Page 1

SERVICE MANUAL

REMOTE CONTROL UNIT

RM-P210U/RM-P210E

RM-P210U/RM-P210E

CALLTALLY

INTERCOM

LEVEL

FULL AUTO F1

BARS

MENU/SHUTTER GAIN

SHUTTER

F2

GAIN

F3

VARIABLE

SHUTTER

PUSH-ON

DOWN UP

PUSH-ON

DOWN UP

F4

MENU

STEP

HIGH

LOW

PAINT AUTO

MID

WHITE MASTER BLACK

REMOTE CONTROL UNIT RM-P210

W.BAL

B

A

BR

PRESET

AUTO

MANU

IRIS

CLOSE OPEN

POWER

I

O

VICTOR COMPANY OF JAPAN, LIMITED

Printed in Japan

(V.P.) A.I

No. 60136

100% recycled paper

COPYRIGHT ' 2001 VICTOR COMPANY OF JAPAN, LTD.

No. 60136

April 2001

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY PRECAUTIONS

■

INSTRUCTIONS

■

1. SERVICE CAUTIONS AND DISASSEMBLY ............................................................................................................ 1-1

1.1 REMOVAL OF EXTERNAL COVER..................................................................................................................... 1-1

1.2 FUNCTIONS AND SETTINGS OF INTERNAL SWITCHES .................................................................................. 1-2

1.3 ADJUSTMENT AND CHECK MODES ................................................................................................................ 1-3

2. ELECTRICAL ADJUSTMENT .................................................................................................................................... 2-1

2.1 INSTRUMENTS REQUIRED FOR ADJUSTMENTS, THEIR SETUPS ................................................................. 2-1

2.2 ADJUSTMENT MODE ........................................................................................................................................ 2-2

2.3 TRANSMIT VOLTAGE ADJUSTMENT ................................................................................................................ 2-3

2.4 COMPOSITE SIGNAL OUTPUT ADJUSTMENT ................................................................................................. 2-3

2.5 COMPONENT/RGB SIGNAL OUTPUT ADJUSTMENT ...................................................................................... 2-4

2.6 INTERCOM LEVEL ADJUSTMENT .................................................................................................................... 2-5

3. CHARTS AND DIGRAMS .......................................................................................................................................... 3-1

3.1 MAIN/FR1/FR2/CC/SUB1 BOARD SCHEMATIC DIAGRAM 01 / 02 / 03 / 04 / 05 ................................. 3-1

3.2 MAIN CIRCUIT BOARD 01 .............................................................................................................................. 3-2

3.3 FR1 CIRCUIT BOARD 02 ................................................................................................................................. 3-2

3.4 FR2 CIRCUIT BOARD 03 ................................................................................................................................. 3-2

3.5 CC CIRCUIT BOARD 04 ................................................................................................................................... 3-2

3.6 SUB1 CIRCUIT BOARD 05 ............................................................................................................................... 3-2

3.7 IC BLOCK DIAGRAM.......................................................................................................................................... 3-3

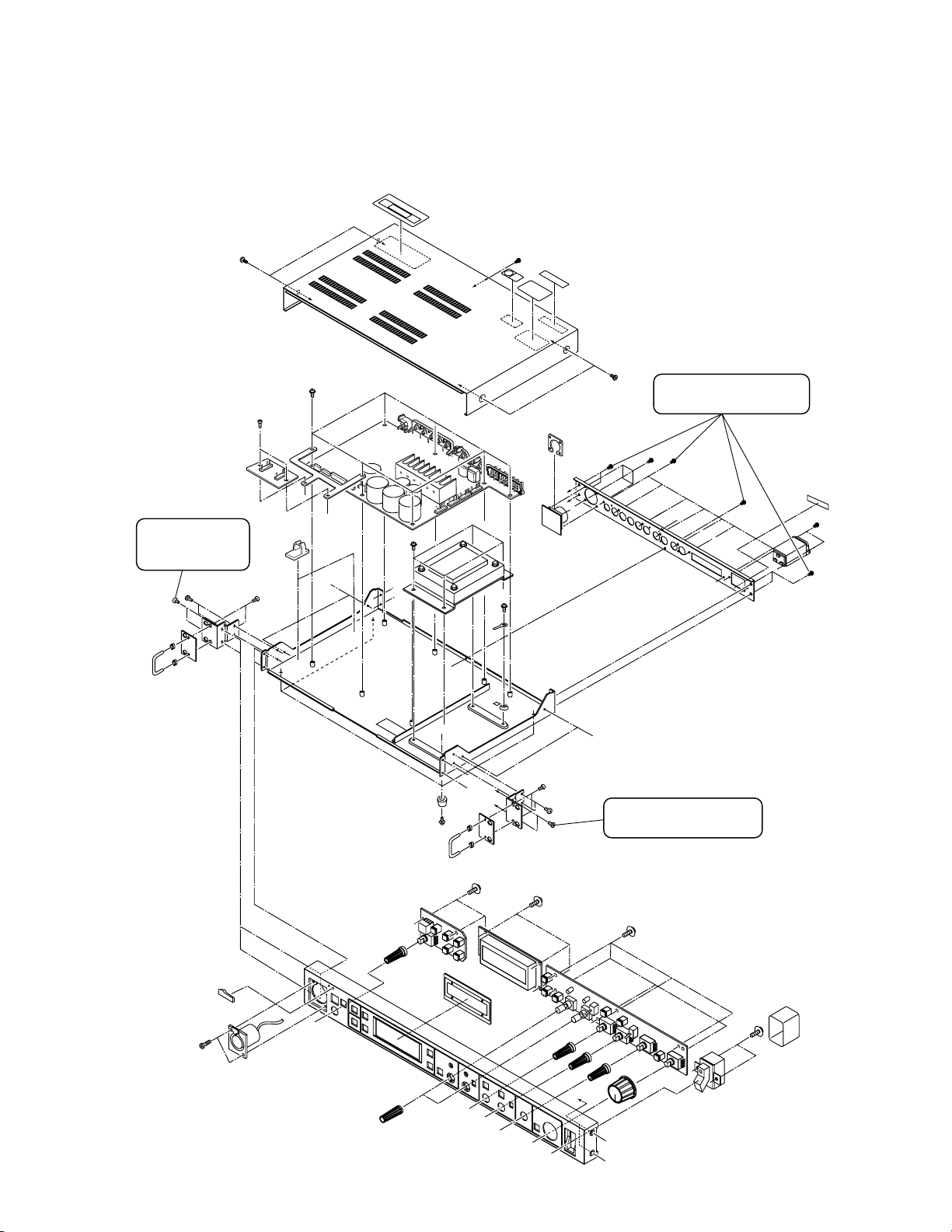

4. EXPLODED VIEW AND PARTS LIST ....................................................................................................................... 4-1

4.1 RM-P210 ASSEMBLY M2 ................................................................................................................................. 4-1

5. ELECTRICAL PARTS LIST ......................................................................................................................................... 5-1

5.1 MAIN BOARD ASSEMBLY PARTS LIST 01..................................................................................................... 5-2

5.2 FR1 BOARD ASSEMBLY PARTS LIST 02........................................................................................................ 5-7

5.3 FR2 BOARD ASSEMBLY PARTS LIST 03........................................................................................................ 5-8

5.4 CC BOARD ASSEMBLY PARTS LIST 04 ......................................................................................................... 5-8

5.5 SUB1 BOARD ASSEMBLY PARTS LIST 05..................................................................................................... 5-8

6. PACKING ................................................................................................................................................................... 6-1

6.1 PACKING ASSEMBLY M1................................................................................................................................ 6-1

Page 3

SERVICE CAUTIONS AND DISASSEMBLY

1.1 REMOVAL OF EXTERNAL COVER

SECTION 1

‘‘D’’

Remove these 2

screws to remove

the front panel.

‘‘D’’

‘‘F’’

‘‘E’’

‘‘E’’

Remove these 12 screws

to remove the rear panel.

‘‘C’’

‘‘C’’

‘‘D’’

‘‘C’’

‘‘C’’

‘‘E’’

‘‘F’’

‘‘B’’

‘‘A’’

‘‘B’’

‘‘A’’

Remove these 2 screws

to remove the front panel.

‘‘B’’

‘‘A’’

‘‘A’’

1-1

Page 4

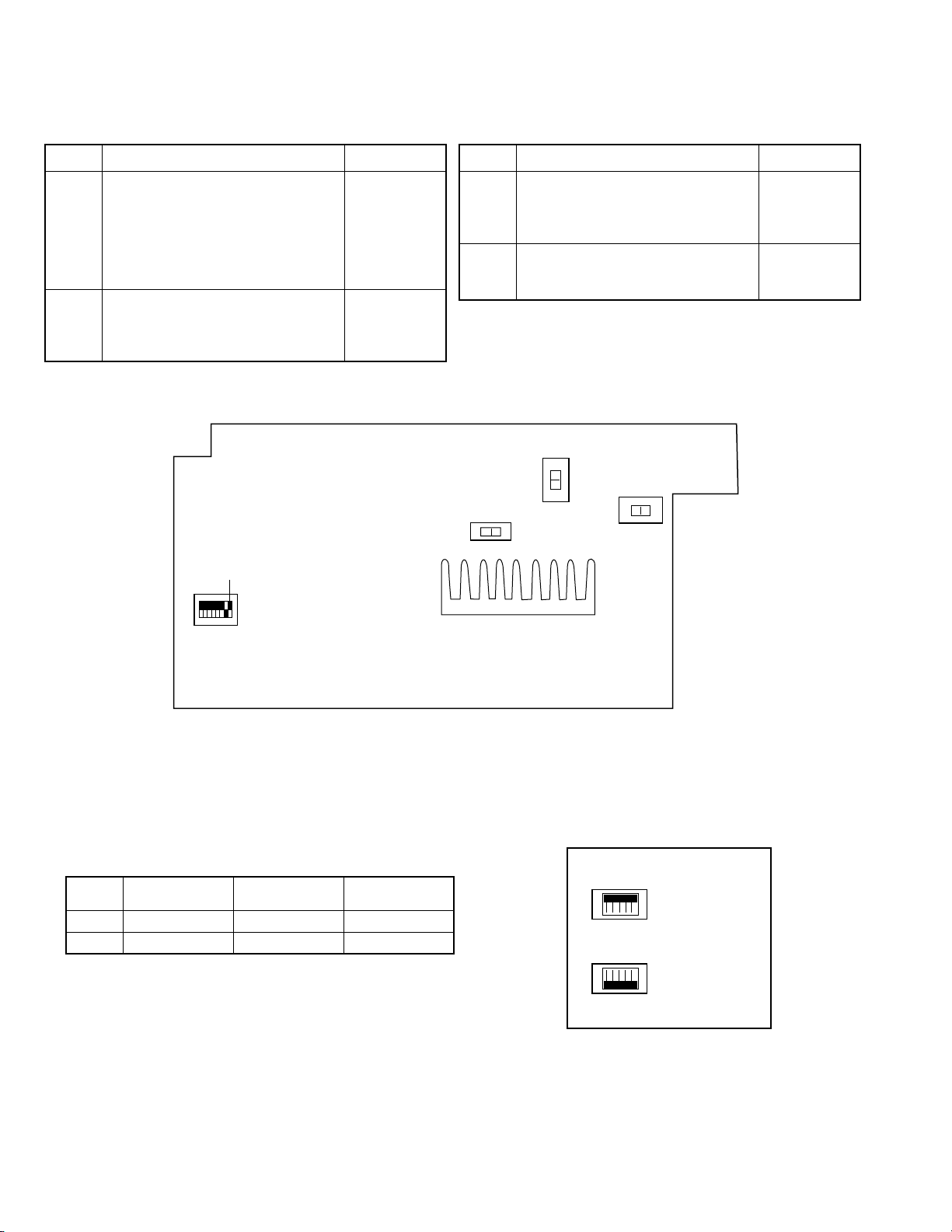

1.2 FUNCTIONS AND SETTINGS OF INTERNAL SWITCHES

1.2.1 MAIN Board

Symbol Function Factory Setting

S1 U model:

8-segment DIP switch to be set

according to the destination type.

No. 1 ON : PAL. OFF: NTSC

No. 2 ON: Japan OFF: USA

Nos. 3 to 8: Not used. (Set to OFF.)

S601 U model: M

Tally input M/V switch

M: Make contact (ON when shorted)

V: Voltage (ON when AC or DC is applied)

No. 1 OFF

No. 2 OFF

E model:

No. 1 ON

No. 2 OFF

E model: V

MAIN Board (Rear Side)

No.1

OFF

Symbol Function Factory Setting

S602 U model: RTS

S603 DYNAMICIntercom headset microphone

Intercom headset 2W/RTS switch.

2W: 2-wire intercom

RTS: RTS intercom

DYNAMIC/CARBON switch.

E model: 2W

RTS

S601S602

MV

S603

2W

CARBONDYNAMIC

ON

S1

1.2.2 CC Board

Set switches S35 and S36 according to the connected camera cable.

Symbol

S35

S36

Sony Cable

CCZ-A100 (100 m)

All ON

All OFF

JVC Cable Factory Setting

All OFF

All ON

All OFF

All ON

S35

S36

CC Board

ON

OFF

ON

OFF

1-2

Page 5

*HOW TO SET IT FOR USING SONY CABLE CCZ-A100.

Sony cable can be used by changing the setting as below only when RM-P210 is connected with GY-DV550. Sony has many type of

the cables but we can not check all the cable. Please do not use other than CCZ-A100.

1. GY-DV550 setting

Change the connection of the connector CN77 to CN83 on 56 CN board.

2. RM-P210 setting

(1) Change the setting of the switch on CC board

a) S35 : All switch have to be set to ON (UP side).

CN77

b) S36 : All switch have to be set to OFF (DOWN side).

(2) Re-adjustment of the transmit voltage (see “2.3 TRANSMIT VOLTAGE

ADJUSTMENT)

After re-adjustment, check the voltage between pin A and pin B in 26P

connector of RM-P210. It MUST be less than 15V. If it was more than

15V, adjustment of the b) and c) (+17V and +19V adjustment) have to

re-adjust to 15V from 16V.

a) +15V supply adjustment : adjust to 15 ± 0.2V

DC

CN83

b) +17V supply adjustment : adjust to 16 ± 0.2VDC

c) +19V supply adjustment : adjust to 16 ± 0.2VDC

Note 1: If the Voltage was not readjusted the View Finder will be damaged due to the heating problem.

Note 2: Difference between Sony cable and JVC cable is the impedance.

JVC cable: 1.3 Ohm Sony cable: 0.8 Ohm.

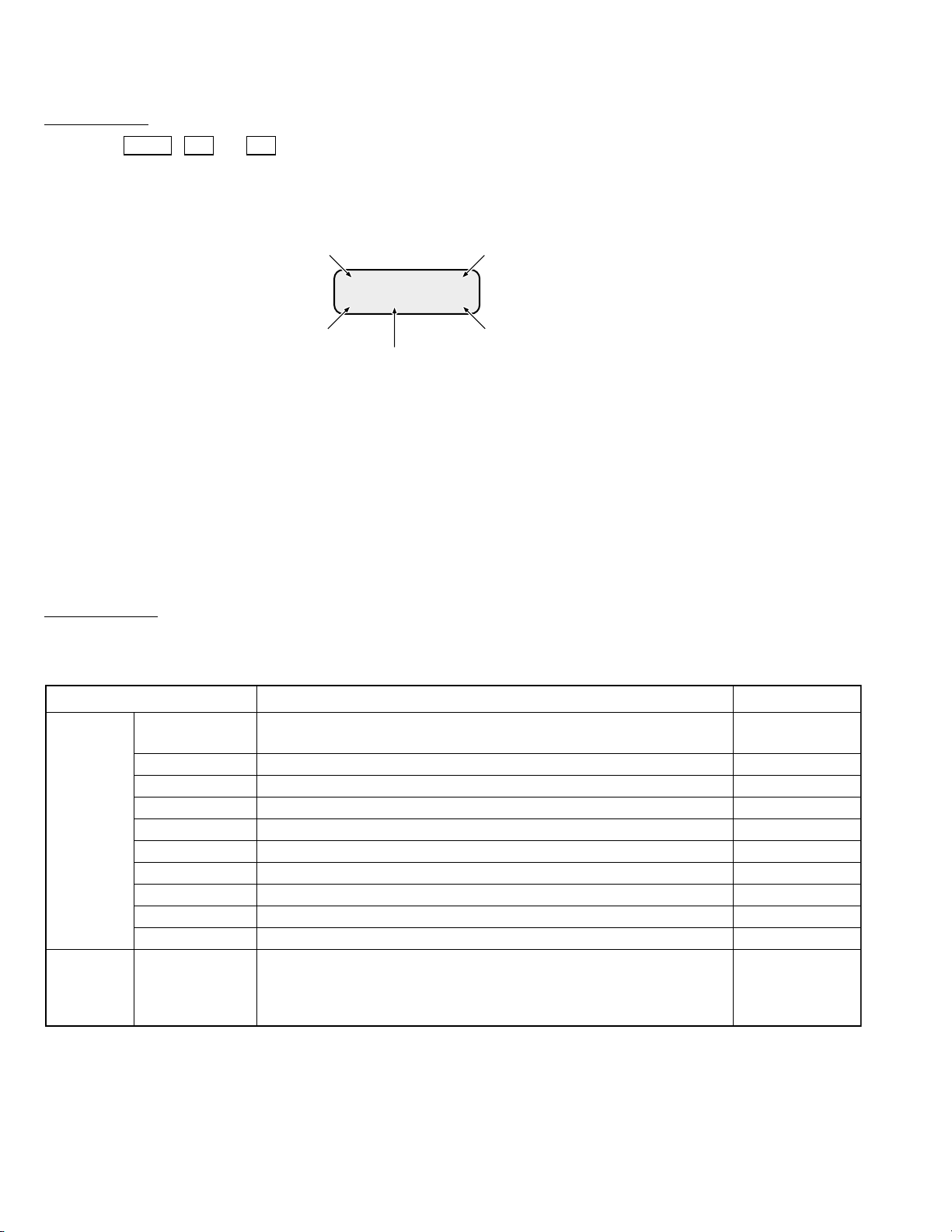

1.3 ADJUSTMENT AND CHECK MODES

1.3.1 Starting the Service Modes and Front Panel Check Mode

The RM-P210 incorporates the following service modes for use in servicing. Each of the service modes can be entered at the same

time as turning the RM-P210 ON and continues until it is turned OFF. Communications with the camera are not performed except in

the normal mode.

The following table shows the names of the modes and their details.

Mode Name Startup Method Contents

Normal

Data Clear

Any other method than those described below.

Hold FULL AUTO , BARS and IRIS buttons

This mode starts in normal operation by user.

All EEPROM and SRAM data are initialized.

simultaneously while turning power ON.

Hardware Check

Adjustment

Hold CALL , F1 and F2 buttons

simultaneously while turning power ON.

Hold MENU , F3 and F4 buttons

Displays the program version.

Check of LEDs, SW, VR, JOG dials, etc.

For adjustments of supply voltage and cable length.

simultaneously while turning power ON.

1.3.2 Data Clear Mode

Startup method

Hold the FULL AUTO , BARS and IRIS buttons simultaneously while press the POWER switch.

Operation Details

When the unit is started in the Data Clear mode, all EEPROM and SRAM data is initialized and the following message appears in

the LCD. After this, all operations are inhibited.

DATA C L EARED ! !

1-3

Page 6

1.3.3 Hardware Check Mode

Startup method

Hold the CALL , F1 and F2 buttons simultaneously while pressing the POWER switch.

The LEDs other than TALLY lights.

When the unit is turned ON, the LCD shows the program number and software version as shown below (initial display).

Program No. EEPROM check result OK/NG

CV1∗3.5∗9

∗ <UE>EPSRROAMMOOKK

Version

SRAM check result OK/NG

Model type

Japan: I

USA: U

Europe: E

The LCD also shows the results, either OK or NG, of the EEPROM and SRAM checking executed at the moment the unit is turned

ON.

The SRAM check consists of verifying the data retention status at the moment the unit is turned ON. The SRAM is backed up by

a super-capacitor. Therefore, “NG” is displayed even when the back-up power supply is down.

The initial display above disappears when any of the operations accompanied with the LCD display, described on the next page, is

executed.

To view the initial display again, press the CALL button.

Operation details

Turning a button or terminal ON or OFF causes an operation as described below. The switches can be checked by turning the LEDs

on or off. All LEDs are turned off at the moment the unit is turned ON

Check Point Check Details Remark

Each press of this button should turn the LED on/off and the initial display

appears when it is on.

Each press of this button should turn the LED on/off.

Each press of this button should turn the LED on/off.

Each press of one of these buttons should turn the corresponding LED on/off.

Each press of this button should turn the LED on/off.

Each press should turn the LED on/off.

Each press should turn the LED on/off.

Each press of this button should turn the LED on/off.

Each press of this button should turn the LED on/off.

Each press of this button should turn the LED on/off.

The green LED should light when TALLY PVW on the rear panel is Active

and the red should light when TALLY PGM is Active. Only the red LED

should light when both tallies are Active.

No LED should light when no tallies are Active.

Buttons/

LEDs

Rear-panel

terminal/

LED

CALL

FULL AUTO

BARS

F1 to F4

MENU

SHUTTER JOG

V.GAIN JOG

PAINT (WHITE)

AUTO (WHITE)

IRIS

TALLY

1-4

Page 7

With the checking of VR, JOG dials and switches, operating a control causes information to be displayed on the LCD. The LCD

display is retained until other information is displayed on the LCD. However, pressing the CALL button displays the initial display.

Check Point Check DetailsLCD Display Remark

Turn this VR and confirm that data varies between 0 and 255.

Turning clockwise should increase the value.

This VR also controls the LCD contrast. It is Normal at the

center. Turning the VR clockwise should increase contrast

and counter-clockwise should decrease it. The LCD back light

should be OFF at the most clockwise position.

IRIS

IRIS

128

VR

JOG

SW

MASTER

BLACK

WHITE Bch

WHITE Rch

SHUTTER JOG

V.GAIN JOG

W.BAL

STEP GAIN

M.BLACK (SC FINE)

128

WHITE Bch(C)

128

WHITE Rch(Y)

128

SHUT JOG(LENGTH)

20M

V.GAIN JOG(SC)

0°

W.BAL(ASPECT)

PRE(4:3)

GAIN(VOLT)

LOW(15V)

Turn this VR and confirm that data varies between 0 and 255.

Turning it clockwise should increase the value.

This VR also controls the SC FINE data output.

Turn this VR and confirm that data varies between 0 and 255.

Turning it clockwise should increase the value.

This VR also controls the LENGTH HF data output

Turn this VR and confirm that data varies between 0 and 255.

Turning it clockwise should increase the value.

This VR also controls the LENGTH Y data output

Turn this JOG and confirm that data is switched to 5M, 20M,

50M and 100M. Turning it clockwise should increase the

value.

The initial value when the unit is turned ON is 20M.

This JOG also checks the JOG rotation and JOG hardware

when LENGTH is selected in addition to SHUTTER JOG

check.

Turn JOG and confirm that data is switched to 0°, 90°, 180°

and 270°. Turning clockwise should increase the value.

The initial value when the unit is turned ON is 0°.

This JOG also checks the JOG rotation and JOG hardware

when SC COARSE is selected in addition to V.GAIN JOG

check.

Operate this SW and confirm that A, B and PRE are displayed

correctly when the SW is in the corresponding position.

This SW should also vary ASPECT internally: When A (16:9),

B (Letter Box) and PRE (4:3) are displayed, the internal mode

should vary accordingly.

Operate this SW and confirm that LOW, MID and HIGH are

displayed correctly when the SW is in the corresponding

position.

This SW should also vary the supply voltage to the camera

internally: When LOW (15 V), MID (17 V) and HIGH (19 V) are

displayed, the internal voltage should vary accordingly.

When the unit is

turned ON, 15 V is

output regardless

of the position of

this SW, until this

SW is changed to

another position.

DIP

SW

SW 1 to 8

DIP SW12345678

LLLLLLLLL

Set each SW to ON and OFF and confirm that the

corresponding display changes to H (ON) or L (OFF).

1.3.4 Adjustment Mode

The Adjustment mode is detailed in the description of the adjustment procedures. Please see section 2.2.

1-5

Page 8

SECTION 2

HGCCPVWPGM

TALLY

AC~IN AC100V 50V/60Hz

INTERCOM AUX VIDEO INPUT GENLOCK INPUT VIDEO OUTPUT Y/C OUT

CAMERA CABLE

R/R-Y B/B-Y

COMPOSITE VIDEO

G/Y

Camera cable

VC-P112 (20 m)

Intercom

KA-310U or equivalent

Intercom

KA-310U or equivalent

Monitor

To poer supply

75 Ω termination

GY-DV550/KY-D29/KY-D29W/KY-27C/KY-19

(Illustration: GY-DV550)

RM-P210

SHUTTERSTATUS

MENU

FILTER

3200k

1

5600k+1/8ND

2

5600k+1/64ND

3

ALARM

MONITOR

OPERATE

NG

G

A

I

N

O

U

T

P

U

T

W

H

T

.

B

A

L

V

T

R

ON OFF

AUTO IRIS

LOLUX

BACK L

NORMAL

SPOT L

STRETCH

NORMAL

COMPRESS

LIGHT

ON

OFF

COUNTER

AUDIO SELECT

MANUAL

AUTO

CH-1 CH-2 CH-1 CH-2

REAR

FRONT

RM

AUDIO INPUT

MODE

CTL

TC

UB

CH-1

MIX

CH-2

RESET

OPERATE/WARNING

MONITOR

SELECT

CH-1

AUDIO

LEVEL

CH-2

VTR

ON

OFF

INCOM

MIC

INCOM

MIC

LEVEL

POWER

OFFRM

DC IN

/BATT.

CALL

CARBON

DYNAMIC

FULL AUTO BLACK

ELECTRICAL ADJUSTMENTS

2.1 INSTRUMENTS REQUIRED FOR ADJUSTMENTS, THEIR SETUPS

2.1.1 Instruments to be Prepared

(1) Color video camera: GY-DV550, KY-D29, KY-D29W, KY-27C or KY-19 (With the KY series camera, a KA-27 camera adapter is an

additional requirement.)

(2) Camera cable: VC-P112 (20 m)

(Always use a 20-meter cable. Correct adjustment is not possible with other cable lengths.)

(3) Color monitor TV

(4) Digital voltmeter (input impedance 10 MΩ or more)

(5) Oscilloscope (2-trace scope)

(6) 75 Ω termination resistance

(7) Headset: KA-310U or a headset with 200 Ω to 600 Ω impedance at 1 kHz

(8) IN MEGA CYCLE Chart (Part No. RESC-014)

(9) Camera Extension Board (Part No. SCK2164) ...... (Required when the connected camera model is the KY-29 or the KY-D29W.)

2.1.2 Standard Setup

2.1.3 Setup for Adjustments

• Complete the adjustments of the camera itself in advance.

• Use the same lighting and other conditions as those used in the camera adjustments.

• Set the camera switches as follows.

䡵 GY-DV550

POWER : RM

MODE : RM

OPERATE : RM

VTR : STBY

26 PIN OUT in Camera Setup Menu : RGB

䡵 KY-D29, KY-D29W, KY-27C, KY-19 + KA-27

POWER : RM/VTR

MODE : RM

SIG : RGB

OPERATE : ON/ST-BY

2-1

Page 9

2.2 ADJUSTMENT MODE

Adjust the power supply of the RM-P210 by using the Adjustment mode (menu).

2.2.1 Procedures

(1)

CALLTALLY

INTERCOM

LEVEL

FULL AUTO F1

BARS

SHUTTER

F2

GAIN

MENU/SHUTTER GAIN

F3

MENU

F4

DOWN UP

SHUTTER

PUSH-ON

VARIABLE

PUSH-ON

DOWN UP

STEP

HIGH

MID

LOW

WHITE MASTER BLACK

PAINT AUTO

W.BAL

B

BR

PRESET

REMOTE CONTROL UNIT RM-P210

A

AUTO

MANU

IRIS

CLOSE OPEN

POWER

I

O

LCD Display (1), (5)(2),(3),(4)

(1) (1)

(1) Starting the Adjustment mode

Hold the MENU , F3 and F4 buttons simultaneously while pressing the POWER switch ON.

All of the front panel LEDs light in the Adjustment mode.

(2) Selecting the adjustment item

Turn the SHUTTER potentiometer to select a menu item, and then press the SHUTTER potentiometer. The “→“ cursor moves

to the adjustment value area, indicating that the adjustment is ready.

(3) Adjustment method

After selecting the adjustment item, turn the SHUTTER potentiometer again to adjust the value. See the description of each

adjustment item for details. Note that “4. LENGTH” is not used in the adjustments.

(4) Saving the adjustment data

After adjustment, press the SHUTTER potentiometer to save the adjusted data. The display returns to the adjustment item

selection menu in step (2).

(5) Exiting from the Adjustment mode

Press the POWER switch to OFF.

Turn SHUTTER to adjust the voltage to 15 V.

(“150” shown below is an example of display.)

→

SHUTTER

Turn clockwise to move

downward.

Turn counterclockwise

to move upward.

1.VOLT ADJ 1155V

→

2.VOLT ADJ 1177V

→

3.VOLT ADJ 1199V

→

4.LENGTH 1250V

SHUTTER

0

push

Saves data.

SHUTTER

0

push

Saves data.

SHUTTER

0

push

Saves data.

SHUTTER

M

push

1.VOLT ADJ→1155V

0

Turn SHUTTER to adjust the voltage to 17 V.

(“170” shown below is an example of display.)

2.VOLT ADJ→1177V

0

Turn SHUTTER to adjust the voltage to 19 V.

(“190” shown below is an example of display.)

3.VOLT ADJ→1199V

0

Turn SHUTTER to vary LENGTH then adjust

VR on the PCB.

4 . LENGTH

→

20M

2-2

Page 10

No. Item instruments & Mode

Measuring

Input signals

2.3 TRANSMIT VOLTAGE ADJUSTMENT

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

Adjustment procedure

1 +15 V supply

adjustment

Digital voltmeter Adjustment

mode

1: VOLT ADJ

15 V

2 +17 V supply

adjustment

Digital voltmeter Adjustment

mode

2: VOLT ADJ

17 V

3 +19 V supply

adjustment

Digital voltmeter Adjustment

mode

3: VOLT ADJ

19 V

2.4 COMPOSITE SIGNAL OUTPUT ADJUSTMENT

1 Video level

adjustment

• Color bar

• Oscilloscope

(H-rate)

• BARS swtch:

ON

• Menu No. 2A

LENGTH:

20 M

* TP9

- SHUTTER VR

+ 15 ± 0.2 VDC

* TP9

- SHUTTER VR

+ 17 ± 0.2 VDC

* TP9

- SHUTTER VR

+ 19 ± 0.2 VDC

COMPOSITE VIDEO

OUTPUT

(75 Ω terminated)

-

VR102 (IRIS LEVEL)

[Main board]

+

1 ± 0.03 Vp-p

1. Start the Adjustment mode without connecting the camera (i.e. camera cable). (See section 2.2.)

2. Select each adjustment mode and adjust

SHUTTER to the specified level.

1. Adjust to the specified level.*

2 Frequency

response

adjustment

• Color bar

• Oscilloscope

(H-rate)

• BARS swtch:

ON

• Menu No. 2A

LENGTH:

20 M

*

COMPOSITE VIDEO

OUTPUT

(75 Ω terminated)

-

VR101 (VBS FREQ)

[Main board]

+

1 Vp-p

1 Vp-p

1. Adjust to the specified level.

2. If adjustment to the specified level is not possible, use a vectorscope and adjust so that all

of the spots come inside

1 Vp-p

.

2-3

Page 11

No. Item instruments & Mode

Measuring

Input signals

2.5 COMPONENT/RGB SIGNAL OUTPUT ADJUSTMENT

Note: The measuring points for this adjustment are variable depending on the connected camera models. (See the “Measur-

ing Point Table for Each Camera Model” below.)

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

Adjustment procedure

1 Level

adjustment

Same

level

CH1

CH2

• Color bar

generator

• Oscilloscope

(H-rate)

• BARS swtch:

ON

• Menu No. 2A

LENGTH:

20 M

• R Channel

*

See Measuring Point

Table.

-

VR201 (R LEVEL)

[Main board]

+

Same level

*

See Measuring Point

Table.

-

VR301 (G LEVEL)

[Main board]

+

Same level

• B Channel

*

See Measuring Point

Table.

-

VR401 (B LEVEL)

[Main board]

+

Same level

1. Connect oscilloscope CH1 and CH2 as shown

in the Measuring Point Table.

2. Adjust so that the CH1 and CH2 levels are

same levels.

3. Adjust in the same way as the R Channel.• G Channel

Measuring Point Table for Each Camera Model

Channel

R

G

B

Camera

Model

GY-DV550 R OUTPUT terminal

Oscilloscope CH1

Measuring Points on

RM-P210

TP402 (R) [SE board: B-1D]

(75 Ω terminated)

KY-D29

KY-D29W

KY-27C/19 CN31 pin 7 [SE board: A-6B]

TP202 (R OUT)

[Main board]

GY-DV550 G OUTPUT terminal

TP2 (Extension board)

[Connect extension board to SE board.]

TP202 (G) [SE board: B-1D]

(75 Ω terminated)

KY-D29

KY-D29W

KY-27C/19 CN31 pin 6 [SE board: A-6B]

TP302 (G OUT)

[Main board]

GY-DV550 B OUTPUT terminal

TP4 (Extension board)

[Connect extension board to SE board.]

TP302 (B) [SE board: B-1D]

(75 Ω terminated)

KY-D29

KY-D29W

KY-27C/19 CN31 pin 4 [SE board: A-6B]

TP402 (B OUT)

[Main board]

TP5 (Extension board)

[Connect extension board to SE board.]

Oscilloscope CH2

Measuring Points on

Camera

2-4

Page 12

No. Item instruments & Mode

Measuring

Input signals

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

Adjustment procedure

2 Frequency

response

adjustment

CH1

Same

level

CH2

• IN MEGA chart

(precisely

scanned size)

• Oscilloscope

(H-rate)

• BARS swtch:

OFF

• Menu No. 2A

LENGTH:

20 M

6 MHz

• R Channel

*

See Measuring Point

Table.

-

VR202 (R FREQ)

[Main board]

+

Same levels of the

6 MHz section

*

See Measuring Point

Table.

-

VR302 (G LEVEL)

[Main board]

+

Same levels of the

6 MHz section

• B Channel

*

See Measuring Point

Table.

-

VR402 (B LEVEL)

[Main board]

+

Same levels of the

6 MHz section

1. Shoot the IN MEGA chart so that it becomes

precisely scanned size.

2. Connect oscilloscope CH1 and CH2 as shown

in the Measuring Point Table.

3. Adjust so that the levels of CH1 and CH2 of

the 6 MHz sections are same levels.

4. Adjust in the same way as the R Channel.• G Channel

2.6 INTERCOM LEVEL ADJUSTMENT

For intercom operation using headsets, the intercom levels can be adjusted with the following controls.

• Camera : INCOM LEVEL control on the adapter at the rear.

• RM-P210 : INTERCOM LEVEL control on the front panel.

Although adjustments on the circuit board are usually unnecessary, perform the following adjustment if the amplification gain seems

to be insufficient.

1 Side tone

adjustment

(Feedback of

the microphone to the

earphone of

Headset 1. Connect 560 Ω resistance across H and C IN-

• S602: 2W

[Main board]

*

INTERCOM jack on the

RM-P210 front panel

-

VR15 (2W S.TONE)

[Main board]

TERCOM terminals on the rear panel.

2. Plug the headset into the front panel INTERCOM jack.

3. Talk and adjust to optimize the side tone level.

(Adjust it to the clockwise direction.)

the same

headset)

2 RTS side tone

adjustment

(U model

only)

RTS headset 1. Connect 220 Ω resistance across H and G IN-

• S602: RTS

[Main board]

*

INTERCOM jack on the

RM-P210 front panel

-

VR16 (RTS S.TONE)

[Main board]

TERCOM terminals on the rear panel.

2. Plug the headset into the front panel INTERCOM jack.

3. Talk and adjust to optimize the side tone level.

(Adjust it to the clockwise direction.)

2-5

Page 13

3.7 IC BLOCK DIAGRAMS

䡵 AD603AR-X [ANALOG DEVICES]

(Variable Gain CTL Amplifier)

䡵 AD817AR-X [ANALOG DEVICES]

(Hi-Speed Low Power Op.Amp)

䡵 CY62256LL-70SN-X [CYPRESS]

(32k x 8 Static RAM)

3-3

Page 14

䡵 DS8922M-X [NATIONAL SEMICONDUCTOR]

(RS-422 Dual Differential Line Driver and Receiver Pairs)

䡵 LM1881M-X [National Semiconductor]

(Video Sync Separator)

䡵 IC-PST600M/E/-W [MITSUMI]

(System Reset IC)

1

3

2

(Top View)

Co1

OP1

1

Voo

3

Vout

2

GND

3-4

Page 15

䡵 M62352GP-W [MITSUBISHI]

(8 bit 12Channel D/A Converter with Buffer Op.Amp.)

䡵 MB90611APF [FUJITSU]

(CPU)

䡵 NJM4556AM-X [JRC]

(Dual High Current Op.Amp)

䡵 NJM4558M-X [JRC]

(Dual Op.Amp)

3-5

Page 16

䡵 NJM7812FA [JRC]

(3-Terminal Positive Voltage Regulator (+12V))

䡵 NM93C86AEM8-X [NATIONAL SEMICONDUCTOR]

(16,384-Bit Serial Interface, Standard Voltage CMOS

EEPROM)

䡵 NJM7905FA [JRC]

(3-Terminal Negative Voltage Regulator (-5V))

3-6

Page 17

䡵 PLSC1359 [SST27SF020-70NH/Silicon Strage Technology]

(2M Bit Flash Memoly)

䡵 TC74HC14AF-X [TOSHIBA]

(Hex Schmitt-Trigger Inverters)

X-Decoder

A17-A

0

Address Buffer

CE#

OE#

A

9

V

PP

Control Logic

PGM#

䡵 SI-8120S [SANKEN]

(Separate Excitation Switching Regulator IC)

IN

1V

V

OUT

IN

1

2SW

3 GND

4V

12345

OS

5S.S

(Bottom View)

Reg.

OSC Reset

Comp.

2,097,152Bit

EEPROM

Cell Array

Y-Decoder

I/O Buffers

DQ7-DQ

OCP

0

Drive

TSD

2

SW

OUT

䡵 TA7805S [TOSHIBA]

(3-Terminal Positive Voltage Regulator (+5V))

Amp.

REF

V

GNDS.S.53

OS

V

4

䡵 TA7809S [TOSHIBA]

(Refer to TA7805S.)

3-7

Page 18

䡵 TC74HC165AF-X [TOSHIBA]

(8-Bit Serial or Parallel-In/Serial Out Shift Registers With

Complementary Out)

䡵 TC74HC373AF-X [TOSHIBA]

(Octal D-Type Latch With NON-Inverted 3-State Output)

䡵 TC74HC4052AFT-X [TOSHIBA]

(Dual 4-Channel Analog Multiplexer)

䡵 TC74HC74AF-X [TOSHIBA]

(Dual D-Type Positive-EDGE-Triggered Flip-Flops

With Preset AND Clear)

3-8

Page 19

䡵 TC74HC4094AF-X [TOSHIBA]

(8 Stage Bus Compatible Shift/Store Register)

3-9

Page 20

SECTION 3

3.1 MAIN/FR1/FR2/CC/SUB1 SCHEMATIC DIAGRAM / / / /

6.9

4.6

3.9

2.2

1.7

0

0

6.9

4.6

3.9

2.2

1.7

0

1.6

0

2.3

0.1

0

0

1.7

0.9

1.0

1.6

0.9

2.3

0.1

DIAGRAMS AND CIRCUIT BOARDS

6.9

7.7

1.4

6.9

1.7

1.0

-0.1

0

-4.9

7.7

4.0

0

5.0

0

0

0

5.0

-0.2

0

-4.9

-0.1

0

-0.1

-0.1

0

-0.1

-0.1

0

5.0

0

-0.7

0

0

1.5

-0.7

-4.9

-0.7

0

5.0

5.0

0

0

1.2

1.5

0.8

0

-0.7

0

0

0

0

-2.4

0

0.8

0

0.1

0.8

0.8

4.9

4.9

-0.4

0

0

-2.4

0

0

0

0

0

0

-1.9

-1.9

0

0

-2.5

-0.1

IC2

PLSC1359

5.2

5.2

5.2

8.9

8.9

0

8.9

8.9

0

10.4

9.8

9.8

10.4

10

10

5.3

5.2

5.2

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.2

5.2

5.2

5.2

5.4

5.1

5.1

5.1

5.2

5.2

CAMERA

CABLE

TO

SUB1

CN902

SUB1

TO

CN21

CC

SHORT CONNECTOR

WIRE

BLUE

WIRE

12.0

10.6

5.0

12.0

9.0

25.0

2.5

-5.0

WIRE

WHITEBLUE

-13.7

16.3

12.3

0

3.6

3.4

3.6

3.6

AC IN

POWER

SWITCH

3-1

Page 21

3.2 MAIN CIRCUIT BOARD

SIDE A

E

D

C

B

A

12345678910

ADDRESS TABLE OF BOARD PARTS

Each address may have an address error by one interval.

A-1C

Side

Y axis

X axis

A-3C

R311

A-2A

R23

A-2C

D18

A-6B

IC1

IC2

IC3

IC4

IC5

IC7

IC17

IC18

IC19

IC21

IC22

IC24

IC25

IC30

IC35

IC101

IC102

IC103

IC104

IC201

IC301

IC401

IC501

IC502

IC503

IC504

IC505

IC506

IC507

IC601

IC602

IC604

IC605

Q1

Q14

Q17

Q18

Q19

Q59

Q61

Q101

Q102

Q103

Q104

Q105

Q106

Q107

Q112

Q201

Q202

Q203

Q204

Q205

Q206

Q207

Q212

Q301

Q302

Q303

Q304

Q305

Q306

Q307

Q312

Q401

Q402

Q403

Q404

Q405

Q406

Q407

Q412

Q501

Q502

Q503

Q505

Q506

Q507

Q508

Q509

Q510

Q511

D1

D2

D3

D4

D6

D7

D8

D9

D10

A-1B

A-7B

A-6B

A-7B

A-5B

A-2A

A-3B

A-3B

A-3B

A-3A

A-1B

A-2B

A-4B

A-3A

A-1D

A-1D

A-1D

A-2D

A-4D

A-3D

A-2D

A-5D

A-5D

A-4D

A-5D

A-5D

A-6D

A-6D

A-6C

A-7C

A-7C

A-6C

A-2B

A-7C

A-8C

A-5C

A-6C

A-1A

A-4B

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-5D

A-5D

A-5D

A-5D

A-5D

A-4D

A-4D

A-6D

A-6D

A-6D

A-2D

A-2C

A-2C

A-4B

A-2C

A-2C

A-2C

A-2C

A-2B

D19

D20

D21

D22

D23

D24

D25

D26

D27

D28

D29

D30

D31

D32

D33

D34

D35

D44

D47

D50

D101

D201

D301

D501

D502

D503

D504

D505

D506

D507

D508

D509

D510

D511

D512

D513

D514

D515

D516

D517

D518

D519

D520

D521

D522

D523

D601

D602

D604

D605

D606

D607

D608

D609

D610

D611

D612

D613

D614

D615

D616

D617

D618

D619

D620

D621

D622

D623

D624

D625

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R16

R17

R18

R19

R20

R21

R22

A-2C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-8B

A-5B

A-8B

A-1D

A-3D

A-2D

A-6D

A-2D

A-2D

A-2D

A-2D

A-5D

A-3D

A-3D

A-4D

A-4D

A-5D

A-3D

A-3D

A-4D

A-4D

A-6D

A-6D

A-8D

A-8D

A-2C

A-2C

A-2C

A-2C

A-8D

A-8C

A-5C

A-5C

A-5C

A-6C

A-9D

A-9D

A-9D

A-9D

A-9D

A-9D

A-10D

A-10D

A-10D

A-10D

A-1A

A-1A

A-1A

A-1A

A-1C

A-1C

A-1C

A-1C

A-3B

A-2A

A-1D

A-2B

A-3A

A-3A

A-2A

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

A-2B

A-3B

A-3B

A-3B

A-1B

A-3A

A-2C

A-3A

R24

R25

R26

R27

R28

R29

R30

R31

R32

R101

R102

R103

R104

R105

R106

R107

R108

R109

R110

R111

R112

R113

R114

R115

R116

R117

R118

R119

R123

R124

R125

R126

R127

R128

R129

R130

R131

R132

R133

R134

R135

R136

R137

R138

R142

R177

R178

R180

R181

R182

R186

R187

R188

R194

R195

R201

R202

R203

R204

R205

R206

R207

R208

R209

R210

R211

R212

R213

R214

R215

R216

R217

R218

R219

R224

R226

R227

R228

R229

R230

R231

R232

R301

R302

R303

R304

R305

R306

R307

R308

R309

R310

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

A-1B

A-1B

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1D

A-1D

A-1D

A-2D

A-1D

A-1D

A-1D

A-2D

A-1D

A-2D

A-2D

A-2D

A-1C

A-4B

A-4B

A-4B

A-4B

A-4B

A-2A

A-1A

A-1A

A-2B

A-2A

A-4C

A-4C

A-4C

A-3C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-4C

A-3C

A-4D

A-3C

A-4D

A-3D

A-3D

A-4D

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

R312

R313

R314

R315

R316

R317

R318

R319

R324

R328

R329

R330

R331

R332

R333

R401

R402

R403

R404

R405

R406

R407

R408

R409

R410

R411

R412

R413

R414

R415

R416

R417

R418

R424

R425

R426

R427

R428

R429

R430

R431

R501

R502

R503

R504

R505

R506

R507

R508

R509

R510

R511

R512

R513

R514

R515

R516

R517

R518

R519

R520

R521

R522

R523

R526

R527

R528

R529

R530

R531

R532

R533

R534

R535

R536

R537

R538

R539

R540

R541

R542

R543

R544

R545

R546

R547

R548

R549

R550

R551

R552

R553

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3D

A-2C

A-3D

A-3D

A-3D

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2D

A-2D

A-2D

A-2D

A-1D

A-1D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-6D

A-5D

A-5D

A-5D

A-5D

A-5D

A-4D

A-4D

A-5D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-7D

A-6D

A-2D

A-2D

A-3D

A-6D

A-7D

A-5D

A-5D

R554

R556

R557

R558

R561

R562

R563

R564

R601

R602

R603

R604

R605

R606

R607

R608

R609

R610

R611

R612

R613

R614

R616

R617

R618

R619

R620

R621

R622

R623

R624

R625

R626

R627

R628

R629

R630

R631

R632

R633

R634

R635

R636

R637

R638

R639

R640

R641

R642

R643

R644

R645

R646

R647

R648

R650

R651

R652

R653

R654

R655

R656

R657

R658

R659

R660

C1

C2

C3

C4

C5

C7

C8

C9

C10

C11

C12

C14

C15

C17

C23

C24

C25

C26

C29

C61

C62

C63

C64

C65

C66

C67

A-4D

A-6D

A-5D

A-5D

A-5D

A-4D

A-4D

A-5D

A-7C

A-7C

A-7C

A-7C

A-7C

A-8C

A-8C

A-8C

A-7C

A-7C

A-5C

A-5C

A-6C

A-5C

A-7C

A-7C

A-6C

A-6C

A-6C

A-6C

A-6C

A-6C

A-6C

A-7C

A-7D

A-7D

A-7D

A-7D

A-7D

A-7D

A-8D

A-7D

A-6D

A-7C

A-7C

A-7C

A-10D

A-10D

A-10D

A-10D

A-7C

A-8C

A-5C

A-5C

A-6C

A-6C

A-6C

A-6C

A-6C

A-6C

A-6C

A-7C

A-6D

A-6C

A-6C

A-8D

A-5C

A-5C

A-8A

A-5A

A-5C

A-5C

A-6A

A-6C

A-1A

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

A-4B

A-6C

A-7C

A-4B

A-1D

A-4B

A-4B

A-5B

A-4B

A-8B

A-2A

A-3B

C68

C69

C71

C72

C74

C75

C76

C77

C81

C82

C83

C84

C85

C86

C87

C88

C93

C101

C102

C103

C104

C105

C107

C114

C115

C116

C117

C118

C119

C120

C121

C149

C188

C196

C197

C198

C199

C201

C202

C203

C204

C205

C207

C214

C215

C216

C217

C218

C220

C221

C222

C223

C301

C302

C303

C304

C305

C307

C314

C315

C316

C317

C318

C319

C320

C321

C401

C402

C403

C404

C405

C407

C414

C415

C416

C417

C418

C420

C421

C422

C501

C502

C503

C504

C505

C507

C508

C509

C510

C511

C512

C513

C514

A-3A

A-3A

A-1A

A-1B

A-2B

A-2B

A-1B

A-3B

A-4B

A-4A

A-8B

A-4B

A-7A

A-7A

A-4C

A-4B

A-2B

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1C

A-1D

A-2D

A-4D

A-1D

A-2D

A-1C

A-2D

A-2D

A-1D

A-2D

A-1D

A-1D

A-2D

A-4C

A-3C

A-4C

A-4C

A-4C

A-3C

A-3C

A-4D

A-3D

A-3D

A-4D

A-3D

A-3D

A-4D

A-3C

A-3C

A-2C

A-3C

A-3C

A-3C

A-3C

A-3C

A-3D

A-3D

A-3D

A-3D

A-3D

A-3C

A-3D

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2C

A-2D

A-2D

A-2D

A-2D

A-2C

A-2D

A-2D

A-1D

A-5D

A-5D

A-5D

A-5D

A-5D

A-5D

A-4D

A-4D

A-5D

A-5D

A-4D

A-5D

C515

C516

C517

C518

C519

C520

C522

C523

C524

C525

C526

C527

C528

C529

C530

C601

C602

C603

C604

C605

C606

C607

C608

C609

C610

C611

C612

C613

C614

C615

C616

C617

C618

C619

C620

C621

C622

C623

C624

C625

C626

C627

C628

C629

C630

C631

C632

L1

L4

L5

L501

L502

L503

L504

L505

X2

RA1

S1

S2

S601

S602

S603

JK1

JK2

JK3

JK4

CN1

CN2

CN4

CN5

CN8

CN9

CN12

CN15

CN23

CN26

TB1

F1

F2

PC1

PC2

VR14

VR15

A-5D

A-6D

A-6D

A-5D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-6D

A-5D

A-7C

A-7C

A-7C

A-7C

A-5C

A-6C

A-6C

A-7C

A-7C

A-6C

A-6C

A-6C

A-6C

A-7C

A-7D

A-7D

A-7D

A-7D

A-7C

A-8D

A-8D

A-7C

A-7C

A-6C

A-6C

A-6C

A-6C

A-6C

A-5C

A-6C

A-5C

A-5C

A-7D

A-8D

A-5B

A-4C

A-1D

A-1D

A-5D

A-5D

A-2B

A-1B

A-1B

A-3B

A-8D

A-7D

A-6D

A-2E

A-4E

A-6D

A-7D

A-2A

A-9C

A-4A

A-2A

A-9B

A-9C

A-8B

A-2C

A-1A

A-4A

A-9D

A-8C

A-9A

A-7C

A-7C

A-6C

A-7D

VR16

VR17

VR101

VR102

VR201

VR202

VR301

VR302

VR401

VR402

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP18

TP19

TP20

TP21

TP22

TP23

TP24

TP25

TP26

TP27

TP28

TP29

TP101

TP102

TP201

TP202

TP203

TP301

TP302

TP401

TP402

TP501

TP502

TP503

TP504

TP601

TP602

TP604

TP608

K1

K2

K3

K4

K5

K6

K7

K8

K9

K10

K11

K12

K13

K14

K15

K16

K17

K18

A-6C

A-7C

A-1C

A-1D

A-4D

A-3C

A-3D

A-2C

A-2D

A-2C

A-3A

A-3A

A-3A

A-2A

A-2A

A-2A

A-2A

A-2D

A-4B

A-1B

A-1B

A-1B

A-4B

A-4B

A-4A

A-4A

A-4A

A-3A

A-3A

A-3A

A-4A

A-2B

A-3A

A-3A

A-3A

A-1B

A-1B

A-7C

A-6D

A-1C

A-1D

A-3C

A-4D

A-3D

A-2C

A-3D

A-1C

A-2D

A-5D

A-6D

A-6D

A-6D

A-6C

A-6C

A-7C

A-6C

A-9D

A-9D

A-10D

A-10D

A-9D

A-1A

A-1A

A-3A

A-3A

A-3A

A-2A

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

A-3A

3.3

FR1 CIRCUIT BOARD

SIDE A

FR2 CIRCUIT BOARD

3.4

SIDE A

CC CIRCUIT BOARD

3.5

1

S35

S36

SIDE A

2

CN21

SUB1 CIRCUIT BOARD

3.6

SIDE A

R286

R288

26

25

R287

R289

2

1

CN16

R285

R283

R284

R282

Page 22

SECTION 4

EXPLODED VIEWS AND PARTS LIST

4.1 RM-P210 ASSEMBLY

S10

S2

SUB1 BOARD

ASSEMBLY

S8

7

8

05

MAIN BOARD

ASSEMBLY

S10

5

6

01

21

M2

S8

19

S4

35

29

‘‘D’’

4

‘‘D’’

S11

‘‘F’’

‘‘E’’

S10

30

31

28

‘‘E’’

S10

37

17

S9

S10

S7

32

‘‘C’’

‘‘C’’

CC BOARD

9

S5

‘‘D’’

‘‘C’’

‘‘C’’

ASSEMBLY

S5

20

04

‘‘F’’

S9

27

S9

10

S9

3

33

2

34

‘‘E’’

4-1

S6

18

13

FR2 BOARD

ASSEMBLY

1

23

36

03

26

16

S3

37

15

‘‘B’’

‘‘A’’

‘‘B’’

‘‘A’’

7

6

8

S1

S8

S10

S8

5

S2

S1

37

12

25

24

FR1 BOARD

ASSEMBLY

23

‘‘B’’

22

‘‘A’’

‘‘A’’

11

02

S1

14

Page 23

● RM-P210 ASSEMBLY PARTS LIST

M2

M2MM````

Symbol

No.

1 SC10252-001 FRONT PANEL

2 SC10253-001 BOTTOM COVER

3 SC20741-001 REAR PANEL

4 SC20742-001 TOP COVER

5 SC30558-001 L. BRACKET

6 SC41550-003 FRONT PLATE

7 SC43639-001 HANDLE

8 SC40617-001 WASHER

! 9 QQT0346-001 TRANSFORMER U model

! QQT0347-001 TRANSFORMER E model

! 10 QNC0087-001 AC INLET

! 11 QSW0015-004 POWER SWITCH

12 QLD0191-001 LCD DISPLAY

13 QNZ0252-001 CONNECTOR FOR INCOM

14 SCV1327-001 SWITCH COVER

15 SC46802-001 WINDOW

16 QZF1510-001 FOOT

17 SC43454-001 NUT PLATE

18 — MARK JVC

19 SCV3045-001 BOARD BRACKET

20 SCV0518-008 WIRE CLAMP

21 SCV3045-MN-2 MINI CLAMP

22 SC46207-011 KNOB FOR IRIS (VR700)

23 SC45572-011 KNOB FOR MASTER BLK (VR701), INCOM LEV (VR800)

24 SC45572-031 KNOB FOR WHITE B (VR702)

25 SC45572-021 KNOB FOR WHITE R (VR703)

26 SC44668-001 KNOB FOR GAIN (S706), SHUTTER (S707)

27 SC46804-001 LABEL

! 28 — RATING LABEL

29 SC41058-002 CAUTION LABEL

30 QZL1001-012 UL LABEL U model

SS412174-002 CE/TUV LABEL E model

31 SC40865-001 WARNIING LABEL E model only

32 SC46804-001 LABEL U model only

33 SC45464-001 EARTH LABEL

! 34 SC41252-001 FUSE CAUTION U model only

35 SC46836-001 PAD

36 — SERIAL NO. LABEL

! 37 SCV2803-2614B FFC WIRE

S1 QYSPSPL3006Z SCREW M3 x 6

S2 QYSPSPL2606Z SCREW M2.6 x 6

S3 QYSPSPL3010Z SCREW M3 x 10

S4 SS49420-B3006N SCREW M3 x 6

S5 QYSPSPD4008Z SCREW M4 x 8

S6 QYSPSP2606N SCREW M2.6 x 6

S7 QYSDSF3008M SCREW M3 x 8

S8 QYSSSP3008N SCREW M3 x 8

S9 QYSDST3006M SCREW M3 x 6

S10 QYSDSP3006M SCREW M3 x 6

S11 QYSPSPD3008Z SCREW M3 x 8

DescriptionPart No. Part Name

4-2

Page 24

5.1 MAIN BOARD ASSEMBLY PARTS LIST

01

SCV3045-PB502A(1)-N (U MODEL)

SCV3045-PB502A(1)-P (E MODEL)

Symbol

No.

IC1 NJM7905FA I.C.(M) JRC

IC2 PLSC1359 I.C.(M) SST27SF020-70NH

SK2 SCV2768-001X IC SOCKET (FOR IC2)

IC3 NJM7812FA I.C.(M) JRC

IC4 TA7805S I.C.(M) TOSHIBA

IC5 TA7809S I.C.(M) TOSHIBA

IC7 SI-8120S I.C.(M) SANKEN

IC17 MB90611APF I.C.(M) FUJITSU

IC18 TC74HC373AF-X I.C.(M) TOSHIBA

IC19 M62352GP-W I.C.(M) MITSUBISHI

IC21 IC-PST600M/E/-W I.C.(M) MITSUMI

IC22 NM93C86AEM8-X I.C.(M) NATIONAL SEMICO

IC24 DS8922M-X I.C.(M) NATIONAL SEMICO

IC25 CY62256LL-70SN-X I.C.(M) CYPRESS

IC30 NJM4556AM-X I.C.(M) JRC

IC35 TC74HC4094AF-X I.C.(M) TOSHIBA

IC101 AD817AR-X I.C.(M) ANALOG DEVICE

IC102 AD603AR-X I.C.(M) ANALOG DEVICE

IC103 AD817AR-X I.C.(M) ANALOG DEVICE

IC104 AD817AR-X I.C.(M) ANALOG DEVICE

IC201 AD817AR-X I.C.(M) ANALOG DEVICE

IC301 AD817AR-X I.C.(M) ANALOG DEVICE

IC401 AD817AR-X I.C.(M) ANALOG DEVICE

IC501 LM1881M-X I.C.(M) NATIONAL SEMICO

IC502 AD817AR-X I.C.(M) ANALOG DEVICE

IC503 TC74HC4052AFT-X I.C.(M) TOSHIBA

IC504 AD817AR-X I.C.(M) ANALOG DEVICE

IC505 AD817AR-X I.C.(M) ANALOG DEVICE

IC506 AD817AR-X I.C.(M) ANALOG DEVICE

IC507 AD817AR-X I.C.(M) ANALOG DEVICE

IC601 NJM4556AM-X I.C.(M) JRC

IC602 NJM4556AM-X I.C.(M) JRC

IC604 NJM4556AM-X I.C.(M) JRC

IC605 NJM4558M-X I.C.(M) JRC

Q1 2SC3311A TRANSISTOR MATSUSITA

Q14 2SA0684/R/ TRANSISTOR MATSUSITA

Q17 2SA0684/R/ TRANSISTOR MATSUSITA

Q18 2SA0684/R/ TRANSISTOR MATSUSITA

Q19 2SA0684/R/ TRANSISTOR MATSUSITA

Q59 DTC123JUA-X TRANSISTOR TOSHIBA

Q61 DTC124EUA-X TRANSISTOR TOSHIBA

Q101 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q102 2SK663/QR/-W TRANSISTOR MATSUSITA

Q103 2SK663/QR/-W TRANSISTOR MATSUSITA

Q104 2SK663/QR/-W TRANSISTOR MATSUSITA

Q105 2SK663/QR/-W TRANSISTOR MATSUSITA

Q106 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q107 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q112 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q201 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q202 2SK663/QR/-W TRANSISTOR MATSUSITA

Q203 2SK663/QR/-W TRANSISTOR MATSUSITA

Q204 2SK663/QR/-W TRANSISTOR MATSUSITA

Q205 2SK663/QR/-W TRANSISTOR MATSUSITA

Q206 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q207 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q212 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q301 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q302 2SK663/QR/-W TRANSISTOR MATSUSITA

Q303 2SK663/QR/-W TRANSISTOR MATSUSITA

Q304 2SK663/QR/-W TRANSISTOR MATSUSITA

Q305 2SK663/QR/-W TRANSISTOR MATSUSITA

Q306 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q307 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q312 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q401 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q402 2SK663/QR/-W TRANSISTOR MATSUSITA

Q403 2SK663/QR/-W TRANSISTOR MATSUSITA

Q404 2SK663/QR/-W TRANSISTOR MATSUSITA

Q405 2SK663/QR/-W TRANSISTOR MATSUSITA

Q406 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q407 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q412 2SA1532/BC/-X TRANSISTOR MATSUSITA

Part No. Part Name Description

01``````

Symbol

No.

Q501 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q502 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q503 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q505 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q506 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q507 2SA1532/BC/-X TRANSISTOR MATSUSITA

Q508 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q509 2SC3930/BC/-X TRANSISTOR MATSUSITA

Q510 2SK663/QR/-W TRANSISTOR MATSUSITA

Q511 2SK663/QR/-W TRANSISTOR MATSUSITA

D1 SVC341/L/-X DIODE SANYO

D2 HZM6C-X ZENER DIODE HITACHI

D3 HZM6C-X ZENER DIODE HITACHI

D4 RD7.5ES/B2/-T2 ZENER DIODE FUJITSU

D6 HZM6C-X ZENER DIODE HITACHI

D7 HZM6C-X ZENER DIODE HITACHI

D8 HZM6C-X ZENER DIODE HITACHI

D9 HZM6C-X ZENER DIODE HITACHI

D10 1SS187-X DIODE TOSHIBA

D18 HZM6C-X ZENER DIODE HITACHI

D19 HZM6C-X ZENER DIODE HITACHI

D20 HZM18NB2-X ZENER DIODE HITACHI

D21 HZM18NB2-X ZENER DIODE HITACHI

D22 HZM18NB2-X ZENER DIODE HITACHI

D23 HZM18NB2-X ZENER DIODE HITACHI

D24 HZM18NB2-X ZENER DIODE HITACHI

D25 HZM18NB2-X ZENER DIODE HITACHI

D26 HZM18NB2-X ZENER DIODE HITACHI

D27 HZM18NB2-X ZENER DIODE HITACHI

D28 HZM18NB2-X ZENER DIODE HITACHI

D29 HZM18NB2-X ZENER DIODE HITACHI

D30 HZM18NB2-X ZENER DIODE HITACHI

D31 HZM18NB2-X ZENER DIODE HITACHI

D32 HZM18NB2-X ZENER DIODE HITACHI

D33 HZM18NB2-X ZENER DIODE HITACHI

D34 HZM18NB2-X ZENER DIODE HITACHI

D35 HZM18NB2-X ZENER DIODE HITACHI

D44 GBL02 DIODE GI

D47 RK46 DIODE SANKEN

D50 FMM-22S DIODE SANKEN

D101 SVC341/L/-X DIODE SANYO

D201 SVC341/L/-X DIODE SANYO

D301 SVC341/L/-X DIODE SANYO

D501 SVC341/L/-X DIODE SANYO

D502 HZM18NB2-X ZENER DIODE HITACHI

D503 HZM18NB2-X ZENER DIODE HITACHI

D504 HZM3.0NB1-X ZENER DIODE HITACHI

D505 HZM3.0NB1-X ZENER DIODE HITACHI

D506 HZM3.0NB1-X ZENER DIODE HITACHI

D507 HZM3.0NB1-X ZENER DIODE HITACHI

D508 HZM3.0NB1-X ZENER DIODE HITACHI

D509 HZM3.0NB1-X ZENER DIODE HITACHI

D510 HZM3.0NB1-X ZENER DIODE HITACHI

D511 HZM3.0NB1-X ZENER DIODE HITACHI

D512 HZM3.0NB1-X ZENER DIODE HITACHI

D513 HZM3.0NB1-X ZENER DIODE HITACHI

D514 HZM3.0NB1-X ZENER DIODE HITACHI

D515 HZM3.0NB1-X ZENER DIODE HITACHI

D516 HZM3.0NB1-X ZENER DIODE HITACHI

D517 HZM3.0NB1-X ZENER DIODE HITACHI

D518 HZM3.0NB1-X ZENER DIODE HITACHI

D519 HZM3.0NB1-X ZENER DIODE HITACHI

D520 HZM3.0NB1-X ZENER DIODE HITACHI

D521 HZM3.0NB1-X ZENER DIODE HITACHI

D522 HZM3.0NB1-X ZENER DIODE HITACHI

D523 HZM3.0NB1-X ZENER DIODE HITACHI

D601 GBL02 DIODE GI

D602 GBL02 DIODE GI

D604 MA16-T2 DIODE MATSUSHITA

D605 MA16-T2 DIODE MATSUSHITA

D606 MA16-T2 DIODE MATSUSHITA

D607 MA16-T2 DIODE MATSUSHITA

Part No. Part Name Description

5-3

5-2

Page 25

Symbol

No.

D608 HZM18NB2-X ZENER DIODE HITACHI

D609 HZM18NB2-X ZENER DIODE HITACHI

D610 HZM18NB2-X ZENER DIODE HITACHI

D611 HZM18NB2-X ZENER DIODE HITACHI

D612 HZM36NB-W ZENER DIODE HITACHI

D613 HZM36NB-W ZENER DIODE HITACHI

D614 HZM36NB-W ZENER DIODE HITACHI

D615 HZM36NB-W ZENER DIODE HITACHI

D616 HZM36NB-W ZENER DIODE HITACHI

D617 HZM36NB-W ZENER DIODE HITACHI

Çc618 HZM18NB2-X ZENER DIODE HITACHI

Çc619 HZM18NB2-X ZENER DIODE HITACHI

Çc620 HZM18NB2-X ZENER DIODE HITACHI

Çc621 HZM18NB2-X ZENER DIODE HITACHI

Çc622 HZM18NB2-X ZENER DIODE HITACHI

Çc623 HZM18NB2-X ZENER DIODE HITACHI

Çc624 HZM18NB2-X ZENER DIODE HITACHI

Çc625 HZM18NB2-X ZENER DIODE HITACHI

PC1 PC817D I.C(PH COUPLER) SHARP

PC2 PC817D I.C(PH COUPLER) SHARP

R1 NRSA63J-333X M.G.RESISTOR 33K 1/16W

R2 NRSA63J-105X M.G.RESISTOR 1M 1/16W

R3 NRSA63J-224X M.G.RESISTOR 220K 1/16W

R4 NRSA63J-101X M.G.RESISTOR 100 1/16W

R5 NRSA63J-470X M.G.RESISTOR 47 1/16W

R6 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R7 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R8 NRSA63J-221X M.G.RESISTOR 220 1/16W

R9 NRSA63J-221X M.G.RESISTOR 220 1/16W

R10 NRSA63J-221X M.G.RESISTOR 220 1/16W

R11 NRSA63J-221X M.G.RESISTOR 220 1/16W

R12 NRSA63J-221X M.G.RESISTOR 220 1/16W

R13 NRSA63J-221X M.G.RESISTOR 220 1/16W

R14 NRSA63J-472X M.G.RESISTOR 4.7K 1/16W

R16 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R17 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R18 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R19 NRSA63J-681X M.G.RESISTOR 680 1/16W

R20 NRSA63J-470X M.G.RESISTOR 47 1/16W

R21 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R22 NRSA63J-470X M.G.RESISTOR 47 1/16W

R23 NRSA63J-470X M.G.RESISTOR 47 1/16W

R24 NRSA63J-470X M.G.RESISTOR 47 1/16W

R25 NRSA63J-470X M.G.RESISTOR 47 1/16W

R26 NRSA63J-470X M.G.RESISTOR 47 1/16W

R27 NRSA63J-470X M.G.RESISTOR 47 1/16W

R28 NRSA63J-470X M.G.RESISTOR 47 1/16W

R29 NRSA63J-470X M.G.RESISTOR 47 1/16W

R30 NRSA63J-470X M.G.RESISTOR 47 1/16W

R31 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R32 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R101 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R102 NRSA63J-333X M.G.RESISTOR 33K 1/16W

R103 NRSA63J-150X M.G.RESISTOR 15 1/16W

R104 NRSA63J-681X M.G.RESISTOR 680 1/16W

R105 NRSA63J-681X M.G.RESISTOR 680 1/16W

R106 NRSA63J-121X M.G.RESISTOR 120 1/16W

R107 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R108 NRSA63J-750X M.G.RESISTOR 75 1/16W

R109 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R110 NRSA63J-390X M.G.RESISTOR 39 1/16W

R111 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R112 NRSA63J-120X M.G.RESISTOR 12 1/16W

R113 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R114 NRSA63J-221X M.G.RESISTOR 220 1/16W

R115 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R116 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R117 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R118 NRSA63J-151X M.G.RESISTOR 150 1/16W

R119 NRSA63J-182X M.G.RESISTOR 1.8K 1/16W

R123 NRSA63J-561X M.G.RESISTOR 560 1/16W

R124 NRSA63J-471X M.G.RESISTOR 470 1/16W

Part No. Part Name Description

Symbol

No.

R125 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R126 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R127 NRSA63J-153X M.G.RESISTOR 15K 1/16W

R128 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R129 NRSA63J-331X M.G.RESISTOR 330 1/16W

R130 NRSA63J-471X M.G.RESISTOR 470 1/16W

R131 NRSA63J-224X M.G.RESISTOR 220K 1/16W

R132 NRSA63J-332X M.G.RESISTOR 3.3K 1/16W

R133 NRSA63J-221X M.G.RESISTOR 220 1/16W

R134 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R135 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R136 NRSA63J-221X M.G.RESISTOR 220 1/16W

R137 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R138 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R142 NRSA63J-561X M.G.RESISTOR 560 1/16W

R177 NRSA63J-472X M.G.RESISTOR 4.7K 1/16W

R178 NRSA63J-221X M.G.RESISTOR 220 1/16W

R180 NRSA63J-222X M.G.RESISTOR 2.2K 1/16W

R181 NRSA63J-822X M.G.RESISTOR 8.2K 1/16W

R182 NRSA02J-471X M.G.RESISTOR 470 1/8W

R186 NRSA63J-681X M.G.RESISTOR 680 1/16W

R187 NRSA63J-220X M.G.RESISTOR 22 1/16W

R188 NRSA63J-220X M.G.RESISTOR 22 1/16W

R194 NRSA63J-561X M.G.RESISTOR 560 1/16W

R195 NRSA63J-473X M.G.RESISTOR 47K 1/16W

R201 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R202 NRSA63J-333X M.G.RESISTOR 33K 1/16W

R203 NRSA63J-150X M.G.RESISTOR 15 1/16W

R204 NRSA63J-681X M.G.RESISTOR 680 1/16W

R205 NRSA63J-681X M.G.RESISTOR 680 1/16W

R206 NRSA63J-121X M.G.RESISTOR 120 1/16W

R207 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R208 NRSA63J-750X M.G.RESISTOR 75 1/16W

R209 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R210 NRSA63J-390X M.G.RESISTOR 39 1/16W

R211 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R212 NRSA63J-120X M.G.RESISTOR 12 1/16W

R213 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R214 NRSA63J-221X M.G.RESISTOR 220 1/16W

R215 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R216 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R217 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R218 NRSA63J-151X M.G.RESISTOR 150 1/16W

R219 NRSA63J-182X M.G.RESISTOR 1.8K 1/16W

R224 NRSA63J-471X M.G.RESISTOR 470 1/16W

R226 NRSA63J-561X M.G.RESISTOR 560 1/16W

R227 NRSA63J-122X M.G.RESISTOR 1.2K 1/16W

R228 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R229 NRSA63J-153X M.G.RESISTOR 15K 1/16W

R230 NRSA63J-332X M.G.RESISTOR 3.3K 1/16W

R231 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R232 NRSA63J-750X M.G.RESISTOR 75 1/16W

R301 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R302 NRSA63J-333X M.G.RESISTOR 33K 1/16W

R303 NRSA63J-150X M.G.RESISTOR 15 1/16W

R304 NRSA63J-681X M.G.RESISTOR 680 1/16W

R305 NRSA63J-681X M.G.RESISTOR 680 1/16W

R306 NRSA63J-121X M.G.RESISTOR 120 1/16W

R307 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R308 NRSA63J-750X M.G.RESISTOR 75 1/16W

R309 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R310 NRSA63J-390X M.G.RESISTOR 39 1/16W

R311 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R312 NRSA63J-120X M.G.RESISTOR 12 1/16W

R313 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R314 NRSA63J-221X M.G.RESISTOR 220 1/16W

R315 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R316 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R317 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R318 NRSA63J-151X M.G.RESISTOR 150 1/16W

R319 NRSA63J-182X M.G.RESISTOR 1.8K 1/16W

R324 NRSA63J-471X M.G.RESISTOR 470 1/16W

R328 NRSA63J-561X M.G.RESISTOR 560 1/16W

Part No. Part Name Description

5-4

5-3

Page 26

[MAIN]

Symbol

No.

R329 NRSA63J-122X M.G.RESISTOR 1.2K 1/16W

R330 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R331 NRSA63J-153X M.G.RESISTOR 15K 1/16W

R332 NRSA63J-332X M.G.RESISTOR 3.3K 1/16W

R333 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R401 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R402 NRSA63J-333X M.G.RESISTOR 33K 1/16W

R403 NRSA63J-150X M.G.RESISTOR 15 1/16W

R404 NRSA63J-681X M.G.RESISTOR 680 1/16W

R405 NRSA63J-681X M.G.RESISTOR 680 1/16W

R406 NRSA63J-121X M.G.RESISTOR 120 1/16W

R407 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R408 NRSA63J-750X M.G.RESISTOR 75 1/16W

R409 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R410 NRSA63J-390X M.G.RESISTOR 39 1/16W

R411 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R412 NRSA63J-120X M.G.RESISTOR 12 1/16W

R413 NRSA63J-182X M.G.RESISTOR 1.8K 1/16W

R414 NRSA63J-221X M.G.RESISTOR 220 1/16W

R415 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R416 NRSA63J-273X M.G.RESISTOR 27K 1/16W

R417 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R418 NRSA63J-151X M.G.RESISTOR 150 1/16W

R424 NRSA63J-471X M.G.RESISTOR 470 1/16W

R425 NRSA63J-561X M.G.RESISTOR 560 1/16W

R426 NRSA63J-122X M.G.RESISTOR 1.2K 1/16W

R427 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R428 NRSA63J-153X M.G.RESISTOR 15K 1/16W

R429 NRSA63J-332X M.G.RESISTOR 3.3K 1/16W

R430 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R431 NRSA63J-750X M.G.RESISTOR 75 1/16W

R501 NRSA63J-822X M.G.RESISTOR 8.2K 1/16W

R502 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R503 NRSA63J-221X M.G.RESISTOR 220 1/16W

R504 NRSA63J-471X M.G.RESISTOR 470 1/16W

R505 NRSA63J-222X M.G.RESISTOR 2.2K 1/16W

R506 NRSA63J-222X M.G.RESISTOR 2.2K 1/16W

R507 NRSA63J-562X M.G.RESISTOR 5.6K 1/16W

R508 NRSA63J-562X M.G.RESISTOR 5.6K 1/16W

R509 NRSA63J-684X M.G.RESISTOR 680K 1/16W

R510 NRSA63J-331X M.G.RESISTOR 330 1/16W

R511 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R512 NRSA63J-221X M.G.RESISTOR 220 1/16W

R513 NRSA63J-183X M.G.RESISTOR 18K 1/16W

R514 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R515 NRSA63J-122X M.G.RESISTOR 1.2K 1/16W

R516 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R517 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R518 NRSA63J-183X M.G.RESISTOR 18K 1/16W

R519 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R520 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R521 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R522 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R523 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R526 NRSA63J-221X M.G.RESISTOR 220 1/16W

R527 NRSA63J-122X M.G.RESISTOR 1.2K 1/16W

R528 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R529 NRSA63J-153X M.G.RESISTOR 15K 1/16W

R530 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R531 NRSA63J-102X M.G.RESISTOR 1K 1/16W

R532 NRSA63J-562X M.G.RESISTOR 5.6K 1/16W

R533 NRSA63J-562X M.G.RESISTOR 5.6K 1/16W

R534 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R535 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R536 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R537 NRSA63J-682X M.G.RESISTOR 6.8K 1/16W

R538 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R539 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R540 NRSA63J-750X M.G.RESISTOR 75 1/16W

R541 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R542 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R543 NRSA63J-682X M.G.RESISTOR 6.8K 1/16W

R544 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

Part No. Part Name Description

Symbol

No.

R545 NRSA63J-152X M.G.RESISTOR 1.5K 1/16W

R546 NRSA63J-750X M.G.RESISTOR 75 1/16W

R547 NRSA63J-750X M.G.RESISTOR 75 1/16W

R548 NRSA63J-750X M.G.RESISTOR 75 1/16W

R549 NRSA63J-750X M.G.RESISTOR 75 1/16W

R550 NRSA63J-750X M.G.RESISTOR 75 1/16W

R551 NRSA63J-750X M.G.RESISTOR 75 1/16W

R552 NRSA63J-471X M.G.RESISTOR 470 1/16W

R553 NRSA63J-221X M.G.RESISTOR 220 1/16W

R554 NRSA63J-750X M.G.RESISTOR 75 1/16W

R556 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R557 NRSA63J-681X M.G.RESISTOR 680 1/16W

R558 NRSA63J-681X M.G.RESISTOR 680 1/16W

R561 NRSA63J-272X M.G.RESISTOR 2.7K 1/16W

R562 NRSA63J-221X M.G.RESISTOR 220 1/16W

R563 NRSA63J-221X M.G.RESISTOR 220 1/16W

R564 NRSA63J-750X M.G.RESISTOR 75 1/16W

R601 NRSA63J-392X M.G.RESISTOR 3.9K 1/16W

R602 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R603 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R604 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R605 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R606 NRSA63J-392X M.G.RESISTOR 3.9K 1/16W

R607 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R608 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R609 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R610 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R611 NRSA63J-472X M.G.RESISTOR 4.7K 1/16W

R612 NRSA63J-470X M.G.RESISTOR 47 1/16W

R613 NRSA63J-472X M.G.RESISTOR 4.7K 1/16W

R614 NRSA63J-470X M.G.RESISTOR 47 1/16W

R616 NRSA63J-472X M.G.RESISTOR 4.7K 1/16W

R617 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R618 NRSA63J-560X M.G.RESISTOR 56 1/16W

R619 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R620 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R621 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R622 NRSA63J-822X M.G.RESISTOR 8.2K 1/16W

R623 NRSA63J-822X M.G.RESISTOR 8.2K 1/16W

R624 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R625 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R626 NRSA63J-563X M.G.RESISTOR 56K 1/16W

R627 NRSA63J-153X M.G.RESISTOR 15K 1/16W

R628 NRSA63J-561X M.G.RESISTOR 560 1/16W

R629 NRSA63J-563X M.G.RESISTOR 56K 1/16W

R630 NRSA63J-822X M.G.RESISTOR 8.2K 1/16W

R631 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R632 NRSA63J-122X M.G.RESISTOR 1.2K 1/16W

R633 NRSA63J-393X M.G.RESISTOR 39K 1/16W

R635 NRSA63J-101X M.G.RESISTOR 100 1/16W

R637 NRSA63J-223X M.G.RESISTOR 22K 1/16W

R638 NRSA63J-682X M.G.RESISTOR 6.8K 1/16W

R639 NRSA63J-682X M.G.RESISTOR 6.8K 1/16W

R640 NRSA63J-682X M.G.RESISTOR 6.8K 1/16W

R641 NRSA63J-682X M.G.RESISTOR 6.8K 1/16W

R642 NRSA63J-392X M.G.RESISTOR 3.9K 1/16W

R643 NRSA63J-392X M.G.RESISTOR 3.9K 1/16W

R644 NRSA63J-470X M.G.RESISTOR 47 1/16W

R645 NRSA63J-470X M.G.RESISTOR 47 1/16W

R646 NRSA63J-222X M.G.RESISTOR 2.2K 1/16W

R648 NRSA63J-392X M.G.RESISTOR 3.9K 1/16W

R650 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R651 NRSA63J-472X M.G.RESISTOR 4.7K 1/16W

R652 NRSA63J-104X M.G.RESISTOR 100K 1/16W

R653 NRSA63J-822X M.G.RESISTOR 8.2K 1/16W

R654 NRSA63J-473X M.G.RESISTOR 47K 1/16W

R655 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R656 NRSA63J-473X M.G.RESISTOR 47K 1/16W

R657 NRSA63J-473X M.G.RESISTOR 47K 1/16W

R659 NRSA63J-103X M.G.RESISTOR 10K 1/16W

R660 NRSA63J-103X M.G.RESISTOR 10K 1/16W

RA1 QRB085J-104 RESISTOR ARRAY 10K

Part No. Part Name Description

5-5

5-4

Page 27

Symbol

No.

VR15 NVP1415-103X TRIM.RESISTOR 10K 2W S.TONE

VR16 NVP1415-103X TRIM.RESISTOR 10K RTS S.TONE

VR101 NVP1415-203X TRIM.RESISTOR 20K VBS FREQ

VR102 NVP1415-103X TRIM.RESISTOR 10K VBS LEVEL

VR201 NVP1415-501X TRIM.RESISTOR 500 R LEVEL

VR202 NVP1415-203X TRIM.RESISTOR 20K R FREQ

VR301 NVP1415-501X TRIM.RESISTOR 500 G LEVEL

VR302 NVP1415-203X TRIM.RESISTOR 20K G FREQ

VR401 NVP1415-501X TRIM.RESISTOR 500 B LEVEL

VR402 NVP1415-203X TRIM.RESISTOR 20K B FREQ

C1 QEZ0298-688 E.CAPACITOR 6800 50V

C2 QEZ0298-688 E.CAPACITOR 6800 50V

C3 NCB31EK-103X CER.CAPACITOR 0.01

C4 QETC1EM-477 E.CAPACITOR 470 25V

C5 QEZ0548-828 E.CAPACITOR 8200 25V

C8 NCB31CK-104X CER.CAPACITOR 0.1

C9 NCB31CK-73X CER.CAPACITOR 0.047

C10 NCB31CK-73X CER.CAPACITOR 0.047

C11 NCB31CK-73X CER.CAPACITOR 0.047

C12 NCB31CK-73X CER.CAPACITOR 0.047

C14 NCB31CK-73X CER.CAPACITOR 0.047

C15 NCB31CK-104X CER.CAPACITOR 0.1

C17 NCB31CK-73X CER.CAPACITOR 0.047

C23 NCB31CK-104X CER.CAPACITOR 0.1

C24 NCB31CK-104X CER.CAPACITOR 0.1

C25 NCB31CK-104X CER.CAPACITOR 0.1

C26 NCB31EK-103X CER.CAPACITOR 0.01

C29 NCB31CK-73X CER.CAPACITOR 0.047

C61 NCB31EK-103X CER.CAPACITOR 0.01

C62 NCB31EK-103X CER.CAPACITOR 0.01

C63 NCB31EK-103X CER.CAPACITOR 0.01

C64 NCB31EK-103X CER.CAPACITOR 0.01

C65 NCZ1024-103X CER.CAPACITOR 0.01 250V

C66 NCB31CK-104X CER.CAPACITOR 0.1

C67 NCB31CK-104X CER.CAPACITOR 0.1

C68 NCB31CK-104X CER.CAPACITOR 0.1

C69 NCB31CK-104X CER.CAPACITOR 0.1

C71 NCB31CK-104X CER.CAPACITOR 0.1

C72 NCB31CK-104X CER.CAPACITOR 0.1

C74 NCB31CK-73X CER.CAPACITOR 0.047

C75 NCB31CK-104X CER.CAPACITOR 0.1

C76 NCB31CK-104X CER.CAPACITOR 0.1

C77 NCB31CK-104X CER.CAPACITOR 0.1

C81 QER61HM-105Z E.CAPACITOR 1 50V

C82 QEZ0290-828 E.CAPACITOR 8200 35V

C83 QETM1EM-228 E.CAPACITOR 2200 25V

C84 QETC1EM-477 E.CAPACITOR 470 25V

C85 QEZ0298-688 E.CAPACITOR 6800 50V

C86 QEZ0548-828 E.CAPACITOR 8200 25V

C86 QEZ0548-828 E.CAPACITOR 8200 25V

C87 QETC1EM-477 E.CAPACITOR 470 25V

C88 QETC1EM-477 E.CAPACITOR 470 25V

C93 QEZ0171-22A CAPACITOR 0.22 5.5V

C101 QETC0JM-476Z E.CAPACITOR 47 10V

C102 QETC0JM-476Z E.CAPACITOR 47 10V

C103 NDC31HJ-121X CER.CAPACITOR 120P

C104 NDC31HJ-560X CER.CAPACITOR 56P

C105 NCB31CK-73X CER.CAPACITOR 0.047

C107 NDC31HJ-470X CER.CAPACITOR 47P

C114 NDC31HJ-151X CER.CAPACITOR 150P

C115 QETC0JM-476Z E.CAPACITOR 47 10V

C116 NCB31CK-73X CER.CAPACITOR 0.047

C117 NCB31CK-73X CER.CAPACITOR 0.047

C118 NCB31CK-73X CER.CAPACITOR 0.047

C119 NCB31CK-73X CER.CAPACITOR 0.047

C120 NCB31CK-73X CER.CAPACITOR 0.047

C121 NCB31CK-73X CER.CAPACITOR 0.047

C149 QETC0JM-476Z E.CAPACITOR 47 10V

C188 QETC0JM-476Z E.CAPACITOR 47 10V

C196 NCB31CK-73X CER.CAPACITOR 0.047

C198 QETC0JM-476Z E.CAPACITOR 47 10V

C199 NCB31CK-73X CER.CAPACITOR 0.047

Part No. Part Name Description

Symbol

No.

C201 QETC0JM-476Z E.CAPACITOR 47 10V

C202 QETC0JM-476Z E.CAPACITOR 47 10V

C203 NDC31HJ-121X CER.CAPACITOR 120P

C204 NDC31HJ-560X CER.CAPACITOR 56P

C205 NCB31CK-73X CER.CAPACITOR 0.047

C207 NDC31HJ-220X CER.CAPACITOR 22P

C214 NDC31HJ-680X CER.CAPACITOR 68P

C215 QETC0JM-476Z E.CAPACITOR 47 10V

C217 NCB31CK-73X CER.CAPACITOR 0.047

C218 NCB31CK-73X CER.CAPACITOR 0.047

C220 QETC0JM-476Z E.CAPACITOR 47 10V

C221 QETC0JM-476Z E.CAPACITOR 47 10V

C222 QETC0JM-476Z E.CAPACITOR 47 10V

C223 NCB31CK-73X CER.CAPACITOR 0.047

C301 QETC0JM-476Z E.CAPACITOR 47 10V

C302 QETC0JM-476Z E.CAPACITOR 47 10V

C303 NDC31HJ-121X CER.CAPACITOR 120P

C304 NDC31HJ-560X CER.CAPACITOR 56P

C305 NCB31CK-73X CER.CAPACITOR 0.047

C307 NDC31HJ-220X CER.CAPACITOR 22P

C314 NDC31HJ-680X CER.CAPACITOR 68P

C315 QETC0JM-476Z E.CAPACITOR 47 10V

C317 NCB31CK-73X CER.CAPACITOR 0.047

C318 NCB31CK-73X CER.CAPACITOR 0.047

C319 QETC0JM-476Z E.CAPACITOR 47 10V

C320 NCB31CK-73X CER.CAPACITOR 0.047

C321 QETC0JM-476Z E.CAPACITOR 47 10V

C401 QETC0JM-476Z E.CAPACITOR 47 10V

C402 QETC0JM-476Z E.CAPACITOR 47 10V

C403 NDC31HJ-121X CER.CAPACITOR 120P

C404 NDC31HJ-560X CER.CAPACITOR 56P

C405 NCB31CK-73X CER.CAPACITOR 0.047

C407 NDC31HJ-220X CER.CAPACITOR 22P

C414 NDC31HJ-680X CER.CAPACITOR 68P

C415 QETC0JM-476Z E.CAPACITOR 47 10V

C417 NCB31CK-73X CER.CAPACITOR 0.047

C418 NCB31CK-73X CER.CAPACITOR 0.047

C420 NCB31CK-73X CER.CAPACITOR 0.047

C421 QETC0JM-476Z E.CAPACITOR 47 10V

C501 QETC0JM-476Z E.CAPACITOR 47 10V

C502 NDC31HJ-151X CER.CAPACITOR 150P (U)

C502 NDC31HJ-121X CER.CAPACITOR 120P (E)

C504 NCB31CK-73X CER.CAPACITOR 0.047

C505 NCB31CK-73X CER.CAPACITOR 0.047

C507 NCB31CK-73X CER.CAPACITOR 0.047

C508 NDC31HJ-7R0X CER.CAPACITOR 7P

C509 NDC31HJ-560X CER.CAPACITOR 56P (U)

C509 NDC31HJ-470X CER.CAPACITOR 47P (E)

C510 NDC31HJ-8R0X CER.CAPACITOR 8P (U)