-VSFY:CD+G (Subcode)Frame Sync. Indicates frame-start or composite synchronization input.

CDG-SOS1:CD+G (Subcode) Block Sync.Indicates block-start synchronization input.

CDG-SCLK: CD+G(Subcode)Clock. Indicates subcode data clock input or output.

Programmable I/O pins. Input mode after reset.

I/O

Video request. Decoder asserts VREQUEST to indicate that the video input buffer has available

O

space.Polarity is programmable.

Video strobe. Programmable dual mode pulse. Asynchronous and synchronous. In Asynchronous

I

mode, an external source pulses VSTROBE to indicate data is ready for transfer. In synchronous

mode VSTROBE clock data.

3.3-V supply voltage for I/O signals.

-

No Connection

O

Ground for core logic and I/O signals.

-

In synchronous mode, Video data acknowledge. Asserted when DVD data is valid.Polarity is

I

programmable.

2.5-V supply voltage for core logic.

-

Tie to VSS or VDD-3.3

I

Ground for core logic and I/O signals.

-

Error in input data. If ERROR signal is not available from the DSP it must be grounded.

I

Always Ttie to VDD-3.3

I

Host address bus. 3-bit address bus selects one of eight host interface registers.

I

Tie HIGH to select WAIT signal, LOW to select DTACK signal (Motorola 68K mode).

I

Host chip select.Host asserts CS to select the decoder for a read or write operation.The falling

I

edge of this signal triggers the read or write operation.

Read/write strobe in M mode. write strobe in l mode.Host asserts R/W LOW to select write and

I

LOW to select read.

Read strobe in I mode. Must be held HIGH in M Mode

I

ZIVA3-PEO (5/5)

Function

1-38

Page 39

XV-521BK/523GD

XV-525BK/421BK

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINSS DIVISION

PERSONAL & MOBILE NETWORK B.U. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

No.20836

Printed in Japan

2000 06 (S)

Loading...

Loading...