Page 1

SERVICE MANUAL

MICRO COMPONENT SYSTEM

MB26220046

UX-P400

Area suffix

US ------------------------ Singapore

UF ------------------------------ China

UP ----------------------------- Korea

UT ---------------------------- Taiwan

UW ----------- Brazil,Mexico,Peru

CA-UXP400

SP-UXP400SP-UXP400

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.MB262

2004/6

Page 2

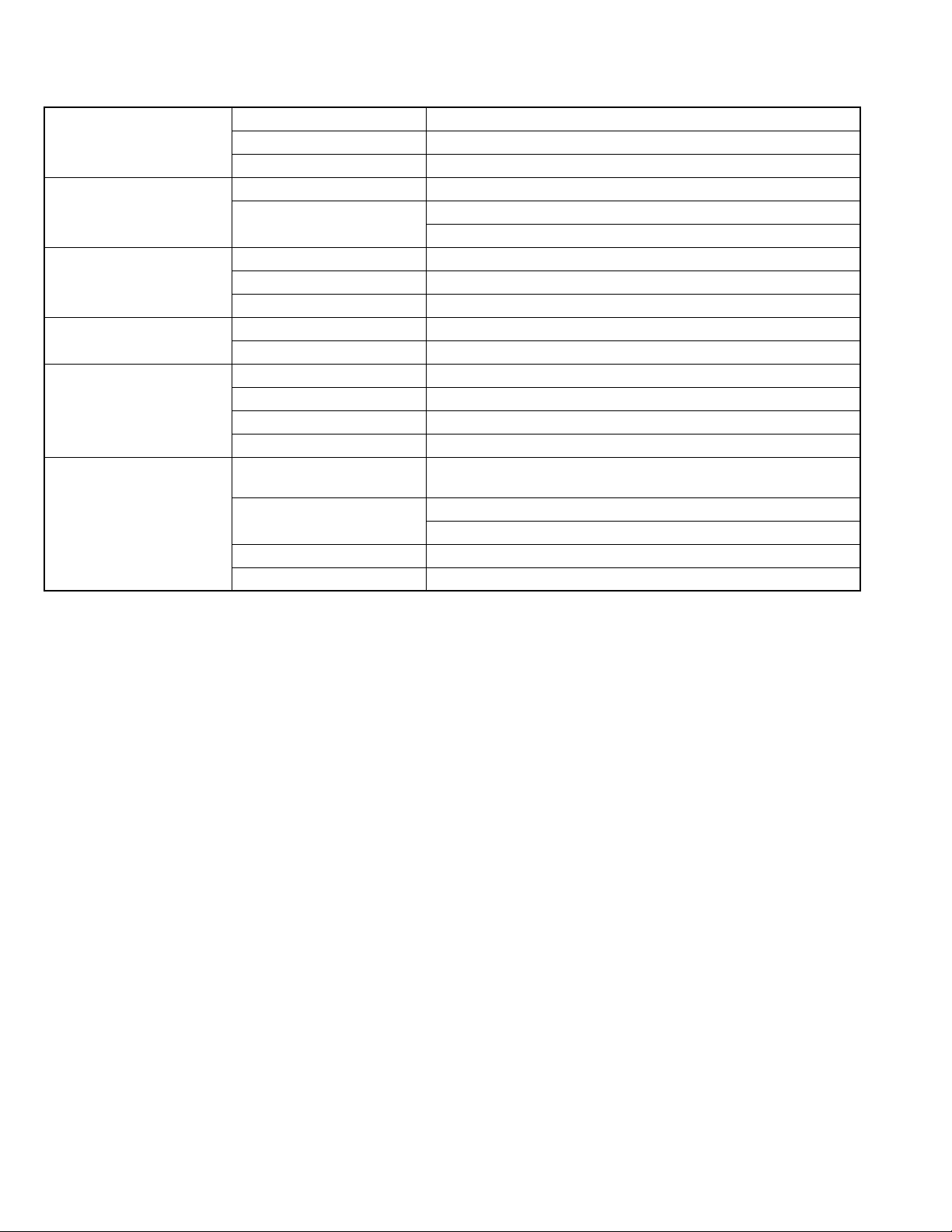

SPECIFICATION

Amplifier section Output Power 40 W (20 W + 20 W) at 4 Ω (10% THD)

Speakers/Impedance 4 Ω - 16 Ω

Audio Input AUX 400 mV/50 kΩ

Tuner section FM tuning range 87.50 MHz - 108.00 MHz

AM (MW) tuning range 531 kHz - 1 710 kHz (at 9 kHz intervals)

530 kHz - 1 710 kHz (at 10 kHz intervals)

CD player section Dynamic range 88 dB

Signal-to-noise ratio 93 dB

Wow and flutter Immeasurable

Cassette deck section Frequency response Normal (type I):50 Hz - 14 000 Hz

Wow and flutter 0.15% (WRMS)

Speakers Speaker units 10 cm cone × 1

Impedance 4 Ω

Dimensions (approx.) 145 mm × 230 mm × 191 mm (W/H/D)

Mass (approx.) 1.8 kg each

General Power requirement AC 110 V/AC 127 V/AC 220 V/AC 230 V - AC 240 V

(adjustable with the voltage selector), 50 Hz/60 Hz

Power consumption 50 W (at operation)

4.4 W (on standby)

Dimensions (approx.) 170 mm × 230 mm × 311 mm (W/H/D)

Mass (approx.) 4.5 kg

Design and specifications are subject to change without notice.

1-2 (No.MB262)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

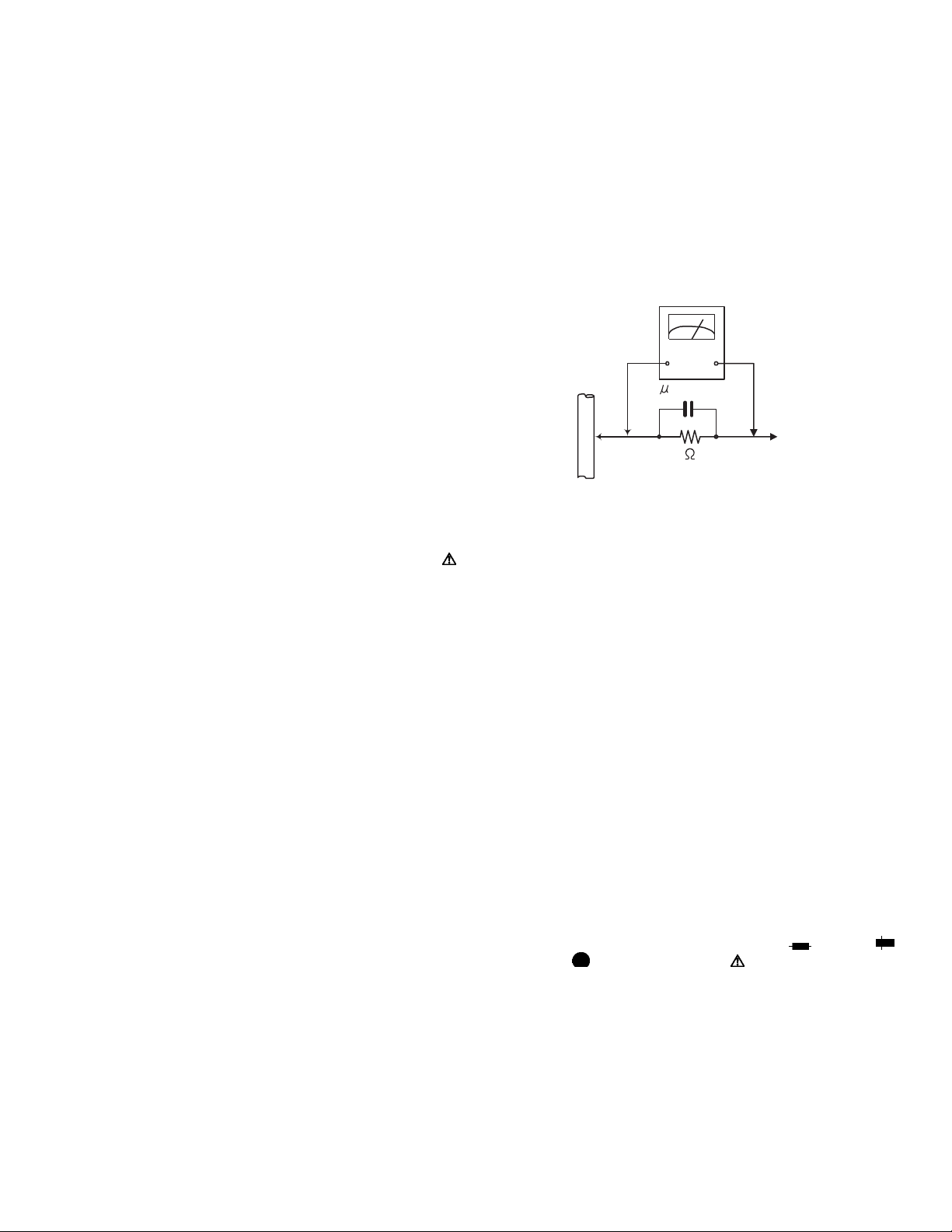

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB262)1-3

Page 4

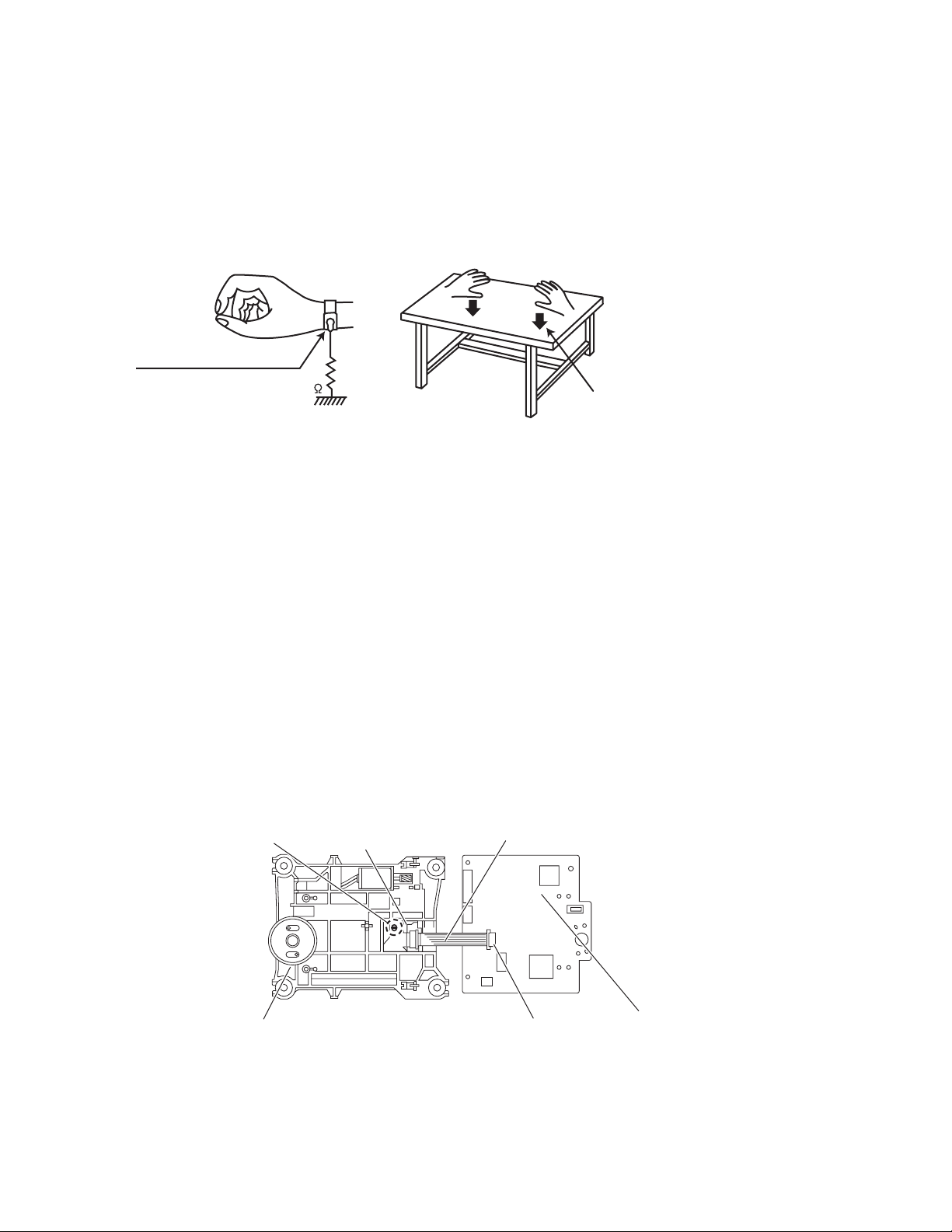

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Short land section

CD pickup

Card wire

1-4 (No.MB262)

Traverse mechanism assembly

CN601

CD servo board

Page 5

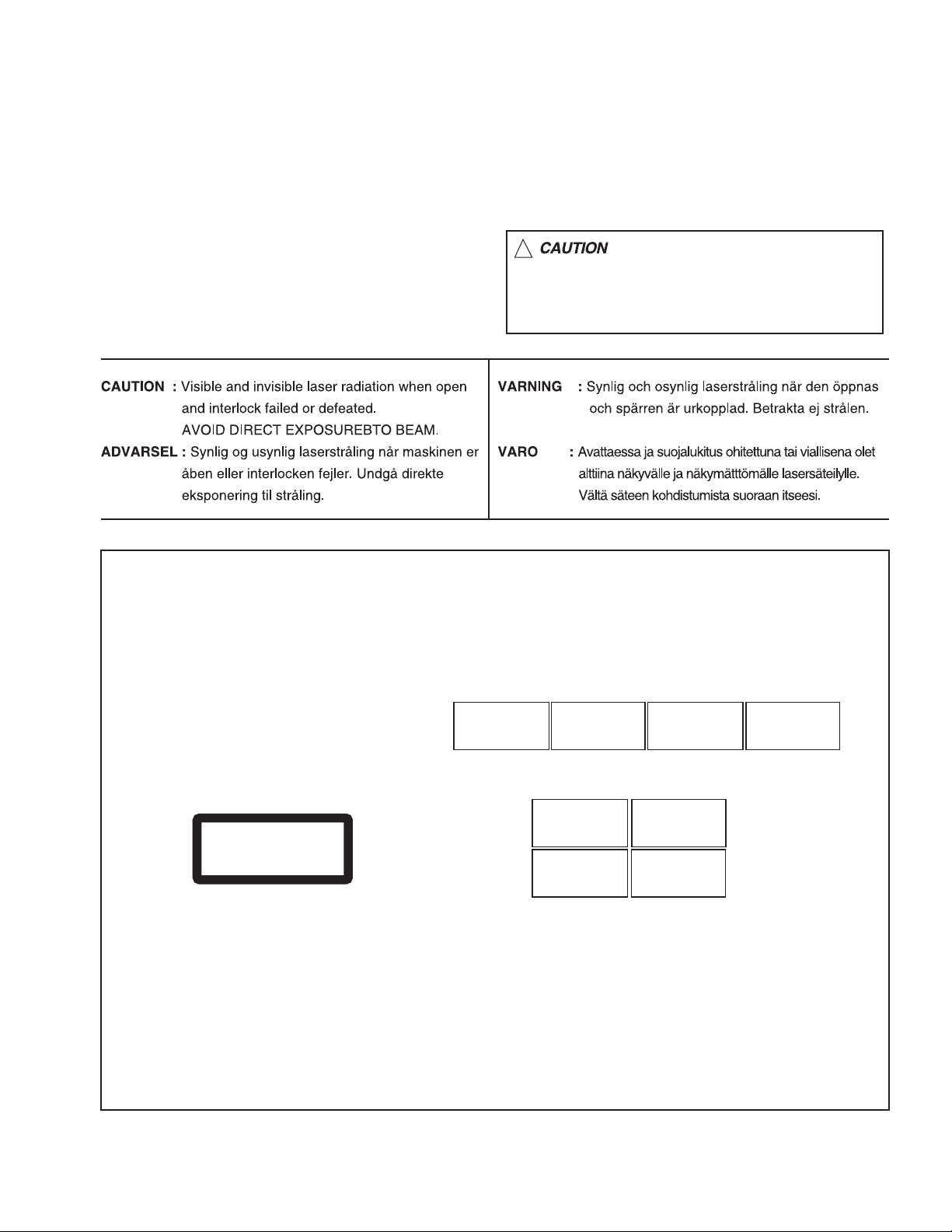

1.8 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

CLASS 1

LASER PRODUCT

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MB262)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB262)

Page 7

SECTION 3

DISASSEMBLY

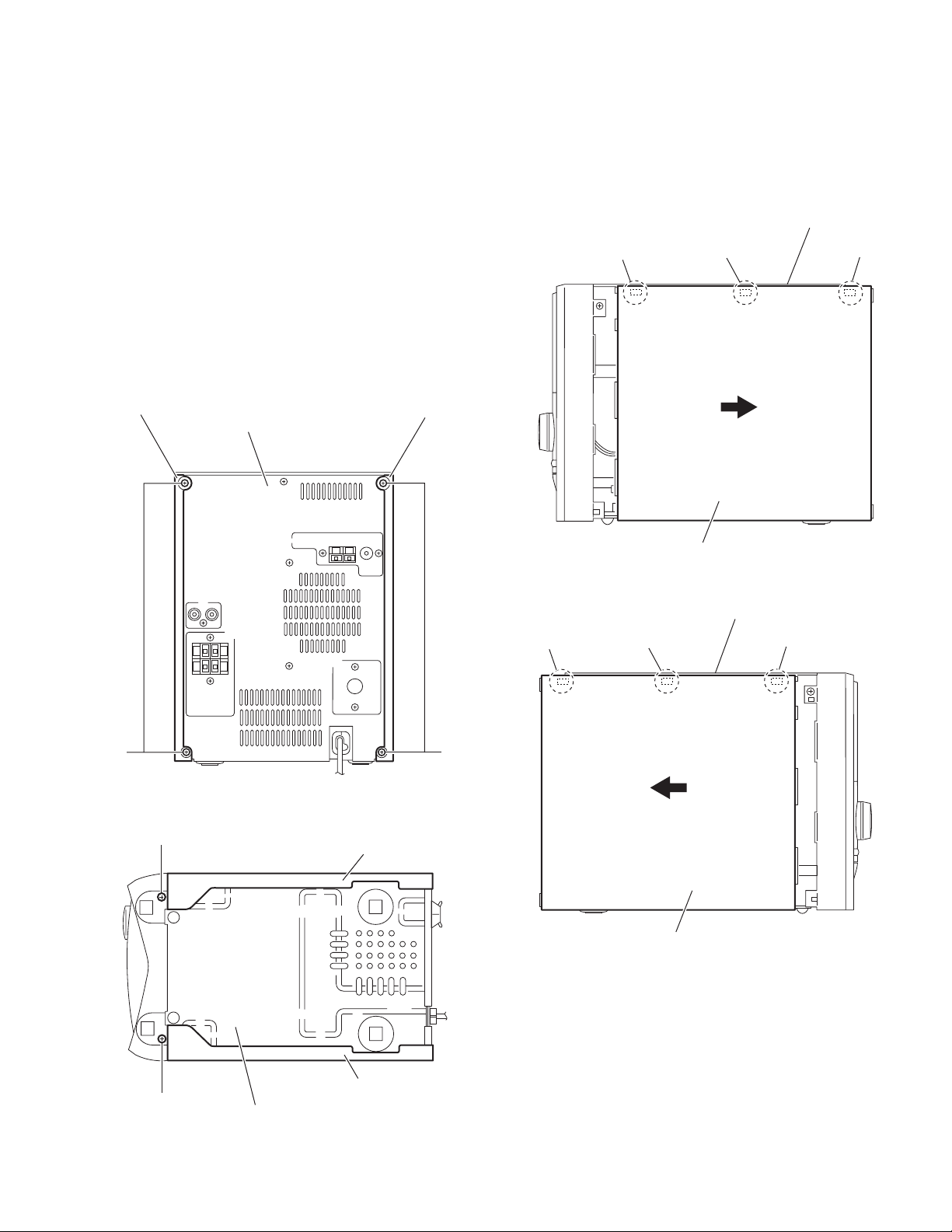

3.1 Main body section

3.1.1 Removing the side panels L/R

(See Figs.1 to 4)

(1) From the back side of the main body, remove the four

screws A attaching the side panels L/R to the rear panel.

(See Fig.1.)

(2) From the bottom side of the main body, remove the two

screws B attaching the side panels L/R to the bottom chassis. (See Fig.2.)

(3) From the both sides of the main body, release the engage-

ment sections (a, b) of the side panels L/R from the top

cover assembly in the direction of the arrow. (See Figs.3

and 4.)

(4) Remove the side panels L/R toward this side.

Top cover assembly

a

a

a

Side panel R

A

B

Rear panel

Fig.1

Side panel L

Side panel R

A

Side panel R

Fig.3

Top cover assembly

b

b

b

B

Side panel L

Fig.4

Side panel L

Bottom chassis

Fig.2

(No.MB262)1-7

Page 8

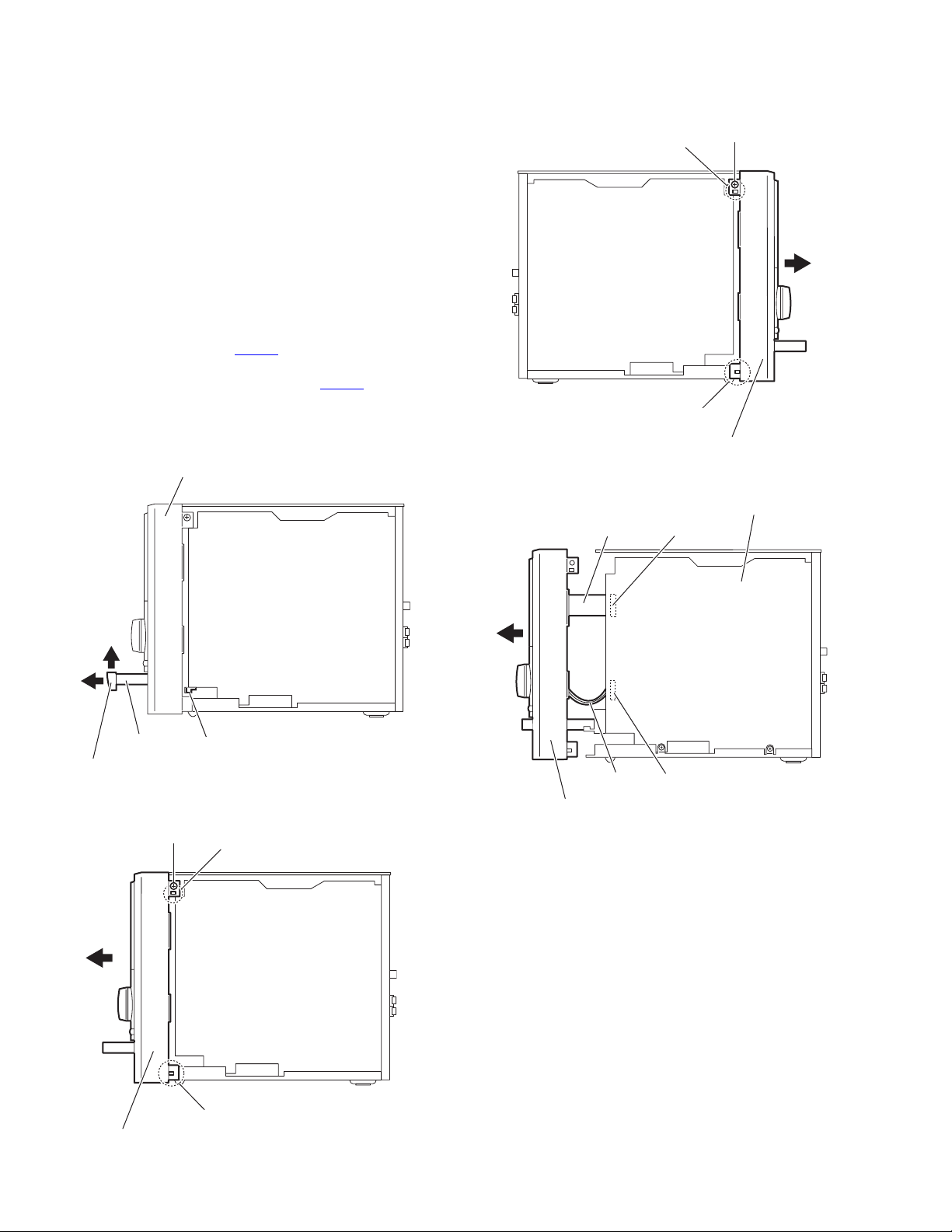

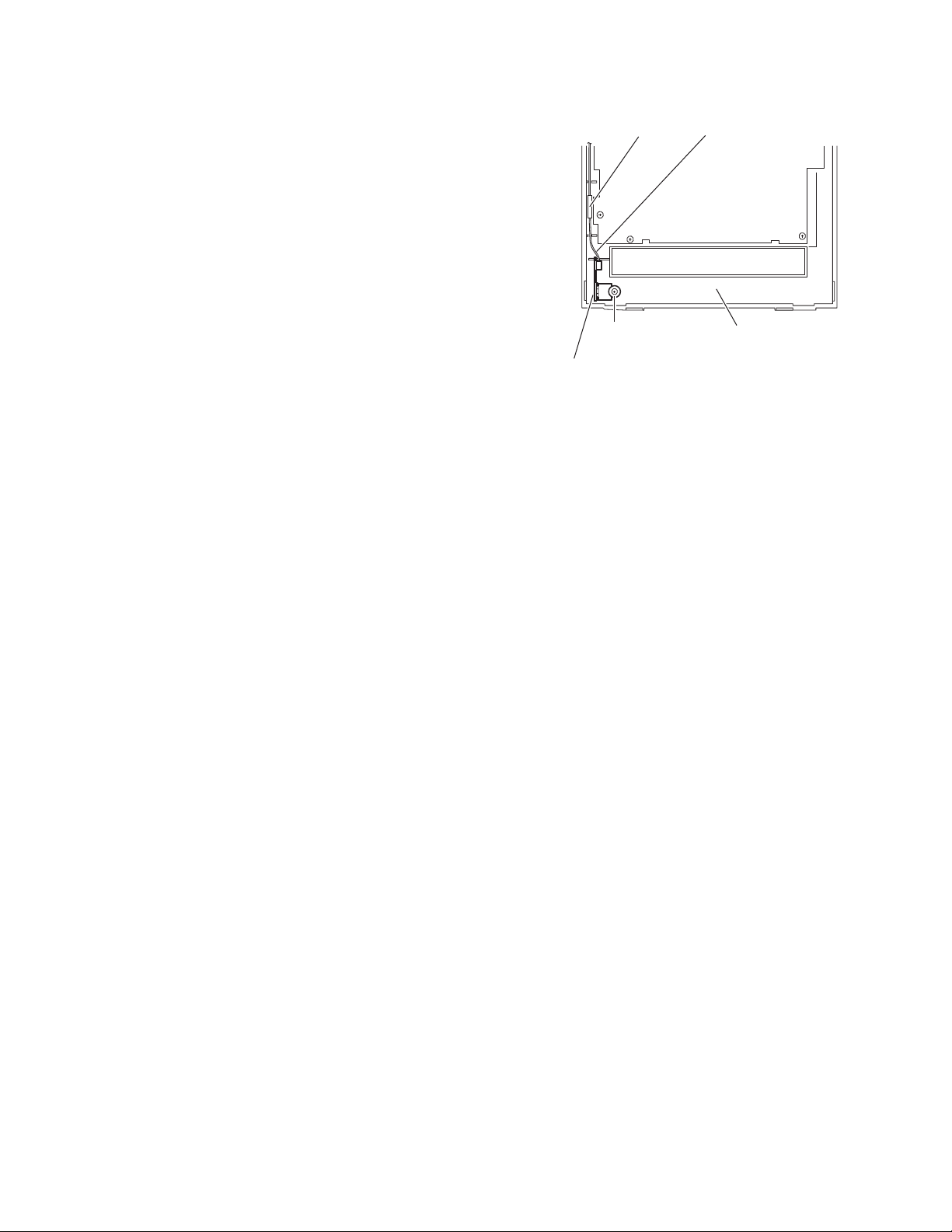

3.1.2 Removing the front panel assembly

(See Figs.5 to 8)

• Prior to performing the following procedures, remove the side

panels L/R.

(1) From the right side of the main body, push the slide cam

and pull the tray out of the main body in the direction of the

arrow 1. (See Fig.5.)

(2) Remove the tray fitting from the tray in the direction of the

arrow 2. (See Fig.5.)

(3) From the both sides of the main body, remove the two

screws C attaching the front panel assembly. (See Figs.6

and 7.)

(4) Release the two claws c and claws d to draw out the front

panel assembly in the direction of the arrow. (See Figs.6

and 7.)

(5) From the right side of the main body, disconnect the card

wire from the connector CN730

Fig.8.)

(6) Disconnect the wire from the connector CN271

board. (See Fig.8.)

(7) Remove the front panel assembly in the direction of the ar-

row. (See Fig.8.)

Front panel assembly

on the main board. (See

on the main

c

Front panel assembly

Fig.7

CN730Card wire

C

d

Main board

2

1

Tray fitting

Tray

Slide cam

C

Fig.5

c

Wire

Front panel assembly

CN271

Fig.8

Front panel assembly

1-8 (No.MB262)

d

Fig.6

Page 9

3.1.3 Removing the top cover assembly

(See Figs.9 and 10)

• Prior to performing the following procedures, remove the side

panels L/R and front panel assembly.

(1) From the back side of the main body, remove the screw D

attaching the top cover assembly to the rear panel. (See

Fig.9.)

(2) From the right side of the main body, disconnect the card

wires from the connectors (CN701

board. (See Fig.10.)

(3) Take out the top cover assembly from the main body.

, CN702) on the main

Top cover assembly

D

Rear panel

Fig.9

Top cover assembly

CN702

Main board

Fig.10

Card wires

CN701

(No.MB262)1-9

Page 10

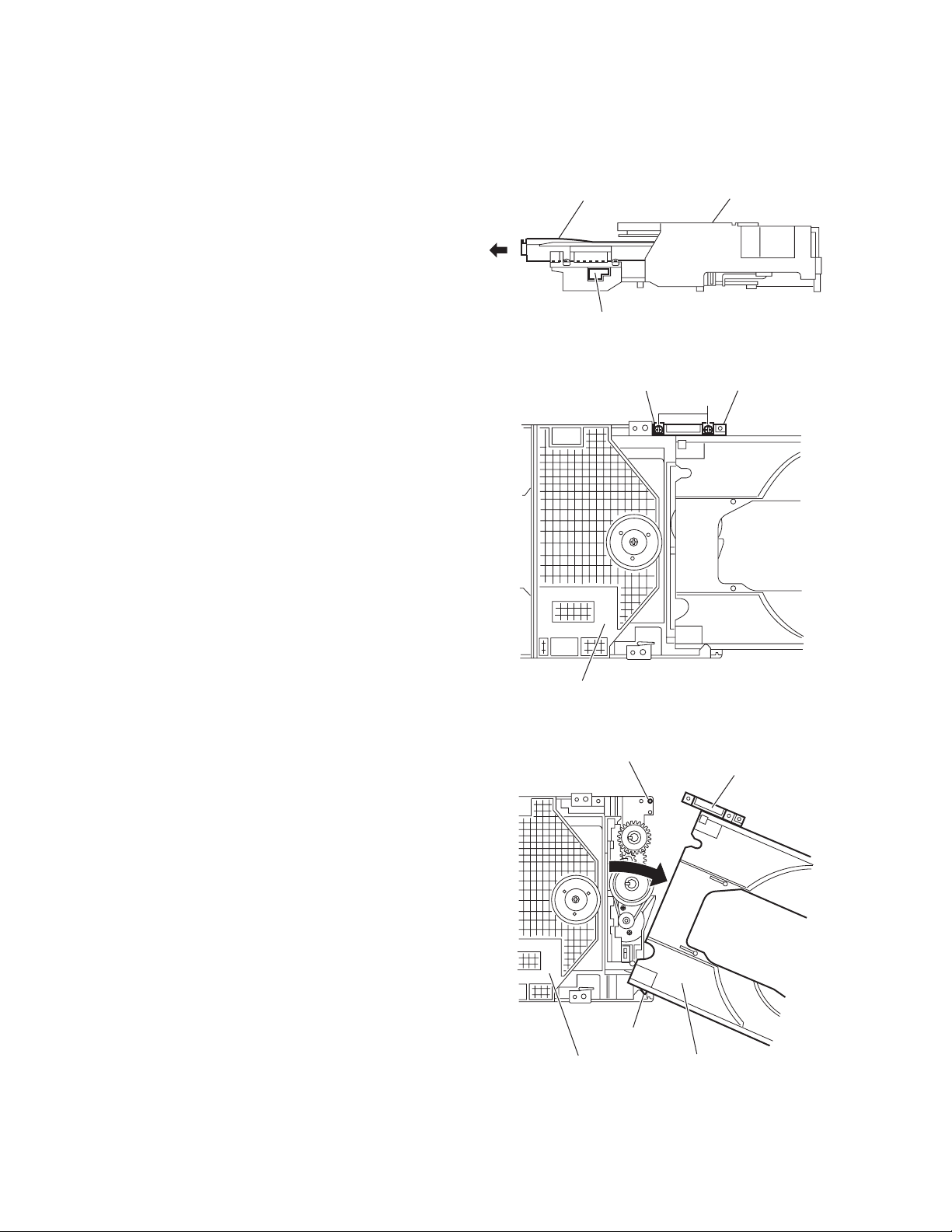

3.1.4 Removing the cassette mechanism assembly

(See Fig.11)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly and top cover assembly.

(1) From the bottom side of the top cover assembly, discon-

nect the card wires from the connectors (CN33

the head amp. & mechanism control board.

(2) Remove the four screws E attaching the cassette mecha-

nism assembly and take out the cassette mechanism assembly from the top cover assembly.

, CN34) on

Top cover assembly

Card wires

E

CN34

Head amp. & mechanism control board

CN33

Cassette mechanism assembly

Fig.11

E

1-10 (No.MB262)

Page 11

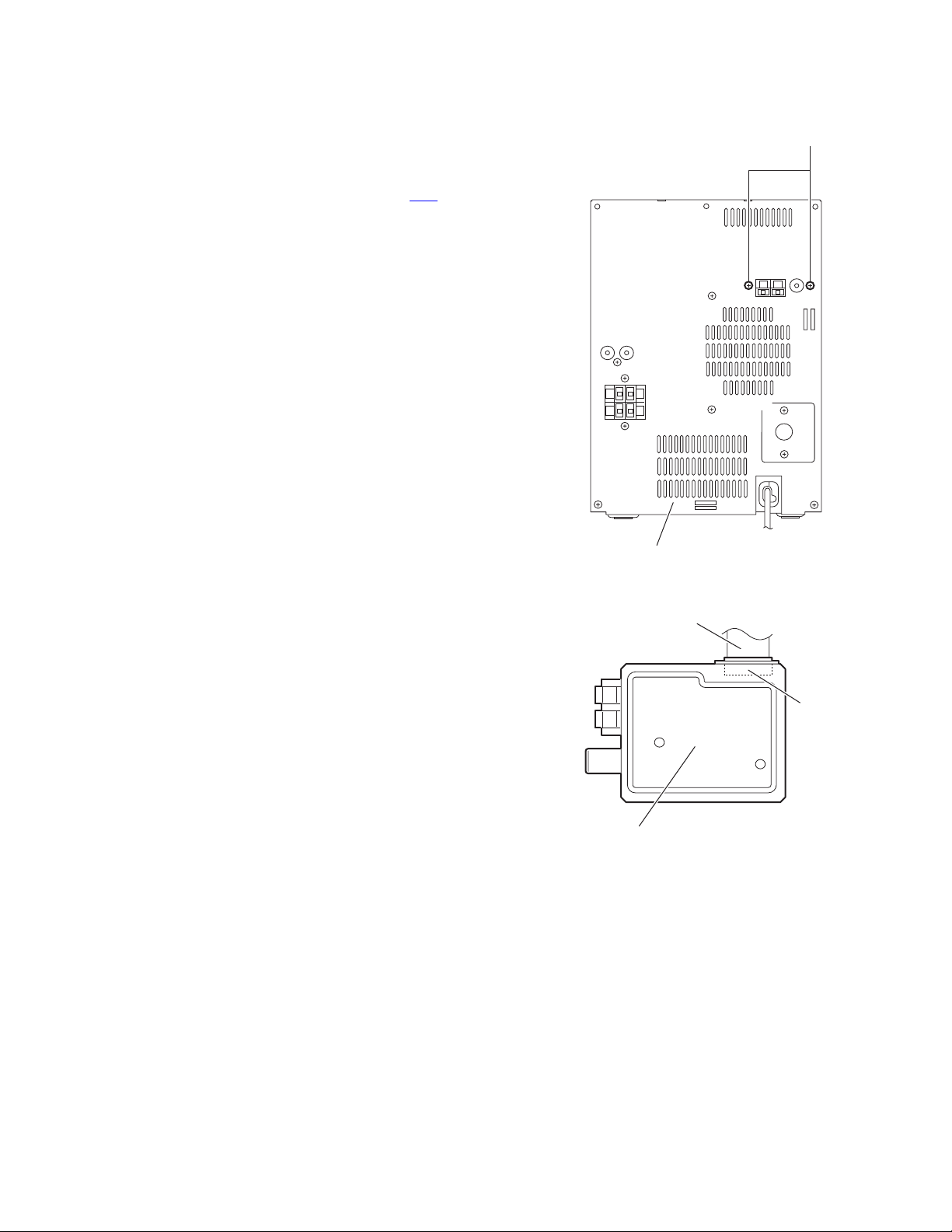

3.1.5 Removing the tuner

(See Figs.12 and 13)

• Prior to performing the following procedures, remove the side

panel L.

(1) From the back side of the main body, remove the two

screws F attaching the tuner to the rear panel. (See

Fig.12.)

(2) Disconnect the card wire from the connector CN1

tuner. (See Fig.13.)

on the

F

Rear panel

Card wire

Tuner

Fig.12

CN1

Fig.13

(No.MB262)1-11

Page 12

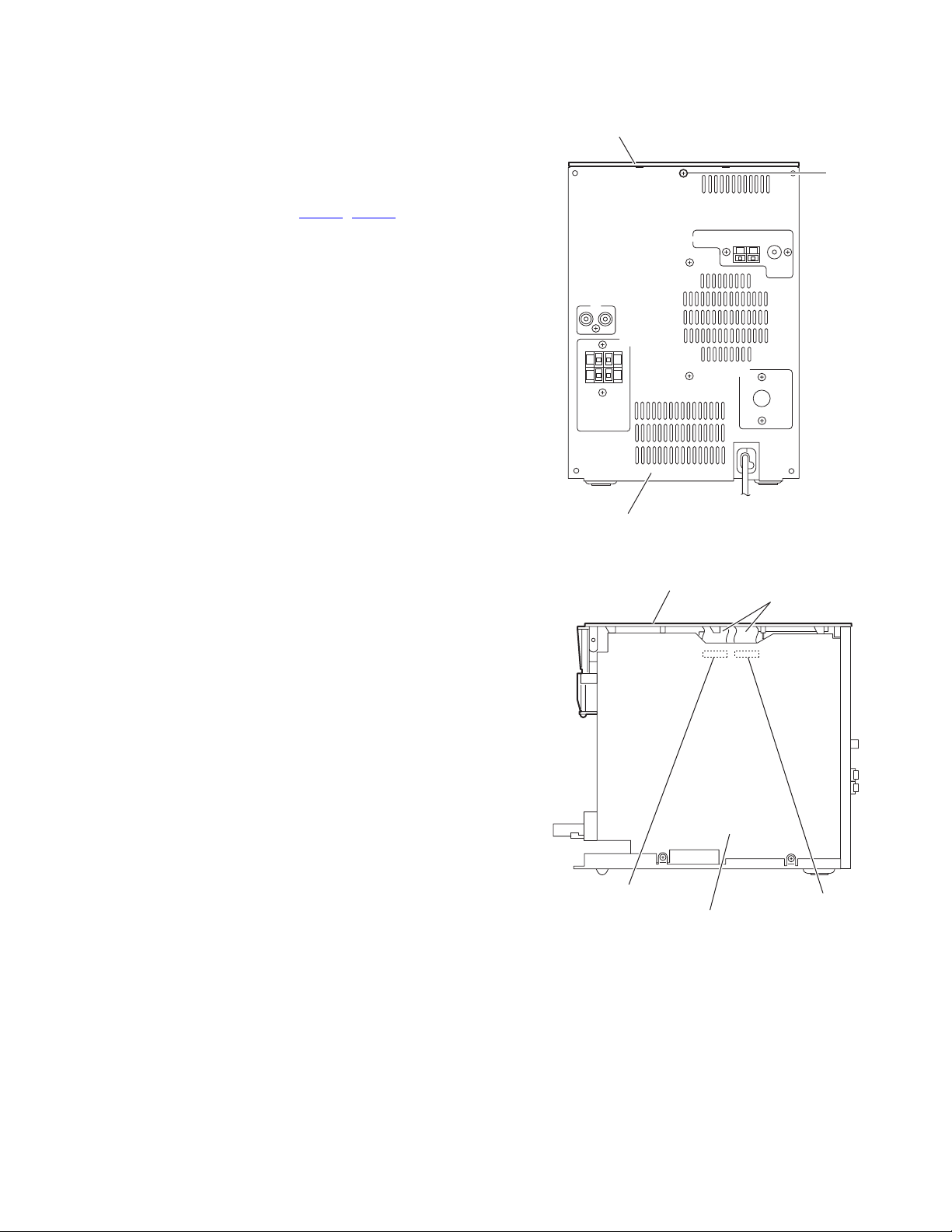

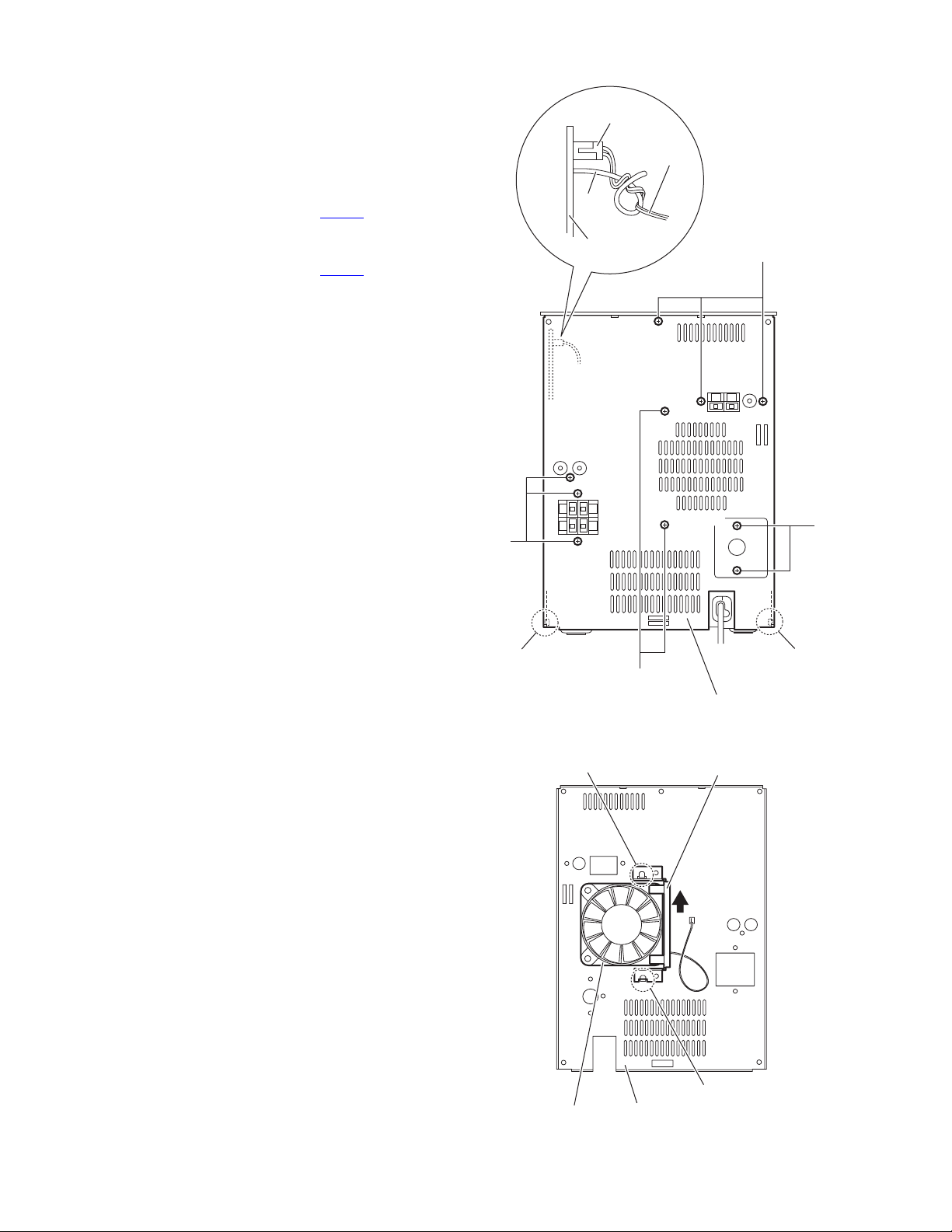

3.1.6 Removing the rear panel

(See Fig.14)

• Prior to performing the following procedures, remove the side

panels L/R.

(1) From the back side of the main body, remove the eight

screws G attaching the rear panel.

(2) Release the engagement sections e and remove the rear

panel.

(3) Disconnect the wire from the connector CN711

board.

Reference:

After connecting the wire to the connector CN711

with the wire holder.

3.1.7 Removing the fan

(See Figs.14 and 15)

• Prior to performing the following procedures, remove the side

panels L/R and rear panel.

(1) From the outside of the rear panel, remove the two screws

H attaching the fan bracket to the rear panel. (See Fig.14.)

(2) From the inside of the rear panel, move the fan bracket in

the direction of the arrow to release the engagement sections (f, g). (See Fig.15.)

(3) Remove the fan bracket from the rear panel and remove

the fan. (See Fig.15.)

on the main

, fix the wire

CN711

Wire

holder

Main board

Wire

G

G

G

e

e

H

Rear panel

Fig.14

f

Fan bracket

1-12 (No.MB262)

Fan

g

Rear panel

Fig.15

Page 13

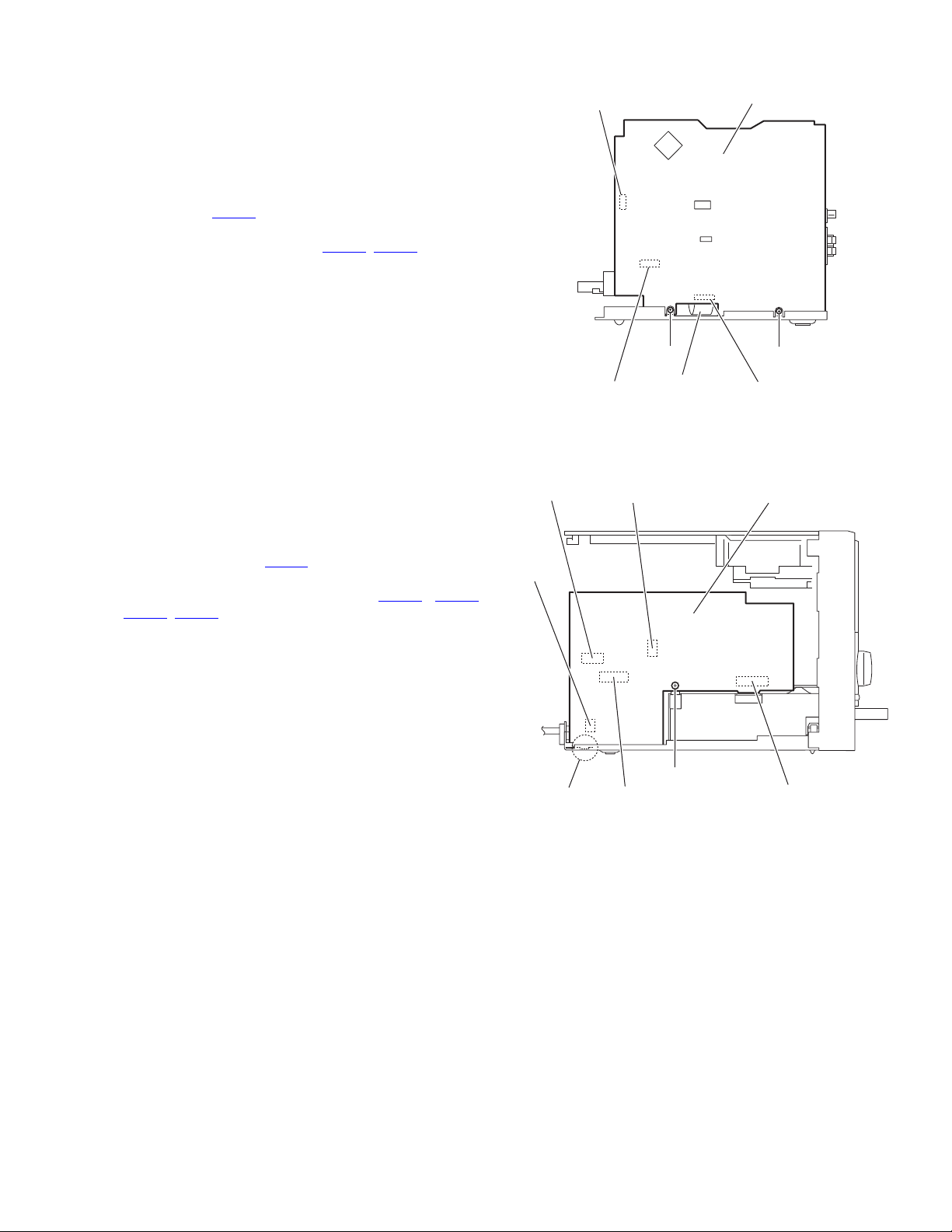

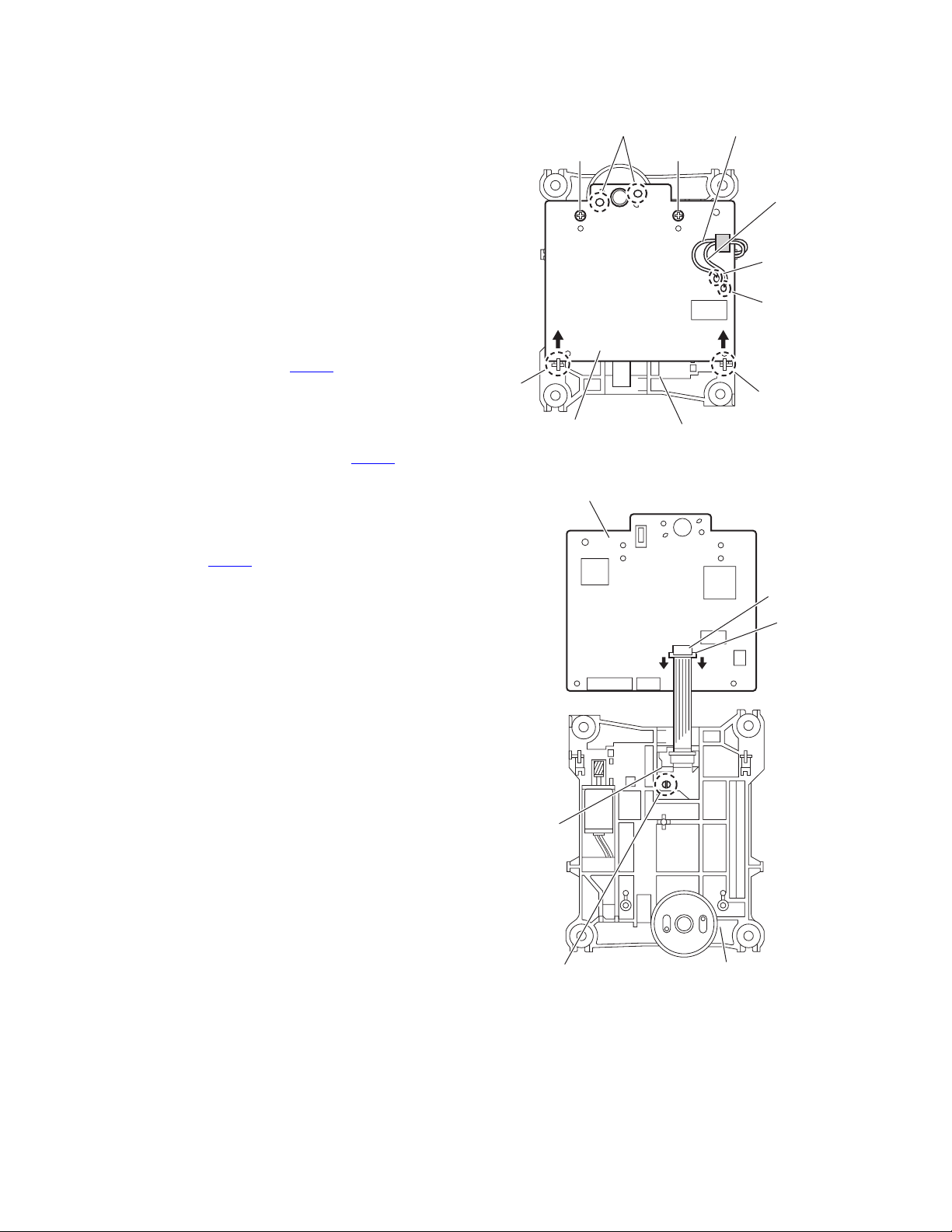

3.1.8 Removing the main board

(See Fig.16)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly, tuner

and rear panel.

(1) From the right side of the main body, remove the two

screws J attaching the main board.

(2) Remove the main board toward this side and disconnect

the connector CN200

(3) From the forward side of the main board, disconnect the

card wires from the connectors (CN210

on the main board.

, CN221).

CN210

Main board

3.1.9 Removing the power supply board

(See Fig.17)

• Prior to performing the following procedures, remove the side

panel L and rear panel.

(1) From the left side of the main body, remove the screw K at-

taching the power supply board.

(2) Remove the power supply board toward this side and dis-

connect the connector CN104

(3) From the forward side of the power supply board, discon-

nect the wires from the connectors (CN101

CN103, CN105).

Reference:

When attaching the power supply board, insert the section h of

the power supply board in the hole of the bottom chassis before attaching the screw K.

on the power supply board.

, CN102,

CN102

CN101

h

CN200

CN103

CN105

J

Card wire

Fig.16

K

J

CN221

Power supply board

CN104

Fig.17

(No.MB262)1-13

Page 14

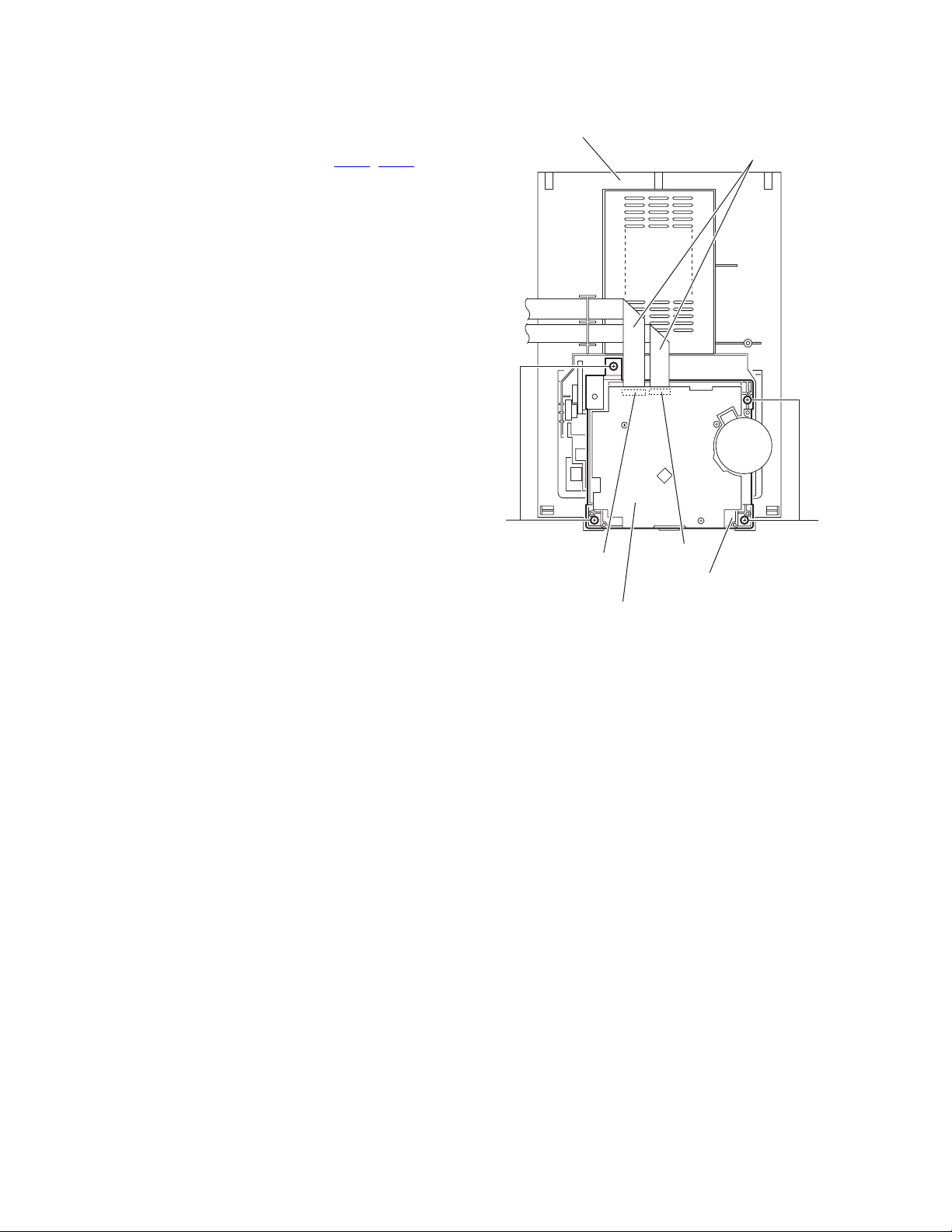

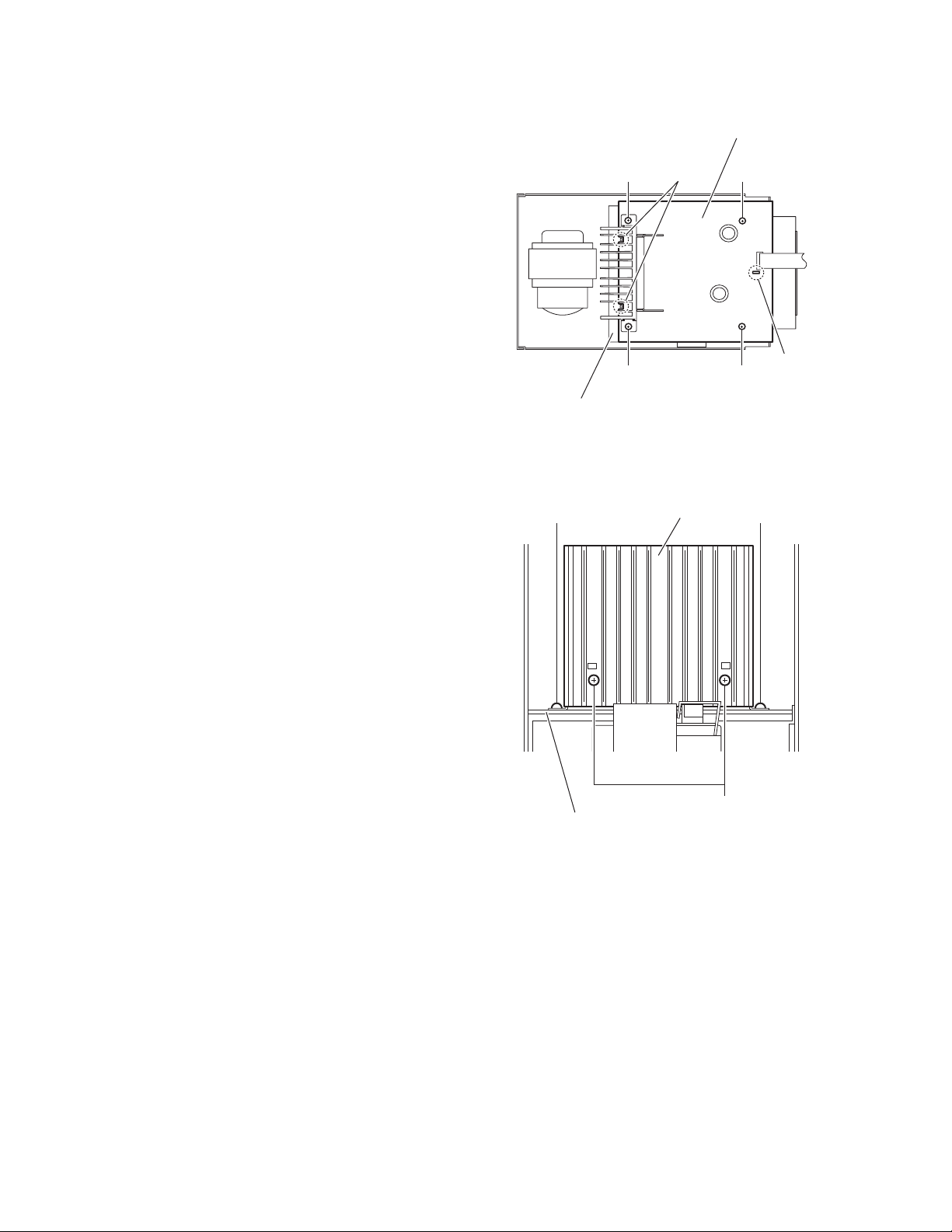

3.1.10 Removing the power amplifier board

(See Fig.18)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly, tuner,

rear panel, main board and power supply board.

(1) From the top side of the main body, remove the four screws

L attaching the power amplifier board.

(2) Lift the power amplifier board and remove it from the en-

gagement sections (i, j) of the shield case.

3.1.11 Removing the heat sink

(See Fig.19.)

• Prior to performing the following procedure, remove the side

panels L/R, front panel assembly, top cover assembly, tuner,

rear panel, main board, power supply board and power amplifier board.

(1) From the side of the power amplifier board, remove the two

screws M attaching the heat sink.

(2) From the side of the power amplifier board, remove the two

screws N attaching the heat sink.

Power amplifier board

L

i

L

LL

Shield case

Fig.18

M M

Heat sink

j

1-14 (No.MB262)

Power amplifier board

Fig.19

N

Page 15

3.1.12 Removing the CD mechanism assembly

(See Figs.20 and 21)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly, tuner,

rear panel, main board and power supply board.

(1) From the top side of the main body, remove the four screws

P attaching the shield case to the bottom chassis. (See

Fig.20.)

Reference:

When attaching the shield case on the bottom chassis,

align the projections (k, m, n) of the bottom chassis in the

holes of the shield case. (See Fig.20.)

(2) Take out the shield case with the power amplifier board

from the bottom chassis.

(3) Remove the three screws Q attaching the CD mechanism

assembly to the bottom chassis. (See Fig.21.)

P

Shield case

k

Bottom chassis

P

m

Power amplifier board

CD mechanism assembly

Bottom chassis

n

P

Fig.20

Q

Q

Fig.21

(No.MB262)1-15

Page 16

3.1.13 Removing the power transformer

(See Figs.22 and 23)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly and rear

panel.

(1) From the forward side of the power supply board, discon-

nect the wires from the connectors (CN102

CN105). (See Fig.22.)

Reference:

Remove the power supply board as required. (See

Fig.17.)

(2) From the top side of the main body, remove the four screws

R attaching the power transformer. (See Fig.23.)

, CN103,

CN102

Power supply board

CN103

CN105

Fig.22

Power transformer

R

R

R

Fig.23

1-16 (No.MB262)

Page 17

3.1.14 Removing the FL board

(See Fig.24)

• Prior to performing the following procedures, remove the side

panels L/R and front panel assembly.

(1) From the inside of the front panel assembly, remove the

four screws S attaching the FL board.

(2) Take out the FL board from the front panel assembly and

disconnect the card wire from the connector CN751

FL board.

Reference:

When attaching the FL board, align the projections p of the

front panel assembly in the holes of the FL board.

on the

CN751

Card

wire

S

FL board

p

S

p

S

S

Front panel assembly

Fig.24

(No.MB262)1-17

Page 18

3.1.15 Removing the switch board

(See Figs.25 and 26)

• Prior to performing the following procedures, remove the side

panels L/R and front panel assembly.

(1) From the front side of the front panel assembly, pull out the

mic volume knob. (See Fig.25.)

(2) From the inside of the front panel assembly, remove the

ten screws T attaching the switch board. (See Fig.26.)

(3) Take out the switch board from the front panel assembly

and disconnect the card wire from the connector CN760

the switch board. (See Fig.26.)

Reference:

When attaching the switch board, align the projections q of the

front panel assembly in the holes of the switch board. (See

Fig.26.)

on

Front panel assembly

Mic volume knob

Fig.25

Card wire

T

Switch board

CN760

q

T

q

T

Fig.26

1-18 (No.MB262)

Page 19

3.1.16 Removing the headphone jack board

(See Fig.27)

• Prior to performing the following procedure, remove the side

panels L/R and front panel assembly.

(1) From the inside of the front panel assembly, remove the

screw U attaching the headphone jack board.

Reference:

After attaching the headphone jack board, fix the wire with the

spacer.

Spacer

Wire

U

Headphone jack board

Fig.27

Front panel assembly

(No.MB262)1-19

Page 20

3.2 CD mechanism section

• Remove the CD mechanism assembly from the main body.

(See "3.1.12 Removing the CD mechanism assembly".)

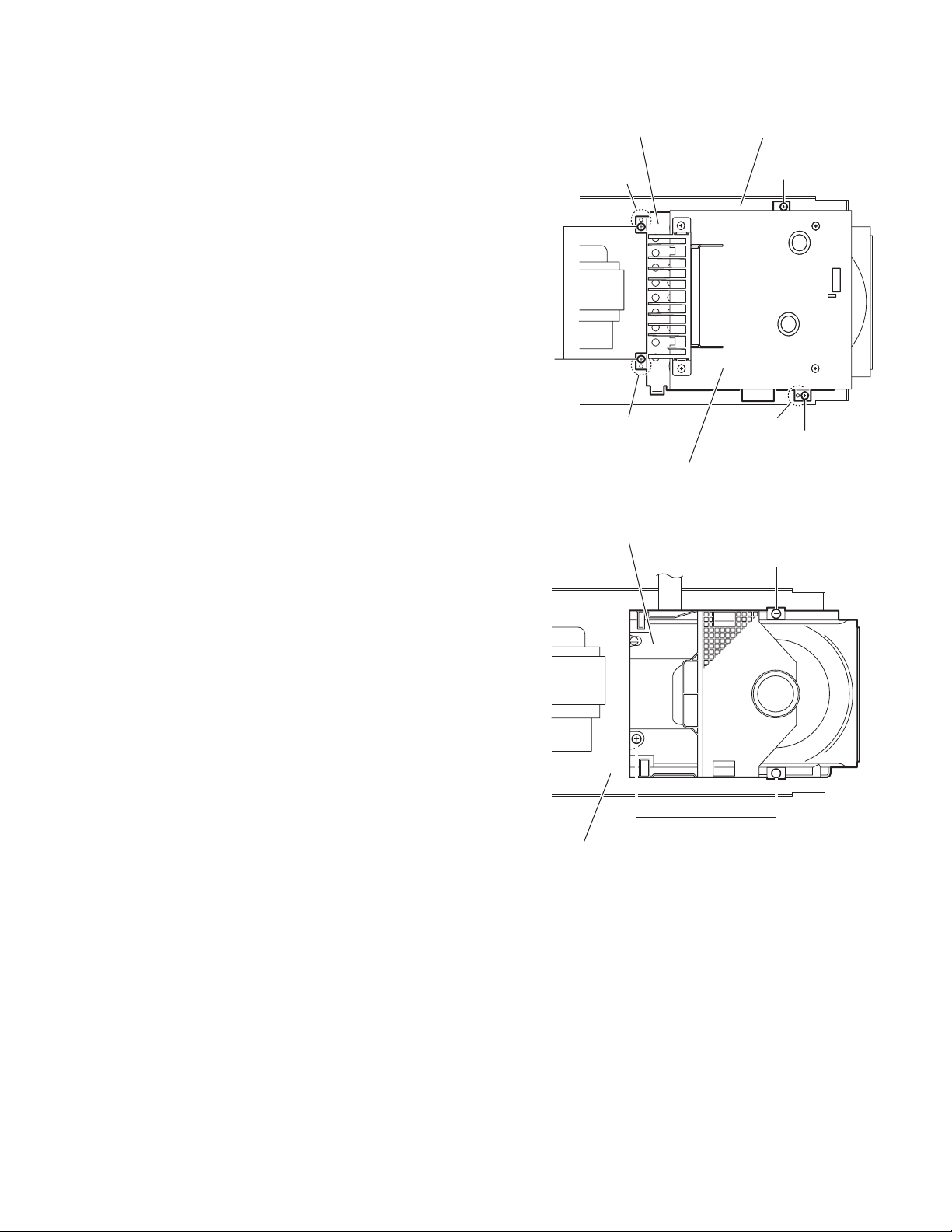

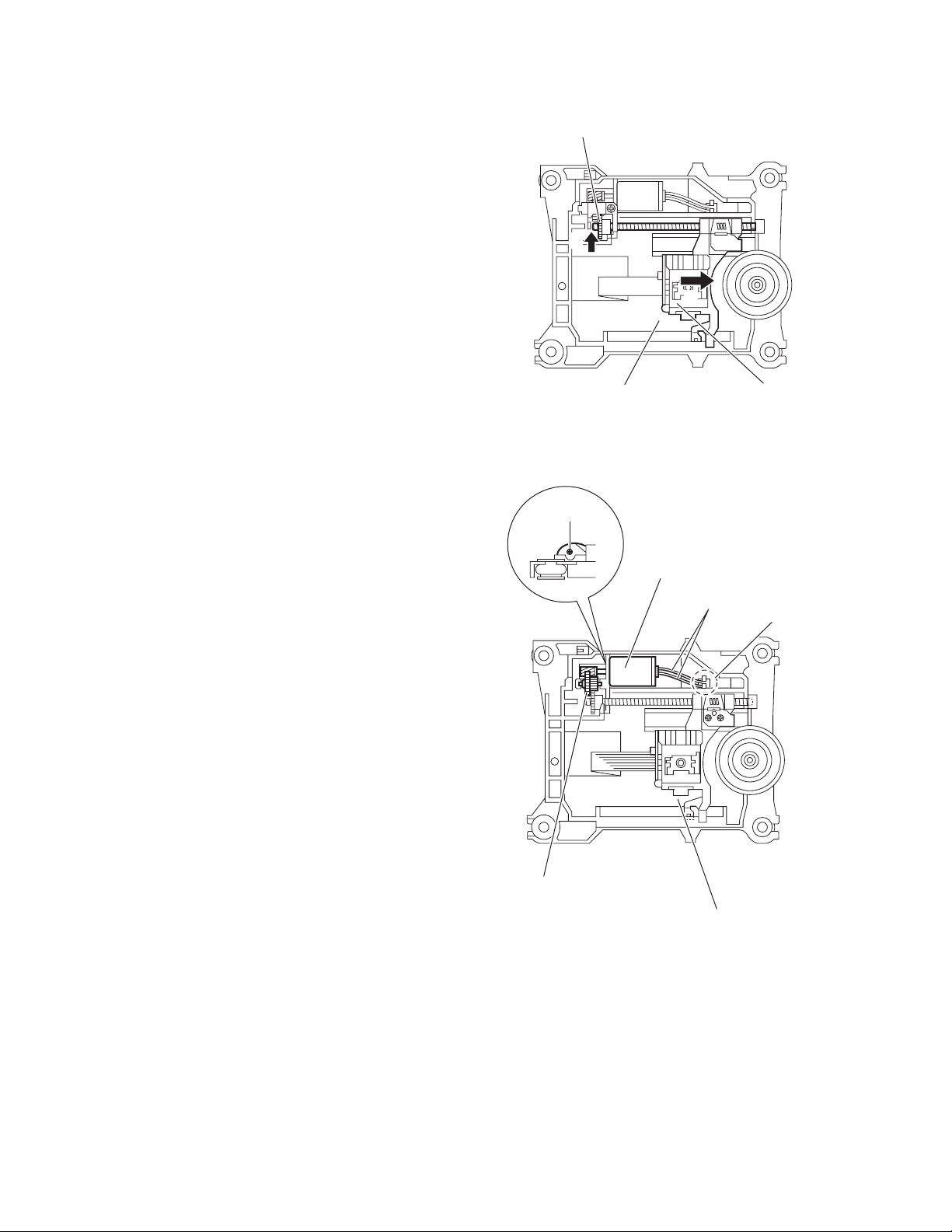

3.2.1 Removing the tray assembly

(See Figs.1 to 3)

(1) From the right side of the CD mechanism assembly, push

the slide cam and pull the tray assembly out of the CD

mechanism assembly in the direction of the arrow. (See

Fig.1)

(2) From the top side of the CD mechanism assembly, remove

the two screws A attaching the leaf spring to the bushing

and remove the leaf spring. (See Fig.2)

(3) Remove the bushing of the tray assembly from the projec-

tion a on the CD mechanism assembly and move the tray

assembly in the direction of the arrow. (See Fig.3)

(4) Remove the claw b of the tray assembly from the CD

mechanism assembly and take out the tray assembly. (See

Fig.3)

Tray assembly CD mechanism assembly

Slide cam

Fig.1

Leaf spring

Bushing

A

3.2.2 Removing the traverse mechanism assembly

(See Figs.4)

(1) From the bottom side of the CD mechanism assembly, re-

move the four screws B attaching the traverse mechanism

1-20 (No.MB262)

CD mechanism assembly

Projection a

Claw b

CD mechanism assembly

assembly.

Fig.2

Bushing

Tray assembly

Fig.3

Page 21

(2) Disconnect the card wire from the connector CN602

CD servo board and take out the CD traverse mechanism

assembly with the CD servo board.

on the

CD mechanism assembly

CD servo board

B

Traverse mechanism assembly

Fig.4

B

CN602

(No.MB262)1-21

Page 22

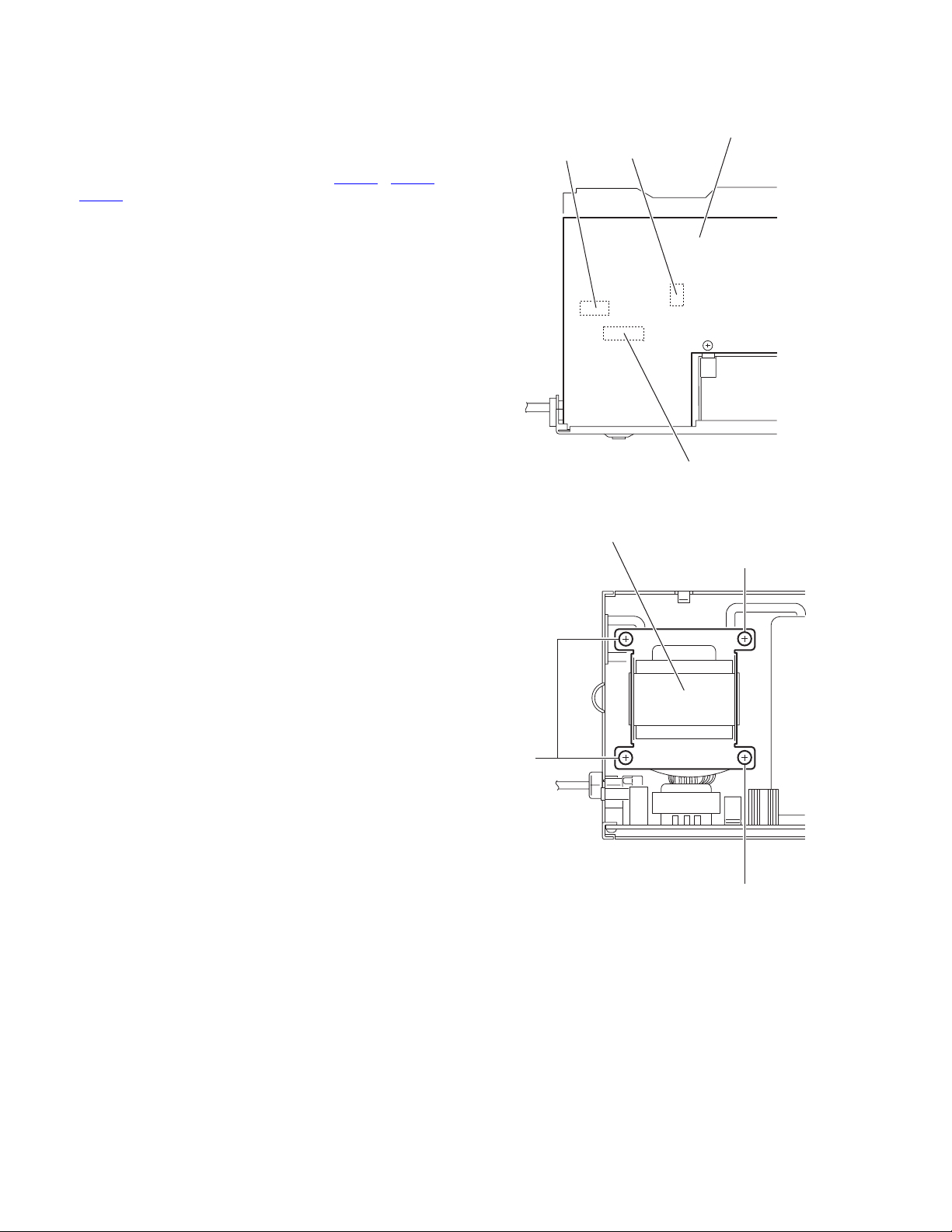

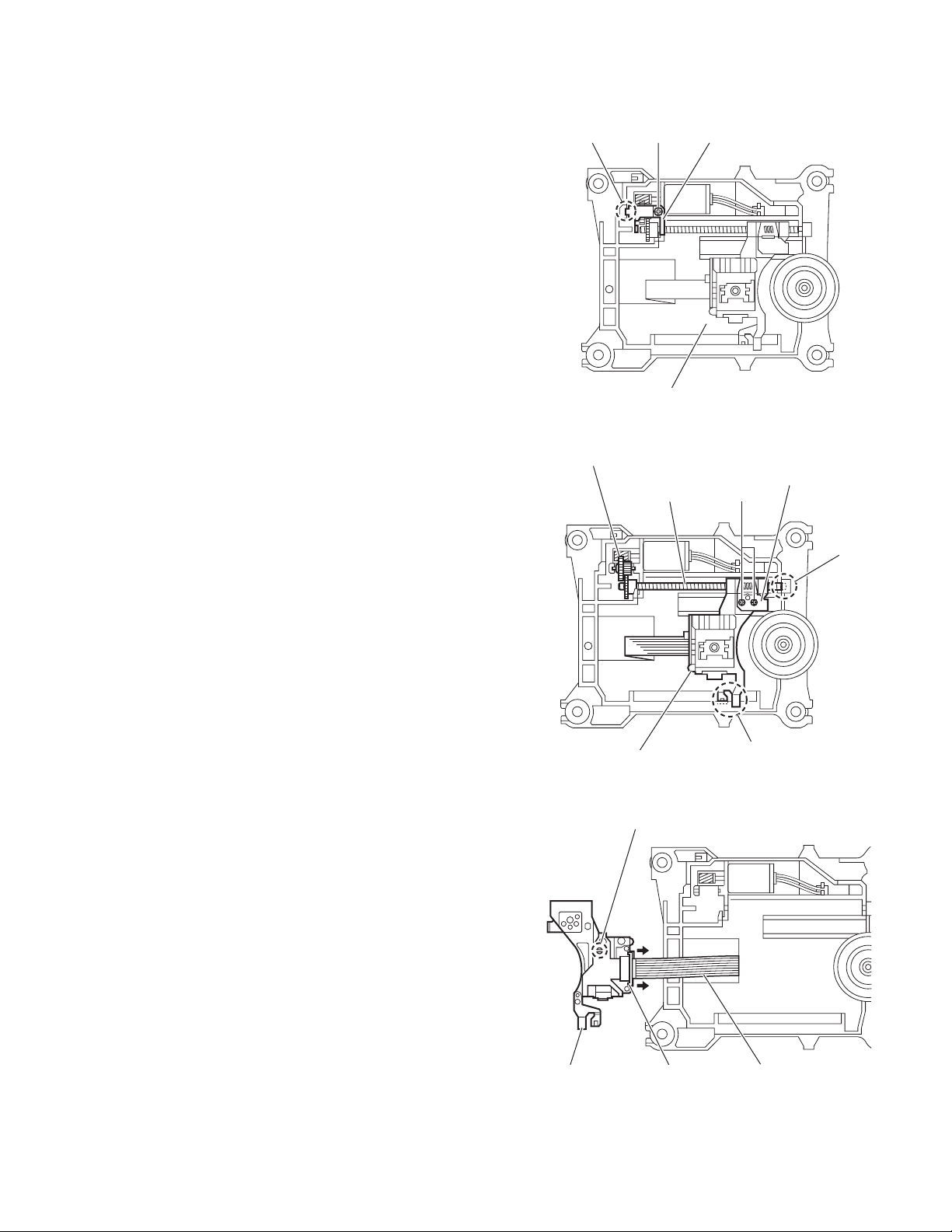

3.2.3 Removing the CD servo board

(See Figs.5 and 6)

• Remove the traverse mechanism assembly.

(1) From the bottom side of the traverse mechanism assem-

bly, remove the solders from the solder sections c. (See

Fig.5)

(2) Remove the wire (yellow) from the solder sections d. (See

Fig.5)

(3) Remove the wire (white) from the solder sections e. (See

Fig.5)

(4) Remove the two screws C attaching the CD servo board.

(See Fig.5)

(5) Remove the CD servo board from the claws f in the direc-

tion of the arrow and turn the CD servo board over. (See

Fig.5)

(6) Solder the short land sections g on the CD pickup. (See

Fig.6)

(7) Release the lock of the connector CN601

board in the direction of the arrow and disconnect the card

wire. (See Fig.6)

Caution:

• Solder the short land sections g on the CD pickup before disconnecting the card wire from the connector CN601

CD servo board. If the card wire is disconnected without attaching solder, the CD pickup may be destroyed by static

electricity. (See Fig.6)

• When attaching the CD servo board, be sure to remove solders from the short land sections g after connecting the card

wire to the connector CN601

Fig.6)

on the CD servo board. (See

on the CD servo

on the

Claw f

Solder section c

CD servo board

Wire (yellow)

CC

Wire (white)

Solder

section d

Solder

section e

Claw f

Traverse mechanism assemblyCD servo board

Fig.5

CN601

CD pickup

Short land section g

Lock

Traverse mechanism assembly

Fig.6

1-22 (No.MB262)

Page 23

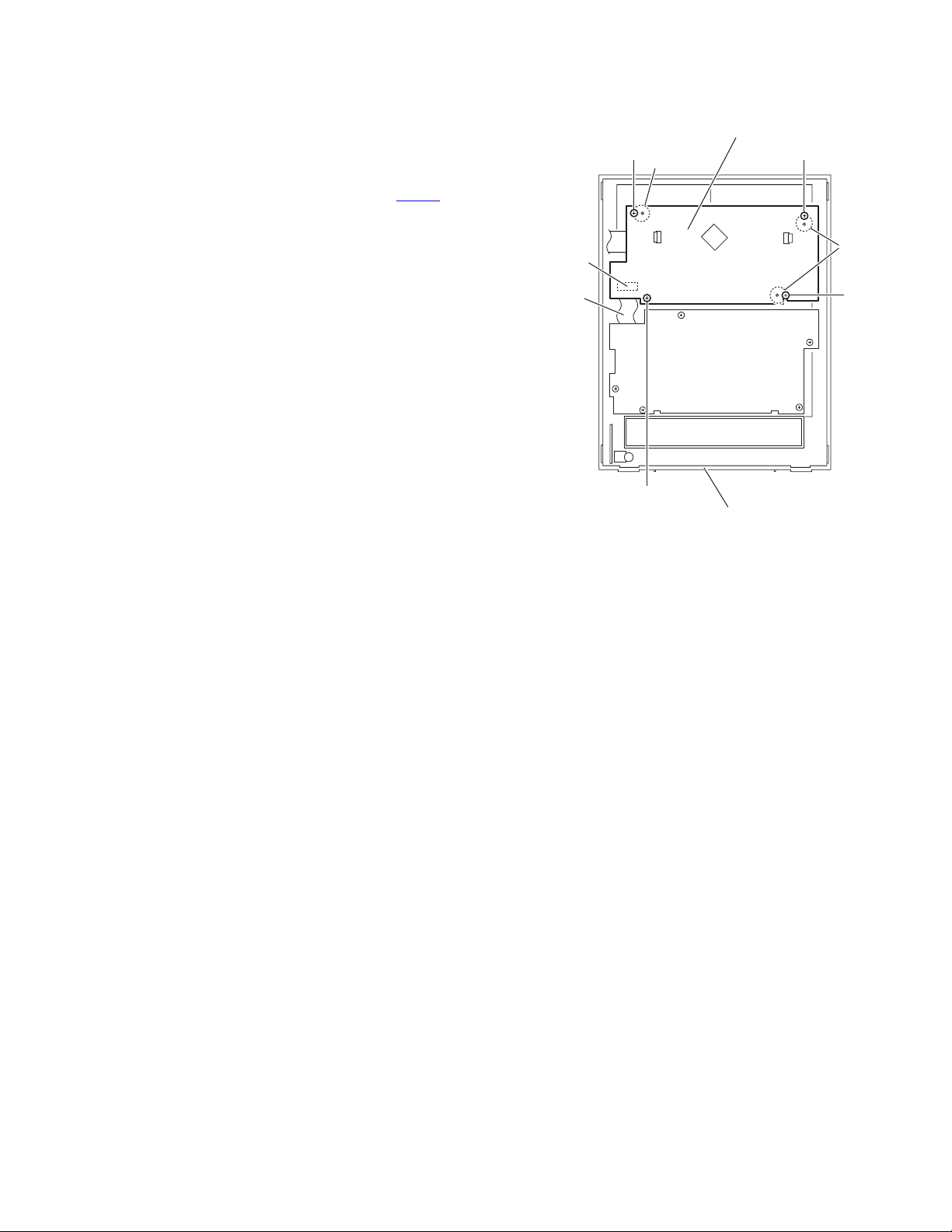

3.2.4 Removing the CD pickup

(See Figs.7 to 9)

• Remove the traverse mechanism assembly.

(1) From the top side of the traverse mechanism assembly, re-

move the screw D attaching the shaft holder. (See Fig.7)

(2) Release the joint h and take out the shaft holder. (See

Fig.7)

(3) Remove the two screws E attaching the rack arm and take

out the rack arm. (See Fig.8)

(4) Remove the feed middle gear and remove the screw shaft

of the CD pickup from the section i on the traverse mechanism assembly. (See Fig.8)

(5) Remove the CD pickup from the section j of the traverse

mechanism assembly and take out the CD pickup with the

screw shaft. (See fig.8)

(6) Pull the screw shaft out of the CD pickup. (See Fig.8)

(7) From the bottom side of the CD pickup, solder the short

land sections k on the CD pickup. (See Fig.9)

(8) Release the lock of the connector on the CD pickup in the

direction of the arrow and disconnect the card wire. (See

Fig.9)

Caution:

• Solder the short land sections k on the CD pickup before dis-

connecting the card wire from the connector on the CD pickup. If the card wire is disconnected without attaching solder,

the CD pickup may be destroyed by static electricity. (See

Fig.9)

• When attaching the CD pickup, be sure to remove solders

from the short land sections k after connecting the card wire

to the connector on the CD pickup. (See Fig.9)

Traverse mechanism assembly

Feed middle gear

Screw shaft

DJoint h

Shaft holder

Fig.7

Rack arm

E

Section i

CD pickup

Short land section k

CD pickup Connector Card wire

Section j

Fig.8

Fig.9

(No.MB262)1-23

Page 24

3.2.5 Attaching the CD pickup

(See Figs.7 to 10)

• See "3.2.4 Removing the CD pickup".

(1) Remove solders from the short land sections k after con-

necting the card wire to the connector on the CD pickup.

(See Fig.9)

(2) Attach the shaft. (See Fig.8)

(3) Align the CD pickup to the section j of the traverse mecha-

nism assembly first, and set the screw shaft of the CD pick-

up in the sections i of the traverse mechanism assembly.

(See Fig.8.)

(4) Attach the rack arm and feed middle gear. (See Fig.8)

(5) Attach the shaft holder. (See Fig.7)

(6) Turn the SS gear in the direction of the arrow 1 to move the

CD pickup in the direction of the arrow 2. (See Fig.10)

SS gear

1

2

3.2.6 Removing the feed motor

(See Figs.5, 7 and 11)

• Remove the traverse mechanism assembly.

(1) From the top side of the traverse mechanism assembly, re-

move the wire (yellow) from the solder sections d on the

CD servo board. (See Fig.5)

(2) Remove the wire (white) from the solder sections e on the

CD servo board. (See Fig.5)

(3) Remove the screw D attaching the shaft holder and take

out the shaft holder. (See Fig.7)

(4) Remove the feed middle gear and remove the screw E at-

taching the feed motor. (See Fig.11)

(5) Take out the feed motor from the traverse mechanism as-

sembly.

Reference:

When attaching the feed motor, pass the wires through the

section m on the traverse mechanism assembly. (See Fig.11)

Traverse mechanism assembly

Fig.10

E

Feed motor

Wires

Pickup

Section m

1-24 (No.MB262)

Feed middle gear

Traverse mechanism assembly

Fig.11

Page 25

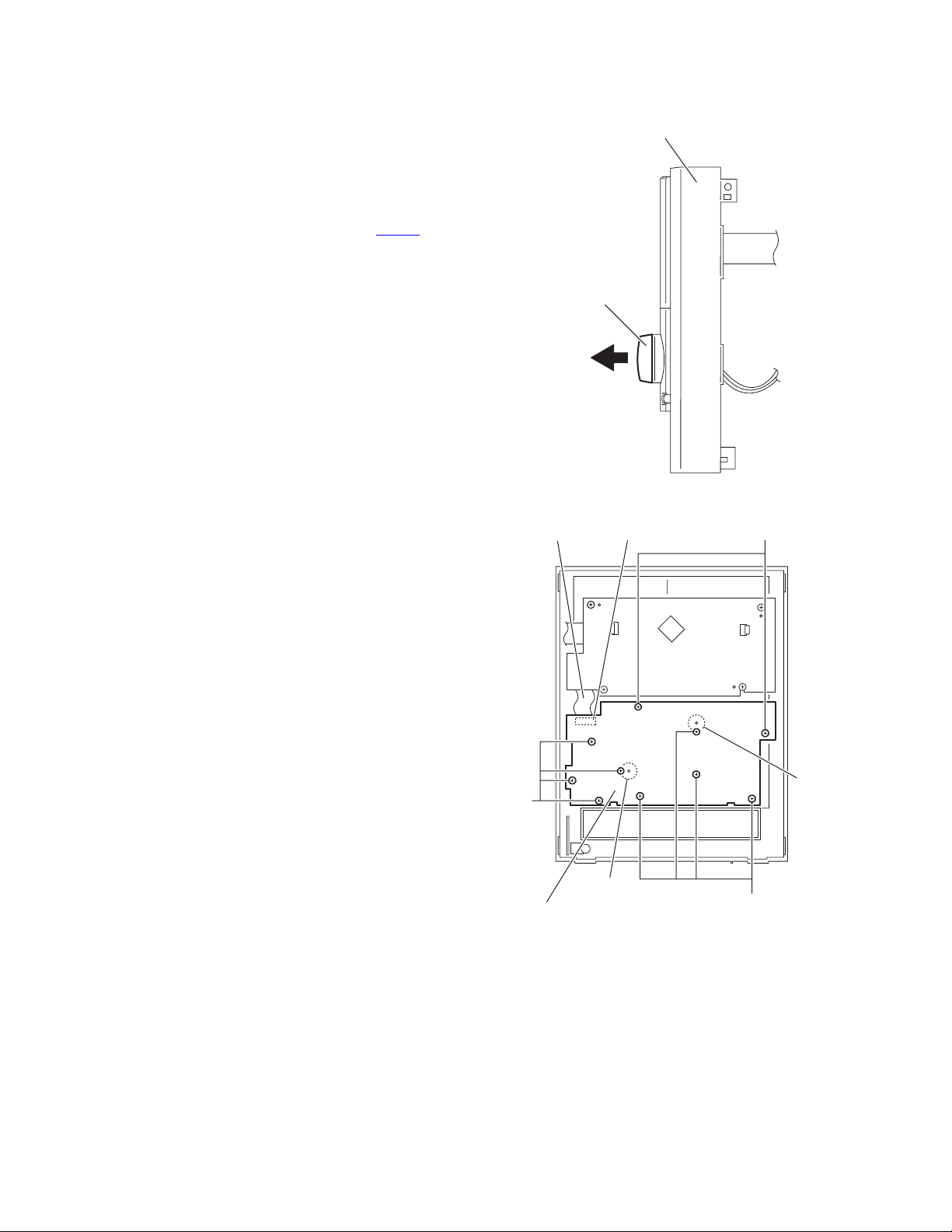

3.2.7 Removing the CD loading switch board

(See Fig.12)

(1) From the bottom side of the CD mechanism assembly, dis-

connect the card wire from the connector CN1

loading switch board.

(2) Remove the wires from the solder section n on the CD

loading switch board.

(3) Lift the CD loading switch board while pressing the claw p

of the CD mechanism assembly in the direction of the arrow and remove it from the section q.

Reference:

• Put the wires on the section r after attaching the CD loading

switch board to the CD mechanism assembly.

• Fix the claw p on the CD mechanism assembly with bonds

after attaching the CD loading switch board.

3.2.8 Removing the motor

(See Figs.12 and 13)

• Remove the tray assembly.

(1) From the bottom side of the CD mechanism assembly, re-

move the wires from the solder section n on the CD loading

switch board. (See Fig.12)

(2) From the top side of the CD mechanism assembly, remove

the belt from the motor pulley. (See Fig.13)

Note:

Take care not to attach grease on the belt.

(3) Remove the two screws F attaching the motor to the CD

mechanism assembly and take out the motor from the bottom side of the CD mechanism assembly. (See Fig.13)

Reference:

Put the wires on the section r after attaching the motor to the

CD mechanism assembly. (See Fig.12)

on the CD

CD loading switch board

Wire

Solder

section n

CN1

section q section r

CD mechanism assembly

F

Claw p

CD mechanism assembly

Fig.12

Belt

Fig.13

Motor pulley

(No.MB262)1-25

Page 26

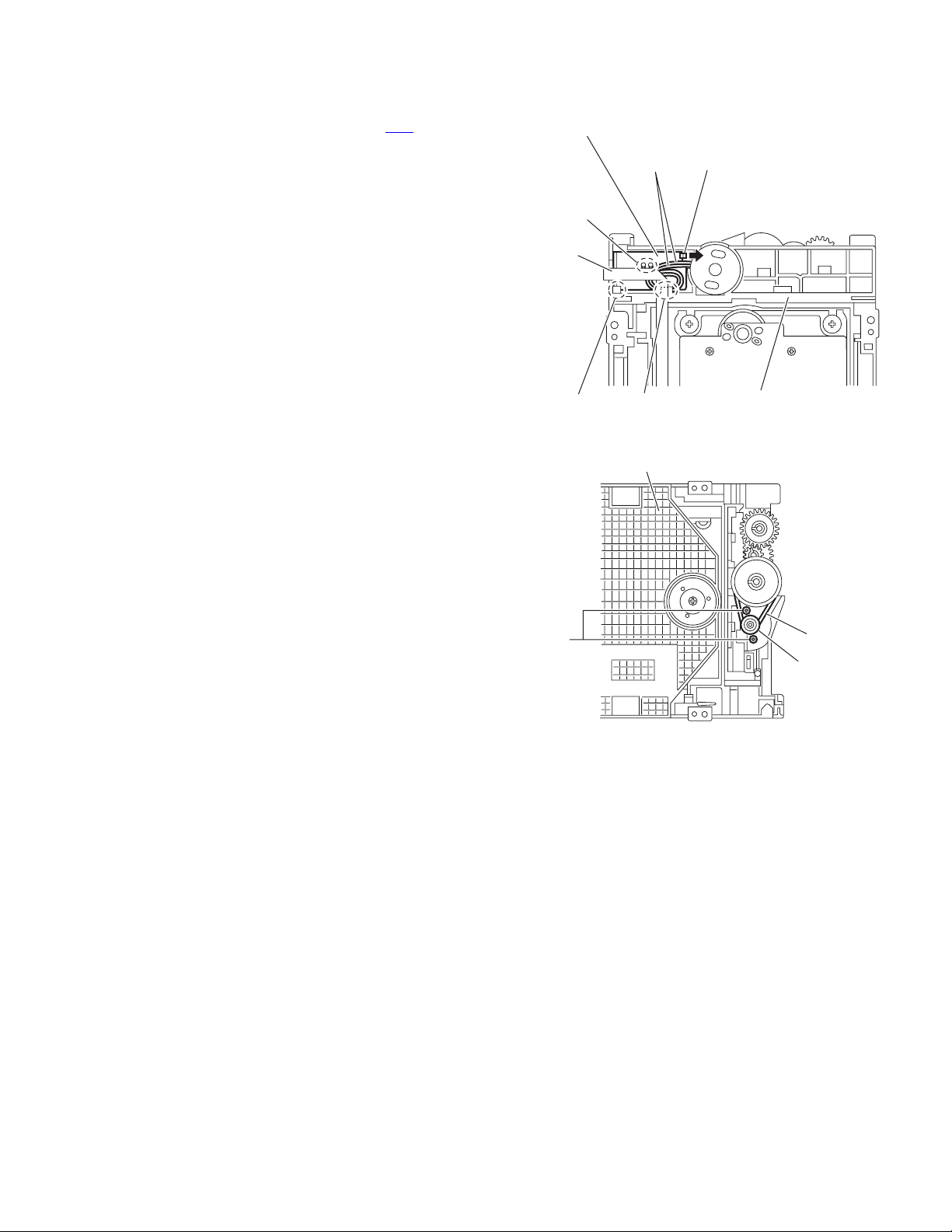

3.3 Cassette mechanism assembly

3.3.1 Removing the Play/Record & Clear head

(See Fig.1~3)

(1) While moving the trigger arm on the right side of the head

mount in the direction of the arrow, turn the flywheel R

counterclockwise until the head mount comes ahead and

clicks.

(2) The head turns counterclockwise as you turn the flywheel

R counterclockwise (See Fig.2 and 3).

(3) Disconnect the flexible wire from connector CN31

head amplifier & mechanism control board.

(4) Remove the spring from the back of the head.

(5) Loosen the azimuth screw for reversing attaching the head.

(6) Remove the head on the front side of the head mount.

on the

Cassette mechanism assembly

Fig.1

Head

Fly wheelR

Trigger armHead mount

Flexible wire

Fly wheel R

Fig.2

Azimuth screw

Head

for reversing

Spring

CN31

Head amplifer & mecha control board

Fig.3

1-26 (No.MB262)

Page 27

3.3.2 Removing the head amplifier & mechanism control board

(See Fig.4)

(1) Turn over the cassette mechanism assembly and remove

the three screws A attaching the head amplifier & mechanism control board.

(2) Disconnect the flexible wire from connector CN31

head amplifier & mechanism control board.

(3) Disconnect connector CN32

anism control board from connector CN1

board.REFERENCE: If necessary, unsolder the 4-pin wire

soldered to the main motor.

3.3.3 Removing the main motor

(See Fig.4~7)

(1) Remove the two screws B .

(2) Half raise the motor and remove the capstan belt from the

motor pulley.

ATTENTION:

Be careful to keep the capstan belt from grease. When reassembling, refer to Fig.6 and 7 for attaching the capstan belt.

Head amplifier & mecha control board

of the head amplifier & mech-

on the reel pulse

on the

Main motor assembly

Capstan belt

Fig.5

Main motor assembly

CN31

Flexible wire

A

AA

Fig.4

CN32

4pin wire

B

Main motor assembly

Motor pulley

Capstan belt

Fig.6

Main motor assembly

Fly wheel

Capstan belt

Motor pulley

Fig.7

(No.MB262)1-27

Page 28

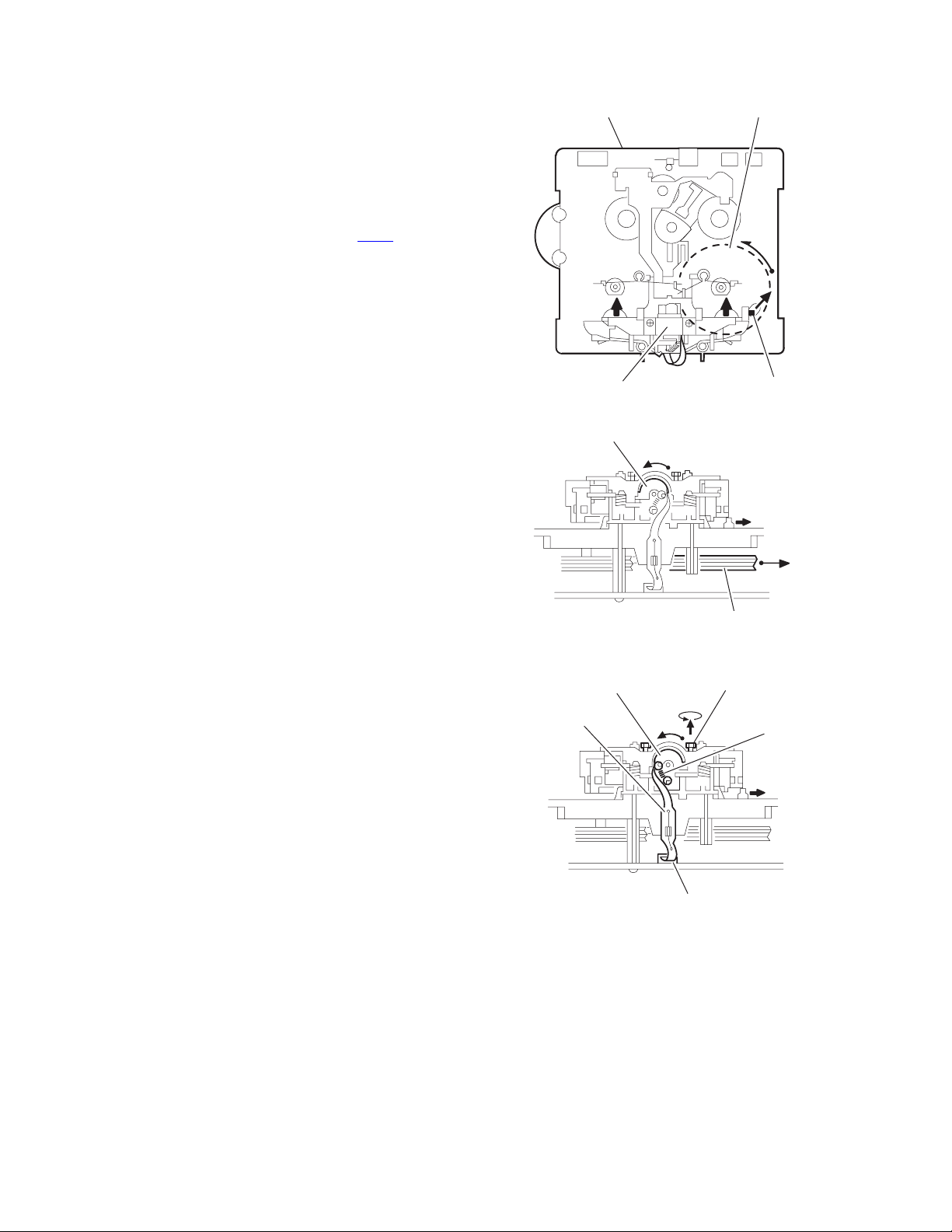

3.3.4 Removing the flywheel

(See Fig.8, 9)

• Prior to performing the following procedure, remove the head

amplifier & mechanism control board and the main motor assembly.

(1) From the front side of the cassette mechanism, remove the

slit washers attaching the capstan shaft L and R. Pull out

the flywheels backward.

Fly wheel R Fly wheel L

Fig.8

Fly wheel R

Capstan shaft R Capstan shaft L

Slit washer

Fig.9

3.3.5 Removing the reel pulse board and solenoid

(See Fig.10)

• Prior to performing the following procedure, remove the head amplifier & mechanism control board.

(1) Remove the screw C.

(2) Release the tab a, b, c, d and e retaining the reel pulse board.

(3) Release the tab f and g attaching the solenoid on the reel pulse board.

(4) The reel pulse board and the solenoid come off.

Fly wheel L

bc

a

Solenoid

g

f

d

Reel pulse board

C

e

Fig.10

1-28 (No.MB262)

Page 29

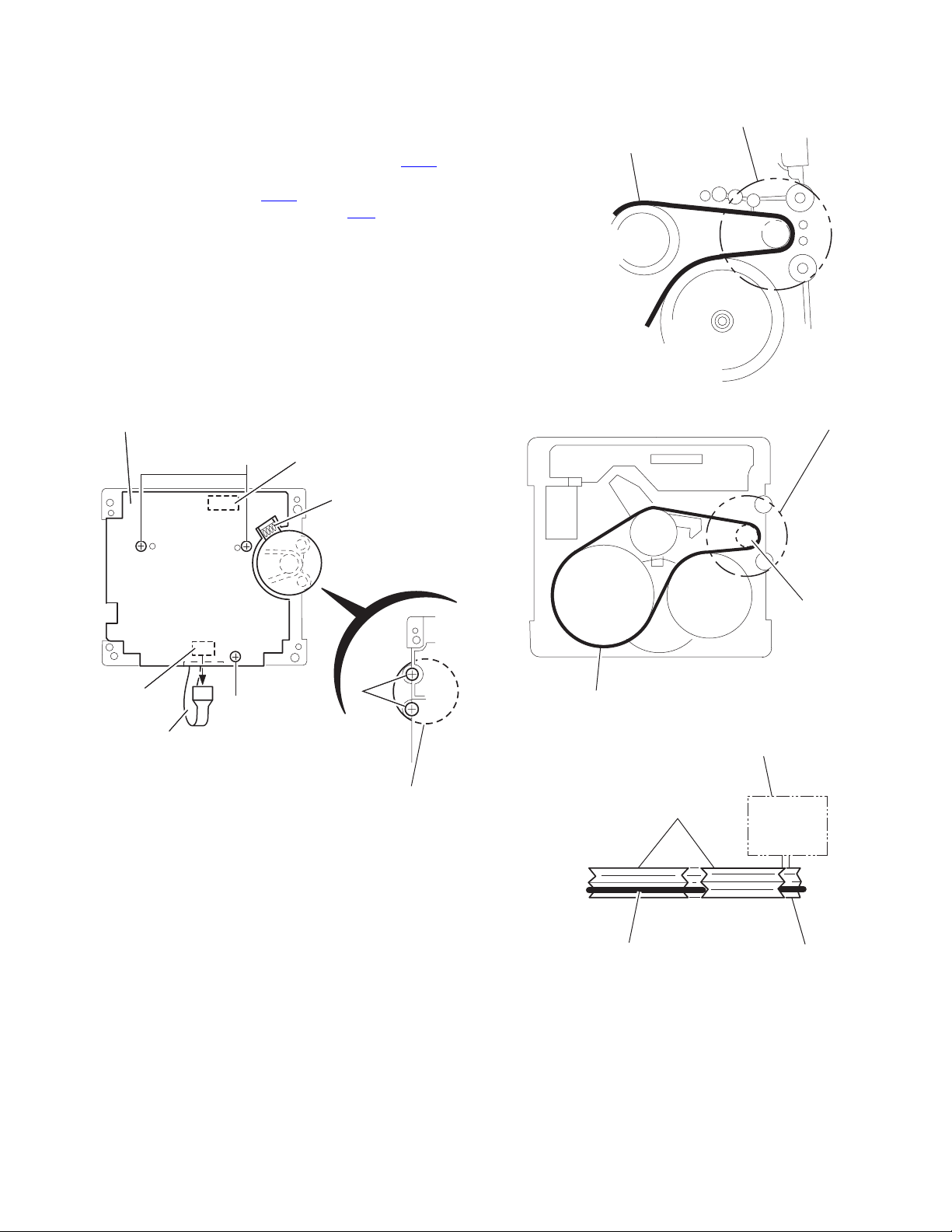

3.3.6 Reattaching the Play/ Record & Clear head

r

r

(See Fig.11~13)

(1) Reattaching the head mount assembly.

a) Change front of the direction cover of the head

mount assembly to the left (Turn the head forward).

b) Fit the bosses O', P', Q', U' and V' on the head mount

assembly to the holes P and V, the slots O, U and Q

of the mechanism sub assembly (See Fig.11 to 13).

CAUTION:

To remove the head mount assembly, turn the direction

cover to the left to disengage the gear. If the gear can not

be disengaged easily, push up the boss Q' slightly and

raise the rear side of the head mounts slightly to return

the direction lever to the reversing side.

(2) Tighten the azimuth screw for reversing.

(3) Reattach the spring from the back of the Play/ Record &

Clear head.

(4) Connect the flexible wire to connector CN31

amplifier & mechanism control board.

on the head

U' Q'

Head mount assembly

Head mount assembly

O'

Fig.11

P'

P'

V'

V'

Direction cove

Spring

Flexible wire

V

O

P

Q

Head

Direction cove

U

Fig.12

Azimuth screw for reversing

Head mount

CN31

Fig.13

Head amplifier &

mechanism control board

(No.MB262)1-29

Page 30

4.1 Jigs and test instruments

• Remote controller

4.2 Adjustment and check method

4.2.1 Initialize all data to the factory setting

SECTION 4

ADJUSTMENT

4.2.4 Fan motor ON/OFF check

Pressing the [STOP] , [SLEEP] and

[STANDBY/ON] together at Power

ON condition.

FL indication

COLD

Initialize is complete.

4.2.2 Confirmation of the system micro computer

Pressing the [STOP] , [SLEEP] and

[STANDBY/ON] together at Power

ON condition.

FL indication

08 02 E

or

09 00 E

Setup is complete.

Pressing the [STOP] , [SLEEP] and

[STANDBY/ON] together at Power

ON condition.

Fan motor is rotating.

Setup is complete.

4.2.3 FL all lighting-up check

Pressing the [STOP] , [SLEEP] and

[STANDBY/ON] together at Power

ON condition.

FL indication

All of the FL displays light up.

Setup is complete.

1-30 (No.MB262)

Page 31

TROUBLE SHOOTING

5.1 Flow of functional operation untill TOC read (CD)

Power ON

Disc play Key

Automatic tuning of FO offset and TE offset

SECTION 5

Slider turns REST

SW ON.

Laser ON

Detection of disc

Check Point

Confirm that the voltage at

the pin68 of IC251 is 0V.

(ON: 0V)

Tracking error waveform at TOC reading

IC601

20pin(TEOUT)

Approx.

1.4V

VREF

Disc status

to rotate

Approx. 3sec

Tracking

servo

off status

Automatic measurement

of TE amplitude and

automatic tuning of TE

balance

Tracking

servo

on status

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Confirm that the Focus error

S-curve signal at the pin32 of

IC651 is approx. 1.4Vp-p.

Confirm that the signal from

pin22 of IC651 is 0V as a accelerated

pulse during approx. 640ms.

Confirm the waveform of the

Tracking error signal at the

pin20 of IC601(one side of

R604) (See Fig.1.)

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eye-pattern

at the pin5 of IC601

(No.MB262)1-31

Page 32

5.2 Maintenance of laser pickup (CD)

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output : ampli tude of eye

pattern) will below.

5.3 Replacement of laser pickup (CD)

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one. (Refer

to "Pickup Removal" on the previous page)

Is RF output

0.9 0.22Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power. Since this adjustment should be performed to

match the characteristics of the whole optical block, do not

touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is

functioning normally, the laser pickup may be damaged

due to excessive current.

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3 seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at 5pin of IC601.

Finish.

1-32 (No.MB262)

Page 33

(No.MB262)1-33

Page 34

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB262)

Printed in Japan

WPC

Page 35

SERVICE MANUAL

MICRO COMPONENT SYSTEM

MB26220046

UX-P400

Area suffix

US ------------------------ Singapore

UF ------------------------------ China

UP ----------------------------- Korea

UT ---------------------------- Taiwan

UW ----------- Brazil,Mexico,Peru

CA-UXP400

SP-UXP400SP-UXP400

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.MB262

2004/6

Page 36

SPECIFICATION

Amplifier section Output Power 40 W (20 W + 20 W) at 4 Ω (10% THD)

Speakers/Impedance 4 Ω - 16 Ω

Audio Input AUX 400 mV/50 kΩ

Tuner section FM tuning range 87.50 MHz - 108.00 MHz

AM (MW) tuning range 531 kHz - 1 710 kHz (at 9 kHz intervals)

530 kHz - 1 710 kHz (at 10 kHz intervals)

CD player section Dynamic range 88 dB

Signal-to-noise ratio 93 dB

Wow and flutter Immeasurable

Cassette deck section Frequency response Normal (type I):50 Hz - 14 000 Hz

Wow and flutter 0.15% (WRMS)

Speakers Speaker units 10 cm cone × 1

Impedance 4 Ω

Dimensions (approx.) 145 mm × 230 mm × 191 mm (W/H/D)

Mass (approx.) 1.8 kg each

General Power requirement AC 110 V/AC 127 V/AC 220 V/AC 230 V - AC 240 V

(adjustable with the voltage selector), 50 Hz/60 Hz

Power consumption 50 W (at operation)

4.4 W (on standby)

Dimensions (approx.) 170 mm × 230 mm × 311 mm (W/H/D)

Mass (approx.) 4.5 kg

Design and specifications are subject to change without notice.

1-2 (No.MB262)

Page 37

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB262)1-3

Page 38

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Short land section

CD pickup

Card wire

1-4 (No.MB262)

Traverse mechanism assembly

CN601

CD servo board

Page 39

1.8 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

CLASS 1

LASER PRODUCT

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MB262)1-5

Page 40

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB262)

Page 41

SECTION 3

DISASSEMBLY

3.1 Main body section

3.1.1 Removing the side panels L/R

(See Figs.1 to 4)

(1) From the back side of the main body, remove the four

screws A attaching the side panels L/R to the rear panel.

(See Fig.1.)

(2) From the bottom side of the main body, remove the two

screws B attaching the side panels L/R to the bottom chassis. (See Fig.2.)

(3) From the both sides of the main body, release the engage-

ment sections (a, b) of the side panels L/R from the top

cover assembly in the direction of the arrow. (See Figs.3

and 4.)

(4) Remove the side panels L/R toward this side.

Top cover assembly

a

a

a

Side panel R

A

B

Rear panel

Fig.1

Side panel L

Side panel R

A

Side panel R

Fig.3

Top cover assembly

b

b

b

B

Side panel L

Fig.4

Side panel L

Bottom chassis

Fig.2

(No.MB262)1-7

Page 42

3.1.2 Removing the front panel assembly

(See Figs.5 to 8)

• Prior to performing the following procedures, remove the side

panels L/R.

(1) From the right side of the main body, push the slide cam

and pull the tray out of the main body in the direction of the

arrow 1. (See Fig.5.)

(2) Remove the tray fitting from the tray in the direction of the

arrow 2. (See Fig.5.)

(3) From the both sides of the main body, remove the two

screws C attaching the front panel assembly. (See Figs.6

and 7.)

(4) Release the two claws c and claws d to draw out the front

panel assembly in the direction of the arrow. (See Figs.6

and 7.)

(5) From the right side of the main body, disconnect the card

wire from the connector CN730

Fig.8.)

(6) Disconnect the wire from the connector CN271

board. (See Fig.8.)

(7) Remove the front panel assembly in the direction of the ar-

row. (See Fig.8.)

Front panel assembly

on the main board. (See

on the main

c

Front panel assembly

Fig.7

CN730Card wire

C

d

Main board

2

1

Tray fitting

Tray

Slide cam

C

Fig.5

c

Wire

Front panel assembly

CN271

Fig.8

Front panel assembly

1-8 (No.MB262)

d

Fig.6

Page 43

3.1.3 Removing the top cover assembly

(See Figs.9 and 10)

• Prior to performing the following procedures, remove the side

panels L/R and front panel assembly.

(1) From the back side of the main body, remove the screw D

attaching the top cover assembly to the rear panel. (See

Fig.9.)

(2) From the right side of the main body, disconnect the card

wires from the connectors (CN701

board. (See Fig.10.)

(3) Take out the top cover assembly from the main body.

, CN702) on the main

Top cover assembly

D

Rear panel

Fig.9

Top cover assembly

CN702

Main board

Fig.10

Card wires

CN701

(No.MB262)1-9

Page 44

3.1.4 Removing the cassette mechanism assembly

(See Fig.11)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly and top cover assembly.

(1) From the bottom side of the top cover assembly, discon-

nect the card wires from the connectors (CN33

the head amp. & mechanism control board.

(2) Remove the four screws E attaching the cassette mecha-

nism assembly and take out the cassette mechanism assembly from the top cover assembly.

, CN34) on

Top cover assembly

Card wires

E

CN34

Head amp. & mechanism control board

CN33

Cassette mechanism assembly

Fig.11

E

1-10 (No.MB262)

Page 45

3.1.5 Removing the tuner

(See Figs.12 and 13)

• Prior to performing the following procedures, remove the side

panel L.

(1) From the back side of the main body, remove the two

screws F attaching the tuner to the rear panel. (See

Fig.12.)

(2) Disconnect the card wire from the connector CN1

tuner. (See Fig.13.)

on the

F

Rear panel

Card wire

Tuner

Fig.12

CN1

Fig.13

(No.MB262)1-11

Page 46

3.1.6 Removing the rear panel

(See Fig.14)

• Prior to performing the following procedures, remove the side

panels L/R.

(1) From the back side of the main body, remove the eight

screws G attaching the rear panel.

(2) Release the engagement sections e and remove the rear

panel.

(3) Disconnect the wire from the connector CN711

board.

Reference:

After connecting the wire to the connector CN711

with the wire holder.

3.1.7 Removing the fan

(See Figs.14 and 15)

• Prior to performing the following procedures, remove the side

panels L/R and rear panel.

(1) From the outside of the rear panel, remove the two screws

H attaching the fan bracket to the rear panel. (See Fig.14.)

(2) From the inside of the rear panel, move the fan bracket in

the direction of the arrow to release the engagement sections (f, g). (See Fig.15.)

(3) Remove the fan bracket from the rear panel and remove

the fan. (See Fig.15.)

on the main

, fix the wire

CN711

Wire

holder

Main board

Wire

G

G

G

e

e

H

Rear panel

Fig.14

f

Fan bracket

1-12 (No.MB262)

Fan

g

Rear panel

Fig.15

Page 47

3.1.8 Removing the main board

(See Fig.16)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly, tuner

and rear panel.

(1) From the right side of the main body, remove the two

screws J attaching the main board.

(2) Remove the main board toward this side and disconnect

the connector CN200

(3) From the forward side of the main board, disconnect the

card wires from the connectors (CN210

on the main board.

, CN221).

CN210

Main board

3.1.9 Removing the power supply board

(See Fig.17)

• Prior to performing the following procedures, remove the side

panel L and rear panel.

(1) From the left side of the main body, remove the screw K at-

taching the power supply board.

(2) Remove the power supply board toward this side and dis-

connect the connector CN104

(3) From the forward side of the power supply board, discon-

nect the wires from the connectors (CN101

CN103, CN105).

Reference:

When attaching the power supply board, insert the section h of

the power supply board in the hole of the bottom chassis before attaching the screw K.

on the power supply board.

, CN102,

CN102

CN101

h

CN200

CN103

CN105

J

Card wire

Fig.16

K

J

CN221

Power supply board

CN104

Fig.17

(No.MB262)1-13

Page 48

3.1.10 Removing the power amplifier board

(See Fig.18)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly, tuner,

rear panel, main board and power supply board.

(1) From the top side of the main body, remove the four screws

L attaching the power amplifier board.

(2) Lift the power amplifier board and remove it from the en-

gagement sections (i, j) of the shield case.

3.1.11 Removing the heat sink

(See Fig.19.)

• Prior to performing the following procedure, remove the side

panels L/R, front panel assembly, top cover assembly, tuner,

rear panel, main board, power supply board and power amplifier board.

(1) From the side of the power amplifier board, remove the two

screws M attaching the heat sink.

(2) From the side of the power amplifier board, remove the two

screws N attaching the heat sink.

Power amplifier board

L

i

L

LL

Shield case

Fig.18

M M

Heat sink

j

1-14 (No.MB262)

Power amplifier board

Fig.19

N

Page 49

3.1.12 Removing the CD mechanism assembly

(See Figs.20 and 21)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly, tuner,

rear panel, main board and power supply board.

(1) From the top side of the main body, remove the four screws

P attaching the shield case to the bottom chassis. (See

Fig.20.)

Reference:

When attaching the shield case on the bottom chassis,

align the projections (k, m, n) of the bottom chassis in the

holes of the shield case. (See Fig.20.)

(2) Take out the shield case with the power amplifier board

from the bottom chassis.

(3) Remove the three screws Q attaching the CD mechanism

assembly to the bottom chassis. (See Fig.21.)

P

Shield case

k

Bottom chassis

P

m

Power amplifier board

CD mechanism assembly

Bottom chassis

n

P

Fig.20

Q

Q

Fig.21

(No.MB262)1-15

Page 50

3.1.13 Removing the power transformer

(See Figs.22 and 23)

• Prior to performing the following procedures, remove the side

panels L/R, front panel assembly, top cover assembly and rear

panel.

(1) From the forward side of the power supply board, discon-

nect the wires from the connectors (CN102

CN105). (See Fig.22.)

Reference:

Remove the power supply board as required. (See

Fig.17.)

(2) From the top side of the main body, remove the four screws

R attaching the power transformer. (See Fig.23.)

, CN103,

CN102

Power supply board

CN103

CN105

Fig.22

Power transformer

R

R

R

Fig.23

1-16 (No.MB262)

Page 51

3.1.14 Removing the FL board

(See Fig.24)

• Prior to performing the following procedures, remove the side

panels L/R and front panel assembly.

(1) From the inside of the front panel assembly, remove the

four screws S attaching the FL board.

(2) Take out the FL board from the front panel assembly and

disconnect the card wire from the connector CN751

FL board.

Reference:

When attaching the FL board, align the projections p of the

front panel assembly in the holes of the FL board.

on the

CN751

Card

wire

S

FL board

p

S

p

S

S

Front panel assembly

Fig.24

(No.MB262)1-17

Page 52

3.1.15 Removing the switch board

(See Figs.25 and 26)

• Prior to performing the following procedures, remove the side

panels L/R and front panel assembly.

(1) From the front side of the front panel assembly, pull out the

mic volume knob. (See Fig.25.)

(2) From the inside of the front panel assembly, remove the

ten screws T attaching the switch board. (See Fig.26.)

(3) Take out the switch board from the front panel assembly

and disconnect the card wire from the connector CN760

the switch board. (See Fig.26.)

Reference:

When attaching the switch board, align the projections q of the

front panel assembly in the holes of the switch board. (See

Fig.26.)

on

Front panel assembly

Mic volume knob

Fig.25

Card wire

T

Switch board

CN760

q

T

q

T

Fig.26

1-18 (No.MB262)

Page 53

3.1.16 Removing the headphone jack board

(See Fig.27)

• Prior to performing the following procedure, remove the side

panels L/R and front panel assembly.

(1) From the inside of the front panel assembly, remove the

screw U attaching the headphone jack board.

Reference:

After attaching the headphone jack board, fix the wire with the

spacer.

Spacer

Wire

U

Headphone jack board

Fig.27

Front panel assembly

(No.MB262)1-19

Page 54

3.2 CD mechanism section

• Remove the CD mechanism assembly from the main body.

(See "3.1.12 Removing the CD mechanism assembly".)

3.2.1 Removing the tray assembly

(See Figs.1 to 3)

(1) From the right side of the CD mechanism assembly, push

the slide cam and pull the tray assembly out of the CD

mechanism assembly in the direction of the arrow. (See

Fig.1)

(2) From the top side of the CD mechanism assembly, remove

the two screws A attaching the leaf spring to the bushing

and remove the leaf spring. (See Fig.2)

(3) Remove the bushing of the tray assembly from the projec-

tion a on the CD mechanism assembly and move the tray

assembly in the direction of the arrow. (See Fig.3)

(4) Remove the claw b of the tray assembly from the CD

mechanism assembly and take out the tray assembly. (See

Fig.3)

Tray assembly CD mechanism assembly

Slide cam

Fig.1

Leaf spring

Bushing

A

3.2.2 Removing the traverse mechanism assembly

(See Figs.4)

(1) From the bottom side of the CD mechanism assembly, re-

move the four screws B attaching the traverse mechanism

1-20 (No.MB262)

CD mechanism assembly

Projection a

Claw b

CD mechanism assembly

assembly.

Fig.2

Bushing

Tray assembly

Fig.3

Page 55

(2) Disconnect the card wire from the connector CN602

CD servo board and take out the CD traverse mechanism

assembly with the CD servo board.

on the

CD mechanism assembly

CD servo board

B

Traverse mechanism assembly

Fig.4

B

CN602

(No.MB262)1-21

Page 56

3.2.3 Removing the CD servo board

(See Figs.5 and 6)

• Remove the traverse mechanism assembly.

(1) From the bottom side of the traverse mechanism assem-

bly, remove the solders from the solder sections c. (See

Fig.5)

(2) Remove the wire (yellow) from the solder sections d. (See

Fig.5)

(3) Remove the wire (white) from the solder sections e. (See

Fig.5)

(4) Remove the two screws C attaching the CD servo board.

(See Fig.5)

(5) Remove the CD servo board from the claws f in the direc-

tion of the arrow and turn the CD servo board over. (See

Fig.5)

(6) Solder the short land sections g on the CD pickup. (See

Fig.6)

(7) Release the lock of the connector CN601

board in the direction of the arrow and disconnect the card

wire. (See Fig.6)

Caution:

• Solder the short land sections g on the CD pickup before disconnecting the card wire from the connector CN601

CD servo board. If the card wire is disconnected without attaching solder, the CD pickup may be destroyed by static

electricity. (See Fig.6)

• When attaching the CD servo board, be sure to remove solders from the short land sections g after connecting the card

wire to the connector CN601

Fig.6)

on the CD servo board. (See

on the CD servo

on the

Claw f

Solder section c

CD servo board

Wire (yellow)

CC

Wire (white)

Solder

section d

Solder

section e

Claw f

Traverse mechanism assemblyCD servo board

Fig.5

CN601

CD pickup

Short land section g

Lock

Traverse mechanism assembly

Fig.6

1-22 (No.MB262)

Page 57

3.2.4 Removing the CD pickup

(See Figs.7 to 9)

• Remove the traverse mechanism assembly.

(1) From the top side of the traverse mechanism assembly, re-

move the screw D attaching the shaft holder. (See Fig.7)

(2) Release the joint h and take out the shaft holder. (See

Fig.7)

(3) Remove the two screws E attaching the rack arm and take

out the rack arm. (See Fig.8)

(4) Remove the feed middle gear and remove the screw shaft

of the CD pickup from the section i on the traverse mechanism assembly. (See Fig.8)

(5) Remove the CD pickup from the section j of the traverse

mechanism assembly and take out the CD pickup with the

screw shaft. (See fig.8)

(6) Pull the screw shaft out of the CD pickup. (See Fig.8)

(7) From the bottom side of the CD pickup, solder the short

land sections k on the CD pickup. (See Fig.9)

(8) Release the lock of the connector on the CD pickup in the

direction of the arrow and disconnect the card wire. (See

Fig.9)

Caution:

• Solder the short land sections k on the CD pickup before dis-

connecting the card wire from the connector on the CD pickup. If the card wire is disconnected without attaching solder,

the CD pickup may be destroyed by static electricity. (See

Fig.9)

• When attaching the CD pickup, be sure to remove solders

from the short land sections k after connecting the card wire

to the connector on the CD pickup. (See Fig.9)

Traverse mechanism assembly

Feed middle gear

Screw shaft

DJoint h

Shaft holder

Fig.7

Rack arm

E

Section i

CD pickup

Short land section k

CD pickup Connector Card wire

Section j

Fig.8

Fig.9

(No.MB262)1-23

Page 58

3.2.5 Attaching the CD pickup

(See Figs.7 to 10)

• See "3.2.4 Removing the CD pickup".

(1) Remove solders from the short land sections k after con-

necting the card wire to the connector on the CD pickup.

(See Fig.9)

(2) Attach the shaft. (See Fig.8)

(3) Align the CD pickup to the section j of the traverse mecha-

nism assembly first, and set the screw shaft of the CD pick-

up in the sections i of the traverse mechanism assembly.

(See Fig.8.)

(4) Attach the rack arm and feed middle gear. (See Fig.8)

(5) Attach the shaft holder. (See Fig.7)

(6) Turn the SS gear in the direction of the arrow 1 to move the

CD pickup in the direction of the arrow 2. (See Fig.10)

SS gear

1

2

3.2.6 Removing the feed motor

(See Figs.5, 7 and 11)

• Remove the traverse mechanism assembly.

(1) From the top side of the traverse mechanism assembly, re-

move the wire (yellow) from the solder sections d on the

CD servo board. (See Fig.5)

(2) Remove the wire (white) from the solder sections e on the

CD servo board. (See Fig.5)

(3) Remove the screw D attaching the shaft holder and take

out the shaft holder. (See Fig.7)

(4) Remove the feed middle gear and remove the screw E at-

taching the feed motor. (See Fig.11)

(5) Take out the feed motor from the traverse mechanism as-

sembly.

Reference:

When attaching the feed motor, pass the wires through the

section m on the traverse mechanism assembly. (See Fig.11)

Traverse mechanism assembly

Fig.10

E

Feed motor

Wires

Pickup

Section m

1-24 (No.MB262)

Feed middle gear

Traverse mechanism assembly

Fig.11

Page 59

3.2.7 Removing the CD loading switch board

(See Fig.12)

(1) From the bottom side of the CD mechanism assembly, dis-

connect the card wire from the connector CN1

loading switch board.

(2) Remove the wires from the solder section n on the CD

loading switch board.

(3) Lift the CD loading switch board while pressing the claw p

of the CD mechanism assembly in the direction of the arrow and remove it from the section q.

Reference:

• Put the wires on the section r after attaching the CD loading

switch board to the CD mechanism assembly.

• Fix the claw p on the CD mechanism assembly with bonds

after attaching the CD loading switch board.

3.2.8 Removing the motor

(See Figs.12 and 13)

• Remove the tray assembly.

(1) From the bottom side of the CD mechanism assembly, re-

move the wires from the solder section n on the CD loading

switch board. (See Fig.12)

(2) From the top side of the CD mechanism assembly, remove

the belt from the motor pulley. (See Fig.13)

Note:

Take care not to attach grease on the belt.

(3) Remove the two screws F attaching the motor to the CD

mechanism assembly and take out the motor from the bottom side of the CD mechanism assembly. (See Fig.13)

Reference:

Put the wires on the section r after attaching the motor to the

CD mechanism assembly. (See Fig.12)

on the CD

CD loading switch board

Wire

Solder

section n

CN1

section q section r

CD mechanism assembly

F

Claw p

CD mechanism assembly

Fig.12

Belt

Fig.13

Motor pulley

(No.MB262)1-25

Page 60

3.3 Cassette mechanism assembly

3.3.1 Removing the Play/Record & Clear head

(See Fig.1~3)

(1) While moving the trigger arm on the right side of the head

mount in the direction of the arrow, turn the flywheel R

counterclockwise until the head mount comes ahead and

clicks.

(2) The head turns counterclockwise as you turn the flywheel