Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MX-KA7

MX-KA7

CA-MXKA7SP-MXKA7 SP-MXKA7

Contents

Safety precautions ---------------------------- 1- 2

Preventing static electricity ----------------- 1- 3

Important for laser products ---------------- 1- 4

Disassembly method ------------------------ 1- 5

Adjustment method -------------------------- 1- 18

Flow of functional

operation until TOC read -------------- 1- 20

Area Suffix

JW ........ Mexico, Panama

Maintenance of laser pickup -------------- 1- 21

Replacement of laser pickup -------------- 1- 21

Description of major ICs ------------------- 1- 22

Wiring connection ---------------------------- 1- 33

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No. MB039

2003/11

Page 2

MX-KA7

1. This design of this product contains special hardware and many circuits and components specially for

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the

Safety Precautions

safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personnel only.

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacture of responsibility for personal injury or property damage

resulting therefrom.

characteristics are often not evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are identified in the Parts List of

Service Manual. Electrical components having such features are identified by shading on the

!

schematics and by (

which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or other hazards.

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention

of electric shock and fire hazard. When service is required, the original lead routing and dress should

be observed, and it should be confirmed that they have been returned to normal, after re-assembling.

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock. Do not use a line isolation

transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each exposed metal parts of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground. Any leakage current must not

exceed 0.5mA AC (r.m.s.)

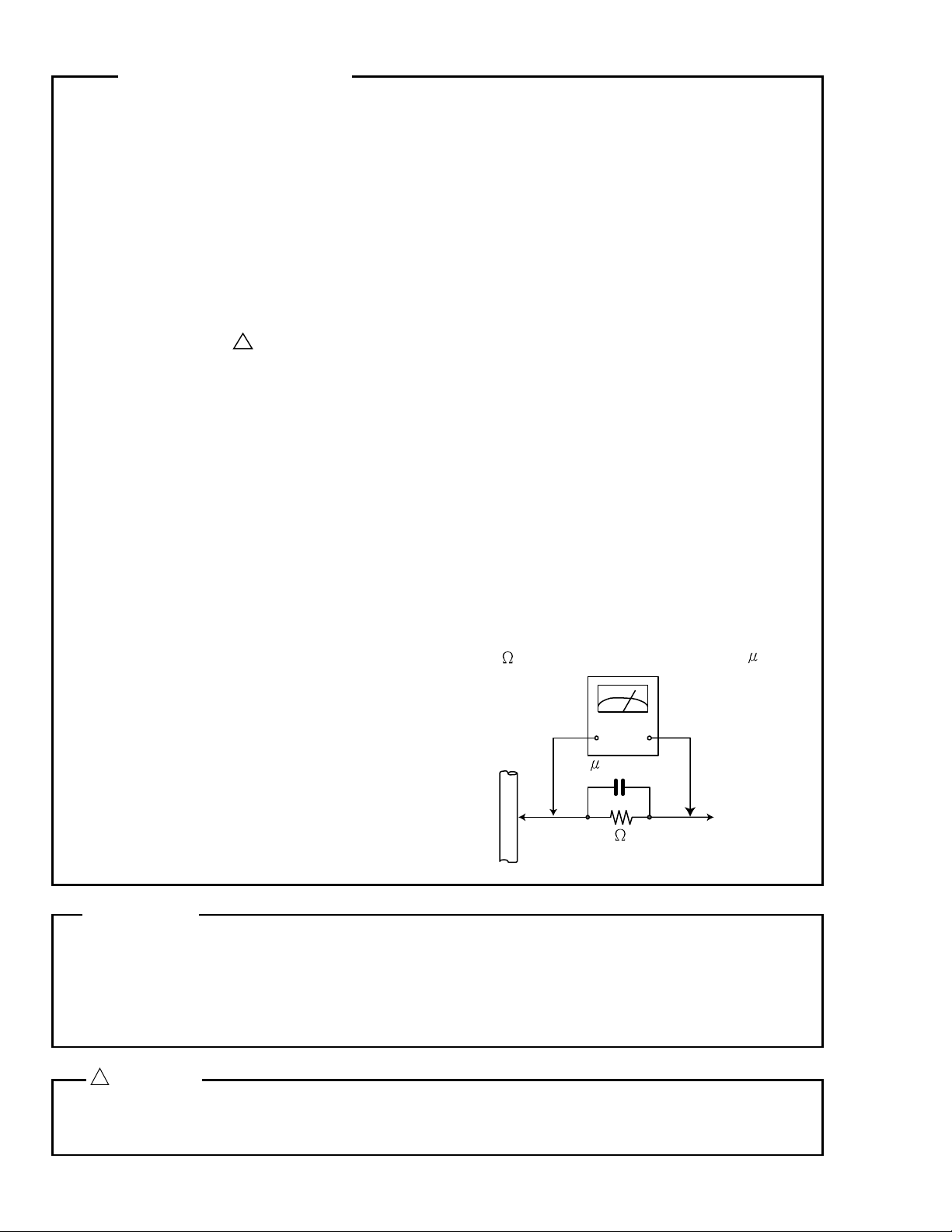

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or

more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F ACtype capacitor between an exposed metal part

and a known good earth ground. Measure the AC

voltage across the resistor with the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly any exposed metal part

having a return path to the chassis, and meausre

the AC voltage across the resistor. Now, reverse

the plug in the AC outlet and repeat each

measurement. Voltage measured Any must not

exceed 0.75 V AC(r.m.s.). This corresponds to 0.5

mA AC(r.m.s.).

) on the Parts List in the Service Manual. The use of a substitute replacement

AC VOLTMETER

(Having 1000

ohms/v

olts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

each exposed

metal part.

1-2

Good earth ground

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

CAUTION

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

Preventing static electricity

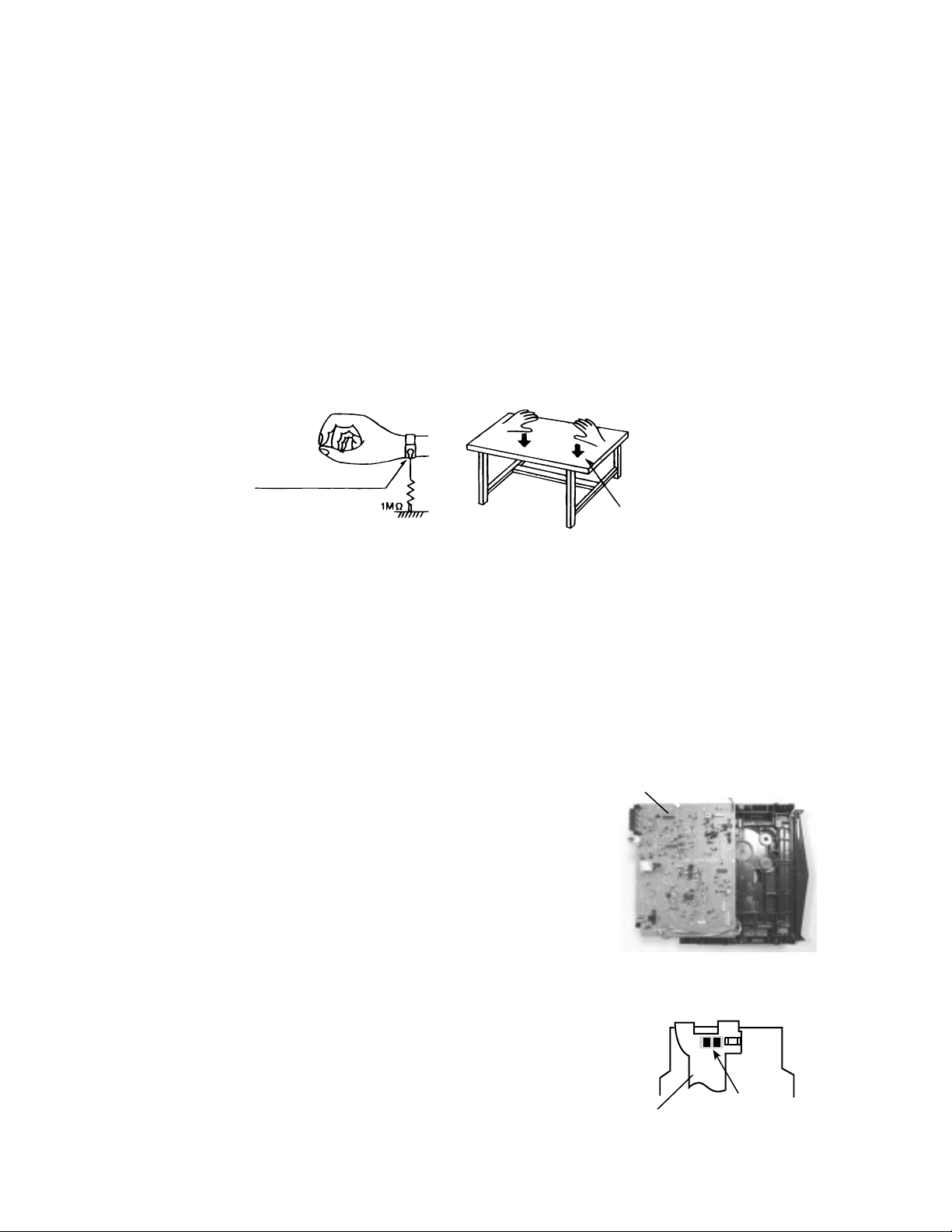

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is

discharged, can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when

performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity

of the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it

before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

MX-KA7

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The testers internal power

source can easily destroy the laser diode.

4. Handling the CD changer unit (optical pickup)

1. Do not subject the CD changer unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text.

Remove the anti-static pin when replacing the CD changer

unit. Be careful not to take too long a time when attaching it

to the connector.

3. Handle the flexible cable carefully as it may break when

subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that

adjusts the laser power. Do not turn it.

CD changer

unit

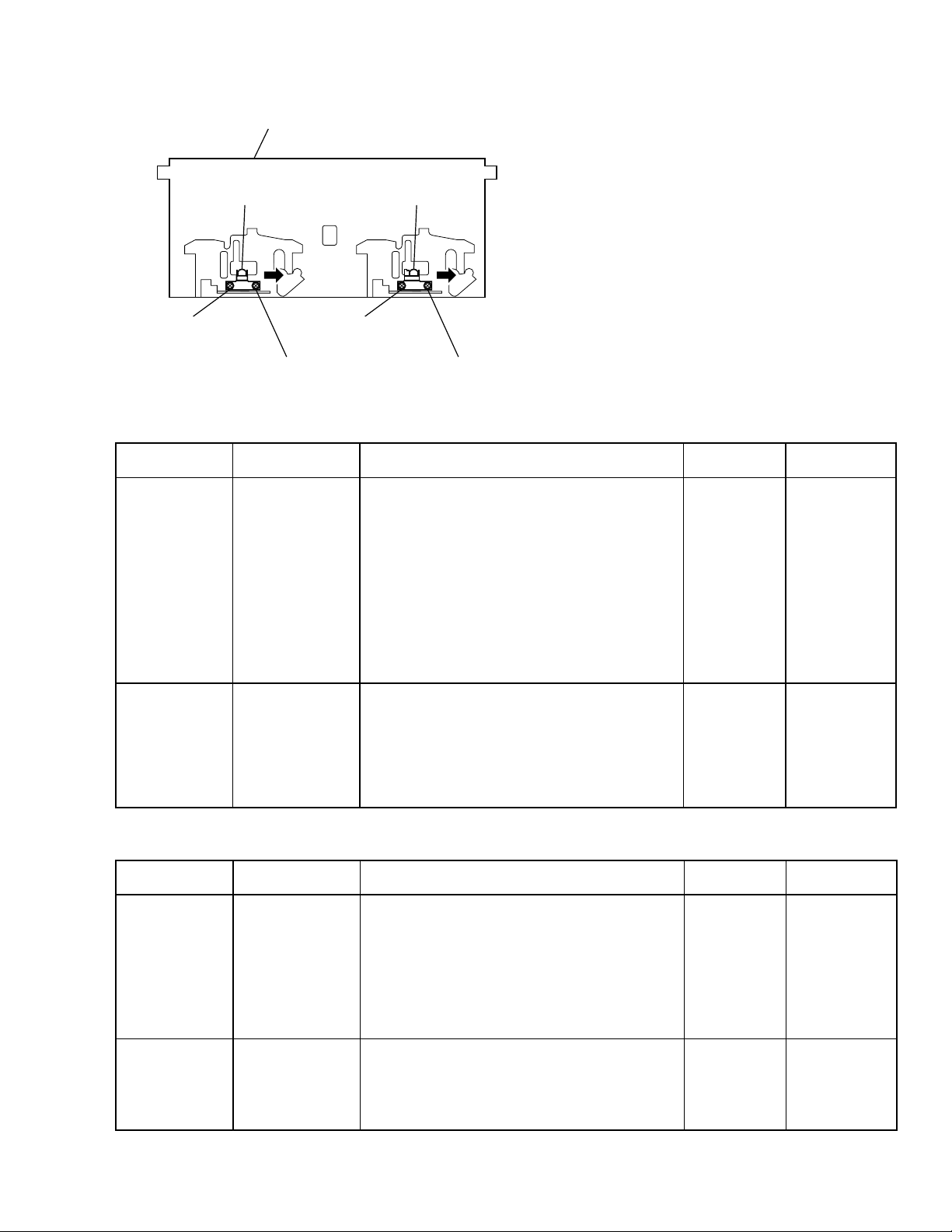

Attention when traverse unit is decomposed

Please refer to “Disassembly method” in the text for

*

pick up and how to detach the CD changer mechanism.

1. Remove the CD changer unit.

2. Disconnect the harness from connector on the CD motor

board.

3. Solder is put up before the card wire is removed from connector

Cn601on the main board as shown in Fig.1 and Fig. 2.

(When the wire is removed without putting up solder, the

CD pick-up assembly might destroy.)

4. Please remove solder after connecting the card wire with

CN601 when you install picking up in the substrate.

Flexible cable

Fig.1

Soldering

Fig.2

1-3

Page 4

MX-KA7

Important for laser products

1. CLASS 1 LASER PRODUCT

2. DANGER :

lock failed or defeated. Avoid direct exposure to beam.

3. CAUTION :

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4. CAUTION :

laser radiation and is equipped with safety switches

which prevent emission of radiation when the drawer is

open and the safety interlocks have failed or are

defeated. It is dangerous to defeat the safety switches.

Invisible laser radiation when open and inter

There are no serviceable parts inside the

The compact disc player uses invisible

5. CAUTION :

able to function.

6. CAUTION :

of procedures other than those specified herein may

result in hazardous radiation exposure.

!

CAUTION Please use enough caution not

If safety switches malfunction, the laser is

Use of controls, adjustments or performance

to see the beam directly or touch

it in case of an adjustment or

operation check.

FUSE CAUTION

CAUTION:

REPLACE WITH SAME TYPE

AND RATING FUSE (S).

ATTENTION:

REMPLACER PAR UN(LES)

FUSIBLE(S) DE MEME TYPE

ET DE MEME VALEUR

1-4

Page 5

MX-KA7

Disassembly method

Commence disassembly of the set by removing the main units and then proceed to the components

and assemblies inside the units.

Replacement of the fuses and the power IC

Top cover

CD changer unit

Front panel assembly

Chassis unit

CD changer unit

Removing the main PCB

Removing the CD changer mechanism assembly

Removing the CD pickup

Replacing the loading motor and belt of the CD changer tray

Replacing the CD tray rotor belt of CD changer, and removing the motor

Front panel assembly

Removing the cassette deck mechanism

Removing the earphone jack PCB

Removing the control/FL PCB

Removing the switch PCB and ACTIVE BASS EX. switch PCB

Removing the cassette deck main motor, and replacing the main belts

Removing the leaf switches of the cassette deck mechanism

Removing the cassette deck heads

Chassis unit

Removing the 3-pin regulator

Removing the power amp and supply PCB and the Power Trans PCB

Removing the sub power PCB

1-5

Page 6

MX-KA7

<Disassembly of the main blocks of the set>

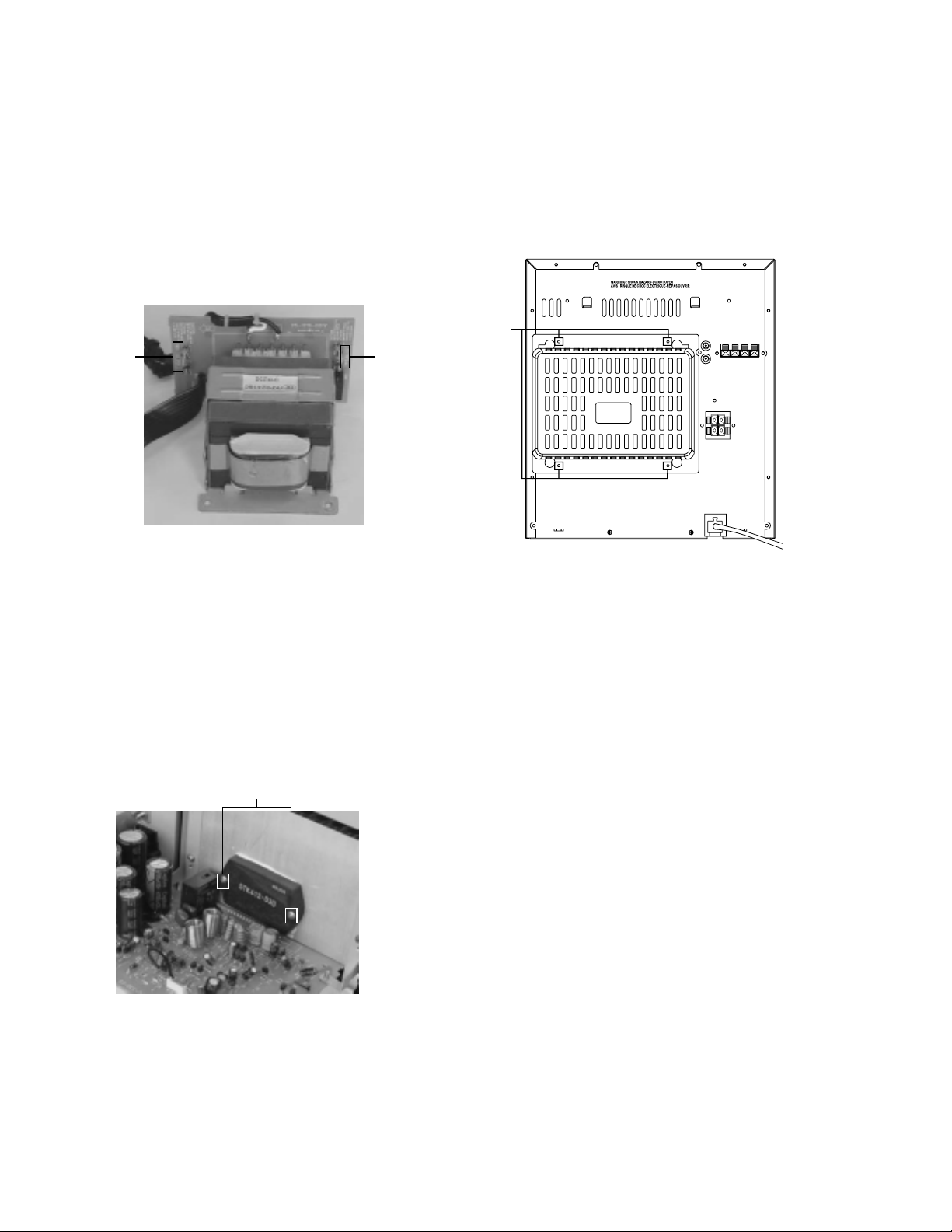

Replacement of the fuses and the power IC

Replacing the fuses (See Fig.1)

Prior to performing the following procedure, remove

the top cover.

1. Replace the fuses inside.

Replacing the heat sink cover (See Fig.3)

1. Remove four screws B from the rear panel.

2. Pull the heat sink cover outward.

[Caution]

Be sure to use fuses with the specified

ratings.

Fuse (F952)

1.6A 250V

Fig.1

Replacing the power IC (See Fig.2)

Prior to performing the following procedure, remove

the top cover.

Remove the two screws A from the heat sink between

1.

the power IC.

2. Remove the solder fixing the power IC.

B

Fuse (F951)

3.15A 250V

Fig.3

1-6

A

Fig.2

Page 7

C

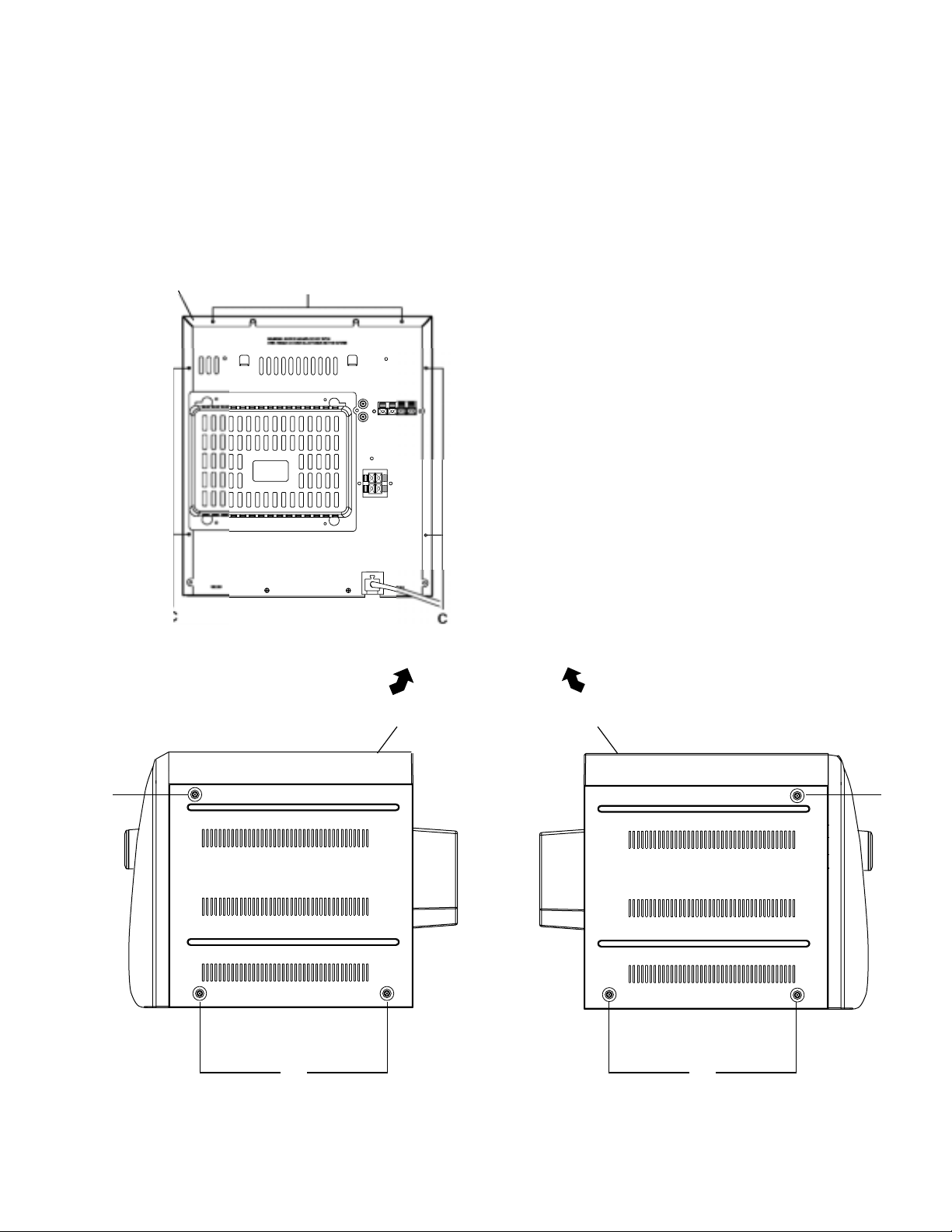

Removing the top cover

(See Fig.4 and 5)

1. Remove six screws C that retain the top cover from

the panel rear of the body.

2.

Remove six screws D that retain the top cover from

the two sides of the body.

3. Remove the top cover from the body by lifting it

toward the rear.

MX-KA7

Top cover

C

Fig.4

Right Front panel assembly

Left Front panel assembly

D

D

Fig.5

D

D

1-7

Page 8

MX-KA7

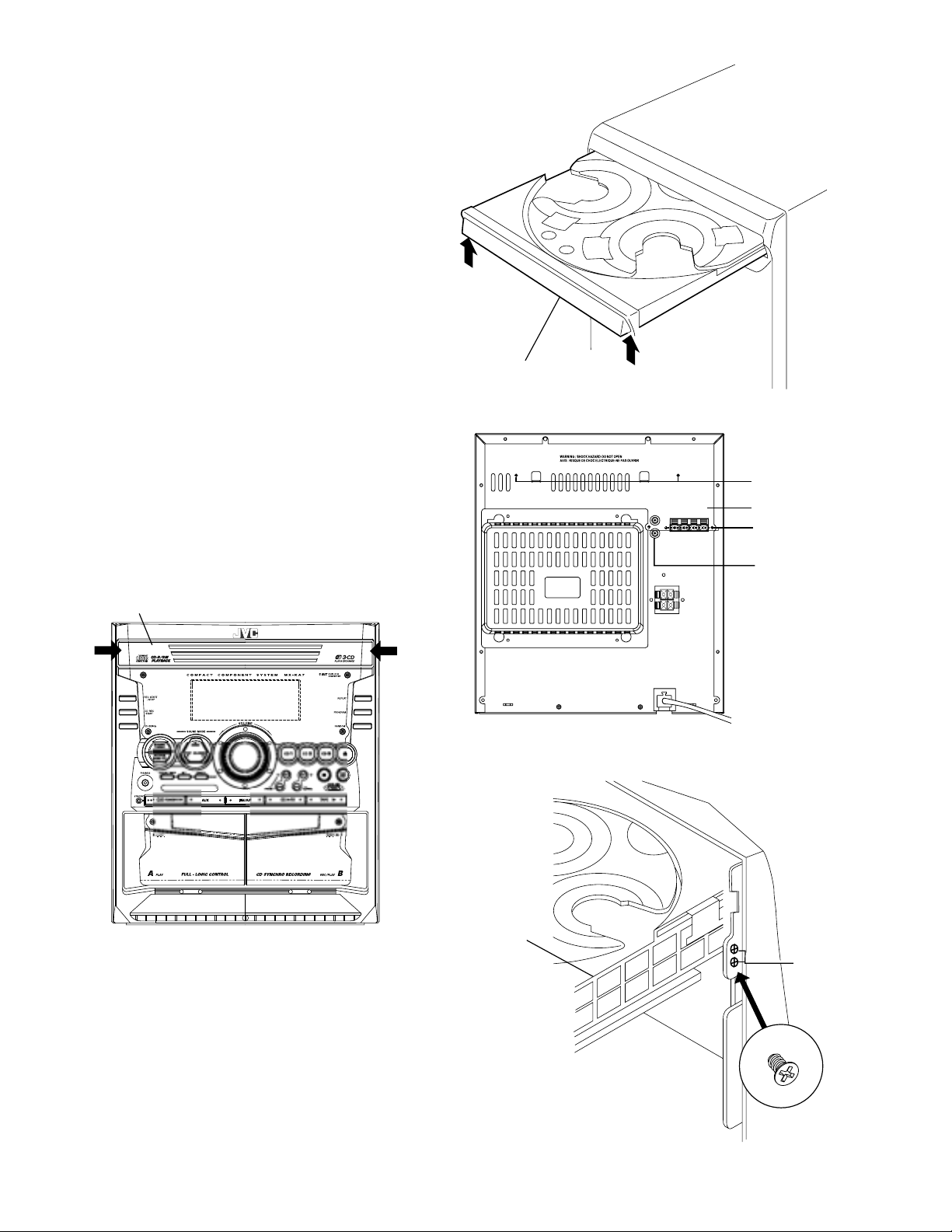

Removing the CD changer unit

Prior to performing the following procedures, remove

the top cover.

(See Fig.6 to 9)

[Caution]

Although the CD mechanism unit can be

removed without removing the CD tray

panel, it is still recommended to remove it

in order to prevent damage.

a. From the front panel side of this set, push in the

sections marked with arrows and pull out the CD

tray toward the front.

b. Remove the CD tray panel by pushing both of

its extremities upward in the direction of the

arrows.

c. Push the CD tray deep into the set.

Disconnect the cord wires from the CD PCB CN703

1.

and CN203.

From the rear of the set, remove two screws E

2.

F

three screws

and four screws G on the front

panel left and right side.

3. Handle the CD changer unit rear, take out the unit.

CD tray panel

CD tray panel

Fig.7

E

Antenna

termianl

F

Aux

terminal

Fig.6

Fig.8

CD changer

unit

G

Fig.9

1-8

Page 9

Removing the front panel assembly

(See Fig.10 to 11)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Disconnect the parallel wire and the cord wire from

the connectors CN701, CN101 on the power amp.

PCB.

2. Remove one screws

assembly onto the bottom of the body.

3. Remove two screws I on the left and right side of the set

retaining the panel front from the bottom and then

remove then GND lug

amp and supply PCB.

4. Disengage the claws

panel assembly and then remove the assembly.

H

retaining the front panel

b

that comes from the power

c

on both sides of the front

MX-KA7

H

Fig.10

GND lug

Fig.11

er amp andPow

supply PCB

b

Claw

I

c

1-9

Page 10

MX-KA7

<Disassembly of units and assembly

inside this set>

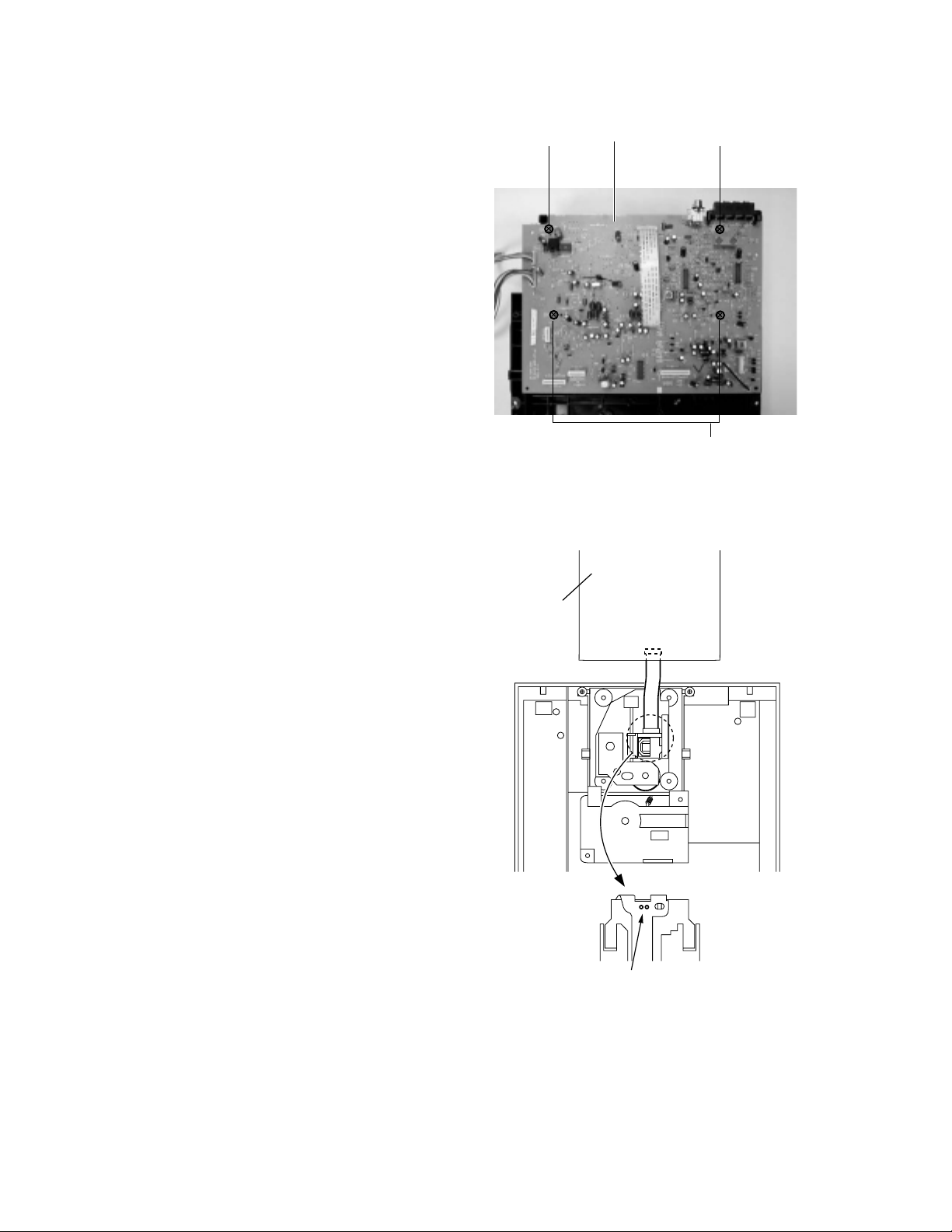

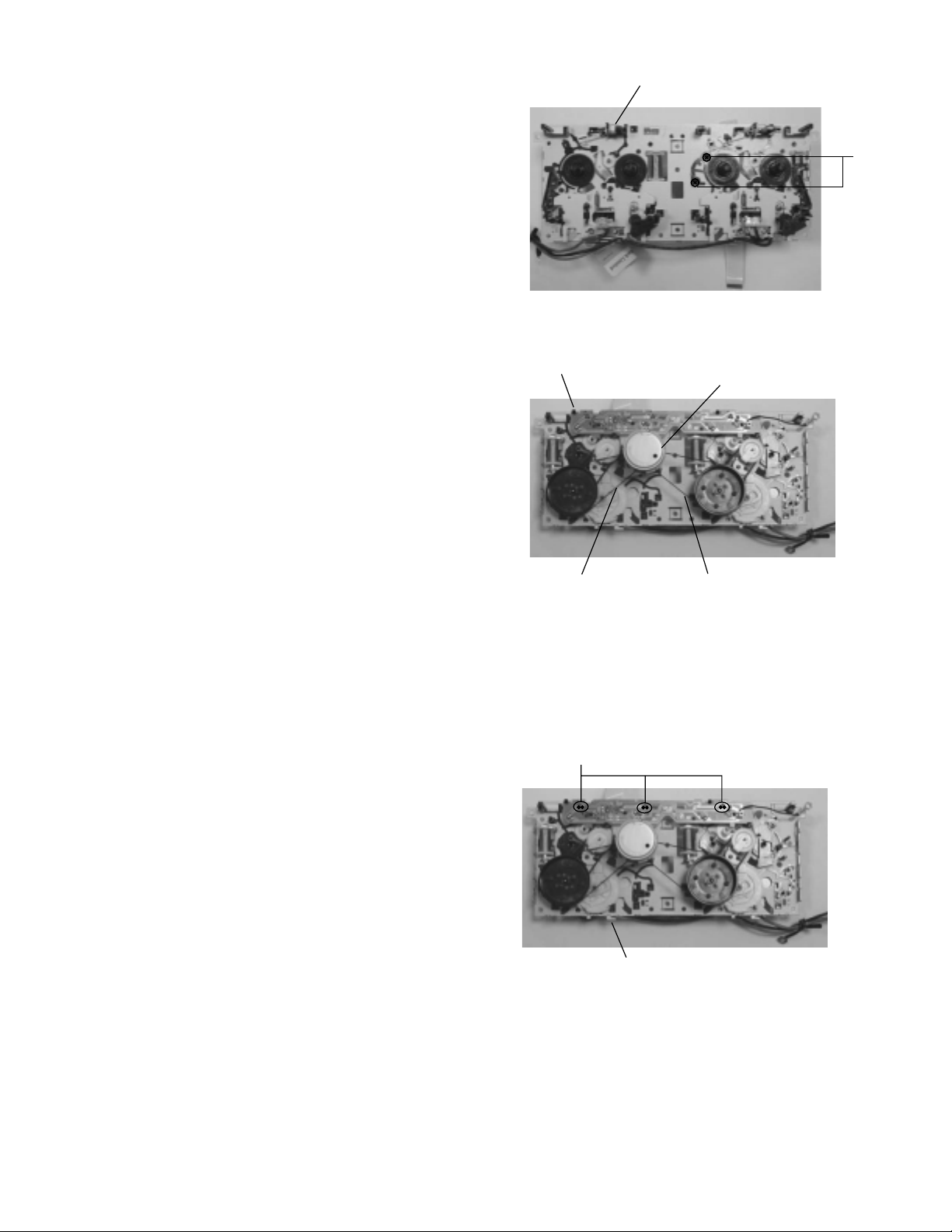

Removing the CD PCB

(See Fig.12 to 13)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Disconnect the wires from CN603A, CN603B and

CN604 on the CD PCB, which is located on the

back side of the CD changer unit.

J

2. The four screws

removed.

3. Remove the CD PCB by pulling it toward the side

where the CN601 is located.

Using solder, short the CD pickup to connect to

4.

short round.

[Caution]

After re-connecting the wires, be sure to

remove the shorting solder from the GND

connection.

5. Disconnect the card wire from the connector CN601

on the main PCB and then remove the main PCB.

that retain the CD PCB should be

J

CD PCB

CD PCB

J

J

Fig.12

CN601

Short round

Fig.13

1-10

Page 11

Removing the CD changer mechanism

assembly (See Fig.14 to 15)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Turn the CD changer mechanism cover base and

remove the screws

changer mechanism assembly.

2. Removing four screws

holder assembly.

d

connecting the unit to the CD

e

retaining the CD mechanism

MX-KA7

CD changer

unit

[Caution]

CD changer

mechanism

assemb

ly

When replacing the CD changer mechanism

assembly, be sure not to mistake the positions

of the silver color and copper color spring.

e

e

( Silver color)

( copper color)

d

Fig.14

e

( Silver color)

Fig.15

e

( copper color)

1-11

Page 12

MX-KA7

Removing the CD pickup (See Fig.16)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the CD changer mechanism.

CD pickup

1. Widen the section

2. While keeping the section

section

g

in the direction of the arrow to remove

f

.

f

wide open, push the

the shaft, and then remove the CD pickup.

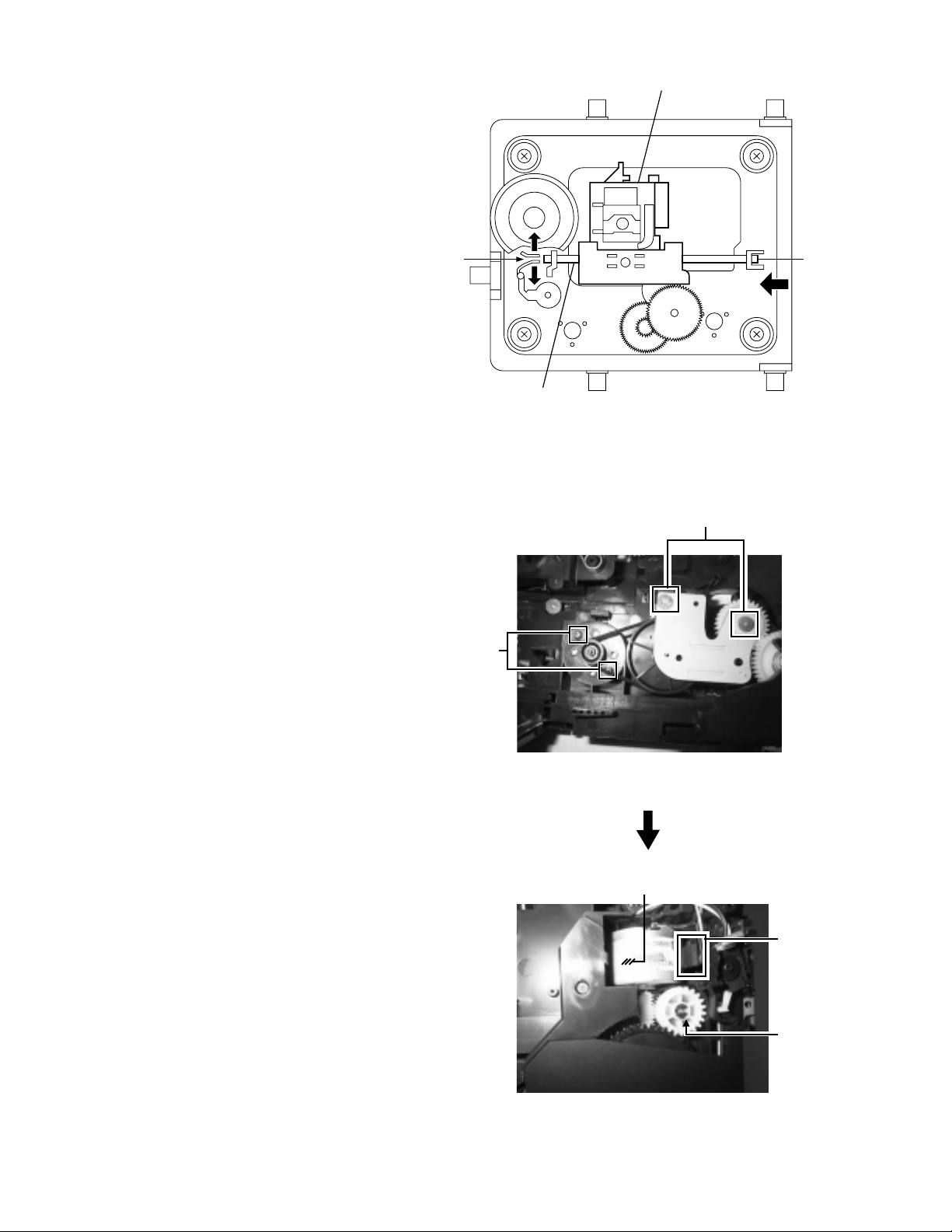

Replacing the loading motor and rotor

belt of the CD changer (See Fig .17)

Prior to performing the following procedures, remove

the top cover.

Also open the CD changer tray.

1. Remove the two screws

L

retaining the CD

changer tray loading motor.

2. Remove the two screws

M

retaining the gear

plate and take it out, after remove the rotor belt

from the pulley.

Replacing the CD turn table and remov-

ing the motor (See Fig. 19 )

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Remove the one screws

table).

2. Remove the two screws

brackets on both sides of the CD changer unit.

3. Remove the stopper brackets from both sides of

the CD changer unit.

4. Pull out the CD tray from the CD changer unit, all

the way and lift the tray (u/~ ward) to remove.

5. Remove the gear and after push out the tray motor

locker and pull out the tray motor from the CD tray.

N

retaining the CD (Turn

O

retaining the stopper

f

Shaft

Fig.16

M

L

Fig.17

g

1-12

Turn table motor

, and then remove the CD tray

Motor locker

Obligue gear

Fig.18

Page 13

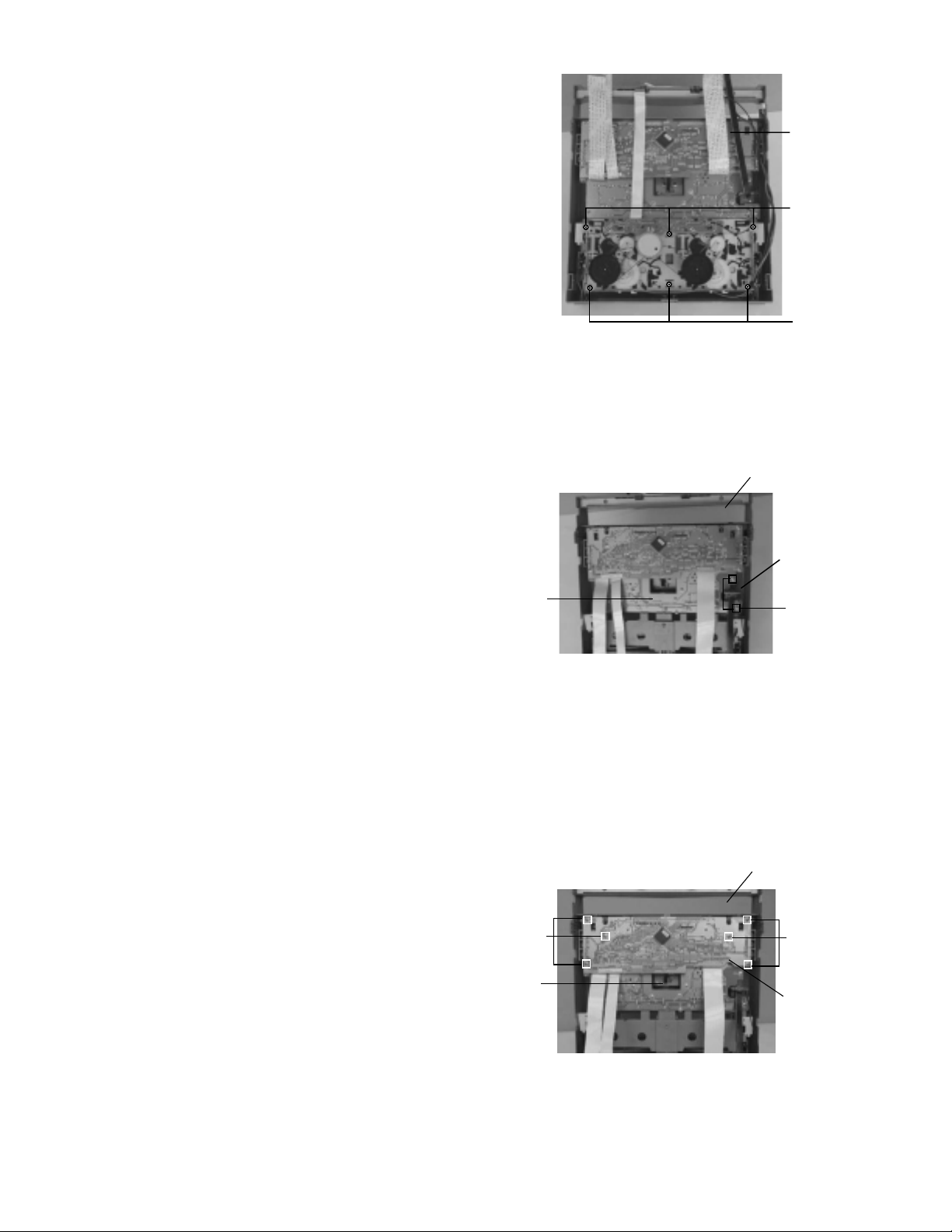

Removing the cassette deck mechanism

(See Fig.19)

MX-KA7

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

1. Remove six screws

Z

retaining the cassette deck

mechanism.

Removing the earphone jack PCB

(See Fig.20)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

1. Remove the screw with the washer,

retains the earphone jack PCB.

P

that

KEY 1

PCB

Front panel

assembly

Z

Z

Fig.19

Front panel

assembly

Earphone jack

PCB

P

Removing the control/FL PCB

(See Fig.21)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

1. Remove six screws Q that retain the control/FL PCB

from the back of the front panel unit.

Q

KEY 2

PCB

Fig.20

Front panel

assembly

Q

Control/FL

PCB

Fig.21

1-13

Page 14

MX-KA7

Removing the switch PCB and sound

mode and CD function switch PCB

(See Fig.20 to 23)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

1. Pull out the volume control knob from the front of

the front panel assembly.(Fig.22)

2. Remove six screws

assembly.(Fig.21)

3. Remove the control/FL PCB.

4. Remove eleven screws

PCB.(Fig.20)

5. Remove two screws

and CD function (key 2) switch PCB.(Fig.21)

Q

retaining the front panel

R

retaining the switch (key 1)

S

retaining the sound mode

Front panel assembly

Volume knob

Fig.22

Fig.23

Front panel

assembly

Volume

shaft

1-14

Page 15

Removing the cassette deck main motor,

and replacing the main belts

(See Fig.19, 24 and 25)

Prior to performing the following procedures, remove

the top cover and both sides board.

Also remove the CD changer unit.

Also remove the front panel assembly.

Z

1. Remove six screws

mechanism. (Fig.19)

2. Remove the cassette deck mechanism.

3. Remove two screws

the front side of the cassette deck.

retaining the cassette deck

t

retaining the main motor from

MX-KA7

Cassette deck mechanism

(Front side)

t

Fig.24

[Caution]

After attaching the main motor, check the

orientation of the motor and the polarity of

the wires.

4. From the backside of the cassette deck, remove the

main motor and two main belts.

[Caution]

The lengths of the cassette A(playback

only) and cassette B(record/play) main

belts are different. When attaching the main

belts, use the longer belt for cassette

Removing the leaf switches of the cassette

A

.

deck mechanism (See Fig. 19 and 26)

Prior to performing the following procedures, remove

the top cover and both sides board.

Also remove the CD changer unit.

Also remove the front panel assembly.

Cassette deck mechanism

(Back side)

Main belt

(For B cassette)

Fig.25

Solder side of leaf switch

Cassette deck main motor

Main belt

(For

A

cassette)

1. Remove the six screws

Z

that retain the cassette

deck mechanism. (Fig.19)

2. Remove the cassette deck mechanism.

3. Turn the cassette deck mechanism upside down.

4. Remove the solder from around the leaf switches.

5. Pull out the leaf switches from the front side of the

cassette deck mechanism.

Cassette deck mechanism

(Back side)

Fig.26

1-15

Page 16

MX-KA7

Removing the cassette deck heads

Prior to performing the following procedures, remove

the top cover and both sides board.

Also remove the CD changer unit.

Also remove the front panel assembly.

(See Fig. 19 and 27)

Cassette deck mechanism

(Front side)

1. Remove six screws

Z

that retain the cassette deck

mechanism. (Fig.19)

2. Remove the cassette deck mechanism and place

it so that the front side faces up.

3. Remove the solder from the bottom side of the

head terminal and disconnect the wire.

U

4. Remove screw

5. Remove screw

that retains the head.

V

that retains the head.

6. Hold the head and slide it in the direction of the

arrow to remove it.

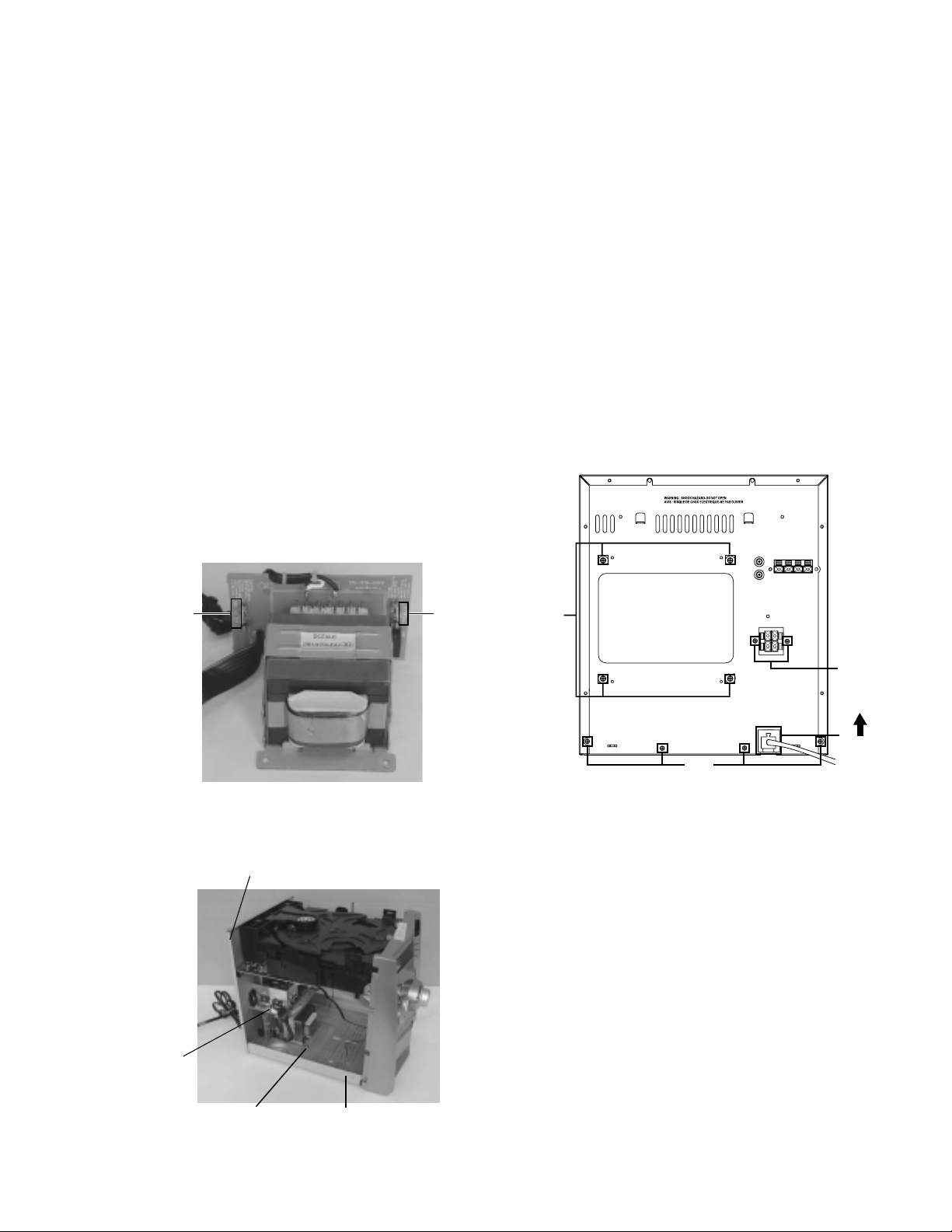

Removing the 3-pin regulator and bridge

diode

(See Q904, Q907, D901, D914 and Fig.28)

Prior to performing the following procedures, remove

the top cover and both sides board.

A

1. Remove two screws

2. Remove two screws

3. Remove the solder fixing the the 3-pin terminal regulator

Q904, Q907.

4. Remove the solder fixing the 4-pin bridge diode

(D901, D914).

that connect the heat sink.

W

that connect the heat sink.

PB Head REC/PB Head

V U

V U

Fig.27

AW

1-16

Fig.28

Page 17

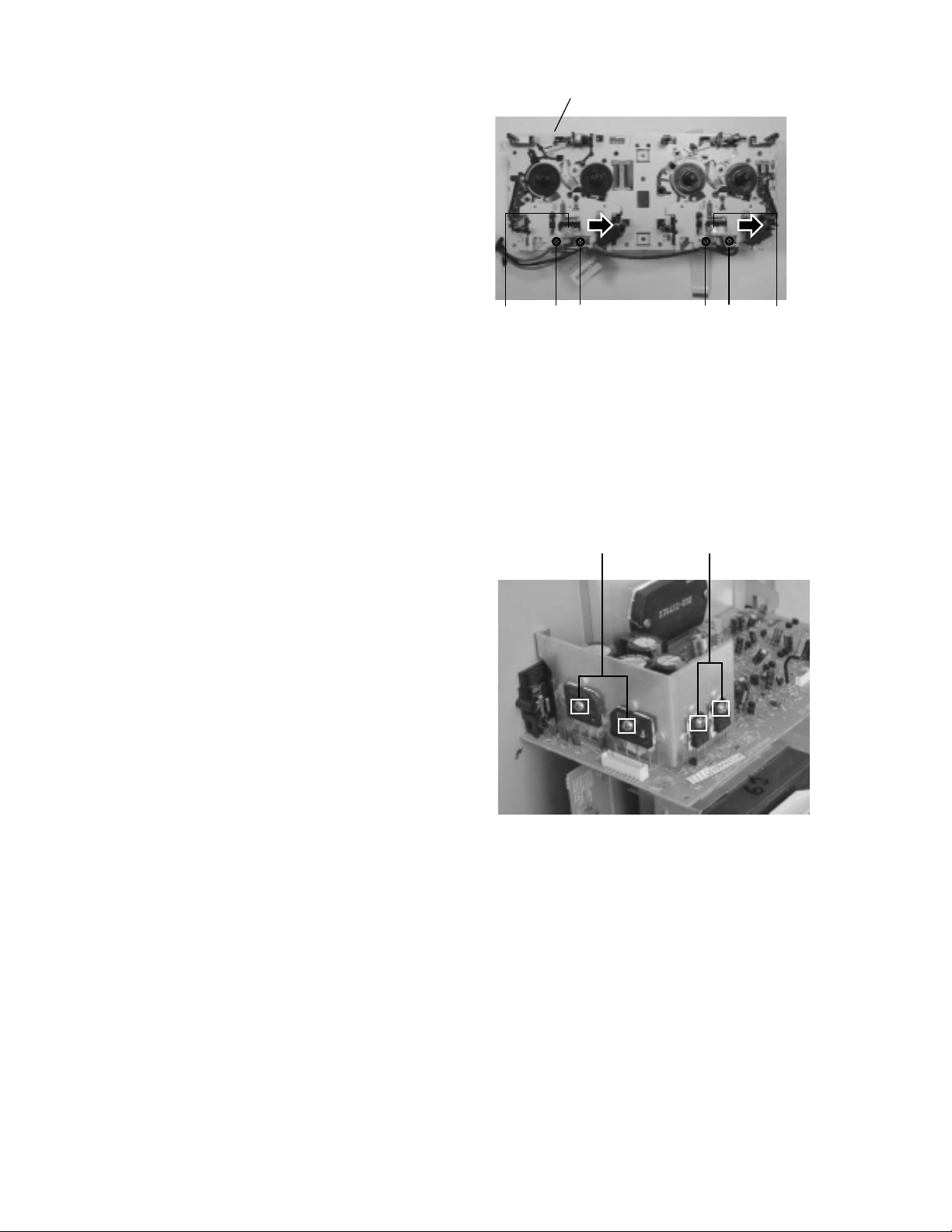

Removing the power amp and supply PCB

and the power trans PCB

(See Fig. 2, 29 to 31)

Prior to performing the following procedures, remove

the top cover and CD changer unit.

B

1. Remove four screws

2. Pull the heat sink cover outward.

3. Remove

four screws AA from the rear panel between

the heat sink holder.

4. Remove two screws X that retain the speaker terminals

and AUX terminal.

5. Remove screws

then remove the rear panel.

6. Disconnect the parallel wires from the connectors

FW951 on the power trans PCB.

7. Remove the clamp of AC power cord from the chassis.

8. Remove four screws AB that retain the power trans

PCB and then remove the assembly.

from the rear panel. (Fig.3)

YY

that retains the rear panel, and

MX-KA7

Fuse (F952)

1.6A 250V

Power amp and

supply PCB

Rear panel

Fig.29

Fuse (F951)

3.15A 250V

AA

X

Clamp

YY

Fig.30

AB

Chassis

Fig.31

1-17

Page 18

MX-KA7

Adjustment method

Measurement instruments required

for adjustment

Radio input signal

1. Low frequency oscillator.

This oscillator should have a capacity to output

0dB to 600ohm at an oscillation frequency of

50Hz-20kHz.

2. Attenuator impedance : 600ohm

3. Electronic voltmeter

4. Frequency counter

5. Wow flutter meter

6. Test tape

VT712 : For Tape speed and wow flutter ( 3kHz)

VT703 : For Head angle (10kHz)

7. Blank tape

TAPE I : AC-225 TAPE II : AC-514

8. Torque gauge : For play and back tension forward;

TW2111A, Reverse; TW2121A Fast Forward and

Rewind; TW2231A

9. Test disc: CTS-1000(12cm),GRG-1211(8cm)

10. Jitter meter

Measurement conditions

Power supply voltage

AC 120V (60Hz)

Measurement

output terminal : Speaker out

: TP101(Measuring for TUNER/

DECK/CD)

: Dummy load 6ohm

AM modulation frequency : 400Hz

Modulation factor : 30%

FM modulation frequency : 1kHz

Frequency displacement : 22.5kHz

Frequency Range

AM 530kHz~1710kHz

FM 87.5MHz~108MHz

Standard measurement positions of

volume and switch

Power : Standby (Light STANDBY Indicator)

Sound Turbo, A, BASS EX : OFF

Sound mode : OFF

Main VOL. : 0 Minimum

Travers mecha set position : Disc 1

Precautions for measurement

1. Apply 30pF and 33kohm to the IF sweeper output

side and 0.082 F and 100kohm in series to the

sweeper input side.

2. The IF sweeper output level should be made as

low as possible within the adjustable range.

3. Since the IF sweeper is a fixed device, there is no

need to adjust this sweeper.

4. Since a ceramic oscillator is used, there is no need

to perform any MPX adjustment.

5. Since a fixed coil is used, there is no need to adjust

the FM tracking.

6. The input and output earth systems are separated.

In case of simultaneously measuring the voltage in

both of the input and output systems with an

electronic voltmeter for two channels, therefore, the

earth should be connected particularly.

7. In the case of BTL connection amplifier, the minus

terminal of speaker is not for earthing. Therefore,

be sure not to connect any other earth terminal to

this terminal. This system is of an OTL system.

1-18

Page 19

Arrangement of adjusting positions

Cassette deck mechanism

(Front side)

MX-KA7

PB Head

k-A)

(Dec

Head azimuth screw

(Forward side)

Head azimuth screw

(Rev

Tape recorder section

Items

Cassette Head

Azimuth Alignments

Measurement

Test tape

: VT703 (10kHz)

Measurement output

terminal

: Left and Right

speaker output

(6-ohm loaded)

or

Headphone Output

(32-ohm loaded)

Head azimuth screw

(Forw

erse side)

conditions

REC/PB Head

(Deck-B)

ard side)

Head azimuth screw

(Reverse side)

Measurement method

1. Playback the test tape VT703 (10KHz) or equivalent.

2. Adjust the head azimuth screw to obtain maximum

output and both output of L / R is in 3dB.

3. Put on the screw lock paint after alignments.

Standard

values

Maximum output

Adjusting

positions

Adjust the

head azimuth

screw only

when the head

has been

changed.

Recording Bias

F

requency Alignment

Tuner section

Items

AM Tracking

Alignments

AM IFT Alignments

Note: The adjustment of CD section is not required.

Test tape

: TYPE I AC-514

Measurement output

terminal

: Erase head terminal

(CN308 8-Pin)

Measurement

conditions

Input signal

: 530kHz

600kHz

Adjustment point

: Antenna coil (L2)

Input signal

: 530kHz

Adjustment point

: IFT (T1)

1. Insert the recording tape in deck-B.

2. Starting the recording.

3. Adjust the oscillation frequency to 80KHz+/-3KHz by

core of Oscillation coil of L301.

1. Set the Signal Generator signal to 530KHz the feed

to Loop Antenna.

2. Receiving the signal and the adjust the OSC coil (L2)

obtain the V.T is 1.40V +/-0.05V.

3. Change the receiving frequency to 600KHz (603KHz).

4. Adjust the Antenna coil ( L2 ) obtain maximum

sensitivity. (Adjust the SSG output to out of AGC range.)

1. Set the receiving frequency to 530KHz.

2. Feed the 450KHz signal to AM antenna input.

3.Adjust the IFT Block T1 obtain to maximum output.

(Adjust the SSG output to out of AGC range.)

Measurement method

80kHz+/-3kHz

Standard

values

V. T

: 1.40V+/-0.05V

Maximum

sensitivity

Maximum output

Use the HighImpedance

Probe or

Frequency

counter input.

Adjusting

positions

Adjust the OSC

coil only when

the AM coil block

has been changed.

Adjust the IFT

only when the

IFT block has

been changed.

1-19

Page 20

MX-KA7

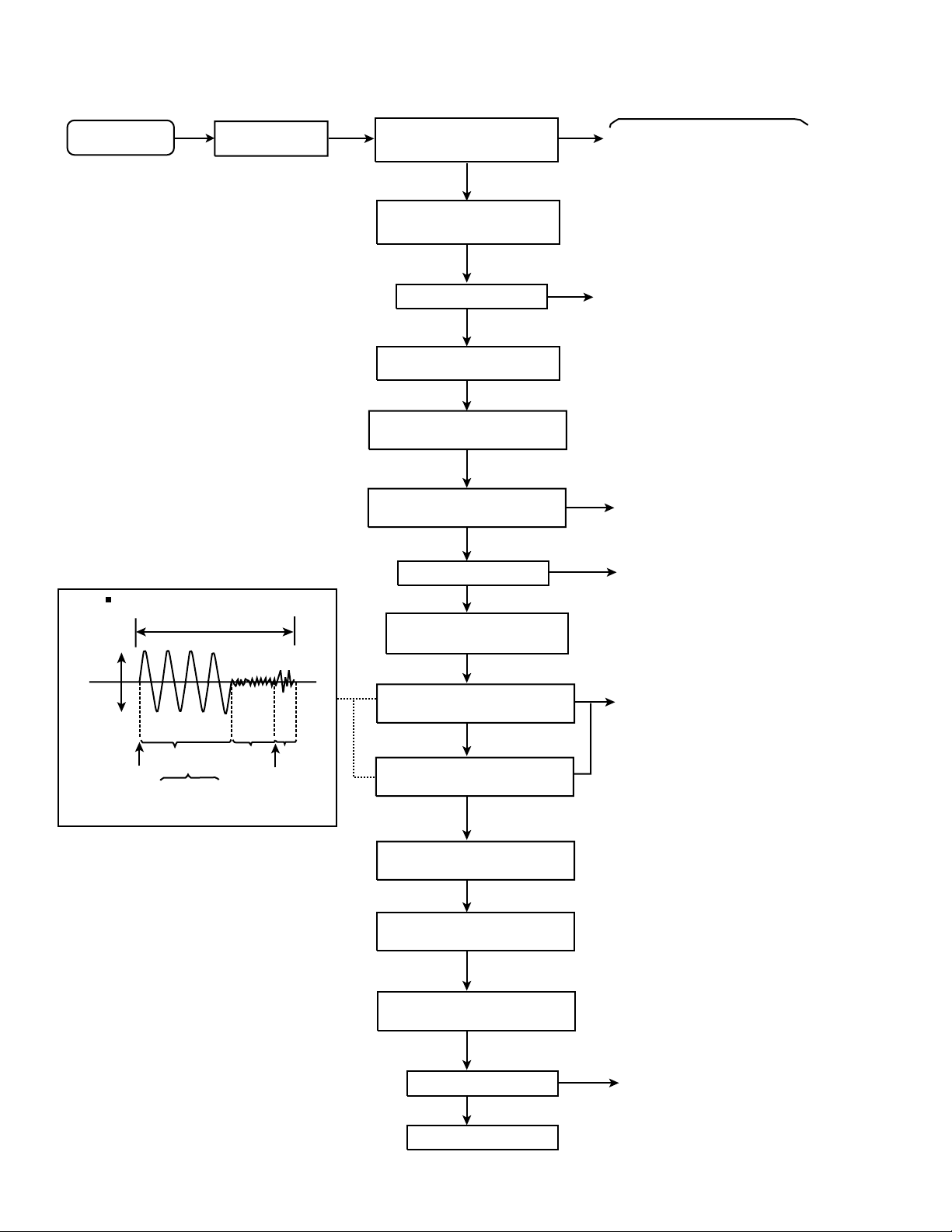

Flow of functional operation until TOC read

Power ON

Play Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Check Point

Confirm that the voltage at the pin5

of CN602 is "H"\"L"\"H".

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 20 of

IC611(TE)

Approx

0.3V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig-1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin40 of IC601 is + 5V?

Confirm that the Focus error

S-cuve signal at the pin32 of

IC601 is approx.2Vp-p

Confirm that the signal from

pin24 IC601 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 20 of IC611 (R643)

(See fig-1)

1-20

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of Pin 5 of IC 611

Page 21

MX-KA7

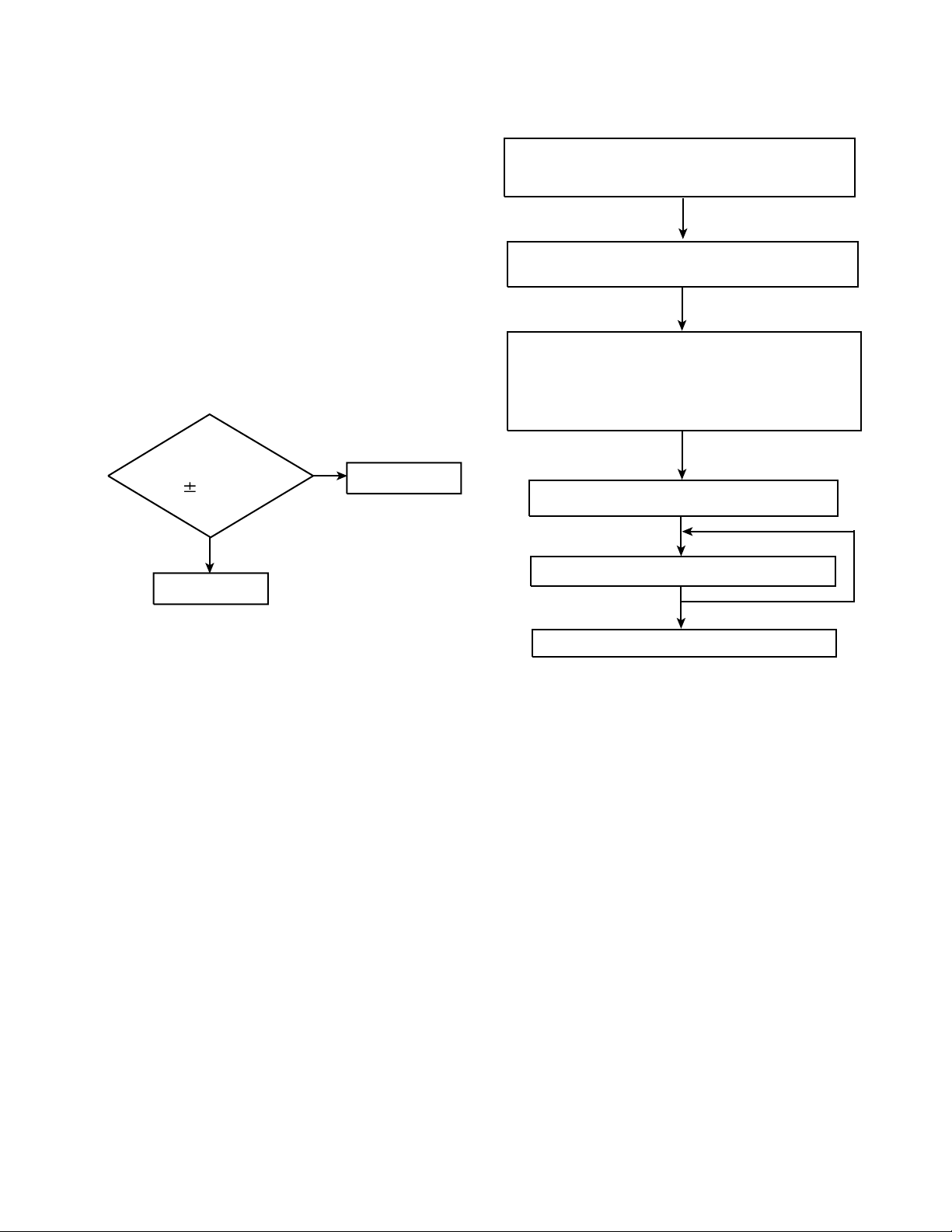

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean

the lens with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the

following symptoms will appear.

1. The level of RF output (EFM output : ampli tude of

eye pattern) will below.

Is the level of

RFOUT under

0.48V 0.1Vp-p?

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the AC OUTLET.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

YES

Check the eye-pattern at

O.K

Finish.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the

laser power.Since this adjustment should be performed to match the characteristics of the whole optical

block, do not touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup

should be replaced.

If the semi-fixed resistor would be adjusted when the pickup operates normally, the laser pickup may be

damaged due to excessive current.

Pin 5 of IC 611

1-21

Page 22

MX-KA7

3

3

6

/

/

/

/

Description of major ICs STK412-030 (IC301) : Dual low noise operational

1.

Block Diagram

1

18

17

TR41

R41

1

TR1

14

TR3

15

1

TR5

R2

2.

Test Circuit

R17

TR17

R13

TR16

R16

R14

R15

C12

D12

TR11TR12

R11

TR13TR14

TR15

R12

D2

TR2

C1

R1

TR4

R3

TR6

TR7

TR8

TR9

TR10

911

812

C2 C11

R4

R5

R6

R7

D1

10

TR19

TR20

TR18

TR51

D41

D51

Comparator

Comparator

R51

SUB

D42

D4

3

2

7

D53

D52

5

4

6

+VH

+VL

GND

-VL

-VH

100uF

/50V

100uF

/50V

100uF

/100V

100uF

/100V

234567

1

GZA

15X

1.5kohm

/1W

1.5kohm

/1W

GZA

15X

SUB.GND

891011 12

*1*1*1

56kohm

3pF

100ohm/1W

100uF

/100V

100uF

/100V

100ohm/1W

*1

56kohm

3pF

13

14

560ohm

100uF

10V

16

33kohm

17

100pF100pF

560ohm

100uF

10V

3uH

4.7ohm

4.7ohm/1W

4.7ohm/1W

3uH

4.7ohm

(*1)Metal Plate Cement Resistor 0.22ohm+-10%(5W)

1815

56kohm 56kohm

2.2uF

50V

2.2uF

50V

1kohm

0.1uF

0.1uF

1kohm

Ch2 IN

GND

470pF 470pF

Ch1 IN

Ch2 OUT

GND

Ch1 OUT

1-22

Page 23

Optical disc ICs

1. Pin descriptions

MX-KA7

BA5936S. (IC621)

2. Block diagram

1-23

Page 24

MX-KA7

Optical disc ICs HA12237F (IC401)

1. Block Diagram

21222324252627282930

RECOUT(L)

NC

Test mode

(Open for normal use)

20

EQ

IREF

19

GND

18

+

V

ALC DET

17

REC MUTE OFF/ ON

CC

16

15

ALC

High/ Norm

A/

(REC Return ON/ OFF )

MUTE ON/ OFF

14

13

12

ALC ON/ OFF

11

+

1098

EQ

RECOUT(R)

NC

ALC(L)

RECIN(L)

NC

++

PBOUT(L)

38NC

BA

39

AIN(R)

MUTE

93/120

(High/Norm)

+

40

+

PB-NF1(R)

TAI(L)

EQOUT(L)

PB-EQ(L)

PB-NF2(L)

Pin Description, Equivalent Circuit (cont)

MUTE

93/120

(High/Norm)

+

31

AIN(L)

+

PB-NF1(L)

32

B

A

33

RIP

+

34

BIN(L)

Return SW

35

REC-

RETURN

GND

Return SW

36

37

BIN(R)

(VCC = 12V, Ta = 25°C, No Signal, The value in the table shows typical value.)

ALC(R)

765432

1

RECIN(R)

NC

+

TAI(R)

PBOUT(R)

EQOUT(R)

PB-EQ(R)

PB-NF2(R)

1-24

Pin No. Pin Name Note Equivalent Circuit Description

33 RIP V = VCC/2

V

CC

Ripple filter

V

GND

29

2

PB-EQ(L)

PB-EQ(R)

NAB output

Page 25

Pin Description, Equivalent Circuit

(V

CC

= 12V, Ta = 25°C, No Signal, The value in the table shows typical value.)

Pin No. Pin Name Note Equivalent Circuit Description

16 V

CC

21 RECOUT(L)

V = V

V = V

CC

/2

CC

V

CC

10 RECOUT(R)

26

PBOUT(L)

5 PBOUT(R)

28 EQOU

T(L)

V = 2.9 V

3 EQOUT(R)

GND

35 REC-RETURN REC Retu

V = 0 V

V

CC

34 BIN(L)

37 BIN(R)

PB-NF

BIN

120 k

VCC pin

output

REC

PB outpu

t

EQ output

rn

PB B deck input

MX-KA7

32 AIN(

L)

39 AIN(R)

24 RECIN(L

)

7RECIN(R)

27

TAI(L)

4TAI(R)

REC Return

V = 0 V

V

CC

PB A deck input

PB-NF

AIN

120 k

GND

V = VCC/2 REC-EQ input

V = VCC/2

V

CC

Tape input

100 k

VCC/2

1-25

Page 26

MX-KA7

Pin Description, Equivalent Circuit (cont)

(V

CC

= 12V, Ta = 25°C, No Signal, The value in the table shows typical value.)

Pin No. Pin Name Note Equivalent Circuit Description

11 ALC ON/OFF

12 High/

13 A/

14 MUTE ON/

15 REC MUTE OFF/ON

19 IREF

Norm

B

OFF

(Control

voltage = 3 V)

100 k

V = 1.2 V Equalizer refernce

I

22 k

V

GND

Mode control input

CC

current input

18, 36 GND

6, 9, 22,

25, 38

20

31 PB-NF

40 PB-NF

30 PB-NF

1 PB-NF2(R)

NC

Test mode

1(L)

1(R)

2(L)

V = 0.6 V

PBNF1

GND TEST

V

CC

330 k180

PBNF2

GND pin

NC pin

Test mode pin

PB EQ feed back

1-26

Page 27

AN22000A (IC611) : CD-DA Head Amp.

1. Terminal layout

MX-KA7

2. Pin function

1

16

3. Block diagram

RFOUT

RF_EQ

624754 8

RFIN

NRFDET

AGC

23

17

Pin

No.

Symbol

I/O

Function

1 PD I APC Amp. input terminal

2 LD O APC Amp. output terminal

3 VCC - Power supply terminal

4 RFN I RF adder Amp. inverting input

terminal

5 RFOUT O RF adder Amp. output terminal

6 RFIN I AGC input terminal

7 CAGC I Input terminal for AGC loop

filter capacitor

8 ARF O AGC output terminal

9 CBA I Capacitor connecting terminal

for HPF-Amp.

10 3TOUT O 3 TENV output terminal

11 CBOO I Capacitor connecting terminal

for envelope detection on the

darkness side

12 BDO O BDO output terminal

13 COFTR I Capacitor connecting terminal

for envelope detection on the

light side

14 OFTR O OFTR output terminal

11 12

BDO

13 14

OFTR

3TENV

9

10

Pin

No.

Symbol

I/O

Function

15 NRFDET O NRFDET output terminal

16 GND - Ground

17 VREF O VREF output terminal

18 VDET O VDET output terminal

19 TEBPF I VDET output terminal

20 TEOUT O TE Amp. output terminal

21 TEN I TE Amp. inverting input

terminal

22 FEN I FE Amp. inverting input

terminal

23 FEOUT O FE Amp. output terminal

24 GCTL O GCTL & APC terminal

25 FBAL O FBAL control terminal

26 TBAL O TBAL control terminal

27 E I Tracking signal input terminal 1

28 F I Tracking signal input terminal 2

29 D I Focus signal input terminal 4

30 B I Focus signal input terminal 3

31 C I Focus signal input terminal 2

32 A I Focus signal input terminal 1

32

31

30

29

27

28

AMP

AMP

AMP

AMP17GCA BCA

+

-

GCA BCA

GCA BCA

GCA BCA

GCTL

SUBT

SUBT

TBAL

26

FBAL

25 16 3

+

+

VDET

+

15

22

23

21

20

19

18

2

LD

PD

1

1-27

Page 28

MX-KA7

MN6627482WA (IC601) : Digital servo & digital signal processor

1. Terminal layout

80~61

1

60

20

21~40

2. Pin function

Pin

No

1 BCLK

2 LRCK

3 SRDATA

4 DVDDI

5 DVSSI

6TX

7 MCLK

8 M D ATA

9 MLD

10 SENSE

11 FLOCK

12 TLOCK

13 BLKCK

14 SQCK

15 SUBQ

16 DMUTE

17 STAT

18 RST

19 SMCK

20 PMCK

21 TRV

22 TVD

23 PC

24 ECM

25 ECS

26 KICK

27 TRD

28 FOD

29 VREF

30 FBAL

31 TBAL

32 FE

33 TE

34 RFENV

35 VDET

36 OFT

37 TRCRS

38 /RFDET

39 BDO

40 LDON

41

Symbol Function

I/O I/O

-

Not use

-

Not use

-

Not use

-

Power supply for digital circuit

-

GND for digital circuit

-

Not use

I

Micro computer command

clock signal input

I

Micro computer command

data input

I

Micro computer command

load signal input (L: Load)

-

Not use, connect to TP7

-

Not use, connect to TP6

-

Not use, connect to TP5

O

Sub code block clock

signal output

I

External clock input for sub

code Q register input

O

Sub code Q data output

I

Muting input (H: Mute)

O

Status signal input

I

Reset signal input (L: Reset)

-

Not use

-

Not use, connect to TP8

O

Traverse enforced output

O

Traverse drive output

-

Not used

O

Spindle motor drive signal

(Enforced mode output)

O

Spindle motor drive signal

(Servo error signal output)

O

Kick pulse output

O

Tracking drive output

O

Focus drive output

I

Reference voltage

for D/A output block

O

Focus balance adjust

signal output

O

Tracking balance adjust

signal output

I

Focus error signal input

(Analog input)

I

Tracking error signal input

(Analog input)

RF envelope signal input

I

(Analog input)

Vibration detect signal

I

input (H:Detect)

Off track signal input

I

(H:Off track)

Track cross signal input

I

RF detect signal input

I

(L:Detect)

Drop out signal input

I

(H:Drop out)

Laser on signal output

O

(H:ON)

Pin

Symbol Function

No

41 PLLF2

42 TOFS

43 WVEL

44 ARF

45 IREF

46 DRF

47 DSLF

48 PLLF

49 VCOF

50 AVDD2

51 AVSS2

52 EFM

53 PCK

54 VCOF2

55 SUBC

56 SBCK

57 VSS

58 X1

59 X2

60 VDD

61 BYTCK/TRVSTP

62 CLDCK

63 FCLK

64 IPFLAG

65 FLAG

66 CLVS

67 CRC

68 DEMPH

69 RESY

70 IOSEL

71 /TEST

72 AVDD1

73 OUTL

74 AVSS1

75 OUTR

76 RSEL

77 CSEL

78 PSEL

79 MSEL

80

SSEL

-

-

I

I

I

I/O

I/O

I/O

-

-

-

O

I/O

-

-

-

I

O

-

-

O

-

O

O

-

-

O

-

I

I

-

O

-

O

I

I

I

I

I

Not use

Not use

Not use

RF signal input

Reference current input

Bias pin for DSL

Loop filter pin for DSL

Loop filter pin for PLL

Loop filter pin for VCO

Power supply for analog

circuit

GND for analog circuit

Not use, connect to TP12

Clock output for PLL

Loop filter pin for Digital

servo VCO

Not use

Not use

GND for crystal oscillation

circuit

Input for crystal oscillation

circuit (f=16.9344MHz)

Output for crystal oscillation

circuit (f=16.9344MHz)

Power supply for crystal

oscillation circuit

Not use

Sub code frame clock

signal output

Not used

Interpolation flag signal

output, Connect to TP11

Flag signal output,

Connect to TP10

Not use

Not use

De-emphasis detect signal

output, Connect to TP9

Not use

Mode select pin, Connect

to DVDD1 (H fix)

Test pin, Connect to

DVDD1 (H fix)

Power supply for analog

circuit

L-channel audio output

GND for analog circuit

R-channel audio output

RF signal polarity setting pin,

Connect to DVDD1 (H fix)

Oscillation frequency setting

pin, Connect to GND (L fix)

IOSEL=H, Test pin,

Connect to GND (L fix)

IOSEL=H, SMCK output,

Frequency select pin

IOSEL=H, SMCK output,

SUBQ output mode select pin

1-28

Page 29

BA15218DIP (IC102) : Dual low noise operational amp.

1. Terminal layout

MX-KA7

OUT1

- IN1

+IN1

VEE

LA1823DIP (IC1) : 1chip AM/FM, MPX tuner system

+-

Vcc

OUT2

- IN2

-+

+IN2

1. Block diagram

24

FM

RF

AM

RF

23

GND2

REG VCC1 GND1

22

AM

MIX

AM

OSC

21

VCC2

B

UFFER

OSC

20

FM

OSC

FM

MIX

MUTE

B

UFFER

IF

ST SW

17 16

DECODER

VCO FF FF

TRIG

STSD

15

PHASE

COMP

FM

S-METERAMDET

FM

IF

14

PILOT

DET

FF

AM

IF

1319 18

FM

DET

AG

C

1 2 4 5 10 11 126 7 8 93

2. Pin function

Pin

No.

Symbol

I/O

1 AM_RFIN I AMRF signal input

2 REG. -

3 AM_OSC - AM local oscillation circuit

4 VCC_1 - Power supply terminal

FM_MIXOUT

5

O Output terminal for FM mixer

6 GND_1 - Ground

7

IF_BUFFER

O IF buffer output

8 ST_IND O Stereo indicator output

AM_MIXOUT

9

O Output terminal for AM mixer

10 FM_IF IN I Input of FMIF signal

11 AM_IF IN I Input of AMIF signal

12 AGC I AGC voltage input terminal

Function

Pin

No.

Symbol

I/O

Function

13 FM_DET O FM detection signal output

ST/MON_SW

14

AM/FM_SW

15

I Stereo/Monaural switching signal input

I AM/FM switching signal input

16 L_OUT O Output L-channel

17 R_OUT O Output R-channel

18 MPX_IN I Multiplex signal input

19 DET_OUT O AM/FM detection output

20 FM_OSC - FM local oscillation circuit

21 VCC_2 - Power supply terminal

22

FM_RFOUT

O Output of FMRF signal

23 GND_2 - Ground

24 FM_RFIN I

Input of FMRF signal

1-29

Page 30

MX-KA7

TDA7440D (IC101) : Audio processor

1. Terminal layout

2. Block diagram

4

LIN1

5

LIN2

6

LIN3

7

LIN4

3

RIN1

2

RIN2

1

RIN3

28

RIN4

RIN3

RIN2

RIN1

LIN1

LIN2 VS

LIN3

LIN4

MUXO-L

IN(L)

MUXO-R

IN(R)

BIN(R)

BOUT(R)

BIN(L)

100K

100K

100K

100K

100K

100K

100K

100K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

G

0/30dB

2dB STEP

G

INPUT MULTIPLEXER

+ GAIN

MUXO-L IN(L)

MUXO-R IN(R)

RIN4

28

LOUT

27

ROUT

26

25

AGND

24

CREF23

SDA

22

SCL

21

DGND

20

TRE(R)

19

18

TRE(L)

17

N.C.

16

N.C.

15

BOUT(L)

BASS

BASS

R

R

B

B

BOUT(L)

BOUT(R)

15

SPKR ATT

SPKR ATT

RIGHT

SUPPLY

LEFT

V

REF

CREF

TRE(L)

8 9 18 14

VOLUME

VOLUME

10 11 19 12 13 23

TREBLE

2

CBUS DECODER + LATCHES

I

TREBLE

TRE(R)

BIN(L)

BIN(R)

27

LOUT

21

SCL

22

SDA

20

DGND

26

ROUT

24

VS

25

AGND

1-30

Page 31

TC74HC4094AP (IC402)

hif

MX-KA7

: 8-bit s

t and store resister

1. Terminal layout

1

ST

2

SI

3

CK

4

Q1

5

Q2

6

Q3

7

Q4

8

GND

2. Block diagram

16

V

CC

OE

15

Q5

14

Q6

13

Q7

12

Q8

11

Q'S

10

QS

9

9

QS

10

Ø

Ø

Q'S

2

SI D Q

3

CK

1

ST

15

OE

D

F/F

ØØ

Ø Ø

D

ØS

4

Q1

ØØ

Q

LATCH

ØS ØS

Q

F/F

Ø Ø

ØS

LATCH

Q

D

QØS ØS

5

Q2

DQ

F/F

Q

Ø Ø

D

TCH

LA

Q

ØS ØS

6

Q3

DQ

F/F

Q

Ø Ø

D

TCH

LA

Q

ØS ØS

7

Q4

DQ

F/F

Q

Ø Ø

D

TCH

LA

Q

ØS ØS

14

Q5

DQ

F/F

Q

Ø Ø

D

TCH

LA

Q

ØS ØS

13

Q6

DQ

F/F

Q

Ø Ø

D

TCH

LA

Q

ØS ØS

12

Q7

DQ

F/F

Q

Ø

Ø

D

TCH

LA

Q

ØS ØS

11

Q8

Ø

Ø

1-31

Page 32

MX-KA7

LC72136N (IC2) : PLL Frequency synthesizer

1.Terminal layout

1

CLOCK

VCOSTOP

AM/FM

MW

SDIN

2. Block diagram

XTI

FM

CE

DI

DO

LW

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFI

LPFO

PD

VCC

FMIN

AMIN

NC

IFCNT

IFIN

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

XTI

1

FM

2

CE

3

4

5

6

7

8

9

10

11

DI

CLOCK

DO

VCOSTOP

AM/FM

NC

NC

SDIN

Reference

Driver

Swallow Counter

1/2

2

B

C

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75KHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

-

Input/output port

-

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

No.

12

13

14

15

16

17

18

19

20

21

22

Symbol

IFIN

IFCNT

NC

AMIN

FMIN

VCC

PD

LPFO

LPFI

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power supply(VDD=4.5 5.5V)

-

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Output for active lowpassfilter of PLL

O

Input for active lowpassfilter of PLL

I

Connected to GND

-

X'tal oscillator(75KHz)

I

1-32

Page 33

MX-KA7

Wiring

5

4

connection

P/N : BI12P60143U

P/N : BI1203941

P/N : BI12P80102U

P/N : BI1205281U

3

P/N : BI1205251U

P/N : BI1205441U

P/N : BI12P30215U

P/N : BI1205241U

P/N : BI12P40251U

P/N : BI12P90055U

2

1

AB C

P/N : BI1205291U

P/N : BI1205261U

P/N : BI12P100035U

P/N : BI12P60142U

1-33

Page 34

MX-KA7

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

No.MB039

Printed in Japan

WPC

Page 35

n Tuner section

MX-KA7

2-1

Page 36

n Main section

MX-KA7

2-2

Page 37

n CD section

MX-KA7

2-3

Page 38

n Amplifier

MX-KA7

2-4

Page 39

n FL Display and CPU Control

MX-KA7

2-5

Page 40

n

Power transformer section

MX-KA7

2-6

Page 41

n Block diagram

MX-KA7

2-7

Page 42

n Wiring diagram

MX-KA7

2-8

Page 43

n Main top PWB

MX-KA7

2-9

Page 44

n Main bottom PWB

MX-KA7

2-10

Page 45

n FL Display and CPU (TOP)

MX-KA7

2-11

Page 46

n FL Display and CPU (BOTTOM)

MX-KA7

2-12

Page 47

n Power Amp. PWB

MX-KA7

2-13

Page 48

n Power trans PWB

MX-KA7

2-14

Page 49

PARTS LIST

t

[ MX-KA7]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

JW -------------- Mexico,Panama

MB039

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD changer mechanism

Cassette mechanism assembly

Electrical parts list (Block No.01~05)

Packing materials and accessories parts list (Block No.M3)

assembly and parts list (Block No.MA)

and parts list (Block No.MP)

3- 2

3- 5

3- 7

3- 8

3-12

- Note-

Parts number of normal capacitors and normal resistors doesn't listed on the parts lis

3-1

Page 50

Exploded view of general assmbly and parts list

e

1

Block No.

64

M

M

1

M

38

34

22

Main board

Vol board

61

54

52

VFD board

56

Headphone

board

54

22

51

36

17

20

51

Front

33

55

58

7

6

62

59

29

18

54

board

41

57

3

51

24

8

5

15

50

30

9

20

4

65

51

35

64

64

AMP

board

26

54

32

31

64

53

64

54

5

27

14

Pow

boa

66

23

16

2

39

21

49

60

37

10

11

12

25

55

54

13

3-2

Page 51

Block No.

M

M

1

M

38

oard

rd

64

1

54

52

VFD board

56

Headphone

board

51

Front

33

51

36

55

58

17

7

6

62

board

57

3

51

24

8

5

15

50

51

35

64

64

AMP

board

54

32

64

53

64

54

64

54

28

31

64

52

54

63

19

52

59

29

20

18

54

54

22

30

41

9

20

4

65

26

27

14

40

63

Power

board

66

23

3-3

Page 52

General assembly

Block No. [M][1][M][M]

Symbol No.

1 ------------ CD CHANGER MACH

2 BI109835010201 BADGE JVC

3 BI300856010101 BELT CLIP WASHE

4 BI301789010101 BUSHING 5RF-5B

5 BI107475030101 CAP CD3

6 BI107475020101 CAP CD2

7 BI107475010101 CAP CD1

8 BI107475040101 CAP OPEN CLOSE

9 BI201789010102 CASS LOCK SPRIN (x2)

10 BI107468010101 CASS DOOR WIN L

11 BI107467010101 CASS DOOR WIN R

12 BI107466010101 CASSETTE HLDE L

13 BI107465010101 CASSETTE HLDR R

14 ------------ CASSETTE MECHA CMAT6Z219A

15 BI107477010101 CD EJECT BUTTON

16 BI107463010101 CD FITTING

17 BI107471010101 CD SE BUTTON A

18 BI202547010101 CHAS MAIN

19 BI107483010101 COVER HTSINK

20 BI301388010101 DAMPING GEAR (x2)

21 BI1074640801U1 DISPLAY WINDOW

22 BI103362020102 EVA FOOT (x2)

23 BI301779010101 EVA FOOT C (x2)

24 BI107473010101 FRAME CD SELECT

25 BI107462010201 FRONT PANEL

26 BI402991 FUSE 1.6A 250V F952

27 BI403011 FUSE 3.15A 250V F951

28 BI202556010101 HEAT SINK 2

29 BI104143010102 HLDR LOCK L

30 BI104143010202 HLDR LOCK R

31 BI202560010101 HLDR R

32 BI202553010101 HLDR L

33 BI107480010101 HLDR SOUND MODE

34 BI202592010101 HOLDER BRACKET

35 BI202555010101 HEAT SINK AMP

36 BI107485010101 INDICATOR STAND

37 BI109819030201 KNOB VOLUME TAB

38 BI202548010101/S/ METAL COVER

39 BI301922010101 MIRROR SHEET

40 BI2025500301U1 REAR PANEL

41 BI104142010102 PLATE LOCK 1

49 BI107482010101 RING VOLUME

50 BIPMW001101S3 SCREW 4.0XL6 METAL(x4)

51 BIBT000418 SCREW

52 BIRT000617B3 SCREW

53 BIBT0006091 SCREW

54 BIRM000603S3 SCREW

55 BIKT000627 SCREW (x4)

56 BI107470010101 SELECT BUTTON

57 BI107469010101 SELECT BUTTON

58 BI107472010101 SOUND MODE BUTT

59 BI107478010101 SOURCE BUTTON

60 BI202566010101 SPRING L

61 BI202565010101 SPRING R

62 BI107476010101 SUB BUTTON SET

63 BIRM000604S3 SCREW RH/TS 3XL8(x8)

64 BIRT000611B3 SCREW RH/TS 3XL8(x17)

65 BI1400864 POWER CORD

66 BI211041004001W POWER TRANS T951

Part No. Part Name Description Local

2.6XL8

PLASTIC(x23)

3.0XL10

PLASTIC(x14)

3.0XL14

PLASTIC(x2)

3.0XL6

METAL(x19)

3-4

Page 53

CD changer mechanism assembly and parts list

BI3400931

7

8

Block No.

6

M

M

M

A

23

24

25

28

26

9

10

2

12

13

11

1

3

15

17

14

19

27

29

16

21

37

38B

18

20

38A

36

22

4

5

37

37

38A

37

35

33

34

32

38B

39

3-5

Page 54

CD changer mechanism

Block No. [M][A][M][M]

Symbol No.

1 BIAJ7200601J BASE-MAIN 1X1

2 BIAJ6100601P BRKT-CHUCK

3 BI3302000158 MAGNET-FERRITE

4 BIAJ7200601L TABLE-CHUCK 1X4

5 BIAJ6300601A SHEET-CHUCK (x3)

6 BIAJ7300601B BELT-LOAD

7 BIAJ6600601N GEAR-SYNCRO 1X2

8 BIAJ6600601L GEAR-CONVERT 1X4

9 BIAJ6600601M GEAR-TRAY 1X4

10 BIAJ6600601R GEAR-CAM 1X2

11 BIAJ6600601K GEAR-LOAD 1X4

12 BIAJ6600601J GEAR-PULLEY 1X4

13 BIAJ7200601N SLIDER-CAM 1X4

14 BI3405000101 SWITCH-MICRO (x2)

15 BI3711003379

16 BIAJ4100601K PCB-SW

17 BIAJ6100601K PULLEY-MOTOR 1X4

18 BIAJ3100601F MOTOR-DC

19 BI3710001248 CONNECTOR-SOCE

20 BI3711003692

21 BI3708001163 CONNECTOR-FPC

22 BIAJ4100601L PCB-MECHA

23 BIAJ7200601P TRAY- ROULETTE 1X2

24 BIAJ7200601Q TRAY-DISC 1X2

25 BIAJ6600601Q GEAR-ROULETTE 1X4

26 BIAJ6600601P GEAR-WORM 1X2

27 BIAJ3100601K MOTOR-LOADING

28 BIAJ6300601B SHEET-MOTOR

29 BIAJ3900601A WIRE-ROULETTE

32 BIAJ3900601B WIRE-TRAY

33 BI3711000003

34 BIAJ4100601J PCB-SENSOR

35 BIAJ3200601A SENSOR-ROULETTE

36 BIAJ9050605F CMS-B31NG6U

37 BIAJ6000601F SCREW (x4)

38A BIAJ7300601F RUBBER-B31Y (x2)

38B BIAJ7300601D RUBBER-B31 (x2)

39 BIAJ7200602F LEVER-LIFTER 1X2

Part No. Part Name Description Local

CONNECTORHEADE

CONNECTORHEADE

CONNECTORHEADE

3-6

Page 55

Cassette mechanism assembly and parts list

y

)

CMAT6Z219A

L SIDE

TYPE

10

L SIDE

Block No.

M

M

M

P

3

9

4

2

5

4

8

6

8

5

7

1

R SIDE

Casette mechanism

Block No. [M][P][M][M]

Symbol No.

1 BIF513858 PLATE HD BLK

2 BIF525346 MTR MAIN BLK

3 BIF567843 PCB CONTROL BLK

4 BIUE20P12 LEAF SWITCH (x3)

5 BIF522063 CLUTCH ASY BLK (x2)

6 BIFF19N31 MAIN BELT

7 BIF51435 ROLLIER PINCH B (x2)

8 BIFF19S31 F/R BELT MO (x2)

9 BIFF19N22 MAIN BELT

10 BIF513855 PLATE HD BLK

Part No. Part Name Description Local

7

R SIDE

TYPE

Note: Parts listed on the Parts List below can be supplied.

However, parts that are not listed below cannot be supplied

individually but only by purchasing the whole Cassette

Mechanism Assembly Unit. (When ordering, use the Parts No.

CMAT6Z219A for Cassette Mechanism Assembl

Unit.

3-7

Page 56

Electrical parts list

AMP. board

Symbol No.

C901 BICM682101KP015 M CAPACITOR

C902 BICM682101KP015 M CAPACITOR

C903 BICM682101KP015 M CAPACITOR

C904 BICM682101KP015 M CAPACITOR

C905 BICE33865M2 E CAPCITOR

C906 BICE33865M2 E CAPCITOR

C923 BICM682101KP015 M CAPACITOR

C924 BICM682101KP015 M CAPACITOR

C925 BICM682101KP015 M CAPACITOR

C926 BICM682101KP015 M CAPACITOR

C927 BICE47835M61 E CAPCITOR

C928 BICE47835M61 E CAPCITOR

CN307 BI12S90024U FFC CONNECTOR

CN701 BI12S110020 CONNECTOR

CN951 BI12S90025U CONNECTOR

D304 1SS133 DIODE

D305 1SS133 DIODE

D325 1SS133 DIODE

D326 1SS133 DIODE

D327 1SS133 DIODE

D331 1SS133 DIODE

D333 1SS133 DIODE

D334 MTZJ15C ZENER DIODE

D335 MTZJ15C ZENER DIODE

D336 1SS133 DIODE

D901 G5SBA60L DIODE

D902 FR202 RECTIFIER DIODE

D903 FR202 RECTIFIER DIODE

D904 FR202 RECTIFIER DIODE

D905 FR202 RECTIFIER DIODE

D906 1N4001 DIODE

D907 UZ36BSA DIODE ZENER

D908 MTZJ6.2B DIODE ZENER

D909 1SS133 DIODE

D910 MTZJ6.2B DIODE ZENER

D911 MTZJ5.6B DIODE ZENER

D912 MTZJ13B ZENER DIODE

D913 MTZJ12C DIODE ZENER

D914 RS402M RECTIFIER

D916 1SS133 DIODE

IC304 STK412-030 IC

L101 BI2601141 COIL

L201 BI2601141 COIL

PWB BI251227G01V AMP PWB

Q103 KTC3199GR TRANSISTOR

Q104 KTA1267GR TRANSISTOR

Q105 KTC3199GR TRANSISTOR

Q203 KTC3199GR TRANSISTOR

Q204 KTA1267GR TRANSISTOR

Q205 KTC3199GR TRANSISTOR

Q307 KTC3199GR TRANSISTOR

Q334 KRA107M TRANSISTOR

Q335 KRA107M TRANSISTOR

Q336 KTC3199GR TRANSISTOR

Q337 KTC3199GR TRANSISTOR

Q338 KTC3199GR TRANSISTOR

Q339 DTC114YS TRANSISTOR

Q901 8550C SI.TRANSISTOR

Q902 DTC114YS TRANSISTOR

Q903 DTC114YS TRANSISTOR

Q904 KTB1366 TRANSISTOR

Q905 KTC3199GR TRANSISTOR

Q906 KTC3199GR TRANSISTOR

Q907 KTB1366 TRANSISTOR

Q909 KRA107M TRANSISTOR

Q911 KTC3199GR TRANSISTOR

Q912 DTC114ES TRANSISTOR

R390 1SS133 DIODE

RY301 BI8RL00071 RELAY

Part No. Part Name Description Local

Block No. [0][1][0][0]

Wiring diagram

Symbol No.

CN305 BI1205441U FF-CABLE

CN306 BI1205261U FF-CABLE

CN309 BI1205241U FF-CABLE

CN601 BI1205291U FF-CABLE

CN604 BI1205251U FF-CABLE

CN701 BI1205281U FF-CABLE

DECK BI11AT065B0U WIRE

DECKA BI12P30215U WIRE

DECKB BI12P80102U WIRE

Part No. Part Name Description Local

Front board

Symbol No.

CN701 BI12S110021 FFC CONNECTOR

CN702 BI12P60143U CONNECTOR. WIRE

CN703 BI12P60143U CONNECTOR. WIRE

CN704 BI1203941 CABLE

CN705 BI1203941 CABLE

CN706 BI12S160034U FFC CONNECTOR

CN707 BI12S210005 FFC CONNECTOR

D1051 1SS133 DIODE

D1052 1SS133 DIODE

D701 1SS133 DIODE

D702 1SS133 DIODE

D703 1SS133 DIODE

D705 1SS133 DIODE

D706 1SS133 DIODE

FL701 BI2701941 FL DISPLAY

HJ105 BI2301211 MINI JACK

IC701 MN101C35D IC

IC702 RPM7140 IC

L1051 BI26047000KM002 FIXED INDUCTOR

L1052 BI26047000KM002 FIXED INDUCTOR

L1053 BI18A843556N000 F-BEAD

L702 BI26100000KM002 FIXED.INDUCTOR

L703 BI18A843556N000 F-BEAD

L707 BI26100000KM002 FIXED.INDUCTOR

LE701 BI28B4531EP0110 RED LED

P1 BI11AT160B0U BLACK WIRE

PWB BI251205G02V FRONT PCB

Q704 KTC3195Y TRANSISTOR

Q705 KTC3195Y TRANSISTOR

Q711 KRA102M TRANSISTOR

Q713 DTC114YS TRANSISTOR

Q716 DTC114TK TRANSISTOR

Q717 DTC114TK TRANSISTOR

Q718 DTC114TK TRANSISTOR

Q719 DTC114TK TRANSISTOR

Q720 DTC114TK TRANSISTOR

Q721 DTC114TK TRANSISTOR

Q722 DTC114TK TRANSISTOR

Q723 DTC114TK TRANSISTOR

Q724 DTC114TK TRANSISTOR

Q725 DTC114TK TRANSISTOR

Q726 DTC114TK TRANSISTOR

Q727 DTC114TK TRANSISTOR

Q728 DTC114TK TRANSISTOR

S1 BI8EVQ21405P015 TACT SWITCH

S1002 BI8EVQ21405P015 TACT SWITCH

S1003 BI8EVQ21405P015 TACT SWITCH

S1004 BI8EVQ21405P015 TACT SWITCH

S1005 BI8EVQ21405P015 TACT SWITCH

S1006 BI8EVQ21405P015 TACT SWITCH

S1007 BI8EVQ21405P015 TACT SWITCH

S1008 BI8EVQ21405P015 TACT SWITCH

S1009 BI8EVQ21405P015 TACT SWITCH

Part No. Part Name Description Local

Block No. [0][2][0][0]

Block No. [0][3][0][0]

3-8

Page 57

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

S1010 BI8EVQ21405P015 TACT SWITCH

S1011 BI8EVQ21405P015 TACT SWITCH

S1012 BI8EVQ21405P015 TACT SWITCH

S1013 BI8EVQ21405P015 TACT SWITCH

S1014 BI8EVQ21405P015 TACT SWITCH

S1015 BI8EVQ21405P015 TACT SWITCH

S1016 BI8EVQ21405P015 TACT SWITCH

S1017 BI8EVQ21405P015 TACT SWITCH

S1018 BI8EVQ21405P015 TACT SWITCH

S1019 BI8EVQ21405P015 TACT SWITCH

S1020 BI8EVQ21405P015 TACT SWITCH

S1021 BI8EVQ21405P015 TACT SWITCH

S1022 BI8EVQ21405P015 TACT SWITCH

S1023 BI8EVQ21405P015 TACT SWITCH

S2 BI8EVQ21405P015 TACT SWITCH

S701 BI8EVQ21405P015 TACT SWITCH

S702 BI8EVQ21405P015 TACT SWITCH

S703 BI8EVQ21405P015 TACT SWITCH

S704 BI8EVQ21405P015 TACT SWITCH

S705 BI8EVQ21405P015 TACT SWITCH

S706 BI8EVQ21405P015 TACT SWITCH

SW701 BI804221 JOG SWITCH

V1051 BI12P40251U CONNECTOR. WIRE

X701 BI29ZTA 8.00P 015 CERAMIC RESONTO

X702 BI2102471 CRYSTAL

Main board

Symbol No.

BF601 BI18A843556N000 F-BEAD

CF1 BI29LT10.7MP015 C.FILTER

CF2 BI29LT10.7MP015 C.FILTER

CF3 BI29JT10.7MP015 C.FILTER

CN305 BI12S110023U FFC CONNECTOR

CN306 BI12S90024U FFC CONNECTOR

CN307 BI12S30039 CONNECTOR

CN308 BI12S80024 CONNECTOR

CN309 BI12S210004 FFC CONNECTOR

CN601 BI12S160031 FFC CONNECTOR

CN602 BI12P60142U CONNECTOR.WIRE

CN603 BI12P100035U CONNECTOR.WIRE

CN604 BI12S160033U FFC CONNECTOR

D1 1SS133 DIODE

D10 1SS133 DIODE

D2 1SS133 DIODE

D3 1SS133 DIODE

D306 MTZJ9.1B ZENER DIODE

D307 MTZJ5.1B ZENER DIODE

D308 1SS133 DIODE

D309 1SS133 DIODE

D310 1SS133 DIODE

D311 1SS133 DIODE

D312 1SS133 DIODE

D313 1SS133 DIODE

D314 1SS133 DIODE

D321 1SS133 DIODE

D322 1SS133 DIODE

D323 1N4001 DIODE

D324 1SS133 DIODE

D328 1SS133 DIODE

D329 1SS133 DIODE

D330 1SS133 DIODE

D4 1SS133 DIODE

D401 1SS133 DIODE

D402 1SS133 DIODE

D5 1SS133 DIODE

D50 1SS133 DIODE

D51 1SS133 DIODE

D6 1SS133 DIODE

D605 1N4001 DIODE

D7 SVC203 VARASTOR.DIODE

D8 SVC203 VARASTOR.DIODE

Part No. Part Name Description Local

Block No. [0][4][0][0]

D9 1SS133 DIODE

IC1 LA1823 IC

IC101 TDA7440D IC

IC102 BA15218F IC

IC2 LC72136N IC

IC401 HA12237 IC

IC402 M74HC4094B IC

IC601 MN6627482WA IC

IC611 AN22000A I.C C.M

IC621 BA5936S IC

IC631 NJM7808FA IC

JA301 BI2301181 RCA W/R JACK

JA302 BI2301201 TERMINAL ANT

L1 BI26022000KM002 FIXED INDUCTOR

L2 BI605082 AM PACK COIL

L3 BI7A0170 FM COIL

L301 BI605071 BIAS-COIL

L304 BI18A843556N000 F-BEAD

L306 BI18A843556N000 F-BEAD

L307 BI18A843556N000 F-BEAD

L4 BI7A0171 FM COIL

L5 BI26101000KM002 FIXED INDUCTOR

L50 BI26221000KM002 FIXED INDUCTOR

L6 BI26220000KM002 FIXED INDUCTOR

L601 BI26100000KM002 FIXED.INDUCTOR

L602 BI26100000KM000 FIXED.INDUCTOR

LC1 BI29GFMB3TP0151 BAND PASS FILTE

PWB BI251206G01V MAIN PWB

Q1 KTC3194 TRANSISTOR

Q101 KTC3199GR TRANSISTOR

Q2 KTC3195 TRANSISTOR

Q201 KTC3199GR TRANSISTOR

Q3 DTC114YS TRANSISTOR

Q302 KTC3200GR TRANSISTOR

Q303 KTC3203Y TRANSISTOR

Q304 KTA1267GR TRANSISTOR

Q305 DTC144ES TRANSISTOR

Q308 DTC144ES TRANSISTOR

Q309 KTA1273 TRANSISTOR

Q310 KTC3199GR TRANSISTOR

Q311 KTA1273 TRANSISTOR

Q312 KTC3199GR TRANSISTOR

Q313 KTA1273 TRANSISTOR

Q314 DTC114YS TRANSISTOR

Q316 KTC3199GR TRANSISTOR

Q317 KTC3199GR TRANSISTOR

Q318 DTC114YS TRANSISTOR

Q319 KA1270 TRANSISTOR

Q321 DTC114YS TRANSISTOR

Q322 KRA107M TRANSISTOR

Q327 KTA1267GR TRANSISTOR

Q4 DTC114YS TRANSISTOR

Q401 KTA1267GR TRANSISTOR

Q402 2SD2144S TRANSISTOR

Q403 KTC3199GR TRANSISTOR

Q404 KTC3199GR TRANSISTOR

Q5 KRA107 TRANSISTOR

Q502 2SD2144S TRANSISTOR

Q503 KTC3199GR TRANSISTOR

Q504 KTC3199GR TRANSISTOR

Q601 KTA1267GR TRANSISTOR

Q7 KTC3199GR TRANSISTOR

Q8 KTA1267GR TRANSISTOR

T1 BI2901541 CO. FILTER

X1 BI2100942 CRYSTAL

X601 BI2102361 CRYSTAL

XXXXX BI11A050M0 BLACK.WIRE

XXXXX BI202426010101 PLATE ANT

3-9

Page 58

T ransformer board

Symbol No.

C951 BICT224275M M.CAPACITOR

F951A BI201196010101 FUSE HOLDER

F951B BI201196010101 FUSE HOLDER

F952A BI201196010101 FUSE HOLDER

F952B BI201196010101 FUSE HOLDER

FW951 BI12P90055U CONNECTOR.ASSY

PWB BI251223G01V TRANS PWB

R951 BIRC3352 RESISTOR

TB901 BI201323010101 TERMINAL

TB902 BI201323010101 TERMINAL

Part No. Part Name Description Local

Block No. [0][5][0][0]

3-10

Page 59

<MEMO>

3-11

Page 60

Packing materials and accessories parts list

P9

P7

A5

Block No.

M

3

M

M

A6

A7

P4

P10

P2

A1

P6

A4

A2

A3

P8

P5

P3

3-12

P1

FRONT

Page 61

Packing and accessories

Block No. [M][3][M][M]

Symbol No.

A 1 BI600MXKA6380 REMOTE CONTROL

A 2 ------------ BATTERY (x2)

A 3 BIAN01031 AM LOOP ANT

A 4 BIAN01012 ANT WIRE

A 5 BI4412201U INSTRUCTIONS LVT1075-001A

A 6 MXKA7JW-SPBOX-L SPEAKER BOX L

A 7 MXKA7JW-SPBOX-R SPEAKER BOX R

P 1 BI4313451U CARTON BOX

P 2 BI4512251 POLY FORM Left

P 3 BI4512261 POLY FORM Right

P 4 BI4005355 POLY BAG

P 5 BI4710321 POLY BAG SET

P 6 BI4511451 EPE FOAM PAPER SET

P 7 BI4710311 POLY BAG INSTRUCTIONS

P 8 BI4710511 POLY BAG ANT LOOP

P 9 BI4512351 POLY FORM Top

P 10 BI4512361 POLY FORM Bottom

Part No. Part Name Description Local

REMOTE

CONTROL

3-13

Page 62

MB-MCI-00057 (1/6)

JW

Addition of part Date : 14. Feb. 2005

Location

Parts list

Reference Information

------

Performed at factory

#1~

SUBJECT :

The following parts have been changed. Please note these new parts in your service manual.

We suggest that you order the parts concerned as apares.

Parts identified by the symbol are critical for safety. Replace only with specified part numbers.

Model & Manual No.

MX-KA7

(No.MB039)

CD-ROM No.

SML200311V11

Some parts numbers are missing on Service Manual No.MB039.

Please utilize the following parts list together with original one.

COMMENTS :

ATTACHMENT

( ) NONE ( ) COMPONENT / PWBLAYOUT

( ) SCHEMATIC DIAGRAM ( ) ADJUSTMENT

( ) EXPLODED VIEW

PROCEDURE

FOB

(New Parts)

----

INTERCHANGEABILITY

A. Completely interchangeable.

B. Previous part can be used for new set,but new

part can not be used for previous set.

C. New part can be used for previous set,but

previous part can not be used for new set.

D. Not interchangeable.

E. Addition

F. Deletion

REASON FOR CHANGE

A. To improve performance. E. Standardization of part.

B. To improve reliability. F. For your demand.

C. To improve safety. G. Correction of misprint.

D. To improductivity H. Others.

Itg

Rsn

E H

VICTOR COMPANY OF JAPAN,LTD, AV & Multimedia Company

Global Quality Management Dept.

AV Group. 15300

1-10-1,Ohwatari-chou. Maebashi-shi,Gunma-ken.371-8543, Japan Facsimile : 81-27-254-8977 Telephone : 81-27-254-8952

Note

Page 63

Main board

r

p

p

p

p

y

T

p

p

p

K

! !

Item Parts number Parts name Remarks

Q302 BI2KTC3200P0008 Transisto

KTC3200 GR

D314 BI31SS133M0007 Diode 1SS133

C923 BICC22350Z POLYFILM CAP. 0.022UF

C319 BICE10816M ELECT. CAP 1000 UF/16 V

C334 BICE105500MP015 ELECT. CAP 1UF/50V

C336 BICE105500MP015 ELECT. CAP 1UF/50V

C405 BICE105500MP015 ELECT. CAP 1UF/50V

C520 BICE105500MP015 ELECT. CAP 1UF/50V

C327 BICE106160MP015 ELECT. CAP 10UF/16V

C346 BICE106160MP015 ELECT. CAP 10UF/16V

C306 BICE106160MP015 ELECT. CAP 10UF/16V

C419 BICE106250MP015 ELECT. CAP 10UF/25V

C519 BICE106250MP015 ELECT. CAP 10UF/25V

C115 BICE107100MP015 ELECT. CAP 100UF/ 10V

C215 BICE107100MP015 ELECT. CAP 100UF/ 10V

C324 BICE107100MP015 ELECT. CAP 100UF/ 10V

C331 BICE107100MP015 ELECT. CAP 100UF/ 10V

C305 BICE107160MP015 ELECT. CAP 100UF/ 16V

C310 BICE107160MP015 ELECT. CAP 100UF/ 16V

C317 BICE107160MP015 ELECT. CAP 100UF/ 16V

C107 BICE475500MP015 ELECT. CAP 4.7UF/50V

C109 BICE475500MP015 ELECT. CAP 4.7UF/50V

C207 BICE475500MP015 ELECT. CAP 4.7UF/50V

C209 BICE475500MP015 ELECT. CAP 4.7UF/50V

C318 BICE475500MP015 ELECT. CAP 4.7UF/50V

C335 BICE475500MP015 ELECT. CAP 4.7UF/50V

C407 BICE475500MP015 ELECT. CAP 4.7UF/50V

C408 BICE475500MP015 ELECT. CAP 4.7UF/50V

C415 BICE475500MP015 ELECT. CAP 4.7UF/50V

C507 BICE475500MP015 ELECT. CAP 4.7UF/50V