Page 1

MB061200312

SERVICE MANUAL

DOUBLE CASSETTE DECK

TD-W271

AUTO REVERSE

A

3MOTOR SILENT MECHANISM

PLAYBACK

POWER

STANDBY/ON ON OFF

DOUBLE CASSETTE DECK

REVERSE MODE

DOLBY NR

B OFF C

STANDBY

COUNTER RESET

PLAY

PHONES

INPUT LEVEL

5

46

37

28

19

MIN MAX

COUNTER RESET

AUTO TAPE SELECTOR / CONTINUOUS PLAY

PLAY

REC / REC MUTE PAUSE

AUTO REVERSE

3MOTOR SILENT MECHANISM

DOLBY B-C NR HX PRO

B

REC/PLAYBACK

A B SYNCHRO DUBBING

NORM SPEED

HIGH SPEED

Area Suffix

UF -------------- China

U -------- Other Areas

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Page 2

SPECIFICATION

Type Double cassette deck

Track system 4-track, 2-channel

Tape speed 4.8 cm/sec (1-7/8 inch/sec) (Normal)

9.5 cm/sec (3-3/4 inch/sec) (High)

Frequency response

(-20 dB recording)

S/N ratio 58 dB (S = 315 Hz, k3 = 3%, N = A-weighted, Type IV tape)

Improvement of MOL 4 dB at 10 kHz with Dolby C NR on.

Wow and flutter 0.08% (WRMS), ±0.2% (DIN/IEC)

Channel separation 10 dB (1 kHz)

Crosstalk 60 dB (1 kHz)

Harmonic distortion k3; 0.8% (Type IV tape, 315 Hz, 0 VU)

Heads Deck A METAPARM head for playback × 1

Motors Electric govemed DC motor for capstan × 1

Fast forward/rewind time Approx. 110 sec. with C-60 cassette

Input terminals LINE IN (× 1 circuit) Input sensitivity 80 mV (0 VU)

Output terminals LINE OUT (× 1 circuit) Output level 300 mV (0 VU)

Other terminals COMPU LINK-3/SYNCRO × 2

Power requirement AC 220 V, 50 Hz

Power consumption With power on 17 W

Dimensions 435 × 139 331 mm

Mass 5.0 kg

Type IV tape 20-17000Hz

30-16000 Hz (±3dB)

Type II tape 20-16000 Hz

30-15000 Hz (±3dB)

Type I tape 20-16000 Hz

30-15000 Hz (±3dB)

The S/N is improved by about 15 dB at 500 Hz and by max.

20 dB at 1kHz ~ 10 kHz with Dolby C NR on and improved by 5 dB

at 1 kHz and by 10 dB at above 5 k Hz with DOLBY B BR on.

Deck B METAPARM head for recording/playback,

2-gap ferrite head for erasure; combination head × 1

DC motor for reel × 1

DC motor for mechanism drive × 1 (For both decks A and B)

Input impeadance 50 kΩ

Output impeadance 5 kΩ

PHONES × 1 Output level 0.3 mW/8 Ω(0 VU)

Matching impedance 8 Ω - 1 k Ω

With power standby 4.0 W

Design and specifications are subject to change without notice.

1-2 (No.MB061)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of th is product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

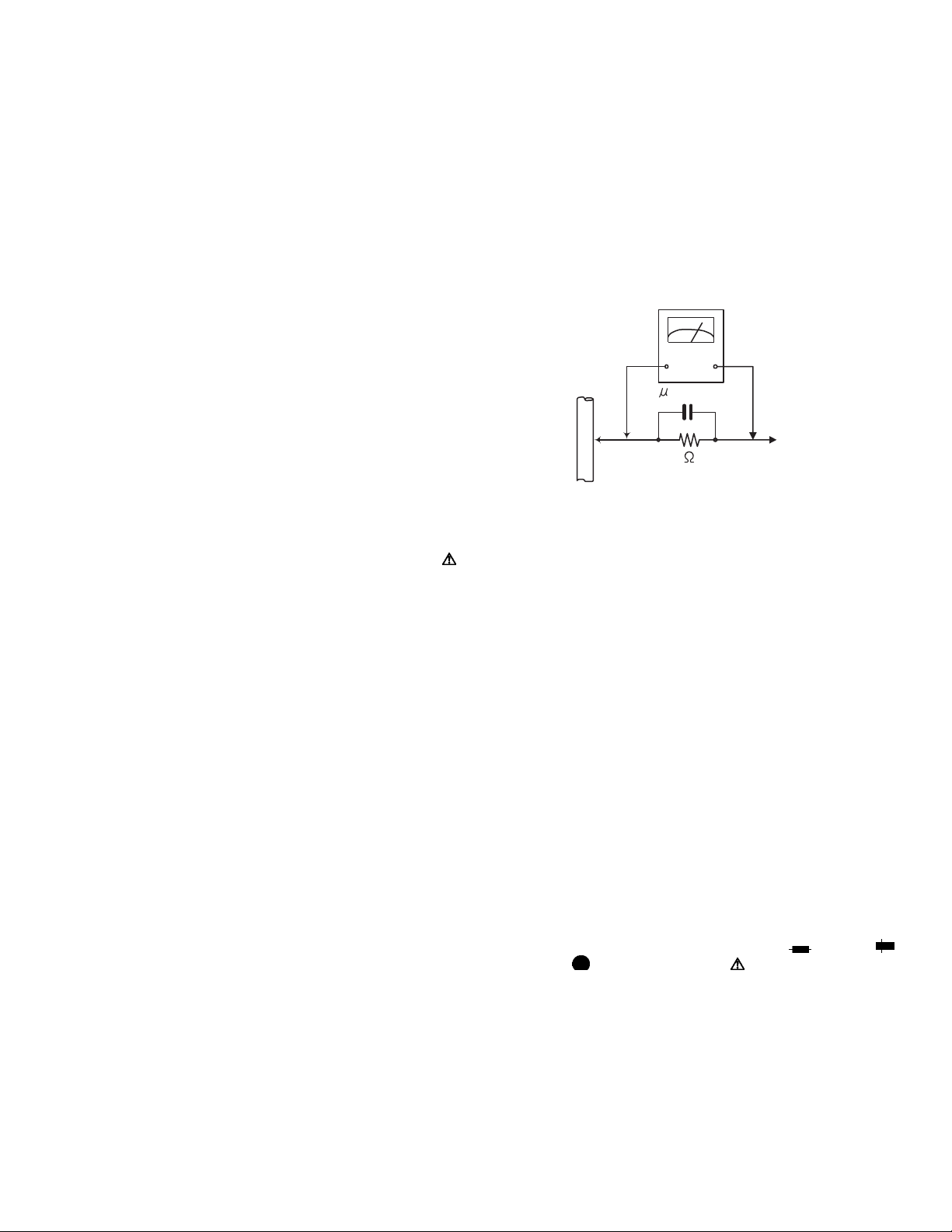

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• P lug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB061)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-4 (No.MB061)

Page 5

SECTION 3

DISASSEMBLY

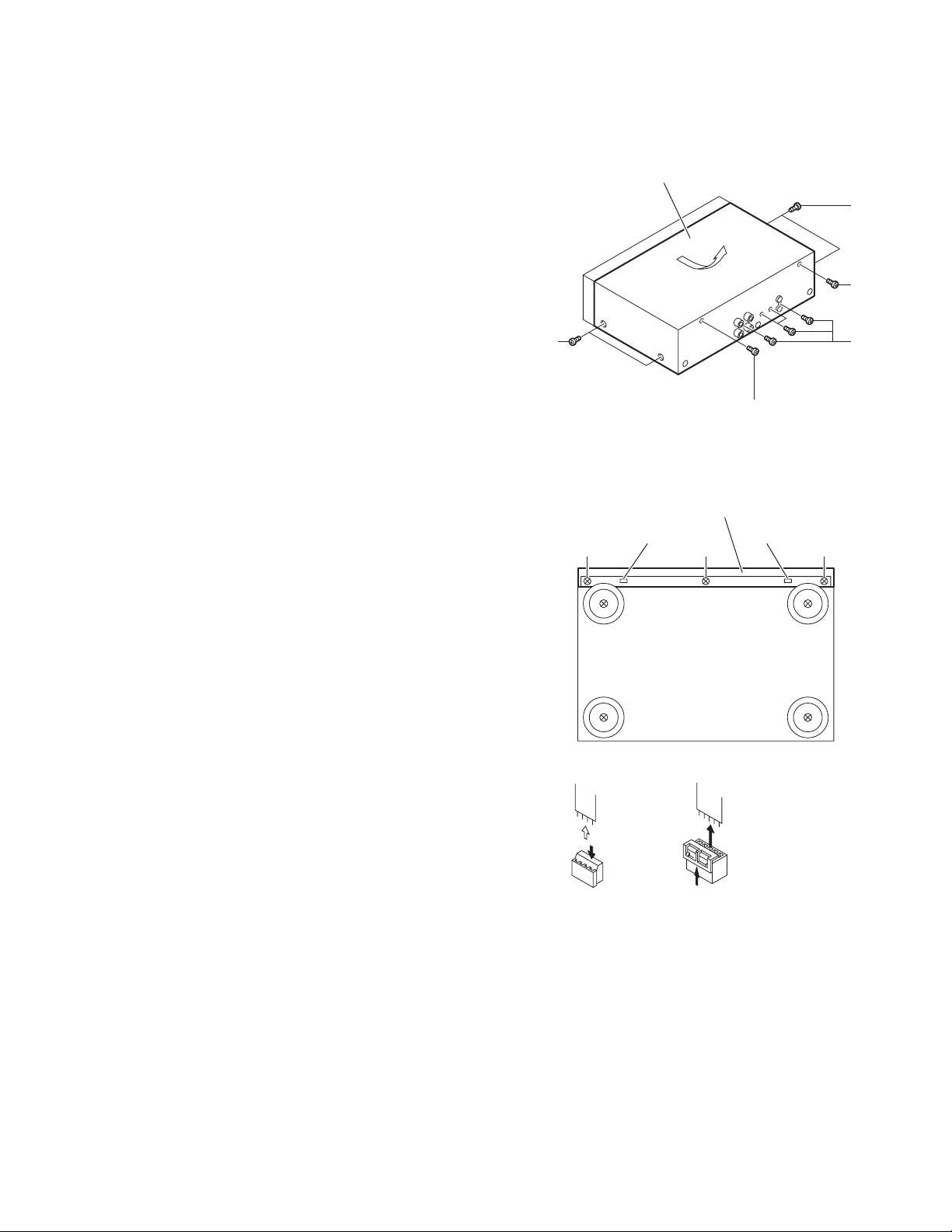

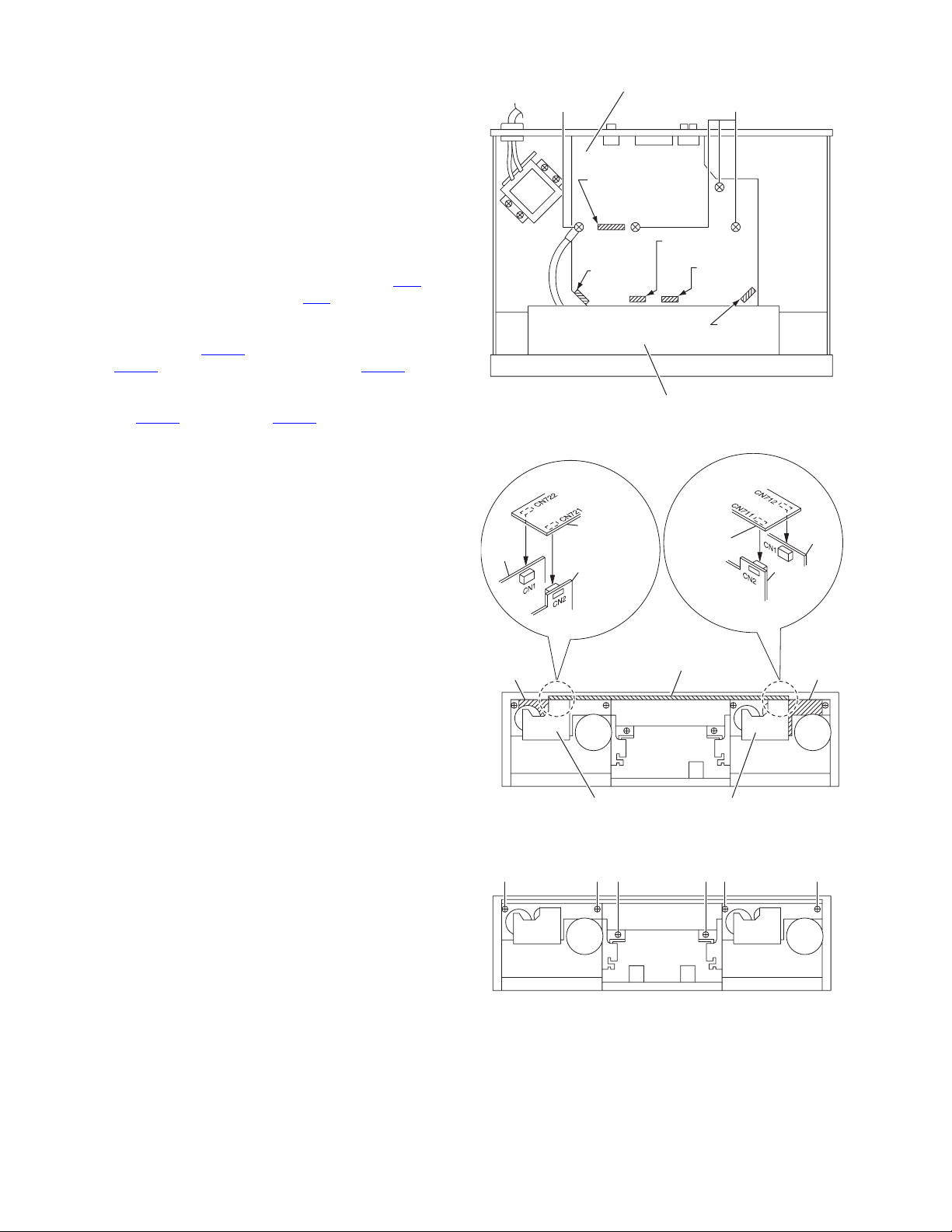

3.1 Enclosure section

3.1.1 Removing the top cover

(See Fig.1)

(1) Remove four screws A retaining the top cover from both

side.

(2) Remove two screws B retaining the top cover from the

back side.

(3) To remove the top cover, slide in direction of arrow and lift

away (refer to Fig.1).

Top cover

A

B

3.1.2 Removing the front panel assembly

(See Fig.2, 3)

(1) Remove the top cover as described in above.

(2) Remove the three screws C retaining the front panel as-

sembly from bottom side.

(3) Release the front panel assembly from two pawls in the

front and bottom sides and draw it to the front side.

(4) Disconnect all connectors between the mechanism assem-

bly, front panel assembly and main board.

A

C

Fig.1

Front panel assembly

Pawl

C C

Fig.2

M

B

Pawl

Pull 2

Push 1

Push up with a screwdriver, etc. 1

Pull 2

Fig.3

(No.MB061)1-5

Page 6

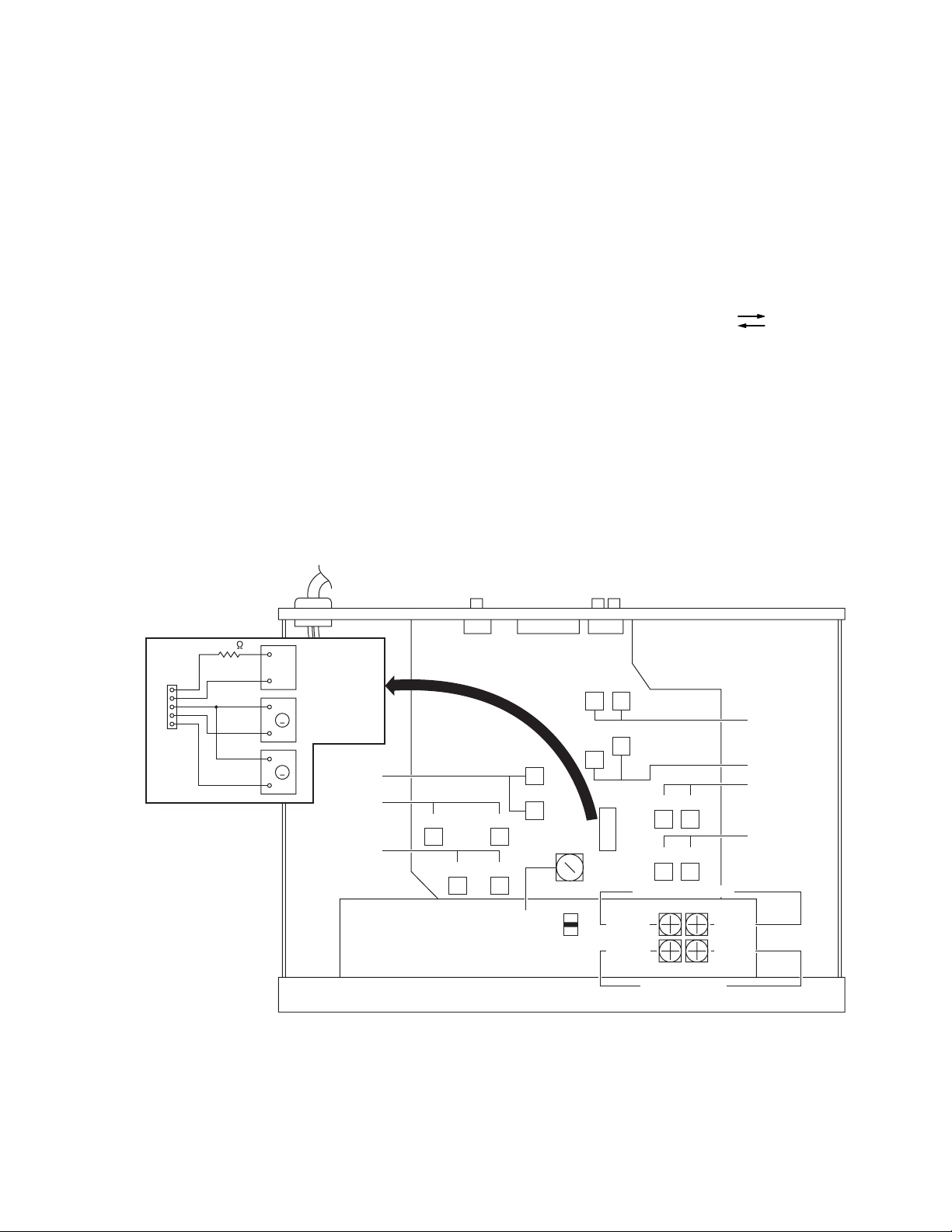

3.1.3 Removing the mechanism assembly

• Although the mechanism assembly can be removed without

detaching the front panel assembly, it is recommended to detach the front panel assembly to do the work with ease.

(1) Remove the two screws D or two screws E from the cor-

ners of the mechanism. (Fig.6)

(2) Open the door and remove the mechanism assembly.

(At this time, door lock arm spring and door lock arm are removed together with.)

(3) For moving the mechanism assembly only, disconnect the

following wirings.

a) Mechanism assembly side (Fig.5)

Top side connector of the cam switch board (CN2

).

Connector of the motor board (CN1). (Board to board

connector)

b) Main board side (Fig.4)

Disconnects CN802

from switch/volume board and CN861 from

CN801

from mecha control board,

headphone jack board.

Disconnect wire coming from the head mount assembly CN811

at deck A and CN815 at deck B.

Remove one screw F and remove one GND wire

from mechanism control board.

3.1.4 Removing the eject arm assembly

(Fig.6)

(1) Remove the screws G retaining the eject arm assembly

and pull it out.

DECK A

Motor

board

Main board

F

From Mechanism

control board

CN802

From DECK A

CN861

CN811

Mechanism control board

Mechanism

control

board

Cam

switch

board

CN801

Fig.4

L

From Headphone jack

board

From Switch/

Volume board

CN815

From DECK B

Mechanism

control

board

DECK B

Motor

board

Cam

switch

board

Motor

board

Mechanism control board

Motor

board

DECK B DECK A

Cam switch board

Cam switch board

Fig.5

DDGGE E

DECK B DECK A

Fig.6

1-6 (No.MB061)

Page 7

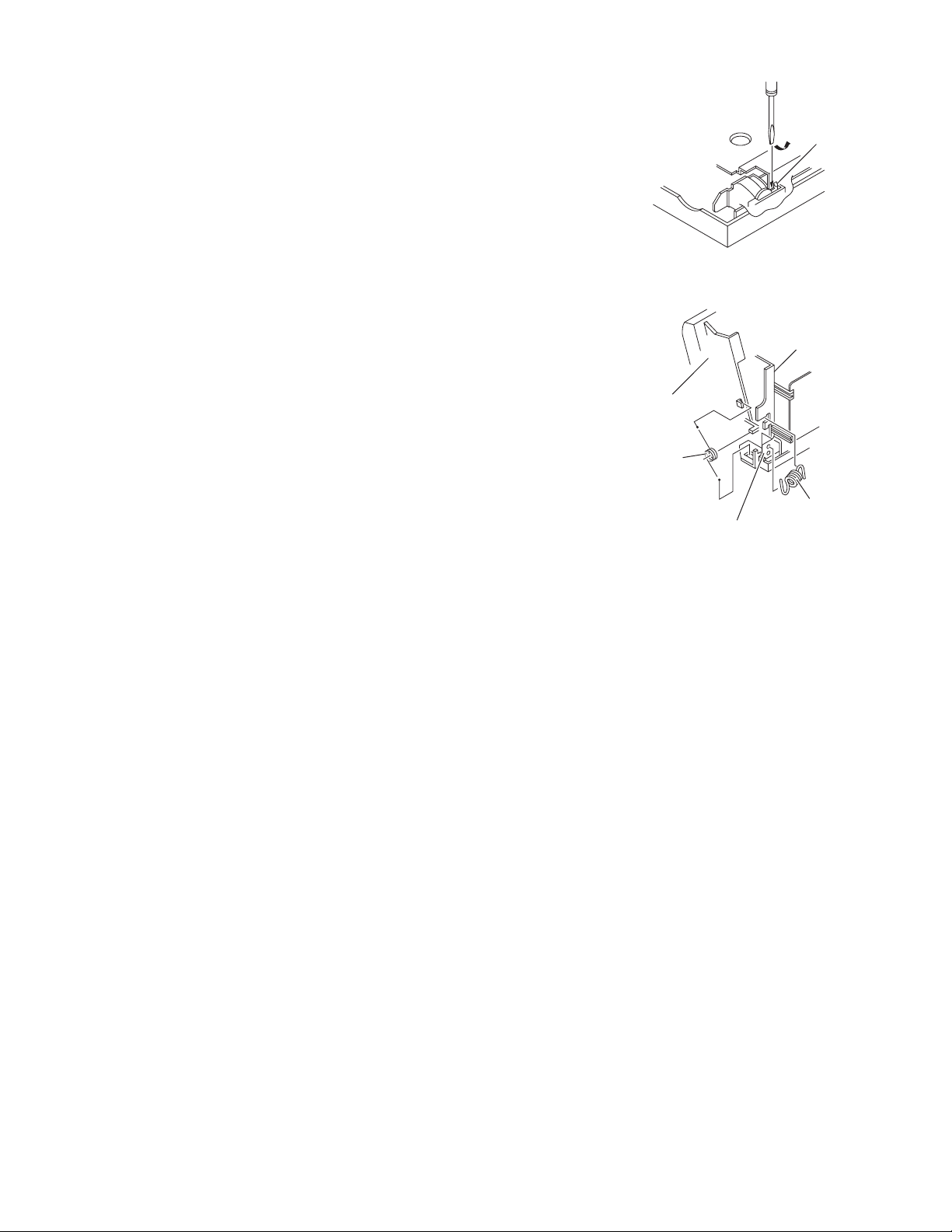

3.1.5 Removing the mechanism holder and door assembly

(Fig.7, 8)

(1) Remove four screws H retaining the mechanism holder.

(2) Remove the damper assembly (for easy reassembling

work).

Insert an originary (-) screwdriver or the like in to the gap

between the damper and the front panel to disengage the

pawl, and draw the damper assembly outwards. (See

Fig.7)

(3) Remove the arm shaft of the cassette holder (door assem-

bly) from the mechanism holder. (The door spring is engaged with the door side by the longer side.) (See Fig.8)

(4) Remove the eject spring from lock lever and mechanism

assembly. (See Fig.8)

How to remove damper

Pawl

Fig.7

How to engage the door and eject spring

Lock lever

Cassette door

Longer side

door spring

Shorter side

eject spring

Mechanism assembly

Fig.8

(No.MB061)1-7

Page 8

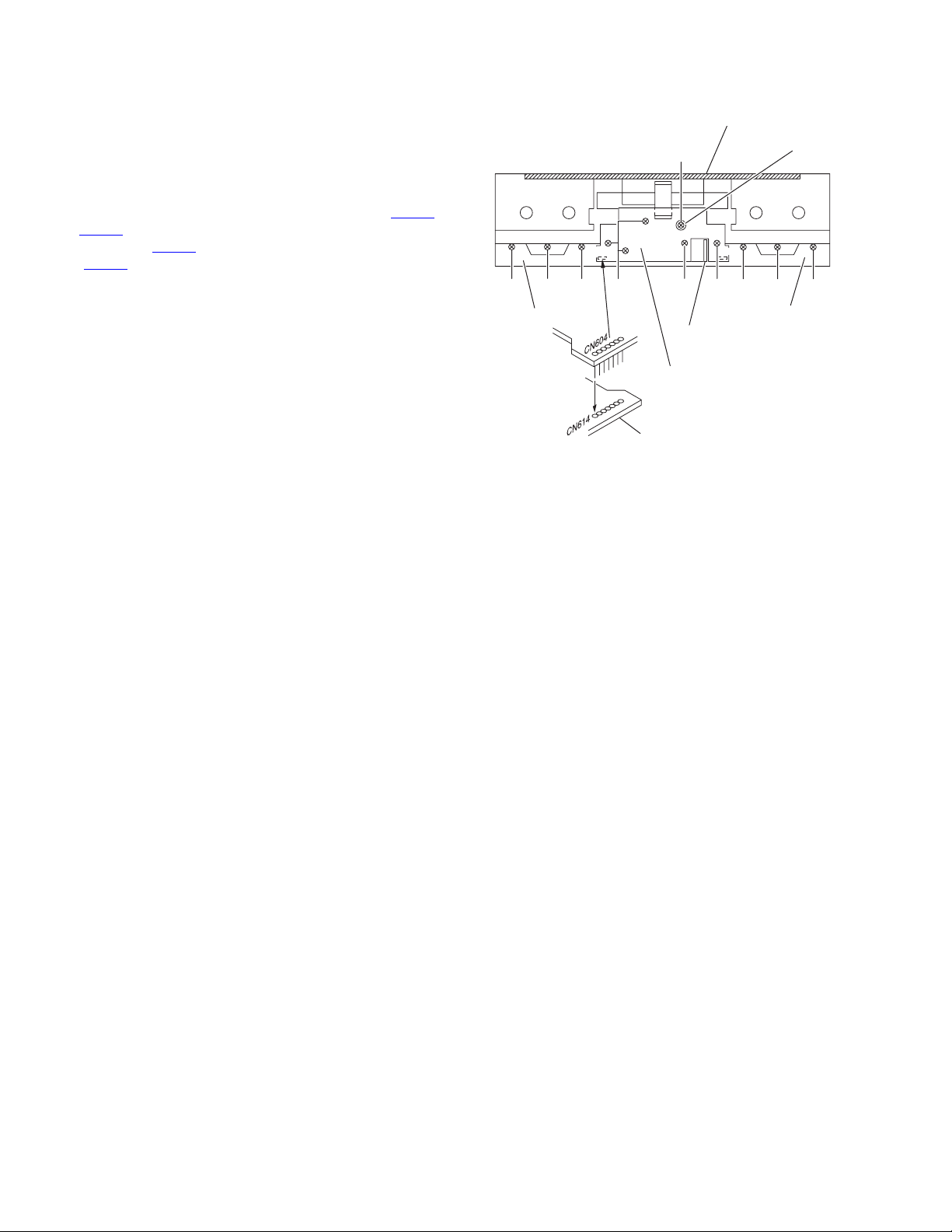

3.1.6 Removing the switch & volume board

(Fig.9)

(1) After removing the mechanism hold er, proceed to the fol-

lowing steps.

(2) Pull out the INPUT volume knob.

(3) Remove four screws J, one screw N and cap retaining the

switch/volume board.

(4) Lift the board right upwards to remove it since it is connect-

ed to the key switch board with connector pins (CN603

).

CN604

(5) Disconnect CN602 coming from Mechanism control board

(CN702

).

3.1.7 Removing the headphone jack board

(Fig.9)

(1) After removing the switch/volume board, pull the head-

phone jack board outwards while pushing it down toward

the bottom side to remove it.

3.1.8 Removing the key switch board

(Fig.9)

(1) Remove one screw K (Deck A or B) retaining the board.

(2) Do the same for the other side.

3.1.9 Removing the main board

(see Fig.4 and 1)

(1) Remove three screws L retaining the board.

(2) Remove four screws M retaining the board to the rear pan-

el.

3.1.10 Reassembling procedure of the front panel assembly

(1) Attach the key switch board to the panel with two screws.

(2) Attach the mechanism holder to the front panel assembly

with four screws.

(3) Put the door assembly on the front panel.

(4) Engage the door spring properly.

(5) Install the damper. (Push the pawl side last to engage it.)

(6) Install the mechanism assembly.

(7) Attach the mechanism control bo ard to the panel with two

screws.

(8) Install the eject arm assembly.

(9) Attach the switch/volume board to the panel with five

screws.

(10) Hook the eject spring between lock lever and mechanism

assembly.

Mechanism control board

N

CN702

/

CN604

Key switch board

CN602

CN603

J

JH HKHKH J

Key witch board

Cap

Headphone jack board

Switch/Volume board

Key switch board

Fig.9

1-8 (No.MB061)

Page 9

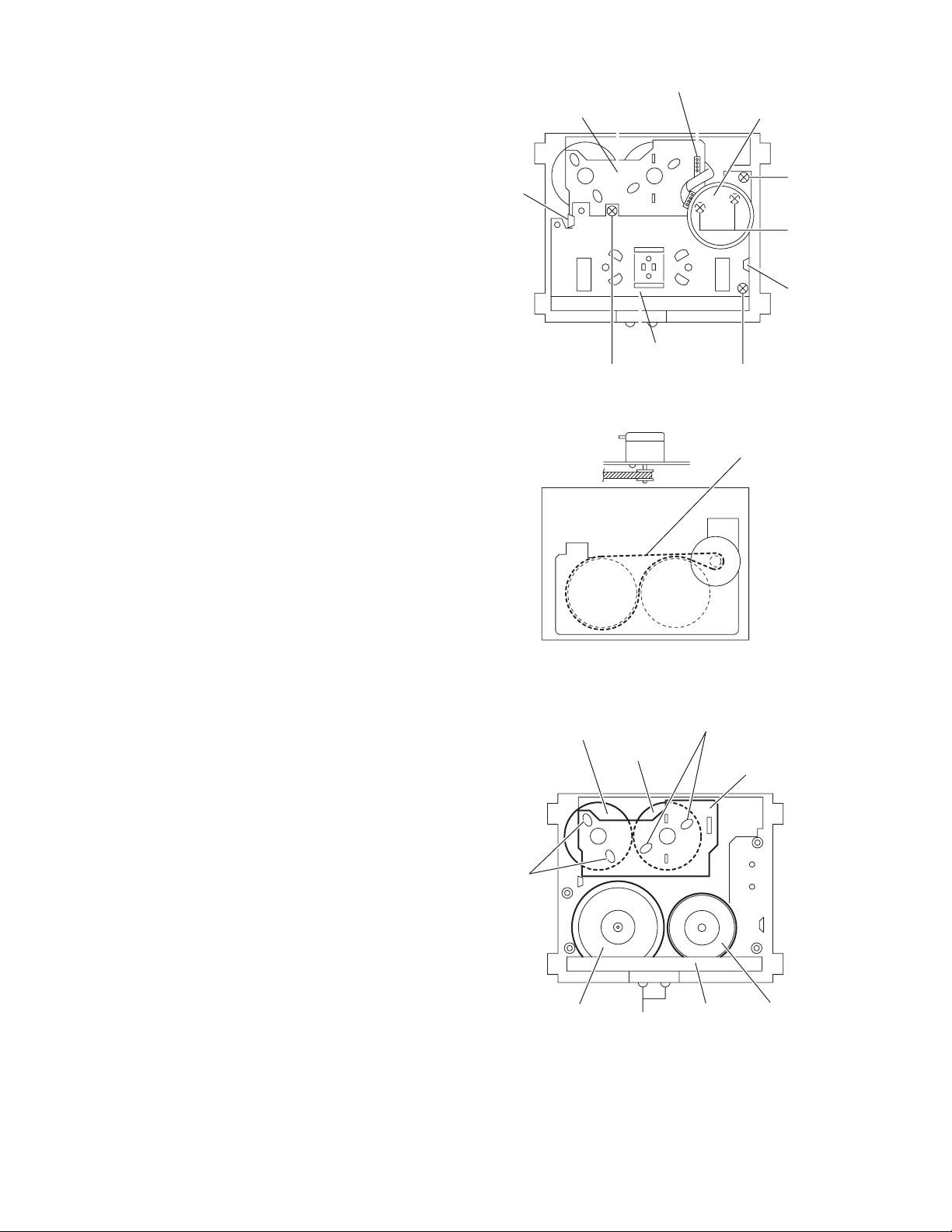

3.2 Cassette mechanism section

r

r

3.2.1 Removing the head mount assembly

(Fig.10 and 11)

(1) Remove the FPC holder from the me chani sm frame in the

direction indicated by the arrow (A).

(2) Remove three screws A retaining the he ad mo unt assem-

bly.

3.2.2 Removing the pinch roller assembly

(Fig.10 and 12)

(1) Remove the pinch roller an d pinch roller spring, refer to

Fig.12.

Mechanism A

Pinch roller (left) Pinch roller (right)

Head mount assembly

Fig.10

A

Head mount assembly

Head base

(A)

FPC Holder

Fig.11

Pinch roller

(left)

Pinch roller

spring

Pawl

Pinch rolle

(right)

Pinch rolle

spring

Pawl

Fig.12

(No.MB061)1-9

Page 10

3.2.3 Removing the FM bracket/Capstan motor assembly

(Mechanism A and B)

(1) Remove soldering of connector FM on reel motor board.

(Fig.13)

(2) Remove three screws B and disengage two pawls, and

then the FM bracket and the capstan belt can be removed.

(Fig.13 and 14)

(3) Remove two screws C retaining the capstan motor from the

FM bracket. (Fig.13)

(4) For reengaging the capsta n belt, refer to Fig.14.

Reel motor board

Pawl

Connector FM

FM bracket

B

Fig.13

Capstan motor

B

C

Pawl

B

Capstan belt

3.2.4 Removing the flywheel assembly

(Fig.15)

(1) Remove two screws D and remove the shield plate.

(2) Pull up the flywheel (L) and (R), and remove them.

3.2.5 Removing the reel motor board

(Fig.15)

(1) Remove four solde ring of the reel motor and actuator mo-

tor, and remove the reel motor board.

Actuator motor

Soldering

Reel motor

Flywheel (R)

Fig.14

Shield plate

D

Fig.15

Soldering

Reel motor board

Flywheel (L)

1-10 (No.MB061)

Page 11

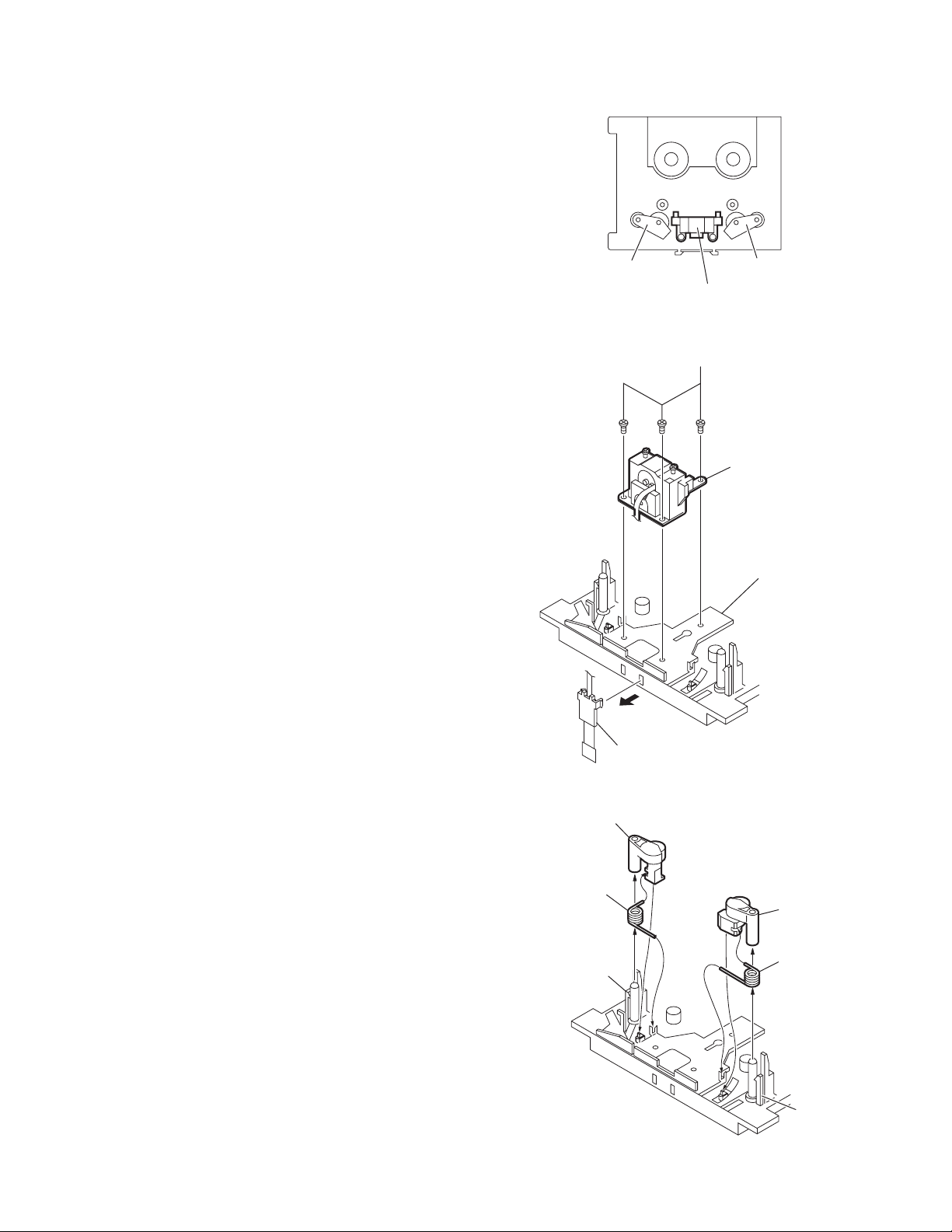

3.2.6 Removing the reel motor assembly

A

(Fig.16)

(1) Remove two screws E from rear of chassis and remove the

reel motor assembly toward upward.

3.2.7 Removing the actuator motor assembly

(Fig.16)

(1) Remove two screws F from rear of chassis and remove the

actuator motor assembly toward upward.

3.2.8 Removing the mechanism board

(Fig.17)

(1) Remove one screw G retaining the board.

(2) Release the mechanism bo ard from five pawls.

(3) For gearing between the mechanism board and control

cam, see the magnified illustration in a circle.

ctuator motor assembly

Reel motor assembly

Mechanism board

EF

Fig.16

Mechanism board

Pawl

Pawl

G

Fig.17

(No.MB061)1-11

Page 12

3.2.9 Removing the control cam

(Fig.18 and 19)

(1) Release the control cam from two pawls. (Fig.18)

(2) For assembling the control cam, fits a zone (groove) of con-

trol cam to a position of pinch lever and b zone (groove) to

b position of head base shaft. (Fig.18 and 19)

3.2.10 Removing the actuator gear A and B (small)

(Fig.18)

(1) Release the actuator gear A (small) from one pawl and re-

move it toward upward.

(2) Release the actuator gear B (small) from one pawl and re-

move it toward upward.

3.2.11 Removing the actuator gear (large)

(Fig.18)

(1) After removing the control cam, actuator gear A (small) and

actuator gear B (small), remove the actuator gear (large).

Actuator gear A

(small)

Pawl

Pawl

Actuator gear

(large)

Control cam

(chassis side)

b

zone

a

zone

Pinch lever Control cam

Actuator gear B

(small)

Head base shaft

Pawl

Fig.18

a

b

Pinch lever

Fig.19

1-12 (No.MB061)

Page 13

SECTION 4

ADJUSTMENT

4.1 Measuring instruments required for adjustment

(1) Low - frequency oscillator (oscillation frequency 50 Hz - 20

kHz, 0 dB output with 600 Ω impedance)

(2) Attenuator (600 Ω impedance)

(3) Electronic voltmeter and oscilloscope

(4) Standard tapes

VT712 (tape speed, wow and flutter measurement)

VT727 (400 Hz reference level)

VT742 (63 Hz, 1 kHz, 12.5 kHz) (play back frequency)

VT705 (12.5 kHz) (azimuth)

(5) Recording reference tapes

AC-225 (Normal), AC-514 (TDK SA) (CrO2)

AC-713 (TDK MA) (Metal)

(6) 600 Ω resistors (for attenuator matching)

(7) Distortion meter (band pass filter)

(8) Torque gauge (cassette) for CTG-N, TW2111, TW2121,

TW2231 and TW2241, mechanism adjustments

(9) Wow & flutter meter

(10) Frequency counter meter

(11) M300 gauge

(12) Band pass filter

4.3 Location of adjustment

4.2 Measurement conditions

(1) Power supply voltage (your local voltage)

AC230 V 50 Hz : B/E/EN version

AC120 V 60 Hz : J/C version

AC230/127/110 V 50/60 Hz : UT/U version

(2) Standard position of the switch and volume knob Switches

and volume knobs setting position

INPUT LEVEL : MAXIMUM

DOLBY NR : OFF

REVERSE MODE :

(3) Standard level (0 dBs) is 0.775 V unless otherwise speci-

fied.

(4) The reference value of recording input level is LINE IN level

of a signal whose LINE OUT level is -8 dBs and H.PHONE

OUT level is -24 dBs.

Connection of CN845

CN845

1

5

470k

(L)

(R)

+

F. COUNTER

(BIAS

GND

FREQUENCY

adj.)

+

DC VOLTMETER

V

(HX PRO adj.)

-

+

V

-

DECK B

REC LEVEL

adj.

DECK A

PB FREQ.

RESPONSE adj.

DECK A

PB LEVEL

adj.

VR211 VR111

LR

VR212 VR112

LR

BIAS

FREQUENCY

VR216

L

VR226

R

VR246 VR146

L2401

L8401

B7101

H.SPEED

TP

R L

L1401

L

R

15

CN845

DECK A

DECK A

VR216 VR116

RRL

VR217 VR117

L

NORMAL SPEED adj.

VR703

VR701

VR704

VR702

HIGH SPEED adj.

DECK B

DECK B

DECK B

REC FREQ.

RESPONSE

adj.

HX PRO adj

DECK B

FREQ.

RESPONSE

adj.

DECK B

PB LEVEL

adj.

(No.MB061)1-13

Page 14

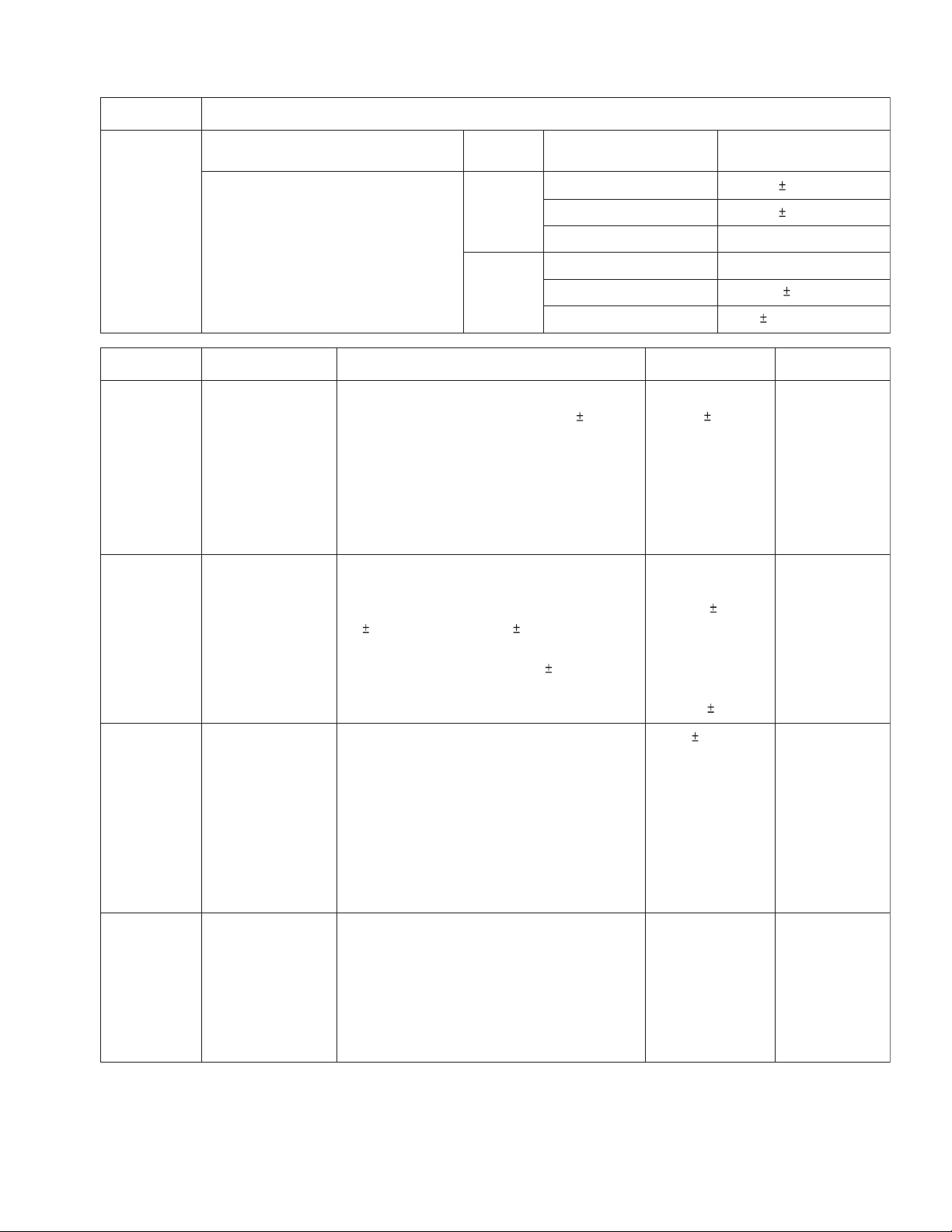

4.4 Mechanism adjustment

Before using test tapes, tape transporting past should be demagnetized.

* Adjustments required after head replacement are marked with an asterisk(*).

Item Conditions Adjustment and Confirmation Standard value Adjust point

* Adjusting

Head

azimuth

Adjusting

tape speed

(motor speed)

Test tape : VT704

or VT705 (12.5 kHz)

1.

Test tape :

VT712 (3 kHz)

After adjustment

of normal speed,

then adjust high

speed.

2.

For high speed

adjustment, set

the deck for play

mode and short

circuit between

B7101 and GND.

Connect an electronic voltmeter to the LINE

1.

OUT terminals.

Play back the VT704 (12.5 kHz) test tape.

2.

Adjust the head angle with the screw (FWD

3.

and REV) until the reading of the electronic

voltmeter becomes maximum for both

channels (phase difference must be "0".)

Repeat the adjustment in FWD and REV

modes as well as for the decks A and B.

4.

1.

Connect a frequency counter to the LINE OUT

terminals.

2.

Perform normal speed adjustment first, and

3.

then do high speed adjustment.

Play back the VT712 test tape.

Adjust for decks A. :

Adjust VR701 for normal speed at 3000 Hz,

and VR702 for high speed at 6000 Hz.

4.

Adjust for decks B. :

Adjust VR703 for normal speed at 3000 Hz,

and VR704 for high speed at 6000 Hz.

Difference in FWD and REV frequencies must

be less than 48 Hz.

Maximum Screws

(FWD, REV)

Deck B

FWD

Deck A

FWD

Normal speed:

Deck A,B ;

3000 15 Hz

High speed:

Deck A,B ;

6000 30 Hz

Deck A :

Normal ; VR701

High ; VR702

Deck B :

Normal ; VR703

High ; VR704

REV Adj.

REV Adj.

Checking

wow and

flutter

Checking

play back

torque

Checking

back

tension

Checking

FF/REW

time

Test tape : VT712 (3

kHz)

1.

Connect a wow and flutter meter to the LINE

OUT terminals.

2.

Play back the VT712 test tape.

3.

Check to see if the reading of the meter is

within 0.17 % (WRMS).

Torque gauge :

TW2111 (FWD)

TW2121 (REV)

Employ a torque testing cassette tape

(TW2111[FWD] / TW2121[REV]) for the

checking, or remove the cassette cover and use

a torque gauge.

Torque gauge :

TW2111 (FWD)

TW2121 (REV)

Employ a torque testing cassette tape

(TW2111[FWD] / TW2121[REV]) for the

checking, play the torque gauge and read the

back tension value to confirm that the back

tension is 1 - 5 g cm.

Tape : AC-225 Play back AC-225 tape in FF/REW mode, check

that the FF/REW time during tape running from

begin to end.

Less than 0.17 %

(WRMS)

27 - 70 g cm

1 - 5 g cm

Less than 120 sec

1-14 (No.MB061)

Page 15

4.5 Electrical adjustment procedure

Item

Checking

1

DOLBY

circuit

(Rec. mode)

(BIAS-CUT)

Signal input: LINE IN Cal. level :

400 Hz, -8 dBs

Output terminal TP : NR IC831 53 and 8

pin.

Check and Adjustment

(Frequency, level)

1 kHz, Cal. - 40 dB

DOLBY B

(Rec)

5 kHz, Cal. - 20 dB

1 kHz, Cal.

1 kHz, Cal. - 40 dB

DOLBY C

(Rec)

5 kHz, Cal. - 20 dB

1 kHz, Cal.

Input signal

Output raise value,

deviation value

+5.7 dB 2 dB

+3.5 dB 1.5 dB

0 dB +0.5 dB -1.0 dB

+16.2 dB +3 dB -2 dB

+2.9 dB 2.5 dB

0 dB 1 dB

Item Conditions Adjustment and Confirmation Standard value Adjust point

*2

Play back

level

adjustment

Test tape :

VT727 (400 Hz)

Play back VT727 in FWD mode, then confirm

that the level at LINE OUT is -4.5 dBs 0.5 dB.

Adjust VR112/VR212 and VR117/VR217 so that

LINE OUT level becomes -4.5 dBs.

Difference level between Lch and Rch must less

than 0.5 dB at LINE OUT.

LINE OUT

-4.5 dBs 0.5 dB

Phone Out

-21 dB

+2.5 dB -1.5 dB

Deck B

L : VR117

R : VR217

Deck A

L : VR112

R : VR212

Confirm that difference playback level between

FWD and REV modes within 1.5 dB.

*3

Play back

frequency

response

adjustment

*4

Bias

frequency

adjustment

*5

Slave

oscillation

(HX PRO)

adjustment

Test tape :

VT742

(63 Hz, 1 kHz,

12.5 kHz)

Frequency counter

TP: CN845 pin 1

Tape: Metal

Mode: REC

Frequency counter

input impedance:

more than 470kohm

(see 3.3 Location of

adjustment.)

DC. Voltmeter

TP: CN845

Lch (pin 3 - 4)

Rch (pin 3 - 5)

Play back VT742 test tape, and adjust VR116,

VR216 (deck B) and VR111, VR211 (deck A) so

that deviation of 12.5 kHz to that of 1kHz is

0.5 0.5 dB (deck A) and 0 0.5 dB (deck B).

Then play back VT742 test tape to confirm that

deviation of 63 Hz to 1 kHz is +2 3 dB.

Connect frequency counter to the pin 1 of CN845

and adjust L8401 so that the counter reads

95 kHz.

This step must be performed after the bias

frequency adjustment.

Load a metal tape and set the deck to the

recording mode.

Adjust L1401 and L2401 to minimize respective

DC voltage of CN845 (pin 3 - 4) at Lch and (pin 3

- 5) at Rch.

Difference level of

12.5 kHz from 1kHz

within 0.5 0.5 dB

(both decks A and

B)

Difference level of

Deck B

L : VR116

R : VR216

Deck A

L : VR111

R : VR211

63 Hz from 1 kHz

within +2 3 dB.

95 kHz 1 kHz Deck B

L8401

Minimum Deck B

L : L1401

R : L2401

(No.MB061)1-15

Page 16

Item Conditions Adjustment and Confirmation Standard value Adjust point

6

Checking

recording

bias current

(Value

appearing

here are

just for

reference

7

Input

sensitivity

level check

*8

REC/PB

frequency

response

adjustment

Measuring point:

Both ends of

100 ohm resistor

connected to the

R/P head terminal

LINE INPUT level:

Ref. -20 dB

(-40 dBs 2 dB)

NR switch : OFF

Connect 100 ohm resistor to the R/P head in

series, and measure voltage at both ends of the

resistor to check to see if measured voltage

meets the following requirements on both

channels.

In recording with metal tape, the bias current

is 1150 uA (1.15 mA).

In recording with CrO

2 tape, the bias current

is 700 uA (0.7 mA).

In recording with normal tape, the bias current

is 590 uA (0.59 mA).

1.

Supply at 1kHz signal to the LINE IN terminals

at -19 dBs, confirm that LINE OUT level is 8dBs.

2.

Confirm that difference level between left and

right within 2 dB.

This step must be performed after the slave

oscillation adjustment.

Record the 1.25 kHz and 12.5 kHz signals at the

level of -20 dB (20 dB lower than the reference

level).

Playing back the recorded signals, adjust VR146

and VR246 so that the level of the 12.5 kHz

signal is 0 0.5 dB to the level of the 1.25 kHz.

Reference values

Metal tape:1150 uA

CrO

2 tape: 700 uA

Normal tape:590 uA

LINE IN:

-19 dBs 2 dB

12.5 kH level:

0 0.5 dB

higher than the

1 kHz level.

Deck B

L : VR146

R : VR246

*9

REC/PB

sensitivity

adjustment

Spec. of freq. area

250 Hz 1 Hz 10 Hz 12.5 Hz

3 dB

NR switch : Off

TAPE switch :

Normal

LINE INPUT level:

Ref. -20 dB

Increase in high

frequencies

Decrease in

high frequencies

5 dB

Response (dB)

0 50 Hz 1 kHz

1.

Apply 400 Hz signal to the LINE IN terminals,

12.5 kHz

record 400 Hz signal at -20 dB input for both

(L and R) channels on a normal tape.

2.

While recording the recorded signal and play it

back, adjust VR126(L) and VR226(R) so that

difference between the recording/playback

level and the reference level is

-28 dBs 0.5 dB on both channels.

Low bias current

Appropriate bias current

High bias current

Frequencies

Normal:

-28 dBs 0.5 dB

CrO

2/Metal:

-28 dBs 1 dB

(Difference between

L and R within

0.5 dB)

Deck B

L : VR126

R : VR226

1-16 (No.MB061)

Page 17

Item Conditions Adjustment and Confirmation Standard value Adjust point

10

Checking

dubbing

calibration

Test tape : VT742

Normal tape :

AC-225

1.

Insert test tape VT742 into deck A and

AC-225 into deck B.

2.

Dubbing the 1kHz signal of VT742 to AC-225

during high speed mode.

Playback the dubbing part of AC-225 (deck B)

and confirm that output level of 1kHz is

-28 dBs +1.5/-2 dB on both channels through

the band pass filter.

11

Maximum

output

check

Checking

12 Record a 1 kHz, -20 dB signal to LINE IN

record/

playback

distortion

Supply 1 kHz signal to the LINE IN terminal in

the Rec. monitoring mode, and read non-clipped

signal level at the LINE IN terminal.

1.

terminals.

2.

Play back the recorded part. Check the output

with a distortion meter to see if the value

conforms to the standard value.

-28 dBs +1.5/-2 dB

LINE OUT:

more than 8 dBs

PHONES OUT:

more than -16 dBs

Normal:

Less than 2 %

CrO

2/Metal:

Less than 3 %

13 Record a 1 kHz, -20 dB signal. Stop the input

Checking

signal to

noise ratio

recording

play back

1.

by disconnecting from the terminal to perform

non-signal recording.

2.

Play back the recorded part. Measure the

-8dBs recording output and the non-signal

recording output for comparison using an

electronic voltmeter. Check to see if the value

conforms to the standard value.

14 Apply a 400 Hz, +20 dB signal to the LINE

Checking

erasing

coefficient

1.

terminals.

2.

Perform recording with the signal enhanced

by 20 dB.

3.

Erase a part of the recording.

4.

Measure the output difference between the

erased part and non-erased part to compare

with an electronic voltmeter.

For the measurement using a metal tape,

connect a band pass filter between the deck and

the electronic voltmeter.

Normal:

More than 40 dB

CrO

2/Metal:

More than 41 dB

LINE OUT:

More than 55 dB

Input

(400 Hz)

(400 Hz)

Band pass filter

Tape deck

(recording,

erasing)

Electronic

voltmeter

(No.MB061)1-17

Page 18

Item Conditions Adjustment and Confirmation Standard value Adjust point

1.

Checking

15

MPX filter

effect

Signal input:

LINE IN

Input level:

Maximum

Connect an electronic voltmeter and

oscilloscope to the LINE OUT terminals.

2.

Set the INPUT volume to the maximum

position.

Supply 1 kHz and 19 kHz signals reference

19 kHz level:

-30 dB (including

18.99 to 19.01 kHz)

lower than 1 kHz

signal

level to the LINE IN terminals respectively in

record/pause mode.

While recording monitor the 1 kHz and 19 kHz

signals respectively, confirm that level

difference between 19 kHz signal to 1 kHz

signal is more than 30 dB.

16 Connect an electronic voltmeter to the LINE

Checking

peak

indicator

calibration

Operation mode:

REC/PAUSE

Input frequency:

1 kHz

Signal input:

LINE IN

LINE OUT: -4 dBs

1.

OUT terminals.

2.

Supply the 1 kHz reference signal (-4 dBs) to

the LINE IN terminals.

3.

While rising the input signal level at the LINE

4.

OUT so that each peak indicator is turned on

with the output level specified on the light.

(Indicator reads at 0

position)

Indicator

- 30

- 20

- 15

- 12

- 10

- 8

- 6

- 4

- 2

0

+ 2

+ 4

+ 6

+ 8

Signal level

(LINE OUT)

- 34 dBs 5 dB

- 24 dBs 4 dB

- 19 dBs 3 dB

- 16 dBs 3 dB

- 14 dBs 2 dB

- 12 dBs 2 dB

- 10 dBs 2 dB

- 8 dBs 1 dB

- 6 dBs 2 dB

- 4 dBs 2 dB

- 2 dBs 2 dB

0 dBs 2 dB

+ 2 dBs 2 dB

+ 4 dBs 2 dB

1-18 (No.MB061)

Page 19

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB061)1-19

Page 20

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB061)

Printed in Japan

WPC

Page 21

SCHEMATIC DIAGRAMS

DOUBLE CASSETTE DECK

TD-W271

CD-ROM No.SML200401

Area suffix

UF ---------------------------- China

U ---------------------- Other Areas

DOUBLE CASSETTE DECK

AUTO REVERSE

A

3MOTOR SILENT MECHANISM

PLAYBACK

REVERSE MODE

DOLBY NR

POWER

B OFF C

STANDBY/ON ON OFF

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

STANDBY

COUNTER RESET

28

PLAY

PHONES

INPUT LEVEL

5

46

37

19

MIN MAX

COUNTER RESET

AUTO TAPE SELECTOR / CONTINUOUS PLAY

PLAY

REC / REC MUTE PAUSE

AUTO REVERSE

3MOTOR SILENT MECHANISM

DOLBY B-C NR HX PRO

B

REC/PLAYBACK

A B SYNCHRO DUBBING

NORM SPEED

HIGH SPEED

2-1

2-2

2-5 to 7

COPYRIGHT 2004 VICTOR COMPANY OF JAPAN, LTD.

No.MB061SCH

2004/1

Page 22

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 23

Block diagram

LINE IN

L

DECK A

PB HEAD

R

L

R

VR111

A PB EQ ADJ

(L)

VR211

A PB EQ ADJ

(R)

2

15 1375

Input Level

VCA

VCA

VR601

Q1101

Q2101

4

D8101

HS

IC851

VOL. CONTROL

& DD RP

DECK A

PB HEAD AMP

4

IC811

6

3

7

A PB LEVEL ADJ

2

8

IC812

PB EQ SWITCH

VR112VR212

(L)(R)

HS

PB SIGNAL

A70

IC818

SELECT

5, 6

Q8172

B PB

1

4 3

2 11 10

8 9

REC IN

12, 13

Q8171

PB IN

A PB

(R)

(L)

REC

1

30 22

28 3

PB IN

PB

IN

OUT

(L)

(L)

IC835

DOLBY NR

REC

OUT

(R)

(R)

15 16

PB OUT

(R)

9

REC

OUT

(L)

HEADPHONES

5

7

IC861

1

3

IC852

LEVEL METER AMP

5

3

L

LINE OUT

R

J8601

H. P. JACK

7

1

DECK B

REC/PB HEAD

ERASE HEAD

L

REC/PB SELECT

VR116

B PB EQ ADJ

(L)

R

IC816

3 1 4

7

VR216

B PB EQ ADJ

(R)

IC845

7

L2401 L1401

8

X

B

HX PRO

2

VR246

BIAS ADJ

-7V -7V

(R)

11

12

10 2

17

VR146

BIAS ADJ

Q8153

9

(L)

REC

DECK B

PB HEAD AMP

VR217

B PB LEVEL ADJ

(R)

FREQUENCY ADJ

4

IC815

7

6

L8401

2

8

3

VR117

B PB LEVEL ADJ

(L)

BIAS OSC

Q8491

Q8492

Q1152

Q2152

B70

Q8481

Q8482

REC AMP

7

IC825

1

REC LEVEL ADJ

+B

-B

Q705

FL MUTE

DI701

Q1251 Q2251

Q8251

REC MUTE

Q706

Q707

5

3

VR226

(R)

VR126

REC LEVEL ADJ

(L)

24

1

2

3

4

5

6

7

9

IC701

G0-G6

S1-S16

47

48

METER

(R)

METER

(L)

2-1

Page 24

Standard schematic diagrams

System control / FL display / Key section

(SHEET 2)

(SHEET 2)

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 1

2-2

Page 25

Head amplifier section

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

(SHEET 1)

(SHEET 1)

(SHEET 3)

SHEET 2

2-3

Page 26

Amplifier / Power supply section

(SHEET 2)

2-4

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 3

Page 27

Printed circuit boards

Main board

CN861

C8492

C8493

C8495

R8493

CN801

C8494

C2101

R8151

R8152

R1601

R2601

R1603

R1605

C1602

C8602

C2602

R2605

R2603

C2108

C8601

R2102

CN815

Q8163

C1101

VR212

CN811

C8491

C8496

R8491

R1102

C2107

IC816

L8401

C1107

VR112

Q2101

C1102

C2155

R1101

C2102

C1155

VR217

R8492

Q8492

Q8491

C1108

R1159

VR117

R2159

R1109

R2109

IC861

R2101

R2602

Q1101

C1105

R1602

R1604

VR111

C8102

C2105

VR211

C2153

C2254

C1153

L2251

C2256

R2604

IC815

C1151

C2151

C8452

C1452

L1251

C1256

C8151

CN845

C2251

C1103

C2103

R1152

R2152

R1451

D8251

R1271

R2252

C8101

Q8481

C2452

VR116

VR216

R2253

Q8251

IC811

R2104

R1453

R1252

R2451

VR226

R1272

D8101

R8101

C1104

C2104

C8252

Q8253

R1104

R8102

C1254

R2251

C1152

C2152

R8482

C8481

R2257

IC825

Q2251

D8352

R2154

R1273

R2272

Q8352

R1154

R8483

C2451

Q1253

Q2253

C2360

R1105

Q8101

IC812

C8483

R1257

C1251

R8104

C1154

C2154

VR126

R2273

C1360

R1107

R2105

C8482

R8481

C2255

R1106

R1155

R1165

R2165

R2155

R8486

Q8482

R8485

R1253

R1251

D8351

R2107

Q1251

R2271

Q8351

R1108

R2106

R1256

C1359

C1358

C2357

C2358

C2454

C1255

C1357

C2359

C1106

C8152

C2106

C1457

C8251

R8103

R2108

Q1152

Q2152

D8481

C2253

R2256

C1253

R8484

C2453

R1255

R2357

R1158

R2158

R1254

R1357

L2401

C2355

C2356

C1451

R2254

IC835

C1156

C2156

R2255

C1356

R2353

R2160

C8455

C2457

R1258

C1355

R2356

L1401

C2258

L2252

L1252

R1356

R1351

R8354

C1354

R1353

C2354

R2270

C1258

R2351

L2351

R2258

R1160

CN802

C2257

C1257

C2456

C2455

C2259

R2354

C1453

C1454

C1456

R8355

R8351

C1259

C8352

C8351

L1351

IC845

C8451

IC826

R1352 R2352

R2452 R2453

Q2252

R1259

Q1252

C1455

R2259

R1270

R2355

C8901

C8902

R1354 R1355

C8454

R1452

C8453

R1263

C1263

R1262

C1261

R1261

R8353

R8352

C2252

C2267

C1252

R2265

C2265

R2267

R2268

Q8353

VR146

VR246

R8253

IC891

R8505

Q8502

R8451

D8252

R2266

R1264

R8172

Q8501

Q8503 Q8504

R2504

D8514

R8504

R8503

R8501

R8502

C8503

L8402

R8452

R8453

Q8471

R2261

C2266

C2261

C2263

R2264

C2268

Q2261 Q2262

Q1261

R1268

R1267

C1267

C1264

R1266

C1265

R1265

C1262

R8171

IC818

Q8172

R8173

Q8171

C928

R1110

D8451

R8471

R2262

R2263

R2505

R8251

Q1262

C1268

C1266

R8473

Q8252

C2262

C2264

R940

C941

R8472

IC851

R8475

R8252

R1111

C1109

R2111

C2109

R2110

C2351

D8452

R2161

Q915

R8474

R1161

R930

R929

R1505

D8513

R941

C918

C2169

R2516

D926

C2501

C1501

R1504

C924

R1516

D925

C1351

C1169

R8255

C927

Q907

C8501 C8502

D922

D8253

R937

C923

Q908

C2511

C1511

Q912

D921

R928

R938

R927

Q905

D1511

R1515

R1513

C908

R913

C906

D913

R2515

D909

R923

R921

R2511

R8511

Q913

C917

IC852

C8511

D2511

R8516

D907

D910

R8515

C921

C915

C914

C8512

R2512

R2513

D8512

C907

D903

R8514

R914

D914

C904

C8513

R910

D902

IC901

D923

R2514

D908

R902

C902

D924

R908

D8511

C931

C909

R918

Z902

R1512

R1514

R1511

C920

D918

R917

C910

Q2511

C911

R912

Q1511

R1517

R2517

R901

C901

Z901

R1502

R8513

R915

D906

C903

CN901

R2502

Q8511

D901

D917

R2501

R1501

R1503

R2503

D905

D904

Z904

R933

J8501

R8901

J701

Z903

Q901 Q903

Q909

R931

C925

2-5

Page 28

Sub board

W702

R626

R623

CN604

D722

C705

D721

D720

S623

D723

S627

D719

R736

R735

R625

R624

S624

R734

CN722

CN721

IC732

IC734

S626

S625

C734

C733

(Switch/Volume board)

CN602

VR601

D711

D724

R750

VR704

VR703

VR702

R742

VR701

R752

R743

Q742

R751

R745

Q709

Q743

Q741

Q740

R786

CN601

R749

Q708

R741

Q711

R785

R748

R753

R754

D705

Q752

Q744

DI701

D702

R756

C703

Q745

D706

D704

R746

R747

R740

R609

R610

D710

R775

R716

B7101

S606

S607

R719

R774

D708

D707

D703

R773

C706

R608

R772

R771

R607

R669

S608

R670

R770

W703

R652

R671

IC701

R606

R653

R672

R654

R605

R673

R657

R761

D712

S605

R762

S604

R766

R767

CN603

R768

R664

R668

R769

CN702

R665

R666

R667

R659

R702

R661

R662

R663

R658

R660

C701

Q703

D701

R715

R782

X701

R701

C702

Q704

S630

R656

R711

R710

Q707

R712

R628

R655

Q706

S601

R651

R781

CN701

Q705

R627

(A:Key switch board)

(Standby LED board)

FW701

R780

R764

Q712

D713

Q702

R783

(B:Key switch board)

D741

R765

FW701

R708

Q701

R706

R709

R707

Q751

R755

R703

R705

S621 S622 S628 S629

R704

S610

R604

R622

R621

S602

S603

R603

(Headphone jack board)

J8601

IC731

C731

C732

C1601

C2601

IC733

R731

R732

R733

R717

R601

R718

CN614

CN613

C704

D717

D716

CN712

D715

CN711

CN862

D718

R784

Q710

D709

W701

(Mechanism control board)

Trans board (UF version) Trans board (U version)

(Trans board)

(Power switch board)

P1

S901

P3

C900

W2

W3

W2

W3

T901

FW901

C930

W1

Z906 Z905

W2

W3

2-6

(Trans board)(Voltage selector board)

W5

W4

W1

C930

W4

W5

FW901

T901

W2

W3

P3

P1

Page 29

Mechanism board

(Cam switch board) (Motor board)

CN1

S5

S4

B7

B5

B4

S3

B3

S2

B1

S1

IC2

S6

IC1

B8

CN2

FW1

C2

2-7

Page 30

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB061SCH)

Printed in Japan

WPC

Page 31

PARTS LIST

[ TD-W271 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

UF ---------------------------- China

U ---------------------- Other Areas

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Cassette mechanism assembly and parts list (Block No.MP)

Electrical parts list (Block No.01~03)

Packing materials and accessories parts list (Block No.M3)

No. MB061 3-1

3- 2

3- 5

3- 7

3-12

Page 32

Exploded view of general assembly and parts list

4

4

Block No.

27

M

M

1

M

49

28

48

32

47

A:Mechanism

Ass'y

40

22

45

51

50

22

F

53

41

39

40

19

A:Key switch

board Ass'y

70

30

20

Mechanism control

52

54

37

F

35

36

board Ass'y

60

J

63

34

Q

66

62

33

65

M

4

26

24

4

B

3

24

24

N

27

N

16

24

H

G

13

24

17

Head phone

jack boad

P

25

Switch/Volume board

Ass'y

29

P

42

44

58

44

59

43

44

23

69

44

23

21

21

23

51

61

36

50

46

35

55

E

56

57

38

31

3-2

Page 33

7

6

M

4

4

24

26

24

25

itch/Volume board

Ass'y

5

12

4

8

11

4

A

M

15

9

10

12

77

B

24

3

13

D

14

14

Q

74

18

24

85

12

Power swich

board ass'y

75

P

Main boad Ass'y

13

UF Version

86

83

85

29

51

61

36

50

46

35

55

E

64

48

62

66

65

H

G

22

B:Mechanism

Ass'y

22

72

72

73

J

80

81

71

73

D

87

84

K

76

C

82

L

47

40

49

49

B

L

K

1

A

72

38

57

56

40

31

41

39

B:Key swich board Ass'y

67

68

2

C

67

E

68

3-3

Page 34

General assembly

Block No. [M][1][M][M]

Symbol No.

1 VKL1333-013 CHASSIS BASE

2 VYSR110-016 SPACER

3 QQT0330-003 POWER TRANSF T 901

3 QQT0330-002 POWER TRANSF T 901

4 QYSBST3006Z TAPPING SCREW 3mm x 6mm(x4)

5 VJC2579-005 REAR PANEL

5 VJC2579-004 REAR PANEL

6 QMPR110-200-JN POWER CORD 2m BLACK

6 QMPR490-200-JC POWER CORD 2m BLACK

7 QHS3771-108 CORD STOPPER

8 QYSBSF2608M TAP SCREW M2.6 x 8mm(x2)

9 QYSBSF3008M TAP SCREW 3mm x 8mm(x2)

10 QYSBSF3008M TAP SCREW 3mm x 8mm

11 QYSBSF3008M TAP SCREW 3mm x 8mm

12 QYSBST3006M TAPPING SCREW 3mm x 6mm(x3)

13 QYSBSTG3006Z TAP SCREW M3 x 6mm(x4)

14 QMF51E2-R80-J1 FUSE

15 QMF51E2-R315-J1 FUSE

16 QUQ412-0612CJ FFC WIRE

17 QUQ412-0612CJ FFC WIRE

18 QUQ412-2021CJ FCC WIRE

19 VJG1458-013 FRONT PANEL

19 VJG1458-014 FRONT PANEL

20 VJD5429-002SS JVC MARK

21 VYSA1R4-110 SPACER (x2)

22 QYSBSF3010Z TAP SCREW 3mm x 10mm(x4)

23 QYSBST3006N TAP SCREW M3 x 6mm(x3)

24 QYSBSF2610Z SCREW 2.6mm x 10mm(x6)

25 VYSS201-014 SPACER

26 VYH7979-001MM CAP

27 QYSDST2604Z SCREW 2.6mm x 4mm(x2)

28 VXP5345-003 PUSH BUTTON

29 VXP2131-003 MECHA BUTTON

30 VXP5350-002 MECHA BUTTON

31 VXP3835-003 MECHA BUTTON

32 VXS4398-003 SLIDE KNOB (x2)

33 VKL7856-001 HEAD PHONE BKT

34 VKL6752-001 SNAP PLATE

35 VYH7779-00B DUMPER ASSY (x2)

36 VYSS2R3-024 SPACER (x2)

37 VKW3006-236 TORSION SPRING

38 VKW3006-237 TORSION SPRING

39 VYH2323-001 MECHA HOLDER (x2)

40 QYSBSF2610Z SCREW 2.6mm x 10mm(x4)

41 QYSBSF2610Z SCREW 2.6mm x 10mm(x2)

42 VJT2317-007 CASSETTE HOLDER

43 VJT2317-008 CASSETTE HOLDER

44 VKY4180-401 CASSETTE SPRING (x4)

45 VYH7941-005 LOCK LEVER(L)

46 VYH7941-006 LOCK LEVER(R)

47 VMA4718-001 SHIELD (x2)

48 VKS3655-002 F.P.C. HOLDER (x2)

49 QYSDST2603Z TAP SCREW M2.6 x 3mm(x4)

50 VKW5199-001 TENSION SPRING (x2)

51 VKZ4749-001 SPECIAL SCREW (x2)

52 VKL7293-001SS EJECT SAFTY(R)

53 QYSBSF3010Z TAP SCREW 3mm x 10mm

54 VKW5069-002 TORSION SPRING

55 VKL7663-001 EJECT SAFTY(L)

56 QYSBSF3010Z TAP SCREW 3mm x 10mm

57 VKW5104-003 TORSION SPRING

58 VJT2380-011 CASSETTE LID

59 VJT2380-012 CASSETTE LID

60 VXP5289-007 PUSH BUTTON

61 VXP5289-008 PUSH BUTTON

62 VKW3001-077 SPRING (x2)

63 VKL7857-002 REMOTE ARM

64 VKL7858-002 REMOTE ARM

65 VYH7773-001 BUTTON HOLDER (x2)

66 QYSBSF2610Z SCREW 2.6mm x 10mm(x2)

67 QZF6018-003 FOOT 60mm x 18mm(x4)

68 QYSBST3008Z TH TAP SCREW 3mm x 8mm(x4)

Part No. Part Name Description Local

F901 F902 0.8A

AC250V(x2)

F 903 0.315A

AC250V

W271U

W271UF

W271U

W271UF

W271U

W271UF

W271U

W271U

W271UF

Symbol No.

69 VXL3025-005 KNOB

70 VJK3652-012 FINDER

71 VJG1459-003S TOP COVER

72 E406308-004 SPECIAL SCREW (x4)

73 QYSBST3006M TAPPING SCREW 3mm x 6mm(x2)

74 LV34380-001A NAME PLATE

74 LV34380-002A NAME PLATE

75 QYSPSPD3008Z SCREW 3mm x 8mm(x3)

76 LV30092-0E5A UF LABEL

77 LV43268-001A CCC LABEL

80 VXP5346-002 PUSH BUTTON

81 VKL7859-002 REMOTE BRACKET

82 VYH8119-002 SW BRACKET

83 VKS5569-001 REMOTE BAR

84 VKS5570-001 SLIDER

85 QYSBST3006Z TAPPING SCREW 3mm x 6mm(x3)

86 QYSSST3008Z SCREW 3mm x 8mm

87 QYSDST3006Z TAP SCREW 3mm x 6mm

Part No. Part Name Description Local

W271U

W271UF

W271UF

W271UF

W271UF

W271UF

W271UF

W271UF

W271UF

W271UF

W271UF

W271UF

3-4

Page 35

Cassette mechanism assembly and parts list

NY1000-T1A

NY1000-T1B

Block No.

M

MM

P

28

30

46

13

46

13

47

DECK A

DECK B

13

A

4

45

44

2

14

5

23

3

26

11

1

31

27

29

S5

43

S4

CN1

43

S3

DECK B

S2

S1

37

36

34

34

20

6

35

A

B

S4

40

43

CN1

9

8

43

S2

DECK A

7

39

40

41

42

22

19

16

21

B

B

CN2

38

C2

A

C3

37

C

4.8~5.2

mm

6.2

+

0.2

mm

3-5

Page 36

Cassette mechanism

Block No. [M][P][M][M]

Symbol No.

A VKS3626-00E H.MOUNT ASSY A MECHA

A VKS3629-00E H.MOUNT ASSY B MECHA

B MSN5D257A-SA1 D.C MOTOR ASSY

C MSI5B2LW-SA2 CAPSTAN MOTOR

1 VKS1126-00B CHASSIS BASE

2 VKS5428-00B T-UP REEL ASSY

3 VKW5043-001 B.T. SPRING

4 VKS3617-002 REEL

5 VKW5043-001 B.T. SPRING

6 VKS3627-002 PINCH LEVER

7 VKS2224-002 CONTROL CAM

8 VKS5454-001 ACT GEAR(2) (x2)

9 VKS5455-001 ACT GEAR(3)

11 VKM3632-001 HEAD BASE

13 SDSR2004Z SCREW (x3)

14 VKZ4708-001 SPECIAL SCREW

16 VKS5430-00CMM FR ARM ASSY

19 VKF3195-00A FLY WHEEL(R) ASSY

20 VKF3197-00A FLY WHEEL(L) ASSY

21 MMN-6F4RA38 D.C. MOTOR FOR REEL MOTOR

22 VKS5432-001 REEL MOT. GEAR GEAR KIT S

23 VKZ4705-001 SCREW (x2)

26 VKZ4705-002 SCREW (x2)

27 VKP4227-00B PINCH R.(R)ASSY

28 VKP4229-00B PINCH R.(L)ASSY

29 VKW5045-003 P.R. SP(R) FOR PINCH (R)

30 VKW5046-003 P.R. SP(L) FOR PINCH (L)

31 VKY4670-001 CASSETTE SPRING PRESS KIT S

34 SPSP2603Z SCREW M2.6 x 3mm(x2)

35 VKM3636-002 FM BRACKET

36 VKS5327-005MM THRUST PLATE

37 SBSF2608Z TAPPING SCREW 2.6mm x 8mm(x3)

38 VKB3001-068 BELT

39 SDST2612Z SCREW 2.6mm x 12mm

40 VKS3616-00A CAM SW UNIT S6

41 DN6851-HI HALL IC

42 VKS3630-001MM IC HOLDER IC1

43 MXS00220MVL0 CASSETTE SWITCH A MECHA(x2)

43 MXS00220MVL0 CASSETTE SWITCH S1 S2 S3 S4 S5(x5)

44 VKS3614-001 TURN OVER GEAR

45 VKW5126-001 HEAD SPRING

46 VKZ4730-001 SPECIAL SCREW (x2)

47 VKS3654-001 HEAD MT. COVER

C 2 QFV41HJ-104ZM TF CAPACITOR C2

C 3 QFV41HJ-104ZM TF CAPACITOR C3

CN 1 VMC0234-R15 CONNECTOR CN1

CN 2 VMC0234-R08 CONNECTOR CN2

Part No. Part Name Description Local

3-6

Page 37

Electrical parts list

Main board

Block No. [0][1][0][0]

Symbol No.

IC811 AN6557F IC

IC812 BU4066BC IC

IC815 AN6557F IC

IC816 UPC1330HA IC Head switch

IC818 BU4066BC IC

IC825 BA15218N IC Dual ope amp

IC826 CD4066BE IC

IC835 HA12142NT IC

IC845 UPC1297CA IC

IC851 AN7384N IC

IC852 BA15218N IC Dual ope amp

IC861 BA15218N IC Dual ope amp

IC891 BU2090 IC

IC901 M5218AL IC

Q901 2SD882/QP/ TRANSISTOR

Q903 2SB772/QP/ TRANSISTOR(ACC)

Q905 2SB647/CD/-T TRANSISTOR

Q907 2SC3576-JVC-T TRANSISTOR

Q908 2SC3576-JVC-T TRANSISTOR

Q909 2SD882/QP/ TRANSISTOR

Q912 2SD468/BC/-T TRANSISTOR

Q913 KRA103M-T TRANSISTOR

Q915 2SD468/BC/-T TRANSISTOR

Q1101 KRC103M-T TRANSISTOR

Q1152 2SK301/RS/-T TRANSISTOR

Q1251 KTC3203/OY/-T TRANSISTOR

Q1252 KRC103M-T TRANSISTOR

Q1261 KTC3199/GL/-T TRANSISTOR

Q1262 KRC103M-T TRANSISTOR

Q1511 KTC3203/OY/-T TRANSISTOR

Q2101 KRC103M-T TRANSISTOR

Q2152 2SK301/RS/-T TRANSISTOR

Q2251 KTC3203/OY/-T TRANSISTOR

Q2252 KRC103M-T TRANSISTOR

Q2261 KTC3199/GL/-T TRANSISTOR

Q2262 KRC103M-T TRANSISTOR

Q2511 KTC3203/OY/-T TRANSISTOR

Q8101 KRA103M-T TRANSISTOR

Q8163 KRC103M-T TRANSISTOR

Q8171 KRA103M-T TRANSISTOR

Q8172 KRA103M-T TRANSISTOR

Q8251 KRA103M-T TRANSISTOR

Q8252 KRA103M-T TRANSISTOR

Q8351 KRC103M-T TRANSISTOR

Q8352 KRA103M-T TRANSISTOR

Q8353 KRA103M-T TRANSISTOR

Q8471 KTC3199/GL/-T TRANSISTOR

Q8481 2SC2001/LK/-T TRANSISTOR

Q8482 2SA1175/HFE/-T TRANSISTOR

Q8491 2SC2001/LK/-T TRANSISTOR

Q8492 2SC2001/LK/-T TRANSISTOR

Q8501 KRC103M-T TRANSISTOR

Q8502 KRA103M-T TRANSISTOR

Q8503 KRC103M-T TRANSISTOR

Q8504 KRA103M-T TRANSISTOR

Q8511 2SA1175/HFE/-T TRANSISTOR

D901 11ES2-T4 DIODE

D902 11ES2-T4 DIODE

D903 11ES2-T4 DIODE

D904 11ES2-T4 DIODE

D905 MA700A-T2 SB DIODE

D906 1SS133-T2 DIODE

D907 MTZJ3.6A-T2 ZENER DIODE

D908 1SS133-T2 DIODE

D909 11ES2-T4 DIODE

D910 11ES2-T4 DIODE

D913 MTZJ24D-T2 Z DIODE I/M

D914 1SS133-T2 DIODE

D917 1SS133-T2 DIODE

D918 MTZJ12C-T2 Z DIODE

Part No. Part Name Description Local

Symbol No.

D921 1SS133-T2 DIODE

D922 MTZJ6.2B-T2 Z DIODE

D923 1SS133-T2 DIODE

D924 1SS133-T2 DIODE

D925 1SS133-T2 DIODE

D926 MTZJ6.8B-T2 Z DIODE

D1511 1SS133-T2 DIODE

D2511 1SS133-T2 DIODE

D8101 1SS133-T2 DIODE

D8252 1SS133-T2 DIODE

D8253 1SS133-T2 DIODE

D8351 1SS133-T2 DIODE

D8451 1SS133-T2 DIODE

D8452 1SS133-T2 DIODE

D8481 1SS133-T2 DIODE

D8513 1SS133-T2 DIODE

D8514 1SS133-T2 DIODE

C901 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C902 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C903 QETM1EM-228 E CAPACITOR 2200uF 25V M

C904 QETM1EM-228 E CAPACITOR 2200uF 25V M

C906 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C907 QETN1EM-107Z E CAPACITOR 100uF 25V M

C908 QETN1AM-477Z E CAPACITOR 470uF 10V M

C909 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C910 QETN1AM-337Z E CAPACITOR 330uF 10V M

C911 QETN1AM-337Z E CAPACITOR 330uF 10V M

C914 QETN1HM-337Z E CAPACITOR 330uF 50V M

C915 QETN1HM-227Z E CAPACITOR 220uF 50V M

C917 QETN1EM-107Z E CAPACITOR 100uF 25V M

C918 QETN1EM-106Z E CAPACITOR 10uF 25V M

C920 QETN1CM-107Z E CAPACITOR 100uF 16V M

C921 QETN1CM-477Z E CAPACITOR 470uF 16V M

C923 QETN1AM-337Z E CAPACITOR 330uF 10V M

C924 QETN1AM-107Z E CAPACITOR 100uF 10V M

C927 QETN1AM-107Z E CAPACITOR 100uF 10V M

C928 QETN1EM-476Z E CAPACITOR 47uF 25V M

C931 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C941 QETN1HM-224Z E CAPACITOR 0.22uF 50V M

C1101 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C1102 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C1103 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C1104 QFLC1HJ-103Z M CAPACITOR 0.01uF 50V J

C1105 QETN1AM-227Z E CAPACITOR 220uF 10V M

C1106 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C1107 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C1108 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C1151 QFLC1HJ-102Z M CAPACITOR 1000pF 50V J

C1152 QCBB1HK-331Y C CAPACITOR 330pF 50V K

C1153 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C1154 QFLC1HJ-123Z M CAPACITOR 0.012uF 50V J

C1155 QETN1AM-227Z E CAPACITOR 220uF 10V M

C1156 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C1169 QCBB1HK-271Y C CAPACITOR 270pF 50V K

C1251 QCSB1HJ-330Y C CAPACITOR 33pF 50V J

C1252 QFLC1HJ-472Z M CAPACITOR 4700pF 50V J

C1253 QETN1HM-334Z E CAPACITOR 0.33uF 50V M

C1254 QETN1HM-105Z E CAPACITOR 1uF 50V M

C1255 QCS31HJ-471Z C CAPACITOR 470pF 50V J

C1256 QCS32HJ-151Z C CAPACITOR 150pF 500V J

C1257 QFLC1HJ-123Z M CAPACITOR 0.012uF 50V J

C1258 QFLC1HJ-682Z M CAPACITOR 6800pF 50V J

C1261 QFLC1HJ-822Z M CAPACITOR 8200pF 50V J

C1262 QDX31EM-333Z C CAPACITOR 0.033uF 25V M

C1263 QCB31HK-332Z C CAPACITOR 3300pF 50V K

C1264 QDX31EM-473Z C CAPACITOR 0.047uF 25V M

C1265 QFLC1HJ-682Z M CAPACITOR 6800pF 50V J

C1266 QDX31EM-273Z C CAPACITOR 0.027uF 25V M

C1267 QDX31EM-123Z C CAPACITOR 0.012uF 25V M

C1351 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C1354 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C1355 QFN31HJ-222Z M CAPACITOR 2200pF 50V J

C1356 QFN31HJ-222Z M CAPACITOR 2200pF 50V J

Part No. Part Name Description Local

3-7

Page 38

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C1357 QFN31HJ-222Z M CAPACITOR 2200pF 50V J

C1358 QETN1HM-104Z E CAPACITOR 0.1uF 50V M

C1359 QETN1HM-104Z E CAPACITOR 0.1uF 50V M

C1360 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C1451 QFP32AJ-561Z PP CAPACITOR 560pF 100V J

C1452 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C1453 QCS31HJ-561Z C CAPACITOR 560pF 50V J

C1454 QFN31HJ-103Z M CAPACITOR 0.01uF 50V J

C1455 QFLC1HJ-223Z M CAPACITOR 0.022uF 50V J

C1456 QFLC1HJ-393Z M CAPACITOR 0.039uF 50V J

C1457 QETN1EM-106Z E CAPACITOR 10uF 25V M

C1501 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C1511 QETN1EM-106Z E CAPACITOR 10uF 25V M

C1602 QCB31HK-222Z C CAPACITOR 2200pF 50V K

C2101 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C2102 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C2103 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C2104 QFLC1HJ-103Z M CAPACITOR 0.01uF 50V J

C2105 QETN1AM-227Z E CAPACITOR 220uF 10V M

C2106 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C2107 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C2108 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C2151 QFLC1HJ-102Z M CAPACITOR 1000pF 50V J

C2152 QCBB1HK-331Y C CAPACITOR 330pF 50V K

C2153 QCBB1HK-151Y C CAPACITOR 150pF 50V K

C2154 QFLC1HJ-123Z M CAPACITOR 0.012uF 50V J

C2155 QETN1AM-227Z E CAPACITOR 220uF 10V M

C2156 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C2169 QCBB1HK-271Y C CAPACITOR 270pF 50V K

C2251 QCSB1HJ-330Y C CAPACITOR 33pF 50V J

C2252 QFLC1HJ-472Z M CAPACITOR 4700pF 50V J

C2253 QETN1HM-334Z E CAPACITOR 0.33uF 50V M

C2254 QETN1HM-105Z E CAPACITOR 1uF 50V M

C2255 QCS31HJ-471Z C CAPACITOR 470pF 50V J

C2256 QCS32HJ-151Z C CAPACITOR 150pF 500V J

C2257 QFLC1HJ-123Z M CAPACITOR 0.012uF 50V J

C2258 QFLC1HJ-682Z M CAPACITOR 6800pF 50V J

C2261 QFLC1HJ-822Z M CAPACITOR 8200pF 50V J

C2262 QDX31EM-333Z C CAPACITOR 0.033uF 25V M

C2263 QCB31HK-332Z C CAPACITOR 3300pF 50V K

C2264 QDX31EM-473Z C CAPACITOR 0.047uF 25V M

C2265 QFLC1HJ-682Z M CAPACITOR 6800pF 50V J

C2266 QDX31EM-273Z C CAPACITOR 0.027uF 25V M

C2267 QDX31EM-123Z C CAPACITOR 0.012uF 25V M

C2351 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C2354 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C2355 QFN31HJ-222Z M CAPACITOR 2200pF 50V J

C2356 QFN31HJ-222Z M CAPACITOR 2200pF 50V J

C2357 QFN31HJ-222Z M CAPACITOR 2200pF 50V J

C2358 QETN1HM-104Z E CAPACITOR 0.1uF 50V M

C2359 QETN1HM-104Z E CAPACITOR 0.1uF 50V M

C2360 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C2451 QFP32AJ-561Z PP CAPACITOR 560pF 100V J

C2452 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C2453 QCS31HJ-561Z C CAPACITOR 560pF 50V J

C2454 QFN31HJ-103Z M CAPACITOR 0.01uF 50V J

C2455 QFLC1HJ-223Z M CAPACITOR 0.022uF 50V J

C2456 QFLC1HJ-393Z M CAPACITOR 0.039uF 50V J

C2457 QETN1EM-106Z E CAPACITOR 10uF 25V M

C2501 QENC1EM-475Z BP E CAPACITOR 4.7uF 25V M

C2511 QETN1EM-106Z E CAPACITOR 10uF 25V M

C2602 QCB31HK-222Z C CAPACITOR 2200pF 50V K

C8101 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8102 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8151 QETN1EM-106Z E CAPACITOR 10uF 25V M

C8152 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8251 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8252 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8351 QETN1AM-477Z E CAPACITOR 470uF 10V M

C8352 QETN1AM-477Z E CAPACITOR 470uF 10V M

C8451 QETN1EM-106Z E CAPACITOR 10uF 25V M

C8452 QCSB1HJ-100Y C CAPACITOR 10pF 50V J

C8453 QETN1HM-105Z E CAPACITOR 1uF 50V M

C8454 QETN1AM-107Z E CAPACITOR 100uF 10V M

C8455 QETN1AM-107Z E CAPACITOR 100uF 10V M

C8481 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C8482 QETN1AM-107Z E CAPACITOR 100uF 10V M

C8483 QETN1EM-337Z E CAPACITOR 330uF 25V M

C8491 QFP32AJ-103Z PP CAPACITOR 0.01uF 100V J

C8492 QETN1EM-476Z E CAPACITOR 47uF 25V M

C8493 QFLC1HJ-223Z M CAPACITOR 0.022uF 50V J

C8494 QFN31HJ-102Z M CAPACITOR 1000pF 50V J

C8495 QFLC1HJ-152Z M CAPACITOR 1500pF 50V J

C8496 QFLC1HJ-152Z M CAPACITOR 1500pF 50V J

C8501 QETN1AM-107Z E CAPACITOR 100uF 10V M

C8502 QETN1AM-107Z E CAPACITOR 100uF 10V M

C8503 QETN1HM-105Z E CAPACITOR 1uF 50V M

C8511 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8512 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8513 QETN1HM-105Z E CAPACITOR 1uF 50V M

C8601 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8602 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

C8901 QCF31HZ-103Z C CAPACITOR 0.01uF 50V Z

R901 QRZ9006-4R7X F.RESISTOR 4.7Ω 1/4W J

R902 QRZ9006-4R7X F.RESISTOR 4.7Ω 1/4W J

R908 QRE141J-181Y C RESISTOR 180Ω 1/4W J

R910 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R912 QRE141J-103Y C RESISTOR 10k

R913 QRE141J-103Y C RESISTOR 10k

R914 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R915 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R917 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R918 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R921 QRZ9005-100X FUSI RESISTOR 10

R923 QRJ146J-821X UNF C RESISTOR 820Ω 1/4W J

R927 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R928 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R929 QRE141J-391Y C RESISTOR 390Ω 1/4W J

R930 QRE141J-391Y C RESISTOR 390Ω 1/4W J

R933 QRK126J-271X UNF C RESISTOR 270Ω 1/2W J

R937 QRZ9006-4R7X F.RESISTOR 4.7Ω 1/4W J

R938 QRE141J-331Y C RESISTOR 330Ω 1/4W J

R940 QRZ9031-6R8 FUSI RESISTOR 6.8

R941 QRE141J-471Y C RESISTOR 470Ω 1/4W J

R1101 QRE141J-105Y C RESISTOR 1MΩ 1/4W J

R1102 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R1104 QRE141J-274Y C RESISTOR 270kΩ 1/4W J

R1105 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R1106 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R1107 QRE141J-202Y C RESISTOR 2kΩ 1/4W J

R1108 QRE141J-362Y C RESISTOR 3.6kΩ 1/4W J

R1109 QRE141J-150Y C RESISTOR 15Ω 1/4W J

R1110 QRE141J-333Y C RESISTOR 33kΩ 1/4W J

R1111 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R1152 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R1154 QRE141J-274Y C RESISTOR 270kΩ 1/4W J

R1155 QRE141J-682Y C RESISTOR 6.8k

R1158 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R1159 QRE141J-150Y C RESISTOR 15

R1160 QRE141J-333Y C RESISTOR 33k

R1161 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R1165 QRE141J-105Y C RESISTOR 1M

R1251 QRE141J-472Y C RESISTOR 4.7k

R1252 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R1253 QRE141J-333Y C RESISTOR 33k

R1254 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R1255 QRE141J-822Y C RESISTOR 8.2k

R1256 QRE141J-152Y C RESISTOR 1.5k

R1257 QRE141J-153Y C RESISTOR 15kΩ 1/4W J

R1258 QRE141J-181Y C RESISTOR 180

R1259 QRE141J-105Y C RESISTOR 1M

R1261 QRE141J-562Y C RESISTOR 5.6kΩ 1/4W J

R1262 QRE141J-682Y C RESISTOR 6.8k

R1263 QRE141J-222Y C RESISTOR 2.2k

R1264 QRE141J-222Y C RESISTOR 2.2k

R1265 QRE141J-562Y C RESISTOR 5.6k

R1266 QRE141J-682Y C RESISTOR 6.8kΩ 1/4W J

R1267 QRE141J-182Y C RESISTOR 1.8k

R1270 QRE141J-105Y C RESISTOR 1M

R1273 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R1351 QRE141J-222Y C RESISTOR 2.2k

R1352 QRE141J-103Y C RESISTOR 10k

R1353 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R1354 QRE141J-104Y C RESISTOR 100k

R1355 QRE141J-152Y C RESISTOR 1.5k

Ω

1/4W J

Ω

1/4W J

Ω

Ω

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

Ω

1/4W J

1/4W J

3-8

Page 39

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R1356 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R1357 QRE141J-561Y C RESISTOR 560Ω 1/4W J

R1451 QRE141J-274Y C RESISTOR 270kΩ 1/4W J

R1452 QRE141J-333Y C RESISTOR 33kΩ 1/4W J

R1453 QRJ146J-100X UNF C RESISTOR 10Ω 1/4W J

R1501 QRE141J-393Y C RESISTOR 39k

R1502 QRE141J-124Y C RESISTOR 120k

R1503 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R1504 QRE141J-183Y C RESISTOR 18kΩ 1/4W J

R1505 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R1511 QRE141J-272Y C RESISTOR 2.7kΩ 1/4W J

R1512 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R1513 QRE141J-683Y C RESISTOR 68kΩ 1/4W J

R1514 QRE141J-273Y C RESISTOR 27kΩ 1/4W J

R1515 QRE141J-220Y C RESISTOR 22Ω 1/4W J

R1516 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R1517 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R1601 QRE141J-151Y C RESISTOR 150Ω 1/4W J

R1602 QRE141J-124Y C RESISTOR 120kΩ 1/4W J

R1603 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R1604 QRE141J-562Y C RESISTOR 5.6k

R1605 QRE141J-182Y C RESISTOR 1.8k

R2101 QRE141J-105Y C RESISTOR 1MΩ 1/4W J

R2102 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R2104 QRE141J-274Y C RESISTOR 270kΩ 1/4W J

R2105 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R2106 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R2107 QRE141J-202Y C RESISTOR 2kΩ 1/4W J

R2108 QRE141J-362Y C RESISTOR 3.6kΩ 1/4W J

R2109 QRE141J-150Y C RESISTOR 15Ω 1/4W J

R2110 QRE141J-333Y C RESISTOR 33kΩ 1/4W J

R2111 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R2152 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R2154 QRE141J-274Y C RESISTOR 270kΩ 1/4W J

R2155 QRE141J-682Y C RESISTOR 6.8kΩ 1/4W J

R2158 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R2159 QRE141J-150Y C RESISTOR 15Ω 1/4W J

R2160 QRE141J-333Y C RESISTOR 33kΩ 1/4W J

R2161 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R2165 QRE141J-105Y C RESISTOR 1MΩ 1/4W J

R2251 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R2252 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R2253 QRE141J-333Y C RESISTOR 33kΩ 1/4W J

R2254 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R2255 QRE141J-822Y C RESISTOR 8.2kΩ 1/4W J

R2256 QRE141J-152Y C RESISTOR 1.5kΩ 1/4W J

R2257 QRE141J-153Y C RESISTOR 15kΩ 1/4W J

R2258 QRE141J-181Y C RESISTOR 180Ω 1/4W J

R2259 QRE141J-105Y C RESISTOR 1MΩ 1/4W J

R2261 QRE141J-562Y C RESISTOR 5.6k

R2262 QRE141J-682Y C RESISTOR 6.8kΩ 1/4W J

R2263 QRE141J-222Y C RESISTOR 2.2k

R2264 QRE141J-222Y C RESISTOR 2.2k

R2265 QRE141J-562Y C RESISTOR 5.6kΩ 1/4W J

R2266 QRE141J-682Y C RESISTOR 6.8k

R2267 QRE141J-182Y C RESISTOR 1.8k

R2270 QRE141J-105Y C RESISTOR 1MΩ 1/4W J

R2273 QRE141J-472Y C RESISTOR 4.7k

R2351 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R2352 QRE141J-103Y C RESISTOR 10k

R2353 QRE141J-472Y C RESISTOR 4.7k

R2354 QRE141J-104Y C RESISTOR 100kΩ 1/4W J

R2355 QRE141J-152Y C RESISTOR 1.5k

R2356 QRE141J-223Y C RESISTOR 22k

R2357 QRE141J-561Y C RESISTOR 560Ω 1/4W J

R2451 QRE141J-274Y C RESISTOR 270k

R2452 QRE141J-333Y C RESISTOR 33k

R2453 QRJ146J-100X UNF C RESISTOR 10Ω 1/4W J

R2501 QRE141J-393Y C RESISTOR 39k

R2502 QRE141J-124Y C RESISTOR 120kΩ 1/4W J

R2503 QRE141J-102Y C RESISTOR 1k

R2504 QRE141J-183Y C RESISTOR 18k

R2505 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R2511 QRE141J-272Y C RESISTOR 2.7k

R2512 QRE141J-103Y C RESISTOR 10k

R2513 QRE141J-683Y C RESISTOR 68kΩ 1/4W J

R2514 QRE141J-273Y C RESISTOR 27k

R2515 QRE141J-220Y C RESISTOR 22

Ω

1/4W J

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/4W J

Ω

Ω

Ω

1/4W J

Ω

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

R2516 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R2517 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R2601 QRE141J-151Y C RESISTOR 150Ω 1/4W J

R2602 QRE141J-124Y C RESISTOR 120kΩ 1/4W J

R2603 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R2604 QRE141J-562Y C RESISTOR 5.6k

R2605 QRE141J-182Y C RESISTOR 1.8k

R8101 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8102 QRE141J-104Y C RESISTOR 100kΩ 1/4W J

R8103 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R8104 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R8151 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8152 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8171 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R8172 QRE141J-104Y C RESISTOR 100kΩ 1/4W J

R8173 QRE141J-104Y C RESISTOR 100kΩ 1/4W J

R8251 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R8252 QRE141J-104Y C RESISTOR 100kΩ 1/4W J

R8253 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8255 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8351 QRE141J-183Y C RESISTOR 18k

R8352 QRJ146J-470X UNF C RESISTOR 47Ω 1/4W J

R8353 QRJ146J-470X UNF C RESISTOR 47Ω 1/4W J

R8354 QRE141J-153Y C RESISTOR 15kΩ 1/4W J

R8355 QRE141J-183Y C RESISTOR 18kΩ 1/4W J

R8451 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R8452 QRE141J-362Y C RESISTOR 3.6kΩ 1/4W J

R8453 QRE141J-302Y C RESISTOR 3kΩ 1/4W J

R8471 QRE141J-182Y C RESISTOR 1.8kΩ 1/4W J

R8472 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8473 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R8474 QRE141J-182Y C RESISTOR 1.8kΩ 1/4W J

R8475 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R8481 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R8482 QRZ9005-150X FUSI RESISTOR 15