Page 1

XL-R2010BK

SERVICE MANUAL

CD/CDR MULTIPLE COMPACT DISC RECORDER

XL-R2010BK

Area Suffix

J ------------- U.S.A.

C ---------- Canada

Contents

STANDBY/ON

CD EDIT FINALIZE DISPLA

CD REC

REC MUTING

R

S

PITCH

1 2

4 5

7 8

10

PLAY

MODE

REPEAT CD

REC

E

EC

OURC

0

RM-SXLR2010A

+

PITCH

SET

PITCH-

10

FADE SYNCHRO

+

REMOTE CONTROL

Y

3

6

9

CONTROL

CDR

REC MUTING

MULTI JOG/REC LEVEL

OPEN/CLOSEOPEN/CLOSE

+

-

CD

LINE

MIX BLANCE

MIC

REC/

LINE

MIC

MEN

U

STANDBY

STANDBY/ON

PLAY MODE CD EDIT

LEVEL

PHONES

L

E

NC

A

H

C

MAXMIN

STOP PLAY

CD REC

REC SOURCE

PAUSE

SELECTOR

REC SOURCE

DIGITAL CD LINE MIC

SYNCHRO

FINALIZE

CANCELSETMENU

PAUSE

PLAYSTOP

<ATTENTION of CD-R/RW mechanism unit>

Because the CD-R/RW mechanism unit is a unit exchange,

Moreover, the [Disassembly method],[Adjustment method],[Description of major ICs],

[Standard schematic diagram],[Printed circuit board],[Block diagram] of the CD-R/RW

mechanism unit is not described.

Safety precautions ------------------------ 1-2

Preventing static electricity ------------- 1-3

Importance admistering point

on the safety ------ 1-4

This service manual is printed on 100% recycled paper.

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

Precautions for service ------------------ 1-5

Disassembly method -------------------- 1-6

Confirm method of operation ----------- 1-17

Description of major ICs ---------------- 1-20

No.A0013

Oct. 2001

Page 2

XL-R2010BK

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

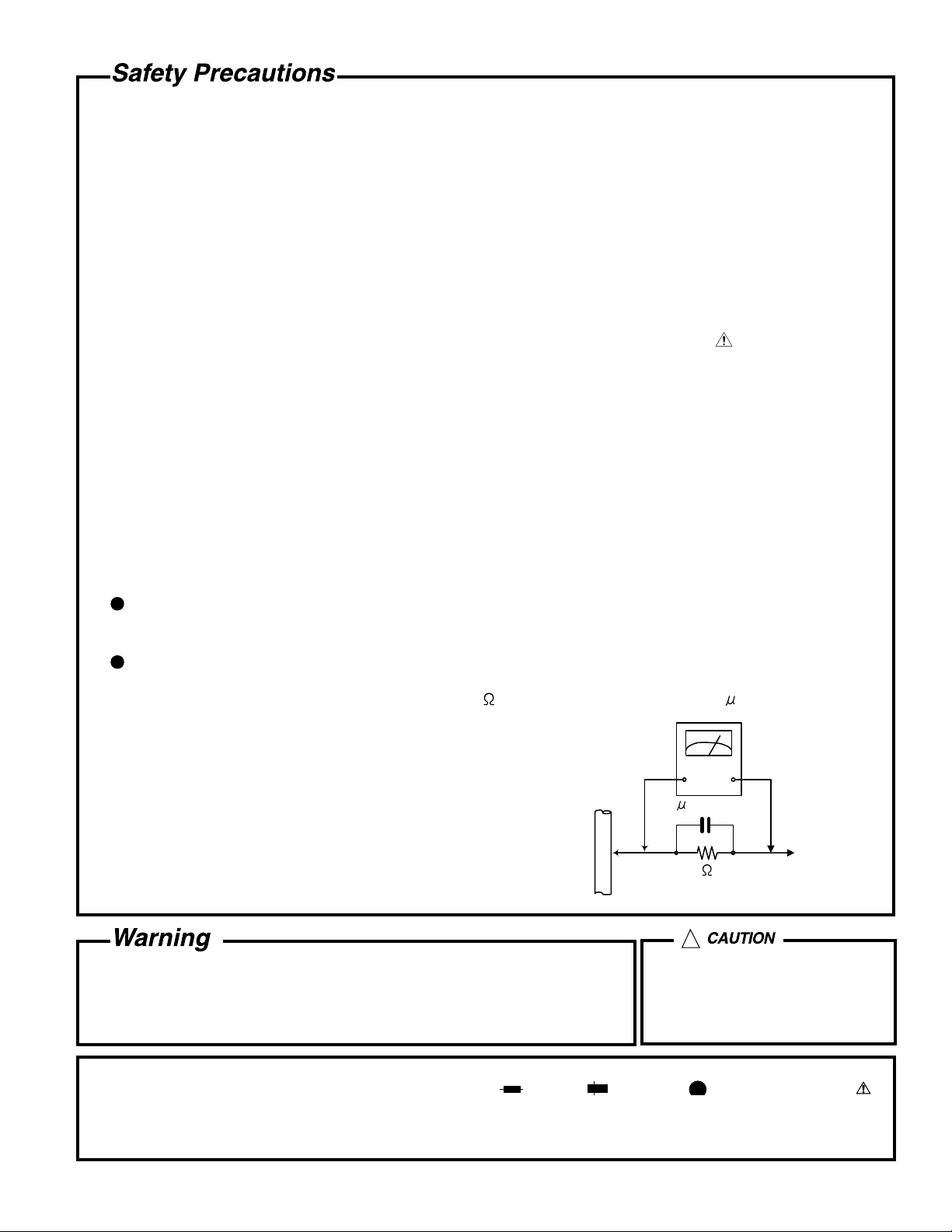

5. Leakage current check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

1-2

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the J and C version)

Page 3

XL-R2010BK

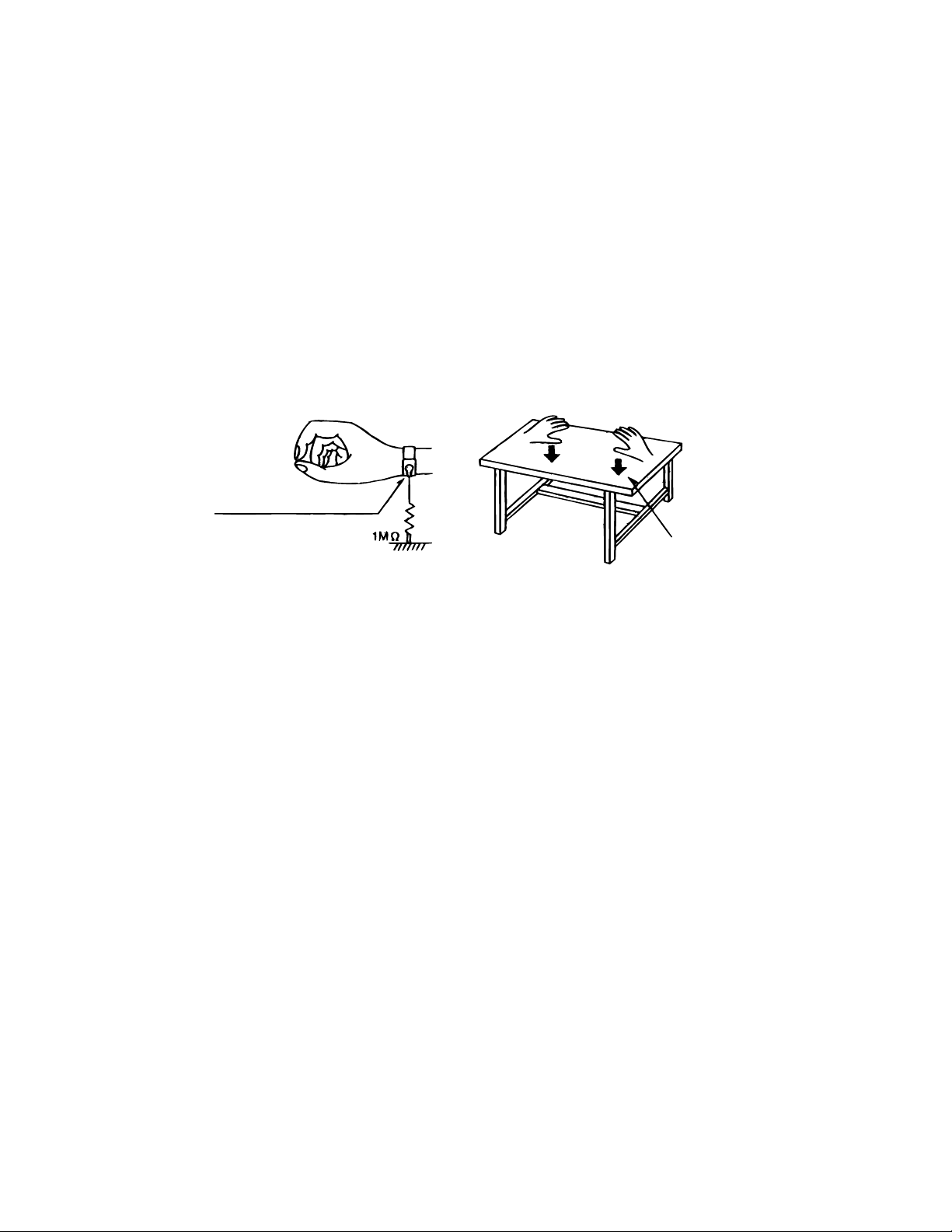

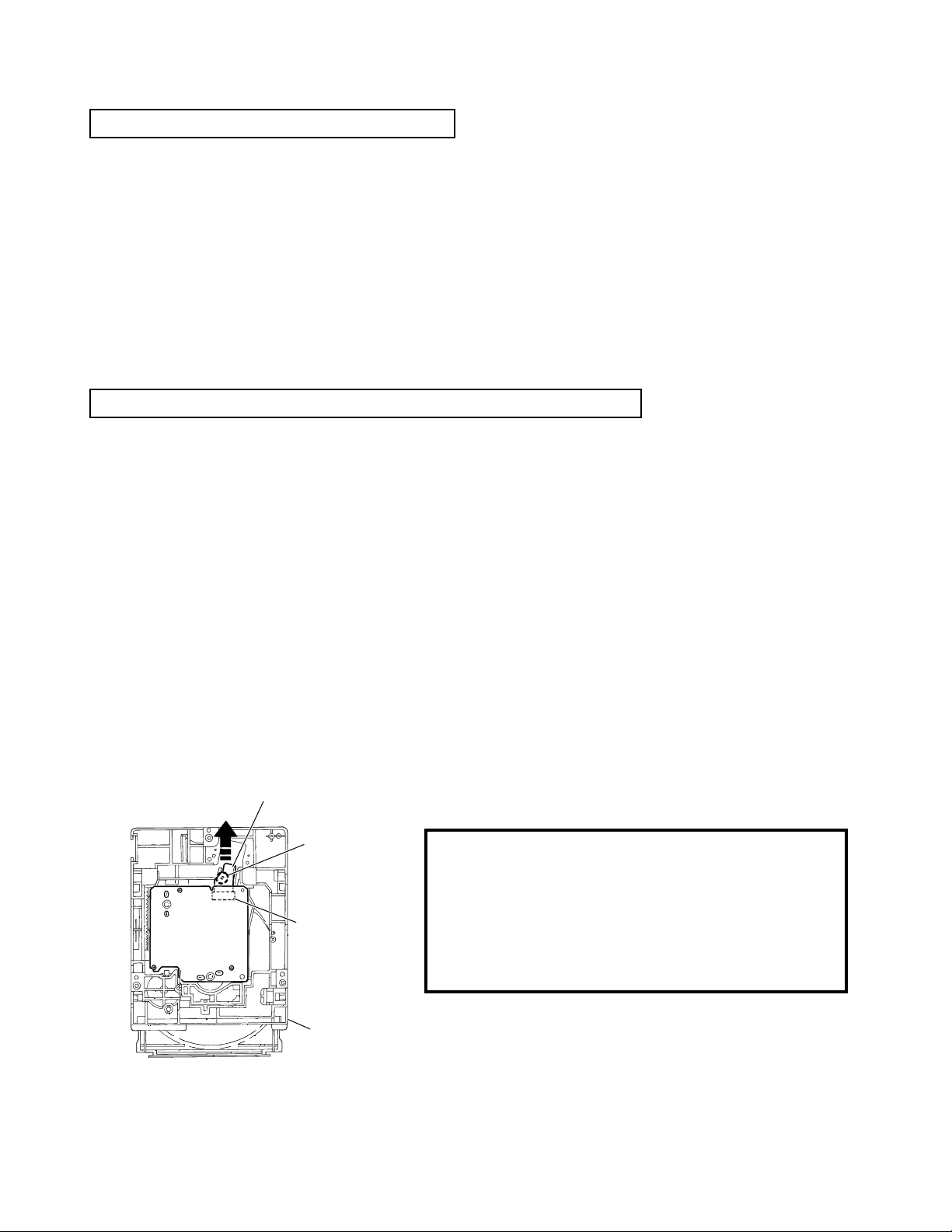

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-3

Page 4

XL-R2010BK

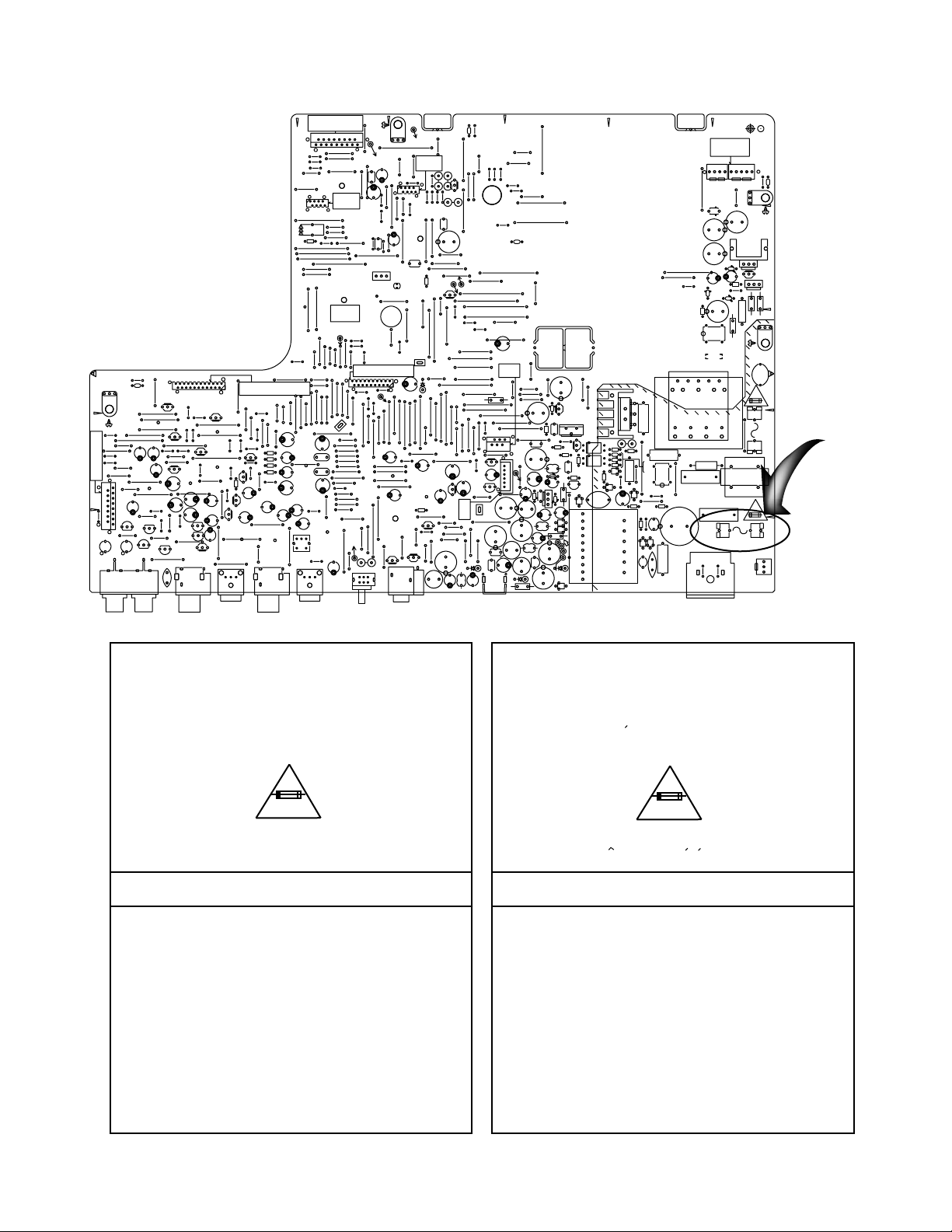

Importance Admistering point on the Safety

W913

B58

W903

CN501

B61

B43

B305

B42

B529

B309

B142

B235

CN723

B912

B914

B137

B233

R501

C501

B39

B310

B752

B758

B757

B756

B330

B329

B619

B618

W900

B27

B141

B131

B326

B327

B229

B230

B997

EP997

C917

B505

B504

B503

B502

B1

B707

B164

B302

B2

B3

C272

B162

B201

B401

B163

B501

CN841

C872

B102

B44

Q183

Q283

B101

C271

C171

Q181

J871

CN722

B303

Q841

B106

B6

Q842

B62

B5

B105

B202

C172

Q191

C874

C182

C282

B10

B12

B139

B11

Q182

Q282

B103

Q281

B304

B402

J354 J541

C543

B407

Q831

B8

B603

B602

B7

B601

Q832

B152

B9

B203

C1303

B405

C183

C283

C2303

C881

Q881

B24

B204

B161

B36

B306

B236

B17

B16

B107

Q821

R803

R802

B933

R801

Q822

B18

B15

B146

R821

B25

C1312

B63

C1301

Q1301

Q2301

B406

C2301

B506

B404

B113

B403

J353

J352

B130

B129

B408

B128

B412

B413

B111

B112

B110

R804

B20

C2302

B510

B411

B205

B323

B322

B206

B509

B410

B409

WC100

B945

C114

C804

C802

C214

C1302

T301

B507

B127

B207

C111

B208

C115

B209

B210

B307

B211

C215

B308

B417

B212

B913

C211

B116

B213

B214

B115

B21

B215

B158

C356

B22

B604

J351

C352

S531

EP998

B751

C381

B104

B234

C380

B48

B434

B331

CN616

B52

B40

C394

B41

B143

B156

B3612

B918

B138

C362

C361

B3603

B3604

B136

B620

X501

C367

X502

B328

B28

B29

B132

B31

B324

B325

W900

B114

B134

B133

B34

B30

CN615

W904

B33

B946

B612

B312

B216

K801

WC101

B32

C812

B528

B512

B416

B527

B607

B702

B608

B754

B610

B609

C840

B943

B511

B23

B3605

B3606

B418

B419

C830

R861

Q862

B701

B117

B753

Q541

B217

Q542

B159

C998

B998

B166

B135

K3601

K3600

B916

Q361

B915

B332

K3602

B38

B917

B3613

B3611

B126

C365

C366

B524

B37

B605

B55

B118

B301

R390

W902

W913

Q369

B169

B931

B926

B923

B508

B929

B928

B432

B615

B525

D812

B109

B526

B755

B932

B705

B613

B513

B108

B514

B919

B703

B920

B944

B934

B935

B936

B937

B611

C151

C1505

C251

Q861

B313

B939

B940

B941

B51

B942

B530

B150

B54

B160

C983

D956

C982

L957L958

C984

B144

B436

B35

B145

B49

B45

B46

B59

B47

B930

B435

B167

B14

C994

B153

B433

B155

B125

B157

B168

B925

B517

B50

CN505

B938

Q501

B56

C502

IC502

C2505

B57

WC102

B123

C975

C967

B119

C981

B905

B924

B521

C990

B909

B124

B147

B122

B320

R956

B224

C960

B422

B614

B121

C961

B222

C963

B120

CN721

C964

W901

C977

B53

L960

C985

C966

C987

L955

L953

C997

D971

EP951

C973

B140

B60

D970

Q965

C970

IC951

R972

B226

PC902

R975

Q967

R969

L951

R913

C919

PC901

R917

D960

C962

CP951

D972

C916

D973

R954

C980

B154

R952

C989

L959

L952

CP952

R973

D951

Q966

D952

D957

R974

D953

C965

W901

W902

W903

W904

D954

C979

HS901

IC901

R907

K901

R912

R906

C918

D907

R908

R918

D910

B906

R904

B947

D901

B907

D904

D905

B910

B948

C914

R910

R911

B911

R903

C913

D902

D903

C909

C908

T901

CN712 CN711

B999

C999

B165

EP999

B904

D913

C921

C922

B706

B64

B13

R914

T902

R905

R909

C903

B901

C907

R901

B148

C974

HS922

D974

Q922

C924

Q921

C923

D912

C920

D921

L901

C902

P901

Q980

R919

D980

B26

R980

R981

R982

R915

EP801

C906

FC904

B151

FC903

FC901FC902

F901

CN900

B149

Full Fuse Replacement Marking

Marquage Pour Le Remplacement

Complet De Fusible

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

F901 : 1.6 A / 125 V F901 : 1.6 A / 125 V

1-4

Page 5

Precautions for Service

Handling of Traverse Unit and Laser Pickup

1. Do not touch any peripheral element of the pickup or the actuator.

2. The traverse unit and the pickup are precision devices and therefore must not be subjected to

strong shock.

3. Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the

internal power supply of the tester.)

4. To replace the traverse unit, pull out the metal short pin for protection from charging.

5. When replacing the pickup, after mounting a new pickup, remove the solder on the short land

which is provided at the center of the flexible wire to open the circuit.

6. Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the

characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body. Before repairing peripheral elements of the traverse

unit or pickup, be sure to take the following electrostatic protection:

XL-R2010BK

1. Wear an antistatic wrist wrap.

2. With a conductive sheet or a steel plate on the workbench on which

the traverse unit or the pick up is to be repaired, ground the sheet

or the plate.

3. After removing the flexible wire from the connector (CN601),

short-circuit the flexible wire by the metal clip.

4. Short-circuit the laser diode by soldering the land which is provided

at the center of the flexible wire for the pickup. After completing the repair, remove the solder

to open the circuit.

Please refer to [ Removing the mechanism board ] and [ Removing the pickup ] of the

Disassembly method < CD Mechanism assembly >.

Flexible wire

Shorting round

CN601 on

mechanism

board

<ATTENTION of CD-R/RW mechanism unit>

Because the CD-R/RW mechanism unit is a unit exchange,

the pick-up need not be detached alone.

Moreover, the [Disassembly method],[Adjustment method],

[Description of major ICs],[Standard schematic diagram],

[Printed circuit board],[Block diagram] of the CD-R/RW

mechanism unit is not described.

CD Mechanism assembly

1-5

Page 6

XL-R2010BK

Disassembly method

<Main body>

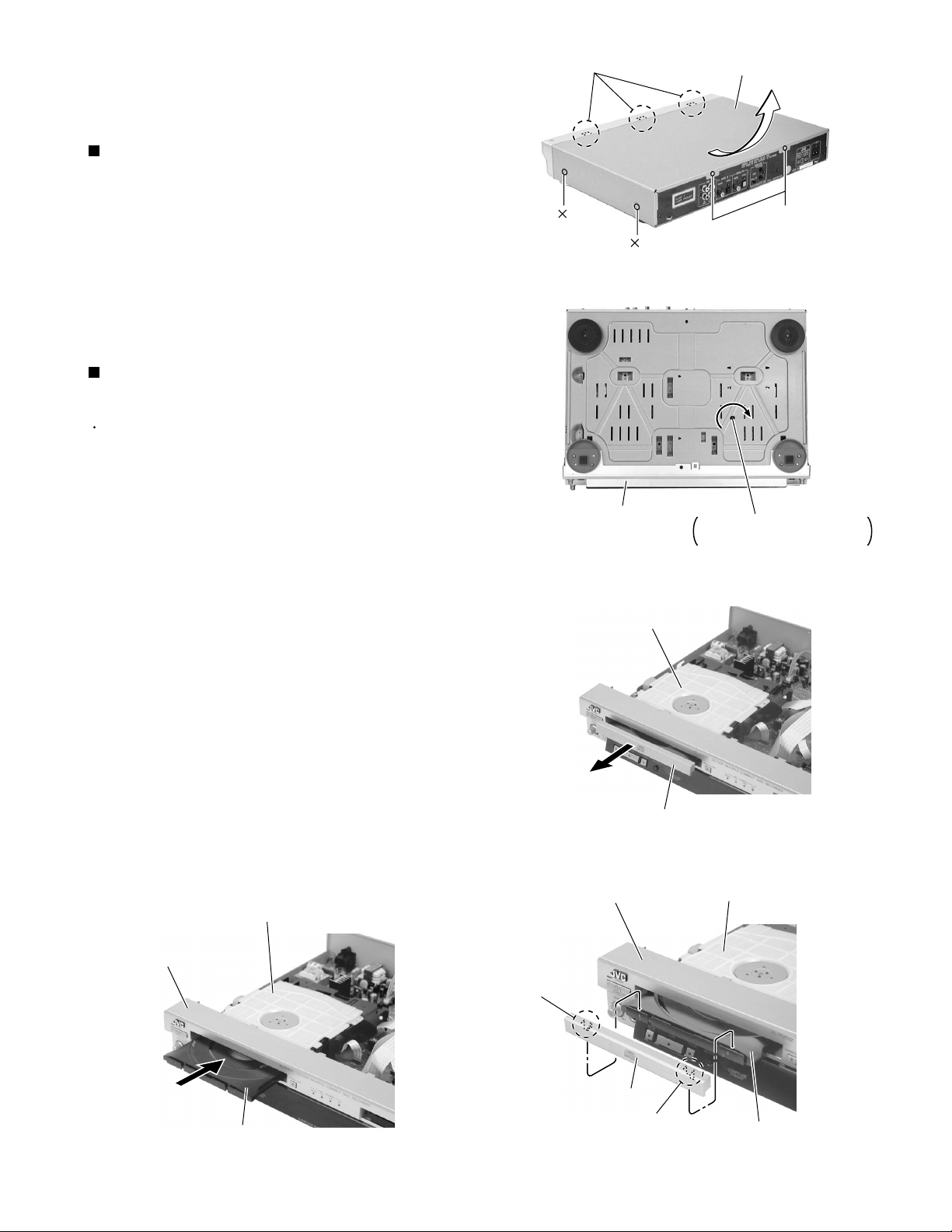

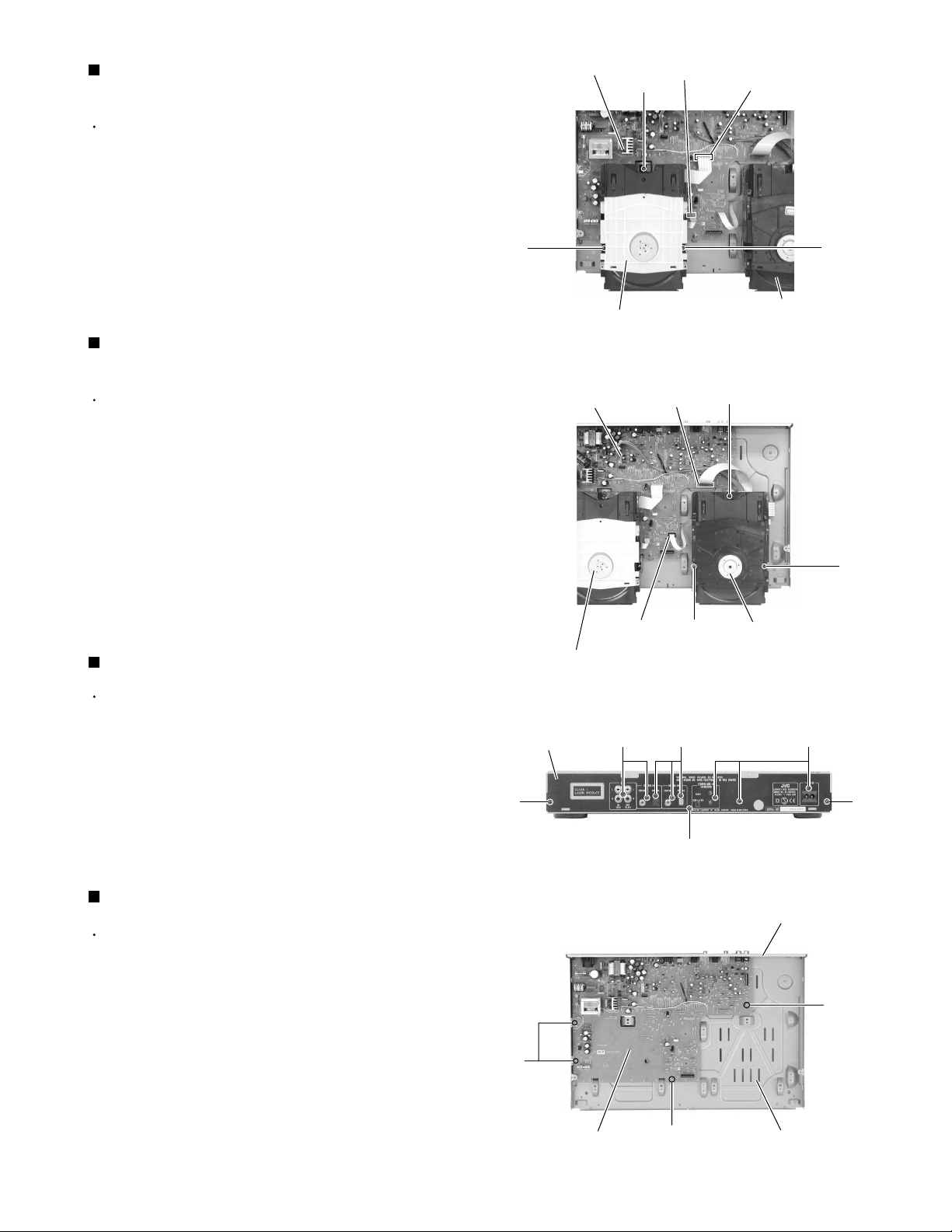

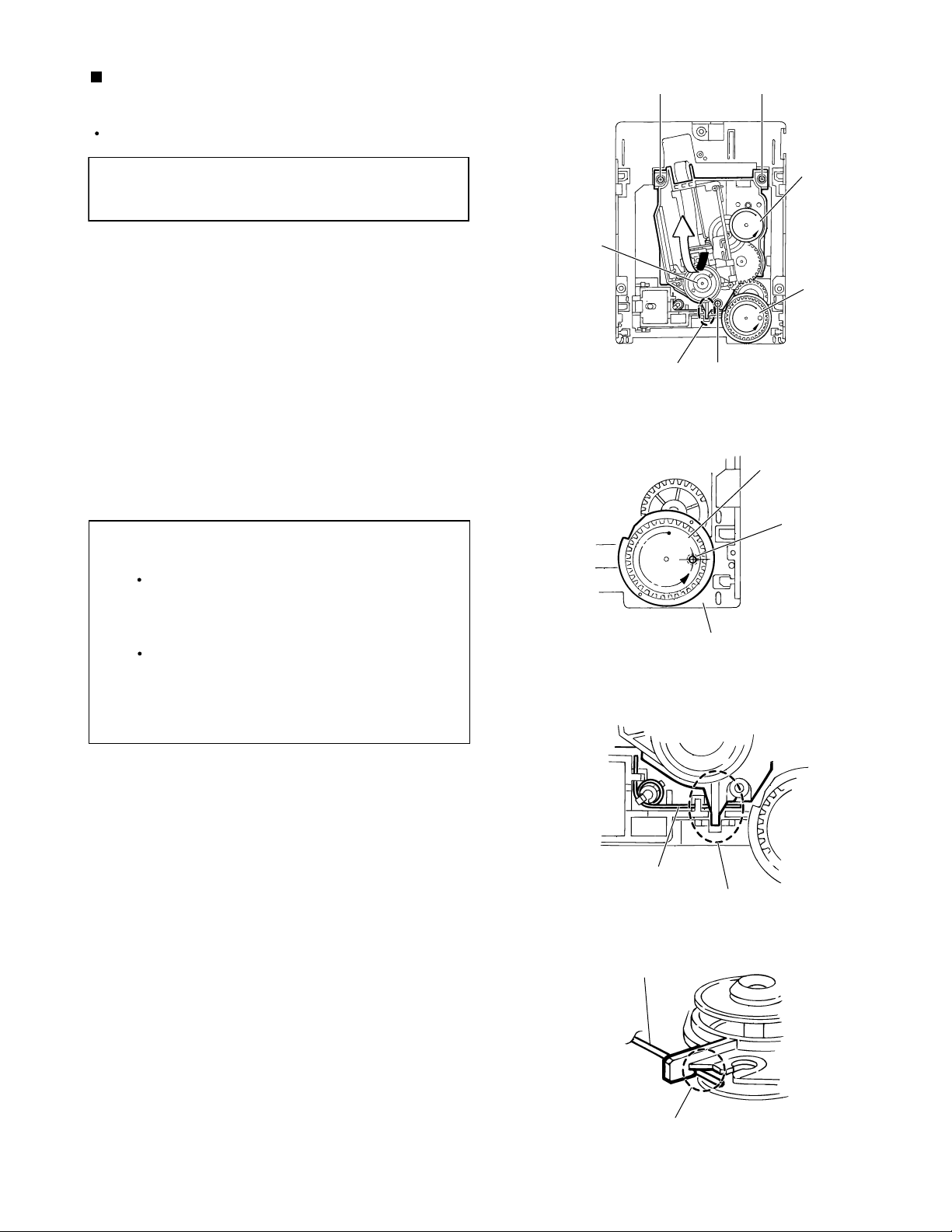

Removing the top cover (See Fig.1)

Remove the four screws A on both sides of the body.

1.

Remove the two screws B on the back of the body.

2.

Remove the top cover from behind in the direction of

3.

the arrow while pulling its sides outwards. Disengage

the three joints a with the front panel section.

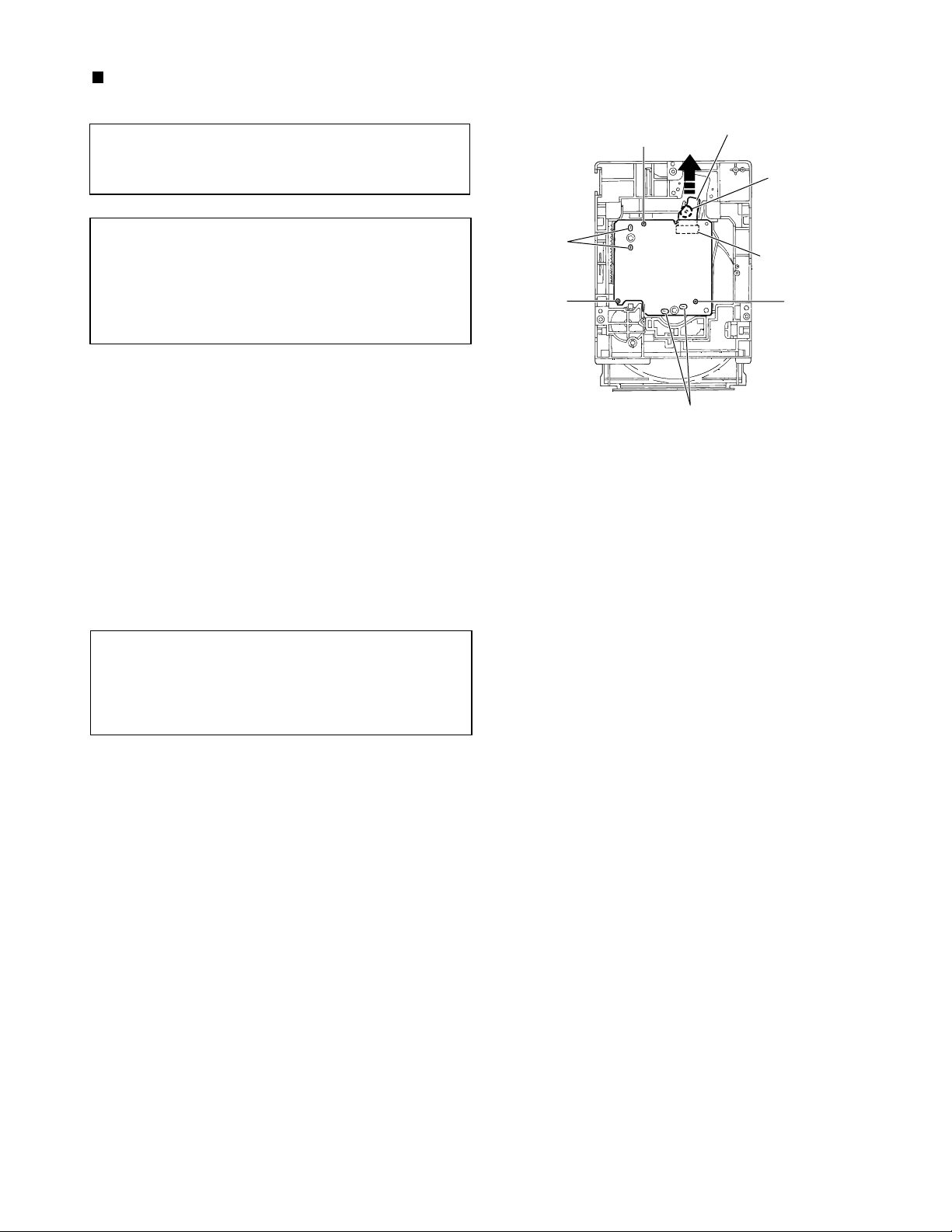

Removing the fitting of the CD

mechanism section (See Fig.2 to 5)

Prior to performing the following procedure, remove

the top cover.

Insert a Philips screwdriver into the hole of the

1.

chassis base on the bottom and turn it as shown in

the figure. The tray will move forward.

Pull out the tray manually.

2.

Joints a

A

2

A

2

Fig.1

Front panel assembly

Fig.2

Top cover

B

(Bottom)

Hole of the CD mechanism

section to pull out the tray

Release the joint b on each side of the fitting

3.

upward, then remove the fitting from the tray.

Push and return the tray.

4.

CD mechanism assembly

Front panel assembly

CD mechanism assembly

Front panel assembly

Joint b

Fitting

Fig.3

CD mechanism assembly

1-6

Tray

Fitting

Joint b

Tray

Fig.4Fig.5

Page 7

XL-R2010BK

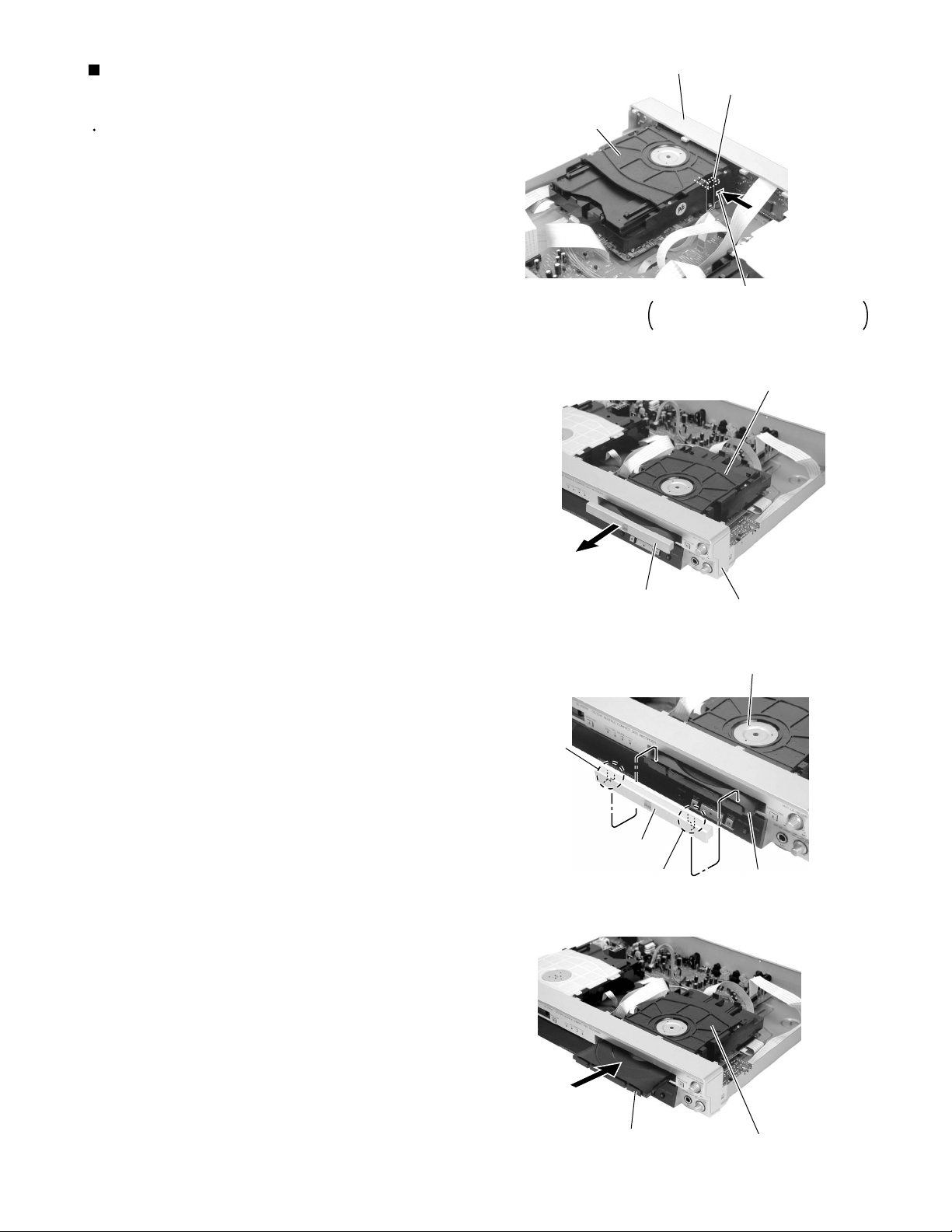

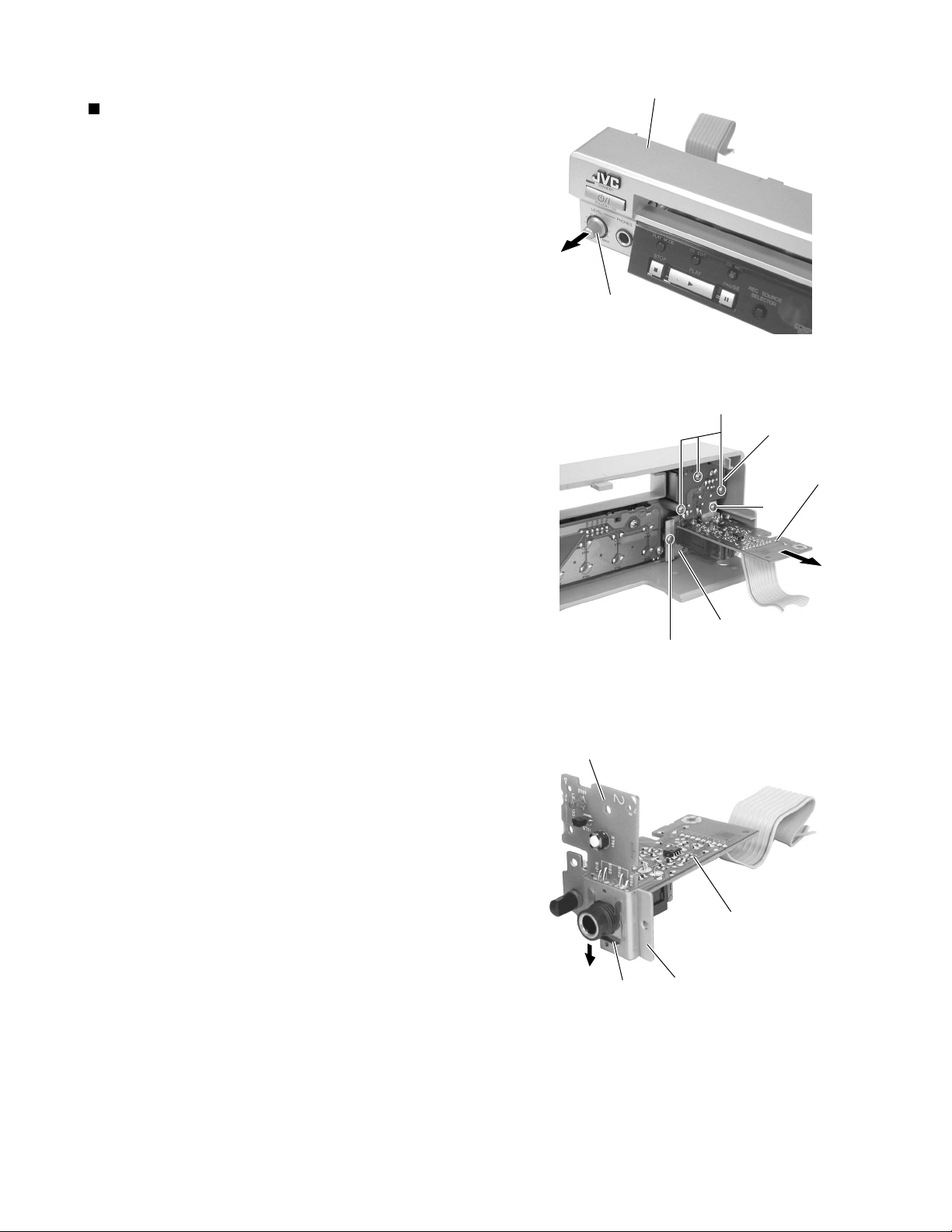

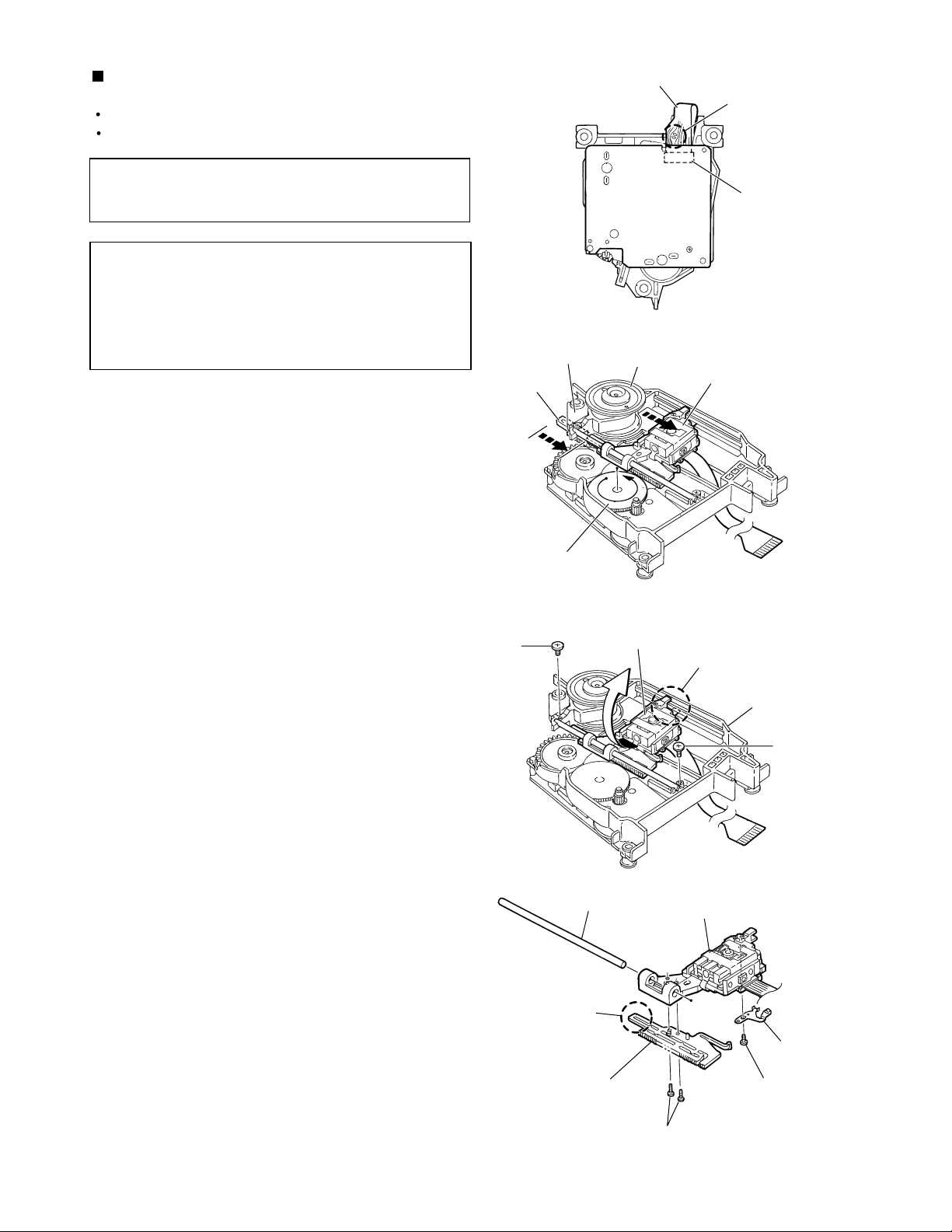

Removing the fitting of the CD-R/RW

mechanism section (See Fig.6 to 9)

Prior to performing the following procedure, remove

the top cover.

Push the slide cam c until it stops through the slot on

1.

the left side of the CD-R/RW mechanism assembly.

Pull out the tray manually.

2.

Release the joint d on each side of the fitting

3.

upward, then remove the fitting from the tray.

Push and return the tray.

4.

Front panel assembly

Slide cam c

CD-R/RW mechanism

assembly

Slot

Slot of the CD-R/RW mechanism

section to pull out the tray

Fig.6

CD-R/RW mechanism assembly

Joint d

Fitting

Fitting

Joint d

Front panel assembly

Fig.7

CD-R/RW mechanism assembly

Tray

Fig.8

Tray

CD-R/RW mechanism assembly

Fig.9

1-7

Page 8

XL-R2010BK

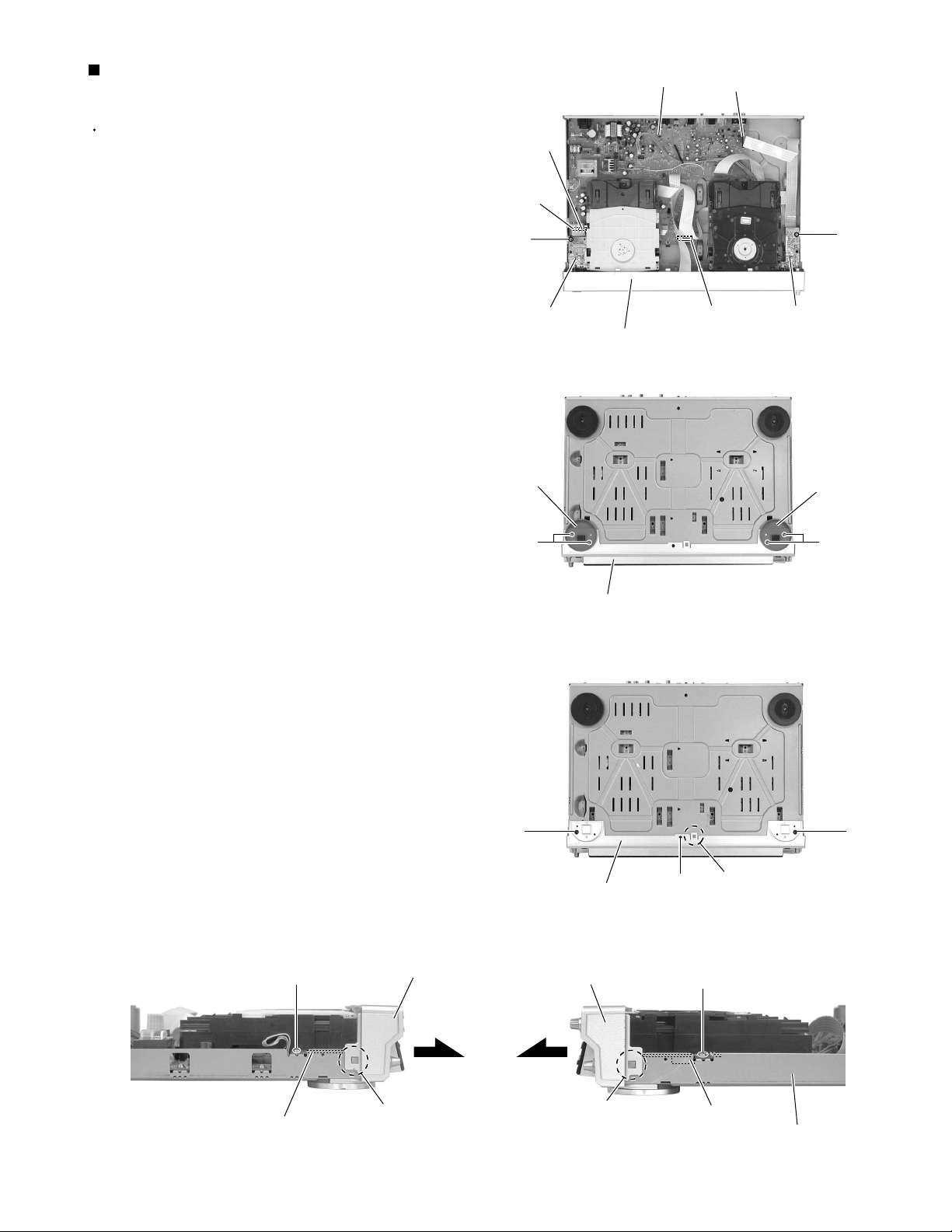

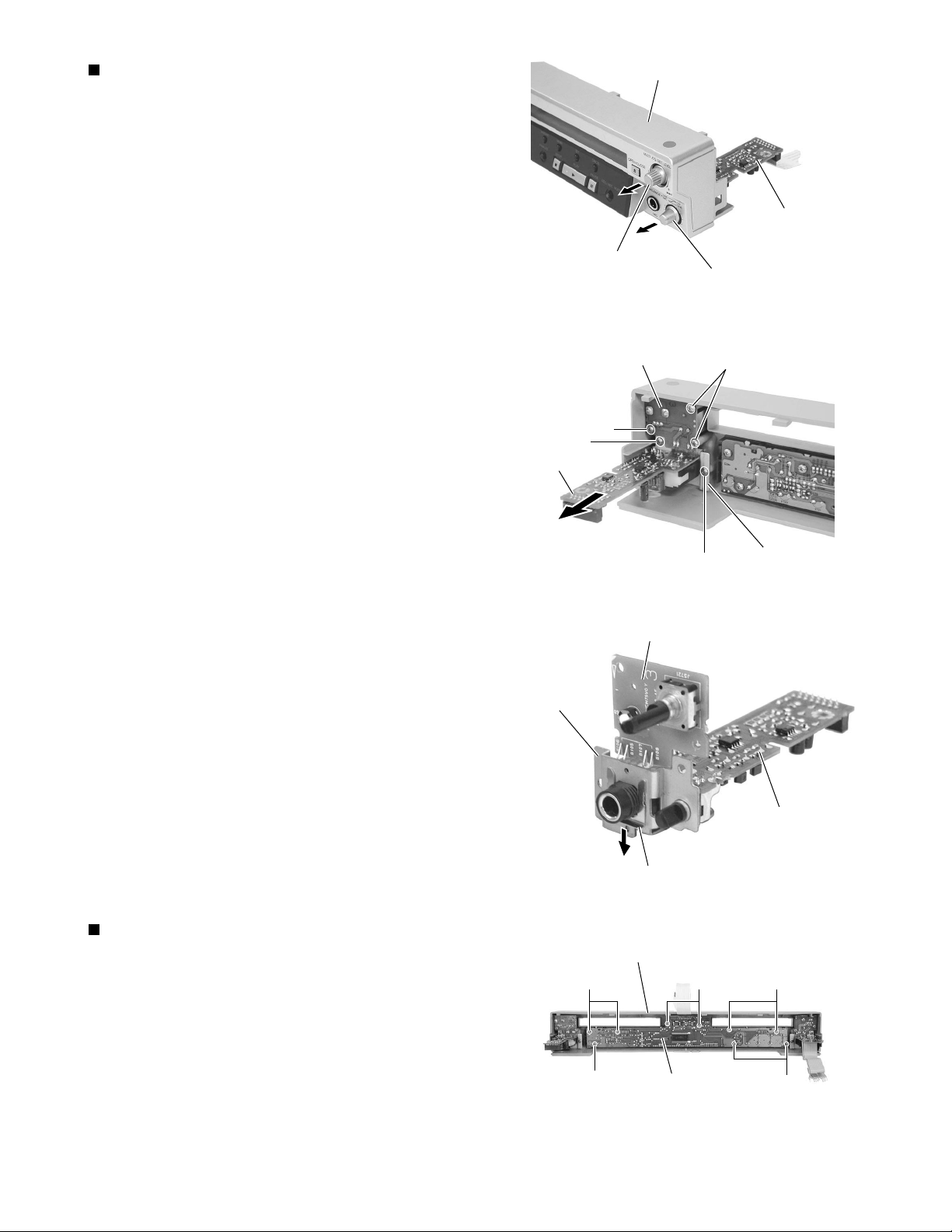

Removing the front panel assembly

(See Fig.10 to 14)

Prior to performing the following procedure, remove

the top cover and both fittings of the CD mechanism

section and the CD-R/RW mechanism section.

Disconnect the card wires from connector CN501,

1.

CN841 and the wires from CN711 and CN712 on the

main board from above.

Remove the screw C and the screw D attaching the

2.

headphone board and the mic board on the top of

the body.

Remove the four screws E attaching the right and

3.

left foot at the bottom.

Remove the two screws F and the screw G

4.

attaching the front panel assembly at the bottom.

Disengage the joint e on the bottom and the joints f

5.

on each side of the body to release the front panel

assembly from the chassis base using a slotted

screwdriver. Then remove the front panel assembly

toward the front.

CN712

CN711

C

Headphone board

Front panel assembly

Foot

E

Main board

Fig.10

(Bottom)

CN841

CN501

D

Mic board

Foot

E

C

Front panel assembly

Front panel assembly

F

Front panel assembly

Front panel assembly

Fig.11

(Bottom)

G

Fig.12

D

F

Joint e

1-8

Headphone board

Joint f

Joint f

Mic board

Fig.13Fig.14

CN801

Chassis base

Page 9

XL-R2010BK

Removing the CD mechanism assembly

(See Fig.15)

Prior to performing the following procedure, remove

the top cover and the fitting.

(Remove the front panel assembly is easy to work.)

Disconnect the card wire from connector CN615 and

1.

CN616 on the main board from above.

Remove the three screws H attaching the CD

2.

mechanism assembly.

Removing the CD-R/RW mechanism

assembly (See Fig.16)

Prior to performing the following procedure, remove

the top cover and the fitting.

(Remove the front panel assembly is easy to work)

Disconnect the wire from connector CN721 and the

1.

card wires from CN722 and CN723 on the main

board from above.

Main board

H

H

CD mechanism assembly

CN721

Main board

CN722

CN616

Fig.15

CN615

H

CD-R/RW mechanism

assembly

I

Remove the three screws I attaching the CD-R/RW

2.

mechanism assembly.

Removing the rear panel (See Fig.17)

Prior to performing the following procedure, remove

the top cover.

Remove the three screws J and the eight screws K

1.

on the back of the body.

Removing the main board (See Fig.18)

Prior to performing the following procedure, remove

the top cover, the front panel assembly, the CD

mechanism assembly, the CD-R/RW mechanism

assembly and the rear panel.

Remove the four screws L attaching the main board.1.

CN723

CD mechanism assembly

Rear panel

K

J

I

Fig.16

K

J

Fig.17

I

CD-R/RW mechanism

assembly

K

J

Rear panel

L

L

Main board

L

Fig.18

Chassis base

1-9

Page 10

XL-R2010BK

<Front panel assembly>

Removing the headphone board / power

switch board (See Fig.19 to 21)

Pull out the volume knob on the front panel

1.

assembly.

Remove the two screws M attaching the headphone

2.

board bracket and the three screws N attaching the

power switch board. Remove the headphone board

and the power switch board at the same time.

Pull out the stopper attaching the headphone board

3.

bracket in the direction of the arrow.

Front panel assembly

Volume knob

Fig.19

N

Power switch board

Headphone board

Power switch board

M

Headphone board bracket

M

Fig.20

Headphone board

1-10

Stopper

Headphone board bracket

Fig.21

Page 11

XL-R2010BK

Removing the mic board / jog dial board

(See Fig.22 to 24)

Pull out the jog dial knob and the mix balance knob

1.

on the front panel assembly.

Remove the two screws O attaching the mic board

2.

bracket and the three screws P attaching the jog dial

board. Remove the mic board and the jog dial board

at the same time.

Pull out the stopper attaching the mic board bracket

3.

in the direction of the arrow.

Jog dial knob

Mic board

Front panel assembly

Jog dial board

P

O

Mic board

Mix balance knob

Fig.22

P

Removing the front board (See Fig.25)

Remove the nine screws Q on the back of the front

1.

panel assembly.

Mic board bracket

Front panel assembly

Q

Fig.23

Jog dial board

Stopper

Fig.24

Q

O

Mic board bracket

Mic board

Q

Q

Front board

Fig.25

Q

1-11

Page 12

XL-R2010BK

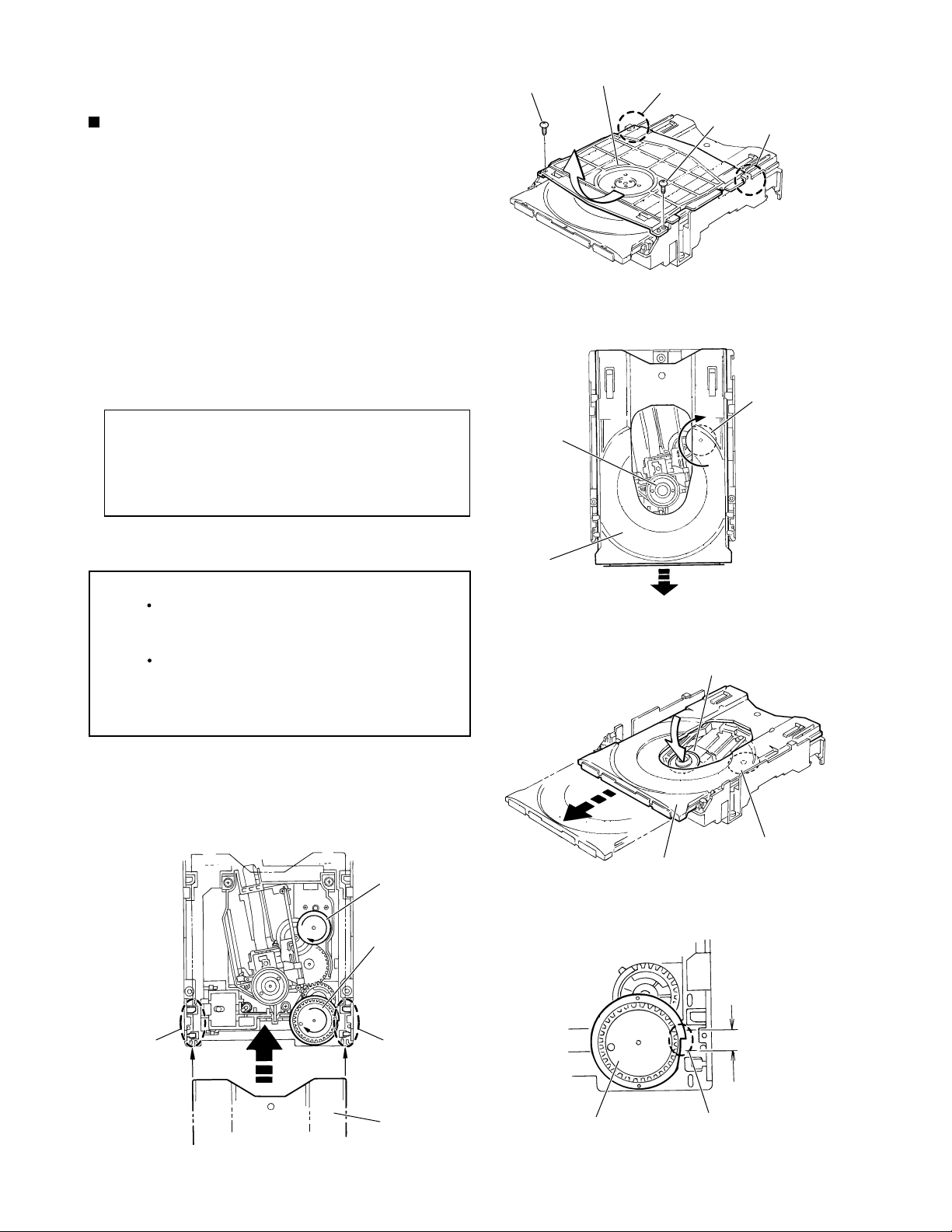

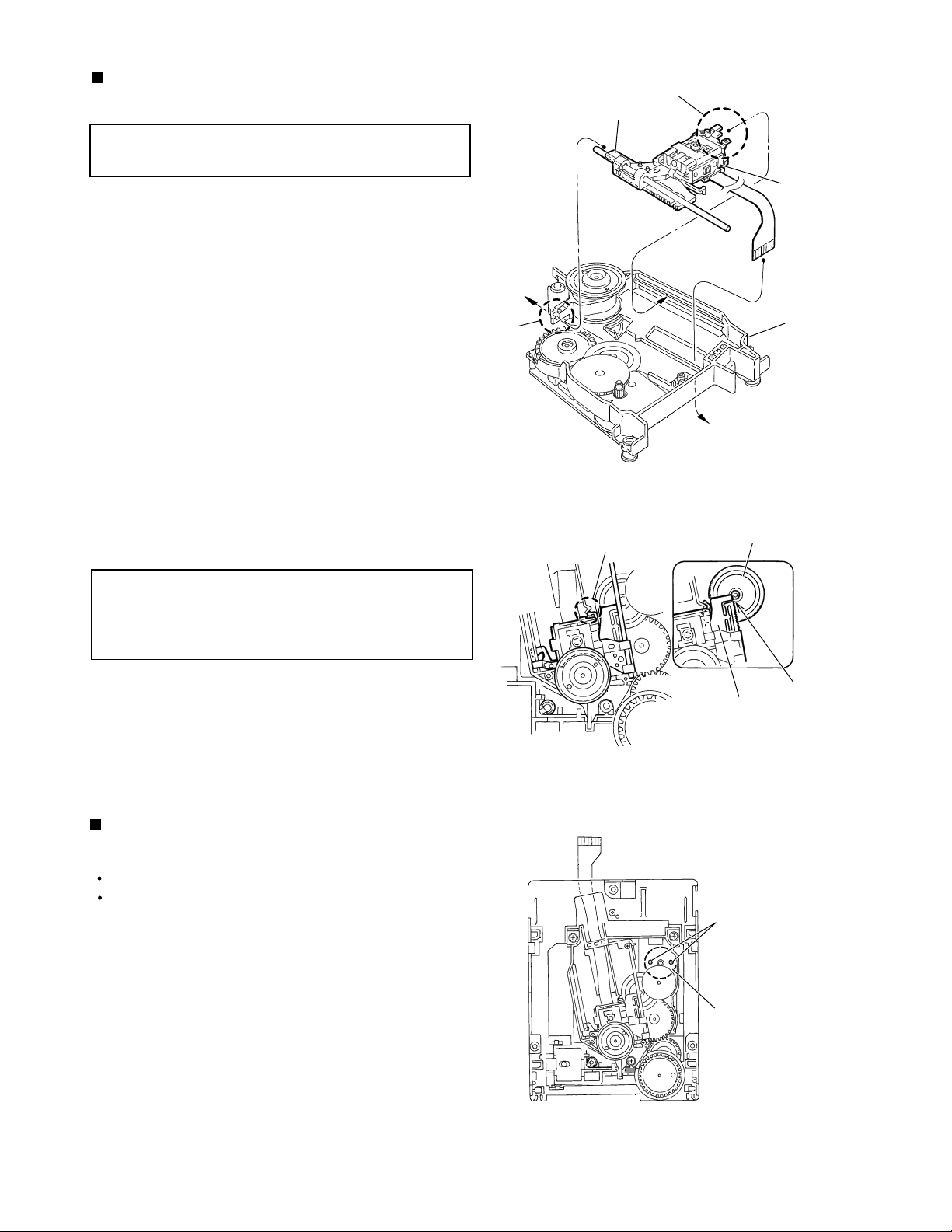

<CD Mechanism assembly>

Clamper base assembly

A

Hook a

Removing the clamper base assembly and

tray (See Figs. 1 to 5)

1. Remove the two screws A attaching the clamper

base assembly from the top of the CD mechanism

assembly.

2. Move the clamper base assembly diagonally

upwards as indicated by the arrow to release it from

the two hooks a.

3. Turn the idle gear in the arrow-marked direction

from the upper side of the CD mechanism

assembly. Accordingly, the traverse mechanism

assembly moves downwards.

Note: When drawing out the tray, shift down the

traverse mechanism assembly to the

position where the tray does not contact the

turn table assembly of the traverse

mechanism assembly.

4. Draw out the tray frontwards for removing it.

Traverse

mechanism

assembly

Tray

Fig. 1

A

Hook a

Idle gear

Note: When reinstalling the tray:

Turn the idle gear so that the part b of the

tray gear is positioned in the part c shown in

Fig. 4. (Eject position)

Engage the right and left hooks d and e of

the tray with the right and left grooves of the

loading mechanism assembly respectively

for retaining the tray.

Idle gear

Tray gear

Hook d

Hook e

Fig. 2

Traverse mechanism assembly

Idle gear

Tray

Fig. 3

Part c

1-12

Tray

Tray gear

Part b

Fig. 4Fig. 5

Page 13

XL-R2010BK

Removing the traverse mechanism assembly

(See Figs. 6 to 9)

Remove the clamper base assembly and tray.

Reference: The traverse mechanism assembly can

be removed without removal of the

mechanism board.

1. If the traverse mechanism assembly is lowered and it is

located out of the PLAY position, turn the idle gear in the

arrow-marked direction so that the hole in the part f of the

tray gear meets the hole on the loading base assembly.

(Set the traverse mechanism assembly at the PLAY

position.)

2. Remove the three screws B attaching the traverse

mechanism assembly and then remove the traverse

mechanism assembly upwards from the front side.

3. At the same time, remove the spring from the groove of the

CH. base assembly in the part g of the traverse

mechanism assembly.

Note: When reinstalling the traverse mechanism

assembly:

Check to see if the spring is properly

engaged with groove of the CH. base

assembly in the part g of the traverse

mechanism assembly.

After making sure that the three insulators of

the traverse mechanism assembly are

properly set on the bosses of the loading

base assembly's guide, fasten them with the

screws.

Traverse

mechanism

assembly

B

Part g

Fig. 6

Loading base assembly

Fig. 7

B

B

Tray gear

Idle gear

Tray gear

Part f

Spring

Part g

Fig. 8

Spring

Groove of CH. base assembly

Fig. 9

1-13

Page 14

XL-R2010BK

Removing the mechanism board

Reference:The mechanism board can be removed

(See Fig 10)

without removal of the traverse

mechanism assembly.

C

Flexible wire

Shorting round

Note: Before disconnecting the flexible wire coming

from the pickup from the connector, be sure to

solder its shorting round.

If the flexible wire is connected without

soldering, it may cause breakdown of the

pickup.

1. Solder the shorting round of the flexible wire

connected with the mechanism board from the back

of the mechanism assembly.

2. Disconnect the flexible wire from the connector

CN601 on the mechanism board.

3. Remove the three screws C attaching the

mechanism board.

4. Unsolder the two points of the part h and two point

of the part i of the mechanism board. Then, remove

the mechanism board upwards.

Note: When reinstalling the mechanism board,

connect the flexible wire coming from the

pickup to the connector first and then remove

the solder from the shorting round of the

flexible wire.

Soldered

part h

C

CN601 on

mechanism

board

C

Soldered part i

Fig. 10

1-14

Page 15

XL-R2010BK

Removing the pickup (See Figs. 11 to 14)

Remove the clamper base assembly and tray.

Remove the traverse mechanism assembly.

Reference: The pickup can be removed without

removal of the mechanism board.

Note: Before disconnecting the flexible wire coming

from the pickup from the connector, be sure to

solder its shorting round.

If the flexible wire is connected without

soldering, it may cause breakdown of the

pickup.

1. Solder the shorting round of the flexible wire

connected with the mechanism board from the back

of the traverse mechanism assembly.

2. Disconnect the flexible wire from the connector

CN601 on the mechanism board.

3. Turn the idle gear in the arrow-marked direction from

the top of the traverse mechanism assembly so that

the pickup assembly is shifted to the reverse side of

the turn table assembly.

Move the pickup assembly until the part j of the rack

plate in the lower part of the pickup assembly comes

out of the CH. base assembly.

4. Remove the two screws D attaching the shaft of the

pickup assembly. Next, disengage the part k from

the CH. base assembly and then remove the pickup

assembly together with the shaft.

5. Pull the shaft out of the pickup.

Part j of

rack plate

Idle gear

D

CH. base

assembly

Pickup assembly

Flexible wire

Shorting round

CN601 on

mechanism

board

Fig. 11

Turn table assembly

Pickup assembly

Fig. 12

Par t k

CH. base

assembly

D

6. Remove the two screws E attaching the rack plate

from the pickup.

7. Remove the screw F attaching the P.S. spring from

the pickup.

Shaft

Par t j

Rack plate

Fig. 13

Pickup

P.S. spring

F

E

Fig. 14

1-15

Page 16

XL-R2010BK

Reinstalling the pickup assembly

(See Figs. 15 and 16)

Reference: Refer to the explanation of "Removing

the Pickup" on the preceding page.

1. Fit the P.S. spring and rack plate to the pickup.

2. Insert the shaft into the pickup.

3. Engage the part k of the pickup assembly with the

CH. base assembly first, and set the part j of the

rack plate in the opening I next. Then, reinstall the

pickup assembly while shifting it to the turn table

side (inward) so that the part m of the rack plate is

positioned as shown in Fig. 16.

4. Move the pickup assembly to the center position

and fasten the shaft with the two screws D. (Make

sure that the part n of the rack plate is correctly

engaged with the middle gear.)

5. After passing the flexible wire coming from the

pickup through the opening of the CH. base

assembly, connect it to the connector CN601.

Part I

Part j

Part m

Part k

Pickup

assembly

CH. base

assembly

Fig. 15

Middle gear

Note: When reinstalling the pickup assembly,

remove the solder from the shorting round

after connecting the flexible wire coming from

the pick to the connector CN601.

Removing the feed motor assembly

(See Fig. 17)

Remove the clamper base assembly and tray.

Remove the mechanism board.

Remove the two screws G attaching the feed motor

assembly from the top of the mechanism assembly.

Rack plate

Part n

Fig. 16

G

Feed motor assembly

1-16

Fig. 17

Page 17

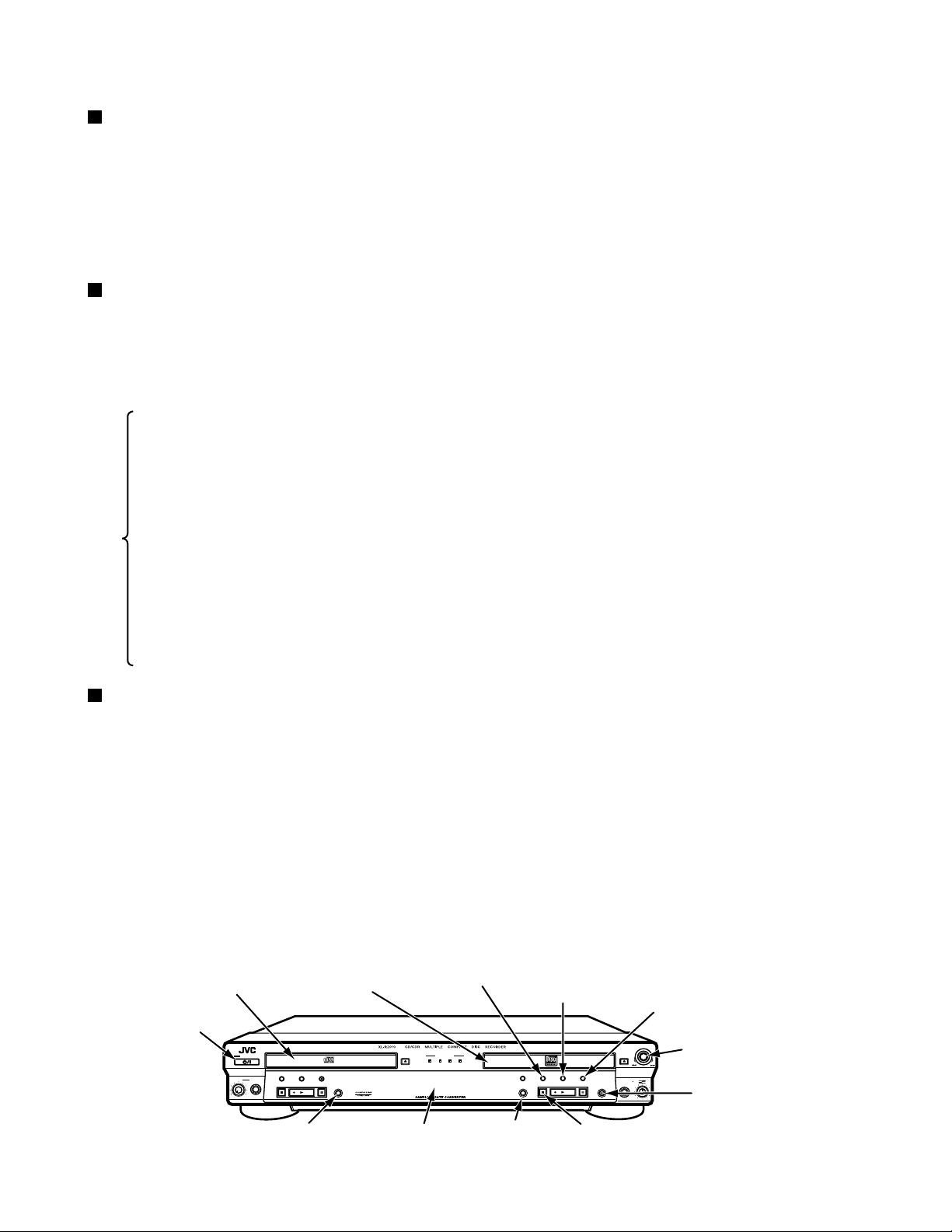

Confirm method of operation

Check mode (All lighting FL display)

<Setting method>

"STANDBY/ON" key is pushed while pushing "REC/REC MUTING" key by the stand-by state.

<Release method>

The key to "STANDBY/ON" is pushed.

(Please set the above-mentioned again to light all FL displays again after the check mode is made clear

after pulling out the power cord once.)

All release of set content

All content of the item in the following set is returned to initial state. (State of factory shipment)

<Setting method>

"STANDBY/ON" key is pushed while pushing "REC SOURCE SELECTOR" key by the stand-by state.

[Set items]

The program of the program play is deleted.

The content of the registration of the listening editing and the program editing is deleted.

The repeat setting is turned off.

Release of disc lock

A current unit is set to the CD mechanism unit side.

The play mode of CD mechanism unit is made a normal mode.

The pitch control setting is turned off.

The selection of the recording source is made DIGITAL of CD.

DUB-SPEED setting is made HIGH.

AUTO TRACK setting is turned ON.

TRACK SPACE setting is turned ON.

CONVERTER setting is turned ON.

D-IN SYNCHRO setting is START

FINALIZE setting is OFF

XL-R2010BK

Service menu

The running operation and the version of the firmware can be confirmed by the undermentioned method.

(Does not use excluding "SYSTEM_AGING" and "READ_VERSION" by the item displayed in the service menu.)

<Setting method of service menu>

1."STANDBY/ON" key is pushed while pushing "FINALIZE" key by the stand-by state.

2.When the blinking display of the disc distinction ends, "MENU" key is pushed.

The menu display changes if "MULTI JOG" knob of the main body is turned.

3.The execution of the each item is completed or either "CANCEL"key, "CD-RW STOP"key or "MENU"key

is pushed when going out of the menu mode.

<Release method>

If "STANDBY/ON" key is pushed, and the power supply is turned off once, becomes a normal menu.

MENU key

(Menu mode ON)

REC SOURCE

DIGITAL CD LINE MIC

FL Display

SET key

(Execution)

SYNCHRO

FINALIZE

FINALIZE key

(Service menu)

(Release of menu mode)

MULTI JOG/REC LEVEL

OPEN/CLOSEOPEN/CLOSE

+

REC MUTING

-

CD

LINE

MIX

LINE

MIC

REC/

MIC

CANCELSETMENU

PAUSE

PLAYSTOP

STOP key

(Release of menu mode)

CANCEL key

MULTI JOG knob

(Service menu display switch)

REC/REC MUTING key

(All lighting FL display)

CD Mechanism unit

STANDBY/ON key

REC SOURCE SELECTOR key

(All release of set content)

CD-R/RW

Mechanism unit

STANDBY

STANDBY/ON

PLAY MODE CD EDIT

STOP PLAY PAUSE

CD REC

REC SOURCE

SELECTOR

LEVEL

PHONES

MAXMIN

1-17

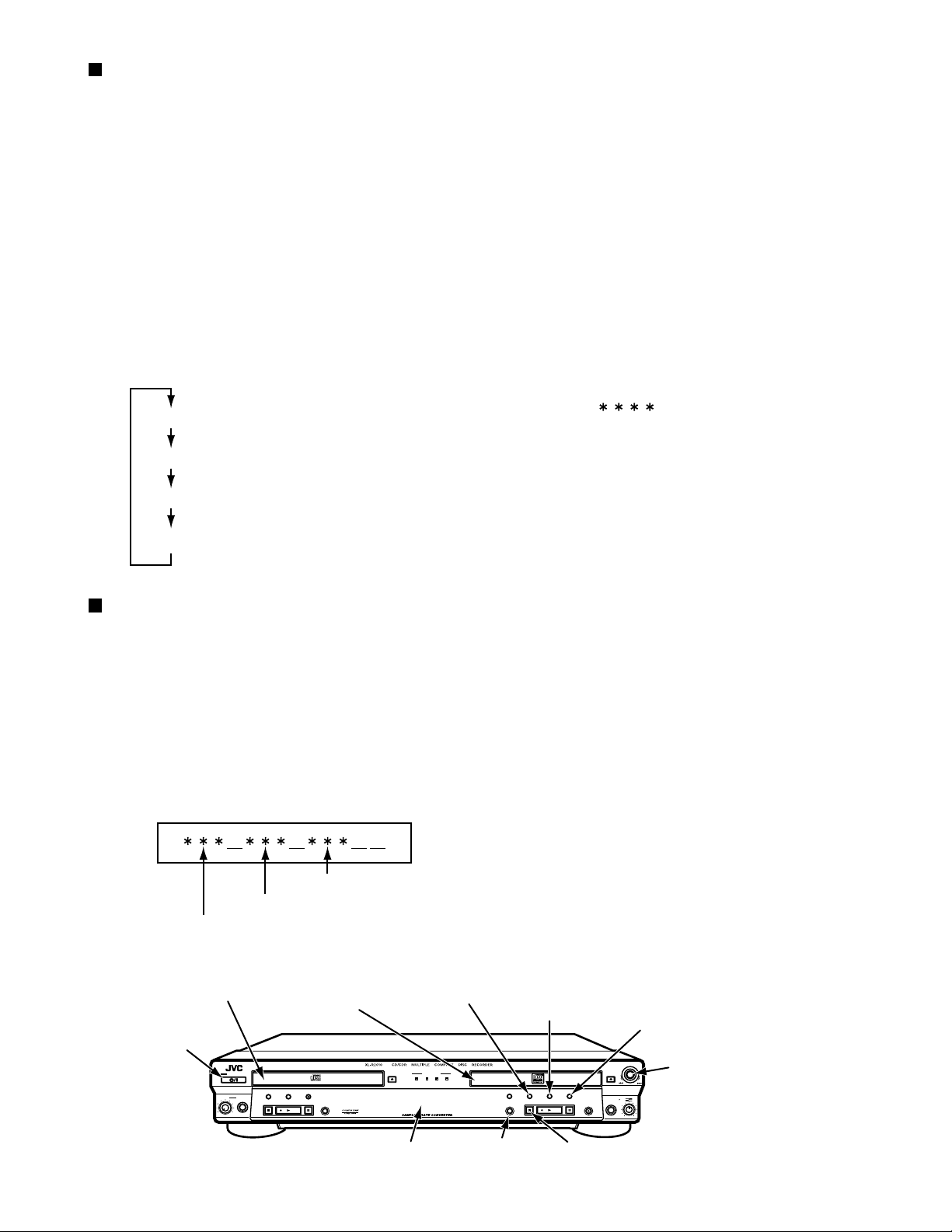

Page 18

XL-R2010BK

Running operation

When this mode is executed, the operation of the recording and the playback is repeated.

Please use to confirm operation.

It is necessary to put the recorded disc or CD-DA in tray of CD mechanism unit beforehand to

execute this item, and put CD-RW of the blank disc in CD-R/RW mechanism unit.

<Setting method of running operation>

1."Service menu" is made to be displayed on the FL display referring to the previous page.

2."SYSTEM_AGING" is made to turn "MULTI JOG" knob, and to be displayed on the FL display.

3.The undermentioned operation starts when "SET" key is pushed.

The undermentioned control becomes possible according to the content of the disc turned on to tray

of CD mechanism unit.

* The time required of operation of running once

* Movement frequency of pick-up

1 Disc recording

Finalize

F L display becomes " ", and the frequency to

which the running operation is done is displayed by the

figure when "STOP" key is pushed to the running working

or interrupted because of the error etc.

CD-RW is playback to the last minute.

DISC ERASE for CD-RW.

Display of version number

When this item is executed, version number "system controller", "CD-R/RW mechanism unit", and

"CD mechanism unit" respectively is displayed in FL display for five seconds.

When five seconds pass, this mode is automatically made clear.

<Setting method of display of version number>

1."Service menu" is made to be displayed on the FL display referring to the previous page.

2."READ_VERSION" is made to turn "MULTI JOG" knob, and to be displayed on the FL display.

3.The undermentioned operation starts when "SET" key is pushed.

FL Display

1-18

System controller version number

CD Drive unit

STANDBY/ON key

CD mechanism unit version number

CD-R/RW mechanism unit version number

MENU key

CD-R/RW Drive unit

STANDBY

STANDBY/ON

PLAY MODE CD EDIT

STOP PLAY PAUSE

CD REC

REC SOURCE

SELECTOR

LEVEL

PHONES

MAXMIN

(Menu mode ON)

REC SOURCE

DIGITAL CD LINE MIC

FL Display

FINALIZE key

(Service menu)

SET key

(Execution)

SYNCHRO

FINALIZE

It is displayed instead of version

number when failing in reading

version number, "000".

(Release of menu mode)

MULTI JOG/REC LEVEL

OPEN/CLOSEOPEN/CLOSE

+

REC MUTING

-

CD

LINE

MIX

LINE

MIC

REC/

MIC

CANCELSETMENU

PLAYSTOP

PAUSE

STOP key

(Release of menu mode)

CANCEL key

MULTI JOG knob

(Service menu display switch)

Page 19

Extension cord for diagnosis of CD mechanism unit

It is an extension cord to operate with the CD mechanism unit removed from the main body.

Each connector is connected by the extension cord and used as shown in the figure below.

Parts No. QUQ110-1936AJ

CN651

XL-R2010BK

CN606

CD Servo control board

Parts No. QUQ110-0838AJ

CN615

CN616

Main board

1-19

Page 20

XL-R2010BK

Dscription of major ICs

AN22000A-W(IC601):RF & SERVO AMP

1. Pin layout

PD

1

LD

2

VCC

3

RFN

RFIN

ARF

CEA

BDO

GND

4

5

6

7

8

9

10

11

12

13

14

15

16

RFOUT

CAGC

3TOUT

CBDO

COFTR

OFTR

RFDET

2. Pin function

Pin

Symbol Description

No.

1

PD

2

LD

3

VCC

4

RFN

5

RF OUT

6

RF IN

7

C.AGC

8

ARF

9

CEA

10

3TOUT

11

CBDO

12

BDO

13

COFTR

14

OFTR

15

RFDET

A

32

C

31

B

30

D

29

PDF

28

PDE

27

TBAL

26

FBAL

25

GCTRL

24

FEOUT

23

FEN

22

TEN

21

TEOUT

20

TEBPF

19

VDET

18

VREF

17

APC Amp. Input terminal

APC Amp.Output terminal

Power supply terminal

RF addition Amp.Reversing input terminal

RF addition Amp.Output terminal

AGC input terminal

Terminal of connection of capacity of AGC loop

filter.

AGC output terminal

Capacity connection terminal for HPF-Amp.

3TENV output terminal

Capacity connection terminal for RF shade side

envelope detection

BDO output terminal

Capacity connection terminal for RF discernment

side envelope detection

OFTR output terminal

RFDET output terminal

Pin

Symbol Description

No.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

GND

VREF

VDET

TEBPF

TEOUT

TEN

FEN

FEOUT

GCTRL

FBAL

TBAL

PDE

PDF

D

B

C

A

Connect to ground

VREF output terminal

VDET output terminal

VDET input terminal

TE Amp. output terminal

TE Amp. reversing input terminal

FE Amp. reversing input terminal

FE Amp. output terminal

Terminal GCTL & APC

FBAL control terminal

TBAL control terminal

Tracking signal input terminal 1

Tracking signal input terminal 2

Focus signal input terminal 4

Focus signal input terminal 2

Focus signal input terminal 3

Focus signal input terminal 1

BU4066BCF-X(IC821,IC831,IC841,IC861):Source selector

1.Pin layout & block diagram 2.Truth table

1-20

I/O1

O/I1

O/I2

I/O2

C2

C3

Vss

1

2

3

4

5

6

7

14

13

12

11

10

9

8

Vdd

C1

C4

I/O4

O/I4

O/I3

I/O3

Control

H

L

Switch

ON

OFF

Page 21

LA6541-X (IC801) : Focus & Spindle & Feed & Tracking BTL driver

1. Pin layout & Block diagram

Vcc Vref Vin4 Vg4 Vo8 Vo7

24 23

22

21

20

19

11k

ohm

Vcc

Gnd

Vo6 Vo5 Vg3 Vin3 Cd Res

18

17 16

XL-R2010BK

15

14

11k

ohm

13

- +

- +

Level

shift

Level

shift

B T L

driver

B T L

driver

B T L

driver

B T L

driver

Level

shift

Level

shift

11k

ohm

1

Vcc Mute Vin1 Vg1 Vo1 Vo2 Vo3 Vo4 Vg2 Vin2 Reg

2

3456

Gnd

7 8 9101112

2. Pin function

Pin No. Symbol Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Vcc

Mute

Vin1

Vg1

Vo1

Vo2

Vo3

Vo4

Vg2

Vin2

Reg Out

Reg In

Res

Cd

Vin3

Vg3

Vo5

Vo6

Vo7

Vo8

Vg4

Vin4

Vref

Vcc

Power supply (Shorted to pin 24)

All BTL amplifier outputs ON/OFF

BTL AMP 1 input pin

BTL AMP 1 input pin (For gain adjustment)

BTL AMP 1 input pin (Non inverting side)

BTL AMP 1 input pin (Inverting side)

BTL AMP 2 input pin (Inverting side)

BTL AMP 2 input pin (Non inverting side)

BTL AMP 2 input pin (For gain adjustment)

BTL AMP 2 input pin

External transistor collector (PNP) connection. 5V power supply output

External transistor (PNP) base connection

Reset output

Reset output delay time setting (Capacitor connected externally)

BTL AMP 3 input pin

BTL AMP 3 input pin (For gain adjustment)

BTL AMP 3 output pin (Non inverting side)

BTL AMP 3 output pin (Inverting side)

BTL AMP 4 output pin (Inverting side)

BTL AMP 4 output pin (Non inverting side)

BTL AMP 4 output pin (For gain adjustment)

BTL AMP 4 output pin

Level shift circuit's reference voltage application

Power supply (Shorted to pin 1)

11k

ohm

out

RESET

Regulator

Reg

In

1-21

Page 22

XL-R2010BK

M66004FP-X(IC721):FL Driver

1.Block diagram

FLCS

14

FLCLKK

15

16

FLDAT

13

RESET

Cereal

receive

circuit

Vcc Vcc2

19

60

Display code

register

(8bit 16)

control circuit

Code/Command

Display

control

register

RAM write

code select

CGROM

(35bit 160)

DecoderDecoder

CGRAM

(35bit 16)

Segment output circuit

Output port

(2bit)

23

P36

31

P28

P27

33

59

P01

P1

17

P0

18

XIN

21

XOUT

20

2.Pin function

Pin.No.

1~12

13

14

15

16

17

18

19

20

21

22

23~31

32

33~59

60

61~64

Clock

generation

circuit

12G~1G

FLCLK

FLDATA

P36~P28

P27~P01

16G~13G

Symbol

SRST

FLCS

P1

P0

VCC1

XOUT

XIN

VSS

VP

VCC2

Display

controller

22 32

Vss

I/O

FL grid control signal output.

O

Reset signal input

I

Chip select signal input.

I

Shift clock signal input.

I

Serial data input.

I

Output port (static operation)

O

Output port (static operation)

O

Power supply for internal logic.

-

Clock signal output.

O

Clock signal input.

I

Connect to ground.

-

FL Segment control signal output.

O

Power supply.

-

FL Segment control signal output.

O

Power supply for grid output and segment output.

-

FL grid control signal output.

O

Description

Grid

output

circuit

Vp

12G

1

12

1G

16G

61

64

13G

1-22

Page 23

MN662790RSC(IC651):Digital servo & processor

1.Pin layout

60 41

61

40

XL-R2010BK

80

21

1 20

2.Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

M DATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

S TAT

LSI_RST

SMCK

CSEL

TEST2

TVD

PC

ECM

ECS

VDETMON

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RFENV

TEST3

OFT

TRCRS

RFDET

BDO

LDON

O

O

O

-

-

O

I

I

I

-

-

-

O

I

O

I

O

I

O

I

-

O

O

O

O

O

O

O

I

I

I

I

I

I

I

I

-

MN662790RSC (1/2)

Description

Bit clock output for SRDATA

Identifying signal output of L,R

Serial data output

Power supply for digital circuit

Connect to ground for digital circuit

Digital audio interface output signal

Micom command clock signal input

Micom command data signal input

Micom command load signal input L:load

Non connect

Non connect

Non connect

Sub code block clock signal

Export clock signal input for sub code Q resister

Sub code Q data output

Muting input H:muting

Status signal output

Reset signal input L:reset

Clock signal output MSEL is H : 8.4672 MHz MSEL is L : 4.2336 MHz

Oscillation frequency specification terminal H:33.8688 MHz L:16.9344 MHz

TEST2 terminal usually : open

Traverse drive output

Non connect

Spindle motor drive signal output (Compulsion mode output)

Spindle motor drive signal output (Servo error signal output)

Non connect

Tracking drive signal output

Focus drive signal output

Reference voltage for DA output section

Focus balance adjust signal output

Tracking balance adjust signal output

Focus error signal input (analog input)

Tracking error signal input (analog input)

RF Envelope signal input (analog input)

TEST3 Terminal usually : Fixation L

Off track signal input H : off track

Track cross signal input (analog input)

RF detection signal input L : detection

Dropout signal input H : dropout

Non connect

(Command execution : CD-TEXT data readout enabling signal (DQSY) output)

1-23

Page 24

XL-R2010BK

2.Pin function

Pin No. Symbol I/O

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

PLLF2

DSLBDA

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

DSLB

VCOF2

SUBC

SBCK

VSS

X1

X2

VDD

BYTCK

LDON

GCTRL

IPFLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUTL

AVSS1

OUTR

DQSY

VCC5V

PSEL

MSEL

SSEL

I/O

-

-

I

I

I

I/O

I/O

I/O

-

-

-

O

I/O

O

I

-

I

O

-

O

O

O

-

O

-

I

I

O

O

I

O

O

O

MN662790RSC (2/2)

Functions

Terminal for loop filter characteristic switch for PLL

Non connect

Non connect

RF Signal output

Standard electric current input terminal

Bias terminal for DSL

Loop filter terminal for DSL

Loop filter terminal for PLL

Loop filter terminal for VCO

Power supply terminal for analog circuit

Connect to ground terminal for analog circuit

Non connect

PLL extraction clock output

Loop filter terminal for VCO

Sub code serial output

Clock signal input for sub code serial output

Connect to ground terminal for oscillation circuit

Oscillation circuit input terminal f=16.9344 MHz, 33.8688 MHz

Oscillation circuit output terminal f=16.9344 MHz, 33.8688 MHz

Power supply terminal for oscillation circuit

Non connect

Laser ON signal output H : ON

General I/O port

Non connect

Flag signal output

Non connect

Non connect

De-emphasis detection signal output

Non connect

Mode switch terminal

TEST terminal usually : H

Power supply terminal for analog circuit (for audio output section)

Lch audio output

Connect to ground terminal for analog circuit (for audio output section)

Rch audio output

RF signal polarity specification terminal

Power supply terminal (5V)

IOSEL=H TEST terminal IOSEL=L SRDATA input

IOSEL=H SMCK terminal output (frequency switch terminal) IOSEL=L LRCK input

IOSEL=H SUBQ terminal output mode switch terminal IOSEL=L BCLK input

1-24

Page 25

TC74HC00AF-W(IC301,IC311):Digital I/O selector

Pin layout & block diagram

Vcc 4B 4A 4Y 3B 3A 3Y

14 13

12

11 10 9 8

XL-R2010BK

2

1

1A 1B 1Y 2A 2B 2Y GND

6

543

7

TC74HCU04AF-W(IC331):Digital input selector

1.Pin layout & block diagram 2.Truth table

1A

1Y

2A

2Y

3A

3Y

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

VCC

6A

6Y

5A

5Y

4A

4Y

A

L

H

Y

H

L

1-25

Page 26

XL-R2010BK

TC9412AF-X(IC891) : Rec Level

1.Pin layout

VSS

NC

L-OUT

L-IN

LD1

LD2

A-GND

NC

CS1

NC

GND

CK

3.Pin functions

Pin No. Symbol Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

10

11

12

2.Block diagram

1

2

3

4

5

6

7

8

9

24

23

22

21

20

19

18

17

16

15

14

13

VSS

NC

L-OUT

L-IN

LD1

LD2

A-GND

NC

CS1

NC

GND

CK

DATA

STB

NC

CS2

NC

A-GND

LD2

LD1

R-IN

R-OUT

NC

VDD

VDD

NC

3

R-OUT

R-IN

LD1

LD2

A-GND

L-ch R-ch

OUT

IN

LD1

LD2

A-GND

4

5

6

7

NC

8

CS2

NC

STB

DATA

NC

CS1

NC

GND

CK

9

10

11

12

Negative power supply terminal

Non connect

L-ch Volume output terminal

L-ch Volume input terminal

L-ch Loudness tap output terminal

L-ch Loudness tap output terminal

L-ch Analog ground

Non connect

Chip select input terminal

Non connect

Digital ground

Data transfer clock input terminal

Volume setup serial data input terminal

Data write strobe input terminal

Non connect

Chip select terminal

Non connect

R-ch Analog ground

R-ch Loudness tap output terminal

R-ch Loudness tap output terminal

R-ch Volume input terminal

R-ch Volume output terminal

Non connect

Positive power supply terminal

Level

Shift

Circuit

VSS VDD NCNC

L-ch

Data

Latch

Circuit

Shift Register

(13bit)

generating

Strove

circuit

24 2312

R-ch

Data

Latch

Circuit

Level

Shift

Circuit

22

21

20

19

18

17

16

15

14

13

OUT

IN

LD1

LD2

A-GND

NC

CS2

NC

STB

DATA

1-26

Page 27

UPD780024AGKB21(IC251) : Unit microcomputer

1.Pin layout

48 33

49

32

XL-R2010BK

64

1 16

2.Pin function

Pin No. I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

17

Symbol Description

P50/A8

P59/A9

MCS

MRDY

CDINDEX

CDEMP

CDTNO

CDCOPY

VSS0

VDD0

P30

P31

P32

MUTE

SUBQ

P35/SO31

SQCK

KCMND

M STAT

MCLK

RXDO

TXDO

P25/SCK0

VDD1

AVSS

KEY1

KEY2

PCHK

P14/AN14

P13/AN13

/OPEN

/REST

P10/AN10

AVREF

AVDD

/RESET

Connect to ground

Non connect

Pull-up +B

Non connect

Non connect

Detection of CD emphasis

I

Detection of CD track number

I

Detection of CD copy

I

Connect to ground

Power supply terminal

Non connect

Non connect

Non connect

Muting output

O

Sub-code Q data input from IC651

I

Non connect

Clock output for sub-code Q resistor to IC651

O

Kick command data output

O

CD control to IC801 (status output)

O

CD control from IC801 (command clock input)

I

Digital data input

I

Digital data output

O

Connect to ground

Power supply terminal

Connect to ground

Key input 1

I

Key input 2

I

parity check

I

Connect to ground

Connect to ground

OPEN switch input

I

REST switch input

I

Connect to ground

Standard voltage for analog circuit

(connect to power supply terminal for analog circuit)

Power supply terminal for analog circuit

CD control from IC801 (reset input)

I

UPD780024AGKB21 1/2

1-27

Page 28

XL-R2010BK

2.Pin function

Pin No. I/O

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Symbol Description

XT2

XT1

IC

X2

X1

VSS1

FLAG

BLKCK

/RFDET

EQx2

EQx4

VCOx4

OPEN

/CLOSE

IREFx4

P75/BUZ

/RESET

S TAT

/DMUTE

/P.ON

MLD

M DATA

MCLK

CLKSW

JIG

JIG

JIG

JIG

Non connect

Connect to power supply terminal

Control of flash microcomputer

O

Connect with external oscillator

Connect with external oscillator

Connect to ground

Flag signal input from IC651

I

Sub-code,block,clock signal input from IC651

I

RF signal amplitude detection input terminal

I

x2 equalizer switch

O

x4 equalizer switch

O

Non connect

Tray open detection

I

Tray close detection

I

Electric current switch of x4 DSP

O

Non connect

Reset signal output to IC651 L:reset

O

Status signal input from IC651

I

Muting signal output to IC651

O

Power ON/OFF switch signal output to IC291

O

Microcomputer command load signal output to IC651

O

Microcomputer command data output to IC651

O

Microcomputer command clock signal output to IC651

O

Non connect

Non connect

Non connect

Non connect

Connect to ground

-

UPD780024AGKB21 2/2

1-28

Page 29

UPD784214AGF523(IC501):System controller

1.Pin layout

80 51

81

50

XL-R2010BK

100

1 30

2.Pin function

Pin No. I/O

1~3

4

5

6

7

8

9

10,11

12,13

14

15

16

17~19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34,35

36

37

38

39

40

41

42

31

Symbol

NC

TEST-

VR_STB

VR_DATA

VR_CK

NC

VDD

CS1/CS2

JOGA/JOGB

FLDAT

FLCLK

FLCS

MPLAY/REC/STOP

DIN_COA

AIN_HI

VPP

DIG_LED

CD_LED

LIN_LED

MIC_LED

LLEVE

MIXBL

DIN_OPT

SMUTE

DACMUTE

CD_DRT

SCD

SLIN1/SLIN2

SMIC

VDD

X2

X1

VSS

XT2

XT1

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

UPD784214AGF523 1/2

Description

Non connect

Test mode input terminal L : Test mode

I

Strobe signal output to IC891

Data output to IC891

Clock signal output to IC891

Non connect

Power supply terminal +5V

Chip select terminal

I

Multi jog dial A/B input

I

Serial data output to FL driver

Shift clock signal output to FL driver

Chip select signal output to FL driver L : data output

Non connect

When digital input is coaxial for output H

LINE IN gain control output H : high gain

Connect to ground

Digital LED control signal output

CD LED control signal output

Line IN LED control signal output

MIC LED control signal output

Non connect

Mix balance volume level input

I

When digital input is optical for output H

System muting signal output

Non connect

It is a power output to the direct connection of analog recording

source 3CD to the A/D input of CD-RW as for L

Analog recording source 3CD select control output

L : selected 3CD

Analog recording source select control output

Analog recording source MIC select control output

L : selected MIC

Power supply terminal +5V

(connects with the backup capacitor at power supply off. )

Main system clock output terminal 10MHz

Main system clock input terminal 10MHz

I

Connect to ground

Sub clock output terminal 32.768KHz

Sub clock input terminal 32.768KHz

I

1-29

Page 30

XL-R2010BK

2.Pin function

Pin No. I/O

43

44

45

46

47

48

49

50

51

52

53~56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84~97

98

99

100

Symbol

RESET

REM

NC

ACON

CDR_RREQ

NC

DOCD

SLCDR

AVDD

AVREF0

KEY1~4

NC

3CDINR

3CDINL

MODE

AVSS

DCSI

DCSO

AVREF1

NBUSI

NBUSO

ASCK2

STAT

COMD

ASCK1

SRST

POWER

CDR_DTI

CDR_DTO

XDR_ACLK

CDR_SREQ

SYS_RDY

NC

DACPD

NC

3CD_RES

NC

DOCDR

CDRRST

STBY_LED

VSS

O

O

O

O

O

O

O

O

O

O

O

O

O

O

UPD784214AGF523 2/2

Description

Reset signal input

I

Remote control signal input

I

Non connect

The AC power supply existence detection terminal

I

L : No AC power supply (backup mode)

H : AC power supply having (normal mode : Backup mode Release)

Request demand input from CD-RW unit

I

Non connect

Output select control H : selected 3CD L : selected CD-RW

Output select control H : selected CD-RW L : selected 3CD

Power supply terminal +5V

(connects with the backup capacitor at power supply off.)

Power supply terminal +5V

Operation switch input terminal 1~4

I

Non connect

3CD analog signal level input (for Rch level meter)

I

3CD analog signal level input (for Lch level meter)

I

DCS mode setting switch input

I

Connect to ground

DCS command input

I

DCS command output

Power supply terminal +5V

Connect to Q541

I

Non connect

Connect to ground

3CD status input

I

3CD command output

Connect to ground

I

System reset signal output L : active

System power supply control terminal / standby LED control

H : power OFF / LED turning off L : power ON / LED lighting

Serial data input from CD-RW unit

I

Serial data output to CD-RW unit

Clock signal input from CD-RW unit

I

Request signal output to CD-RW unit L : active

System ready output to CD-RW unit L : active

Non connect

DAC power down control output

Non connect

Reset signal output to 3CD unit micom (IC251)

Non connect

Output select control H : selected CD-RW L : selected 3CD

Non connect

Reset signal output to CD-RW unit L : reset ON

Standby LED control signal output L : lighting

Connect to ground

-

1-30

Page 31

XL-R2010BK

VICTOR COMPANY OF JAPAN, LIMITED

PERSONAL & MOBILE NETWORK BUSINESS UNIT

1644, Shimotsuruma, Yamato, Kanagawa 242-8514, Japan

No.A0013

Printed in Japan

200110(S)

Page 32

XL-R2010BK

In regard with component parts appearing on the silk-screen pr inted side (par ts side) of

the PWB diagrams, the parts that are printed over with black such as the resistor ( ),

diode ( ) and ICP ( ) or identified by the " " mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified

by the manufacturer. (Except the JC version)

2-2

Page 33

Block diagrams

Main section (SHEET 1,2)

XL-R2010BK

TO CD Servo control section

CN616

CN606

Mechanism unit

DATA

LRCK

TO CD-R/RW

CN722 CN615

BCK

TO CD-R/RW

Mechanism unit

CN723

DATA

LRCK

BCK

K2 Interface

IC851

DAC

IC361

DADAT A

DALRCK

DABCK

OUT2C/D

IC363

LIN RIN

CD Direct switch

IC861

IC891

OUT1C/D

MROUT

MLOUT

IC362

J541

3CDLOUT

3CDROUT

DCS

CD-R TAPE

DCS I/O

System controller

STB

DATA

CK

IC501

S531

MODE

TO FL Display & Operation

switch section

CN501

CN711,712

HP

CN841

& Power switch section

TO Headphone

FW701

TO Multi jog & balance

volume section

CN801

control section

TO CD Servo

CN651

digital output

J353

COAXIAL

OUT

J354

COAXIAL

IN

STAT

COMD

3CDRES

CDDOUT

Optical

J351

Optical

digital input

J352

DOUT

IC302

T301

IC331

CD-R/RW LPF

IC811

DOCDR

DOCD

Digital output

selector

IC301

DIN

DIN_COA

Digital input

selector

IC311

MLIN1

MRIN1

MLIN2

MRIN2

3CDLOUT

3CDROUT

Line out

selector

3CDLOUT

3CDROUT

REC Source

selector 1

IC831

REC Source

selector 2

IC841

IC821

CDRLOUT

CDRROUT

LNLI

LNRI

MIC IN

LINE OUT LINE IN

Line out

buffer

IC881

Line input

amplifier

IC871

2-3

Page 34

XL-R2010BK

CD Servo control section (SHEET 4)

Optical

CN601

CN001

Spindle motor

pick-up

Feed motor

FM+/-

IC601

Tracking

coil

Focus

coil

F+ FT+ T-

RF & Servo AMP

Focus,Tracking,Spindle

Feed,BTL driver

IC801

Headphone & Power switch section (SHEET 3)

Headphone

jack

J6201

Headphone

amplifier

IC621

HP L/R

STBY_LED

Rest switch Open switch

REST OPEN

SM+/-

Unit Microcomputer

IC251

Digital servo

processor

IC651

KEY1

CN651 CN606

FW701

TO Main section

CN711,712

TO Main section

CN615

TO Main section

CN616

FL Display & operation switch

section (SHEET 3)

LED

D755~D758

FLDATA FLCLK FLCS SRST

TO Main

section

CN501

CN541

KEY1

REM

KEY3

KEY4

Operation switch

S721~S726,S710

Operation

switch

S702~S708

Remote

control input

IC701

Operation switch

S761~S762,S751

Headphone

volume

VR701

F+,F-

FL Driver

IC721

P01~P36

1G~16G

FL Display

DI721

Standby

indicator

D701

Power

switch

S701

Multi jog & Balance volume

section (SHEET 3)

TO Main section

CN841

CN801

JOGA,B

MIC

Mic

amplifier

IC601

KEY3

Mic jack

J6001

MLIN1,2 MRIN1,2

MLOUT MROUT

IC722

CD-R/RW

Eject switch

S760

Multi jog

JS721

Mix balance

volume

VR641

2-4

Page 35

XL-R2010BK

Standard schematic diagrams

Power supply & Line input/output section

7

R1305

27K

C1303

R1304

1/50

6.8K

6

C2303

R2304

1/50

5

4

CN615

QGF1016C1-19

TO CN651

D811

STAT

COMD

R811

22K

3CD_RES-

R812

0

SHEET 4

CN721

QGA2001C1-06

M9V

C812

D812

470/10

1SR35-400A

C993

0.001

C992

0.001

3

TO CD-R/RW

Mechanism unit

2

Q1301

KRC103M

C1301

R1301

1/50

D1301

R1307

R1306

15K

82K

R2305

27K

Q2301

KRC103M

6.8K

R2307R2306

82K

15K

K801

QQR0779-001Z

3.3K

R1302

15K

R1303

C1302

220K

0.22/50

C1312

C2302

0.22/50

C2301

R2301

1/50

D2301

3.3K

R2302

15K

C811

27P

C115

0.0056

C215

0.0056

EP801

100/10

R2303

220K

0.1

47/25

C801

C802

C112

100P

C111

10/35

R112

22K

R111

22K

R211

22K

R212 R213

C211

22K 22K

10/35

C212

100P

TO SHEET 2

F-

5V

F+

A5V

CD_DOUT

CDRROUT

CDRLOUT

R1313

15K

3CDINL

R1312

620

3CDINR

220

R801

R802

220

R803

220

220

R804

0.1

47/25

C803

C804

R114

2.2K

R113

22K

R115

1.5k

C113

100P

R117

1.5k

R215

1.5k

C213

100P

R217

1.5k

R214

2.2K

IC811

NJM4580M

C114

10/35

R116

47K

R216

47K

C214

10/35

3CDLOUT

3CDROUT

VP

JOGA

JOGB

DD5V

DS5V

M1XBL

SMUTE-

R821

470

R822

10K

Q821

KRA103M

IC821

BU4066BCF

R823

47K

Q822

R131

KRC103M

47K

R231

47K

KEY1

KEY3

AIN_HI

STBY_LED

C182

NJM4580M

0

C881

1/50

R883

IC831

R842

10K

IC841

BU4066BCF

IC881

100

BU4066BCF

R881

Q831

KRA103M

KRA103M

Q841

KRA103M

22/25

C183

22/50

C282

22/25

C283

22/50

10K

Q881

2SA933AS/RS/

R882

22K

SLCDR

R831R832

2.2K10K

SCD-

R833

47K

R834

47K

Q832

Q842

KRA103M-T

SLIN1-

R841

2.2K

SMIC-

R843

47K

R844

47K

SLIN2-

R132 R232

12K 12K

R181

470K

R281

470K

R599

Q191

KRA103M

CN712

QGD2501C1-04Z

TO FW701

SHEET 3

HPRIN

HPLIN

PON-

ACON

EP951

CN711

QGD2501C1-05Z

2SC3422/OY/ 1SR35-400A-T5

C977

100/16

MTZJ5.6B-T2

C973

1000/10

Q182

2SC2001/LK/

R186

4.7K

R185

1K

R285

1K

C952

T901

L951

MTZJ4.7B-T2

D972

Q966

R952

D973

C990

47/50

Q964

2SB1184/QR/-X

Q965

KTC3199/Y/-T

C970

0.1

1SS133-T2

L958

L957

10

220

820

1000/10

C980

47/10

C985

1000/10 220/10

L960

220

C961

0.1

R956

4.7

R972

1.2K

R971

4.7K

C967

D970

0.1

D956

1GWJ42-T5

C984C983

C982

220/10

220/10

C987

220/10

C989

ERA18-04

L959

10

C981

220/16

0.1

C960

470/10

CP951

ICP-N10-T

L953

L952

220

C966

C975

1000/10

1000/10

C962

22/50

D960

C956

100p

1GWJ42-T5

D957

C957

100p

L955

C997

1

22

C964

47/50

D971

R973

2.2

R974

2.2

C954

100p

22

D954

ERA18-04

C979

1000/16

C951

100p

D951

ERA18-04

D953

1GWJ42-T5

CP952

NI

C965

1000/10

1SR35-400A-T5

C974

1000/10

100p

R954

10

D952

ERA18-04

C963

220/50

ERA18-04

R969

C953

100p

Q967

KTC3199/Y/-T

D912

1SS133-T2

D913

D915

MTZ5.6B

C923

C922

0.47/50

1000/10

270

R975

R913

47

2.2K

IC951

SE005N

R914

10K

Q922

2SC3422/OY/

C921 C920

1000/10

Q921

KTC3199/Y/

D974

MTZ6.8B

47/25V

Q282

R286

4.7K

C172

4.7/50

C272

4.7/50

R901

68K

D903

D902

R918

3.3

C914

47/50

PC902

PC123Y02

PC901

PC123Y02

C916

0.0022/AC250V

R982 R981

C908

0.0047/1k

C918

0.01u

1SS133-T2

BA15218F

R874

R912

3.3K

D907

R872

R177

0

C173

330P

R178

100K

IC871

R278

100K

C273

330P

R277

0

C907

C913

220P

R907

0.47

K901

R906

680

C915

470P

R915

4.7

2SC2001/LK/

R176

10K

R276

10K

C909

100P

ERA18-04

ERA18-04

D904

R903

ERA18-04

22

D905

R904

2.2K

D910

ERA18-04

C910

1000p

R900

220

C919

0.1u

R917

1K

B26