Page 1

SERVICE MANUAL

PDP COLOUR TELEVISION

BASIC CHASSIS

PD-35DX

Supplementary

These models corresponded to the printed circuit board exchange in the PDP panel.

Therefore, this service manual describes only the information relevant to it.

For detail s other than thos e describe d in this manual , pleas e refer to the PD-35DX

service manual (No.52089 2003/03).

TABLE OF CONTENTS

1. CONFIRMING THE MODEL NAME, SERIAL NUMBER, ID NUMBER AND CODE NUMBER

2. MAIN PARTS LOCATION

3. INSPECTION OF COMPONENTS ON THE PW BOARD

4. DISASSEMBLY PROCEDURE

5. CONFIRMING REFERENCE VOLTAGE

6. ADJUSTMENTS

7. PARTS LIST

㨯

MK

2

2

3

6

8

9

10

NOTES AT THE TIME OF PW BOARD EXCHANGE

It will become the cause of failure if dust adheres to the inside of a connector, or a flat wire and

a point-of-contact part.

When the PW board is exchanged , be carefu l of the dust and dirt of the inside of a connecto r,

or a flat wire and a point-of-contact part enough.

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.52089B

2004/6

Page 2

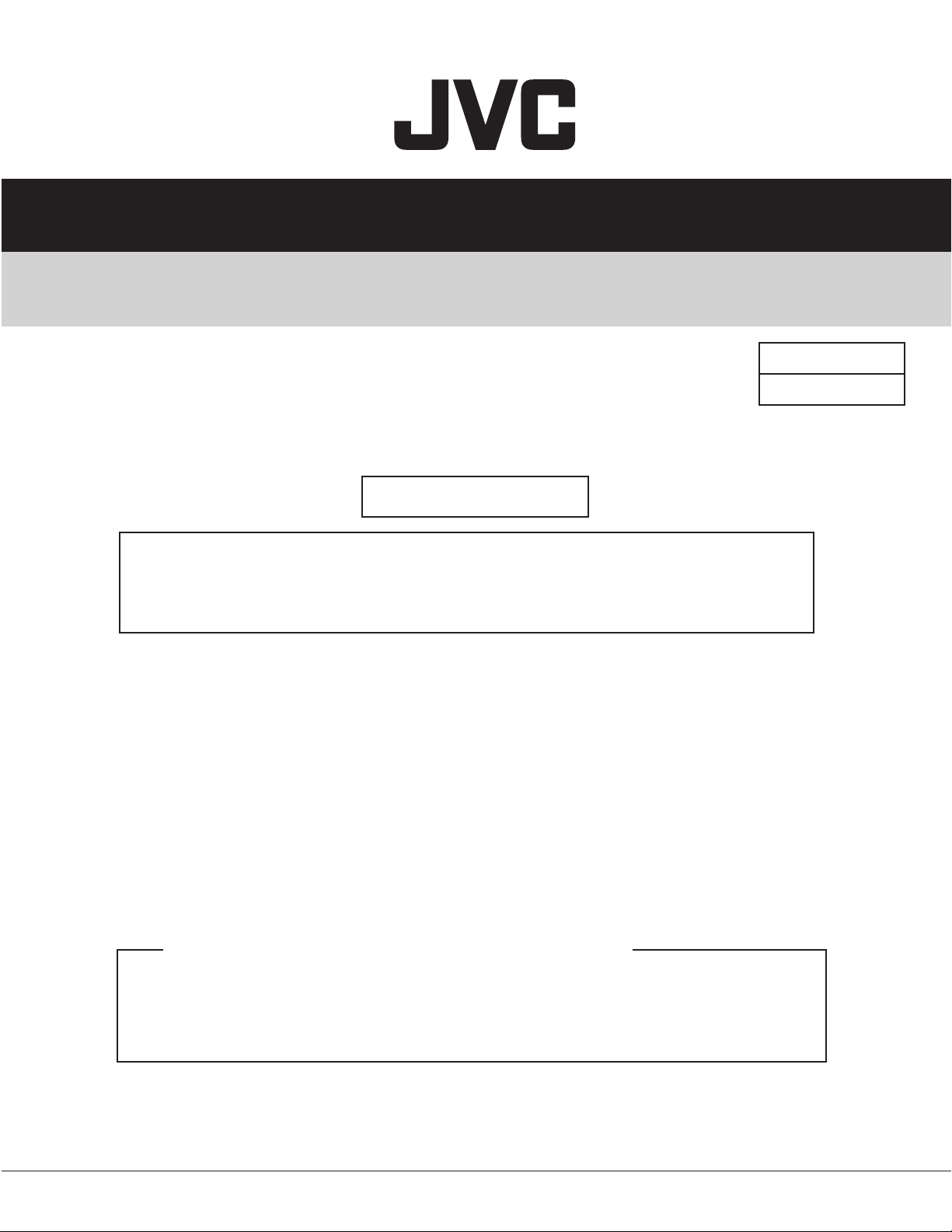

عCONFIRMING MODEL NAME, SERIAL NUMBER, ID NUMBER AND CODE NUMBER

NOTE : The panel's ID number is used when you reference the characteristic voltage value of the panel

on web site.

Voltage and CODE No.

SERIAL NO.

301201327

Vd=60V

Vs=180V

CODE AA-01

For example

CODE : AA

Model name and serial No.

NEC NP35B2MF01AA

301201327

*********************

*********************

*********************

For example

Model : NP35B2MF01AA

Serial No. : 301201327 (9 figures)

عMAIN PARTS LOCATION

COMMON PWB

Flexible cable

Common-side A

Flexible cable

Common-side B

COMMON BRANCH PWB

SCAN RELAY PWB

HIGH VOLTAGE

PWB

PANEL ID No.

222212260043

(12 figures)

Flexible cable

Scan-side A

Flexible cable

Scan-side B

Flexible cable

Common-side C

2(No.52089B)

DIGITAL PWB

SIGNAL RELAY PWB (left) SIGNAL RELAY PWB (right)

Heat-sink

ABCDE F GHI

Flexible cable

Scan-side C

Flexible cable

Scan-side D

J

Page 3

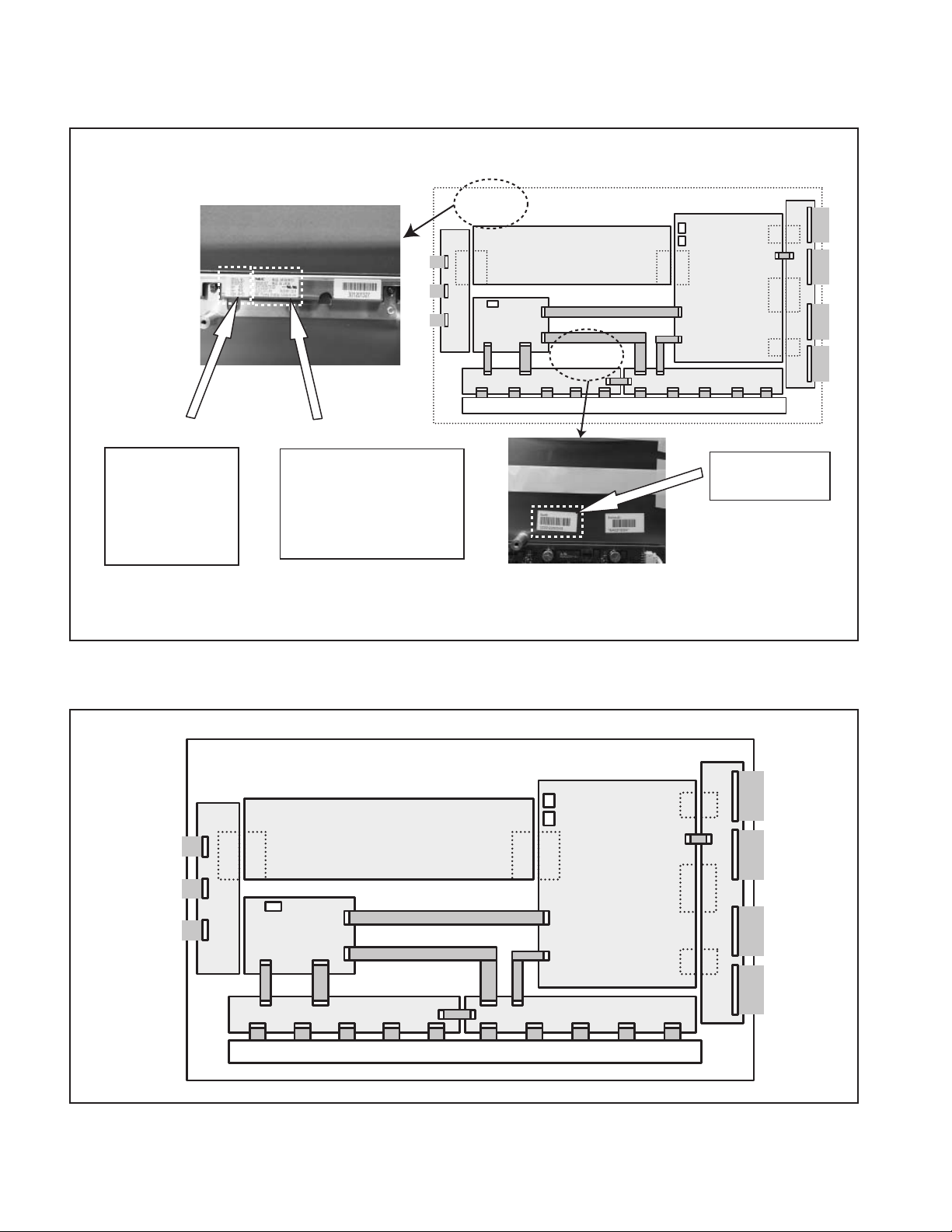

عINSPECTION OF COMPONENTS ON THE PW BOARD

Diagnose the PW board in PDP unit by checking defects based on the following items.

1. Inspection of fuses

Measure the resistance of each fuse with a circuit tester, and check OK or NG.

1.1 Glass fuses (F301, F307) on the HIGH VOLTAGE PWB 1.2 Chip fuse (FU701) on the DIGITAL PWB

㨀㧼

㧲

㧲

1.3 Fuse resistances (R10, R4, R6) and chip fuse (R20)

on the HIGH VOLTAGE PWB

OK: Short

NG: Open

In case of F303, check

between the pin 6 (or

pin 7) of CN303 and

TP307.

R10

OK: Approx. 2.2ǡ

NG: Open

R4

R10

R6

R4

OK: Approx. 2.2ǡ

NG: Open

R6

OK: Approx. 2.2ǡ

R20

NG: Open

R20

OK: Approx. 10ǡ

NG: Open

㧲㨁

OK: Short

NG: Open

1.4 Fuse resistance (R7) and chip fuse (R9) on the

HIGH VOLTAGE PWB

R7

R7

OK: Approx. 2.2ǡ

NG: Open

R9

R9

OK: Approx. 10ǡ

NG: Open

R1

R1

OK: Approx. 2.2ǡ

NG: Open

1.6 Fuse resistances (R2, R3) on the HIGH VOLTAGE PWB1.5 Fuse resistance (R1) on the HIGH VOLTAGE PWB

R3

R2

OK: Approx. 2.2ǡ

NG: Open

R3

OK: Approx. 2.2ǡ

R2

NG: Open

(No.52089B)3

Page 4

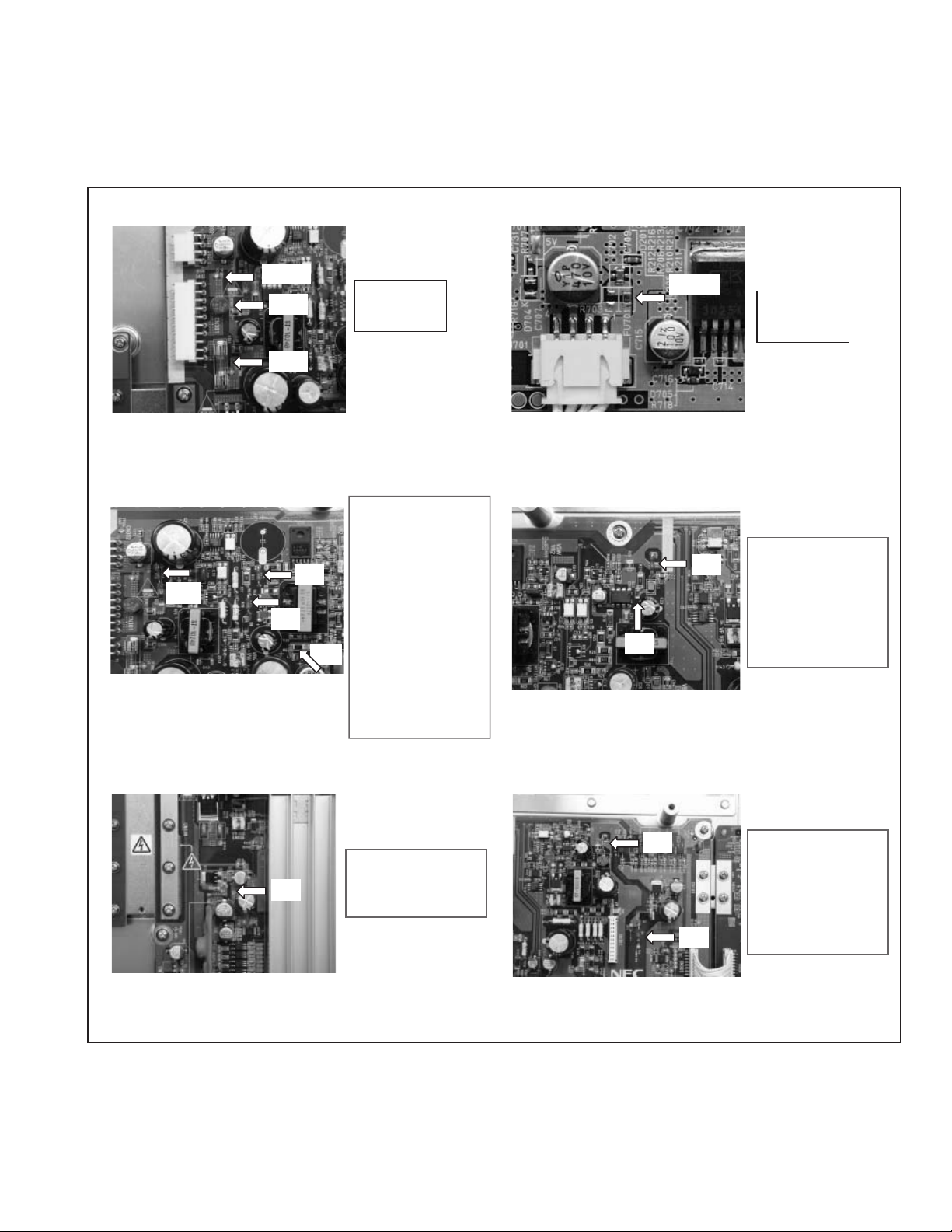

2. Inspection of data ICs

According to the following procedures, measure with a circuit tester and check OK or NG.

Check the pin 5 or pin 6 of the connector [CN11] on the SIGNAL RELAY PWB (right).

OK: Open

NG: Short

Detach the connector [CN11] on the SIGNAL RELAY PWB (right) and check the conduction between the pin 5 (or

pin 6) and the ground.

In case of "short", one of the data ICs connecting the signal relay board may be defective, and you should check

whether there is any trace of damage on the data IC's surface after removing the heat-sink on the data IC.

3. Inspection of power IC

According to the following procedures, measure with a circuit tester and check OK or NG.

The allocation of power IC to be checked is shown below.

HIGH VOLTAGE PWB

PH2201N

4(No.52089B)

Page 5

3.1 PH2201N on the HIGH VOLTAGE PWB

Turn over the board and check each point of power IC as shown below.

R

Q

P

PH2201N

A

B

C

D

E

F

G

H

I

J

K

L

M

N

Check point

Between

A - B

A - R

B - C

B - H

B - J

B - K

Between

C - J

E - F

F - G

F - R

G - L

H - Q

Between

I - J

I - Q

M - Q

N - Q

O - Q

OK: Over 1kǡ

NG: Short

R

A

B

C

D

E

F

G

PH2201N

H

I

J

K

L

Q

M

N

P

O

4. Inspection of scan IC drivers

According to the following procedures, measure with a circuit tester and check OK or NG.

4.1 Scan IC driver on the SCAN RELAY PWB

NEGA

Check point

Between NEGA - POSI

POSI

OK: Over 1kǡ

NG: Short

NEGA

(No.52089B)5

Page 6

عDISASSEMBLY PROCEDURE

1. Removing the COMMON PWB

(1) Detach the 3 connectors.

(2) Remove the 8 screws [A].

(3) Remove the COMMON PWB.

(1) Detach the 8 connectors.

(2) Remove the 5 screws [D].

(3) Remove the SIGNAL RELAY PWB (left).

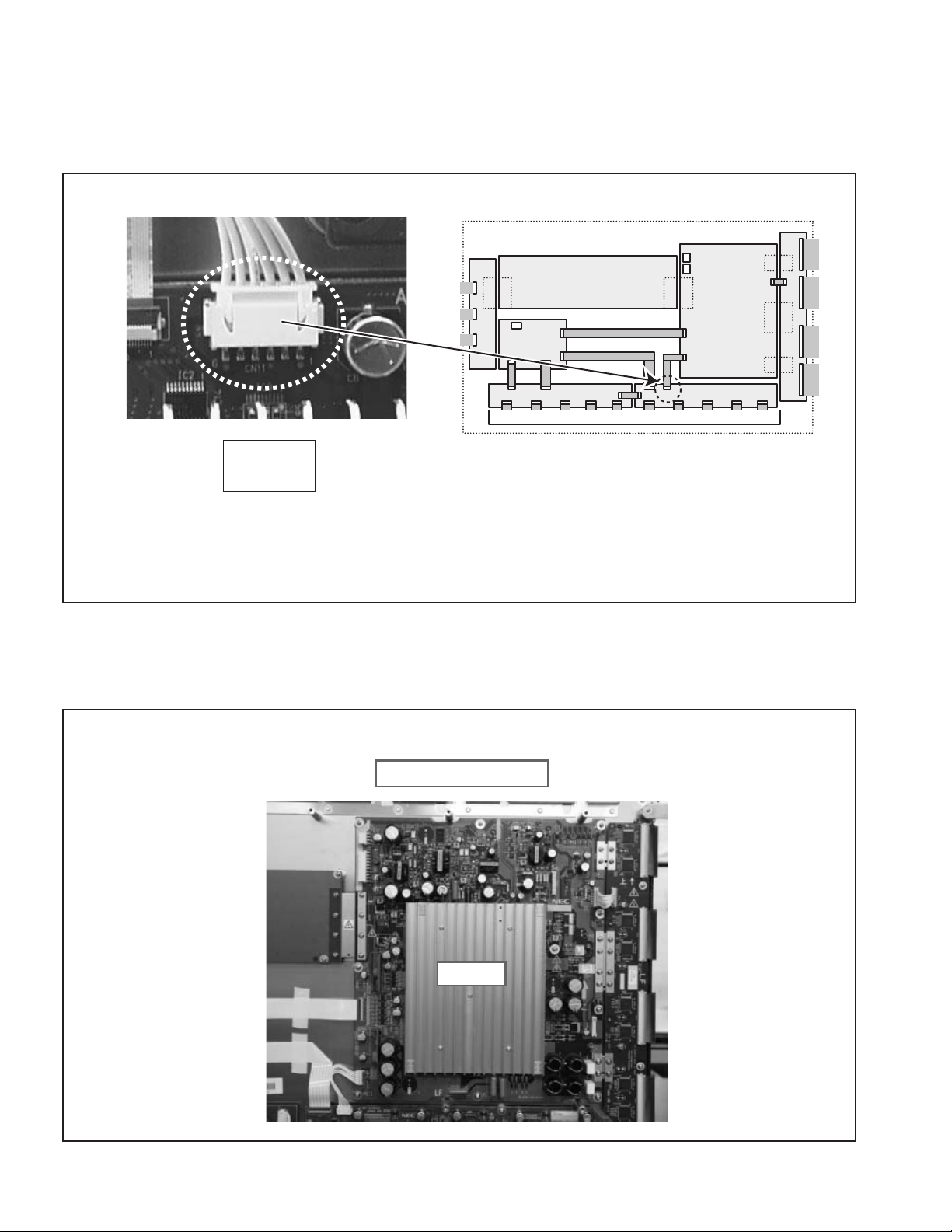

2. Removing the DIGITAL PWB

(1) Detach the 4 connectors.

(2) Remove the 6 screws [B].

(3) Remove the DIGITAL PWB.

3. Removing the HIGH VOLTAGE PWB

(1) Detach the 3 connectors.

(2) Remove the 22 screws [C].

(3) Remove the HIGH VOLTAGE PWB.

4. Removing the SIGNAL RELAY PWB (left)

Note : Removing the heat-sink in advance

is required. Refer to the following page

to remove the heat-sink.

COMMON PWB

A

COMMON BRANCH PWB

5. Removing the SIGNAL RELAY PWB (right)

(1) Detach the 8 connectors.

(2) Remove the 4 screws [E].

(3) Remove the SIGNAL RELAY PWB (right).

6. Removing the SCAN RELAY PWB

(1) Detach the 5 connectors.

(2) Remove the 10 screws [F].

(3) Remove the SCAN RELAY PWB.

C

SCAN RELAY PWB

F

B

DIGITAL PWB

E

D

: connector

SIGNAL RELAY PWB (left)

Note : Check the state of the detached cables and connectors.

(1) Check any dirt or peeling in the contact part of the flat cable, and any crack, crease, disconnection

and short-circuit of wires.

(2) Check any foreign substance in the connector's contact .

(3) Check the state of plugging the flat cable into the connector, and confirm it locks completely.

HIGH VOLTAGE

PWB

Heat-sink

SIGNAL RELAY PWB (right)

G

6(No.52089B)

Page 7

heat-sink

silicone and PC

appearance of

separation jig

separation jig

TCP

REMOVING THE HEAT SINK

(1) Remove the 7 screws [G] shown in the previou s

ޓ page.

(2) With a hot air blower, carry out eliminary heating

ޓof the whole heat - sink . Th e temperatur e of the

ޓheat-sin k an d surroundin g part s shoul d no t

ޓexceed 100 .

(3) Remove the heat-sink from TCP by inserting the

ޓseparatio n ji g in the crevic e betwee n the heat -

ޓsin k an d TC P, heatin g the heat-sin k with a ho t

ޓair blower sequentially from an end.

hot air blower

Fig.1

Fig.2

separation jig

(4) Inser t the separatio n jig sequentiall y fro m an

ޓend of the heat-sink and separate it.

Note :

(1) The silicone sheet is stuck on the back of the

ޓheat-sink , an d if yo u tea r it o f f forcibl y,

ޓdamaging the data TCP tips may becaused.

(2) Do not give stres s to the fin of the heat-sin k

ޓand data TCP.

(3) Th e heat-sin k canno t be re-used , when the

ޓsilicon e (gra y color ) o f th e heat-sin k i s

ޓdamage d and PC (phas e chang e : white) is

ޓexposed.

Fig.3

(No.52089B)7

Page 8

عCONFIRMING REFERENCE VOLTAGE

Each PDP panel has the characteristic voltage value.

In the adjustment after fix or exchange of a PW board,

this voltage value is used as reference.

You can get it from the vendor's web site on the Internet.

1. Getting the characteristic voltage value of the PDP panel

1.1 Access the following address by the Web browser of

ޓޓyour PC.

http://203.126.119.92/necpd/

1.2 After [NEC-ITLS] screen is displayed, click "Click here

ޓޓto log on to NPD". (Fig. 1)

1.3 Type the following user name and password into the

ޓޓdialog box and click "Enter" button. (Fig. 2)

Username: JVCJPN01

Password: jvckoseki (lower-case)

1.4 After [WELCOME TO NEC-ITLS] is displayed (Fig. 3),

ޓޓclick the "Voltage" icon in the "Enquiry" holder on the

ޓޓupper left part of the window. (Fig. 4)

1.5 After [VOLTAGE ENQUIRY] is displayed (Fig. 5), enter

ޓޓthe panel ID number, which is shown on the panel (refer

ޓޓto page 2), into the dialog box and click "GO".

Fig. 1

1.6 Then, the characteristic voltage value will be displayed.

(Fig. 6)

Fig. 5

Fig. 2

Fig. 3

8(No.52089B)

Fig. 6

Fig. 4

Page 9

عADJUSTMENTS

Item

Vbw / -Vw

VOLTAGE

ADJUSTMENT

Measuring

instrument

Test point Adjustment part Description

DC voltmeter TP (Vbw)

TP (-Vw)

GND

[HIGH VOLTAGE

PWB]

VR4(-Vw)

VR3 (Vbw)

VR4 (-Vw)

[HIGH VOLTAGE

PWB]

(1) Measure the voltage between TP(-Vw) and

ޓTP(Vbw) on the HIGH VOLTAGE PWB.

(2) Adjus t the voltag e same as the referenc e

ޓdata of Vbw shown in web site by VR3.

The adjustment accuracy is within r0.5V.

(3) Measure the voltage between TP(-Vw) and

ޓGND on the HIGH VOLTAGE PWB.

(4) Adjus t the voltag e same as the referenc e

ޓdata of -Vw shown in web site by VR4.

The adjustment accuracy is within r0.5V.

Vsw / Vp

VOLTAGE

ADJUSTMENT

TP(-Vw)

DC voltmeter TP (Vp)

TP (Vsw)

GND

[HIGH VOLTAGE

PWB]

VR2(Vsw)

VR1 (Vp)

VR2 (Vsw)

[HIGH VOLTAGE

PWB]

VR3 (Vbw)

TP(Vbw)

(1) Measure the voltage between TP(Vsw) and

ޓGND on the HIGH VOLTAGE PWB.

(2) Adjus t the voltag e same as the referenc e

ޓdata of Vsw shown in web site by VR2.

The adjustment accuracy is within r0.5V.

(3) Measur e the voltag e betwee n TP(Vp ) and

ޓGND on the HIGH VOLTAGE PWB.

(4) Adjus t the voltag e same as the referenc e

ޓdata of Vp shown in web site by VR1.

The adjustment accuracy is within r1.5V.

VR1 (Vp)

TP(Vp)

TP(Vsw)

(No.52089B)9

Page 10

عPARTS LIST

2

PDP UNIT

3

6

1

5

#$%&' ()*+

Heat-sink

5 6

NOTE(1)Please check a code number with the seal stuck on the rear side

of the PDP panel.

ޓޓޓ(2)Version is indicated by the seal stuck on each PW board.

ޓ

Ref No. Parts No. Parts name Description

1

2

3

4

5

6

7

CODE

AA, BA

AA, BA

AA, BA

AA, BA

AA, BA

AA, BA

AA

BA

Version

01E

01C

01A

01A

01B

01B

02E-10

01D-10

NE-9S899437

NE-9S899376

NE-9S899594

NE-9S899382

NE-9S899510

NE-9S899492

NE-9S899276

NE-9S899281

HIGH VOLTAGE PWB

SCAN RELAY PWB

COMMON BRANCH PWB

COMMON PWB

SIGNAL RELAY PWB

SIGNAL RELAY PWB

DIGITAL PWB

,

(left

(right)

01A

FK2600686

The written example of

the seal on a PWB

Indication of Version

10(No.52089B)

NOTES AT THE TIME OF PW BOARD EXCHANGE

It will become the cause of failure if dust adheres to the inside of a connector, or a flat wire and

a point-of-contact part.

When the PW board is exchanged, be careful of the dust and dirt of the inside of a connector, or

a flat wire and a point-of-contact part enough.

Page 11

(No.52089B)11

Page 12

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY VIDEO DISPLAY CATEG ORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.52089B)

Printed in Japan

WPC

Loading...

Loading...