Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB19620045

MX-KB4

Area suffix

J ---------------------------- U.S.A.

C ------------------------- Canada

STANDBY/ON

SLEEP

AUX

FM /AM

FM MODE

CD

CD1CD2CD

3

PROGRAM/RANDOM

REPEAT

TAPE

TAPE

A

B

SOUND

VOLUME

MODE

FADE

MUTING

RHYTHM AX

REMOTE CONTROL

CA-MXKB4SP-MXKB4 SP-MXKB4

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.MB196

2004/6

Page 2

SPECIFICATION

Amplifier Output Power 180 W per channel, min. RMS, driven into 6 Ω at 1kHz, with no more

than 10% total harmonic distortion

Input Sensitivity/Impedance (1 kHz) AUX IN:400 mV/50 kΩ

Speaker terminals 6 - 16 Ω

Phones 32 Ω - 1 kΩ

Cassette Deck Frequency Response 15 mW/ch output into 32 Ω

Type I (NORMAL) 63 Hz - 12 500 Hz

Wow And Flutter 0.15% (WRMS)

CD Player CD Capacity 3 CDs

Dynamic Range 85 dB

Signal-To-Noise Ratio 85 dB

Wow And Flutter Unmeasurable

Tuner FM Tuner Tuning Range:87.5 MHz - 108.0 MHz

AM Tuner Tuning Range:530 kHz - 1 710 kHz

Unit Dimensions 270 mm × 306 mm × 456 mm (W/H/D) (10-11/16" × 12-1/16" × 18")

Mass Approx. 8.6 kg (19.0 lbs)

Speaker Specifications

SP-MXKB4 (each unit)

Power Specifications Power Requirements AC 120 V , 60 Hz

Type 3-way bass-reflex type

Speaker Unit Woofer:20 cm (7-7/8") cone × 1

Mid:5cm (2") cone × 1

Tweeter:2 cm (13/16") dome × 1

Power Handling Capacity 180 W

Impedance 6 Ω

Frequency Range 45 Hz - 22,000 Hz

Sound pressure level 87 dB/W·m

Dimensions 257 mm × 321 mm × 261 mm (W/H/D) (10-1/8" × 12-11/16" × 10-5/16")

Mass Approx. 4.9 kg (10.9 lbs)

Power Consumption 150 W (power on mode)

22 W (in Standby mode)

Design and specifications are subject to change without notice.

1-2 (No.MB196)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

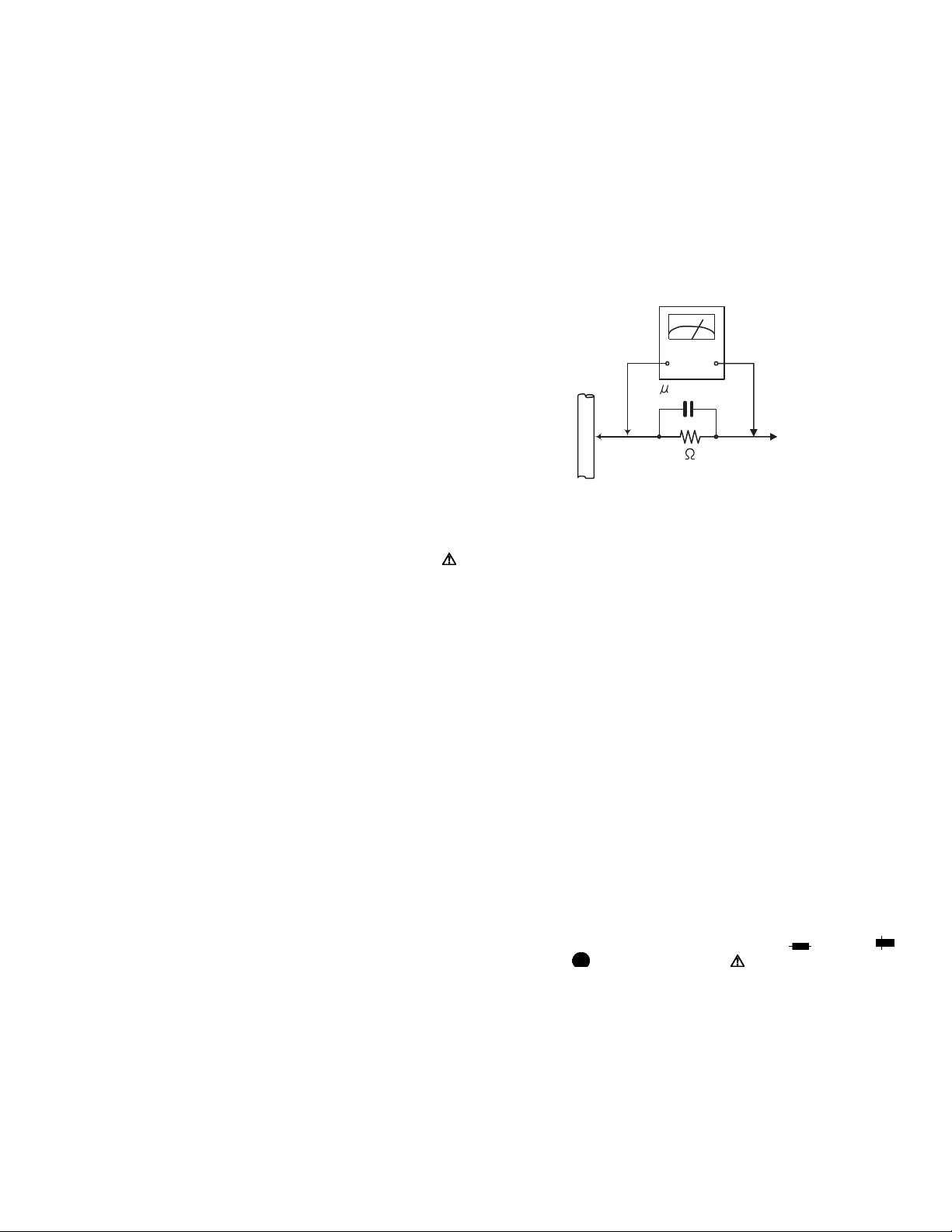

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

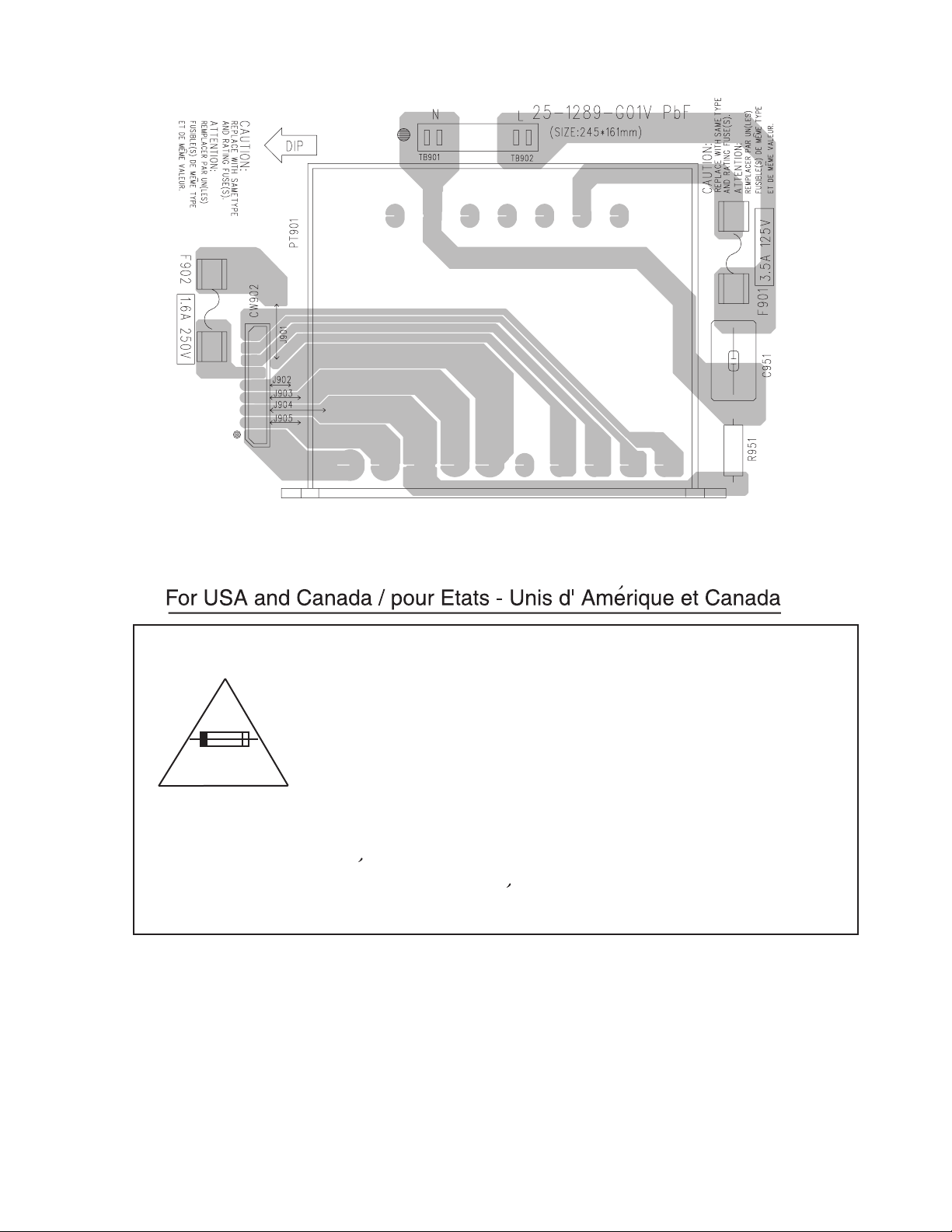

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB196)1-3

Page 4

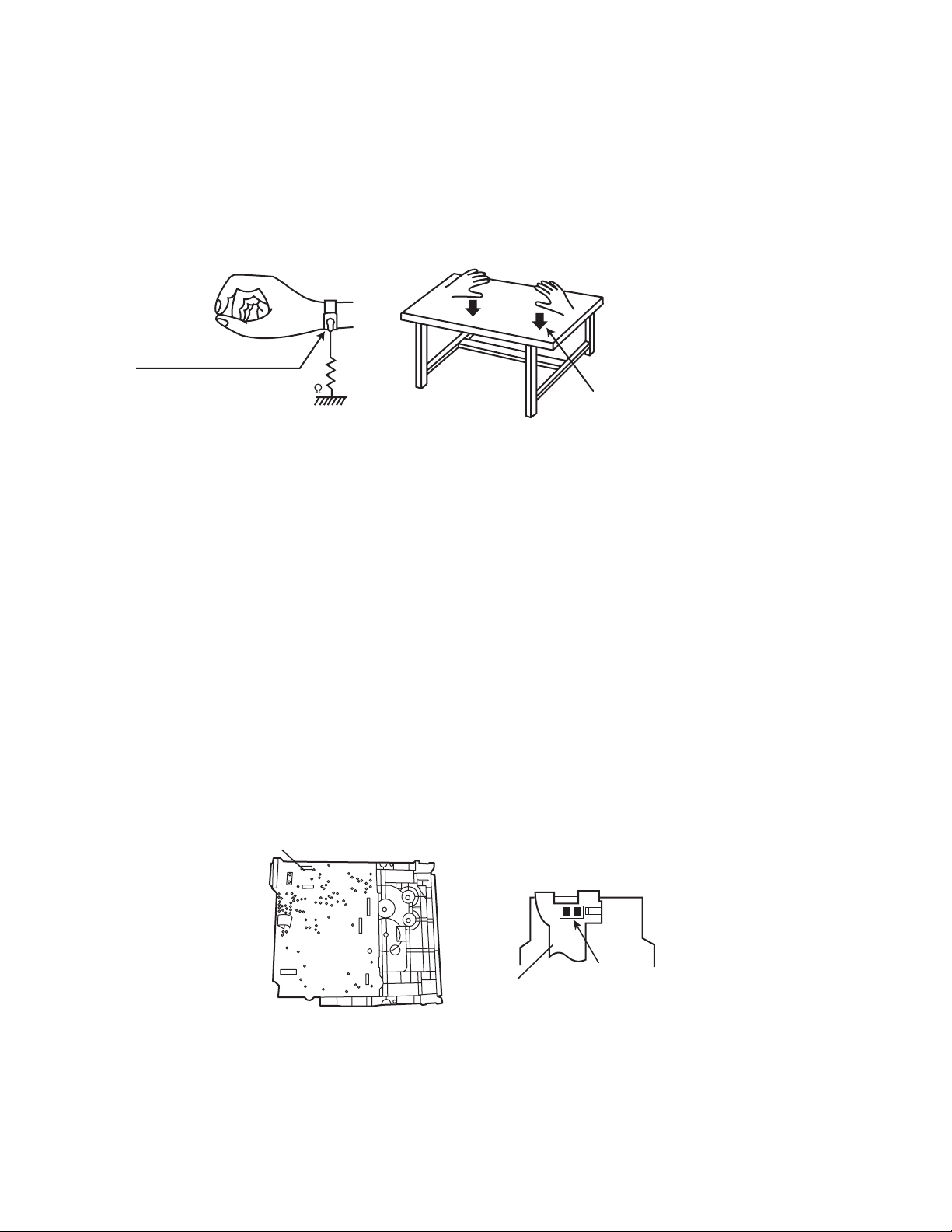

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

CD changer

unit

1-4 (No.MB196)

Flexible cable

Soldering

Page 5

1.8 Importance administering point on the safety

Caution: For continued protection against risk of

fire, replace only with same type 3.5A/125V for

F901 and 1.6A/250V for F902.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F901 comme le meme type

que 3.5A/125V et 1.6A/250V pour F902.

Ce sont des fusibles suretes qui functionnes rapide.

^

(No.MB196)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB196)

Page 7

SECTION 3

DISASSEMBLY

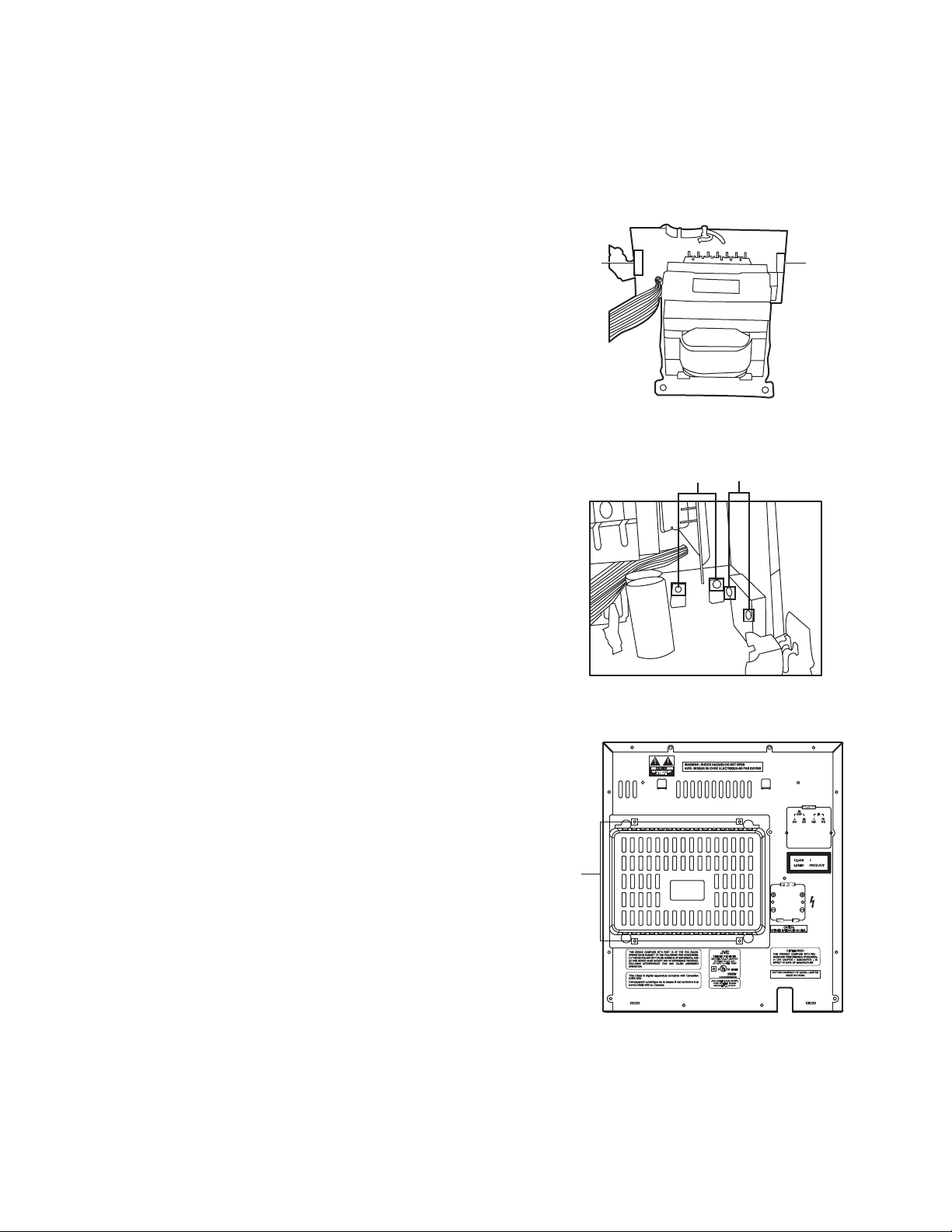

3.1 Disassembly of the main blocks of the set

Replacement of the fuses and the power IC

3.1.1 Replacing the fuses

(See Fig.1)

• Prior to performing the following procedure, remove the left

side board.

(1) Replace the fuses inside.

Caution:

Be sure to use fuses with the specified ratings.

3.1.2 Replacing the power IC

(See Fig.2)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the two screws A from the heat sink between the

power IC.

(2) Remove the solder fixing the power IC.

Fuse (F902)

1.6A 250V

Fig.1

W

Fuse (F901)

3.5A 125V

A

3.1.3 Replacing the heat sink cover

(See Fig.3)

(1) Remove four screws B from the rear panel.

(2) Pull the heat sink cover outward.

Fig.2

B

Fig.3

(No.MB196)1-7

Page 8

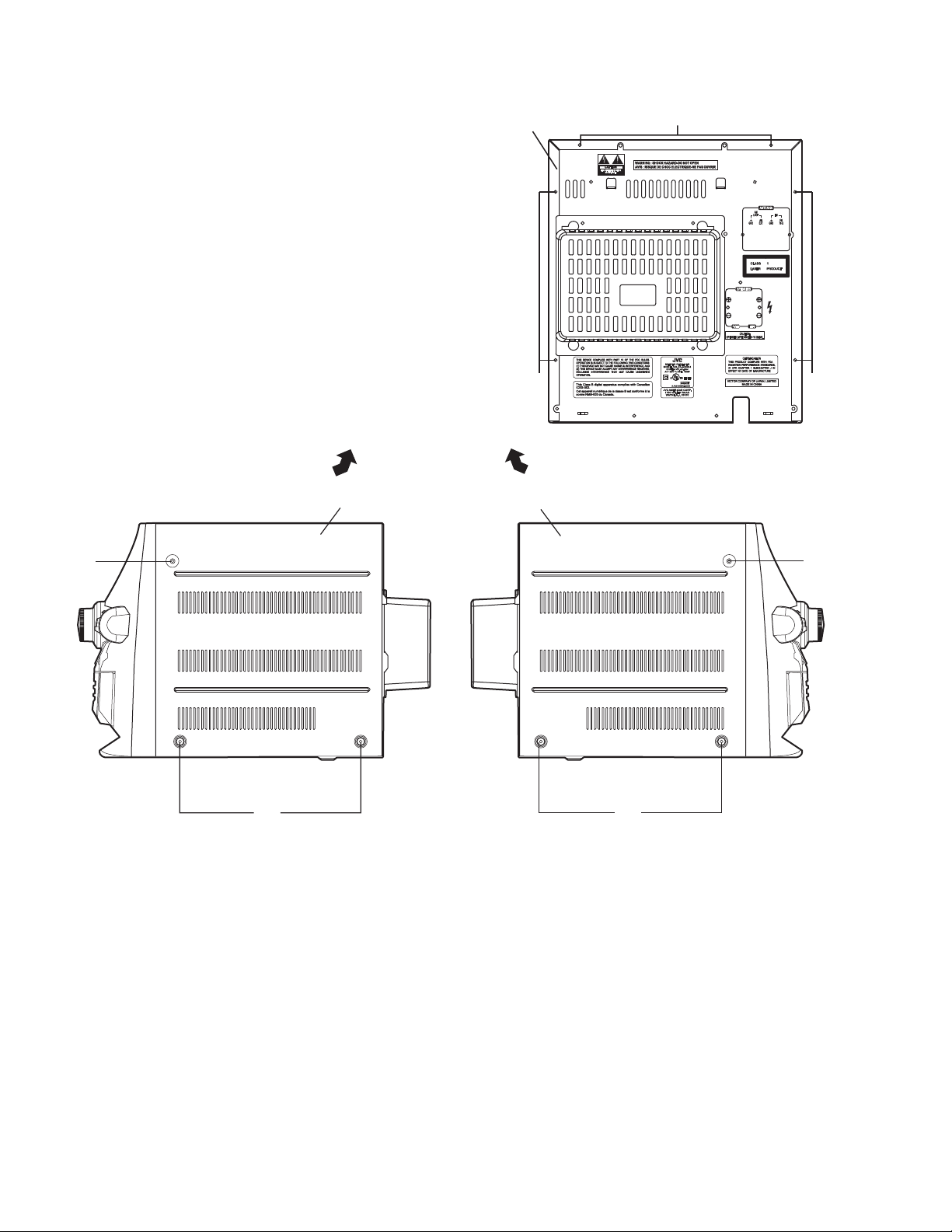

3.1.4 Removing the top cover

(See Fig.4 and 5)

(1) Remove six screws C that retain the top cover from the

panel rear of the body.

(2) Remove six screws D that retain the top cover from the two

sides of the body.

(3) Remove the top cover from the body by lifting it toward the

rear.

Top cover

C

CC

Fig.4

Right Front panel assembly

D

D

Left Front panel assembly

D

D

Fig.5

1-8 (No.MB196)

Page 9

3.1.5 Removing the CD changer unit

(See Fig.6 to 9)

• Prior to performing the following procedures, remove the top

cover.

Caution:

Although the CD mechanism unit can be removed without removing the CD tray panel, it is still recommended to remove it

in order to prevent damage.

a. From the front panel side of this set, push in the sections

marked with arrows and pull out the CD tray toward the

front.

b. Remove the CD tray panel by pushing both of its extremi-

ties upward in the direction of the arrows.

c. Push the CD tray deep into the set.

(1) Disconnect the cord wires from the CD board CN703

.

CN203

and

(2) From the rear of the set, remove two screws E, two screws

F and four screws G on the front panel left and right side.

(3) Handle the CD changer unit rear, take out the unit.

CD tray panel

E

Antenna

terminal

F

Fig.8

Fig.6

CD tray panel

Fig.7

G

Fig.9

(No.MB196)1-9

Page 10

3.1.6 Removing the front panel assembly

(See Fig.10 to 11)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Disconnect the parallel wire and the cord wire from the con-

nectors CN701

(2) Remove one screws H retaining the front panel assembly

onto the bottom of the body.

(3) Remove two screws I on the left and right side of the set re-

taining the panel front from the bottom and then remove

then GND lug b that comes from the amp and supply

board.

(4) Disengage the claws c on both sides of the front panel as-

sembly and then remove the assembly.

, CN101 on the power amp. PCB.

H

Fig.10

a

Fig.11

GND lugGND lug

b

Claw

c

1-10 (No.MB196)

Page 11

3.2 Disassembly of units and assembly inside this set

3.2.1 Removing the Main board

(See Fig.12 to 13)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Disconnect the wires from CN603A

on the Main board, which is located on the back side of the

CD changer unit.

(2) The four screws J that retain the CD board should be re-

moved.

(3) Remove the CD board by pulling it toward the side where

the CN601

(4) Using solder, short the CD pickup to connect to short

round.

Caution:

After re-connecting the wires, be sure to remove the

shorting solder from the GND connection.

(5) Disconnect the card wire from the connector CN601

Main board and then remove the Main board.

is located.

, CN603B and CN604

on the

CD PCB

J

PAIN PCB

J

Fig.12

CN601

J

Short round

Fig.13

(No.MB196)1-11

Page 12

3.2.2 Removing the CD changer mechanism assembly

(See Fig.14 to 15)

• Also remove the CD changer unit.

(1) Turn the CD changer mechanism cover base and remove

the screws d connecting the unit to the CD changer mechanism assembly.

(2) Removing four screws e retaining the CD mechanism hold-

er assembly.

Caution:

When replacing the CD changer mechanism assembly, be

sure not to mistake the positions of the silver color and copper

color spring.

CD changer

unit

CD changer

mechanism

assembly

d

Fig.14

e

( Green color )

e

( Green color )

Fig.15

e

( Red color )

e

( Red color )

1-12 (No.MB196)

Page 13

3.2.3 Removing the CD pickup

r

(See Fig.16)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the CD changer mechanism.

(1) Widen the section f.

(2) While keeping the section f wide open, push the section g

in the direction of the arrow to remove the shaft, and then

remove the CD pickup.

CD pickup

f

3.2.4 Replacing the loading motor and rotor belt of the CD changer

(See Fig .17)

• Prior to performing the following procedures, remove the top

cover.

• Also open the CD changer tray.

(1) Remove the two screws L retaining the CD changer tray

loading motor.

(2) Remove the two screws M retaining the gear plate and take

it out, after remove the rotor belt from the pulley.

g

Shaft

Fig.16

M

L

3.2.5 Replacing the CD turn table and removing the motor

(See Fig.18 )

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Remove the one screws retaining the CD (Turn table).

(2) Remove the two screws retaining the stopper brackets on

both sides of the CD changer unit.

(3) Remove the stopper brackets from both sides of the CD

changer unit.

(4) Pull out the CD tray from the CD changer unit, all the way

and lift the tray to remove.

(5) Remove the gear and after push out the tray motor locker

and pull out the tray motor from the CD tray.

Fig.17

Turn table motor

Motor locker

Obligue gea

Fig.18

(No.MB196)1-13

Page 14

3.2.6 Removing the cassette deck mechanism

(See Fig.19)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z retaining the cassette deck mecha-

nism.

3.2.7 Removing the Key open board & the Key rec board

(See Fig.20)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove two screws P that retains the Key open board.

(2) Remove three screws L that retains the Key REC board.

Key open

board

P

Front panel

assembly

Z

Z

Fig.19

Front panel

assembly

Front panel

assembly

L

3.2.8 Removing the Display board

(See Fig.21)

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Q that retain the Display board from the

back of the front panel unit.

Key REC

board

Fig.20

Display

PCB

Q

Fig.21

Q

1-14 (No.MB196)

Page 15

3.2.9 Removing the Switch board and sound mode and CD function switch board

y

(See Fig.20 to 23)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Pull out the volume control knob from the front of the front

panel assembly.(Fig.22)

(2) Remove six screws Q retaining the front panel assembly.

(3) Remove the Control/FL board.

(4) Remove eleven screws retaining the Switch (key 1)

board.(Fig.20)

(5) Remove two screws S retaining the sound mode and CD

function (key 2) switch board.(Fig.21)

Volume knob

Front panel assembl

Fig.22

Front panel

assembly

Volume

shaft

Fig.23

(No.MB196)1-15

Page 16

3.2.10 Removing the cassette deck main motor, and replacing the main belts

r

(See Fig.19, 24 and 25)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z retaining the cassette deck mecha-

nism. (Fig.19)

(2) Remove the cassette deck mechanism.

(3) Remove two screws t retaining the main motor from the

front side of the cassette deck.

Caution:

After attaching the main motor, check the orientation of

the motor and the polarity of the wires.

(4) From the backside of the cassette deck, remove the main

motor and two main belts.

Caution:

The lengths of the cassette A(playback only) and cassette B(record/play) main belts are different. When attaching the main belts, use the longer belt for cassette A.

Cassette deck mechanism

(Back side)

Cassette deck mechanism

(Front side)

t

Fig.24

Cassette deck main moto

3.2.11 Removing the leaf switches of the cassette deck mechanism

(See Fig. 19 and 26)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove the six screws Z that retain the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism.

(3) Turn the cassette deck mechanism upside down.

(4) Remove the solder from around the leaf switches.

(5) Pull out the leaf switches from the front side of the cassette

deck mechanism.

Main belt

(For B cassette)

Fig.25

Solder side of leaf switch

Cassette deck mechanism

Fig.26

Main belt

(For A cassette)

(Back side)

1-16 (No.MB196)

Page 17

3.2.12 Removing the cassette deck heads

(See Fig. 19 and 27)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z that retain the cassette deck mecha-

nism. (Fig.19)

(2) Remove the cassette deck mechanism and place it so that

the front side faces up.

(3) Remove the solder from the bottom side of the head termi-

nal and disconnect the wire.

(4) Remove screws U that retains the head.

(5) Remove screws V that retains the head.

(6) Hold the head and slide it in the direction of the arrow to re-

move it.

3.2.13 Removing the 3-pin regulator and bridge diode

(See Fig. 28)

• Prior to performing the following procedures, remove the top

cover and both sides board.

Remove two screws A that connect the heat sink.

(1) Remove two screws A that connect the heat sink.

(2) Remove two screws W that connect the heat sink.

(3) Remove the solder fixing the the 3-pin terminal regulator

, Q608.

Q604

(4) Remove the solder fixing the 4-pin bridge diode (D614

D615).

PB Head

Cassette deck mechanism

(Front side)

V

U

VU

REC/PB Head

Fig.27

W

A

,

Fig.28

(No.MB196)1-17

Page 18

3.2.14 Removing the Power amp and Supply board and the Power trans board

A

(See Fig. 3, 29 to 31)

• Prior to performing the following procedures, remove the top

cover and CD changer unit.

(1) Remove four screws B from the rear panel. (Fig.3)

(2) Pull the heat sink cover outward.

(3) Remove four screws AA from the rear panel between the

heat sink holder.

(4) Remove four screws YY that retains the rear panel, and

then remove the rear panel.

(5) Disconnect the parallel wires from the connectors FW951

on the Power trans board.

(6) Remove screws Z that retain the Power amp and Supply

board and then remove the assembly.

(7) Remove the clamp of AC power cord from the chassis.

(8) Remove four screws that retain the Power trans board and

then remove the assembly.

Fuse (F902)

1.6A 250V

A

Fuse (F901)

3.5A 125V

Fig.29

Rear panel

YY

Fig.30

Power amp and

supply board

Chassis

Z

Fig.31

Clamp

1-18 (No.MB196)

Page 19

SECTION 4

ADJUSTMENT

4.1 Measurement Instruments Required for Adjustment

(1) Low frequency oscillator

This oscillator should have a capacity to output 0dBs to

600Ω at an oscillation frequency of 50Hz-20kHz.

(2) Attenuator impedance : 600Ω

(3) Electronic voltmeter

(4) Frequency counter

(5) Wow & flutter meter

(6) Test tape

VT712 : For Tape speed and wow flutter ( 3kHz)

VT703 : For Head angle (10kHz)

(7) Blank tape

TYPE l : AC-225

TYPE ll : AC-514

(8) Torque gauge

For play and back tension forward; TW2111A

Reverse; TW2121A

Fast Forward and Rewind; TW2231A

(9) Test disc

CTS-1000(12cm)

GRG-1211(8cm)

(10) Jitter meter

4.2 Measurement conditons

Power supply voltage AC 120V ~, 60Hz

Measurement

output terminal

4.2.1 Radio Input signal

AM modulation frequency 400Hz

Modulation factor 30%

FM modulation frequency 1 kHz

Frequency displacement 22.5kHz

Speaker out

TP101

(Measuring for TUNER/ DECK/CD)

Dummy load 6Ω

4.2.2 Standard measurement position of volume and

switch

Power Standby

(Light STANDBY Indicator)

Sound Turbo,A,BASS EX OFF

Sound mode OFF

Main VOL. 0 Minimum

Travers mecha set position Disc 1

Precautions for measurement

(1) Apply 30pF and 33kΩ to the IF sweeper output side and

0.082µ F and 100kΩ in series to the sweeper input side.

(2) The IF sweeper output level should be made as low as

possible within the adjustable range.

(3) Since the IF sweeper is a fixed device, there is no need

to adjust this sweeper.

(4) Since a ceramic oscillator is used, there is no need to

perform any MIX adjustment.

(5) Since a fixed coil is used, there is no need to adjust the

FM tracking.

(6) The input and output earth systems are separated. In

case of simultaneously measuring the voltage in both of

the input and output systems with an electronic voltmeter

for two channels, therefore, the earth should be connected particularly carefully.

(7) In the case of BTL connection amp., the minus terminal

of speaker is not for earthing. Therefore, be sure not to

connect any other earth terminal to this terminal. This

system is of an BTL system.

(8) For connecting a dummy resistor when measuring the

output, use the wire with a greater code size.

(9) Whenever any mixed tape is used, use the band pass fil-

ter (DV-12).

(No.MB196)1-19

Page 20

4.3 Arrangement of adjusting positions

Cassette deck mechanism

(Front side)

4.3.1 Tape recorder section

Items

Cassette Head

Azimuth Alignments

Measurement

conditions

Test tape

: VT703 (10kHz)

Measurement output

terminal

: Left and Right

speaker output

(6-ohm loaded)

or

Headphone Output

(32-ohm loaded)

PB Head

(Deck-A)

Head azimuth screw

(Forward side)

Head azimuth screw

1. Playback the test tape VT703 (10KHz) or equivalent.

2. Adjust the head azimuth screw to obtain maximum

output and both output of L / R is in 3dB.

3. Put on the screw lock paint after alignments.

Head azimuth screw

(Forward side)

(Reverse side)

Measurement method

REC/PB Head

(Deck-B)

Head azimuth screw

(Reverse side)

Standard

values

Maximum output

Adjusting

positions

Adjust the

head azimuth

screw only

when the head

has been

changed.

Recording Bias

Frequency Alignment

Test tape

: TYPE AC-514

Measurement output

terminal

1. Insert the recording tape in deck-B.

2. Starting the recording.

3. Adjust the oscillation frequency to 80KHz+/-3KHz by

core of Oscillation coil of L301.

: Erase head terminal

(CN308 8-Pin)

4.3.2 Tuner section

Items

AM Tracking

Alignments

Measurement

conditions

Input signal

: 530kHz

600kHz

Adjustment point

: Antenna coil (L2)

1. Set the Signal Generator signal to 530KHz the feed

to Loop Antenna.

2. Receiving the signal and the adjust the OSC coil (L2)

obtain the V.T is 1.40V +/-0.05V.

3. Change the receiving frequency to 600KHz (603KHz).

4. Adjust the Antenna coil ( L2 ) obtain maximum

sensitivity. (Adjust the SSG output to out of AGC range.)

AM IFT Alignments

Input signal

: 530kHz

Adjustment point

: IFT (T1)

1. Set the receiving frequency to 530KHz.

2. Feed the 450KHz signal to AM antenna input.

3.Adjust the IFT Block T1 obtain to maximum output.

(Adjust the SSG output to out of AGC range.)

Note: The adjustment of CD section is not required.

Measurement method

80kHz+/-3kHz

Standard

values

V. T

: 1.40V+/-0.05V

Maximum

sensitivity

Maximum output

Use the HighImpedance

Probe or

Frequency

counter input.

Adjusting

positions

Adjust the OSC

coil only when

the AM coil block

has been changed.

Adjust the IFT

only when the

IFT block has

been changed.

1-20 (No.MB196)

Page 21

TROUBLESHOOTING

5.1 Flow of functional operation until TOC read

Power ON

Play Key

SECTION 5

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Check Point

Confirm that the voltage at the pin5

of CN702 is "H"\"L"\"H".

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 20 of

IC611(TE)

Approx

0.3V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig-1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin10 of IC701 is + 0V?

Confirm that the Focus error

S-cuve signal at the pin31 of

IC701 is approx.2Vp-p

Confirm that the signal from

pin26 IC701 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 29 of IC701 (R729)

(See fig-1)

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of Pin 2 of IC 701

(No.MB196)1-21

Page 22

5.2 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output : ampli tude of eye

pattern) will below.

5.3 Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the AC OUTLET.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Is the level of

RFOUT under

0.48V 0.1Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power. Since this adjustment should be performed to

match the characteristics of the whole optical block, do not

touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is

functioning normally, the laser pickup may be damaged

due to excessive current.

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at

Pin 2 of IC 701

Finish.

1-22 (No.MB196)

Page 23

(No.MB196)1-23

Page 24

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB196)

Printed in Japan

WPC

Loading...

Loading...