Page 1

JVC

MODEL

taL-Fe

QUARTZ

TURNTABLE

FULLY AUTOMATIC

No. 2464

. FEB. 1979

Page 2

Contents

1. Specifications ...................................................................

2. ServicePrecautions................................................................

Features.......................................................................

4. NamesofPartsandTheirFunctions.....................................................

5. Replacement Procedures

(1) Stylus..................................................................

Headshell "

(2)

(3) Cartridge..............................................

(4) Motor..................................................................

(5) HO/VODampingKnobs "

6. Lubrication

(1) HO/VODampingMechanism ..................................................

(2) Motor..................................................................

(3) FullyAutomaticMechanism...................................................

7. Adjustment Procedures

(1) ~UARTZ LOCK/PITCH CONTROL Meter ........................................

(2) OuartzLockAdjustment

Tonearm Section

(3) HeadsheliAngle "

(4) TonearmElevator..........................................................

(5) Overhang ...............................................................

(6) Lead-in.................................................................

(7) Lead-out................................................................

(8) TrackingForce...........................................................

(9) Anti-skating.............................................................

(10) HO/VODamping .........................................................

F6BlockDiagram .............................................................

8. OL-

9. Troubleshooting Charts

Platter does not rotate.

(1)

Platter rotates at high speed. .................................................

(2)

Pitch Control operates abnormally. .............................................

(3)

10. Exploded Views and

10-(1) Cabinet & Mechanism Ass

10-(2) Mechanism Ass

10-(3) TonearmAss

11. Printed Circuit Board Ass

11-(1) MDC-938G .............................................................

11-

(2) TPS-206 ...............................................................

12. Accessories List .................................................................

13. OL-

14. PackingMaterialsandPartNumbers....................................................

15. Parts List with Specified Numbers for Designated Areas. .

F6 Schematic Diagram ..........................................................

Parts List

y and Parts List

..................................................... 8

Back page

Pages

'" 6

OL-

No. 2464

1 -

Page 3

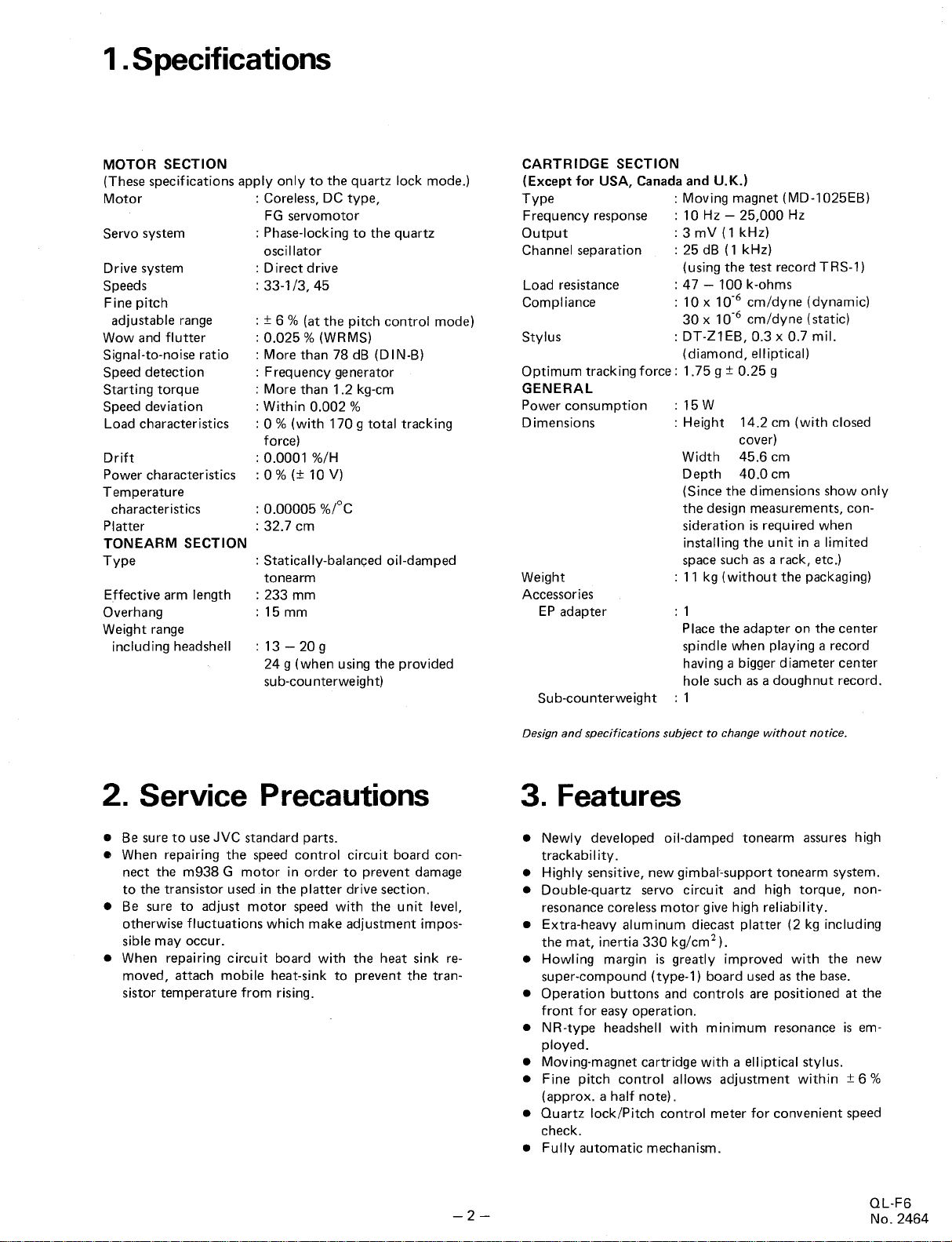

Specifications

MOTOR SECTION

(These specifications apply only to the quartz lock mode.

Motor

Servo system

Drive system

Speeds

: Core less

FG servomotor

: Phase-

oscillator

: Direct drive

: 33-

, DC type

locking to the quartz

1/3

Fine pitch

adjustable range

Wow and flutter

to-noise ratio

Signal-

Speed detection

Starting torque

Speed deviation

Load characteristics

Drift

Power characteristics

: :!: 6 % (at the pitch

: 0.

025 % (WRMS)

: More than 78 dB (DIN-

control mode)

: Frequency generator

: More than 1.

: Within 0.

2 kg-cm

002 %

: 0 % (with 170 g total tracking

force)

: 0.0001 %/H

: 0 % (:!: 10 V)

Temperature

characteristics

Platter

TONEARM SECTION

Type

: 0.

00005

7 cm

: 32.

: Statically-

%tc

balam;ed oil-damped

tonearm

Effective arm length

Overhang

Weight range

including headshell

: 233 mm

: 15 mm

: 13 - 20 g

24 g (when using the provided

sub-counterweight)

CARTRIDGE SECTION

(Except for USA, Canada and U.

Type

Frequency response

: Moving magnet (MD-l025EB)

: 10 Hz - 25 000 Hz

Output : 3 mV (1 kHz)

Channel separation

Load resistance

Compliance

Stylus

Optimum tracking force: 1.

GENERAL

Power consumption

Dimensions

Weight

Accessories

EP adapter

Sub-counterweight

: 25 dB (1 kHz)

(using the test record TRS-

: 47 - 100 k-ohms

: 10 x 10

30 x 10

: DT-

(diamond

6 cm/dyne (dynamic)

6 cm/dyne (static)

Zl EB

, 0.3 x 0.7 mil.

, elliptical)

75 g :!: 0.

25 g

: 15W

: Height 14.

cover)

Width 45.6 cm

Depth 40.

(Since the dimensions show only

the design measurements

sideration is requ

installing the unit in a limited

space such as a rack

: 11 kg (without the packaging)

: 1

Place the adapter on the center

spindle when playing a record

having a bigger diameter center

hole such as a doughnut record.

: 1

2 cm (with closed

0 cm

, con-

ired when

, etc.

2. Service Precautions

. Be sure to use JVC standard parts.

. When

. Be sure to adjust motor speed with the u nit level

. When repairing circuit board with the heat sink

repairing the speed control circuit board con-

nect the m938

to the transistor used.in the platter drive section.

G motor in order to prevent damage

otherwise fluctuations which make adjustment impos-

sible may occur.

, attach mobile heat-sink to prevent the tran-

moved

sistor temperature from rising.

re-

Design and specifications subject to change without notice.

3. Features

. Newly developed oil-damped tonearm

trackability.

Highly sensitive, new gimbal'support tonearm system.

. Double-

resonance coreless motor give high reliability.

. Extra-

the mat

Howling margin is greatly

super-compound (type-

quartz servo circu it and high torque

heavy aluminum diecast platter (2 kg including

, inertia 330 kg/cm

improved with the new

l) board used as the base.

Operation buttons and controls are positioned at the

front for easy operation.

. NR-

type headshell with minimum

ployed.

Moving-magnet cartridge with a elliptical stylus.

Fine pitch control allows adjustment

(approx. a half note).

. Quartz lock/Pitch control meter for convenient speed

check.

Fully automatic mechanism.

assures high

, non-

resonance is em-

within:!: 6 %

QL-

No. 2464

Page 4

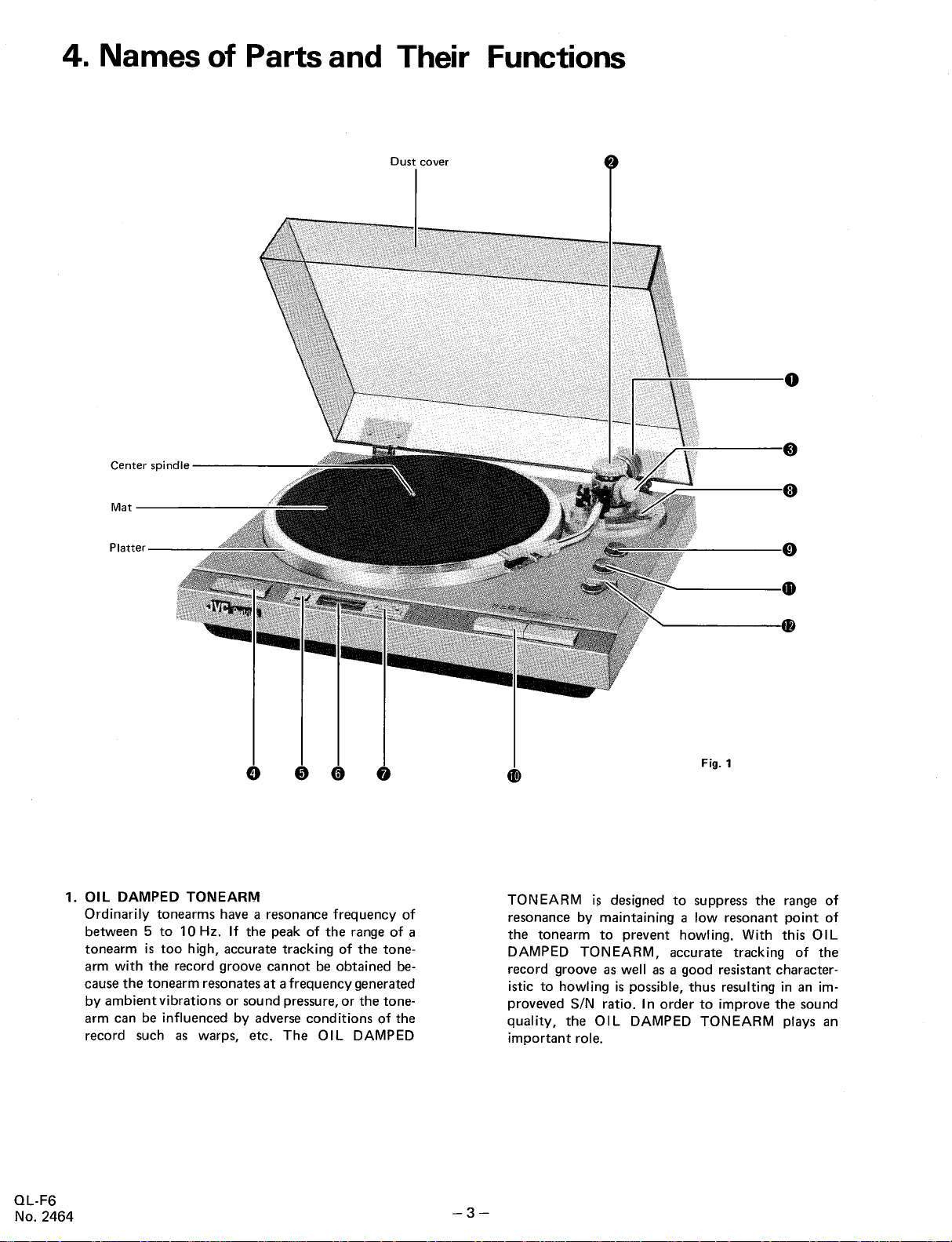

4. Names of Parts and Their

Dust cover

Center spindle

Mat

Functions

Platter

1. OIL

DAMPED TONEARM

Ordinarily tonearms have a resonance frequency of

between 5 to 10Hz.

tonearm is too high

arm with the record groove cannot be obtained be-

cause the tonearm resonates at a frequency generated

If the peak of the range of a

, accurate tracking of the tone-

by ambient vibrations or sound pressure, or the tone-

arm can be influenced by adverse conditions of the

record such as warps

, etc. The

OIL DAMPED

Fig. 1

TONEARM i~ designed to suppress the range of

resonance by maintaining a low resonant point of

the tonearm to prevent howling. With this OIL

DAMPED TONEARM

, accurate tracking of the

record groove as well as a good resistant character-

istic to howling is possible

proveved SIN ratio. I

quality, the OIL

DAMPED TONEARM plays an

, thus resulting in an im-

n order to improve the sound

important role.

QL-

No. 2464

Page 5

2. HQ

DAMPING knob

This controls the horizontal movement of the tone-

arm while aiding to keep the tonearm

s resonating

point low. Set the knob to the same indication

ber as the optimum tracking force of this unit.

3. VQ

DAMPING knob

This controls the vertical movement of the tonearm

while aiding to keep the tonearm

low. Set the knob to the same

the optimum tracking force of this unit.

4. Speed

select knob

s resonating point

indication number as

Select a proper position of the speed select

accordance with the rpm of the record.

1/3 rpm record (LP)

33-

45rpmrecord(EP).............

5. QUARTZ

QUARTZ LOCK:

Depress the button to the

speed in the quartz lock mode. In this case

meter lights green.

PITCH CONTROL:

Depress the button a second time to obtain

P ITCH CO NT RO L position (---) in order to

form fine pitch adjustment for the sound meeting

your preference. I

6. PITCH

When the QUARTZ

select button is set to the QUARTZ LOCK position

the meter is green-

When the QUARTZ

select button is set to the

tion

the PITCH

orange-

7. PITCH CONTROL knob

Fine pitch

QUARTZ

set to the PITCH CONTROL position. Pitch

ment

deflecting to the left (#)

cates an increase to the accurate 33-

and the deflection to the right (b) means a decrease.

8. ANTI-

This device cancels out the centripetal force that

pulls the tonearm to the center of the platter. This

prevents the stylus tip from skating toward the

center of the platter and at the same

any excessive stylus tip force on the inner

the record groove. Use the 8 marked dial when

ploying a spherical stylus. Use the marked dial

when employing an elliptical stylus or a SHIBATA

stylus.

Turn the dial to the

force dial.

LOCK/PITCH CONTROL select button

QUARTZ LOCK position

) for playing a record at an accurate rotation

n this case, the meter I ights orange.

CONTROL meter

LOCK/PITCH CONTROL

lit and the indicator displays "

LOCK/PITCH CONTROL

PITCH CONTROL posi-

, pitch control can be

performed by turning

CONTROL knob and the

I it.

#6 % means +6 %

% means -

b6

control can be performed with the

LOCK/PITCH CONTROL select button

range is

SKATING knob

6 %

:!: 6 %. The

indicator in the meter

from the center (0) indi-

1/3 or 45 rpm

time eliminates

same number as on the track ing

num-

knob in

33"

45"

, the

the

per-

meter is

adjust-

wall of

em-

REPEAT knob

9.

Decide how many times you want to re-

record by using this knob.

When you set the knob

listen to the

to " , the record will continue to play repeatedly.

Note: This knob cannot be

1 - 0 or 0 - 1

pressed with the power cord

from the outlet. For this

in the section "

to record playing

10. START/REJECT buttons

When you start playing a record

ST ART

button. The

the position of the first groove of the

selected and gently lowers itself onto the surface of

the record to play it.

record, depress the REJECT button. The

, returns automatically to its rest and the platter

lifts

stops rotating.

, however, the

number of repeats

respond ing number

REPEAT knob has been set for a

, the tonearm

of prepeats before the platter

stops rotating.

Note: When the dial of the repeat

numbers other than "

set to

continues to rotate and the

be turned off even though you depress

turned to indicate from

if the START button is de-

disconnected

, refer to the note

Necessary procedures prior

" on page 2.

, depress the

tonearm moves automatically

When you stop playing the

performs the cor-

knob has been

, the platter

power will not

REJECT button or even if the

record has

power to be turned off after the

played once

to the "0" mark.

RECORD SIZE select knob

11.

Set the knob to the corresponding

size of the record before you play it.

30 cm diameter record. . . .

25 cm diameter record. . . .

17cmdiameterrecord...... "

12. Arm lifter lever

This is

used when you want to

gently or gently lower it.

UP" position

when you pull it to the "

be lowered down gently onto the record surface.

finished. When you want the

, be sure to set the repeat knob

position to the

17"(7")

raise the tonearm

When you push it to the

, the tonearm will be lifted up,

DOWN" position

record pre-

tonearm

the

playing

record has

30" (12"

25" (10"

and

, it will

QL-

No. 2464

Page 6

5. Replacement Procedures

1)

5-(

Replacement of the stylus can be

inserting the stylus plug (A) into the

cartridge. Service life of the stylus

unit (DT-

ing on the record condition (dirty record groove etc.

Stereo LP record (30 cm) . . . Approx. 300

Stylus are disposable items. Therefore, it is recommended

to buy a supply of styli when you buy the unit.

purchasing them

Stylus

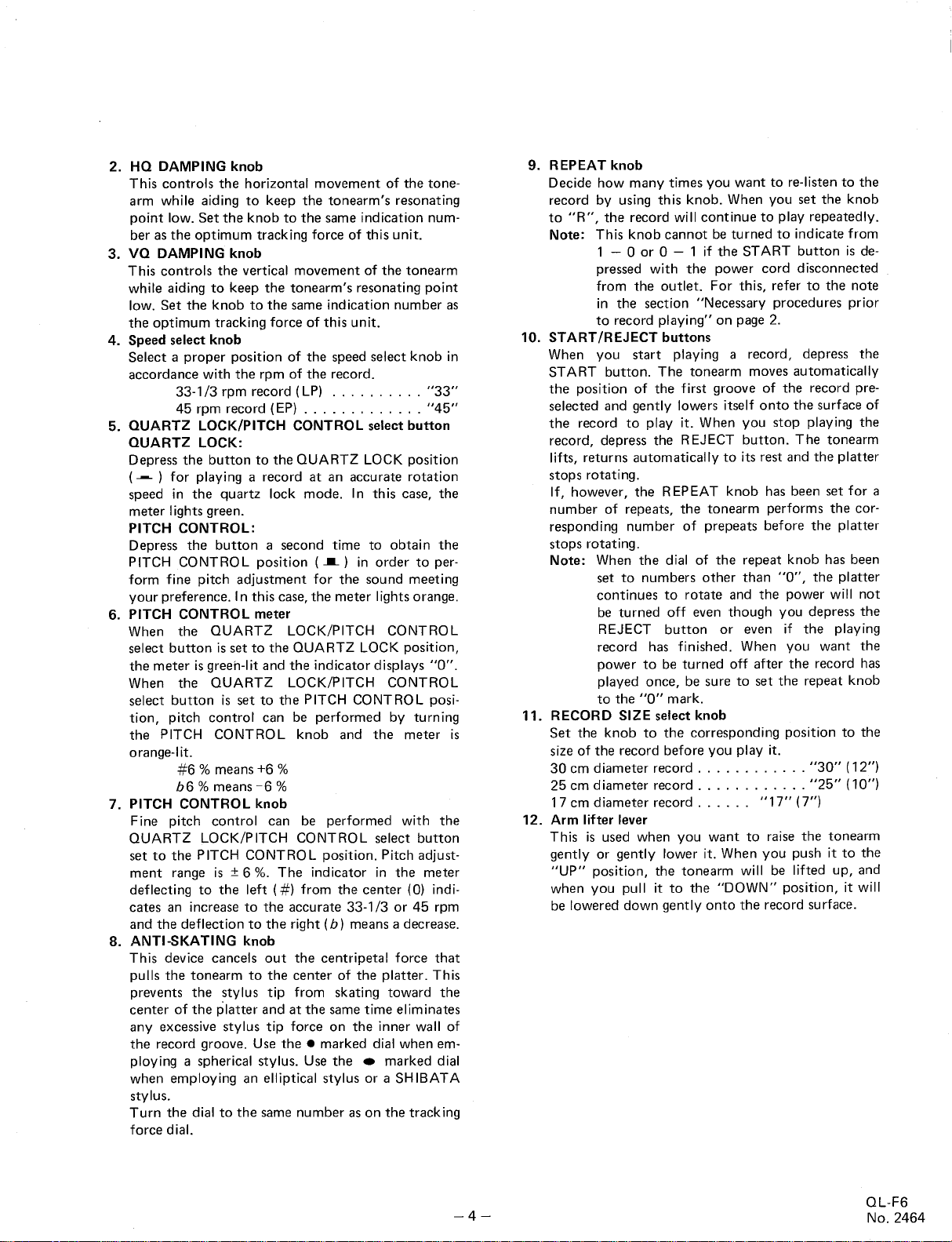

Stylus replacement (See Fig. 2)

easily made by simply

jack (B) of the

employed for this

Zl EB) is generally as follow; varying, depend-

- 500 hours

When

, specify the DT-Zl EB (JVC standard).

5-(2) Headshell

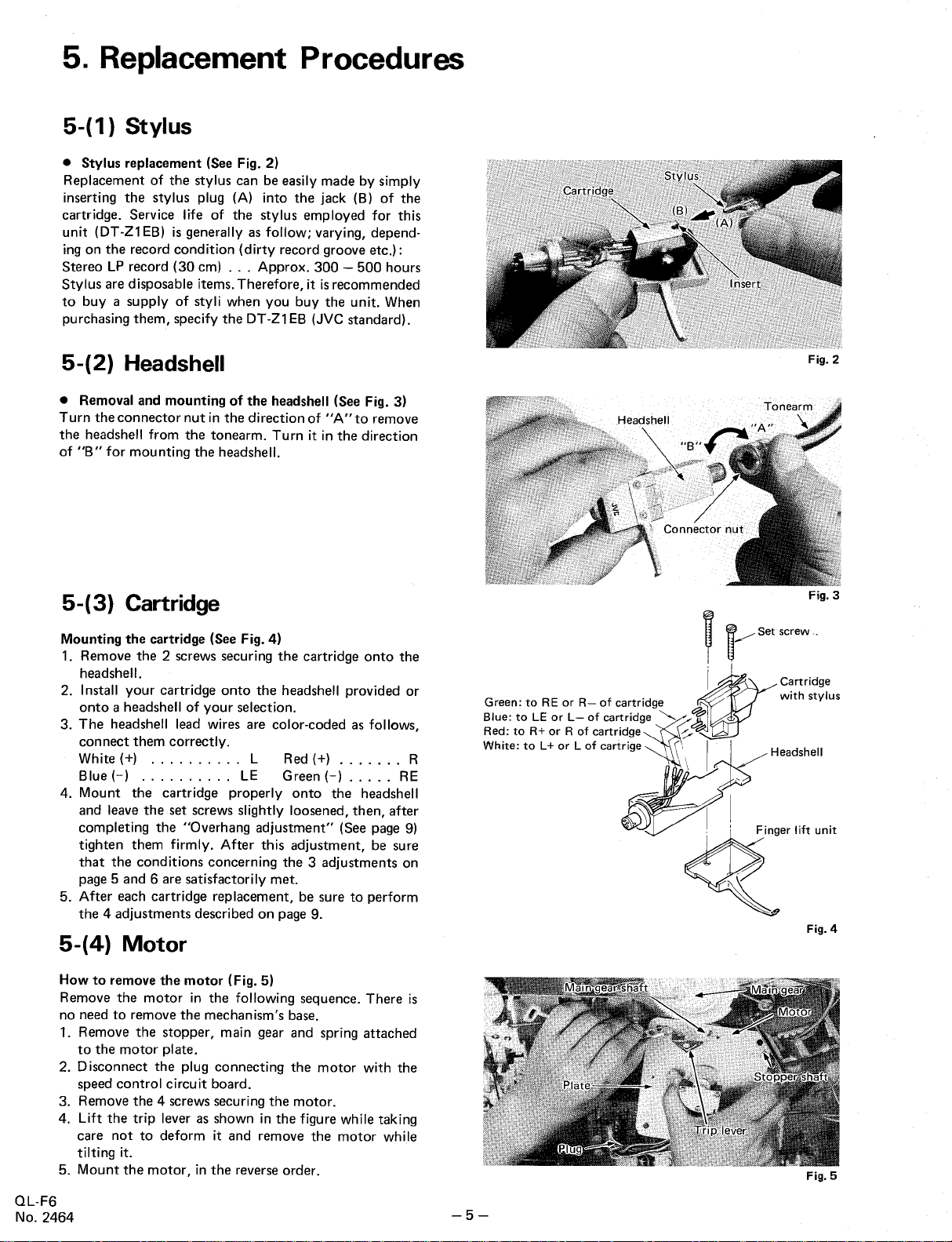

Removal and mounting of the headshell (See Fig. 3)

Turn the connector nut in the direction of "

the headshell from the tonearm. Turn it in the direction

A" to remove

of "B" for mounting the headshell.

5-(3) Cartridge

Mounting the cartridge (See Fig. 4)

1. Remove the 2 screws securing the cartridge onto the

headshell.

nstall your cartridge onto the

2. I

headshell provided or

onto a headshell of your selection.

3. The

headshell lead wires are color-coded as follows

connect them correctly.

White(+)

L Red(+).......

BlueH " " LE Green(-

4. Mount the

and leave the set screws slightly loosened

completing the "

tighten them firmly. After this adjustment

that the conditions concerning the 3 adjustments on

page 5 and 6 are satisfactorily met.

5. After each cartridge replacement, be sure to perform

the 4 adjustments described on page 9.

cartridge properly onto the

, then, after

Overhang adjustment

" (See page 9)

headshell

, be sure

(4) Motor

Green: to RE or R- of cartridge

Blue: to LE or L- of cartridg

Red: to R+ or R of cartridge

White: to L+ or L of cartrige \

Fig. 2

Fig. 3

, ~s~"'-

Cartridge

with stylus

Headshell

lift "0"

Fig. 4

How to remove the motor (Fig. 5)

Remove the motor in

no need to remove the mechanism

the following sequence. There is

s base.

1. Remove the stopper, main gear and spring

to the motor plate.

2. Disconnect the plug connecting the motor with the

speed control circuit board.

3. Remove the

4. Lift the trip lever as shown in the figure while taking

4 screws securing the motor.

care not to deform it and remove the motor while

tilting it.

5. Mount the motor, in the reverse order.

QL-

No. 2464

attached

Fig.

Page 7

(5) HQ/VQ

Damping Knobs

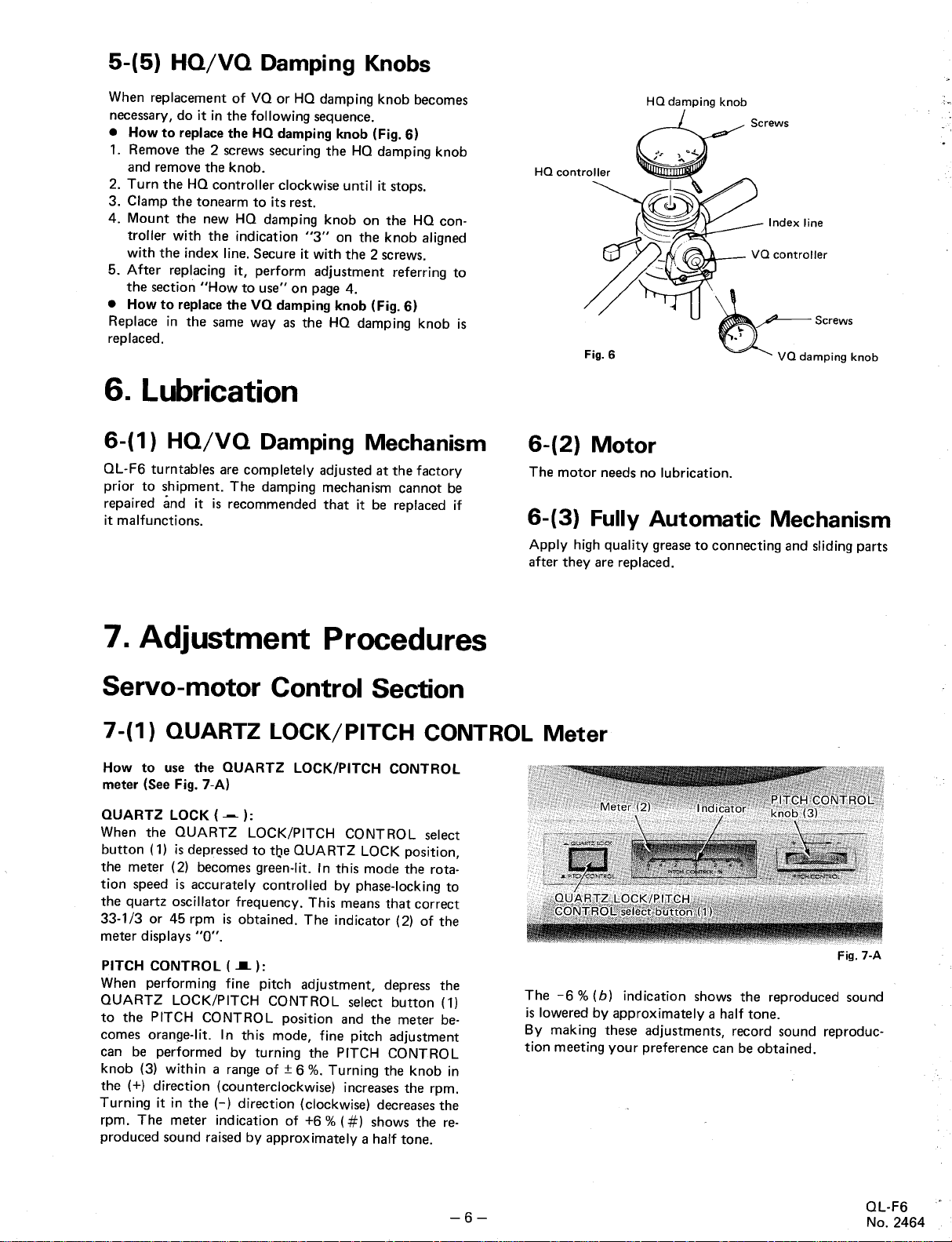

When replacement of VQ or HQ damping knob becomes

necessary, do it in the following sequence.

. How to replace the HQ damping knob (Fig. 6)

1. Remove the 2

screws securing the HQ damping knob

and remove the knob.

2. Turn the HQ controller clockwise until it

stops.

3. Clamp the tonearm to its rest.

4. Mount the new

troller with the

with the index line. Secure it with the 2

5. After replacing it

the section "

. How to replace the VQ damping knob (Fig. 6)

Replace in the same

replaced.

HQ damping knob on the HQ

indication "

, perform adjustment

How to use

way as the HQ

3" on the knob

" on page 4.

damping knob is

con-

aligned

screws.

referring to

6. Lubrication

6-(1) HQ/VQ

QL-F6 turntables are completely adjusted at the factory

prior to shipment. The

repaired imd it is

it malfunctions.

Damping Mechanism

damping mechanism cannot be

recommended that it be

replaced if

Ha damping knob

Ha controller

Index line

va controller

Screws

"t.

Fig. 6

va damping knob

6-(2) Motor

The motor needs no lubrication.

6-(3) Fully Automatic

Apply high quality grease to connecting and sliding parts

after they are replaced.

Mechanism

7. Adjustment Procedures

Servo-motor Control

7 -(

1)

QUARTZ LOCK/ PITCH

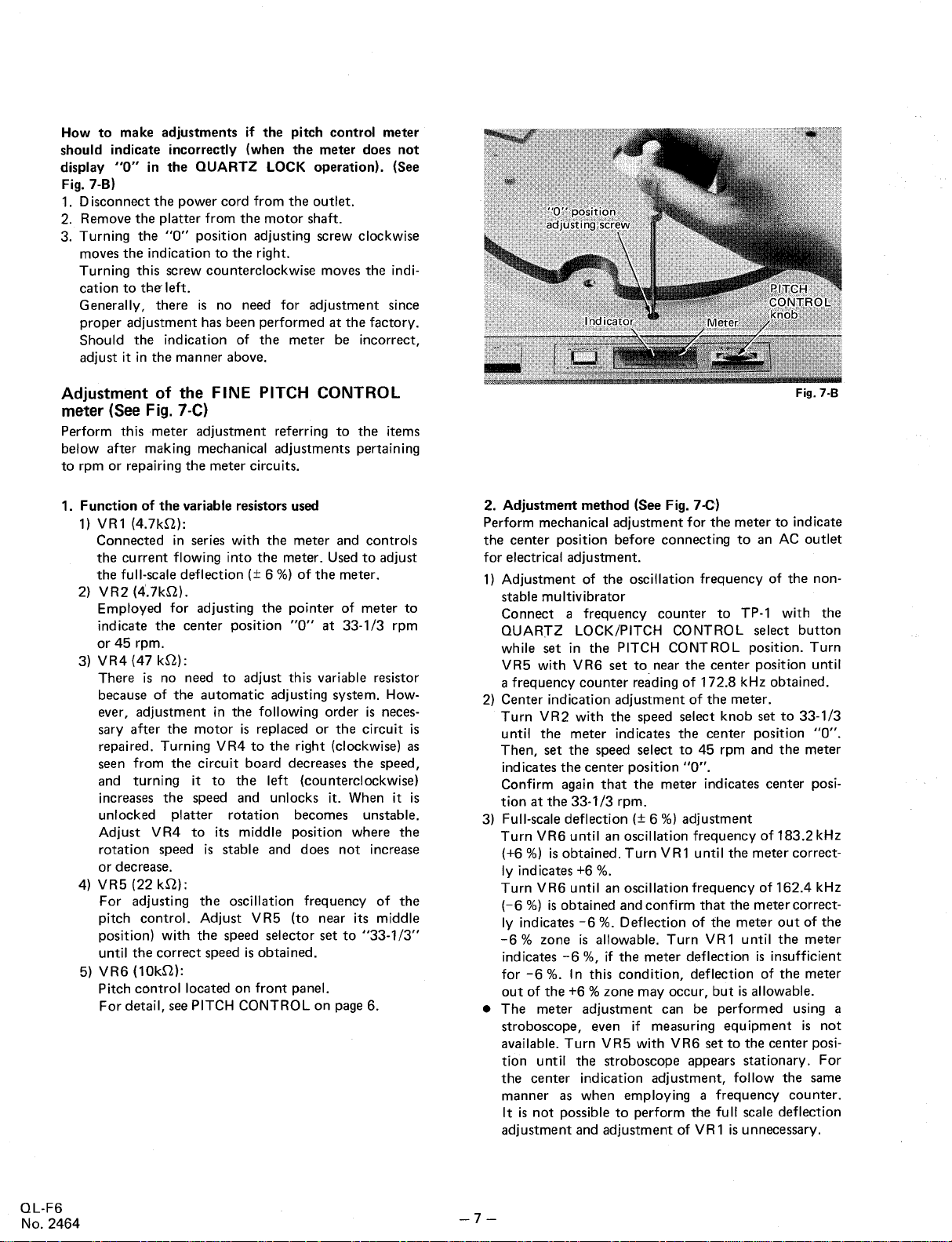

How to use the QUARTZ

meter (See Fig. 7-

LOCK/PITCH CONTROL

Section

CONTROL Meter

QUARTZ LOCK (~):

When the QUARTZ

button (1) is

the meter (2) becomes green-

tion speed is

depressed to tbe QUARTZ

accurately controlled by phase-

LOCK/PITCH CONTROL select

LOCK position

lit. In this mode the rota-

locking to

the quartz oscillator frequency. This means that correct

1/3 or 45 rpm is

33-

obtained. The indicator (2) of the

meter displays "

PITCH CONTROL

When performing fine pitch adjustment

QUARTZ

to the PITCH

comes orange-lit. In this mode

can be performed by

knob (3) within a

the (+) direction (counterclockwise)

Turning it in the (-)

rpm. The meter

LOCK/PITCH CONTROL select button (1)

CONTROL position and the meter be-

, fine pitch adjustment

turning the PITCH CONTROL

range of

indication of +6 % (#)

:!: 6 %. Turning the

direction (clockwise) decreases the

, depress the

knob in

increases the rpm.

shows the re-

produced sound raised by approximately a half tone.

The -6 %

(b) indication shows the

reproduced sound

is lowered by approximately a half tone.

By making these adjustments

, record sound reproduc-

tion meeting your preference can be obtained.

Fig.

QL-

No. 2464

Page 8

How to make

should indicate incorrectly (when the meter

display "

Fig.

adjustments if the pitch control meter

0" in the

QUARTZ LOCK operation). (See

does not

1. Disconnect the power cord from the outlet.

2. Remove the

3. Turning the "

platter from the motor shaft.

0" position adjusting screw clockwise

moves the indication to the right.

Turning this screw counterclockwise

cation to

Generally, there is no

tl:1e-left.

need for adjustment since

moves the indi-

proper adjustment has been performed at the factory.

Should the

indication of the meter be incorrect

adjust it in the manner above.

Adjustment of the FINE

PITCH CONTROL

meter (See Fig. 7-

Perform this meter adjustment referring to the

below after making mechanical adjustments pertaining

items

to rpm or repairing the meter circuits.

1. Function of the variable

1) VRl

(4.7k.Q):

resistors used

Connected in series with the meter and controls

the current flowing into the meter. Used to adjust

the full-scale deflection

(:1: 6 %)

of the meter.

2) VR2 (4.7k.Q).

Employed for

indicate the center position "0" at 33-

or 45 rpm.

3) VR4 (47 k.Q):

There is no need to

because of the automatic

ever, adjustment in the following order is

sary after the motor is

repaired. Turning VR4 to the right

seen from the circuit board

and turning it to

increases the speed and

unlocked

Adjust VR4 to

adjusting the pointer of meter to

1/3 rpm

adjust this variable resistor

adjusting system. How-

neces-

replaced or the circuit is

(clockwise) as

decreases the speed

the left (counterclockwise)

unlocks it. When it is

platter rotation becomes unstable.

its middle position where the

rotation speed is stable and does not increase

or decrease.

4) VR5 (22 k.Q):

For adjusting the oscillation frequency of the

pitch control. Adjust V R5 (to

position) with the speed

until the correct speed is obtained.

5) VR6 (10k.Q):

Pitch control located on front panel.

For detail

, see PITCH CONTROL on page 6.

selector set to "33-1/3"

near its middle

Fig.

2. Adjustmerrt method (See Fig.

7-C)

Perform mechanical adjustment for the meter to indicate

the center position before connecting to an AC outlet

for electrical adjustment.

1) Adjustment of the

oscillation frequency of the non-

stable multivibrator

Connect a

frequency counter to TP-

l with the

QUARTZ LOCK/PITCH CONTROL select button

while set in the

PITCH CONTROL position. Turn

VR5 with VR6 set to near the center position until

a frequency counter re

ading of 172.

8 kHz obtained.

2) Center indication adjustment of the meter.

Turn VR2 with the speed select knob set to 33-

until the meter

, set the speed select to

Then

indicates the center position "

45 rpm and the meter

1/3

indicates the center position "

Confirm again that the meter

tion at the 33.

3) Full-scale deflection

1/3 rpm.

(:1: 6 %)

Turn VR6 until an oscillation frequency of 183.

(+6 %) is obtained. Turn VRl until

indicates center posi-

adjustment

2 kHz

the meter correct-

ly indicates +6 %.

Turn VR6 until an oscillation frequency of 162.4 kHz

(-6 %) is obtained and confirm that the meter correct-

Iy indicates -6 %. Deflection of the meter out of the

-6 % zone

indicates -6 %, if the meter deflection is insufficient

for -6 %. I n this condition

out of the +6 % zone may occur

. The meter adjustment can be performed

stroboscope

is allowable. Turn VR 1 until the meter

, deflection of the meter

, but is allowable.

using a

, even

if measuring equipment

is not

available. Turn VR5 with VR6 set to the center posi-

tion until the stroboscope appears

the center indication adjustment

manner as when

employing a frequency counter.

It is not possible to perform the full scale

adjustment and adjustment of VR 1 is

stationary. For

, follow the same

deflection

unnecessary.

QL-

No. 2464

7 -

Page 9

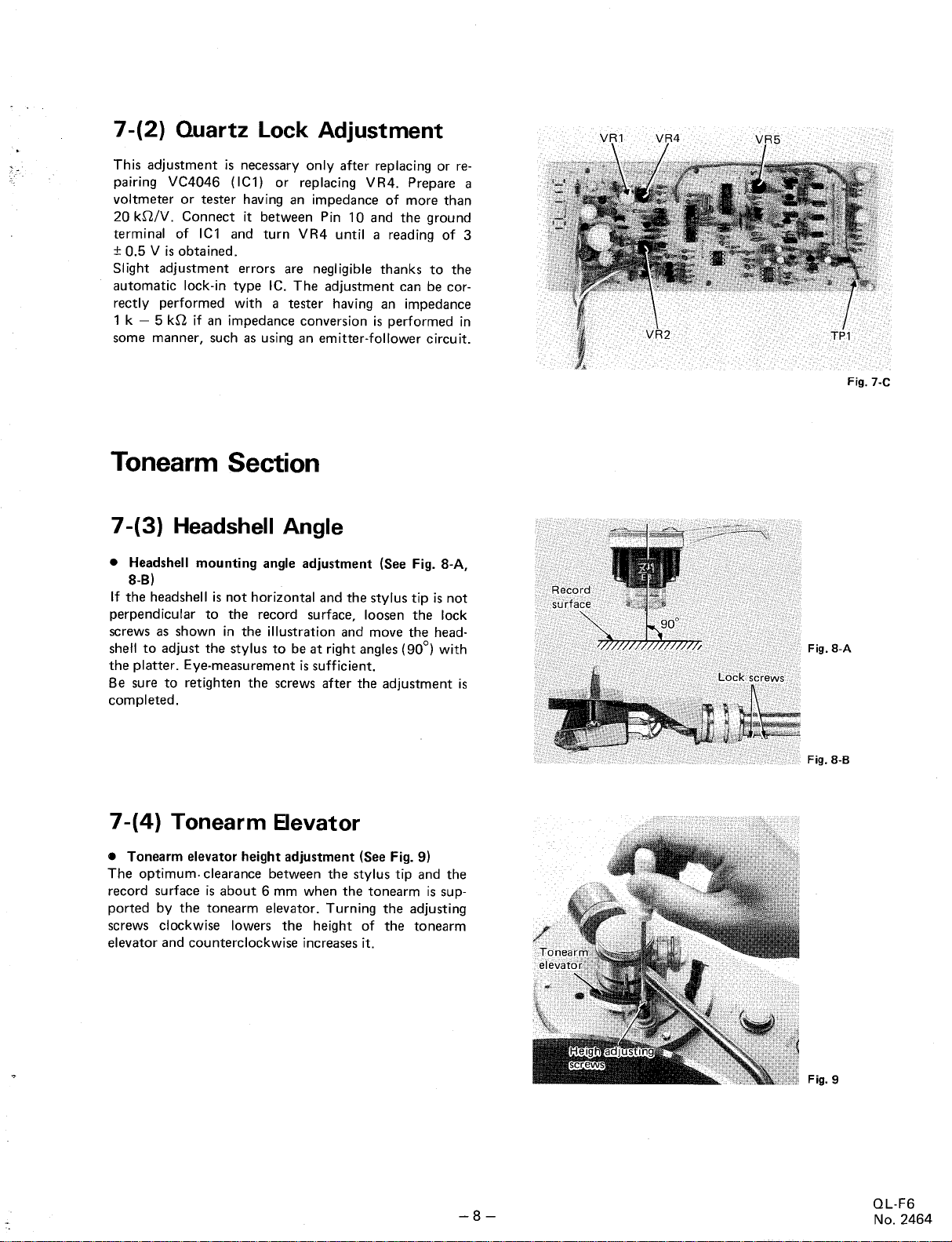

(2) Quartz Lock Adjustment

This adjustment is

pairing

VC4046 (IC1) or

voltmeter or tester having an

20 kD,/V . Connect it between Pin 10 and the ground

terminal of ICl and turn VR4 until a

:1: 0.

5 V is obtained.

Slight adjustment errors are

automatic lock-

rectly performed with a

1 k - 5 kSt

some manner, such as using an emitter-

necessary only after replacing or re-

replacing VR4. Prepare a

impedance of more than

reading of 3

negligible thanks to the

in type IC. The

adjustment can be cor-

tester having an

impedance

if an impedance conversion is performed in

follower circuit.

Tonearm Section

7 -(3)

If the headshell is not horizontal and the stylus tip is not

perpendicular to the record surface

screws as shown in the

shell to adjust the stylus to be at right angles

the platter.

Be sure to retighten the screws

completed.

Headshell Angle

Headshell mounting angle adjustment (See Fig. 8-

, loosen the lock

illustration and move the head-

with

Eye-measurement is sufficient.

after the adjustment is

(90

Fig.

Fig.

7-(4) Tonearm 8evator

. Tonearm

The optimum. clearance between the stylus tip and the

record surface is about 6 mm when the tonearm is

ported by the tonearm elevator. Turning the

screws clockwise lowers the

elevator and counterclockwise increases it.

elevator height adjustment (See Fig. 9)

sup-

adjusting

height of the tonearm

Fig.

Fig. 9

QL-

No. 2464

Page 10

7-(5) Overhang

. Overhang

obtain optimum overhang, when mounting the

To

cartridge

that of the headshell and position the

the distance between the headshell'

adjustment (See Fig. 10)

, first align the cartridge s longitudinal axis to

cartridge so that

s end face and the

stylus tip equals 48 mm.

Be sure to tighten the set

Errors within 1

point of view.

mm are negl

screw after the adjustment.

igible from a practical

7 -( 6) lead-

Stylus lead-

Your QL-

stylus lead-

, if the stylus lead-

ever

cartridge changes

1. Place a 30 cm record on the platter.

2. Set the record

operate the turntable in automatic play.

3. Confirm if the

4 mm inward from the outermost edge of the record

disc.

4. If the lead.

the adjustor screw with a

increase the distance between the lead-

the outermost edge

the distance. Thus determ

tion point to be about 3 to 4

disc edge.

in position adjustment (See Fig. 11)

F6 was shipped from the JVC factory with its

in position adjustment made properly. How-

in position is changed due to

, etc., adjust it as in the following:

size select knob to "

stylus lead- in position is about 3 to

in position is not in the proper range

screwdriver clockwise to

, and counterclockwise to decrease

ine the proper lead- in posi-

30" (12"

in position and

mm inward from the

Fig. 10

) and

, turn

Fig. 11

7-(7) lead-out

Stylus lead-out adjustment (Fig. 12)

Be sure to perform this adjustment after replacing the

tonearm, motor or related mechanism.

1. Use a 17 cm (7") record (with a lead-out groove

diameter of about 110 mm).

2. Remove the platter from the motor shaft. Turn the

adjustor screw accessible through the hole shown in

the figure clockwise with a - screwdriver to increase

lead-out tuning.

3. Confirm the

record with its inter-band track as near to the inner-

most groove as

incorrect, re-adjust, it by

screw.

QL-

No. 2464

lead-out position with a

possible. If the lead-out position is

turning the adjustment

17 cm (7")

Fig. 12

Page 11

7-(8) Tracking Force

Fig. 13

Fig. 14

Fig. 15

Fig. 16

1. Tracking force adjustment

1. Turn the

the "

anti-skaing knob until

0" mark is

aligned with the

index line. (See Fig. 13)

2. Turn the HQ

the "

0" mark is al igned with the

damping knob until

index line. (See Fig. 6)

3. Turn the VQ

the "

0" mark is aligned with the

index line. (See Fig. 14J

4. Place a disc on the platter.

5. Remove the

stylus. (See Fig. 15)

6. Release the tonearm clamp. (See

Fig. 16)

7. Zero balance adjustment (See

17)

damping knob until

stylus cover from the

Turn the counterweight until the

tonearm is balanced. Stop turning

the counterweight when the stylus

tip is almost touching the

surface.

8. Return the tonearm to the

and clamp it.

9. Hold the

adjusted position and turn the

tracking force dial until the "

mark is

line on

shaft. (See Fig. 19)

10. Turn the counterweight

direction until the "

on the

index

means an optimum tracking force

of 1.75 g is

Fig. 20)

Note:

Turning the counterweight in the

direction A decreases the tracking

force and

tion B. Turning the dial only, has

no effect on the tracking force.

counterweight at the

aligned with the index

the

tonearm

dial is aligned with the

line. The "

being applied. (See

increase it in the direc-

weight

in the B

75" mark

75" mark

Fig. 17

Fig. 18

Fig.

disc

rest

Fig. 19

Fig. 20

10 -

QL-

No. 2464

Page 12

7-(9) Anti-skating

Anti-skaing adjustment

Adjust the anti-skaing force accord ing to the cartridge

being used. Turn the anti-skating knob dial to the same

number on the tracking force dial. Use the 8 marked dial

when employing a spherical stylus. Use the

dial for an

of the - marked dial to the index

F6 is provided with an elliptical stylus and the track-

QL-

ing force has been adjusted to 1.75 g. (See Fig. 21)

7 -( 10) HO/VO

elliptical or a Shibata stylus. Set the "

Damping

marked

75"

line since the

Fig. 21

Turn the HQ

control knobs until the "

aligned with the index line

force for this unit

damped function turn the knobs

damping control and the VQ

75" marks on the dial are

, since the optimum tracking

is 1.75 g. When not

until the "

using the oil-

0" mark is

damping

aligned with the index line. (See Fig. 22)

Caution:Turning the HQ and VQ damping control knobs

while playing a record may cause damage to the

disc or to the stylus

tip. Do not touch

them

while playing a disc.

Release the tonearm clamp and start playing the record.

8. OL-

F6 Block Diagram

Platter

AC Amp.

Schmitt circuit

1----

Push-

pull

drive circuit

F /V conversion

!+24V

Mono-multi

vibrator

Fig. 22

Meter drive

circuit

+6% -

QL-

No. 2464

AC 100V

50/60Hz

DC amp.

Power

supply

circuit

+24V

+ 8V

GND

L_-

P/D circuit

Oscillator/

Frequency

divider

r- -

Speed selection

QUARTZ LOCK/PITCH CONTROL selection

Non-stable

multivibrator

11 -

Pitch control

Tal

5.5296MHz

Fig. 23

Page 13

transistors

from electronic

t disconnect the motor

in drive circuit may be damaged.

circuits while troubleshooting as

discon-

R68 are

Check if C22

open.

Observe the FG

output and IC4

performance to

trase the defect.

No. 2464

QL-

Check all driving

coils.

Yes

Note: Don

, and

elements

, HG2.

X1 - X12

Hall

HG1

Check transistors

IC5 is defective.

Replace.

Yes

Is R70

nected or badly

soldered?

Yes

Yes

IC1 is defective.

Replace

Perform locking

adjustment or

check the phase.

Yes

X16 is defective.

Fig. 24

Cooo,ct

R,p""

Yes

Replace the pilot

lamp.

Yes

dis-

Check the trans-

former for

connected wires

and damaged

printed pattern.

Check X15, 02.

is defective.

Yes -+/ X17

12 -

not rotate when

Turntable does

start button is

depressed.

1. Turntable does not rotate.

9. Troubleshooting Charts

9-( 1) Platter does not rotate

Page 14

QL-

No. 2464

X 16 is defective.

Replace.

grounded

of R30

When the terminals

, R31

stop?

, does rotation

, R32 are

base of X16 to +24 V

Does connecting the

stop rotation?

(2) Platter rotates at high speed.

Platter rotates at high speed.

when the start button is

depressed.

Rotates at high speed

Fig. 25

Yes

X17 is defective.

Replace.

Check the Schmitt cir-

cuit and AC

sections

output of motor.

, and the FG

amplifier

Yes

waveform present at

Pin 7 of IC4?

I s rectangular

Yes

shown in the circuit

diagram present at

Is the waveform

Pin 4 of IC1?

13 -

Note: Don t disconnect the motor from

Check if C22

circuits while troubleshooting as this

damage the transistors in the drive circuit.

are disconnected.

Replace if they are.

, R6

, R68

electronic

tive

Check if

may

Replace if necessary.

, VR4 is open.

, R67 is disconnect-

IC1 is defec-

Yes

Yes

IC5 is defective.

Replace.

Page 15

Yes

Check if R12 is dis-

connected. Replace if

disconnected.

Readjust and observe.

is dis-

Check if R53

so.

connected. Replace if

No. 2464

QL-

short-

short-

The collector and emit-

ter of X 19 are

circuited. Replace this

transistor .

is dis-

Check if R52

connected. Replace if

defective.

Yes

Fig. 26

de-

Is D6 or D7

circu ited? Replaced.

abnormally.

Pitch control functions incorrectly.

(3) Pitch Control operates

is dis-

open. Replace

Check if R64

X22 is

if necessary.

connected and whether

if the meter leads are

Check for disconnected

wire(s) in the meter

whether VR1 is open or

disconnected.

Yes

to positive side and remains there.

2. Meter deflects

Disconnected or

fective R 11. Replace.

Readjust and observe

this

are short-cir-

Collector and emitter

of X 18

cuited. Replace

transistor.

14 -

Page 16

9::1-

179171::

0 L

(L)-

18 :a.au!q~

(j/;-

- 9L-

sSV ws!ue4:)all\l

pue SMa!J\ papoldx3 .

:a.S!l s:a.Jed

Page 17

No. Parts Number

See table below.

E65588-

001

E49447-

004

E66140-

001

E35480-

002

E35869.o01

G4942-

G4942-4

E22873-

001

E22911.o01

OSP221 0-

E65912-

OVD7A2B-

E61713-

35981-

Ol.P3201-

E04353E04353-

059

001

014 V. Resistor

003

001

1240

001

002

LPSP3008ZS

F2001

SBSB3008Z

SBSB2608Z

E65714-

001

E65715-

003

See table below.

E60331-

005

M938G

See table below.

DPSP3008ZS

E35915-

002

E65718-

001

E22876-

003

E65282-

001

E65283-

001

REE1200

E60912.o01

E65719-

001

See page 21

E35838.o01

E35839-

001

E35839.o01

E65726-

001

REE3000

E65876-

001

E65875-

001

Descrip~ion

Motor Board Ass

Lock Plate

Shaft

Rubber Sheet

Mark

Fittings

Speed Nut

Panel

Base

Push Switch

Knob

VR. Knob

Meter Ass

Lamp

Color Cap (Green)

Ass

(Blue)

y Screw

Mechanism Base Ass

Tapping Screw

Knob

Lever Knob

Tonearm Ass

Screw

Motor Ass

Servo Control P

Screw

Stopper

Spring

Main Gear Ass

Engagement Pawl

Lawer Trip Pawl

E. Ring

Speed Nut

Connect. Rod

Fuse P

Push Knob Ass

B. Ass

Push Knob (START)

(REJECT)

Pivot

E. Ring

Leaf Spring

Rod Holder

B. Ass

No.

Parts Number

E65729-

E35841E65730E35842E35842E65733-

REE2000

E65735-

E35844-

See table below.

See table below.

SBSB4008Z

E49631.o03

E49633-

See table below.

E50670.o05

E03724-

OM LOO02-

See table below.

See table below.

E60090-

OSRO085-

E65329.o01

OSE2235-

E66153-

E61284-

E35845.o01

GBGB3012M

See table below.

E65877-

E65878-

E22874.o01

See table below.

E35828.o01

E10298-

E61992.o05

SDSP3010RS

REE4000

REE3000

LPSP3008ZS

E66154.o01

E66089.o01

001

001 Push Knob Ass

001

001

Start Rod

Bracket Ass

Push Knob (33 rpm)

002

Description

0~H

001

001

Pivot

E. Ring

Reject Rod

Trans. Bracket

Shield Cover

Power Transformer

Tapping Screw

001

Rubber Bushing

Motor Holder

Rubber Sheet

Wire Clamp

002G

051

003

001

Signal Cord Ass

Lug Strip Ass

Power Cord Ass

Cord Bushing

Shield Cover

Voltage Selector (for U.

Mil itary Market and other

countries only)

Holder

203BS

001

001

Seesaw Switch

Weight

Tapping Screw

Bottom Cover Ass

Tapping Screw

001

001

Foot Ass

Latch

Pin

Turntable

Turntable Sheet

001

Dust Cover Ass

Dust Cover

Hinge Ass

Screw

E. Ring

Ass

y Screw

Rubber Sheet

Caution Label

(45 rpm)

Parts List with Specified Numbers for Designated Areas

Item

No.

Motor Board Ass

Tonearm Ass

Servo Control

Fuse

C101

Capacitor &,

Fuse (Primary) &,

Fuse (Secondary)

Fuse CliP&'

Shield Cover

Power

Transformer &,

Rubber Sheet

Power Cord&'

Cord Bushing

Foot Ass

Turntable Sheet

Description

C. Board Ass

C. Board Ass

E 1

0302.004

ARM-

529

MDC938G-

TPS-

206B

OFH72BM-473M

OMF61 U1-

5 A)

(0.

OMF61U1-

(1A)

E45524.o01

E03032-

33B

OMP1200-

OHS3876-

E65893.o02

E22936.o02

R50

1RO

200

162

Canada

E 1

0302.004

ARM-

529

MDC938G-

TPS-

206C

OFA72BM-

OMF61U1-

(0.5 A)

OMF61U1-

(1A)

E45524.

001

E03032-

33B

aMP 1200-

OHS3876-

E65893-

002

E22936.o02

473M

R50

1RO

200

162

Europe

E 1

0302.004

MP-

201S

MDC938G-

TPS-

OFZ9007-

OMF51A2-

(0.2 AT)

OMF51 A2-

(0.

E48965-

E65716.o01

E03032-

E61796.o03

OMP3910-

A37897

E65893.o01

E22936.o01

16 -

206E

104

R20

R80

8AT)

002 E48965-

33C

244

E 10302-

003 E 1

ARM-

529

MDC938G-

TPS-

206GBS

OFZ9007-

OMF51A2-

OMF51A2-

(0.2 AT)

(0.

8AT)

104B~

R20BS

R80BS

002

E65716.o01

E03032-

33CBS

E61796.o03

OMP9017.o07BS

A37897BS

E65893-

001 E65893.o01

E22936.o01

Australia

0302.004

MP-

201S

MDC938G-

TPS-

206F

OFZ1007-104

OMF51A2-

(0.

2 AT)

OMF51A2-

(0.8AT)

E48965.o02

E65716.o01

E03032-

33C E03032-

E61796.o03

OMP2500-

200

A37897

E22936.o01

S. Military

Market and

Other Countries

E 1 0302-

MP-

201S

MDC938G-

TPS-

206D

OFH53AM-

R20 OMF60S1-

(0.5 A)

OMF60S1-

R80

(0.

8A)

E45524.o01

E65716.o01

E61796.o03

OMP1200-

A37897

E65893.o01

E22936.o01

002

104

R50

R80

33D

200

QL-

No. 2464

Page 18

10-(2) Mechanism Ass

C(ID

QL-

No. 2464

Parts Number

No.

E22883-002

E60395-001

E60394-003

E60392-O02 Switch Plate

E60393-

002

G4942-

E65740-O01 Spring

E35851-

001

E35850-O01

E60398-O01 Lead-

E65741-

001

E60912-001 Speed Nut

E60399-

001

E65742-O01

E60400-O02 Idler Gear

E60405-003 Sub Gear Ass

E60402-

002

E60403-O01

E60912-001 Speed Nut

E60404-001 Spring

E65744-O01

E65745-001 Spring

E60912-001 Speed Nut

E65746-O01

E65747-001 Spring

Description

Base Ass

Reset Plate

Switch Plate Ass

Switch Lever

Speed Nut

Dr. Gear Ass

Driving Gear

I n Lever

Push Lever

Spring

Sub Gear

Hook

Ratchet Cam

Start Lever

17 -

Parts Number

No.

E65748-

001

E60416-

001

E35852-001

E60426-

003

E60427-001 Spring

E65873-O01

E65749-O01 Select Lever

E60488-001 Spring

G41505-O05

E60390-002

E 65874-

00 1 Spring

REE3000X

E65750-O01 Cueing Shaft

E49608-

002

E60414-

001

E65956-

001

E65957-O01

E65958-O01

E65959-

001

E65960-O01

SBSB3010Z

E65720-O01 Trip Lever Ass

E65959-

002 Washer

E65959-O01

Description

Lock Lever

Spring

Index Lever

Lever

Select Plate

Steel Ball

Elevator Cam

E. Ring

Spring

Rod

Cueing Ass

Cueing Base

Cueing Lever

Washer

Spring

Tapping Screw

Page 19

10-(3) Tonearm Ass'

102-16

110

110-3

III

112~ c.

113

102-II

102-12--j 'r (

110

-2 . .

~~IIO-'

Yi

~I

~l

1\

/105

d:.~

110-4 0

Jl~

~1

107 "

t!:r~

I"~

~1C

0;&

1)~

106 102-15~"-..

( "'-3

I \

(j) I

Ei

10213

106 /

I 1

/J~

i QI6U ~

\ C)

\ "'102-191

I / -

101-5 I I

1 I

101

103 )i

eY

I~/

6!

\1

,!J

102-18 \

102-14 '

'r /

~02

"1 ~

1 ~1'l

~ i

102-19

104

102-17

~102

102-3 \

1",--i--

~!Ye

~102-7

\ ~7 i--

~1--!--102-9

, I!r

102-4

102-5

L ~

102-6

102-8

--1--102-10

No.

101

101-

101-

101-4

101-

102

102-

102-

102-4

102-

102-

102-

102-8

102102-

102-

102-

102102102-

Parts Number

E22901-

001

E35894-

TCS2002NS

E35895-

TRS2006NS

E22902-

E10308-O01

35897-001

E35900-

E49602E35901E65825E65827-

65826-

SBSB2608Z

E65829-

E49649-

E61194-

E49655-

REE3000

001

001

001

001

002

001

001

001

001

001

001

001

007

Description

Tonearm Ass

Cap (A)

Screw

Cap (B)

Screw

Tonearm Base Ass

Tonearm Base Sub Ass

Plate

Anti-skating Knob

Wave Washer

Anti-skating Lever

Anti-skating Plate

Anti-skating Spring

Spring Holder

Tapping Screw

Elevator Ass

Spring

Elevator Shaft

E" Ring

18 -

No.

102102102102-

103

104

105

106

107

108

109

110

110-

110-

110-4

110-

111

112

113

Parts Number

E65835-

001

E65824-

SBSB2616Z

SBSB2605Z

E65837E65830-

E300015-O01

SPSP3006ZS

E61775-O01

E65823-

E65938-

E35991-

E35989-

E60501E60502-

E22962-

MD-

DT-Z1EB

E34268-

001

001

001

001

001

002

002

005

001

001

1025EB

001

Description

Screw

Rest Ass

Tapping Screw

Washer

Nut

Tonearm Lever

Screw

Shield Tube

Counterweight Ass

Subweight

Headshell Ass

Finger

Wire Ass

Screw

Headshell Boay .

Cartridge

Stylus

Stylus Covering

QL-

No. 2464

Page 20

11. Printed Circuit

Board Ass y and Parts

List

11-(1) MDC-

(Different in Different Area

see back page)

938G

QL-

No. 2464

19 -

Page 21

Transistors

No,

Parts Number

2SD794(P

2SD794(P

2SD794(P

2SD794(P

2SA733(P

2SA733(P

2SA733(P

2SA733(P

2SB605(K

X10

2SB605(K

X11

2SB605(K

X12

2SB605(K

X13

2SC2259(G

X14

2SD325V(D

X15

2SC945(P

X16

2SA733(P

X17

2SC945(P

X18

2SC945(P

X19

2SC945(P

X20

2SC641K(B

X21

2SC641K(B

X22

2SC945(P

X23

2SC945(P

X24

2SC945(P

X25

2SC945(P

X26

2SC945(P

X27

2SC945(P

I ntegrated Circuits

No. Parts Number

IC1

VC4046

IC2

NJM78L08A

IC3

MSM4001

IC4

NJM4558D-

IC5

NHM4558D

Diodes

Parts Number

WO2

RD5.

6EKVM2

VC1220

15553

15553

1S953(A

1S953(A

D11

15553

Capacitors

No.

Parts Number

QCF11HP-

QET41VR-

QCT05UJ-

QCY41HK-

QET41HR-

QET41ER-

QET41HR-

C10

QEN41EA-

C11

QEN41EA-

C12

QET41ER-

C13

QET41JR-

C14

QET41JR-

C15

QET41JR-

C16

QCT05UJ-

K)

K)

K)

223

330

475

474

336

336

476

107

476

477

330

Q)

Q)

Q)

Q)

L)

L)

L)

K)

K)

K)

K)

K)

106

102

105

Q)

Q)

F)

C)

10W

250 mW

800 mW

10W

250 mW

100 mW

250 mW

Rating

Rating

022 Jl.F

10 Jl.F

33 pF

1000 pF

1 Jl.F

7 Jl.F

0.47 Jl.F

33 Jl.F

47 Jl.F

100 Jl.F

47 Jl.F

470Jl.F

33 pF

Rating

180 MHz

120 MHz

8MHz

250

180 MHz

250 MHz

400

250

Description

Description

Silicon

Zener

Varistor

Silicon

Rating

DC 50 V

DC 25 V

DC 50V

DC 25V

DC 63 V

DC 50 V

55 MHz

MHz

MHz

MHz

DC 50 V

DC 35 V

Description

Maker

Silicon

Sanyo

Hitachi

Maker

Dki Denki Kogyo

Shin Nihon Musen

Oki Denki Kogyo

Shin Nihon Musen

Maker

Description

Ceramic

Electrolytic

Ceramic

Electrolytic

Nonpolarized

Electrolytic

Electrolytic

Ceramic

Capacitors

No,

C17

C18

C19

C20

C21

C22

C23

C24

C27

C28

C29

C30

C35

Resistors

No.

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R23

R24

R25

R26

R27

R28

R29

R30

R31

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

Parts Number

QCT05UJ-

QCE12HP-

QCF11 HP-

QFM41HK-

QCF11HP-

QFM41HK-

QFM41HK-

QCF11HP-

QCT05CHQCT05CH-

QET41VR-

QCF11HP-

QCF11

Parts Number

QRD143J-

QRD143JQRD143JQRD143JQRD143J-

QRD143J-

QRD143J-

QRD143J-

QRD143J-

RE36YQRE35YQ-

RE35YQ-4.

QRD143JQRD143JQRD143J-

QRD143J-

QRD143J-

QRD143JQRV141FQRV141F-

QRD143JQRD143J-

QRD143J-

QRD143J-

QRD143J-

QRD143J-

QRD143J-

QRD143JQRD143JQRD143J-

QRD143J-

QRX016J-

QRD143JQRD143J-

QRD141JQRD141J-

QRD141J-

QRD141J-

QRD143JQRD143J-

QRD123J-

QRD143J-

QRD143J-

QRD123J-

QRD123J-

QRD123JQRD143JQRD143J-

QRD143J-

QRD143J-

473

HP-473

102

105

103

102

104

103

472

473

473

8KF

7KF

7KF

222

473

473

394

272

182

2702

1802

182

334

223

222

123

391

332

101

680

680

680

2R7

3R3

3R3

392

392

392

392

472

472

561

472

472

561

561

561

471

220

103

101

330

103

223

473

103

104

473

103

151

151

106

33 pF

01 Jl.F

022 Jl.F

047 Jl.F

01 Jl.F

1 Jl.F

047 Jl.F

01 Jl.F

150 pF

10 Jl.F

047 Jl.F

1kn

1Mn

10kn

1 kn

10kn

1 kn

47kn

47kn

47 kn

390

7 kn

8 kn

330

22 kn

12 kn

390 n

100 n

68n

560 n

7 kn

560 n

470 n

22n

10 kn

100 n

7kn

8kn

7kn

2 kn

kn

kn

kn

kn

kn

kn

kn

kn

kn

Rating

Rating

DC 50 V

DC 500 V

DC 50 V

DC 50 V

DC 35 V

DC 50V

Y:,W

Y:,W

Description

Ceramic

Mylar

Ceramic

Mylar

Ceramic

Electrolytic

Ceramic

Description

Carbon

Metalized Film

Carbon

Metalized Film

Carbon

Metalized Film

Carbon

20-

QL-

No. 2464

Page 22

Resistors

Parts Number

No.

R52 R E35YQ-

RE35YQ-

R53

QRD143J-

R55

R58 RE35YQ-

RE35YQ-

R59

QRD146J-

R60

R61 QRD143J-

R62 QRD143J-

R63 QRD143J-

QRD143J-

R64

QRD143J-

R66

R67 QRD143J-

QRD143J-

R68

QRD143J-

R69

QRD143J-

R70

QRD143J-

R71

R72 QRD143J-

R73 QRD143J-

R74 QRD143J-

QRD143J-

R76

3KF

7KF

3 k.l1

4:7 k.l1

473 47 k.l1

15KF

15 k.l1

6KF

10.11

100

10 k.l1

103

103

103

47 k.l1

473

15 k.l1

153

103 10 k.l1

1 k.l1

102

27 k.l1

273

100 k.l1

104

104

182

100 k.l1

104

122

102 1 k.l1

Rating Description

Metalized Film

Carbon

Metalized Film

k.l1

Carbon

k.l1

k.l1

Resistors

Parts Number

No.

QRD143J-

R77

QRD143J-

R78

R80 QRD143J-

RVAV310-

VR1

RVGV811-

VR2

RVGV413-

VR4

VR5 RVGV811-

Others

Parts Number

No.

LA-O303

E03732-0 15A

E65674

QSPO026-001

562 6 k.l1

561 560.11

102 1 k.l1

472 7 k.l1

472

47 k.l1

473

103 10 k.l1

Rating

Rating

Description

Carbon

Variable

Description

Quartz Crystal

Plug

Heat Sink

Push Switch

11-(2) TPS-

206 Fuse

(Different in Different Area

P .

C. Board Ass

, see back page)

1 2. Accessories List

Description

I nstruction Book

Warranty Card

Special

Replay Card

Service Procedure

Siemens Plug

Screw Ass

E30580-717A

BT20032

BT20024B

BT20023

E61153-

003

(for Cartridge)

E.P. Adapter E48820-001 E48820-

Envelope E64207-

001 E64207-001

Canada

E30580-717A

E30580-

BT20025

E61153-

Europe

E30580-717 A

717B E30580-

003

001

E48820-

E64207-001

Item No.

Cl01

ffi : Safety Parts

717B

001

E30580-

BT20013B

E61153-003

E48820E64207-

Part Number

See back page.

Australia

717A E30580-

BT20029

001

001

E48820E64207-

717A

001

001

Description

Capacitor ffi

Fuse ffi

Fuse clip ffi

S. Military

Market and

Other Cou ntries

717A

E30580-

BT20032

(U.S. Military

Market)

E04066

(Other Countries)

001

E48820-

001

E64207-

QL-

No. 2464

- 21 -

Page 23

14. Packing Materials

E34725-

002

Nylon Covering

E36997-

020

Protect Sheet

G6771-

Caution Label

E22934-

Platter Case

001

and Part

Numbers

E22949-

002

Sheet Ass

NZ-

QLF6

Packing Sheets

and Pad

E22493-

Corner Pad

311

PK-

QLF6E

Carton Box

E61848-

Plate

001

24-

QL-

No. 2464

Page 24

15. Parts List with

Designated Areas

Specified Numbers for

Item

Description

No.

Motor Board Ass E 10302-

Tonearm Ass

Servo Control

C. Board Ass

Fuse

P .

C. Board Ass

C101

Capacitor it

Fuse (Primary) it

Fuse (Secondary)

FuseClipit

Shield Cover

Power

Transformer it

Rubber Sheet

Power Cord it

Cord Bushing

Foot Ass

Turntable Sheet

004 E 1 0302-

ARM-

529 ARM-

MDC938G-

TPS-

206B TPS-

OFH72BM-473M

OMF61 U1-

OMF61U1-1RO

E45524-

E03032-

OMP1200-

OHS3876-

E65893-

R50

(0.5 AI

(1A)

001 E45524-

33B E03032-

200

162

002 E65893-

E22936.o02

Canada

004

529 MP-201S

MDC938G-

206C

OF A 72BM-

OMF61U1-R50

OMF61U1-

OMP1200-

OHS3876-162

E22936-

4 73M

(0.5 A)

1RO

(lA)

001

33B

200 OMP3910-

002

002 E22936-

Europe

E 1 0302-

004

MDC938G-

TPS-206E

OFZ9007-104 OFZ9007-104BS

OMF51A2-R20

2 AT)

(0.

OMF51A2-

(O.8AT)

E48965-

002

E65716-

001

E03032-33C

E61796-

003

A37897

E65893.o01

001 E 22936-

E 10302-

ARM-529

MDC938G-

TPS-206GBS

OMF51A2-R20BS

(0.2 AT)

R80

OMF51 A2-

(O.8A T)

E48965-

E65716-

E03032-

E61796-

244 OMP9017-

A37897BS

E65893-

003 E 1

R80BS

002 E48965-

001 E65716.o01 E65716-

33CBS

003 E61796-

007BS OMP2500-

001

00 1 E22936.o01 E22936.o01

Austral ia Market and

0302.004

MP-201S MP-

MDC938G-

TPS-206F TPS-206D

OFZ1007-104

OMF51A2-R20 OMF60S1-R50

2 AT) (0.5 A)

(0.

OMF51 A2-R80

(0.8AT)

002

E03032-

33C E03032-

003

A37897

E65893-

200 OMP1200-

001

s. Military

Other Cou ntries

E 1 0302-

002

201S

MDC938G-

OFH53AM-

OMF60S1-R80

E45524-

E61796.o03

A37897

EG5893.o01

(0.

104

8A)

001

001

33D

200

JVC

VICTOR COMPANY OF JAPAN, LIMITED

, TOKYO

, JAPAN

Printed in Japan

AI

V 8012-

Page 25

13. QL-

Schematic

Diagram

i Motor 1

i HG-1

I r-:

HG-2 I

FG

I I

1"11,1I!11~11.11111,1I,1 . r

r -

N-'='f--~ ~

l::_

f--;:;-;;;

r,...

Lf---- -

R61

10K

R45

1/2W

5600

R42

1I2W

560(1

!23.

(Q)

a: lJlJ

f--~

~I-. -

;:: a, ;;;--

f--W:'

R40

R41

0" /35V

0 - N

f--

rn ~

r-

Ii

lr~l 1

O! ~ J

(2;!

c-

~4.7K

~~7 ~1

, rp;;;-

I EART

'bW

t~L

8~

~~R

L'::"

.J 5tgnalclrcultafQL-

=;--(g,~ SPE

.J

grml

TMoc 938

https://manualmachine.com/2W i7V1

~~ X

g,1V

~ 1 ;~V (

R72

1.BK 0

Tg~

:~'M

GJ ,

Gf =:~ D

I+V

I ~+

I -

R21M ~,

1 c

~Jo, + R62

gl!!2'!J ~

4)-' ~

3 P IC4

C2~ 10)J

~v

!OK

FIN

'O ~~:IT

IRE I

I ~

I B

250794 25B605(K

~ E

XI-X4

C~/7 E

X9 -X'

25A733(P'K)

L) 25C641K(B

X5-XB, X15-X24

~SELECT SW.

C'

~~Z;

~ O

CD

m :'

I K

47K

7K 47K

R52

(!l

X24

1?t

I+V

L..

1!J1

-v I

Jcl

5 4.

R76

l ~ 3.

/IJ

F-'

D11 c

R23

330

25A733(P'Q)

C) 25C945(K

PITCH CONTROL METE

o----

~ RI

3K

,:J)

R64

47K

RI5

RI4

47K

47K

R5~

47'

251

rpS-

~O )(

9K 3.9K 3.

NP

i~?25V ~3

h ~

0 3

~1i3:5Vl

31

9K 3.

~ NP

~~1

/25V ~~3

tR

W;"'1

o:~ o

l2..-'!J

R33 1W

rn~~

455

EBS(forEngland)

206GBS

106

E03032 -

\(IVI~

33C BS P.

\~ \J1 \his

TRANS

240V BLU

220VGRY

0 BRN

IrPS- 2o6DT

. I

. I

16

f~

:' ;I,

r:

6!l m

~n+-+ ~::\

R79

?'.' D3

0.455 -

Vcc RED

l-Q:~yf

EP&EU(forPacex&Otherareas)

R7 /

7K

li,

I~-

CB

7~1

25V

I )~om

~ IC3"'t,"IQ.

E03032 - 33D

P. TRANS

ib~

n:

R68

IK ~

120V BLU

C16 ~

33P

o~

~~; I---.: ~D,

R66

1. v

C17

33P,

1Y-#~%~3

101

C0-0",%Ji'.""-0 -

0(Q)G5Vl

2VI. 10

0~13.

C2 C23

C69 0

33K

"' PICTH r1\ol1",,' n

\~I

~g2 C

R16 "

~'T" )if

01 0047 ~

LOCK 0 6V3.

VOLTAGE SELECTOR

) OIAGRAM ',0V

I 1/

.J..

12

CZ4

001

/: 55

~~7 --

11

: i

31415

3.5VI 0 I~BVI';

6VI0 0

6V3.6V3.

/~40ms

R70

lOOK

1C3 "~NO.

PICTH CON

10 11 12

8 9

0\/1 3.

59VI,

9V 0

0 0 7.

4V 0 7.

I ~~

PILOT LAMP

lZV 4DmAx4

EJ & EC ( for

r;:

14 -4

I+V I

7V n

OAG L,

SW.

C101

01~/450V-

L_-

~Wl (POWER)

Notes:

1. The voltage indicated in

c:::::J 33-

c::J 45 rpm

(Q)

(!) c::J

22 -

when locked

SW.

1/3 rpm

2 (POWER)

AC110, 120. 220, 240V

SO/60Hz

is measured by a tester having an internal impedance 33kD..

2(POWER)

SW.

2.

3.

4. When

5. This is the sta

indicat,

indicat,

replacir

The design an

Page 26

(fq

Page 27

25D325 (D, F)

25C2259 (F, G)

15553

15953

VDI220

RD24EB3

W02

NJM4558D-

D. NJM4558D

X14

METER (t270)JA)

GRY

RI3

ORG

C12

47~125

R58

15K

X 13

R77

D4~D9, DIO~DI2

D'5 , DI6

Out

D3, D13, D14

NJM78L08A

IC2

FUSE 2

Cia

O11500V I

-7, /

VC4046

rips-iaGAr

I m

REO

REO

104

AC DI

MSM4001

E03032-

P. TRANS

IC4, IC5

I 2

R55

A7K

12 13

V 14 In.

GRN LAMP

RI2 4.

RI7

. TPI

BRN CD BL

QL

QL ON

QL OFF 0

i LAMP

Ir USA & Canada)

EO3032-33B P. TRANS

ORG

1.8

(Q) GND

QUARTZ

RIO 6.

Uli

G'I

R20

IlK

R19

27K

6KHz

R21

l.aK

C35 I

0.047 I

GND I

lC3t,W,~NO. I

2..:..~

EE & EA(for Europe& Aushalia)

E03032 - 33C

P. TRANS

CP In FsOut Fs In

. 240V BLU

CP Out STOut 33L145H RC

15

FG In RC HC

250794

2SA733 (P

25B605 (K,

25C2259 (F

2~,0325iV(D

2SA733 (P

2~A:945 ( K.

25C641 K( B

W02

RO5. 6EKVM2

VD1220

15553

15953

VC4046

NJM78LO8A

M5M4001

NJM45580-

NJM45580

13

----v--------'

F/V

X 1- X4

X 5 - X8

X9- XI2

X I 3

X 14

X 16

XI5

X20 X21

D3,

ICI

IC2

lC3

IC4

1C5

HC

Oul

X17-XI9, X22-X/27

, 07 0 II

09,

Oul

GNO

...J

5W. 2 (POWER)

Ites positive B power supply.

Ites the signal path.

:ing the parts

ill in the

darkened ares (

). be sure to use the designated parts to ensure safety.

tandard circuit diagram.

md constants are subject to change without notice.

AC 220V- 50Hz lEE)

AC' 240V- 50Hz lEA)

QL-

No. 2464

Loading...

Loading...