Page 1

SERVICE MANUAL

PDP COLOR TELEVISION

PD-42V475

/S

PD-42V485/S

BASIC C

POWER

TV

CATVVCR

DVD

MULTI SCREEN

TWIN

INDEX

C.C.

SWAP

SELECT

INPUT

FREEZE

DISPLAY

1

3

2

SLEEP TIMER

5

4

6

SOUND

7

9

8

RETURN+

TUNE

VIDEO STATUS

0

THEATER PRO

LIGHT

ASPECT

MUTING

OK

CH +

VOL

VOL

+

Ð

CH Ð

BACK

MENU

VCR/DVD

VCR CHANNEL

TV/VCR

POWER

PREV NEXT

PLAY FFREW

REC

STOP PAUSE

OPEN/CLOSE

STILL/PAUSE

RM-C1257G

TV

HASSIS

FP2

1 PRECAUTION

......................................................................................................................................................... 1-3

2 SPECIFIC SERVICE INSTRUCTIONS

3 DISASSEMBLY

4 ADJUSTMENT

5 TROUBLESHOOTING

..................................................................................................................................................... 1-11

...................................................................................................................................................... 1-22

........................................................................................................................................... 1-31

COPYRIGHT © 2004 Victor Company of Japan, Limited

TABLE OF CONTENTS

...................................................................................................................... 1-6

No.YA099

2004/7

Page 2

SPECIFICATION

Items

Dimensions (W x H x D)

Mass 48.3kg (106.3

TV RF System CCIR (M)

Color System NTSC

Sound System BTSC (Multi channel sound)

TV Receiving Channels VHF Low 02ch to 06ch : 54MHz to 88MHz

and Frequency VHF High 07ch to 13ch : 174MHz to 216MHz

TV/CATV Total Channel 180 channel

Intermediate Frequency VIF 45.75MHz

Color Sub Carrier Frequency

Power Input AC120V, 60Hz

Power Consumption Operate : 364W, Stand by: 0.94W

Plasma Display Panel (PDP) QLE0028-001

Screen Size Visible size : 107.5cm (Diagonel) / 93.3 cm x 53.3 cm (H x V)

Display Pixels

Speaker 6.6cm round x4 (Oblique cone)

Audio Power Output 10W + 10W

Antenna terminal (VHF / UHF) F-type connector, 75Ω unbalanced, coaxial

Video / Audio Iutput S-Video [1/3/4] Mini-DIN 4 pin connector x3

[1/2/3/4] Y: 1V(p-p), 75Ω, positive (negative sync)

Component video [1/2] RCA pin jack x 3

1125i / 750p Y : 1V(p-p), 75

525i / 525p Y : 1V(p-p), 75Ω, positive (negative sync)

Audio Output RCA pin jack x2

Center Channel Input 500mV (rms), low impedance, RCA pin jack x 1

PC (RGB) Input D-sub 15pin x 1

AV COMPULINK ΙΙΙ 3.5mm mini jack x1

Digital-in HDMI connector x 1

Remote Control Unit RM-C1257G (AA/R6 TYPE battery x 2)

104.5cm x 79.1cm x 30.8cm (41-1/4” x 31-1/4” x 12-1/4”) [Included stand]

104.5cm x 72.9cm x 11.0cm (41-1/4” x 28-3/4” x 4-3/8”) [TV only]

l

bs) [Included stand]

38.3kg (84.33lbs) [TV only]

UHF 14ch to 69ch : 470MHz to 806MHz

CATV 54MHz to 804MHz

Low Band : 02 to 06, A-8 by 02 to 06&01

High Band : 07 to 13 by 07 to 13

Mid Band : A to I by 14 to 22

Super Band : J to W by 23 to 36

Hyper Band : W+1 to W+28 by 37 to 64

Ultra Band : W+29 to W+84 by 65 to 94, 100 to 125

Sub Mid Band : A4 to A1 by 96 to 99

SIF

41.25MHz (4.5MHz)

3.58MHz

42V wide aspect (16:9)

H: 852 pixels / V: 480 pixels

C: 0.286V(p-p), (Burst signal), 75

Video 1V(p-p), 75Ω, negative sync, RCA pin jack x4

Audio 500mV(rms) (-4dBs), high impedance, RCA pin jack x8

Ω

, 3-value sync : ±0.35V(p-p)

Pb/Pr : ±0.35V(p-p), 75

Pb / Pr : 0.7V(p-p), 75

VARI More than 0 - 1000mV(rms) (+2.2dBs)

FIX 500mV (rms) (-4dBs), low impedance (400Hz when modulated 100%)

R/G/B : 0.7V (p-p), 75

HD / VD : 1V (p-p) to 5V (p-p), high impedance

<Available signal>

VGA : 640 pixels x 480 pixels (Horizontal : 31.5kHz / Vertical : 60Hz)

(Digital-in terminal is not compatible with picture signals of personal computer.)

Video Digital : HDMI connector

Audio Digital : HDMI connector

Analog : 500mV(rms) (-4dBs), high impedance, RCA pin jack x 2

[W-VGA]

Ω

Ω

Ω

Contents

Ω

Design & specifications are subject to change without notice.

1-2 (No.YA099)

Page 3

D

SECTION 1

PRECAUTION

1. 1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should

be made to the original design unless authorized in writing

by the manufacturer. Replacement parts must be identical

to those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by () on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list

of Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : (

GND, the ISOLATED (NEUTRAL) : (

EARTH : (

) side GND. Don't short between the LIVE

) side GND and

side GND and ISOLATED (NEUTRAL) side GND or EARTH

side GND and never measure the LIVE side GND and

ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope

etc.).If above note will not be kept, a fuse or any parts will

be broken.

(5) If any repair has been made to the chassis, it is

recommended that the PDP POWER SUPPLY setting

should be checked or adjusted.

(6) The high voltage applied to the PDP must conform with

that specified in Service manual. Excessive high voltage

can cause an increase in arcing and possible component

damage, therefore operation under excessive high voltage

conditions should be kept to a minimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect installation, cracked or melted high voltage

harness, poor soldering, etc.). To maintain the proper

components in the circuitry including the PDP must be

the exact replacements or alternatives approved by the

manufacturer of the complete product.

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

) side

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence

of overheating should be replaced. Always use the

manufacturer's replacement components.

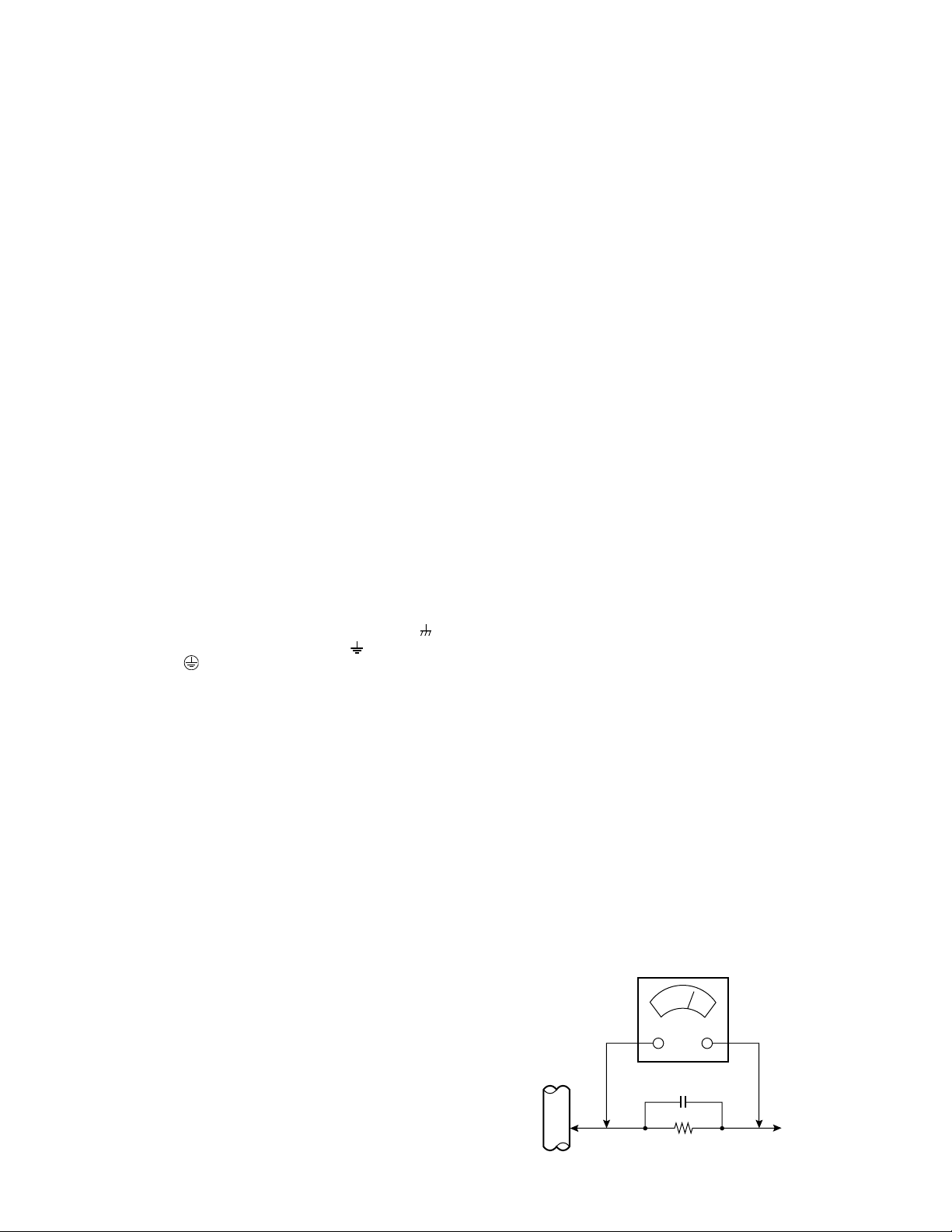

(9) Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output

terminals, Control knobs, metal cabinet, screw heads,

earphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand

a voltage of 3000V AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternative Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.).

Use an AC voltmeter having 1000 ohms per volt or

more sensitivity in the following manner. Connect a

1500Ω 10W resistor paralleled by a 0.15µF AC-type

capacitor between an exposed metal part and a known

good earth ground (water pipe, etc.). Measure the AC

voltage across the resistor with the AC voltmeter. Move

the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds

to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000Ω/V,

OR MORE SENSITIVITY)

0.15µF AC-TYPE

PLACE THIS PROBE

1500Ω 10W

GOOD EARTH GROUND

ON EACH EXPOSE

ME TA L PA RT

(No.YA099) 1-3

Page 4

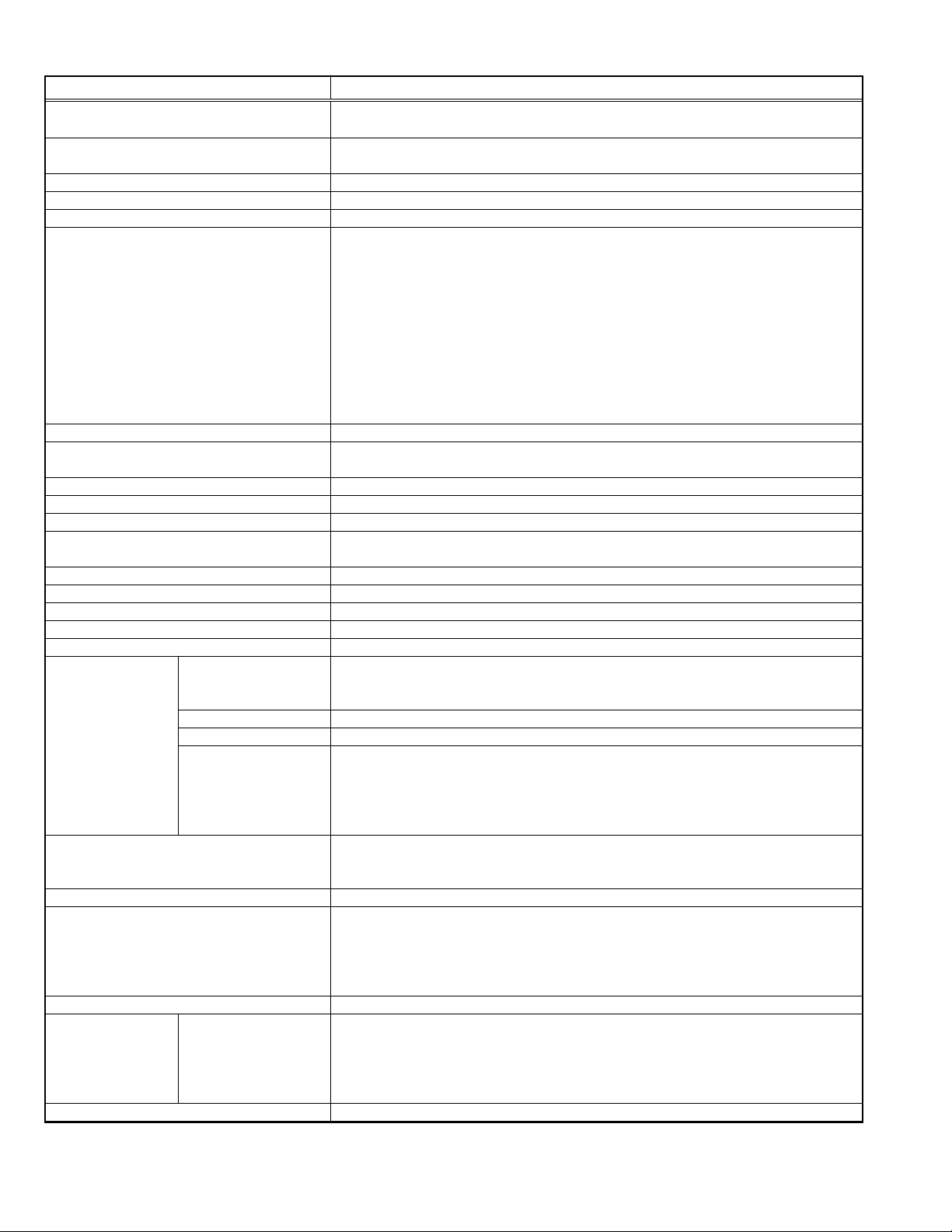

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling

efficiency may deteriorate and temperature inside the unit will

rise. The temperature sensor that protects the unit will be

activated when internal temperature exceeds the predetermined level and power will be turned off automatically.

Therefore, please make sure pay attention not to block the heat

dissipation vent as well as the ventilation outlet behind the unit

and ensure that there is room for ventilation around it.

SPACE REQUIRED FOR INSTALLATION

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified

below, between the unit with and the surrounding walls, as well

as the floor etc.

Install the unit on stable flooring or stands.

Take precautionary measures to prevent the unit from tipping in

order to protect against accidents and earthquakes.

150 mm or

150 mm

more

200 mm or

200 mm

more

50 mm

50 mm or more

1.2.3 FALL TIP PREVENTION MEASURES

Take precautionary measures to prevent the unit from falling or

tipping to protect against emergencies such as earthquakes as

well as accidents.

Fasten the supplied hook for tip fall prevention using the screws,

also supplied, behind the display unit, and use them together

with durable cords (to be purchased separately) to secure the

unit to a robust part such as the wall surface or pillars.

150 mm

or more

150 mm

200 mm

200 mm

or more

50 mm

50 mm or more

1-4 (No.YA099)

The supplied hook for tipfall prevention

Page 5

1. 3 PRECAUTIONS REGARDING PDP

1.3.1 PRECAUTIONS DURING NOTES FOR TRANSPORTATION

When transporting the unit, pressure exerted on the internal

PDP (Plasma Display Panel) due to improper handling (such

as tossing and dropping) may cause damages even when the

unit is carefully packed. To prevent accidents from occurring

during transportation, pay careful attention prior to delivery such

as through explaining the handling instructions to transporters.

Ensure that the following requirements are met during

transportation, as the PDP of this unit is made of glass and

therefore fragile:

(1) Avoid vibrations and impacts

The unit may be broken if it is toppled sideways even

when properly packed. Ensure that the unit is carried by at

least 2 persons and pay careful attention not to exert any

vibration or impact on it.

(2) Do not place equipment horizontally

Ensure that it is placed upright and not horizontally during

transportation and storage as the PDP is very vulnerable

to lateral impacts and may break easily under such

circumstances.

During transportation, ensure that the unit is loaded along

the traveling direction of travel of the vehicle, and avoid

stacking them on one another.

For storage, ensure that they are stacked in 2 layers or

less even when placed upright.

1.3.2 RESIDUAL IMAGE / BURN-IN ON SCREEN

Like CRTs, “burn-in” may occur when a same image is

continuously displayed over an extended period of time.

As this may also shorten the life span of the PDP. Therefore, turn

off the display when not in use, scroll the screen, make use

of screen-savers, or allow even distribution on the display by

inverting the brightness, switching to complementary colors or

inserting animated images at periodic intervals.

As burn-in is more likely to occur with high brightness and contrast

settings, try to use neutral gradations or medium tone colors.

Burn-in does not occur in the case of animated images.

When switching to another image after continuous display of

the previous image, residual images may become prominent,

as luminance in a part of the display is higher than the other

parts.

This is not a defect but is because due to the discharge surface

of the lighted portion has become being relatively activated and

its luminance higher than the unlighted parts.

1.3.4 OPTICAL FILER (PANEL FILTER)

Avoid placing the unit under direct sunlight over a prolonged

period of time. This may cause the optical filter to deteriorate in

quality and color.

Clean the filter surface by wiping it softly lightly with outing flannels

a soft and lightly fuzz cloth (such as flannel).

Do not use solvents such as benzine or thinner to wipe the filter

surface. This may cause the filter to deteriorate in quality or the

coating on the surface to come off.

As the filter surface is fragile., do not scratch or hit it with hard

materials.

1.3.5 NOTES PRECAUTIONS FOR REPLACEMENT OF

EXTERIOR PARTS

Take note of the following when replacing exterior parts (back

REAR COVER, FRONT PANEL, optical filter)

• Do not exert pressure on the front of the PDP (glass surface).

• Pay careful attention not to scratch or stain the front of the PDP

(surface) with hands.

• When replacing exterior parts, the front of the PDP should be

placed facing downward. Place a mat, etc. underneath to avoid

causing scratches to the front surface. However, never use

materials that are too soft (such as blanket cloth). If

replacement is made with the PDP surface facing downward

and in contact with the blanket, pressure may be exerted on

the PDP, thus causing damages to it.

1.3.3 INFRARED RAYS

Near Near-infrared rays (800nm to 1000nm) are emitted from

the front of the panel, and this may give rise to malfunctions in

infrared remote controls or communication systems placed near

it. In this case, avoid direct infrared rays (and reflected rays in

some cases) from the screen by either changing the direction of

the unit or other infrared systems or securing a longer keeping

a distance from the screen.

(No.YA099) 1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

2.1.1 HIGH-DEFINITION IMAGE TECHNOLOGY (DIST)

• DIST (Digital Image Scaling Technology)

Employs an interpolation method that doubles the scanning

lines to realize 480-line flickerfree picture making it especially

suitable for reproducing high-resolution pictures even on largescreen displays.

2.1.2 MAIN FUNCTION

•

DIGITAL NOISE CLEAR

With digital noise clear, this helps take our static or noise from

a channel that may not be coming in clearly.

• NATURAL CINEMA

Natural cinema corrects the problem of blurred edges which

may occur when viewing a program originally shot on film (such

as motion pictures) or animation. If you notice blurring at the

edges of these programs, choose NATURAL CINEMA and set

it to AUTO.

•

COLOR MANAGEMENT

This TV supports the COLOR MANAGEMENT function to ensure

dull colors are compensated to produce natural hues.

•

DYNAMIC GAMMA

JVC's Dynamic Gamma Circuitry (DGC) makes it easier to

see dark areas when a picture has many dark areas, and

makes it easier to see the bright areas when a picture has

many bright areas. DGC is turned on, DGC analyzes and

adjusts the total level of picture brightness balance, especially

in dark areas where the level of greyscale is often lost, turning

completely to black.

• MTS (Multi-Channel Television Sound)

MTS technology allows several audio signals to be broadcast

at once, giving you a choice in what you wish to hear with a TV

program. In addition to mono or stereo sound, an MTS

broadcast may also include a second audio program (SAP).

• THEATER PRO D6500K

The TheaterPro D6500K color temperature technology function

makes sure that the video you watch is set to the standard

color temperature, so that what you see is as true to what the

film to video editors intended it to be.

• V-CHIP

Your TV is equipped with V-Chip technology which enables

you to block channels or content that you feel to be inappropriate

for children, based on US and Canada rating guidelines.

V-Chip has no effect on video signals from a DVD discs, VCR

tapes or Camcorder connection.

• AUTO SHUT OFF

This function automatically shuts off your TV when there is no

signal from the channel the TV is on.

2.1.3 ASPECT CONTROL

The screen size can be changed according to the picture aspect

ratio.

• ASPECT function

Desired screen size (PANORAMA / CINEMA / FULL / HD

PANORAMA / REGULAR / CINEMA ZOOM) can be selected.

2.1.4 MULTI-SCREEN FUNCTION

• Twin-pictures function

With the function, two pictures can be displayed at the Twin

pictures mode.

• Index-picture function

With this function, one of index-picture (12 pictures) can be

displayed at the same time.

• Freeze function

The images that are currently seen can be viewed on the memo

screen (still picture).

It is convenient for taking down notes like application address

and recipe of cooking program etc, while enjoying the current

program.

2. 2 MAIN DIFFERENCE LIST

Item PD-42V475/S PD-42V485/S

FRONT PANEL COLOR SILVER BLACK

SMART SOUND NO YES

SMART CAPTION NO YES

1-6 (No.YA099)

Page 7

2. 3 TECHNICAL INFORMATION

2.3.1 PDP STRUCTURE AND CHARACTERISTIC

This unit uses the flat type panel PDP (Plasma Display Panel), instead of the conventional CRT (Cathode Ray Tube), as a display

unit.

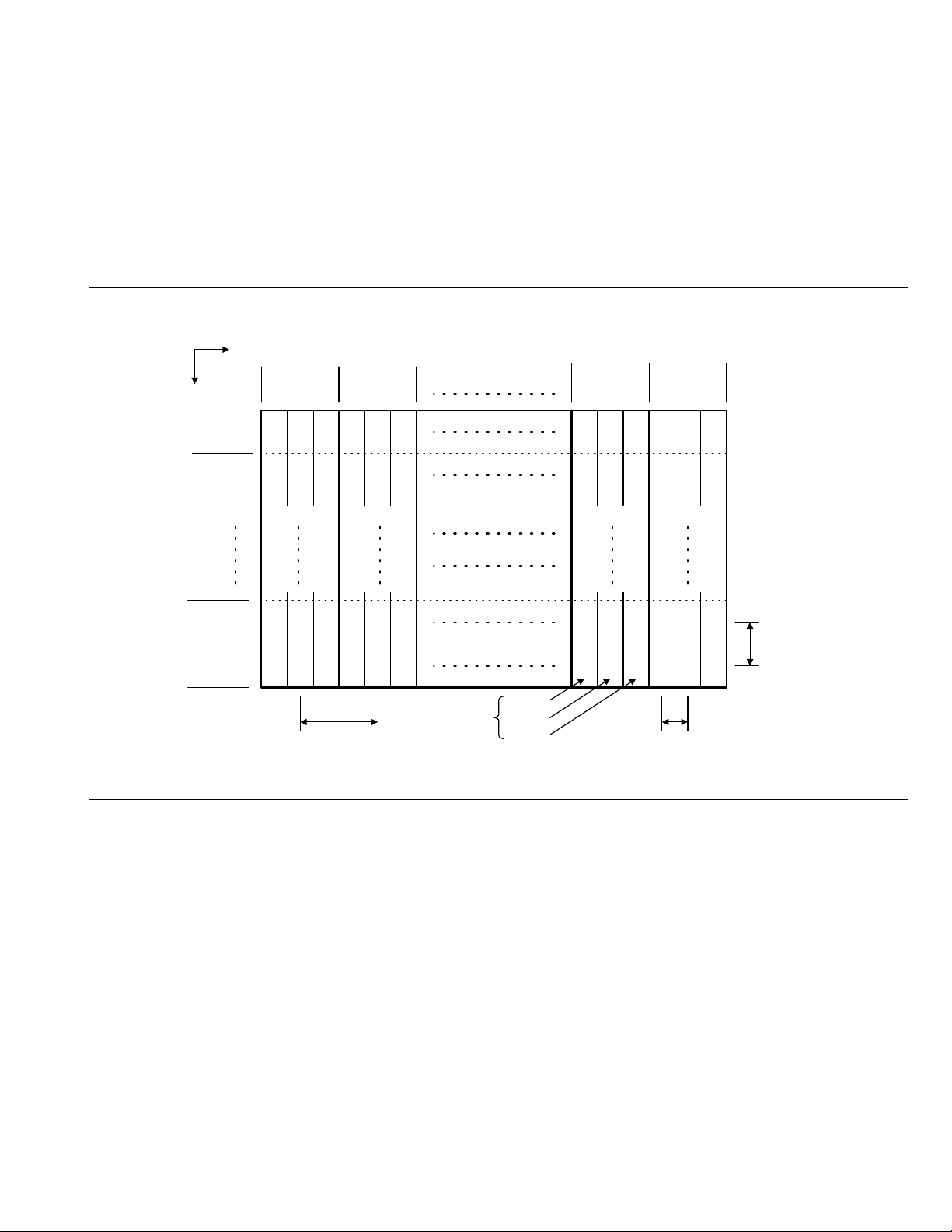

2.3.1.1 PIXEL (CELL) ARRAY

PDP is constructed by sealing the xenon, which emits neon and ultraviolet rays for discharging purpose, in between the electrodes

lay on the front glass substrate and rear glass substrate.

One pixel is composed of 3 RGB cells, with cell pitch of 0.365mm (1 pixel 1.095mm) horizontally and 1.110mm vertically.

The cell is arrayed in each RGB color as shown in Fig. 1. One pixel is formed by interlacing each RGB color cell.

One cell size is 0.365mm horizontally and 1.110mm vertically.

Direction

Vertically

No.1

Pixel line

No.2

Pixel line

No.479

Pixel line

No.480

Pixel line

Horizontally

No.1

Pixel

sequence

B G R B G R

BG

B

B

(Horizontally) Pixel pitch

RBGR

G RBG R

GRBGR

1.095mm

No.2

Pixel

sequence

1 pixel

(1 dot)

B Cell

G

Cell

R Cell

No.851 No.852

Pixel

sequence

Pixel

sequence

B GRBG R

BGRBGR

G RBG R

B

GRBGR

B

0.365mm

(Horizontally) Cell pitch

1.110 mm

(Vertically)

Pixel pitch

(Cell pitch)

Fig.1

2.3.1.2 PIXEL DEFECTS

Though PDP is made by means of ultra precise technology, there are cases whereby not all pixels (cell) will function properly. In

some cases, there may be defective pixels that do not light at all or the ones that always light on.

There are 3 types of Pixel defects, [Bright Dot Defects], [Dark Dot Defects] and [Flicker Dot Defects], as defined respectively in the

following:

(1) Bright Dot Defects

Bright dot defect is a pixel cell that lights though it should not light.

The presence of bright dot defects can be confirmed by inputting a full black signal (pattern).

(2) Dark Dot Defects

Dark dot defect is a pixel cell that does not light, though it should light.

The presence of dark dot defects can be confirmed by inputting a 100% full white signal (pattern).

(3) Flicker Dot Defects

Flicker dot defect is a pixel cell that blinks though it should light or not light.

The presence of flicher dot defects can be confirmed by inputting a full black signal (pattern).

(No.YA099) 1-7

Page 8

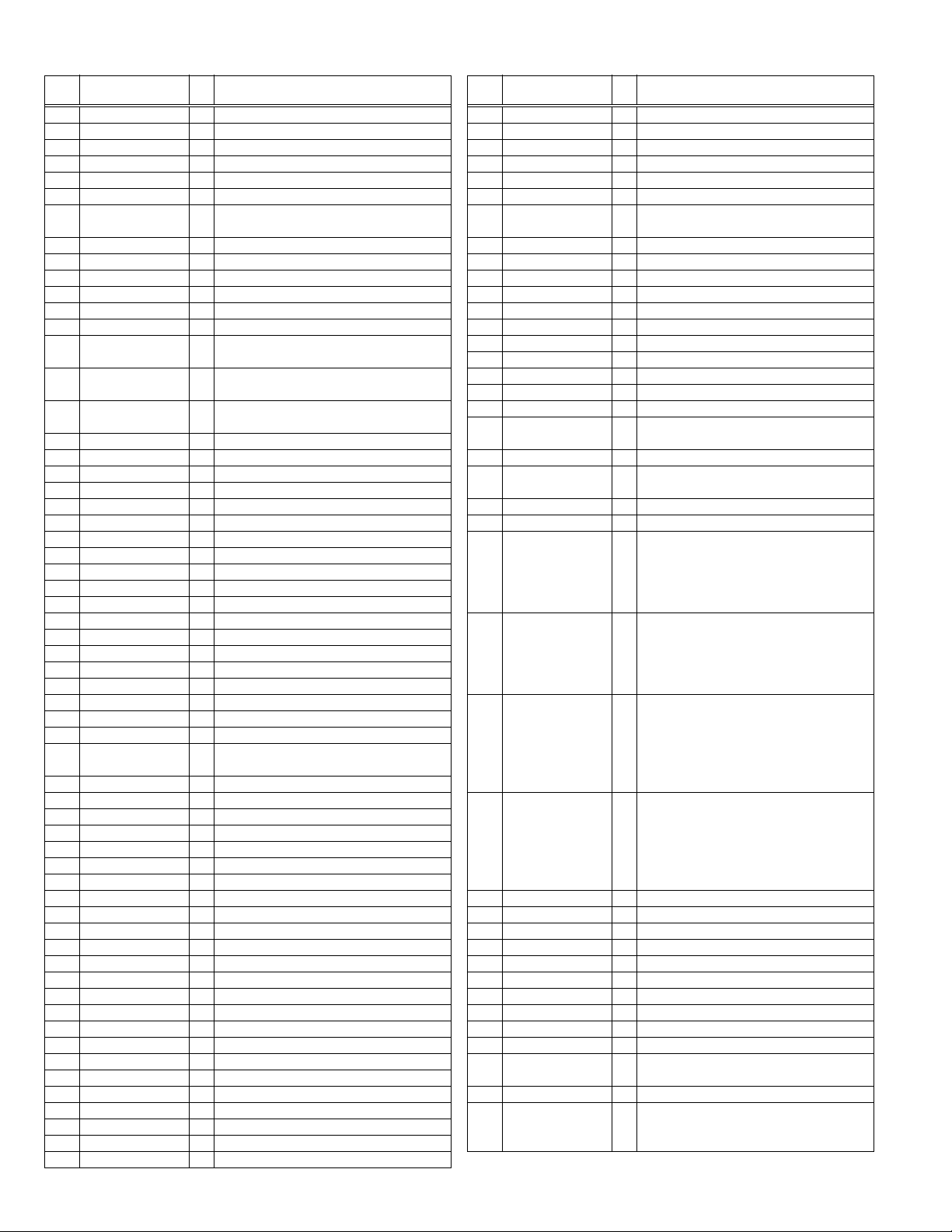

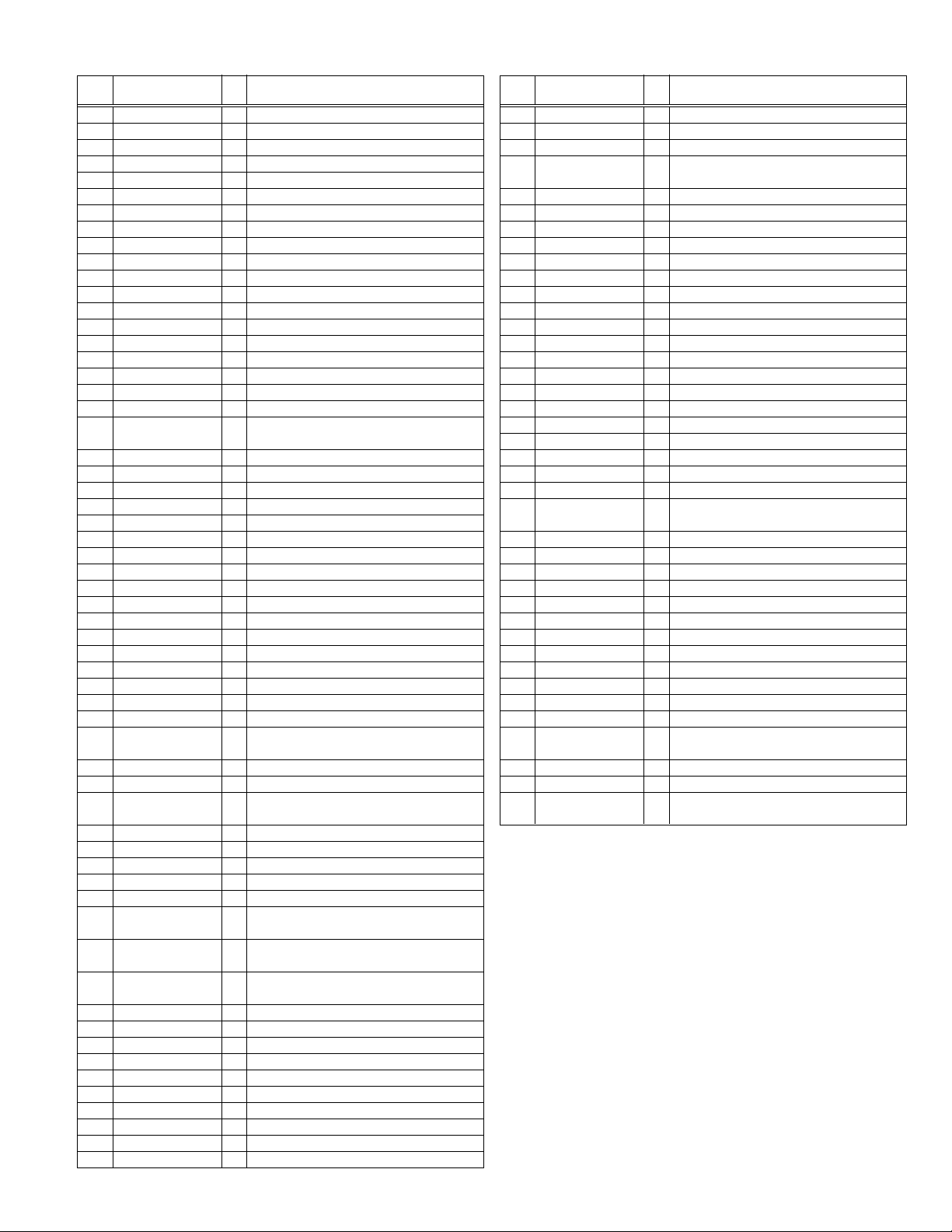

2.3.2 CHASSIS CPU [DIGITAL SIGNAL PWB : IC7001] PIN FUNCTION

Pin

No.

Pin name I/O Function

1 NC O Not used

2 P_MU O Video muting [Muting : H]

3 FUNC_LED O Not used

4 A_MU O Audio muting [Muting : H]

5 M_MU O Not used

6 PC_SW O PC input select [ON : H]

7 DIMMER_LED O Power LED dimmer control

Pin

No.

61 GND - GND

62 DIN_PH I Optical DET. out

63 ATSC_REC I Not used

64 YS1 I Not used

65 YS2 I Not used

66 3.3V I 3.3V

67 DIN_PRO O Digital-in voltage detection

[Low dimmer : L]

8 NC O Not used

9 NC O Not used

10 NC O Not used

11 POW_LED O Power LED control [ON : H]

12 WORD O Programming control

13 SBT2 I Clock for main CPU communication

14 SBI2 I Data receive for main CPU

communication

15 SBO2 O Data transmission for main CPU

communication

16 REQ O Request for main CPU

communication

68 NC O Not used

69 NC O Not used

70 NC O Not used

71 NC O Not used

72 NC O Not used

73 SBD5 I/O Flash writing for chassis CPU

74 SBT5 I Flash writing for chassis CPU

75 3.3V I 3.3V

76 NC I Not used

77 REMOCON I Remote control

78 V_SYNC I Vertical sync

79 WAKEUP_SHM I Sleep state release for chassis

17 3.3V I 3.3V

18 NC O Not used

19 GND - GND

80 POWERGOOD I Power error detection [Detection : H]

81 REC_LED O Stand-by power LED control

20 3.3V I 3.3V

21 NC O Not used

22 3.3V I 3.3V

23 OSCI I 16MHz for system clock

82 RST I Chassis CPU reset [Reset : L]

83 3.3V I 3.3V

84 SCL3A O I

24 OSCO O 16MHz for system clock

25 3.3V I 3.3v

26 NC O Not used

27 A92_RST O 3D YC separation reset [Reset : L]

28 NC O Not used

85 SDA3A I/O I

29 LIP_RST O Not used

30 NC O Not used

31 NC I Not used

32 NC O Not used

33 MDR_CON I Not used

86 SCL3B O I

34 3.3V I 3.3V

35 NC O Not used

36 DsyncSW2 O Digital sync signal select

[Digital sync : L]

37 NC O Not used

38 NC O Not used

87 SDA3B I/O I

39 HOTPLUG I Not used

40 MECA_SW I Power switch monitor [ON : L]

41 MAIN_POW O Main power control [ON : L]

42 VARI / FIX O Audio out select [VARI : L / FIX : H]

43 0V - GND

44 NC I Not used

45 AFT1 I AFT detection [Detection : H]

46 NC I Not used

47 NC I Not used

48 NC O Not used

49 NC O Not used

50 NC I Not used

51 NC O Not used

52 NC I Not used

53 NC O Not used

54 3.3V I 3.3V

55 PDP_TX O

56 PDP_RX I

PDP communication for panel CPU

PDP communication for panel CPU

57 SDA0 I/O I2C bus data (for chassis memory)

88 DIN_sel O Not used

89 LR_SW O Digital-in control

90 DIN_INT O Digital-in reset [Reset : H]

91 DVI_RST O Not used

92 GND - GND

93 SCL5055 O I2C bus clock (for DIST)

94 NC O Not used

95 SDA5055 I/O I2C bus data (for DIST)

96 NC O Not used

97 NC O Not used

98 15K/OTH O Y signal select for 3D YC separation

99 DsyncSW1 O Not used

100 JCC5057_BUSY I Busy for gamma correction / color

58 SCL0 O I2C bus clock (for chassis memory)

59 SDA_DVI I/O Not used

60 SCL_DVI I/O Not used

Pin name I/O Function

[Detection : H]

CPU [Relese : L]

[Stand-by :H]

2

C bus clock (for 3D YC separation,

gamma correction / color

management / RGB process / OSD

composition, U / V frontend, HDMI

driver)

2

C bus data (for 3D YC separation,

gamma correction / color

management / RGB process / OSD

composition, U / V frontend, HDMI

driver)

2

C bus clock (for video / audio

select, color demod. / sync sep.,

3 line comb filter, component

video / audio select, sync sep. /

SW / detect, MTS demod. /

surround / audio control)

2

C bus data (for video / audio

select, color demod. / sync sep.,

3 line comb filter, component

video / audio select, sync sep. /

SW / detect, MTS demod. /

surround / audio control)

[525i : H / other : L]

management / RGB process / OSD

composition [Busy : H]

1-8 (No.YA099)

Page 9

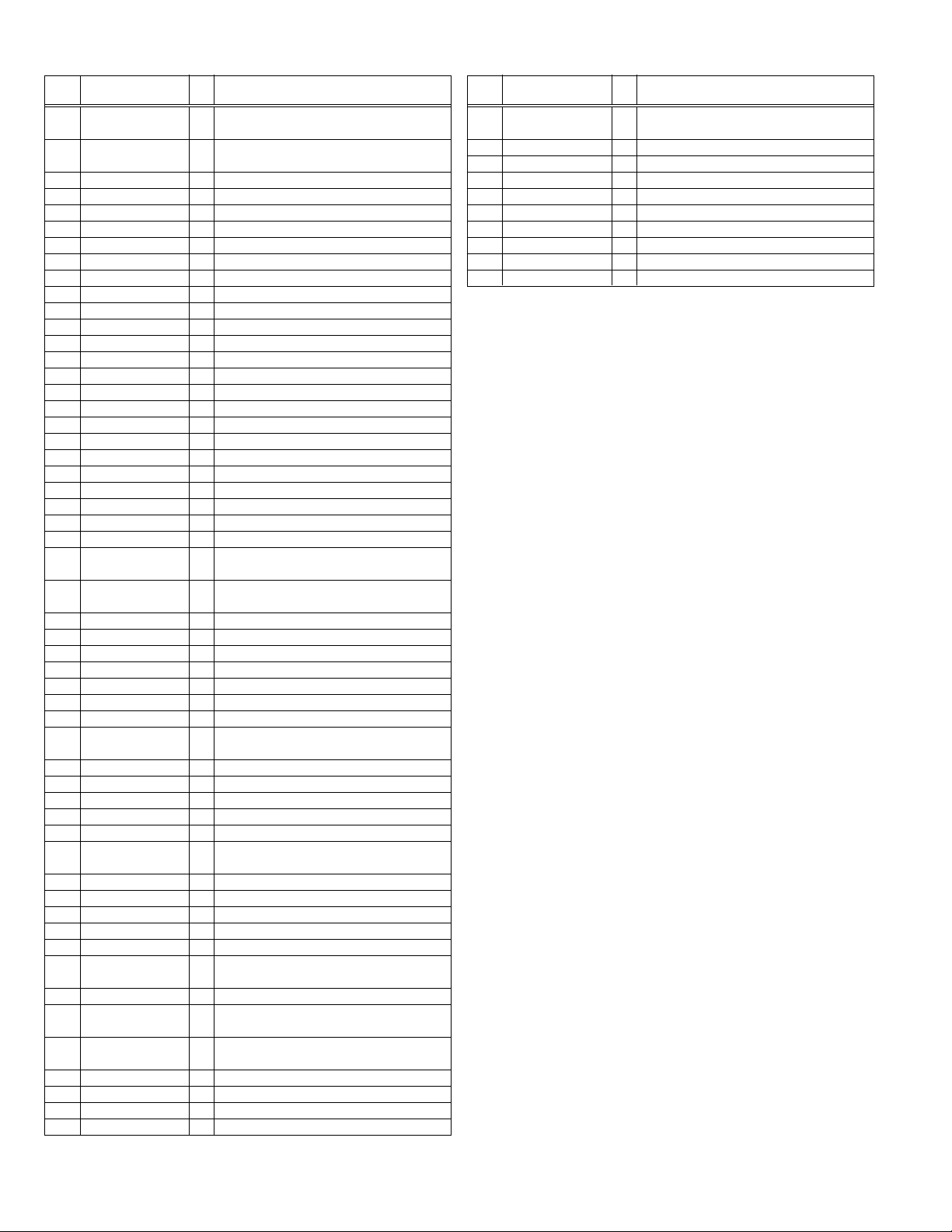

2.3.3 MAIN CPU [DIGITAL SIGNAL PWB : IC7601] PIN FUNCTION

Pin

No.

Pin name I/O Function

1 VHOLD1 I Data slicer (closed caption) for main

2 HFLT1 I/O

LPF of video signal (closed caption)

3 NC I/O Not used

4 NC I/O Not used

5 DIGR0 O Red for OSD

6 TB1in I Clock information

7 REMO I Remote control

8BYTE -GND

9 CNVss I

CPU mode select [CPU : L / Writing : H]

10 DIGG0 O Green for OSD

11 DIGB0 O Blue for OSD

12 RESET I Main CPU reset [Reset : L]

13 Xout O 16MHz for system clock

14 Vss - GND

15 Xin I 16MHz for system clock

16 Vccl I 3.3V

17 OSC1 I Clock input for OSD

18 OSC2 O Not used

19 INT1 I AV COMPULINK

ΙΙΙ

20 INT0 I Request for chassis CPU

communication

21 OUT1 O YS for OSD

22 OUT2 O YM for OSD

23 NC I/O Not used

24 NC I/O Not used

25 NC I/O Not used

26 NC I/O Not used

27 CTA2/RTS2 I/O Not used

28 CLK2 I/O Not used

29 RxD2 I/O Not used

30 TxD2 I/O Not used

31 SDA2 I/O Not used

32 DIGR1 O Red for OSD

33 DIGG1 O Green for OSD

34 DIGB1 O Blue for OSD

35 TxD0 I Programming control

36 RxD0 O Flash writing for main CPU

37 CLK0 I Programming clock

38 RTS0 I/O Busy for flash writing composition

[Busy : H]

39 P5.7 I Not used

40 P5.6 O Not used

41 HOLD I Main CPU hold for flash writing

[Hold : L]

42 P5.4 O Not used

43 P5.3 O Not used

44 P5.2 O Not used

45 P5.1 O Not used

46 WR O

CPU mode select [CPU : L / Writing : H]

47 P4.7 O Data transmission for chassis CPU

communication

48 P4.6 I Data receive for chassis CPU

communication

49 P4.5 O Clock for chassis CPU

communication

50 P4.4 I/O Not used

51 NC I/O Not used

52 NC I/O Not used

53 NC I/O Not used

54 NC I/O Not used

55 NC I/O Not used

56 NC I/O Not used

57 NC I/O Not used

58 NC I/O Not used

59 NC I/O Not used

Pin

No.

Pin name I/O Function

60 NC I/O Not used

61 NC I/O Not used

62 HSYNC I Horizontal sync for OSD

63 NC I/O Not used

64 VSYNC I Vertical sync for OSD

65 NC I/O Not used

66 NC I/O Not used

67 NC I/O Not used

68 NC I/O Not used

69 NC I/O Not used

70 NC I/O Not used

71 NC I/O Not used

72 NC I/O Not used

73 NC I/O Not used

74 NC I/O Not used

75 NC I/O Not used

76 NC I/O Not used

77 NC I/O Not used

78 NC I/O Not used

79 NC I/O Not used

80 NC I/O Not used

81 NC I/O Not used

82 NC I/O Not used

83 NC I/O Not used

84 WAKE O Sleep state release for chassis

CPU [Relese : L]

85 CARD_DET I/O Not used

86 POWER_SW I Main power switch [ON : L]

87 SDAM O I2C bus clock (for main memory)

88 SCLM I/O I2C bus Data (for main memory)

89 DIGR2 O Red for OSD

90 DIGG2 O Green for OSD

91 DIGB2 O Blue for OSD

92 NC I/O Not used

93 KEY2 I Key scan data 1 [ON :H]

94 KEY1 I Key scan data 2 [ON :H]

95 VHOLD2 I Data slicer (closed caption) for sub

96 HLF2 I/O LPF of video signal (closed caption)

97 CVIN2 I Composite video input for closed

caption (SUB-CCD)

98 TVSETB - GND

99 VCCE - 5V

100 CVIN1 I Composite video input for closed

caption (MAIN-CCD)

(No.YA099) 1-9

Page 10

2.3.4 PANEL CPU [INTERFACE PWB : IC807] PIN FUNCTION

Pin

No.

Pin name I/O Function

1 SYSTEM0 I PDP size select

[1.75V : 42V VGA 3.25V : 35V VGA]

2 SYSTEM3 I PDP maker select

[0V : SAMSUNG 3.25V : NEC]

3 AVCC I 5.0V

4 X2 - Not used

5X1 -GND

6 VCL - GND

7 RES I Reset [Reset : L]

8 TEST I GND

9 VSS - GND

10 OSC2 O 16MHz for system clock

11 OSC1 I 16MHz for system clock

12 VCC I 5.0V

13 PW_LOB O Power control [ON : L]

14 PANEL_PW_ON O Panel power control [ON : L]

15 TALK_RST O Not used

16 CODEC_RST O Not used

17 I2C_STOP O I2C bus stop control [Stop : L]

18 NC O Not used

19 NC O Not used

20 NC O Not used

21 NC O Not used

22 NC O Not used

23 SDA1 I/O I2C bus data (for panel memory)

24 FAN O Not used

25 SCL1 O I2C bus clock (for panel memory)

26 SDA0 I/O I

27 SCL0 O I

2

C bus data (for BBE / surround /

audio control, temp. sensor)

2

C bus clock (for BBE / surround /

audio control, temp. sensor)

28 SDA2 I/O

29 SCL2 O

I2C bus data (for PDP communication)

I2C bus clock (for PDP communication)

30 NC O Not used

31 SDA3 I/O Not used

32 SCL3 O Not used

33 NC O Not used

34 NC O Not used

35 NMI I Port for writing on board control

[Writing : L]

36 A_MU O Audio muting [Muting : H]

37 (HD) I Not used

38 ON_TIMMER O Not used

39 REMO I Not used

40 POWERLED O Not used

41 P85 I Emulator connection / Port for

writing on board [Writing : H]

42 P86 I Emulator connection

43 P87 I Emulator connection

44 SCK3 O Port for writing on board

45 RXD I Port for writing on board

46 TXD O Port for writing on board

47 AC_DET I AC power frequency detection

[Detection : H]

48 NC O Not used

49 RXD2 I Data receive for main CPU

communication

50 TXD2 O Data transmision for main CPU

communication

51 NC O Not used

52 MECA_SW I Not used

53 VD I Vertical sync

54 REC_DET I Not used

Pin

No.

Pin name I/O Function

55 I2C_READY I PDP I2C communication select

[Prohibition : L Permission : H]

56 FAN_LOCK I Not used

57 SYSTEM2 I Not used

58 SYSTEM 1 I Not used

59 THEM_DET I

Temp. sensor detection [Detection : H]

60 (AMP_PRO2) - GND

61 AMP_PRO1 I Not used

62 EE_CDS I Not used

63 KEY_IN1 I Not used

64 KEY_IN2 I Not used

1-10 (No.YA099)

Page 11

SECTION 3

LOB OK FAN OK

SYNC M:OK S:OK HD:NG

TIM OK

MSM OK DIGI 0000

MEM OK AVSW OK

YC OK AIO OK

TUN OK GCR NG 1

IP OK RGB OK 8

DVI OK HDMI OK

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

DISASSEMBLY

3.1 SYSTEM SETTEING

When the DIGITAL SIGNAL PWB is replaced or the DIGITAL

INPUT is not normal, SYSTEM SETTING in the following

procedure.

(1) Press the [SLEEP TIMER] key, and set it to 0 minutes.

(2) Press the [DISPLAY] key and the [VIDEO STATUS] key

simultaneously, then the SERVICE MENU screen will be

displayed.

(3) In the SERVICE MENU, press the [2] key. Then, the SELF-

CHECK screen will be displayed.

(4) Turn off the power by pressing the [POWER] key on the

remote control unit.

SERVICE MENU SCREEN

SERVICE MENU

1.ADJUST

2.SELF_CHK

3.I2C STOP

SELF-CHECK SCREEN

LOB OK FAN OK

SYNC M:OK S:OK HD:NG

TIM OK

MSM OK DIGI 0000

MEM OK AVSW OK

YC OK AIO OK

TUN OK GCR NG 1

IP OK RGB OK 8

DVI OK HDMI OK

SOLDER SIDE

RECEIVER PWB

IC3106

Masking tape

Fig. 2

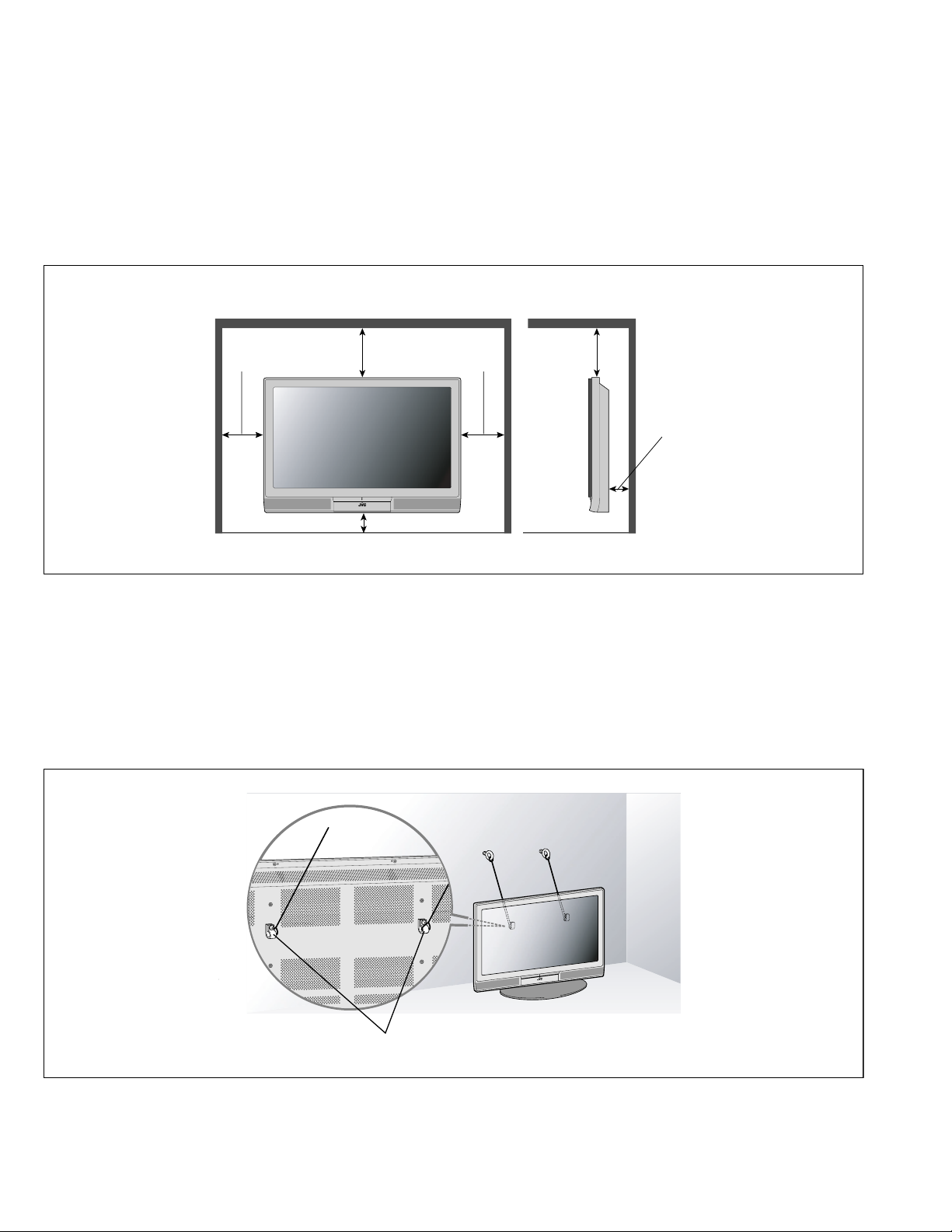

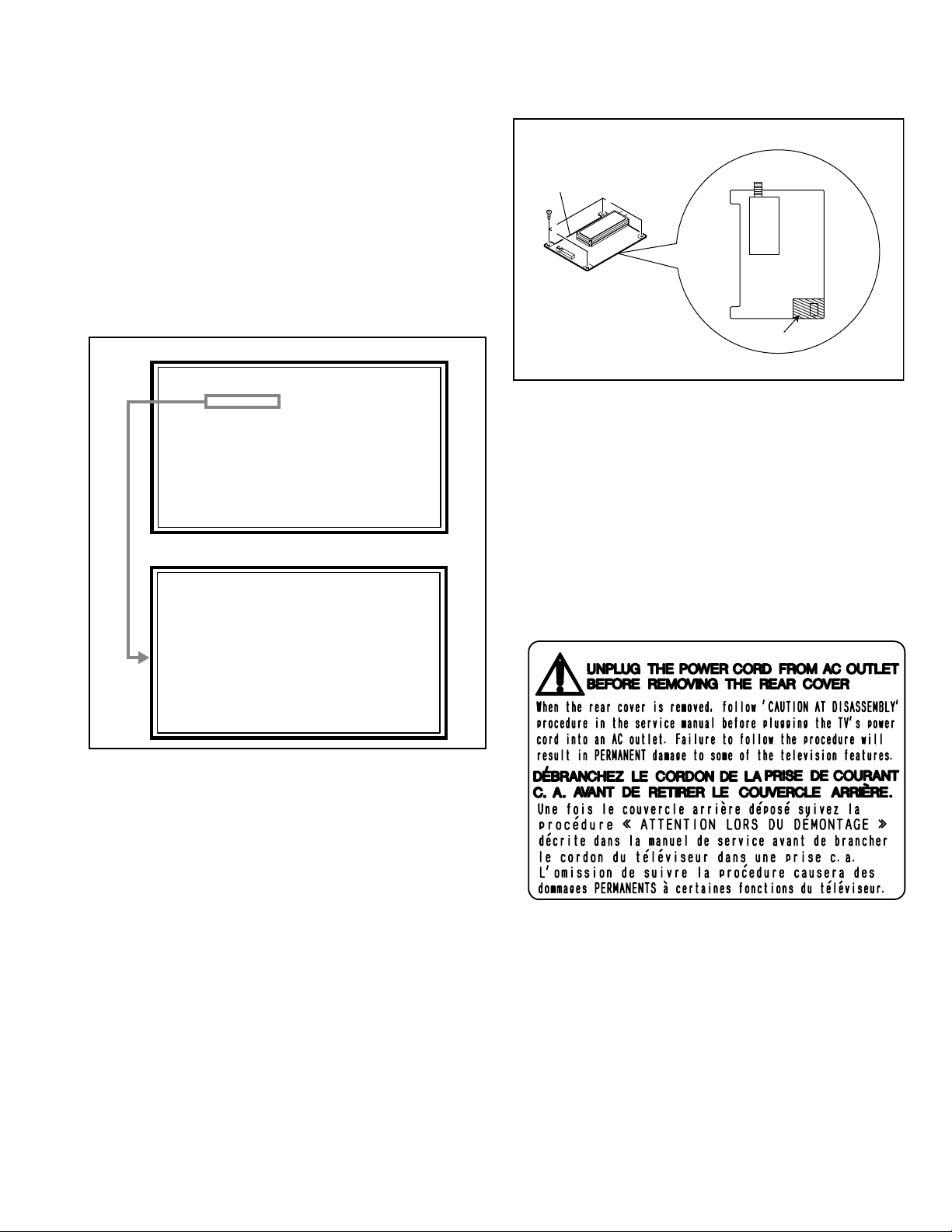

3.2.1 REMOVING THE REAR COVER (Fig.3)

(1) Remove the power cord.

(2) Remove the 4 screws [A], and remove the STAND COVER.

(3) Remove the 2 screws [B] and the 6 screws [C].

(4) Remove the TABLE TOP STAND.

(5) Remove the 15 screws [D], the 4 screws [E], the 8 screws

[F], and remove the REAR COVER.

CAUTION:

• Prior to starting the work, be sure to read the following written

instructions on the CAUTION LABEL attached to the REAR

COVER.

Fig. 1

3.2 DISASSEMBLY PROCEDURE

CAUTION:

• When exchanging parts etc. with the front side (PDP side)

facing down, please place a protection sheet below before

starting, so as to prevent scratches on the front side.

• Pay extra attention in the following matter when turning the

power on with the REAR COVER removed.

(1) Prior to disassembly, unplug the power cord from the AC

outlet without fail. (Turn the power "off".)

(2) Make sure that the

RECEIVER PWB: IC3106

covered with black masking tape. (Fig.2)

(3) Make sure to remove the masking of

IC3106

when attaching the REAR COVER.

(4) Do not turn the power on until the REAR COVER is

attached properly, after the masking is removed.

is completely

RECEIVER PWB:

3.2.2 REMOVING THE TERMINAL COVER AND CENTER COVER

(Fig.3)

• Remove the REAR COVER.

(1) Remove the 7 screws [G], and remove the CHASSIS

SHIELD COVER.

(2) Remove the 6 screws [H], and remove the CENTER

COVER.

(3) Remove the 6 screws [I], the 12 screws [J], the 1 screw

[K], the 1 nut [L], the 1 washer [M], and remove the

TERMINAL COVER.

(No.YA099) 1-11

Page 12

D

(x11)

A

B

(x6)

REAR COVER

A

A

B

A

STAND COVER

C

D

(x4)

F

(x8)

TABLE TOP STAND

(x2)

E

(x2)

I

(x2)

E

H

(x6)

G

(x7)

CENTER COVER

(x12)

I

(x2)

J

CHASSIS

SHIELD

TERMINAL

COVER

M

L

I

(x2)

K

COVER

TOP

1-12 (No.YA099)

Fig. 3

Page 13

3.2.3 REMOVING THE AUDIO PWB (Fig. 4)

• Remove the REAR COVER.

(1) Remove the 4 screws [N], and remove the AUDIO CHASSIS

COVER.

(2) Disconnect the connectors [CN600B], [CN600C],

[CN600Y], [CN60SL], [CN60SR] from the AUDIO PWB.

(3) Remove the 4 screws [O], and remove the AUDIO PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.4 REMOVING THE AV JACK PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

(1) Disconnect the connectors [CN0J01], [CN0J02] from the

AV JACK PWB.

(2) Remove the 4 screws [P], and remove the AV JACK PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.5 REMOVING THE INTERFACE PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

(1) Disconnect the connectors [CN00B], [CN00C], [CN00Q],

[CN00G], [CN00T], [CN00V], [CN00X], [CN0FC] from the

INTERFACE PWB.

(2) Remove the 2 screws [Q], and withdraw the INTERFACE

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.6 REMOVING THE REGULATOR PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the INTERFACE PWB.

(1) Disconnect the connectors [CN003], [CN008], [CN00D]

from the REGULATOR PWB.

(2) Remove the 4 screws [R], and remove the REGULATOR

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.7 REMOVING THE LINE FILTER PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the INTERFACE PWB.

(1) Remove the 1 screw [S] and the 1 screw [T], and remove

the AC INLET PANEL.

(2) Disconnect the connector [CN8001] from the MAIN POWER

PWB.

(3) Remove the 1 screw [U], the 1 screw [V] and the 2 screws

[W], and remove the LINE FILTER PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.8 REMOVING THE RECEIVER PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

(1) Disconnect the connectors [CN00A], [CN00T] from the

RECEIVER PWB.

(2) Withdraw the RECEIVER PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.9 REMOVING THE ANALOG SIGNAL PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the RECEIVER PWB.

(1) Disconnect the connectors [CN001], [CN002], [CN00D],

[CN00F], [CN00G], [CN0J1], [CN0J2] from the ANALOG

SIGNAL PWB.

(2) Remove the 4 screws [X], and remove the ANALOG SIGNAL

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.10 REMOVING THE DIGITAL SIGNAL PWB (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

(1) Disconnect the connectors [CN001], [CN002], [CN003],

[CN0FC], [CN0LV2] from the DIGITAL SIGNAL PWB.

(2) Remove the 5 screws [Y], and remove the DIGITAL SIGNAL

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

CAUTION:

• Make sure to perform the "SYSTEM SETTING" on page

1-11, when DIGITAL SIGNAL PWB is replaced.

3.2.11 REMOVING THE MAIN BASE, CHASSIS BASE AND AUDIO

PWB BASE (Fig.4)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the AUDIO PWB.

• Remove the AV JACK PWB.

• Remove the INTERFACE PWB.

• Remove the REGULATOR PWB.

• Remove the LINE FILTER PWB.

• Remove the RECEIVER PWB.

• Remove the ANALOG SIGNAL PWB.

• Remove the DIGITAL SIGNAL PWB.

(1) Remove the 1 screw [Z], and remove the DIGITAL

TERMINAL COVER.

(2) Remove the 1 screw [a].

(3) Lift the MAIN BASE upright and remove it.

(4) Remove the 2 screws [b], and remove the CHASSIS BASE.

(5) Remove the 1 screw [c], and remove the AUDIO PWB BASE.

(No.YA099) 1-13

Page 14

RECEIVER PWB

INTERFACE PWB

(x4)

R

Q

d

(x2)

U

W

(x2)

V

ANALOG

SIGNAL PWB

(x5)

Y

DIGITAL

SIGNAL

PWB

DIGITAL TEMINAL

COVER

e

d

MAIN BASE

b

c

b

X

(x4)

REGULATOR

PWB

LINE FILTER

a

PWB

a

P

(x4)

c

b

S

b

AC INLET

PANEL

a

T

CHASSIS BASE

c

AV JACK PWB

N

(x4)

O

(x4)

AUDIO CHASSIS

COVER

AUDIO PWB

1-14 (No.YA099)

AUDIO PWB BASE

Z

TOP

Fig. 4

Page 15

3.2.12 REMOVING THE FRONT CONTROL PWB (Fig.5)

• Remove the REAR COVER.

• Remove the CENTER COVER.

(1) Remove the 4 screws [d] and the 2 screws [e].

(2) Disconnect the connectors [CN00F], [CN00T] from the

FRONT CONTROL PWB.

(3) Remove the FRONT CONTROL PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.13 REMOVING THE FRONT LED PWB (Fig.5)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the FRONT CONTROL COVER.

(1) Remove the 2 screws [f], and withdraw the FRONT PWB

BASE.

(2) Disconnect the connector [CN00X] from the FRONT LED

PWB.

(3) Remove the 2 screws [g], and remove the FRONT LED

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.14 REMOVING THE TEMP. SENSOR PWB (Fig.5)

• Remove the REAR COVER.

(1) Disconnect the connector [CN00V] from the TEMP.

SENSOR PWB.

(2) Remove the 1 screw [h], and remove the TEMP. SENSOR

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.17 REMOVING THE PDP UNIT (Fig.5)

• Remove the REAR COVER.

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the MAIN BASE, CHASSIS BASE and AUDIO PWB

BASE (with each PWB affixed on the MAIN BASE, CHASSIS

BASE and AUDIO PWB BASE).

• Remove the TEMP. SENSOR PWB.

• Remove the MAIN POWER PWB.

• Remove the SUB POWER PWB.

(1) Remove the 8 screws [k] and the 8 screws [m], and remove

the BACK FRAME.

(2) Lift the PDP UNIT upright and remove it with enough care

not to impose shock to the PDP UNIT.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

CAUTION:

• Two or more people are required to remove the PDP UNIT.

• The gas pouring port is covered with the protection material.

In operation, be careful not to damage the gas pouring port.

• Do not touch the front side (glass) of the PDP with your

fingers.

3.2.15 REMOVING THE MAIN POWER PWB (Fig.5)

• Remove the REAR COVER.

(1) Disconnect the connectors [CN8001], [CN8002],

[CN8003], [CN8006], [CN8008], [CN8009], [CN9001] from

the MAIN POWER PWB.

(2) Remove the 7 screws [i], and remove the MAIN POWER

PWB and the POWER PWB BRACKET.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.16 REMOVING THE SUB POWER PWB (Fig.5)

• Remove the REAR COVER.

(3) Disconnect the connectors [CN9001], [CN9005] [CN9010]

from the SUB POWER PWB.

(4) Remove the 4 screws [j], and remove the SUB POWER

PWB and the INSULATOR.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

(No.YA099) 1-15

Page 16

(x4)

k

m

(x4)

j

(x4)

INSULATOR

MAIN POWER PWB

i

(x7)

m

(x4)

k

(x4)

SUB POWER PWB

TEMP. SENSOR PWB

GAS insertion

hole

PDP UNIT

BACK FRAME

h

INSULATOR

POWER PWB

BRACKET

(x2)

d

e

e

(x4)

FRONT

CONTROL PWB

f

(x2)

1-16 (No.YA099)

TOP

Fig. 5

FRONT LED

PWB

FRONT PWB

BASE

g

(x2)

Page 17

3.2.18 REMOVING THE PWB IN PDP UNIT

3.2.18.1 REMOVING THE X-MAIN PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN4001], [CN4002],

[CN4003], [CN4004], [CN4005] from the X-MAIN PWB.

(2) Remove the 8 screws [n], and remove the X-MAIN PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.18.2 REMOVING THE Y-MAIN PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN5001], [CN5002],

[CN5003], [CN5004], [CN5005], [CN5006], [CN5007],

[CN5008] from the Y-MAIN PWB.

(2) Remove the 7 screws [o], and remove the Y-MAIN PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.18.5 REMOVING THE Y-BUFFER-L PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN5501], [CN5502],

[CN5503], [CN5504], [CN5505], [CN5506] from the Y-

BUFFER-L PWB.

(2) Remove the 5 screws [r], and remove the Y-BUFFER-L

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.18.6 REMOVING THE E-BUFFER PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN401], [CN806], [EC1], [EC2],

[EC3], [EC4], [EC5], [EC6], [EF1] from the E-BUFFER PWB.

(2) Remove the 6 screws [s], and remove the E-BUFFER PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.18.3 REMOVING THE LOGIC-MAIN PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN101], [CN201], [CN401],

[CN402], [CN403], [CN803] from the LOGIC-MAIN PWB.

(2) Remove the 7 screws [p], and remove the LOGIC-MAIN

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.18.4 REMOVING THE Y-BUFFER-U PWB (Fig. 6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN5401], [CN5402],

[CN5403], [CN5404], [CN5405], [CN5406] from the YBUFFER-U PWB.

(2) Remove the 5 screws [q], and remove the Y-BUFFER-U

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

(x7)

o

(x7)

3.2.18.7 REMOVING THE F-BUFFER PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN402], [FC1], [FC2], [FE1],

[FG1] from the F-BUFFER PWB.

(2) Remove the 3screws [t], and remove the F-BUFFER PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

3.2.18.8 REMOVING THE G-BUFFER PWB (Fig.6)

• Remove the PDP UNIT.

(1) Disconnect the connectors [CN403], [GC1], [GC2], [GC3],

[GC4], [GC5], [GC6], [GF1] from the G-BUFFER PWB.

(2) Remove the 6 screws [u], and remove the G-BUFFER

PWB.

NOTE:

• It is advisable to take note of the connecting location

(connector number) of the removed connectors.

X-MAIN PWB

p

(x8)

n

u

(x6)

q

(x5)

Y-BUFFER-U

PWB

Y-BUFFER-L

PWB

Y-MAIN PWB

E-BUFFER PWB

r

(x5)

Fig. 6

F-BUFFER PWB

LOGIC-MAIN PWB

s

(x6)

G-BUFFER PWB

t

(x3)

(No.YA099) 1-17

Page 18

3.2.19 REMOVING THE SPEAKER (Fig.7)

• Remove the REAR COVER

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the MAIN BASE, CHASSIS BASE and AUDIO PWB

BASE (with each PWB affixed on the MAIN BASE, CHASSIS

BASE and AUDIO PWB BASE).

(1) Remove the 3 screws [v], and remove the SPEAKER.

(2) Follow the same steps when removing the other hand

SPEAKER.

CAUTION:

• Please do not disassembly the SPEAKER.

When the speaker is decomposed, the performance cannot

be kept.

3.2.20 REMOVING THE FRONT PANEL AND THE FRONT FILTER

(Fig.7)

• Remove the REAR COVER

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the MAIN BASE, CHASSIS BASE and AUDIO PWB

BASE (with each PWB affixed on the MAIN BASE, CHASSIS

BASE and AUDIO PWB BASE).

• Remove the PDP UNIT.

(1) Remove the 8 screws [w].

(2) Lift the FRAME BRACKETS and FRONT FILTER upright

and remove it with enough care not to damage the FRONT

FILTER.

(3) Remove the FRONT PANEL.

(4) Remove the 16 screws [x], and remove the FILTER

BRACKET.

(5) Remove the FRONT FILTER.

3.2.21 REMOVING THE TOP FRAME, BOTTOM FRAME AND SIDE

FRAME (Fig.7)

• Remove the REAR COVER

• Remove the CENTER COVER.

• Remove the CHASSIS SHIELD COVER.

• Remove the TERMINAL COVER.

• Remove the MAIN BASE, CHASSIS BASE and AUDIO PWB

BASE (with each PWB affixed on the MAIN BASE, CHASSIS

BASE and AUDIO PWB BASE).

• Remove the PDP UNIT.

• Remove the FRONT FILTER.

(1) Remove the 4 bosses [y] and the 8 screws [z], and remove

the TOP FRAME, BOTTOM FRAMEand SIDE FRAME.

y

(x2)

x (x5)

y

z

SIDE FRAME

FRONT FILTER

(x2)

TOP FRAME

w

(x4)

y

z

(x2)

w(x4)

z

f

SIDE FRAME

BOTTOM

FRAME

y

x (x3)

FILTER

BRACKET

z

(x2)

x (x5)

v

(x3)

SPEAKER

f

1-18 (No.YA099)

TOP

v(x3)

FRONT PANEL

Fig. 7

Page 19

3.3 REPLACEMENT OF MEMORY IC

SERVICE MENU SCREEN

ADJUST SCREEN

3.3.1 MEMORY IC

This unit uses the nonvolatile memory IC.

The memory IC memories data for video and deflection circuits. To replace the memory IC without the data written, malfunctions

might occurred while power is on, and the normal image might not appear. When replacing the memory IC, be sure to use the IC

written with the initial values of data.

3.3.2 PROCEDURE FOR REPLACING THE MEMORY IC

1. Power off

Switch the power off and unplug the power cord from the

SERVICE MENU SCREEN

wall outlet.

2. Replacing the memory IC

Replace the memory IC with new one. Be sure to use the

memory IC written with the initial data values.

SERVICE MENU

1. ADJUST

2. SELF_CHECK

3. I2C STOP

3. Power on

Plug the power cord into the wall outlet and switch the

power on.

4. Receive channel setting

Refer to the OPERATING INSTRUCTIONS and set the

receive channels (channels preset).

5. User setting

ADJUST SCREEN

Check the user setting values in Table 1 to Table 5. If

setting value is different, set the correct value.

For setting, refer to the OPERATING INSTRUCTIONS.

6. Setting of SERVICE MENU

Verify the setting for each setting item in the SERVICE

S001 PREPATE 0

NTSC3 FULL STD L

MENU.(See Table 6.) If readjustment is necessary,

perform adjustment referring to “ADJUSTMENTS

PROCEDURE”.

3.3.3 FACTORY SETTING VALUE

3.3.3.1 SETTING OF SWITCHS ON FRONT SIDE OF MAIN BODY

Setting item Setting value

POWER OFF

CHANNEL CABLE-02

VOLUME 10

INPUT TV

Table 1

3.3.3.2 SETTING OF REMOTE CONTROL UNIT

Setting item Setting value

DISPLAY OFF

ASPECT PANORAMA

VIDEO STATUS DYNAMIC

MULTI PICTURE 1 SCREEN

A.H.S OFF

BBE ON

SMART SOUND [PD-42V485/S]

AHB ON

OFF

CLOSED CAPTION OFF

Table 2

Fig.1

(No.YA099) 1-19

Page 20

3.3.3.3 SETTING OF MENU SCREEN

(1) PICTURE ADJUST

VIDEO STATUS

Setting item

STANDARD DYNAMIC GAME THEATER

NTSC HD NTSC HD NTSC HD NTSC HD

PICTURE 00 00 +05 +05 -05 -05 0 0 00

BRIGHT 00 0 0 00 00 0 0 00 00 00

COLOR 00 00 00 00 -03 -03 00 00

TINT 0 0 0 0 00 0 0 00 00 0 0 00

DETAIL 00 00 +05 +05 -03 -03 00 00

COLOR TEMPERATURE LOW LOW HIGH HIGH HIGH HIGH HIGH LOW

DIGI. NOISE CLEAR OFF OFF OFF OFF OFF OFF OFF OFF

NATURAL CINEMA ON ON ON ON ON ON ON ON

COLOR MANAGEMENT ON ON ON ON ON ON ON ON

DYNAMIC GAMMA ON ON O N O N ON ON O N O N

Table 3

(2) SOUND ADJUST

Setting item Setting value

BASS Center

TREBLE Center

BALANCE Center

MTS STEREO

Table 4

(3) INITIAL SET UP

Setting item Setting value

TV SPEAKER ON

AUDIO OUT FIX

DIGITAL-IN SIZE1

DIGITAL-IN AUDIO DIGITAL

CENTER CH INPUT OFF

NOISE MUTING ON

FRONT PANEL LOCK OFF

V1 SMART INPUT OFF

VIDEO INPUT LABEL Space

POSITION ADJUSTMENT CENTER

POWER INDICATOR HIGH

IMAGE SHIFT STD

LANGUAGE ENG.

COLSED CAPTION OFF

AUTO SHUT OFF OFF

XDS ID ON

V-CHIP OFF

AUTO DEMO OFF

Setting item Setting value

Table 5

3.3.3.4 SERVICE MENU SETTING ITEMS

Service menu Setting item

1. ADJUST

2. SELF CHECK

3. I2C STOP

S001 ~ S039

T001 ~ T010

P001 ~ P010

D001 ~ D187

Z001 ~ Z010

[Refer to “SECTION 5

TROUBLESHOOTING” (page 1-31)]

[Do not adjust]

Table 6

CAUTION

When a number key other than the [1] to [3] key is pressed in the SERVICE MENU screen, the other relevant screen may be displayed.

This is not used in the adjustment procedure.

Press the [MENU] key to return to the SERVICE MENU.

1-20 (No.YA099)

Page 21

3.4 REPLACEMENT OF CHIP COMPONENT

A

B

C

3.4.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.4.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.4.3 REPLACEMENT STEPS

1. How to remove Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with tweezers and remove the chip part.

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of

the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

Note :

After removing the part, remove remaining solder from

the pattern.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(4) Then solder leads B and C.

A

B

C

(No.YA099) 1-21

Page 22

SECTION 4

SERVICE MENU SCREEN

ADJUST SCREEN

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) You can make the necessary adjustments for this unit

with either the remote control unit or with the adjustment

equipment and parts as given below.

(2) Adjustment with the remote control unit is made on the

basis of the initial setting values, however, the new

setting values which set the screen to its optimum

condition may differ from the initial settings.

(3) Make sure that AC power is turned on correctly.

(4) Turn on the power for the set and test equipment before

use, and start the adjustment procedures after waiting at

least 30 minutes.

(5) Unless otherwise specified, prepare the most suitable

reception or input signal for adjustment.

(6) Never touch any adjustment parts, which are not specified

in the list for this variable resistors, transformers, trimmer

capacitors, etc.

(7) Presetting before adjustment.

Unless otherwise specified in the adjustment instructions,

preset the following functions with the remote control unit.

4. 2 PRESETTING BEFORE ADJUSTMENT

Unless otherwise specified in the adjustment instructions,

preset the following functions with the remote control unit.

Setting item Settings

VIDEO STATUS STANDARD

PICTURE adjustments All center (00)

COLOR TEMPERATURE LOW

DIGI. NOISE CLEAR OFF

COLOR MANAGEMENT ON

DYNAMIC GAMMA ON

SOUND adjustments All center (00)

A.H.S OFF

BBE ON

AHB ON

MTS STEREO

SMART SOUND [PD-42V485/S]

AUDIO OUT FIX

ASPECT FULL

OFF

4.4 BASIC OPERATION OF THE SERVICE MENU

4.4.1 TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the remote control unit.

4.4.2 HOW TO ENTER THE SERVICE MENU

(1) Press the [SLEEP TIMER] key, and set it to 0 minutes.

(2) Press the [DISPLAY] key and the [VIDEO STATUS] key

simultaneously, and the SERVICE MENU screen of Fig.1

will be displayed.

4.4.3 SELECT THE SERVICE MENU ITEM

(1) When the Main Menu is displayed, press any key of the [1]

to [3] key to enter the corresponding menu mode.

CAUTION:

When a number key other than the [1] to [3] key is

pressed in the SERVICE MENU screen, the other

relevant screen may be displayed.

This is not used in the adjustment procedure.

Press the [MENU] key to return to the SERVICE MENU.

4.4.4 SELECT THE SETTING ITEM AND SETTING VALUE

(1) Select the service item using the [CHANNEL +/– (/)]

key.

(2) Set the value using the [VOLUME +/– (

(3) Press the [MUTING] key to memorize the set value.

/)] key.

SERVICE MENU SCREEN

SERVICE MENU

1. ADJUST

2. SELF_CHECK

3. I2C STOP

ADJUST SCREEN

4.3 MEASURING INSTRUMENT AND FIXTURES

• DC voltmeter (or Digital voltmeter)

• Oscilloscope

• Signal generator (Pattern generator)

[NTSC / 525i COMPONENT / 1125i / PC (VGA)]

• Audio multiplex signal generator

• Remote control unit

1-22 (No.YA099)

S001 PREPATE 0

NTSC3 FULL STD L

Fig.1

4.4.5 HOW TO EXIT THE SERVICE MENU MODE

Press the [MENU] key to exit the Service Menu mode.

Page 23

4.4.6 SERVICE CONTROL KEY LAYOUT ON THE REMOTE

CONTROL UNIT

CATV VCR

MULTI SCREEN

FREEZE

DISPLAY

SOUND

MUTING

VOL

Ð

MENU

VCR CHANNEL

PREV NEXT

REC

DVD

TWIN

SWAP

1

4

7

TUNE

ASPECT

CH +

CH Ð

VCR/DVD

PLAY FFREW

STOP PAUSE

RM-C1257G

TV

INDEX

SELECT

POWER

POWER

C.C.

INPUT

2

5

8

RETURN+

0

LIGHT

OK

VOL

+

BACK

TV/VCR

STILL/PAUSE

3

1 3

6

9

CHANNEL +/-- (/)

DISPLAY

SLEEP TIMER

VIDEO STATUS

MUTING

VOLUME +/-- (/)

MENU

TV

SLEEP TIMER

VIDEO STATUS

THEATER PRO

OPEN/CLOSE

Fig.2

4.4.7 SETTING OF THE SERVICE MENUS

4.4.7.1 [1.ADJUST]

[Do not change setting values of items that are not included in

the “ADJUSTMENT PROCEDURE”. They are fixed values]

Set output data of the port of the video, audio, panel control, drive

and main CPU setting.

(1)

SIGNAL

The signal displayed on the screen is displayed.

NTSC3 : 525i (Composite / S-video)

525I : 525i (Component)

525P : 525p

750P : 750p

1125I6 : 1125i 60Hz

H525I : HDMI525i

H525P : HDMI525p

H750P : HDMI750p

H125I6 : HDMI1125i

PCVGA : PC (VGA)

SCREEN SIZE / MULTI PICTURE

(2)

State of the SCREEN SIZE or MULTI PICTURE is displayed.

• SCREEN SIZE

1409 : FULL

1609 : PANORAMA, HD PANORAMA

1609S : CINEMA, CINEMA ZOOM

FULL : REGULAR

• MULTI PICTURE

FRZ : 2 pictures

STD : 12 pictures

PICTURE MODE

(3)

The PICTURE MODE is displayed.

STD : STANDARD

DYN : DYNAMIC

TH : THEATER

GAME : GAME

(4)

COLOR TEMP.

The COLOR TEMP. is displayed.

H : HIGH

M : LOW

ITEM No.

(5)

The ITEM No. is displayed.

• [CHANNEL +/– (/)] key

For scrolling up / down the setting items.

→→

→ S001...

→→

↔↔

↔ T001...

↔↔

↔↔

↔ P001...

↔↔

↔↔

↔ D001...

↔↔

↔↔

↔ Z001...

↔↔

←←

←

←←

• [SLEEP TIMER] key

For seitching to next items.

→→

→ S001

→→

→→

→ T001

→→

→→

→ P001

→→

→→

→ D001

→→

→→

→ Z001

→→

(6 ) SETTING VALUE

The SETTING VALUE is displayed.

• [VOLUME +/– (/)] key

For scrolling up / down the setting values.

Item No. Setting items

S001~S039 This item adjusts the setting values of the video

circuit.

T001~T010 This item adjusts the setting values of the

audio circuit.

P001~P010 This item adjusts the setting values of the

panel control circuit.

D001~D187 This item adjusts the setting values of the drive

circuit.

Z001~Z010 This item adjusts the setting values of the main

CPU circuit.

4.4.6.2 [2.SELF CHECK]

[Refer to “SECTION 5 TROUBLESHOOTING” (page 1-31)]

4.4.6.3 [3.I2C STOP]

[Setting for this item is not required in servicing]

(5) ITEM NO.

S001 PREPATE 0

NTSC3 FULL STD L

(1) SIGNAL (3) PICTURE MODE

(2) SCREEN SIZE / MULTI PICTURE

(6) SETTING VALUE

(4) COLOR TEMP.

Fig.3

(No.YA099) 1-23

Page 24

4.5 INITIAL SETTING VALUES IN THE SERVICE MENU SETTING MODE

• Perform fine-tuning based on the “initial setting values” using the remote control when in the SERVICE MENU setting mode.

• The “initial setting values” serve only as an indication rough standard and therefore the values with which optimal display can be

achieved may be different from the initial setting values. But, don't change the values that are not written in “ADJUSTMENT

PROCEDURE”. They are fixed values.

4.5.1 [1.ADJUST]

4.5.1.1 VIDEO SYSTEM

Item No. Item

S001 PREPARE 000~031 000

S002 NTSC BL 000~015 000

S003 NTSC CNT 000~255 033

S004 NT CR OF 000~015 006

S005 NT CB OF 000~015 006

S006 525i BL 000~015 000

S007 525i CNT 000~255 033

S008 5i CB OF 000~015 000

S009 5i CR OF 000~015 000

S010 5i CR GN 000~015 006

S011 5i CB GN 000~015 006

S012 HD BL 000~063 057

S013 HD CB OF 000~063 054

S014 HD CR OF 000~063 055

S015 RT CONT 000~015 007

S016 RT CB OF 000~015 002

S017 RT CR OF 000~015 002

S018 RT CL GA 000~015 004

S019 PC CL MB 000~007 000

S020 PC CL LB 000~031 000

S021 PC CL MR 000~007 000

S022 PC CL LR 000~031 000

S023 (NO DISPLAY) 000~255 000

S024 (NO DISPLAY) 000~255 000

S025 (NO DISPLAY) 000~255 000

S026 (NO DISPLAY) 000~255 000

S027 (NO DISPLAY) 000~255 000

S028 (NO DISPLAY) 000~255 000

S029 (NO DISPLAY) 000~255 000

S030 R DRIVE 000~255 136

S031 G DRIVE 000~255 135

S032 B DRIVE 000~255 132

S033 (NO DISPLAY) 000~255 000

S034 (NO DISPLAY) 000~255 000

S035 (NO DISPLAY) 000~255 000

S036 (NO DISPLAY) 000~255 000

S037 (NO DISPLAY) 000~255 000

S038 (NO DISPLAY) 000~255 000

S039 ILA COM 000~001 000

4.5.1.2 AUDIO SYSTEM

Item No. Item

T001 IN LEVEL 000~255 255

T002 LOW SEP 000~255 255

T003 HIGH SEP 000~255 255

T004 AFC 000~255 000

T005 (NO DISPLAY) 000~255 000

T006 ATT V ON 000~001 000

T007 ATT U ON 000~001 000

T008 ATT C ON 000~001 000

T009 (NO DISPLAY) 000~255 000

T010 (NO DISPLAY) 000~255 000

Variable range

Variable range

Setting value

Setting value

4.5.1.3 PANEL CONTROL SYSTEM

Item No. Item

P001 TM HOR H 00~FF 0 0

P002 TM HOR L 00~FF 00

P003 TM MIN 00~FF 39

P004 TEMP 000~255 000

P005 (NO DISPLAY) 000~255 000

P006 (NO DISPLAY) 000~255 000

P007 (NO DISPLAY) 000~255 000

P008 (NO DISPLAY) 000~255 000

P009 (NO DISPLAY) 000~255 000

P010 (NO DISPLAY) 000~255 000

4.5.1.4 DRIVE SYSTEM

Item No. Item

D001 SLV GN 00~3F 20

D002 SLVH GN 00~3F 20

D003 SLH GN 00~3F 20

D004 SLV Pf 00~03 01

D005 SLH Pf H 00~01 01

D006 SLH Pf L 00~03 03

D007 SL EGCON 00~3F 04

D008 SL EGONF 00~01 01

D009 SL CRGON 00~3F 05

D010 SL CRGON 00~01 01

D011 SL ON OF 00~01 01

D012 SV GN 00~3F 18

D013 SVH GN 00~3F 13

D014 SH GN 00~3F 2F

D015 SV Pf 00~03 02

D016 SV PfH 00~01 01

D017 SV PfL 00~03 02

D018 SYL CON 00~3F 30

D019 SYL CONF 00~01 01

D020 SYH CON 00~3F 18

D021 SYH CONF 00~01 01

D022 SC CON 00~3F 36

D023 SC CNONF 00~01 01

D024 SPM BLC 00~3F 0C

D025 SPM BLCO 00~01 01

D026 SLIM 00~3F 25

D027 SLIMONF 00~01 01

D028 SCRG 00~3F 08

D029 SRGONF 00~01 01

D030 S ONF 00~01 01

D031 pb GN 00~3F 15

D032 pb PfH 00~01 00

D033 pb PfL 00~03 03

D034 pb CRG 00~3F 04

D035 pb CRGON 00~01 01

D036 pb ONF 00~01 01

D037 pr GN 00~3F 15

D038 pr PfH 00~01 00

D039 pr PfL 00~03 03

Variable range

Variable range

Setting value

Setting value

1-24 (No.YA099)

Page 25

Item No. Item

D040 pr CRG 00~3F 04

D041 pr CRGON 00~01 00

D042 pr ONF 00~01 01

D043 ENH ONF 00~01 01

D044 (NO DISPLAY) 00~FF 00

D045 (NO DISPLAY) 00~FF 00

D046 (NO DISPLAY) 00~FF 00

D047 (NO DISPLAY) 00~FF 00

D048 (NO DISPLAY) 00~FF 00

D049 (NO DISPLAY) 00~FF 00

D050 (NO DISPLAY) 00~FF 00

D051 (NO DISPLAY) 00~FF 00

D052 (NO DISPLAY) 00~FF 00

D053 (NO DISPLAY) 00~FF 00

D054 (NO DISPLAY) 00~FF 00

D055 (NO DISPLAY) 00~FF 00

D056 (NO DISPLAY) 00~FF 00

D057 (NO DISPLAY) 00~FF 00

D058 (NO DISPLAY) 00~FF 00

D059 (NO DISPLAY) 00~FF 00

D060 (NO DISPLAY) 00~FF 00

D061 (NO DISPLAY) 00~FF 00

D062 (NO DISPLAY) 00~FF 00

D063 (NO DISPLAY) 00~FF 00

D064 (NO DISPLAY) 00~FF 00

D065 (NO DISPLAY) 00~FF 00

D066 (NO DISPLAY) 00~FF 00

D067 (NO DISPLAY) 00~FF 00

D068 (NO DISPLAY) 00~FF 00

D069 (NO DISPLAY) 00~FF 00

D070 (NO DISPLAY) 00~FF 00

D071 (NO DISPLAY) 00~FF 00

D072 (NO DISPLAY) 00~FF 00

D073 (NO DISPLAY) 00~FF 00

D074 (NO DISPLAY) 00~FF 00

D075 (NO DISPLAY) 00~FF 00

D076 (NO DISPLAY) 00~FF 00

D077 (NO DISPLAY) 00~FF 00

D078 (NO DISPLAY) 00~FF 00

D079 (NO DISPLAY) 00~FF 00

D080 (NO DISPLAY) 00~FF 00

D081 (NO DISPLAY) 00~FF 00

D082 (NO DISPLAY) 00~FF 00

D083 (NO DISPLAY) 00~FF 00

D084 (NO DISPLAY) 00~FF 00

D085 (NO DISPLAY) 00~FF 00

D086 (NO DISPLAY) 00~FF 00

D087 (NO DISPLAY) 00~FF 00

D088 (NO DISPLAY) 00~FF 00

D089 (NO DISPLAY) 00~FF 00

D090 (NO DISPLAY) 00~FF 00

D091 (NO DISPLAY) 00~FF 00

D092 (NO DISPLAY) 00~FF 00

D093 (NO DISPLAY) 00~FF 00

D094 (NO DISPLAY) 00~FF 00

D095 (NO DISPLAY) 00~FF 00

D096 (NO DISPLAY) 00~FF 00

D097 (NO DISPLAY) 00~FF 00

Variable range

Setting value

Item No. Item

D098 (NO DISPLAY) 00~FF 00

D099 (NO DISPLAY) 00~FF 00

D100 (NO DISPLAY) 00~FF 00

D101 (NO DISPLAY) 00~FF 00

D102 (NO DISPLAY) 00~FF 00

D103 (NO DISPLAY) 00~FF 00

D104 (NO DISPLAY) 00~FF 00

D105 (NO DISPLAY) 00~FF 00

D106 (NO DISPLAY) 00~FF 00

D107 (NO DISPLAY) 00~FF 00

D108 (NO DISPLAY) 00~FF 00

D109 (NO DISPLAY) 00~FF 00

D110 (NO DISPLAY) 00~FF 00

D111 (NO DISPLAY) 00~FF 00

D112 (NO DISPLAY) 00~FF 00

D113 (NO DISPLAY) 00~FF 00

D114 (NO DISPLAY) 00~FF 00

D115 (NO DISPLAY) 00~FF 00

D116 (NO DISPLAY) 00~FF 00

D117 (NO DISPLAY) 00~FF 00

D118 (NO DISPLAY) 00~FF 00

D119 (NO DISPLAY) 00~FF 00

D120 (NO DISPLAY) 00~FF 00

D121 (NO DISPLAY) 00~FF 00

D122 (NO DISPLAY) 00~FF 00

D123 (NO DISPLAY) 00~FF 00

D124 (NO DISPLAY) 00~FF 00

D125 (NO DISPLAY) 00~FF 00

D126 (NO DISPLAY) 00~FF 00

D127 (NO DISPLAY) 00~FF 00

D128 (NO DISPLAY) 00~FF 00

D129 (NO DISPLAY) 00~FF 00

D130 (NO DISPLAY) 00~FF 00

D131 (NO DISPLAY) 00~FF 00

D132 (NO DISPLAY) 00~FF 00

D133 (NO DISPLAY) 00~FF 00

D134 (NO DISPLAY) 00~FF 00

D135 (NO DISPLAY) 00~FF 00

D136 (NO DISPLAY) 00~FF 00

D137 (NO DISPLAY) 00~FF 00

D138 (NO DISPLAY) 00~FF 00

D139 (NO DISPLAY) 00~FF 00

D140 (NO DISPLAY) 00~FF 00

D141 (NO DISPLAY) 00~FF 00

D142 (NO DISPLAY) 00~FF 00

D143 (NO DISPLAY) 00~FF 00

D144 (NO DISPLAY) 00~FF 00

D145 (NO DISPLAY) 00~FF 00

D146 (NO DISPLAY) 00~FF 00

D147 (NO DISPLAY) 00~FF 00

D148 (NO DISPLAY) 00~FF 00

D149 (NO DISPLAY) 00~FF 00

D150 (NO DISPLAY) 00~FF 00

D151 (NO DISPLAY) 00~FF 00

D152 (NO DISPLAY) 00~FF 00

D153 (NO DISPLAY) 00~FF 00

D154 (NO DISPLAY) 00~FF 00

D155 (NO DISPLAY) 00~FF 00

Variable range

Setting value

(No.YA099) 1-25

Page 26

Item No. Item

D156 (NO DISPLAY) 00~FF 00

D157 (NO DISPLAY) 00~FF 00

D158 (NO DISPLAY) 00~FF 00

D159 (NO DISPLAY) 00~FF 00

D160 (NO DISPLAY) 00~FF 00

D161 (NO DISPLAY) 00~FF 00

D162 (NO DISPLAY) 00~FF 00

D163 (NO DISPLAY) 00~FF 00

D164 (NO DISPLAY) 00~FF 00

D165 (NO DISPLAY) 00~FF 00

D166 (NO DISPLAY) 00~FF 00

D167 (NO DISPLAY) 00~FF 00

D168 (NO DISPLAY) 00~FF 00

D169 (NO DISPLAY) 00~FF 00

D170 (NO DISPLAY) 00~FF 00

D171 (NO DISPLAY) 00~FF 00

D172 (NO DISPLAY) 00~FF 00

D173 (NO DISPLAY) 00~FF 00

D174 (NO DISPLAY) 00~FF 00

D175 (NO DISPLAY) 00~FF 00

D176 (NO DISPLAY) 00~FF 00

D177 (NO DISPLAY) 00~FF 00

D178 (NO DISPLAY) 00~FF 00

D179 (NO DISPLAY) 00~FF 00

D180 (NO DISPLAY) 00~FF 00

D181 (NO DISPLAY) 00~FF 00

D182 (NO DISPLAY) 00~FF 00

D183 (NO DISPLAY) 00~FF 00

D184 (NO DISPLAY) 00~FF 00

D185 (NO DISPLAY) 00~FF 00

D186 (NO DISPLAY) 00~FF 00

D187 (NO DISPLAY) 00~FF 00

Variable range

Setting value

4.5.1.5 MAIN CPU SETTING

Item No. Item

Z001 (NO DISPLAY) 00~FF 00

Z002 (NO DISPLAY) 00~FF 00

Z003 (NO DISPLAY) 00~FF 00

Z004 (NO DISPLAY) 00~FF 00

Z005 (NO DISPLAY) 00~FF 00

Z006 (NO DISPLAY) 00~FF 00

Z007 (NO DISPLAY) 00~FF 00

Z008 (NO DISPLAY) 00~FF 00

Z009 (NO DISPLAY) 00~FF 00

Z010 (NO DISPLAY) 00~FF 00

Variable range

Setting value

1-26 (No.YA099)

Page 27

4.6 ADJUSTMENT PROCEDURE

Item

Measuring

instrument

Test point Adjustment part Description

PDP POWER

VOLTAGE

MAIN POWER PWB voltage adjustment point

CN0C4

1 : Vs

2 : Vset

3 : Ve

4 : NC

5 : Va

6 : NC

7 : Vscan

8 : NC

9 : GND

10 : POWER

11 : PANEL POWER

12 : Vs_ON

PANEL POWER

MAIN POWER PWB

Signal generator

DC voltmeter

Resistor (1kΩ)

DC power

supply

CN0C4

Vs

1

Vset

2

Ve

3

NC

4

Va

5

NC

6

Vscan

7

NC

GND

POWER

Vs_ON

Vscan

8

9

10

11

12

Connector

CN0C4

Vs

Vset

Ve

Va

Vscan

[MAIN POWER

PWB]

Ve

Vs

Vset

Vscan

Fig. 1

Va Ve

Vset

SW1

Fig. 2

Vs VR:170V ADJ

(R9424)

Vset VR:160V ADJ

(R9640)

Ve VR:155V ADJ

(R9646)

Va VR:70V ADJ

(R9219)

Vscan VR:-60V ADJ

(R9628)

[MAIN POWER PWB]

Va

Voltage adjustment VR

Vs

3.3V ~ 5.0V

(DC power supply)

1kΩ

(Resistor)

Voltage label

NTSC

Va

XX XX XX XX XX

NTSC/PAL

Ve VsetVsc Vs

CAUTION:

• During adjustment operation of PDP POWER VOLTAGE,

don't touch the heat sink of the MAIN POWER PWB. If you

touch it, electric shock may be caused.

< When MAIN POWER PWB is not replaced >

(1) Connect the DC voltmeter, load resistor (1kΩ), DC

power supply and switch SW1 to the CN0C4 connector

and turn on the main power and switch SW1. (See

Fig.2)

(2) Adjust Vs (170V ADJ) VR, Vset (160V ADJ) VR, Ve (155V

ADJ) VR, Va (70V ADJ) VR and Vscan (-60V ADJ) VR so

that the Vs, Vset, Ve, Va and Vscan voltage coincides

with the values in the voltage label.

(3) Input a NTSC all-black signal and check that it

coincides with the values in the voltage label.

(4) Readjust if the adjusted value is different from those

in the voltage label.

NOTE:

• Designed value for the panel is printed on a label on the

upper-right at the back of the PDP. (See Fig.3)

< When MAIN POWER PWB is replaced >

CAUTION:

• Before making adjustments, be sure not to turn on the

power when the CN8002, CN8003, CN8005, CN8006

and CN8008 connectors are connected, as this may

cause the PDP to break down.

(1) Disconnect the CN8002, CN8003, CN8005, CN8006

and CN8008 connectors on the MAIN POWER PWB.

(2) Connect the DC voltmeter, load resistor (1kΩ), DC

power supply and switch SW1 to the CN0C4 connector

and turn on the main power and switch SW1. (See

Fig.2)

(3) Adjust Vs (170V ADJ) VR, Vset (160V ADJ) VR, Ve (155V