Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB15720042

MX-KB30

STANDBY/ON

SLEEP

AUX

FM MODE

FM /AM

CD

CD1CD2CD

3

PROGRAM/RANDOM

REPEAT

TAPE

TAPE

A/B

SOUND

VOLUME

MODE

FADE

ACTIVE

SOUND

MUTING

BASS EX.

TURBO

CA-MXKB30SP-MXKB30 SP-MXKB30

Area Suffix

J ------------------- U.S.A.

C ----------------- Canada

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.MB157

2004/2

Page 2

SPECIFICATION

Amplifier Output Power 150 W per channel, min. RMS, driven into 6 Ω at 1kHz, with no more

than 10% total harmonic distortion

Input Sensitivity/Impedance (1 kHz) AUX IN : 300 mV/50 kΩ

Speaker terminals 6 - 16 Ω

Phones 32 Ω - 1 kΩ

Cassette Deck Frequency Response

Type I (NORMAL)

Wow And Flutter 0.15% (WRMS)

CD Player CD Capacity 3 CDs

Dynamic Range 85 dB

Signal-To-Noise Ratio 85 dB

Wow And Flutter Unmeasurable

Tuner FM Tuner Tuning Range : 87.5 MHz - 108.0 MHz

AM Tuner Tuning Range : 530 kHz - 1 710 kHz

Unit Dimensions 267 mm × 305 mm × 433 mm (W/H/D)

Mass Approx. 8.7 kg (19.2 lbs)

Speaker Specifications

(each unit)

Power Specifications Power Requirements AC 120 V , 60 Hz

SP-MXKB30 3-way bass-reflex type

Type Woofer: 16 cm (6-5/16") cone × 1

Speaker Unit Mid: 5cm (2") cone × 1

Power Handling Capacity 150 W

Impedance 6 Ω

Frequency Range 45 Hz - 22,000 Hz

Sound pressure level 87 dB/W

Dimensions 244 mm × 321 mm × 258 mm (W/H/D)

Mass Approx. 3.6 kg (8.0 lbs)

Power Consumption 135 W (power on mode)

15 mW/ch output into 32 Ω

63 Hz - 12 500 Hz

(10-9/16" × 12-1/16" × 17-1/16")

Tweeter: 2 cm (13/16") dome × 1

·m

(9-5/8" × 12-11/16" × 10-3/16")

18 W (in Standby mode)

Design and specifications are subject to change without notice.

1-2 (No.MB157)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

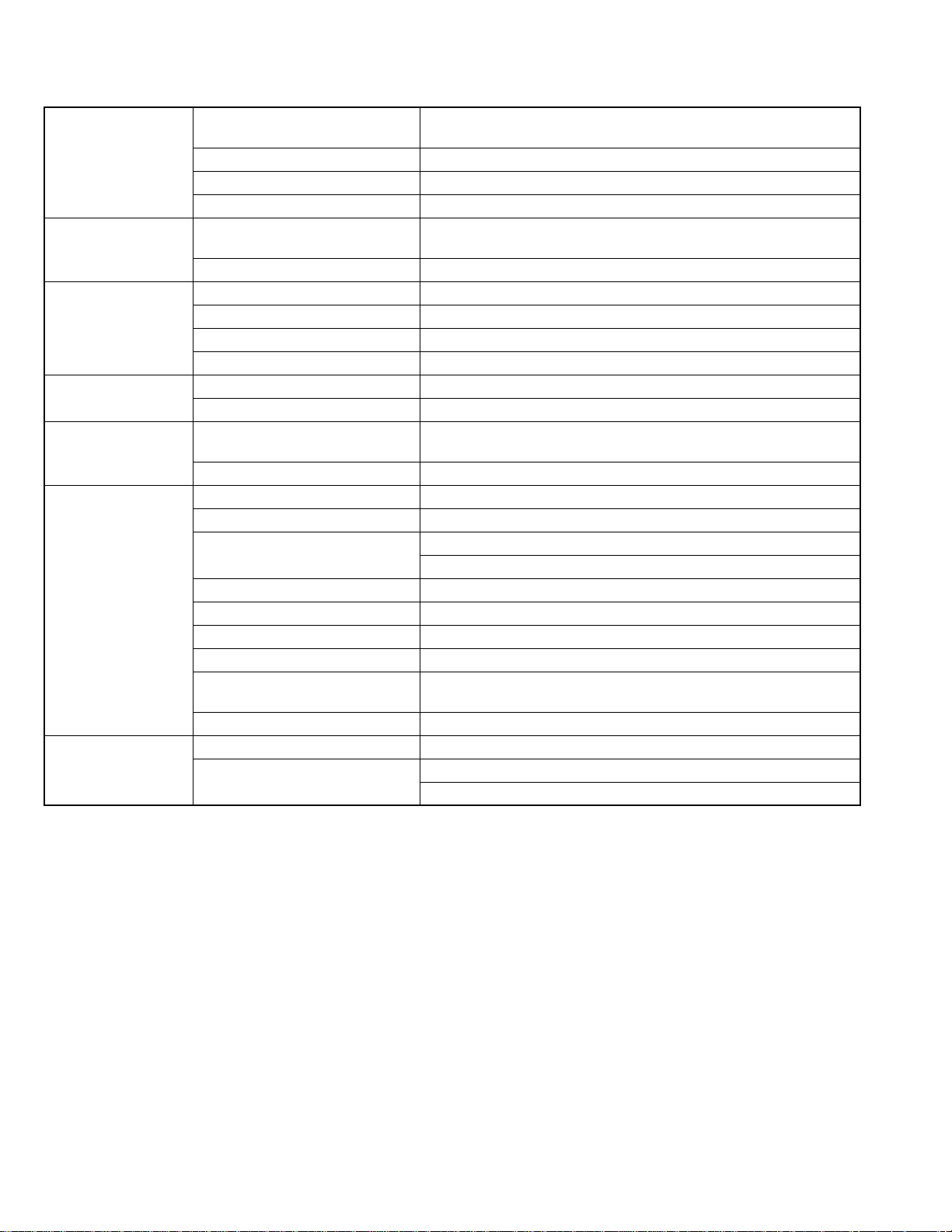

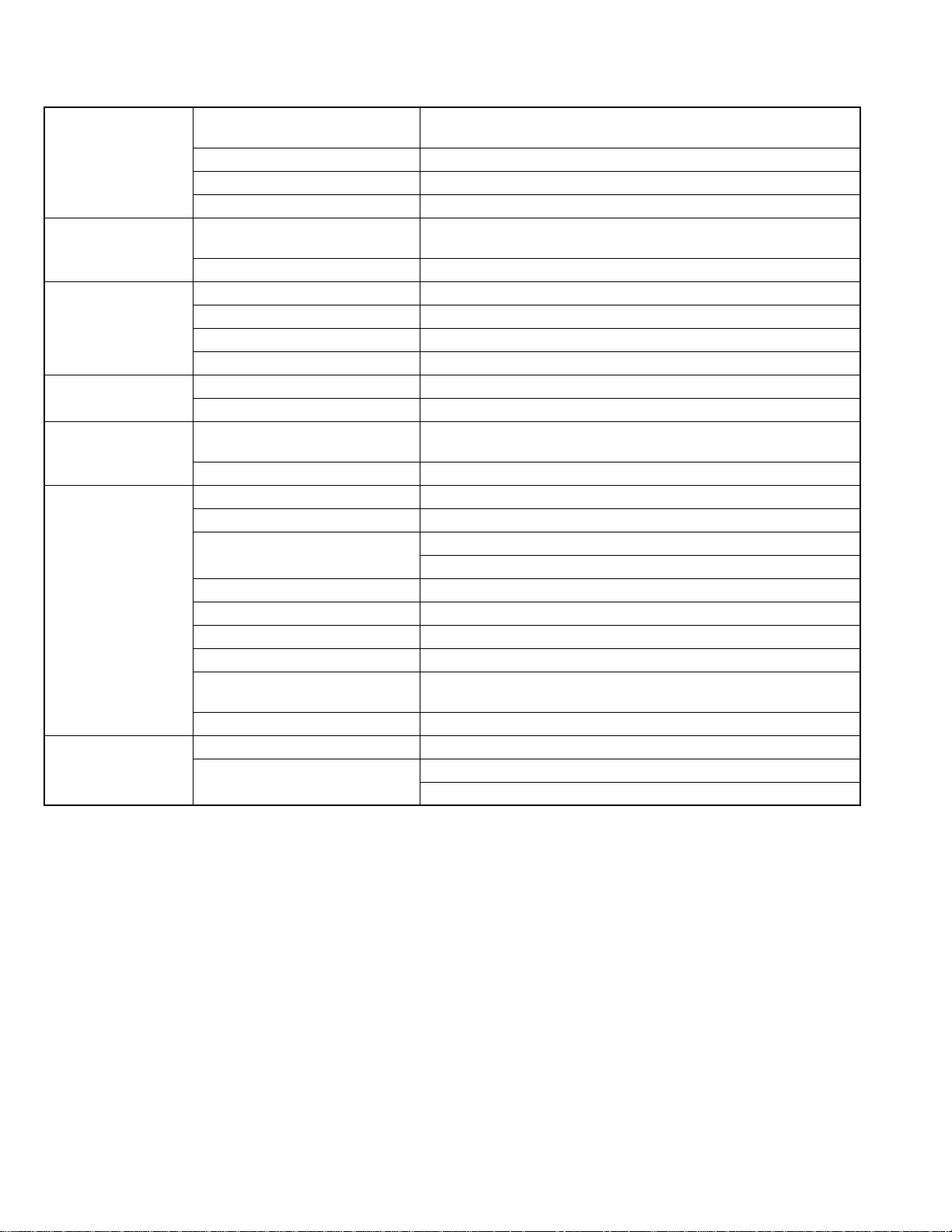

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Pl ug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB157)1-3

Page 4

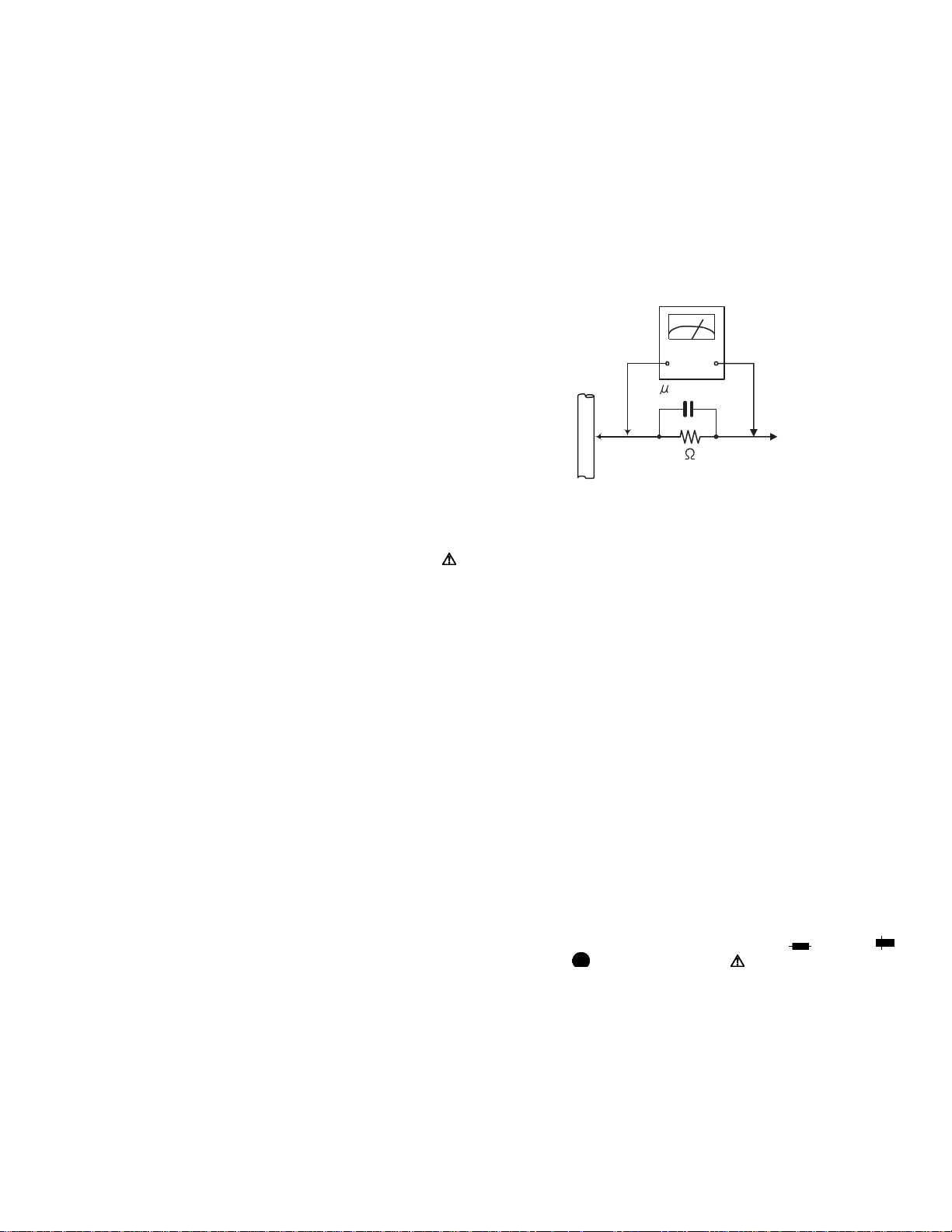

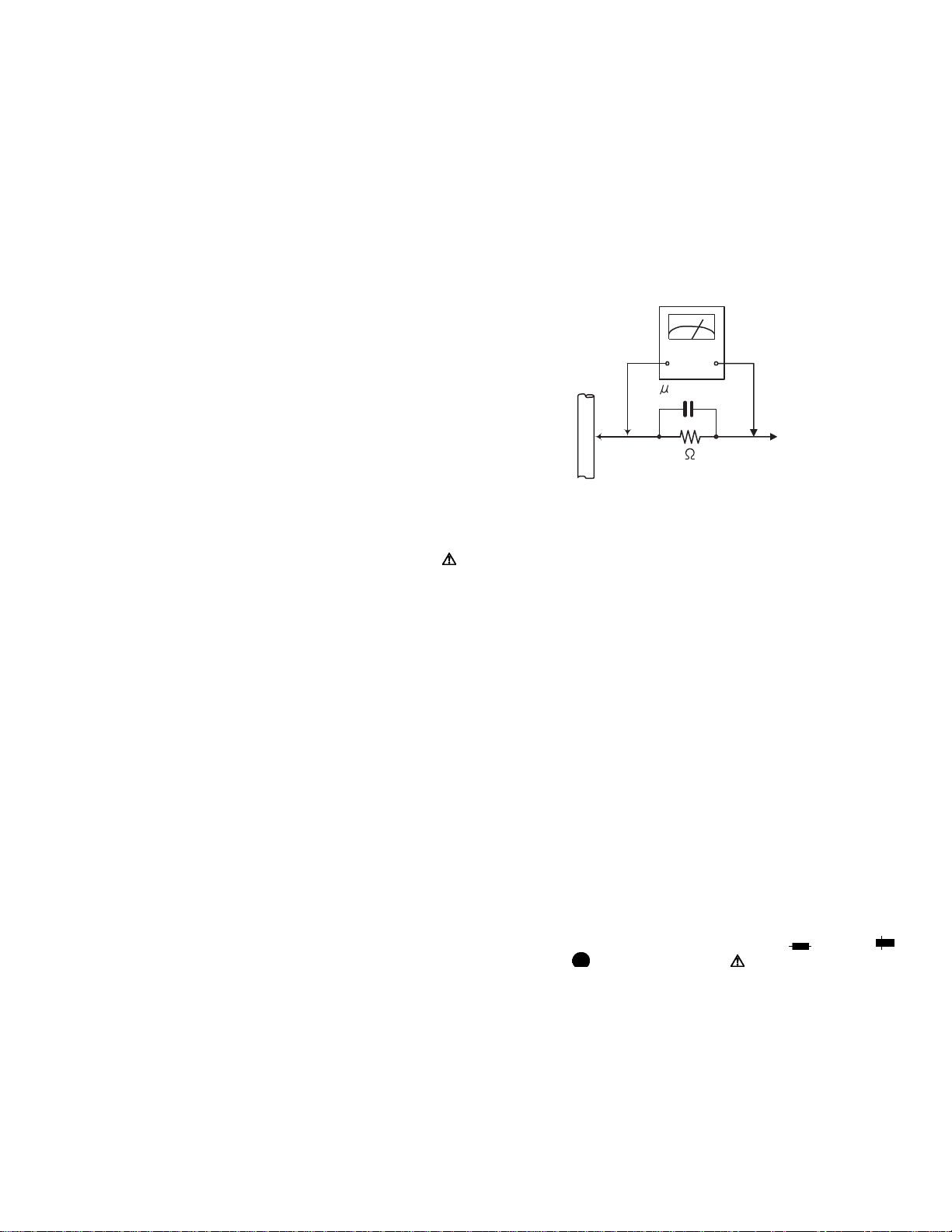

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before instal lation, both sides of the laser di ode on the replacement optica l

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

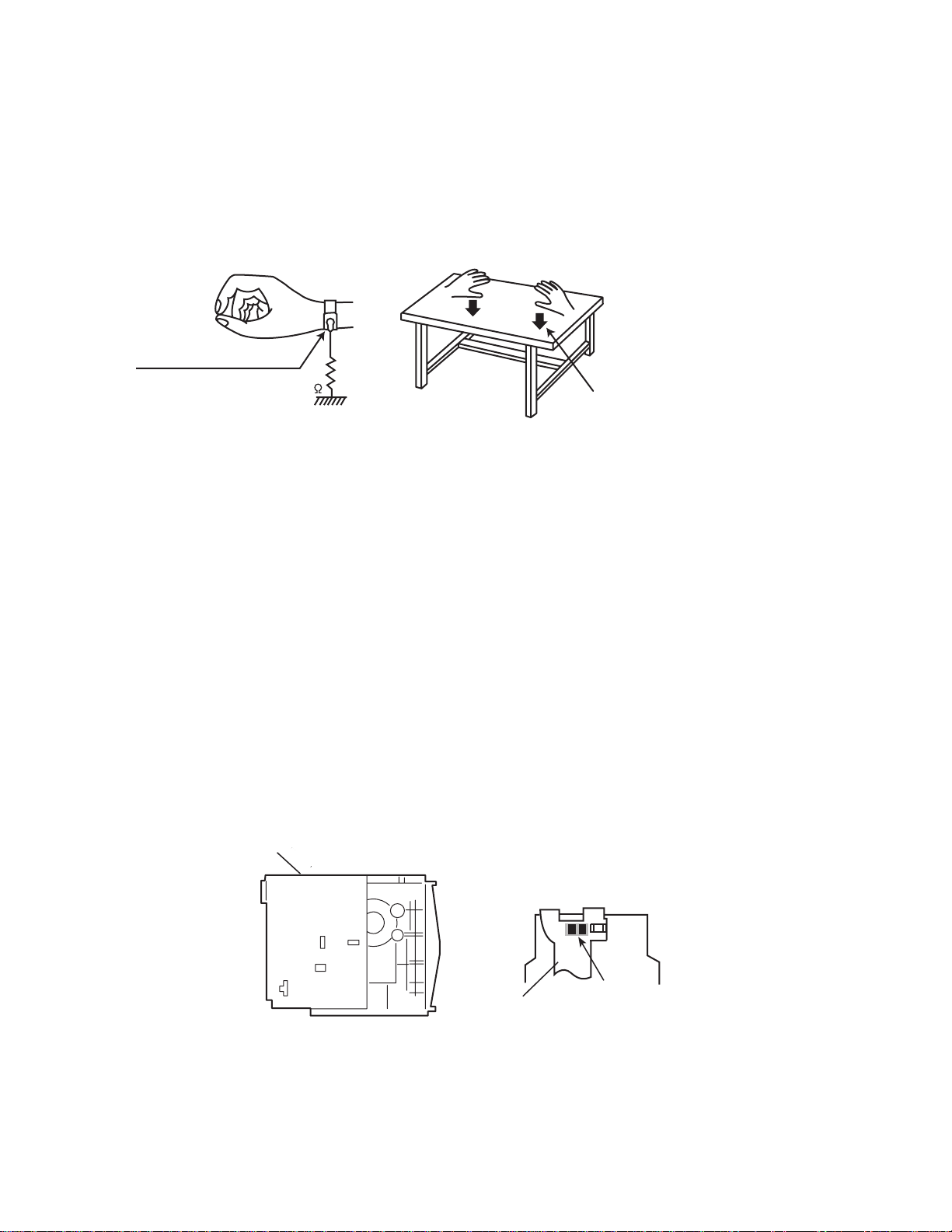

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

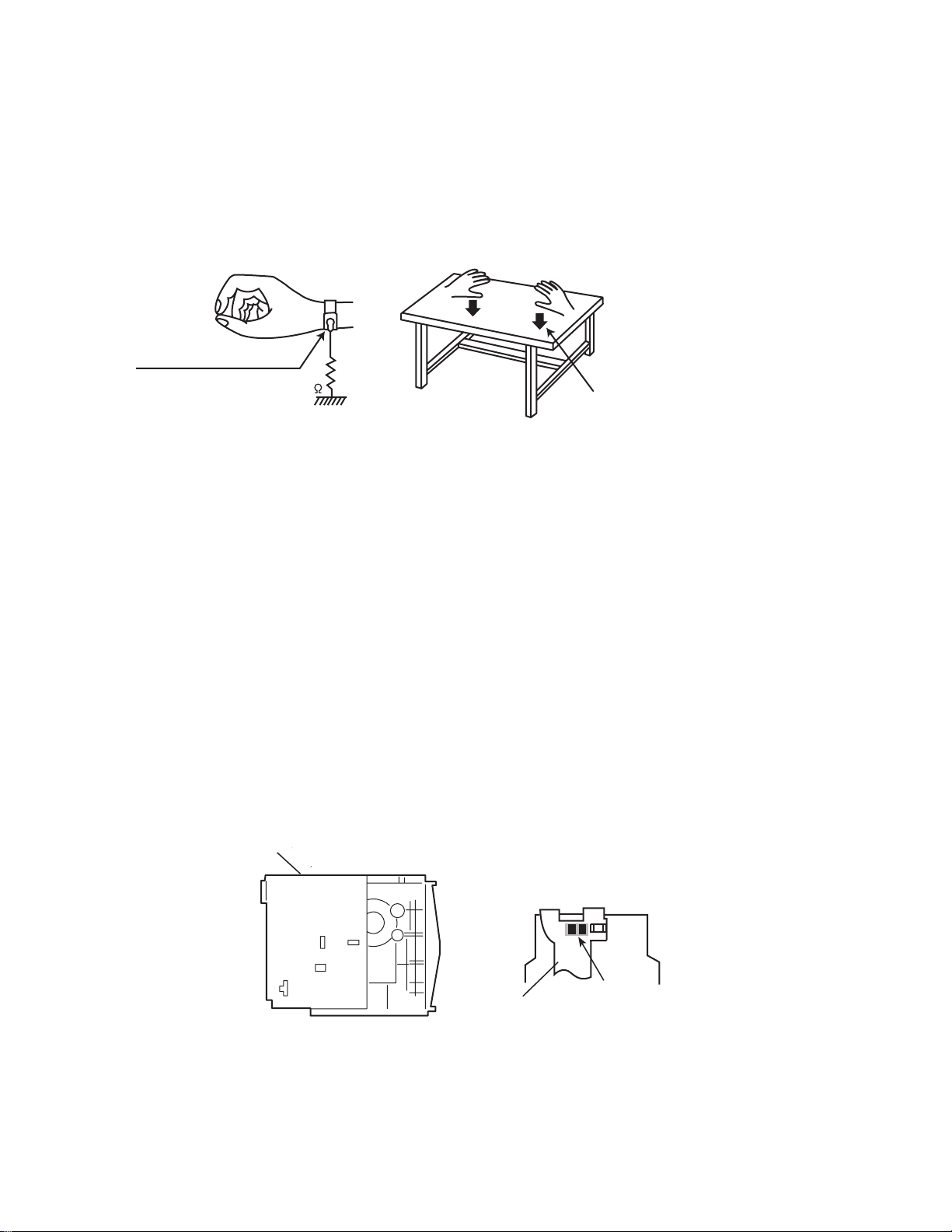

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land sections before the flexible wir e is disconnected from the connector on the CD servo board. (If the

flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

CD changer

unit

1-4 (No.MB157)

Flexible cable

Soldering

Page 5

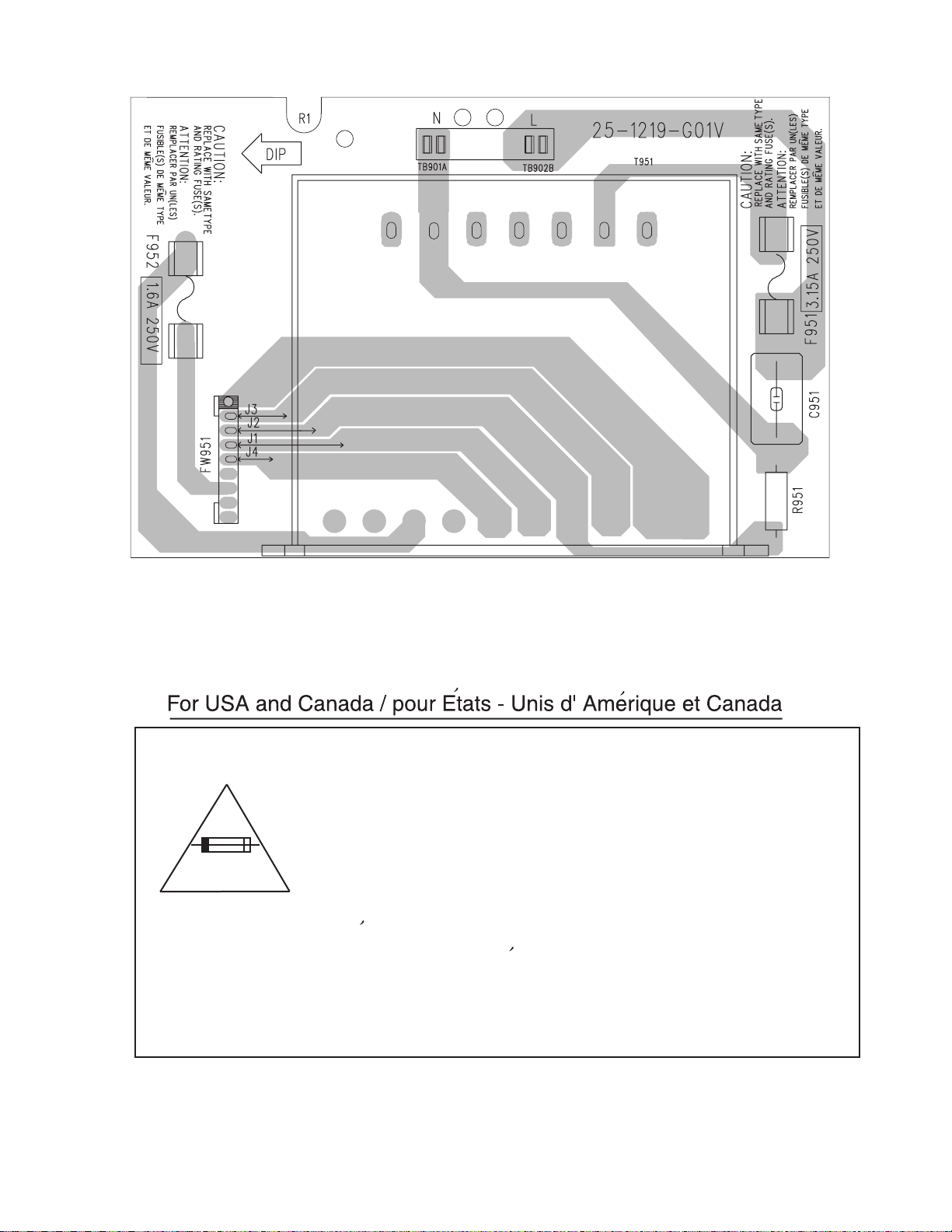

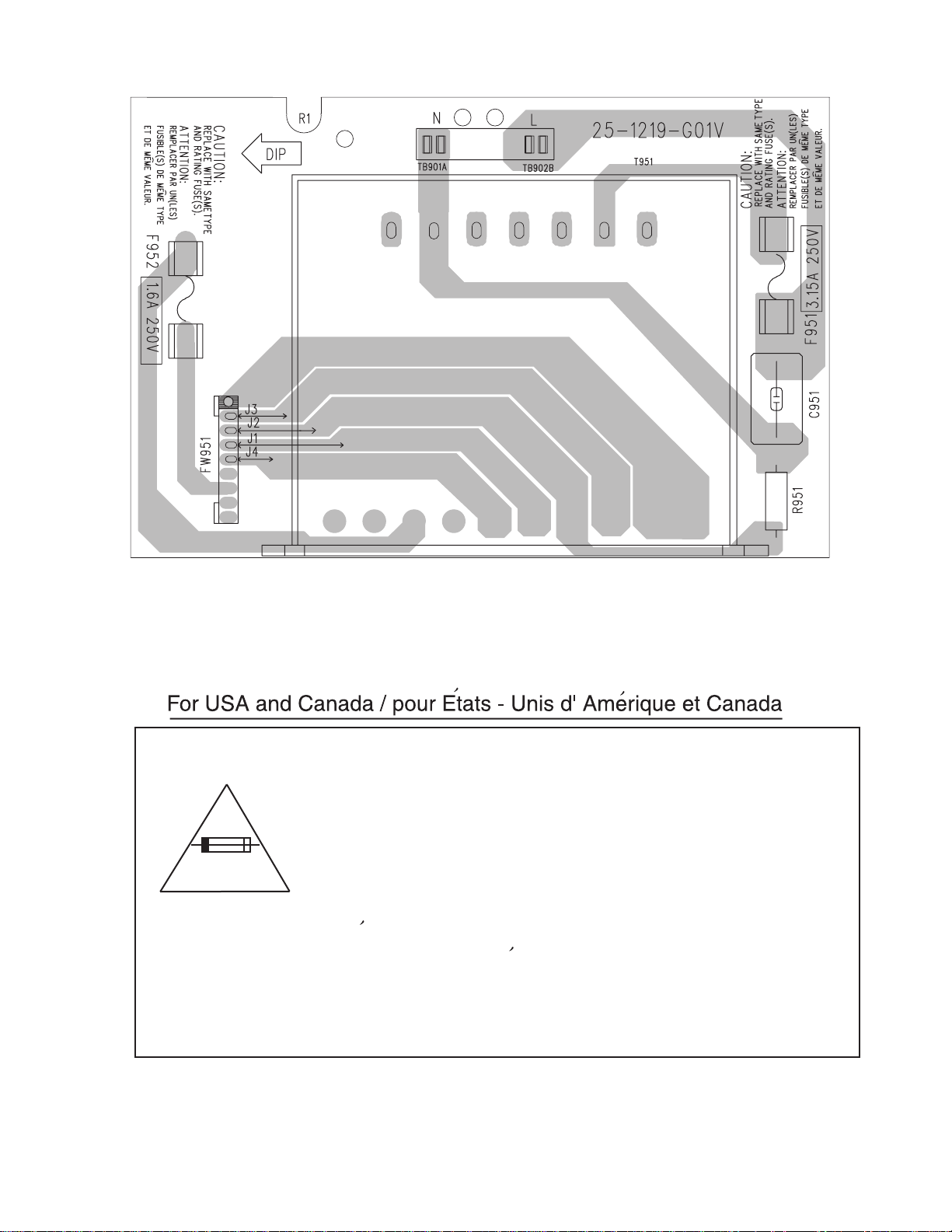

1.8 Importance administering point on the safety

Caution: For continued protection against risk of

fire, replace only with same type 3.15A/250V for

F951 and 1.6A/250V for F952. This symbol

specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F951 comme le meme type

que 3.15A/250V, et 1.6A/250V pour F952.

Ce sont des fusibles suretes qui functionnes rapide.

^

(No.MB157)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB157)

Page 7

SECTION 3

DISASSEMBLY

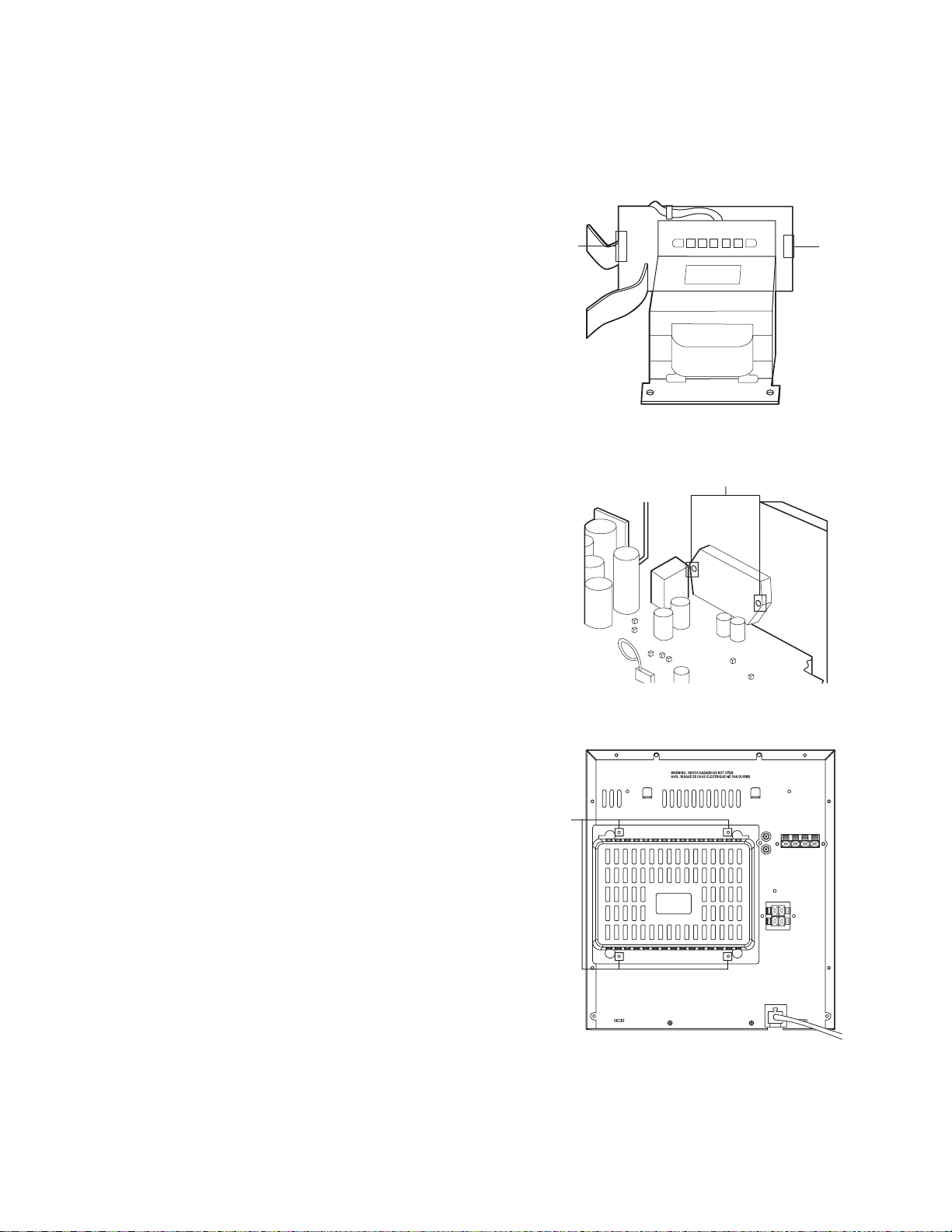

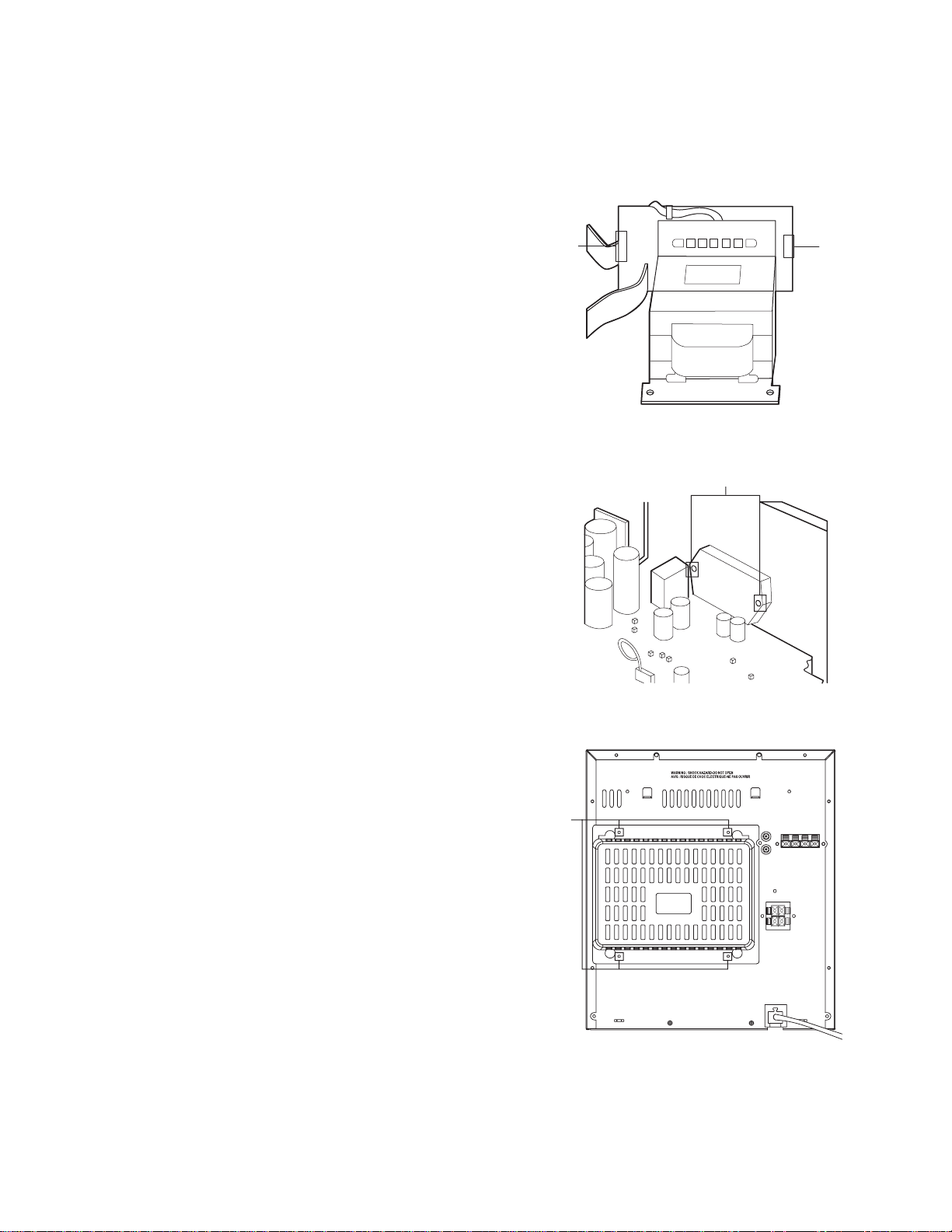

3.1 Main body

3.1.1 Replacing the fuses

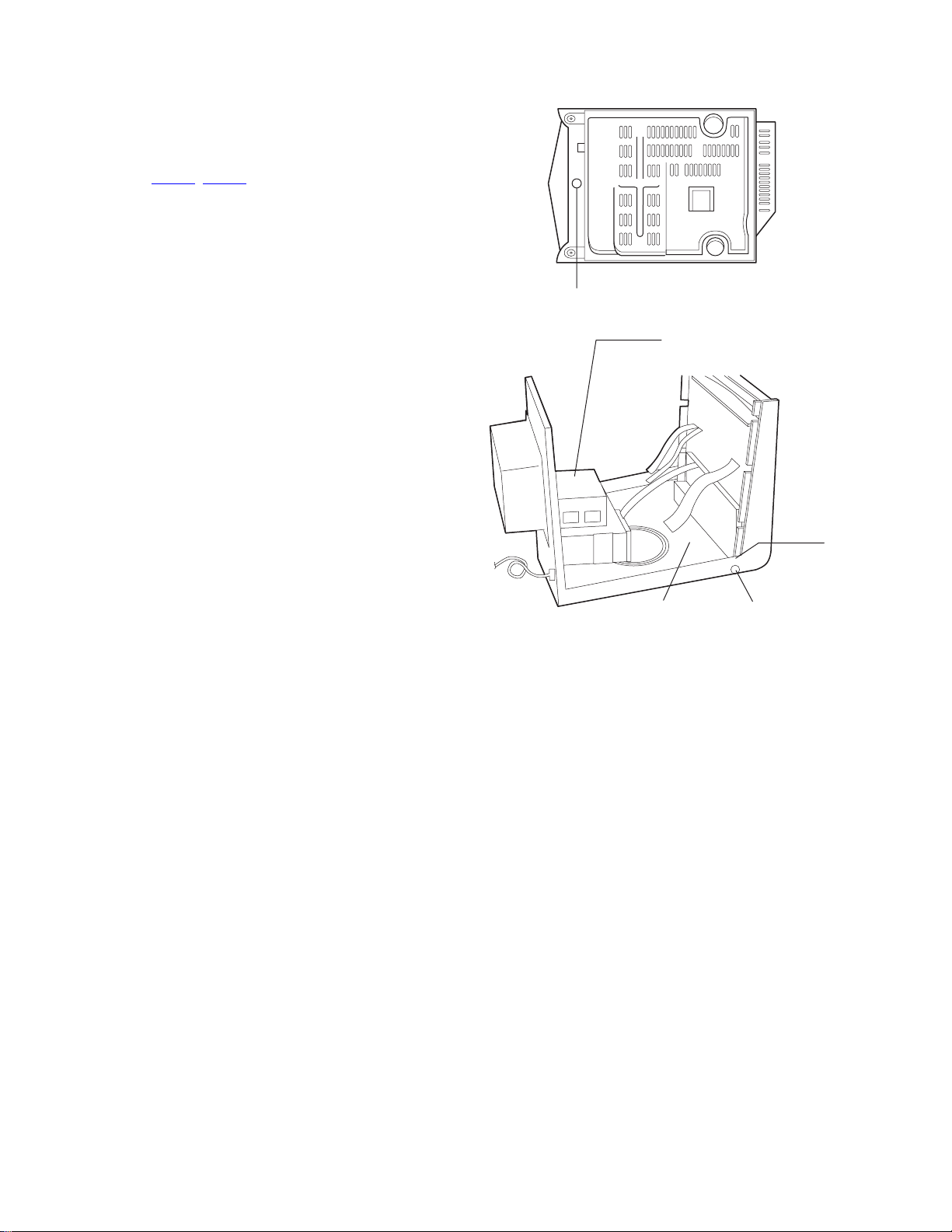

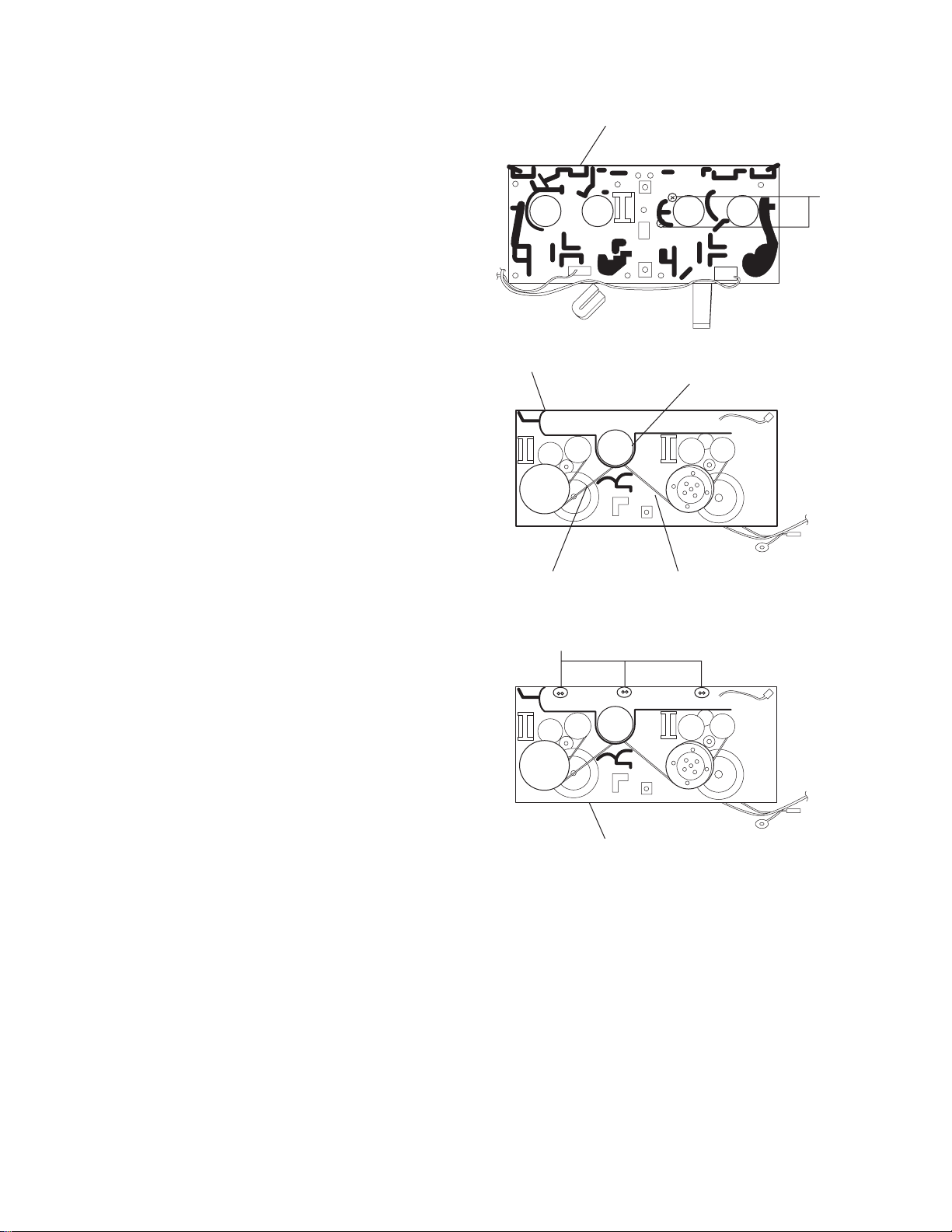

(See Fig.1)

• Prio r to performing the following procedure, remove the top

cover.

(1) Replace the fuse s inside.

Caution:

Be sure to use fuses with the specified ratings.

3.1.2 Replacing the power IC

(See Fig.2)

• Prio r to performing the following procedure, remove the top

cover.

(1) Remove the two screws A from the heat sink between the

power IC.

(2) Remove the solder fixing the power IC.

Fuse(F952)

1.6A 250V

Fuse(F951)

3.15A 250V

Fig.1

A

3.1.3 Replacing the heat sink cover

(See Fig.3)

(1) Remove four screws B from the rear panel.

(2) Pull the heat sink cover outward.

Fig.2

B

Fig.3

(No.MB157)1-7

Page 8

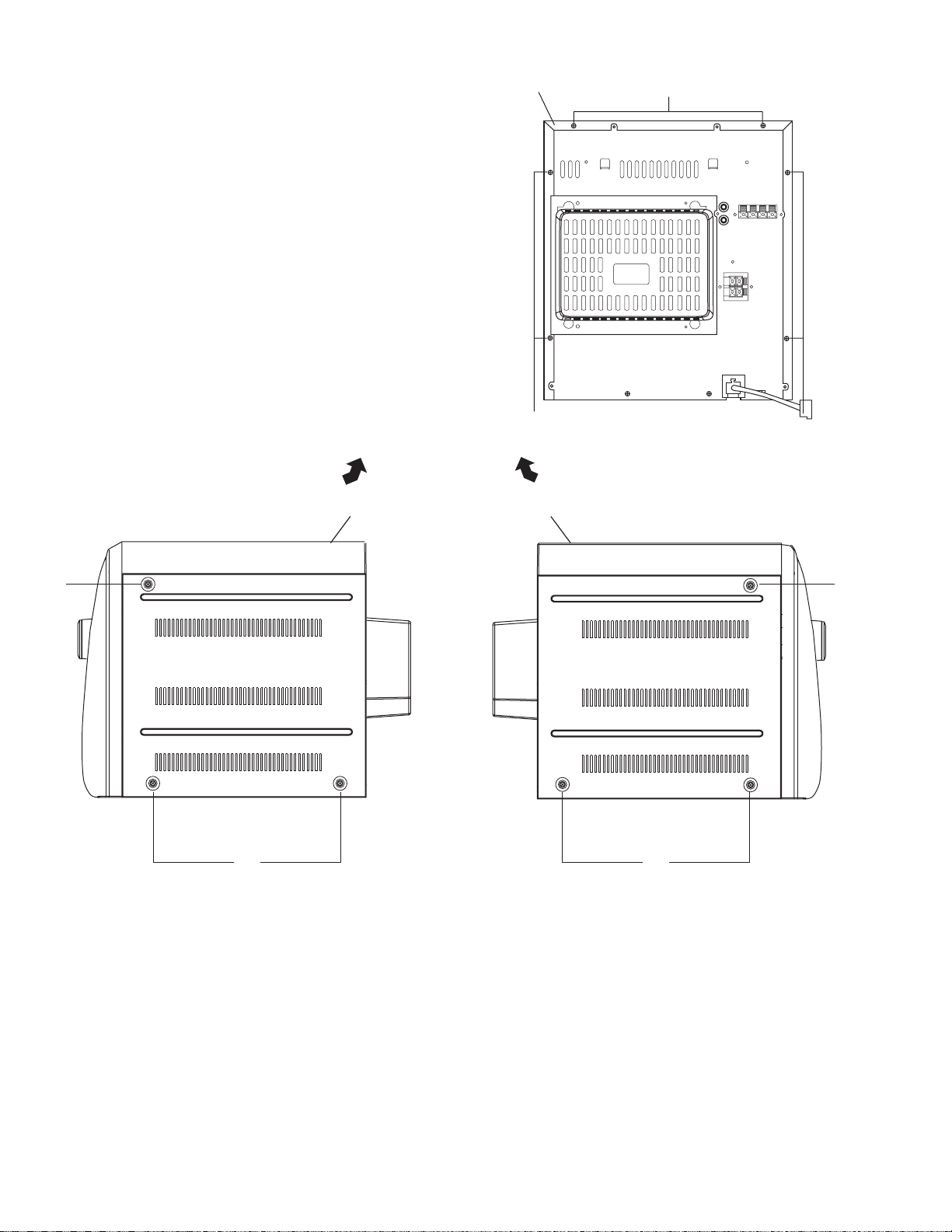

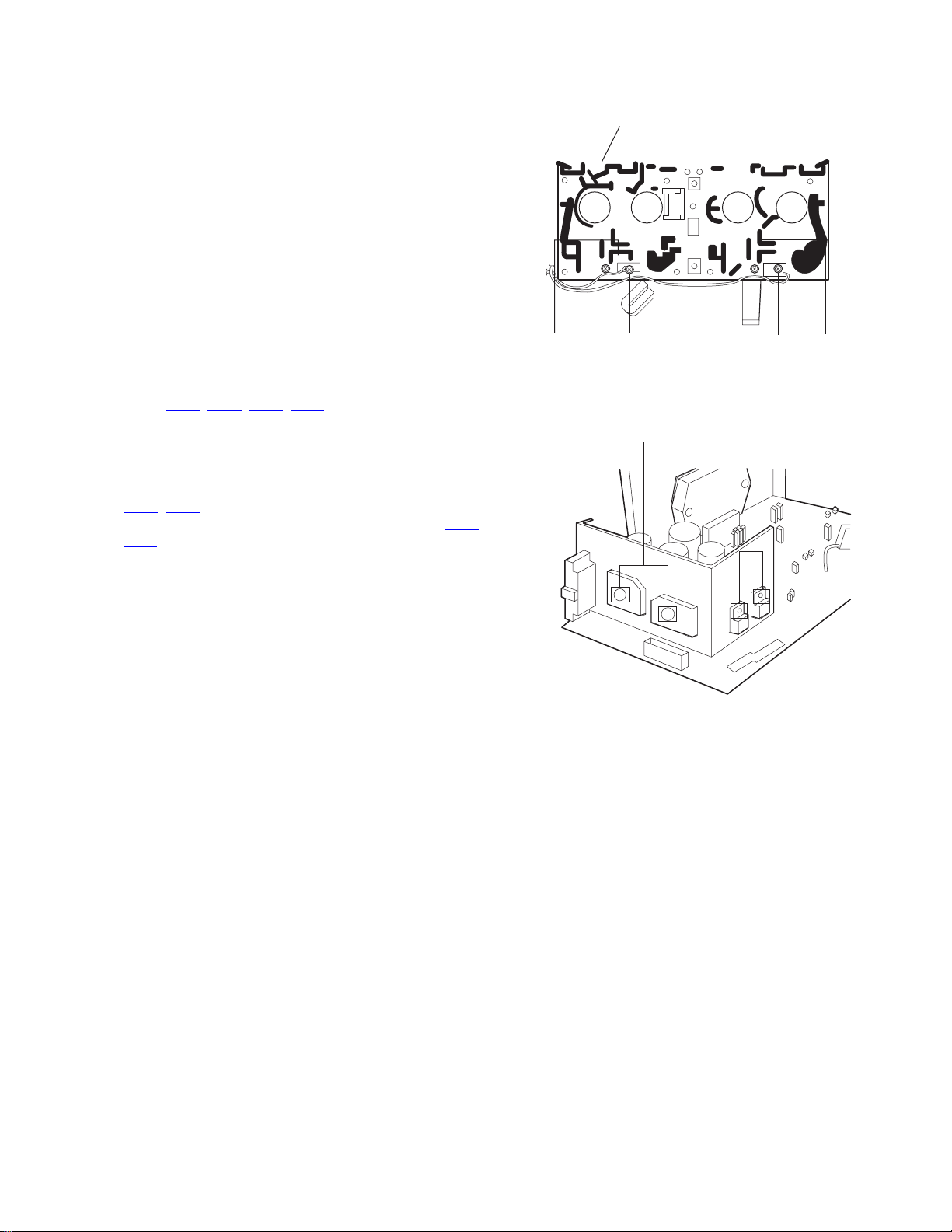

3.1.4 Removing the top cover

(See Fig.4 and 5)

(1) Remove six screws C that retain the top cover from the

panel rear of the body.

(2) Remove six screws D that retain the top cover from the two

sides of the body.

(3) Remove the top cover from the body by lifting it toward the

rear.

Top cover

C

C

Fig.4

Right Front panel assembly

Left Front panel assembly

D

C

D

DD

Fig.5

1-8 (No.MB157)

Page 9

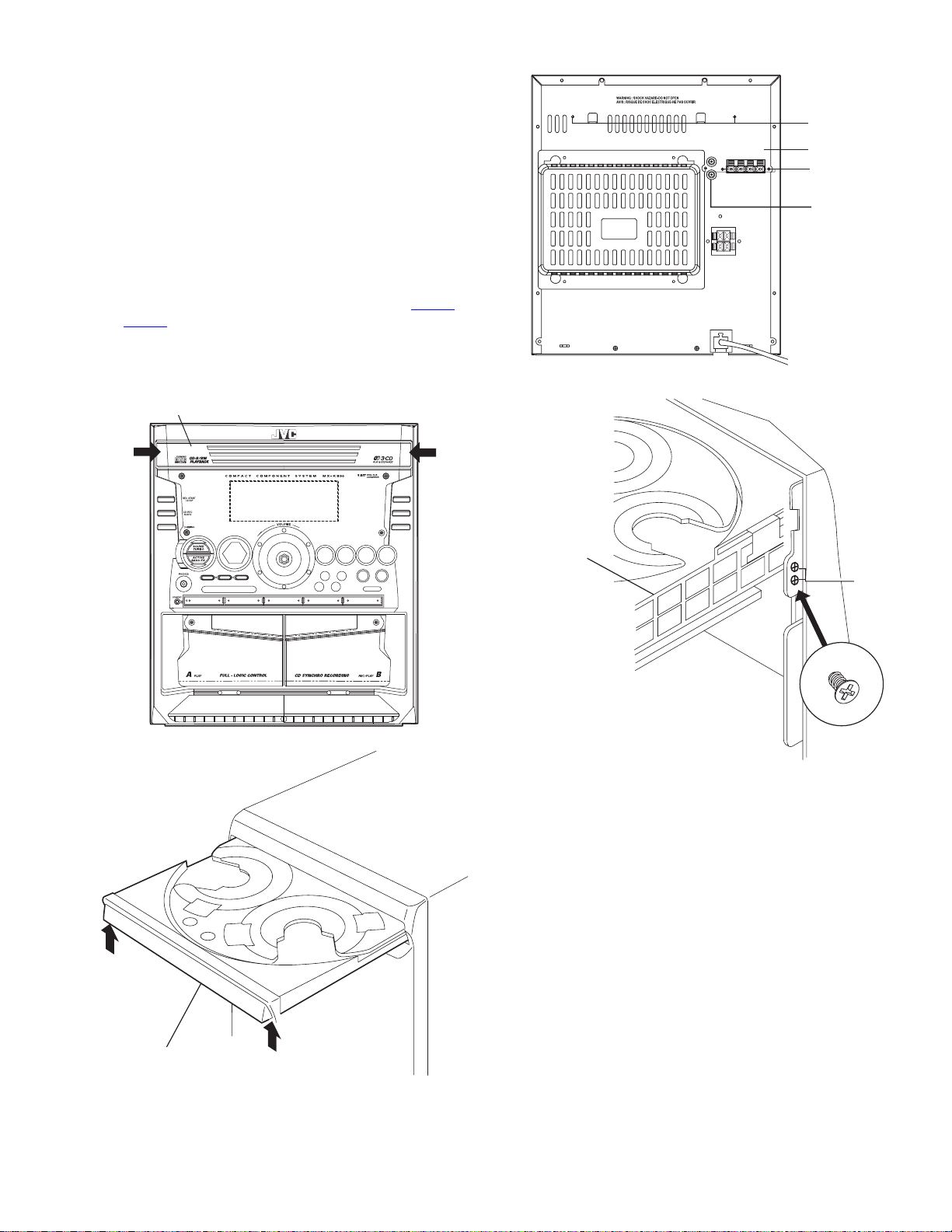

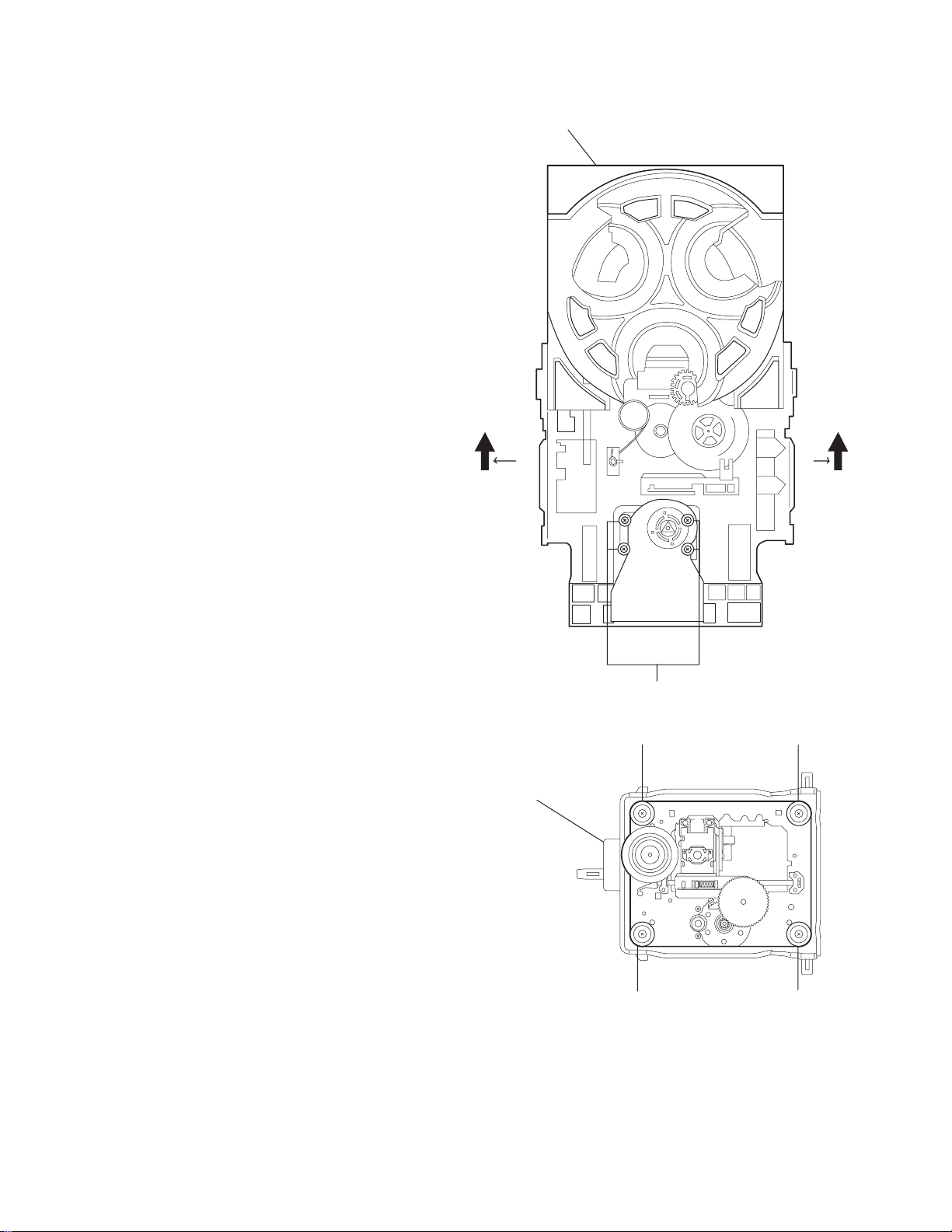

3.1.5 Removing the CD changer unit

y

(See Fig.6 to 9)

• Prio r to performing the following procedures, remove the top

cover.

Caution:

Although the CD mechanism unit can be removed without

removing the CD tray panel, it is still recommended to remove

it in order to prevent damage.

• From the fron t panel side of this set, push in the sections

marked with arrows and pull out the CD tray toward the front.

• Remove the CD tray panel by pushing both of its extremities

upward in the direction of the arrows.

• Push the CD tray deep into the set.

(1) Disconnect the cord wires from the CD board CN703

and

CN203.

(2) From the rear of the set, remove two screws E three screws

F and four screws G on the front panel left and right side.

(3) Handle the CD changer unit rear, take out the unit.

CD tray panel

E

Antenna

terminal

F

Accessor

terminal

Fig.8

Fig.6

CD changer

unit

G

Fig.9

CD tray panel

Fig.7

(No.MB157)1-9

Page 10

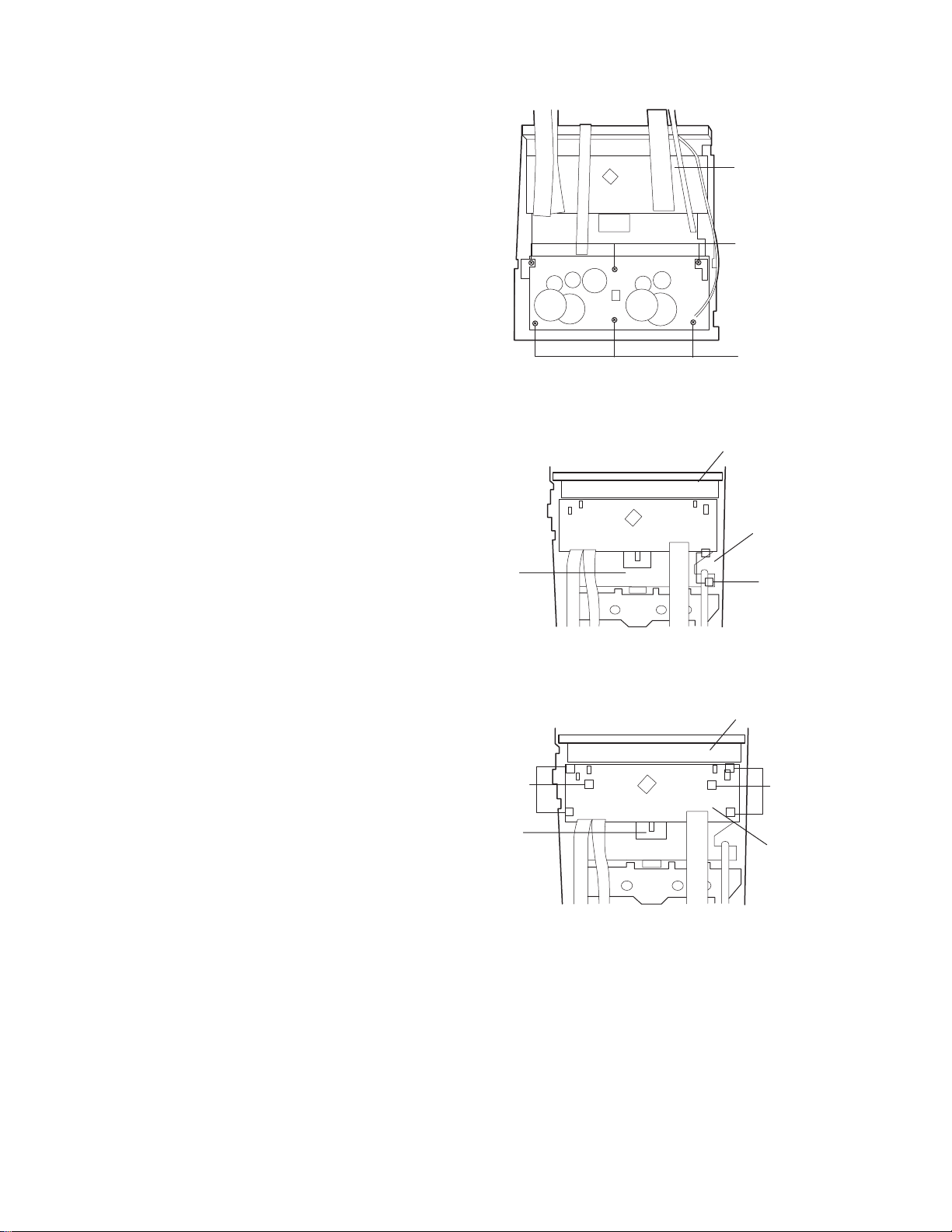

3.1.6 Removing the front panel assembly

(See Fig.10 to 11)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Disconnect the parallel wire and the cord wire from the

connectors CN701

(2) Remove one screws H retaining the front panel assembly

onto the bottom of the body.

(3) Remove two screws I on the left and right side of the set

retaining the panel front from the bottom and then remove

then GND lug b that comes from the power amp and supply

PCB.

(4) Disengage the claws c on both sides of the front panel

assembly and then remove the assembly.

, CN101 on the power amp. board.

*

Fig.10

Power amp and

supply PCB

GND lug b

Fig.11

I

Claw c

1-10 (No.MB157)

Page 11

3.1.7 Removing the CD board

(See Fig.12 to 13)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Disconnect the wires from CN603A

on the CD board, which is located on the back side of the

CD changer unit.

(2) The four screws J that retain the CD board should be

removed.

(3) Remove the CD board by pulling it toward the side where

the CN601

(4) Using solder, short the CD pickup to connect to short

round.

Caution:

After re-connecting the wires, be sure to remove the

shorting solder from the GND connection.

(5) Disconnect the card wire from the connector CN601

main board and then remove the main board.

is located.

, CN603B and CN604

on the

CD PCB

J

J

J

Fig.12

CD PCB

CN601

Short round

Fig.13

(No.MB157)1-11

Page 12

3.1.8 Removing the CD changer mechanism assembly

(See Fig.14 to 15)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Turn the CD changer mech anism cover base an d remove

the screws d connecting the unit to the CD changer

mechanism assembly.

(2) Removing four screws e retaining the CD mechanism

holder assembly.

Caution:

When replacing the CD changer mechanism assembly, be

sure not to mistake the positions of the silver color and copper

color spring.

CD changer

unit

CD changer

mechanism

assembly

Fig.14

e (Silver color)

e (Silver color)

Fig.15

d

e (copper color)

e (copper color)

1-12 (No.MB157)

Page 13

3.1.9 Removing the CD pickup

r

(See Fig.16)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the CD changer mechanism.

(1) Widen the section f.

(2) While keeping the section f wide open, pu sh the sectio n g

in the direction of the arrow to remove the shaft, and th en

remove the CD pickup.

CD pic kup

f

3.1.10 Replacing the loading motor and rotor belt of the CD changer

(See Fig .17)

• Prio r to performing the following procedures, remove the top

cover.

• Al so open the CD changer tray.

(1) Remove the two screws L retaining the CD cha nger tray

loading motor.

(2) Remove the two screws M retaining the gear plate and take

it out, after remove the rotor belt from the pulley.

3.1.11 Replacing the CD turn table and removing the motor

(See Fig. 18)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Remove the one screws N retaining the CD (Turn table).

(2) Remove the two screws O retaining the sto pper brackets

on both sides of the CD changer unit.

(3) Remove the stopper brackets from both sides of the CD

changer unit.

(4) Pull out the CD tray from the CD chang er unit, all the way

and lift the tray (u/~ ward) to remove.

(5) Remove the gear and after push out the tray motor locker

and pull out the tray motor from the CD tray.

g

Shaft

Fig.16

M

L

Fig.17

Turn table motor

Motor locker

Obligue gea

Fig.18

(No.MB157)1-13

Page 14

3.1.12 Removing the cassette deck mechanism

(See Fig.19)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z retaining the cassette deck

mechanism.

3.1.13 Removing the earphone jack board

(See Fig.20)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove the screw with the washer, P that retains the

earphone jack PCB.

KEY 1

PCB

Front panel

assembly

Z

Z

Fig.19

Front panel

assembly

Earphone jack

PCB

P

3.1.14 Removing the control/FL board

(See Fig.21)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Q that retain the control/FL PCB from

the back of the front panel unit.

Q

KEY 2

PCB

Fig.20

Front panel

assembly

Q

Control/FL

PCB

Fig.21

1-14 (No.MB157)

Page 15

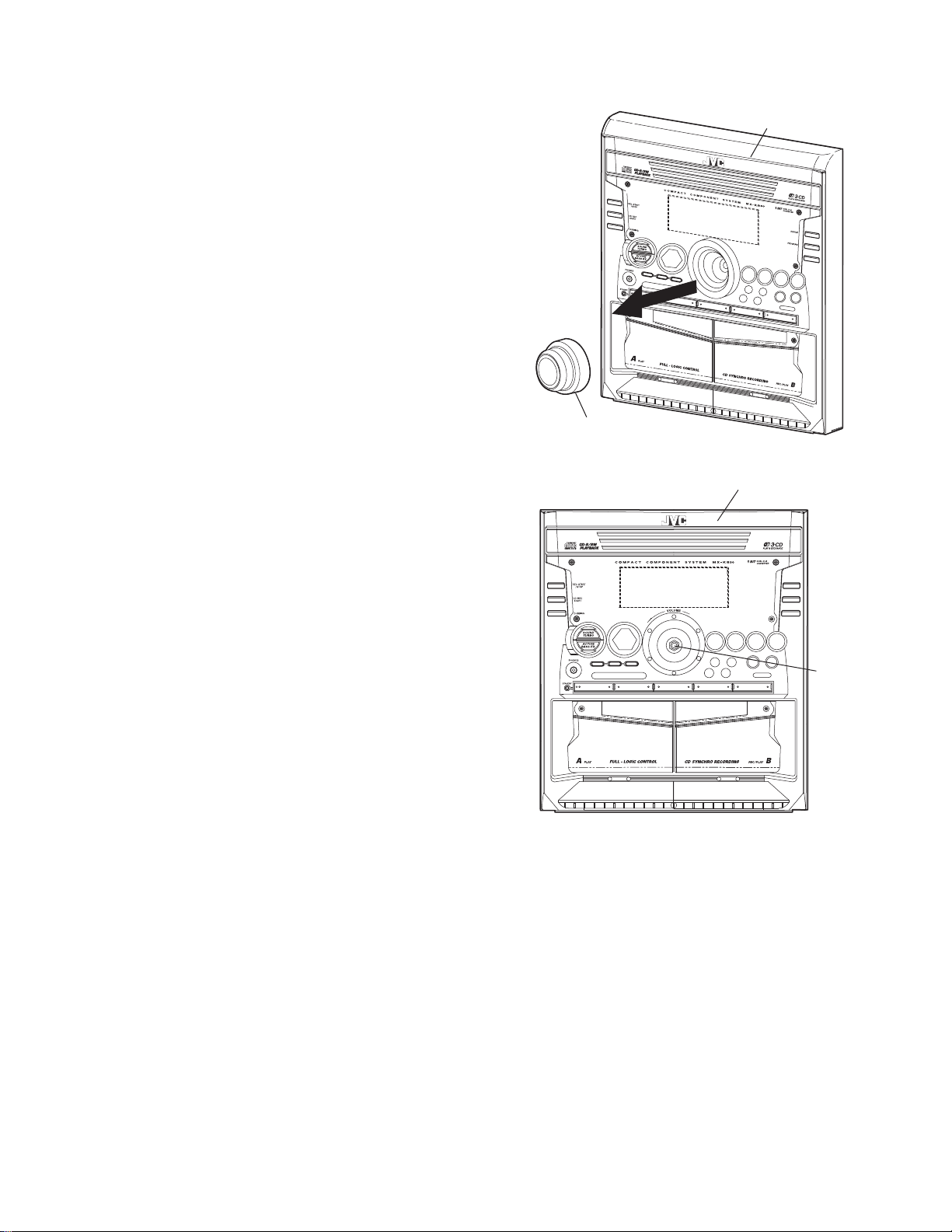

3.1.15 Removing the switch board and sound mode and CD function switch board

y

(See Fig.20 to 23)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Pull out the volume control knob from the front of the front

panel assembly.(Fig.22)

(2) Remove six screws Q retaining the front panel

assembly.(Fig.21)

(3) Remove the control/FL board.

(4) Remove eleven screws R retaining the switch (key 1)

board.(Fig.20)

(5) Remove two screws S retaining the sound mode and CD

function (key 2) switch board.(Fig.21)

Volume Knob

Front panel assembl

Fig.22

Front panel

assembly

Volume

shaft

Fig.23

(No.MB157)1-15

Page 16

3.1.16 Removing the leaf switches of the cassette deck mechanism

r

(See Fig. 19 and 26)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove the six screws Z that retain the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism.

(3) Turn the cassette deck mechanism upside down.

(4) Remove the solder from around the leaf switches.

(5) Pull out the leaf switches from the front side of the cassette

deck mechanism.

3.1.17 Removing the cassette deck main motor, and

replacing the main belts

(See Fig.19, 24 and 25)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z retaining the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism.

(3) Remove two screws t retaining the main motor from the

front side of the cassette deck.

Caution:

After attaching the main motor, check the orientation of

the motor and the polarity of the wires.

(4) From the backside of the cassette deck, remove the main

motor and two main belts.

Caution:

The lengths of the cassette A(playback only) and

cassette B(record/play) main belts are different. When

attaching the main belts, use the longer belt for cassette

A.

Cassette dec k mechanism

Cassette dec k mechanism

(Bac k side)

Main belt

(For B cassete)

Solder side of leaf switch

(Frint side)

t

Fig.24

Casset dec k main moto

Main belt

(For A cassete)

Fig.25

1-16 (No.MB157)

Cassette dec k mechanism

(Bac k side)

Fig.26

Page 17

3.1.18 Removing the cassette deck heads

(See Fig. 19 and 27)

• Prio r to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z that retain the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism and place it so that

the front side faces up.

(3) Remove the solder from the bottom side of the head

terminal and disconnect the wire.

(4) Remove screw U that retains the head.

(5) Remove screw V that retains the head.

(6) Hold the head and slide it in the direction of the arrow to

remove it.

3.1.19 Removing the 3-pin regulator and bridge diode

(See Q904

• Prio r to performing the following procedures, remove the top

cover and both sides board.

(1) Remove two screws A that connect the heat sink.

(2) Remove two screws W that connect the heat sink.

(3) Remove the solder fixing the the 3-pin terminal regulator

Q904

(4) Remove the solder fixing the 4-pin bridge diode (D901,

D914

, Q907, D901, D914 and Fig.28)

, Q907.

).

PB Head

Cassette dec k mechanism

(Front side)

V

U

Fig.27

WA

U

V

REC/PB Head

Fig.28

(No.MB157)1-17

Page 18

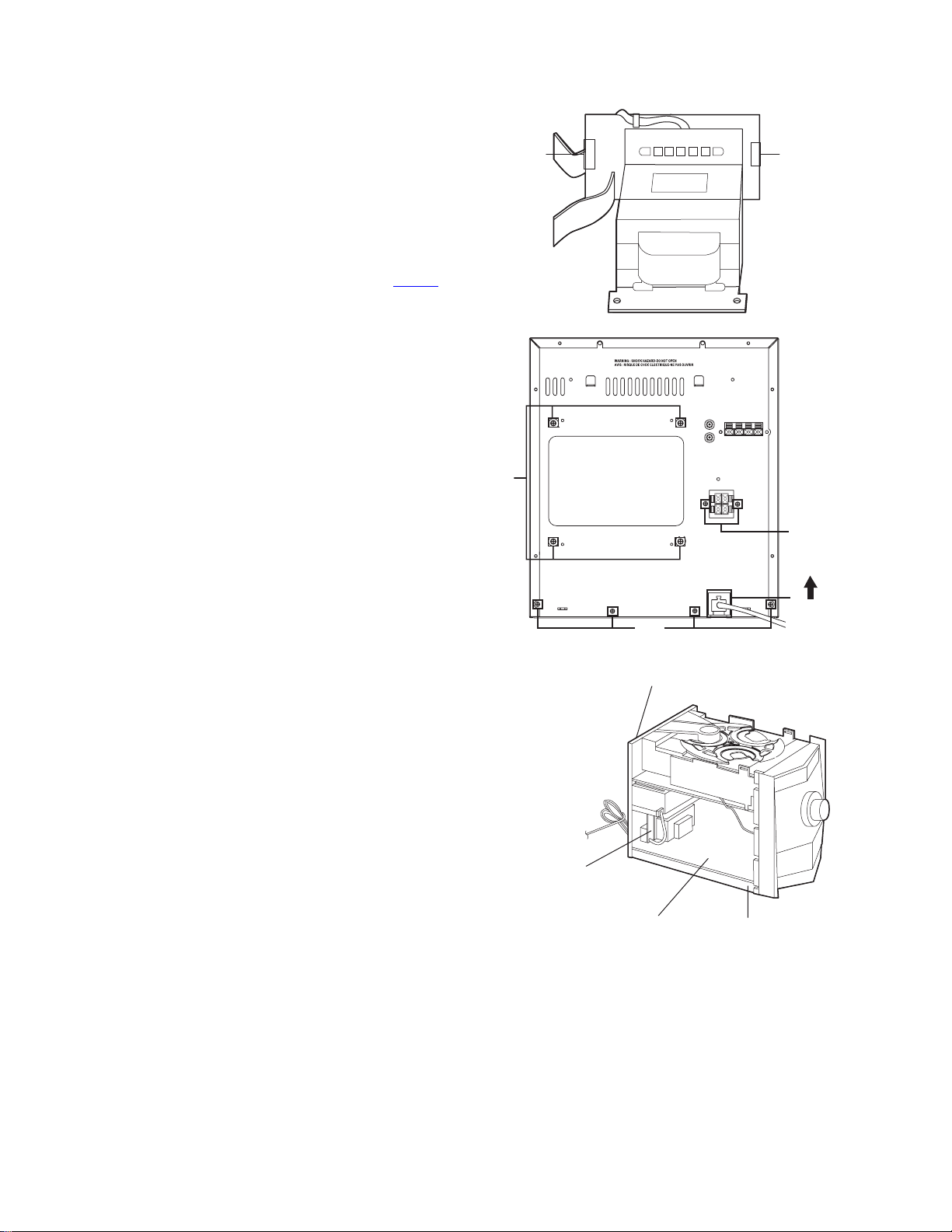

3.1.20 Removing the power amp and supply board and the power trans board

A

(See Fig. 3, 29 to 31)

• Prior to performing the following procedures, remove the top

cover and CD changer unit.

(1) Remove four screws B from the rear panel. (Fig.3)

(2) Pull the heat sink cover outward.

(3) Remove four screws AA from the rear panel between the

heat sink holder.

(4) Remove two screws X that retain the speaker terminals

and AUX terminal.

(5) Remove screws YY that retains the rear panel, and then

remove the rear panel.

(6) Disconnect the parallel wires from the connectors FW951

on the power trans board.

(7) Remove the clamp of AC power cord from the chassis.

(8) Remove four screws AB that retain the pow er trans board

and then remove the assembly.

Fuse(F952)

1.6A 250V

A

Fuse(F951)

3.15A 250V

Fig.29

Power amp and

supply PCB

X

Clamp

YY

Fig.30

Rear panel

AB Chassis

Fig.31

1-18 (No.MB157)

Page 19

SECTION 4

ADJUSTMENT

4.1 Measurement instruments required for adjustment

(1) Low frequency oscillator

This oscillator should have a capacity to output 0dB to

600ohm at an oscillation frequency of 50Hz-20kHz.

(2) Attenuator impedance : 600Ω

(3) Electronic voltmeter

(4) Frequency counter

(5) Wow flutter meter

(6) Test tape

VT712 : For Tape speed and wow flutter ( 3kHz)

VT703 : For Head angle (10kHz)

(7) Blank tape

TAPE I : AC-225

TAPE II : AC-514

(8) Torque gauge

For play and back tension forward : TW2111A

Reverse : TW2121A

Fast Forward and Rewind : TW2231A

(9) Test disc : CTS-1000(12cm),GRG-1211(8cm)

(10) Jitter meter

4.2 Measurement conditions

Power supply voltage : AC 120V (60Hz)

Measurement output terminal

: Speaker out

: TP101(Measuring for TUNER/DECK/CD)

: Dummy load 6Ω

4.3 Radio input signal

AM modulation frequency : 400Hz

Modulation factor : 30%

FM modulation frequency : 1kHz

Frequency displacement : 22.5kHz

4.4 Frequency Range

AM : 530kHz~1710kHz

FM : 87.5MHz~108MHz

4.5 Standard measurement positions of volume and

switch

Power : Standby (Light STANDBY Indicator)

Sound Turbo,A,BASS EX : OFF

Sound mode : OFF

Main VOL. : 0 Minimum

Travers mecha set position : Disc 1

4.6 Precautions for measurement

(1) Apply 30pF and 33k<ohm> to the IF sweeper output side

and 0.082<micro>F and 100kohm in series to the sweeper

input side.

(2) The IF sweeper output level should be made as low as pos-

sible within the adjustable range.

(3) Since the IF sweep er is a fixed device, there is no need to

adjust this sweeper.

(4) Since a ceramic oscillator is used, there is no need to per-

form any MPX adjustment.

(5) Since a fixed coil is used, there is no need to adjust the FM

tracking.

(6) The input and output earth systems are separated.

In case of simultaneously measuring the voltage in both of

the input and output systems with anelectronic voltmeter

for two channels, therefore, the earth should be connected

particularly.

(7) In the case of BTL connection amplifier, the minus terminal

of speaker is not for earthing. Therefore, be sure not to connect any other earth terminal to this terminal. This system

is of an OTL system.

(No.MB157)1-19

Page 20

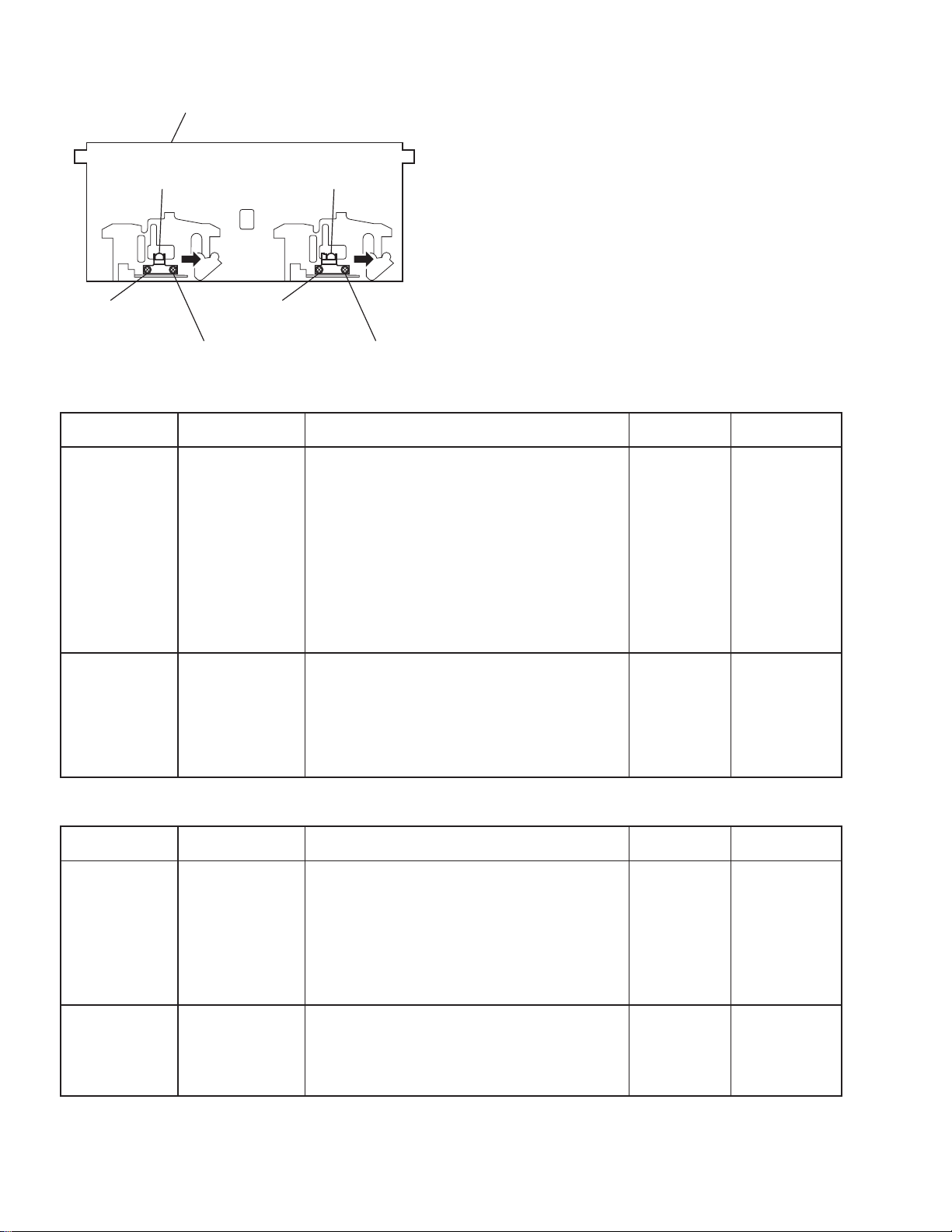

4.7 Arrangement of adjusting positions

Cassette deck mechanism

(Front side)

PB Head

k-A)

(Dec

Head azimuth screw

(Forward side)

Head azimuth screw

erse side)

(Rev

4.8 Tape recorder section

Items

Cassette Head

Azimuth Alignments

Measurement

conditions

Test tape

: VT703 (10kHz)

Measurement output

terminal

: Left and Right

speaker output

(6-ohm loaded)

or

Headphone Output

(32-ohm loaded)

REC/PB Head

(Deck-B)

Head azimuth screw

(Forw

ard side)

Head azimuth screw

1. Playback the test tape VT703 (10KHz) or equivalent.

2. Adjust the head azimuth screw to obtain maximum

3. Put on the screw lock paint after alignments.

(Reverse side)

Measurement method

output and both output of L / R is in 3dB.

Standard

values

Maximum output

Adjusting

positions

Adjust the

head azimuth

screw only

when the head

has been

changed.

Recording Bias

F

requency Alignment

Test tape

: TYPE I AC-514

Measurement output

terminal

1. Insert the recording tape in deck-B.

2. Starting the recording.

3. Adjust the oscillation frequency to 80KHz+/-3KHz by

core of Oscillation coil of L301.

: Erase head terminal

(CN308 8-Pin)

4.9 Tuner section

Items

AM Tracking

Alignments

Measurement

conditions

Input signal

: 530kHz

600kHz

Adjustment point

: Antenna coil (L2)

1. Set the Signal Generator signal to 530KHz the feed

to Loop Antenna.

2. Receiving the signal and the adjust the OSC coil (L2)

obtain the V.T is 1.40V +/-0.05V.

3. Change the receiving frequency to 600KHz (603KHz).

4. Adjust the Antenna coil ( L2 ) obtain maximum

sensitivity. (Adjust the SSG output to out of AGC range.)

AM IFT Alignments

Input signal

: 530kHz

Adjustment point

: IFT (T1)

1. Set the receiving frequency to 530KHz.

2. Feed the 450KHz signal to AM antenna input.

3.Adjust the IFT Block T1 obtain to maximum output.

(Adjust the SSG output to out of AGC range.)

Note: The adjustment of CD section is not required.

Measurement method

80kHz+/-3kHz

Standard

values

V. T

: 1.40V+/-0.05V

Maximum

sensitivity

Maximum output

Use the HighImpedance

Probe or

Frequency

counter input.

Adjusting

positions

Adjust the OSC

coil only when

the AM coil block

has been changed.

Adjust the IFT

only when the

IFT block has

been changed.

1-20 (No.MB157)

Page 21

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB157)1-21

Page 22

1-22 (No.MB157)

Page 23

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB157)

Printed in Japan

WPC

Page 24

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB15720042

MX-KB30

STANDBY/ON

SLEEP

AUX

FM MODE

FM /AM

CD

CD1CD2CD

3

PROGRAM/RANDOM

REPEAT

TAPE

TAPE

A/B

SOUND

VOLUME

MODE

FADE

ACTIVE

SOUND

MUTING

BASS EX.

TURBO

CA-MXKB30SP-MXKB30 SP-MXKB30

Area Suffix

J ------------------- U.S.A.

C ----------------- Canada

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.MB157

2004/2

Page 25

SPECIFICATION

Amplifier Output Power 150 W per channel, min. RMS, driven into 6 Ω at 1kHz, with no more

than 10% total harmonic distortion

Input Sensitivity/Impedance (1 kHz) AUX IN : 300 mV/50 kΩ

Speaker terminals 6 - 16 Ω

Phones 32 Ω - 1 kΩ

Cassette Deck Frequency Response

Type I (NORMAL)

Wow And Flutter 0.15% (WRMS)

CD Player CD Capacity 3 CDs

Dynamic Range 85 dB

Signal-To-Noise Ratio 85 dB

Wow And Flutter Unmeasurable

Tuner FM Tuner Tuning Range : 87.5 MHz - 108.0 MHz

AM Tuner Tuning Range : 530 kHz - 1 710 kHz

Unit Dimensions 267 mm × 305 mm × 433 mm (W/H/D)

Mass Approx. 8.7 kg (19.2 lbs)

Speaker Specifications

(each unit)

Power Specifications Power Requirements AC 120 V , 60 Hz

SP-MXKB30 3-way bass-reflex type

Type Woofer: 16 cm (6-5/16") cone × 1

Speaker Unit Mid: 5cm (2") cone × 1

Power Handling Capacity 150 W

Impedance 6 Ω

Frequency Range 45 Hz - 22,000 Hz

Sound pressure level 87 dB/W

Dimensions 244 mm × 321 mm × 258 mm (W/H/D)

Mass Approx. 3.6 kg (8.0 lbs)

Power Consumption 135 W (power on mode)

15 mW/ch output into 32 Ω

63 Hz - 12 500 Hz

(10-9/16" × 12-1/16" × 17-1/16")

Tweeter: 2 cm (13/16") dome × 1

·m

(9-5/8" × 12-11/16" × 10-3/16")

18 W (in Standby mode)

Design and specifications are subject to change without notice.

1-2 (No.MB157)

Page 26

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Pl ug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby a re critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB157)1-3

Page 27

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before instal lation, both sides of the laser di ode on the replacement optica l

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land sections before the flexible wir e is disconnected from the connector on the CD servo board. (If the

flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

CD changer

unit

1-4 (No.MB157)

Flexible cable

Soldering

Page 28

1.8 Importance administering point on the safety

Caution: For continued protection against risk of

fire, replace only with same type 3.15A/250V for

F951 and 1.6A/250V for F952. This symbol

specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F951 comme le meme type

que 3.15A/250V, et 1.6A/250V pour F952.

Ce sont des fusibles suretes qui functionnes rapide.

^

(No.MB157)1-5

Page 29

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB157)

Page 30

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Replacing the fuses

(See Fig.1)

• Prio r to performing the following procedure, remove the top

cover.

(1) Replace the fuse s inside.

Caution:

Be sure to use fuses with the specified ratings.

3.1.2 Replacing the power IC

(See Fig.2)

• Prio r to performing the following procedure, remove the top

cover.

(1) Remove the two screws A from the heat sink between the

power IC.

(2) Remove the solder fixing the power IC.

Fuse(F952)

1.6A 250V

Fuse(F951)

3.15A 250V

Fig.1

A

3.1.3 Replacing the heat sink cover

(See Fig.3)

(1) Remove four screws B from the rear panel.

(2) Pull the heat sink cover outward.

Fig.2

B

Fig.3

(No.MB157)1-7

Page 31

3.1.4 Removing the top cover

(See Fig.4 and 5)

(1) Remove six screws C that retain the top cover from the

panel rear of the body.

(2) Remove six screws D that retain the top cover from the two

sides of the body.

(3) Remove the top cover from the body by lifting it toward the

rear.

Top cover

C

C

Fig.4

Right Front panel assembly

Left Front panel assembly

D

C

D

DD

Fig.5

1-8 (No.MB157)

Page 32

3.1.5 Removing the CD changer unit

y

(See Fig.6 to 9)

• Prio r to performing the following procedures, remove the top

cover.

Caution:

Although the CD mechanism unit can be removed without

removing the CD tray panel, it is still recommended to remove

it in order to prevent damage.

• From the fron t panel side of this set, push in the sections

marked with arrows and pull out the CD tray toward the front.

• Remove the CD tray panel by pushing both of its extremities

upward in the direction of the arrows.

• Push the CD tray deep into the set.

(1) Disconnect the cord wires from the CD board CN703

and

CN203.

(2) From the rear of the set, remove two screws E three screws

F and four screws G on the front panel left and right side.

(3) Handle the CD changer unit rear, take out the unit.

CD tray panel

E

Antenna

terminal

F

Accessor

terminal

Fig.8

Fig.6

CD changer

unit

G

Fig.9

CD tray panel

Fig.7

(No.MB157)1-9

Page 33

3.1.6 Removing the front panel assembly

(See Fig.10 to 11)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Disconnect the parallel wire and the cord wire from the

connectors CN701

(2) Remove one screws H retaining the front panel assembly

onto the bottom of the body.

(3) Remove two screws I on the left and right side of the set

retaining the panel front from the bottom and then remove

then GND lug b that comes from the power amp and supply

PCB.

(4) Disengage the claws c on both sides of the front panel

assembly and then remove the assembly.

, CN101 on the power amp. board.

*

Fig.10

Power amp and

supply PCB

GND lug b

Fig.11

I

Claw c

1-10 (No.MB157)

Page 34

3.1.7 Removing the CD board

(See Fig.12 to 13)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Disconnect the wires from CN603A

on the CD board, which is located on the back side of the

CD changer unit.

(2) The four screws J that retain the CD board should be

removed.

(3) Remove the CD board by pulling it toward the side where

the CN601

(4) Using solder, short the CD pickup to connect to short

round.

Caution:

After re-connecting the wires, be sure to remove the

shorting solder from the GND connection.

(5) Disconnect the card wire from the connector CN601

main board and then remove the main board.

is located.

, CN603B and CN604

on the

CD PCB

J

J

J

Fig.12

CD PCB

CN601

Short round

Fig.13

(No.MB157)1-11

Page 35

3.1.8 Removing the CD changer mechanism assembly

(See Fig.14 to 15)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Turn the CD changer mech anism cover base an d remove

the screws d connecting the unit to the CD changer

mechanism assembly.

(2) Removing four screws e retaining the CD mechanism

holder assembly.

Caution:

When replacing the CD changer mechanism assembly, be

sure not to mistake the positions of the silver color and copper

color spring.

CD changer

unit

CD changer

mechanism

assembly

Fig.14

e (Silver color)

e (Silver color)

Fig.15

d

e (copper color)

e (copper color)

1-12 (No.MB157)

Page 36

3.1.9 Removing the CD pickup

r

(See Fig.16)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the CD changer mechanism.

(1) Widen the section f.

(2) While keeping the section f wide open, pu sh the sectio n g

in the direction of the arrow to remove the shaft, and th en

remove the CD pickup.

CD pic kup

f

3.1.10 Replacing the loading motor and rotor belt of the CD changer

(See Fig .17)

• Prio r to performing the following procedures, remove the top

cover.

• Al so open the CD changer tray.

(1) Remove the two screws L retaining the CD cha nger tray

loading motor.

(2) Remove the two screws M retaining the gear plate and take

it out, after remove the rotor belt from the pulley.

3.1.11 Replacing the CD turn table and removing the motor

(See Fig. 18)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

(1) Remove the one screws N retaining the CD (Turn table).

(2) Remove the two screws O retaining the sto pper brackets

on both sides of the CD changer unit.

(3) Remove the stopper brackets from both sides of the CD

changer unit.

(4) Pull out the CD tray from the CD chang er unit, all the way

and lift the tray (u/~ ward) to remove.

(5) Remove the gear and after push out the tray motor locker

and pull out the tray motor from the CD tray.

g

Shaft

Fig.16

M

L

Fig.17

Turn table motor

Motor locker

Obligue gea

Fig.18

(No.MB157)1-13

Page 37

3.1.12 Removing the cassette deck mechanism

(See Fig.19)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z retaining the cassette deck

mechanism.

3.1.13 Removing the earphone jack board

(See Fig.20)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove the screw with the washer, P that retains the

earphone jack PCB.

KEY 1

PCB

Front panel

assembly

Z

Z

Fig.19

Front panel

assembly

Earphone jack

PCB

P

3.1.14 Removing the control/FL board

(See Fig.21)

• Prior to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Q that retain the control/FL PCB from

the back of the front panel unit.

Q

KEY 2

PCB

Fig.20

Front panel

assembly

Q

Control/FL

PCB

Fig.21

1-14 (No.MB157)

Page 38

3.1.15 Removing the switch board and sound mode and CD function switch board

y

(See Fig.20 to 23)

• Prio r to performing the following procedures, remove the top

cover.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Pull out the volume control knob from the front of the front

panel assembly.(Fig.22)

(2) Remove six screws Q retaining the front panel

assembly.(Fig.21)

(3) Remove the control/FL board.

(4) Remove eleven screws R retaining the switch (key 1)

board.(Fig.20)

(5) Remove two screws S retaining the sound mode and CD

function (key 2) switch board.(Fig.21)

Volume Knob

Front panel assembl

Fig.22

Front panel

assembly

Volume

shaft

Fig.23

(No.MB157)1-15

Page 39

3.1.16 Removing the leaf switches of the cassette deck mechanism

r

(See Fig. 19 and 26)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove the six screws Z that retain the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism.

(3) Turn the cassette deck mechanism upside down.

(4) Remove the solder from around the leaf switches.

(5) Pull out the leaf switches from the front side of the cassette

deck mechanism.

3.1.17 Removing the cassette deck main motor, and

replacing the main belts

(See Fig.19, 24 and 25)

• Prior to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z retaining the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism.

(3) Remove two screws t retaining the main motor from the

front side of the cassette deck.

Caution:

After attaching the main motor, check the orientation of

the motor and the polarity of the wires.

(4) From the backside of the cassette deck, remove the main

motor and two main belts.

Caution:

The lengths of the cassette A(playback only) and

cassette B(record/play) main belts are different. When

attaching the main belts, use the longer belt for cassette

A.

Cassette dec k mechanism

Cassette dec k mechanism

(Bac k side)

Main belt

(For B cassete)

Solder side of leaf switch

(Frint side)

t

Fig.24

Casset dec k main moto

Main belt

(For A cassete)

Fig.25

1-16 (No.MB157)

Cassette dec k mechanism

(Bac k side)

Fig.26

Page 40

3.1.18 Removing the cassette deck heads

(See Fig. 19 and 27)

• Prio r to performing the following procedures, remove the top

cover and both sides board.

• Also remove the CD changer unit.

• Also remove the front panel assembly.

(1) Remove six screws Z that retain the cassette deck

mechanism. (Fig.19)

(2) Remove the cassette deck mechanism and place it so that

the front side faces up.

(3) Remove the solder from the bottom side of the head

terminal and disconnect the wire.

(4) Remove screw U that retains the head.

(5) Remove screw V that retains the head.

(6) Hold the head and slide it in the direction of the arrow to

remove it.

3.1.19 Removing the 3-pin regulator and bridge diode

(See Q904

• Prio r to performing the following procedures, remove the top

cover and both sides board.

(1) Remove two screws A that connect the heat sink.

(2) Remove two screws W that connect the heat sink.

(3) Remove the solder fixing the the 3-pin terminal regulator

Q904

(4) Remove the solder fixing the 4-pin bridge diode (D901,

D914

, Q907, D901, D914 and Fig.28)

, Q907.

).

PB Head

Cassette dec k mechanism

(Front side)

V

U

Fig.27

WA

U

V

REC/PB Head

Fig.28

(No.MB157)1-17

Page 41

3.1.20 Removing the power amp and supply board and the power trans board

A

(See Fig. 3, 29 to 31)

• Prior to performing the following procedures, remove the top

cover and CD changer unit.

(1) Remove four screws B from the rear panel. (Fig.3)

(2) Pull the heat sink cover outward.

(3) Remove four screws AA from the rear panel between the

heat sink holder.

(4) Remove two screws X that retain the speaker terminals

and AUX terminal.

(5) Remove screws YY that retains the rear panel, and then

remove the rear panel.

(6) Disconnect the parallel wires from the connectors FW951

on the power trans board.

(7) Remove the clamp of AC power cord from the chassis.

(8) Remove four screws AB that retain the pow er trans board

and then remove the assembly.

Fuse(F952)

1.6A 250V

A

Fuse(F951)

3.15A 250V

Fig.29

Power amp and

supply PCB

X

Clamp

YY

Fig.30

Rear panel

AB Chassis

Fig.31

1-18 (No.MB157)

Page 42

SECTION 4

ADJUSTMENT

4.1 Measurement instruments required for adjustment

(1) Low frequency oscillator

This oscillator should have a capacity to output 0dB to

600ohm at an oscillation frequency of 50Hz-20kHz.

(2) Attenuator impedance : 600Ω

(3) Electronic voltmeter

(4) Frequency counter

(5) Wow flutter meter

(6) Test tape

VT712 : For Tape speed and wow flutter ( 3kHz)

VT703 : For Head angle (10kHz)

(7) Blank tape

TAPE I : AC-225

TAPE II : AC-514

(8) Torque gauge

For play and back tension forward : TW2111A

Reverse : TW2121A

Fast Forward and Rewind : TW2231A

(9) Test disc : CTS-1000(12cm),GRG-1211(8cm)

(10) Jitter meter

4.2 Measurement conditions

Power supply voltage : AC 120V (60Hz)

Measurement output terminal

: Speaker out

: TP101(Measuring for TUNER/DECK/CD)

: Dummy load 6Ω

4.3 Radio input signal

AM modulation frequency : 400Hz

Modulation factor : 30%

FM modulation frequency : 1kHz

Frequency displacement : 22.5kHz

4.4 Frequency Range

AM : 530kHz~1710kHz

FM : 87.5MHz~108MHz

4.5 Standard measurement positions of volume and

switch

Power : Standby (Light STANDBY Indicator)

Sound Turbo,A,BASS EX : OFF

Sound mode : OFF

Main VOL. : 0 Minimum

Travers mecha set position : Disc 1

4.6 Precautions for measurement

(1) Apply 30pF and 33k<ohm> to the IF sweeper output side

and 0.082<micro>F and 100kohm in series to the sweeper

input side.

(2) The IF sweeper output level should be made as low as pos-

sible within the adjustable range.

(3) Since the IF sweep er is a fixed device, there is no need to

adjust this sweeper.

(4) Since a ceramic oscillator is used, there is no need to per-

form any MPX adjustment.

(5) Since a fixed coil is used, there is no need to adjust the FM

tracking.

(6) The input and output earth systems are separated.

In case of simultaneously measuring the voltage in both of

the input and output systems with anelectronic voltmeter

for two channels, therefore, the earth should be connected

particularly.

(7) In the case of BTL connection amplifier, the minus terminal

of speaker is not for earthing. Therefore, be sure not to connect any other earth terminal to this terminal. This system

is of an OTL system.

(No.MB157)1-19

Page 43

4.7 Arrangement of adjusting positions

Cassette deck mechanism

(Front side)

PB Head

k-A)

(Dec

Head azimuth screw

(Forward side)

Head azimuth screw

erse side)

(Rev

4.8 Tape recorder section

Items

Cassette Head

Azimuth Alignments

Measurement

conditions

Test tape

: VT703 (10kHz)

Measurement output

terminal

: Left and Right

speaker output

(6-ohm loaded)

or

Headphone Output

(32-ohm loaded)

REC/PB Head

(Deck-B)

Head azimuth screw

(Forw

ard side)

Head azimuth screw

1. Playback the test tape VT703 (10KHz) or equivalent.

2. Adjust the head azimuth screw to obtain maximum

3. Put on the screw lock paint after alignments.

(Reverse side)

Measurement method

output and both output of L / R is in 3dB.

Standard

values

Maximum output

Adjusting

positions

Adjust the

head azimuth

screw only

when the head

has been

changed.

Recording Bias

F

requency Alignment

Test tape

: TYPE I AC-514

Measurement output

terminal

1. Insert the recording tape in deck-B.

2. Starting the recording.

3. Adjust the oscillation frequency to 80KHz+/-3KHz by

core of Oscillation coil of L301.

: Erase head terminal

(CN308 8-Pin)

4.9 Tuner section

Items

AM Tracking

Alignments

Measurement

conditions

Input signal

: 530kHz

600kHz

Adjustment point

: Antenna coil (L2)

1. Set the Signal Generator signal to 530KHz the feed

to Loop Antenna.

2. Receiving the signal and the adjust the OSC coil (L2)

obtain the V.T is 1.40V +/-0.05V.

3. Change the receiving frequency to 600KHz (603KHz).

4. Adjust the Antenna coil ( L2 ) obtain maximum

sensitivity. (Adjust the SSG output to out of AGC range.)

AM IFT Alignments

Input signal

: 530kHz

Adjustment point

: IFT (T1)

1. Set the receiving frequency to 530KHz.

2. Feed the 450KHz signal to AM antenna input.

3.Adjust the IFT Block T1 obtain to maximum output.

(Adjust the SSG output to out of AGC range.)

Note: The adjustment of CD section is not required.

Measurement method

80kHz+/-3kHz

Standard

values

V. T

: 1.40V+/-0.05V

Maximum

sensitivity

Maximum output

Use the HighImpedance

Probe or

Frequency

counter input.

Adjusting

positions

Adjust the OSC

coil only when

the AM coil block

has been changed.

Adjust the IFT

only when the

IFT block has

been changed.

1-20 (No.MB157)

Page 44

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB157)1-21

Page 45

1-22 (No.MB157)

Page 46

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB157)

Printed in Japan

WPC

Page 47

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

MX-KB30

CD-ROM No.SML200402

STANDBY/ON

SLEEP

AUX

FM MODE

FM /AM

CD

CD1CD2CD

3

PROGRAM/RANDOM

REPEAT

TAPE

TAPE

A/B

SOUND

VOLUME

MODE

FADE

ACTIVE

SOUND

MUTING

BASS EX.

TURBO

CA-MXKB30SP-MXKB30 SP-MXKB30

Area Suffix

J ------------------- U.S.A.

C ----------------- Canada

Contents

Block diagram ------------------------------------------------------- 2-1

Standard schematic diagrams ---------------------------------- 2- 2

Printed circuit boards --------------------------------------------- 2- 8

COPYRIGHT 2004 VICTOR COMPANY OF JAPAN, LTD.

No.MB157SCH

2004/2

Page 48

In regard with component parts appearing on the silk-screen printed side (parts side) of

the PWB diagrams, the parts that are printed over with black such as the resistor ( ),

diode ( ) and ICP ( ) or identified by the " " mark nearby are critical for safety.

Page 49

< MEMO >

Page 50

Block diagram

AM/FM

ANT

AUX IN

JA302

IC1

LA1823

AM/FM-MPX

TUNER

IC2

LC72136N

PLL

Deck-A

PB-Head

TO

Deck-B

R/P-Head

TO

Cassette

Mechanism

TO

CD PICKUP

TO

SPINDLE

SLEED

TO

CD MECHA

CN307 JA302CN308CN305CN601CN602CN603

Q303

Bias osc

Q309~Q314

Mechan

Control

AN22000A

CD RF AMP

IC621

BA5936S

IC611

IC401

HA12273F

Tape PB/Rec

Q402,Q502

PB mute

IC402

74HC4094

Q401 REC

mute cont

IC103

TDA7440D

VOL,TONE,

SELECTOR

IC601

MN6627482WA

Digital Servo

Q101

AHB

IC102

BA15215F

Q201

AHB

CN306CN309CN604

TO AMP BOARD

TO FRONT BOARD

CN103

CN707

CN703

TO

AMP CN101

2-1

HEAD PHONE

FW1051

MAAIN BOARD

PHONE JACK

HJ1053

TO

(CN951)

FW951

TO FRONT BOARD

Transformer board

T951

TRANSFORMER

Page 51

TO

Headphone

CN101

Q101

AHB

IC102

BA15215F

Q201

AHB

CN306CN309CN604

TO AMP BOARD

TO FRONT BOARD

TO FRONT BOARD

AMP BOARD

CN103

CN707

CN703

TO

CN306

CN103

VFD

Q203

Mute

Q103

Mute

CN701

TO FRONT

CN701

IC701

MN101C350DFB

MCU

IC301

2CH Power Amp

STK412-030

TO AMP

CN701

CN701

IC702

IR Sensor

F702A

F701A

Speaker

Out

J303

TO

(FW951)

CN951

VOLUME

F702B

JOG KEY'S

F701B

r board

R

AC IN

CN707 CN703

TO MAIN

CN309

TO MAIN

CN604

2-2

Page 52

Standard schematic diagrams

Power transformer section

F952

2-3

Page 53

ams

C951

F952

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-4

Page 54

Main section

2-5

Page 55

2-6

Page 56

Amplifier

2-7

Page 57

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-8

Page 58

FL Display and CPU Control

2-9

Page 59

2-10

Page 60

CD section

2-11

Page 61

2-12

Page 62

Tuner section

2-13

Page 63

2-14

Page 64

Printed circuit boards

Main board (forward side)

2-15

Page 65

2-16

Page 66

Main board reverse side)

2-17

Page 67

2-18

Page 68

FL display and CPU board (forward side)

2-19

Page 69

ard side)

2-20

Page 70

FL display and CPU board (reverse side)

2-21

Page 71

(reverse side)

2-22

Page 72

Power amp. board

2-23

Page 73

Power trans board

2-24

Page 74

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB157SCH)

Printed in Japan

WPC

Page 75

PARTS LIST

t

[ MX-KB30 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

MB157

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD changer mechanism assembly and parts list (Block No.MA)

Cassette mechanism assembly and parts list (Block No.MP)

Electrical parts list (Block No.01~05)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 5

3- 7

3- 8

3-12

- Note-

Parts number of normal capacitors and normal resistors doesn't listed on the parts lis

3-1

Page 76

Exploded view of general assmbly and parts list

5

2

8

Block No.

1

M

M

1

M

64

37

10

21

12

11

49

39

60

64

57

9

3

54

8

5

15

30

6

16

Main board

52

34

Volme board

2

51

56

33

Headphone board

55

13

54

25

22

61

54

22

51

36

17

62

41

9

29

20

54

18

51

58

6

7

59

Front board

64

51

3

55

Key board

41

20

4

3-2

Page 77

54

5

64

64

38

54

54

32

Front board

51

64

51

3

57

64

51

64

35

Amp. board

55

Key board

6

5

15

9

41

20

4

30

9

51

24

8

26

50

F952

F951

28

53

54

64

14

27

Transformer board

52

31

64

54

52

19

63

40

63

65

66

23

3-3

Page 78

General assembly

Block No. [M][1][M][M]

Symbol No.

1 ------------ CD CHANGER MECH

2 BI109835010201 BADGE JVC

3 BI300856010101 WASHER

4 BI301789010101 BUSHING 5RF-5B

5 BI1074751301U1 CAP CD3

6 BI1074751201U1 CAP CD2

7 BI1074751101U1 CAP CD1

8 BI1074751401U1 CAP OPEN CLOSE

9 BI201789010102 LOCK SPRING CASSETTE(x2)

10 BI107468010101 CASS DOOR WIN L

11 BI107467010101 CASS DOOR WIN R

12 BI107466010101 CASS HOLDER L

13 BI107465010101 CASS HOLDER R

14 ------------ CASSETTE MECHA CMAT6Z219A

15 BI107477010101 CD EJECT BUTTON

16 BI107463010201 CD FITTING

17 BI107471010101 CD SEL BUTTON A

18 BI202547010201 CHAS MAIN

19 BI107483010101 HEATSINK COVER

20 BI301388010101 DAMPING GEAR (x2)

21 BI1074640901U1 DISPLAY WINDOW

22 BI103362020102 EVA FOOT (x2)

23 BI301779010101 EVA FOOT C (x2)

24 BI107473010101 FRAME CD SELECT

25 BI107462910201 FRONT PANEL

26 BI402991 FUSE F952 1.6A 250V

27 BI403011 FUSE F951 3.15A 250V

28 BI202556010102 HEAT SINK

29 BI104143010102 HOLDER LOCK L

30 BI104143010202 HOLDER LOCK R

31 BI202560010101 HOLDER R

32 BI202553010101 HOLDER L

33 BI107480010101 HOLDER SOUND MODE

34 BI202592010101 HOLDER BRACKET

35 BI202555010101 HEAT SINK AMP

36 BI107485010101 INDICATOR STANDBY

37 BI109819030201 KNOB VOLUME TAB

38 BI202548010101 METAL COVER

39 BI301922010101 MIRROR SHEET

40 BI2025500501U1 REAR PANEL

41 BI104142010102 PLATE LOCK 1 (x2)

49 BI107482010101 RING VOLUME

50 BIPMW001101S3 SCREW 4.0XL6 METAL(x4)

51 BIBT000418 SCREW

52 BIRT000617B3 SCREW

53 BIBT0006091 SCREW

54 BIRM000603S3 SCREW

55 BIKT000627 SCREW (x4)

56 BI107470010101 SELECT BUTTON L

57 BI107469010101 SELECT BUTTON R

58 BI107472010201 BUTTON SOUND MODE

59 BI107478010101 SOURCE BUTTON A

60 BI202566010101 SPRING L

61 BI202565010101 SPRING R

62 BI107476010101 SUB BUTTON SET

63 BIRM000604S3 SCREW RH/TS 3XL8(x8)

64 BIRT000611B3 SCREW RH/TS 3XL8(x18)

65 BI1400864 POWER CORD UL/CSA

66 BI211041004001W TRANSFORMER T951 UL/CSA

Part No. Part Name Description Local

2.6XL8

PLASTIC(x23)

3.0XL10

PLASTIC(x14)

3.0XL14

PLASTIC(x2)

3.0XL6

METAL(x19)

3-4

Page 79

CD changer mechanism assembly and parts list

BI3400931

M

Block No.

7

6

8

9

10

12

11

2

13

A

M

M

1

23

24

25

28

26

27

33

35

29

34

14

15

19

32

22

16

21

37

38B

17

18

20

36

37

38A

3

4

5

37

38A

37

38B

39

3-5

Page 80

CD changer mechanism

Block No. [M][A][M][M]

Symbol No.

1 BIAJ7200601J BASE-MAIN 1X1

2 BIAJ6100601P BRKT-CHUCK

3 BI3302000158 MAGNET-FERRITE

4 BIAJ7200601L TABLE-CHUCK 1X4

5 BIAJ6300601A SHEET-CHUCK (x3)

6 BIAJ7300601B BELT-LOAD

7 BIAJ6600601N GEAR-SYNCRO 1X2

8 BIAJ6600601L GEAR-CONVERT 1X4

9 BIAJ6600601M GEAR-TRAY 1X4

10 BIAJ6600601R GEAR-CAM 1X2

11 BIAJ6600601K GEAR-LOAD 1X4

12 BIAJ6600601J GEAR-PULLEY 1X4

13 BIAJ7200601N SLIDER-CAM 1X4

14 BI3405000101 SWITCH-MICRO (x2)

15 BI3711003379

16 BIAJ4100601K PCB-SW

17 BIAJ6100601K PULLEY-MOTOR 1X4

18 BIAJ3100601F MOTOR-DC

19 BI3710001248 CONNECTOR-SOCE

20 BI3711003692

21 BI3708001163 CONNECTOR-FPC

22 BIAJ4100601L PCB-MECHA

23 BIAJ7200601P TRAY-ROULETTE 1X2

24 BIAJ7200601Q TRAY-DISC 1X2

25 BIAJ6600601Q GEAR-ROULETTE 1X4

26 BIAJ6600601P GEAR-WORM 1X2

27 BIAJ3100601K MOTOR-LOADING

28 BIAJ6300601B SHEET-MOTOR

29 BIAJ3900601A WIRE-ROULETTE

32 BIAJ3900601B WIRE-TRAY

33 BI3711000003

34 BIAJ4100601J PCB-SENSOR

35 BIAJ3200601A SENSOR-ROULETTE

36 BIAJ9050605F CMS-B31NG6U

37 BIAJ6000601F SCREW (x4)

38A BIAJ7300601F RUBBER-B31Y (x2)

38B BIAJ7300601D RUBBER-B31 (x2)

39 BIAJ7200602F LEVER-LIFTER 1X2

Part No. Part Name Description Local

CONNECTORHEADE

CONNECTORHEADE

CONNECTORHEADE

3-6

Page 81

Cassette mechanism assembly and parts list

CMAT6Z219A

L SIDE

TYPE

10

Block No.

M

M

M

P

3

9

4

5

2

4

8

6

8

5

L SIDE

7

R SIDE

Cassette mechanism

Block No. [M][P][M][M]

Symbol No.

1 BIF513-858 PLATE HD BLK

2 BIF525-346 MTR MAIN BLK

3 BIF567-843 PCB CONTROL BLK

4 BIUE20P-12 LEAF SWITCH (x3)

5 BIF522-063 CLUTCH ASY BLK (x2)

6 BIFF19N-31 MAIN BELT

7 BIF514-35 ROLLIER PINCH B (x2)

8 BIFF19S-31 F/R BELT MO (x2)

9 BIFF19N-22 MAIN BELT

10 BIF513-855 PLATE HD BLK

Part No. Part Name Description Local

1

7

R SIDE

TYPE

Note: Parts listed on the Parts List below can be supplied.

However, parts that are not listed below cannot be supplied

individually but only by purchasing the whole Cassette

Mechanism Assembly Unit. (When ordering, use the Parts No.

CMAT6Z219A for Cassette Mechanism Assembly Unit.)

3-7

Page 82

Electrical parts list

Main board

Block No. [0][1][0][0]

Symbol No.

IC1 LA1823 IC BI113251

IC2 LC72136N IC BI113271

IC101 TDA7440D IC BI113231

IC102 BA15218F IC BI113241

IC401 HA12237 IC BI115011

IC402 M74HC4094B IC BI114371

IC601 MN6627482WA IC BI114621

IC611 AN22000A IC BI113161

IC621 BA5936S IC BI113141

IC631 NJM7808FA IC BI110061

Q1 KTC3194 TRANSISTOR BI2KTC3194P0008

Q2 KTC3195 TRANSISTOR BI2KTC3195YP000

Q3 DTC114YS TRANSISTOR BI2DTC114YSP002

Q4 DTC114YS TRANSISTOR BI2DTC114YSP002

Q5 KRA107 TRANSISTOR BI2KRA107MP0008

Q7 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q8 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q101 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q201 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q302 KTC3200GR TRANSISTOR BI2KTC3200P0008

Q303 KTC3203Y TRANSISTOR BI2KTC3203YP000

Q304 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q305 DTC144ES TRANSISTOR BI2DTC144ESP002

Q308 DTC144ES TRANSISTOR BI2DTC144ESP002

Q309 KTA1273 TRANSISTOR BI2KTA1273P0008

Q310 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q311 KTA1273 TRANSISTOR BI2KTA1273P0008

Q312 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q313 KTA1273 TRANSISTOR BI2KTA1273P0008

Q314 DTC114YS TRANSISTOR BI2DTC114YSP002

Q316 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q317 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q318 DTC114YS TRANSISTOR BI2DTC114YSP002

Q319 KA1270 TRANSISTOR BI2KTA1270YP000

Q321 DTC114YS TRANSISTOR BI2DTC114YSP002

Q322 KRA107M TRANSISTOR BI2KRA107MP0008

Q327 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q401 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q402 2SD2144S TRANSISTOR BI2SD2144SVP002

Q403 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q404 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q502 2SD2144S TRANSISTOR BI2SD2144SVP002

Q503 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q504 KTC3199GR TRANSISTOR BI2KTC3199GP000

Q601 KTA1267GR TRANSISTOR BI2KTA1267GP000

D1 1SS133 FR DIODE BI31SS133M0007

D2 1SS133 FR DIODE BI31SS133M0007

D3 1SS133 FR DIODE BI31SS133M0007

D4 1SS133 FR DIODE BI31SS133M0007

D5 1SS133 FR DIODE BI31SS133M0007

D6 1SS133 FR DIODE BI31SS133M0007

D7 BI3SVC203SPP000 VARACTOR DIODE SVC203

D8 BI3SVC203SPP000 VARACTOR DIODE SVC203

D9 1SS133 FR DIODE BI31SS133M0007

D10 1SS133 FR DIODE BI31SS133M0007

D50 1SS133 FR DIODE BI31SS133M0007

D51 1SS133 FR DIODE BI31SS133M0007

D306 MTZJ9.1B Z DIODE BI3MTZJ9.1BM000

D307 MTZJ5.1B Z DIODE BI3MTZJ5.1BM0007

D308 1SS133 FR DIODE BI31SS133M0007

D309 1SS133 FR DIODE BI31SS133M0007

D310 1SS133 FR DIODE BI31SS133M0007

D311 1SS133 FR DIODE BI31SS133M0007

D312 1SS133 FR DIODE BI31SS133M0007

D313 1SS133 FR DIODE BI31SS133M0007

D314 1SS133 FR DIODE BI31SS133M0007

D321 1SS133 FR DIODE BI31SS133M0007

D322 1SS133 FR DIODE BI31SS133M0007

D323 1N4001 FR DIODE BI31N40011

D324 1SS133 FR DIODE BI31SS133M0007

Part No. Part Name Description Local

Symbol No.

D328 1SS133 FR DIODE BI31SS133M0007

D329 1SS133 FR DIODE BI31SS133M0007

D330 1SS133 FR DIODE BI31SS133M0007

D401 1SS133 FR DIODE BI31SS133M0007

D402 1SS133 FR DIODE BI31SS133M0007

D605 1N4001 FR DIODE BI31N40011

R601 BIRC1520165A005 CHIP JUMPER 0

R607 BIRC0000165A005 JUMPER 0

R608 BIRC0000165A005 JUMPER 0

R609 BIRC0000165A005 JUMPER 0

R641 BIRC0000165A005 JUMPER 0

R669 BIRC0000165A005 JUMPER 0

L1 BICH473500KM019 CAP 0.047uH

L2 BI605082 AM PACK COIL 7RBW

L3 BI7A0170 FM COIL

L4 BI7A0171 FM COIL

L5 BI26101000KM002 FIXED INDUCTOR 100uH

L6 BI26220000KM002 FIXED INDUCTOR 22uH

L50 BI26221000KM002 FIXED INDUCTOR 220uH

L301 BI605071 BIAS-COIL 864306

L304 BI18A843556N000 FILTER BEAD 843556 TB36

L306 BI18A843556N000 FILTER BEAD 843556 TB36

L307 BI18A843556N000 FILTER BEAD 843556 TB36

L601 BI26100000KM002 COIL 10uH

L602 BI26100000KM000 FIXED INDUCTOR 10uH

T1 BI2901541 CO. FILTER AC009 450KHz

BF601 BI18A843556N000 FILTER BEAD 843556 TB36

CF1 BI29LT10.7MP015 CER.FILTER 10.7MHz

CF2 BI29LT10.7MP015 CER.FILTER 10.7MHz

CF3 BI29JT10.7MP015 C FILTER 10.7MHz

CN305 BI12S110023U FFC CONNECTOR 11P V 1.25mm