Page 1

SERVICE MANUAL

SYSTEM CONTROLLER

RM-RE9000

RM-RE9000

Area Suffix

PRESENCE

SPEAKER

1

1

2

EACH

4

3

5

2

6

1

7

8

ALL

AMP GAIN

SOURCE GAIN

PRESET

PRESET

Contents

Safety Precautions

Adjustment method

Description of major ICs

2

MASTER VOLUME

dB

dB

LINE 1 LINE 2 LINE 3

MUTING

-180û

LINE 5LINE 4 LINE 6

ATT

DISPLAYSLEEP

EXT

PROCESSOR

PHASE

E

Continental Europe

1-2

1-3

1-6~8

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20934

Apr. 2001

Page 2

http://getMANUAL.com

RM-RE9000

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

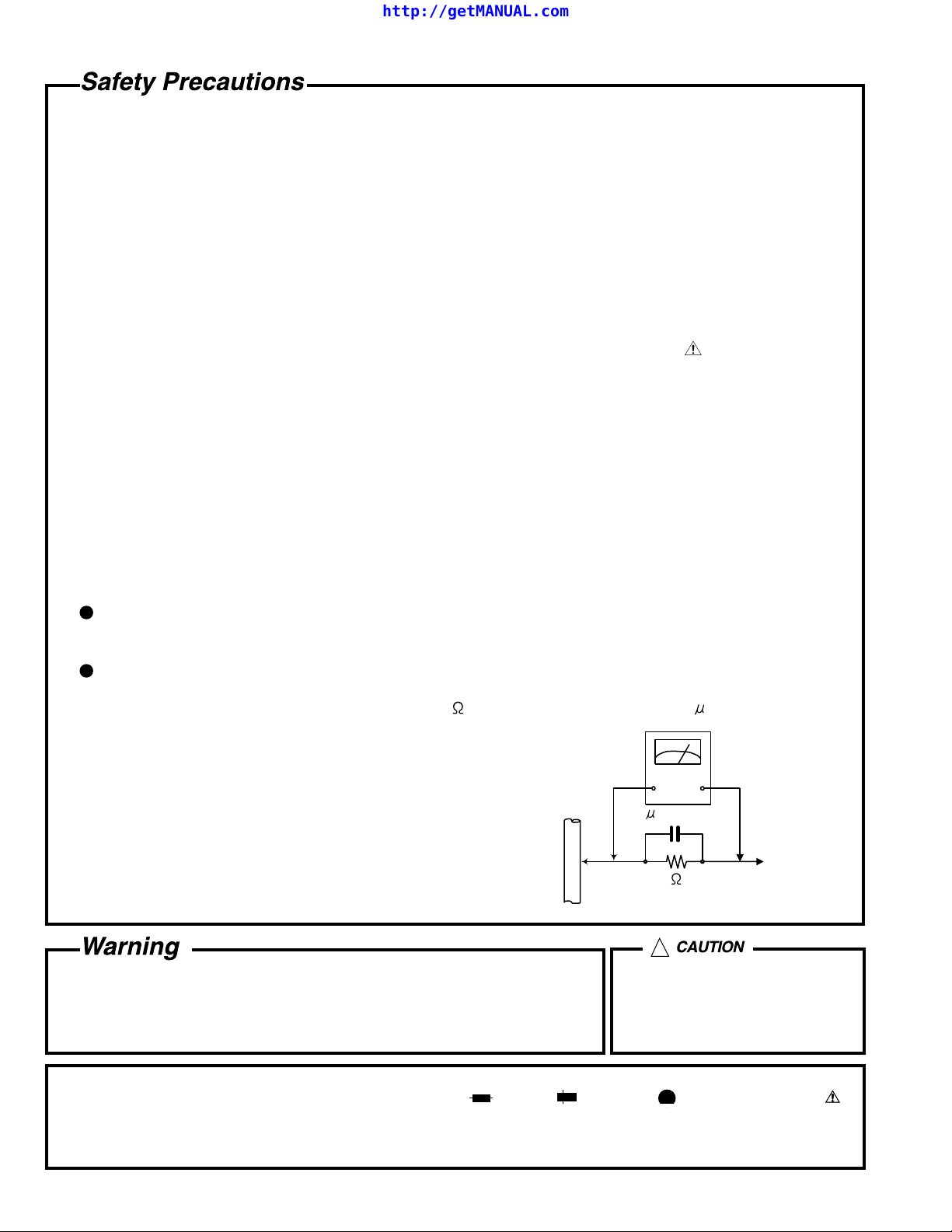

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to eachexposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. voltage measured Any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the JC version)

1-2

Page 3

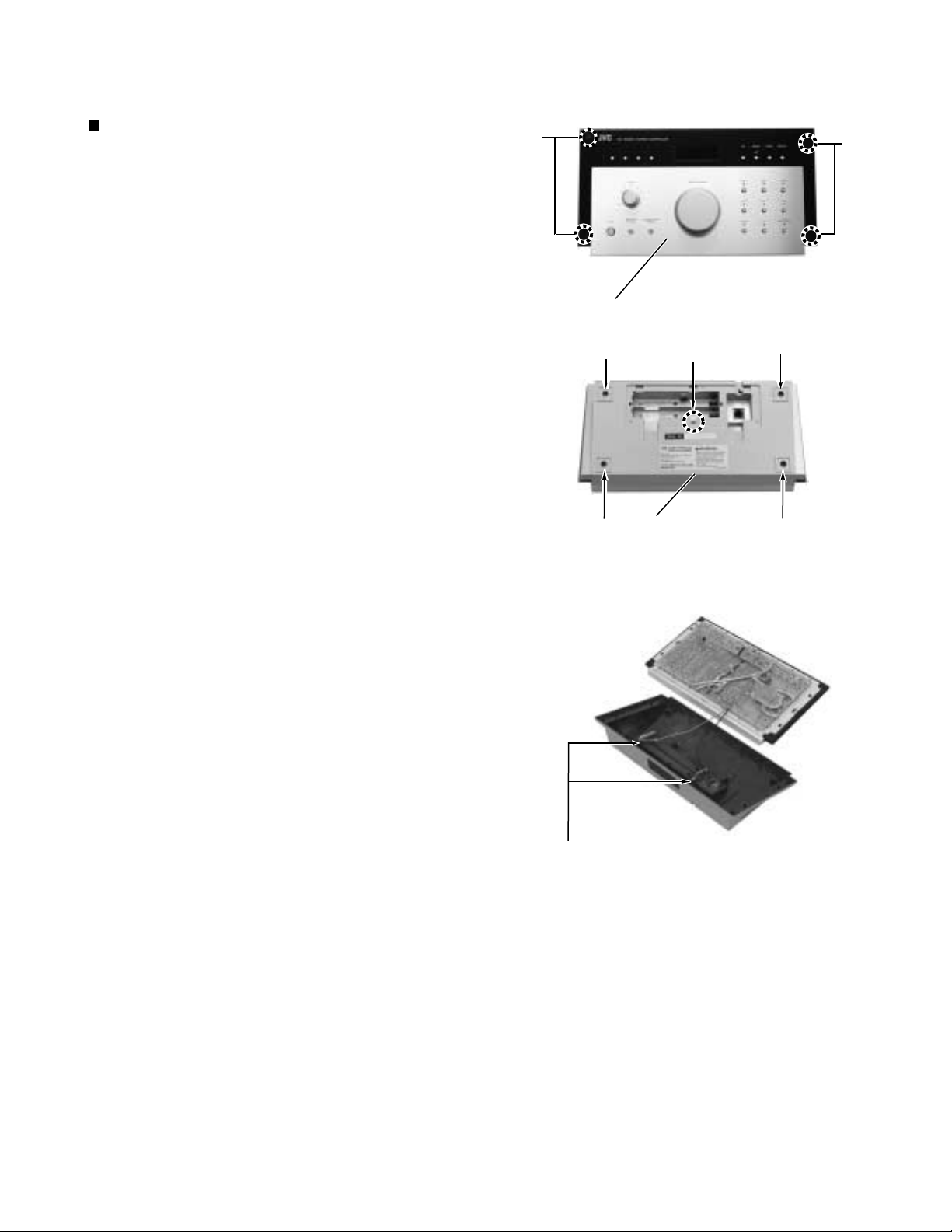

Disassembly method

RM-RE9000

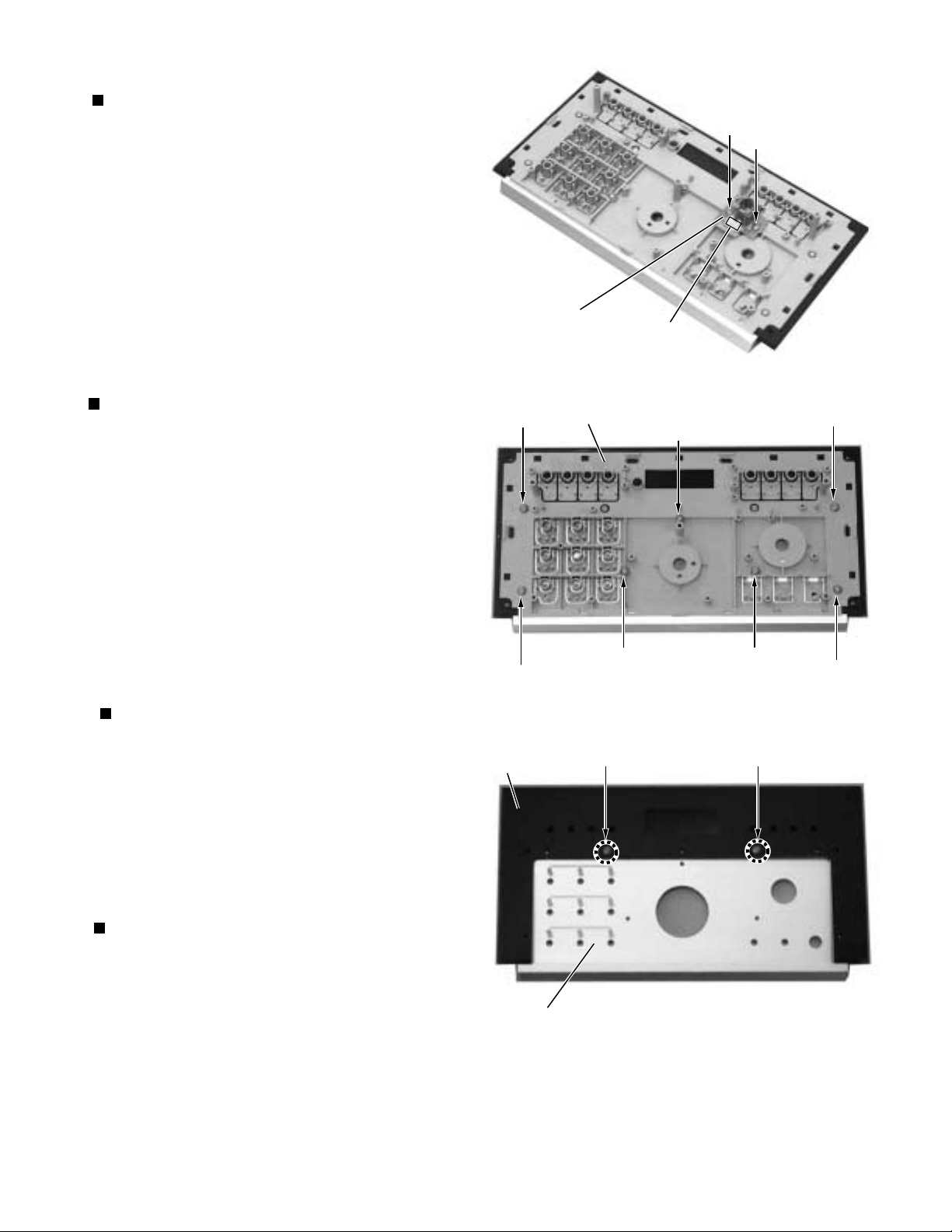

Removing the rear cover (See Fig.1 to 3)

1.

Remove the four screws A on the front with a

hexagon wrench.

2.

Place the reverse side of the set upward.

3.

After taking off the cushions from the four places,

remove the four screws B at the inside of the rear

cover.

4.

Remove the screw B' at the inside of the battery

cover.

5.

Remove the rear cover and the front panel

assembly. (Because they should have been tightly

engaged, remove them with due care.)

6.

Remove the battery holder board assembly from the

rear cover by pulling it up.

A

Front panel assembly

B

Rear cover

B

Fig.1

B'

Fig.2

A

B

B

Battery holder board

assembly

Fig.3

1-3

Page 4

RM-RE9000

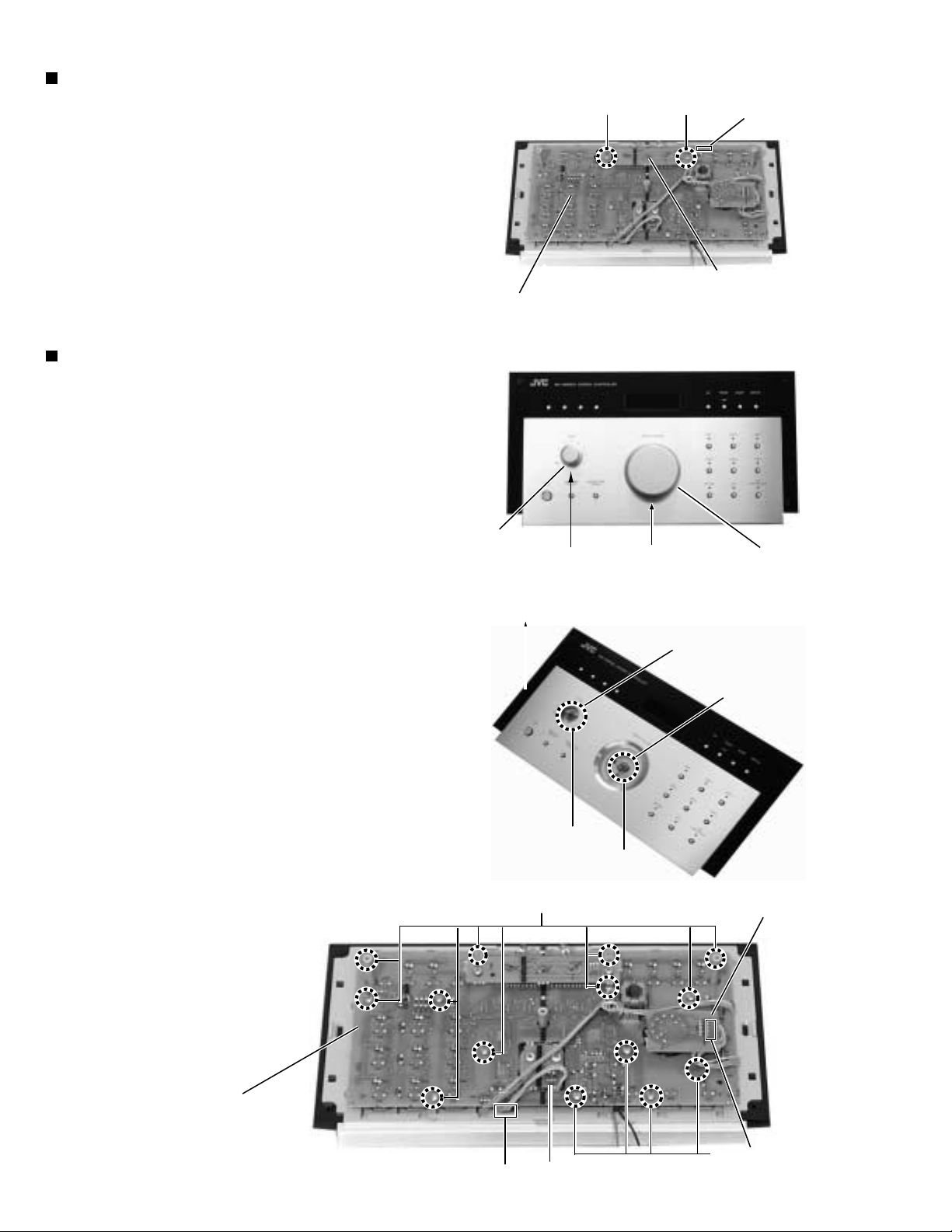

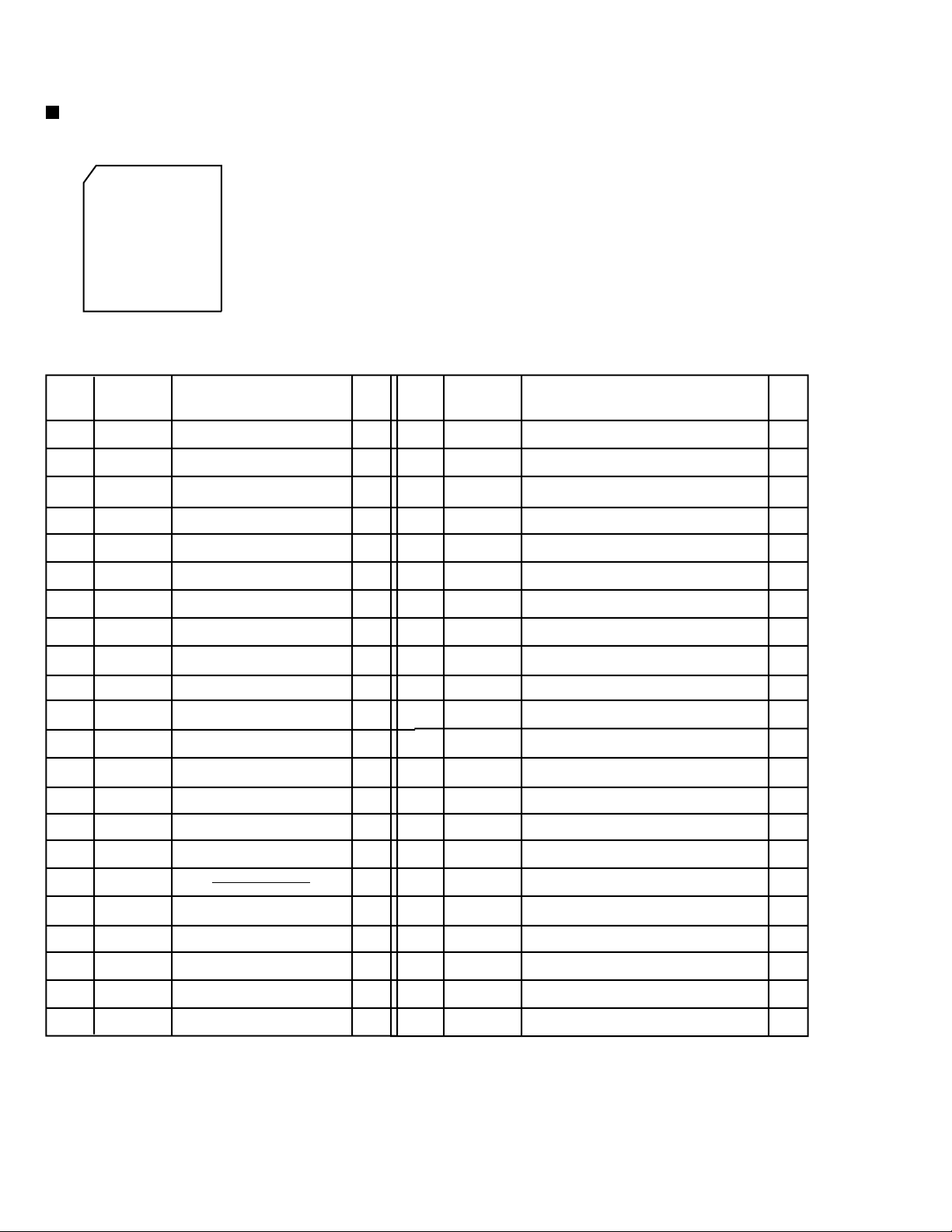

Removing the remote controller

transmission board assembly (See Fig.4)

1.

Remove the rear cover.

2.

Remove the two screws C attaching the remote

controller transmission board assembly.

3.

Remove the connector CN201 connecting the main

board assembly to the remote controller transmission

board assembly.

Removing the main board assembly

(See Fig.5 to 7)

Remove the rear cover.

1.

Remove the remote controller transmission board

2.

assembly.

Main board assembly

C

Fig.4

C

Remote controller

transmission board

assembly

CN201

After taking off the screws D & E attaching the

3.

volume knob and the rotary switch, remove their

knobs.

After taking off the nut F attaching the volume board

4.

assembly with a box-type driver, remove the volume

board assembly.

After taking off the nut G attaching the rotary switch

5.

board assembly with a box-type driver, remove the

rotary switch board assembly.

Remove the fourteen screws H attaching the main

6.

board assembly.

Remove the connector CN103 connecting the main

7.

board assembly to the volume board assembly, and

the connector CN301 connecting the main board

assembly to the rotary switch board assembly,

respectively.

Rotary

switch knob

H

G

E

D

Fig.5

Rotary switch knob

F

Fig.6

Rotary switch board assembly

Volume knob

Volume knob

1-4

Main board assembly

Fig.7

CN103

Volume board assembly

CN301

H

Page 5

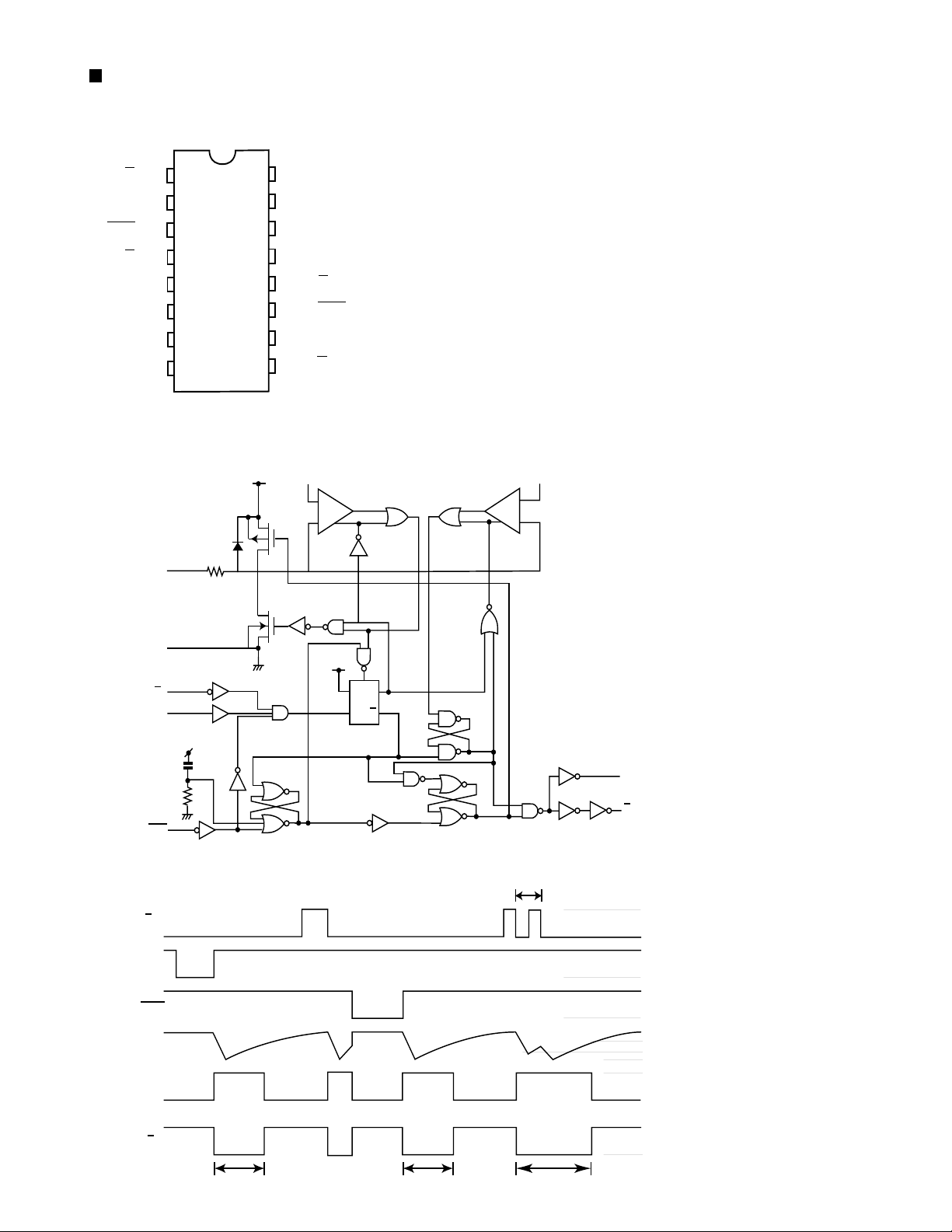

Removing the modular jack board

assembly (See Fig.8)

1.

Remove the rear cover.

2.

Remove the remote controller transmission board

assembly.

3.

Remove the main board assembly.

4.

Remove the two screws I attaching the modular jack

board assembly.

5.

Remove the connector CN501 connecting the main

board assembly to the connector terminal board

assembly.

Modular jack board

assembly

CN501

RM-RE9000

I

I

Fig.8

Removing the switch board (See Fig.9)

1.

Remove the rear cover.

2.

Remove the remote controller transmission board

assembly.

3.

Remove the main board assembly.

4.

Remove the modular jack board assembly.

5.

Remove the seven screws J attaching the switch

board.

6.

Remove the board by lifting it.

Removing the top panel (See Fig.10)

1.

Remove the rear cover.

2.

Remove the remote controller transmission board

assembly.

3.

Remove the main board assembly.

4.

Remove the modular jack board assembly.

5.

Remove the board.

6.

Remove the two screws K attaching the lens and the

top panel.

J

Lens

Switch board

J

K

J

J

J

Fig.9

J

J

K

Reminder when the top panel is

reassembled

1.

When the top panel is reassembled, use the screws

with the specified size (M3x8mm) without fail

(Screws marked K).

Using longer screws may damage the top panel and

cause the top panel unstable.

Top panel

Fig.10

1-5

Page 6

RM-RE9000

Description of major ICs

MN101CP117(IC101) : System controller

1.Pin layout

~

3444

1

33

~

11

12

2.Pin function

Pin

Symbol Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

KY13

ROT1

ROT2

ROT3

ROT4

ROT5

ROT6

N.C

N.C

VOL1

VOL2

AD

VDD

OSC2

OSC1

VSS

NC

SDATO

BRI

SCLK

KY1

RMOUT

~

~

23

22

Key input 8

Rotary output 1

Rotary output 2

Rotary output 3

Rotary input 1

Rotary input 2

Rotary input 3

GND

GND

Volume input 1

Volume input 2

AD input

2.0V~5.0V Supply

clock output

clock input

0.0V

Serial output data

Blight adjustment

Serial clock

Key input 1

Remocon output

I/O I/O

Pin

No.

I

O

O

O

I

I

I

I

I

I

I

I

O

I

O

O

O

O

O

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

CK1

LATCH1

RST1

SIN1

WAKE

KY2

KY3

KY4

KY5

KY6

CK2

LATCH2

RST2

SIN2

KY7

KY8

RST

MMOD

KY9

KY10

KY11

KY12

7segment circuit clock 1

7segment circuit latch output 1

7segment circuit latch reset 1

Output data 1

Wake

Key input 2

Key input 3

Key input

Key output 1

Key output 2

LED circuit clock 2

LED circuit latch output 2

LED circuit reset 2

LED circuit data output 2

Key output 3

Key output 4

Reset

GND

Key output 5

Key input 5

Key input 6

Key input 7

FunctionFunction

O

O

O

O

O

O

O

O

O

O

O

O

O

I

I

I

I

I

I

I

I

I

1-6

Page 7

TC74VHC123AF-X(IC112) :Shift register for relay control

1. Pin layout

16

15

14

13

12

11

10

9

Vcc

1Rx/Cx

1Cx

1Q

2Q

2CLR

2B

2A

1A

1B

1CLR

1Q

2Q

1Cx

2Rx/Cx

GND

1

2

3

4

5

6

7

8

(TOP VIEW)

RM-RE9000

2. Block diagram

X/CX

R

C

X

A

B

CLR

3. Timing diagram

A

B

CLR

RX/CX

Q

V

CC

Vref Vref

L

-

Q

Q

N

+

P

V

CC

R

D

Q

F/F

CK

Q

C2

H

+

-

Q

Q

t

rr

V

IH

VIL

VIH

VIL

VIH

VIL

VCC

V

refH

V

refL

GND

VOH

VOL

Q

t

w OUT

t

w OUT

t

w OUT+

t

rr

VOL

1-7

VOH

Page 8

RM-RE9000

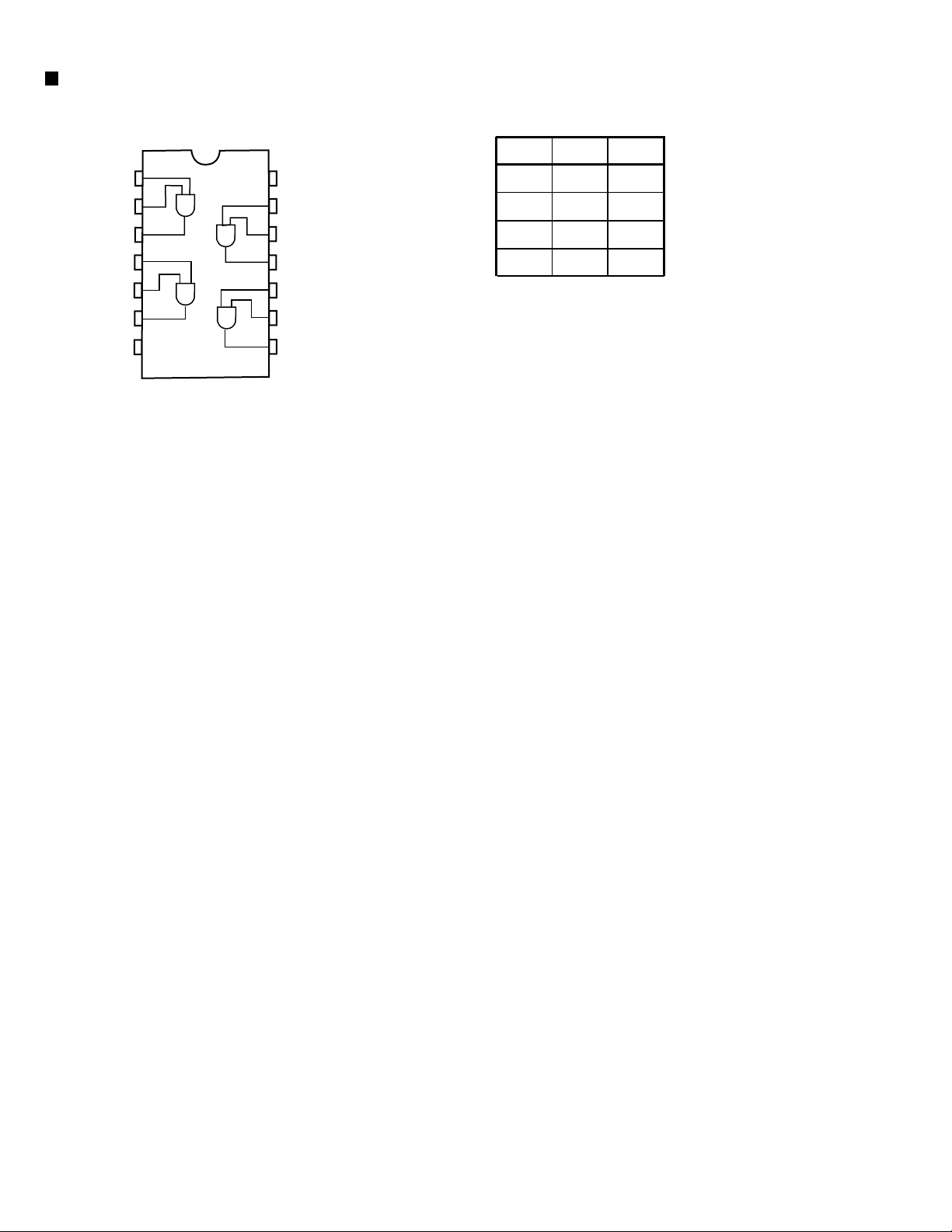

TC74VHC08F-X (IC112) :Data line buffer

1. Pin. layout 2. True table

1A

1B

1Y

2A

2B

2Y

GND

A

14

13

12

11

10

9

8

Vcc

4B

4A

4Y

3B

3A

3Y

L

L

H

H

1

2

3

4

5

6

7

(TOP VIEW)

B

L

H

L

HH

X : Don't Care

Y

L

L

L

1-8

Page 9

< MEMO >

RM-RE9000

1-9

Page 10

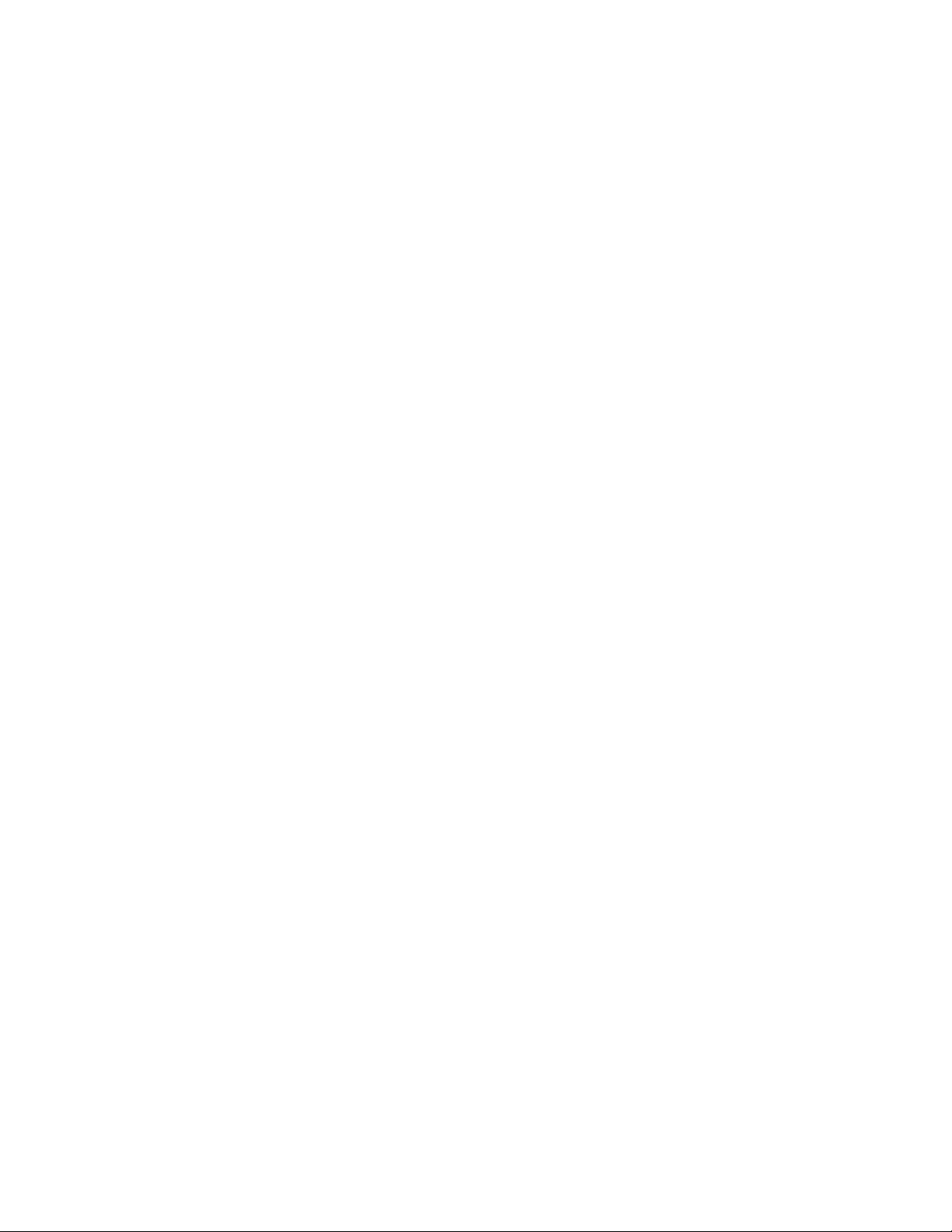

Block diagram

Transmission part

5

4

Battery

holder

RMOUT

Key1~6

Key7~13

DC-DC converter

IC103

Power

supply

GND

IC101

Micro controller

LATCH1

SIN1

RST1

CK1

LATCH2

SIN2

RST2

CK2

LED driver

IC104

LED driver

IC105

LED driver

IC106

to

IC110

PRESENCE2

PRESENCE1

SPEAKER2

SPEAKER1

MUTING

LINE1~6

ATT

EXT

RM-RE9000

LED

LED

LED

Rotary switch

ROT1 to ROT6

Data line buffer

SDA TO

IC112

3

3

1

2

VOL 2

SCL IC

Volume

Modular

jack

2

1

A

BC D

2-1

Page 11

RM-RE9000

< MEMO >

2-2

Page 12

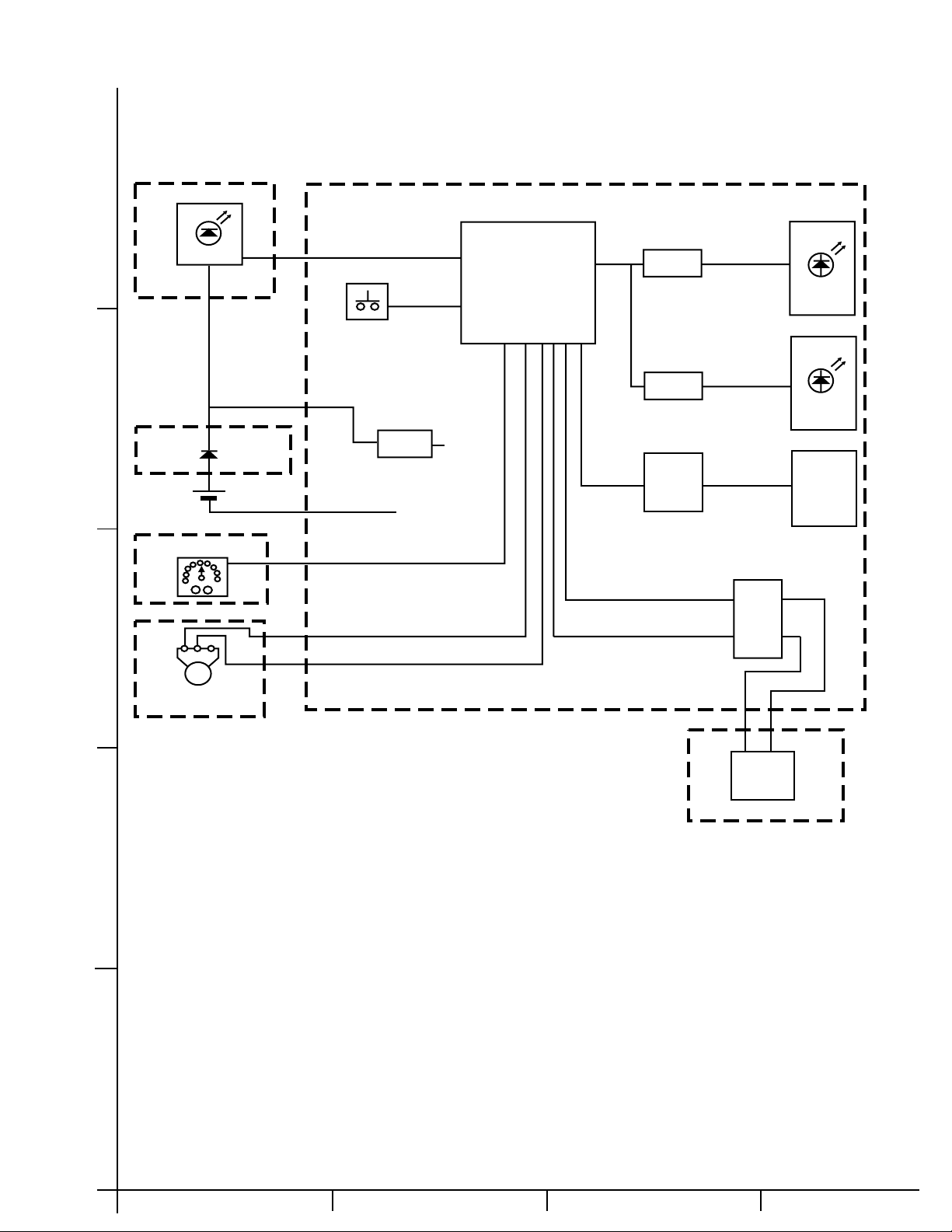

Standard schematic diagram

RM-RE9000

22K

QSW0802-001Z

S101

QSW0802-001Z

S105

R166

5

D133

1SS133-T1

QSW0802-001Z

S102

QSW0802-001Z

S106

22K

22K

R167

D134

1SS133-T1

QSW0802-001Z

S103

QSW0802-001Z

S107

22K

R168

R169

D135

KY6

1SS133-T1

QSW0802-001Z

S104

QSW0802-001Z

S108

KY4

KY5

D136

1SS133-T1

SLR-342VC-T

SLR-342MC-T

SLR-342DC-T

SLR-342DC-T

SLR-342DC-T

SLR-342DC-T

SLR-342DC-T

SLR-342DC-T

SLR-342MC-T

SLR-342MC-T

SLR-342VC-T

SLR-342MC-T

SLR-342MC-T

SLR-342MC-T

3.9

3.9

SRZ-932C-22-T14

3.9

R203

SRZ-932C-22-T14

D203

D101

D102

D103

D104

D105

R201

D201

CN201

QGA2001F1-03

KY3

KY2

KY1

CN101

QJB002-031803

SRZ-932C-22-T14

R202

D202

SLR-342MC-T

C108

R108

D107

C109

R109

D108

D109

D110

D112

D113

D114

D111

D115

SLR-342DC-T

D116

D117

4

220

270

270

270

270

270

270

120

120

330

120

120

120

120

R101

22K

22K

R170

1SS133-T1

D137

QSW0802-001Z

S109

QSW0802-001Z

S113

QSW0802-001Z

3

S117

QSW0802-001Z

S110

QSW0802-001Z

S114

QSW0802-001Z

S118

KY13

22K

R171

R172

1SS133-T1

QSW0802-001Z

QSW0802-001Z

QSW0802-001Z

1SS133-T1

D139

QSW0802-001Z

S112

QSW0802-001Z

S116

QSW0802-001Z

S120

KY11

D138

S111

S115

S119

KY12

22K

R173

KY10

D140

KY9

IC102

IC-PST529

R175

1K

NI

1SS133-T1

R174

KY8

CK2

LATCH2

KY7

RST2

SIN2

KY7

KY8

KY9

KY10

KY11

KY12

KY13

KY3

KY4

KY5

KY6

IC101

MN101CP117

ROT2

ROT1

ROT4

ROT3

SIN1

RST1

KY2

ROT6

ROT5

2

22K

22K

22K

R181

R179

R180

D153

R192

NI

R191

NI

R190

C102

0.1

IC103

MAX1674EUA-X

NI

L101

22

C103

0.1

D701

RB160L-40-X

D702

RB160L-40-X

WR701

WR101

W701 W702

QUY260-050H QUY260-050H

W601

VYH7199-001

1

W602

VYH7199-001

WR601

WR102

C101

47/6.3

NI

R177

0

R176

C104

47/6.3

D151

11E2-T5

D143

D144

11E2-T5

11E2-T5

CN102

ROT1

ROT2

ROT3

ROT4

ROT5

ROT6

QJB002-060801

CN301

QGA2001F1-06

S301

S301

S301

QSW0864-001

D152

MTZJ6.8A-T2

CN401

QJB002-030803

MTZJ6.8A-T2

JS401

QSW0867-001

CN103

QGA2001F1-03

Q101

2SD1328/ST/-X

LATCH1

CK1

KY1

R182

R183

220

R106

1M

22K

22K

D145

1SS133-T1

CN501

QGA2001C1-04

C106

0.1

R184

6.8K

QAX0246-001Z

R185

22K

X101

220/10

C107

CN104

QJB002-040904

QNZ0004-001

J501

R186

10K

SIN1

RST1

LATCH1

CK1

C123

330P

SIN2

RST2

LATCH2

CK2

1SS133-T1

1SS133-T1

D149

D148

Q103

DTB113ZK-X

Q104

DTC114YKA-X

C124

330P

1.5

1SS133-T1

D150

C112

1.5

C118

IC111

TC74VHC123AF-X

R110

330

R126

IC106

1.5

R111

R112

D120

330

330

R127

R128

D146

1SS133-T1

R113

R114

LA-401VD

330

330

R129

R130

BU2114F-X

R189

10K

C119

1.5

560

R115

R116

R117

C122

330P

LA-401VD

D121

330

330

330

R131

R132

R133

D147

1SS133-T1

330

R134

C113

1.5

IC107

330

330

R135

R136

C120

IC112

TC74VHC08F-X

330

330

R137

R138

BU2114F-X

1.5

330

330

330

R139

R140

R141

R118

C111C110

1.5

330

R142

C114

1.5

IC108

270

R119

R120

R121

R122

R124

R123

R125

IC105IC104

BU2114F-XBU2114F-X

LA-401VD

D123

330

330

330

330

330

330

330

R143

R144

R145

R146

R147

R148

R149

C115

1.5

BU2114F-X

D124

LA-401VD

330

330

330

330

330

330

330

330

R150

R151

R152

R153

R154

R155

R156

R157

C116

1.5

IC109

BU2114F-X

D125

LA-401VD

330

330

330

330

330

330

330

330

R158

R159

R160

R161

R162

R163

R164

R165

C121

330P

IC110

BU2114F-X

AB CD E F G

2-3

Page 13

Printed circuit boards

RM-RX9000

Main board (Front side)

IC109

R156

D151

R101

Q101

R161

C107

C103

R159

R176

C104

R162

C121

C116

C102

R164

R177

R165

C101

R106

IC101

IC110

R186

D148

D150

R188

R144

D153

R142

C122

C112

R147

CN101

R149

R128

D145

R152

R126

R187

R150

R131

D152

IC105

C110

R155

R133

R112

D103

CN103

C111

C113 C114

IC106

R157

R158

R160

R163

R127

R129

R134

R136

R139

R141

D120 D121 D123

IC104

R130

IC107

R132

R137

R135

R138

R140

IC108

R145

R143

R146

R148

C115

R151

R153

R154

D124 D125

R117R118R119

D109D110D111

R120R121R122

R123

D112D113D114

D115D116D117

R174

S112

S111

S110

D136

R169

S120

S116

5

R171R172R173

D138D139D140

S115

S114

R124

S119

S118

R125

4

D133

D134

D135

D147

D146

C118

R166

C119

R189

IC111

S105 S106 S107 S108

R110 R111

D101 D102

R168

R167

IC103

WR101

D144

Q104

Q103

D149

R190

R191

WR102

R192

S109

D143

R175

L101

R184

C106

IC102

X101

R182

R185

R183

R181

R180

C120

R179

IC112

S101

R113 R114 R115 R116

D104 D105 D107 D108

S113

S102

C108

R108

S103 S104

C109

R109

D137

R170

WR103

S117

CN102

CN104

Remote controller transmission board

CN201

D202

Battery holder board

WR601

W602

W701

W601

W702

WR701

Rotary switch board

CN301

S301

3

Main board (Reverse side)

D101 D102

D103

S107 S108

2

S118

1

S119

S120

D138 D139 D140

D146

D147

D136

D133

D134

D135

D115D116D117

S114

S115

S116

S110

D112D113D114

S111

D152

D153

D109D110D111

S112

CN101

D120 D121

D145

CN103

D123

D124 D125

D151

C104

C107

C101

D150

D148

D149

D104 D105 D107 D108

S101

S102

S103 S104S105 S106

WR103

Volume board

CN401

JS401

CN104

Modular jack board

X101

CN102

WR101

D144

WR102

IC102

D143

D137

S109

S113

S117

J501

CN501

2-4

HAB C DE FG

Page 14

PARTS LIST

[ RM-RE9000 ]

* All printed circuit boards and its assemblies are not available as service parts.

RM-RE9000

Area suffix

E ----------- Continental Europe

- Contents -

Exploded view of general assembly and parts list

Electrical parts list

Packing materials and accessories parts list

3-2

3-4

3-6

3-1

Page 15

RM-RE9000

Exploded view of general assembly and parts list

Block No.

17

Lower

side

16

19

Battery

1

8

board

14

Battery

board

M

1

12

13

M

M

8

2

14

8

14

15

15

3

8

5

5

15

11

6

7

4

7

Modular jack

board

7

18

9

9

7

Main

board

3-2

Rotary switch

board

Remote

controller

9

transmission

board

10

9

9

Volume board

Page 16

RM-RE9000

M1MM

(General assembly)

Parts list

Item Parts number Parts name Area

A

1 LV20618-003A TOP PANEL 1

2 LV20624-005A LENS 1

3 QYSPSP3008M SCREW 2 TOP-LENS

4 LV10323-002A BASE 1

5 LV41482-001A INDICATOR 3

6 LV41547-001A CAP 1

7 QYSPSP3010Z SCREW 6 TOP-BASE

8 LV40744-002A SOCKET BOLT 4 LENS-BASE

9 QYSDSF2608Z SCREW 16 C.B-BASE

10 QYSDSF2608Z SCREW 2

11 LV20623-001A BATT. COVER 1

12 LV41481-001A REMOTE LENS 1

13 LV10322-002A BOTTOM CASE 1

14 QYSBSF3010Z SCREW 5 BOTTOM-BASE

15 E75896-001 FELT SPACER 4 BOTTOM CASE

16 LV31626-001A VOL KNOB 1

17 LV31627-001A SEL KNOB 1

18 QYSPSPL3012Z SCREW 1 TOP-BASE

19 LV41797-001A SPACER 1 VOL KNOB

Q'ty Description

Block No.

3-3

Page 17

RM-RE9000

Q

Q

Q

Electrical parts list

Item

A

C 101 QER60JM-476Z E CAPACITOR 47MF 20% 6.3V

C 102 NCF21EZ-104X C CAPACITOR

C 103 NCF21EZ-104X C CAPACITOR

C 104 QER60JM-476Z E CAPACITOR 47MF 20% 6.3V

C 106 NCF21EZ-104X C CAPACITOR

C 107 QER61AM-227Z E CAPACITOR 220MF 20% 10V

C 108 NCF21CZ-155X C CAPACITOR

C 109 NCF21CZ-155X C CAPACITOR

C 110 NCF21CZ-155X C CAPACITOR

C 111 NCF21CZ-155X C CAPACITOR

C 112 NCF21CZ-155X C CAPACITOR

C 113 NCF21CZ-155X C CAPACITOR

C 114 NCF21CZ-155X C CAPACITOR

C 115 NCF21CZ-155X C CAPACITOR

C 116 NCF21CZ-155X C CAPACITOR

C 118 NCF21CZ-155X C CAPACITOR

C 119 NCF21CZ-155X C CAPACITOR

C 120 NCF21CZ-155X C CAPACITOR

C 121 NCS21HJ-331X C CAPACITOR

C 122 NCS21HJ-331X C CAPACITOR

C 123 NCS21HJ-331X C CAPACITOR

C 124 NCS21HJ-331X C CAPACITOR

CN101 QJB002-031803 E-S-ID WIRE C-B

CN102 QJB002-060801 E-S-ID WIRE C-B

CN103 QGA2001F1-03 CONNECTOR

CN104 QJB002-040904 E-S-ID WIRE C-B

CN201 QGA2001F1-03 CONNECTOR

CN301 QGA2001F1-06 6P PLUG ASSY

CN401 QJB002-030803 E-S-ID WIRE C-B

CN501 QGA2001C1-04 4P PLUG ASSY

D 101 SLR-342MC-T L ED

D 102 SLR-342MC-T L ED

D 103 SLR-342VC-T LED

D 104 SLR-342MC-T L ED

D 105 SLR-342MC-T L ED

D 107 SELU2E10C LED

D 108 SELU2E10C LED

D 109 SLR-342VC-T LED

D 110 SLR-342MC-T L ED

D 111 SLR-342DC-T LED

D 112 SLR-342DC-T LED

D 113 SLR-342DC-T LED

D 114 SLR-342DC-T LED

D 115 SLR-342DC-T LED

D 116 SLR-342DC-T LED

D 117 SLR-342DC-T LED

D 120 LA-401VD 7 SEGMENT LED

D 121 LA-401VD 7 SEGMENT LED

D 123 LA-401VD 7 SEGMENT LED

D 124 LA-401VD 7 SEGMENT LED

D 125 LA-401VD 7 SEGMENT LED

D 133 1SS133-T1 SI DIODE

D 134 1SS133-T1 SI DIODE

D 135 1SS133-T1 SI DIODE

D 136 1SS133-T1 SI DIODE

D 137 1SS133-T1 SI DIODE

D 138 1SS133-T1 SI DIODE

D 139 1SS133-T1 SI DIODE

D 140 1SS133-T1 SI DIODE

D 143 11E2-T5 DIODE

D 145 1SS133-T1 SI DIODE

D 146 1SS133-T1 SI DIODE

D 147 1SS133-T1 SI DIODE

Parts number Parts name Area

(Main board)

Block No. 01

Remarks

Item

A

D 148 1SS133-T1 SI DIODE

D 149 1SS133-T1 SI DIODE

D 150 1SS133-T1 SI DIODE

D 151 11E2-T5 DIODE

D 152 MTZJ6.8A-T2 ZENER DIODE

D 153 MTZJ6.8A-T2 ZENER DIODE

D 201 SRZ-932C-22-T14 LED

D 202 SRZ-932C-22-T14 LED

D 203 SRZ-932C-22-T14 LED

D 701 RB160L-40-X SB DIODE

D 702 RB160L-40-X SB DIODE

IC101 MN101CP117 IC(MCU)

IC102 PST529G IC

IC103 MAX1674EUA-X IC

IC104 BU2114F-X IC

IC105 BU2114F-X IC

IC106 BU2114F-X IC

IC107 BU2114F-X IC

IC108 BU2114F-X IC

IC109 BU2114F-X IC

IC110 BU2114F-X IC

IC111 TC74VHC123AF-X IC

IC112 TC74VHC08F-X IC

J 501 QNZ0004-001 MODULAR JACK

JS401 QSW0867-001 ROTARY ENCODER

L 101 NQL32CM-220X INDUCTOR

R 101 NRSA02J-221X MG RESISTOR

R 106 NRSA02J-105X MG RESISTOR

R 108 NRSA02J-103X MG RESISTOR

R 109 NRSA02J-103X MG RESISTOR

R 110 NRSA02J-121X MG RESISTOR

R 111 NRSA02J-121X MG RESISTOR

R 112 NRSA02J-331X MG RESISTOR

R 113 NRSA02J-121X MG RESISTOR

R 114 NRSA02J-121X MG RESISTOR

R 115 NRSA02J-331X MG RESISTOR

R 116 NRSA02J-331X MG RESISTOR

R 117 NRSA02J-561X MG RESISTOR

R 118 NRSA02J-221X MG RESISTOR

R 119 NRSA02J-271X MG RESISTOR

R 120 NRSA02J-271X MG RESISTOR

R 121 NRSA02J-271X MG RESISTOR

R 122 NRSA02J-271X MG RESISTOR

R 123 NRSA02J-271X MG RESISTOR

R 124 NRSA02J-271X MG RESISTOR

R 125 NRSA02J-271X MG RESISTOR

R 126 NRSA02J-331X MG RESISTOR

R 127 NRSA02J-331X MG RESISTOR

R 128 NRSA02J-331X MG RESISTOR

R 129 NRSA02J-331X MG RESISTOR

R 130 NRSA02J-331X MG RESISTOR

R 131 NRSA02J-331X MG RESISTOR

R 132 NRSA02J-331X MG RESISTOR

R 133 NRSA02J-331X MG RESISTOR

R 134 NRSA02J-331X MG RESISTOR

R 135 NRSA02J-331X MG RESISTOR

R 136 NRSA02J-331X MG RESISTOR

R 137 NRSA02J-331X MG RESISTOR

R 138 NRSA02J-331X MG RESISTOR

R 139 NRSA02J-331X MG RESISTOR

Parts number Parts name Area

101 2SD1328/ST/-X TRANSISTOR

103 DTB113ZK-X D TRANSISTOR

104 DTC114YKA-X D TRANSISTOR

Remarks

3-4

Page 18

RM-RE9000

Electrical parts list

Item

A

R 140 NRSA02J-331X MG RESISTOR

R 141 NRSA02J-331X MG RESISTOR

R 142 NRSA02J-331X MG RESISTOR

R 143 NRSA02J-331X MG RESISTOR

R 144 NRSA02J-331X MG RESISTOR

R 145 NRSA02J-331X MG RESISTOR

R 146 NRSA02J-331X MG RESISTOR

R 147 NRSA02J-331X MG RESISTOR

R 148 NRSA02J-331X MG RESISTOR

R 149 NRSA02J-331X MG RESISTOR

R 150 NRSA02J-331X MG RESISTOR

R 151 NRSA02J-331X MG RESISTOR

R 152 NRSA02J-331X MG RESISTOR

R 153 NRSA02J-331X MG RESISTOR

R 154 NRSA02J-331X MG RESISTOR

R 155 NRSA02J-331X MG RESISTOR

R 156 NRSA02J-331X MG RESISTOR

R 157 NRSA02J-331X MG RESISTOR

R 158 NRSA02J-331X MG RESISTOR

R 159 NRSA02J-331X MG RESISTOR

R 160 NRSA02J-331X MG RESISTOR

R 161 NRSA02J-331X MG RESISTOR

R 162 NRSA02J-331X MG RESISTOR

R 163 NRSA02J-331X MG RESISTOR

R 164 NRSA02J-331X MG RESISTOR

R 165 NRSA02J-331X MG RESISTOR

R 166 NRSA02J-223X MG RESISTOR

R 167 NRSA02J-223X MG RESISTOR

R 168 NRSA02J-223X MG RESISTOR

R 169 NRSA02J-223X MG RESISTOR

R 170 NRSA02J-223X MG RESISTOR

R 171 NRSA02J-223X MG RESISTOR

R 172 NRSA02J-223X MG RESISTOR

R 173 NRSA02J-223X MG RESISTOR

R 175 NRSA02J-102X MG RESISTOR

R 176 NRSA02J-0R0X MG RESISTOR

R 179 NRSA02J-223X MG RESISTOR

R 180 NRSA02J-223X MG RESISTOR

R 181 NRSA02J-223X MG RESISTOR

R 182 NRSA02J-223X MG RESISTOR

R 183 NRSA02J-223X MG RESISTOR

R 184 NRSA02J-682X MG RESISTOR

R 185 NRSA02J-223X MG RESISTOR

R 186 NRSA02J-103X MG RESISTOR

R 189 NRSA02J-103X MG RESISTOR

R 201 NRSA02J-3R9X MG RESISTOR

R 202 NRSA02J-3R9X MG RESISTOR

R 203 NRSA02J-3R9X MG RESISTOR

S 101 QSW0802-001Z TACT SWITCH

S 102 QSW0802-001Z TACT SWITCH

S 103 QSW0802-001Z TACT SWITCH

S 104 QSW0802-001Z TACT SWITCH

S 105 QSW0802-001Z TACT SWITCH

S 106 QSW0802-001Z TACT SWITCH

S 107 QSW0802-001Z TACT SWITCH

S 108 QSW0802-001Z TACT SWITCH

S 109 QSW0802-001Z TACT SWITCH

S 110 QSW0802-001Z TACT SWITCH

S 111 QSW0802-001Z TACT SWITCH

S 112 QSW0802-001Z TACT SWITCH

S 113 QSW0802-001Z TACT SWITCH

S 114 QSW0802-001Z TACT SWITCH

S 115 QSW0802-001Z TACT SWITCH

Parts number Parts name Area

(Main board)

Block No. 01

Remarks

Item

A

S 116 QSW0802-001Z TACT SWITCH

S 117 QSW0802-001Z TACT SWITCH

S 118 QSW0802-001Z TACT SWITCH

S 119 QSW0802-001Z TACT SWITCH

S 120 QSW0802-001Z TACT SWITCH

S 301 QSW0864-001 ROTARY SWITCH

W 601 VYH7199-001 BATTERY SPRING

W 602 VYH7199-001 BATTERY SPRING

X 101 QAX0246-001Z RESONATOR

Parts number Parts name Area

Remarks

3-5

Page 19

RM-RE9000

Packing materials and accessories parts list

P5

A1 A4

Block No.

Block No.

M

M

2

M

M

3

M

M

P2

P4

P3

P1

3-6

Page 20

RM-RE9000

M2MM

)

)

M3MM

(Packing)

(Accessories)

Parts list

Item Parts number Parts name Area

A

P 1 LV31629-002A CARTON BOX 1

P 2 LV31630-001A CUSHION(L

P 3 LV31631-001A CUSHION(R

P 4 QPC02204515 POLY BAG 1 FOR SET

P 5 QPB01702404P POLY BAG 1 FOR INST

Q'ty Description

1

1

Parts list

Item Parts number Parts name Area

A

A 1 LVT0653-001A INST.BOOK 1 ENG

A 2 ----------- AL BATTERY 2

A 3 QPH01501510 SHEET 1 AL BATTERY

A 4 BT-54013-2 W.CARD 1

Q'ty Description

Block No.

Block No.

3-7

Page 21

RM-RE9000

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20934)

Printed in Japan

200104(V)

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Loading...

Loading...