JVC PD-42WV74 Diagram

YA029200311

SERVICE MANUAL

PDP COLOR TELEVISION

PD-42WV74 /S

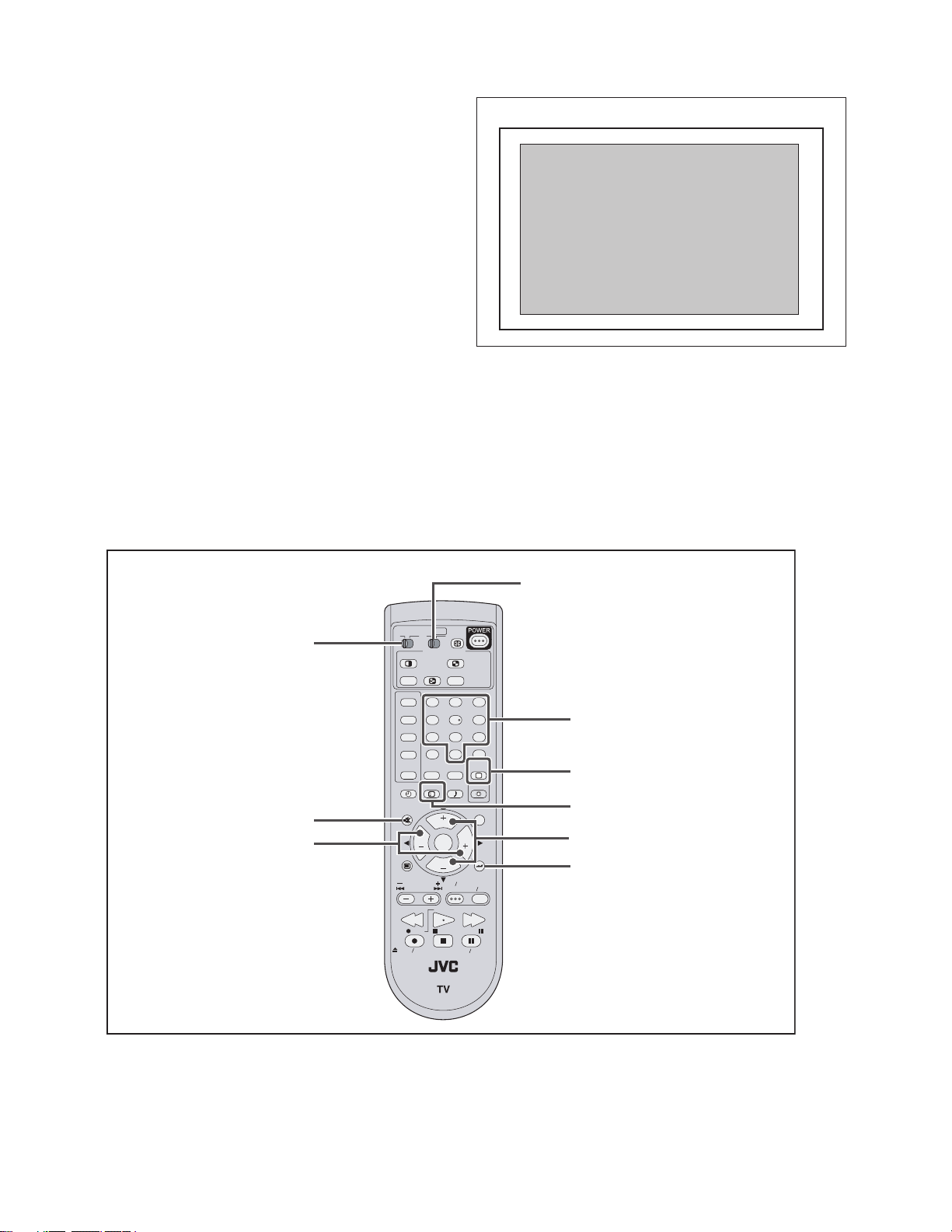

TV

CATV VCRDVD

ASPECT

MULTI SCREEN

INDEX

SPLIT

FREEZE

SWAP SELECT

INPUT 1

V1

123

INPUT 2

V2

456

INPUT 3

V3

789

RETURN+

INPUT 4

100+

TV

0

V4

THEATER

NATURAL

VIDEO

DIGITAL-IN

PRO

CINEMA

STATUS

D-IN

SLEEP TIMER

DISPLAY SOUND

LIGHT

+

MUTING

C.C.

C.C.

CH

VOL

VOL

OK

CH

MENU

BACK

VCR CHANNEL

VCR DVD

PREV NEXT

POWER

TV VCR

REW

FFPLAY

REC PAUSE

STOP

OPEN CLOSE

STILL PAUSE

RM-C13G

VM-42WV74

[PLASMA DISPLAY UNIT]

BASIC CHASSIS

SB3

TU-42WV74

[RECEIVER UNIT]

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.YA029

2003/11

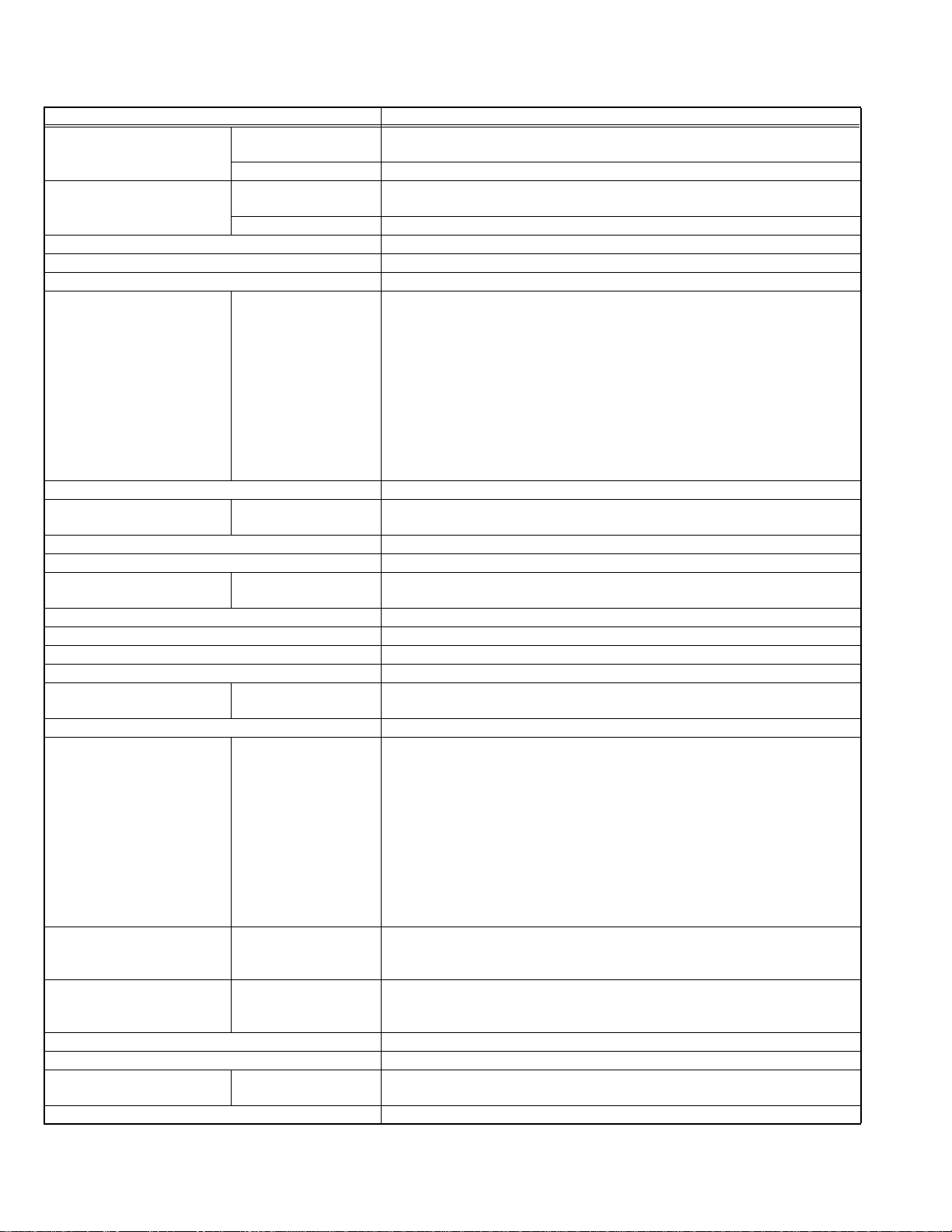

SPECIFICATION

Items Contents

Dimensions (W × H × D) Plasma display unit 116.0cm × 79.8cm × 30.8cm (45-11/16" × 31-7/16" × 12-3/16") [with the stand]

116.0cm × 73.1cm × 9.8cm (45-11/16" × 28-13/16" × 3-7/8") [main TV body]

Receiver unit 43.5cm × 9.9cm × 38.2cm (17-3/16" × 3-15/16" × 15-1/16")

Mass Plasma display unit 48kg (106lbs) [with the stand]

38kg (84lbs) [main TV body]

Receiver unit 5.1kg (11.3lbs)

TV RF System CCIR (M)

Color System NTSC

Sound System BTSC (Multi Channel Sound)

TV Receiving Channels and

Frequency

TV / CATV Total Channel 180 Channels

Intermediate Frequency Video IF

Color Sub Carrier 3.58 MHz

Power Input AC 120V, 60Hz

Power Consumption Plasma display unit

Plasma Display Panel (PDP) 42-inch wide aspect (16:9)

Screen Size Diagonal : 107.5cm (H:51.8cm × V : 105.7cm)

Display Pixels Horizontal : 852 dots × Vertica l : 480 dots (W-VGA)

Audio Power Output 18W + 18W (Main/Woofer)

Speaker Main

Antenna terminal (VHF/UHF) F-type connector, 75Ω unbalanced, coaxial

Video / Audio input

Input-1/2/3/4

Component Video

Digital-in Video

Audio output

Sub woofer output 0~1000mV (rms), Low impedance, RCA pin jack × 1

AV compulink III 3.5mm mini jack × 1

Display Input / Output

(For system cable)

Remote Control Unit RM-C13G (AA/R6 /U M-3 battery × 2)

Design & specifications are subject to change without notice.

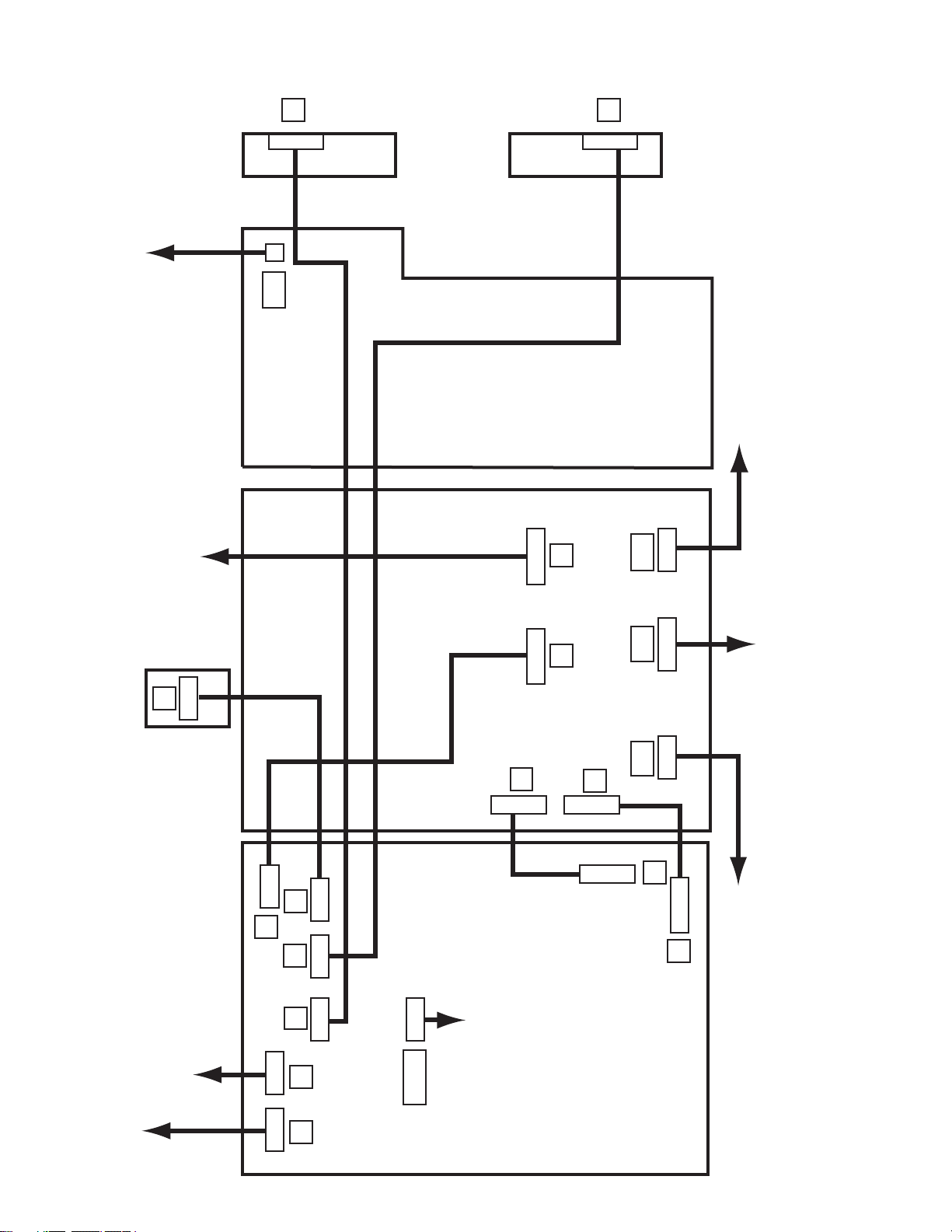

VHF Low

VHF High

UHF

CATV

Sound IF

Receiver unit

Woofer

S-Video

[Input-1/2/4]

Video

Audio

[Input-1/2]

1125i / 750p

525p / 525i

Audio

Variable

Fix

Control / Audio

Video

02ch~06ch : 54MHz~88MHz

07ch~13ch : 174MHz~216MHz

14ch~69ch : 470MHz~806MHz

54MHz~804MHz

Low Band : 02~06, A-8 by 02~06&01

High Band : 07~13 by 07~13

Mid Band : A~I by 14~22

Super Band : J~W by 23~36

Hyper Band : W+1~W+28 by 37~64

Ultra Band : W+29~W+84 by 65~125

Sub Mid Band : A8, A4~A1 by 01, 96~99

45.75 MHz

41.25 MHz (4.5MHz)

340W

27W

10cm × 3cm (3-15/16" × 1-3/16"), oval type × 2

13cm × 6.5cm (5-1/8" × 2-9/16"), oval type × 2

Mini-DIN 4 pin × 3

Y: 1V (p-p), Positive (Negative sync provided), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

1V (p-p), Positive (Negative sync provided), 75 Ω , RCA pin jack × 4

500mV (rms), High impedance, RCA pin jack × 8

RCA pin jack × 6

Y : 1V (p-p) (Sync signal: 0.35V(p-p), 3-value sync.), 75 Ω

Pb/Pr : 0.35V(p-p), 75 Ω

Y : 1V (p-p), Positive (Negative sync provided), 75 Ω

Pb/Pr : 0.35V(p-p), 75 Ω

DVI-D 24-pin connector × 1

(Digital-input terminal is not compatible with computer signal)

500mV (rms), Low impedance, RCA pin jack × 2

RCA pin jack × 2

More than 0 to 1000mV(rms) (+2.2 dBs)

500mV(rms) (-4dBs) Low impedance (400Hz when modulated 100%)

D-sub 26-pin connector × 2

DVI-D 24pin connector × 2

1-2 (No.YA029)

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel only.

(2) Alterations of the design or cir cuitry of the pr oducts shou ld n ot be

made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer

of responsibility for personal injury or property damage resulting

therefrom.

(3) Many electrical and me chanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts w hich have these

special safety characteristics are identified in the parts list of Service

manual. Electrical components having such features are

identified by shading on the schematics and by ( ) on the

parts list in Service manual. The use of a substitute replacement

which does not have the same safety characteristics as the

recommended replacement part shown in the part s list of Service

manual may cause shock, fire, or other hazards.

(4) Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in some products are

connected to one side of the AC power line. An isolation

transformer of adequate capacity should be inserted between the

product and the AC power supply point while performing any

service on some products when the HOT chassis is exposed.

(5) Don't short between the LIVE side ground and ISOLATED (NEU-

TRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The difference of the GND is shown by the L IVE : ( ) side GND, the ISOLAT ED (NEUTRAL) : ( ) side GND and EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND and never measu re the LIVE side

GND and ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope etc.). If

above note will not be kept, a fuse or any parts will be broken.

(6) If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See B1 POWER

SUPPLY check).

(7) Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead

to the ground frame and connecting the other end of the lead

through a 10kΩ 2W resistor to the anode button.

(8) When service is required, observe the original lea d dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those

components that indicate evidence of overheating should be

replaced. Always use the manufacturer's replacement

components.

(9) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control knobs,

metal cabinet, screw heads, earphone jack, control shafts, etc.) to

be sure the product is safe to operate without danger of electrical

shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 1100V AC

(r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance rat-

ed up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V

or more, for a period of one second.) This method of test requires

a test equipment not generally found in the service trade.

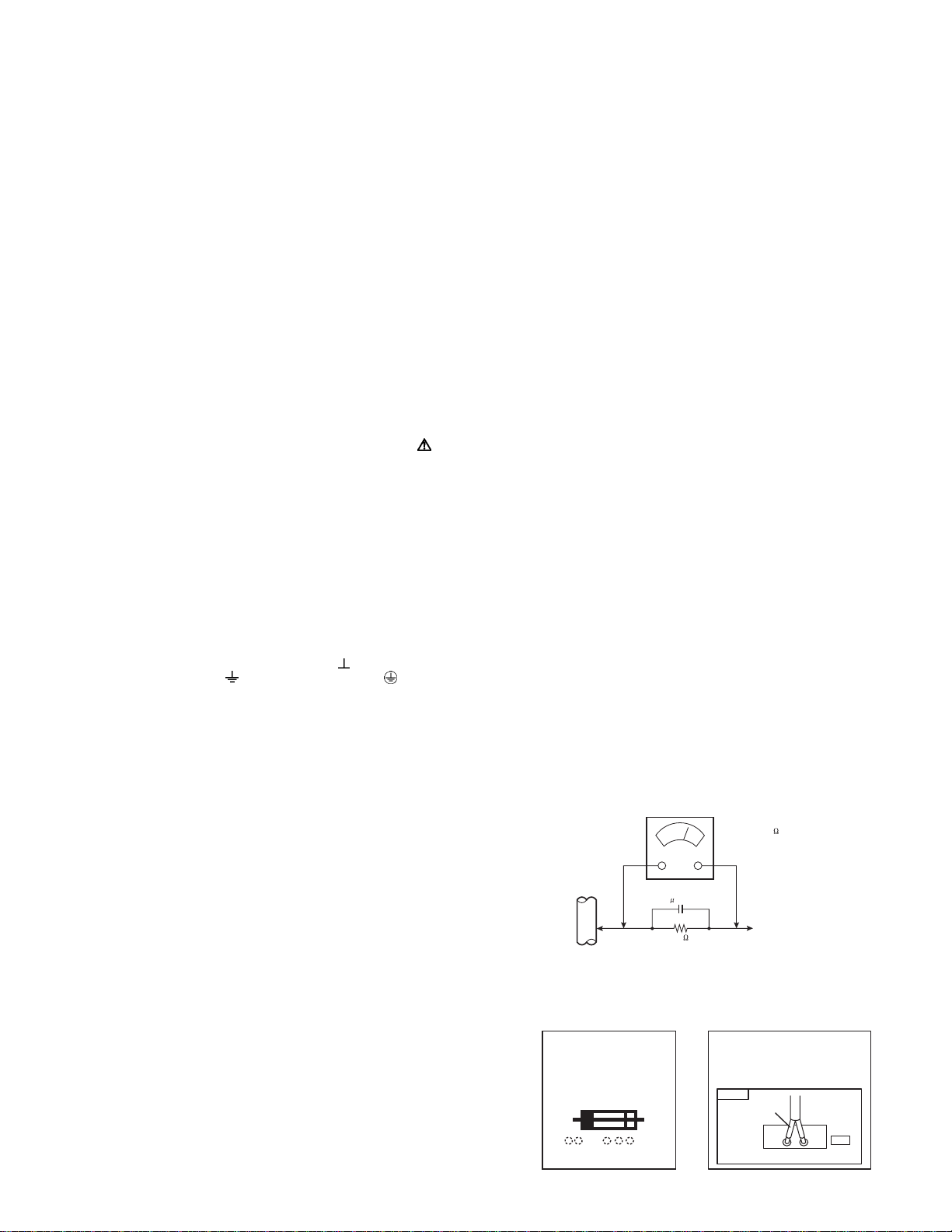

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground

(water pipe, etc.). Any leakage current must not exceed 0.5mA AC

(r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC (r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Use an AC

voltmeter having 1000Ω per volt or more sensitivity in the

following manner. Connect a 1500Ω 10W resistor paralleled by

a 0.15µF AC-type capacitor between an exposed metal part and

a known good earth ground (water pipe, etc.). Measure the AC

voltage across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part, particularly any

exposed metal part having a return path to the chassis, and

measure the AC voltage across the resistor. Now, reverse the

plug in the AC outlet and repeat each measurement. Any

voltage measured must not exceed 0.75V AC (r.m.s.). This

corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

GOOD EARTH GROUND

ON EACH EXPOSED

METAL PART

(10) High voltage hold down circuit check.

After repair of the high voltage hold down circuit, this circuit shall

be checked to operate correctly.See item "How to check the high

voltage hold down circuit".

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

A V

POWER CORD

REPLACEMENT WARNING.

Connecting the white line side of power

cord to "WHT" character side.

PWB

White line side

WHT

PW

(No.YA029)1-3

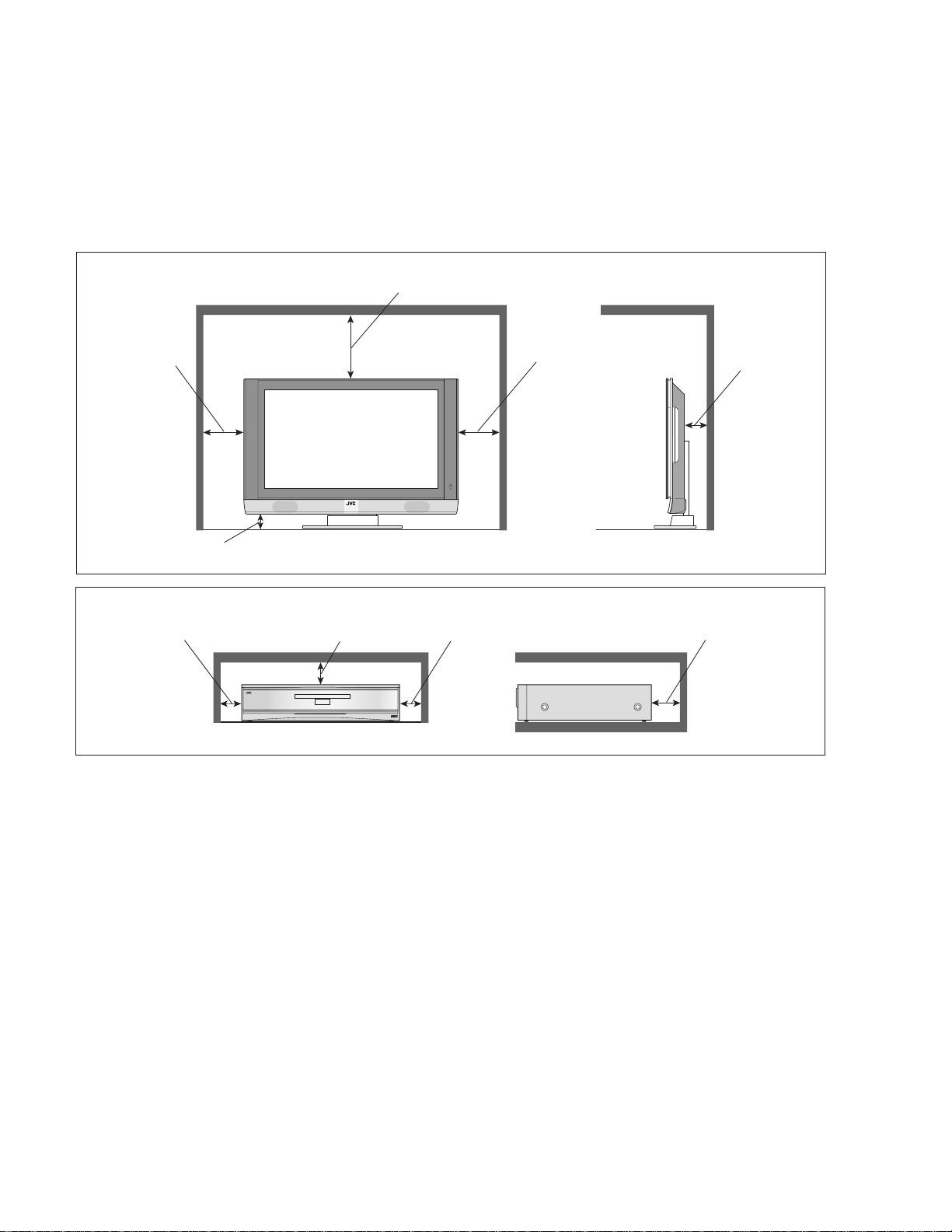

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling

efficiency may deteriorate and temperature inside the unit will

rise. The temperature sensor that protects the unit will be

activated when internal temperature exceeds the pre-determined

level and power will be turned off automatically.Therefore,

please make sure pay attention not to block the heat dissipation

vent as well as the ventilation outlet behind the unit and ensu re

that there is room for ventilation around it.

SPACE REQUIRED FOR INSTALLATION OF THE DISPLAY UNIT

8 inch/200 mm

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified

below, between the unit with and the surrounding walls, as well

as the floor etc.Install the unit on stable flooring or stands.Ta ke

precautionary measures to prevent the unit from tipping in order

to protect against accidents and earthquakes.

6 inch/150 mm

2 inch/50 mm

SPACE REQUIRED FOR INSTALLATION OF THE RECEIVER UNIT

4 inch/100 mm

4 inch/100 mm4 inch/100 mm 4 inch/100 mm

6 inch/150 mm

2 inch/50 mm

1-4 (No.YA029)

1.3 HANDLING FOR PLASMA DISPLAY PANEL

1.3.1 PRECAUTIONS DURING NOTES FOR TRANSPORTATION

When transporting the display unit, pressure exerted on the

internal PDP (Plasma Display Panel) due to improper handling

(such as tossing and dropping) may cause damages even when

the unit is carefully packed. To prevent accidents from occurring

during transportation, pay careful attention prior to delivery such

as through explaining the handling instructions to transporters.

Ensure that the following requirements are met during

transportation, as the PDP of this unit is made of glass and

therefore fragile:

(1) Avoid vibrations and impacts

The unit may be broken if it is toppled sideways even when

properly packed. Ensure that the unit is carried by at lea st

2 persons and pay careful attention not to exert any

vibration or impact on it.

(2) Do not place equipment horizontallyEnsure that it is placed

upright and not horizontally during transportation and

storage as the PDP is very vulnerable to lateral impacts

and may break easily under such circumstances.During

transportation, ensure that the unit is loaded along the

traveling direction of travel of the vehicle, and avoid

stacking them on one another.For storage, ensure that

they are stacked in 2 layers or less even when placed

upright.

1.3.2 RESIDUAL IMAGE / BURN-IN ON SCREEN

Like CRTs, ‘burn-ins’ may occur when a same image is

continuously displayed over an extended period of time.As Tthis

may also shorten the life span of the PDP. Therefore, turn off the

display when not in use, scroll the screen, make use of screensavers, or allow even distribution on the display by inverting the

brightness, switching to complementary colors or inserting

animated images at periodic intervals.As burn-in is more likely to

occur with high brightness and contrast settings, try to use

neutral gradations or medium tone colors.Burn-in does not occur

in the case of animated images.When switching to another

image after continuous display of the previous image, residual

images may become prominent, as luminance in a part of the

display is higher than the other parts. This is not a defect b ut is

because due to the discharge surface of th e lighted porti on has

becomebeing relatively activated and its luminance higher than

the unlighted parts.

1.3.3 INFRARED RAYS

Near Near-infrared rays (800nm to 1000nm) are emitted from the

front of the panel, and this may give rise to glitchescause

malfunctions in infrared remote controls or communication

systems placed near it. In this case, avoid direct infrared rays

(and reflected rays in some cases) from the screen by either

changing the direction of the unit or other infrared systems or

securing a longer keeping a distance from the screen.

1.3.4 OPTICAL FILTER (PANEL FILTER)

Avoid placing the unit under direct sunlight over a prolonged

period of time. This may cause the optical filter to deteriorate in

quality and color.Clean the filter surface by wiping it softly lightly

with outing flannels a soft and lightly fuzz cloth (such as

flannel).Do not use solvents such as benzine or thinner to wipe

the filter surface. This may cause the filter to deteriorate in quality

or the coating on the surface to come off.As Tthe filter surface is

fragile., Ddo not scratch or hit it with hard materials.

1.3.5 NOTES PRECAUTIONS FOR REPLACEMENT OF

EXTERIOR PARTS

Take note of the following when replacing exterior parts (back

REAR COVER, FRONT PANEL, optical filter):Do not exert

pressure on the front of the PDP (glass surface).Pay careful

attention not to scratch or stain the front of the PDP (surface) with

hands.When replacing exterior parts, the front of the PDP should

be placed facing downward. Place a mat, etc. underneath to

avoid causing scratches to the front surface.However, never use

materials that are too soft (such as blanket cloth). If replacement

is made with the PDP surface facing downward and in contact

with the blanket, pressure may be exerted on the PDP, thus

causing damages to it.

(No.YA029)1-5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

2.1.1 HIGH-DEFINITION IMAGE TECHNOLOGY (DIST)

DIST is a digital high-definition image processing technology that converts various image input signals such as NTSC(480i), 480p,

720p, and 1080i into a format with the best reso lution for a display device such as a plasma display panel, and displays highdefinition images.

2.1.2 MAIN FUNCTION

AUTO POWER OFF

The power supply of the TV will be cut off automatically when there is a continuous absence of signal for 4 minutes, or when there

is a maximum of 3 consecutive hours of no operation from user.

OFF TIMER

Setting for situations such as falling asleep while watch ing TV , and for preventio n against forgetti ng to turn off the TV. The power

supply of the TV will be cut off automatically when the time exceeds the set up timing (maximum 2 hours).

NATURAL CINEMA

When viewing film-originated movie and animation, misty outline can be seen in fast moving image s. Using natural cinema will

enable viewing of clear images even in fast moving images.

2.1.3 ASPECT CONTROL

SCREEN SIZE SWITCHING

Desired screen size (PANORAMA / CINEMA / FULL / HD PANORAMA / REGULAR / CINEMA ZOOM) can be selected.

MOVING THE SCREEN UP & DOWN

Adjusts the vertical position of the screen.

2.1.4 MULTI-SCREEN FUNCTION

SPLIT-SCREEN

2 programs an be viewed at the same time.

INDEX-SCREEN

This allows you to quickly look at to 12channels at a time so that you can decide which one to watch.

FREEZE SCREEN

The images that are currently seen can be viewed on the memo screen (still picture).

It is convenient for taking down notes like application address and recipe of cooking program etc, while enjoying the current program.

1-6 (No.YA029)

2.2 TECHNICAL INFORMATION

2.2.1 PDP (PLASMA DISPLAY PANEL) DESCRIPTION

2.2.1.1 CAUTION

Although a PDP is made with highly advanced precision, this does not necessarily mean all of the cells operate correctly.

The PDP inevitably includes cell that do not light or light constantly.

If the specifications (PDP performance) are unclear at the time of shipment, an adequate description cannot be conveyed to the

customer. In event of inquiries from customers regarding PDP performance, check the followi ng specifications in order to offer a

suitable reply.

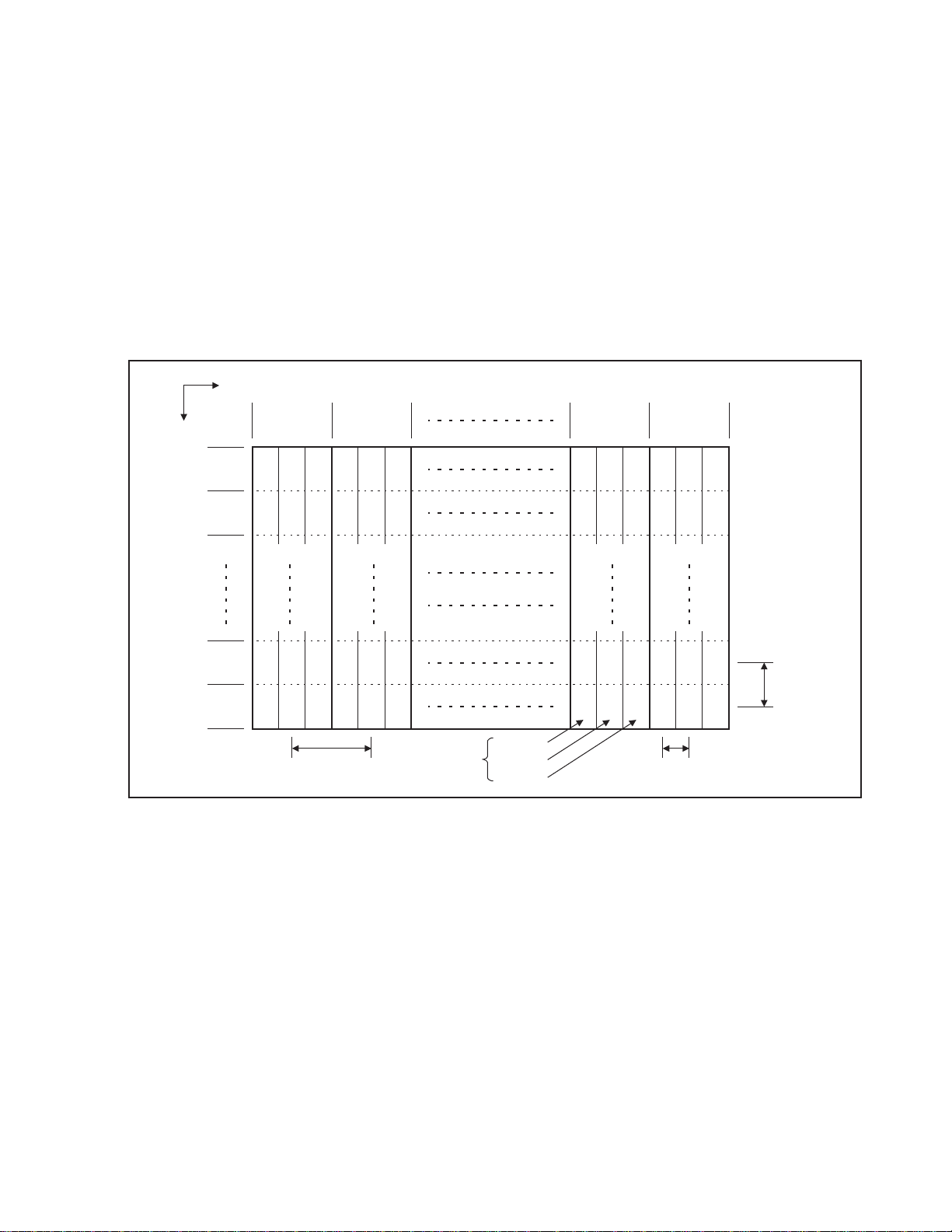

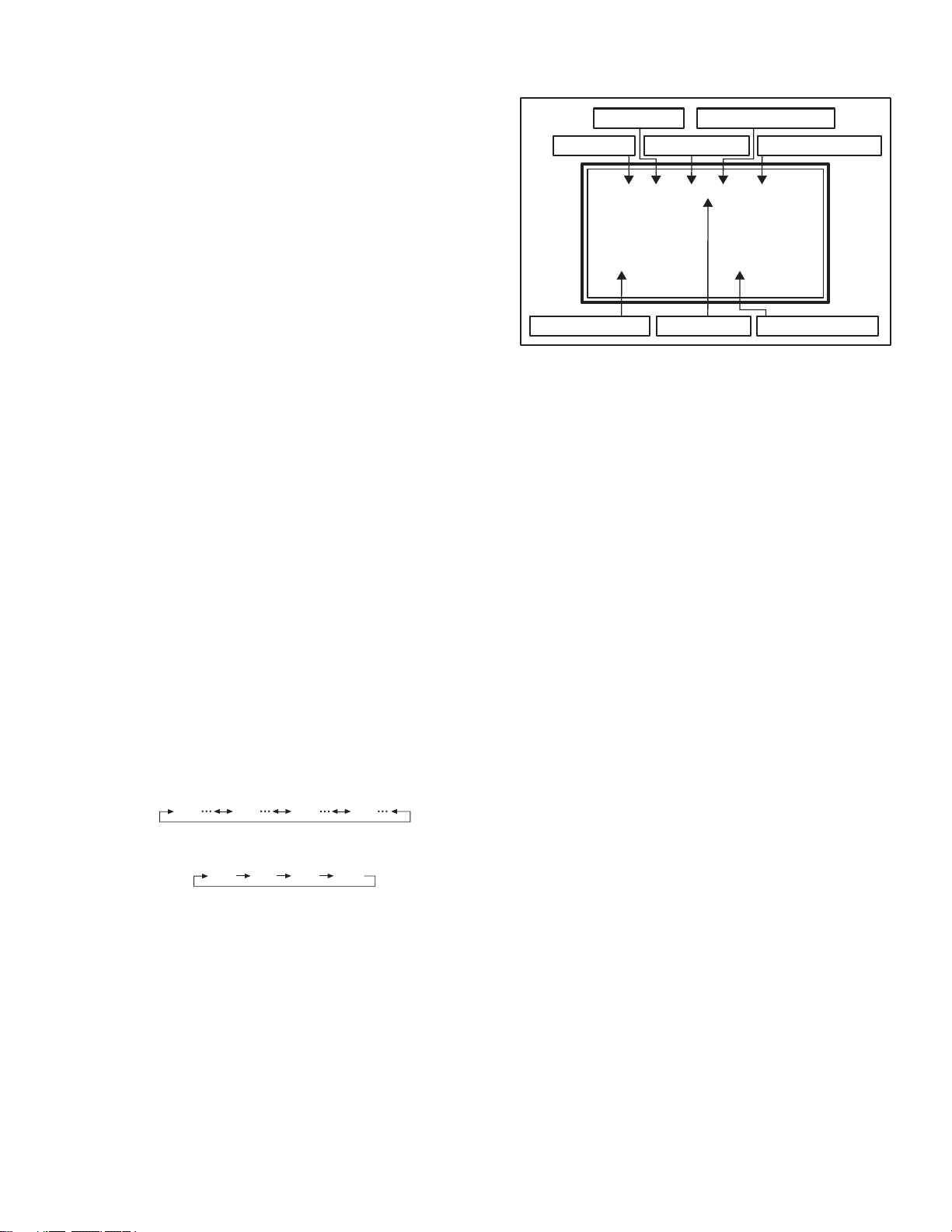

2.2.1.2 CELL ARRANGEMENT

The PDP is constructed of front and rear glass substrates provided wit h respective discharge electrodes. Between these, neon for

discharging and xenon for generating ultraviolet rays are enclosed.

One picture element (pixel) is composed of Red, Green and Blue (RGB) cells. The cell p itch is 0.365mm horizontal (1.095mm per

pixel) by 1.110mm vertical.

As shown in Fig. 1, the cells are arranged for each R / G / B colour. A pixel consists of each cell of R/G/B/ colour. The size of a cell is

0.365mm horizontally and 1.110mm vertically.

Direction

Vertical(V)

Horizontal(H)

1st pixel

line

2nd pixel

line

479th pixel

line

480th pixel

line

1st pixel

array

B G R B G R

BG

G RBG R

B

GRBGR

B

H 1.095mm

Pitch of pixel

2nd pixel

array

RBG R

One pixel

(1dot)

B cell

G cell

R cell

851th pixel

array

B GRBG R

BGRBGR

G RBG R

B

GRBGR

B

852th pixel

array

H 0.365mm

Pitch of cell

V 1.110mm

Pitch of pixel

(Pitch of cell)

Fig.1 PIXEL (CELL) ARRANGEMENT

2.2.1.3 PIXEL FAULT

There are three pixel faults - bright fault , dark fault and flicker fault - that are respectively defined as follows.

(1) BRIGHT FAULT

In this pixel fault, a cell that should not light originally is lighting on and off.

For checking this pixel fault, input ALL BLACK SCREEN and find out the cell that is lighting on and off.

(2) DARK FAULT

In this pixel fault, a cell that should light originally is not lighting or lighting with the brightness twice as brighter as originally lighting.

For checking this pixel fault, input 100% of each R/G/B colour and find out the cell that is not lighting.

(3) FLICKER FAULT

In the pixel fault, a cell that should light originally or not light originally is flashing on and off.

For checking this pixel fault, input ALL BLACK SCREEN signal or 100% of each RGB colour and find out the cell that is flashing on

and off.

(No.YA029)1-7

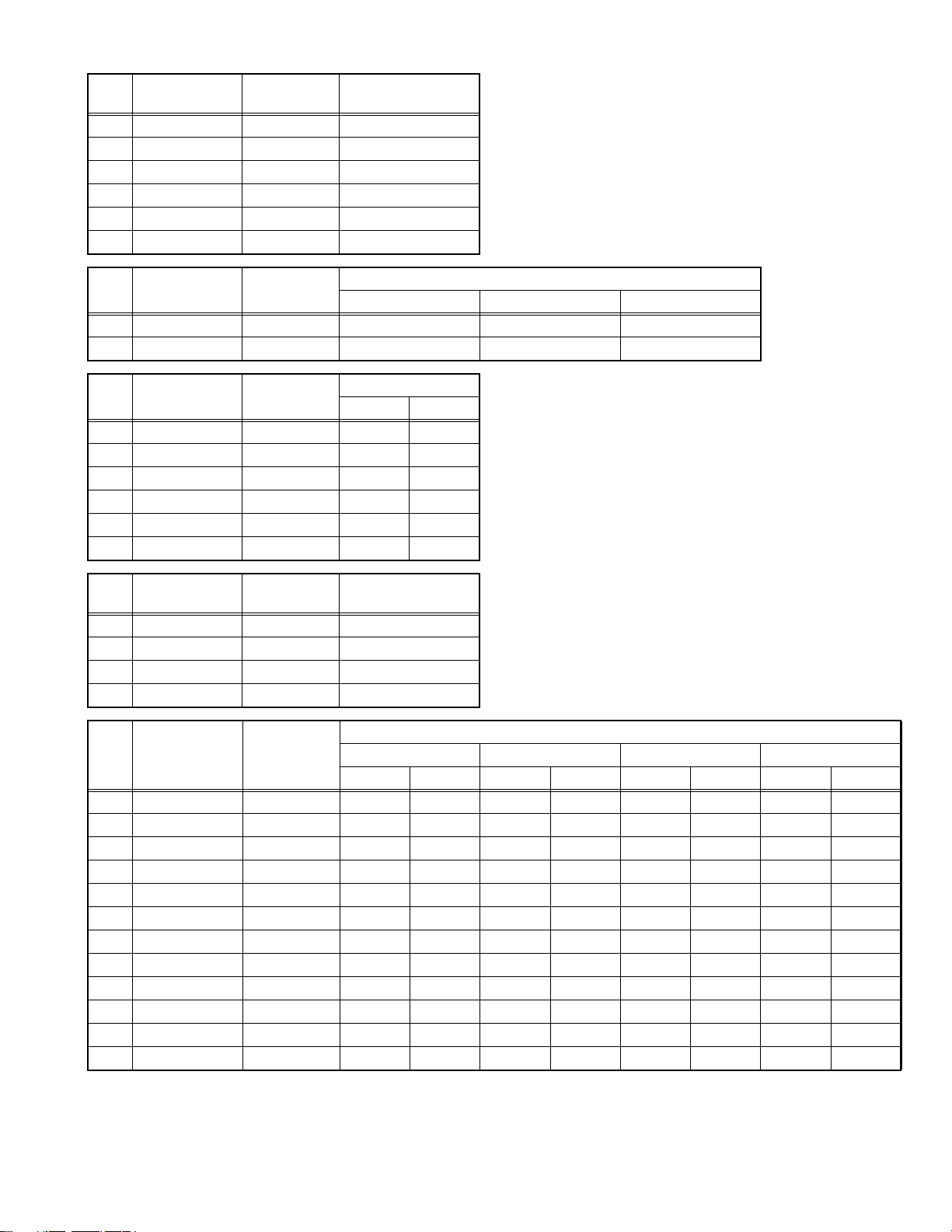

2.2.2 MAIN MI-COM FUNCTIONAL TABLE [RECEIVER UNIT]

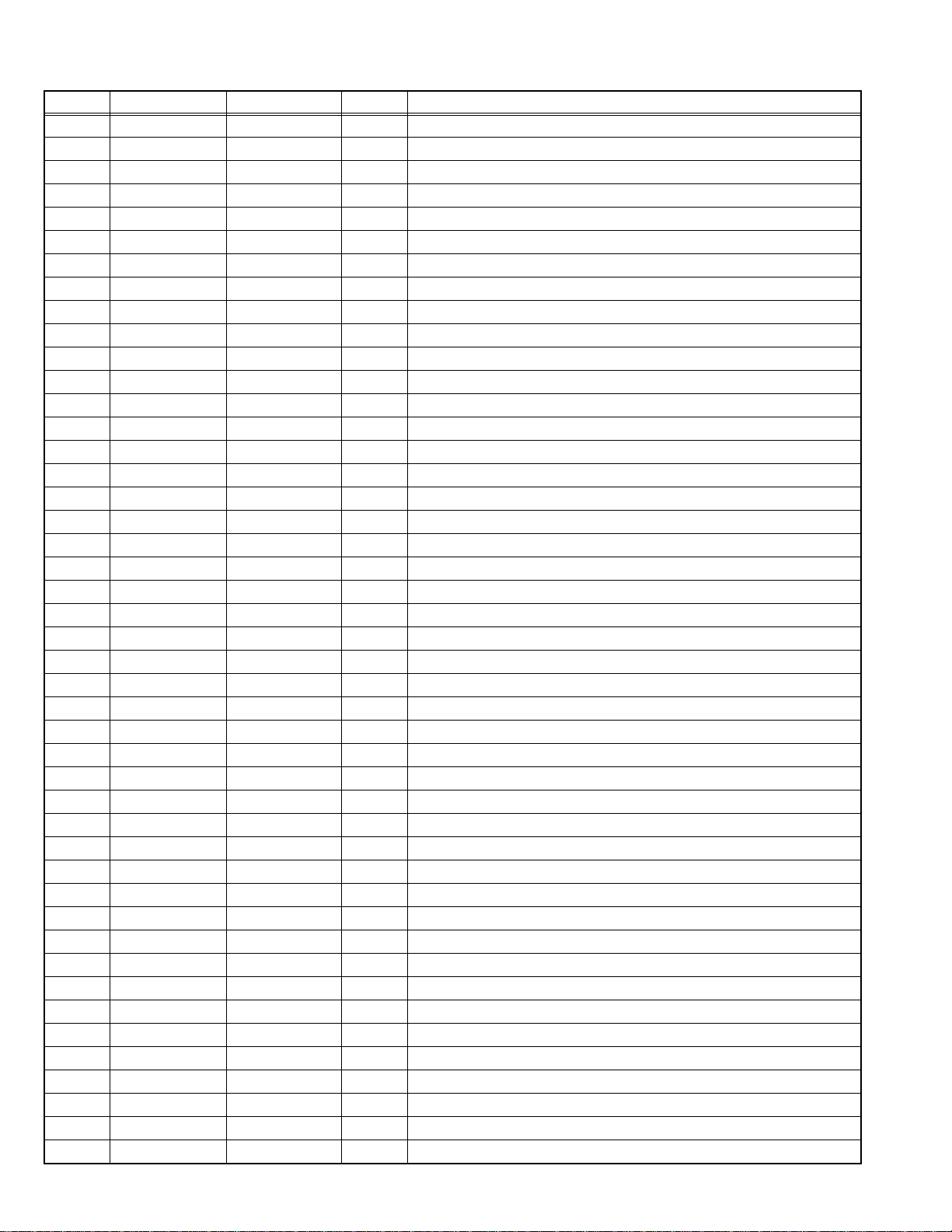

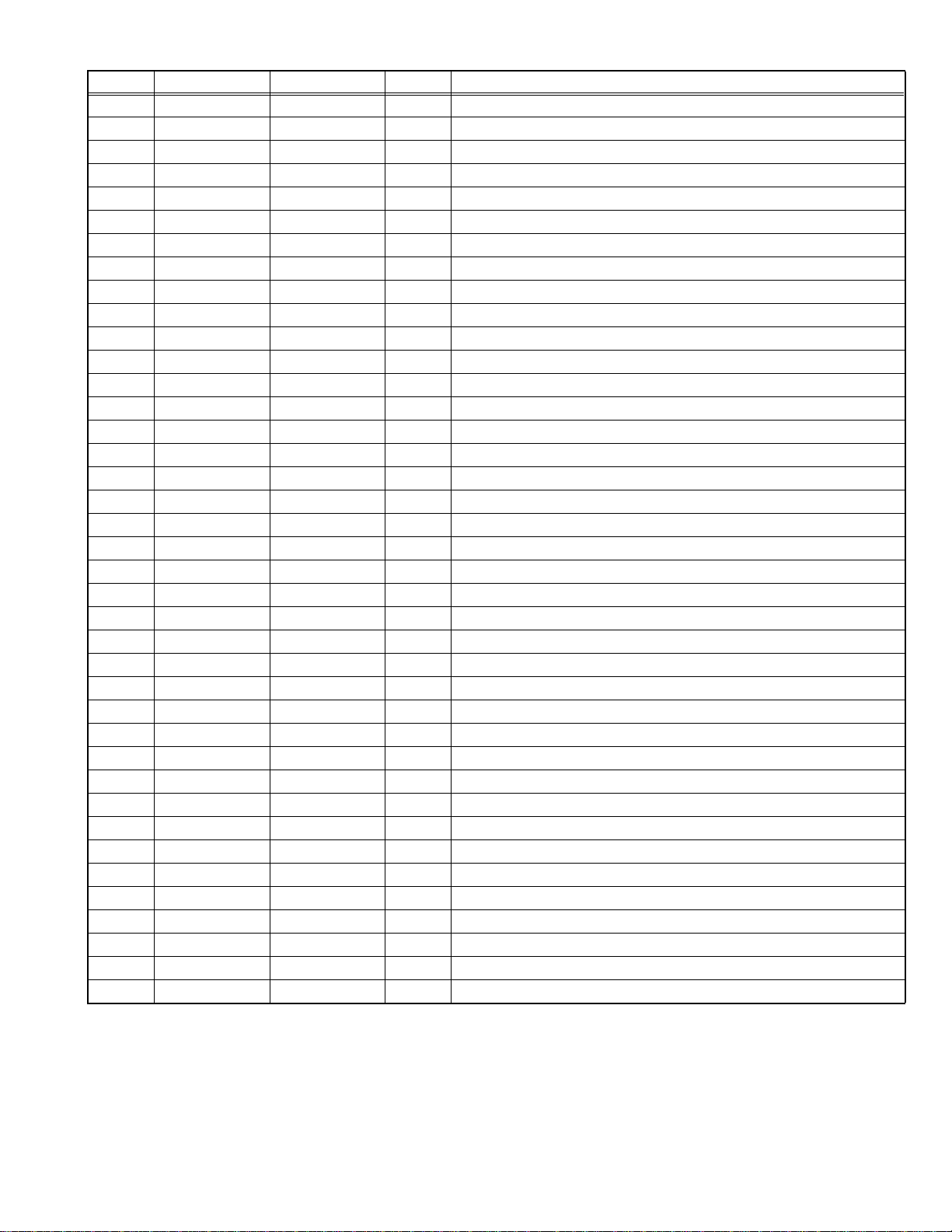

Pin No. Terminal name Port name I/O Function

1 BS-RxD SBO0 O PDP communication

2 /MICON_V /VSYNC I Vertical sync for OSD

3 LB_PRO P84 I Low B protection detect [Detection : H]

4 NC NC - Not used

5 /RST /RST I Reset for CPU [Reset : L]

6 CONV.BUSY P52 IRQ4 I Not used

7 /TEST /TEST I 3.3V

8 OSD_YS YS O OSD Ys

9 /DPCRST P83 O Not used

10 BS/D P50 O Not used

11 A_MU P82 O Audio muting [Muting: H]

12 /MICON_H /HSYNC I Horizontal sync for OSD

13 M_MU P81 O Not used

14 P46.OSDXI P46 OSDXI - Not used

15 P45.OSDXO P45 OSDXO - Not used

16 SDA2 P44 I/O Not used

17 AC_IN TM5IOB I AC power supply (60Hz)

18 SCL2 P42 O Not used

19 TU_POW P41 O Tuner power control [ON : L]

20 VCOI VCOI I LPF input

21 PDO PDO O LPF output

22 /IP_RESET P80 O Reset (L) [Reset : L]

23 OSD_YM DAYMOUT O OSD YM

24 OSD_B DABOUT O OSD B

25 POW_LED P77 O Lighting for power [Lighting : H]

26 OSD_G DAGOUT O OSD G

27 OSD_R DAROUT O OSD R

28 VREF VREF I Not used

29 IP_ERR P76 I AMDP program load

30 IREF IREF I Not used

31 COMP COMP I Not used

32 AVDD AVDD I 3.3V

33 CLL CLL O Not used

34 VREFLS VREFLS I Standard voltage (For SUB CCD)

35 SUB_CCD CVBS1 I Not used

36 NC NC - Not used

37 VSS VSS I GND

38 MAIN_CCD CVBS0 I Not used

39 VREFHS VREFHS I Standard voltage (For MAIN CCD)

40 CLH CLH I Not used

41 VDD/VPP VDD(VPP) I 3.3V

42 CLKSW1 P75 O IP clock switch [ON : L]

43 CLKSW2 P74 O IP clock switch [ON : L]

44 ON_TIM P27 O Not used

45 PDP-Rx SBO1 O PDP communication

1-8 (No.YA029)

Pin No. Terminal name Port name I/O Function

46 PDP-Tx P25 SBD1 I PDP communication

47 SBT1 SBT1 I Port for writing on board

48 NC P23 I Not used

49 NC P22 O Not used

50 SRQ P21 O Not used

51 BS1.5CTL P20 O Not used

52 /DVI_RST PWM2 O Not used

53 DVI_HP PWM1 O DVI Connection detect [Connect : H]

54 /MDR_CON PWM0 O Panel connection detect [Connect : L]

55 /BS_POW P73 O Not used

56 BS_CLK_SEL P14 O Not used

57 TU2_AID ADIN8 I Not used

58 /LOB_POW P72 O LOW B power control

59 /COMPULINK /IRQ3 I Not used

60 /POWERGOOD /IRQ2 I Power condition check [ON : L]

61 MECHA_SW P10/IRQ1 I Discontinuation of mechanical swtich detection [Pussing : L]

62 /MAIN_POW P71 O Main power control [ON : L]

63 NC NC - Not used

64 /B1_POW P70 O Not used

65 C/N ADIN4 I Not used

66 X_RAY ADIN3 I Not used

67 EE_CDS ADIN2 I Not used

68 KEY2 ADIN1 I Key scan data [ON : H]

69 KEY1 ADIN0 I Key scan data [ON : H]

2

70 SCL1 SCL1 O I

71 SDA1 SDA1 I/O I

C bus clock (For Main memory)

2

C bus data (For Main memory)

72 REMO RMIN/IRQ0 I Remote control data

73 NC P87 O Not used

74 VSS VSS I GND

75 OSC2 OSC2 O 4MHz oscillation for system clock

76 OSC1 OSC1 I 4MHz oscillation for system clock

77 VDD VDD I 3.3V

2

78 SCL0 SCL0 O I

C bus clock (for general)

79 NC P86 O Not used

2

80 SDA0 SDA0 I/O I

81 DVI_SDA P57SBT0 O I

C bus data (for general)

2

C bus data (for digital input)

82 NC P56SBD0 I Not used

83 NC NC - Not used

84 P_MU P85 O Picture muting [Muting : H]

(No.YA029)1-9

SECTION 3

DISASSEMBLY

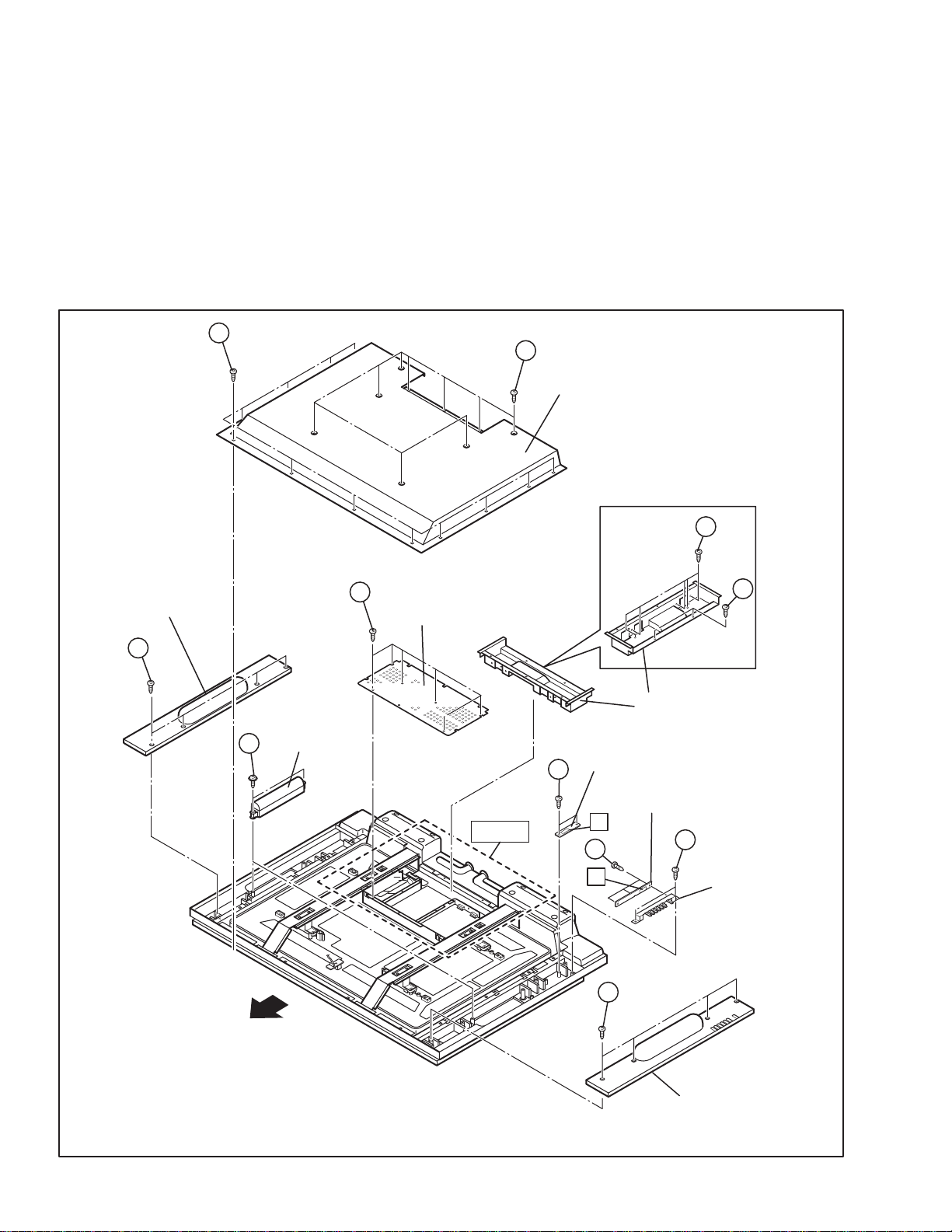

3.1 DISASSEMBLY PROCEDURE (DISPLLAY UNIT)

• Prior to assembly/disassembly procedure of the set, be sure to

disconnect the power cord from the wall outlet.

• Perform the following procedures on a flat and strong place.

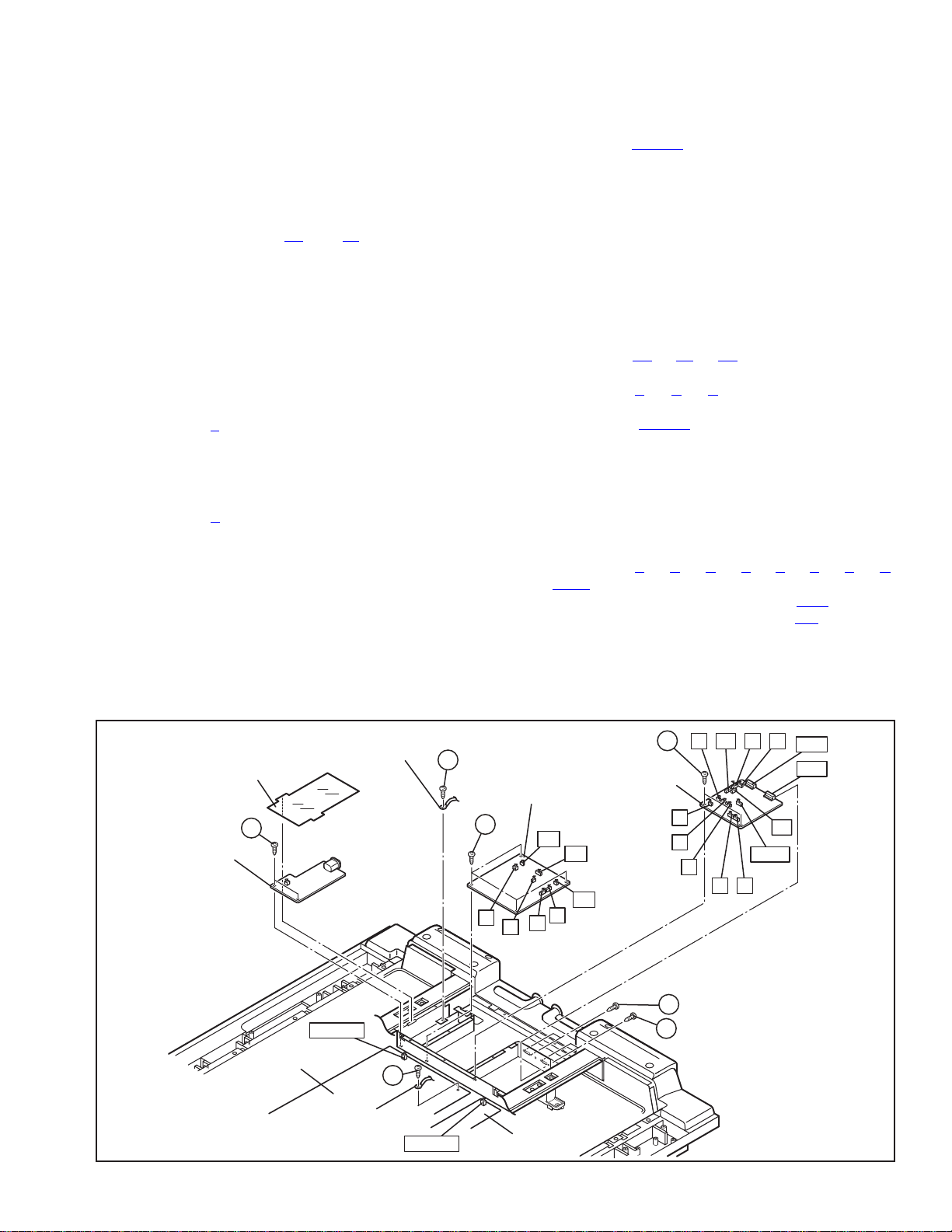

3.1.1 REMOVING THE REAR COVER (Fig.1)

(1) Remove the 9 screws [ A ] .

(2) Remove the 12 screws [ B ].

(3) Take out the REAR COVER.

B

SIDE SPEAKER

COVER

H

SHIELD COVER

3.1.2 REMOVING THE SIDE SPEAKER COVER (Fig.1)

(1) Remove the 4 screws [ C ].

(2) Take out the SIDE SPEAKER COVER.

(3) Remove the other hand SIDE SPEAKER COVER same

steps.

A

REAR COVER

I

J

C

TERMINAL

BRACKET

DISPLAY SW PWB

X

T

C

E

DISPLAY SW

ASS'Y

SIDE SPEAKER

COVER

TOP

D

MAIN

SPEAKER

ASS'Y

Fig.2

DISPLAY LED PWB

G

F

1-10 (No.YA029)

Fig.1

3.1.3 REMOVING THE MAIN SPEAKER ASS'Y (Fig.1, Fig.2)

NOTE:

Please do not disassembly MAIN SPEAKER ASS'Y. A

performance may be influenced if it disassembly.

• Remove the SIDE SPEAKER COVER.

(1) Remove the 2 screws [ D ].

(2) Take out the MAIN SPEAKER ASS'Y.

(3) Remove the other hand MAIN SPEAKER ASS'Y same

steps.

(4) If necessary, remove the [SR

] and [SL] connector.

3.1.4 REMOVING THE DISPLAY SW ASS'Y (Fig.1)

• Remove the SIDE SPEAKER COVER.

(1) Remove the 2 screws [ E ].

(2) Take out the DISPLAY SW ASS'Y.

3.1.5 REMOVING THE DISPLAY SW PWB (Fig.1)

• Remove the SIDE SPEAKER COVER.

• Remove the DISPLAY SW ASS'Y.

(1) Remove the 3 screws [ F ].

(2) Take out the DISPLAY SW PWB.

(3) Remove the [ T

] connector on the DISPLAY SW PWB.

3.1.6 REMOVING THE SENSOR PWB (Fig.1)

• Remove the SIDE SPEAKER COVER.

(1) Remove the 2 screws [ G ].

(2) Take out the SENSOR PWB.

(3) Remove the [ X

] connector on the SENSOR PWB.

3.1.7 REMOVING THE SHIELD COVER (Fig.1)

• Remove the REAR COVER.

(1) Remove the 6 screws [ H ].

(2) Take out the SHIELD COVER.

3.1.8 REMOVING THE TERMINAL BRACKET (Fig.1)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

(1) Remove the 5 screws [ I ].

(2) Remove the 2 screws [ J ].

(3) Take out the TERMINAL BRACKET.

3.1.9 REMOVING THE LINE FILTER PWB (Fig.2)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

(1) Remove the [ CN8001

] ( AC IN ) connector on the SMPS

PWB.

(2) Remove the 1 screw [ K ] attaching the earth wire ( black )

on the PDP UNIT.

(3) Remove the 1 screw [ L ] attachin g the earth wire ( green

and yellow ).

(4) Remove the 2 screws [ M ] .

(5) Take out the LINE FILTER PWB.

3.1.10 REMOVING THE AUDIO PWB (Fig.2)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

(1) Remove the [ SR

], [ SL ], [ CB ] connector on the AUDIO

PWB.

(2) Remove the [ A

], [ C ], [ D ] connector on the DISPLAY

INTERFACE PWB.

(3) Remove the [ CN9003

] ( B ) connector on the VIDEO

SMPS PWB.

(4) Remove the 4 screws [ N ].

(5) Take out the AUDIO PWB.

3.1.11 REMOVING THE DISPLAY INTERFACE PWB (Fig.2)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

(1) Remove the [ A

], [ C ], [ D ], [ E ], [ T ], [ X ], [ V ], [ G ],

[ LVDS ] connector on the DISPLAY INTERFACE PWB.

(2) Remove the 2 screws [ O ] attaching the MDR connector.

(3) Remove the 2 screws [ P ] attaching the DVI

connector.

(4) Remove the 2 screws [ Q ].

(5) Take out the DISPLAY INTERFACE PWB.

INSULATOR

LINE FILTER

PWB

M

SMPS PWB

EARTH WIRE

(GREEN &YELLOW)

CN8001

K

EARTH

WIRE

(BLACK)

CN9003

L

AUDIO PWB

N

B

A

VIDEO SMPS PWB

Fig.2

Q

V D

C2

DISPLAY

INTERFACE

PWB

A

SL

CB

SR

D

C

X

T

O

P

GE

LVDS

C

C1

MDR

DVI

(No.YA029)1-11

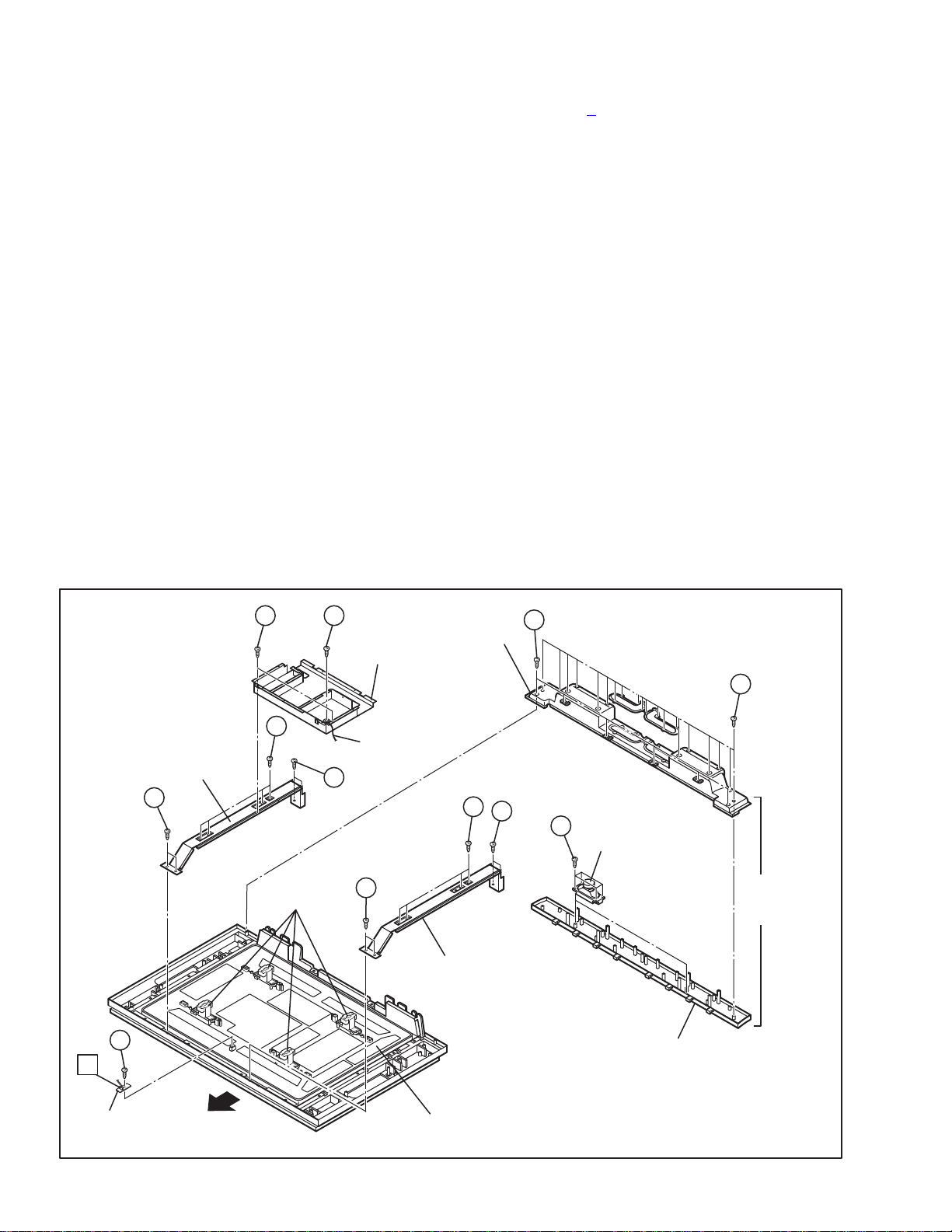

3.1.12 REMOVING THE CHASSIS BASE (Fig.3)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

• Remove the LINE FILTER PWB.

• Remove the AUDIO PWB.

• Remove the DISPLAY INTERFACE PWB.

(1) Remove the 2 screws [ R ].

(2) Remove the 1 screw [ S ] attaching the earth wire.

(3) If necessary, remove the cable and wires from wire clamp.

(4) Pull up the CHASSIS BASE.

3.1.13 REMOVING THE BACK FRAME BRACKET (Fig.3)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

• Remove the LINE FILTER PWB.

• Remove the AUDIO PWB.

• Remove the DISPLAY INTERFACE PWB.

• Remove the CHASSIS BASE.

(1) Remove the 4 screws [ T ].

(2) Remove the 4 screws [ U ].

(3) If necessary, remove the cable and wires from wire clamp.

(4) Pull up the BACK FRAME BRACKET.

(5) The other hand BACK FRAME BRACKET is removed

same steps.

3.1.14 REMOVING THE TEMP. SENSOR PWB (Fig.3)

• Remove the REAR COVER.

(1) Remove the [ V

] connector on the TEMP. SENSOR PWB.

(2) Remove the screw [ V ].

(3) Take out the TEMP. SENSOR PWB.

3.1.15 REMOVING THE PDP UNIT (Fig.3)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

• Remove the LINE FILTER PWB.

• Remove the AUDIO PWB.

• Remove the DISPLAY INTERFACE PWB.

• Remove the CHASSIS BASE.

• Remove the BACK FRAME BRACKET.

• Remove the TEMP. SENSOR PWB.

(1) Rise with the back frame spacer on the PDP UNIT back

side.

(2) Take out the PDP UNIT.

3.1.16 REMOVING THE WOOFER SPEAKER BOX (Fig.3)

(1) Remove the 6 screws [ W ].

(2) Take out the WOOFER SPEAKER BOX.

3.1.17 REMOVING THE SPEAKER (WOOFER) (Fig.3)

• Remove the WOOFER SPEAKER BOX.

(1) Remove the 20 screws [ X ].

(2) Pull up the WOOFER SPEAKER HOLDER.

(3) Remove the 4 screws [ Y ].

(4) Take out the WOOFER.

(5) Remove the other hand WOOFER same steps.

R

U

BACK FRAME

BRACKET

T

BACK FRAME

SPACER

V

V

S

CHASSIS BASE

EARTH

WIRE

T

T

WOOFER

SPEAKER

HOLDER

U

BACK FRAME

BRACKET

W

X

T

Y

SPEAKER

(WOOFER )

WOOFER

SPEAKER

BOX

WOOFER SPEAKER

BACK COVER

TEMP. SENSOR

PWB

1-12 (No.YA029)

TOP

PDP UNIT

Fig.3

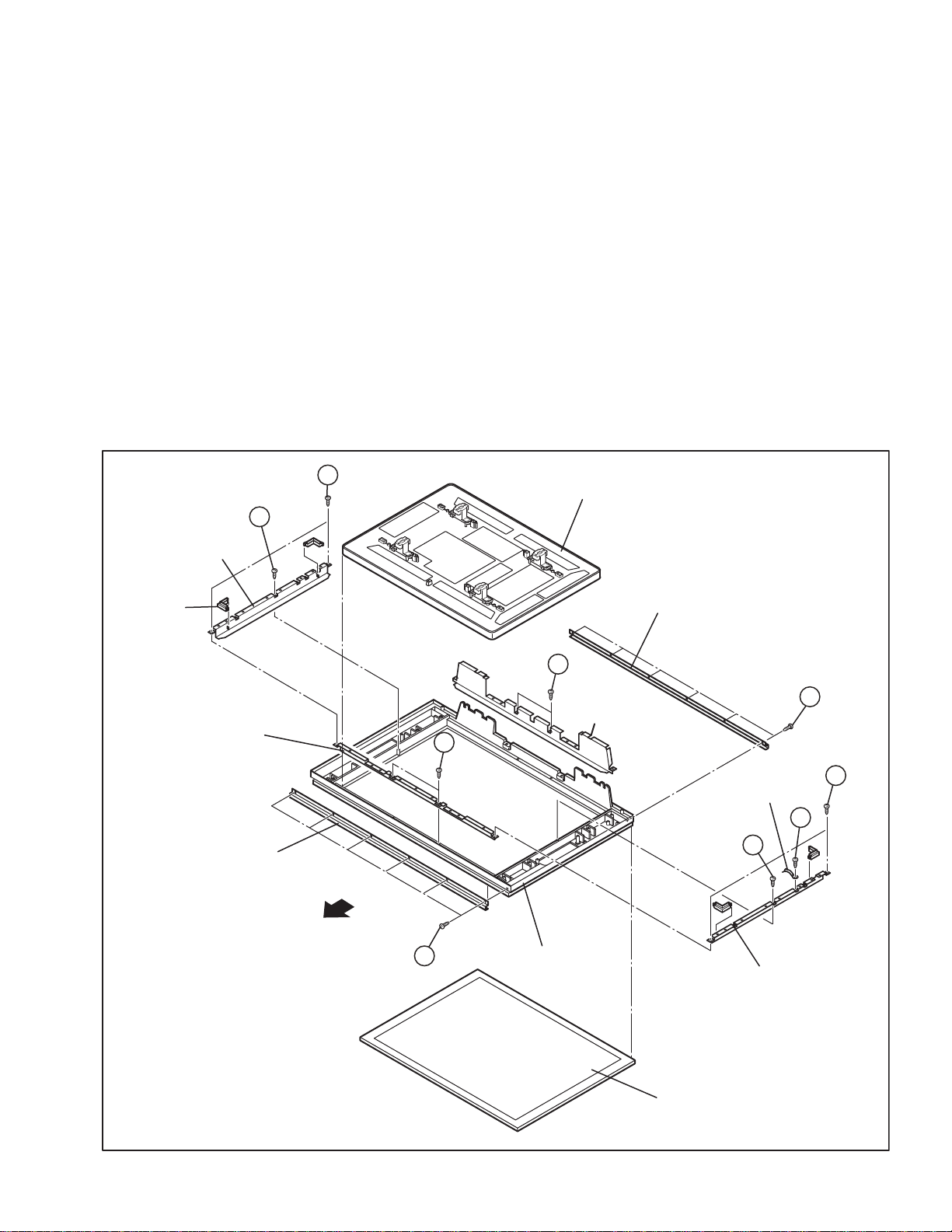

3.1.18 THE SIDE BLACKET (Fig.4)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

• Remove the LINE FILTER PWB.

• Remove the AUDIO PWB.

• Remove the DISPLAY INTERFACE PWB.

• Remove the CHASSIS BASE.

• Remove the BACK FRAME BRACKET.

• Remove the PDP UNIT.

(1) Remove the 2 screws [ Z ].

(2) Remove the screw [ a ].

(3) Remove the screw [ b ] attaching the earth wire.

(4) Pull up the SIDE BRACKET.

(5) Remove the other hand SIDE BRACKET same steps.

Z

a

3.1.19 REMOVE THE FRONT FILTER (Fig.4)

• Remove the REAR COVER.

• Remove the SHIELD COVER.

• Remove the TERMINAL BRACKET.

• Remove the LINE FILTER PWB.

• Remove the AUDIO PWB.

• Remove the DISPLAY INTERFACE PWB.

• Remove the CHASSIS BASE.

• Remove the BACK FRAME BRACKET.

• Remove the PDP UNIT.

(1) Remove the 2 screws [ c ] attaching the UPPER

BRACKET.

(2) Remove the 6 screws [ d ] attaching the GLASS HOLDER

(UPPER) from upper side.

(3) Pull up the UPPER BRACKET.

(4) Remove the 2 screws [ e ] attaching the UPPER

BRACKET.

(5) Remove the 6 screws [ f ] attaching the GLASS HOLDER

(UPPER) from under side.

(6) Take out the FRONT FILTER .

PDP UNIT

SIDE BRACKET

MOUNTING

BOSS

UPPER

BRACKET

GLASS HOLDER

(UPPER)

TOP

GLASS HOLDER

(UNDER)

e

UNDER

BRACKET

c

EARTH

WIRE

a

d

FRONT PANEL

SIDE BRACKET

f

Z

b

Fig.4

FRONT FILTER

(No.YA029)1-13

3.1.20 DISASSEMBLY PDP UNIT

3.1.20.1 REMOVING THE SMPS PWB

• Remove the REAR COVER.

(1) Remove the CN8007

CN8009

(2) Remove the 8 screws [g].

(3) Remove the SMPS PWB.

3.1.20.2 REMOVING THE X-MAIN PWB

• Removing the REAR COVER.

(1) Remove the CN4001

connectors on the X-MAIN PWB.

(2) Remove the 8 screws [h].

(3) Remove the X-MAIN PWB.

3.1.20.3 REMOVING THE Y-BUF-U PWB

• Remove the REAR COVER.

(1) Remove the CN5401

connectors on the Y-BUF-U PWB.

(2) Remove the 5 screws [I].

(3) Lift the Y-BUF-U PWB slightly, and remove th e CN5404

CN5405 connectors on the Y-BUF-U PWB.

(4) Remove the Y-BUF-U PWB.

3.1.20.4 REMOVING THE Y-BUF-L PWB

• Remove the REAR COVER.

(1) Remove the CN5501

connectors on the Y-BUF-L PWB.

(2) Remove the 5 screws [j].

(3) Lift the Y-BUF-L PWB slightly, and remove the CN5504/

CN5505

(4) Remove the Y-BUF-L PWB.

3.1.20.5 REMOVING THE Y-MAIN PWB

• Remove the REAR COVER.

• Remove the CHASSIS BASE.

• Remove the Y-BUF-U PWB.

• Remove the Y-BUF-L PWB.

(1) Remove the CN5001

PWB.

(2) Remove the 7 screws [k].

(3) Remove the Y-MAIN PWB.

/CN8002 connectors on the SMPS PWB.

connectors on the Y-BUF-L PWB.

/CN8008/CN8004/BUFFER/CN8003/

/CN4002/CN4003/CN4004/CN4005

/CN5402/CN5403/CN5406

/CN5502/CN5503/CN5506

/CN5008 connectors on the Y-MAIN

3.1.20.6 REMOVING THE LOGIC-MAIN PWB

• Remove the REAR COVER.

• Remove the CHASSIS BASE.

(1) Remove the CN101

connectors on the LOGIC-MAIN PWB.

(2) Remove the 6 screws [l].

(3) Remove the LOGIC-MAIN PWB.

3.1.20.7 REMOVING THE E-BUF PWB

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the CHASSIS BASE.

• Remove the SPEAKER BRACKET (left).

(1) Remove the EC1

connectors on the E-BUF PWB.

(2) Remove the 6 screws [m].

(3) Remove the E-BUF PWB.

3.1.20.8 REMOVING THE F-BUF PWB

/

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the CHASSIS BASE.

(1) Remove the FC4

BUF PWB.

(2) Remove thr 4 screws [n].

(3) Remove the F-BUF PWB.

3.1.20.9 REMOVING THE G-BUF PWB

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the CHASSIS BASE.

• Remove the SPEAKER BRACKET (right).

(1) Remove the GC5

the G-BUF PWB.

(2) Remove the 6 screws [o].

(3) Remove the G-BUF PWB.

3.1.20.10 REMOVING THE VIDEO SMPS PWB

• Remove the REAR COVER.

(1) Remove the CN9001

CN9007

(2) Remove the 4 screws [p].

(3) Remove the VIDEO SMPS PWB.

connectors on the VIDEO SMPS PWB.

/CN201/CN401/CN402/CN403/CN803

/EC2/EC3/CN401/CN806/EF1

/CN402/FE1/FG1 connectors on the F-

/GC6/GC7/CN403/GF1 connectors on

/CN9002/CN9004/CN9005/CN9006/

1-14 (No.YA029)

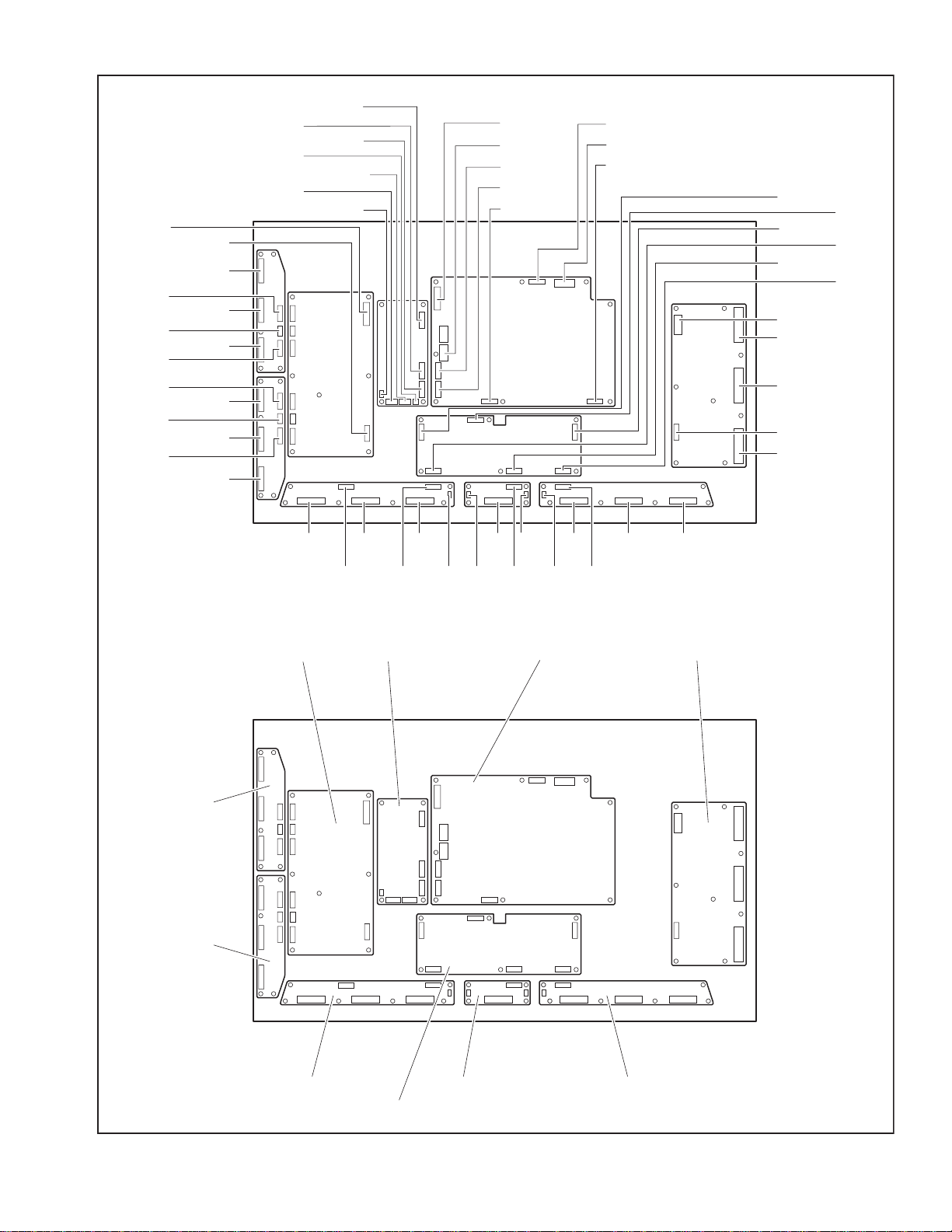

CN5008

CN5404

CN5406

CN5405

CN5505

CN5506

CN5504

CN5001

CN5401

CN5402

CN5403

CN5501

CN5502

CN5503

CN9007

CN9003

CN9001

CN9005

CN9006

CN9002

CN9004

CN8003

BUFFER

CN8004

CN8007

CN8008

CN8009

CN8002

CN8001

CN201

CN803

CN101

CN401

CN402

CN403

CN4001

CN4003

CN4004

CN4002

CN4005

Y-BUF-U PWB

Y-BUF-L PWB

EC1

Y-MAIN PWB

EC2 EC3

CN806 CN401 CN402 CN403

EF1

FC4 FC4

FE1

GC5 GC6 GC7

GF1

SMPS PWBVIDEO SMPS PWB

X-MAIN PWB

E-BUF PWB G-BUF PWBF-BUF PWB

LOGIC-MAIN PWB

Fig.5

(No.YA029)1-15

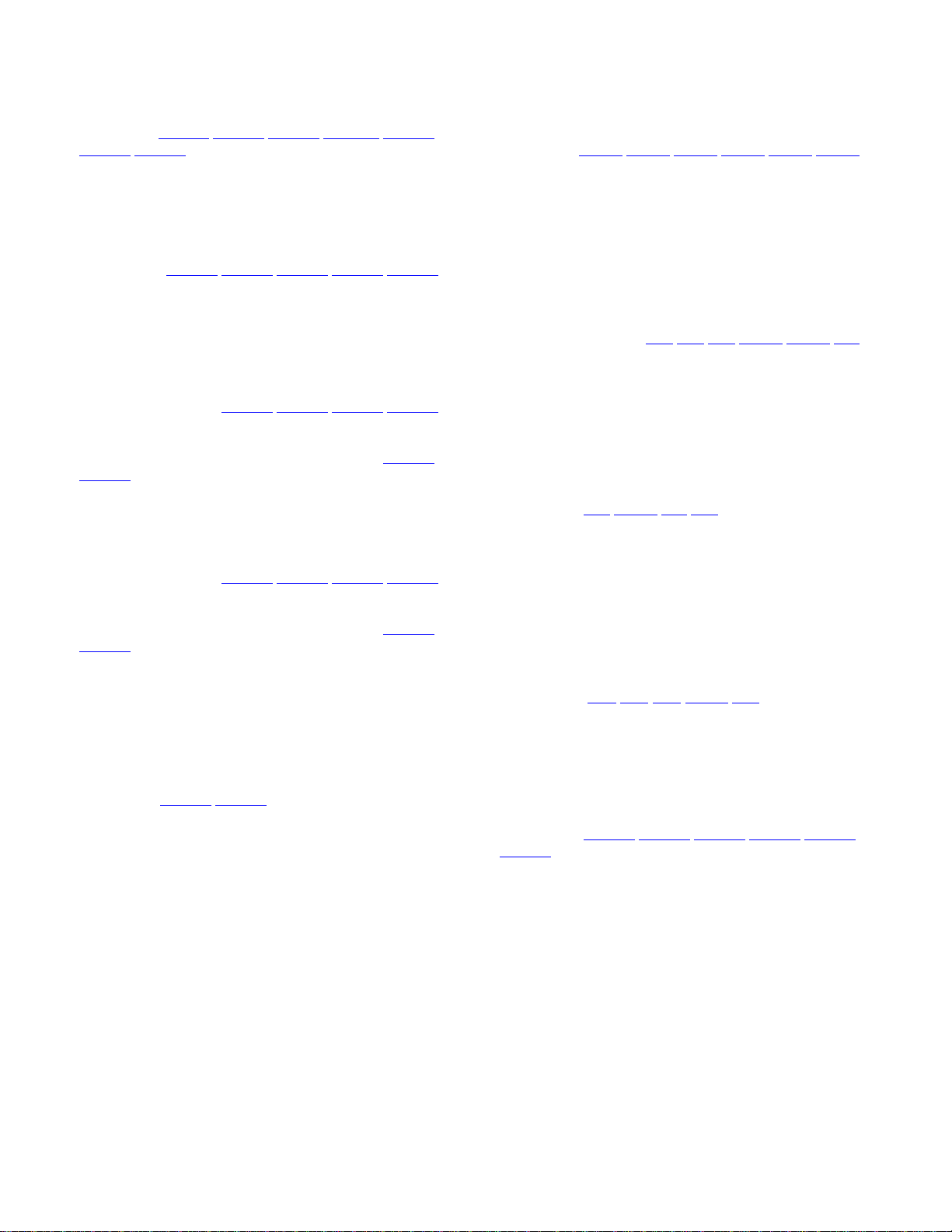

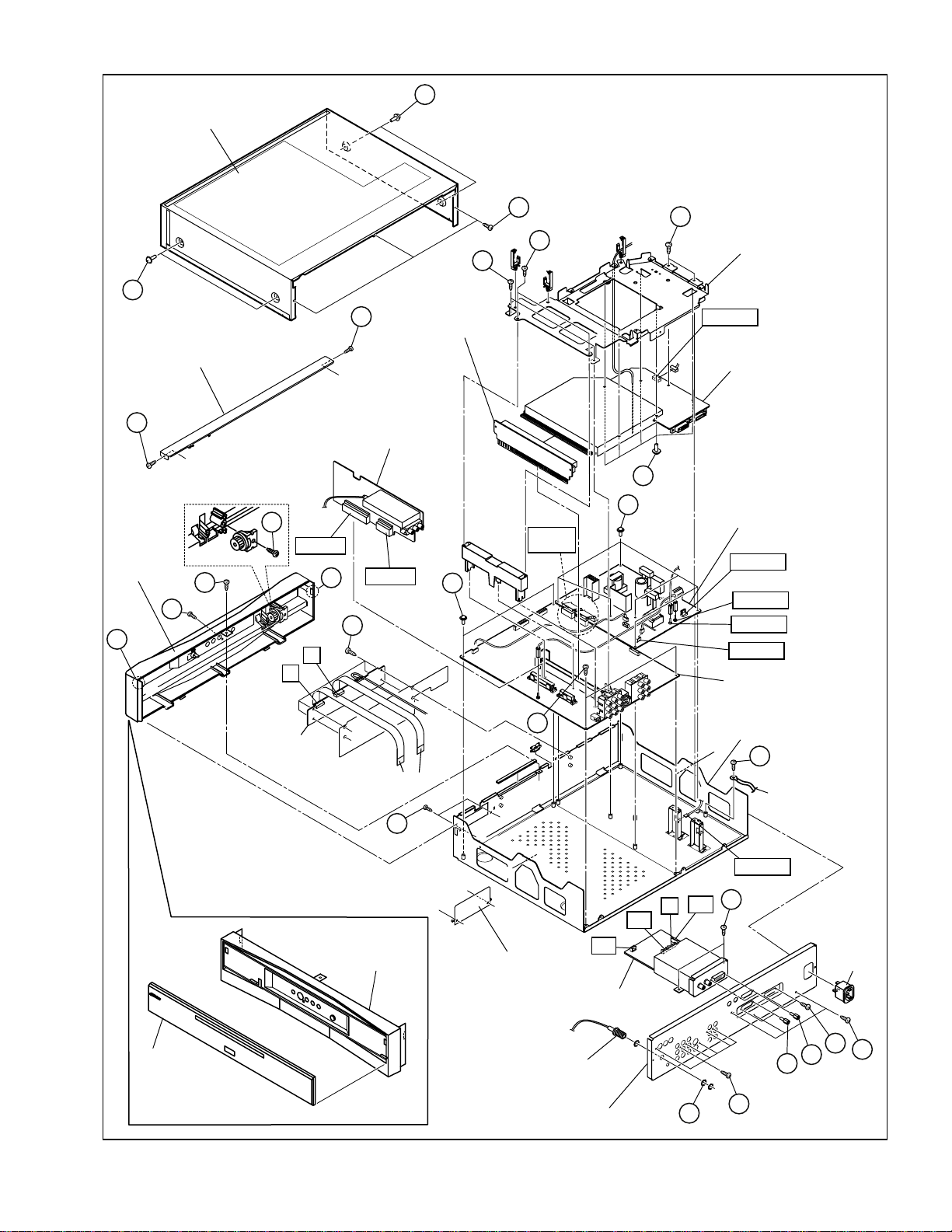

3.2 DISASSEMBLY PROCEDURE (RECEIVER UNIT) (Fig. 6)

• Make sure that the power cord is pulled out from the AC wall

socket.

3.2.1 REMOVING THE TOP COVER

(1) Remove the 4 screws [ A ] from both side of the TOP

COVER.

(2) Remove the 3 screws [ B ] from rear side of the TOP

COVER.

(3) Pull up the TOP COVER.

3.2.2 REMOVING THE BACK COVER

• Remove the TOP COVER.

(1) Remove the 2 screws [ C ] attaching the AC connector.

(2) Remove the 3 screws [ D ].

(3) Remove the 6 screws [ E ] attaching the each jacks.

(4) Remove the 2 screws [ F ] attaching the digital connector.

(5) Remove the 2 screws [ G ] attaching the DIGITAL INPUT

MODULE.

(6) Remove the 2 screws [ H ] attaching the DVI terminal.

(7) Remove the 1 nat [ I ] attaching the antenna terminal.

(8) Take out the rear cover.

3.2.3 REMOVING THE CHASSIS BRACKET

• Remove the TOP COVER.

(1) Remove the 2 screws [ J ].

(2) Pull up the CHASSIS BRACKET.

3.2.4 REMOVING THE DIGITAL INPUT MODULE

• Remove the TOP COVER.

• Remove the BACK COVER.

(1) Remove the connector [ AU

], [ SR ], [ DC ], [ Q ] on the

DIGITAL INPUT MODULE.

(2) Remove the 2 screws [ K ].

(3) Take out the DIGITAL INPUT MODULE.

3.2.5 REMOVI NG THE MI-COM & DIST MODULE PWB AN D

DIST RELAY PWB

• Remove the TOP COVER.

• Remove the BACK COVER.

• Remove the DIGITAL INPUT MODULE.

(1) Remove the [ CN100A

] connector on the MI-COM & DIST

MODULE PWB.

(2) Remove the 2 screws [ L ].

(3) Remove the 2 screws [ M ].

(4) Remove the 2 screws [ N ].

(5) Pull up the DIST RELAY PWB from MAIN PWB.

(6) Remove the 5 screws [ O ] attaching the MI-COM & DIST

MODULE PWB.

(7) Take out the MI-COM & DIST MODULE PWB and DIST

RELAY PWB from the DIST HOLDER.

3.2.6 REMOVING THE RECEIVER POWER PWB

• Remove the TOP COVER.

• Remove the BACK COVER.

• Remove the DIGITAL INPUT MODULE.

• Remove the MI-COM & DIST MODULE PWB and DIST

RELAY PWB.

(1) Remove the [ CN1001

] and [ CN1002 ] connector on the

MAIN PWB.

(2) Remove the [ CN90PW

] [ CN900X ] and [ CN90E1 ]

connector on the RECEIVER POWER PWB.

(3) Remove the earth wire [ CN90E2 ] from chassis.

(4) Remove the 6 screws [ P ].

(5) Take out the RECEIVER POWER PWB.

3.2.7 REMOVING THE FRONT PANEL

• Remove the TOP COVER.

(1) Remove the 1 screw [ Q ] from front side.

(2) Remove the 1 screw [ R ] from top side.

(3) Remove the 2 claws [ Y ] from left and right side.

(4) Pull out the FRONT PANEL.

3.2.8 REMOVING THE DAMPER

• Remove the TOP COVER.

• Remove the FRONT PANEL.

(1) Remove the 1 screw [ S ] from back side of the FRONT PANEL.

(2) Remove the DAMPER.

3.2.9 REMOVING THE FRONT CONTROL PWB

• Remove the TOP COVER.

• Remove the FRONT PANEL.

(1) Remove the card wire from the [ H

] and [ G ] connector.

(2) Remove the 4 screws [ T ].

(3) Take out the FRONT CONTROL PWB.

3.2.10 REMOVING THE RECEIVER PWB

• Remove the TOP COVER.

• Remove the BACK COVER.

• Remove the CHASSIS BRACKET.

• Remove the DIGITAL INPUT MODULE.

• Remove the MI-COM & DIST MODULE PWB and DIST RELAY PWB.

(1) Remove the [ CN1005

] and [ CN1006 ] connector.

(2) Pull up the RECEIVER PWB.

3.2.11 REMOVING THE MAIN PWB

• Remove the TOP COVER.

• Remove the BACK COVER.

• Remove the CHASSIS BRACKET.

• Remove the DIGITAL INPUT MODULE.

• Remove the MI-COM & DIST MODULE PWB and DIST RELAY PWB.

• Remove the FRONT PANEL.

• Remove the RECEIVER PWB.

(1) Remove the 3 screws [ U ] attaching the bracket.

(2) Remove the 2 screws [ V ].

(3) Remove the 2 screws [ W ].

(4) Take out the MAIN PWB.

DIGITAL INPUT MODULE

BACK COVER

1-16 (No.YA029)

1

3

5

SB

connector

CAUTION AT DISASSEMBLY

Prior to disassembly, unplug the power code from the AC outlet without fail. (Turn

the power "off".)

Short the SB connector [1] pin and [2] pin of the DIGITAL INPUT MODULE. (At the

time of assembling)

Before the rear panel is inserted into the cabinet, release the short-circuit between

2

4

6

the SB connector [1] pin and [2] pin of the DIGITAL INPUT MODULE.

After releasing the short-circuit between the SB connectors, do not turn the power

on until the rear panel is inserted into the cabinet.

Negligence in carrying out the above steps may cause the inactivation of the TV.

TOP COVER

A

(x4)

A

CHASSIS BRACKET

J

(x2)

FRONT

PANEL

Y

Claw

a

FRONT PANEL

(BACK SIDE)

DAMPER

R

(x1)

Q

B

(x3)

M

N

(x2)

J

(x2)

L

(x2)

DIST HOLDER

CN100A

DIST RELAY PWB

b

MI-COM & DIST

MODULE PWB

RECEIVER PWB

O

(x5)

S

c

CN1006

Y

Claw

H

T

(x4)

CN1005

(x2)

CN1001

CN1002

V

G

P

(x6)

RECEIVER POWER PWB

g

CN90PW

CN90E1

CN90E2

CN900X

MAIN PWB

FRONT

DOOR

FRONT

CONTROL

PWB

FFC WIRE

U

(x2)

FRONT PANEL

e

e

d

BRACKET

Fig.6

(x2)

d

a

ANTENNA

TERMINAL

W

DC

AU

DIGITAL INPUT

MODULE PWB

c

BACK COVER

BOTTOM CASE

b

C

g

SR

Q

EARTH WIRE

CN90E2

K

(x2)

AC

INLET

F

(x2)

D

(x3)

G

H

(x2)

(x2)

I

E

(x6)

(No.YA029)1-17

3.3 REPLACEMENT OF MEMORY IC

MAIN MENU

This unit uses the nonvolatile memory IC. The memory IC memories data for video-chroma and drive circuits. To replace the memory

IC without the data written, malfunctions might occurred while power is on, and the normal image might not appear. Wh en replaci ng

the memory IC, be sure to use the IC written with the initial values of data.

3.3.1 PROCEDURE FOR REPLACING THE MEMORY IC

NOTE:

Before entering the SERVICE MODE, confirm that the setting

of TV / CATV SW of the REMOTE CONTROL UNIT is at the

"TV" side and the setting of VCR / DVD SW is at the "VCR"

side. If the switches have not been properly set, you cannot

enter the SERVICE MODE.

(1) Switch the power off and unplug the power cord from the

wall outlet.

(2) Replacing the memory IC. [Be sure to use the IC written

with the initial values of data]

(3) Plug the power cord into the wall outlet and switch the

power on.

(4) Receive channel setting

(5) User setting

Memories the user setting items. The [SETTINGS OF

FACTORY SHIPMENT] setting is as next page.

(6) SERVICE MODE

Check the SERVICE MODE setting items of setting mode

in Table 1, set if necessary. For setting method, please

refer to the [ADJUSTMENT PREPARATION :

ADJUSTMENT PROCEDURE ] of ADJUSTMENT section.

MAIN MENU

1.PICTURE/SOUND

2.YC SEP

3.WHITE BALANCE

4.MEMORY SETUP

7.PANEL

8.PP

9.IP

0.HDMI

5.RF AFC

6.DD/CM

1. PICTURE/SOUND (sound and picture setting)

Sound circuits (A) Fixed A01~A27

Video circuits (S) Adjust S01~S99

Deflection circuits (D) Fixed D01~D32

Factory setting items (F) Adjust F01~F59

2. YC SEP

3-dimensional YC separation

setting

3. WHITE BALANCE: Cannot adjust

4. MEMORY SETUP: Do not adjust

Memory data edit Fixed -

5. RF AFC: AFC setting (Automaticaly set)

6. DD/CM

Panel image processing setting Adjust DDT01~DDT34

7. PANEL: Do not adjust

Panel power limit control Fixed PDA001~PDA012

8. PP

Multi-screen processing setting A djust ADM001~ADM034

9. IP

DIST processing setting Fixed IPA001~IPA120

0. HDMI

Digital input process setting Fixed HDM001~HDM080

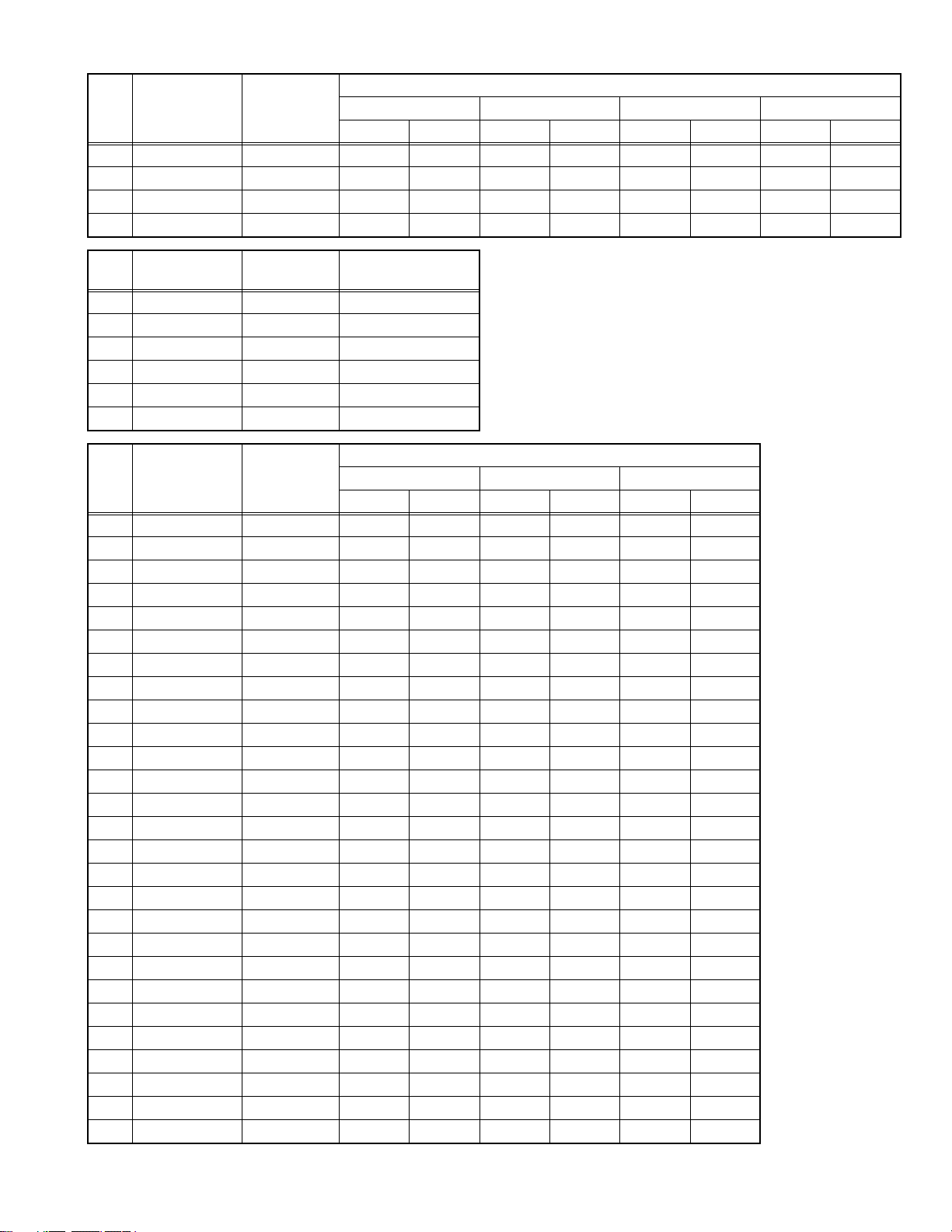

SERVICE MODE SETTING ITEMS

Setting items Settings Item No.

Adjust YCM001~YCM185

Fixed YCS001~YCS114

Fixed CMT01~CMT57

Fixed DDP01~DDP37

Fixed CMP01~CMP03

Fixed PDB001~PDA021

Fixed RGA001~RGA003

Fixed PPA001~PPA008

Fixed PPB001~PPB036

Fixed PPC001~PPC008

Fixed PPD001~PPD025

Fixed IPB001~IPB079

Fixed IPC001~IPC044

Fixed IPD001~IPD026

Fixed IPE001~IPE015

Fixed RHD001~RHD170

1-18 (No.YA029)

3.3.2 SETTINGS OF FACTORY SHIPMENT

3.3.2.1 BUTTON OPERATION (DISPLAY UNIT) 3.3.2.2 REMOTE CONTROL DIRECT OPERATION

Setting item Setting value

INPUT TV

CHANNEL 1

VOLUME 10

3.3.2.3 REMOTE CONTROL MENU OPERATION

(1) PICTURE ADJUSTMENT

Customers can adjust the picture setting of menu screen as their own like but the picture standard value during factory shipment is as

below.

NTSC MODE

PICTURE BRIGHT COLOR TINT DETAIL

DINAMIC +04 -03 +08 00 +06 HIGH OFF VIVID

STANDARD 00 00 00 00 00 LOW OFF VIVID

GAME -05 00 -03 00 -03 HIGH OFF VIVID

THEATER 00 00 00 00 00 HIGH OFF VIVID

INPUT TV

CHANNEL CABLE-02

VOLUME 10

MUTING OFF

DISPLAY OFF

SOUND AHS OFF

ASPECT PANORAMA

OFF TIMER OFF

VIDEO STATUS DINAMIC

NATURAL CINEMA AUTO

Setting item Setting value

BBE ON

AHB ON

COLOR

TEMPERATURE

DIG. NOISE

CLEAR

MANAGEMENT

COLOR

HD MODE

PICTURE BRIGHT COLOR TINT DETAIL

DINAMIC +05 -02 -08 00 +05 HIGH OFF VIVID

STANDARD 00 00 00 00 00 LOW OFF VIVID

GAME -05 00 +03 00 -03 HIGH OFF VIVID

THEATER 00 00 00 00 00 LOW OFF VIVID

(2) SOUND

Setting item Setting value

TREBLE 00

BASS 00

BALANCE 00

MTS STREO

(3) SETTINGS

Setting item Setting value Setting item Setting value

POSITION ADJUSTMENT Center NOISE MUTING ON

VIDEO STATUS DYNAMIC FRONT PANEL LOCK OFF

XDS ID ON AUTO SHUT OFF OFF

POWER INDICATOR HIGH DIGITAL-IN SIZE-1

TV SPEAKER OFF ON V-CHIP OFF

AUDIO OUTPUT FIX AUTO DEMO OFF

LANGUAGE ENG IMAGE SHIFT STD

CLOSED CAPTION OFF V1 SMART INPUT OFF

COLOR

TEMPERATURE

DIG. NOISE

CLEAR

COLOR

MANAGEMENT

(No.YA029)1-19

3.4 REPLACEMENT OF CHIP COMPONENT

3.4.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.4.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for ea sily removing parts.

3.4.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and al-

ternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the sol-

der. Then heat and melt the solder at both ends of the chip

part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the sol-

der.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and al-

ternately melt the solder at each lead. Shift and remove the

chip part.

NOTE :

After removing the part, remove remaining solder from the pattern.

1-20 (No.YA029)

A

B

C

(4) Then solder leads B and C.

A

B

C

SECTION 4

ADJUSTMENTS

4.1 ADJUSTMENT PREPARATION

(1) There are 2 ways of adjusting this TV : One is with the

REMOTE CONTROL UNIT and the other is the

conventional method using adjustment parts and

components.

(2) The adjustment using the REMOTE CONTROL UNIT is

made on the basis of the initial setting values. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting

values.

(3) Make sure that connection is correctly made AC to AC

power source.

(4) Turn on the power of the TV and measuring instruments for

warning up for at least 30 minutes before starting

adjustments.

(5) If the receive or input signal is not specified, use the mo st

appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors,

transformers and condensers) not shown in the adjustment

items of this service adjustment.

4.2 MEASURING INSTRUMENT AND FIXTURES

• DC voltmeter (or Digital voltmeter)

• Oscilloscope

• Signal generator (Pattern generator)

• Remote control unit

(7) Preparation for adju stment. Unless otherwise specified in

the adjustment items, preset the following functions with

the REMOTE CONTROL UNIT.

Setting item Settings

VIDEO STATUS STANDARD

BRIGHT / CONTRAST / COLOR / TINT

COLOR TEMPERATURE LOW

DIG. NOISE CLEAR OFF

COLOR MANEGMENT STD

NATURAL CINEMA OFF

DIGITAL VNR OFF

TREBLE / BASS / BALANCE Center

BBE OFF

AHS OFF

AHB OFF

Center

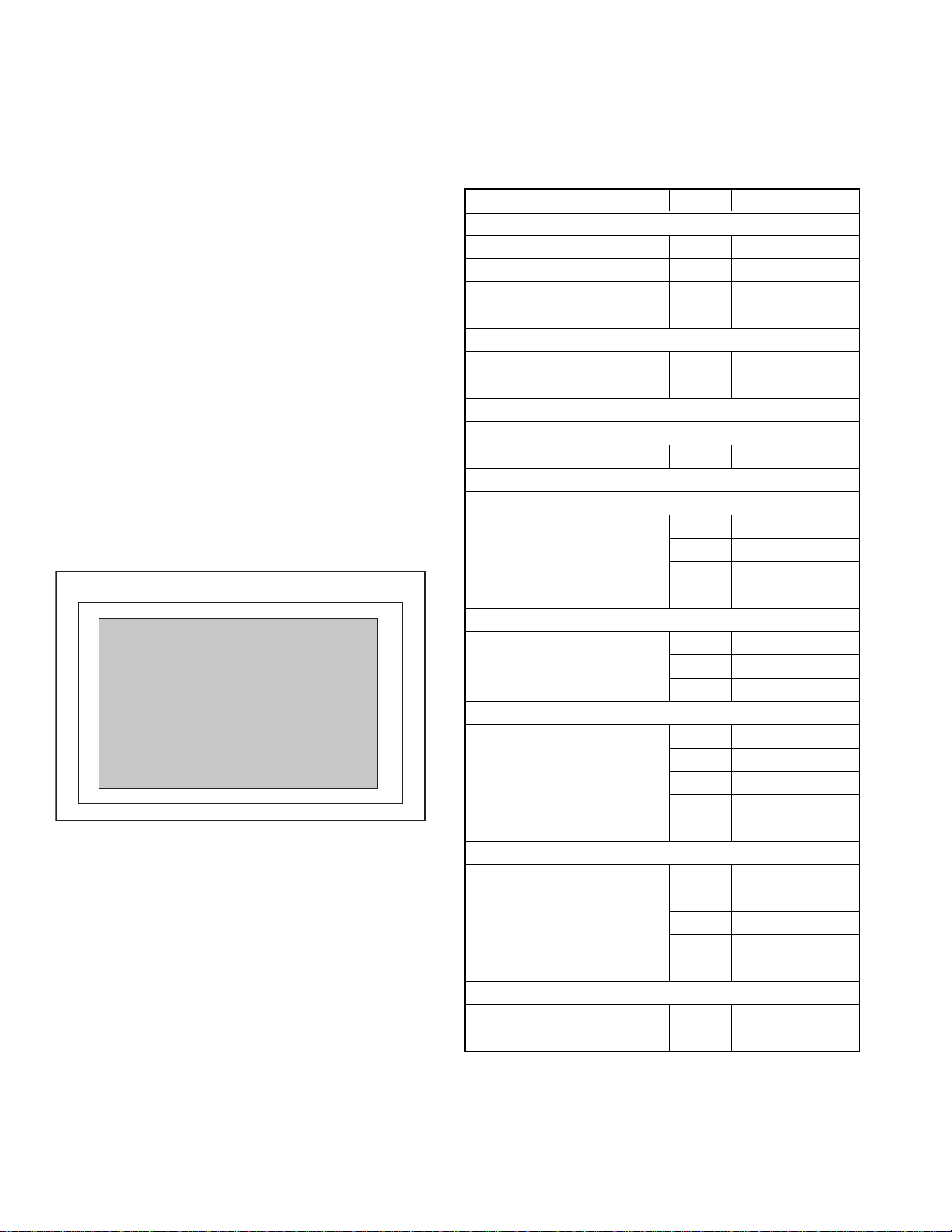

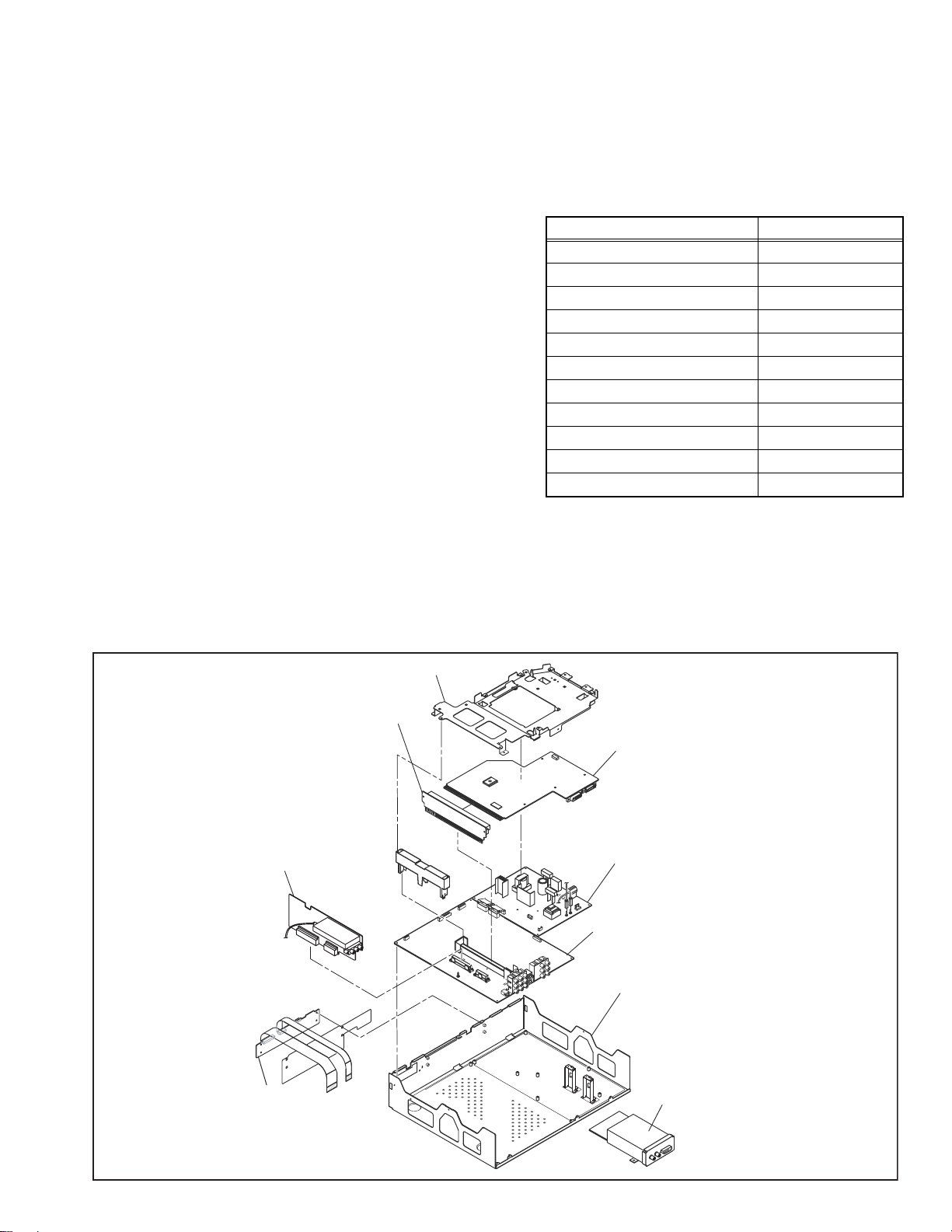

4.3 MAIN PARTS LOCATIONS (RECEIVER UNIT)

DIST RELAY PWB

RECEIVER PWB

DIST HOLDER

MI-COM & DIST MODULE PWB

RECEIVER POWER PWB

MAIN PWB

BOTTOM CASE

FRONT CONTROL PWB

DIGITAL INPUT MODULE

(No.YA029)1-21

4.4 MAIN PARTS LOCATIONS (DISPLAY UNIT)

DISPLAY SW

PWB

CN8001 (PDP UNIT : SMPS PWB)

T

PW

X

DISPLAY LED PWB

MAIN SPEAKERMAIN SPEAKER

LINE FILTER PWB

SL

CN9003 (PDP UNIT : VIDEO SMPS PWB)

V

TEMP. SENSOR PWB

A B

WOOFER

AUDIO PWB

SR CB

D

C

D

V

A

X

C

T

1-22 (No.YA029)

CN9002 (PDP UNIT : VIDEO SMPS PWB)

CN9001 (PDP UNIT : VIDEO SMPS PWB)

LVDS

Q E

DISPLAY INTERFACE PWB

LA01 (PDP UNIT : LOGIC-MAIN PWB)

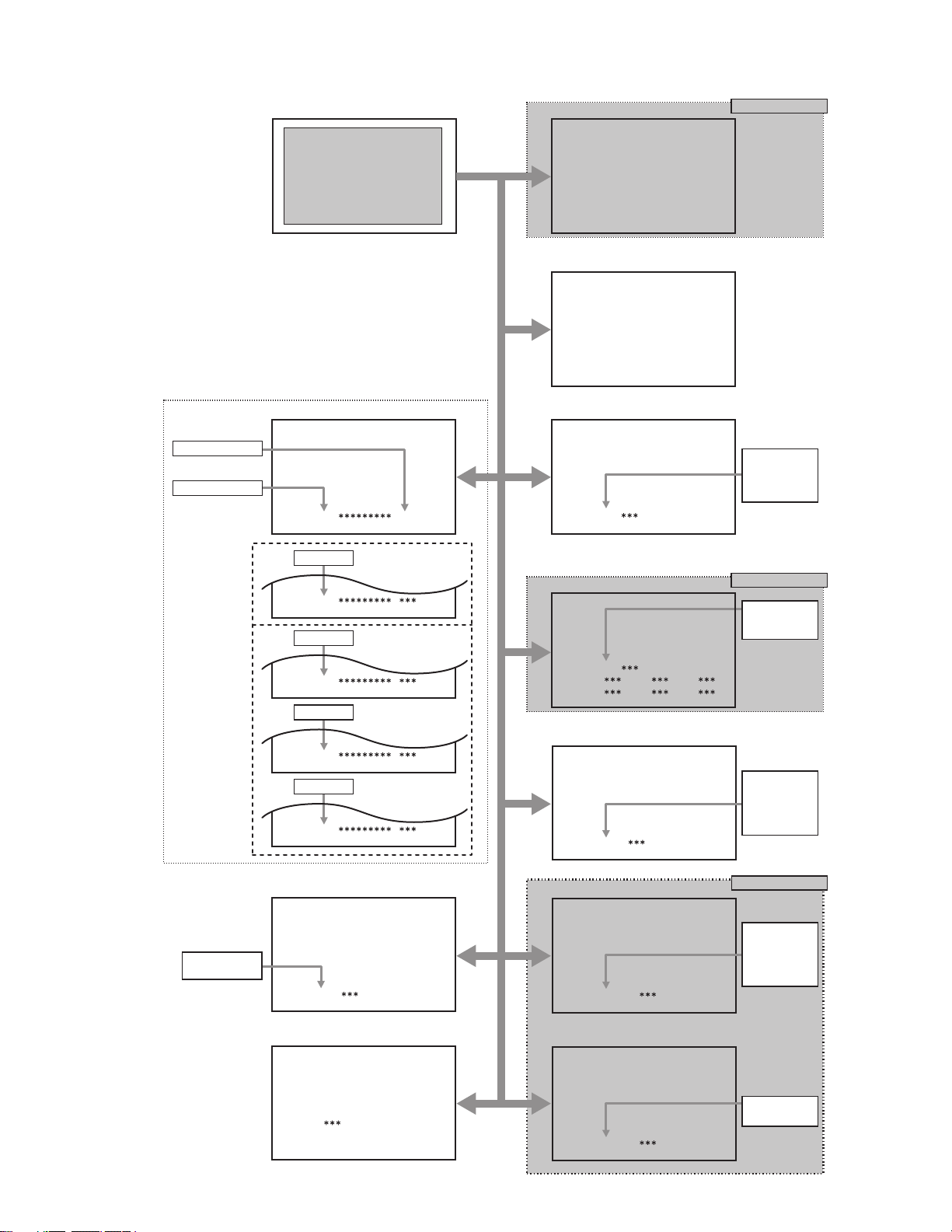

4.5 SERVICE MENU SCREEN

VOLUME(+/-) key

CHANNEL(+/-) key

MAIN MENU

1.PICTURE/SOUND

2.YC SEP

3.WHITE BALANCE

4.MEMORY SETUP

5.RF AFC

6.DD/CM

1.PICTURE/SOUND

NTSC CINE ST L FL MUTE

A01 001

7.PANEL

8.PP

9.IP

0.HDMI

4.MEMORY SETUP

ADDRESS(H) 0000

0

1

2

3

4

AA

55

00

0

1

AA

55

00

5

00

FF

00

2

3

4

5

00

FF

00

5.RF AFC

TOO HIGH GOOD TOO LOW

TUNER MAIN

AFC ON

FINE -10

6.DD/CM

NTSC CINE ST L FL MUTE

DDT01

DO NOT ADJUST

6

7

00

00

6

7

00

00

DDT01~34

CMT01~57

DDP01~37

CMP01~03

YCM001~185

YCS001~114

A01~A27

A01

S01~S99

S01

D01~D32

D01

F01~F59

F01

2.YC SEP

NTSC CINE ST L FL MUTE

YCM01

7. PANEL

PDA001

IN

APL

OUT

MIN

8.PP

NTSC CINE ST L FL MUTE

PPA001

9.IP

NTSC CINE ST L FL MUTE

IPA001

TEM

MAX

DO NOT ADJUST

PDA001~012

PDB001~022

RGA001~003

ADM001~034

PPA001~008

PPB001~036

PPC001~008

PPD001~025

DO NOT ADJUST

IPA001~120

IPB001~079

IPC001~044

IPD001~026

IPE001~015

3. WHITE BALANCE

BR

DRV R069 B054

CUT R078 G079 B079

0.HDMI

NTSC CINE ST L FL MUTE

GCR001

HDM001~080

RHD001~170

(No.YA029)1-23

4.6 BASIC OPERATION OF THE SERVICE MODE [USING REMOTE CONTROL]

MAIN MENU

4.6.1 HOW TO ENTER THE SERVICE MODE

NOTE:

Ensure that the cursor (arrow) of the User Menu screen is

pointing at Picture Control.

Before entering the SERVICE MODE, confirm that the setting

of TV / CATV SW of the REMOTE CONTROL UNIT is at the

"TV" side and the setting of VCR / DVD SW is at the "VCR"

side. If the switches have not been properly set, you cannot

enter the SERVICE MODE.

(1) Set to 0 minutes using the [SLEEP TIMER] key.

(2) Press the [VIDEO STATUS] key and [DISPLAY] key

simultaneously, then enter the Service Menu mode.

1.PICTURE/SOUND

2.YC SEP

3.WHITE BALANCE

4.MEMORY SETUP

5.RF AFC

6.DD/CM

(3) When the Main Menu is displayed, press any key of the [0]

to [9] key to enter the corresponding menu mode.

*Press any of the [0] to [9] keys before the Service Menu

mode disappears.

(4) Select the service item using the [ CH (+/-)] key.

(5) Set the value using the [ VOL. (+/-)] key.

(6) Press the [MUTING] key to memorize the set value.

4.6.2 HOW TO EXIT THE SERVICE MODE

Press the [ BACK ] key to exit the Service mode.

MAIN MENU

7.PANEL

8.PP

9.IP

0.HDMI

4.6.3 SERVICE CONTROL KEY LAYOUT ON THE REMOTE CONTROL

TV

CATV VCR DVD

TV/CATV SW

[MUTING] key

[VOL (+/-)] key

SPLIT

FREEZE

INPUT 1

INPUT 2

INPUT 3

INPUT 4

DIGITAL-IN

D-IN

SLEEP TIMER

MUTING

MENU

VCR CHANNEL

OPEN CLOSE

ASPECT

MULTI SCREEN

INDEX

SWAP SELECT

V1

123

V2

456

V3

789

100+

V4

THEATER

NATURAL

PRO

CINEMA

DISPLAY SOUND

+

CH

VOL

OK

CH

VCR DVD

PREV NEXT

POWER

REW

REC PAUSE

STOP

RM-C13G

RETURN+

0

STATUS

VOL

TV VCR

STILL PAUSE

VIDEO

LIGHT

BACK

FFPLAY

TV

C.C.

C.C.

VCR / DVD SW

[0]~[9] key

[VIDEO STATUS] key

[DISPLAY] key

[CH (+/-)] key

[BACK] key

1-24 (No.YA029)

4.6.4 SETTINGS OF THE SERVICE MENUS

4.6.4.1 [1. PICTURE/SOUND (Picture/sound setting)]

Adjusts output data to ports such as Audio, Drive, Video and

others (Item F):

(1) SIGNAL TYPE

The signal currently displayed on the screen is displayed.

NTSC : NTSC (525i = S/Composite)

DVD : 525i (Component)

ED : 525p

HD : 1125i

750p : 750p

HED1 : HDCP 525p size1

HED2 : HDCP 525p size2

HHD : HDCP 1125i

H750 : HDCP 750p

(2) ASPECT / MULTI

ONE SCREEN

FULL : FULL

PANO : PANORAMA

CINE : CINEMA

REGU : REGULER

MULTI SCREEN

M1 : SINGLE (for adjustment)

M2-1 : SPLIT (4 : 3)

M2-2 : SPLIT (16 : 9)

M4 : POP

M12 : INDEX

(3) PICTURE SELECTION

Displays current picture selection mode

ST : STANDARD

DA : DINAMIC

TH : THEATER

GA : GAME

(4) WHITE BALANCE

Displays white balance setting item in the picture selection mode

H : HIGH

L: LOW

(5) SERVICE ITEM CODES

Displays corresponding codes for A: Sound, S: Signal, D:

Deflection and F: Factory Settings.

< Settings of Service Item >

• [ CH (+/-)] key

For scrolling up/ down the item codes.

A01 S01 D01 F01

• [ SLEEP TIMER ] key

For switching to the next item.

A01 S01 D01 F01

(6) VALUE SETTING (DATA)

Specify values for each of the items in sequence.

• [ VOL (+/-)] key

For selecting the value (data) of each item by scrolling

up/down the key.

• [MUTING] key

For saving the entered values (data).

(7) DATA SAVING METHOD

Displays the method for saving the entered values (data).

MUTE : Press [MUTING] key

DIR : Change data then memory at the same time.

(8) I-P interpolation MODE

Not required in servicing.

FL : FRAME

L1 : LINE

23 : COMPULSORY NATURAL CINEMA IN

(2) Adpect / Multi

(1) Signal Type

NTSC FULL ST L FL MUTE

A01

(3) Picture Selection

(8) I-P interpolation MODE

***

(4) White Balance

(7) Data Saving Method

(6) Value Setting(Data)(5) Service Item Codes

NOTE:

Setting for any of the following items that is not included in the

“ADJUSTMENT PROCEDURE” section found in the later part

of this manual will not be performed in servicing.

4.6.4.2 [2. YC SEP (3D Y/C Separation setting)]

< Do not change settings of items that are not included in the

"ADJUSTMENT PROCEDURE" section. >

Sets output data to the 3D Y/C separation circuit.

• [ CH (+/-)] key

For scrolling up/down the item codes.

• [ VOL (+/-)] key

For scrolling up/down the data values.

4.6.4.3 [3. WHITE BALANCE (White Balance setting)]

Setting for this item is not required in servicing.

4.6.4.4 [4. MEMORY SETUP (Memory setting)]

[Do not change settings]

4.6.4.5 [5. RF AFC]

Setting for this item is not required in servicing.

4.6.4.6 [6. DD/CM]

< Do not change settings of items that are not included in the

"ADJUSTMENT PROCEDURE" section. >

Adjustment of color manegment and device driver

• [ CH (+/-)] key

For scrolling up/down the item codes.

• [ VOL (+/-)] key

For scrolling up/down the data values.

4.6.4.7 [7. PANEL]

[Do not change settings]

Panel power limit control

4.6.4.8 [8. PP (Multi-screen Processing setting)]

< Do not change settings of items that are not included in the

"ADJUSTMENT PROCEDURE" section. >

Sets output data to the multi-screen processing circuit.

• [ CH (+/-)] key

For scrolling up/down the item codes.

• [ VOL (+/-)] key

For scrolling up/down the data values.

4.6.4.9 [9. IP (DIST setting)]

[Do not change settings]

Sets output data to the DIST circuit.

4.6.4.10 [0. HDMI]

[Do not change settings]

Sets output data to the DIGITAL INPUT circuit

(No.YA029)1-25

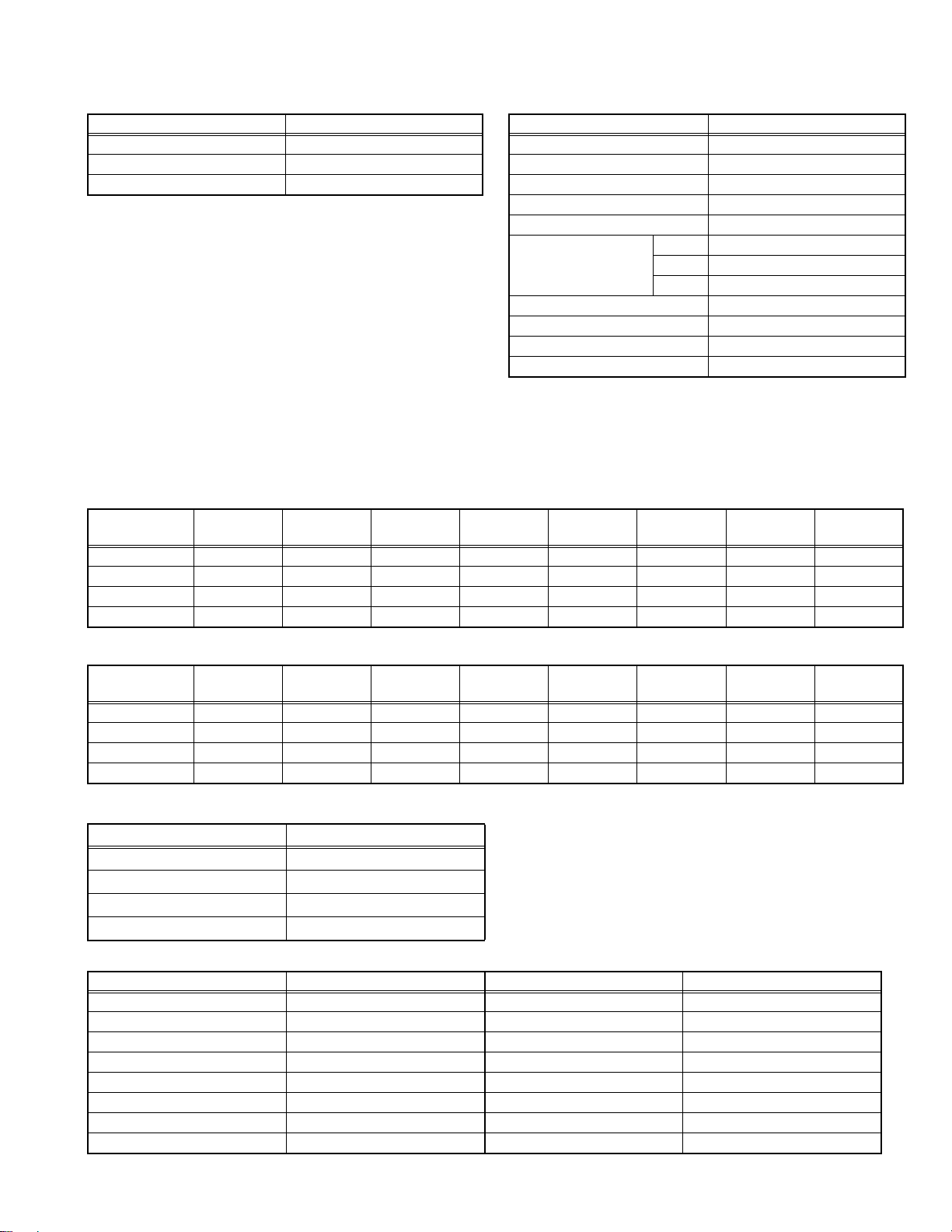

4.7 INITIAL SETTING VALUES IN THE SERVICE MODE

• Perform fine-tuning based on the "initial values" using the remote control when in the Service mode.

• The "initial values" serve only as an indication rough standard and therefore the values with which optimal display can be achieved

may be different from the default values. But, don't change the values that are not written in "ADJUSTMENT PROCEDURE". They

are fixed values.

NOTE:

As for the items whose settings are "Fixed" in Table 1 in "3.3 REPLACEMENT OF MEMORY IC", the following tables show initial

values in NTSC signal input mode. As for the items whose conditions of SETTING VALUE are not written in the following tables,

the following tables show initial values in NTSC signal input mode.

• Among the initial values, there are some that are displayed "( )"as offset values. These are values relative to the base or absolute

values. Set the values by addinG offset values to the base values. Base values are displayed as "---".

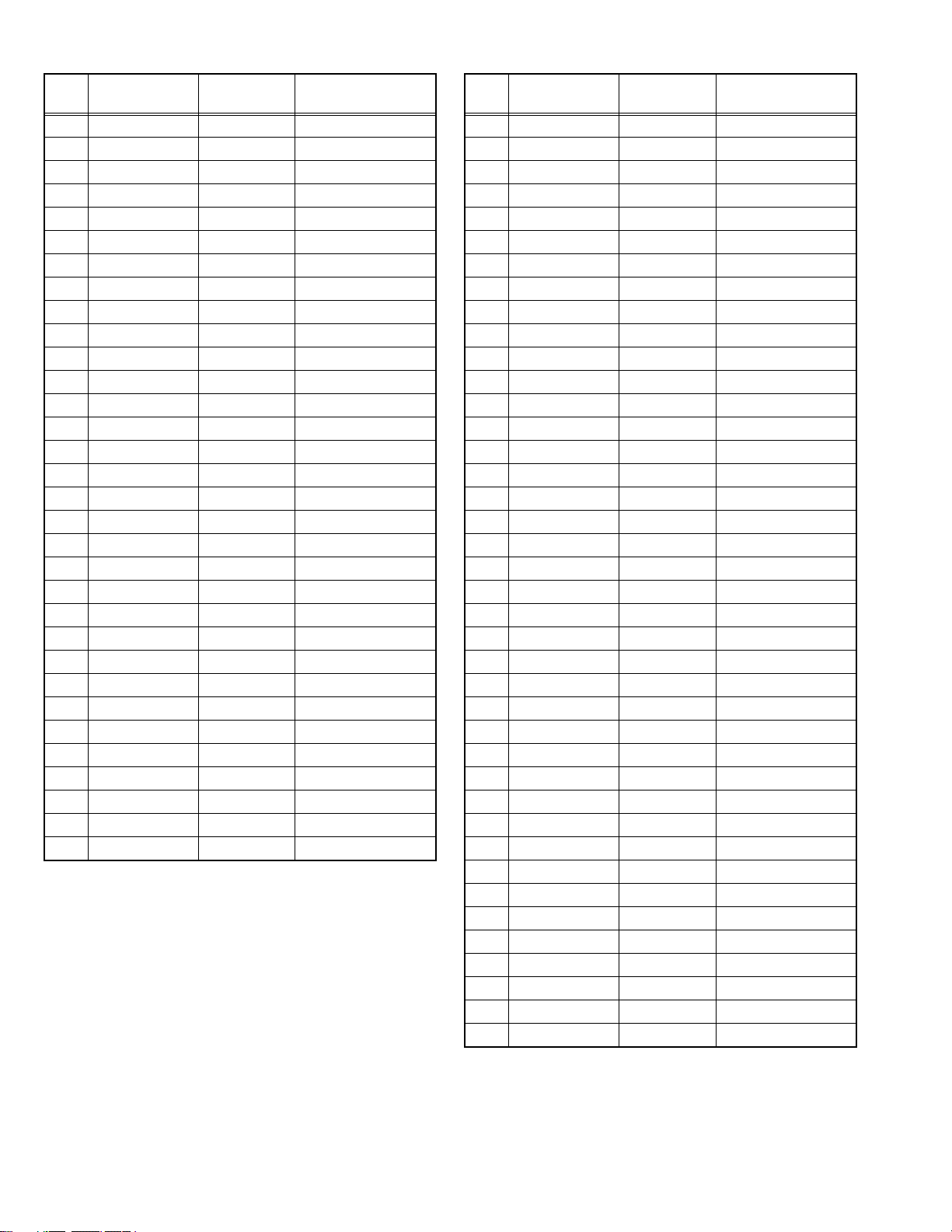

4.7.1 [1.PICTURE/SOUND]

Item

No.

A01 (Not display) 000~007 003

A02 (Not display) 000~007 003

A03 (Not display) 000~007 003

A04 (Not display) 000~007 004

A05 (Not display) 000~015 009

A06 (Not display) 000~015 006

A07 (Not display) 000~015 006

A08 (Not display) 000~015 003

A09 (Not display) 000~007 006

A10 (Not display) 000~007 004

A11 (Not display) 000~063 063

A12 (Not display) 000~063 063

A13 (Not display) 000~003 000

A14 (Not display) 000~007 000

Item

Variable

range

Setting value

Item

No.

A15 (Not display) 000~003 000

A16 (Not display) 000~003 000

A17 (Not display) 000~003 000

A18 IN LEVEL 000~255 (Not used)

A19 LOW SEP 000~255 (Not used)

A20 HI SEP 000~255 (Not used)

A21 AHS MVE -128~+127 000

A22 AHS MSC -128~+127 000

A23 (Not display) 000~001 (Not used)

A24 (Not display) 000~001 (Not used)

A25 (Not display) 000~001 (Not used)

A26 (Not display) 000~001 (Not used)

A27 (Not display) 000~001 (Not used)

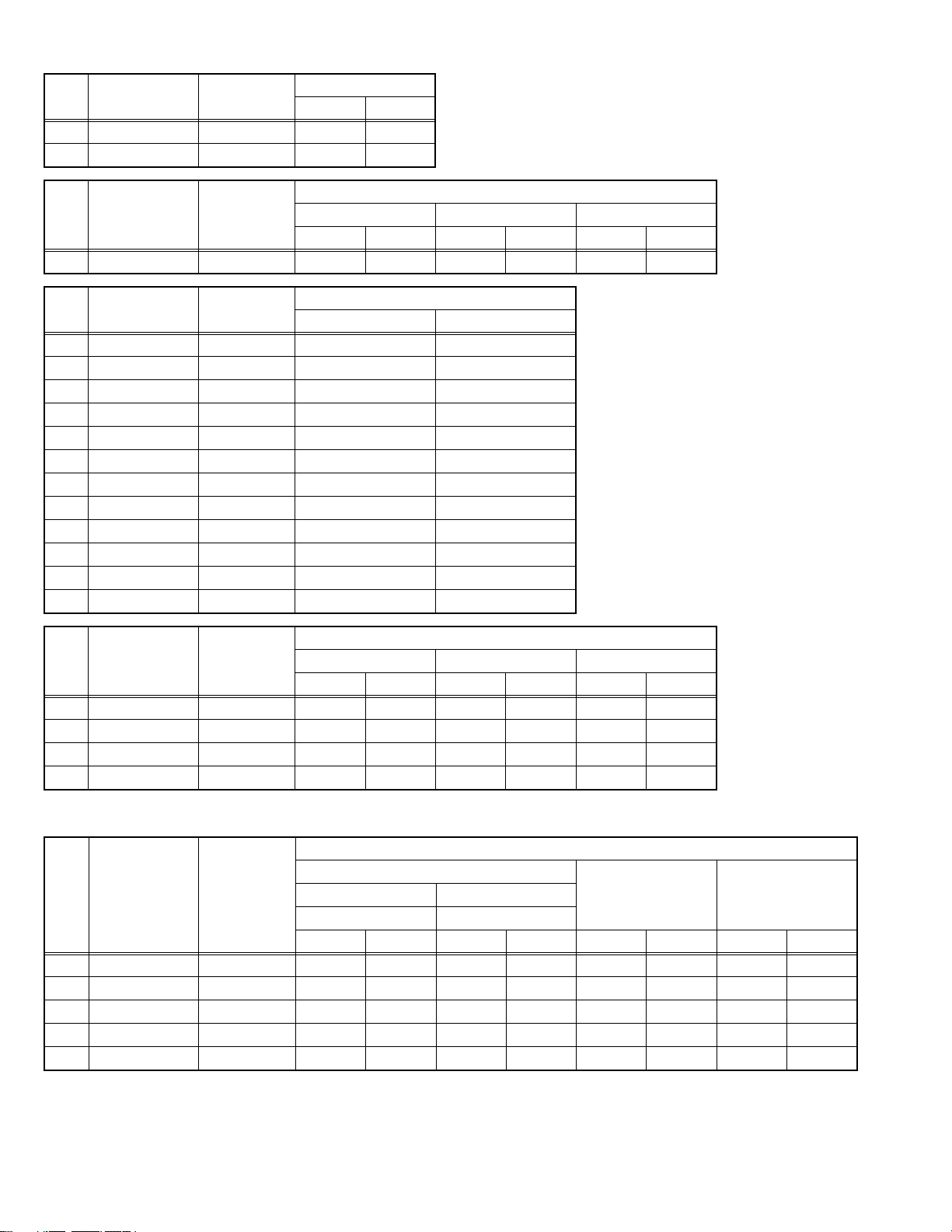

Item

Variable

range

Setting value

Item

No.

S01 COLOR 000~255 140 135 140 130 140 130 148 140

S02 TINAD 000~255 000 000 000 000 000 000 000 000

S03 OF COLOR -127~128 (---) (---) (---) (---) (---) (---) (---) (---)

S04 OF TINAD -127~128 (---) (---) (---) (---) (---) (---) (---) (---)

Item

No.

S05 BRIG 000~ 255 038 038 044 040 043 038

S06 CONT 000~255 125 125 128 128 128 128

S07 OF BRIG -127~128 (---) (---) (---) (---) (---) (---)

S08 OF CONT -127~128 (---) (---) (---) (---) (---) (---)

Item

Item

Variable

range

Variable

range

NTSC 525i 525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD THEATER STANDARD THEATER

Setting value

NTSC 525i/525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD THEATER

Setting value

1-26 (No.YA029)

Item

No.

S09 BYGN 000~255 126 130 125 130 128 130 118 120

S10 OF BYGN -127~128 (---) (---) (---) (---) (---) (---) (---) (---)

S11 RYAXIS -127~128 +006 000 +006 000 +006 000 000 000

S12 MTX 000~003 000 000 000 000 000 000 001 001

Item

Variable

range

NTSC 525i 525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD THEATER STANDARD THEATER

Setting value

Item

No.

S13 (Not display) --- (Not used)

S14 (Not display) --- (Not used)

S15 (Not display) --- (Not used)

S16 (Not display) --- (Not used)

S17 (Not display) --- (Not used)

S18 (Not display) --- (Not used)

Item

No.

S19 CUTR 000~255 128 128 128 128 128 128

S20 OF CUTR -127~128 000 000 000 000 000 000

S21 CUTG 000~255 128 128 128 128 128 128

S22 OF CUTG -127~128 128 128 128 128 128 128

S23 CUTB 000~255 128 128 128 128 128 128

S24 OF CUTB -127~128 000 000 000 000 000 000

S25 CUTR 000~001 000 000 000 000 000 000

S26 CUTG 000~001 000 000 000 000 000 000

S27 CUTB 000~001 000 000 000 000 000 000

S28 BTHN 000~001 001 000 001 000 001 000

S29 BCALM 000~001 000 000 000 000 000 000

S30 BKAKOU 000~031 008 003 002 000 002 004

S31 BLIM 000~063 016 010 015 000 015 003

S32 BSTPO 000~063 048 050 050 050 055 050

S33 BKAKON 000~001 001 001 001 001 001 001

S34 WTHN 000~001 001 001 001 001 001 001

S35 WCALM 000~001 000 000 000 000 000 001

S36 WKAKOU 000~031 000 000 000 000 000 000

S37 WLIM 000~255 200 255 220 255 225 225

S38 WSTPO 000~063 050 000 054 000 018 000

S39 WPEAK 000~063 060 063 065 063 060 063

S40 WKAKON 000~001 001 000 001 000 001 000

S41 WGAINC 000~001 000 001 001 001 000 001

S42 GAINB 000~003 001 000 001 000 000 000

S43 SLIC 000~031 011 031 013 031 012 031

S44 APG 000~003 001 003 001 003 001 003

S45 GAINA 000~003 001 003 001 003 001 003

Item

Item

Variable

range

Variable

range

Setting value

Setting value

NTSC 525i525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD THEATER

(No.YA029)1-27

Item

No.

S46 (Not used) 000~015 015 015

S47 (Not used) 000~015 015 015

Item

Variable

range

Setting value

STANDARD THEATER

Item

No.

S48 DCTRAN 000~015 015 015 015 015 015 015

Item

No.

S49 HSTR 000~001 000 000

S50 HSTR 000~255 013 019

S51 HEND 000~001 000 000

S52 HEND 000~255 076 067

S53 VSTR 000~001 000 000

S54 VSTR 000~255 005 005

S55 VEND 000~001 000 000

S56 VEND 000~255 094 094

S57 BHSTR 000~255 000 000

S58 BHSTR 000~015 000 000

S59 BHEND 000~255 013 013

S60 BHEND 000~015 000 000

Item

No.

S61 PLPOL2 000~001 001 001 001 001 001 001

S62 PLEV2 000~127 016 016 016 016 016 016

S63 PLPOL1 000~001 000 000 000 000 000 000

S64 PLEV1 000~127 000 000 000 000 000 000

Item

Item

Item

Variable

range

Variable

range

Variable

range

NTSC 525i/525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD TH EATER

Setting value

SPLIT-SCREEN REGULAR

NTSC 525i/525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD TH EATER

Setting value

Setting value

NOTE:

Data of the setting value is selected in the order of "SPLIT-SCREEN" and "REGULAR".

Setting value

Item

No.

S65 MODC 000~003 003 003 003 003 002 002 002 002

S66 RMC 000~003 001 001 003 003 001 003 003 003

S67 RGA 000~003 003 003 003 003 002 003 003 003

S68 CLIP 000~015 000 000 000 000 000 000 000 000

S69 COR 000~063 019 019 019 019 019 019 019 019

1-28 (No.YA029)

Item

Variable

range

SPLIT REGULAR

STANDARD THEATER STANDARD THEATER STANDARD THEATER STANDARD THEATER

NTSC

525i/525p 750p/1125iMULTI-SCREEN ASPECT

Item

No.

S70 TINTON 001~001 001

S71 DRIVER 001~255 240

S72 DRIVEG 001~255 240

S73 DRIVEB 001~255 240

S74 EECONT 001~031 006

S75 EEBRT 001~031 003

Item

Variable

range

Setting value

Item

No.

S76 EETBRT -127~128 000 000 000

S77 EETCONT -127~128 000 000 000

Item

No.

S78 PICMAX 001~255 255 255

S79 PICMIN 001~255 000 000

S80 BRTMAX 001~255 255 255

S81 BRTMIN 001~255 000 000

S82 COLMAX 001~255 255 255

S83 COLMIN 001~255 000 000

Item

No.

S84 (Not display) 001~015 (Not used)

S85 (Not display) 001~255 (Not used)

S86 (Not display) 001~255 (Not used)

S87 (Not display) 001~003 (Not used)

Item

Item

Item

Variable

range

Variable

range

Variable

range

NTSC 525i/525p 750/1125i

Setting value

STANDARD THEATER

Setting value

Setting value

Item

No.

S88 APLGAIN 001~007 007 007 007 007 007 007 007 007

S89 APLLIM 001~255 030 030 030 030 030 030 030 030

S90 ABSGAIN 001~127 000 000 000 000 000 000 000 000

S91 BLKGAIN 001~007 007 007 007 007 007 007 007 007

S92 BLKLIM 001~031 031 031 031 031 031 031 031 031

S93 WHTGAIN 001~007 007 007 007 007 007 007 007 007

S94 WHTLIM 001~031 031 031 031 031 031 031 031 031

S95 DCSTART 001~255 060 060 055 060 055 060 060 060

S96 DCGAIN 001~015 008 006 018 006 008 008 006 006

S97 DCLIM 001~063 030 025 025 019 025 025 030 025

S98 (Not display) 001~001 000 000 000 000 000 000 000 000

S99 (Not display) 001~001 000 000 000 000 000 000 000 000

Item

Variable

range

NTSC 525i 525p 750p/1125i

STANDARD THEATER STANDARD THEATER STANDARD THEATER STANDARD THEATER

Setting value

(No.YA029)1-29

Item

No.

D01 (Not display) 000~127 000

D02 (Not display) 000~063 000

D03 (Not display) 000~127 000

D04 (Not display) 000~063 000

D05 (Not display) 000~031 000

D06 (Not display) 000~127 000

D07 (Not display) 000~127 000

D08 (Not display) 000~031 000

D09 (Not display) 000~031 000

D10 (Not display) 000~007 000

D11 (Not display) 000~007 000

D12 (Not display) 000~001 000

D13 (Not display) 000~031 000

D14 (Not display) 000~031 000

D15 (Not display) 000~255 000

D16 (Not display) 000~255 000

D17 (Not display) 000~001 000

D18 (Not display) 000~015 000

D19 (Not display) 000~015 000

D20 (Not display) 000~015 000

D21 (Not display) 000~015 000

D22 (Not display) 000~001 000

D23 (Not display) 000~031 000

D24 (Not display) 000~031 000

D25 (Not display) 000~015 000

D26 (Not display) 000~015 000

D27 (Not display) 000~127 052

D28 (Not display) 000~003 000

D29 (Not display) 000~001 000

D30 (Not display) 000~001 000

D31 (Not display) 000~001 000

D32 (Not display) 000~001 000

Item

Variable

range

Setting value

Item

No.

F01 (Not display) 000~255 008

F02 (Not display) 000~255 001

F03 (Not display) 000~255 000

F04 (Not display) 000~255 032

F05 (Not display) 000~001 000

F06 (Not display) 000~001 001

F07 (Not display) 000~255 111

F08 (Not display) 000~255 039

F09 (Not display) 000~015 000

F10 (Not display) 000~015 000

F11 (Not display) 000~015 000

F12 (Not display) 000~015 000

F13 (Not display) 000~015 000

F14 (Not display) 000~015 000

F15 (Not display) 000~015 000

F16 (Not display) 000~127 070

F17 (Not display) 000~001 000

F18 (Not display) 000~001 000

F19 (Not display) 000~001 000

F20 (Not display) 000~255 005

F21 (Not display) 000~255 002

F22 (Not display) 000~001 000

F23 (Not display) 000~255 098

F24 (Not display) 000~255 006

F25 (Not display) 000~255 040

F26 (Not display) 000~255 040

F27 (Not display) 000~255 000

F28 (Not display) 000~001 000

F29 (Not display) 000~001 000

F30 (Not display) 000~001 000

F31 (Not display) 000~001 000

F32 (Not display) 000~255 006

F33 (Not display) 000~255 000

F34 (Not display) 000~255 251

F35 (Not display) 000~255 030

F36 (Not display) 000~255 255

F37 (Not display) 000~001 000

F38 (Not display) 000~001 000

F39 (Not display) 000~001 000

F40 (Not display) 000~001 000

Item

Variable

range

Setting value

1-30 (No.YA029)

Loading...

Loading...