Page 1

SERVICE MANUAL

PDP COLOUR TELEVISION

YA22920052

PD-Z50DX4,

PD-Z50DX4

VM-Z50DX4, VM-Z50DX4/S

[PLASMA DISPLAY UNIT]

PO

WE

R

/S

BASIC CHASSIS

FP2

TU-Z50DX4, TU-Z50DX4/S

[RECEIVER UNIT]

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YA229

2005/2

Page 2

SPECIFICATION

Items Contents

Dimensions ( W × H × D ) Plasma display unit 135.0cm × 83.6cm × 11.0cm

Receiver unit 43.5cm × 7.0cm × 31.3cm

Mass Plasma display unit 51.0kg

Receiver unit 3.6kg

TV RF System B, G, I, D, K, K1, M

Colour System PAL / SECAM / NTSC 3.58 / NTSC 4.43

Stereo System A2 (B/G, D/K), NICAM (B/G, I, D/K)

Teletext System FLOF (Fastext), TOP, WST (World Standard System)

Receiving

Frequency

Intermediate Frequency VIF

Colour Sub Carrier PAL

Power Input AC110V - AC240 V, 50 Hz / 60 Hz

Power Consumption Plasma display unit

Plasma Display Panel (PDP) 50V wide aspect (16:9)

Screen Size Diagonal : 127.0cm (H:110.7cm × V : 62.2cm)

Display Pixels Horizontal : 1366 dots × Vertical : 768 dots (W-XGA)

Audio Power Output 20W + 20W

Speaker Main (DD)

Aerial Terminal 75Ω unbalanced, coaxial

Video / Audio input

[VIDEO-1/2/3/4]

Digital Input Video

PC (RGB) Input D-sub 15pin × 1

Center Channel Input 500mV(rms) (-4dBs), high impedance,RCA pin jack × 1

Monitor Output Video

Audio Output RCA pin jack × 2

Subwoofer Output More than 0 to 1000mV (rms) (+2.2dBs), low impedance (80Hz when modulated 100%), RCA pin jack × 1

AV COMPULINK 3.5mm mini jack × 1

Display Input / Output

(For system cable)

Remote Control Unit RM-C1830 (AA/R6 / UM-3 battery × 2)

Component Video

625i / 625p / 525p / 525i

VHF Low

VHF High

SECAM

Receiver unit

Tweeter

[VIDEO-1/3]

1125i / 750p

S-Video

[VIDEO-1/2/4]

Control / Audio

Design & specifications are subject to change without notice.

46.25MHz - 168.25MHz

175.25MHz - 463.25MHz

471.25MHz - 863.25MHz

UHF

Mid (X - Z+2, S1 - S10) / Super (S11 - S20) / Hyper (S21 - S41) bands

CATV

38.0MHz (B, G, I, D, K, L)

SIF

32.26MHz (5.74MHz: B), 32.15MHz (5.85MHz: G), 31.45MHz (6.55MHz: I)

31.75MHz (6.25MHz: D), 32.15MHz (5.85MHz: K)

4.43MHz

4.40625MHz / 4.25MHz

3.58MHz / 4.43MHz

NTSC

Opearate: 434W, Stand by: 3.3W

Opearate: 21W, Stand by: 0.6W

9.5cm × 1cm, oval type × 2

2cm, round type × 2

13cm × 6.5cm, oval type × 2

Woofer

RCA pin jack × 6

Y : 1V (p-p) (Sync signal: 0.35V(p-p), 3-value sync.), 75 Ω

Pb/Pr : ±0.35V(p-p), 75 Ω

Y : 1V (p-p), Positive (Negative sync provided), 75 Ω

Cb/Cr : 0.7V(p-p), 75 Ω

Mini-DIN 4 pin × 3

Y: 1V (p-p), Positive (Negative sync provided), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

1V (p-p), Positive (Negative sync provided), 75 Ω, RCA pin jack × 3

Video

500mV (rms), High impedance, RCA pin jack × 6

Audio

HDMI connector × 1

(Digital-input terminal is not compatible with picture signals of computer signal)

Digital: HDMI connector × 1

Audio

Anarog: 500mV(rms) (-4dBs), high impedance, RCA pin jack × 2

R/G/B : 0.7V (p-p), 75Ω

HD / VD : 1V (p-p) to 5V (p-p), high impedance

< Available signal >

VGA : 640 pixels × 480 pixels (Horizontal : 31.5kHz / Vertical : 60Hz)

XGA : 1024 pixels × 768 pixels (Horizontal : 42.0kHz / Vertical : 60Hz)

1V (p-p), 75Ω, RCA pin jack × 1

Audio

250mV (rms) (-10dBs), Fs-18dB low impedance, RCA pin jack × 2

500mV(rms), (-4dBs), low impedance (400Hz when modulated 100%)

D-sub 26-pin connector × 2

Video

DVI-D 24-pin connector × 2

1-2 (No.YA229)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

The design of this product contains special hardware, many

(1)

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to those

used in the original circuits. Service should be performed by

qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics

are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special

safety characteristics are identified in the parts list of Service

manual. Electrical components having such features are

identified by shading on the schematics and by ( ) on

the parts list in Service manual. The use of a substitute

replacement which does not have the same safety

characteristics as the recommended replacement part

shown in the parts list of Service manual may cause shock,

fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND. Don't short between the LIVE side

GND and ISOLATED (NEUTRAL) side GND or EARTH side

GND and never measure the LIVE side GND and

ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope

etc.). If above note will not be kept, a fuse or any parts will

be broken.

(5) If any repair has been made to the chassis, it is

recommended that the PDP POWER SUPPLY setting

should be checked or adjusted.

(6) The high voltage applied to the PDP must conform with that

specified in Service manual. Excessive high voltage can

cause an increase in arcing and possible component

damage, therefore operation under excessive high voltage

conditions should be kept to a minimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect installation, cracked or melted high voltage

harness, poor soldering, etc.). To maintain the proper

components in the circuitry including the PDP must be the

exact replacements or alternatives approved by the

manufacturer of the complete product.

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10k

resistor to the anode button.

Ω 2W

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, screw heads, earphone jack, control

shafts, etc.) to be sure the product is safe to operate without

danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly any

exposed metal part having a return path to the chassis, to a

known good earth ground (water pipe, etc.). Any leakage

current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.).

Use an AC voltmeter having 1000

sensitivity in the following manner. Connect a 1500

resistor paralleled by a 0.15

Ω per volt or more

Ω 10W

µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage across

the resistor with the AC voltmeter. Move the resistor

connection to each exposed metal part, particularly any

exposed metal part having a return path to the chassis,

and measure the AC voltage across the resistor. Now,

reverse the plug in the AC outlet and repeat each

measurement. Any voltage measured must not exceed

0.75V AC (r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

GOOD EARTH GROUND

ON EACH EXPOSED

ME TAL PAR T

(No.YA229)1-3

Page 4

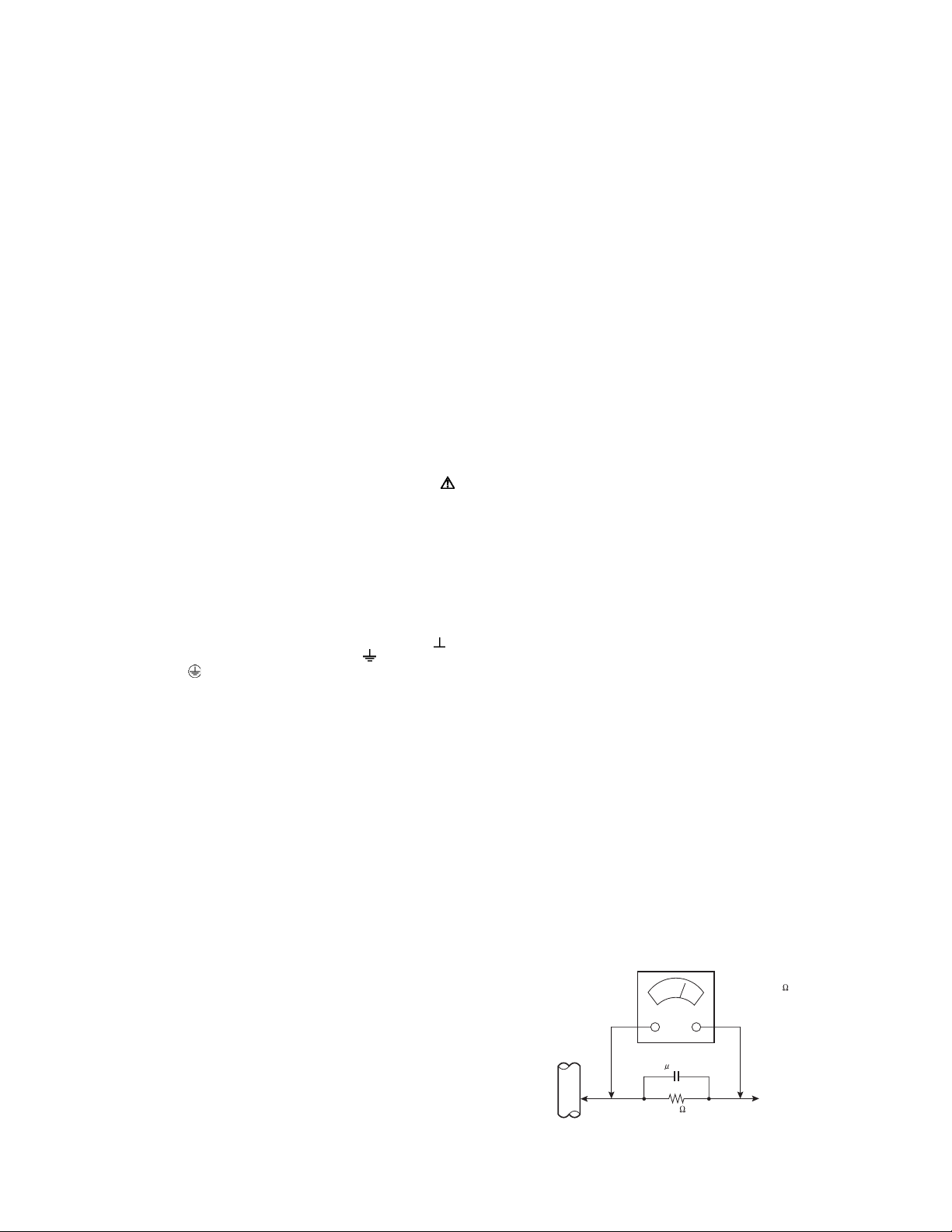

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling efficiency may deteriorate and temperature inside the unit will rise. The

temperature sensor that protects the unit will be activated when internal temperature exceeds the pre-determined level and power will

be turned off automatically.

Therefore, please make sure pay attention not to block the heat dissipation vent as well as the ventilation outlet behind the unit and

ensure that there is room for ventilation around it.

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified below, between the unit with and the surrounding walls, as well as the

floor etc. Install the unit on stable flooring or stands. Take precautionary measures to prevent the unit from tipping in order to protect

against accidents and earthquakes.

SPACE REQUIRED FOR INSTALLATION OF THE DISPLAY UNIT

200 mm

150 mm

50 mm

SPACE REQUIRED FOR INSTALLATION OF THE RECEIVER UNIT

100 mm

POWER

PLASMA DISPLAY RECEIVER

100 mm100 mm 100 mm

1.2.3 FALL TIP PREVENTION MEASURES

Take precautionary measures to prevent the unit from falling or

tipping to protect against emergencies such as earthquakes as

well as accidents.

Fasten the supplied hook for tip fall prevention using the screws,

also supplied, behind the display unit, and use them together

with durable cords (to be purchased separately) to secure the

unit to a robust part such as the wall surface or pillars.

150 mm

50 mm

1-4 (No.YA229)

The supplied hook for tipfall prevention

Page 5

1.3 PRECAUTIONS REGARDING PDP

1.3. 1 PRECAUTIONS DURING NOTES FOR TRANSPORTATION

When transporting the unit, pressure exerted on the internal PDP

(Plasma Display Panel) due to improper handling (such as

tossing and dropping) may cause damages even when the unit

is carefully packed. To prevent accidents from occurring during

transportation, pay careful attention prior to delivery such as

through explaining the handling instructions to transporters.

Ensure that the following requirements are met during

transportation, as the PDP of this unit is made of glass and

therefore fragile:

(1) Avoid vibrations and impacts

The unit may be broken if it is toppled sideways even when

properly packed. Ensure that the unit is carried by at least

2 persons and pay careful attention not to exert any

vibration or impact on it.

(2) Do not place equipment horizontally

Ensure that it is placed upright and not horizontally during

transportation and storage as the PDP is very vulnerable to

lateral impacts and may break easily under such

circumstances.

During transportation, ensure that the unit is loaded along

the traveling direction of travel of the vehicle, and avoid

stacking them on one another.

For storage, ensure that they are stacked in 2 layers or less

even when placed upright.

1.3.2 RESIDUAL IMAGE / BURN-IN ON SCREEN

Like CRTs, "burn-in" may occur when a same image is

continuously displayed over an extended period of time.

As this may also shorten the life span of the PDP. Therefore, turn

off the display when not in use, scroll the screen, make use of

screen-savers, or allow even distribution on the display by

inverting the brightness, switching to complementary colors or

inserting animated images at periodic intervals.

As burn-in is more likely to occur with high brightness and

contrast settings, try to use neutral gradations or medium tone

colors.

Burn-in does not occur in the case of animated images.

When switching to another image after continuous display of the

previous image, residual images may become prominent, as

luminance in a part of the display is higher than the other parts.

This is not a defect but is because due to the discharge surface

of the lighted portion has become being relatively activated and

its luminance higher than the unlighted parts.

1.3.4 OPTICAL FILTER (PANEL FILTER)

Avoid placing the unit under direct sunlight over a prolonged

period of time. This may cause the optical filter to deteriorate in

quality and color.

Clean the filter surface by wiping it softly lightly with outing

flannels a soft and lightly fuzz cloth (such as flannel).

Do not use solvents such as benzine or thinner to wipe the filter

surface. This may cause the filter to deteriorate in quality or the

coating on the surface to come off.

As the filter surface is fragile., do not scratch or hit it with hard

materials.

1.3.5 NOTES PRECAUTIONS FOR PEPLACEMENT OF

EXTERIOR PARTS

Take note of the following when replacing exterior parts (back

REAR COVER, FRONT PANEL, optical filter)

• Do not exert pressure on the front of the PDP (glass surface).

• Pay careful attention not to scratch or stain the front of the PDP

(surface) with hands.

• When replacing exterior parts, the front of the PDP should be

placed facing downward. Place a mat, etc. underneath to avoid

causing scratches to the front surface. However, never use

materials that are too soft (such as blanket cloth). If

replacement is made with the PDP surface facing downward

and in contact with the blanket, pressure may be exerted on

the PDP, thus causing damages to it.

1.3.3 INFRARED RAYS

Near Near-infrared rays (800nm to 1000nm) are emitted from the

front of the panel, and this may give rise to malfunctions in

infrared remote controls or communication systems placed near

it. In this case, avoid direct infrared rays (and reflected rays in

some cases) from the screen by either changing the direction of

the unit or other infrared systems or securing a longer keeping a

distance from the screen.

(No.YA229)1-5

Page 6

SECTION 2

LOB OK FAN OK

SYNC M:OK S:OK HD:NG

TIM OK

MSM OK DIGI 0000

MEM OK AVSW OK

YC OK AIO OK

TUN OK GCR NG 1

IP OK RGB OK 8

DVI OK HDMI OK

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

D.I.S.T. (Digital Image Scaling Technology)

This system uses line interpolation to double the number of

scanning lines and achieve high resolution, flicker-free picture.

COLOUR MANAGEMENT

This function ensures dull colours are compensated to

produce natural hues.

PICTURE MANAGEMENT

This function makes it easier to see the dark areas when a

picture has many dark areas, and makes it easier to see the

bright areas when a picture has many bright areas.

ZOOM

This function can change the screen size according to the

picture aspect ratio.

DIGITAL VNR

This function cuts down the amount of noise in the original

picture.

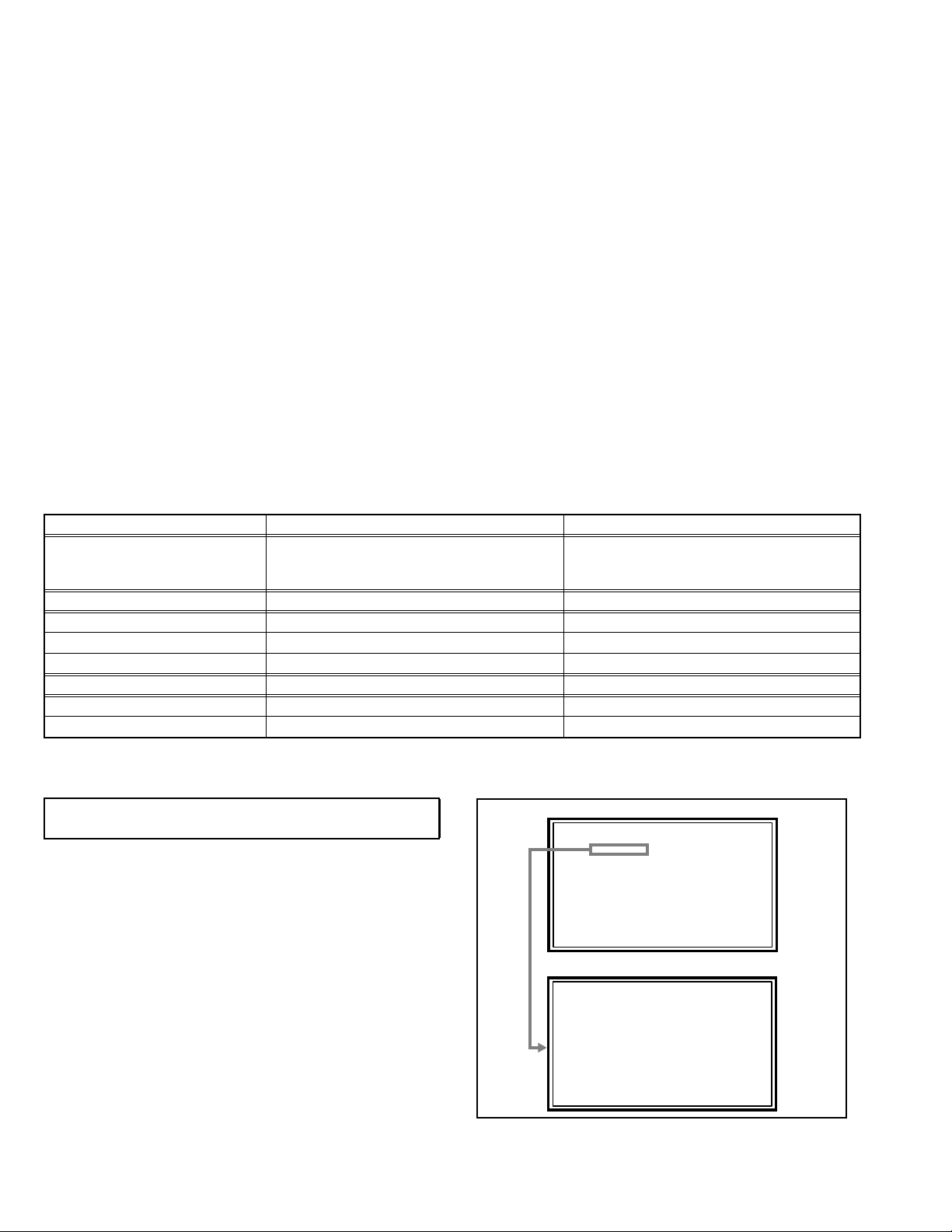

2.2 MAIN DIFFERENCE LIST

Item PD-Z50DX4 PD-50DX4/S

POWER CORD UK type(3pin)

EU type(2pin with Earth)

Flat type(with Earth)

DISPLAY UNIT

DISPLAY INTERFACE P.W.B LCA10360-09E (SFP-7307A) LCA10360-10E (SFP-7308A)

LINE FILTER P.W.B LCA90143-13B (SFP-9308A) LCA90143-14B (SFP-9309A)

SUB POWER P.W.B LCA10353-03D (SFP-9312A) LCA10353-04D (SFP-9313A)

RECEIVER UNIT

REGULATOR P.W.B LCA10426-13C (SFP-9306A) LCA10426-14C (SFP-9317A)

DIGITAL SIGNAL P.W.B LCA10428-41H (SFP-0D307A) LCA10428-42H (SFP-0D308A)

SUPER DIGIPURE

This function uses the latest in digital technology to give you a

natural-looking picture.

PULL DOWN

This function displays a cinema film picture more smoothly and

naturally on the screen.

3D CINEMA SOUND

You can enjoy sounds with a widerambience.

DIGITAL INPUT

Digital-in will display when any picture signal in Digital-in is

displayed.

BBE

High definition audio adds natural, clear and extraordinary

sound quality to any program.

A.H.S.

Adds a more spacious surround sound. Music gives basic

effect and Movie for more effect.

UK type(3pin)

Flat type(with Earth)

2.3 SYSTEM SETTEING

Be sure to carry out the following operation at the end of

the procedure.

(1) Press the [DISPLAY] key and [MUTING] key simultaneous-

ly, then enter the SERVICE MODE.

(2) When the Main Menu is displayed, press [2] key to enter

the self check mode.

(3) Turn off the power by pressing the [POWER] key on the

remote control unit.

1-6 (No.YA229)

MAIN MENU SCREEN

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

SELF CHECK MODE SCREEN

LOB OK FAN OK

SYNC M:OK S:OK HD:NG

TIM OK

MSM OK DIGI 0000

MEM OK AVSW OK

YC OK AIO OK

TUN OK GCR NG 1

IP OK RGB OK 8

DVI OK HDMI OK

Page 7

2.4 TECHNICAL INFORMATION

2.4.1 PDP STRUCTURE AND CHARACTERISTIC

This unit uses the flat type panel PDP (Plasma Display Panel), instead of the conventional CRT (Cathode Ray Tube), as a display unit.

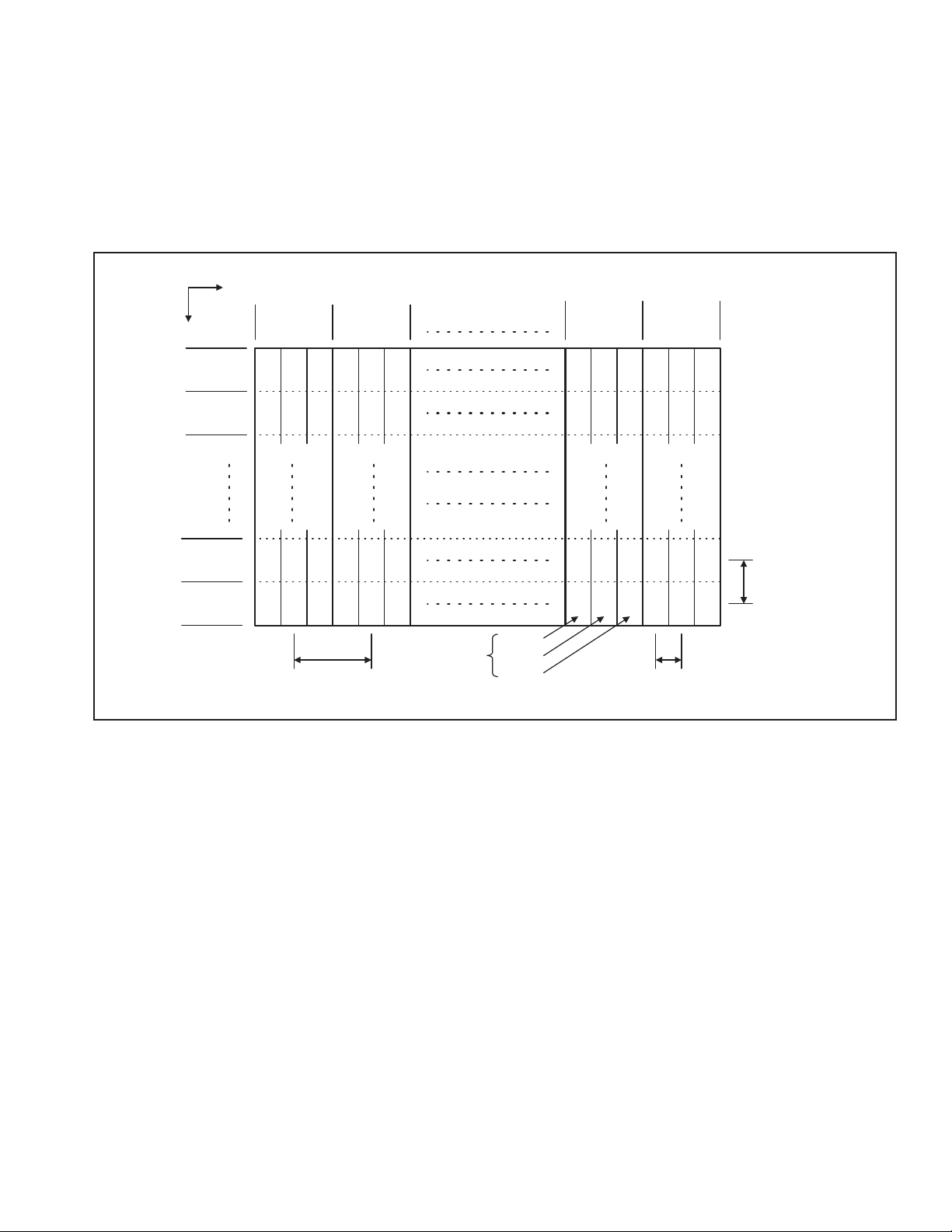

2.4.1.1 PIXEL (CELL) ARRAY

PDP is constructed by sealing the xenon, which emits neon and ultraviolet rays for discharging purpose, in between the electrodes

lay on the front glass substrate and rear glass substrate.

One pixel is composed of 3 RGB cells, with cell pitch of 0.270mm (1 pixel 0.810mm) horizontally and 0.810mm vertically.

The cell is arrayed in each RGB color as shown in Fig. 1. One pixel is formed by interlacing each RGB color cell.

One cell size is 0.270mm horizontally and 0.810mm vertically.

Direction

Vertically

No.1

Pixel line

No.2

Pixel line

No.767

Pixel line

No.768

Pixel line

Horizontally

No.1

Pixel

sequence

B G R B G R

BG

B

B

(Horizontally) Pixel pitch

RBGR

G RBG R

GRBGR

0.810mm

No.2

Pixel

sequence

1 pixel

(1 dot)

B Cell

G

Cell

R Cell

No.1365 No.1366

Pixel

sequence

Pixel

sequence

B GRBG R

BGRBGR

G RBG R

B

GRBGR

B

0.270mm

(Horizontally) Cell pitch

0.810mm (Vertically)

Pixel pitch (Cell pitch)

Fig.1

2.4.1.2 PIXEL DEFECTS

Though PDP is made by means of ultra precise technology, there are cases whereby not all pixels (cell) will function properly. In some

cases, there may be defective pixels that do not light at all or the ones that always light on.

There are 3 types of Pixel defects, [Bright Dot Defects], [Dark Dot Defects] and [Flicker Dot Defects], as defined respectively in the

following:

(1) BRIGHT FAULT

In this pixel fault, a cell that should not light originally is lighting on and off.

For checking this pixel fault, input ALL BLACK SCREEN and find out the cell that is lighting on and off.

(2) DARK FAULT

In this pixel fault, a cell that should light originally is not lighting or lighting with the brightness twice as brighter as originally lighting.

For checking this pixel fault, input 100% of each R/G/B colour and find out the cell that is not lighting.

(3) FLICKER FAULT

In the pixel fault, a cell that should light originally or not light originally is flashing on and off.

For checking this pixel fault, input ALL BLACK SCREEN signal or 100% of each RGB colour and find out the cell that is flashing on

and off.

(No.YA229)1-7

Page 8

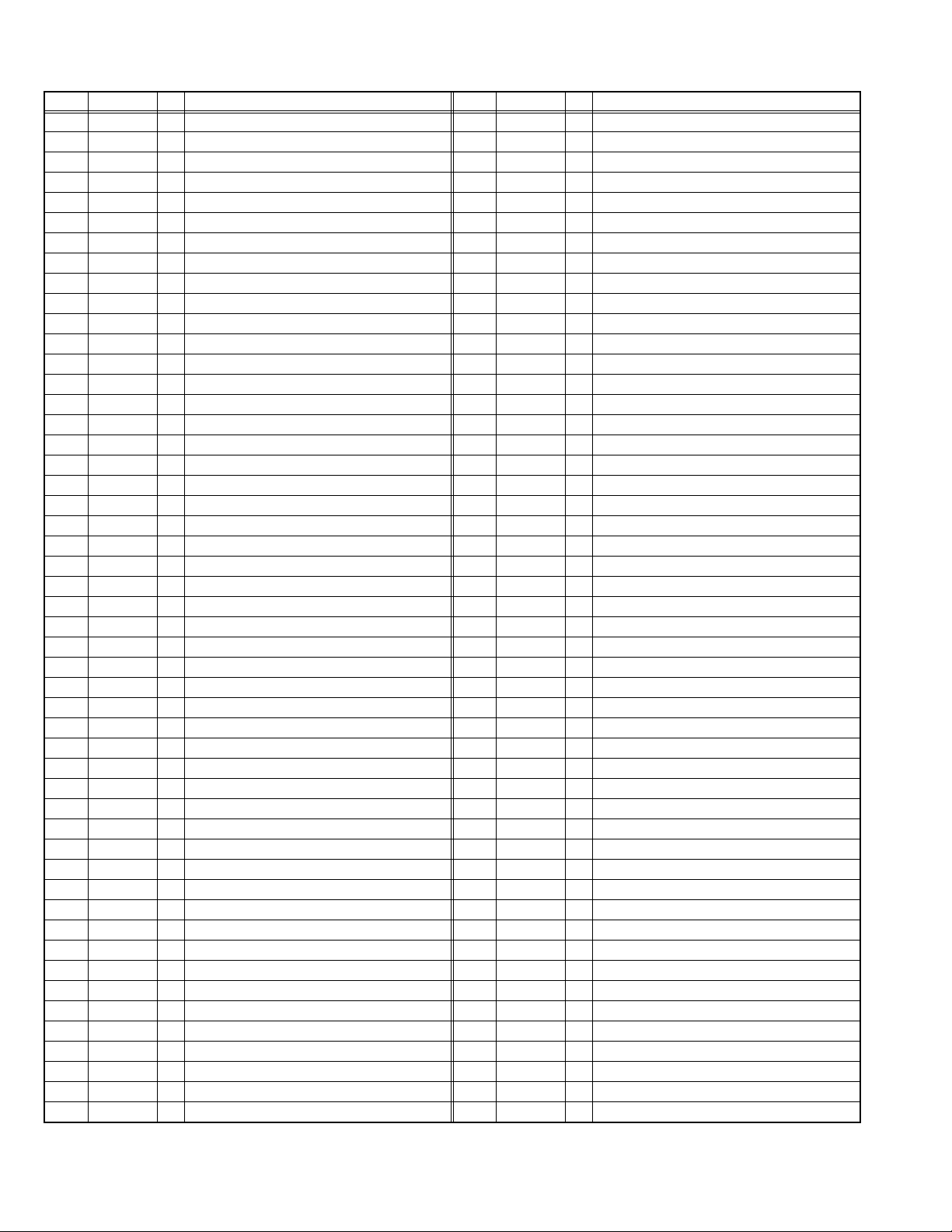

2.4.2 MAIN CPU PIN FUNCTION [IC7601 : DIGITAL SIGNAL PWB ASS'Y / RECEIVER UNIT]

Pin Pin name I/O Function Pin Pin name I/O Function

1 VHOLD1 I Data slice for main screen closed caption 51 NC O Not used

2 HFLT1 I/O LPF for main screen closed caption video input 52 NC O Not used

3 NC O Not used 53 NC O Not used

4 NC O Not used 54 NC O Not used

5 DIGR0 O R [0] for OSD 55 NC O Not used

6 TB1in I AC power for timer clock 56 NC O Not used

7 REMO I Remote control 57 NC O Not used

8 BYTE I Data bus width select [L = 16bit (fixed)] 58 NC O Not used

9 CNVss I CPU programming mode select [Normal = L] 59 NC O Not used

10 DIGG0 O G [0] for OSD 60 NC O Not used

11 DIGB0 O B [0] for OSD 61 NC O Not used

12 RESET I Reset for main CPU [Reset = L] 62 HSYNC I H. sync for OSD

13 Xout O System clock osillation (crystal) : 16MHz 63 NC O Not used

14 Vss - GND 64 VSYNC I V. sync for OSD

15 Xin I System clock osillation (crystal) : 16MHz 65 NC O Not used

16 VccI I 3.3V stand-by power supply 66 NC O Not used

17 OSC1 I Clock for OSD 67 NC O Not used

18 OSC2 O Not used : Clock for OSD 68 NC O Not used

19 INT1 I AV COMPULINK control 69 NC O Not used

20 INT0 I

21 OUT1 O Ys (blanking) for OSD 71 NC O Not used

22 OUT2 O YM (transparence) for OSD 72 NC O Not used

23 NC O Not used 73 NC O Not used

24 NC O Not used 74 NC O Not used

25 NC O Not used 75 NC O Not used

26 NC O Not used 76 NC O Not used

27 CTA2/RTS2 O Not used : Digital tuner control 77 NC O Not used

28 CLK2 O Not used : Digital tuner control 78 NC O Not used

29 RxD2 I Not used : Digital tuner control 79 NC O Not used

30 TxD2 O Not used : Digital tuner control 80 NC O Not used

31 SDA2 I/O Not used 81 NC O Not used

32 DIGR1 O R [1] for OSD 82 NC O Not used

33 DIGG1 O G [1] for OSD 83 NC O Not used

34 DIGB1 O B [1] for OSD 84 WAKE O Reset for sub(chassis) CPU

35 TxD0 I Data receive (serial) for external programming 85 CARD_DET I Not used : Card detection for ATSC digital tuner

36 RxD0 O Data transmission (serial) for external programming 86

37 CLK0 I Clock for external programming 87 NC I/O Data for Inter IC (serial) bus control : memory

38 RTS0 O Busy for external programming [Operation = H] 88 NC O Clock for Inter IC (serial) bus control : memory

39 P5.7 I Not used 89 DIGR2 O R [2] for OSD

40 P5.6 O Not used 90 DIGG2 O G [2] for OSD

41 HOLD I CPU programming mode select [Normal = H] 91 DIGB2 O B [2] for OSD

42 P5.4 O Not used 92 NC O Not used

43 P5.3 O Not used 93 KEY2 I

44 P5.2 O Not used 94 KEY1 I

45 P5.1 O Not used 95 VHOLD2 I Data slice for sub screen closed caption

46 WR O CPU programming mode select [Normal = L] 96 HLF2 I/O LPF for sub screen closed caption video input

47 P4.7 O

48 P4.6 I

49 P4.5 I Clock for sub(chassis) CPU communication (serial) 99 VCCE I 5V stand-by power supply

50 P4.4 O Not used 100 CVIN1 I Video(Y) for main screen closed caption

Request for sub(chassis) CPU communication (serial data)

Data transmission for sub(chassis) CPU communication (serial)

Data receive for sub(chassis) CPU communication (serial)

70 NC O Not used

POWER_SW

97 CVIN2 I Video(Y) for sub screen closed caption

98 TVSETB I Test terminal [L Fixed]

I Not used : Power switch (mechanical) detection

Key scan data for front control button (MENU/CH+/CH-) KEY2

Key scan data for front control button (VOL+/VOL-) KEY1

1-8 (No.YA229)

Page 9

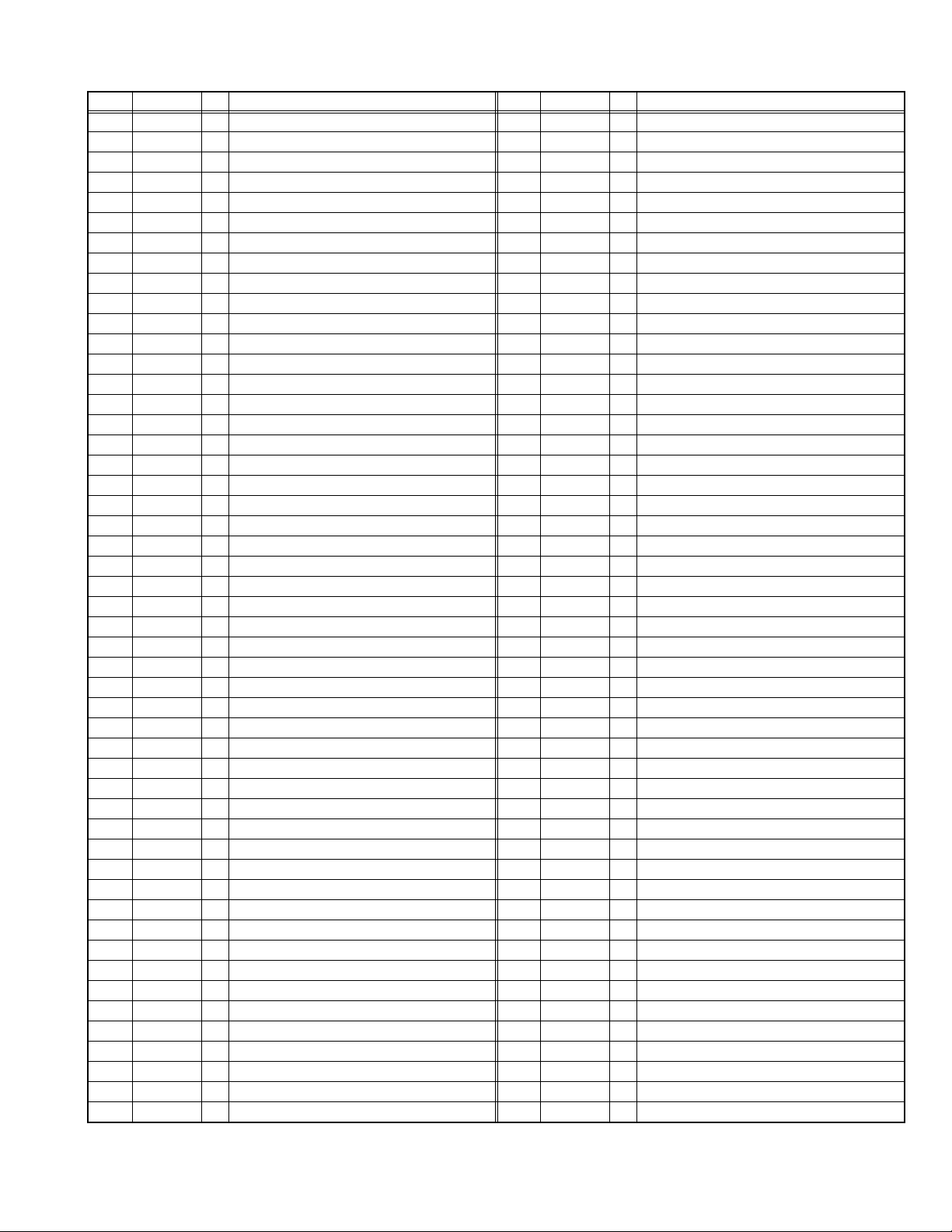

2.4.3 SUB (CHASSIS) CPU PIN FUNCTION [IC7001 : DIGITAL SIGNAL PWB ASS'Y / RECEIVER UNIT]

Pin Pin name I/O Function Pin Pin name I/O Function

1 LB_PRO O Not used 51 BS_TXD O

2 P_MU O Picture muting [Muting = H] 52 BS_RXD I Not used : Data receive for digital tuner communication

3 JP_CSB O Not used (NC) 53 NC O Not used (NC)

4 A_MU O Audio muting [Muting = H] 54 VREF+ I 3.3V power supply

5 M_MU O Audio muting (for AUDIO OUT) [Muting = H] 55 PDP_TX O

6 PC_SEL O Not used : RGB(PC) INPUT select 56 PDP_RX I Data receive for SUB (DRIVE) CPU communication

7 ON_TIMER O POWER INDICATOR (LED) brightness [LOW = L] 57 SDA0 I/O Data for Inter IC (serial) bus : EEP-ROM (IC7002)

8 ILA0 O Not used : LCD back light lighting 58 SCL0 O Clock for Inter IC (serial) bus : EEP-ROM (IC7002)

9 ILA1 O Not used : LCD panel overshoot refresh timing 59 SDA_DVI I/O Data for Inter IC (serial) bus for panel communication

10 ILA2 O Not used 60 SCL_DVI O Clock for Inter IC (serial) bus for panel communication

11 POW_LED O POWER LED lighting [ON = H] 61 AVSS - GND

12 WORD O Not used 62 DIGII_PHOT I Photo sensor for DIGITAL-IN illegal copy protection

13 MI_CK I Clock for SUB (OSD) CPU communication 63 AGC I Not used

14 MI_TX I Data receive for SUB (OSD) CPU communication 64 EXT_YS1 I Not used

15 MI_RX O Data transmission for SUB (OSD) CPU communication 65 EXT_YS2 I Not used

16 MI_REQ O

17 VDD I 3.3V power supply 67 DIGI_PRO O for DIGITAL-IN (HDMI)

18 FOSC O Not used (NC) 68 GCR_RST O Not used (NC)

19 VSS - GND 69 GR_ON O Not used (NC)

20 X1 I Not used : Low speed oscillatior 70 SYNC_SEL O Not used : Sync select for digital tuner

21 X0 O Not used : Low speed oscillatior 71 NC O Not used (NC)

22 VDD I 3.3V power supply 72 NC O Not used (NC)

23 OSC1 I System clock osillation (crystal) : 16MHz 73 SBD5 I/O

24 OSC0 O System clock osillation (crystal) : 16MHz 74 SBT5 I

25 MODE I Single chip mode 75 NMI I 3.3V power supply

26 BS1.5CTL O Not used : Digital tuner power / reset control 76 COMP I AV COMPULINK lll control

27 A92RES O

28 BS_RST O Not used: Reset for Digital tuner power / reset control 78 VSYNC I V. sync pulse

29 LIP_RST O Not used: Reset for Sound delay (Lip sync) 79 WAKE I Reset for sub(chassis) CPU

30 SOFT_OFF O Not used 80

31 VMUTE I No use : Picture muting request from digital tuner 81 NC O Not used (NC)

32 VOUTENB O No use : Video cutoff for digital tuner 82 RST I Reset for MAIN CPU [Reset = L]

33 MDR_CON I System cable connection monitor for PDP 83 VDD I 3.3V power supply

34 AVDD I 3.3V power supply 84 SCL3A O Clock for Inter IC (serial) bus control

35 BS_POW O Not used : Digital tuner power control 85 SDA3A I/O Data for Inter IC (serial) bus control

DsyncSW2

36

37 LB_POW O Not used : Power control for low bias line 87 SDA3B I/O Data for Inter IC (serial) bus control

38 NC O Not used (NC) 88

39 HOTPLUG I Video communiation monitor for receiver unit (PDP) 89 DIGI_LRSW O For DIGITAL-IN (HDMI)

40 MECA_SW I Mechanical monitor for POWER switch [Push = L] 90 DIGI_INT I Reset for HDMI process [Reset = L ]

41 MAIN_POW O Main power control [ON = L] 91 DVI_RST O Reset for DVI format conversion

42 MSP_RST O AUDIO OUT output mode select [VARIABLE = L] 92 VSS - GND

43 VREF- I Not used 93 SCL5055 O

44 AFT2 I Not used : AFT voltage for sub tuner 94

45 AFT1 I AFT voltage for VHF/UHF tuner 95 SDA5055 I/O Data for Inter IC (serial) bus : JCC5055 (DIST process)

46 KEY2 I Key scan data for front switch (MENU/CH+/CH-) 96

47 KEY1 I Key scan data for front switch (VOL+/VOL-) 97 NC O Not used (NC)

48 NC O Not used (NC) 98 15K/OTH O Main video select [Fixed H]

49 NC O Not used (NC) 99 DsyncSW1 O Sync select for DIGITAL-IN [Cotrolled with 36-pin]

50 AC_IN I AC power pulse for timer clock 100 57 BUSY I Busy monitor for JCC5057 (New DIST process)

Data request for SUB (OSD) CPU communication [Request = L]

Reset for IC1001(3D YC SEP / COLOR DEMODULAT) [Reset = H]

O Sync select for DIGITAL-IN [Cotrolled with 99-pin] 86 SCL3B O Clock for Inter IC (serial) bus control

66 VDD I 3.3V power supply

77 REMO I Remote control

POWERGOOD

DIGI_SYNCSEL

VFORMATSEL

OSD_MODE_SEL

Not used : Data transmission for digital tuner communication

Data transmission for SUB (DRIVE) CPU communication

Not used : Data for writing on board (connect CN01P : for Frash ROM type)

Not used : Clock for writing on board (connect CN01P : for Frash ROM type)

I Power error detection [NG = H]

O Not used

Clock for Inter IC (serial) bus : JCC5055 (DIST process)

O Not used : Digital tuner clock control

O Not used : OSD mode select

(No.YA229)1-9

Page 10

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE (DISPLAY UNIT)

NOTE:

• When exchanging parts etc. with the front side (PDP side) fancing down, place a protection sheet under the DISPALY UNIT to

prevent scratches on the front side.

• It is advisable to take notes of the connecting locations (connector numbers) of the removed connectors.

3.1.1 REMOVING THE REAR COVER (Fig.1)

(1) Remove the power cord and the system cable.

(2) Remove the 11 screws [A] and the 14 screws [B], then

remove the REAR COVER.

3.1.2 REMOVING THE BACK COVER AND SPEAKER

HOLDER (Fig.1)

(1) Remove the 8 screws [C], then remove the BACK COVER.

(2) Remove the SPEAKER HOLDER.

3.1.3 REMOVING THE CHASSIS SHIELD BRACKET NAD

THE TERMINAL COVER (Fig.1)

• Remove the REAR COVER.

(1) Remove the 6 screws [D], then remove the CHASSIS

SHIELD BRACKET.

(2) Remove the 2 screws [E] and the 5 screws [F], then

remove the TERMINAL COVER.

3.1.4 REMOVING THE LINE FILTER PWB (Fig.1)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

(1) Remove the 2 claws [G], then remove the LINE FILTER

INSULATOR.

(2) Disconnect the connector [CN8001

POWER UNIT.

(3) Remove the 2 screws [H] and the 1 screw [I], then remove

the LINE FILTER PWB.

] from the MAIN

3.1.6 REMOVING THE DISPLAY INTERFACE PWB (Fig.1)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

(1) Disconnect the connector [CN00A

[CN00E] / [CN00G] / [CN00Q] / [CN00T] / [CN00X] /

[CN00V

DISPLAY INTERFACE PWB .

(2) Remove the 3 screws [K], the 2 screws [L] and the 2 screws

[M] , then remove the DISPLAY INTERFACE PWB.

3.1.7 REMOVING THE CHASSIS BASE (Fig.1)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

• Remove the LINE FILTER PWB.

• Remove the AUDIO PWB.

• Remove the DISPLAY INTERFACE PWB.

(1) Remove the 2 screws [N], then remove the CHASSIS

BASE.

] / [CN0FL] / [CN0FR] / [CN601] / [CNAH1] from the

] / [CN00C] / [CN00D] /

3.1.5 REMOVING THE AUDIO PWB (Fig.1.)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

(1) Disconnect the connector [CN60SL

[CN60SR

(2) Disconnect the connector [CN9001] from the SUB POWER

PWB.

(3) Disconnect the connector [CN00A

from the DISPLAY INTERFACE PWB.

(4) Remove the 4 screws [J], then remove the AUDIO PWB.

1-10 (No.YA229)

] from the AUDIO PWB .

] / [CN60CB] /

] / [CN00C] / [CN00D]

Page 11

C

B

BACK COVER

A

A

REAR COVER

C

G

BACK COVER

CHASSIS SHIELD

BRACKET

DISPLAY

INTERFACE PWB

D

K

N

AUDIO PWB

J

CHASSIS BASE

G

LINE FILTER

INSULATOR

H

I

LINE FILTER

PWB

N

TERMINAL

COVER

F

M

L

F

E

E

F

F

SPEAKER HOLDER

SPEAKER HOLDER

Fig.1

(No.YA229)1-11

Page 12

3.1.8 REMOVING THE TEMP. SENSOR PWB (Fig.2)

• Remove the REAR COVER.

(1) Disconnect the connector [CN800V

SENSOR PWB PWB .

(2) Remove the 1 screw [O], then remove the TEMP.

SENSOR PWB.

3.1.9 REMOVING THE MAIN POWER UNIT (Fig.2)

• Remove the REAR COVER.

(1) Disconnect the connector [CN805

[CN8009

UNIT .

(2) Remove the 8 screws [P], then remove the MAIN POWER

UNIT.

3.1.10 REMOVING THE SUB POWER PWB (Fig.2)

• Remove the REAR COVER.

(1) Disconnect the connector [CN9001

from the SUB POWER PWB .

(2) Remove the 4 screws [Q], then remove the SUB POWER

PWB.

3.1.11 REMOVING THE COOLING FAN (Fig.2)

• Remove the REAR COVER.

(1) Disconnect the connector [CN0FL

DISPLAY INTERFACE PWB .

(2) Remove the 4 screws [R], then remove the FAN

BRACKET by lifting upward.

(3) Remove the 4 screws [S], then remove the COOLING FAN

by pulling in hte arrowed direction.

3.1.12 REMOVING THE POWER CHASSIS BASE (Fig.2)

• Remove the REAR COVER.

• Remove the MAIN POWER UNIT.

• Remove the SUB POWER PWB.

• Remove the COOLING FAN.

(1) Remove the 5 screws [T], then remove the POWER

CHASSIS BASE.

3.1.13 REMOVING THE DISPLAY SWITCH PWB (Fig.2)

• Remove the BACK COVER.

• Remove the SPEAKER HOLDER.

(1) Remove the 2 screws [U], then remove the CONTROL

KNOB.

(2) Remove the 3 screws [V], then remove the DISPLAY

SWITCH PWB.

(3) Disconnect the connector [CN000T

SWITCH PWB .

] / [CN8011] / [CN9001] from the MAIN POWER

] from the TEMP.

] / [CN806] / [CN8001] /

] / [CN9002] / [CN9005]

] / [CN0FR] from the

] from the DISPLAY

3.1.14 REMOVING THE DISPLAY LED PWB (Fig.2)

• Remove the BACK COVER.

• Remove the SPEAKER HOLDER.

• Remove the DISPLAY SWITCH PWB.

(1) Remove the 2 screws [W], then remove the DISPLAY LED

PWB.

(2) Disconnect the connector [CN000X

LED PWB .

3.1.15 REMOVING THE DD SPEAKER (Fig.2)

• Remove the REAR COVER.

• Remove the BACK COVER.

• Remove the SPEAKER HOLDER.

(1) Disconnect the connector [CN60SR

AUDIO PWB .

(2) Remove the 4 screws [X], then remove the DD SPEAKER.

3.1.16 REMOVING THE WOOFER SPEAKER (Fig.2)

• Remove the REAR COVER.

(1) Disconnect the connector [CN60CB

PWB.

(2) Remove the 6 screws [Y], then remove the WOOFER

SPEAKER UNIT.

(3) Remove the 14 screws [Z], then remove the WOOFER

BACK COVER.

(4) Remove the 8 screws [A'], then remove the WOOFER

SPEAKER.

3.1.17 REMOVING THE PDP (PANEL) UNIT (Fig.2)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

• Remove the CHASSIS BASE (with each PWB affixed on the

CHASSIS BASE).

• Remove the POWER CHASSIS BASE (with each PWB affixed

on the CHASSIS BASE).

• Remove the TEMP. SENSOR.

(1) Remove the 8 screws [B'] and the 8 screws [C'], then

remove the BACK BRACKET.

(2) Remove the 4 screws [D'] then Lift the PDP straight

upward and remove it with extra attention no to impose any

shock to the PDP.

CAUTION:

• More than two people are required to remove the PDP unit.

• The gas pouring port is covered with the protection material.

Durring the operation, be careful not to damage the gas

pouring port.

• Do not touch the front side (glass) of the PDP with your

fingers.

] from the DISPLAY

] / [CN60SL] from the

] from the AUDIO

1-12 (No.YA229)

Page 13

P

B'

MAIN POWER UNIT

SUB POWER PWB

C'

PDP (PANEL) UNIT

D'

C'

Q

T

POWER CHASSIS PWB

B'

TEMP. SENSOR PWB

R

FAN BRACKET

COOLING FAN

S

S

T

C'

B'

C'

D'

O

BACK BRACKET

B'

D'

GAS insertion

hole

DISPLAY SWITCH PWB

U

CONTROL KNOB

X

D'

X

LED PWB

W

DD SPEAKER

DD SPEAKER

DISPLAY

Z

V

Z

Y

A'

WOOFER

SPEAKER

WOOFER

BACK

COVER

A'

WOOFER

SPEAKER

Fig.2

WOOFER SPEAKER HOLDER

(No.YA229)1-13

Page 14

3.1.18 REMOVING THE PWB IN PDP UNIT

3.1.18.1 REMOVING THE X LEFT TOP PWB (Fig.3)

• Remove the PDP UNIT.

(1) Disconnect the connector [P4

] / [P5] / [P501] / [P502] /

[P503] / [P504] from the X-LEFT TOP PWB .

(2) Remove the 2 screws [a] and the 1 screw [b], then remove

the X LEFT TOP PWB.

3.1.18.2 REMOVING THE X CENTER TOP PWB (Fig.3)

• Remove the PDP UNIT.

(1)

Disconnect the connector [P5] / [P6] / [

/ [

P506

] / [

P507

] / [

P508

] from the X-CENTER TOP PWB .

P10

] / [

P100

] / [

(2) Remove the 1 screw [b] and the 2 screws [c], then remove

the X CENTER TOP PWB.

3.1.18.3 REMOVING THE X RIGHT TOP PWB (Fig.3)

• Remove the PDP UNIT.

(1) Disconnect the connectors [P1

] / [P511] from the X-RIGHT TOP PWB .

[P510

(2)

Remove the 2 screws

[d]

, then remove the X RIGHT TOP PWB

] / [P4] / [P5] / [P6] / [P509] /

3.1.18.4 REMOVING THE Z SUS PWB (Fig.3)

• Remove the PDP UNIT.

(1) Disconnect the connectors [P1

[P9

] / [P12] from the Z SUS PWB .

] / [P2] / [P3] / [P5] / [P6] /

(2) Remove the 9 screws [e], then remove the Z SUS PWB.

3.1.18.5 REMOVING THE LVDS CONTROL PWB (Fig.3)

• Remove the PDP UNIT.

(1) Disconnect the connectors [P3

[P103

] / [P104] / [P105] / [P106] / [P200] / [P201] / [P300]

] / [P6] / [P101] / [P102] /

from the LVDS CONTROL PWB .

(2) Remove the 4 screws [f], then remove the LVDS

CONTROL PWB.

3.1.18.6 REMOVING THE Y SUS PWB (Fig.3)

• Remove the PDP UNIT.

(1) Disconnect the connectors [1

/ [P9

] / [P11] from the Y SUS PWB .

] / [P2] / [P3] / [P4] / [P5] / [P7]

(2) Remove the 8 screws [g], then remove the Y SUS PWB.

P505

3.1.18.7 REMOVING THE Y DRIVE UPPER PWB (Fig.3)

• Remove the PDP UNIT.

(1)

Disconnect the connectors [P2] / [

P10

] from the Y-SUB PWB .

(2) Disconnect the connector [P6] / [P7] / [P8] / [P9] / [P10] /

[P12

] / [P13] from the Y-DRIVE UPPER PWB .

(3) Remove the 2 screws [h], then remove the Y DRIVE

UPPER PWB.

3.1.18.8 REMOVING THE Y DRIVE LOWER PWB (Fig.3)

• Remove the PDP UNIT.

]

(1)

Disconnect the connector [P2] / [

P10

] from the Y-SUB PWB .

(2) Disconnect the connector [P1] / [P2] / [P3] / [P4] / [P5] /

[P11

] from the Y-DRIVE LOWER PWB .

(3) Remove the 2 screws [i], then remove the Y DRIVE

LOWER PWB.

3.1.18.9 REMOVING THE X RIGHT BOTTOM PWB (Fig.3)

• Remove the PDP UNIT.

.

(1) Disconnect the connector [P2

/ [P403

] from the X-RIGHT BOTTOM PWB .

] / [P3] /[P7] / [P401] / [P402]

(2) Remove the 2 screws [j], then remove the X RIGHT

BOTTOM PWB.

3.1.18.10 REMOVING THE X CENTER BOTTOM PWB (Fig.3)

• Remove the PDP UNIT.

Disconnect the connectors [P1] / [P4] / [P7] / [

(1)

/ [

P407

] / [

P408

] / [

P425

] from the X-CENTER BOTTOM

P405

PWB.

(2) Remove the 2 screws [k] and the 1screw [k], then remove

the X CENTER BOTTOM PWB.

3.1.18.11 REMOVING THE X LEFT BOTTOM PWB (Fig.3)

• Remove the PDP UNIT.

(1) Disconnect the connectors [P1

[P403

] / [P404] from the X LEFT BOTTOM PWB .

] / [P2] / [P401] / [P402] /

(2) Remove the 1 screw [m] and the 2 screws [n], then remove

the X-LEFT BOTTOM PWB.

] / [

P406

]

X LEFT TOP PWB

h

Y DRIVER UPPER PWB

Y SUS PWB

X CENTER TOP PWB

c

a

g

i

g

Y DRIVER LOWER PWB

X RIGHT TOP PWB

f

c

LVDS CONTROL PWB

X LEFT BOTTOM PWB

Fig.3

d e

m

n

e

Z-SUS PWB

j

X RIGHT BOTTOM PWB

k

X CENTER BOTTOM PWB

1-14 (No.YA229)

Page 15

3.1.19 REMOVING THE FRONT FILTER (Fig.4)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

• Remove the CHASSIS BASE (with each PWB affixed on the

CHASSIS BASE).

• Remove the POWER CHASSIS BASE (with each PWB affixed

on the CHASSIS BASE).

• Remove the TEMP. SENSOR.

• Remove the PDP UNIT.

(1) Remove the 12 screws [u], then remove the FILTER

BRACKET.

(2) Remove the FRONT FILTER with enough care not to

damage it.

3.1.20 REMOVING THE TOP FRAME BRACKET, BOTTOM

FRAME BRACKET AND SIDE FRAME BRACKET (Fig.4)

• Remove the REAR COVER.

• Remove the CHASSIS SHIELD BRACKET.

• Remove the TERMINAL COVER.

• Remove the CHASSIS BASE (with each PWB affixed on the

CHASSIS BASE).

• Remove the POWER CHASSIS BASE (with each PWB affixed

on the CHASSIS BASE).

• Remove the TEMP. SENSOR.

• Remove the PDP UNIT.

• Remove the FRONT FILTER.

Remove the 6 screws

(1)

[v], then remove

the FRONT PANEL.

(2) Remove the 8 screws [w], then remove the SPACER.

(3) Remove the 4 screws [x], then remove the TOP FRAME

BRACKET, BOTTOM FRAME BRACKET and SIDE

FRAME BRACKET.

FILTER BRACKET

SIDE FRAME

u

SPACER

w

v

w

x

v

w

SIDE FRAME

TOP FRAME

w

BOTTOM FRAME

v

u

x

v

FILTER BRACKET

FRONT FILTER

Fig.4

FRONT PANEL

(No.YA229)1-15

Page 16

3.2 DISASSEMBLY PROCEDURE (RECEIVER UNIT)

CAUTION AT DISASSEMBLY:

• Be sure to perform the SYSTEM SETTING on the page 1-6, at the end of the procedure.

• Make sure that the power cord is disconnected from the outlet.

• Pay special attention not to break or damage the parts.

• When removing each board, remove the connectors as required. Taking notes of the connecting points (connector numbers)

makes service procedure manageable.

• Make sure that there is no bent or stain on the connectors before inserting, and firmly insert the connectors.

3.2.1 REMOVING THE TOP COVER

(1) Remove the 9 screws [A] then remove the TOP COVER.

3.2.2 REMOVING THE FRONT PANEL

• Remove the TOP COVER.

(1) Remove the 3 screws [B] and the 1 screw [C].

(2) Remove the 3 claws [D] and the 2 claws [E].

(3) Remove the FRONT PANEL toward you.

3.2.3 REMOVING THE FRONT CONTROL PWB

• Remove the TOP COVER.

• Remove the FRONT PANEL.

(1) Remove the [CN00F]

PWB.

(2) Remove the 4 screws [F], then remove the FRONT

CONTROL PWB.

3.2.4 REMOVING THE REAR COVER

• Remove the TOP COVER.

(1) Remove the 10 screws [G], the 2 screws [K], the 2 screws

[L] , the 2 screws [M] and 1 screw [N].

(2) Remove the REAR COVER toward you.

connector on the ANALOG SIGNAL

3.2.7 REMOVING THE DIGITAL SIGNAL PWB

• Remove the TOP COVER.

• Remove the REAR COVER.

(1) Remove the [CN001]

SIGNAL PWB.

(2) Remove the [CN003]

PWB.

(3) Remove the 4 screws [T], then remove the TUNER

HOLDER.

(4) Remove the 4 screws [U], then remove the DIGITAL

SIGNAL PWB.

CAUTION:

Make sure to perform the "SYSTEM SETTING" on page 1-6,

when DIGITAL SIGNAL PWB is replaced.

3.2.8 REMOVING THE REGULATOR PWB

• Remove the TOP COVER.

• Remove the FRONT PANEL.

(1) Remove the [CN00D]

PWB.

(2) Remove the [CN003]

REGULATOR PWB.

(3) Remove the 4 screws [V], then remove the REGULATOR

PWB.

/ [CN002] connectors on the ANLOG

connector on the REGULATOR

connector on the ANLOG SIGNAL

and [CN00B] connector on the

3.2.5 REMOVING THE RECEIVER PWB

• Remove the TOP COVER.

• Remove the REAR COVER.

(1) Remove the [CN00A]

RECEIVER PWB.

(2) Remove the RECEIVER PWB.

3.2.6 REMOVING THE REAR JACK PWB

• Remove the TOP COVER.

• Remove the REAR COVER.

(1) Remove the [CNJ0J1]

ANLOG SIGNAL PWB.

(2) Remove the 2 screws [S], then remove the REAR JACK

PWB.

/ [CN00T] connectors on the

/ [CNJ0J2] connectors on the

3.2.9 REMOVING THE SYSTEM POWER PWB

• Remove the TOP COVER.

(1) Remove the [CN00G]

SIGNAL PWB.

(2) Remove the [CN00B]

PWB.

(3) Remove the [CN00Q]

SYSTEM POWER PWB.

(4) Remove the 7 screws [W], then remove the SYSTEM

POWER PWB.

3.2.10 REMOVING THE ANLOG SYGNAL PWB

• Remove the TOP COVER.

• Remove the REAR COVER.

• Remove the RECEIVER PWB.

(1) Remove the [CN001]

[CN00G] / [CN00K] / [CNJ0J1] / [CNJ0J2] connector on the

ANLOG SIGNAL PWB.

(2) Remove the 2 screws [X], then remove the ANLOG

SYGNAL PWB.

/ [CN00K] connector on the ANLOG

connector on the REGULATOR

/ [CN0PW] connector on the

/ [CN002] / [CN00D] / [CN00F] /

1-16 (No.YA229)

Page 17

TOP COVER

a

A

A

C

FRONT PANEL

b

T

A

DIGITAL HOLDER

RECEIVER PWB

DIGITAL SIGNAL PWB

c

d

X

Y

Y

V

U

SYSTEM POWER PWB

REGULATOR PWB

B

D

E

ANALOG SIGNAL

PWB

F

f

REAR JACK PWB

d

D

D

E

FRONT CONTROL PWB

c

Y

f

a

S

G

G

REAR COVER

N

K

b

L

M

M

Fig.9

(No.YA229)1-17

Page 18

3.3 MEMORY IC REPLACEMENT

S001 PREPARE 0

PAL50 FULL STD M

1.ADJUST

2.SELF_CHK

3.I2C STOP

SERVICE MENU

• This model uses the memory IC.

• This memory IC stores data for proper operation of the video and drive circuits.

• When replacing, be sure to use an IC containing this (initial value) data.

3.3.1 MEMORY IC REPLACEMENT PROCEDURE

1. Power off

Switch off the power and disconnect the power plug from the AC outlet.

2. Replace the memory IC

Be sure to use the memory IC written with the initial setting values.

3. Power on

Connect the power plug to the AC outlet and switch on the power.

4. Receiving channel setting

Refer to the OPERATING INSTRUCTIONS and set the receive channels (Channels Preset) as described.

5. User setting

Check the user setting items according to the given in page later. Where these do not agree, refer to the OPERATING

INSTRUCTIONS and set the items as described.

6. SERVICE MODE setting

Verify what to set in the SERVICE MODE, and set whatever is necessary (Fig.1). Refer to the SERVICE ADJUSTMENT for setting.

3.3.2 SERVICE MODE SETTING

SERVICE MODE SCREEN

MAIN MENU SCREEN

SETTING ITEM

Setting items Settings Item No.

Video system setting Adjust S001 - S039

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

Audio system setting Fixed T001 - T010

Panel control system setting Fixed P001 - P010

Drive system setting Fixed D001 - D187

Main CPU system setting Fixed Z001 - Z010

ADJUSTMENT MODE SCREEN

S001 PREPARE 0

PAL50 FULL STD M

Fig.1

1-18 (No.YA229)

Page 19

3.3.3 SETTINGS OF FACTORY SHIPMENT

3.3.3.1 BUTTON OPERATION 3.3.3.2 REMOTE CONTROL DIRECT OPERATION

Setting item Setting position

POWER Off

CHANNEL PR1

VOLUME 10

TV/AV TV

3.3.3.3 REMOTE CONTROL MENU OPERATION

(1) PICTURE

Setting item Setting position

PICTURE MODE STANDARD

WHITE BALANCE MID

FEATURES

DIGITAL VNR AUTO (HIGH)

Super DigiPure AUTO

PULL DOWN AUTO

COLOUR MANAGEMENT ON

PICTURE MANAGEMENT ON

COLOUR SYSTEM MAIN Depends on PR/CH

SUB AUTO

4:3 AUTO ASPECT PANORAMIC

(2) SOUND

Setting item Setting position

STEREO / I•II Stereo sound

BASS Centre

TREBLE Centre

BALANCE Centre

CINEMA SURROUND OFF

A.H.B. ON

BBE ON

SPEAKER TV

CHANNEL PR1

VOLUME 10

ZOOM PANORAMIC

CINEMA OFF

(4) FEATURES

SLEEP TIMER OFF

APPEARANCE TYPE D

BLUE BACK ON

CHILD LOCK ID NO.0000, All CH off

AUTO SHUTOFF OFF

FAVOURITE SETTING RESET

(5) SET UP

AUTO PROGRAM TV channel automatically set

EDIT/MANUAL PRESET CH only

LANGUAGE ENGLISH

VIDEO-1 SETTING COMPONENT

VIDEO-3 SETTING COMPONENT

AI VOLUME ON

TELETEXT LANGUAGE GROUP-1

PICTURE SHIFT FAST

HDMI SETTING SIZE 1

Setting item Setting position

Setting item Setting position

Setting item Setting position

AUDIO DIGITAL

(No.YA229)1-19

Page 20

3.4 REPLACEMENT OF CHIP COMPONENT

3.4.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.4.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.4.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-20 (No.YA229)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 21

SECTION 4

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

S001 PREPARE 0

PAL50 FULL STD H

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) There are 2 ways of adjusting this TV : One is with the

REMOTE CONTROL UNIT and the other is the

conventional method using adjustment parts and

components.

(2) The adjustment using the REMOTE CONTROL UNIT is

made on the basis of the initial setting values. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting

values.

(3) Make sure that connection is correctly made AC to AC

power source.

(4) Turn on the power of the TV and measuring instruments for

warming up for at least 30 minutes before starting

adjustments.

(5) If the receive or input signal is not specified, use the most

appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors,

transformers and condensers) not shown in the adjustment

items of this service adjustment.

4.2 PRESET SETTING BEFORE ADJUSTMENTS

Unless otherwise specified in the adjustment items, preset the

following functions with the REMOTE CONTROL UNIT.

Setting item Settings position

PICTURE MODE STANDARD

PICTURE adjustments Centre

WHITE BALANCE MID

DIGITAL VNR MIN

Super DigiPure AUTO

PULL DOWN AUTO

COLOUR MANAGEMENT ON

PICTURE MANAGEMENT ON

SOUND adjustments Centre

BBE OFF

CINEMA SORROUND OFF

A.H.B OFF

ZOOM FULL

4.3 MEASURING INSTRUMENT AND FIXTURES

• Oscilloscope

• Signal generator (Pattern generator)

[PAL / 625i / 625p / 1125i(50Hz)]

• Remote control unit

4.4 ADJUSTMENT ITEMS

POWER CIRCUIT [DISPLAY UNIT]

• PDP POWER VOLTAGE adjustment

VIDEO CIRCUIT [RECEIVER UNIT]

• 625i A-D OFFSET adjustment

• 1125i(50Hz) BRIGHTNESS adjustment

• 1125i(50Hz) A-D OFFSET adjustment

• SUB SCREEN A-D OFFSET adjustment

• WHITE BALANCE (HIGH LIGHT) adjustment

4.5 BASIC OPERATION OF SERVICE MODE

4.5.1 HOW TO ENTER THE SERVICE MODE

(1) Press [DISPLAY] key and [MUTING] key on the remote

control unit simultaneously to enter the SERVICE MODE

SCREEN.

(2) In the SERVICE MENU, press the [1] key to display

ADJUSTMENT MODE SCREEN.

NOTE:

• Before entering the SERVICE MODE, confirm that the

setting of PIP/TV/DVD switch is at the "TV" side. If the

switches have not been properly set, you cannot enter the

SERVICE MODE.

• When a number key other than the [1] to [3] key is pressed

in the SERVICE MODE SCREEN, the other relevant screen

may be displayed.

This is not used in the adjustment procedure. Press the

[MENU] key to return to the SERVICE MODE SCREEN.

SERVICE MODE SCREEN

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

ADJUSTMENT MODE SCREEN

S001 PREPARE 0

PAL50 FULL STD H

4.5.2 HOW TO EXIT THE SERVICE MODE

Press the [MENU] key to exit the Service mode.

(No.YA229)1-21

Page 22

4.5.3 DESCRIPTION OF STATUS DISPLAY

S0010000 PREPARE 0

PAL50000 FULL STD M

SETTING VALUE (DATA)SETTINGITEM No. SETTING ITEM

S0010000 PREPARE 0

PAL50000 FULL STD M

SIGNAL SYSTEM

ZOOM MODE

PICTURE MODE

COLOUR TEMP.

(1) SIGNAL SYSTEM

The signal displayed on the screen is displayed.

PAL50 : PAL50Hz (Composite / S-video)

PAL60 : PAL60Hz (Composite / S-video)

SECAM : SECAM

NTSC3 : NTSC3.58

NTSC4 : NTSC4.43

525I : 525i (Component)

525P : 525p

625I : 625i (Component)

625P : 625p

1125I5 : 1125i 50Hz

1125I6 : 1125i 60Hz

PCVGA : PC (VGA)

PCXGA : PC (XGA)

H525I : HDMI 525i

H525P : HDMI 525p

H625I : HDMI 625i

H625P : HDMI 625p

H750P : HDMI 750p

H125I5 : HDMI 1125i 50Hz

H125I6 : HDMI 1125i 60Hz

(2) ZOOM MODE

State of the SCREEN SIZE or MULTI PICTURE is displayed.

SINGLE SCREEN

FULL : FULL

PANO : PANORAMIC

1609 : 16:9 ZOOM

1609S : 16:9 ZOOM SUBTITLE

1409 : 14:9 ZOOM

REGU : REGULAR

(5) SETTING ITEM NAME

Setting item name are displayed. The setting item numbers to

be displayed are listed below.

Item No. Setting item

S001 - S039 Video system setting

T001 - T010 Audio system setting

P001 - P010 Panel control system setting

D001 - D187 Drive system setting

Z001 - Z010 Main CPU system setting

(6) SETTING ITEM NO.

Setting item numbers are displayed. For the setting item

names to be displayed, refer to "INITIAL SETTING VALUES

IN THE SERVICE MODE".

(7) SETTING VALUE (DATA)

The SETTING VALUE is displayed.

4.5.4 CHANGE AND MEMORY OF SETTING VALUE

SELECTION OF SETTING ITEM

• [FUNCTION /] key.

For scrolling up / down the setting items.

S001... ↔ T001... ↔ P001... ↔ D001... ↔ Z001...

CHANGE OF SETTING VALUE (DATA)

• [FUNCTION /] key.

For scrolling up / down the setting values.

MEMORY OF SETTING VALUE (DATA)

Changed setting value is memorized by pressing [MUTING]

key.

4.5.5 SERVICE MODE SELECT KEY LOCATION

MUTING

NUMBER

PIP/TV/DVD

switch

ZOOM

FUNCTION /

CINEMA

MENU

FUNCTION /

DISPLAY

MULTI SCREEN

M2 : 2-pictures multi

M12 : 12-pictures multi

(3) PICTURE MODE

STD : STANDARD

BRI : BRIGHT

SOFT : SOFT

(4) WHITE BALANCE

L: WARM

H : MID, COOL

1-22 (No.YA229)

Page 23

4.6 INITIAL SETTING VALUES IN THE SERVICE MODE

• Perform fine-tuning based on the "initial values" using the remote control when in the Service mode.

• The "initial values" serve only as an indication rough standard and therefore the values with which optimal display can be achieved

may be different from the default values. But, don't change the values that are not written in "ADJUSTMENT PROCEDURE". They

are fixed values.

4.6.1 VIDEO SYSTEM SETTING 4.6.2 AUDIO SYSTEM SETTING (*Fixed values)

Item

S001 PREPARE 0 - 31 0 0 0

S002 NTSC BL 0 - 15 0 0 0

S003 NTSC CNT 0 - 255 39 39 39

S004 NT CR OF 0 - 15 7 7 7

S005 NT CB OF 0 - 15 7 7 7

S006 525i BL 0 - 15 0 0 0

S007 525i CNT 0 - 255 39 39 39

S008 5i CB OF 0 - 15 0 0 0

S009 5i CR OF 0 - 15 0 0 0

S010 5i CR GN 0 - 15 7 7 7

S011 5i CB GN 0 - 15 7 7 7

S012 HD BL 0 - 63 54 54 54

S013 HD CB OF 0 - 63 52 52 52

S014 HD CR OF 0 - 63 55 55 55

S015 RT CONT 0 - 15 7 7 7

S016 RT CB OF 0 - 15 2 2 2

S017 RT CR OF 0 - 15 5 5 5

S018 RT CL GA 0 - 15 4 4 4

S019 PC CL MB 0 - 7 0 0 0

S020 PC CL LB 0 - 31 0 0 0

S021 PC CL MR 0 - 71 0 0 0

S022 PC CL LR 0 - 31 0 0 0

S023 (Not display) 0 - 255 0 0 0

S024 (Not display) 0 - 255 0 0 0

S025 (Not display) 0 - 255 0 0 0

S026 (Not display) 0 - 255 0 0 0

S027 (Not display) 0 - 255 0 0 0

S028 (Not display) 0 - 255 0 0 0

S029 (Not display) 0 - 255 0 0 0

S030 R DRIVE 0 - 255 104 104 104

S031 G DRIVE 0 - 255 133 133 133

S032 B DRIVE 0 - 255 130 130 130

S033 (Not display) 0 - 255 0 0 0

S034 (Not display) 0 - 255 0 0 0

S035 (Not display) 0 - 255 0 0 0

S036 (Not display) 0 - 255 0 0 0

S037 (Not display) 0 - 255 0 0 0

S038 (Not display) 0 - 255 0 0 0

S039 ILA COM 0 - 1 0 0 0

No.

Item name

Variable

range

Setting value

PAL SECAM NTSC

Item

T001 IN LEVEL 0 - 255 0 0 0

T002 LOW SEP 0 - 255 0 0 0

T003 HIGH SEP 0 - 255 0 0 0

T004 AFC 0 - 255 0 0 0

T005 (Not display) 0 - 255 0 0 0

T006 ATT V ON 0 - 1 0 0 0

T007 ATT U ON 0 - 1 0 0 0

T008 ATT C ON 0 - 1 0 0 0

T009 (Not display) 0 - 255 0 0 0

T010 (Not display) 0 - 255 0 0 0

4.6.3 PANEL CONTOROL SYSTEM SETTING (*Fixed values)

Item

P001 TM HOR H 00 - FF 00 00 00

P002 TM HOR L 00 - FF A6 A6 A6

P003 TM MIN 00 - FF 33 33 33

P004 TEMP0 0 - 255 39 39 39

P005 (Not display) 0 - 255 0 0 0

P006 (Not display) 0 - 255 0 0 0

P007 (Not display) 0 - 255 0 0 0

P008 (Not display) 0 - 255 0 0 0

P009 (Not display) 0 - 255 0 0 0

P010 (Not display) 0 - 255 0 0 0

4.6.4 DRIVE SYSTEM SETTING (*Fixed values)

Item

D001 SLV GN 00 - 3F 20 20 20

D002 SLVH GN 00 - 3F 20 20 20

D003 SLH GN 00 - 3F 20 20 20

D004 SLV Pf 00 - 03 01 01 01

D005 SLH Pf H 00 - 01 01 01 01

D006 SLH Pf L 00 - 03 01 01 01

D007 SL EGCON 00 - 3F 07 07 07

D008 SL EGONF 00 - 01 01 01 01

D009 SL CRGON 00 - 3F 04 04 04

D010 SL CRGON 00 - 01 01 01 01

D011 SL ON OF 00 - 01 01 01 01

D012 SV GN 00 - 3F 17 17 17

D013 SVH GN 00 - 3F 15 15 15

D014 SH GN 00 - 3F 26 26 26

D015 SV Pf 00 - 03 01 01 01

D016 SV PfH 00 - 01 01 01 01

No.

No.

No.

Item name

Item name

Item name

Variable

range

Variable

range

Variable

range

Setting value

PAL SECAM NTSC

Setting value

PAL SECAM NTSC

Setting value

PAL SECAM NTSC

(No.YA229)1-23

Page 24

Item

D017 SV PfL 00 - 03 01 01 01

D018 SYL CON 00 - 3F 25 25 25

D019 SYL CONF 00 - 01 01 01 01

D020 SYH CON 00 - 3F 22 22 22

D021 SYH CONF 00 - 01 01 01 01

D022 SC CON 00 - 3F 33 33 33

D023 SC CNONF 00 - 01 01 01 01

D024 SPM BLC 00 - 3F 08 08 08

D025 SPM BLCO 00 - 01 01 01 01

D026 SLIM 00 - 3F 30 30 30

D027 SLIMONF 00 - 01 01 01 01

D028 SCRG 00 - 3F 03 03 03

D029 SRGONF 00 - 01 01 01 01

D030 S ONF 00 - 01 01 01 01

D031 pb GN 00 - 3F 1F 1F 1F

D032 pb PfH 00 - 01 00 00 00

D033 pb PfL 00 - 03 03 03 03

D034 pb CRG 00 - 3F 03 03 03

D035 pb CRGON 00 - 01 01 01 01

D036 pb ONF 00 - 01 01 01 01

D037 pr GN 00 - 3F 1F 1F 1F

D038 pr PfH 00 - 01 00 00 00

D039 pr PfL 00 - 03 03 03 03

D040 pr CRG 00 - 3F 03 03 03

D041 pr CRGON 00 - 01 01 01 01

D042 pr ONF 00 - 01 01 01 01

D043 ENH ONF 00 - 01 01 01 01

D044 (Not display) 00 - FF 00 00 00

D045 (Not display) 00 - FF 00 00 00

D046 (Not display) 00 - FF 00 00 00

D047 (Not display) 00 - FF 00 00 00

D048 (Not display) 00 - FF 00 00 00

D049 (Not display) 00 - FF 00 00 00

D050 (Not display) 00 - FF 00 00 00

D051 (Not display) 00 - FF 00 00 00

D052 (Not display) 00 - FF 00 00 00

D053 (Not display) 00 - FF 00 00 00

D054 (Not display) 00 - FF 00 00 00

D055 (Not display) 00 - FF 00 00 00

D056 (Not display) 00 - FF 00 00 00

D057 (Not display) 00 - FF 00 00 00

D058 (Not display) 00 - FF 00 00 00

D059 (Not display) 00 - FF 00 00 00

D060 (Not display) 00 - FF 00 00 00

D061 (Not display) 00 - FF 00 00 00

D062 (Not display) 00 - FF 00 00 00

D063 (Not display) 00 - FF 00 00 00

D064 (Not display) 00 - FF 00 00 00

D065 (Not display) 00 - FF 00 00 00

No.

Item name

Variable

range

Setting value

PAL SECAM NTSC

Item

D066 (Not display) 00 - FF 00 00 00

D067 (Not display) 00 - FF 00 00 00

D068 (Not display) 00 - FF 00 00 00

D069 (Not display) 00 - FF 00 00 00

D070 (Not display) 00 - FF 00 00 00

D071 (Not display) 00 - FF 00 00 00

D072 (Not display) 00 - FF 00 00 00

D073 (Not display) 00 - FF 00 00 00

D074 (Not display) 00 - FF 00 00 00

D075 (Not display) 00 - FF 00 00 00

D076 (Not display) 00 - FF 00 00 00

D077 (Not display) 00 - FF 00 00 00

D078 (Not display) 00 - FF 00 00 00

D079 (Not display) 00 - FF 00 00 00

D080 (Not display) 00 - FF 00 00 00

D081 (Not display) 00 - FF 00 00 00

D082 (Not display) 00 - FF 00 00 00

D083 (Not display) 00 - FF 00 00 00

D084 (Not display) 00 - FF 00 00 00

D085 (Not display) 00 - FF 00 00 00

D086 (Not display) 00 - FF 00 00 00

D087 (Not display) 00 - FF 00 00 00

D088 (Not display) 00 - FF 00 00 00

D089 (Not display) 00 - FF 00 00 00

D090 (Not display) 00 - FF 00 00 00

D091 (Not display) 00 - FF 00 00 00

D092 (Not display) 00 - FF 00 00 00

D093 (Not display) 00 - FF 00 00 00

D094 (Not display) 00 - FF 00 00 00

D095 (Not display) 00 - FF 00 00 00

D096 (Not display) 00 - FF 00 00 00

D097 (Not display) 00 - FF 00 00 00

D098 (Not display) 00 - FF 00 00 00

D099 (Not display) 00 - FF 00 00 00

D100 (Not display) 00 - FF 00 00 00

D101 (Not display) 00 - FF 00 00 00

D102 (Not display) 00 - FF 00 00 00

D103 (Not display) 00 - FF 00 00 00

D104 (Not display) 00 - FF 00 00 00

D105 (Not display) 00 - FF 00 00 00

D106 (Not display) 00 - FF 00 00 00

D107 (Not display) 00 - FF 00 00 00

D108 (Not display) 00 - FF 00 00 00

D109 (Not display) 00 - FF 00 00 00

D110 (Not display) 00 - FF 00 00 00

D111 (Not display) 00 - FF 00 00 00

D112 (Not display) 00 - FF 00 00 00

D113 (Not display) 00 - FF 00 00 00

D114 (Not display) 00 - FF 00 00 00

No.

Item name

Variable

range

Setting value

PAL SECAM NTSC

1-24 (No.YA229)

Page 25

Item

D115 (Not display) 00 - FF 00 00 00

D116 (Not display) 00 - FF 00 00 00

D117 (Not display) 00 - FF 00 00 00

D118 (Not display) 00 - FF 00 00 00

D119 (Not display) 00 - FF 00 00 00

D120 (Not display) 00 - FF 00 00 00

D121 (Not display) 00 - FF 00 00 00

D122 (Not display) 00 - FF 00 00 00

D123 (Not display) 00 - FF 00 00 00

D124 (Not display) 00 - FF 00 00 00

D125 (Not display) 00 - FF 00 00 00

D126 (Not display) 00 - FF 00 00 00

D127 (Not display) 00 - FF 00 00 00

D128 (Not display) 00 - FF 00 00 00

D129 (Not display) 00 - FF 00 00 00

D130 (Not display) 00 - FF 00 00 00

D131 (Not display) 00 - FF 00 00 00

D132 (Not display) 00 - FF 00 00 00

D133 (Not display) 00 - FF 00 00 00

D134 (Not display) 00 - FF 00 00 00

D135 (Not display) 00 - FF 00 00 00

D136 (Not display) 00 - FF 00 00 00

D137 (Not display) 00 - FF 00 00 00

D138 (Not display) 00 - FF 00 00 00

D139 (Not display) 00 - FF 00 00 00

D140 (Not display) 00 - FF 00 00 00

D141 (Not display) 00 - FF 00 00 00

D142 (Not display) 00 - FF 00 00 00

D143 (Not display) 00 - FF 00 00 00

D144 (Not display) 00 - FF 00 00 00

D145 (Not display) 00 - FF 00 00 00

D146 (Not display) 00 - FF 00 00 00

D147 (Not display) 00 - FF 00 00 00

D148 (Not display) 00 - FF 00 00 00

D149 (Not display) 00 - FF 00 00 00

D150 (Not display) 00 - FF 00 00 00

D151 (Not display) 00 - FF 00 00 00

D152 (Not display) 00 - FF 00 00 00

D153 (Not display) 00 - FF 00 00 00

D154 (Not display) 00 - FF 00 00 00

D155 (Not display) 00 - FF 00 00 00

D156 (Not display) 00 - FF 00 00 00

D157 (Not display) 00 - FF 00 00 00

D158 (Not display) 00 - FF 00 00 00

D159 (Not display) 00 - FF 00 00 00

D160 (Not display) 00 - FF 00 00 00

D161 (Not display) 00 - FF 00 00 00

D162 (Not display) 00 - FF 00 00 00

D163 (Not display) 00 - FF 00 00 00

No.

Item name

Variable

range

Setting value

PAL SECAM NTSC

Item

D164 (Not display) 00 - FF 00 00 00

D165 (Not display) 00 - FF 00 00 00

D166 (Not display) 00 - FF 00 00 00

D167 (Not display) 00 - FF 00 00 00

D168 (Not display) 00 - FF 00 00 00

D169 (Not display) 00 - FF 00 00 00

D170 (Not display) 00 - FF 00 00 00

D171 (Not display) 00 - FF 00 00 00

D172 (Not display) 00 - FF 00 00 00

D173 (Not display) 00 - FF 00 00 00

D174 (Not display) 00 - FF 00 00 00

D175 (Not display) 00 - FF 00 00 00

D176 (Not display) 00 - FF 00 00 00

D177 (Not display) 00 - FF 00 00 00

D178 (Not display) 00 - FF 00 00 00

D179 (Not display) 00 - FF 00 00 00

D180 (Not display) 00 - FF 00 00 00

D181 (Not display) 00 - FF 00 00 00

D182 (Not display) 00 - FF 00 00 00

D183 (Not display) 00 - FF 00 00 00

D184 (Not display) 00 - FF 00 00 00

D185 (Not display) 00 - FF 00 00 00

D186 (Not display) 00 - FF 00 00 00

D187 (Not display) 00 - FF 00 00 00

4.6.5 MAIN CPU SYSTEM SETTING (*Fixed values)

Item

Z001 (Not display) 00 - FF 00 00 00

Z002 (Not display) 00 - FF 00 00 00

Z003 (Not display) 00 - FF 00 00 00

Z004 (Not display) 00 - FF 00 00 00

Z005 (Not display) 00 - FF 00 00 00

Z006 (Not display) 00 - FF 00 00 00

Z007 (Not display) 00 - FF 00 00 00

Z008 (Not display) 00 - FF 00 00 00

Z009 (Not display) 00 - FF 00 00 00

Z010 (Not display) 00 - FF 00 00 00

No.

No.

Item name

Item name

Variable

range

Variable

range

Setting value

PAL SECAM NTSC

Setting value

PAL SECAM NTSC

(No.YA229)1-25

Page 26

4.7 ADJUSTMENT PROCEDURE

4.7.1 POWER CIRCUIT [DISPLAY UNIT]

Item

PDP POWER

VOLTAGE

Measuring

instrument

Signal

generator

Test point Adjustment part Description

Connector

CN806

Vs

DC voltmeter

Va

[MAIN

POWER

UNIT]

MAIN POWER UNIT voltage adjustment point

CN806

1. Vs

2. Vs

3. Vs

4. NC

5. GND

6. GND

7. GND

8. GND

9. Va

10. Va

CN806

CN8011

CN805

CN9001

R551

R531

Va

Vs

Fig.1

CN806

1

Vs

2

Vs

3

Vs

4

NC

5

GND

6

GND

7

GND

8

GND

9

Va

10

Va

Fig.2

Voltage label

MODEL:PDP50x2xxxx

ALL Voltage:DC5V

Va:xxV Vs:xxxV

Max Watt:xxxW

Vs VR:190V ADJ (R551

Va VR:60V ADJ (R351

[MAIN POWER UNIT]

CN8009

CN8001

Voltage adjustment VR

Vs

Va

MAIN POWER UNIT

)

)

CAUTION:

• During adjustment operation of PDP POWER

VOLTAGE, don't touch the heat sink of the MAIN

POWER UNIT. If you touch it, electric shock may

be caused.

< When MAIN POWER UNIT is not replaced >

(1) Connect the DC voltmeter to the CN806

connector and turn on the power. (See Fig.2)

(2) Adjust Vs (190V ADJ) VR and Va (60V ADJ) VR

so that the Vs and Va voltage coincides with the

values in the voltage label.

(3) Input a PAL all-black signal and check that it

coincides with the values in the voltage label.

(4) Readjust if the adjusted value is different from

those in the voltage label.

NOTE:

• Designed value for the panel is printed on a label

on the upper-left at the back of the PDP. (See

Fig.3)

< When MAIN POWER UNIT is replaced >

CAUTION:

• Before making adjustments, be sure not to turn

on the power when the CN805

connector are

connected, as this may cause the PDP to

break down.

(1) Disconnect the CN805

connector on the MAIN

POWER UNIT.

(2) Connect DC voltmeter to the CN806 connector

and turn on the power. (See Fig.2)

(3) Adjust Vs (190V ADJ) VR and Va (70V ADJ) VR

so that the Vs and Va voltage coincides with the

values in the voltage label.

(4) Turn off the power, and connect the CN805

connector and turn on the power again.

(5) Input a PAL all-black signal and check that it

coincides with the values in the voltage label.

(6) If the adjusted value is different from those in

the voltage label, fine-tune without unplugging

the connectors.

CAUTION:

• Designated power supply voltage of the panel

(Vs, Va) varies according to the PDP unit.

• Pay careful attention during adjustment, as

any error in procedure may cause the PDP to

break down.

1-26 (No.YA229)

Fig.3

Page 27

4.7.2 VIDEO CIRCUIT [RECEIVER UNIT]

Item

625i

A-D OFFSET

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

Signal

generator

Disappears the color at both ends.

1125i (50Hz)

BRIGHTNESS

Remote

control unit

Signal

generator

Set the 0% black part to be brightest.

1125i (50Hz)

A-D OFFSET

Remote

control unit

Signal

generator

Minimize the red and blue noises in

the upper half of the screen.

[1.ADJUST]

S001: PREPARE

(Adjustment setting mode change)

S008: 5i CB OF(625i cb offset)

S009: 5i CR OF(625i cr offset)

S030: R DRIVE(Red drive)

S031: G DRIVE(Green drive)

S032: B DRIVE(Blue drive)

[1.ADJUST]

S001: PREPARE

(Adjustment setting mode change)

S012: HD BL(1125i brightness)

S030: R DRIVE(Red drive)

S031: G DRIVE(Green drive)

S032: B DRIVE(Blue drive)

[1.ADJUST]

S001: PREPARE

(Adjustment setting mode change)

S013: HD CB OF(1125i cb offset)

S014: HD CR OF(1125i cr offset)

S030: R DRIVE(Red drive)

S031: G DRIVE(Green drive)

S032: B DRIVE(Blue drive)

(1) Receive a 625i component ramp pattern signal.

(2) Set "PICTURE MODE" to STANDARD.

(3) Set "ZOOM" to FULL.

(4) Set "WHITE BALANCE" to MID.

(5) Select "1.ADJUST" from the SERVICE MODE.

(6) Set < S030 > (R DRIVE), < S031> (G DRIVE)

and < S032 > (B DRIVE) to "133".

(7) Set < S001 >(adjustment setting mode change)

to set "8" and it change to the 625i A-D offset

adjustment setting mode.

(8) Adjust < S008 > (625i Cb offset) and < S009 >

(625i Cr offset) to lose the gap (red line, green

line and blue line) which appears at both ends

of a white part at the centre of the screen.

(9) Set < S001 > to set "0" and it change to the

normal mode.

(10) Press the [MUTING] key to memoirze the set

value.

(1) Receive a 1125i (50Hz) gray scale pattern signal.

(2) Set "PICTURE MODE" to STANDARD.

(3) Set "ZOOM" to FULL.

(4) Set "WHITE BALANCE" to MID.

(5) Select "1.ADJUST" from the SERVICE MODE.

(6) Set < S030 > (R DRIVE), < S031> (G DRIVE)

and < S032 > (B DRIVE) to "133".

(7) Set < S001 > (adjustment setting mode change)

to set the values "12" and it change to the 1125i

black level adjustment setting mode.

(8) Adjust < S012 > (1125i brightness) to set the

0% black part in the upper half of the screen to

be brightest.

(9) Set < S001 > to set "0" and it change to the

normal mode.

(10) Press the [MUTING] key to memoirze the set

value.

(1) Receive a 1125i (50Hz) 30% all white pattern

signal.

(2) Set "PICTURE MODE" to STANDARD.

(3) Set "ZOOM" to FULL.

(4) Set "WHITE BALANCE" to MID.

(5) Select "1.ADJUST" from the SERVICE MODE.

(6) Set < S030 > (R DRIVE), < S031> (G DRIVE)

and < S032 > (B DRIVE) to "133".

(7) Set < S001 > (adjustment setting mode change)

to set "13" and it change to the 1125i A-D offset

adjustment setting mode.